DECEMBER

50 years of grit and vision

FEATURES

High-rise solutions

AI on the frontline

Taking over Australia

Chasing one million tonnes

PROUDLY

How 50 years of grit and vision built an organics recovery powerhouse.

SOILCO is pursuing national expansion with the ambition to become an Australia-wide resource recovery platform.

“WE SEE THE AG MARKET AS OUR GREAT EMERGING MARKET. A LOT’S CHANGED IN THE PAST 15 YEARS.

FARMERS COMING THROUGH.”

Growth, expansion and evolution –2025 was a big year.

A look at the sector’s challenges and the road ahead.

Australia’s organics industry delivers results.

Cutting-edge infrastructure leads the way.

Which

Fifty

Moving beyond equipment supply.

New equipment maximises recovery.

Giving operators the ability to act fast.

Navigating the changing waste landscape.

SOILCO pursues national expansion.

A

Combining

Proposed advanced methanol production and greenhouse facility.

Revolutionising tight access waste collection.

ON THE FRONTLINE

Common questions answered.

Meet the 2025 Waste Innovation and Recycling Award winners.

Waste Expo 2025 has sharp focus on the future.

If 2025 had a central theme, it was the harsh reality check provided by the lithium battery crisis. e spike in facility res isn’t just an operational hazard; it’s a national wake-up call that solidi ed the urgent need for robust, mandated, and nationally harmonised Extended Producer Responsibility.

It was the year where ambitious national targets hit the reality of operational challenges, particularly in contamination and capacity.

As the calendar prepares to ip to 2026, Waste Management Review o ered industry leaders a chance to re ect on the hard-won gains of 2025 and forecast the key battles of 2026.

As always, despite the ongoing pressures of market volatility, labour shortages, and evolving regulatory landscapes, the industry remains resilient and poised for a transformative year ahead.

If anyone knows the power of transformation, it’s Van Schaik’s Bio Gro. From humble origins, the company has transformed into a sustainability powerhouse operating across four strategic sites.

In our cover story, Stephen Van Schaik recalls how his father’s vision to see value in waste became the backbone of a company that is now championing a soil health revolution in Australian agriculture.

In New South Wales there’s another transformation taking shape. e former cement works in Kandos once supplied the material that hardened the foundations of modern Sydney, including the iconic Harbour Bridge and Opera House. Now it’s set to be the site of an industrial integration rede ning resource recovery, sustainable fuel production and food security.

We also take a look at the companies powering our organics recycling industry, and all the winners of this year’s Waste Innovation and Recycling Awards, plus lots more.

As this year winds down, the team at Waste Management Review would like to say thank you to every company, leader, and essential worker across the waste and recycling industry for sharing your stories with us.

We wish you and your families a safe, peaceful, and joyous Christmas and a restful holiday season. Here’s to a resilient and productive New Year.

Lisa Korycki

CEO

Christine Clancy christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGN

Laura Drinkwater

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia P: +61 3 9690 8766 info@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. e rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COVER

Cover image: BioGro

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Growth, expansion and evolution – 2025 was a big year for Resource Hub. But it’s not stopping there.

The calendar is about to ip to 2026, and the feeling across the resource recovery sector is one of purposeful, intense e ciency.

e era of massive, high-risk capital projects has ceded ground to the necessity of operational excellence, as businesses focus on the

fundamentals: making sure every site, every weighbridge, and every regulatory compliance step is awless and cost-e ective.

is shift, says Lacey Webb, Resource Hub Founder and Chief Executive O cer, is driving changes in how companies manage their daily operations and what external expertise they seek out.

For Lacey, re ecting on 2025 is dominated by the success of scaling the team and expanding Resource Hub’s national footprint – moving from a Queensland-focused consultancy to one with a presence across the entire country.

In the past 12 months, the Resource Hub team has grown from 12 to 20, including sta and contractors. Not bad for a one-woman show that was focused on land ll levies just ve years ago. e latest growth was strategic and focused on building internal capacity.

“We’ve been growing intentionally in capacity so that as our customers need more of a hand, we’ve got more bodies,” Lacey says.

“We’ve added a number of specialists to make sure that our experts, who’ve got lots of waste experience, are not bogged down in our internal process. We’ve even got specialists to help to improve our own e ciencies.”

is allowed Resource Hub to ful l a key ambition: national representation. e company has successfully expanded

its geographical reach, with clients in every state in Australia and adding sta in two more states, leading to a physical presence (work from home or in-o ce) in ve states.

“We are everywhere now,” Lacey says. “I think when we started, there was still very much a perception that we’re a Queensland business. But by December this year, we will have sta in every state, just not the territories.”

Lacey believes the core of Resource Hub’s evolution is its transition from simple admin and data entry to becoming dedicated regulatory support specialists. A service that is critical given the intensifying complexity of statebased regulations.

much and that’s our niche,” Lacey says.

“Making sure that when the regulation changes, when there’s a change that could be on the horizon, that we know what needs to happen in your software, what needs to happen on your sites, and what training needs to be delivered to your sta .”

Regulatory response is probably the biggest challenge, particularly during audits. It’s one of the reasons Resource Hub has focused on its waste levy exemption team, adding dedicated resources to support compliance across Queensland, Victoria, New South Wales, and South Australia.

e other key evolution is the adoption of a collaborative, specialistdriven model, allowing Resource Hub to deliver quick, decisive support.

Recognising that no single company can be an expert in everything, Resource Hub is partnering with complementary specialists for services such as land contamination and nonwaste-speci c compliance.

“I don’t want to compete with people who are experts in elds when I’m not

is approach means a fast turnaround – with an average project timeframe being well under two weeks – providing quick, decisive support without demanding multimonth commitments from clients.

Looking ahead to 2026, Lacey says the focus remains on deepening geographical reach with a formalised New South Wales o ce and continuing to build strategic partnerships.

More broadly, as the industry faces increased complexity, from organics mandates to shifting container deposit schemes, she says success will hinge on the disciplined use of data and the mastery of the small, nonglamorous details.

“2025 was a year where people started to move away from really large investment-based projects and I think 2026 will be a year where people will get into the nitty gritty,” Lacey says.

“ ey’ll be asking ‘How do we do the little things well? How do we make sure we’re as e cient and cost e ective as possible? at’s going to be 2026,

Ais evolving quickly, driven by new regulations, sharper expectations, and the realisation that good intentions aren’t good enough to build a functioning (and genuine) circular economy.

e past few years have shown what happens when policy ambition races ahead of infrastructure, and when end markets don’t keep pace with investment.

Every major shift – from re management to end-market reform –demands a response grounded in realism and ambition. Re.Group’s approach is simple: face change directly, invest with intent, and help shape a smarter, safer, more circular system. We’re here for the challenge and excited for what’s ahead.

Battery res have become a de ning challenge for recyclers. Lithium-ion batteries are increasingly found in everyday items, from vapes to cordless

they end up in our trucks and facilities and can (and have) resulted in res when crushed or punctured, triggering thermal runway events that are di cult to extinguish.

A 2024 industry survey by the Australian Council of Recycling (ACOR) and the Waste Contractors and Recyclers Association of NSW (WCRA), showed Australia’s waste and recycling facilities experienced between 10,000 and 12,000 battery-related res in the past year – an average of 30 res per day. ese incidents pose signi cant risks to workers and infrastructure, have increased costs for businesses by an average of $400,000 per facility, and have driven insurance premiums higher than ever.

