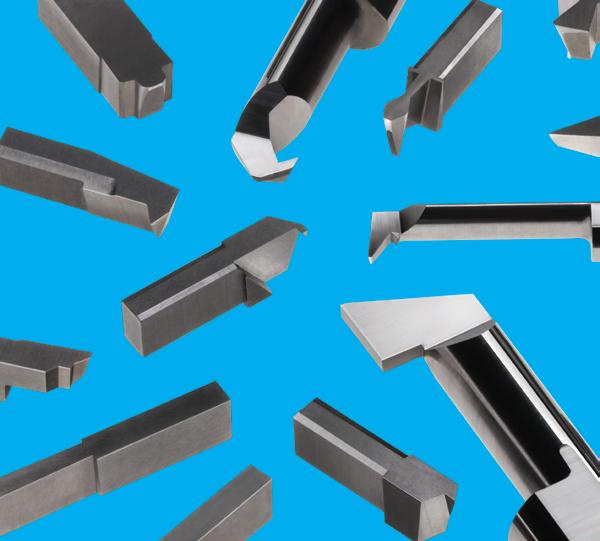

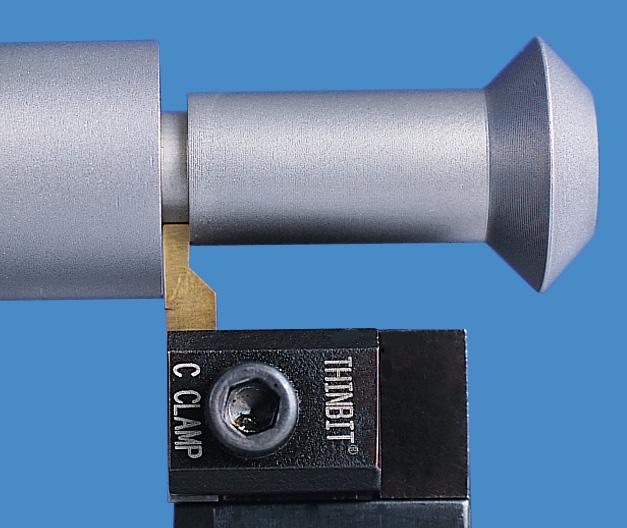

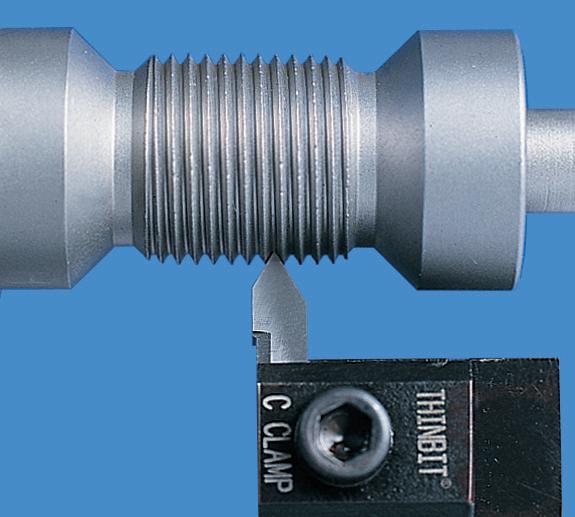

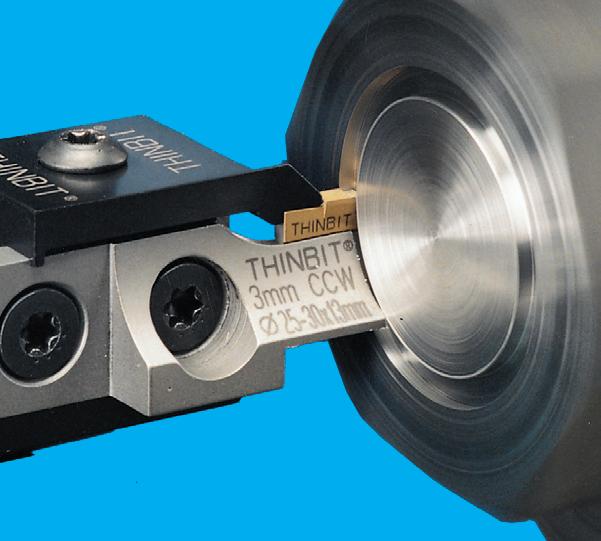

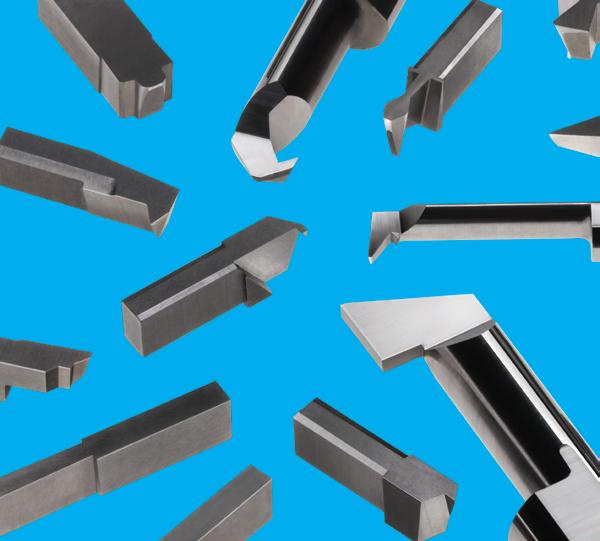

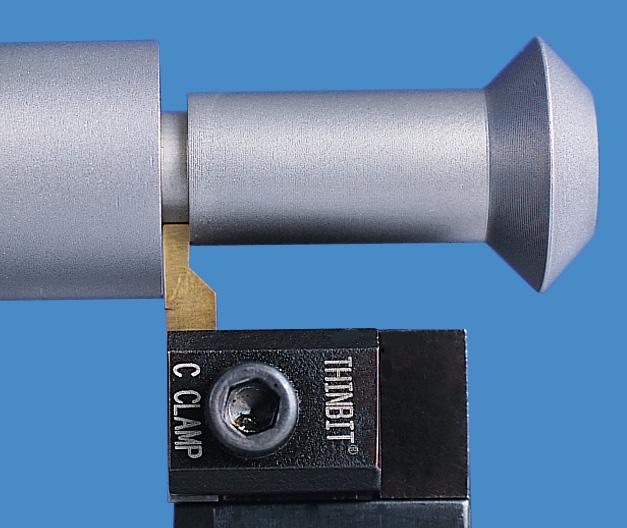

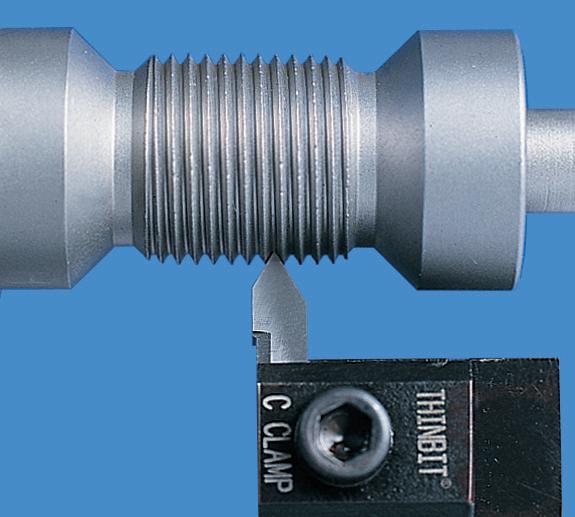

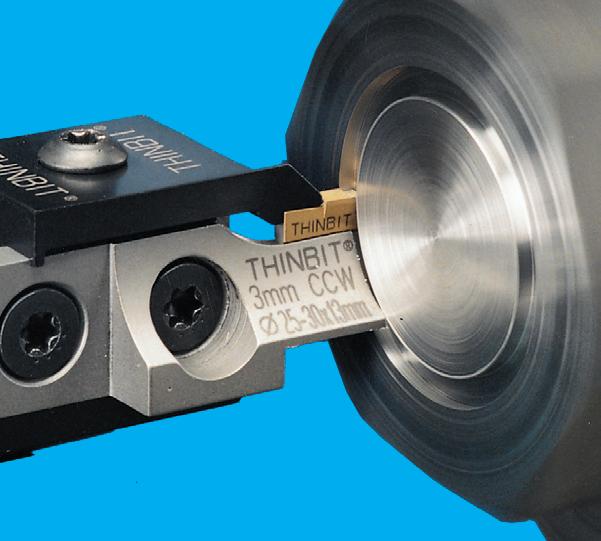

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING

For Construction Of First Bwrx-300 Small Modular Reactor In The U.S.

Tennessee Valley Authority (TVA) has submitted an application to the U.S. Nuclear Regulatory Commission to construct a GE Vernova Hitachi Nuclear Energy (GVH) BWRX-300 small modular reactor (SMR) at the Clinch River site in Oak Ridge, Tennessee. It is the first construction permit application for a BWRX-300 in the U.S.

“TVA’s investment in the standard design of the BWRX-300 technology will accelerate its deployment, helping meet the rising demand for energy and enhancing energy security,” said Craig Ranson, President & CEO, GVH. “This milestone, in addition to this month’s decision by the Province of Ontario to build the western world’s first SMR, demonstrates that this technology is advanced and real.”

TVA has invested in the standard design of the BWRX-300 as part of a technical collaboration agreement with Ontario Power Generation (OPG), Synthos Green Energy and GVH. TVA is also leading a coalition of utility companies and supply chain partners that has applied for an $800 million U.S. Department of Energy grant to accelerate construction of the nation’s first SMR.

Momentum continues to build around the global deployment of the BWRX-300. Earlier this month, the Province of Ontario and OPG announced approval to proceed with construction of the first BWRX-300 at OPG’s Darlington site near Toronto. A total of four BWRX-300s are planned for the site with construction of the first unit to be complete by the end of the decade.

In January, it was announced that Duke Energy has entered into an agreement to invest in activities to advance the standard design and licensing of the BWRX-300 SMR and that American Electric Power (AEP) has selected the BWRX-300 for potential deployment at the Indiana Michigan Power Rockport Plant in Spencer County, Indiana, pending approval of the DOE funding request that TVA is leading.

