Science and Industry

Elegant Solutions to Support

High-Performance Environments

We value relationships built on trust, and we’ll work tirelessly to earn yours.

We value relationships built on trust, and we’ll work tirelessly to earn yours.

Progressive Companies is a multidisciplinary national design firm connecting people, places and communities through transformative spaces, structures, pathways, and environments. We believe innovation is more than leading with the best technologies and latest trends – it’s a creative process beginning with curiosity and diving deep into understanding your world. As problem-solvers, our team of designers, architects, consultants, engineers, and strategists enthusiastically work alongside you to envision a bold, new future.

From modest beginnings of four original engineering partners in 1962, to over 300 employees serving clients across the nation today, Progressive Companies has always thrived on an entrepreneurial mindset. As an employee-owned business, individuals take personal accountability for representing the firm’s values of leadership, learning, trust, and diversity.

Our talented workforce brings decades of expertise in all facets of architecture, engineering construction, and planning – with a broad and deep portfolio reflecting projects in 49 states.

Having an experienced design team by your side can positively impact your science and industry projects – helping you develop purposeful strategies to increase efficiency, growth, client and customer satisfaction, and safety. Whether it’s tying back to your mission, vision, and values through inclusive and sustainable design strategies, or increasing productivity through principles of lean design, Progressive Companies has the depth, breadth and expertise to help you succeed.

We understand science and industry environments, and we recognize each project comes with its own challenges. As your dedicated design partner, we’re with you every step of the way – listening, learning, and responding quickly to find flexible solutions. By immersing ourselves in your world, we can approach your needs with curiosity and imagination to advance your vision.

As bold designers in science and industry environments, our specialized team passionately employs peoplecentric experiential solutions – activating human interaction and safety. We focus on the overall atmosphere, unique conditions, and user-experience to ensure design solutions have a meaningful impact for your company, processes, and employees.

Design isn’t something done to you, but rather a highly collaborative engagement. We work tirelessly to build trusting relationships, understand what’s unique about you and your project, and offer meaningful insights connecting design to performance.

Each project comes with its own challenges, and we’re with you every step of the way – listening, learning, and responding quickly to find flexible solutions. Together we will explore a range of high-level, future-facing topics to ensure we’re moving forward as innovators.

Brandon Yancharas

SENIOR ARCHITECTURAL TECHNICIAN

byancharas@weareprogressive.com

616.988.4908

Brandon serves as both project architect and manager at Progressive Companies, overseeing planning, team coordination, design documentation, budgets, schedules, and permit approvals. His client-focused approach and commitment to timely, profitable delivery have earned the trust of clients and project owners alike.

I believe great architecture begins with understanding the client’s vision and delivering solutions that exceed expectations — on time and with precision.

Eric Bratt, PE

SENIOR MECHANICAL ENGINEER

ebratt@weareprogressive.com

616.988.4873

Eric, a mechanical engineer with 15+ years of experience, specializes in HVAC and plumbing design for diverse markets, including cleanrooms, healthcare, and laboratories. He excels in high-performance environments, delivering precise, creative solutions and leading projects with collaboration to meet client goals for ISO 5-8 cleanrooms, BSL-2/3 labs, and more.

My goal with every project is to deeply understand a client’s process and requirements, tailor the systems to their needs, and clearly explain the ‘why’ behind my choices, ensuring they are informed and involved in the design process.

dstivers@weareprogressive.com

704.731.8088

Dane brings over 20 years of experience and leadership in multi-discipline project management, team building, and market sector development. He is responsible for support and mentorship of engineering teams, client relationship development, managing complex projects, and strategic advancement of the firm’s industrial and health and wellness practices in North Carolina.

No two projects are the same, but the vision held by both client and designer for project outcomes should be. Intentionality in listening, then doing, within each project is vital for shared visions and successful outcomes.

LOGISTICS PROGRAM LEADER

kjacot@weareprogressive.com

616.447.3318

Kevin Jacot brings over 13 years of experience as a program leader, client lead, project manager, and architectural job captain. As a senior project manager for logistics, commercial, and industrial clients, Kevin oversees business development, program and teammanagement, project proposals, site design, scheduling, budgeting, and resource management.

My approach is built on strong relationships — with both internal teams and clients. By understanding their values and needs, we act as an extension of their team to design highperformance/prodcution environments.

PRINCIPAL, PROGRAM PRACTICE LEADER

dwurl@weareprogressive.com

616.447.3439

With over two decades of experience, Doug helps clients execute efficient go-to-market strategies nationwide. By focusing on client goals, he designs flexible solutions to meet immediate needs while anticipating future challenges. Doug leverages his multidisciplinary team to navigate complexities, ensuring timely, successful project delivery and lasting client relationships.

Empowering team members to take ownership of their roles is critical to providing exceptional client service. Not only does this approach build leaders in our organization, but it also ensures our clients have access to an entire team.

rnoakes@weareprogressive.com

616.447.3437

With over 25 years of experience as a client manager, team leader, project manager, and architectural job captain, Ryan oversees project proposals, management, scheduling, budgeting, and resource allocation for projects nationwide. Known for building trust with clients and the internal team, he provides strong leadership and mentorship to our program delivery group.

