CAT 100 YEARS

Australia’s Daracon has received a Special Edition Caterpillar backhoe painted in Cat Centennial Grey

Australia’s Daracon has received a Special Edition Caterpillar backhoe painted in Cat Centennial Grey

Daracon Group has joined Caterpillar in celebrating its centenary, welcoming a limited-edition Cat Centennial Grey backhoe from WesTrac.

Daracon divisional manager plant & transport Cory Hay says Caterpillar’s reputation mirrors the business principles that have guided Daracon throughout the past four decades.

“The Cat brand is synonymous with quality and efficiency, and that’s what we like to model our business upon –quality work, delivered efficiently, on time and on budget,” he says.

That alignment has underpinned a relationship stretching back decades, making it particularly fitting to secure one of just 25 commemorative backhoes produced worldwide.

“The battleship grey marks Caterpillar’s original brand colour,” WesTrac major accounts manager Kyle Morton says.

“This backhoe is number 15 of 25 produced, and we really wanted a customer like Daracon to get one.”

“We currently have about 10 backhoes in our fleet, and it came time to renew a couple of them,” Daracon plant manager Jason Jeffries says

“When the opportunity for a Cat 100-year backhoe came up, we jumped on it.”

The new machine will be put straight to work in the hands of long-term team member, Bruce Woodward.

“Caterpillar have always been

machinery collectors at this year’s Henty Machinery Field Days celebrated 100 years of Caterpillar

The 2025 edition of the Henty Machinery Field Days celebrated 100 years of Caterpillar at the vintage machinery site.

The Henty and District Antique Farm Machinery Club alongside special guest Surf to Summit Tractors Chapter 19 of the

Antique Caterpillar Machinery Owners Club in Australia came together to display a collection 16 vintage tractors, loaders and tractors with blade attachments.

The display by six members of Chapter 19 ranged from a 1928 Cat

(L to R) Jason Jeffries Daracon plant manager; Bruce Woodward Daracon plant operator; Kyle Morton WesTrac Cat major accounts manager

at the forefront of machine development, safety improvements and technology advancements,” Hay says.

“As the industry evolves, whether it’s through electrification, alternate power sources or autonomy, I’ve no doubt Caterpillar will continue leading the charge.”

As Caterpillar celebrates 100 years, Daracon looks forward to building on this partnership into the years ahead, continuing to invest in equipment that supports safe, efficient and reliable project delivery.

two-tonne crawler tractor up to a 1980 Cat 930 loader.

The crawler tractor was displayed next to a 2025 Cat 950 loader with Centenary Grey livery – a nod to the original battleship grey colour of the first Twenty crawler tractor to roll off the production line in 1925.

A competition to find the biggest Caterpillar fan was also held, in which collector Marty Turpin was awarded a limited-edition scale model of a 1925 Twenty tractor from Westrac Cat.

He has 14 Cat machines, including a working 1913 Russell grader which predates Caterpillar, a two-tonne crawler tractor and Twenty-Two model crawler tractors from the late 1930s, through to D2s, D4s and graders.

,

Construction has finished on Melbourne CBD’s first new train station in more than 40 years

Works have finished on Melbourne’s Town Hall Station, one of five new stations being built as part of the city’s Metro Tunnel, which will run from Sunbury to Cranbourne/ Pakenham.

The total space excavated for Town Hall Station, including the platform and concourse levels, was 260 metres long and up to 33 metres underground.

Each of the eight concourse columns are made up of a 7.5-metre concrete post plus three 6.5-metre steel branches extending to the ceiling of the station.

More than 7,000 cubic metres of concrete and more than 2,200 tonnes of steel were used to building the station’s internal structures.

Town Hall Station makes use of a ‘trinocular’ design of three overlapping tunnels at platform level, featuring a cathedral-like arched ceiling.

It also features 18-metre-wide platforms, which are among the widest underground metro platforms in the world. The station’s 18-metre-wide platforms are 220 metres long and 27 metres below street level.

Huge productivity boost with Komatsu’s latest excavator launch as PC950-11 reaches Australia

Komatsu has launched its latest hydraulic excavator, the PC950-11, in Australia.

Delivering up to 48 per cent greater productivity while using up to 40 per cent less fuel than its predecessor, the PC950-11 lowers cost per tonne and reduces emissions at a time when fuel costs and sustainability pressures are top of mind for operators.

Komatsu national business manager for construction excavators

Mark Boyes says customers have been asking for a machine that can move more tonnes, burn less fuel and keep operators safe and comfortable – exactly what the PC950-11 delivers.

“Our development teams took this customer feedback on board and delivered more power, increased dig forces, greater drawbar pull, superior durability, easy safe access and surround visibility systems, all while maintaining ultra-low fuel consumption,” Boyes says.

“It’s designed to handle Australia’s toughest conditions, while helping our customers run more efficient, sustainable operations, whether that be on mine sites or in quarry operations.”

Standard features like the KomVision 360-degree camera

The PC950-11 excavator has three work modes for improved productivity and fuel use. Image: Komatsu

system, hydraulic access stairway and wide catwalks improve site safety and make inspection tasks easier, says Komatsu.

Inside the cab, there is upgraded seating, climate control and intuitive controls for easier operation.

Boyes adds that thanks to its reinforced structures and durable components, the excavator is built to last in demanding quarrying and mining environments.

“Maintenance is simple and safe with ground-level refuelling, extended service intervals and longlife filters,” he says.

“This excavator is not just about power. Every feature has been designed with the operator in mind, from safety and comfort through to lower total cost of ownership. We believe the PC950-11 will quickly become the new benchmark for large-scale earthmoving in Australia.”

The PC950-11 has an operating weight of between 89,200kg and 99,800kg with a 405kW (543hp) engine and a bucket capacity of four to six cubic metres.

Volvo’s Next Generation articulated haulers bring cutting-edge technology to quarries, mines and civil projects

Volvo’s Next Generation articulated haulers continue the legacy of high level performance and durability in demanding applications

For decades, Volvo Construction Equipment has been the global benchmark for articulated hauling performance. From pioneering the very first articulated hauler in 1966 to delivering the largest capacity model on the market today, Volvo’s name has become synonymous with power, efficiency and durability.

Now, Volvo’s Next Generation articulated haulers – the A25, 30, 35, 40, 45, 50 and 60 – are redefining productivity and safety for Australia’s most demanding industries. From quarrying and civil construction to large-scale mining operations, these haulers bring together smarter design, cutting-edge technology

and operator focused comfort like never before.

For Australian businesses that depend on long-lasting machines and reliable support, the new lineup represents a major leap forward in how loads are transported, tracked and managed.

Every detail inside and out of the new hauler range emphasises endurance and ease of use. Volvo has re-engineered its chassis and suspension to reduce vibration, simplify servicing and extend durability under even the harshest site conditions.

The operator cab has also seen significant upgrades. Improved visibility through expansive window designs, a more ergonomic control layout and reduced cabin noise all contribute to a smoother, less fatiguing experience.

The air suspended seat and smart climate control support operators through long shifts, while intuitive controls and the digital display place vital machine data at their fingertips. Combined, these refinements transform daily operation –simplifying tasks, improving confidence and supporting sustained productivity throughout the workday.

Volvo’s Next Generation Haulers deliver measurable improvements in drivetrain efficiency, traction performance and payload capacity. Each model builds upon the brand’s decades of engineering excellence, balancing torque, speed and stability for different site conditions. Compact, responsive, and economical, the A25 and A35 models are perfect for mid-sized jobs or sites with constrained access. Both machines feature Volvo’s renowned all-wheel drive system with automatic traction control and 100 per cent differential locks, providing confident control across loose or uneven terrain.

These models are designed to keep fuel consumption low without compromising speed or gradient performance – key benefits when transporting materials efficiently between short hauls or mixed ground conditions.

At the upper end of the lineup, the A45G and A60H are built for those who demand maximum productivity from every load. The A45 carries up to 41 tonnes while maintaining class leading stability on inclines and uneven surfaces. The flagship A60, the largest articulated hauler on the global market, carries up to 55 tonnes with the same ease and agility of its smaller siblings.

Despite their size, these machines maintain balanced weight distribution and fast cycle times, ensuring more tonnes moved per hour – especially valuable in mining or high-volume quarry operations.