The BWRX-300 SMR represents a cutting-edge technology designed to deliver reliable and carbon-free power with enhanced safety and efficiency. Each BWRX-300 will provide approximately 300 MW of electricity, enough to produce the equivalent electricity needed to power 300,000 homes while significantly reducing the complexity and cost associated

with traditional nuclear reactors.

GE Vernova’s Nuclear energy business, through its global alliance with Hitachi, is a world-leading provider of nuclear fuel bundles, services, and advanced nuclear reactor designs. Technologies include boiling water reactors and small modular reactors, such as the BWRX-300, which is one of the simplest, yet most innovative boiling water reactor designs. GE Vernova’s Nuclear fuel business, Global Nuclear Fuel (GNF), is a worldleading supplier of boiling water reactor fuel and fuel-related engineering services. GNF is a GE Vernova-led joint venture with Hitachi, Ltd. and operates primarily through Global Nuclear Fuel-Americas, LLC in Wilmington, N.C., and Global Nuclear Fuel-Japan Co., Ltd. in Kurihama, Japan. HITACHI is a trademark of Hitachi, Ltd. used under trademark license. | GE is a trademark of General Electric Company used under trademark license.

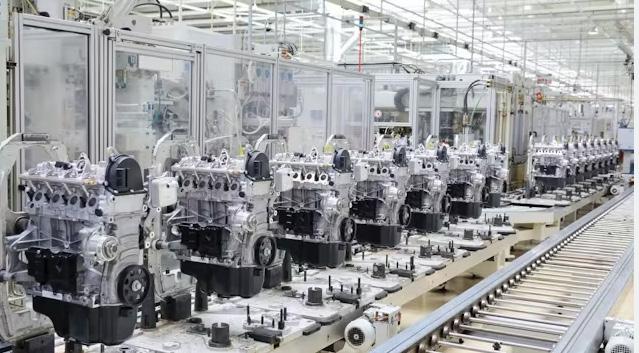

Precision manufacturing, the meticulous process of creating intricate components with stringent tolerances, stands at the cusp of a transformative era in 2025. Driven by cutting-edge advancements and the ever-increasing demand for complex, high-quality products across industries, this field is poised for significant growth and evolution.

At the heart of this evolution lies the synergistic integration of sophisticated technologies. CNC machining, is the bedrock of precision manufacturing, and is becoming increasingly entwined with automation. This allows for enhanced efficiency, tighter tolerances, and minimized costs, particularly in industries like aerospace, automotive, and medical device manufacturing.

The Industrial Internet of Things (IIoT), with its network of sensors and algorithms, enables real-time monitoring, predictive maintenance, and process optimization within precision manufacturing operations.

Additive manufacturing, specifically 3D printing, is also playing a key role, facilitating rapid prototyping, intricate designs, and material waste reduction. Large-scale 3D metal printing, for instance, allows for the on-site fabrication of robust and complex metal components, offering significant cost and timesavings.

The precision manufacturing market itself is exhibiting resilience and growth. Despite geopolitical volatility, many businesses in the sector maintain a positive outlook.

The industry is not without its challenges. Supply chain disruptions, a persistent issue since 2020, remain a concern due to factors like shipping delays, labor challenges, and rising costs. Labor shortages, particularly for skilled workers with expertise in CNC manufacturing and automation also pose a significant hurdle.

To navigate this evolving landscape, manufacturers are focusing on strategies that enhance agility, efficiency, and sustainability. Investing in advanced technologies like AI, robotics, and IIoT is crucial for streamlining operations and staying competitive.

The emphasis on sustainability is growing, with manufacturers exploring ways to reduce their environmental impact through energy efficiency, material recycling, and circular economy models. Reshoring, bringing production closer to home, is also gaining momentum as a means of improving supply chain resilience and strengthening local economies.

Precision manufacturing in 2025 is a dynamic and evolving field characterized by technological innovation, increasing demand for complex products, and a strategic focus on efficiency and sustainability. By embracing advancements in automation, AI, and digital integration, manufacturers can unlock new levels of productivity, meet the evolving demands of various industries, and secure a competitive edge in the global marketplace. This is an era of immense potential for those who are ready to adapt and lead the way. Let’s lead the way in the USA!

We would like to help you all lead the way. Contact us with your story. Until next issue, Thank you all for your continued support, and God Bless our Troops!

Kim Carpenter

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly Kim@A2ZManufacturing.com

Mail Address: PO Box 459 Higley AZ 85296

Telephone: (480) 773-3239

Website: www.A2ZManufacturing.com E-mail:Kim@A2ZManufacturing.com

CONTRIBUTORS

Linda Daly, Stephen Hannemann

Published bi-monthly to keep precision manufacturers abreast of news, contracts, trends, and to supply a viable supplier source for the industry.

Circulation: A2Z Manufacturing West Coast mails to~7,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 21,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

By Stephen Hannemann

If you do not have a sense of humor, you should not attempt the game of golf! At this year’s Columbia chapter of the Society of Plastics Engineers (SPE) Annual Golf Tournament in June, the team fielded by 3D Plastics took the statement to heart!

The 3D team invaded Portland, Oregon’s venerable-108-year old Eastmoreland golf course dressed in a cross between 1920’s golf attire and Barnum and Bailey circus clowns! They showed up simply to have fun. As you can see from the team photo, they were serious about that.

Insert Team Photo

The 3D team, from left to right: Colman York - Maintenance Manager, Kelly DundasPresident, Elliott Dundas - Vice President, and Steve Waddle – Controller and HR Manager.

SPE is a worldwide organization founded in 1942.The Columbia chapter was founded in 1967 by Al Foleen, Merrill Roth, and Lee Dundas, Sr., Kelly’s father.The new chapter was formed for the purpose of helping people in the local plastics industry succeed and strengthen their skills through networking, events, training, and knowledge sharing – and the occasional golf tournament.

As for how the 3D team did, they had no idea where they placed, nor was keeping score part of their agenda. Their goal was to have fun! For the “dapper” 3D Plastics golf team this was a total and unabashed PLAY DAY!

In the business of injection molding, 3D Plastics has garnered a stellar reputation for their ability to take on viable molding projects. Now in their 26th year, 3D is a company with heart and it shows in many ways. For a new customer – an honest evaluation of a part for viability and molding success. For existing customers their highest priority is followthrough on delivery commitments, quality parts and stellar customer service. Then there are their value added services too numerous to list in the space allowed. For the full list of additional 3D services visit the 3D website.

If you are considering an injection molded part, consider 3D Plastics in Newberg, Oregon first.

3D Plastics, Inc., 2701 E. 2nd St, Newberg, OR 97132, call 503.537.0979 or visit www.3d-plastics.com. If in northernWashington call 425.501.7342 or email stephen@smhincllc.com.