‘Safety First’ is a core value at Re.Group and the company’s commitment to safety is re ected in both culture and investment.

invested in advanced re mitigation technologies, including the Fire Rover system – a 24/7 monitoring and suppression solution that uses militarygrade thermal detection and highde nition video to pinpoint hotspots before a re ares up.

e Fire Rover system, recently installed at Re.Group’s Dandenong Material Recovery Facility, can neutralise threats within seconds using an environmentally-friendly suppression agent – setting a new benchmark for re safety in the sector.

While technology is critical, the long-term solution lies in product stewardship. Batteries don’t belong in kerbside bins, and it shouldn’t be left to operators to carry the full risk. New South Wales’s new mandatory battery stewardship laws, introduced under the Product Lifecycle Responsibility Act, mark an important shift, placing

responsibility where it belongs: with the manufacturers and importers, holding them accountable for the full lifecycle of their products. Similar national measures can’t come soon enough.

e COAG Export Bans were meant to be a turning point for Australia’s recycling landscape and they were, in principle, the right move. However, implementation came well before lengthy approvals, funding, and infrastructure development could catch up. As a result, the sector experienced a painful period of adjustment, with bottlenecks in processing and limited markets for recovered materials.

Plastics have been the hardest hit. Approvals for new or upgraded facilities often stretch years, while supply chain lead times have increased, leaving recyclers with limited outlets for recovered materials.

Government investment through the $1.5 billion Recycling Modernisation Fund has helped, and today, ve years after the bans were announced, a few new and upgraded facilities have come online. But infrastructure and technology alone do not close the loop –markets do.

e success of these investments depends on strong end-market demand for recycled content yet currently, and despite the signi cant investment by both government and industry, there are no restrictions on the import of virgin packaging materials while recovered plastic continues to face export barriers and volatile domestic demand.

is imbalance undermines the economics of recycling and highlights the urgent need for packaging reform. Until brand owners are required to use recycled content, investment in resource recovery will always run uphill.

e Australian Packaging Covenant Organisation (APCO) set clear National Packaging Targets for 2025, but

progress has stalled. As of 2023, only 19 per cent of plastic packaging is recycled, and average recycled content sits at 44 per cent. at shortfall isn’t a collection problem; it’s a procurement problem.

APCO’s 2030 strategy calls for eco-modulated fees – charging brand owners based on the recyclability and recycled content of their packaging –to incentivise sustainable design and support domestic markets.

Re.Group supports stronger producer responsibility, urging federal action to mandate the use of Australian recycled content in packaging. e recent communique from Australia’s environment ministers agged packaging reform as a priority for 2026, following the completion of Environment Protection and Biodiversity Conservation (EPBC) reforms. Recycling only works if materials come full circle, and the next few years will determine whether the system can mature beyond good intentions.

Australia’s container deposit schemes (CDS) are proof that the right incentives work. Every jurisdiction now operates a CDS, with more than 10 billion containers collected since their introduction.

For Re.Group’s Return-It business, the next step is speed and accessibility. We have introduced new AI-powered Machinex CountAIner units that can process up to 1500 containers per minute, drastically reducing redemption times and enhancing the customer experience.

e expansion of CDS to include wine and spirit bottles in New South Wales, South Australia, Western Australia and the Northern Territory by 2027 will remove another half a billion containers from land ll annually. It’s measurable, data-backed impact the public can see and understand.

Still, Australia’s return rates lag the best-performing countries, sitting around 68 per cent compared to over 90 per cent in parts of Europe. One factor is the static 10-cent refund. If South Australia’s original ve cent deposit from 1977 had been indexed to consumer price index it would now sit closer to 37 cents. Indexing the refund to modern values would push recovery rates higher and further reduce litter.

e broader lesson from CDS is that participation grows when systems are simple, fair, and local. It’s a model of how shared responsibility between government, industry, and community can work, and a reminder that the public will do the right thing when it’s made easy and available (and when there is an incentive).

e Australian waste and recycling sector is entering its most consequential phase yet. Fires, limited end markets, and policy gaps are not isolated challenges – they’re symptoms of a system still nding balance between ambition and practicality.

Re.Group’s approach has been to respond with investment in technology, advocacy for product stewardship, and a commitment to improving safety and customer experience. But industry alone can’t carry the reform agenda.

Stronger regulation, smarter incentives, and a consistent national framework will be key to delivering a system that works at scale and one that keeps pace with changing market dynamics and global best practice.

e circular economy isn’t just about diverting waste. It’s about rebuilding value chains to turn risk into resource and cost into opportunity. e work has started and the next few years will determine whether we nish it.

For more information, visit: www.re-group.com

The AP18 E-REC Vertical Shredder is purpose-built for scrap recycling, featuring a continuous processing system that combines size

The machine’s hammer blades are mounted to the main shaft via a heavy-duty hinged connection. During operation, the centrifugal force generated by the rotating shaft enables the hammers to efficiently break down materials. Simultaneously, the hammer blades strike against the chamber liners, helping to liberate different material components — such as steel, non-ferrous metals, plastics, and other light fractions — ensuring optimal preparation for the subsequent separation process.

Thanks to the hinged coupling between the hammers and the main shaft, the shredder can tolerate occasional oversized foreign objects entering the chamber without causing damage to core components. In addition, the gap between the bottom disc plate and the chamber can be adjusted to meet different production requirements, allowing precise control of the discharge particle size.

Typical Applications

•Small Domestic Appliances (SDA)

e-shredded E-waste

omotive Shredder Residue (ASR)

/ Shredder Light Fraction (SLF)

e-shredded Aluminium

e-shredded Light Scrap

•Meatballs (motor armatures and copper-bearing components)

Contact us for a quote

03 9706 8066

sales@appliedmachinery.com.au

55-61 Nissan Drive, Dandenong VIC 3175 www.appliedmachinery.com.au

The past year has been one of progress, collaboration, and ongoing challenges or the organics recycling industry. ohn Mc ew, ational Executive cer o the Australian Organics Recycling Association looks back at the year that was.

Making waves was the theme for the Australian Organics Recycling Association (AORA) throughout 2025, as the organisation delivered tangible and important results for the industry.

John McKew, National Executive O cer of AORA, says the organisation made particular headway by advancing policy and position statements addressing key industry challenges.

One of which was an updated version of the AORA Food Organics and Garden Organics (FOGO) Position Paper which, for the rst time, states that the industry and the association support a national target of less than two per cent contamination within the FOGO feedstock stream.

It’s new Position Paper, ‘Bans for a Better Compost’ was developed with

hopes to address which problematic contaminants should be banned, removed, or limited. AORA also worked closely with other industry bodies throughout the year to tackle industry-wide concerns, including a call to action to remove batteries and electronics from conventional waste and recycling streams.

It also updated its AORA/ Australian Bioplastics Association (ABA) Joint Position Paper on Certi ed Compostable Packaging

John says AORA was active in its contributions to various industry forums and events, taking opportunities to inform, educate, promote, and advocate for the work and achievements of the organics recycling industry.

He says a 2023-24 update to the Economic Contribution of the Australian

Organics Recycling Industry, released in June 2025, represents an important piece of work for the industry, highlighting a signi cant issue that cannot be ignored.

e report shows that Australia’s overall organic material recycling rate in 2023-24 was 51.4 per cent, compared to 52.3 per cent in 2021-22.

e reduction in the recycling rate for 2023-24 re ects a higher number of tonnes recycled but a comparatively higher amount of organic material generated.

All states, except for Tasmania, experienced a reduction in their overall organic material recycling rate in 2023-24.

Organic material recycling is in uenced by a variety of factors, including population growth, economic growth, technological change, access to recycling markets, local government collection changes, and commonwealth and state government waste and carbon reduction policies.

John says this indicates that Australia is producing more organic waste, driven in part by immigration and population growth, than can currently be processed.

e national average is 282 kilograms of organic material recycled per person, while more than 500 kilograms of organic waste are generated per person.

