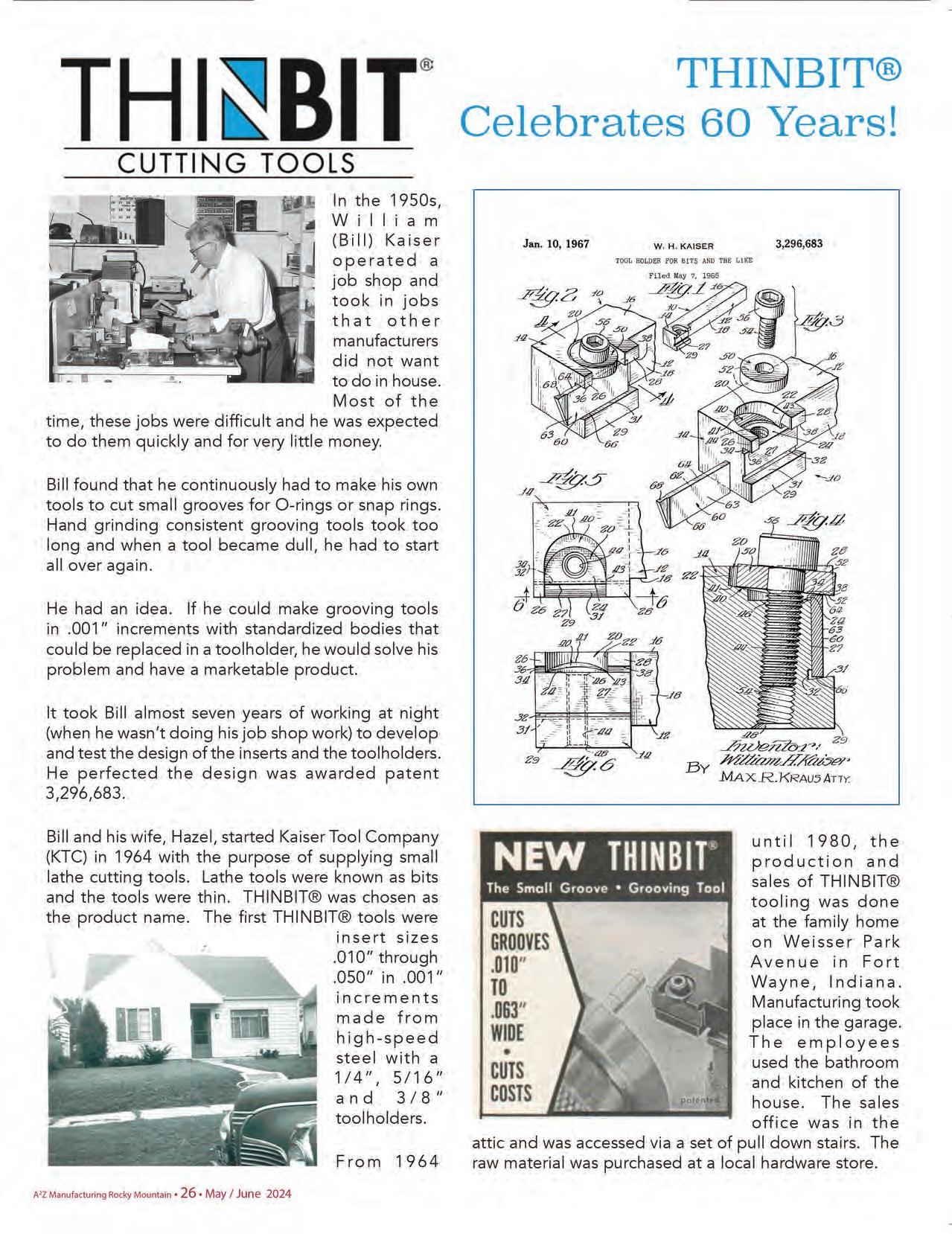

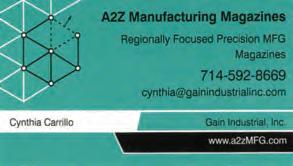

A2Z MANUFACTURING WEST COAST • 1 • APR - MAY ’24 60 Years of Precision Machining ® Vol. 14, No. 2 , APR / MAY 2024 BUYER’S GUIDE PAGES 34-45 a2zMFG.com West Coast Edition (WA, OR, and CA)