The program delivery method is based on relationships, both with the internal teams and with the clients. Our goal is to understand the client’s values and needs, allowing us to act as an extension of their team.

Our Science and Industry practice is comprised of 30+ dedicated team members and backed by an additional 270+ multidisciplinary experts across the firm – enabling us to deliver holistic, integrated strategies from planning through design. As a learning organization, we are continually growing, researching, and innovating to ensure we are staying informed of design trends impacting science and technology environments. And of course, we share these insights and best practices with you and apply them to the projects we’re working on.

• Architectural Planning

• Civil Engineering

• Client Engagement

• Conceptual Design

• Construction Management

• Controlled Environments

• Electrical Engineering

• Healthcare Planning

• Interior Design

• Landscape Architecture

• Lighting Design

• Logistics

• Master Planning

• Mechanical Engineering

• Program Design and Delivery

• Structural Engineering

• Sustainable Design

• Universal Design

• Workplace Strategy

Our designers leverage their deep understanding of the way people, things, and environments interact. Because industrial and manufacturing facilities are highly performance driven, these three elements

From typical laboratory and manufacturing, to pharmaceutical and medical, to high technology and aerospace, our team can design cleanrooms and controlled environments to your standard of certification or ISO level of compliance needed.

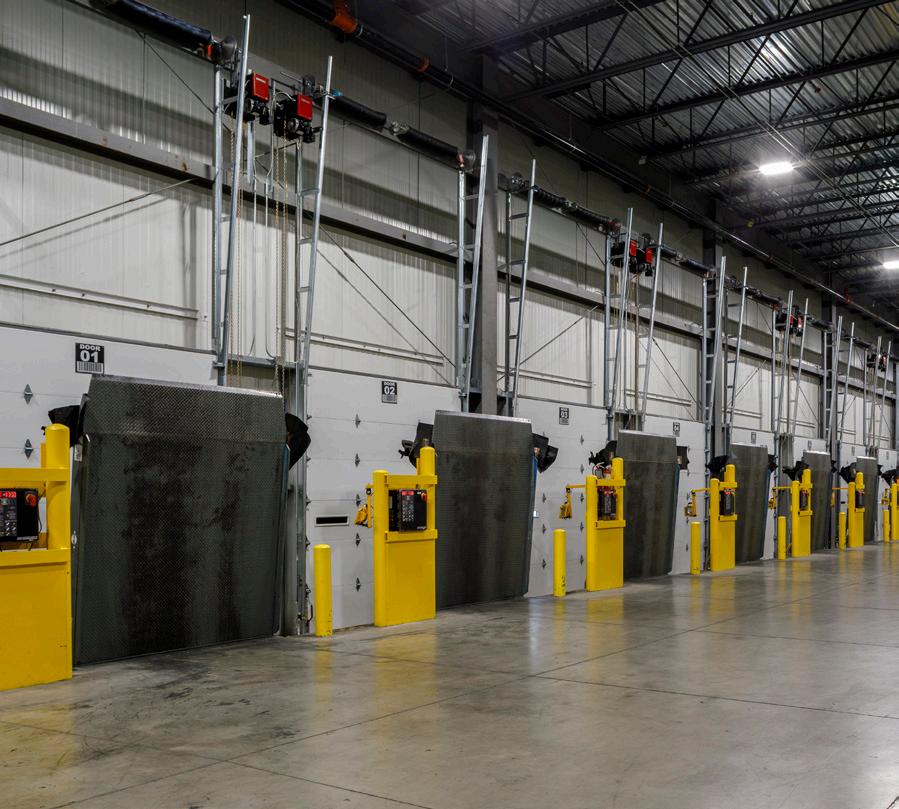

A nimble and viable supply chain is critical to our economy. We understand that distribution centers are as much about moving goods as about storage. Our team has extensive experience in planning, designing and delivering cost-effective, operationally efficient facilities supporting productive flow and operation—including cold storage.

Quality solutions are critical to food and beverage production. Scalability and adaptability are essential to keep pace with changing consumer demands, evolving regulations, and important safety protocols. Systems required are highly complex, must be integrated in performance, and monitored and serviced on a regular basis. Our team is skilled in assessing production support needs and identifying efficient solutions to meet your production requirements.

We understand these facilities are critical to the communities they serve. They need to be failsafe against inclement weather, security threats, and other risks, while also embracing sustainability. Our experience in providing support facility design ranges from technical operations centers to power generation buildings. We have served both nuclear and fossil fuel programs providing solutions to meet critical service needs.

From consumer goods such as automotive, building products, medical devices, and packaging to high technology, aerospace and advanced manufacturing, we can help you layout, configure and design systems support for reliable and robust production. Our lean thinking and systems solutions focused processes can help you improve productivity, increase operational excellence and support your goals of growing your business.

We are experienced in working with medical product manufacturers for both pharmaceutical and medical product programs. Our team collaborates with clients in navigating legal and regulatory mandates and creatively developing opportunities to improve efficiency, productivity, and safety.

