WManaging Editor: Mike Wheeler

ould a product that was perfect 50 years ago have the same recognition today? Most likely not.

For businesses, striving for perfection is the wrong approach. It is not just difficult to obtain – it is impossible. One may look at a work of art and call it perfect, while the artist loses sleep over what they see as incomplete. Even definitions of perfection are not fixed. They depend on individual taste, cultural expectations and time. In fact, perfection can make a business complacent.

The food and beverage industry is no stranger to this. New flavours emerge in a moment and fizzle out just as quickly, becoming yesterday’s news. What seems like it will last forever often proves us wrong. Even a popular company like The Magnum Ice Cream Company, now in the process of demerging from Unilever, recognises the sector’s impermanence without forward thinking. Understanding there is always room for improvement, the company has upgraded its facility to diversify its product range and meet sustainability goals.

Cloudy Bay Clams provides another example. The company actively communicates its sustainable clam farming processes to build a story that elevates the business. Meanwhile, transitioning from sheep and cattle to quail, the owner of Rannoch Quail embraces new challenges and assesses technologies every week to keep the team motivated.

While perfection cannot be fully achieved, efforts in the sector can create the illusion of perfection. The downside is that consumers expect more,

better and faster, making it challenging for new players to stand out. Fortunately, problems often meet solutions.

APS Industrial provided a solution for an aroma recovery and extraction manufacturer struggling to meet customer demand. A fully integrated Siemens solution brought the company up to speed. Fishbowl Inventory simplified an ice cream manufacturer’s traceability system for food safety and operational efficiency. Trimatt Systems supports SMEs by localising packaging through an on-demand production model, reducing the need for bulk purchases that often end up in landfill.

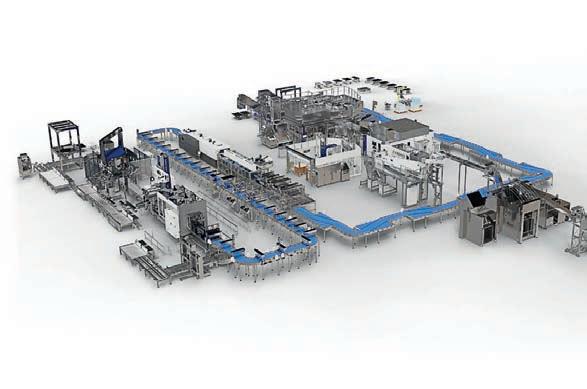

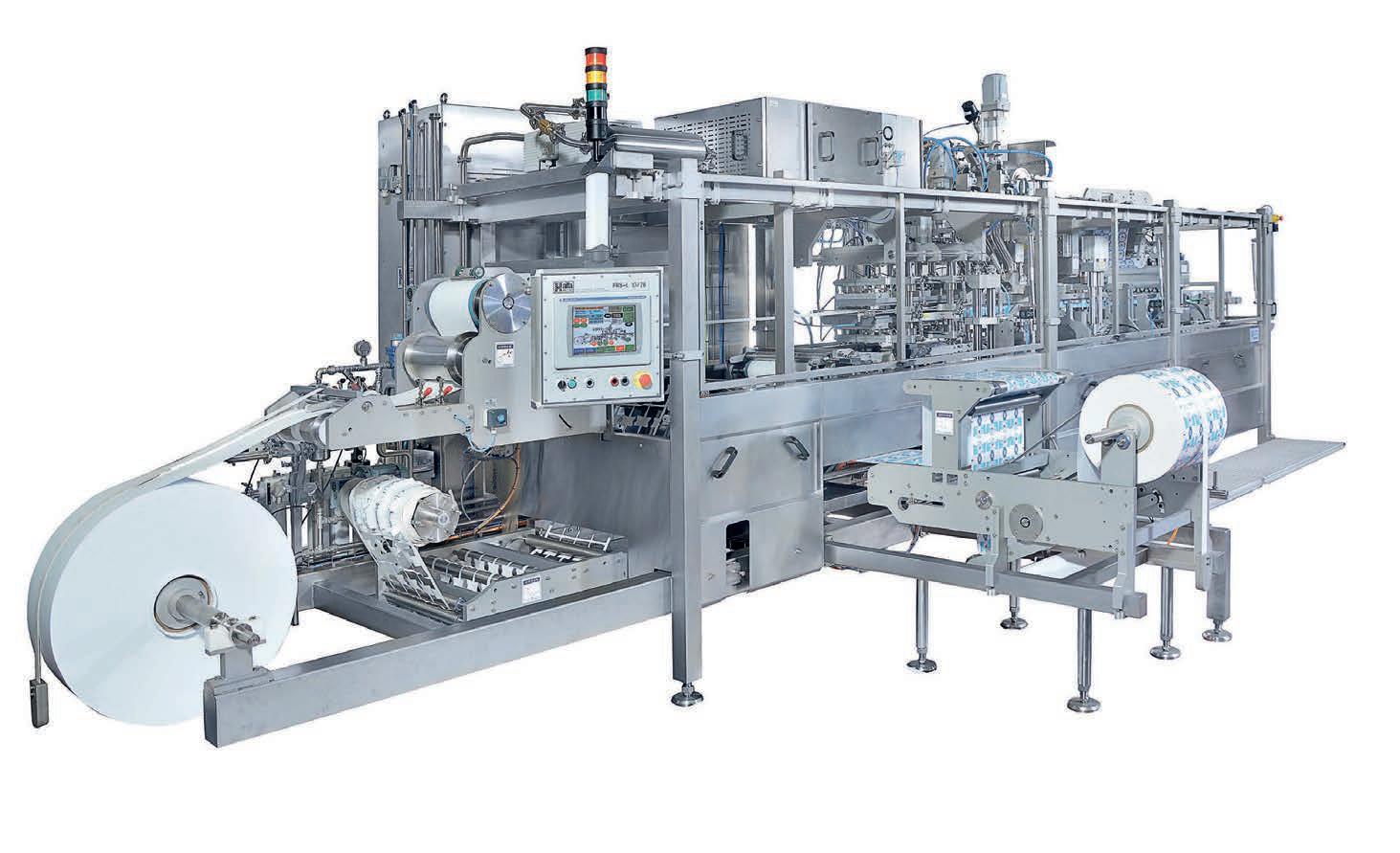

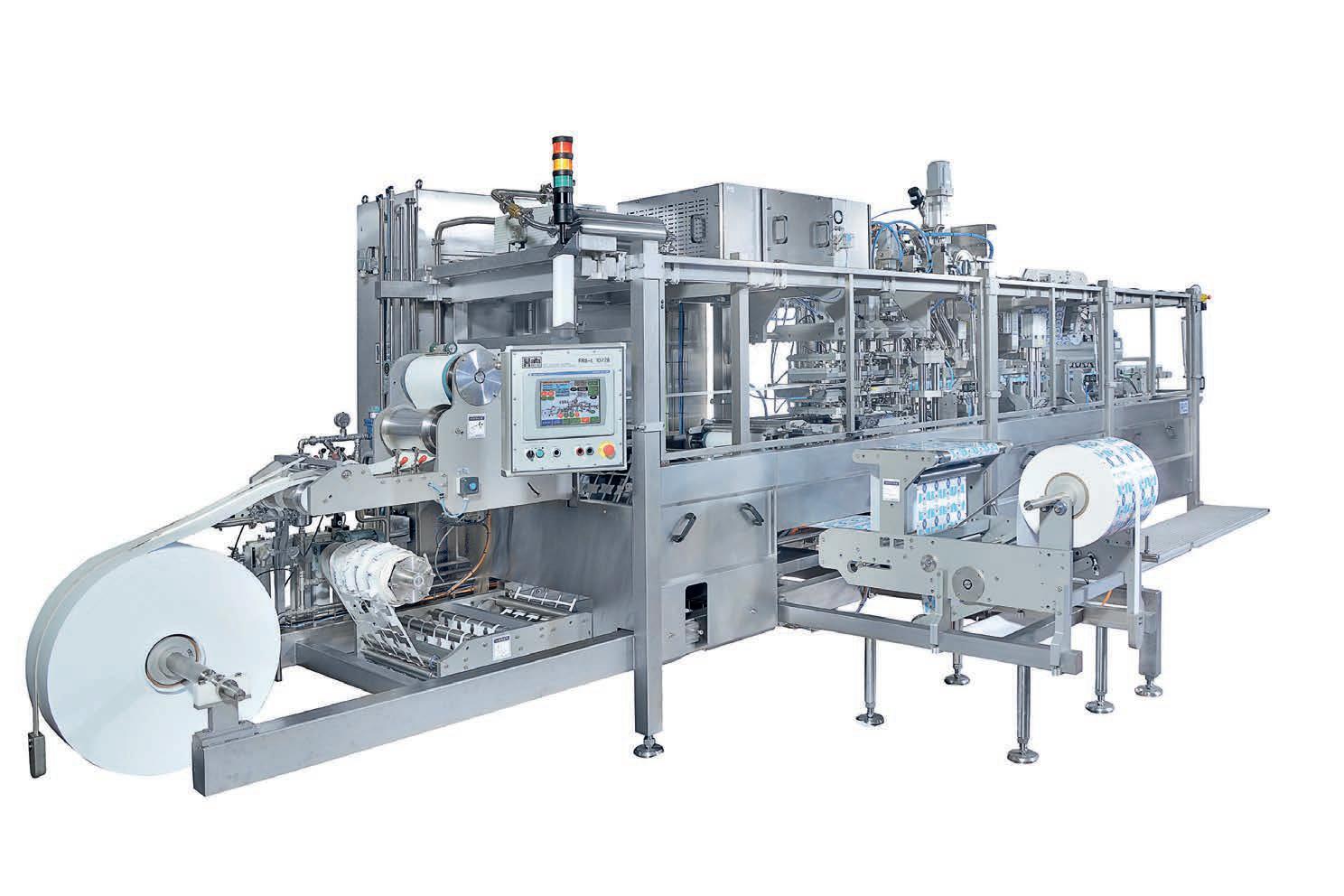

Then there are industry partnerships, which are key to growth and innovation. Esko Australia’s collaboration with Alfa Machines to deliver smarter and sustainable Form-Fill-Seal packaging technology is one example. Programs like Cluster Connect bring the industry together, providing tailored support for startups and SMEs through strategic connections.

The pursuit of perfection yields a different result: a competitive, innovative and growing food and beverage sector. By using older innovations as stepping stones, better ones can emerge, such as Monash University’s breakthrough research on compostable bioplastics derived from previous work on microbial plastics.

While our hands cannot grasp a perfect product, system or world, the food and beverage industry is forward-thinking and resilient, trying to reach perfection in an imperfect world.

Happy reading! F

CEO: Christine Clancy

Managing Editor: Mike Wheeler

Ph: 041 557 2106

mike.wheeler@primecreative.com.au

Journalist: Dae Hong david.hong@primecreative.com.au

Art Director: Michelle Weston

michelle.weston@primecreative.com.au

Sales/Advertising: Joanne Davies Ph: 0434 785 611

joanne.davies@primecreative.com.au

Client Success: Cait Pillay Ph: (03) 9690 8766

caitlin.pillay@primecreative.com.au

Cover

Image: The Magnum Ice Cream Company

Subscriptions AUS NZ O/S

1 year subscription99109119

2 year subscription189199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive

Docklands VIC 3008

Ph: +61 3 9690 8766

enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office

Suite

6 Meet the Manufacturer: The Magnum Ice Cream Company

The Magnum Ice Cream Company delivers a “magical” scoop with its upgraded facility.