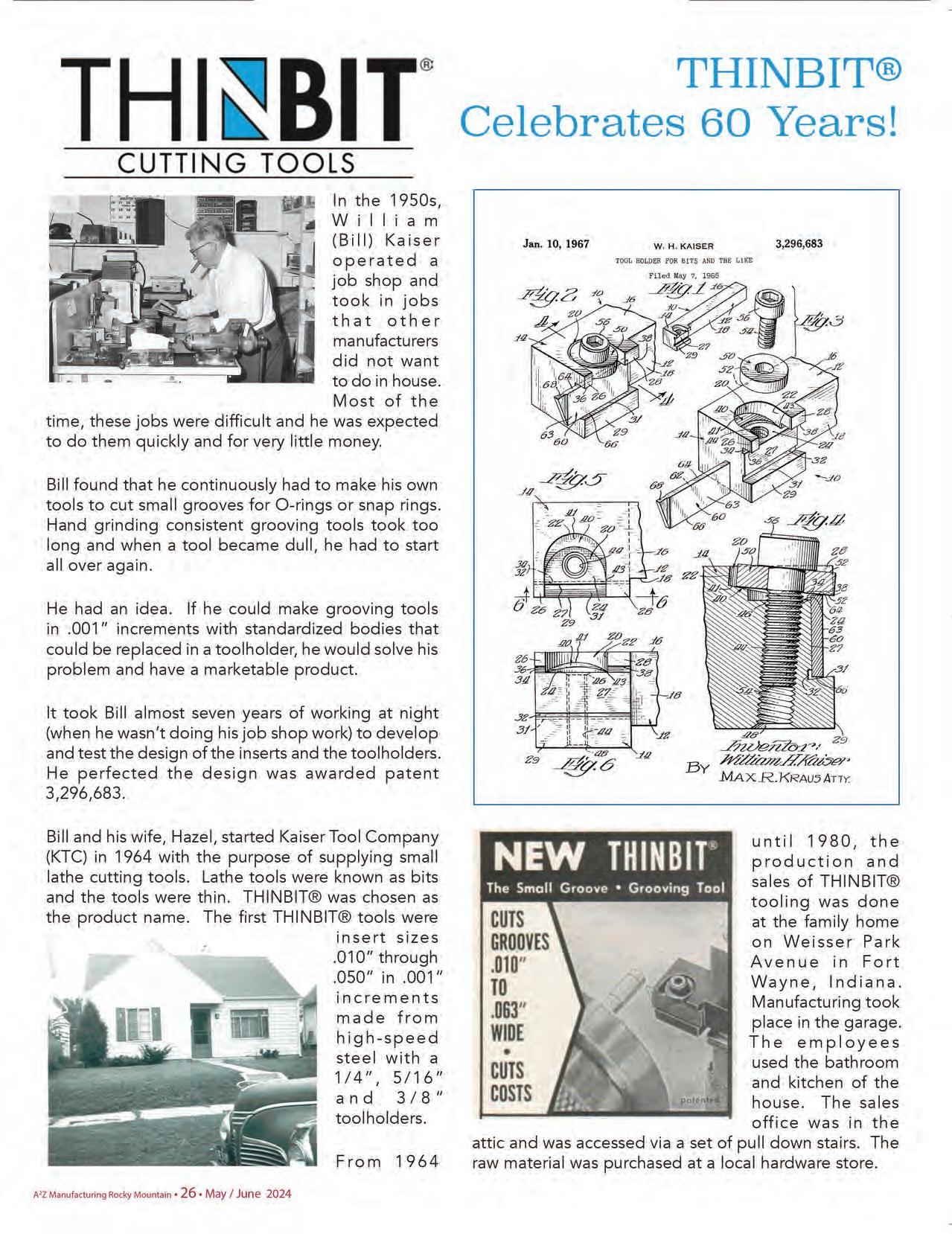

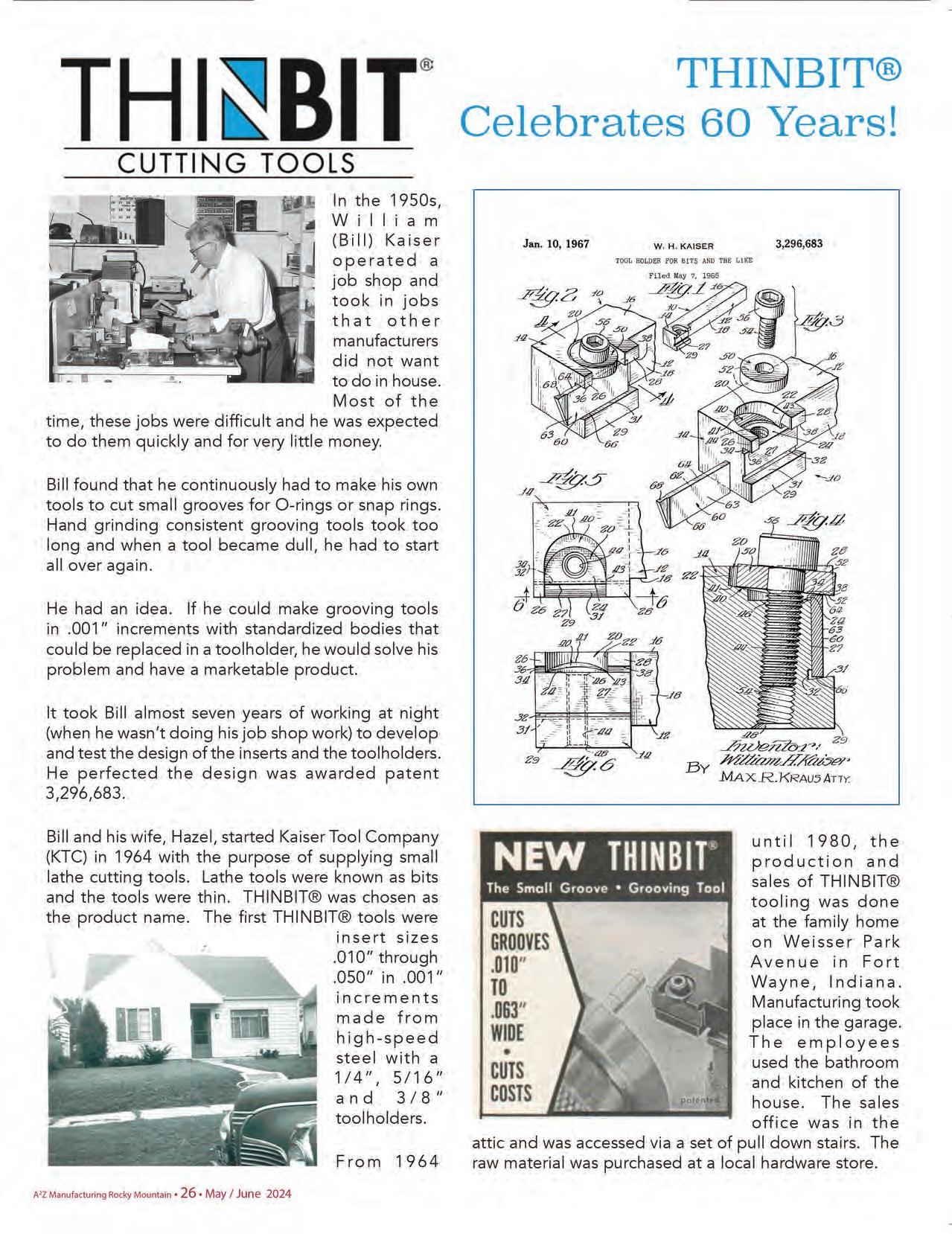

888-THINBIT | WWW.THINBIT.COM GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING 1964 - 2024 Face Grooving Dove Tail inserts are available starting at .030” wide and .300” major diameter.

High performing, long lasting coolants

Hysol® MB products are the best-selling, highest volume coolants sold by Castrol® due to their all-around performance and overall value.

Product advantages

• High-quality finish across multi-metals and operations

• Excellent anti-corrosion properties

• Clean running and have a very mild odor

• Wide tolerance to water hardness

• Robust pH stability fights bacterial growth

Simplify operations and make it easier to meet the demands of your business.

Contact Star Metal Fluids today to learn why Hysol® MB products are the favorite among machine operators.

Editor’s Corner

Second Chance Hiring Betters Businesses and Communities

The U.S. added a record 3.8 million jobs, there was a deficit of 3.4 million Americans participating in the workforce. More recent studies show that there are approximately 10 million job openings, with only around 6 million unemployed workers. While many companies have gone to great lengths to try and attract new talent, they still overlook one resource: second-chance hiring.

The concept of second-chance hiring isn’t new, yet it’s still largely overlooked. Second-chance hiring is the practice of hiring individuals who have been convicted of a crime. While this may seem controversial, the reality is that second-chance hiring can benefit businesses and communities, and we’ll explain why. Due to the stigma associated with their past actions, those with a criminal record are often denied employment opportunities, even after completing rehabilitation and job training programs.

Updated data shows that roughly two-thirds of previously incarcerated individuals are considered jobless at any given point within four years of their release.

On average, more than 600,000 individuals are released from both state and federal prisons. Unfortunately, more than two–thirds of those individuals will find themselves back in jail within three years of their release, with nearly half reincarcerated.

While there are dozens of reasons why this could happen, one of the most common reasons cited is a lack of purpose, employment, and inability to support themselves or their families. So they fall back into the cycle of crime and wind up back behind bars.

Hiring managers and human resource professionals have historically hesitated to hire talent impacted by incarceration. The theory behind this hesitation was that these incarcerated individuals could not perform the job to the expected standard due to a lack of education or a poor work ethic.

That myth has been debunked thanks to recent research into education provided to incarcerated individuals. One of the latest studies on the topic showed that of prison inmates surveyed, approximately 70 wanted to participate in some sort of educational training program. Another 23% said that they had some job training during their incarceration.

If you are looking to hire, a candidate impacted by incarceration could be more of an asset than you think.You have to vet your candidates as you would any other candidate.

According to the U.S. Chamber of Commerce, data from SHRM shows that second-chance hiring is good for both the individual and the community and the companies hiring them.

In closing, I highly recomend that all manufacturing companies consider looking at second chance hiring. Many men and women have turned their lives around after being givien the second chance by manufacturing businesses that find it very difficult hiring and keeping employees. These second chance employees can be the most loyal, hard working, and productive team mates and they tend to be so thankful that they have a second chance, and will do everything to support you.

Kim Carpenter

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly Kim@A2ZManufacturing.com

Mail Address: PO Box 459 Higley AZ 85296

Telephone: (480) 773-3239 Website: www.A2ZManufacturing.com E-mail:Kim@A2ZManufacturing.com

CONTRIBUTORS

Linda Daly, Stephen Hannemann, Eugene Wirth

Published bi-monthly to keep precision manufacturers abreast of news, contracts, trends, and to supply a viable supplier source for the industry.

Circula tion: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

T he Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

Cover Published

A2Z Manufacturing

by:

West Coast

Announcements/Releases ................... 6-14 Feature Articles ...................... 1,20-21, 28-29 Buyers Guide Equipment Services ..... 32-38 Buyers Guide Processes ...................... 39-45 Card Gallery ........................................ 34-45 Index Of Advertisers ............................... 46 Editorial .................................. Throughout A2Z MANUFACTURING WEST COAST • 4 • APR - MAY ’24

Years Of Precision Machining

THINBIT 60

Announcements & Releases

Where Scrap Meets Innovation, Excellence Follows.

Spectrum Alloys LLC is the Alternative for the Western US Scrap Metal Market. We cater to our commercial and industrial clients with our fullservice metal management and over 200+ years of combined experience in buying, transporting, processing, marketing and selling of commercial and industrial scrap metal. As a result of our expertise, our customers enjoy the financial benefits.

In addition to our commercial business, we provide the following industrial services:

• Complete industrial scrap metal collection services to aircraft & aerospace companies, refineries, machine shops and manufacturing facilities.

• Plant clean-up services.

• Inventory Liquidation’s.

• Certified Destruction & Demilitarization.

We specialize in the purchase of Stainless Steels, Copper and Brass Alloys, Ni Refinery Scrap, Nickel and Nickel base alloys, Hastelloys, Monel, Cupro-Nickel, Nickel-Chromes, Cobalt base alloys, Stellites, Heat-Treat alloys, Complex-Nickels, Corrosion Resistant metals,Titanium,Tungsten, and Superalloys.

GLOBAL COVERAGE. LOCAL REACH. The right relationship can make all the difference.

For more information on Spectrum Alloys call: 323-587-2277, chris@spectrualloysllc.com

blanks are now available from OnlineMetals.com, the World’s leading e-commerce metal and plastics supplier.The pre-machined blanks allow customers to order flat, square, and parallel materials to close tolerance specifications.

C110 copper is 99.9% pure copper and has a conductivity of 101% IACS (International Annealed Copper Standard). C110 copper plate and sheet material is well suited for environmentally challenging applications. For marine usage, copper provides natural antifouling properties, making it ideal for many boat components, both above and below the waterline. Given the natural conductivity of copper, it is an excellent choice for electrical components. The thermal properties of copper make it an excellent choice for heating and cooling applications. Copper is often specified for aerospace and defense applications for its conductivity and corrosion resistance.

“C110 copper Ready to Ship Blanks help customers shorten setup time, reduce scrap, and increase overall throughput up to 25% or more by eliminating material prep. Blanks arrive machine-ready for production,” said Ben Belzer, President, and CEO of TCI Precision Metals.

Precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations, and outside processing. Blanks are

consistent, part-to-part, which reduces setup time. In the case of flat blanks, the production process alleviates the material’s residual stress, resulting in reduced part movement during CNC machining.

C110 copper Ready-to-Ship blanks are available in common thickness from 0.25” to 1.00” and are guaranteed flat +/- .002”. Precision saw or waterjet cut dimensional sizes are available up to 24” x 24”, +.125”0” of specified length and width. Each blank is deburred, cleaned, and individually packaged to avoid damage during shipping.

“We are seeing a growing number of customers looking for pre-machined materials. At OnlineMetals.com, we specialize in cut-to-size, small-to-

A2Z MANUFACTURING WEST COAST • 6 • APR - MAY ’24

OnlineMetals.com Adds C110 Copper Ready-to-Ship Blanks from TCI Precision Metals TCI Precision Metals announces that its C110 copper, Ready-to-Ship

medium-quantity orders shipped directly to any location. Pre-machined C110 copper blanks provide that extra processing value that lets customers order materials that arrive ready to go directly from receiving to machining. Customers can use the time they previously spent in setup and prep for more productive use of CNC machining centers,” said Matt Holzhauer, Marketplace Manager at OnlineMetals.com

Founded in 1956, TCI Precision Metals is a family-owned manufacturer producing precision Machine-Ready Blanks from aluminum, stainless steel, and other alloys. The company also provides Sawing, Grinding, Milling, and Finishing operations on customer-supplied materials.

OnlineMetals.com is the world’s leading eCommerce metal and plastics supplier, specializing in cut-to-size, small to medium quantity orders shipped directly to any location. Online Metals was a garage start-up founded in Seattle in 1998. The company has grown over the years and expanded to six facilities across the U.S., offering over 55,000 products.

3D Plastics, Inc.

Celebrating 25 Years of Delivering

MOLDING SOLUTIONS

3D Plastics – 25 Years

By Stephen Hannemann

Twenty-five years go by in the blink of an eye! This coming August, 3D Plastics in Newberg, Oregon will celebrate their silver anniversary. A milestone for sure when one considers the historical mortality rate of startup endeavors.

3D has accumulated a loyal following for many reasons, drawing from dozens of industries since day one.They have earned their solid reputation for embracing challenging projects, setting a high bar for quality, responsiveness, reliability, and great customer service. Those attributes comprise a great business model that has brought them continuous growth since 1999. They may not be the largest injection molder in the Portland metro area, but they have the biggest heart in the industry.

Call and schedule a private tour and get the full 3D experience!