The standout introduction to Volvo’s latest generation is undeniably the A50. Positioned between the A45 and A60, the A50 offers a perfect balance of power and efficiency for operators needing extra capacity without stepping into the largest hauler class.

Under the hood, the A50 is equipped with a sophisticated Volvo engine optimised for low emissions and high torque delivery. Its smart load sensing hydraulics and automatic traction control ensure smooth movement under all load conditions.

The cab experience has also been taken to new heights with improved digital integration, enhanced visibility, and customisable operator settings. Volvo’s commitment to human centred design shines here – every function is built to boost operator confidence and reduce the learning curve for mixed fleets.

What sets the A50 apart, however, is its fuel efficiency. Through refined drivetrain tuning and intelligent load adapted control, the A50 can deliver exceptional performance per litre, lowering total operating costs while

Technology now plays a central role in maximising uptime and productivity, and Volvo’s Haul Assist platform leads the industry in digital site integration. This suite of tools connects directly with the hauler’s onboard sensors, giving operators and managers real time insights to optimise performance.

On Board Weighing (OBW) automatically measures payload per cycle, preventing under- or overloading and ensuring each haul is as efficient as possible.

Tyre Pressure Monitoring tracks individual wheel pressures, sending instant alerts to operators if levels drop below optimum thresholds –protecting uptime and reducing tyre wear.

Meanwhile, the map feature allows operators and site managers to visualise fleet movement across the jobsite in real time, improving coordination, reducing delays, and enhancing site safety. These connected systems transform the hauler from a simple transport machine into an intelligent productivity hub, helping entire fleets work smarter, not just harder.

Safety by design

Safety has always been a core Volvo principle, and this generation raises the standard yet again. The entire

range benefits from Volvo Smart View, a real time 360-degree camera system that eliminates blind spots and gives operators full awareness of surrounding activity.

Additional systems like Hill Assist, Rollover Protection, and Dynamic Stability give operators extra confidence, especially when navigating challenging grades or uneven terrain. Volvo’s hydraulic retarders and automatic downhill control ensure smoother braking and descent management, preventing excess wear and maintaining full control even with heavy loads.

Together, these systems don’t just safeguard people – they protect uptime, minimise unplanned downtime, and extend the lifespan of every component.

Sustainability and lower cost per tonne

Volvo’s engineering innovation also extends to its environmental footprint. Each Next Generation Hauler complies with the latest emissions standards while delivering improved fuel economy and performance consistency.

The use of Volvo’s Smart Power Management system allows the hauler to automatically balance power output with real operational needs, ensuring full engine efficiency only when required. This reduces fuel burn and extends service intervals, supporting greener performance without sacrificing muscle.

For owners and contractors alike, this translates into clear total cost of ownership benefits –fewer fuel stops, reduced servicing downtime, and a longer machine lifespan. Over a machine’s working life, that can mean significant savings while contributing to sustainability targets across civil, quarrying and mining projects.

Choosing the right hauler for the job

Every construction or mining operation demands a different balance between payload, ground conditions, and operating costs. Volvo’s latest lineup is built for flexibility, meaning there’s a purpose built solution for

every material handling challenge.

• A 25 and A35: ideal for medium haul distances, job sites with variable terrain, and sustainable fuel management.

• A45 and A50: the optimal mid to heavy duty performers for large infrastructure projects and high output quarries.

• A60: for the biggest haulage tasks where maximum payload capacity and consistent uptime are mission critical.

No matter the size or requirement, each model reflects Volvo’s DNA –robust, adaptable and easy to operate. CJD Equipment’s team of experts can help customers assess site conditions, job requirements, and production goals to determine the most cost effective configuration for their fleet.

Every Volvo articulated hauler sold in Australia is backed by CJD Equipment’s nationwide support network, delivering unmatched after sales service, technical expertise and genuine Volvo parts availability. From preventive maintenance programs to connected CareTrack monitoring, CJD ensures every hauler keeps performing at its peak. Whether you’re based in the Pilbara, regional Queensland, or the heart of New South Wales infrastructure projects, CJD’s technicians and

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

Komatsu’s new 24.5-tonne PC220LCi-12 excavator

Komatsu is resetting the playing field with its new PC220LCi-12 excavator – giving each operator the ability to customise the machine controls to suit their skills and style of working

At Komatsu’s Boots On showcase event in May the star of the show was the 24.5-tonne PC220LCi-12 excavator, sporting the next generation of intelligent machine control.

The first units of the new model arrived at the end of October and are now making their way to customers, but the dash 12 has already been generating interest with the Boots

On display unit travelling around Australia for customer demos.

“The machine is a gamechanger. We’re pretty much redefining what the standard is for excavators for the future,” Komatsu national business manager – construction excavators and mobile crushers

Mark Boyes says.

“We put a GoPro inside the demo

unit’s cab to record customer reactions and it’s been interesting to watch their faces as they experience the performance of the excavator, how comfortable it is, how quick it is to operate and the configurability.

“It still has the traditional Komatsu quality touch and feel, but with a lot more modern technology to support the modern operator.

“It’s been well received, and a lot of customers are seeing a lot of leverage that they can put into market, especially when we talk about some slightly higher risk work in and around obstructions, bridges, buildings, etc, whereby the technology will allow them to operate a little bit safer.”

There’s been a full top-to-track revamp of the dash 11 model, covering everything from cab size to customisation of controls, a new hydraulic system, repositioning of cab features and the latest generation of Komatsu’s intelligent machine control system.

The PC220LCi comes with a 129kW (172hp) engine and a bucket capacity of 0.5 to 0.93 cubic metres. A Productivity mode boosts productivity by 18 per cent compared with the PC210LC-11,

Up to 50 individual operator profiles can be programmed on the machine

while maintenance costs have been decreased by 20 per cent.

Boyes says the redesign was driven by ‘the voice of the customer’ – with requests for a more modern cab and greater functionality driving the changes.

“We looked at configurability not just for the cab, but also for our new hydraulics, which allows us to set the machine up for individual operators,” he says.

“This means we can now link the setup and configuration of the machine to an operator ID. This means they can set priorities, the speed of individual work equipment and also the responsiveness of the sticks to effectively suit their style.

“Some operators may want to have the dipper arm or the bucket be fast and the boom to be slow, for example, so we can configure individual work equipment movements to their skill set, but also application. In final trim work, we want it to be smooth, so we can tune the machine to do that.

“As it’s tied to the operator ID, this means operators aren’t having to reconfigure the machine every time they get in the cab. And this isn’t just for machine performance –they can also configure the buttons on the joysticks with a whole host of features.”

The cab is larger than the dash 11, with 30 per cent more leg room and 50 per cent more visibility. Boyes says the latter has been achieved by having more glass and repositioning the machine monitor screen from the corner of the cab to the seat.

“One big advantage of that is that all of the machine telemetry information is now within reach of the operator on the seat,” Boyes says.

“Regardless of their seating position, they can see engine hours, depth, fuel levels, machine health and hydraulic temperatures. They also get the KomVision there. So the first reaction coming in is not only is the cab ingress a lot bigger, you’ve got a lot more visibility inside the cab.”

The iMC 3.0 system brings new features to the market, such as 3D boundary control, tiltrotator integration and control, auto swing, swing-to-line, travel-along-line and an advanced payload meter.

The 3D boundary control improves operator safety by preventing the boom, arm or bucket from moving outside of a set boundary, to protect structures such as overhead wiring or buildings.

iMC 3.0 also includes auto-stop control, which stops the bucket edge on the design surface to stop over-digging past the desired grade, and auto grade assist, which

automatically raises the boom and bucket edge to accurately trace the design surface when grading.

Minimum distance control calculates the bucket’s nearest point to the design model to prevent deviation from the design and accidental damage to a surface, while auto-tilt control automatically adjusts the bucket edge for accurate grading on an angle. The operator can also automatically set the bucket grading or digging angle to ease final grading or trimming work.

While digging, iMC 3.0 automatically logs the lowest point of the bucket edge which is used to create an upto-date terrain surface which can be

A new hydraulics system helps reduce fuel use by 18 per cent on average

visualised on the Smart Construction Dashboard. Volume calculations can then be made to measure the volume of material moved in a day.

Boyes adds that the PC220LCi-12 and PC220LC-12 base version now come with 2D machine control.