We specialize in designing environments where individuals of every background and ability know they belong. Employees shouldn’t have to worry about inaccessible spaces, confusing signage, or unsafe environments. From flexible and adaptable workspaces, to anti-slip, lowreflective finishes, our design team is wellversed in Universal Design strategies which remove physical and social barriers and go above and beyond those mandated by ADA— ensuring everyone has a safe, welcoming, and equitable experience at work.

We’ve worked with hundreds of clients, from Amazon to Starbucks, helping design spaces where people know they belong. We look forward to bringing our inclusive design expertise and lessons learned to your project.

The Pfizer workplace strategy team hired Progressive Companies to advance their inclusive design initiatives. Our work started with a Universal Design (UD) assessment of the company’s Groton, Connecticut campus establishing a baseline for accessibility, inclusion, and safety best practices for all Pfizer workplaces going forward. We reviewed their current global design guidelines, created new Pfizer UD standards, and led a global training program on UD.

We acknowledge the impact that the built environment has on climate change and the natural environment. We are committed to an integrated design approach, reducing our environmental impact, and providing restorative solutions for the overall well-being of our clients and communities. As early advocates for sustainable design, and with over 50 LEED accredited professionals, we have guided hundreds of projects through LEED certification, often going above and beyond requirements. In 2021, our firm became a signatory of the AIA 2030 Commitment, further enhancing the company’s commitment to reduce carbon emissions.

We will carefully balance initial expense with long-term operational efficiencies to reduce your carbon footprint and make your science and industry space more resilient for the future — looking for solutions that offer benefits both in terms of the initial design and the ongoing operation and maintenance. Our approach encompasses large scale decisions like building orientation, daylighting, and energy usage to details like selection of regional materials.

Indoor air quality, acoustics, and access to natural light all have a major impact on the health and well-being of your employees — in fact, studies have shown that connection to nature benefits both mental and physical well-being and improves focus. We will employ sustainable design best practices and elements of biophilic design wherever possible in order to meaningfully connect people with place, for the benefit of both.

Design for Change

Design for Energy and Resources

Design for Integration

Design for Equitable Communities

With recent labor shortages within the science, industry, and manufacturing fields, organizations must be intentional about how they attract and retain talent. In the past, companies didn’t have to do much other than offer good wages—now they need to offer a beautiful and comfortable place to work, excellent benefits, opportunities, and a positive and intentional company culture to attract quality employees.

Good design makes the brand visible and tangible so that employees feel connected to the mission, vision, and values of the company. We work to create spaces that cause positive interactions between employees in different departments-- helping clients create spaces where warehouse workers and factory floor workers are just as much a part of a business as marketing, sales, and executives.

Plant floors used to be considered blue-collar, but as manufacturing gets more sophisticated the cultures are becoming increasingly similar between the plant floor and the administrative side. Many jobs in advanced manufacturing can pay $70-$80,000 a year. Plants don’t have to be dingy worlds anymore, and there’s a strong drive for more amenities adjacent to the work nodes, enabling people to socialize and connect with each other as well as work.

We also specialize in Universal Design (UD) and inclusive design strategies, which aim to create spaces that are designed with all employees in mind. As we hear about the need to attract and retain talent, there is no single paradigm for what a quality employee looks like. We want to be as inclusive as possible to give companies a wider talent pool. UD embraces safety considerations that respond to slips, trips, and falls, overexertion, repetitive motion injuries, and collisions with equipment. A safer work environment can help reduce employee turnover, absenteeism, and workers’ compensation claims — all of which can have a significant impact on your bottom line, and employee morale.

In addition, a number of our team members are certified WELL APs, which means they are trained in WELL building best practices—the leading tool for advancing health and well-being in buildings globally. WELL seeks to make spaces healthier for employees by prioritizing human health and well-being.

One example is giving employees access to natural lighting throughout the day. In an industrial environment the plant floor can be dark. As employees move through the plant, we try to bring natural light into the main area if possible, or the break/training area to give them some relief.

A 130,000 square-foot facility, nestled within a picturesque natural environment, exemplifies Progressive Companies’ unwavering commitment to sustainability, holding the prestigious Envision Platinum Verification from the Institute for Sustainable Infrastructure.

Many types of production have become more sophisticated and precise. The spaces in which production occurs are much more controlled environments, from temperature and humidity to highly filtered air. Often, they’re more pristine than an office environment, especially where food and beverage is concerned. Our architects and engineers are well-versed in the safety and design requirements for these highlyspecialized spaces, creating a bright and impressive high-tech place to work.

In addition, companies now can use sensors and AI to identify spaces being utilized (or underutilized), so we can reposition them for better use. When companies invest in spaces, we want to make sure they’re being used for the intended function. If they’re not being used to their fullest, we can alter as needed.

Industry 4.0 has to do with managing your business through big data using sensors, machine-to-machine communication, internet of things, and other emerging technologies. Big data has a lot of value in enabling production success. There are many design options to consider, and we’re committed to assisting clients integrate a right-size approach for their business.