To learn more about 3D Plastics, discuss a concept, or receive a quote, visit 3d-plastics. com or call 503.537.0979. 3D Plastics – Peerless Attention to Detail.

A2Z MANUFACTURING WEST COAST • 7 • APR - MAY ’24

Plastics.com 503 537 0979

3D

Our Showroom At: 3305 Edison Way, Fremont, CA 94538 Is Open Monday - Friday From 8am To 5pm

E-Z LOK Threaded Inserts for Hardwood

E-Z LOK, a leading manufacturer and master distributor of threaded inserts for metal, plastic and wood is now offering E-Z™ Knife brass and stainless steel threaded inserts for wood.

Suited for use in hardwoods like oak, cherry and maple, these inserts are ideal wherever assembly or disassembly could cause thread erosion or stripping. E-Z Knife™ threaded inserts use a proprietary external “knife” thread to slice into the wood and provide superior holding power. They are most often machined out of brass when internal thread sizes range from #4 to or M3 to M8. Notable features include superior hardwood holding power with sizes available in inch (coarse/fine) and metric. The inserts easily install with a bolt/jam nut or optional drive tool.

Brass inserts are ideal for furniture, cabinetry and partitions, while stainless steel is used in marine applications. Several industries including shipping containers, outdoor furniture and storm shutters use either.

E-Z™ Knife threaded inserts and thread repair kits provide an

easy solution for adding machine threads to hard woods.They can also be used for softwood, but they are not recommended for plywood. A proprietary external thread for superior holding power is used by these inserts.

For more information, please contact: Kyle Lindsly-Roach, Director of Sales & Marketing Phone: 310-323-5613 x221, klindsly@ezlok.com www.ezlok.com

Phoenix Heat Treating Announces FDA Drug and Alcohol Compliance

Phoenix Heat Treating is proud to announce that we have formal FAA Drug and Alcohol Program compliance.

Phoenix Heat Treating is especially known for its ability to resolve difficult heat-treating problems that are beyond the capability of a typical application. We offer a wide array of processing and consulting services. We take great pride in finding unique solutions to meet each individual customer’s requirements.

To learn more about how Phoenix Heat Treating can support all your heat treat needs, as well as specialized services, contact Tim Johnston, Director of Business Development.

For more information contact: Tim 623-512-3233 or by email at tjohnston@phxht.com

Profiting With High-Speed Compact Press Brakes

Selecting the right tool is pivotal in optimizing manufacturing processes, and press brakes play a crucial role in bending operations. While many companies opt for larger, versatile press brakes to accommodate a diverse range of materials and bending requirements, the ideal choice may lean towards compact high-speed brakes for enhanced productivity.

Press brakes have a specific bending length and a specific tonnage that are suited for the range of parts that each company processes. Companies normally use press brakes that can process a diverse range of materials to maintain flexibility in their production scheduling. Usually, this means having a ten- or twelve-foot bend length and a tonnage that can process from thin to thick. From a scheduling perspective, this is

A2Z MANUFACTURING WEST COAST • 8 • APR - MAY ’24 CNC AND MANUAL MACHINERY SINCE 1979 New - Used -Appraisals - Auctions

BOB KROHA ROB KROHA CONTACT US TODAY: 510-249-1000, PERMACH.COM

an ideal situation as it provides maximum flexibility in scheduling jobs. But from a productivity /capacity perspective this may not be the ideal situation.

The Physics of Working with Mass - Press brakes come in all different sizes and tonnages and they have vastly different technologies to aid in the bending process. It is possible to process thin small parts on a large tonnage brake. However, it is not possible to process longer thicker parts on a small tonnage brake. The reason is that the longer, thicker parts will most likely exceed the tonnage capacity of the brake. Additionally, running small parts on a large tonnage brake with a long upper ram length is not efficient.

It all comes down to simple physics. A larger, heavier mass is more difficult to accelerate and takes longer to reach top speed than a smaller, lighter mass. Likewise, decelerating a larger, heavier mass is more difficult and will require more time. This all adds up to lost time. Henceforth, small thin parts are more efficiently formed on a smaller press brake.

Doosan Machine Tools is now

MILL S & THRILLS

The versatile VMC lineup at DN Solutions is enough to get anyone excited.

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to. Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

An Opportunity to Realize Greater Profits - If you find that most of your smaller parts are being formed on oversized press brakes, then this is an area of opportunity to investigate. When you compare to larger press brakes, small brakes such as the Bystronic ByBend Star 40 and 80 ton can process two to three times more parts in the same amount of time. The smaller brake press is faster due to the ability of the machine to accelerate and decelerate both the smaller and lighter upper ram and the smaller back gauge system. This provides not only more throughput capability but also more capacity to bend even more parts on your existing press brakes. Processing smaller, thinner parts on the smaller press brakes is much faster which speeds up the capacity for the larger brakes to process more parts in the larger size range.

DEM: entry-level par t producer

SVM: swift and strong

DNM: global best seller

BVM: premium powerhouse

(866) 567-2580 SERVICE (800) 994-0146 PARTS (888) 207-2787

www.ellisontechnologies.com

Speed and Safety- The next big time-saver comes into play once the press brake starts the active bending program. Wide-view Fast Bend safety cameras enable faster approach, bending, and retract speeds without compromising operator safety. Safely achieve bending speeds of up to 1 inch per second, and approach and retract speeds > 590 inches/ minute.

The Right Tool for Increased Efficiency - Using the correct press brake on the right applications can not only speed up bending operations but can also create greater machine capacity and flexibility in scheduling. Compact high-speed press brakes can bend up to two times more parts than larger conventional hydraulic brakes.This makes the perfect complement to the production capabilities of a fiber laser. Fiber lasers produce up to 4 times more parts per unit of time. High-speed bending is a major consideration for eliminating bottlenecks at the press brake.

Keeping The Pace- There are opportunities with compact high-speed press brakes that are different for each production environment. Investing in new technology means being able to maintain the pace within your fabrication process as newer fiber lasers are capable of producing higher part volumes. Compact high-speed press brakes can help eliminate these bending bottlenecks.By Frank Arteaga, Regional Director Marketing – Americas; Bystronic Inc., Voice.bystronic@ bystronic.com

A2Z MANUFACTURING WEST COAST • 9 • APR - MAY ’24

| SALES

ARNO USA’s Barry Powell Signs Next Generation Tooling Rep Firm to Distribute Their Tooling Products in California and Nevada

Barry Powell, Business Development Specialist for ARNO USA, is pleased to announce that Next Generation Tooling will now distribute ARNO USA’s tooling products throughout California.

Barry says, “Next Generation Tooling, founded in 1995, is a technical marketing company that provides sales support and technical product training to industrial distributors, machine tool dealers and end users. The team of Rob Aldama,Tim Fugazi, and Chris Savolainen (Founder), all are highly technical in industrial tooling and provide hands-on technical support on the machine shop floor to their end-user customers as well as valuable feedback on applications and new product design ideas to our principals. I expect them to be an asset to our current and new customers throughout California and Nevada.”

Barry says, “ARNO USA combines German tradition with state-of-theart cutting and turning tool technologies. We offer outstanding tooling, particularly for Swiss Tooling and Production Turning.” He adds, “While not a household name in the Western USA, since 1962, ARNO USA has been manufacturing and selling high-quality products for customers in the industrial tooling and machining markets. ARNO USA represents the US branch of ARNO Werkzeuge, headquartered in Germany.

To learn more about the ARNO German quality industrial tooling and machining products that offer value added solutions to benefit your productivity every day, contact Chris at chris@nextgentooling.com or call 916.765.4227.

A2Z MANUFACTURING WEST COAST • 10 • APR - MAY ’24

From left to right Rob Aldama, Tim Fugazi and owner Chris Savolainen

A2Z MANUFACTURING WEST COAST • 11 • APR - MAY ’24 Agile Production. Scalable Solutions.

Challenged with meeting customer deliveries and adapting to their ever-changing requirements?

Modular end-to-end solutions from Bystronic. bystronic.com

Optimize your manufacturing workflow with modular end-to-end solutions from Bystronic. Combine best-in-class machines, automated production cells, and software for a highly agile and efficient production process that can expand as your business grows. Bystronic will guide you through your transformation journey step-by-step. Your best choice for sheet metal processing.

Perfection Is In The Eyes Of The Beholder And In The Hands Of The Owner, Chuck Zinke

Perfection Industrial

Finishing is one of the leading metal finishing companies in Southern Arizona, providing services to a wide range of industries. Local and national manufacturing businesses in the defense, aerospace, industrial and commercial fields have come to rely on the high quality metal finishing services that Perfection Industrial Finishing has provided for more than 20 years.

The company’s founder, Chuck Zinke, developed the concept from his long time passion – cars. Chuck began rebuilding cars and trucks in his spare time as a teenager, and initially used the services of the only powder coating company in Tucson. As his hobby grew, he began to look at ways of improving the quality of painted parts as well as reducing the overall cost and time for delivery. He decided to try it himself, and by 1991 his garage became his first paint shop – run in his spare time, but taking on

work for others after word quickly spread. A few months later, he turned his hobby into a full time career and established himself as a recognized supplier of painting excellence.

Since those humble beginnings a number of other services have been added to the original powder coat capability, including conventional (wet) paint, chemical processing (such as anodizing and conversion coatings), sandblasting and more. Click here to learn more about our services.

Our business was established in 1992 and has been adding capabilities and prime customers over the past 29 years.We are known in the industry for high quality and quick turns. With the two facilities it enables us to find the best facility to support our customers and their products at the highest levels. Having so many processes in house allows our customers to save time and money with minimizing the outsourcing to multiple companies.

We currently hold NADCAP, AS9100, ISO, and ITAR certifications.

MIL-SPEC LIQUID COATINGS

Sizes up to 20’x20’x 60’. We have multiple booths in both facilities.