“This allows the operator to set a grade point with the bucket so that they can cut either flat or dual grade surfaces,” he says.

“But it’s not just indicated, it is machine control, so you’ve got the benefit of the automation and the machine itself will control the bucket angle as well as the boom lift, so that when you engage the surface, it will prevent you from over-excavating.”

Another change on the dash 12 is a new hydraulics system, with

pressure proportional control (PPC) replaced with an electro-hydraulic system. Boyes says a key advantage of using electric control is that it allows for the configuration to specific operator preferences, but it also means an on average 18 per cent reduction in fuel usage.

“This is due to the way that it manages the oil flow in and around the bucket and the boom cylinders,” he says.

“It regenerates the oil when it is relaxing, so you’re not actually dumping oil back to tank, which also increases response speed because if the oil is already there in the circuit on the cylinder, when the operator does input on the lever, they get a very fast reaction, rather than having to stroke the pump up and then put oil back into the circuit.”

Later this year, an additional feature will be released that will be a major bonus for operators using the PC220LCi-12 to dig trenches.

“We will be releasing our new swing to line and track to line functionality, to effectively automate the trenching process,” Boyes says.

“The swing to line means that with a 3D polyline in the machine control system, we can lock the slew so that when it swings back to that line, it sets alignment for the trench.

“We can set an automated dump location, and then when we start to track back or forward on that trench string, it’ll automatically steer the excavator as well.”

For more information, visit: www.komatsu.com.au

Tilly’s launches new excavator pull and push stick rake for dual-direction operation

Tilly’s Crawler Parts has added a new dimension to its attachment line-up with the release of the pull and push stick rake, designed for improved efficiency in land clearing and vegetation management.

The innovation lies in its dualdirection capability, which allows operators to both push and pull during clearing operations.

Where traditional stick rakes are limited to one-way use, this attachment’s two-way motion gives operators greater control over material handling. By cutting down on repeated passes and machine repositioning, downtime is reduced and productivity increased.

The new rake is intended to simplify the management of vegetation, sticks and debris. Its manoeuvrability supports faster sorting and clearing, while maintaining ease of use for operators at all experience levels.

For contractors managing large-scale projects or farmers maintaining property boundaries,

the ability to switch seamlessly between pushing and pulling translates into practical time savings.

As one operator noted during early use: “The dual-direction saves us time every day on site – it’s a simple change that makes a big difference.”

Developed for versatility, the pull and push stick rake is suitable for:

• land clearing

• vegetation management

• stick and debris raking

• firebreak preparation

• a gricultural and civil projects.

As with the wider Tilly’s attachment range, the new stick rake has been built to handle tough operating conditions. Constructed from heavy-duty materials and engineered for longevity, it is designed to perform reliably across applications in forestry, agriculture and civil construction.

To accommodate different project requirements, the rake is available in 2,000mm and 2,750mm widths, compatible with 20-tonne and 30tonne excavators.

With land clearing, vegetation control and firebreak preparation continuing to be critical tasks across multiple sectors, equipment innovation remains a priority. Tilly’s introduction of the pull and push stick rake responds directly to operator demand for attachments that combine functionality, efficiency and reliability.

By providing a tool that reduces time on site while improving control and versatility, the new attachment underscores how incremental design changes can deliver significant gains in day-to-day operations.

The pull and push stick rake joins an expanding portfolio of excavator attachments supplied by Tilly’s Crawler Parts across Australia and New Zealand. The company’s offering includes rippers, grabs, compaction wheels, hydraulic thumbs and other rakes, all developed to deliver durability and efficiency for contractors and operators.

For more information on the Tilly’s attachment range, visit: www.tillys.com.au

Proudly backed nationally by Toyota Material Handling, Takeuchi mini excavators are rugged, dependable, and productive. They provide exceptional value and outstanding performance, measured by their longevity in the field.

And right now there’s never been a better time to buy a Takeuchi, with our super low 1.69% finance rate for up to 48 months available on new Takeuchi TB210R, TB217R, TB216, TB225 and TB325R models.To dig out a great deal contact Toyota Material Handling today.

*1.69% finance offer is based on a chattel mortgage on 12, 24, 36 or 48 month term no balloon, minimum upfront deposit equivalent to 10% of the purchase price including GST on new Takeuchi TB210R, TB217R, TB216, TB225 and TB325R models. Standard hitch and buckets included. Other interest rates may apply depending on loan structure, accessories and or attachments financed. Credit provided by MKP Finance ABN 56 611 706 784 to approved Australian business applicants only (GST registered). Offer valid on orders from 01/09/2025 while stock lasts. Finance must be settled with equipment delivered to customers before 28/02/2026.Toyota Material Handling Australia Pty Limited and, or MKP Finance reserves the right to change, extend or withdraw any offer at any time. Terms, conditions, fees and charges apply. Offers subject to change without notice and whilst stocks last. Images used for illustration purposes only and not indicative of Takeuchi models available. For more information contact your Toyota Material Handling branch.

Simex’s GEN II ART 1000 cold in situ asphalt recycler will soon be launched on the Australian market

At Bauma 2025 the new version of ART 1000, the patented technology developed by Simex for in-situ regeneration of deteriorated asphalt, was presented in its latest GEN II version.

Simex ART is an innovative technology that focuses on surfacelevel interventions for the functional recovery of road deterioration. It does not require the removal of milled material or the addition of virgin bituminous mix, instead utilising only the existing on-site material. This cuts down on road closure time, with the surface immediately usable after restoration.

During the milling phase, the equipment uses an eco-friendly chemical rejuvenator to cold-recycle the bituminous aggregate produced. Specifically, ART consists of two drums: the first for milling and mixing, and the second for crushing and disintegration.

In its working phase, the ART 1000

combines the following processes:

• m illing of the deteriorated road section

• controlled injection of rejuvenators proportional to the working depth and the carrier’s speed

• reduction of the milled material to the correct grain size

• fi nal mixing to create the recycled bituminous mix ready for compaction.

After regeneration, the bituminous mix is deposited directly into the milled track and is ready to be levelled and compacted with a roller or vibrating plate.

It should also be noted that, as in the case of repairs after the installation of fibre optics, the presence of cement mortars in limited proportions compared to the total volume of milled asphalt does not compromise the success of the final restoration.

“In addition to the logistical

Asphalt can be milled and recycled on-site, for quicker road repairs

advantages on-site and in terms of traffic flow, the ART 1000 technology offers other key benefits,” Queensland Rock Breakers sales manager Peter Muirhead says.

“The costs associated with the purchase and transport of new raw materials is lower, as you are exclusively using the bituminous mix available on-site.

“There’s also the environmental sustainability aspect, because you are recovering and reusing material rather than bringing in new materials, which also cuts down on truck movements as the old material doesn’t need carting off site and disposed of.

“Finally, it’s fast and durable, so road repairs can be undertaken more quickly which helps with planning.”

Over the past year, Simex has enhanced the onboard electronics of

Asphalt before and after repair with the Simex ART 1000

the ART 1000 to better meet the daily needs of road construction sites.

The onboard electronics have been further developed with the addition of a new video interface to improve connectivity between the operator and the ART 1000 technology. This interface displays real-time values such as linear metres (progress), litres per metre (additive dosage), and actual litres (additive consumption). It is possible to manually set a precise amount of rejuvenator (with a sensitivity of 0.1L/min) according to the manufacturer’s specifications and the site’s environmental conditions. The Simex software calibrates and adjusts the rejuvenator dosage according to the change in the carrier’s speed, based on parameters entered by the operator at the start of the job.

The control display is paired with an LED indicator installed above the equipment in an ergonomic position, making it easy for the operator to monitor and ensure the correct speed for effective material mixing.

The eight-LED light scale gradually lights up: the first two indicate a speed that is too low, and the last two indicate a speed that is too high. The middle range, highlighted in green, suggests the ideal speed for proper regeneration of the milled material.

The 100-litre rear tank is now removable from the side, and thanks to a drainage cap located at the bottom, it can be easily emptied if necessary. Additionally, the lateral movement of the tank allows access to the second drum compartment (crusher) from above, for cleaning and maintenance.

The grille that determines the correct grain size of the material exiting under the second drum is also easily removable from the side for proper maintenance and cleaning at the end of the day. The removable

tank and grille have been designed to ensure safe and easy access to the crusher drum of the equipment.