Consequently, a large proportion of this excess material, about 5.7 million

tonnes per annum, still ends up in land ll.

If the rate of organic waste generation continues to outpace processing capacity, John says circular economy aspirations, particularly the goal of reducing organics to land ll, are placed in jeopardy.

To address this challenge, AORA has identi ed several pathways for improvement.

“Approvals for new or expanded organics processing facilities must be expedited,” says John. “In addition, state authorities need to enhance their approval processes.”

He says that in some states, obtaining approval to develop a new organic processing facility can take up to two years. During these delays, more organics fail to be processed into compost and other value-

added products and instead are sent to land ll.

Proposed regulations that “conservatively” restrict levels of contaminants such as per- and poly uoroalkyl substances (PFAS) in end products like compost have also raised concern within the Australian organics recycling industry.

John says that in some states, these proposals have resulted in paused investment while regulation is being developed.

He says AORA and the Australian organics recycling industry do not dismiss or condone concerns over contaminants, however, pragmatic regulation grounded in sound science and reliable data is essential to support any proposed acceptable contaminant levels.

“If contaminant thresholds are set at unrealistic levels, the viability of

the organics recycling industry, and consequently the circular economy, will be threatened,” says John.

He says it’s important to note that the Australian organics recycling industry is a passive recipient of contamination, including PFAS, from incoming materials such as feedstocks.

As attention turns to 2026, the industry faces ongoing headwinds that are unlikely to ease in the near term.

AORA remains committed to pursuing the outcomes necessary to ensure the sustainable growth of the sector. A new policy and advocacy o cer will commence in 2026, tasked with working closely with industry stakeholders to develop a roadmap that de nes the needs and expectations required to sustain and grow the economic and environmental bene ts that organics recycling delivers.

Australia’s organics challenge won’t be solved by a business-as-usual approach, so we’re changing the game.

With global expertise and local insights, we turn food and garden waste into certified compost and soil conditioners that fuel our land, not landfills.

» In-vessel FOGO at Dandenong South – Servicing Melbourne since 2019

» Proven end-to-end process

– AS 4454-certified compost for local Australian markets

» Global backing for local growth

– Owned by leading European waste management company

Got FOGO FOMO? Get in touch. valoriza.au

Turning waste into worth

At Waste Initiatives, we deliver solutions for every stage.

WastePac offers reliable, cost-effective systems for small to medium businesses and first-time recyclers, while Vertech provides premium solutions for large-scale operations with world-leading partners.

Together, they cover the full spectrum of waste management, backed by local project management, engineering, service, and stocked parts.

Contact us today on 1800 673 002 or info@wasteinitiatives.com Discover more at wasteinitiatives.com.au

The accelerating danger rom e-waste res is driving cutting-edge recycling in rastructure. EcoCycle is leading the way.

The escalating risk of lithium battery res is reshaping the waste and resource recovery landscape. What was once considered an emerging hazard has now become one of the sector’s de ning operational challenges.

As more products, such as vapes and power tools to electric toothbrushes, contain embedded batteries, the industry nds itself in a race to deploy technology that can manage the escalating safety crisis. In response, the

EcoCycle Group has been investing in advanced infrastructure to strengthen safety and build a more sustainable recycling network across Australia and New Zealand.

2025 was a landmark year for the group, driven by innovation and the establishment of new, critical infrastructure engineered to process high volumes of complex hazardous material. e year ahead promises to be one of even greater transformation.

“ e increase in battery collections through our network shows a real shift in public and industry awareness,” EcoCycle Group General Manager, Nick Dodd says. “People are becoming more conscious of how they should dispose of batteries, and that’s changing

Among the group’s major milestones was the commissioning of Australia’s rst Battery-in-Device Shredding (BIDS) plant in Melbourne. Designed to safely recycle items such as vapes and mobile phones without manual dismantling, the facility provides an onshore solution for products that previously had limited

“It’s an important step forward for the industry,” Nick says. “ is technology allows us to process entire devices safely and e ciently, regardless of

He says this solution has been a longawaited necessity for both Australia and the world, and it’s exciting to see it now

installed and operational at EcoCycle Group’s facility. e success of this plant is equally encouraging, as it o ers a practical solution for managing many challenging waste streams.

ere are plans to establish more of the plants across the EcoCycle Group network in Australia and New Zealand, which will enhance the region’s waste management capabilities.

Safety remains central to the group’s investment strategy and was a key factor behind a second major infrastructure upgrade. A new battery discharge plant that represents a key part of that approach, enabling the safe removal of residual energy before processing. is signi cantly reduces risk during handling and improves recycling e ciency.

In addition, the group has completed the installation of a mercury retirement plant at its Perth facility, one of the few of its kind in the Southern Hemisphere. e plant converts recovered mercury from lighting, dental, and industrial waste into mercury sulphide, a stable compound suitable for permanent disposal. is ensures compliance with international obligations under the Minamata Convention and strengthens Australia’s capacity to manage legacy mercury waste responsibly.

Looking ahead to 2026, EcoCycle Group is focused on large-scale capacity building and national expansion. Its most ambitious project to date – a

$50 million lithium battery recycling facility – is now underway. All lithium batteries collected will be processed in a dry, nitrogen-controlled environment at this facility. e plant will have a processing capacity of four tonnes of lithium batteries per hour and will be supported by additional infrastructure at the site, including a battery sorting facility and a large-format discharging plant designed to handle the increasing volume of energy-storage and electricvehicle batteries entering the market.

Alongside its major capital investments, the EcoCycle Group is strengthening its logistics network.

A new site in Townsville will support northern Queensland, while the redevelopment of its Kwinana Beach site in Western Australia will allow for more localised processing, reducing transport distances and emissions.

e group is also expanding its South Australian operations and a rming its presence in New Zealand, replicating its end-to-end service for local customers with plans to develop onshore processing capabilities, removing the need to export batteries for processing to other jurisdictions.

With the ongoing growth of battery and electronic waste, Nick says the recycling industry should be commended for its investment in innovation and technology.

“As we wait for government policy to play catch up, the industry is

committed to building infrastructure to deal with the increasing risks of lithiumion batteries,” he says.

“Industry has shown real leadership in building solutions, but national policy needs to keep pace.

“Looking ahead to 2026, a harmonised, well-structured Extended Producer Responsibility (EPR)framework is essential if we’re to ensure long-term sustainability and safety.”

He says the urgency for a comprehensive, nationally mandated EPR framework cannot be overstated.

“We need schemes with clear performance targets, enforceable standards, transparent governance, and designed to be commercially sustainable. Only then can we truly protect our communities, our environment, and unlock the economic opportunities embedded in resource recovery.”

Nick says the EcoCycle Group’s approach re ects the broader direction of the industry, a shift from reactive problem-solving to proactive capacity building.

By combining technical innovation with collaboration across sectors, Australia and New Zealand are positioning themselves as regional leaders in sustainable battery and e-waste management

For more information, visit www.ecocycle.com.au

Ennovo provides comprehensive solutions for the management of recycled organics based on extensive experience with designing, constructing and operating recycled organics facilities.

Specialist Services

FOGO management and processing

Site assessment and approvals

Market assessment and development

Composting – open windrow and in-vessel

Process and product development

Third party compliance support

Carbon credit development and management

Ennovo’s Carbon Air system automates forced aeration for e cient composting in windrow and in-vessel applications. With telemetryenabled automation, it reduces costs, optimises operations, and ensures high-quality output, making it ideal for FOGO composting. Ennovo provides end-to-end solutions from design to market development.

and ll dependency or em race resource regeneration ortair Chie Executive cer eff ang asks which road Australia will choose.