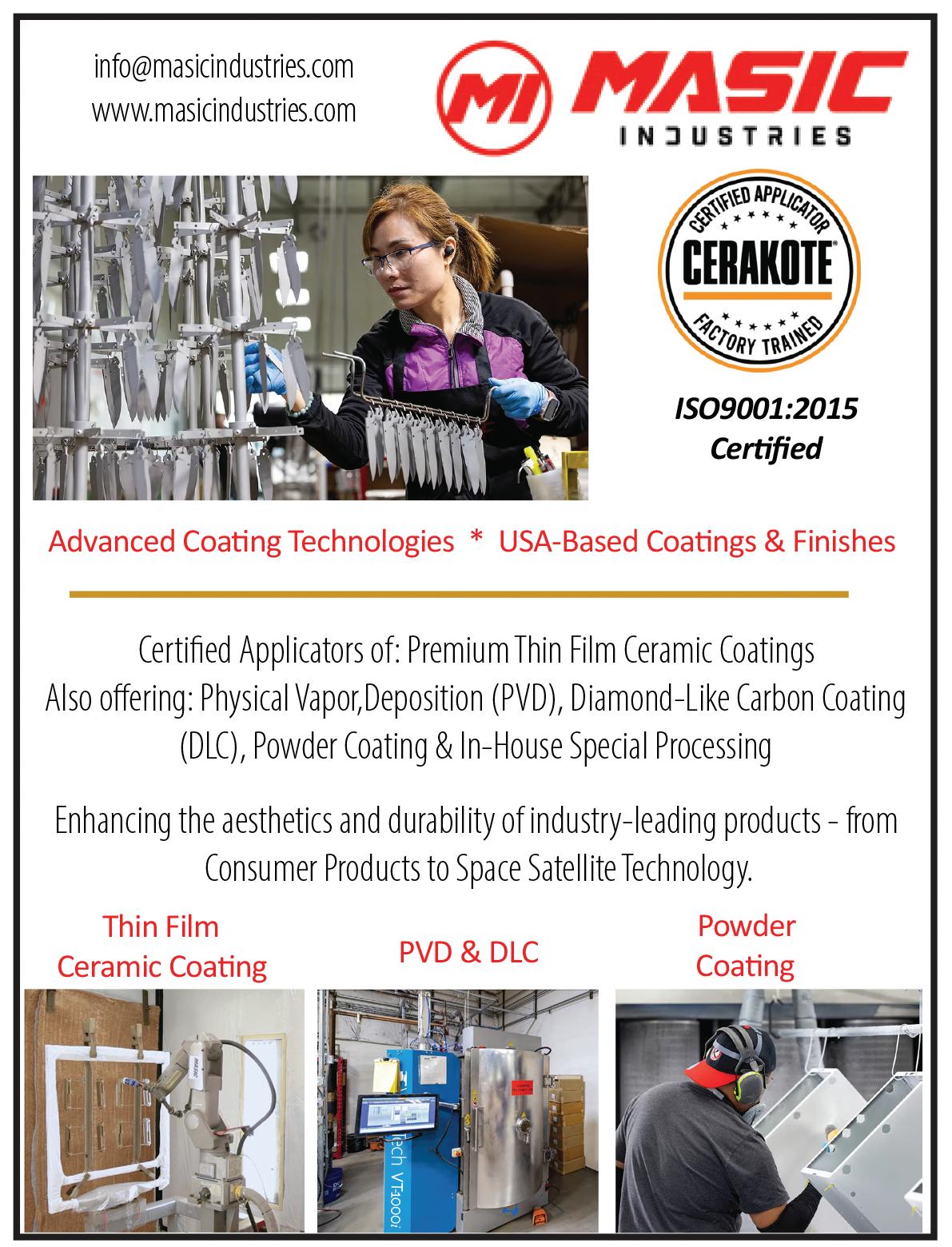

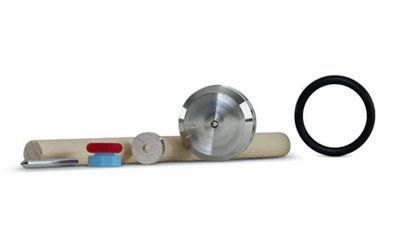

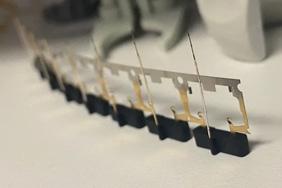

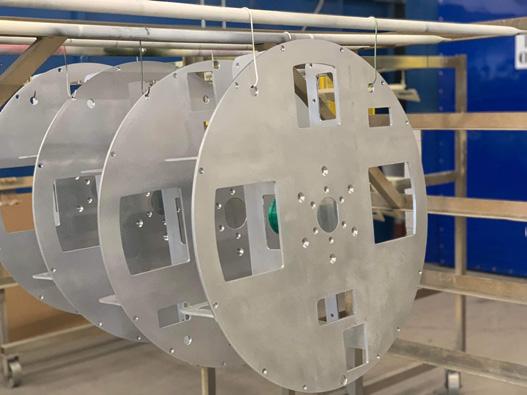

In business for nearly 2 decades, Grovtec Machining provides highquality machined products for a range of specialized fields. Today, they manufacture parts for the aerospace, sporting goods, automotive, transportation, communications, medical/dental, oil & gas, electronics and fastener industries.

Grovtec Machining provides full-service close-tolerance contract machining of metal products. Their design support service includes high mix low volume production in conjunction with your needs. Their diverse manufacturing equipment, including Swiss CNC machining, micro machining, and CNC milling, accommodates exceptional versatility, including finishing process services for those who do not have their own capabilities. Their process begins with your custom part prints, drawings, or samples for evaluations by our engineering team.

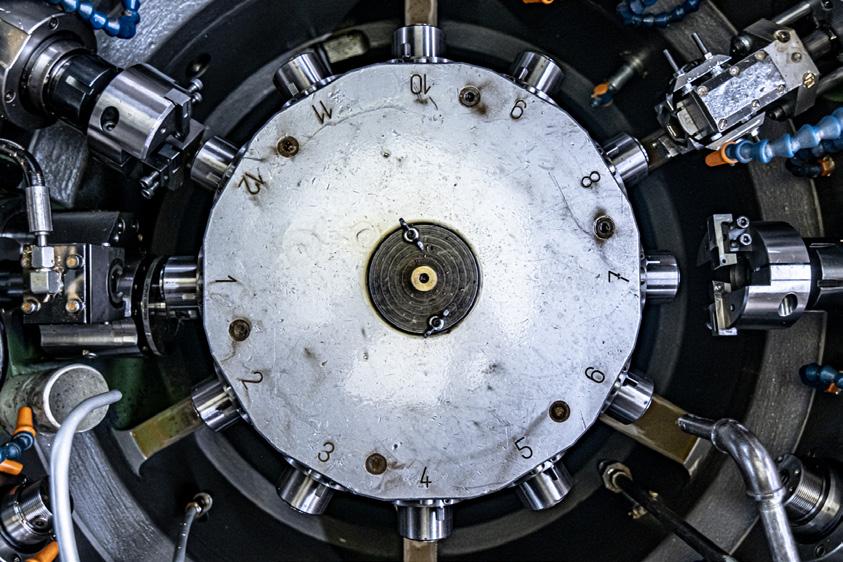

Recently, the company added a Hydromat department for high volume production to their capabilities.The Hydromat machines are versatile rotary transfer machines designed for high-precision, high-volume production. The Hydromat Legacy machines excel in producing parts with extremely tight tolerances, often within microns, ensuring consistent quality across large production runs.Their rigid construction and precise control systems reduce variability, making it ideal for industries that require high precision, such as medical devices and automotive components.

To learn more about how Grovtec Machining can support your close-tolerance machining projects, contact them at: 503.557.4689; info@grovtecmachining.com or visit their website at www.grovtecmachining.com

Methods Machine Tools Promotes Paul Haro to Regional Sales Manager of Pacific Northwest

Methods Machine Tools, Inc., North America’s foremost supplier of leading-edge precision machine tools and automation solutions,has promoted Paul Haro to Regional Sales Manager for the company’s Pacific Northwest territory.

Haro, most recently an area account executive, assumes sales leadership for a newly defined regional territory covering Northern California, Oregon, and Washington.

“I am honored to be chosen to lead this new team and region,” said Haro. “I look forward to providing our best solutions and the highest level of customer service in the industry.

“Paul managed a machine shop, represented dealers and builders, and understands the importance of being in front of the customer. He’s lived all sides of the customer experience” said David Chestnutt, Methods’ SVP of National Sales. “Paul is a top performer and highly recognized sales engineer with a passion for solving shops’ challenges. His leadership and track record make him the right leader to take on this new role.”

Haro, a former machinist and an AMT-certified CMTSE who join Methods in 2021, is actively building a regional sales team. This team will be supported by local service technicians and local application engineering. Open career opportunities can be found at www. methodsmachine.com

Methods Machine Tools, Inc. supplies high-quality, high-precision machine tools, automation solutions, and designs integrated custom machining processes and services. Methods represents FANUC RoboDrill, FANUC ROBOCUT, Nakamura-Tome,YASDA, OKK, KIWA Japan, WEILER, and its own brand of Methods machining centers.

Headquartered in Sudbury, Mass., and in operation since 1958, Methods operates seven technical centers, and a one-of-a-kind precision center. Methods has installed more than 45,000 machine tools throughout North America.

For more information, call 877-668-4262 or visit www.methodsmachine.com.

Steel Warehouse, founded in 1947, is one of the top three carbon sheet and plate steel processors. It has 14 locations in the United States and two in Mexico and Brazil, with a total inventory exceeding 400,000 tons. We offer exceptional support for all our products to help customers improve quality and productivity and reduce costs. This support includes in-house metallurgists who are available to assist with material and design questions, along with inventory management, global shipping and just-intime (JIT) delivery to streamline customers’ operations.

Our steel processing capabilities are unmatched. Steel Warehouse is a global leader in temper passing with eight temper pass/cut-to-length lines — more than any other steel processor, and the only one with lines in Mexico and Brazil. Additional processing capabilities include sheet, coil, hot rolled pickled and oiled steel up to 2”, precision cold-rolled strip and plate, slitting and more.

Steel Warehouse is known in the industry for its reputation for integrity and its dedication to supporting customers in the manufacturing sector. Customers can count on us to uphold our promise to deliver the best solution for their operations — they’ll get the right steel when and where they need it.

Steel Warehouse, 2722 West Tucker Drive, South Bend, IN 46619 Phone: 800-348-2529, steelwarehouse.com

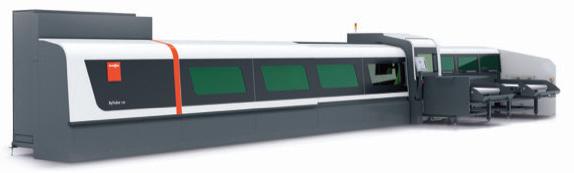

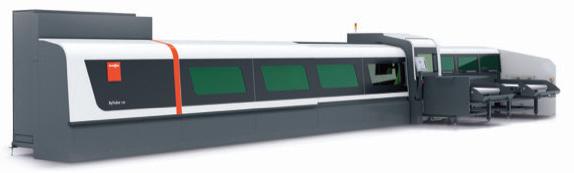

We are tube and more.With over 60 years of expertise, BLM GROUP has earned a reputation as a global leader in tube and sheet metal fabrication machine solutions of the highest quality. Our product portfolio consists of tube lasers, 5-axis lasers, sheet lasers, press brakes, tube benders, wire benders, end-formers and cold saws. Supporting the North American market from Novi, Michigan, BLM GROUP USA provides top-notch service, technical support and preventive maintenance plans that help metal fabricators keep their machines up and running. We help our customers produce more, minimize scrap and lower part cost.

BLM GROUP technologies are integrated in a single management suite that enables multi-level machine connectivity. For example, the new Prometheus Manufacturing Execution System (MES) actively collects data and provides insight into optimizing the workflow of connected machines on the shop floor. This allows processes to be visualized both statistically and through individual reports of actual machine usage on one screen. Through continuous analytics, the system provides data is provided that allows users to create a seamless workflow between the office and shop floor while maximizing machine efficiency — from any location.

These catered solutions eliminate semi-finished part storage, intermediate processes and secondary machining operations working in parallel, as well as errors resulting from the combined effect of several successive jobs. This results in an increase of competitiveness with technological integration by planning and monitoring all processes from a single point

of management. The integration of these technologies working together ensures that part creation is done correctly from the start, minimizing scrap from trial and error.

BLM GROUP provides a comprehensive, tailor-made solution to meet the individual needs of metal fabricators.The company is dedicated to providing support and training for machines that produce parts of the highest quality.

BLM GROUP USA, 46850 Cartier Drive, Novi MI 48377 (248) 560-0080, sales@blmgroupusa.com www.blmgroup.com

By Stephen Hannemann

Landmark Solutions, purveyors of an extensive array of metal fabrication equipment, showcased much of their offerings at an open house event in early June at Fulcrum Technologies Inc. in Tualatin, Oregon. From the time guests entered the parking lot, they knew they were headed for a manufacturing adventure.

After being greeted by Mike Brenner, Landmark’s Regional Sales Manager, and Aaron Watson, Landmark’s Sales Engineer, introductions to the many machine manufacturers representatives took place. Guests were then turned loose to wander Fulcrum’s utopian fabrication heaven. Landmark’s decision to showcase Fulcrum was strategic: what attendees soon learned was, if Landmark Solutions doesn’t have what they need for their metal fabrication operation, it just may not have been invented yet! Fulcrum Technologies truly was a Landmark showroom.