Contact your local SIMEX dealer to learn more. Authorised SIMEX dealers in Australia are:

• Walkers Hammers (VIC, SA, TAS), walkershammers.com.au

• Groundtec (NSW), groundtec. com.au

• QLD Rock Breakers (QLD and NT), rdw.com.au/qld-rock-breakers

• Total Rockbreaking Solutions (WA), totalrockbreaking.com.au

A Victorian builder has found Jetland loading ramps to be the perfect solution for moving its machinery safely across the hilly and steep terrain of the Great Ocean Road

Construction of new residential properties and home renovations on Victoria’s Great Ocean Road present challenges due to the region’s hilly and steep terrain.

Moving machinery on and off building sites can be difficult because of the unstable ground and the unpredictable weather.

Heath Armstrong, one of the partners of building company Sam I Am Building, is no stranger to the tasks involved.

“We have a six-tonne UHI UME-60 excavator that we use for many different jobs such as inserting

screw piling and trenching,” he says.

“We also build using structural insulated panels, where a fork attachment lets us lift panels for second-storey levels.

“The excavator is often required on multiple active construction sites. This means that we need to move the excavator between tasks. At other times, the excavator is used on an agricultural property for tasks such as clearing dams.

“In the early days of the business, we hired excavators and this experience taught us what was needed for safe and efficient

Armstrong moves his equipment effortlessly, thanks to the strength of the Jetland ramps

operation. As the business grew, it made sense to invest in our own excavator and we wanted to ensure we had the best ramps that would give us safety and stability.”

The area in which the business works is typically hilly coastal terrain.

“We’re often working on steep slopes. This means that loading and unloading the excavator can be quite tricky at times,” Armstrong says.

“Very steep hills means you have to take many precautions in setting up for loading and unloading.

“Even though the excavator has rubber tracks, which makes it a bit more stable for loading, you still have to take a lot of care in ensuring that the ramps are positioned with care.

“As these were our first ramp purchase, we put in a considerable amount of time and effort into finding out what was available and which ramps would best suit our application.

“We investigated the best types of loading ramps which would suit our purpose and found Jetland loading ramps would be the best solution.

“We were confident in purchasing our Jetland ramps as this supplier had obviously invested heavily in the design and engineering based on global best practice. The ramps are robust and well-constructed.

“We were impressed by their design features and components that give them their outstanding strength, such as the lip that connects to the back of the truck running down through main structure is all in one piece, so it’s stronger and improves the longevity of the ramps.”

Armstrong adds he could not be happier at the choice.

“Jetland ramps are truly awesome in their performance. The ramps are stable during machine loading and

The ramps (left) are stable during machine loading and unloading, ensuring high levels of safety (below left). The loading ramp is being used to move Sam I Am Building’s excavator in and out of building sites

unloading and this gives the operator great confidence as far as safety is concerned,” he says.

“The main criteria for selection of loading ramps were their strength, longevity and versatility. The balance between quality and weight of the Jetland ramps is ideal for the machine size, while their 3.9 metre length creates a lower operating angle for high stability throughout the machine loading and unloading operation.

“You can see immediately that the ramps are very well built and do not move when the excavator is coming up and down.

“The ramps are given plenty of use as we currently have three active building sites where the excavator is being moved in and out. The ramps are very stable and there is no movement when the machine is being loaded and unloaded.

“Jetland ramps are sufficiently light to be able to be handled by one person but at the same time they have the strength that we need. It’s also great they have been designed to slide easily onto the tray of the truck that is used for transporting the excavator.”

Armstrong says Jetland ramps gave the ideal balance between rigidity, quality and weight.

“The excavator is used with a flatbed truck and when loading and unloading, the excavator and ramps are very stable and do not move under load,” he says.

“We were also impressed with Jetland Ramps’ 12-month warranty and their free Australia-wide shipping that made our ramp purchase process free of any hassles.”

For further information about the full range of Jetland loading ramps, visit www.jetlandramps.com.au

CATERPILLARD5K2XL 2019,4,500hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrservice,workshopreport..S1201. TA1225199. $249,900plusGST

CATERPILLARD8RSERIES2 2003,11,500hrs, SUtilt,CAT4Cylinderripper,servicedwith workshopreport.S1197. TA1225194. $369,900plusGST

CATERPILLAR259D3 2021,1,850hrs,4in1 bucket,250hrservice,verygoodtracks..S1200. TA1225198. $94,900plusGST

KOMATSUD61EX 2018,5,800hrs,6wayblade, MSripper,TopConwired.S1067. TA1163362. $309,900plusGST

CATERPILLARD5K2XL 2018,2018 CATERPILLARD5K2XL233.233. TA1166133. $258,390inc.GST

CATERPILLAR12M3 2015,2015 CATERPILLAR 12M3239.239. TA1166139. $362,890inc.GST

CATERPILLAR12M3 2016,Graderwith4,950hours. 14ftblade,joysticksteering,Autoshift,Lightpackage, soldwithMSripperandpushblock.This12M3Grader willbesoldclean,detailedandservicedwithour comprehensiveworkshopreport.S1013. TA1139678.

CATERPILLARD6K2XL 2017,4,900hrs, VPAT, AROwired,sweeps,screensandMS ripper. 250hrserviceandworkshopreport..S1199. TA1225197. $269,900plusGST

KOMATSUD39EX-24 2021,1,200hrs,6wayblade, 95HP,MSripper,suitnewbuyer.ThisD39EX-24willbe soldclean,detailedandservicedwithour comprehensiveworkshopreport..S1108. TA1173489. $274,890IncludingGST

JOHNDEERE450K 1400hrs,6wayblade, sweeps,screensandMSrippertobefitted. S1063. TA1163359. $229,900plusGST

CATERPILLARD6TLGP 2017,6,590hrs,ARO wired,6wayblade,tankguarding,Conventional undercarriage,rearscreen.Soldwith250hr serviceandworkshopreport.S1165. TA1198871. $419,000plusGST

CATERPILLARD6TXL 7,150hrs,VPAT,ARO wired,nextgenMSripper,goodU/C.Soldwith 250hrserviceandworkshopreport.S1198. TA1225196. $439,900plusGST

The new ADT models all feature Dynamic Roll Protection and Stability Assist

Four new Cat articulated dump truck models are now available in Australia, with a wide range of added features to aid safe and efficient operation

Caterpillar has announced the release of what it says is a smarter articulated truck design with builtin automatic features for the next generation Cat 725, 730, 730 EJ and 735 models.

Offering maximum payloads of 24 to 32 tonnes, the range brings in a suite of assisted and automatic features to improve efficiency and convenience for operators.

Now open for dealer orders, all four new models are powered by a new Cat 13A engine.

The smallest in the range, the 725 has a 257kW (345hp) net power and a 24-tonne rated payload with a heaped capacity of 15.3 cubic metres.

The 274kW (367hp) 730 model comes in an EJ variant that has an ejector body. The standard model has a 28-tonne payload and 17 cubic metre heaped capacity, while the EJ version has a 27.1-tonne payload and heaped capacity of 16.9 cubic metres.

The Cat 730 EJ ejects the load without raising the body to help maintain machine stability. This design allows load dispersal on inclines, side slopes and in very soft underfoot conditions like those found on landfill sites.

Virtually eliminating material sticking to the body to increase productivity, the truck can eject

in areas with low overhead clearance, such as around overhead lines or in tunnelling and underground operations.

Delivering faster cycle times, the versatile 730 EJ can eject and spread material on the go to reduce the need for additional spreading and dozing equipment.

The largest of the new models, the 735 has a net power of 298kW (400hp) and a 32-tonne payload, with a heaped capacity of 20 cubic metres.

The new models feature an upgraded body design that Caterpillar says offers easier loading and a maximised payload.

The redesigned body features a rerouted exhaust heat system that helps minimise material carryback,

improving load efficiency and reducing cleanup time.

An upgraded interior provides access to all functions through a touchscreen or keypad, with the touchscreen also able to be navigated using an integrated jog dial. New push-to-start with operator ID stores up to 50 operator IDs to quickly get to work and safeguard against unauthorised use.

Requiring no operator input, advanced automatic traction control prevents wheel slippage in poor underfoot conditions for maximum traction and productivity. The new engine overspeed control works with Automatic Retarder Control (ARC) to

manage braking and automatically adjust engine speed.