In 2025, Australia nds itself standing at a crossroads in waste management.

On one path sits the familiar pattern of land ll dependency, fragmented policy responses and a costly “business as usual” mindset. On the other is a future built on resource regeneration, circular manufacturing and technologies proven to turn waste streams into pro table commodities.

e question confronting industry, government and community bodies is simple: which road will we choose?

At Vortair, our discussions throughout 2025 with major food producers, agricultural leaders and waste industry primes have revealed a contradiction in Australia’s waste landscape.

Everyone acknowledges the problem. Everyone agrees the volume of biomass and food organics entering land ll is unacceptable. Everyone understands that methane generation from these streams is one of the most potent drivers of greenhouse gas emissions in the country.

Yet movement remains slow. Decisions remain delayed. e urgency simply isn’t there.

Organic waste from agriculture and food processing is one of the largest contributors to land ll. is waste stream, left to decay anaerobically, produces methane up to 80 times the warming impact of carbon dioxide over a 20-year period. Australia cannot meet its emissions targets without addressing this issue head-on.

And yet the technology to do it already exists.

Vortair’s patented autogenous grinding system is one example of what’s possible when we stop treating waste as a cost and start treating it as a commodity.

By transforming high-volume organic and industrial waste into micronised feedstocks, Vortair enables companies to replace disposal fees with high-value outputs: soil enhancers, biochar precursors, animal feed inputs, nutraceutical ingredients and engineered materials.

What was once an expense becomes revenue. What was once a burden becomes an opportunity.

e barrier is no longer technological feasibility. e barrier is institutional willingness.

In 2025, we observed a “wait and see” approach across many sectors. Companies know they need a solution. ey know they could unlock vertical integration of their own waste streams.

ey know circular economics is not a future ideal but a present-day commercial advantage.

Yet the hesitation remains: reluctance to invest in capital equipment, hesitation to modify legacy work ows, and uncertainty about stepping ahead of competitors.

is delay carries a cost greater than the price of new equipment. It costs companies the chance to transform their waste into new value chains. It costs the nation progress toward lower emissions.

It costs future generations the bene ts of an economy built on regenerated rather than extracted resources.

Circularity dismantles the model where land ll remains pro table and disposal remains the default endpoint. Valorisation disrupts it. Regeneration replaces it.

So long as those systems remain dominant, Australia will continue to bury materials that hold undeniable value.

Another issue that emerged strongly throughout 2025 is the fragmentation of decision-making across the waste sector.

According to recent counts, Australia has 3098 industry bodies, 1346 government organisations and 8782 community and interestgroup organisations – more than 13,000 entities, each with a stake in environmental management, resource recovery and sustainability.

Yet the coordination among them remains inconsistent and often ine ective.

With so many voices, committees, advisory groups and agencies, responsibility becomes di use. No single entity is accountable for driving national cohesion in waste-to-resource innovation. e result is a patchwork of programs, pilot trials, isolated projects and announcements that rarely scale beyond their initial phase.

Meanwhile, the land ll trucks keep rolling. e real question is not how but why not?

Australia produces enough organic and industrial waste to justify full-scale resource regeneration. Technologies to valorise virtually all waste streams already exist. ese technologies have been tested, validated and commercialised.

e economics are favourable, with many systems converting a cost centre into a pro t stream.

So the real question is no longer how to solve Australia’s waste crisis. e question is why we are not doing it?

Why are we still treating biomass as waste instead of feedstock?

Why are companies hesitant to act when the return on investment and emissions bene ts are clear?

Why are waste monopolies allowed to control the narrative while delivering the same outcomes they have delivered for decades?

Why is Australia, one of the world’s most resource-rich nations, still burying value in the ground?

If 2025 was the year of identifying the problem, then 2026 must be the year of choosing to solve it.

As the Chief Executive O cer of Vortair, my message to industry leaders, policymakers and community organisations is direct: the time for pilot programs, feasibility studies and

long-term reviews has passed. e solutions are ready. e technology is proven. e economics are sound. e environmental need is urgent.

Australia can lead the world in resource regeneration. We can lead in circular design, low-carbon manufacturing and advanced materials created from waste. We can create industries that convert what is discarded today into what is pro table tomorrow. But only if we choose to move from observation to action.

e next decade will be de ned not by what waste we produce, but by what value we choose to recover from it. And 2026 is the year we decide whether Australia keeps walking the familiar road to land ll or nally takes the sharper, smarter turn toward regeneration.

For more information, visit: www.vortair.com

From initial planning to long-term operation, Kanadevia Inova delivers complete thermal and biological Waste to Energy plants. As an experienced EPC contractor, we handle every step – develop, design, build, operate, maintain. Our track record of more than 1,600 plants worldwide speaks for itself – including one of the world’s largest WtE facilities in Dubai. Check our references.

With 50 years of grit and vision, Van Schaik’s Bio Gro has built an organics recovery powerhouse that’s now driving Australia’s soil health revolution.

The scent of fresh pine bark and sawdust is more than just a memory for Stephen Van Schaik; it’s a reminder of the foundation of what would become Bio Gro – a family business built on the transformative power of sustainability.

Situated in the picturesque Green Triangle region of South Australia, Bio Gro has grown from a disused quarry on the outskirts of Mount Gambier to four strategic sites across South Australia and Victoria.

Fifty years on, the company is celebrating a major milestone.

e story of Bio Gro is rooted in the earthmoving expertise of Stephen’s parents, Hans and Marjan Van Schaik, who established J.A. and M.J. Van Schaik Earth Moving Contractors in the mid-1970s.

Hans, drawing on his Dutch heritage and experience, saw potential in the waste products generated by timber mills in South Australia. Pine bark, sawdust, and wood chip – materials once destined to be buried in land lls or simply burnt – became the building blocks of a new vision.

Hans purchased a small 12-acre property with a disused quarry near Wandilo, just ve kilometres north of Mount Gambier. ere, he began stockpiling and experimenting with timber mill waste, transforming it into valuable growing media, landscape barks, and mulches.

e family lived on-site, with Stephen and his brother operating loaders and screens after school or on weekends, unknowingly laying the groundwork for their future careers. Stephen made the decision to leave school at the age

of 15. Uncertain about his future career path he chose to focus on what he already knew – working for his father at the Wandilo site. is marked the beginning of his full-time involvement in the family business.

“Work life was pretty straightforward for me back then,” Stephen re ects on those early days. “I could step right out of our front door, hop into a front-end loader, and start producing growing media and landscape bark ready for sale.

“Meanwhile, Dad would head o on his backhoe to handle the earthworks for our earthmoving customers.”

e family business was a team e ort. Stephen’s mother played a vital role, managing phone calls and bookkeeping for both sides of the operation – the earthmoving services and the organic recycling business.

“It was your typical husband-andwife family business,” Stephen says highlighting the close-knit nature of their work.

e turning point for the Van Schaik family came in 1985, when the Kimberly-Clark paper mill near Mount Gambier sought a sustainable solution for managing its wastepaper pulp.

Stephen says winning the tender to recycle 150 tonnes of pulp per day was

a pivotal moment that forced the family to make a bold decision: focus entirely on organics recycling or continue with the earth-moving business.

e Kimberly-Clark contract provided the nancial stability needed to invest in advanced composting infrastructure and had the potential to propel the business into a new era of organics resource recovery.

“As a family we were at a crossroads of having to decide which path we were going to take forward – a stable earthmoving business or taking a risk on the organics recycling business,” says Stephen.

e family made a bold decision to sell the earthmoving business and channel all their energy into organics recycling. is decision, Stephen says, marked a de ning moment for Van Schaik’s Organic Soils and Bark Supplies, now known as Van Schaik’s Bio Gro.

rough the ’90s the company experienced rapid growth, and in 1995 the decision was made to bring in two independent shareholders to help support that growth.