The most valuable aspect of the experience for visitors was how many representatives from the various equipment manufacturers were present. The ability to have timely answers to questions regarding the capabilities of any piece of equipment that happened to pique an interest was priceless. From monster press brakes and gantry style vertical machining centers, to lasers, finishing machines, and the latest robotic welding technology – all information was available from the representatives in attendance.

Bystronic – Advanced Solutions for Laser Cutting, Bending, Automation, and Software

Flex Machine Tools – American-madeVertical Machining Centers and Tapping Arms

OTC Daihen – World’s No. 1 Arc Welding Robots & Welding Cells

DAVI – Industry-Leading Plate and Angle Rolling Equipment

Timesavers - Industry Standard for Deburring & Finishing Solutions

Kohler – Precision Plate Leveling Equipment

If you were unable to attend this incredible event at Fulcrum Technologies, visit page XX of this magazine and check out Landmark’s ad, or visit www. LandmarkSolutionsCorp.com and shop until you drop! Landmark Solutions, 1230 N. Jefferson Street, Suite H, Anaheim, CA. Phone 714.393.3783.

Landmark Solutions – Bringing Over 100 Years of Industry Expertise

Tariffs are promoting employment and influencing manufacturers’ investment strategies, according to the Reshoring Initiative, but

U.S. manufacturing costs and skilled worker shortages remain as global cost disadvantages.

The U.S. manufacturing sector generated 244,000 new jobs last year as a result of reshoring and foreign direct investment (FDI) activity, according to the Reshoring Initiative’s 2024 Annual Report. Since it began tracking global manufacturing and U.S. jobs in 2010, Reshoring Initiative credits those reshoring and FDI for creating 1.7 million new jobs over the past 15 years.

“Reshoring” describes the business strategy of transferring manufacturing operations to the U.S. from foreign locations.

The 2024 results reflect the influence of U.S. tariffs on manufacturing activity and supply chains, according to Reshoring Initiative, a not-for-profit organization that works to promote U.S. manufacturing by helping businesses to assess the cost of offshore production and demonstrating to them the benefits of domestic manufacturing, including cost savings, quality control, and supply chain resilience.

The Reshoring Initiative is a not-for-profit organization focused on growing U.S. manufacturing by helping businesses to assess the cost of offshore manufacturing and demonstrating to them the benefits of domestic manufacturing, including cost savings, quality control, and supply chain resilience.

“Reindustrializing America is impossible without reshoring, FDI, and strong industrial policy,” stated Reshoring Initiative president Harry Moser. “Our data shows tremendous progress, but the U.S. must address workforce shortages and manufacturing cost disadvantages to maintain this momentum.”

In addition to the 2024 job totals attributed to reshoring and FDI, the annual report details that reshoring by U.S.-based businesses last year exceeded foreign direct investment by the largest margin recorded to date.

The group classified 88% of the 244,000 new jobs last year as belonging to high- or medium-tech manufacturing sectors, but that figure has risen to 90% of the new jobs in the early tracking of 2025 reshoring activity.

It recognized that low-tech industrial jobs remain “under-reshored, leaving U.S. supply chains vulnerable for mass-market consumer goods.”

The industries leading the reshoring activity in 2024 were computer and electronics, electrical equipment (including EV batteries and solar), and transportation equipment.

Most of the new manufacturing activity (reshoring plus FDI) is being drawn from South Korea, China, and Germany, according to the report. Texas, South Carolina, and Mississippi are the top states where businesses are placing their reshored operations.

As for U.S. tariffs on imports of manufactured goods, the Reshoring Initiative reported that tariffs are rising as a motivating factor for the businesses making the reshoring decision – up by 454% in 2025 over 2024. At the same time, government incentives are receding (-49%) as a motivator, as formerly available incentives are phased out.

Reshoring activity in the current year may not sustain the job growth recorded for 2024. Year-to-date figures project a drop of about 70,000 reshored/FDI jobs, to 174,000 announced jobs for 2025. “Many large tentative announcements are contingent on clearer signals from the administration,” according to Reshoring Initiative.

The group identified the factors that may impede reshoring and FDI activity, starting with U.S. manufacturers requiring more

skilled workers to staff their operations: U.S. manufacturing apprenticeships rose 83% over the past decade, but far more skilled workers are needed to sustain reshoring growth.

Other risks cited include “policy uncertainty” that delays investment planning, retaliatory tariffs that could undercut U.S. export efforts, and the continuing high cost of U.S. manufacturing, which Reshoring Initiative claims is 10 to 50% higher than competing offshore markets.

Early 2025 data projects a drop to 174,000 jobs announced for this year — but that figure could increase if businesses gain confidence in the permanence of new tariff and industrial policies. Some large reshoring or FDI announcements are contingent on clearer signals from the administration, RI reported.

Broadly, the Reshoring Initiative argues that continued progress for growing domestic manufacturing requires “a true national industrial policy” that emphasizes skilled workforce development (based on apprenticeships); a weaker USD currency (-20%) to improve the cost-competitiveness of U.S. manufacturers; and “smarter” application of tariffs and Total Cost of Ownership (TCO) analysis, to make reshoring consistent.

“The U.S. can’t count on tariffs alone to restore its industrial leadership,” according to Moser. “It must level the cost playing field and build a skilled workforce to truly compete and win globally.”

ANAHEIM, CA –

Landmark Solutions and sister company Best Choice Parts are proud to announce the official opening of their new, stateof-the-art facility at 1230 N. Jefferson St., Suite H, Anaheim, CA 92807.

After months of preparation, the new location is now fully operational, offering equipment demonstrations, hands-on customer training, and a significantly expanded inventory of OEM and aftermarket waterjet parts.

Since moving in February 2025, Landmark has welcomed customers from across the West Coast to experience the new space through live

demos, open house events, and technical trainings. The new Anaheim location was designed to better support the region’s growing metal fabrication community with:

* A fully equipped showroom for live machinery demos

* A dedicated training center for in-person workshops and customer education

* A larger warehouse to stock thousands of waterjet parts for immediate delivery

“We’re excited to finally share this new space with our customers,” said Chad Mooneyham,Vice President at Landmark Solutions. “The response so far has been overwhelmingly positive, and we’re looking forward to continuing to grow with the fabricators we serve.”

To schedule a visit, request a live demo, or learn more about upcoming training sessions, please contact:

(714) 393-3783 |

Three domestic locations will add capacity for SUVs and light trucks in a new strategy to address tariff restrictions on imported vehicles and continuing demand for gas-powered vehicles.

General Motors Co. pledged about $4 billion in capital investments for three U.S. assembly plants over the next two years, and will shift production of some SUVs and light trucks from Mexican operations to those plants in Michigan, Kansas, and Tennessee. The plan is an acknowledgement of GM’s intention to adjust its production programs to comply with the 25% U.S. tariffs on imported vehicles and auto parts not addressed by the U.S.-Mexico-Canada pact.

According to the automaker’s statement, the new production strategy will give GM capacity for over 2 million U.S.-built vehicles per year.

“Today’s announcement demonstrates our ongoing commitment to build vehicles in the U.S and to support American jobs,” stated GM chairwoman and CEO Mary Barra. “We’re focused on giving customers choice and offering a broad range of vehicles they love.”

The new investment strategy also signals GM’s renewed commitment to internal combustion engine vehicles, following several years of heavy investments in electric vehicle development and production capabilities. It follows a recent announcement of an $888-million plan to expand V-8 engine production at Tonawanda, N.Y.

The automaker noted that it’s 2025 capital spending guidance remains at $10 to $11 billion, and $10 to $12 billion through 2027, indicating increased domestic investment.

The capital investments are targeted at the GM Orion Assembly plant in Orion Township, Mich., where GM will be producing full-size SUVs and light pickups in 2027, “to help meet continued strong demand,” according to an announcement; the GM Fairfax Assembly plant in Kansas City, Kan.; and the GM Spring Hill Manufacturing plant in Spring Hill, Tenn.

Previously, GM announced it will shift Chevy Silverado and GMC

Sierra pickup production from Silao, Mexico, to the Fort Wayne (Ind.) Assembly plant.

Orion had been one of the locations where GM had planned to produce EVs, starting in 2026, but now it indicates that the Chevrolet Silverado EV, GMC Sierra EV, Cadillac Escalade IQ, and GMC Hummer EV pickups and SUVs will be built at the Factory Zero operation, in Detroit-Hamtramck, Mich.

The GM Fairfax Assembly plant in Kansas City, Kan., will be updated for production of Chevy Equinox SUVs, starting in 2027. It is also slated to assemble the Chevrolet Bolt EV and a new, “affordable” EV model.

The Spring Hill (Tenn.) Manufacturing plant will start producing Chevrolet Blazer SUVs in 2027, while continuing to produce the Cadillac Lyriq and Vistiq EVs, and the Cadillac XT5 luxury SUV. Currently, the Blazer is assembled at Ramos Arizpe, Mex.

The 90-day pause in scheduled U.S. tariffs means that the Boeing CEO’s outlook is being confirmed, with a report that a new aircraft has been shipped to the in-country outfitting operation.

Boeing has resumed transporting new aircraft to China, according to published reports, with a 737 MAX jet leaving the U.S. on June 6 for delivery to Xiamen Airlines. The manufacturer has not corroborated the development, first reported by Reuters.

G E T T O K N O W U S

Servicing our industry and trade customers in intelligence heat treating for over 60 years.

Established in 1963

Real Time Live Job

Tracking

10+ Processes Performed

50+ Furnaces

AOG and Line Down

Services

Over 10+ Prime Approvals

24/7 Processing

602-258-7751

cs@phxht com

www phoenix-heat-treating com

The news confirms a forecast made by Boeing CEO Kelly Ortberg in late May, in remarks to an investor conference, that deliveries to China would begin again soon.

In April, several 737s were returned from the Boeing 737 Completion and Delivery Center in Zhoushan to the U.S. when Chinese carriers declined to take delivery of their orders, in response to the escalating tariff dispute between the U.S. and China.That impasse is now abating since the two countries agreed in May to pause the implementation of tariffs for 90 days and to engage in new trade negotiations.

The Chinese market is critical to Boeing’s revenue forecast, as airlines there represent an estimated 10% of the company’s order backlog.

The backlog totals 5,643 commercial jets, with an estimated value of approximately $460 billion, including several dozen 737 MAX aircraft booked for Chinese carriers.