• MIL-DTL-537072 CARC

• MIL-PRF-32550 (ZINC RICH PRIMER)

• MIL-DTL-53022 (EPOXY PRIMER)

• MIL-PRF-23377 (PRIMER)

A2Z MANUFACTURING WEST COAST • 12 • APR - MAY ’24

• MIL-PRF-85582 (PRIMER / ALUMINUM SURFACES ONLY)

• MIL-PRF-22750 (TOPCOAT)

• MIL-DTL-53039 (TOPCOAT)

• MIL-DTL-64159 (TOPCOAT)

• MIL-C-8514 (METAL PRETREATMENT WASH PRIMER)

• MIL-PRF-85285 (TOPCOAT)

• MIL-PRF-23236 (PRIMER)

• MIL-PRF-24635 (TOPCOAT)

• MIL-PRF-32440 (POLYUREA COATING)

• CHEMICAL PLATING

• PASSIVATION (Sodium Dichromate Tank Size 36x14x42) (Nitric Tank Size 36x36x42)

• AMS-2700

• ASTM A967

• ASTM a380

• CHROMATE CONVERSION COATING

• MIL-DTL-5541 (Type II tank size 34x23x33) (Type I tank size 30x24x42)

• Types I and 2 Classes 1A and 3

• ANODIZE

• MIL-A-8625

• Type 2 Class 1 (clear) (tank size34x23x33)

• Type 2 Class 2 (color Black) (tank size 34x23x33)

• CHEMICAL CLEANING

• TT-C-490

• MEDIA BLASTING

• TT-C-490, SSPC standards

• POWDER COATING

• MIL-PRF-24712B SIZES UP TO 12’X12’X25’ and 8’x8’x30’

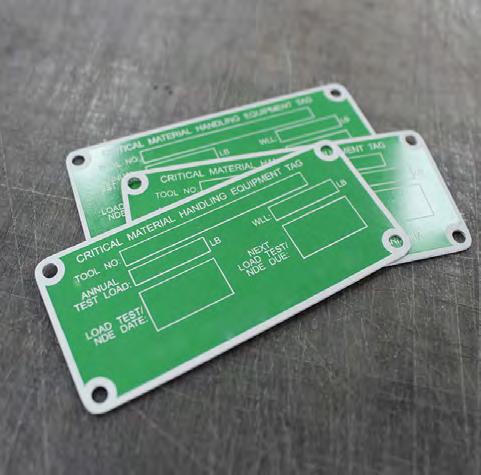

• PART MARKING

• Silk-screening

• Part marking

• MIL-STD-130

• A-A-56032D

• A-A-208

• Laser Marking

Phoenix Heat Treating Phoenix Heat Treating

cs@phxht.com

www.phoenix-heat-treating.com 602-258-7751

• ADDITONAL SERVICES

• Custom Masking

• Light Assembly

• Finish Packaging

• Pick Up and Delivery (local) For more information on how Perfection Industrial Finishing can help you shine contact them at: 520-434-9090, “Toni Gauna” toni@pif-az.com, www.pif-az.com

A2Z MANUFACTURING WEST COAST • 13 • APR - MAY ’24

GET TO KNOW US

Servicing our industry and trade customers in intelligence heat treating for over 60 years.

Tracking

Prime Approvals

Chuck Zinke ‘Center’ and PerfectionTeam

Established in 1963 Real Time Live Job

10+ Processes Performed 50+ Furnaces AOG and Line Down Services Over 10+

24/7 Processing

Contracts

Bell Textron, Inc., Fort Worth, Texas, is awarded a $455,000,000 firm-fixed-price, undefinitized contract for the production and delivery of 12 AH-1Z helicopters for the government of Nigeria, as well as provides associated engineering, program management and logistics support, and non-recurring engineering for obsolescence. Work will be performed in Fort Worth, Texas (80%); and Amarillo, Texas (20%), and is expected to be completed in July 2028. Foreign Military Sales customer funds in the amount of $82,345,771 will be obligated at time of award, none of which will expire at the end of the current fiscal year. This contract was not competitively procured pursuant to 10 U.S. Code 3204(a)(4). Naval Air Systems Command Patuxent River, Maryland, is the contracting activity (N0001924C0030).

Northrop Grumman Systems Corp., San Diego, California, is awarded a $19,227,992 modification (P00038) to a previously awarded cost-plus-fixed-fee contract (N0001921C0060). This modification provides logistics and test support for mission control and operator training systems as well as associated engineering and field service representative technical support to sustain MQ-4C Triton air vehicles, ensuring continued mission-capability for intelligence, surveillance and reconnaissance missions for the Navy and the government of Australia. Work will be performed in Patuxent River, Maryland (37.55%); San Diego, California

(23.54%); Jacksonville, Florida (8.75%); Mayport, Florida (7.54%); Baltimore, Maryland (6.34%); Salt Lake City, Utah (1.94%); Sterling, Virginia (1.64%); and various locations outside of the continental U.S. (12.70%) and is expected to be completed in May 2024. Fiscal 2024 operations and maintenance (Navy) funds in the amount of $6,128,638; fiscal 2024 research, development, test and evaluation (Navy) funds in the amount of $1,100,000; and Royal Australian Air Force cooperative funds in the amount of $780,402 will be obligated at the time of award, $6,128,638 of which will expire at the end of the current fiscal year. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

BAE Systems Land & Armaments L.P., York, Pennsylvania, was awarded a $317,998,029 cost-plus-fixed-fee contract for continuing system technical services for M109 Family of Vehicles. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of March 7, 2029. U.S. Army Contracting Command, Detroit Arsenal, Michigan, is the contracting activity (W56HZV24-D-0020).

General Atomics Aeronautical Systems Inc., Poway, California, has been awarded a not-to-exceed $250,063,810, undefinitized contract action for Taiwan MQ-9B SkyGuardian procurement. This contract provides four MQ-9B unmanned air vehicles, two certifiable ground control stations, spares, and support equipment. The location of

A2Z MANUFACTURING WEST COAST • 14 • APR - MAY ’24

performance is Poway, California, and the work is expected to be complete by Aug. 11, 2027. This award is the result of a sole source acquisition and involves foreign military sales to Taiwan. Foreign military sales funds in the amount of $120,400,030 are being obligated at the time of award. The Air Force Life Cycle Management Center, Wright Patterson Air Force Base, Ohio, is the contracting activity (FA868923-C-2018 P00003).

Raytheon Co., El Segundo, California, is awarded $8,831,086 for a firm-fixed-priced delivery order (N00383-24-F-UX08) under a previously awarded basic ordering agreement (N00383-19-G-UX01) for the procurement of 11 receiver mainframe assemblies in support of the E2D Advanced Hawkeye aircraft. The contract does not include options. All work will be performed in El Segundo, California. Work is expected to be completed by April 2027. Working capital (Navy) funds in the full amount of $8,831,086 will be obligated at time of award, and funds will not expire at the end of the current fiscal year. One company was solicited for this sole-source requirement pursuant to the authority of 10 U.S. Code 3204(a)(1) and one offer was received. Naval Supply Systems Command Weapon Systems Support, Philadelphia, Pennsylvania, is the contracting activity.

Lockheed Martin Rotary and Mission Systems, Moorestown, New Jersey, is awarded a $102,064,704 cost-plus-incentive-fee modification to previously-awarded contract N00024-23-C-5123 for capability package development and fielding, system integration and fielding,

and in-service sustainment in support of current configurations of the AEGIS combat system. Work will be performed in Moorestown, New Jersey, and is expected to be completed by Dec. 31, 2024. Fiscal 2024 research, development, test and evaluation (Navy) funds in the amount of $24,803,348 (71%); fiscal 2020 shipbuilding and conversion (Navy) funds in the amount of $6,183,214 (18%); fiscal 2024 operation and maintenance (Navy) funds in the amount of $2,029,852 (6%); fiscal 2023 research, development, test and evaluation (Navy) funds in the amount of $999,114 (3%); fiscal 2017 shipbuilding and conversion (Navy) funds in the amount of $394,513 (1%); and fiscal 2019 shipbuilding and conversion (Navy) funds in the amount of $9,546 (1%) will be obligated at time of award, and funds in the amount of $3,028,966 will expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity.

Oshkosh Defense LLC, Oshkosh,Wisconsin, is awarded a $40,069,033 hybrid (firm-fixed-price, cost-plus fixed-fee) delivery order for the procurement of Remotely Operated Ground Unit for Expeditionary Fires carriers for use in the Navy/Marine Expeditionary Ship Interdiction System . Work will be performed in Alexandria, Virginia (18%); Gaithersburg, Maryland (15%); and Oshkosh, Wisconsin (67%). Work is expected to be completed in December 2026. Fiscal procurement 2024 (Marine Corps) funds in the amount of $40,069,033 will be obligated at the time of the award and will not expire at the end of the current fiscal year. This action is a negotiated delivery order in accordance with 10 U.S. Code § 3403(c). Marine Corps Systems Command, Quantico, Virginia, is the contracting activity (M6785424-F-1004).

A2Z MANUFACTURING WEST COAST • 15 • APR - MAY ’24

Texas Project To Create Hydrogen ‘Ecosystem’ As Precursor To Hydrogen Hubs

GTI Energy, Frontier Energy, the University of Texas-Centre for Electromechanics (UT-CEM), and almost two dozen industry stakeholders and sponsors are collaborating on a project to design, build and operate what they call one of the largest collections of renewable hydrogen production, on-site storage and end-use technologies in one site.

The project, part of H2@Scale in Texas and Beyond, is supported by the Department of Energy’s (DOE) Hydrogen and Fuel Cells Technology office, and will be located on the UT J.J. Pickle research campus in Austin. The project team says the site will serve as a precursor to hydrogen hub development. Renewable natural gas, wind and solar will be converted to hydrogen for use in transportation and commercial applications, including

3D can provide design assistance and work with existing products to produce them more economically.We are a ‘UL Certified’ molder offering low to high quantity production runs.

We produce many of our customer’s products with metal and plastic sub-components molded in. It is very common to use threaded inserts, bushings, contacts, and plastic substrates.

UT’s data centre, fuel cell drones and a fleet of Toyota Mirai FCEVs.

The project also resulted in the development of a hydrogen framework for the state, quantifying potential pathways for the growth of the Texas Gulf Coast hydrogen economy, and modelling the future supply, distribution, and demand of hydrogen in the region.

Have you read?