Stephen says the decision proved successful, enabling the company

through the acquisition of e Austrian Potting Mix Company and Pro Pine, both reputable growing media businesses.

He says it was through these strategic acquisitions that Bio Gro became a leading supplier of custom blended growing media for large-scale commercial nurseries across Victoria.

Managing growth in any business has challenges, particularly in family business. A profound challenge for Bio Gro came in 2013 when Stephen’s brother decided to leave the family business and his father was recovering from a serious health issue.

Stephen, his wife Heather, and his parents were faced with a di cult decision, continue to run the business or sell it?

Taking a leap of faith, Stephen and Heather secured nance for the company to purchase Stephen’s brother’s share and committed to returning the company once again into a fully familyowned and operated business.

In 2016 the last of the independent shareholders had been bought out and Bio Gro was once again 100 per cent family-owned.

“ is still stands today as my proudest moment working in Bio Gro,” Stephen says.

Today, Bio Gro operates across four strategic sites – Wandilo and Mount Gambier in South Australia, and Dandenong and Newbridge in Victoria – with a team of 220 employees.

e company recovers more than 470,000 tonnes of organic material annually, including 200,000 tonnes of timber and forest residues and 270,000 tonnes of food and green organics. ese raw materials are transformed into about 850,000 cubic metres of high-quality growing media, mulches, and composts, supplied in bulk and packaged forms. In the past nancial

year alone, Bio Gro produced more than six million bags, and with a newly commissioned packaging plant at the Newbridge facility, the company now has the capacity to produce more than 10 million bags annually.

“Bio Gro has been recognised now for many decades as the producers of the highest quality custom blended growing media for the industry, recognition that sits proudly with our company,” Stephen says.

Bio Gro is leading a transformative shift in agriculture by championing the use of compost to enhance soil health and reduce dependence on synthetic fertilisers.

“In agriculture, if your soil is in poor health, then you are on the back foot from the start, and your productivity is obviously going to struggle,” says Stephen.

“By integrating high-quality compost into traditional fertiliser regimes, Bio Gro empowers farmers to boost microbial activity, improve nutrient uptake, and enhance productivity – all while cutting back on synthetic inputs.”

Stephen believes that the agricultural market is now ripe for change, marking a signi cant evolution for Bio Gro.

Although the company ventured into agronomy 15 years ago, the market was not ready for compost at the time. Today, however, the landscape has shifted dramatically.

“We see the Ag market as a very real and emerging market for us now. If you like, it’s all about the timing,” he says.

“A lot has changed in the past 15 years. Now it’s moving even faster, with a new generation of farmers coming through that measure and record productivity daily.

“Modern farmers are increasingly prioritising soil health over expanding land or relying heavily on synthetic inputs.”

He says Bio Gro’s innovative approach is paving the way for a soil health

revolution, helping farmers achieve sustainable productivity while reducing their environmental footprint.

e spirit of research and development (R&D), rst embodied by Hans, has also been re-established. After a period of focusing resources on business growth, Bio Go has formally re-established a small R&D team.

Stephen says this team is essential for ensuring the company remains at the forefront of the organics sector, especially as it delves deeper into the science required to prove the measurable bene ts of applied compost in the agricultural sector.

e company’s longevity and success are a testament to the family’s consistent application of two simple yet powerful traits: humility and hard work.

Stephen believes people are at the heart of Bio Gro’s success and has developed several initiatives, including a ‘people and culture’ division focusing on sta development and mentorship.

Fostering a sense of community and care has resulted in a remarkable number of long-serving employees with tenures over 30 years.

Stephen himself is known around the company for his personal engagement with sta across all sites and he is not averse to jumping into a loader or excavator to lend a hand when things are busy.

“I like to think that we’re quite humble as a family,” he says. “Dad was one of the humblest men you’d ever meet and one of the hardest-working men you’d ever meet.

“He’d be proud of what we have achieved, for sure.”

ose achievements have not gone unnoticed. In 2017, the company was inducted into the Family Business Australia Hall of Fame for South Australia/Northern Territory, and both Hans and Stephen have received prestigious individual awards for their industry contributions, highlighting the successful generational transition and the family’s commitment to excellence.

Hans was honoured with the Australian World Forestry Day Award in 2000, while Stephen was recently named a Green Triangle Forest Industry Legend.

As Bio Gro celebrates its 50th anniversary, the Van Schaik family is focused on the future. With Stephen and Heather’s children now heavily involved in the business, the third generation is ensuring the family connection remains the company’s core strength.

From a weekend hobby to an industry leader, Bio Gro’s journey is an example of how determination, innovation, and family unity can turn challenges into opportunities.

As Bio Gro continues to set new benchmarks for sustainability and innovation, Stephen hopes it o ers a beacon of hope for businesses looking to make a positive impact.

“With a legacy rooted in hard work and a vision for a greener future, Bio Gro proves that the best ideas truly grow from the ground up.”

For more information, visit: www.biogro.com.au

Waste Initiatives is moving beyond equipment supply to deliver complete, custom waste and resource recovery systems.

Across Australia and New Zealand, industry is facing mounting pressure to meet rigorous environmental, social, and governance (ESG) goals and drastically reduce land ll dependence.

For many manufacturers, food producers, and recyclers, this means rede ning how they view what leaves their site – not as a problematic byproduct, but as a valuable resource to be kept in circulation.

Waste Initiatives, an Australianowned and operated company with more than 40 years of experience, is capitalising on this shift. e company has evolved from a pure equipment supplier into a solutions partner, delivering comprehensive waste

systems through a strategic partnership approach that prioritises e ciency and material recovery.

Waste Initiatives delivers complete end-to-end systems backed by in-house engineering expertise, full project management, national after-sales support, and locally stocked parts. is approach ensures customers receive not just machinery, but a fully integrated system designed for long-term reliability.

Managing Director Dwayne Smith says that collaboration is key to the company strategy.

“We work with top international partners from Germany, Ireland and America to

bring in quality and reliable equipment that gives customers in Australia complete solutions,” Dwayne says.

“We then back that with local spare parts and local service to ensure they’re getting all they need and more.”

For producers – manufacturers and food companies – Waste Initiatives designs bespoke systems to tackle complex waste streams generated by reject products. is involves depackaging, shredding, and compaction systems that e ectively separate recyclable packaging from clean organics, turning a contaminated waste stream into two clean recovery streams.

For waste processors and recyclers, the focus is on scalability and integration.

Waste Initiatives provides modular solutions that seamlessly improve throughput and recovery rates in existing operations.

ese systems handle tasks ranging from pre-shredding bulky items and compacting timber crates to sophisticated separation of mixed packaging streams.

Sales Manager Shannon Sangster highlights the strategic blend of expertise and technology required for tailored solutions. An in-house engineering team combines global technology partnerships, including specialised equipment from Mavitec, Bergmann, Eagle International, and Barclay Shredders.

Shannon says whether it’s a Mavitec depacker achieving 99.7 per cent purity in food waste recovery, a Bergmann roll packer crushing bulky manufacturing waste, or an Eagle o -the-road (OTR) system tackling mine-site tyres, each system is tailored for reliability, compliance, and ease of maintenance.

Every project at Waste Initiatives starts with detailed consultation and ends with a fully commissioned, operatorready solution.

e company’s project management team provides complete oversight across every stage, from mechanical and electrical to safety, ensuring all aspects align with Australian standards and speci c site expectations.

Shannon says this depth of experience provides customer con dence.