Machine speed limiting supports safe operation by allowing ground speed to be set by the operator or in service mode – ideal for uneven terrain, high-traffic areas, or sites with strict speed regulations. Additionally, the integrated body height limiter promotes safety by helping ensure the machine operates within jobsite standards and height restrictions.

Improved payload technology allows operators to view real-time load weights on the integrated display, and the system’s updated software and sensors provide accurate data. External payload indicator lights alert the loading operator when approaching rated payload and when payload is reached.

The new ADT models all feature Dynamic Roll Protection alongside Stability Assist to prevent hoisting on uneven terrain and rollovers of the truck.

Configurable to material and jobsite conditions, this new feature monitors conditions to detect when the truck is experiencing high lateral acceleration, provides a visual and audible alarm, reduces fuel and applies service brakes automatically. This reduces the risk of machine rollover due to high-speed cornering. Additionally, Stability Assist software reports information via VisionLink to increase awareness of when an event has occurred.

Reducing operator fatigue, the new Auto Wait Brake (AWB) automatically applies service brakes when the shift lever is in any position other than park and ground speed reaches 0km/h.

The service brakes apply in less than one second after the machine has stopped, and, after eight seconds, the transmission shifts to neutral with AWB engaging. Simply applying the throttle re-engages the transmission and releases the service brakes. This feature also works with the machine’s Hill Assist, by applying the service brakes, preventing rollback.

A new dump body height limit feature for 725, 730 and 735 models allows the bed raise height to be set to meet jobsite conditions. The operator can quickly set the raise height limit by raising the bed to the desired height and holding a button on the keypad. Alternatively, it can be set through the display service mode to meet site-wide limits. This feature helps prevent the dump body from contacting overhead objects and increases cycle time by limiting fullbody travel.

Providing front and rear proximity detection, all next generation articulated trucks offer an optional object detect and multiview camera

The 725 has a 24-tonne rated payload with a heaped capacity of 15.3 cubic metres

via a separate secondary monitor. The system’s radar sensors, mounted fore and aft, provide visual and audible alerts when objects are within the truck’s travel path. Four camera views, that are configurable to the operator’s preference, are mounted at the front, rear and sides in order to enhance the operator’s view around the truck.

An onboard, optional interactive training tool, Operator Coaching, is available on the new models, which measures and reports on individual operator behaviours across 14 areas that impact efficiency, safety and machine health.

Caterpillar senior product consultant – load and haul Noel Sabandal says that this new feature can have a significant positive impact for operators by providing training and assistance.

“The Operator Coaching identifies opportunities to improve operating behaviour, by monitoring areas that can increase performance, reduce repair costs and decrease fatigue,” Sabandal says.

“Experienced operators take the coaching features positively. For new operators, the features support and accelerate learning curve and drive positive behaviour.”

Tips can be viewed on a summary page on the main touchscreen display, while animated video tutorials provide operator instructions. For fleet managers, the GPS function includes maps to show the location of where tips are triggered on the work cycle.

IMS have added the new BP1200-48TB track electric twin power blender to its impressive collection of ed hopper each five meters long holding and controlled by a PLC control and recording system that can be operated from an iPad or phone from its own Wi-Fi system from a loader or ll fitted with invertors offering variable speed to each feed hopper conveyor. The generator can be connected to mains power and could power an

Scalping Screen with a 10 x 4 two deck screen producing three products on high rise tracks

Price $227,000 Plus GST

New IMS-MC1050-14TF

Track Conveyor with a five-meter-long feed hopper with a hydraulic remotecontrol tipping gride

Price $244,000 Plus

offered Braeside fines into roadbase to make spec or ol and CTB. The PLC control and recording system

Used 2021 & 2022 Rubble Master

Three deck screens in good condition – 18x5 & 22x5

Price $295,000 Plus GST

Jaw Crusher with a single deck screen producing two finished products. Diesel electric which is very

and only uses

The new Diamond Mowers Drum Mulcher Pro X2 is now available Down Under

Diamond Mowers is leading the way with its new Drum Mulcher Pro X2, which is now available through Australian distributor Colbrook Industries.

Developed in direct collaboration with mulching contractors and land management professionals, this next-generation attachment is available in open drum (OD) and depth control (DC) profiles. Diamond Mowers says it offers a host of user-friendly enhancements to maximise efficiency, durability, and operator control.

The new Pro X2 was on display for the first time at Elmore Field Days, with Colbrook Industries business development manager Hayley Plageman saying that it is a great addition to the Diamond Mowers range.

“The previous model is an absolute weapon of a machine, and our customers have been running it on a vast array of skid steers, so this mulcher can be pushed into the hardest conditions and still perform,” she says.

“This new drum has the same bearings and motor, etc because it’s

really proven itself, particularly here in Australia. So the upgrades are subtle improvements that enhance an already fantastic mulcher.”

The new Drum Mulcher Pro X2 has been designed with superior stability, improved sightlines and greater control, providing operators with greater precision.

The motor-high profile positions components closer to the carrier, improving the centre of gravity and weight distribution for machine balance. This intentional chassis design also affords easier manoeuvrability, reducing fatigue and allowing for longer, more comfortable operation.

To optimise sightlines for operators, Diamond Mowers has minimised the motor cover height and reconfigured the hose routing. It is also offering multiple hose lengths with the Pro X2 to accommodate different carriers and configurations.

“They’ve brought the drum closer to the carrier, so the weight’s not as far out the front,” Plageman says.

“Skid seeds weren’t traditionally

built to have big attachments on the front, they were built to have a bucket up close. So, with this being a skid steer drum mulcher, they’ve brought it back much closer to the machine to help balance the weight.

There is now the option for a door, which helps control the trajectory of the mulch, a pressure gauge and an emergency brake.

“Traditionally you wouldn’t have a brake, you would just run onto a stump or something to stop the drum running, so this is an added safety feature in case you need to get out of the machine in a hurry,” Plageman says.

“The option of a door came from customer feedback where they are working on roadsides for example and want more control over where the mulch is coming out of the machine.”

The Pro X2 comes with either a 60-inch or 72-inch cutting width –with power to process material up to nine inches in diameter.

A redesigned push bar means serrated edges improve debris manipulation, giving operators better control over material,

while an optimised infeed increases the efficiency of cutting and process material.

For increased operator safety, treads have been added to specific spots on the drum provide secure footing while climbing in and out of the carrier – reducing the risk of slipping.

An integrated toolbox also keeps essential tools like chains, grease guns, spare teeth, and more within reach, enhancing convenience and minimising downtime.

The Pro X2 comes in both open drum (OD) and depth control (DC) profiles. The DC model comes standard with the company’s proprietary Edge hardened steel teeth, which have taller ‘paddles’ to ingest more material for a more comprehensive and cleaner mulch on the first pass.

The OD model comes with Twin Maul carbide teeth, which are ideally suited for heavy ground engagement and rugged terrain.

Both platforms can also accommodate a mix of Twin Maul and Edge Steel teeth to strike the perfect balance between cutting performance and control for maximum productivity, minimal wear and lower operational costs.

Designed for improved serviceability, the Drum Mulcher Pro X2 features removeable covers for quick access to critical connection points and components, making on-the-job cleaning and tuning easy. Additionally, in both

The drum has been moved closer to the skid steer for increased stability

the DC and OD platforms, drums can be removed without detaching the shafts, significantly reducing downtime for service or replacement.

Liner replacements can be done without removing drums, and standard 0.5-inch bolts used across all teeth and covers means one wrench can be used for removal and servicing. This simplifies maintenance, eliminates the need to carry multiple tools, and makes routine service and emergency repairs much quicker.

“The Drum Mulcher Pro X2 is designed by contractors for contractors,” Diamond Mowers vice president of engineering and product management Nate Cleveringa says.

“Delivering faster processing speeds, superior stability, optimal visibility, and the lowest cost of ownership in the industry, it is the ultimate tool for mulching professionals – hands down.”

For more information on the Pro X2 mulcher, visit: www.colbrookindustries.com.au

With population growth and the Olympic Games driving significant infrastructure growth, construction should be considered an essential workforce

Queensland, particularly South-East Queensland, has had enormous population growth in recent years. Population projections suggest that South-East Queensland will have six million people by 2046, up from approximately four million in the middle of 2024.