Why betting on green hydrogen is the key to decarbonising our societies DOE commits $750M to advance US hydrogen industry

GTI Energy is involved in several hydrogen hub projects announced last fall as part of $7 billion in federal hydrogen hub funding from the DOE.

The Gulf Coast Hydrogen Hub (HyVelocity H2Hub) is administered by GTI Energy and includes organizing participants like The University of Texas at Austin, the Centre for Houston’s Future and Houston Advanced Research Centre. The Gulf Coast Hydrogen Hub will be centred in the Houston,Texas region. Large-scale hydrogen production is planned using both natural gas with carbon capture and renewables-powered electrolysis.

GTI Energy is also a member of the Midwest Hydrogen Hub (Midwest Alliance for Clean Hydrogen – MachH2), which includes Illinois, Indiana, Michigan. Hydrogen uses in this hub include steel and glass production, power generation, refining, heavy-duty transportation and sustainable aviation fuel.

A2Z MANUFACTURING WEST COAST • 16 • APR - MAY ’24 3D Plastics, Inc. Custom Injection Molding 800. 280.2278 Precision

What

Do!

Injection Molding Is

We

Contact Us Today: info@3d-plastics.com, 503-537-0979 3d-plastics.com, 503-537-0979

Nearly New DN Solutions NHP 4000 Horizontal Machining

Center (On a 12 Pallet LPS With a 275 Tool Matrix) FOR SALE

$400,000 with Rigging Included

The NHP 4000 Horizontal Machining Center delivers with automatic tool changes in under a second and 15,000 RPM spindle with axes acceleration of up to 1G, thru-spindle and flood coolant, center-thru chip evacuation, highly precise linear guides, larger work area, and a smaller footprint.

• Purchased in August of 2020

• Under power for inspection, and ready to ship immediately

• The machine has 5300 hours on it

• It will come with all 12 tombstones and all of the orange vise vises you see (64 total)

• Travels are 22 x 25.2 x 26

• Spindle RPM is 15,000 and 40.2 Horse power

• Max workpiece size is 24.8” x 35.4”, and 881 lbs

• 300 PSI through spindle coolant pressure

• Renishaw tool setting laser

• BK micro tool touch probe for break detection

• Rapids are 2362 In/min

Enhanced Raytheon Weapon Takes Out Ballistic Missile During Pacific Test

The latest software iteration for a Raytheon-built missile successfully knocked out a medium-range ballistic missile during a test in the Pacific Ocean, demonstrating the weapon’s enhanced capabilities for the U.S. Navy.

The Standard Missile-6, or SM-6, was built by Raytheon, whose missile manufacturing operations are based in Tucson. During this flight test, the Navy used a new configuration with newly qualified software that it said enhances the missiles capabilities.

Fired from the USS Preble at the Pacific Missile Range Facility in Hawaii, the test was dubbed Fight Test Aegis Weapon System. Raytheon said the ballistic missile was intercepted during its final seconds of flight.

Raytheon said the test showed its SM-6 is effective not just for anti-air and anti-surface warfare but also for advanced ballistic missile defense at sea. It’s the only single missile that can handle all three uses.

The SM-6 uses the Standard Missile airframe and propulsion system. Besides being used on Navy ships, sales of the SM-6 have been approved for several allied nations.

I t has been a busy start to 2024 for Raytheon, Arizona's largest defense contractor based on total dollar value of annual contract. The company has also successfully tested a variety of weapons, while reaching a major milestone with a $116 million hypersonic missile program.

Raytheon’s Tucson-based operation also logged a few more contract awards during the past month. They are:

• A $49,413,549 modification of a Marine Corps contract for the procurement of low-rate initial production units of the Navy Marine Expeditionary Ship Interdiction System Launcher. Work will be performed in Tucson and elsewhere.

• A $287,000,000 contract modification from the Navy that adds scope to provide for recertification and modernization of 166 Tomahawk Block IV All-Up-Round Missiles (142 for the Navy and 24 for Foreign Military Sales customers). The work will help make the missiles operational for up to an additional 15 years of service. Most of the work will be performed in Tucson and is expected to be completed in March 2026.

•The Navy also awarded Raytheon a $8,573,968 contract modification to exercise options for design agent and engineering support services for the Rolling Airframe Missile. Work will be performed in Tucson and is expected to be completed by March 2026. By Jeff Gifford – Phoenix Business Journal

A2Z MANUFACTURING WEST COAST • 17 • APR - MAY ’24 A2Z MANUFACTURING SW • 35 • May / June 2024

FOR More Information, Contact: Justin Quinn jquinn@focusedonmachining.com 303-922-3076 Ext. 102

Boeing is Supporting Spirit Aero Financially

The aircraft builder has advanced $425 million to its aerostructures supplier, and offering help to manage higher levels of inventory and reduced cash flows while 737 MAX production rates lag.

Boeing Co. continues an effort to acquire Spirit AeroSystems, but until a deal is completed the jet builder is advancing payments to the supplier, to resolve ongoing complications in their working relationship. According to Spirit Aero, Boeing has advanced $425 million to the Wichita-based manufacturer of aircraft structures, and is offering help to manage higher levels of inventory and reduced cash flows as production rates for the 737 MAX lag.

With Boeing’s cooperation, Spirit will keep up the production rate indicated by the terms of its supply contract with Boeing.

Spirit AeroSystems manufactures fuselage structures for the Boeing 737 MAX and 787 Dreamliner series, and aerostructures for other jet builders too, including Airbus and Bombardier.

Since mid-January, Boeing has reduced its completion rate for the narrowbody 737 MAX, following an in-flight that damaged an Alaska Airlines jet. That brought the Federal Aviation Administration into Boeing’s Renton, Wash., assembly operation, and together the FAA and Boeing continue to evaluate processes there. All the while, the reduced rate of aircraft assembly has stressed Boeing’s suppliers and customers.

Skip Technology Puyallup Tribe of Indiansexpand

Shawna De La Rosa

The Puyallup Tribe of Indians has become the primary investor in Skip Technology, a Portlandbased firm that specializes in renewable energy storage, the tribe announced Wednesday.

Skip Technology has developed a new type of liquid battery for longduration energy storage that uses bromine and hydrogen, rather than lithium. It has no moving parts and is fully recyclable. The investment will allow the company to continue to develop the battery, which can store renewable energy more efficiently. The technology will help bridge the gap between renewable power generation and storage.

The tribe is investing in Skip Technology through its economic development arm, Puyallup Tribe Enterprises, but did not provide additional details

A2Z MANUFACTURING WEST COAST • 18 • APR - MAY ’24

about the size of the investment. The tribe will also manufacture the battery containers — which are similar to shipping containers — at one of its industrial properties in the Port of Tacoma.

The batteries will then be assembled in the tribe’s under-construction 140,000-square-foot manufacturing facility at 3205 Frank Albert Road E. in Fife. The building, which is being built by Sierra Construction Co., is expected to be complete in June.

“When we first heard about what Swift Technology was doing we were blown away with the progress they have already made,” said PTE CEO Matt Wadhwani. “This is an opportunity to make money, diversify our revenue steam, and it aligns with our efforts to be environmentally conscientious.”

Skip Technology’s goal is to have a battery prototype manufactured by the end of this year. The renewable energy storage market is expected to grow at a rate of 30% annually, with an estimated yearly revenue of $750 million, according to the tribe’s news release.

The investment is the latest in a series of initiatives the tribe has undertaken in recent years to economically diversify. It opened the $400 million Emerald Queen Casino in 2020 and an adjacent hotel, partnered with Amazon to develop a sort center in Fife, teamed up with Kenmore Air to operate seaplanes from Ruston Way, and worked with celebrity chef RoyYamaguchi to plan Woven, a Native-inspired waterfront restaurant. The tribe also acquired the Ames International candy company in 2023.

Gulfstream Delivers First Two G700s to Customers

Gulfstream Aerospace has delivered the first two $75 million G700s to customers, the Savannah, Georgia-based aircraft manufacturer said yesterday afternoon. Both are now in service with undisclosed customers in the U.S. The company’s 7,750-nm flagship aircraft received FAA approval on March 29, followed by production certification and cabin interior approval on April 8.

“Beginning G700 customer deliveries less than one month after achieving FAA type certification marks an incredible milestone in Gulfstream’s history

of raising the bar for the business aviation industry,” said Gulfstream president Mark Burns. “We look forward to continuing these deliveries in the weeks ahead.”

Gulfstream had hoped for certification by the end of last year and anticipated delivering as many as 15 before 2023 ended, but the prolonged approval process has shifted those deliveries into this year. As a result, Gulfstream anticipates a 44 percent bump in deliveries this year to 160 jets, including 50 to 52 G700s and fewer G280s due to the conflict in Gaza (G280s are manufactured for Gulfstream by IAI in Tel Aviv).

Meanwhile, FlightSafety International has two level-D simulators and three flight training devices for the G700 online at its Savannah training center, with two more G700 sims under construction. EASA and UK CAA conducted their final evaluations of these devices two weeks ago. G700 pilot training started on March 21, according to FlightSafety.

A2Z MANUFACTURING WEST COAST • 19 • APR - MAY ’24

CEO Barra Says GM Making ‘Extremely Good Progress Across the Board’

Geert De Lombaerde

Five months ago, on the heels of the United Auto Workers’ strike ending, the General Motors Corp. chair and CEO said the company is “much further along than the market is giving us credit for” when it comes to balancing the need to invest in electric vehicles while meeting buyers’ continued demand for internal-combustion products.

“We’ve got momentum. And believe me, we have a very aligned team across GM that is going to seize all these opportunities,” Barra said on a conference call. “From last year to now, much better, much more positive.”

The conversation around GM’s performance is no longer about how much the new UAW contract will add to each vehicle’s production costs. A broader efficiency plan remains on track to deliver $2 billion in cost savings by year’s end and capital spending is settling into a range after several years of big investments.

And the slowdown of the growth rate of EV sales is far less of a worry: Barra and CFO Paul Jacobson reiterated their expectation that GM’s EV business will begin to turn a variable profit this year. On top of that, the company’s portfolio of pickup trucks and SUVs is gaining share in the market, with higher-end models lifting margins.