“It’s not just our range and tailoring the solution. Waste Initiatives has been going for 40 years with a depth of knowledge and experience throughout the team,” he says. “We know what works and what doesn’t.”

Dwayne says the partnership model includes a commitment to minimising costly downtime. Waste Initiatives backs every installation with a national service network and locally stocked spare parts in New South Wales and Victoria.

“No one wants to hear their machine is down and parts are months away,” he says. “We keep critical components on hand and technicians on call to get systems back online fast.” is proactive support for longterm reliability is central to the company’s de ning strength. By transforming waste challenges into circular opportunities, Waste Initiatives helps producers achieve less land ll and greater recovery, while helping processors achieve higher throughput and lower maintenance.

“Our partnerships with customers are built on trust, performance and shared goals,” Dwayne says. “Whether you’re making the product or processing the waste, Waste Initiatives is here to help turn challenges into circular opportunities.”

For more information, visit: www.wasteinitiatives.com.au

JR Hammer recently purchased a new granulator from Applied Machinery, revolutionising the way it operates.

Operating in a sector where precision and consistency dictate environmental and economic outcomes, specialist recycler JR Hammer has spent the past few years re ning its production line to minimise downtime and maximise resource recovery.

Its latest investment, a Genox Granulator integrated into its existing system, marked a step in improving

In the northern suburb of omastown, Victoria, JR Hammer o ers end-of-life solutions for copper cables, mixed PVC and other plastic insulation formulas.

“We don’t just recycle the metals, we recycle the whole cable, so the polymers as well as the metals,” says Josh.

Josh says at the time he had little experience in new technologies and so began working closely with machinery specialist Peter Koueik, Sales Manager of the Recycling Division at Applied Machinery.

Together, they reviewed the production process, identifying key issues and exploring the best long-term solutions. ey concluded the best path forward

“ ere were leakage points and dust factors inside our factory that we needed to get on top of,” says Josh.

“We looked at updating another couple of our units before we got this granulator and decided it would act as one unit, in a series of additional units, that will help JR Hammer achieve our long-term goals.”

He says operations have greatly improved since the installation of the Genox Granulator.

One of the biggest di erences is a reduction in downtime.

“Before the granulator, operations could be down for up to two weeks, depending on what needed to be done,” he says.

“A simple grid changeover that should be a ve-minute job would usually take an hour.”

Much of that unreliability stemmed from the design of the previous granulator and its internal components, which, Josh says, were prone to damage.

In contrast, the new Genox system incorporates design improvements that prevent such failures.

Josh says the engineering extends beyond reliability, it’s also improved the day-to-day experience for JR Hammer’s workforce.

“ e new granulator has electric hydraulic systems, which help our team open and close the machine by themselves without needing me there,” he says.

“ at means they can now handle screen changes or blade adjustments on their own.”

e impact on throughput has been equally positive. Josh has noticed a signi cant decrease in downtime because there are no breakdowns.

e Genox Granulator has also played a key role in improving energy e ciency and overall sustainability, two priorities that underpin JR Hammer’s operations.

“ e old granulator was out of balance, so it used more energy,” says Josh. “We had a diesel generator

previously so the amount of diesel we are using has decreased. Because the new machine is more e cient and has a larger chamber, the material throughput is more consistent.”

JR Hammer’s commitment to improvement doesn’t end there. e company has ordered an additional piece of equipment, not yet released to the market by Applied Machinery, as part of its ongoing investment program.

Building on lessons learned from previous systems, the team is now prioritising energy e ciency.

“Our current shredder system is a rebranded Genox model, but the wear and tear on that, plus my own early learning in maintenance, had deteriorated it quite signi cantly over many years,” says Josh.

“Our throughput and the types of cables we’re now recycling are far greater, so we needed something more suitable to manage heavier-duty cables.”

Applied Machinery has introduced JR Hammer to a new shredder that not only meets operational needs but also o ers a chance to help bring the company’s o erings to the market.

Peter says the acquisition of future additional equipment will work in conjunction with the granulator. When it comes to investing in untested equipment, trust in the supplier plays a pivotal role.

For JR Hammer, its relationship with Applied Machinery has provided that assurance.

“I have a great working relationship with Applied Machinery, so if they’re standing by it, then it must be good,” Josh says.

“ ey’ve supported us through every step of the process, from identifying problems to implementing solutions.”

For more information, visit: www.appliedmachinery.com.au

Tit comes to waste management, every minute counts.

To continue providing premium construction equipment across the waste management sector, Tutt Bryant is now stocking the McCloskey Environmental ES-250 shredder.

Paul Doran, National Business Development Manager for Tutt Bryant, says having the ES-250 readily available, gives operators the ability to act fast when opportunity strikes.

“ ere are so many di erent applications where it can provide a reliable primary shred to knock material down into a manageable size,”

Paul says. “It’s an all-rounder machine that can be used across municipal waste, construction and demolition waste, mattresses, and green waste.”

o ers a compact footprint and impressive mobility, making it suitable for both permanent and mobile operations.

“It can very easily be put on a oat and transported between sites or tracked around a land ll,” Paul says.

“ ere are two di erent tracking speeds, so if operators need to move it quickly across the other side of the site for another shredding run, they can.”

machine to their needs thanks to two knife con gurations – an eight-knife or 10-knife set – depending on the desired nal product size.

“ e knives are welded on and hardfaced to keep them in top condition,” he explains. “ ey’re designed to deliver a high-torque tearing action that breaks down material into a smaller, more

e result is a shredder capable of handling a wide range of materials, from land ll and council waste to green waste, construction and demolition (C&D) debris, cardboard, and paper.

With di erent shredding programs available, operators can con gure the ES-250 to match their speci c waste stream and throughput requirements.

Paul says one of the most signi cant bene ts of the ES-250 is its ability to help operators optimise both transport and land ll e ciency.

By reducing waste into smaller, denser volumes, operators can make better use of the reduced air space, both on trucks and in land lls.

“If the shredded waste is knocked down to a smaller, more manageable size, operators can reduce air voids in the truck,” Paul says. “ at means they can t more material per load and reduce transport costs.

“At the land ll end, higher density means operators can compact more waste into the same area.”

Paul says this is a crucial advantage in today’s landscape, where developing new land ll sites has become increasingly di cult.

“Given how hard it is to get new land lls approved, operators need to maximise the capacity of the ones we already have,” he says.

Beyond logistics, shredding also enhances separation during downstream processing.

“When the material is broken up properly, it makes it easier to extract recyclables from the waste stream via picking or other separating methods like trommels,” Paul says.

“ at improves recovery rates and helps operators divert more material from land ll.”

Sustainability is at the heart of the ES-250’s design. Paul says having the option of diesel or electric versions gives

changer,” he says.

“It’s got all the power of a hydraulic shredder, but it uses less fuel, produces lower emissions, and runs much more quietly. at makes it ideal for indoor or enclosed applications, where exhaust fumes can be a problem.”

Tutt Bryant has embraced its ‘green range’ of crushing and screening equipment, which includes hybrid and electric options, designed to help operators reduce their carbon footprint without sacri cing performance.

“Our customers like that they can be more e cient and lower their production costs at the same time,” Paul says.

“If they can also reduce their emissions and improve their environmental performance, that’s a win-win. It makes them more competitive while supporting their sustainability goals.”

e McCloskey Environmental ES-250 is also equipped with advanced telematics and digital eet management tools that bring greater transparency to operations.

“ e machine’s telematics system lets operators monitor everything from fuel and electricity usage to emissions,” Paul says. “Operators can see their performance data in real time on the

is feature helps companies track their environmental performance, optimise e ciency, and produce accurate sustainability reports.