10 Meet the Manufacturer: Cloudy Bay Clams

Elevating the seafood industry with sustainably farmed clams, one company focuses on telling a story.

14 Meet the Manufacturer: Rannoch Quail

Rannoch Quail is the only quail farm in Tasmania delivering new experiences to the market.

19 Inventory

While a bill is a bill, what makes or breaks success is inventory management.

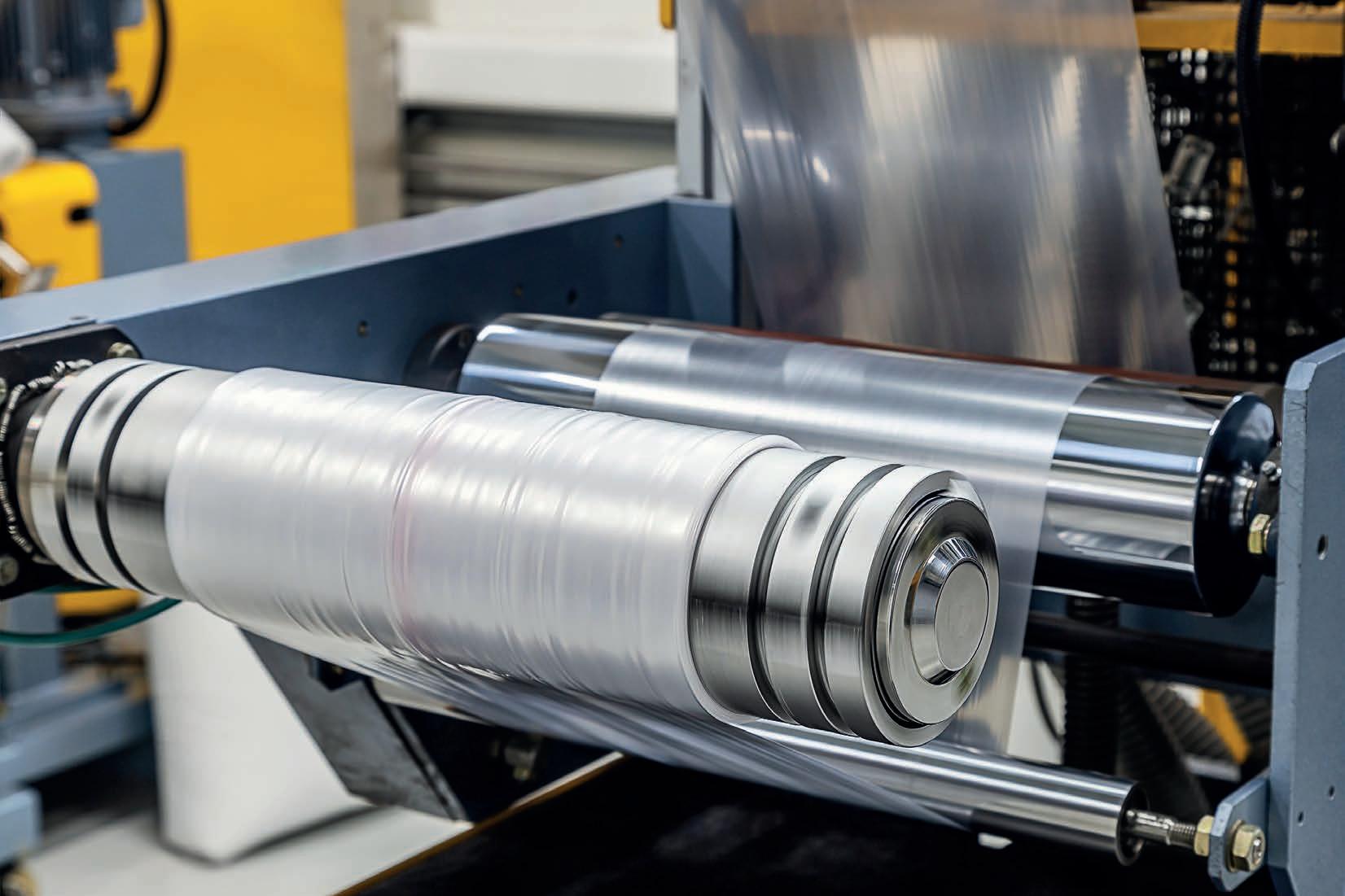

22 Printing

Bulk-bought branded packaging ends up in landfill. An on-demand approach changes the game.

24 Advanced Manufacturing

A technology manufacturer boosted its operations with the support of APS Industrial.

26 Collaboration

Through a program, Food and Agribusiness Network helps startups and SMEs scale through collaboration.

28 Production lines

Krones’ new and efficient line system was showcased at drinktech 2025 in Germany.

30 Packaging

Esko Australia partners with Alfa Machine deliver a sustainable packaging technology.

34 AIP

A new position paper explores food loss, waste and packaging, offering guidance to help find sustainable solutions.

36 Food Waste

The Waste Expo Australia encouraged showed that food waste should be treated as a valuable resource.

40 MICE

With just months to go, organisers are preparing for another year of growth for a 2026 coffee expo.

42 Research

Researchers have turned food waste sugars into natural plastic films.

46 WorldSkills

Two rising stars share their experience at WorldSkills Australia.

48 Bulk

BULK2026 will build on the success of the 2024 event bringing together the industry for a resilient future.

50 New Products

With a recent facility upgrade, The Magnum Ice Cream Company is set to shape the future of premium local ice cream.

Ice cream is many things – cool, tasty and sweet. But what about the process of making ice cream?

Joining Food and Beverage Industry News after a hot weekend, general manager ANZ of The Magnum Ice Cream Company Scott Mingl’s attention was on the excitement around ice cream during the warmer weather.

“I’ve worked in many other categories and there’s something magical about making ice cream,” he said.

An ethereal experience in food manufacturing is rare, yet with the backing of the company’s head of manufacturing Waqas Zaheer, ice cream seems to make it possible.

However, Mingl explained that the manufacturing process for the delectable treat is hard.

“Ice cream is not easy,” he said. “It is a complex science that’s constantly trying to melt.”

Both Mingl and Zaheer worked at Unilever prior to the demerger process of The Magnum Ice Cream

Company, which is currently expected to complete on 6 December 2025. The demerger was part of a strategic decision to allow a simpler and more focused business, expected to allow both companies to concentrate on their respective strengths.

“We’ve always been a big part of Unilever, and we’re excited to finally be a company that can make decisions for ice cream by ice cream,” added Mingl.

With 15 years at Unilever, Mingl’s experience spanned multiple

categories, from deodorant and home care to beauty. He spent the last three years as head of ice cream ANZ. Zaheer has solidified his career in ice cream over the past 20 years, starting as a production manager before becoming sourcing unit director and joining Mingl as a board member of Magnum ICC Australia Pty Ltd.

Mingl named two trends shaping the sector.

“From a category-centric point of view, there are two key growth areas we are focused on – one in premiumisation and the other in the better-for-you space,” said Mingl.

Consumers are willing to pay more for superior taste, quality ingredients and products that align with health-conscious lifestyles. Additionally, social media is backing these trends, triggering impulse purchasing behaviours. To respond to

these health and digital trends, Mingl highlighted that The Magnum Ice Cream Company has been prioritising taste and quality above all else.

“Outside of that, the sector is seeing a move towards localisation,” he added.

With a shift towards producing products tailored to regional preferences while maintaining global standards of quality, localisation is another emerging trend. Along with the importance of speed to market, local manufacturing enables businesses to respond to food and snacking trends as they emerge and complimenting the global strength of innovation.

By focusing on quality and taste to deliver products that consumers want to experience repeatedly, the company believes this is where category growth will come from.

Central to the company’s strategy is its upgraded manufacturing facility

at Minto, New South Wales. The $35 million investment represents a modernisation of the 23-year-old plant, with additional projects planned to expand capacity and improve operational efficiency.

The facility now features cuttingedge production lines, advanced data analytics and real-time monitoring systems. Live dashboards provide actionable insights into production, allowing for informed decisions that reduce waste and optimise processes.

“If you see the data on a daily basis, you can make the right decisions and do some root cause analysis to minimise the losses,” said Zaheer.

Sustainability is the second biggest focus, he said. Initiatives include one of Australia’s first food industry depackaging units, which has contributed to achieving zero waste to landfill and a 72 per cent reduction in overall waste compared to 2023.

Office refurbishments and

enhanced workspaces have set new benchmarks for employee environments in the industrial sector, reflecting the company’s commitment to both workforce wellbeing and operational excellence. Foundational upgrades to legacy assets have further strengthened product safety and quality, establishing Minto as a centre of excellence in ice cream manufacturing.

The Minto facility produces approximately three million servings of ice cream daily, representing 63 per cent of the ice cream sold in Australia and New Zealand.

“We aim to grow this number and our local manufacturing footprint with more investments in the future,” Zaheer said.

The scale of the Minto facility upgrade aligns with the complexities of ice cream manufacturing.

industries,” said Zaheer. “To learn and make ice cream, you have to understand the entire food industry.”

Key machinery, including mixers, pasteurisers, homogenisers and continuous freezers, ensures that products achieve the desired texture, flavour and consistency. The manufacturing process integrates ingredients from multiple sectors such as dairy, chocolate, nuts, fruits and flavourings, creating a complex

the premium ice cream experience. The production process follows strict safety and quality protocols. Ingredients are carefully mixed and pasteurised to ensure consumer safety. This mix is then homogenised for smooth texture, aged to develop flavour, and partially frozen while air is incorporated to achieve creaminess.

Additions such as chocolate, nuts, fruit and sauces are combined and shaped into the desired formats

– popsicles, cones, tubs – before being hardened at -18 °C with a blast freezer.

“All of this has been combined in a systematic and harmonious process,” Zaheer said.

Highlighting the intricate interplay of science, craftsmanship and technology required to deliver a consistent product, there are also unavoidable challenges when it comes to ice cream manufacturing –melting.

All ice cream melts

Ice cream always melts, and any ice cream manufacturer’s priority is to ensure that its product does not melt. This is where temperature control is critical. The Magnum Ice Cream Company’s cold chain is maintained throughout storage and distribution, preserving the integrity and quality of every serving.

Both Mingl and Zaheer said that there are challenges every day.

“Ice cream melts,” said Zaheer. “To prevent it from melting, you have to control the process from end to end.”

When it came to the facility upgrade, a change in systems, processes and equipment is not enough. According to Zaheer, team formation and talent acquisition are essential to the successful implementation of operational improvements. The Magnum Ice Cream Company has invested in recruiting and developing a skilled workforce capable of meeting these challenges end to end.

For Mingl, fostering a healthy culture is fundamental to the company’s success, and growth is at the heart of that mindset. He emphasised that operational speed is critical, and that clear objectives are key to keeping the business focused on delivering results.