Prices of the company’s vehicles held up better than expected early this year thanks to continued demand, and that trend hasn’t changed so far in April. GM’s worldwide total vehicle sales in the first quarter were about 1.35 million, a slight drop from a year earlier, but ticked up to 709,000 in North America.

“The commercial environment continues to be resilient. This is a very common theme that we’ve had now for more than a year worth of quarters,” Jacobson said on the call. “There’s a lot of […] downward bias but we’re continuing to manage commercially month to month and producing in line with demand. […] It’s been very favorable for us on both pricing and margins.”

Also driving GM’s numbers and optimism for what’s ahead: The cost of making EVs and their batteries is coming down as GM scales up that part of its business. Barra and Jacobson said they are sticking to their 2024 EV sales goals of 200,000 to 300,000 units—up from about 76,000 last year—as they prepare to roll out a handful of new models later this year.

On the back of those trends, GM rang up a first-quarter net profit of nearly $3 billion on sales of $43 billion.Those numbers were up 24% and 8%, respectively, from early 2023, and were helped by those better-thanexpected pricing trends—they slipped less than the 2%-2.5% range Barra and Jacobson are assuming for 2024—as well as lower materials costs.

The results were enough to give GM’s leaders confidence to raise their full-year expectations for net income (by $300 million) and adjusted cash flow from automotive operations (by $500 million).

A2Z MANUFACTURING WEST COAST • 23 • APR - MAY ’24

Upgrade Your Waterjet with HYDROBLOC®

Experience cleaner, quieter cutting and better looking parts with HYDROBLOC waterjetbricks. The flat, even, honeycomb surface keeps parts from falling into the tank and drains water away to minimize splash back. HYDROBLOC’s laminated high-density polyethylene layers are welded and screwed together for unrivaled durability.

• Cleaner Cutting

• Better Looking Parts

• Quieter Operation

• Recyclable

Watch the video to learn more at barton.com/hydrobloc

BARTON INTERNATIONAL USA/Canada 800-741-7756

518-798-5462

• info@barton.com

• barton.com

• store.barton.com

The BARTON logo and our brands are registered trademarks of BARTON Mines Corporation.

Green Aviation Startup Zeroavia Opens Engine Plant In Everett

Neetish Basnet

Hydrogen-electric aviation startup ZeroAvia has opened a new manufacturing plant at Paine Field in Everett.

The company announced it plans to manufacture electric propulsion systems out of the 136,000-square-foot facility.

Dubbed the Propulsion Center of Excellence, the plant sits close to the company’s existing research-and-development facility in a building previously occupied by Collins Aerospace. Snohomish County records list the aerospace and defense products supplier as the property owner.

In November, the startup raised $116 million in a funding round co-led by European aviation giant Airbus. That followed a $150 million round in August 2022 that included an investment from American Airlines. ZeroAvia has also received grants from the Washington state Department of Commerce to expand its footprint and research in Everett. SeaTacbased Alaska Airlines is also a financial backer.

Eviation, ZeroAvia ink deals with aircraft leasing companies

Aerospace R&D cluster around Paine Field spurs new industrial demand ZeroAvia anticipates by the end of 2025 it will receive certification for its ZA600 hydrogen-electric engine, a 500- to 750-kilowatt powertrain for aircraft seating up to 20 people for distances of up to 300 miles. A larger powertrain for 30- to 90-seat aircraft is in the works for production by 2027.

ZeroAvia will produce “several hundred ZA600 per year from the (Everett) facility,” the spokesperson said.

The company has so far received pre-orders from airlines around the world for some 2,000 engines, potentially generating over $10 billion in revenue, according to the ZeroAvia.

The company established its R&D hub in Everett in early 2022. The location employed about 30 people as of last summer.

“And with the opening of the new facility today, we are also able show ZeroAvia’s growth from ambitious startup into a clean aerospace manufacturing powerhouse, with a production site officially opened in Everett,” Val Miftakhov, founder and CEO of ZeroAvia, said in a press release. “The future is bright for clean flight, Washington State.”

The company also said that it is scouting for sites to open another facility to support production of its hydrogen fuel cell system.

ZeroAvia was founded in Hollister, California, and in addition to Everett also has teams in London and Kemble in the U.K.

A2Z MANUFACTURING WEST COAST • 24 • APR - MAY ’24 OIL MIST AND SMOKE IN YOUR SHOP? Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry www.mistcollectors.com 1-800-645-4174

Cutting Tool Demand Remains Strong

An important index to manufacturing activity has shown rebounds in monthly orders and growth in shipments to begin 2024, countering the general uncertainty about the strength of industrial activity.

In a critical indicator of the strength of industrial activity, U.S. machine shops and other manufacturers ordered $214.6 million worth of cutting tools during February, +4.9% more than during January and +9.0% more than during February 2023. The twomonth order volume for 2024 is $419.1 million, +6.5% above the total for JanuaryFebruary 2023.

The figures are drawn from the monthly Cutting Tool Market Report, compiled by the U.S. Cutting Tool Institute and AMT - the Assn. for Manufacturing Technology.

Cutting-tool purchases are a marker of overall manufacturing activity because those purchases reflect production across a range of manufacturing market segments served by machining operations. Data in the report summarizes purchases by companies participating in the CTMR program who comprise the majority of the U.S. market for cutting tools – whose customers are contract machine shops (job shops) and OEMs for whom cutting tools are significant consumable. Their demand for cutting tools closely matches U.S. durable goods shipments as a measure of production activity.

“After some declines in orders to end the fourth quarter of 2023, the U.S. cutting tool industry has seen rebounds in monthly orders and growth in shipments to begin the first quarter of 2024,” according to Steve Boyer, president of USCTI.

USCTI/AMT

The month-by-month direction of U.S. cuttingtool consumption, February 2020 to February 2024. For the first two months of 2024 activity, cutting-tool consumption totaled $419.1 million, or 6.5% higher than the January-February 2023 total.

February 2020 to February 2024. For the first two months of 2024 activity, cutting-tool consumption totaled $419.1 million, or 6.5% higher than the January-February 2023 total.

“Inflation continues to add some apprehension for upcoming quarters, but the industry continues to positively show growth even if that pattern is of uneven growth,” Boyer added.

Everede Tools Co. president Bret Tayne noted that the February increase in cutting-tool sales happened against a backdrop of “unease and uncertainty in the general economy”.

“The yield curve remains inverted, and inflation remains stubbornly high,” he noted. “The commercial aircraft sector is in a challenging period. Automobile manufacturers have become increasingly concerned about the direction of the EV market. Elections are approaching, and consumer sentiment is volatile.

A2Z MANUFACTURING WEST COAST • 25 • APR - MAY ’24

The month-by-month direction of U.S. cutting-tool consumption,

Cutting Tool Control services machine shops in Washington, Oregon, Northern Idaho, Montana, and BC Canada 1411 NW 51st St. Seattle, WA 98107, CuttingToolControl.com Phone: 206-789-7277, Fax: 206-784-8122, Email: Orders@CuttingToolControl.com

Adapting to New Possibilities

Chucks and adaptations are available in round or hexagonal configurations

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

The Evolution of Industry: What’s to Come for Industry 5.0?

Micah Statler

Since the Industrial Age began, manufacturing has undergone several transformative waves driven by technological advancements. From the mechanization of the first industrial revolution to the digitalization of Industry 4.0, each wave has reshaped production methods and revolutionized industries worldwide. Now, as we enter a new era, a paradigm shift toward collaborative human-machine interactions emerges, promising unprecedented changes.

A Brief Look into the Evolution of Industry Industry 1.0—Mechanization: This era marked a revolutionary shift with the introduction of steam engines and water wheels, powering

mechanized production processes. It laid the groundwork for factories and mass production, shaping modern manufacturing. The transition from manual labor to mechanized processes revolutionized industries, allowing for increased production capacity and standardized output.

Industry 2.0—Electricity: The advent of electricity heralded a new phase, characterized by widespread electrification and assembly lines. It boosted efficiency and productivity, fueling global industrial growth. Electricity enabled the development of large-scale manufacturing operations, leading to economies of scale and the production of goods on a mass scale.

Industry 3.0—Automation: Automation and computerization defined this era, driven by advancements in electronics. Programmable logic controllers (PLCs) and robotics transformed manufacturing processes, enhancing productivity along the way. The integration of automation technologies allowed for greater precision and consistency in manufacturing, thus reducing human error and increasing production speed.

Industry 4.0—Digitalization: Building upon previous revolutions, this phase embraced digitalization to create smart, interconnected factories. IoT and big data analytics enabled real-time monitoring and predictive maintenance. The adoption of digital technologies revolutionized production systems, enabling data-driven decision-making and the optimization of operational efficiency.

Industry 5.0 builds upon the achievements of Industry 4.0, while placing a heavy emphasis on societal value and well-being. It represents a shift toward a human-centric, sustainable and resilient approach to industry, focusing on prosperity beyond jobs and growth while respecting the planet’s limits. By prioritizing the holistic well-being of workers and the environment, this new era aims to create a more inclusive and equitable future for all stakeholders involved in the manufacturing ecosystem.

A collaborative nature. Industry 5.0 involves humans working alongside robots and smart machines, leveraging technologies such as IoT and big data for enhanced productivity and efficiency.

Supporting humans in manufacturing. Industry 5.0 aims to support, not replace, humans in manufacturing. Recognizing the value of human intuition and problem-solving, it emphasizes collaboration between 1.800.281.5734

A2Z MANUFACTURING WEST COAST • 26 • APR - MAY ’24

Germantown, WI USA www.hainbuchamerica.com

humans and machines to drive innovation and success.

Announcements & Releases Continued

Balancing efficiency and productivity. While Industry 4.0 focused on efficiency, Industry 5.0 emphasizes refining collaborative interactions between humans and machines to optimize productivity and achieve sustainable growth.

leveraging the complementary strengths of both humans and machines, Industry 5.0 paves the way for unprecedented levels of productivity and advancement across various industrial sectors.

from outside North America to North America. Reshoring includes work that is produced either in-house or outsourced. A complete definition of “reshoring” is available here. Applications must be submitted by June 30. To view award details and enter to win, visit this webpage.

Inevitable progress of Industry 5.0.This shift represents the manufacturing world’s event horizon, with advancements such as robotics and AI driving irreversible progress toward collaborative manufacturing for a brighter future.