The economic and social hub of South-East Queensland, Brisbane, is already Australia’s most congested city. Population growth driving the need for new housing and transport, and now the Olympics, have created a perfect storm in the civil construction industry in Queensland.

The Olympics, when combined with this population surge, is projected to create approximately 90,000 full-time ‘job years’ over a 20-year period, with a need for almost 20,000 additional construction workers each year from now until the Games are held. Crucially, a peak shortfall of 50,000 construction workers is expected over the 2026–2027 period.

There is no silver bullet to this problem. But a solution starts with recognition by government and the community that the civil construction workforce is a ‘frontline, essential’ workforce, just like police, fire and health staff are.

There will be no Olympics, and no new housing in Queensland, without a highly skilled and well-trained civil construction workforce. Growth

Damian Long, CEO CCF QLD

is good, and a stagnant state is one which is dying, but managing the next 20 years of growth, with an Olympics and Paralympics in the middle, requires a deliberate, coherent strategy to deliver the infrastructure and housing we need to manage this growth in a way that boosts our economy, productivity and living standards. In my view, it is also likely that the Olympics will drive further population growth, exacerbating underlying issues in the decade following the games.

In the absence of real, tangible and significant policy action from government, the combined effect of these pressures is likely delays, cost and wage inflation, the likes of which we have never seen previously. Government in the short term should leverage migration from overseas and interstate as best as

A highly skilled workforce is required to meet the needs of Queensland’s growth. Image: Jackson Photography/ stock.adobe.com

they can. While the federal government pulls the strings on overseas migration, it may be prudent for the state government to investigate some short-term incentives for interstate and New Zealand workers, particularly over the next two years as we hit ‘peak deficit’ in terms of workers. This, however, is not the long-term, 20-year solution we really need for Queensland to achieve its full potential.

A renewed focus on the promotion and funding of civil construction pathways is crucial to delivering the best possible Queensland in 20 years’ time. Civil construction needs to be seen as a genuine, long-term viable pathway for a career for more of our young people, and the pipeline of work and easy transfer of skills must be promoted.

During the COVID-19 pandemic we were quickly introduced to the concept of front line and essential workers. A rethink of who we see as an essential worker is undoubtedly needed as society changes, and it is high time civil construction workers are viewed as such.

1 D epartment of State Development, Infrastructure and Planning. Shaping SEQ 2023: https://www.planning.qld.gov.au/planning-framework/plan-making/regional-planning/ south-east-queensland-regional-plan

2 D rive. Brisbane is Australia’s most traffic-congested city: https://www.drive.com.au/news/ brisbane-australia-most-traffic-congested-city

3 Queensland government. Brisbane 2032 Olympic and Paralympic Games – Preliminary Economic, Social and Environmental Analysis: https://www.premiers.qld.gov.au/publications/categories/ reports/assets/2032-qld-games-economic-analysis-summary-report-final.pdf

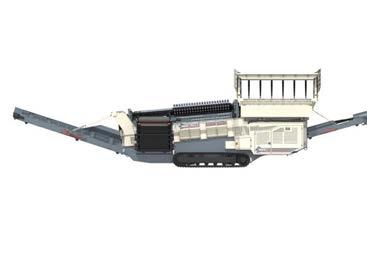

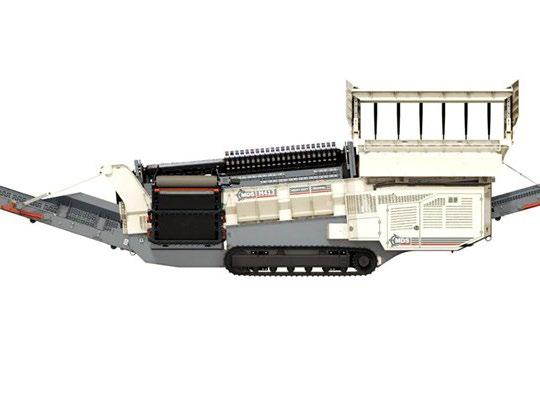

MCCLOSKEYS2503D 2024,Usedmachinewithdemohoursonly, fullminespec,magneticheaddrum. SM337. TA1284860. $899,000+GSTExQld

MCCLOSKEYR155

R155,16'x5',Hardoxapronfeeder.SM289. TA878996. POA

MCCLOSKEYS130 14'x5'twodeck,100mmremotetippinggrid,Cat130hpInstocknow.SM248. TA908181. POA

MCCLOSKEYI3CR 2023,Delivered2024,875+/-crushinghours,magnet,side belt.KM134. TA1286065. $750,000+GSTExsiteNorthQld

MCCLOSKEYTS4080 24mtrackedstacker,1000mmbelt,hydraulictailandtop fold.CM171. TA908173. POA

MCCLOSKEYS190SCREENER 2020,20'x5'twodeck,100mmremotetippinggrid,Cat C4.4130hp.SM242. TA1286558.

$330,000+GSTExsiteNorthQld

MCCLOSKEYC3 MC300cone-directdrive,CaterpillarC13.KM109. TA1059683. POA

MCCLOSKEYS130 2020,14'x5'doubledeck,Catengine,15'hopper.SM238. TA1198773. $280,000+GSTExMSCdepot

MCCLOSKEYS190TRIPLEDECK 20'x5'tripledeckdeck,100mmremotetippinggrid,Cat C4.4130hp.SM284. TA1122980. POA

Nearly 60 years after Grange Resources bought its first Cat® machine for its Tasmanian mine, the fleet is now over 50-strong and continuing to grow

For more than 55 years, Grange Resources has been at the very centre of Australia’s iron ore and pellet production sector, operating Tasmania’s Savage River mine.

Located 100km southwest of the port city of Burnie, on the north-west coast of Tasmania, the Savage River Mine has been producing some of the highest iron-concentrated magnetite in the country with minimal impurities since its inception.

The magnetite produced by Grange Resources at the Savage River mine is transported along an 85km pipeline to the company’s Port Latta

pellet plant and port facility, before being exported as a raw material to make steel.

“We produce a very high-quality pelletised iron ore that is sent mostly overseas, but also used in Australia,” Savage River mine manager Matthew Anderson says.

“Our product is shipped to the big steel-making plants in Asian markets to be used as blast furnace feed.”

Backbone of the fleet

More than 50 Cat machines are in operation at the mine, including approximately 30 mining trucks, around 10 dozers, multiple graders and wheel loaders, and a couple of hydraulic mining shovels.

Key to the success of the Savage River operation has been a long-standing relationship with Caterpillar® and local dealer William Adams, which has supplied the majority of the mine’s heavy equipment fleet.

“Our newest Cat 789 mining trucks are high horsepower and show a significant improvement on speed on the road,” Anderson says.

Savage River has always operated Cat equipment, evidenced by some of the 20-year-old mining trucks still running today, with over 100,000 hours on the clock.

Grange Resources COO Ben Maynard says this achievement speaks to the reliability and durability of Caterpillar machinery.

“We’ve used the full suite of equipment, diggers, dozers, graders, trucks and excavators, and we really appreciate the conditions that the equipment has had to operate in, particularly the rugged environments of the West Coast of Tasmania,” he says.

“Rain, hail, snow, shine, in the wet, in the cold – that gear has been reliable and serviced us to deliver some highquality concentrate and pellet.”

Another significant part of the mine’s success has been the close relationship with established Caterpillar OEM Solutions customer Elphinstone Group.

Also based in Tasmania, Elphinstone Group manufactures mining support vehicles, with all its products, technical assistance, support and access to spare parts available through William Adams.

Having provided Savage River with engineering support, electrical harnesses and bespoke solutions, such as mining truck trays, Maynard says he’s greatly appreciative of the relationship Grange Resources has with Elphinstone Group and William Adams.

“We’ve been able to partner together in delivering solutions and outcomes for our community and for our business, and that’s been a really important piece of our collaboration together,” he says.

“We appreciate the ability for our teams to maintain and look after that gear, and we appreciate the support we get from the local service teams to come apply that extra technical and specialised knowledge when we need it.

“Our relationship with Caterpillar, William Adams and the Elphinstone Group has been a really important one for our business over many years now.

“I reckon the relationship probably

goes back about 57 years since the Savage River project has been in operation.”

Beyond physical equipment, the application of Cat MineStar™ solutions has been integral to Grange Resources, with the integrated suite of technology offerings serving as an essential cog in the Savage River operation.