737s destined for Chinese buyers are customarily transferred from Boeing’s domestic manufacturing site in Renton, Wash., to a final outfitting operation near Shanghai, before they are turned over to the buyer.

The Boeing 737 Completion and Delivery Center in Zhoushan is a joint venture between Boeing and Commercial Aircraft Corp. of China Ltd. (Comac.) Workers there install interior fixtures and paint liveries for 737 MAX airplanes bound for Chinese airlines customers.

The completed jets are handed over to Chinese airlines from a separate, Boeing-owned delivery center.

Initially opposed by two Presidents, the United Steelworkers union, and a raft of rivals, Nippon Steel Co. finalized its deal to acquire 100% of Pittsburgh, Pennsylvania-based U.S. Steel Co. for $14.9 billion.The final deal includes government-approved conditions that, among other things, grants the President of the United States strong oversight into business decisions made by the newly owned U.S. Steel.

In a joint statement, the companies claimed the partnership would create more than 100,000 jobs of “direct, indirect, and induced” jobs in Pennsylvania, Indiana, Arkansas, Minnesota, and Alabama, citing a study commissioned by U.S. Steel by the Parker Strategy Group. In productivity, the companies predict its annual crude steel production capacity will reach 86 million tons.

to invest $11 billion in U.S. Steel by 2028, leave its headquarters in Pittsburgh, and agree not to hinder U.S. Steel’s ability to produce enough steel for the U.S. or to trade its metal following U.S. laws. In terms of management, Nippon Steel has agreed the CEO and a majority of the U.S. Steel board will be U.S. citizen, and a “golden share” granted to the U.S. government that gives it an independent director on the board and novel access to more staffing and business decisions.

The deal requires Nippon to commit to a “National Security Agreement” with the U.S. government, with implications for how U.S. Steel will do business and staff its executive suite under ownership.The deal binds Nippon

In statements, company leadership explicitly thanked President Trump for greenlighting the deal and its terms. Eiji Hashimoto, the CEO of Nippon Steel, credited the sale to “President Trump’s historic and visionary decision.” The CEO of U.S. Steel, Dave Burritt, called the sale a “momentous day” and thanked “President Trump’s bold leadership” for securing the deal, which he added would lead to “transformative investment, cutting-edge technology, and the creation of good-paying jobs across the United States.”

Takahiro Mori, Nippon Steel’s current Vice Chairman and who will serve as Chairman of the U.S. Steel Board, said he was “delighted

that we have made this day a reality. We share President Trump’s commitment to protect the future of the American steel industry, American workers, and American national security.”

The United Steelworkers union, which will represent those workers, took a harder tone. The union had opposed the deal and, unconventionally, attempted to use its “right of first refusal” to support Cleveland, Ohiobased company Cleveland Cliffs Inc. and reject all other comers. After a May 23 statement in which President Trump signaled approval for the conditions of the current deal, USW’s International President, David McCall, called Nippon Steel “a serial trade cheater” and the proposed deal “a disaster.”

In a statement, McCall characterized the decision as one “aggressively promoted” by management and vowed the union would keep a close eye on Nippon Steel.

“As the sale concludes, it seems likely that attention will dissipate. U.S. Steel’s PR machine will power down, and the majority of elected officials will turn their attention elsewhere,” said McCall. “However, our union will remain.We will continue watching, holding Nippon to its commitments.” He also called the “golden share” offered to President Trump “a startling degree of personal power over a corporation.”

That “golden share” isn’t really a share of the company, but essentially a package of consent decrees. It gives the government the right to appoint one independent director, and grant the President specifically consent rights for reducing committed capital investments; changing U.S. Steel’s name or headquarters; offshoring U.S. Steel, its production, or jobs; acquiring competitors in the United States; and “certain decisions on closure or idling of U.S. Steel’s existing U.S. manufacturing facilities, trade, labor, and sourcing outside of the United States.”

The finalization closes the chapter on U.S. Steel’s history that began almost two years ago. The historic company announced it was considering offers in August 2023 after rejecting a series of unsolicited bids from Cleveland-Cliffs. Shortly afterwards, and before any other companies could make an offer, Thomas Conway, then-International President of the USW, authored an open letter saying the USW would not support any non-Cliffs deal. In the letter, Conway noted that Cliffs, after acquiring AK Steel and ArcelorMittal USA in 2020, “rather significantly” increased its union workforce.

Esmark Corp. heeded the USW and backed off, and another would-be-

buyer, Brazilian steelmaker CSN, said it wouldn’t make a bid, but in December, Nippon Steel won an auction with a bid of $14.1 billion, more than double Cliffs’ initial offer. The planned sale of the centenarian U.S. manufacturer with headquarters in a key battleground state roiled the political waves of the 2024 presidential campaign. As a candidate, Trump vocally opposed the sale in January 2025, and then-President Biden followed in March, with Vice President Harris reiterating his stance when she took over his campaign. With the sale on the rocks, Nippon announced more investments to sweeten the deal and argued the move was ideal for countering China.

It wasn’t enough. After the Committee on Foreign Investment in the United States deadlocked, President Biden blocked the sale in January 2025, prompting Cleveland-Cliffs to prepare a joint proposal with Nucor to snag it. Then, in April 2025, President Trump ordered the Committee on Foreign Investment in the United States to give the proposed deal a second look. This time, with the conditions included, the CFIUSA gave it a green light, and Trump gave his blessing to the U.S. Steel-Nippon Steel “partnership.”

Regional carrier SkyWest Inc. is extending its reliance on the E175 with a $3.6-billion booking that will begin deliveries in 2027. Embraer’s best customer is expanding its commitment to the E-Jet series. Skywest Inc. will purchase 60 E175 aircraft in an order listed at $3.6 billion, but may be worth more if an additional 50 aircraft options are fulfilled.

The first deliveries will begin in 2027.

The E175 is one of four models in Embraer’s E-Jet series of twinengine jets designed for short to medium-range flights and typically for regional service, with a range of 2,200 nautical miles (2,532 miles / 4,075 km.) The E175 seats 78 to 88 passengers, depending on the configuration.

Arjan Meijer, president & CEO of Embraer Commercial Aviation, called the E175 ”the cornerstone of regional aviation in North America,” and added that the new order “underscores SkyWest’s confidence in our aircraft’s performance, reliability, and passenger comfort.”

Utah-based SkyWest – which operates regional service under contract for Alaska Airlines, Delta Air Lines, United Airlines –presently has 263 Embraer E175 jets in its fleet, and order in place for 16 more.

“As the largest E175 owner and operator worldwide, we’re pleased to continue growing our E175 fleet and enhance our dual-class footprint,” stated SkyWest president and CEO Chip Childs. “This order enables us to advance our long-term fleet strategy and to continue to deliver the premier regional product in the industry.”

By Karl Sinclair

The Boeing Company (BA) remains upbeat on its annual 20-year commercial aircraft projections, as the aviation industry comes to terms with the economic uncertainty of the current political climate.

Boeing projects a need for 43,600 aircraft over the next 20 years, with 75% of those being single-aisle jets.

This is a drop of 375 aircraft over the previous years outlook, in which the company foresaw a need of 43,975 over the same period.

3D can provide design assistance and work with existing products to produce them more economically.We are a ‘UL Certified’ molder offering low to high quantity production runs.

We produce many of our customer’s products with metal and plastic sub-components molded in. It is very common to use threaded inserts, bushings, contacts, and plastic substrates.

“Passenger traffic has tripled in size as the global economy has doubled. Despite the challenges of the last 25 years that we’ve seen both from an exogenous shock standpoint, from a global pandemic standpoint, and even from an economic standpoint through the last 25 years,” explained Darren Hulst, vice-president of Commercial Marketing.

Boeing is also cognizant of the increased competition in the sector, as over the same time frame, the top ten airlines in the world accounted for a whopping 45% of industry capacity.

The growth has been in the Middle East and Asia Pacific regions, coming at the expense of Europe and North American carriers.

Year-over-year, Boeing expects China to account for a larger percentage of the demand for new aircraft, up 100 basis-points, to 21% of the market.

It also expects that fleet growth will also outpace replacement aircraft, as 22,500 of the projected 43,600 deliveries are used for expansion, while the remaining 21,100 jets will be used to replace aircraft that are currently in fleets.

Given the current climate regarding tariffs and delivery refusals, it will be supremely important for Boeing to have normalized relations with a nation that is expected to accept more then one-fifth of the future commercial aircraft deliveries.

Aircraft shortage

Still recovering from the effects of the global pandemic, the aviation supply chain has been slow to catch-up to demand levels of the OEMs.

At previously exhibited annual production levels of ~800 per manufacturer (Airbus and Boeing), this represents a production loss of about a year, for the industry. Once Embraer and others are added in, the 1,500-2,000 figure is not an unreasonable estimate.

Growth and Replacement

Boeing projects that the lion’s share of growth in the global aircraft fleet, will be in emerging markets.

North America and Eurasia will have the greatest need for fleet replacement, accounting for a combined 54% share of the projected 21,100 future deliveries.

This shrinks to a 29% share of the projected deliveries for future growth.

China, South and Southeast Asia will account for 50% of the growth in the global air fleet, over the next 20 years, according to Boeing.

“I think you can see a kind of two speeds of growth in terms of emerging and advanced economies,” said Hulst. “Emerging economies will be growing about two percentage points per year faster than advanced economies, which means by the end of this forecast, by the mid 2040s, the size of demand within emerging markets and within advanced economies, kind of that short haul and domestic type markets will be about the same size for both the advanced and emerging economies.”

In the 2024 projections, Boeing estimated a need of 20,555 aircraft for fleet replacement and 23,420 for growth.

Eurasia, China, South & Southeast Asia and North America will account for the vast majority of narrow-body deliveries, while the Middle East & Africa and North America & Oceania will receive most of the future wide-body deliveries.

In 2005, Boeing released its 20-year Market Outlook, in which it projected a need for 25,700 commercial aircraft.

The company projected a remarkably accurate 4.8 annual growth in passenger traffic, at the time.

“Twenty years ago, the average load factor was about 73%.Today, it’s about 83% or 84%. So, think about that. If 10% or 10 percentage points more of every aircraft is filled, that’s the effect of 10 or 20 more seats on any airplane,” explained Hulst.