“From 2010 to 2020, more than one million jobs were announced as coming to the United States from offshore. This is a tremendous achievement, and we seek to motivate and honor the companies that have made reshoring a reality,” said Harry Moser, founder and president of the Reshoring Initiative.

Addressing challenges and opportunities. Embracing Industry 5.0 requires addressing challenges like excessive automation while leveraging opportunities for optimal outcomes from human-machine interactions.

The Benefits of a More Collaborative Approach

materials and services to the industry.

At the core of this new era lies collaborative robotics, redefining the relationship between humans and machines. Collaborative robots—or cobots—seamlessly integrate into various tasks alongside humans, augmenting productivity while helping ensure safety. They are designed to adapt to dynamic environments, enhancing flexibility and scalability for a more agile workforce.

Questions about the National Metalworking Reshoring Award can be directed to Harry Moser at 847-867-1144 or harry.moser@ reshorenow.org. For more information on AMT’s efforts on reshoring and supply chain efforts, visit IMTS.com/supplychain.

Industry 5.0 represents a paradigm shift toward collaborative humanmachine interactions. It embodies a symbiotic relationship between robotics, AI and human expertise, maximizing efficiency, creativity and innovation. This collaborative approach fosters a dynamic environment where humans and machines work together to achieve optimal results, shaping the future of industry.

The Association For Manufacturing Technology (AMT) represents U.S. builders and distributors of manufacturing technology – the advanced machinery, devices and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive.

AI amplifies human capabilities and decision-making processes within Industry 5.0, playing a pivotal role in streamlining operations and boosting efficiency. Machine learning algorithms optimize processes, anticipate failures and propel innovation, ultimately fostering agility and responsiveness. By continuously learning from data and interactions, AI systems evolve to better support human workers and enhance overall performance, empowering individuals to achieve more in their roles and contribute to the success of their organizations.

The Reshoring Initiative, founded in early 2010, helps manufacturers realize that local production, in some cases, reduces their total cost of ownership of purchased parts and tooling. The Initiative also trains suppliers how to sell against lower-priced offshore competitors.

As this collaborative ecosystem evolves, we’ll see the integration of human intuition with machine precision generate breakthroughs in problemsolving and product development, as well as a host of other benefits. By

PMA, an inaugural sponsor of the National Reshoring Award, is the full-service trade association representing the North American metalforming industry — the industry that creates precision metal products using stamping, fabricating, spinning, slide forming and roll forming technologies, and other value-added processes. Its

NTMA is the voice for the precision manufacturing and tool and die industries in the United States. Backed by nearly 1,300 member companies, representing more than $30 billion in sales, NTMA provides an array of benefits to members and the industry including advocacy in Washington, training and education programs and networking events nationwide.

The Benefits Of Worki ng With P4Swiss / Lindel CNC Machining

Industry 5.0 emphasizes fortifying workers through cutting-edge digital tools such as augmented reality (AR) glasses and exoskeletons. AR glasses enhance accuracy and efficiency, while exoskeletons reduce strain and injuries, fostering a culture of collaboration and well-being. These digital tools not only enhance individual performance but also promote knowledge sharing and skill development among workers, therefore driving continuous improvement in manufacturing processes.

Founded in 1987, Lindel Precision CNC Machining merged with Precision 4 Swiss in 2019. Together, P4Swiss / Lindel CNC Machining is dedicated to providing quality CNC machined parts at

A2Z MANUFACTURING WEST COAST • 27 • APR - MAY ’24

nearly 900 member companies also include suppliers of equipment,

OUR HISTORY

Sterling Fab Tech is a fabrication machinery supplier that represents the most cutting-edge manufacturing technologies in the fabrication industry. With locally based sales and service employees, we support the Southwest region from California to Louisiana.

OUR APPROACH

We pride ourselves in being the subject matter experts in fabrication processes and machine technologies. Combining this engineering approach to sales, our goal is to understand your needs and educate your team without any sales puffery.

OUR CUSTOMERS

Scan the QR code to get an inside look at customer facility tours and what our customers are saying about SFT.

A2Z MANUFACTURING WEST COAST • 28 • APR - MAY ’24

TECH CENTER SALES ENGINEER APPLICATION ENGINEER SERVICE ENGINEER MACHINE

FOR YOUR FABRICATION CHALLENGES Costa Mesa, CA Dallas, TX Schedule a private demo with us at info@sterlingfabtech.com TECH CENTER LOCATIONS

TOOL SOLUTIONS

MACHINERY SOLUTIONS

PRECISION MACHINE TOOLS

Coil Lines

Flat Sheet & Tube Lasers

Punch and Laser/ Punch Combo

Waterjets

Press Brakes & Robotic Bending Cells

Panel Benders

Plate Rolls

BRANDS

Tube Bending

Deburring & Finishing Machines

Robotic Mig & Laser Welding Cells

Quality Inspection Machines

Sheet & Tube Storage Racks

Nitrogen Generators

INDUSTRIAL MACHINE TOOLS

Plasma & Oxy-Fuel Burning Tables

Gantry Style Machining Centers

Pipe & Tube Cutting

Robotic Plasma for Profile Cutting

High Tonnage Press Brakes

Heavy Duty Plate Rolls

Angle & Pipe Bending

Automated Beam Welding

Power Tools for Bevelings

MACHINERY SERVICE + SUPPORT

SERVICE TEAM

APPLICATIONS TEAM

SFT’s Applications team supports you during machine selection, installation/commissioning throughout the life of the machine. We offer services to improve efficiency and productivity, while reducing the common headaches of implementing new technologies or dealing with labor shortages.

SFT’s Service team are factory trained technicians dedicated to getting your machine installed correctly, preventing unexpected downtime through preventative maintenance, assisting with machine relocations, and promptly completing machine repairs. They are also trained to handle TRUMPF and Bystronic lasers.

A2Z MANUFACTURING WEST COAST • 29 • APR - MAY ’24

ANDY WHITE Applications Engineer

JOSE BOTELLO Applications Engineer

JEREMY GARLAND Senior Applications Engineer

TODD WASKOW Service Engineer FERMIN HERNANDEZ Service Engineer

LUCAS HERBERT Service Engineer JAMES DONOVAN Applications & Service Engineer

EDGAR MONCADA Service Engineer

EDDIE ANZALDUA JR Service Engineer

info@sterlingfabtech.com • sterlingfabtech.com • 855-222-7084

Precious Metals Plating Co.,

Inc

+ Gold Plating

+ Silver Plating

+ Nickel Plating

+ Electroless Nickel Plating

+ Tin Plating

+ Heat Treat With Plate

+ Nadcap Approved Processes

+ Boeing Approved Processes

+ Expedited Turnaround

+ X-ray Fluorescence

Thickness Verification

+ In-House Laboratory With Atomic Absorption (AA)

+ Expanded Capacity In Vibratory Plating

We Are The Noble Partner With The Personal Touch!

481-6271 www.pmplating.com

Five Electric Planes That Will Take You To The Skies Soon

Jamie Whitney

Developing green technology is crucial, especially as aviation accounted for nearly 3% of global CO2 emissions in 2019. While this might seem a small percentage of the total, it’s still over a billion tons of CO2 in the air. Furthermore, unlike jets and turboprops, most piston-engined planes still use leaded fuel, making it one of the biggest sources of lead pollution in the U.S. today. That’s why electric planes are crucial to help the aviation industry clean up its act, Jowi Morales writes for SlashGear. Continue reading original article.

The five aircraft seleted by Morales and SlashGear include the EcoPulse from Airbus/Daher/Safran, Ampaire’s Eco Caravan, the Diamond eDA40, Eviation’s Alice, and the Velis Electro from Pipistrel.

While all the aircraft listed by SlashGear are electric, they vary quite a bit in both readiness and use cases. Pipistrel’s Velis Electro has already received its type certification and is a twin seater with a range of approximatley 50 minutes and a ceiling of 12,000. The electric flyer is based on Pipistrel’s Virus two-seater ultralight.

While electric cars and buses are quite popular nowadays, with Tesla becoming the best-selling luxury car brand in the U.S., it’s still hard to find an electric plane to fly on. Nevertheless, as aeronautical engineers and aviation industry leaders recognize this, there is a push to develop electric planes, Jowi Morales writes for SlashGear.

Eviation’s Alice is envisioned as a regional aircraft with nine seats that was engineered around its twin-engine that can fly up to 250 nautical miles with a payload up to 2,500. Eviation aims for the entry into service by 2027.

A2Z MANUFACTURING WEST COAST • 30 • APR - MAY ’24

(800)

A2Z MANUFACTURING WEST COAST • 31 • APR - MAY ’24

The Manufacturer’s Secret Weapon

It’s All in the Presentation

By Stephen Hannemann

By Stephen Hannemann

Communication is a tricky art! Many more forms of personal contact exist today than in years past. Letters, unless they are of a legal matter, are becoming rarer. Phone calls, unless necessitated by a critical event, are fewer. Texts and emails are the most widely accepted norm, and unless care is taken by the composer, misinterpretation often occurs.

For this article verbal communication will be the topic. Lessons learned can apply to all forms of communication. It only takes one or two words to produce a reaction versus a response. It could be the inflection of one’s voice, a facial expression, body language, voice tone – all contribute to the way a message is perceived.There are those that believe we may have become an overly sensitive society. Maybe so, but a touch of discernment is never a hindrance when communicating in any environment, and especially when interacting on the job.

As always, my perspective is from a manufacturing viewpoint. A positive attitude is always a key ingredient. Being grateful for your position in your

workplace always helps. Being aware of what’s going on around you is another asset. Interacting on the floor in a manufacturing plant, where much is happening all the time, being able to read the room is an invaluable asset. When observant, many opportunities to lend support to the newly hired are plentiful. It only takes a moment to see a bit of frustration on a non-veteran’s face or a tinge of uncertainty. When an opportunity presents to help, show compassion. Introduce yourself and share your experience on how you also struggled to do the task.