“We need to have fun, and we need to grow” he said. “When we’re having fun, growth follows, and if we’re not enjoying ourselves, the ice cream won’t taste as good, which makes everything else harder”.

Sustainability is considered a fundamental aspect of daily operations, with attention on areas where the company has direct influence, ensuring that environmental goals are both practical and achievable. The company works closely with local suppliers to minimise environmental impact. Investments in waste reduction, energy efficiency and innovative packaging demonstrate a commitment to environmental stewardship.

The company’s strategic vision includes expanding product ranges, improving operational efficiency and deepening sustainability achievements. Long-term goals focus on leading all market segments in which the company operates, growing market share and investing in local manufacturing infrastructure.

“I am incredibly passionate about investing in local manufacturing

within Australia,” added Mingl. “We would love to be in a position where The Magnum Ice Cream Company is leading the world in ice cream on key innovations and category performance.”

Mingl said that Australia remains one of the highest consumers of ice cream in the world, with around 20 litres of ice cream per capita on average. Leveraging this through local manufacturing, it is dedicated

to identifying and responding to consumer trends, whether through new flavours, sizes, formats or betterfor-you options.

“We’re very excited for the future and we are only in the early stages,” said Mingl. “I have all the faith in the performance of the organisation in what is a really fun category.”

With increased manufacturing capabilities and expertise, export opportunities to international markets

and new channels, are being explored as part of a broader growth strategy. By strengthening its presence within Australia and New Zealand, The Magnum Ice Cream Company aims to support global operations while enhancing the traceability, quality and appeal of its products.

“Ice cream is not easy. But in the end, it’s magical, it’s beautiful, it makes people smile,” added Zaheer. “What else could you ask for?” F

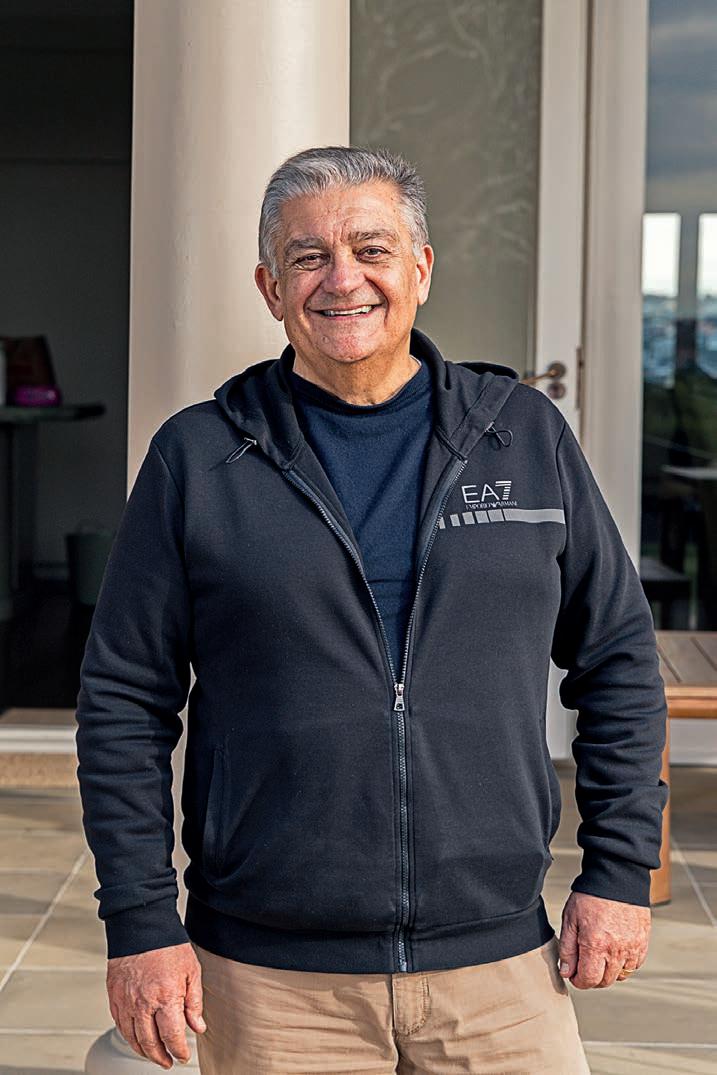

“Fishbowl is an invaluable asset to our entire organisation. We now operate as a unified whole”

Sandra Gosling

- Co-Founder

“Fishbowl has made us confident with traceability. It’s made us confident with our margins as well.”

Simon

West - CEO & Owner

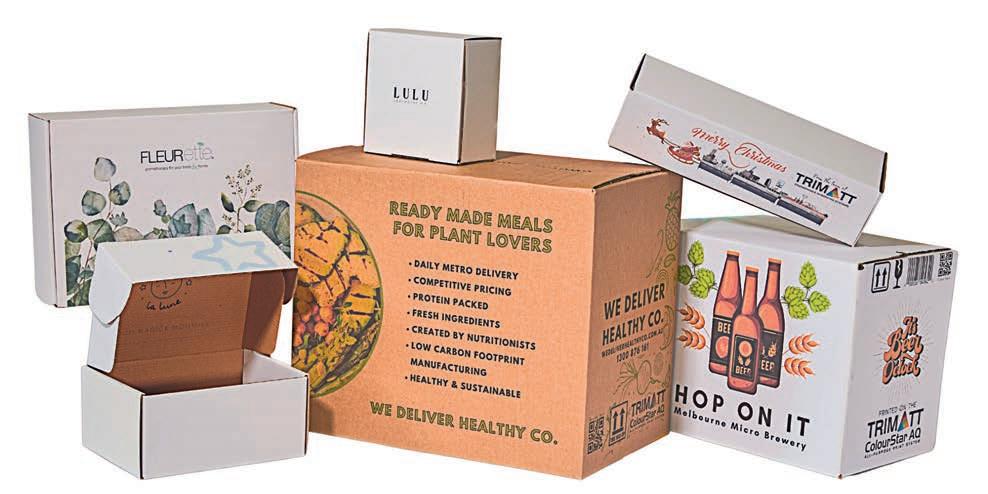

A product’s standalone quality and taste can sometimes be enough to tell a story. Cloudy Bay Clams is one example.

For George Manettas, a seafood specialist of more than 50 years, the story behind a brand is as valuable as the product itself.

Joining Food and Beverage Industry News , he paints a picture: imagine entering a restaurant and coming across a menu section describing a pasta that says, “made with Cloudy Bay Clams”.

Supplying high-quality seafood products to five-star hotels, restaurants, airlines, and cruise ships, he has witnessed many changes in the industry from consumer behaviours, and changes in taste preferences and trends. Once, dishes were often heavily sauced or battered, masking the natural flavours of seafood.

While a business may be susceptible to these shifts, in recent years, chefs and consumers have moved towards healthier options that highlight the intrinsic qualities of seafood. This has allowed culinary professionals to create dishes that are lighter, cleaner, and more nuanced. With a product that can stand on its own, the story and branding around it come naturally.

“The natural flavours that are coming out of the Abrolhos Western Australia scallops, Queensland raw and cooked king prawns and Cloudy Bay Clams speak for themselves now,” he said.

Established in 1990, Cloudy Bay Clams has broken through the industry with decades of expertise committed to sustainable and premium wild shellfish. Originally founded by a pioneering family of fishers, the company built its reputation by capturing the taste of freshness in its clams in NZ.

Under new ownership by Tony Muollo, the company is now marketed by George Manettas and Co to deliver clams across the Asia-Pacific region and is building on new chilled blanched formats for foodservice, updated frozen packaging, and enhanced support tools for chefs, distributors, and retailers.

Alongside the health benefits of clams that are high in omega-3 fatty acids, vitamin B12, vitamin D, and essential minerals including zinc and selenium, what drew Manettas to the business was the company’s pride in its harvesting techniques. These methods are designed to protect the marine environment while delivering clams of the highest quality.

This rake is placed on the back of the fishing boats where they scoop up clams as the boat gently moves out into the surf. He explained that this is an environmentally friendly process as clams are collected from the seabed without disturbing the surrounding habitat.

“Through this winnowing system, smaller clams fall out back into the ocean,” added Manettas.

With the smaller clams returning

clams are then submerged in sea water on deck, with aerated water being frequently refreshed to allow them to continue natural respiration.

Clams remain in a truck until they arrive at the wet store facility.

The facility features seven large tanks which Manettas described as swimming pools. He highlighted the key element of the facility that simulates the clams’ natural environment.

“The important thing about our facility is that the water that comes into the factory is from the ocean,” he said.

Alongside ocean water to provide a natural environment, Cloudy Bay Clams also maintains it at a controlled temperature of around 10°C, which clams thrive in, as required by the NZFSA. Once used, the water is returned to the sea through an infiltration gallery.

The clams are placed in a single layer and stacked to allow uniform flow of water across them. They are kept in the tanks for approximately 24 hours to rid them of grit and sand. As clams are bivalves – molluscs with soft bodies and shells made of two hinged parts – they naturally expel sand and impurities. This method ensures the clams are clean, fresh, and ready for consumption without compromising their quality or nutritional value.

Both the clams and the water are tested regularly to ensure there is no contamination. All water used in this process is USFDA approved and regularly monitored to maintain the highest possible quality.

These nutritional qualities, combined with the sustainable practices, give the product both health and trust advantages. This focus aligns with contemporary trends in consumer awareness, where diners increasingly seek not only flavour but also knowledge about the foods they consume.

“There are always challenges every day,” said Manettas. “From missing a plane going overseas to a truck not turning up in time; that’s just part of the business.”

This is also evident in governmental regulations. Currently, Australian regulations prevent the importation of live clams, limiting the ability to supply this delicacy to domestic markets. To navigate these restrictions, the company supplies frozen clams within Australia and live clams to select

strict temperature control and handling protocols. While challenges occur daily, the company’s experience allows it to adapt quickly, ensuring product integrity and reliability.

In addition to its focus on highquality products and sustainability, Cloudy Bay Clams continues to innovate, with its facility being a core example.

“As we have been selling our clams, we’ve also upgraded our facility to be purpose-built,” said Manettas.

With newly identified key growth

Fishery Improvement Project and is progressing toward full MSC certification. Recent investments in CRM and QA systems will further strengthen communication, traceability, and service delivery.

By placing emphasis on the broader industry context with a growing focus on sustainability, it allows consumers to be more informed about sourcing, environmental impact, and health benefits.

According to Manettas, consumers are becoming more wary of the products they purchase.

“They’re asking questions at restaurants, fish shops and dinner parties about a product’s origins and

its sustainability,” he said.

He continued to say that this shift in consumer behaviour encourages him even more about Cloudy Bay Clams due to its quality products and robust sustainable systems.

Looking ahead, the company is ramping up direct industry engagement through trade activations and tastings in Sydney, Melbourne, Brisbane, and Singapore, along with planned participation in hospitality trade shows in 2025. Long-term plans include achieving certification to enter the European Union market, which presents additional regulatory hurdles but offers substantial growth potential.