Dust. Particulate. Temperature. Humidity. These are things we might not consider in our daily lives — unless you work in healthcare, aerospace, manufacturing, or one of many other highly technical specialties. These jobs involve working in rooms free from foreign components that could damage sensitive equipment and samples. That’s where controlled spaces come in.

With the growing complexity of medications in the healthcare sector and the need for stringent environmental controls, controlled environments, such as cleanrooms and containment suites, are essential for the safe storage, preparation, and dispensing of medications.

Cleanrooms minimize particulates, microbes, and other contaminants. These environments use advanced filtration systems, controlled airflow, and strict cleaning protocols, ensuring medications meet FDA and EMA standards. Some medications are also sensitive to humidity, necessitating robust humidity control systems.

The creation of customized medications for individual patients requires precise conditions for safety and efficacy. Controlled environments in hospital pharmacies must meet USP standards for sterile compounding and handling hazardous drugs, which mandate everything from temperature and room pressure relationships, to operational layouts.

Controlled environments offer stable, contaminant-free spaces. This stability reduces medication errors, production delays, and product rejections, crucial for timely and accurate medication delivery in healthcare settings. Investing in state-of-theart controlled environments allow hospital pharmacies to deliver safe, effective medications, improving health outcomes and ensuring the highest standards of care.

Progressive Companies has completed over 25 controlled environments and cleanrooms across the nation.

“There’s not enough capacity in the switchgear to power your equipment”…“The seal water tank won’t buffer the additional pumps”…“The dust collection system does not have enough CFM for an additional pick-up point”…“The equipment won’t fit.”

Whether it be inaccessible equipment, a process that does not actualize throughput, an unplanned safety exposure, or a lack of process dust capture, virtually every department on a site is affected by poor project planning. What was once thought of as a no-brainer capital expenditure could quickly transform into a nightmare project with no end in sight or spending.

In this unpredictable market of expanded lead times, material shortages, and fluctuating costs, many projects are suffering from the lack of foresight and planning. Rushing the design process to accommodate getting equipment on time has become the norm. This also comes in the advent of engineers with multiple years of project experience retiring or simply leaving careers. Now, there are too few to do too much. As a result, the feasibility phase of project planning is beginning to disappear.

The feasibility phase of a project should not be underestimated. This critical project step can put to bed the things that keep project engineers and managers awake. Helping to eliminate uncertainties and benchmark whether or not a project is going to work within the constraints given.

Not all feasibility studies are the same, they vary per industry, and even within the same industry are varying project scopes and operational demands. But at their core, all feasibility studies should provide stakeholders with supplemental information to help determine whether a proposed project or investment is likely to succeed.

Determining feasibility can include multiple verification steps before the project is designed, key determinants are:

Is the proposed project able to actualize the proposed results? A technical feasibility analysis will quantify if a project can come to fruition without technical concerns. Taking into consideration the size of the project site, access to the area, land topography, geotechnical information, existing facilities or structures on the site, and other environmental factors.

Is there enough existing infrastructure to support the proposed project? Assessing the resources is another component of a technical feasibility analysis. Examining the material availability, personnel availability, required equipment, and other practical requirements unique to the project.

Does the availability of the proposed project equipment and processes allow completion of the project within the desired time frame? A scheduling feasibility analysis considers the overall design, materials, risk areas, and laws and how they could affect the overall amount of time needed to complete a project.

Are the available funds adequate to support completion of the proposed project? An economic feasibility analysis helps determine if the funding is sufficient for the foreseeable project costs and commonly includes a cost benefit analysis section or “CBA”.

Until these critical aspects can be confirmed, the project cannot be determined as feasible.

A good feasibility study costs between 0.75% and 1.5% of the total project cost and can tell you not just whether to spend the other 99% of the budget, but also determine how it should be spent to maximize the return-on-investment and long-term effectiveness of the project. If a consultant is being considered to assist in designing a project, the ability of that consultant to perform the feasibility phase services should be a priority in the firm’s selection.

No matter your needs, Progressive Companies’ full-service capabilities make us your ideal partner for feasibility studies and any other project stage. A team you can trust to be with you every step of the way, working transparently to make sure you are receiving the optimal solutions and resources that align with your design, schedule, and budgetary goals.

Reference:

“Feasibility Study & Its Importance in Construction Project.” Www.blackridgeresearch.com, Blackridge Research & Consulting, 2 Nov. 2022, www.blackridgeresearch.com/blog/what-is-a-feasibility-study-and-importance-of-feasibility-study-in-construction-project.

Change is difficult for people who seem to resist it, for those who readily embrace it, and even for the leaders responsible for driving it. Change also burdens laboratories with small, sometimes unpredictable increases in the cost to perform research and deliver products. So, doesn’t it seem like a paradox, that the only action costing labs more than change itself, is failure to enact change when necessary?