“It’s ideal for businesses that need to demonstrate compliance or report on fuel and emissions performance,” Paul says. “It’s all there, ready to be exported and analysed.”

Tutt Bryant’s service network ensures customers have access to the expertise and spare parts they need to keep operations running smoothly.

“McCloskey Environmental equipment falls under our crushing and screening division,” Paul says.

“We have a dedicated team with the experience to maintain, repair, and diagnose issues with shredders. We’ve invested heavily in stocking parts for the ES-250 to make sure customers are covered for the rst few years of operation.”

With most replacement parts already in stock and delivery times as short as one week, Tutt Bryant is committed to minimising downtime.

“If someone purchases an ES-250 today, we can usually have it delivered and ready for work within a week,” Paul says.

For more information, visit: www.tuttbryant.com.au

Ennovo leverages its land ll gas expertise to navigate the changing waste landscape.

The ground beneath Australia’s traditional waste management sector is shifting.

Ambitious 2030 national waste reduction targets and the removal of organic waste from land ll is rede ning the land ll business model. e most immediate fallout is the reduction in land ll gas generation rates, forcing operators to rethink capital (CapEx) and operating expenditure, and the impact on future revenue.

e change is opening new opportunities for adaptable operators like environmental management company Ennovo.

Ennovo is known for its technologydriven solutions for the waste management, renewable energy, and contaminated land industries.

Managing Director Ben Dearman

says the company’s expansion into the recycled organics space is less a change of direction and more a logical way of complementing its long-standing work in land ll services.

e company’s move is underpinned by the development of its CarbonAir System – an automated control platform designed to support forced aeration systems and streamline the composting process. e technology can be applied to very simple static and turned windrows, tunnels, or compost halls, o ering a exible solution to better manufacture a consistently highquality product in shorter timeframes.

While the technology provides the necessary processing muscle, Ennovo’s new focus is on supporting and driving market pull for the resulting material, rather than just market push.

“We run the risk of being able to collect and process all this organic material, which is great, but we don’t necessarily have well established markets for it,” Ben says.

“We’ve always been aware that the reduction in gas generated at land ll is a possibility. We have started to see reductions on some of the land lls that we manage, and we have had some clients come to us looking for help to process organics that will no longer end up in land ll.

“With the development of the CarbonAir technology we’ve been able to demonstrate that our experience in land ll services –from EPA (Environment Protection Authority) licensing and regulatory support to environmental monitoring requirements and carbon credit

management – is transferable across to recycled organics.”

Ennovo has taken on key people to drive the new division, leveraging Ben’s own 25 years of experience in composting.

For clients seeking to process increasing amounts of diverted organic material, Ennovo o ers designs and processes to better manufacture products that can be successfully sold into dedicated markets.

Ben says this requires a deep understanding of the inputs and outputs, combining both science and market foresight.

“It’s looking at the feedstock inputs into the compost itself and knowing what type of end product that’s going to make, both physically and from a nutrient content perspective,” he says.

“But it’s also understanding which markets are going to use those products, whether it’s horticulture, broadacre, home garden or something that’s more speci c, as well as how they are going to use these products.”

An emphasis on identifying and securing end markets is one of the company’s core strengths, which stems directly from the Ennovo team which has expertise in this area.

Ben says having a large team of experts working across the industry enables the identi cation of innovative practices and fosters close collaboration with agronomy service providers. is strategic alignment strengthens the connection between processed organics and premium agricultural applications. e importance of this market connection was highlighted in a recent case where a client was processing very high carbon, woodbased materials.

Ennovo recommended adding high-strength organic waste to the mix to dramatically increase a particular nutrient component, thereby

e run the risk o eing a le to collect and process all this organic material ut we don t necessarily have well esta lished markets or it.

Ben Dearman, Ennovo Managing Director

improving its value proposition to local horticultural industries.

Ben says this approach ensures that while the total market size for compost is vast, products are speci cally manufactured for guaranteed end-use.

He says the impact of organics diversion is not a distant threat; it’s already changing the calculus for land ll operators.

“ is shift is going to impact the capital expenditure (CapEx) and

operating expenditure (OpEx) decisions of land ll operators,” he says.

“ ey absolutely need to forecast this real impact as the community is encouraged to remove organics, especially food waste, from the waste stream. Operators won’t necessarily become composters, that work may be undertaken by third parties.”

For more information, visit: www.ennovo.com.au

The McCloskey environmental ES-250 and ES250e tracked primary shredders are engineered for heavy-duty performance across a wide range of waste applications, including mattresses, wood, construction and demolition debris, green waste, municipal solid waste, and tyres. Designed to process materials that vary in size, composition, and density, both models feature dual asynchronous shafts with counter-rotating knives, keeping material in constant motion to prevent bridging and ensure consistent, high-throughput shredding. Whether powered by diesel (ES-250) or electric (ES-250e), these machines deliver the hallmark McCloskey reliability, efficiency, and versatility that operators depend on to keep production moving.

Maintaining the status quo is not an option for SOILCO.

e family-founded business, which has more than 50 years of organics recycling experience, is pursuing national expansion with an ambition to become an Australiawide resource recovery platform that processes more than a million tonnes of organics every year.

is push is already reshaping the East Coast, underpinned by strategic acquisitions and green eld developments. Charlie Emery, Chief Executive O cer of SOILCO, says the growth strategy is focused on replicating SOILCO’s successful New South Wales’ network comprising large-scale regional facilities

supported by urban aggregation points. After more than 25 years in the business and six years on the Australian Organics Recycling Association (AORA) board, Charlie is excited to see SOILCO cross state lines and make a signi cant contribution to land ll diversion.

AORA’s Economic Contribution of the Australian Organics Recycling Industry 2023-24 report reveals the challenge facing Australia’s organics recycling sector.

In the 2023-24 nancial year, Australia generated an estimated 14.9 million tonnes of organic waste. While the industry recycled a substantial 7.7 million tonnes and recovered another 1.6 million tonnes through energy, the

overall national recycling rate stood at 51.4 per cent. is means 5.7 million tonnes of valuable organic material was still sent to land ll.

Despite these hurdles, the Australian organics recycling industry is a powerful economic and environmental contributor, providing more than 5000 jobs and contributing $843 million in industry value to the Australian economy in 2023-24.

e industry is not only performing strongly but is also poised for growth. With the continuing focus on source separation of organics, the sector is ready to meet the ever-increasing volume of organics that need to be diverted from land ll.

e report states that achieving higher recycling rates would unlock immense bene ts: reaching a 90 per cent recycling rate, for instance, is projected to generate an extra $2.0 billion in sales, provide more than 4000 extra jobs, and result in massive additional greenhouse gas savings.

To achieve these bene ts requires substantial private sector investment and decisive action from industry leaders. is forward momentum is embodied by SOILCO, which is directly contributing to the future by investing in new capacity.

In 2025, the company entered the Victorian market by acquiring e Good Dirt Company. e acquisition secured a licensed 350-hectare site near Melbourne, which is operating as SOILCO Lethbridge.

While the original operation focused on agricultural waste streams including chicken manure, Charlie says the goal is to use and expand the 48,000-tonne licence to also process kerbside organics, supporting Victoria’s advanced FOGO journey.

“ e location ensures SOILCO continues to strengthen its access to high quality organic feedstocks that will meet the requirements of our customers and the soil improvement needs of our communities,” he says. Further north, SOILCO’s acquisition of Martins Fertilizers, a large-scale bagging facility in New South Wales,

allows the business to expand its distribution network and markets. Simultaneously, the company has been progressing its green eld developments in South East Queensland.

“We’re delivering much-needed infrastructure that future proofs our industry,” says Charlie.

“With that infrastructure comes con dence that the services are t for purpose and sustainable.”