Manettas circles back to the importance of the story. By building

a story that is as effective and true as the product, Cloudy Bay Clams aims to elevate the culinary experience in restaurants and hotels.

“I don’t want to be known as just ‘George Manettas selling clams’ when we have sustainably harvested clams,” said Manettas. “I want to be known for selling the best clams in the world that have both health and taste benefits.”

The company combines a rich heritage in seafood with modern facility management, logistics expertise, and strategic marketing, meeting the evolving demands of the global seafood market.

When the Muollo and Manettas families came together, combining both fishing and marketing expertise, they wanted to be more than just a seafood wholesaler.

“We wanted a story that wasn’t just about selling seafood,” said Manettas. “We wanted something that was sustainable as that is what the industry needs more of now.” F

From breeding, hatching, processing to packaging, Rannoch Quail is the only quail farm in Tasmania delivering new experiences to the market.

There’s a fine line between excitement and fear when approaching new experiences. While they develop character and a broader viewpoint of the world, it’s daunting.

Being adventurous with food is an extension of this. Not only is the taster trying new flavours, but they are also inviting a culture, a tradition, and a story to the palate. With just a little bit of vulnerability, new culinary discoveries widen a worldview.

Owner of Rannoch Quail, Daniel Millar, encourages this openness, highlighting that Australians are often hesitant to try quail.

“If you can cook chicken, you can cook quail,” he said.

Nestled 25 minutes north of Hobart, Tasmania, Rannoch Quail is a boutique producer of quail meat and eggs, operating an integrated facility that spans 10 acres at Tea Tree. Under the ownership of Millar, who purchased the pre-existing business five years ago, the company has expanded its operations to include breeding, incubation, growing, processing, packaging, and distribution, all managed on site.

Previously, Millar worked on a sheep and cattle farm. Although he also had an understanding of chickens and other poultry, the transition to quail production wasn’t easy.

“Learning all the specifics about quail, like the temperature for the eggs to ensuring the food they eat is nutritious, was a big learning curve,” Millar added.

Taking on these challenges with interest rather than as a chore, Millar built a team capable of managing the intricacies of quail farming, from egg collection to finished product.

For quail, a full-cycle production is necessary. Understanding this, Rannoch Quail’s facility is designed to maximise the processes. After a quail lays eggs, they are collected and placed in incubators. The incubators maintain a precise temperature and humidity.

“The optimum temperature is similar to the human body temperature of 37.7 °C,” said Millar. Mimicking natural conditions is crucial to ensure optimal hatching outcomes. For example, the incubator turns the eggs every few hours to mimic what the quail parent would do in nature. The eggs remain in the

incubators for two weeks, followed by a hatching phase of approximately three days.

After hatching, chicks are transferred to growing rooms where they remain for five to six weeks. A standard quail reaches approximately 400 to 450 grams, while larger jumbo quail can grow for up to seven weeks.

“They’re about the size of a 600ml bottle of soft drink,” he said.

The facility operates a weekly cycle, with multiple growing rooms allowing staggered batches to mature concurrently.

“We’ve got several growing rooms so we can have one batch growing per week on a weekly cycle,” Millar added.

Eggs are handled separately by hand, with each weighing approximately 15 to 20 grams.

After the growing stage, the quails are moved out of the barn in crates into the on-site abattoir, where the slaughtering process takes place. The birds are plucked and feathered before being placed in a cool room. This process usually happens at the beginning of the week.

The next day, the quail are graded by weight into small, medium, and large categories according to customer specifications. The

company employs different steps to offer a diversified product range.

“Rannoch Quail produces a range of products, from whole dressed birds to deboned portions, ready-to-cook quail breast, eggs, and pet food,” said Millar.

For example, the boned quail requires a specialised deboning process. A skilled team member removes all bones except for the leg and wing. He highlighted how this process is to make it easier to eat on the plate.

“That process is all manual,” said Millar.

While Rannoch Quail relies on manual processes, it is not foreign to technologies that boost its operations. For example, the company uses a machine for the plucking and feathering process.

It has also recently purchased a tray sealer machine for packaging. Previously, the team manually packed the products into cryovac bags and sealed them. The new machine will save packaging time as it directly puts a film across the top of the plastic tray.

Packaging is a big part of the

business. Eggs are supplied in small cartons suitable for quail size, with consistent quality ensured through hand selection and stamping for traceability. This focus is part of its commitment to sustainable practices, such as shifting from foam trays to compostable options.

“We are also looking at recyclable and compostable bags where possible,” added Millar.

The company’s attention to processing places a strong emphasis on food safety. The facility undertakes regular testing of meat and water, with swabs sent to laboratories to check for common bacteria. Daily quality assurance checks are conducted, blending manual oversight with emerging technology to improve efficiency.

Software and apps are being introduced to support staff in quality assurance and process tracking, complementing existing HACCP systems and manual checks. These upgrades aim to streamline operations while upholding stringent food safety standards.

“There are new technologies coming out every week and we often look out for potential products for implementation,” Millar said.

The operation relies on a small but specialised workforce. One team member oversees the daily care of the birds, including feeding and egg collection, while a processing team of seven staff manage slaughtering, grading, deboning, and packaging.

The boning of quail, in particular, requires skill that takes months of training for efficient performance. Retaining skilled workers and maintaining a motivated team is a priority, ensuring the quality of products and consistency in operations.

“We need to make sure we don’t lose that skill in our workforce,” said Millar.

He added that there are also agricultural problems. Agricultural operations inherently involve day-today issues, including maintenance and the care of live animals. Weather, equipment, and operational breakdowns are factors that the team continually manages to ensure uninterrupted production.

By maintaining a skilled workforce through the adoption of newer technologies that simplify processes, the company can operate smoothly to focus on other areas like education.

Millar highlighted that quail is an accessible protein.

“Quail eggs have high nutritious value,” he said.

However, compared to chicken, quail meat does not have much awareness, and cooking methods and applications remain limited. Rannoch Quail has addressed this through consumer-friendly packaging, boneless options, and recipes designed to simplify preparation at home.

According to him, there are only a few quail farms in Australia, and the company is the only export registered poultry producer in Tasmania. While most strive for big and mainstream, Millar enjoys its niche status, prioritising quality over scale.

While primarily focused on the Australian market, Rannoch Quail has recently entered international markets. The company has been exporting for 12 months, supplying Hong Kong and exploring opportunities in Singapore.

Looking ahead, plans include expanding ready-to-cook offerings, further refining packaging, and exploring new product innovations to meet consumer demand. The focus

remains on delivering a premium quail experience while keeping operations manageable and sustainable.

“We’ve just started having quail breast, which is completely boneless and easy for home cooking,” Millar said.

The combination of careful breeding, skilled processing, food safety practices, and sustainable initiatives allows Rannoch Quail to sustain itself as a boutique quail producer. By

controlling the process from breeding to packaging, the company ensures consistent product standards and meets both domestic and international market needs.

When Millar took over the farm five years ago, he took a bold step to operate a small-scale, high-quality approach to poultry production. Similarly, he encourages consumers to also take a brave step and give quail a shot.

“It’s not scary or hard to cook,” he said. “Have a go.” F

It’s never too late for

Many businesses still rely on manual or outdated inventory systems. Fishbowl Inventory’s APAC MD urges a shift for the food and beverage industry.

“No product in the world is perfect.”

This is a phrase that Simon Jupe, managing director of Fishbowl Inventory Asia Pacific, uses regularly when referring to all businesses. The illusion of a product’s perfection stems from external sources that magnify its characteristics through social presence, marketing, and other strategic embellishments.

However, Jupe focuses on the invisible – inventory management. Inventory management may not be the most visible part of a business, but it is crucial. Behind every welltimed delivery, consistent product line, or compliant packaging record lies a system that keeps the business running smoothly. But are inventory needs for the food and beverage sector similar to those of other industries?

management in food and beverage

“When it comes to the food and beverage sector, you’re dealing with more complex inventory needs,” said Jupe.

Managing stock in the industry is rarely straightforward. Compared with other sectors, food and beverage operations must contend with short shelf life, traceability requirements, and strict vendor and regulatory standards. Producers often face tighter timeframes and compliance obligations than other industries, and that pressure makes visibility across every part of the supply chain critical.

Yet many of these businesses still rely on manual or outdated systems, particularly during their early growth stages.

“Many other businesses, industries or verticals can get away with having poor inventory for a longer period

of time, but the food and beverage industry does not have that luxury,” Jupe said.

Short lead times, perishable materials, and the need for traceability all mesh together, leaving little room for error. A single lapse in compliance can lead to costly recalls or even government interventions, especially when working with large distribution partners that require stringent batch control and documentation.

Beyond compliance, there are also commercial pressures. The growing complexity of vendor order requirements, coupled with tighter margins since the pandemic, has increased the need for accurate cost management and forecasting. Each of these factors adds layers of complexity that make accurate, real-time inventory management essential.

For many manufacturers and distributors, that system is a platform that combines deep operational control with flexibility and data insight – like Fishbowl’s software.

From raw material to finished goods, Fishbowl provides inventory management software to help manufacturers at every stage of the production process. Founded in 2001, the company expanded its solution to the Asia-Pacific in 2011 and now supports around 600 companies with more than 5,000 employees across Australia, New Zealand, and SouthEast Asia.

As the company works across most industries, it is no stranger to the food and beverage sector. Having partnered with companies from dairy to meat, such as Pic’s Peanut Butter, Coyo, and Jimba Lamb, Fishbowl aims to address business challenges and fulfil their needs.

Owned by chief executive Simon West, Lick Ice Cream is a familyowned company supplying gourmet ice creams and sorbets in Australia, known for being the makers of the Ekka sundae.

“We have three retail stores here in Brisbane through to supermarket chains, independent supermarkets, fruit and veg retailers, restaurants, hotels, and convention centres,” said West.

With a diverse distribution network, the company found itself struggling to juggle its channel mix and complex

measurement can make or break a product, consistency is a must. This means improving manufacturing accuracy with precise tracking of ingredient weights. In addition to this, a large range of flavours in a brand’s portfolio presents an extra step. In Lick Ice Cream’s case, West needed visibility into margins by SKU to identify which products were performing well and which needed adjustment.

While industry giants push largescale automation, Lick Ice Cream has taken a strategic approach, focusing on efficiency and traceability through Fishbowl Inventory Management software. By connecting every stage of its operation through an integrated system, West said the company was able to achieve complete inventory visibility and control across its workflow.

“What Fishbowl gives us is full

control over our inventory system, from raw materials to finished products, ensuring accuracy and reducing waste throughout the process,” he said.

Fishbowl streamlined the team’s manufacturing orders, tracked batch numbers for traceability, and generated accurate picking lists that staff could trust. By ensuring quality data input from the start, particularly around ingredient receiving and batch tracking, the company has built a robust foundation for food safety compliance and operational efficiency.

This level of control has given the team confidence not only in compliance but also in margin analysis and inventory reporting.

“Fishbowl has saved us time and made us confident in our numbers, inventory control, traceability, and margins,” West added. “Now we are reporting accurately and have a robust system in place that will benefit us as we move into export markets.”

When asked if it was ever too late for businesses to adopt inventory management software, Jupe said that it is still possible; however, he urged the industry to make the shift quickly.