He noted the expansion of low-cost carriers, who use high-density layouts, filling as many seats as possible, as one of the drivers of increasing load factors.

“I think the biggest takeaway from my perspective is that single aisle as a percentage of the total fleet has grown already from 55% to 66% of total jet aircraft. And over the next 20 years, we expect that to expand about 70% of aircraft flying in the year 2044…in the single aisle market, in the last 25 years, the average seat size has moved up right around 30 seats from the mid 140s to the high 160s,” he noted.

Boeing detailed the trend in the 2024 outlook.

Airlines are working their fleets harder, increasing the amount of seats on their aircraft and are filling them with more passengers, then they did 20 years ago.

Boeing is currently working towards the certification of the 737-10 MAX variant, its largest narrow-body offering, in that regard.

Despite the seemingly endless string of setbacks that the industry has suffered, the commercial aviation sector has remained surprisingly resilient, continuing the cycle of fleet replacement and growth.

With both major OEMs holding onto significant backlogs, the short-term battle will be overcoming the current political uncertainty and rebuilding a supply chain that was heavily damaged during the previous crisis.

When precision is non-negotiable, trust Methods Machine Tools. Our advanced CNC solutions and automation expertise ensure micron-level accuracy, optimized efficiency, and superior craftsmanship for every project.

Boston | Charlotte | Chicago | Detroit Houston | Los Angeles | Phoenix

Machine tools are essential for precision manufacturing, enabling the creation of components with tight tolerances and intricate geometries. Methods Machine Tools, for example, specializes in providing a wide range of CNC machine tools known for their precision and automation capabilities, serving various industries like automotive, aerospace, and medical.

Precision Machining:

Precision machining involves using machine tools to create parts with very tight dimensional tolerances and surface finishes. This is crucial for industries where even minor deviations can affect performance and reliability.

CNC Technology:

Computer Numerical Control (CNC) is a key technology in precision machining. CNC machines use pre-programmed computer software to control the movement and operation of machine tools like lathes, mills, and routers, ensuring high accuracy and repeatability. Methods Machine Tools:

Methods Machine Tools is a prominent supplier of CNC machine tools and automation solutions.They offer a variety of machines, including vertical, horizontal, and five-axis machining centers, as well as multitasking CNC lathes.

Techniques:

Precision machining employs various techniques, including: Turning: Used to create round parts with precise diameters and smooth surfaces.

Milling: Involves using rotating cutters to remove material and create flat surfaces, slots, and other features.

Grinding: Utilizes abrasive wheels to achieve tight tolerances and high surface finishes.

EDM (Electrical Discharge Machining): Employs electrical discharges to erode material, enabling the creation of complex shapes.

Lapping and Honing: Use abrasive substances to achieve highly polished surfaces and tight tolerances.

Micromachining: Focuses on producing extremely small parts with high precision.

Methods Precision Center:

Methods Machine Tools has a dedicated Precision Center where they test and prove out challenging parts with tight tolerances, pushing the boundaries of machining capabilities, according to Methods Machine Tools.

In Southern California’s vast manufacturing ecosystem, David Engineering and Manufacturing, Inc stands out—not for its size, but for its staying power, versatility, and deep commitment to craftsmanship. Founded in 1972 by Journeyman Tool & Die Maker Mike David Sr —“the day before I was born,” jokes President Michael David—the company has grown from a highvolume metal stamping outfit into a 30-person, vertically integrated ISO 9001-certified fabrication and machine shop.

This isn’t a sprawling corporation with layers of middle management. Walk into the office today and you’ll likely be greeted by multiple generations of the David family. Michael leads the company as president; his father, Mike, now 78, still comes in to help support the team with his years of experience.. Rochelle, Michael’s wife, runs HR and book keeping. And today, Michael’s son, daughter, and nephew are integral members of the business.

The company’s real differentiator lies in its scope of services. “We’re a true one-stop shop,” Michael explains. “Laser cutting, tube laser, forming, welding, machining, light assembly—we do it all in-house.” That control allows for rapid prototyping, high precision, and tight quality control.

Many of David Engineering’s customers are located within 100 miles, and the company maintains three delivery trucks to ensure daily service. Their on-time delivery and quality metrics are strong—ISO-certified and graded solid A by customers. Impressively, their very first customer from 1972 is still active today.

David Engineering’s agility is driven by a continuous investment in modern technology, much of it sourced from the longstanding partnership with Bystronic. They are driven to always learn through continuous market research on machines, software and technologies and the ability to learn from any missteps. Last year, the company decided to enter the tube laser market and initially opted for a lower-cost Chinese import. However, due to safety concerns, lack of support, and significant technical limitations, David Engineering chose to upgrade its tube-cutting capabilities by investing in the Bystronic ByTube, a high-speed fiber laser system with 5-axis cutting capability. “With the ByTube, we can now efficiently process round, square, rectangular, and open-angle tubes, with incredible precision and speed—and with no secondary ops,” says Michael. This system has dramatically opened up their capabilities as a company.

Automation has been a game changer for productivity and efficiency. “Before adding automation to our laser machines, we ran multiple shifts to meet demand,” Michael explains. “Now, with the automation and reliability Bystronic provides, we maintain the same output on just one shift. The machine’s quick setup, fast cycle times, and intuitive controls reduce downtime and operator load.”

That machine-level automation is only one part of the equation. Behind the scenes, David Engineering also implemented a robust enterprise resource planning (ERP) system to improve visibility and control across its operations. “The ERP gives us real-time information on job status, inventory levels, and scheduling,” says Michael. “It helps us quote faster, plan smarter, and stay on top of every part that moves through the shop.”

Michael also emphasizes Bystronic’s userfriendly BySoft interface and overall value over time. “The GUI is clean, fast, and easy to train on—even for people without a deep programming background,” he says. “And the total cost of ownership is excellent. The reliability, service, and performance mean we’re not losing money on downtime or repairs. That’s huge for a shop our size.”

This dual investment—in smart machines and management tools—has allowed David Engineering to thrive in the low-tomedium volume, high-precision space. “It’s not just about speed,” Michael adds. “It’s about quality, flexibility, and repeatability—and Bystronic’s equipment delivers all three.”

The ByTube allows David Engineering to meet growing demand for tube-based assemblies across industries, from commercial furniture to architectural elements. “The clean cuts, beveling capabilities, and part repeatability open up so many design possibilities for our customers,” he notes. David Engineering’s relationship with Bys-

tronic goes beyond equipment purchases. “Landmark Solutions, the West Coast Bystronic distributor, and Bystronic, the builder, are true partners,” says Michael. “They understand our needs and provide excellent support—from machine training to maintenance and upgrades.” This partnership extends into collaborative projects, such as the co-design of a material rack storage system with Landmark.

Over the past decade, the company has transitioned from high-volume stamping (though they still offer it as a service) toward low-to-medium volume precision work. “That’s where the industry is going,” Michael says. “Customers want flexibility and customization. That’s our sweet spot.”

David Engineering also partners with suppliers on practical shop solutions. A recent example: the custom material rack system they co-developed with Landmark Solutions. The modular steel structure is designed to maximize vertical storage and improve access to raw materials.

“It wasn’t just about stacking metal,” Michael says. “We looked at forklift access, load limits, and future shop layouts. It had to be safe, scalable, and space-smart.”

While David Engineering has embraced automation and runs lights out—especially in laser cutting and welding—it still relies on a seasoned team that includes several employees with decades of tenure.

“We treat our people well,” Michael says. “That’s why they stick around. Our longest-serving employee was with us for 50 years.”

The company emphasizes cross-training and flexibility, allowing workers to shift between roles as needed. That adaptability is what enables the company to deliver short lead times and complex parts without sacrificing quality. In fact, through automation, David Engineering has equaled the output it took 2 shifts to manufacture and can now be done with 1 shift.

David Engineering & MFG, Inc Corona, CA 92879

��������5��-����5-5��00

������ davidengineering.com

Landmark Solutions, Bystronic Distributor – West Coast Anaheim, CA ����80��

������������.������.����8��

������ landmarksolutionscorp.com

A compact yet powerful tube processing system designed for fabrication shops that require flexibility and efficiency.

The ByTube Star ����0 handles tubes up to ����0mm in diameter and offers rapid changeovers through automated tooling systems. Its intuitive programming interface reduces setup times significantly, while the machine’s advanced fiber laser cutting head delivers precise, burr-free cuts. Ideal for small to medium batch production, it’s especially well-suited for industries like furniture, automotive, and industrial components where versatility and accuracy are essential.

Engineered for heavy-duty applications and highvolume production, the ByTube Star ����0 processes tubes and profiles up to ����0mm in diameter. Featuring full automation—including automatic loading, unloading, and sorting—it enables continuous operation with minimal operator intervention. The machine’s robust construction ensures exceptional cutting precision even on thick or complex materials. High-speed beveling and marking functions add to its versatility, making it a go-to solution for structural fabricators, heavy machinery manufacturers, and large-scale assembly shops.

Contact Information

Bystronic Inc. – U.S. Headquarters ����00 West Central Road Hoffman Estates, IL 60������ ��������8��������������-0��00 sales.us@bystronic.com

������ bystronic.com

Ellison Technologies is a provider of advanced machining solutions to North American metal-cutting manufacturers and their global affiliates.

As a family of companies we are committed to the survival and growth of the American manufacturing industry. Independent offices provide us a local market focus and the flexibility to advocate the needs of each of our valued customers.

Our priority is to introduce technologies that strengthen our customers’ ability to compete in the markets they serve. Whether the solution involves a stand alone machine, multi-process equipment, or an integrated manufacturing system with robotic automation, our goal remains the same; to optimize throughput and quality at the lowest per-part manufacturing cost.

Our team of engineers, equipment and automation specialists, and project management professionals, are dedicated to helping manufacturers get the most from their technology investments. Service and parts engineers provide post-installation support aimed at optimizing machine availability, productivity, and cost of ownership.

We strive to make every customer worldcompetitive. Whether our customer competes globally or not, Ellison Technologies brings its full mastery of advanced manufacturing technology to provide the most comprehensive and productive solutions the industry has to offer.