With everything from fleet management, guidance technologies and machine health applications to safety technologies and autonomous hauling capabilities, Cat MineStar solutions help to address the mine’s specific needs.

For Grange Resources, safety is of the upmost importance, and one solution that has enhanced this is Cat MineStar Command for Dozing –enabling remote operation of Savage River’s dozers.

This technology removes Savage River dozer operators from hazardous environments and instead allows them to safely control the machines from a remote operating station in the mine’s office.

“Cat Command for Dozing allows us to operate dozers in places that it would otherwise be unsafe to do, such as near unstable walls,” Anderson says.

“It means that we can operate higher tip heads or tip into water,

while keeping the operators safe.”

In addition to the safety benefits, he says most operators at Savage River now prefer to stay in the remote operating station due to the enhanced comfort, rather than getting in the machine itself.

“Instead of bouncing around in a noisy and heavy dozer away from the rest of the team, they can operate from a remote quiet station near the break room,” Anderson adds.

To improve productivity, the Savage River mine has also adopted Cat MineStar Terrain, which uses high-precision guidance technologies and material tracking to ensure machines are working to plan.

“Cat MineStar Terrain shows us where all of our equipment is and gives us all the productivity metrics, including how much rock is on each truck, where they’re going to, what the material type is – if it’s ore or waste, what type of waste it is, and what dump it needs to go to,” Anderson says.

“It allows the supervisors to make good decisions as to how they deploy

the fleet, to make it as productive and cost effective as possible.”

Maynard adds this technology has helped ensure the Savage River operation is maximising the payload on each Cat mining truck.

“At Grange Resources, we value safety, being efficient and productive with the equipment that we’ve got, and Caterpillar have really come to the party to help us think differently so we can make sure that we’re maximising the payload,” he says.

“The application of lightweight bodies on our trucks has really helped to ensure that we’re getting over 187 tonnes on every truck. That allows us to increase our payload, reduce our cost and improve our efficiency.”

Savage River has combined this solution with Cat MineStar Health, which has provided the mine with equipment data that can be monitored, such as critical machine parameters, real-time alerts, predictive failures and repair recommendations.

By having access to this information, the Savage River

operation has been able to make more informed decisions to boost its productivity.

“The fact that we can remotely monitor machine health and the performance of the machines, such as the strut pressures, the gears that they’re in and the speed that they’re running, helps us to reintegrate that back into the design of our pits and makes our networks more effective and more productive,” Maynard says.

“This ensures we’re making that haul route safe for our operators, but also cost effective and productive.”

Due to the remote locality of the Savage River mine, all servicing and maintenance of the Cat equipment is done on-site, including rebuilds with the support of William Adams. This means having the right parts readily available is essential to reducing machine downtime.

“The logistics of getting parts to and from us is important to keep our reliability and our availability up where it needs to be,” Savage River

The Savage River mine has around 10 Cat dozers in the fleet mobile maintenance superintendent Allan Baxter says.

“We have a site key account manager, Craig Boatwright from William Adams, who works tirelessly with us all the time to ensure that we get what we need on time to help us ensure that our fleet is available to be able to create the production we need to hit our targets.”

As Grange Resources approaches its sixth decade operating the Savage River mine, the company is looking at how it can unlock the future of the ore body onsite.

One of the options being explored is transitioning from an open cut operation to an underground mine, with the opportunity for a sub level cave and a block cave.

“There’s a real need for innovation as we look to decarbonise a 57-yearold operation,” Maynard says.

“We hope to halve our carbon emissions by 2030 and be Net Zero by 2035. We’re only going to get there with good people, good plans and good innovation, and that’s why we value this continued relationship

with Caterpillar, William Adams and Elphinstone Group to help us adapt to the new challenges that we’re going to face.

“Congratulations to Caterpillar for reaching this amazing milestone of 100 years. We hope they have a great anniversary and a welldeserved celebration.

For more information, visit grangeresources.com.au and williamadams.com.au

© 2025 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. All servicing and maintenance of the Cat equipment is done on-site

A stunning new Cat 938 wheel loader painted Centennial Grey has joined the fleet of Coburn Sand & Gravel, and is turning heads in the yard

In celebration of Caterpillar making and selling machinery for 100 years this year, a special limited edition selection of machinery painted in Centennial Grey was produced –with one Cat 938 wheel loader now the prized possession of Queensland’s Coburn Sand & Gravel.

A family business set up 40 years ago by John and David Coburn, the loader is working in the business’ quarry and yard, loading trucks and stockpiling material as well as undertaking civil earthmoving work with sister company C&C Civil.

Earthmovers & Excavators caught up with C&C Civil co-owner Claire Watt to talk about how the new grey loader is standing out from the crowd.

Starting off 40 years ago with a handful of trucks and loaders, the Coburn family has evolved their business interests over the years to cover the supply of landscaping materials, quarry operation and civil contracting.

Six years ago, when John retired from the business, his grandson Connor joined to co-run operations

and set up a side business with Watt to expand the civil side. Both businesses now operate from Tamrookum, about 75km inland from Gold Coast.

The addition of a new Cat 938 wheel loader from Queensland dealer Hastings Deering, painted in Caterpillar’s Centennial Grey as a nod back to the colour of the first Caterpillar machines produced, heralds a period of growth, with Coburn Sand & Gravel

having recently expanded its yard.

“Connor and his dad have been buying more Cat gear and expanding the businesses,” Watt says.

“Coburn Sand & Gravel have a little retail landscaping yard and eight truck and dog combos. And then we also run the quarry, which is the main use for our loader.

“Our quarry is a bit special because we have a clay-based product and we recently started crushing our own gravel.”

Supplying landscaping material and civil services across South East Queensland, the latest addition to the business’ fleet joined at the end of September and was a proud moment for the team.

“We picked it up ourselves from the Hastings branch and drove it home,” she says.

“That was quite a special moment for David because it’s been his life’s dream to have a big, good-looking loader like that. It was a really nice moment to stand back and look at it and know that it’s ours.”

Watt says they were thinking of getting a larger wheel loader for a while, and the 938 stood out to them at Diesel Dirt & Turf earlier this year. However, it was a test drive at a Hastings Deering Dig Day that sealed the deal.

“We were invited out to Yatala, and gave it a test drive there,” Watt says.

“Connor couldn’t stop thinking about it, so he took his dad back down the next day and made him drive it to see if he’d like it. They knew as soon as they drove it that they wanted it.”

The new loader is now on site, moving up to 1,000 tonnes of quarry material a day.

“We were looking for something that was bigger than what we had, but wasn’t huge, because we have a small quarry,” Watt says.

“We wanted more power, a bigger bucket, and the main attraction was having load scales in the loader, which has transformed our ability to sell commercially.”

The Cat 938 loader has joined a collection of Cat machinery, including 920, 924, 936 and 938 model wheel loaders, 310 and 306 excavators, 259 and 255 posi tracks, a 140M grader and a three-tonne roller.

With its striking paintwork, the limited edition loader has been an eye-catching addition to the yard.

“People absolutely love it,” Watt says.

“It’s different, but it looks amazing. Everyone thinks it looks really tough.

“David absolutely loves it and said he can easily work for another 20 years because it’s so comfortable. He’s loving the upgraded technology of the scales and the cab. The upgraded cameras give him extra peace of mind because trucks are coming in and out of the yard all day. Everything’s just 10 out of 10.”

With the Coburn family having been buying machinery through Hastings Deering for over 30 years,

Watt says it’s been a long-lasting and productive relationship.

“They keep selling machines and we keep buying them!” she says.

“They’re really good to deal with. Their aftermarket service and parts availability meet all of our needs.”

And as to why Cat machinery has been such a favourite, Watt says it’s a mixture of quality and design that make them stand out.

“Caterpillar have been around for so long that they obviously know what they’re doing, and we just trust the technology over anything else,” she says.

“At the end of the day, operators are so happy to jump in a Cat machine because of the comfort and the tech. Everybody loves a Cat machine, and they look great.”