“Companies that adapt early and build their business around the process grow efficiently and can scale on those systems

over time,” he said.

While this is ideal, he highlighted that most under-adopt systemisation of their processes, allowing issues to accumulate until they reach a breaking point that triggers the need for an upgraded system.

Often, the warning signs are clear, such as spreadsheets that can no longer track batch numbers or production dates accurately, or staff spending excessive time reconciling data across departments. These inefficiencies can quickly compound, and by the time businesses decide to implement a system, the process is usually more complicated than it needs to be, requiring both a technology upgrade and substantial change management across the team.

For businesses looking to improve their systems, Jupe advised on the first step.

“Understand what your business growth model looks like,” he said. “You need a platform that’s going to cater to the business needs not just today, but many years down the track.”

While adopting new systems and facing changes in processes can appear daunting, Fishbowl’s approach is built around improving efficiencies. As mentioned, Jupe said that the phrase “no product in the world is perfect” also applies to Fishbowl. While technology is central to the company’s offering, he notes that its

service is the real differentiator.

“A bill is a bill, and an invoice is an invoice,” he said. “What makes or breaks long-term success is the service delivery that complements that product.”

A solution that works today may not be suitable for tomorrow. As technology continues to advance, inventory management in the food and beverage industry is likely to evolve. Yet even as these innovations

emerge, the fundamentals remain the same: businesses need accurate, accessible data and systems that support their people.

Understanding this, the company focuses on collaborating with its customers and assessing their growth journey, identifying gaps in skills or data visibility, and designing a rollout that aligns with their operations. Rather than just offering a product, Fishbowl also provides

ongoing training through videos, resources, or on-site sessions.

Training and integration are not just about learning software but about optimising the way a business runs.

The company views its relationships as long-term collaborations, helping customers adopt smarter processes

without losing the flexibility and creativity that define the food and beverage sector.

“Inventory is unique in every business,” Jupe said. “Fishbowl partners with and understands a company’s goals to enable a unique business approach.” F

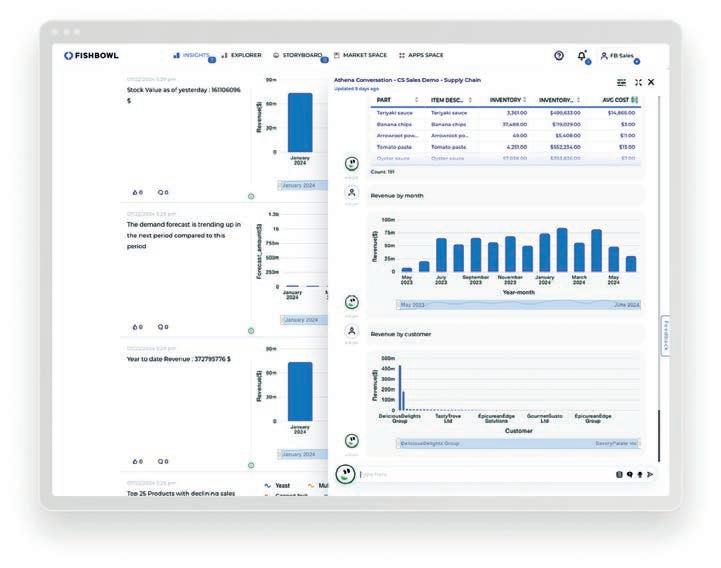

Trimatt is helping food and beverage manufacturers rethink packaging with sustainable printing, reduced inventory, and smarter warehouse management.

While packaging is the final touch for a product, it is also the first thing consumers notice.

Compare two identical gifts, but with a slight difference – one that is ribboned and one that is untouched. While both products serve the same function, the well-packaged gift feels more like a gift. Understanding this, brands across industries have leveraged packaging designs that can elevate their products to a premium feel.

But behind every label or printed surface lies an intricate process that connects sustainability, production efficiency, and cost control. In the food and beverage industry, where branding is imperative in a concentrated and competitive market, manufacturers find themselves struggling. Take inventory and waste for example. What happens to boxes filling up your warehouse, collecting dust and immobilised due to neglect for years? Answer: landfill.

According to Matt Johnson, founder of print and product automation technology supplier Trimatt Systems, Australian companies face a common challenge when it comes to packaging and branded materials.

“When food and beverage companies are looking to purchase branded materials, they are met with a high minimum order quantity (MOQ),” he said.

Businesses that require only 5,000 packaging materials have no choice but to purchase 50,000 to meet the MOQ. Travelling around and meeting businesses that have done this, Johnson has witnessed what happens to the remainder of unused material.

“If businesses have raw material in their warehouse that’s taking up space, they dump it to make more space,” Johnson added.

Additionally, with regulations and trends surrounding packaging, food manufacturers find it difficult

to make capacity to stay afloat. As a result, efficient and sustainable packaging solutions are hard to come by. The Melbourne-based equipment manufacturer aims to simplify that process while helping businesses minimise waste and improve operational flow through Trimatt’s ColourStar AQ V system.

For businesses packaging raw material into paper-based packaging, bulk orders are often the only option. Trimatt’s ColourStar AQ V eliminates the need to store and hold volumes of pre-printed stock while tightening packaging production processes. Johnson said the system’s name reflects its design.

“The ‘AQ’ stands for aqueous and ‘V’ meaning versatile,” he said.

The system prints directly onto paper-based packaging using waterproof and scratch-resistant inks. Its versatility comes from its

ability to print on a range of porous media types. It features an integrated friction feeder, adjustable receiving tray, over 100mm height-adjustable print head, and conveyor.

It gives businesses a digital printing solution with a speed of 27 metres per minute. By allowing them to print on demand, Trimatt helps cut down on unnecessary storage and reduce waste. Companies can produce what they need, when they need it.

“The majority of our packaging machines are targeted at short-run printing directly onto sustainable packaging,” added Johnson.

The just-in-time production model doesn’t just reduce material waste – it also supports broader sustainability goals.

Many food manufacturers previously relied on packaging shipped from overseas, sometimes from as far as China, adding freight emissions to

an already resource-intensive supply chain.

With Trimatt’s local printing solution, those businesses can now bring production closer to home, reducing their carbon footprint and supporting local suppliers. Additionally, businesses are catalysing this change as Johnson highlighted that the willingness to bring branding locally, within their own factory, is growing.

“Because you’re producing your branded products just in time, precisely what you need, there is minimum waste,” he said. “Trimatt’s been able to provide a solution for businesses looking to fulfil their own branding on a local level.”

The company’s strategic focus on building solutions around sustainable packaging aims to enable businesses to move away from plastics and towards recyclable and compostable substrates. For food and beverage producers, that represents a sustainable and practical step forward.

While sustainable efforts and saving storage are commendable, quality still trumps those benefits. The ColourStar AQ V offers improvements in operational efficiency. Printing directly onto packaging eliminates the need for

labels, separate design batches, and manual rework. The result is a cleaner, more streamlined workflow.

Adopting the technology, on the other hand, can be a challenge.

Trimatt assists manufacturers in two ways. First, Trimatt’s technology integrates with enterprise resource planning (ERP) systems such as SAP, allowing businesses to connect production data directly to their packaging output.

“By integrating with their ERP, it makes the workflow throughout their business smooth,” said Johnson.

By digitally printing directly onto the packaging, it removes the need for data re-entry – a challenge common in manual processes. Once the system is connected, production teams can monitor output, inventory, and batch details in real time. This integration ensures traceability from raw materials to finished goods.

Food and beverage manufacturers that must comply with strict traceability and labelling standards can ease the burden with this digital link without slowing production.

Second, the company offers training with a collaborative approach. Every machine is built in Melbourne, and once complete, customers are invited to the factory for in-person training. Trimatt’s team provides hands-on guidance to operators, followed by on-site support when

“The majority of our packaging machines are targeted at short-run printing directly onto sustainable packaging.”

the machinery is installed at the customer’s premises.

“We regularly go to the customer site and provide hands-on one-onone training and production support,” said Johnson. “It’s very consultative and extremely collaborative.”

The easily integrable technology, paired with technical support and training, provides an efficient and sustainable packaging model for businesses without compromising quality.

Trimatt’s clients range across industries from coffee, bakery, flour and medicinal. To help implement

solutions tailored for specific needs, collaboration is valuable when integrating with ERP systems, where fine adjustments often need to be made to align software, data flow, and reporting structures.

Supported by cloud-based systems that allow remote access and diagnostics, Trimatt can log in to a client’s equipment when needed to provide technical support or software updates, minimising downtime.

“The systems generally run within the customer’s operations and network, and operators can just handle the product, not the data,” he said.

This “hands-off” model is one reason Trimatt’s technology has been adopted by players including Vistaprint, which has undergone a successful 12-month installation of the ColourStar system.

In an environment where consumers and regulators alike are demanding transparency and sustainability, Trimatt’s innovation offers a clear advantage. By reducing waste, lowering inventory demands, and enabling on-demand production, it provides manufacturers with a practical pathway to smarter operations.

Through its technology, service, and collaboration, Trimatt shows that packaging can be both sustainable and efficient – a combination that’s fast becoming essential in the modern food and beverage landscape.