SOILCO has now received all environmental approvals for its 161-hectare Bromelton Compost Manufacturing Facility in Scenic Rim, Queensland. With intersection and road works underway and the tender for the facility build progressing, the project is on track to become operational in the second half of 2026.

Queensland is also the planned home for SOILCO’s Pinkenba facility, where infrastructure works are progressing to deliver a transfer station in 2026. e goal, Charlie says, is to receive a diverse array of waste streams at the transfer station, and to transfer organic material toward large regional facilities like Bromelton for processing. e facilities aim to ll a gap for councils seeking a solution for organic waste in the region.

Charlie says councils have been “supportive and pragmatic” and SOILCO has secured several long-term

contracts, a crucial requirement for justifying major infrastructure builds.

“We’ve been impressed by how supportive council and government bodies have been to help us move our Victorian and Queensland projects forward,” he says.

“Queensland has fantastic transfer station infrastructure which is run by the councils or co-managed with a private waste company, so they understand the realities of our industry on the ground. ey understand what’s a risk, and what isn’t, and they’re willing to share that risk.”

However, Charlie says that there are still hurdles to overcome. Many council contracts are structured as panels, meaning the provider is not necessarily guaranteed tonnes.

“In order to justify builds like these, there needs to be a minimum guarantee,” he says. “Some small tweaks to the existing procurement process in Queensland would help ensure that the necessary infrastructure can be built.”

e company also advocates for hypothecation of the state’s land ll levy, arguing that while councils receive grant funding, more direct support to the private sector would help build critical processing infrastructure.

is is particularly timely given the lead-up to the 2032 Brisbane Olympics, which “demands twenty- rst-century waste infrastructure”.

With more opportunities and acquisitions on the horizon, the overarching goal for SOILCO is clear:

“We want to be a national resource recovery platform that processes more than one million tonnes each year,” Charlie says, con rming SOILCO has more than just organics in its sights.

“We are considering other waste streams and other verticals, and we have a plan to get there by 2029.”

For more information, visit: www.SOILCO.com.au

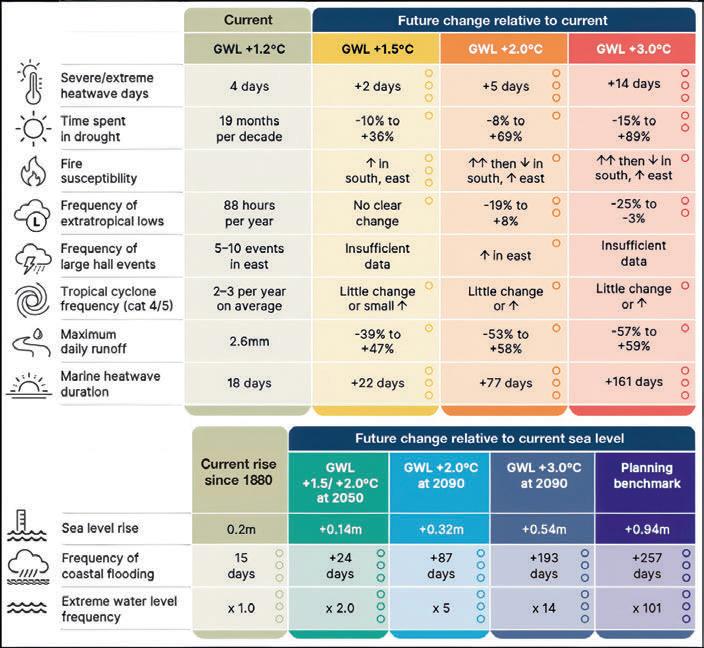

Advanced Methanol Production and Greenhouse Facility Proposed for Kandos

Methanol Production for the World’s Shipping Industry

Cenagen using a patented process will manufacture green methanol processed engineered fuel made from residual household and business waste, helping to decarbonise the world’s shipping industry.

Greenhouse cropping to help achieve net zero emissions

Carbon dioxide, a byproduct from the methanol production process will be beneficially used in a large-scale enclosed greenhouse complex to assist in the commercial production of fresh produce and cut flowers.

A new force in Australian waste and resource recovery is emerging – one that’s ready to challenge conventional approaches and drive meaningful change.

With robust global backing and decades of international operational expertise, Valoriza is not just entering the organics recycling space – it’s positioning itself as a catalyst for a sustainable circular economy in Australia’s waste services sector.

Owned by Spain’s Valoriza Servicios Medioambientales, a major waste and resource recovery player in Europe, Valoriza’s facility in Dandenong South, Victoria, is a signi cant asset in the region’s waste infrastructure.

e in-vessel Food Organics and Garden Organics (FOGO) treatment facility came online in 2019 and continues to deliver end-to-end FOGO composting services to the southeast councils in Melbourne, where the facility team receive, process and provide a quality-assured product into local markets for value adding and bene cial reuse.

A pivotal moment in Valoriza’s Australian strategy came in late 2023, when its Spanish parent company was acquired from Sacyr by global investment rm Morgan Stanley Infrastructure Partners (MSIP). is acquisition sharpened the group’s focus on the waste services sector and injected signi cant nancial strength into its operations. Valoriza’s vertically integrated business in Spain spans collections, recycling, and advanced thermal and biological treatments.

Michael Allaway, Valoriza Country Head for Australia, says the MSIP backing and global know-how of the Spanish business will be a strong catalyst to support growth in Australia.

“It gives us a lot more nancial horsepower behind the operations,” he says. “In addition, there’s a broad range of innovative technology within the Spanish business that we can access and adapt for the Australian market.

“Spain’s waste treatment infrastructure evolution is ahead of

facility. e optimisation program includes a $3.6 million investment plan to be rolled out by the end of 2026, as well as enhancing operating practices and strategically repositioning the facility in the Melbourne organics recycling market.

Michael says the goal is to move

e facility currently produces an AS 4454-certi ed composted product primarily used by market gardeners, farmers and soil yards and is working with partners to develop sustainable product and bene cial reuse solutions for the more complicated oversize materials.

While FOGO waste contamination remains a key area of focus, Michael says Valoriza’s council customers are signi cantly reducing this complexity through proactive engagement within their local communities to in uence improved recycling behaviours.

“ e Dandenong facility is designed to remove as much contamination as possible before composting begins,” Michael says. “Our quality assurance regime is stringent because we’re dealing with highly variable input.”

e facility, which is licensed for 120,000 tonnes a year, currently processes about 85,000 tonnes of FOGO and commercial food.

Valoriza has empowered the facility’s leadership team to drive the improvement and optimisation mandate from within.

Victoria’s maturity in FOGO processing – dating back over a decade – provides a strong foundation for Valoriza’s national growth strategy. e company aims to leverage operational insights from Dandenong to support emerging FOGO initiatives in New South Wales, South East Queensland, and Western Australia, as they evolve their own FOGO transition journeys.

But the biggest opportunity for value lies in closing the loop entirely by working with the councils Valoriza contracts with.

“We are starting to engage with council customers about the changes we’re making. We want to bring them into our business to understand how our facility works and how it interfaces with their requirements,” Michael says. “An example is the explorative

“We’re particularly focused on developing value-added products that can be reintegrated into local communities.”

Michael Allaway, Valoriza Country Head Australia

conversations we’re beginning to have with some council customers about working together in the circular procurement space, which is progressing well. We’re particularly focused on developing value-added products that can be reintegrated into local communities. Partnering with local soil blending operators and councils is key to achieving this.”

One of Valoriza’s ve-year goals is to become a national leading vertically integrated organics company, an ambition that includes actively looking at acquiring complementary businesses across the country.

Valoriza envisions a national waste industry committed to sustainable transformation.