For more information on Hasting Deering, visit: hastingsdeering.com.au

CATERPILLAR

299D2 2017,2SPEED CONTROL

4IN1MPBUCKET AIRCONDITIONER COUPLER,HYDRAULIC EROPS HYDRAULICS, STANDARDFLOW

OnlineOwner'sManual SELFLEVELING. FD203075. TA1192196. $104,500

CATERPILLAR

330FL 2018,AirConditioner Beacon BoomCheckValve EngineEnclosures GPBUCKET HandandFootControl Lighting Mirrors

OnlineOwner'sManual Radio-AMFMRadio StickCheckValve TILTMUDBUCKET. HCK20123. TA1257863. $165,000

CATERPILLAR 349-07

2019,*FIRE SUPPRESSION AIRCONDITIONED EROPSCAB AutoLube Beacon Boom-1Piece CABBREATHSAFE SYSTEM CouplerTypeHydraulic.LKG00146. TA1096046. $434,500

CATERPILLAR

305E2CR 2021,*CANOPY,OPEN ROPS/FOPS 1200MMTILTMUD BUCKET 300,450&600MMGP BKTS Beacon BoomCheckValve CustomerValue Agreement(CVA)24 MonthsHDAdvantage. H5M14815. TA1238853. $64,900

CATERPILLAR

340-08

2022,*CAMERA,360 VISIBILITY AIRCONDITIONED EROPSCAB Beacon CATGradew/3DAssist &Payload CouplerType-Hydraulic CustomerValue Agreement(CVA)24 MonthsHDAdvantage. FKN00443. TA1278435. $396,000

CATERPILLAR 745-04LRC

2019,AirConditioner AirSuspensionSeat Beacon FastFillFuel Lighting Mirrors

OnlineOwner'sManual ProductLink Radio-AMFMRadio ROPS-Enclosed Tailgate.3F601308. TA1261587. $478,500

CATERPILLAR AP355FLRC

2017,"ASISWHEREIS" OnlineOwner'sManual ProductLink Screed,EndGateHeated WashdownTank. NTT00112. TA1227956. $192,500

CATERPILLARD8T 2022,AIR CONDITIONEDEROPS CAB Beacon CustomerValue Agreement(CVA)24 MonthsHDAdvantage FoldableStickRake OnlineOwner'sManual ProductLink Protection12Months/ 1500HoursPTH Ripper-Multi-Shank. JJ501691. TA1282642. $979,000

For a huge range of new and used Cat® parts visit CatUsed.com today.

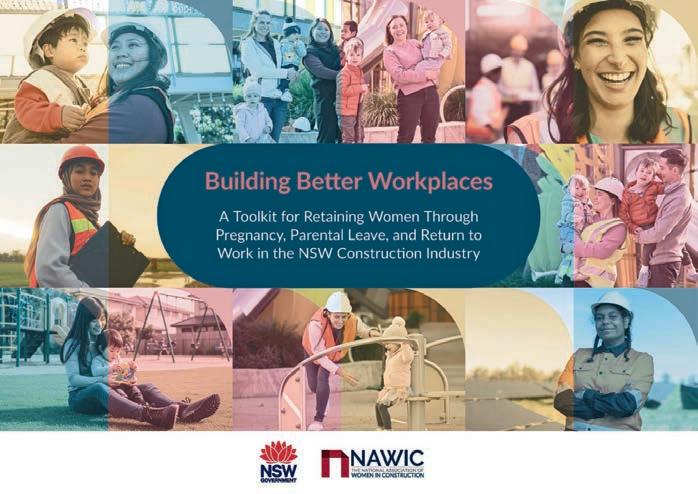

A National Association of Women in Construction (NAWIC)-commissioned research project into parental leave in the construction sector has provided more than just statistics and lived experiences in offering clear recommendations for government and industry.

NAWIC’s mission is to collaboratively drive gender equity through culture change in the sector and we are committed to providing research backed pathways to meaningful reform.

With funding from the NSW government’s Women in Construction Industry Innovation Program (IIP) Year 2, NAWIC’s NSW Chapter partnered with the University of Sydney Business School to conduct the study.

The ‘Boosting retention of women in construction: Supporting women through parental leave’ project explores how to better support women working in frontline construction roles across Australia during pregnancy, parental leave and their return to work.

Research has previously found that the transitional periods in and out of parental leave are pivotal in a woman’s decision to remain in or return to work. This report delves much further into lived experiences of women and offers a pathway to

The NAWIC commissioned ‘Boosting retention of women in construction: Supporting women through parental leave’ project includes a practical toolkit designed for employers, managers and industry leaders. Images: NAWIC.

• i nvestment in safe and inclusive site facilities and practices for pregnant and female workers

• enhanced paid parental leave and support for women and men.

As I regularly say, we simply cannot deliver the pipeline of construction projects in housing, infrastructure and energy without people – lots of them. At no other time has it been more critical to attract, retain and advance women than during this period of massive skills and talent shortages.

Cathryn Greville, CEO, NAWIC

better parental leave support.

The comprehensive parental leave study includes first-hand accounts and a toolkit with practical recommendations to guide change.

The construction industry continues to face real challenges attracting and retaining women.

One of the most critical, and often overlooked, moments in a woman’s career journey is the transition into and out of parental leave.

The research found that women often go it alone, policies are patchy, there are often long hours and rigid roles, there is minimal flexibility and support, and the new generation of women entering the industry are expecting much better.

The report recommends coordinated action by government, trade unions, employers and clients, setting out practical, evidence-based actions focused on:

• t he introduction of a parental leave levy to support small businesses and sole traders

• normalising family-friendly work hours and flex on site

The industry needs more than 400,000 new workers over the next five years, yet a staggering 110,000 workers leave each year through attrition. The full talent pool remains largely untapped, with women making up only 12.4 per cent of the workforce and just 3.4 per cent of trades roles.

Getting culture right doesn’t just make a difference for women, it’s essential to unlocking the potential of our sector. Providing better parental leave options makes the industry more attractive to all workers.

The Workplace Gender equality Agency’s recently released 2025 Gender Equity Insights report, The Power of Balance, shows organisations taking action to improve gender equality see lower staff turnover, more women in leadership and better shareholder value.

It also warns Australian businesses could fall behind their competitors if they don’t take strong action to address gender balance.

Congratulations to everyone involved in bringing our parental leave research project to fruition. Thank you to our NSW Chapter for commissioning this report and to the University of Sydney.

Learn more about the research project and download the toolkit at www.nawic.com.au/parental-leave

CASE Skid Steer and Compact Track Loaders pack serious performance into a compact footprint. With powerful breakout force, precision control, and the durability CASE is known for, they’re built to handle Australia’s toughest jobs — even in the tightest spaces.

Inside the cab, operators get 360-degree visibility and premium comfort, with intuitive controls that keep you productive all day long. Ready to see what compact muscle really feels like? Scan the QR code to learn more.

If your job site has tight spots and you need a compact machine, look no further than the LiuGong 9035F ZTS mini excavator

LiuGong F-Series excavators are built to deliver a strong balance of performance, precision and quality.

With LiuGong machinery now available from new dealer Construction Distribution Australia (CDA), spare parts and technical support are now easier to access than ever in Melbourne, Brisbane and Sydney.

One standout machine for the smaller end of the market is the LiuGong 9035F, which gives contractors access to top-class digging power and speedy operation even in sites with restricted access.

Whether it’s landscaping, digging utilities or operating alongside roads, the LiuGong 9035F can be easily transported and put to work to get the job done. Here, we take a look at how this compact, efficient, zero-tailswing excavator handles on site.

With a maximum operating weight of 3.8 tonnes, the 9035F is a zero-tailswing outfit powered by a Yanmar Stage V diesel offering 22.2kW.

The working range includes a maximum digging reach of 5,385mm, a maximum digging depth of 3,085mm, a maximum dumping height of 3,310mm and a front swing radius of 2,416mm.

The LiuGong 9035F is supplied with three buckets – a mud bucket, 300mm GP bucket and 450mm GP bucket, with a maximum hydraulic flow of 99L/min.

Under the excavator arm is a small dozer blade and the machine has a top travel speed of 4.2km/h.

The cab comes in both closed and open ROPS versions.

Mat Wandmaker, director of Melbourne contractor Blue Ridge Property Maintenance, recently got behind the joystick of a LiuGong 9035F on behalf of Landscape Contractor magazine to give it a test drive – with impressive results.

“It’s quite compact, zero tailswing, which is great for those jobs for landscaping whether it’s full construction or you’re digging out a back yard,” Wandmaker says.