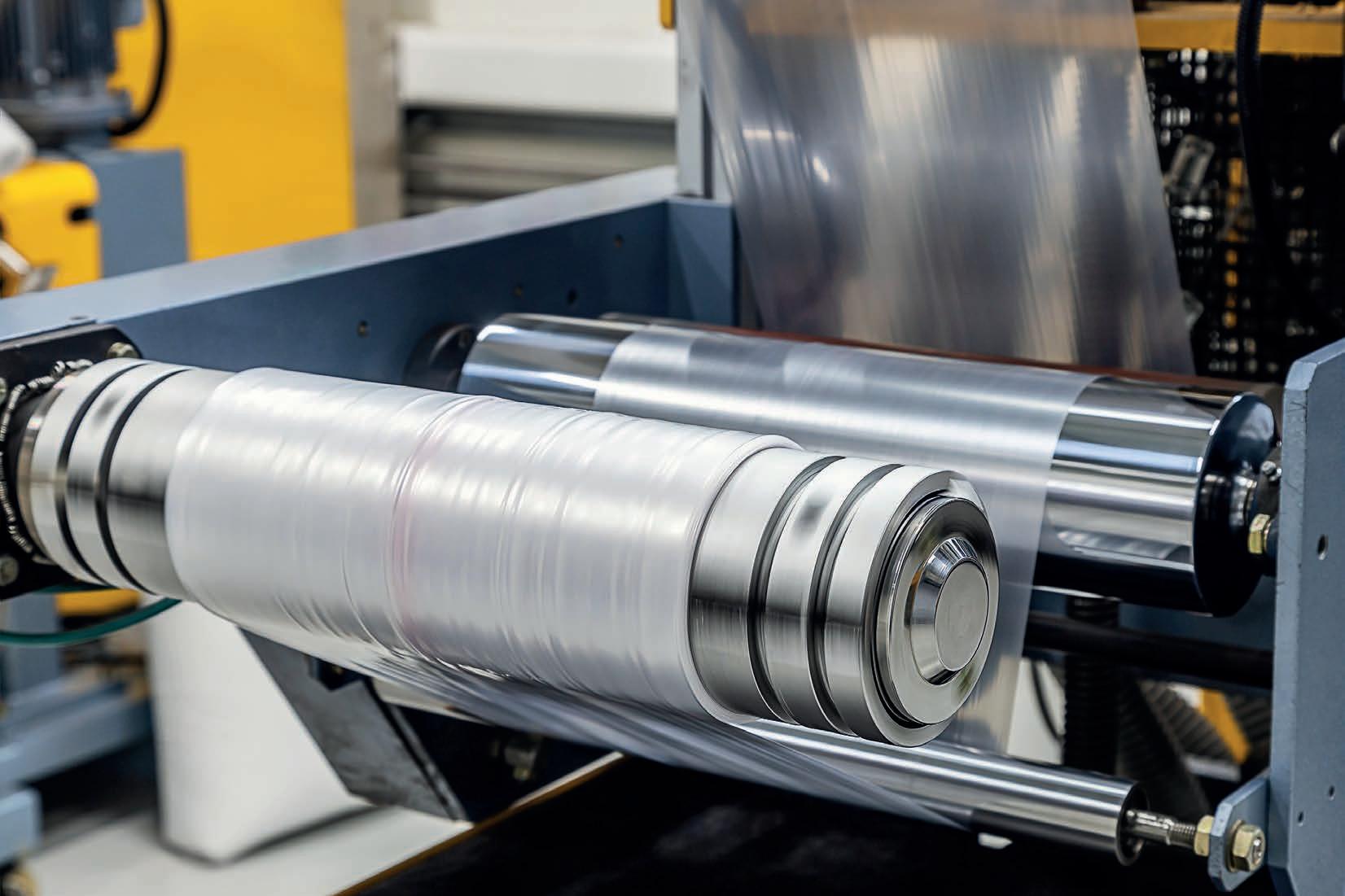

Flavourtech is transforming aroma recovery, extraction and evaporation solutions for the food and beverage industry supported by APS Industrial.

Founded in 1987, Flavourtech is a technology manufacturer specialising in aroma recovery, extraction, and evaporation solutions for the food and beverage, and pharmaceutical industries.

Located in the New South Wales Riverina region of Griffith, every piece of the company’s equipment is tailor-made and built in-house at their facility, working across tea and coffee through to dairy, pharmaceuticals, and more. Additionally, it exports to more than 60 countries around the world.

The Spinning Cone Column (SCC)

is its flagship product and offered in multiple sizes, these units are now used in the coffee industry globally. Other applications of the SCC are also being achieved in other industries such as fruit and vegetables, dairy, and pharmaceuticals.

Flavourtech is committed to balancing its production and delivery demands swiftly and efficiently while maintaining the quality it is well known for. With that front of mind, they recently delivered their first fully integrated Siemens solution with the support of APS Industrial.

The integrated solution from APS featured Siemens SIMATIC PLCs and SINAMICS G220 variable speed drives to streamline the manufacturing process. What used to take around eight hours in factory testing of its old package has been reduced to 45 minutes of factory automation time.

On top of this, Flavourtech also effectively utilised the online Weidmüller Configurator tool to achieve efficiency gains when building out their motor control centres.

“APS Industrial has helped our motor control switchgear evolve,” said electrical design technician Steve Warton, Flavourtech.

“Our efficiencies have been through the roof in terms of how quick we can actually design our Motor Control Centres and get them out onto the workshop floor and onto our pieces of equipment.”

All of this, housed in market leading, Rittal enclosure technology. With the backing of APS’ portfolio of products, Flavourtech can execute their mission to deliver turnkey bespoke equipment nationally and internationally.

More than ever, engineering processes must be completed with greater speed, precision and efficiency. This requires intelligent tools that provide optimum support for complex planning processes.

The Weidmüller Configurator (WMC) is a configuration tool for seamless and secure planning of electrical systems as well as simple procurement and assembly of complete solutions. This free software enables users to unlock their potential of automated production from paperless production all the way up to automatic manufacturing – in just one tool.

From wizards and assistants that enable users to design complete applications within a few clicks – even without detailed product knowledge, through to integrated interfaces that allow product data and further information to be easily transferred

“Our efficiencies have been through the roof in terms of how quick we can actually design our Motor Control Centres and get them out onto the workshop floor and onto our pieces of equipment.”

between the WMC and all common engineering tools – from start to finish, the Weidmüller Configurator offers extensive support in all stages of the configuration process.

At the core of APS Industrial’s value proposition to Australian industry are their exclusive national distribution agreements with the world’s leading industrial manufacturers – led by Siemens, Weidmüller and Rittal. This exclusive local access to market leading technology and products

makes APS Industrial a partner of choice for local food and beverage manufacturer’s like Flavoutech.

Whether it’s the new to market S7-1200 G2 PLCs or SIMATIC G220 variable speed drives, if there is a technology to be leveraged, a solution to be achieved, a competitive advantage to be gained, APS Industrial prides itself on its ability to support local business with locally stocked products backed by local support and expertise.

“The first time I came to Griffith and met the team here at Flavourtech and saw what they

were really about, I was blown away,” said state manager – NSW/QLD at APS Anthony Achermann. “We are immensely proud to be able to support their business.”

To help the food industry remain competitive and responsive to the demands of a rapidly evolving market, APS brings an innovative and collaborative energy to advance the sector.

“We see APS Industrial as more than a part supplier; we see the company as an engineering provider,” said Andrew Menegazzo, Australian operations manager at Flavourtech. “We want to keep innovating, and with APS Industrial involved, we know we can do this together.” F

For more information on this project story, including a video case study, please visit https://apsindustrial.com. au/integrated-siemens-solutions/

Industry connections and collaborations are key drivers in innovation. The food and beverage sector is not shy of them, especially since it is the most interconnected industry with complex supply chains. While innovations for higher outputs and business growth are invaluable, the industry can only remain resilient with catalysts that sustain it.

Take food waste as an example. Food waste in Australia holds serious environmental and economic consequences. A 2021 National Food Waste Strategy Feasibility Study found that Australians discard about 7.6 million tonnes of food across the supply chain each year. This costs the economy around $36.6 billion. Food waste contributes roughly 3 per cent of Australia’s annual greenhouse gas emissions and uses about 2,600 gigalitres of water to grow food that is ultimately thrown away.

The second largest contributors to food waste, other than households, come from agriculture and food production. The land used to produce this wasted food covers more than 25

million hectares. Australia’s National Food Waste Strategy has set a goal to halve the country’s food waste by 2030.

Recent years have seen a plethora of partnerships between brands and charity organisations to fight food waste and address food insecurity. It has also seen new innovations and growth projects that show potential to add value to food manufacturing. However, to catalyse innovations that serve the industry, a support system and guidance are required to bring ideas to fruition.

Understanding this is Food and Agribusiness Network (FAN), working to grow the industry by creating an ecosystem that supports collaboration, accelerates innovation, and drives trade locally and globally.

One of FAN’s focuses is on strengthening and streamlining connections across the food value chain. A way the organisation does this is through programs like Cluster Connect. Cluster Connect is the Industry Partner Organisation (IPO)

for the Australian government’s Industry Growth Program (IGP).

The IGP is for startups and businesses with high growth potential who want to transform and scale up with innovative projects. The program helps build Australian manufacturing capability with advisory services and grant opportunities.

Cluster Connect is powered by five Australian agrifood clusters – one of them being FAN – representing a network of more than 6,000 member businesses, stakeholders, and supporters. With a collective output value exceeding $10 billion, these clusters work together to provide tailored support, strategic connections, and programs to help food and agribusinesses innovate, grow, and achieve sustainable success.

Taking part in Cluster Connect is Pectin 360, founded by chief executive officer Martin Kaderavek. By converting fresh fruit waste into valuable ingredients, the company is pioneering advanced, energy-

assisted manufacturing to produce pectin and fibre in Australia.

Pectin is a natural gelling and thickening agent found in fruits. Traditionally, pectin is imported after undergoing long, high-temperature, and chemical-heavy processes overseas. The company is developing an energy-efficient process to extract pectin from local citrus and apple by-products. This creates a zero-waste, circular economy solution for food manufacturers that rely on these essential ingredients.

With a transformational extraction process that takes materially less time and energy compared to conventional methods, this approach not only reduces carbon impact but also supports local supply chains. Furthermore, Pectin 360 is looking to co-locate on a large-scale fruit waste generator’s site. This includes a large fruit juice manufacturing facility, taking the fresh fruit waste at the source and converting it into valuable ingredients for the food industry such as pectin, fruit dietary fibres and orange oil.

After making their submission for

the IGP, the process of being advised

Queensland-based GS Engineering, was also introduced to Cluster Connect through the IGP. In the food and beverage sector, he believes one of the biggest challenges is building the infrastructure and supply chains

delivers cleaner, faster, and more cost-effective results using less energy and space than traditional spray or freeze dryers. Capable of efficiently drying almost any organic material, the technology positions GS Engineering at the forefront of nextgeneration food drying solutions.

The IGP recognised the potential of GS Engineering’s driers and supported its inclusion as a technology with strong commercial and sustainability prospects.

Compared to rotary and spray dryers, the MPD dryer’s footprint is 60-80 per cent smaller while milling

simultaneously, eliminating the need for an extra mill.

With more than 40 years of industry experience backed by PhD studies in coal-fired power generation, Hayes said the innovation has been recognised and elevated through FAN’s network with experts and industry leaders. This is critical to the growth of Australian food and beverage manufacturing.

Hayes also sees strong value in collaboration between government and business, provided those involved can adapt quickly to changing conditions.

Growth at its core

Other SMEs supported through the program include Airiel Solutions, founded by Suzanne Kambuts. The company aims to help food and beverage manufacturers reduce emissions and improve sustainability through smart air-quality and energy management systems.

Second Squeeze, founded by Brent Beauchamp, turns surplus and imperfect produce into nutrient-rich juices and functional beverages.

Through Cluster Connect’s programs and partnerships, businesses are supported to grow sustainably by building commercial capability, driving innovation, expanding market access, and fostering strategic collaborations.

The program also assists companies in securing investment, navigating grants, and promoting well-being. This helps create strong, resilient, and future-ready workplaces.

Alongside Central Coast Industry Connect, FermenTasmania, Food and Fibre Gippsland, and Noongar Land Enterprise, Cluster Connect gives SMEs access to curated event delegations, capacity-building programs and workshops, and connections to facilities, stakeholders, and the wider agrifood ecosystem.

From waste-to-value technologies to smart manufacturing solutions, the program is driving innovation across Australia’s food and beverage sector. It is helping businesses tackle sustainability challenges, boost competitiveness, and create highvalue opportunities. F

Combining ingenuity and intelligence quotient (IQ), Krones presented Ingeniq at the recent drinktec 2025 exhibition in Munich, Germany.

Taking on the questions and requests of customers, this new concept line system is a data-based, automated line system, designed for filling non-carbonated water in PET containers. Krones calls it “the line of the future”. Translating the vision presented at drinktec 2022, the company has brought a line that blends low total cost of ownership with consistently high efficiency into reality.