Whenever you add a new technology, there’s bound to be a learning curve. At Ellison Technologies, we act as an extension of your operation as you get up to speed. If you have any questions – whether before, during or after the machine install – we’re here to help you identify the best way to do things.

There are Ellison branches all over the United States, and all of our employees bring experience (and a willingness to share it) that’s simply unmatched. No matter how new your machining adventure is to you, we’ve seen it, and we’ve solved for it already. It’s a welcome dose of peace of mind as your journey begins.

Our mission is clear: at Ellison, we equip American manufacturers to compete and win, both locally and globally. If you can’t shake the feeling that there’s a better way to do things, we are ready to help you increase quality and efficiency, win more work and increase your profits.

For more information on Ellison Technologies contact them at: 866-567-2580, www.ellisontechnologies.com

Raytheon Co.,Tucson Arizona, is awarded a $299,694,832 firm-fixedprice modification to previously awarded contract N00024-24-C-5408 to procure test equipment and spares, and to exercise options for Evolved SeaSparrow Missile Block 2 Guided Missile Assemblies. Work will be performed in Tucson, Arizona (12%); Edinburgh, Australia (11%); Mississauga, Canada (10%); San Jose, California (9%); Raufoss, Norway (8%); Hengelo Overijssel, Netherlands (5%); Ottobrunn, Germany (5%); Cambridge, Canada (4%); Nashua, New Hampshire (4%); Koropi, East Attica, Greece (3%); Lystrup, Denmark (3%); Ankara, Turkey (2%); Andover, Massachusetts (2%); Torrance, California (2%); Westlake Village, California (2%); Grenaa, Denmark (2%); Eight Mile Plains, Brisbane, Australia (2%); Canton, New York (2%); Camden, Arkansas (1%); Aranjuez, Spain (1%); Milwaukie, Oregon (1%); Lawrence, Massachusetts (1%); and various other locations each less than 1% (8%), and is expected to be completed by September 2030. Fiscal 2025 weapons procurement (Navy) funds in the amount of $283,710,000 (95%); fiscal 2025 other customer funds in the amount of $7,044,336 (2%); fiscal 2024 weapons procurement (Navy) funds in the amount of $5,404,000 (2%); and fiscal 2024 other customer funds in the amount of $3,536,496 (1%), will be obligated at the time of award and will not expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity.

S&K Aerospace LLC,* St. Ignatius, Montana, is being awarded a

$54,723,078 firm-fixed-price, indefinite-delivery/indefinite-quantity, long-term contract for the repair, overhaul, and upgrade of 351 commercial items used on the P-8A Poseidon maritime aircraft. Work will be performed at various contractor supplier locations (65%); and Byron, Georgia (35%). This contract includes a five-year base period with no options. Work is expected to be completed by June 2030. Working capital (Navy) funds will be obligated as individual orders are issued, and funds will not expire at the end of the current fiscal year.This contract was competitively procured with the solicitation posted to the System for Award Management and Navy Enterprise Commerce Online websites as a 100% small business set-aside, with eight offers received. Naval Supply Systems Command Weapon Systems Support, Philadelphia, Pennsylvania, is the contracting activity (N00383-25-D-A501).

General Dynamics Electric Boat Corp., Groton, Connecticut, is awarded a $986,785,825, cost-plus-fixed-fee modification to previously awarded contract N00024-17-C-2117 for additional component development, class lead yard support, and Submarine Industrial Base (SIB) supplier development enhancements supporting Columbia-class ballistic missile submarines and the nuclear shipbuilding enterprise (Virginia-class submarines and Ford-class aircraft carriers). This contract combines previously scheduled United Kingdom (U.K.) funding modification in the amount of $16,035,000, as annotated herein, for the continued support of the joint U.S. Columbia-class and U.K. Dreadnoughtclass common missile compartment program. The industrial base development work is for the furtherance of the Navy’s plan of serial production of Columbia- Continued Page 24

class and Virginia-class submarines.The Navy and Office of the Secretary of Defense (OSD) Cost Assessment and Program Evaluation (CAPE) conducted the fiscal 2025 SIB Study (SIB25) to determine how to successfully complete the once-in-a-generation recapitalization of the submarine force. The SIB projects in this contract modification directly support the direction of OMB, OSD CAPE, and the Navy. Pursuant to the president’s budget for fiscal 2025, the requirements are included for SIB25 investment for strategic sourcing, supplier development, and shipbuilder and supplier infrastructure. Funding is pursuant to the SIB25 and the 2025 Full-Year Continuing Appropriations and Extensions Act, 2025 (Public Law 119-4). Work will be performed in Groton, Connecticut (70%); Newport News, Virginia (15%); and Quonset Point, Rhode Island (15%), and is expected to be completed by December 2031. Fiscal 2025 national sea-based deterrence fund funds in the amount of $794,112,793 (96%); U.K. funds in the amount of $16,035,000 (2%); fiscal 2025 other procurement (Navy) funds in the amount of $9,208,683 (1%); fiscal 2025 shipbuilding and conversion (Navy) funds in the amount of $5,400,000 (<1%); and fiscal 2025 research, development, test and evaluation (Navy) funds in the amount of $641,000 (<1%), will be obligated at the time of award and will not expire at the end of the current fiscal year; and fiscal 2025 operations and maintenance (Navy) funds in the amount of $1,200,000 (<1%), will be obligated at the time of award and will expire at the end of the current fiscal year. Naval Sea Systems Command, Washington, D.C., is the contracting activity.

Raytheon Co., Integrated Defense Systems, San Diego, California, is

being awarded a $52,284,995 modification to increase the contract ceiling on a previously awarded cost-plus-fixed-fee, indefinitequantity/indefinite-delivery contract (N00039-20-D-0021) for Global Positioning System-Based Positioning, Navigation and Timing Service (GPNTS) software support services. No funding will be placed on contract and obligated at the time of award. GPNTS is used to receive, process and distribute three-dimensional position, velocity, acceleration, attitude, time and frequency in the formats required by shipboard user systems. The software support includes development, integration and test of improvements, correction of deficiencies, preparation and delivery of engineering interim/final software builds and inputs for the GPNTS software requirements and configuration baseline. Work will be performed in San Diego, California, and is expected to be completed by Nov. 14, 2029. This sole source modification award was not competitively procured in accordance with 10 U.S. Code 3204(a) (1) - Only One Responsible Source (Federal Acquisition Regulation subpart 6.302-1). The Naval Information Warfare Systems Command, San Diego, California, is the contracting activity (N00039).

MAST Technologies LLC, San Diego, California, is being awarded $12,021,800 for a firm-fixed-price, commercial requirements contract for the procurement of rubber tiles that support the passive countermeasure system. This is a two-year contract with three oneyear option periods, in accordance with Federal Acquisition Regulation 52.217-8, option to extend services, which, if exercised, will bring the total estimated value to $31,728,760. All work will be performed in San Diego, California. Work is expected to be completed by June

2027; if all options are exercised, work will be completed by June 2030. No funding will be obligated at the time of award. Individual delivery orders will be funded with appropriate fiscal year working capital funds (Navy) at the time of their issuance, and funds will not expire at the end of the current fiscal year. One company was solicited for this sole-source requirement pursuant to the authority set forth in 10 U.S. Code 3204 (a)(1), with one offer received. Naval Supply Systems Command Weapon Systems Support, Mechanicsburg, Pennsylvania, is the contracting activity (N00104-25-D-CM01).

Mercury Mission Systems LLC, Torrance, California, was awarded a $26,559,778 firm-fixed-price, cost-plus-fixed-fee, and costreimbursable contract for the F-15 data transfer module II, data transfer module II remote receptacle and docking station production. This contract provides for procurement of Group B kits, system engineering/ program management, and interim contractor support. Work will be performed at Torrance, California, and is expected to be completed by Dec. 31, 2028. This contract was a sole source acquisition. Fiscal 2023 aircraft procurement funds in the amount of $9,342,516; and fiscal 2025 aircraft procurement funds in the amount of $237,581, are being obligated at time of award.The Air Force Life Cycle Management Center, Wright-Patterson Air Force Base, Ohio, is the contracting activity (FA8634-25-C-B004).

Borsight Inc., Ogden, Utah, has been awarded a ceiling $2,180,000,000 firm-fixed-price, single-award, indefinite-delivery/indefinite-quantity contract for the T-6A avionics replacement program. This contract

provides avionics replacement for the T-6A aircraft and simulators. Work will be performed at Ogden, Utah; Randolph Air Force Base, Texas; Laughlin AFB, Texas; Vance AFB, Oklahoma; Columbus AFB, Mississippi; Sheppard AFB, Texas; and Naval Air Station Pensacola, Florida, and is expected to be completed by Jan. 6, 2034.This contract was a competitive acquisition and 12 offers were received. Fiscal 2024 and 2025 research, development, test and evaluation funds in the amount of $8,774,306 are being obligated at the time of award. The Air Force Life Cycle Management Center, Tinker AFB, Oklahoma, is the contracting activity (FA8106-25-D-B001).

General Atomics Aeronautical Systems Inc., Poway, California, is awarded a $27,873,450 modification (P00002) to a firm-fixed-price, cost-plus-fixed-fee order (N0001924F5565) against a previously issued basic ordering agreement (N0001922G0006).This modification adds scope to provide for the development and integration of a Smart Sensor System capability, to include procurement of associated hardware and software in support of the successful operational capability for the MQ-9A Reaper Marine Air Ground Task Force Expeditionary Medium Altitude Long Endurance Unmanned Aerial System. Additionally, this modification procures spares for the Detect and Avoid System and Smart Sensor System. Work will be performed in Poway, California (60%); Patuxent River, Maryland (30%); and various locations outside the continental U.S. (10%), and is expected to be completed in July 2028. Fiscal 2025 aircraft procurement (Navy) funds in the amount of $20,214,480; and fiscal 2025 research, development, test and evaluation (Defense Wide) funds in the amount of $3,242,667, will

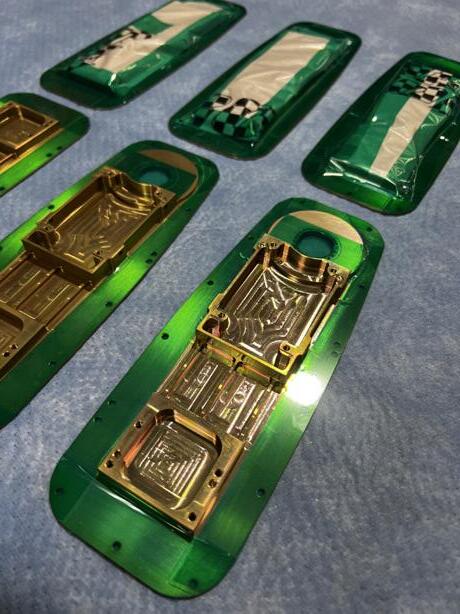

CJ Precision Machine, Inc. is a leading manufacturer of critical parts for a wide variety of industries, including aerospace, semiconductor, medical, solar, food processing, aviation, automotive, and motorsports.