Instill confidence. Always end a positive encounter with a compliment. There may be an occasional heated conflict of one type or another.These are delicate. Avoid at all costs getting into a possibly elevated discussion in public; take it private. During these times, listening is your best asset. While you are listening, try to hear what is not being said. Do not dig in, don’t try to think of a rebuttal while the other person is speaking. Stay open. Make sure the person knows you hear their point of view. Although you might not agree, at all costs, be respectful. Anger is never your ally in an aggravated situation. Look for any point of their presentation that you can agree on and explore it with them.Winning is not the important objective in a situation like this. Finding common ground and arriving at the right solution is. It may take a few conversations to arrive at the right answer, but leading the journey in a respectful manner, you both will be farther ahead.

A2Z MANUFACTURING WEST COAST • 32 • APR - MAY ’24

If you’re looking for help with Injection Molding, Casting, Machining, or Fabrication give me a call! Phone 425.501.7342, email stephen@smhincllc. com, or visit www.smhincllc.com. SMH Inc – “The Manufacture’s Secret Weapon”

Precision Fabrication

Injection

Molding

Investment Casting

Sand Casting

5-axis Machining

Buyer’s Guide & Card Gallery Equipment and Services

Tel: 1-631-273-1010 1-800-645-4174 Fax: 1-631-273-1066 1-800-424-2082

www.royalprod.com

orders@royalprod.com

ACCESSORIES

Abrasive Systems

KBC TOOLS & Machinery___714-278-0500

Air Cleaning Guns

Royal Products 631-273-1010

Auto-Bar Feed Systems

Western Machine Center____408-955-1000

Automation

Hainbuch Workholding____818-970-7874

Ballscrews

C & M Precision Spindle, Inc._ 503-691-0955

Band Saws/Saw Blades

Bandsaw Tech 562--419-7675

Cycle Time Solutions_____510-708-8665

Saw Service

Sterling Saw Blades

www.coastaluminum.com jpalmer@coastaluminum.com

Spinetti Machinery

Boring

THINBIT

775-996-3770

888-844-6248

Caabinet Spray Washers

ALMCO 507-380-1009

Cams

Dayton Lamina. 708-203-6684

Carbide Tools, Indexable

ARNO USA____________815-236-8118

Cycle Time Solutions 510-708-8665

Horizon Carbide 602-524-38028

Ceramic Cutting Tools

NTK Cutting Tools 425-365-3613

877-738-6437

800-828-11800

Band Saw Replacement Parts

Saw Service

Chemicals: Ultrasonic Star Metal Fluids 800-367-9966

ChuckJaws & Adapters

Hainbuch America 253-293-2062

877-738-6437

Sterling Saw Blades 800-828-1180

Saw Service

Band Saw Repair

877-738-6437

Sterling Saw Blades ______ 800-828-1180

Bar Feeders

Lucy’s Machine Company 323-587-6162

Sulli Tool & Supply 714-863-6019

Collets & Chucks Cycle Time Solutions 510-708-8665

America

A2Z MANUFACTURING WEST COAST • 34 • APR - MAY ’24

Coolant Applications Specialities ____ 253-872-0305 Star Metal Fluids 800-367-9966 US Shop Tools _________ 800-243-7701 Coolant Systems & Chillers MP Systems 909-282-7463 Star Metal Fluids 800-367-9966 THINBIT 888-844-6248 US Shop Tools 800-243-7701 Cutting Tool Holders ARNO USA____________815-236-8118 Hainbuch America 253-293-2062 KBC TOOLS & Machinery____714-278-0500 Sulli Tool & Supply 714-863-6019 Cutting Tool Systems ARNO USA____________815-236-8118CyCutting Tools made in the U.S.A. since 1964 www.thinbit.com A2ZWCBG2019.indd 1 12/6/2018 10:33:33 AM Division of Curran Manufacturing Corporation 200 Oser Avenue Hauppauge, NY 11788 U.S.A.

Hainbuch

253-293-2062 Buds Equipment Sales 435-659-9455

4740 NE 166th Avenue Portland, OR 97230 (503) 224-6061 (877) 398-6061 Fax (503) 253-1790 Cell (503) 572-9331

John Palmer Jr. Vice President: Northwest Region Go from Receiving to Machining with Precision Machine-Ready Blanks • Eliminate Material Prep • Flat, Square, and Parallel • Improve Throughput and Quality 800-234-5613 • www.tciprecision.com

cle Time Solutions

510-708-8665

KBC TOOLS & Machinery____714-278-0500

THINBIT 888-844-6248

Deburring Tools

Royal Products 631-273-1010

Die Tooling Springs

Dayton Lamina. 708-203-6684

Dot Peen Markers

MarkinBox 310-214-3367

Draw Tubes

Lucy’s Machine Co._______323-587-6162

Drills/Cutters-Magnetic

ARNO USA____________815-236-8118

Sulli Tool & Supply 714-863-6019

Drills/Reamers/Taps

ARNO USA____________815-236-8118

Sulli Tool & Supply ______ 714-863-6019

EDM Materials & Supplies

Desert EDM 480-816-6300

EDM Network_________480-836-1782

EDM Performance 800-336-2946

End Mills

ARNO USA____________815-236-8118

Horizon Carbide_______602-524-3802

Sulli Tool & Supply ______ 714-863-6019

Filiter Mist Collectors

Royal Products_______631-273-1010

Fixturing

Hainbuch America______253-293-2062

KBC TOOLS & Machinery____714-278-0500

Form Tooling

THINBIT 888-844-6248

CASEY JOHNSON

Head of Marketing (855) 222-7084

casey@sterlingfabtech.com sterlingfabtech.com

Grooving Head, Grooving Tools

Cycle Time Solutions 510-708-8665

THINBIT 888-844-6248

Indexible Tools

SCT-USA.___________805-584-9495

Inserts

ARNO USA____________815-236-8118

Horizon Carbide_______602-524-3802

Sulli Tool & Supply______714-863-6019

Jaws

EDM Network________480-836-1782

US Shop Tools________800-243-7701

Keyseat Cutters

Sulli Tool & Supply 714-863-6019

Lifting & Material Handling

Ingersoll Rand 206-472-0826

Live Centers

Royal Products 631-273-1010

Load Unload Systems

Midaco Corporation 847-593-8420

Lubricants / Systems

Star Metal Fluids 800-367-9966

Machine Tool Acccessories

US Shop Tools _________ 800-243-7701

Mandrels

Hainbuch America 253-293-2062

Mounting Brackets

Lucy’s Machine Company ___ 323-587-6162

Packaging/Shipping Supplies

Alliance Packaging 206-445-5898-

Parts Washing Equipment

Ebbco Inc 800-809-3901

Port Tools

“Equipping Your Success”

Rick Smith C 408.396.1238 Rick@peopletechMT.com N.Calif-Santa Clara Office T 408.598.2200 S.Calif-Irvine Office T 949.398.0400 www.peopletechMT.com

SCT-USA.

805-584-9495

Power Tools

KBC TOOLS & Machinery____714-278-0500

Precision Bearings

C & M Precision Spindle, Inc._ 503-691-0955

Probing Systems

Sherpa Design_ 503-771-3570

Profiling

THINBIT

888-844-6248

Punch Die Tooling

Dayton Lamina. 708-203-6684

Quick Change Systems

Hainbuch Workholding____818-970-7874

stRetention Knobs

Safety Products

US Shop Tools 800-243-7701

Sindle Point Tools

SCT-USA. 805-584-9495

Solvents: Vapor degreasing

Star Metal Fluids 800-367-9966

Solvents:Hand Wipe

Star Metal Fluids 800-367-9966

Solvents: Mil PRF 680

Star Metal Fluids 800-367-9966

SpecialtyTooling

SCT-USA. 805-584-9495

THINBIT

888-844-6248

Spindle Deburring Machines ALMCO 507-380-1009

Spindle Liners

Lucy’s Machine Company 323-587-6162

Stamping Tooling

Dayton Lamina. 708-203-6684

Stationary Clamping Devices

Hainbuch Workholding____818-970-7874

Support Stands

Lucy’s Machine Company 323-587-6162

Testing Measuring Technology

Hainbuch Workholding____818-970-7874

Threading Thread Mills

SCT-USA.

805-584-9495

THINBIT 888-844-6248

Tooling Pins & Bushings

Dayton Lamina. ________ 708-203-6684

Tool Sharpening (Grinding)

Applications Specialities 253-872-0305

Swift Tool Co, Inc. 800-562-0900

Tooling Systems

Applications Specialities 253-872-0305

Bilz USA 224-563-7233 Cycle Time Solutions 510-708-8665

Horizon Carbide 602-524-3802

Rosco Precision Machinery 253-333-2439

RyansDovetails.com 253-876-9981

Sulli Tool & Supply 714-863-6019

Spinetti Machinery ______ 775-996-3770 THINBIT 888-844-6248

Von Ruden Manufacturing, Inc.763-682--3122

Western Sintering 509-375-3096

Tumbling Meda and Compounds

ALMCO 507-380-1009

Vibratory Deburrung Bowls ALMCO 507-380-1009

Vibratory Deburrung Tubs ALMCO 507-380-1009

Vises & Vise Jaws

A2Z MANUFACTURING WEST COAST • 35 • APR - MAY ’24

RyansDovetails.com

Workholding

253-876-9981

Cycle Time Solutions 510-708-8665

KBC TOOLS & Machinery____714-278-0500

APPRENTICESHIPS & TRAINING

Aerospace & Advanced Manufacturing Apprenticeships

AJAC

206-737-8342

Machining Apprenticeships

AJAC _____________ 206-737-8342

Precision Metal Fabrication Apprenticeships

AJAC 206-737-8342

Training & Education

AJAC 206-737-8342

ADDITIVE MFG/3D PRINTING

Bramac Machinery, Inc. 951-383-4195

MLC-CAD 858-358-0067

APPRAISALS

Machinery Resources

480-694-9919

Perfection Global 847-545-6906

AUCTIONS/LIQUIDATIONS

Machinery Resources 480-694-9919

Perfection Global 847-545-6906

BANKING

Quick Turn Financial _____ 415-608-5692

Tech Financial Services 414-224-0209

Valley Financial Services 818-968-4861

BUSINESS ADVISORS

Muerller Prost 314-862-2070

CARRIERS & RIGGING