Consider the following costs associated with both passivity and action in this scenario:

A lab employee spills a strong acid in the fume hood and quickly jumps up just before the acid cascades onto the chair and floor. Although the employee was not hurt, what could happen if another employee was slower to respond? According to the National Council on Compensation Insurance, a passive, “these things happen,” response could incur the average burn-related workers’ compensation claim: nearly $60,000. The alternative approach is to actively workshop and re-train a modified protocol or to purchase a safety upgrade for equipment – a drastically more affordable option.

Most tools, chemicals, equipment, and instrumentation in the average lab can significantly threaten staff safety if used improperly. At Progressive Companies, we use principles of Universal Design (UD) to help lab managers modify the laboratory workspace to maximize the likelihood that a task will be performed both correctly and safely. On the following page are a few solutions we frequently recommend.

Repetitive motion injury

Unsafe equipment usage

Arrange supplies within reach; lower on the shelf and shallower on the bench to discourage overextension

Bumps and bruises

Eliminate outdated signage; create updated signage in key areas with large, clear symbols and contrasting colors, and use deployment as an opportunity to provide re-training

Repeated procedural errors at certain times of the day

Add non-porous bumpers to sharp corners, then select work surfaces with rounded edges when replacing

Provide anti-fatigue mats as well as adjustable chairs and workstations to reduce distraction from discomfort at the workspace and to allow for variable postures throughout the day

Chemical spills in the fume hood

Select fume hoods with a spill containment lip to prevent unintended contact with chemicals

Trips, slips, and falls

Source:

Apply anti-slip floor surface finishes, and visual and tactile warnings for elevation changes. Also provide handrails and enhanced lighting around stairs, and replace stairs with appropriately graded ramps where feasible

1. N.S.C.I.F. (2019). Workers’ Compensation Costs. National Safety Council. https://injuryfacts.nsc.org/work/costs/workers-compensation-costs/2019.

The skills trade gap presents a significant challenge across the United States, with industries struggling to find qualified workers as Baby Boomers retire. By 2020, an estimated 31 million positions were left vacant due to these retirements, and the shortage is intensifying. The Associated General Contractors of America (AGC) reports that 74% of firms are already experiencing a shortfall of skilled trades professionals. Moreover, projections indicate 811,000 career openings through 2024 in fields such as computer science, manufacturing, healthcare, and other professional trades, emphasizing the need for strategic action to address this workforce crisis.

Many community colleges and universities are stepping up to bridge this gap by introducing skills-based, hands-on training programs. In Michigan, institutions like Lake Michigan College, Southwestern Michigan College, and Grand Rapids Community College have invested in facilities like vocational labs, automotive garages, and manufacturing hubs. These spaces immerse students in real-world scenarios, equipping them with the practical expertise employers demand. At Progressive Companies, we are proud to have designed and engineered such facilities, including Lake Michigan College’s Hanson Technology Center and Western Michigan University’s Advanced Manufacturing Partnership Lab, both of which serve as benchmarks for innovative skills training environments.

Western Michigan University’s AMP Lab at the downtown Grand Rapids Innovation Center exemplifies the next evolution of workforce development. Designed and engineered by Progressive Companies, the AMP Lab provides students with a unique “earn and learn” model where they are sponsored by local companies while pursuing certifications, associate, or bachelor’s degrees. With no tuition costs and direct ties to industry sponsors, the lab eliminates traditional barriers to education and creates a clear pipeline from training to employment. This innovative approach connects students directly to career opportunities while addressing regional talent shortages.

The success of programs like the AMP Lab demonstrates the power of collaboration between higher education, businesses, and communities. As these institutions rise to meet workforce demands, Progressive Companies remains committed to creating purpose-built environments that enable students to thrive and industries to grow.

Progressive Companies is transforming education with dynamic, hands-on training environments that empower students and drive the future of skilled trades.

Total Number of Industrial and Controlled Environment Projects by State 1-10 11-50 51-100 100+

We understand your world, speak your language, and drive meaningful results — after all, our measure of success is dependent on yours.

AEP Energy

Agro Farma

Amazon

Angstrom Supply

Angstrom Technology

ATC Trailers

Autocam

Bissell - Homecare, Inc.

Byrne Electrical Specialists

Chobani

Clemens Food Group

Display Pack Inc

Divesco

Drawform

Espec North America

Etheridge Printing

Fabri-Kal Corporation

Flexco, Inc

Foremost Graphics Group

Franklin Partners

Gast Manufacturing

General Mills

Genpak

Gentex

GF Linamar LLC

GHSP

Gill Industries, Inc.

Gissing Automotive Sys-

tems, LLC

Gordon Foods

Graphic Packaging International, Inc.

Hastings Manufacturing Company

Holland BPW

Hutt Trucking

INGlass, Inc.

Interstate Warehousing

JBS Packerland

John Merrell

JTM Foods

Kellogg

Kendall Electric

Kerkstra Precast, Inc.

Kerry Foods

Lansing Board of Water & Light

Lorin Industries

Mead Johnson

Medplast Group, Inc.

Meijer

Metal Flow Corporation

Midwest Cleanroom Associates

ODL

Pierre Foods

Pridgeon & Clay, Inc.

Primera Plastics

Prince/Johnson Controls

Professional Freezing Services

Profile Films

Pure Pulp Products LLC

Ricker Thermline, Inc.