From our vertical machining centers, to our state-of-the art 5-axis mills and 7-axis lathes, we provide superior customer satisfaction from prototype to production.

CJ provides superior customer satisfaction through flexible and dependable service with timely turn-around.

Our precision manufacturing includes working with both plastics and metals in our 9,500 square foot facility in Boise, Idaho. Our machinists have more than 140 years of experience and all manufactured parts are inspected by quality control.

CJ can provide finishing including anodizing, powder-coating, chromate, various types of electro-plating, and many others as required by our customers.

1-208-908-5920

www.cjprecisionmachine.com

ISO 9001 certified

Bill Banta

Our Made-in-America commitment has helped us to achieve a compound annual growth rate (CAGR) of between 40-50% every year since 2014.

The global supply chain is at a tipping point. Tariffs, once considered a tool for stabilizing domestic markets, now fuel sharp cost increases, disrupt sourcing channels and trigger retaliatory trade measures across key industries. Companies reliant on overseas manufacturing to maintain margins now face shrinking profits, longer lead times and greater risk.

In this environment, onshoring—bringing production back to the United

States—isn’t just a patriotic gesture; it’s a strategic imperative. I’m saying that as a manufacturer. My company, Decked, makes truck storage, tool boxes and truck accessories right here in the United States.

Onshoring unlocks faster innovation, tighter quality control and resilience against global disruptions, advantages that are increasingly critical in a volatile economy.

For companies that value speed, security and customer trust, a Made-in-America strategy is no longer just a nice-to-have; it’s a competitive advantage.

Committing to a Made-in-America strategy, even if only for a subset of your business, accelerates the innovation flywheel. Building close relationships with supply-chain partners and sourcing materials domestically enables companies to shorten supply lines, adapt faster to customers and improve products quickly.

At Decked, for example, many of our products are large and heavy, making overseas shipping both costly and complex. By removing international logistics hurdles, we unlocked opportunities to innovate freely and speed up our time to market.

When evaluating U.S. locations for production, it’s essential to consider proximity to a robust network of suppliers, ensuring that what isn’t made in-house remains accessible to key resources in production and engineering. When suppliers are invested in the success of the product, they contribute ideas, improvements and efficiencies that strengthen the entire ecosystem.

Whether facing a sudden spike or a downturn, domestic supply chains enable faster and more agile adjustments, reducing inventory exposure and capital risk. Onshoring requires deliberate design of the end-to-end supply chain—but for those who plan strategically, the benefits are transformative.

The U.S. continues to be a global leader in producing high-quality goods in industries like automotive and aerospace, where precision and excellence are non-negotiable. At the heart of this success is an underrated strength: America’s skilled manufacturing workforce.

Across the country, pockets of specialized expertise exist, from advanced machining in the Midwest to aerospace innovation in the South. Successful domestic companies tap into these localized talent pools, grounding operations where the right skills already thrive. At Decked, we chose Defiance, Ohio, and St. George, Utah, for our manufacturing facilities because of the availability of skilled labor in these areas to attract and retain the best talent. For example, Northwest Ohio has a well-established manufacturing workforce built around the auto industry. CJ Precision

Finding skilled workers is not enough; companies must also retain them. Building a strong brand, offering competitive benefits and fostering a culture that values long-term career growth are essential. Ultimately, investing in America’s skilled workforce leads to higher throughput, greater consistency and better products, delivering more value to customers and reinforcing the brand’s reputation for quality.

Onshoring, or bringing business operations back to the company’s home country, can make good business sense by improving quality control, reducing lead times, fostering stronger customer relationships, and mitigating supply chain risks. It also supports domestic job creation and economic growth, while potentially offering better intellectual property protection.

Here’s a more detailed look at the benefits:

1. Enhanced Quality Control:

Onshoring allows companies to have direct oversight of production processes, leading to better quality control and fewer defects. It simplifies regulatory compliance and allows for quicker identification and resolution of quality issues.

2. Reduced Lead Times and Improved Responsiveness:

Bringing production closer to the customer reduces transportation time and costs, enabling faster delivery and quicker response to market demands.

This agility allows companies to adapt more easily to changing customer needs and market trends.

3. Stronger Customer Relationships:

For businesses with a domestic customer base, onshoring can strengthen brand perception and customer loyalty by signaling a commitment to local production.

It can foster a sense of trust and authenticity, especially when customers are looking for products they can believe in.

4. Mitigated Supply Chain Risks:

Onshoring reduces reliance on potentially unstable global supply chains, minimizing the risk of disruptions due to factors like geopolitical instability or natural disasters.

It provides greater control over the supply chain and allows for more predictable lead times and cost management.

5. Economic and Social Benefits:

Onshoring creates jobs in the local economy, boosting employment and contributing to the overall economic well-being of the community. It can stimulate innovation and investment in domestic manufacturing and related industries.

6. Intellectual Property Protection:

By keeping production within the home country, companies can better protect their intellectual property and sensitive business information. This is especially important in industries where intellectual property is a key competitive advantage.

7. Cost Considerations:

While labor costs may be lower overseas, onshoring can offer cost savings through reduced transportation expenses, lower inventory holding costs, and potentially fewer hidden costs associated with offshoring.

Vivienne Machi Robert Wall

Northrop Grumman is putting $50 million into its joint program with Firefly Aerospace to develop a new medium-lift rocket called the Eclipse.

Credit: Firefly Aerospace/Northrop Grumman

Large swaths of the space industry are adjusting their North Star, increasingly focusing on chasing the booming military space market and deemphasizing other activities.

The course adjustments at many companies reflect changing geopolitical dynamics and spending realities. In the U.S., the Trump administration wants to slash NASA’s budget by about a quarter in the latest spending request while pushing to funnel billions of dollars into the space-heavy Golden Dome for America homeland missile defense architecture (AW&ST June 2-15, p. 15).The European Union is scaling up its military space ambitions, as are many of its member states, and Asia also is seeing an expansion of national-security-linked space activities.

Northrop Grumman turns away from NASA

Rocket Lab eyes opportunities as an end-to-end supplier

In one of the most glaring examples of the new reality, Northrop Grumman CEO Kathy Warden said May 28 that the company’s work with NASA “will not be a growth driver for us,” if the proposed budget cuts hold. The company is NASA’s fourth-largest contractor after the California Institute of Technology’s Jet Propulsion Laboratory, SpaceX and Boeing.

Northrop Grumman recently disclosed a $50 million investment into a joint project with Firefly Aerospace to design, own and operate a medium-lift launch vehicle, newly christened the Eclipse.The 16-metricton-payload rocket, the first launch of which is planned no earlier than next year, is targeting the national security space launch market with the Pentagon’s focus on proliferated constellations.

The company is also maturing national security space technologies, to include missile warning and tracking payloads developed for the Space Development Agency (SDA) and the Missile Defense Agency.

Speaking at the Bernstein Strategic Decisions Conference in late May, Warden pointed to different areas of future focus for its space portfolio, such as restricted space programs and propulsion technology. New U.S. proposals, such as the Golden Dome, are poised to accelerate defense spending from space companies.

Rocket Lab similarly is looking to bolster its military business via a May 27 announced acquisition of U.S. electro-optical/infrared payload developer Geost. Rocket Lab was recently on-ramped to the U.S. Space Force National Security Space Launch Phase 3 Lane 1 contract to compete for low-risk launch opportunities with its Neutron medium-lift rocket. Its first such launch is targeted for this year. Last year, it debuted as a spacecraft manufacturer for the SDA’s proliferated lowEarth-orbit constellation.

While Rocket Lab has long supported U.S. military missions with its Electron rocket, developments such as the Golden Dome architecture present new opportunities, CEO Peter Beck tells Aviation Week. “Make no mistake about it,” he says. “We want to be a big provider to that program.”The announced Geost acquisition allows Rocket Lab to be a key supplier for the tracking element of a future missile defense architecture, he notes.

The company has strategically acquired—or announced intentions to acquire—six companies since 2020 to provide components that together enable Rocket Lab to become an end-to-end provider for the U.S. military. Meanwhile, the ongoing Geost acquisition is “not the end of payload acquisitions for us,” Beck asserts.

In Europe, where national governments and the EU are investing more in military space, that appetite has become a driver in the thinking of investors and startups, industry leaders shared at the recent SmallSat Europe Conference in Amsterdam. “We see much more influx of capital in that particular aspect, both in early-stage deals and late-stage deals,” Starburst Ventures CEO François Chopard said at the conference. Reflex Aerospace Chief Commercial Officer Dennis Moore said the company was set up with a dual-use market in mind, but it has seen the defense focus come to the fore only recently. The company has secured a security clearance for its facilities.

Fossa Systems, a Spanish and Portuguese startup that provides Internet of Things device connectivity from space, is shifting its focus to direct messaging between soldiers and what CEO Julián Fernández called “the Internet of the Battlefield.” “We are all going to have to shift to these defense use cases, because I sincerely think that’s where the money is going to be,” he says.

Impossible is our starting point.

At Northrop Grumman, we work every day to define — and redefine — what’s possible. Our teams are constantly questioning, problem-solving and creating new ways to tackle seemingly impossible challenges. The result? A shared purpose that puts us at the forefront of innovation and technological advancements, contributing everywhere from the depths of the ocean to the mysterious expanse of space.

Precision. Speed. Simplicity.

We combine global machining expertise with hands-on local service—delivering turnkey solutions, training, aftermarket support, and personalized service wherever you are

WWW.CHIRON-GROUP.COM

INFO.AMERICA@CHIRON-GROUP.COM