Founded in 1951, Krones has evolved into a global technology group that provides tailored solutions for every stage of production. With over 20,000 employees worldwide, Krones has built a strong reputation in food and beverage manufacturing. It offers a range of solutions from standalone machines to integrated turnkey production lines. From container production, filling and packaging to recycling, the company

can provide solutions for individual components such as blow moulders, palletisers and fillers, or processing and packaging lines.

Ingeniq is an extension of the company’s commitment to support the sector. The system’s design is simplified and engineered with the customer’s success in mind. With easily navigable modular components that use robotics and artificial intelligence (AI), the system actively assumes joint responsibility with the customer for the life cycle.

Ingeniq is made up of three main components: the line itself, digital access with Connect and Secure software and hardware packages, and the Lifecycle Alliance partnership with the customer.

The system’s new digital automation architecture makes it possible to connect efficient individual machines within a line network and maximise automation.

Prefero, Krones’ preform system, features an injection moulder

designed as a hybrid machine with an electrical mould movement. With a lock-to-lock time of just 1.9 seconds (400 t), it includes an integrated energy recovery system, using up to 20 per cent less energy overall than conventional machines.

It includes a conveying and buffering system, the Prenexo, which ensures smooth and efficient material flows between the Prefero injection moulder and the Contiform stretch blow moulder. Through the Prenexo, the two machines can be block

synchronised for a more compact, efficient and flexible production line.

Additionally, when it comes to performance, the ErgoBloc L stands apart. The wet-end block achieves outputs of up to 100,000 containers per hour with a footprint that is up to 70 per cent smaller than a conventional line. Stretch blow moulding, labelling, filling and capping are made faster and simpler with AI and a direct connection to the autonomous material handling systems.

Ingeniq is built for efficiency. Through automated workflows, the Ingeniq line can automatically reload, prepare and splice label reels without any manual intervention from the operator.

The modular construction of the Ingeniq line provides the customer with flexible options that can deliver a variety of packaging configurations. For example, by including a Krones Variopac Pro packer, the customer can easily change packaging formats from shrink film to trays or wraparound cartons with ease. Connect and Secure allows existing systems to join Krones’ connected and remote digital world with 24/7 access to production data.

Krones takes a partnership-based approach by offering after-sales services, operator training, and access to spare parts through its online shop. Its local footprint is supported by a team of 20 service technicians across Australia and New Zealand, ensuring responsive and consistent support.

With the Lifecycle Alliance built into Ingeniq, it ensures that the intended level of line efficiency is reached through a joint effort. By increasing output and production reliability, reducing operational costs and downtimes, and providing dependable availability, the company offers modular service agreements and personal consultations.

The model shifts the traditional supplier and customer relationship into a more collaborative partnership, with both parties working together toward a shared goal. Based on trust, reliability and responsibility, the alliance forms a cooperative approach in which Krones and its customers jointly commit to achieving an agreed level of plant effectiveness.

While the company is starting with a version that fills non-carbonated water into PET containers, that is just the beginning. According to the company, additional container types and product categories will follow, with the next solution already in development for PET CSD.

All machines in an Ingeniq line are equipped with the enviro package, an inherent part of Krones’ product

development and services and a certified sustainability management system. By adopting smart energy and media analytics, which support full transparency about energy and media consumption, Krones aims to equip the beverage and food industry with future-oriented technologies that enable high-performance production while saving resources over many years.

The system influences the company’s product developments, services and solutions. Optimum consumption data about energy and media efficiency of both existing and new lines in breweries and beverage plants are part of Krones’ day-today tasks.

The enviro system evaluation process also makes it possible to check the ecological efficiency of processes performed on more than one machine, such as in process technology. The components for saving resources that are included in the machines are based on the latest developments and incorporate energy-efficient and media-efficient technologies.

According to Krones, Ingeniq is helpful for manufacturers of all sizes. For small- to mediumsized manufacturers that lack the resources to support efficiency, this is a scalable technology for sustainable growth.

The company’s short-term goal is to have a stable version for PET

still water, with the first line already in operation and 10 more in the pipeline. The long-term goal is to supply more than half of all lines as Ingeniq lines. With innovation at the core of its development and a focus on customer satisfaction, Krones continues to grow as a beverage and liquid food processing and packaging solutions provider. F

With advanced Form-Fill-Seal packaging technology, Esko Australia partners with Alfa Machine to deliver a sustainable solution.

No matter how successful or promising a product is, a business is never secure. For the food and beverage industry, packaging designs are changing rapidly. With impending government regulations and extended producer responsibility (EPR) programs entering the picture, the sector finds itself burdened and stuck on a blocked road, having to find complex solutions to meet evolving requirements and demands of product innovation.

Thankfully, Australian food and beverage businesses has always been keen on adopting new technologies and innovation to remain competitive and resilient. While their openness is key in driving the sector, there are companies behind the scenes that have been paving roads to help businesses navigate these challenges. As sustainability continues to shape the future of packaging, machinery suppliers are rethinking how products are designed, produced, and delivered.

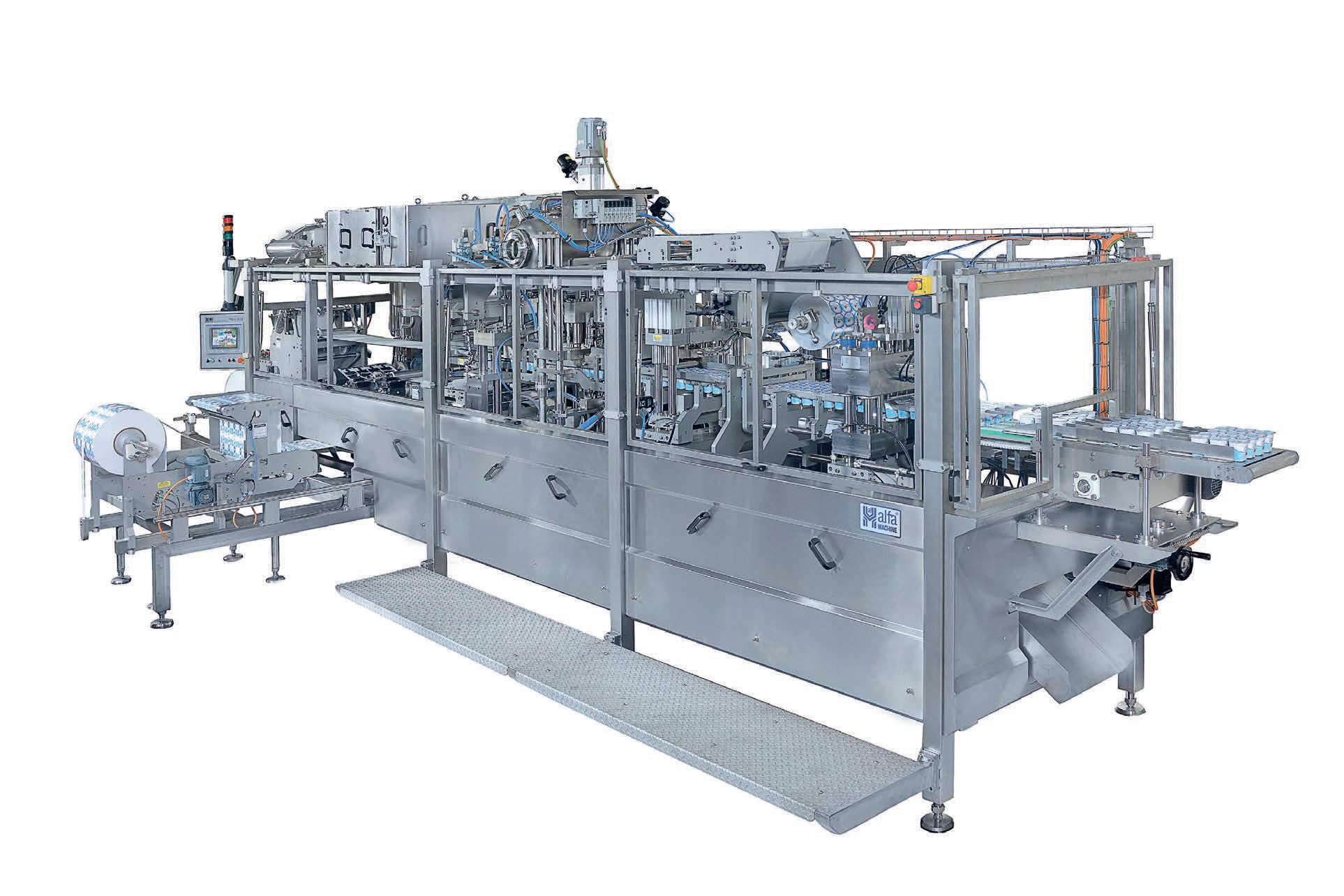

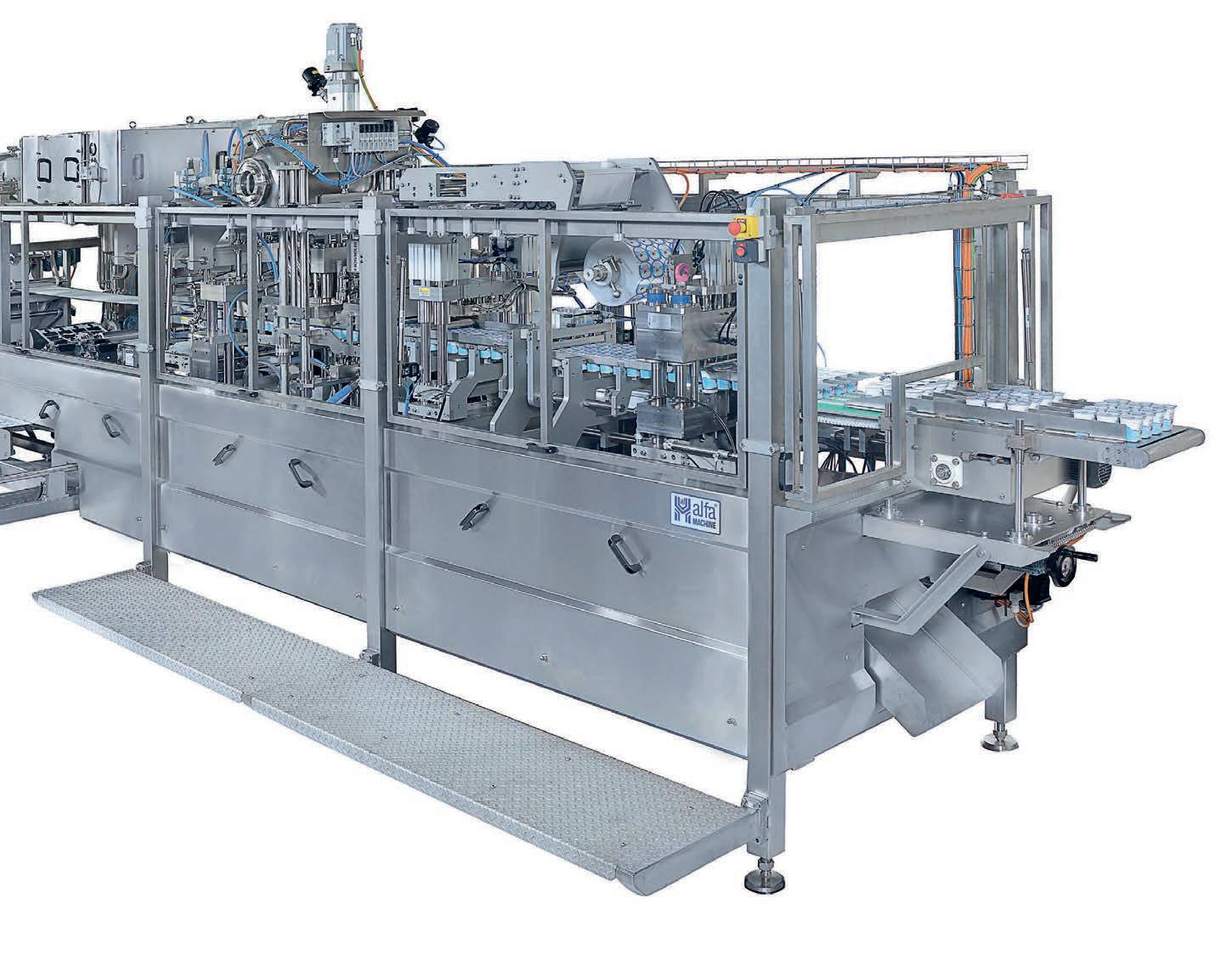

Among them is Esko Australia, a specialist in food and beverage manufacturing systems from processing, packaging, and handling. Partnering with Alfa Machine, a