ROL Ergo

Roskam Baking Company

Rupari Foods

Sara Lee

Scott Custom Carpet Group

SheFit

Siliconature

Smithfield

Spectrum Industries

Steelcase

Stryker

Tesa Tape, Inc.

Tesla Motors

Tippmann Group

Trans-Matic

United Dairy Farmers

Veolia Energy NA

Viant Medical

West Michigan Cabinet Supply

Witmark

X-Rite Corporatio

Zondervan

13

Across the globe, distribution centers are facing a growing problem. How can they keep employee turnover low, save on energy costs, and still maintain or increase product turnover?

It’s a question, we found, with an answer.

In 2016, global pork producer Smithfield Foods recognized the need for a new distribution center. Located in Maryland, this center would serve as standard for all future facilities. To find new answers to these old questions, Smithfield surrounded themselves with leaders in the industrial industry. This started with commercial real estate firm Cresa who then used their network to bring architecture and engineering firm Progressive Companies, and construction partner Whiting-Turner, to the table.

Being a good steward of resources, increasing efficiency, and ensuring the safest working conditions possible were top priorities for Smithfield.

John Morrell Food Group is one of more than fifteen brands under Smithfield’s umbrella. In 2016, Progressive Companies designed a distribution center in Greenfield, IN, for John Morrell with cooler and freezer components. Rare features, like direct access from the cooler to the loading dock, caught the eye of Smithfield and served as inspiration for the Maryland center. More than 20 years later, the design of the center still impressed Smithfield and would be used as inspiration for the new facility.

Standard distribution centers are equipped with a single loading dock. To help increase throughput, the Maryland facility has a second dock. The second loading dock handles all incoming deliveries, while the main dock is dedicated to packing and shipping out product. This second space will give the facility a projected 25% boost in throughput.

A typical loading dock has an office in the middle of the floor, giving managers oversight of the loading and unloading process. However, the location of the office interrupts the flow of the loading dock. Also, given the additional doors on the building’s adjacent side, a standard office wouldn’t provide a view to all overhead doors. To improve flow and give clear sightlines, the office was moved to sit in the corner between the two docks.

Additionally, pallet wrappers were removed from the loading dock and moved to stock rooms. Not having to maneuver around wrappers helps improve flow and maintain focus on the loading process.

Fewer than three dozen distribution centers in the United States are LEED certified. Not only is the Maryland facility certified in LEED, but it has also achieved LEED Silver.

Smithfield’s investment in state-of-the-art and energy efficient refrigeration equipment was a key factor of obtaining LEED certification. A normal building of the same size and cooling needs would require approximately 40,000 lbs. of ammonia. Smithfield’s investment in energy efficient equipment brought the ammonia level down to just 8,000 lbs. That’s a 75% decrease.

Building noise is a leading cause of accidents in warehouse settings. Not only is it a distraction, but industrial fans can create sound levels of more than 80 decibels. Prolonged exposure to this level of noise can lead to hearing loss. Sound intensity was limited in the Maryland facility by placing fans outside on the roof, instead of inside on the ceiling. This move also allows the fans to be more easily accessed. Service providers can reach the fans from the safety of the roof instead of using a scissor lift from the plant floor.

THANK YOU TO OUR PARTNERS

*When compared with a typical distribution center

Smithfield Foods’ 496,000 square-foot distribution center represents success in sustainability and efficiency through innovative distribution design.

Flexco, a global leader in belt conveyor solutions and manufacturing, partnered with Progressive Companies to design a state-of-the-art facility that fosters innovation, equity, and operational excellence for its 175 employees. Previously operating across separate campuses with inefficient workflows, Flexco sought a unified environment to reflect its forward-thinking, technology-driven approach and strengthen its culture of collaboration and continuous improvement.

The resulting 325,000 square-foot facility, completed in 2021 at a cost of $35 million, integrates office, manufacturing, and inventory spaces into a cohesive, world-class environment. Progressive Companies delivered a tailored design that supports Flexco’s strategic focus on material handling, inventory flow, safety, and visual awareness while empowering employees across all functions.

The design reinforces an equitable culture, creating a unified entry point and inclusive workspaces that promote collaboration and align with Flexco’s global brand promise. Flexible, dynamic spaces are customized to the needs of each function, providing an inspiring environment that drives innovation and efficiency. Progressive Companies provided architecture, engineering, interior design, and design-build services, creating a streamlined facility that positions Flexco as a forward-thinking industry leader.

Holland, MI

The Holland Energy Park is a groundbreaking example of innovation and community-driven design that revolutionizes combined-cycle natural gas plants. Progressive Companies partnered with leading architects, engineers, and planners from across the nation to drive profound outcomes for the plant.

This 130,000 square-foot facility, nestled within a picturesque natural environment, exemplifies Progressive’s unwavering commitment to sustainability, holding the prestigious Envision Platinum Verification from the Institute for Sustainable Infrastructure. Yet what truly sets it apart is its deep-rooted connection to the community. Our design includes a captivating public gallery that educates and inspires Holland residents about the energy shaping their lives.

The Holland Energy Park plays a pivotal role in expanding the city’s downtown snowmelt system. By channeling surplus warmth to melt snow, it enhances safety and rejuvenates the city’s vibrant downtown. This project symbolizes Progressive’s dedication to forging enduring partnerships that foster innovation and progress. This facility is a testament to the power of collaboration, trust, and a brighter, more sustainable future for Holland, Michigan.

Progressive Companies partnered with a long-standing global workplace and manufacturing client to transform their facility into a dynamic, branded environment that embodies the company’s shift toward a digital future. The 12,000 square-foot renovation reimagined the second-floor slab, demolishing it to create a dramatic two-story workplace lounge that serves as the centerpiece of the project.

This striking lounge space features floor-to-ceiling glass that provides unobstructed views of the manufacturing process, creating a tangible connection between the workforce and the product they help create. A tasting room and bar area enhance the experience, offering a welcoming atmosphere for guests and clients. A suspended spiral staircase serves as both a functional and architectural focal point, seamlessly linking the lounge to the workplace above. Electronic and printed media are integrated throughout the space, reinforcing the company’s corporate branding and showcasing its products in an immersive way.

Designed to serve both visitors and the primary product team, the space balances functionality with a strong emphasis on storytelling and brand identity.

It reflects the company’s transformation from its traditional roots to a forward-thinking, digitally focused organization. Completed in 2021 with a project cost of $3 million, this branded environment marks a pivotal step in defining the client’s vision for the future.

Progressive Companies provided comprehensive architectural, interior design, and structural engineering services to bring this innovative project to life.

Grand Rapids, MI

Grand River Aseptic Manufacturing (GRAM) was founded in 2010 to address the life sciences industry’s demand for high-quality sterile manufacturing services. Since then, GRAM has experienced rapid growth, supporting fill-and-finish needs from clinical trials to commercialization. The surge in vaccine demand further accelerated its expansion, necessitating state-of-the-art production environments to ensure safety and efficiency.

Progressive Companies played a pivotal role in delivering GRAM’s world-class facilities, including over 40,000 square feet of ISO 7-rated space supporting ISO 5 equipment. Despite the challenges of an urban site adjacent to a mass transit railway, the project team implemented innovative solutions to maximize safe production within a constrained footprint while adhering to rigorous government standards. A dynamic collaboration among government officials, business leaders, scientists, and the design-build team ensured seamless design and construction, meeting urgent deadlines without compromising quality.

Completed in phases (2019, 2021, with an additional phase in design), GRAM’s facilities exemplify operational excellence, supporting the production of life-saving products, including COVID-19 vaccines. In recognition of its sustained growth in sales, profitability, employment, and community impact, GRAM was honored with the 2022 Outstanding Growth Award from ACG West Michigan.

This family-owned cold storage company, known for producing a variety of delicious food products for The Kellogg’s Company and other partners, recently expanded its capabilities to better serve its growing market. Their existing 885,000 square-foot facility, primarily focused on food processing, faced limitations in frozen food storage. To address this, Progressive Companies collaborated with Erhardt Construction to design and build a 106,000 square-foot freezer addition in Grand Rapids, MI.

Completed in February 2020, the project also included administrative offices and employee welfare areas, enhancing both operational efficiency and workplace amenities. The new freezer addition seamlessly connects the production line to the freezer warehouse and truck distribution, optimizing workflow and ensuring smooth operations. With 12,000 pallet positions and infrastructure designed for future expansion, this state-of-the-art facility sets the stage for continued growth while meeting the company’s current needs. Progressive Companies provided architecture and structural engineering services for this transformative project.

Archroma, an international chemical company headquartered in Switzerland, partnered with Progressive Companies to transform its American headquarters into a cohesive and efficient mini-campus. Previously spread across five buildings from the 1950s, Archroma’s labs and private offices were disconnected, limiting collaboration and efficiency. The project consolidated operations into two buildings, creating a centralized 29,000-square-foot facility, including 7,600 square feet of lab space and a 5,800 square-foot warehouse.

The design prioritized collaboration, relocating all lab functions into a larger, shared space to streamline resources and foster cross-departmental innovation. Employees transitioned from private offices to low, open workstations, saving real estate and emphasizing team unity.

Andreas Lotz, Head of Sales Americas, noted the benefits of this new arrangement, embracing his collaborative 6’x8’ workstation after leaving a private office.

Progressive Companies utilized in-house expertise to study workflows and experiment processes, integrating new European equipment and relocating inventory from Archroma’s facilities in Charlotte, NC, and Spartanburg, SC. The $4 million project, completed in 2019, included architecture, interior design, programming, lab layouts, and construction administration, delivering a dynamic environment that supports Archroma’s cutting-edge research and operational excellence.

Grand Rapids, MI

Progressive Companies was entrusted with designing a cutting-edge manufacturing addition to support the production of critical components used in pharmaceutical delivery. This project stemmed from the client’s success in securing a significant long-term contract to supply urgently needed medical treatments, requiring a facility that could meet the highest standards for precision and quality.