Greece-based packaging machinery provider since 1983, the two aim to introduce advanced Form-Fill-Seal (FFS) technology for better and sustainable packaging results.

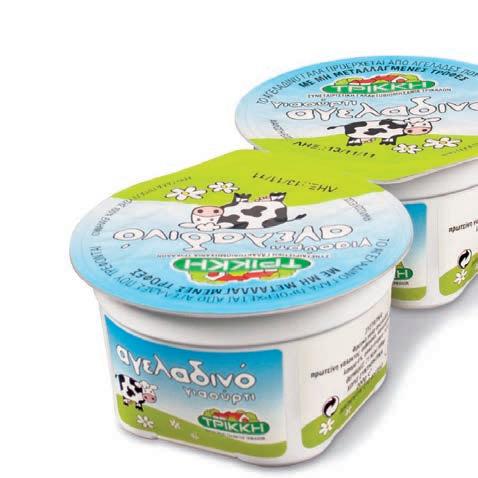

With more than 380 installations of packaging machines across the world and numerous IPs on packaging innovation, Alfa Machine brings extensive knowledge for the implementation of any packaging scope related to the famous Greek yogurt, dairy desserts, cream cheese, butter, sauces, jams, pastes, purees and many others.

With engineering expertise in manufacturing across different products and factories, business development manager at Esko Australia, JJ Wong joined the company three years ago to help with an imminent industry shift towards sustainability. This shift brought about by legislation to remove single use plastics towards more sustainable packaging creates an urgent need for equipment upgrades.

While this was meant to be delivered by 2026, it has been delayed due to the lack of sustainable solutions and the initial costs involved, slowing the

industry down. However, Wong said the delays are temporary and the industry will still undergo a gradual phasing in of the new regulations. He highlighted that the key to solving an issue is not about when it happens, but before it happens.

“The focus is about providing customers with the right equipment and design at the start, rather than fixing poorly selected equipment,” he said.

With early adoption of cleaner, more efficient systems, manufacturers will gain a competitive advantage when compliance deadlines eventually tighten. One of the ways businesses can safeguard operations is to make a head start on the sustainability shift with streamlined and cost-efficient packaging solutions.

Alfa Machine’s sustainable FFS technology is designed to produce and package goods in a single integrated line.

What does the process look like? As the name suggests, the FFS process is an automated and integrated system that involves three main steps – forming, filling, and sealing. Instead

of relying on pre-made containers or external packaging materials, the FFS machine forms the package directly from a roll of film, fills it with product, and seals it, all within a controlled and compact environment.

“The whole process is done in a very controlled environment,” said Wong. “From a food safety and hygiene perspective, it is an extremely efficient process of manufacturing.”

This system allows manufacturers to maintain high standards of hygiene and precision while reducing supply chain inefficiencies. The film used in the process is converted into the desired shape on the line, meaning fewer handling stages and less potential for contamination. Because the packaging is created, filled, and

sealed in one continuous process, it also delivers consistent quality and efficiency to every batch.

The Alfa Machine FRS-L series machine is specially designed to operate with polypropylene (PP) material with labelling. The integrated In-Mould Labelling (IML) system enables full body label application, utilising biaxially oriented polypropylene (BOPP) label from a reel. From cup material, label and lid, the use of PP material allows for sustainable packaging that is 100 per cent recyclable.

PP material is a versatile food packaging material, suitable for ambient temperature filling and hotfilling applications like cream cheese, fruit puree, and tomato paste with filling temperatures of up to 95°C. It is also appropriate for retort packaging applications with processed meat, vegetables, and wet pet food.

With servo-driven symmetric volumetric filling system, the same Alfa Machine FFS can produce different cup volumes up to 360ml

to high filling accuracy. Together with effective nozzles and closing valves, the Alfa Machine FFS ensure a drip-free filling process and sealing integrity.

from 316L stainless with options for CIP & SIP to ensure effective and reliable cleaning. The FRS-L is an Ultra-Clean hygienic version, a class IV according to VDMA standards. It uses a Clean-Air tunnel extended from the forming area up to the sealing station.

With Alfa Machine’s innovative cutting technology, it can produce standard D95 singles or multipacks (in groups of 2, 4, 6, and 8 cups per group) that can snap easily.

The equipment’s compact footprint makes it attractive to facilities seeking to maximise production space. By

combining multiple steps into one

“The cost savings of material storage, transport and handling over pre-made cups is often overlooked,” said Wong.

streamlined system, the FFS approach lowers operational costs and energy use, while improving throughput. This efficiency makes it suited to highvolume products such as sauces, dips, dairy goods, and ready-to-eat meals.

FFS is an automated and integrated system.

This technology is available for demonstration at Alfa Machine and will be on show at Interpack in May 2026.

A key aspect of Esko’s work is ensuring new machinery integrates seamlessly with existing production environments. Working in collaboration with the Customer, Esko and Alfa Machine, each solution is custom-built to match the specifications of the product and packaging design, from the volume to the decoration or branding of the final pack. This is achieved by the in-house design and manufacture of more than 95 per cent of the machine components giving to Alfa Machine the flexibility to integrate innovative solutions.

Each installation is tailored to the customer’s needs, whether that involves integrating the machine into a current line or designing a new process entirely.

“Esko understands Alfa Machine’s advantages to help customers learn these technologies and integrate them into their current processes,” said Wong.

With Alfa Machine’s FFS technology coupled with Esko’s engineering expertise, it is helping clients understand, adopt, and optimise complex systems. The partnership demonstrates how collaboration can accelerate the shift towards sustainable production.

Interest in the technology has been strong since it was showcased at FoodTech PackTech in New Zealand, where Alfa Machine’s FFS system was a finalist in the Sustainability Awards. Visitors to the Esko stand showed enthusiasm for the machine’s versatility and sustainability credentials. Many were keen to understand how the system could be adapted for their own product formats.

“It was a huge response,” he said. “Around 50 per cent of visitors to our stand were inquiring specifically about the Alfa FFS technology.”

Feedback from the event highlighted a growing appetite in the market for sustainable, high-efficiency machinery. With manufacturers increasingly seeking alternatives that reduce waste without compromising performance, Alfa Machine’s compact, controlled FFS process provides a tangible solution.

Working across the food and beverage sector for the past 20 years, Wong highlighted an important lesson.

“Have an open mind,” he said. With new regulations comes new technology. Wong mentioned it is impossible for businesses to be across new developments. Having an adaptable and flexible attitude goes a long way in verbalising a

desired output. A new discovery of a technology could be the turning point of the business.

Alfa Machine FFS technology offers an example of how packaging innovation can be both environmentally and economically sound. For Esko, the goal is to make such technologies accessible,

adaptable, and aligned with a more sustainable manufacturing future.

“At Esko Australia, we can reach out to our partner network to find the desired solutions specific to your business,” added Wong. F

www.eskoaust.com

www.alfamachine.gr

A new international position paper unpacks the food loss, waste and packaging, offering guidance and insights to help find workable, sustainable solutions.

Author Nerida Kelton FAIP, Executive Director AIP – Vice President Sustainability & Save Food – WPO

The United Nations Industrial Development Organisation (UNIDO), the World Packaging Organisation (WPO) and Wageningen University & Research have announced the global release of a collaborative position paper Navigating the Food Loss & Waste Paradox: Balancing Food Loss & Waste with Save Food Packaging.

The paper was co-authored by Eelke Westra (Wageningen University & Research), Nerida Kelton (World Packaging Organisation) and Aleksa Mirkovic (UNIDO).

This collaborative effort leverages the diverse expertise and perspectives of these institutions to provide a nuanced understanding of the complexities involved in achieving a sustainable and resilient global food system. By unravelling these intricacies, the team seek not only to inform, but to inspire actionable solutions that resonate across sectors, borders, and industries.

The Food & Packaging Waste Paradox position paper explores the complex interactions that exist between sustainability challenges posed by food loss and waste and the environmental impact of food packaging.

The purpose of this position paper is to explore the intricacies of the Food & Packaging Waste Paradox, delving into the challenges, opportunities, and potential solutions that lie at the intersection of Food Loss & Waste and Save Food Packaging.

First and foremost, the true role of packaging is its functionality. Packaging needs to be designed to ensure that a product is protected, preserved, contained and transported all the way through the value chain from production until it is used in the household.

Packaging also plays a vital role

in ensuring the health and safety of the products and consumers that product waste is kept to a minimum and the efficiency of the packaging can withstand the rigors of transport.

When re-designing packaging to meet global and local packaging waste and sustainability targets, the functionality cannot be ignored. ‘Sustainable Packaging’, in the simplest of terms, is packaging that performs the primary role of functionality, but is also designed with the lowest possible environmental impact when compared to an existing or conventional pack. Finding the balance between functionality, commercial reality, consumer demands, and environmental criteria is the real challenge for packaging technologists across the globe.

The challenge for packaging technologists is to be able to design optimum packaging with the lowest environmental impact at the start. It is about finding the balance between meeting food waste targets, at the

same time as achieving packaging waste targets.

If the balance is tipped either way, it will create unintended consequences that could see over packing (wasting packaging materials) or under packing (wasting food). Finding the perfect balance can be challenging and requires technical knowledge and understanding of packaging design.

Save Food Packaging is designed to minimise or prevent food waste from paddock to plate using innovative and intuitive design features that can contain and protect, preserve, extend shelf life, easily open and reseal, provide consumer convenience and portion control; all the while meeting global sustainable packaging targets (Francis, C., Kelton, N., Ryder, M., Lowenstern, B. Lockrey, S., Verghese.K, 2023)