The 50,000 square-foot facility includes a 32,000 square-foot ISO 8 cleanroom, complemented by dedicated maintenance and die shop areas. With a fast-track, multi-package schedule and a preselected design and construction team, the project was completed within just 16 months, from design authorization to construction.

Progressive Companies provided comprehensive services, including Lean Solutions Master Planning, architectural and interior design, and structural, mechanical, and electrical engineering. Completed in 2021, the facility underscores Progressive Companies’ ability to deliver complex, high-performance environments on accelerated timelines.

Rochester, MN

Kerry Group, a leading Irish food ingredients company, partnered with Progressive Companies and CSM Group to transform their 1970s-era food production facility in Rochester, Michigan. The ambitious goal: to expand production capacity by an impressive 150% — all while keeping existing operations fully functional.

This facility plays a vital role in producing fermented ingredients, including lactic acid bacteria for processed meats and cultured dairy products, as well as cultured ingredients that extend shelf life and improve product quality. It also manufactures cultured dairy solids that enhance the stability and texture of ice cream, delivering a superior “mouth feel.”

Spanning 68,000 square feet, the $65 million renovation was completed in three meticulously planned phases: Phase 1 in April 2018, Phase 2 in 2019, and Phase 3 in 2021. The project combined cutting-edge design and engineering expertise to deliver a state-of-the-art facility optimized for efficiency and innovation.

Progressive Companies provided a comprehensive range of services, including architectural design and documentation, structural engineering, HVAC design, electrical engineering, wastewater treatment engineering, and process piping. This collaborative effort ensured that Kerry’s Rochester facility now stands as a model of advanced food production, blending increased capacity with operational excellence.

Progressive Companies has proudly maintained a decades-long partnership with Trans-Matic Manufacturing, Inc., starting with the master planning of their manufacturing facility in 1998. Since then, we have collaborated on multiple expansions and interior renovations, ensuring the facility evolves to meet the demands of their growing operations.

Situated on a 15-acre site within a larger 180-acre industrial campus that also features other Progressive Companies’ clients, this project exemplifies our commitment to delivering innovative, tailored solutions for industrial success. From master planning and project entitlement to architecture and engineering across multiple disciplines, our team continues to support Trans-Matic’s vision and operational excellence.

Progressive Companies collaborated with Fabri-Kal to design and construct a state-of-theart production facility focused on polyethylene packaging and innovative paper products derived from plant-based straw pulp technology. This ambitious project spanned 172,000 square feet and was completed in two phases. Phase 1 was successfully delivered in September 2016, and Phase 2 followed in November 2018, with a total investment of $75 million.

The facility reflects Progressive Companies’ comprehensive approach to integrated design, providing architectural design and documentation, structural engineering, and process and house piping systems. The project also included sophisticated HVAC systems and electrical engineering to support the complex production needs of Fabri-Kal. This cutting-edge facility underscores a commitment to sustainable production methods and technological innovation in packaging solutions.

Asheville, NC

Progressive Companies undertook the design of a two-phase expansion to a light metal die-casting and machining foundry in Asheville, North Carolina. This project involved the integration of new additions with the recently completed facility to enhance its manufacturing capabilities. The design includes significant renovations to portions of the existing building, aligning the entire site with the client’s vision for operational efficiency and sustainability.

The additions will encompass a total area of 270,845 square feet, supporting expanded manufacturing functions while incorporating sustainable design principles aimed at achieving LEED Silver Certification from the U.S. Green Building Council. Progressive Companies provided comprehensive services for the project, including architecture, MEPFP engineering, structural engineering, and environmental graphics and signage design.

Phase 1B was completed in 2019, with Phase 2A following in 2020. This expansion represents Progressive Companies’ commitment to delivering innovative solutions that balance industrial performance with environmental stewardship.

Progressive Companies partnered with Italian-based manufacturer Siliconature to deliver their first U.S.-based facility, a milestone design-build project completed in collaboration with Elzinga & Volkers. This state-of-theart, 187,000 square-foot facility seamlessly combines a two-story office building, expansive manufacturing and warehouse spaces, and bulk chemical storage, tailored to support Siliconature’s operations.

Completed in 2019, this $20 million project highlights Progressive Companies’ expertise across multiple disciplines, including architecture, landscape architecture, interior design, and civil, structural, and MEP engineering, creating a dynamic and functional space that drives innovation and efficiency.

Kalamazoo, MI

Progressive Companies designed a state-of-the-art, multi-temperature distribution center tailored to enhance efficiency and safety in every aspect of its operation. The facility features in-swing dock doors to prioritize food safety, wider warehouse aisles, and setback racking frames to improve maneuverability and minimize product damage. A 62 foot-deep dock, seamlessly connected to the cooler, ensures streamlined operations, while the southern dock exposure reduces winter ice buildup for added safety and functionality.

Spanning 157,000 square feet, this innovative facility was completed in 2014, with Progressive Companies providing comprehensive services, including architecture, civil engineering, and electrical, mechanical, and structural engineering.