Plastic’s new life

Soft plastics facility nears launch

FEATURES

Reclaimed rubber

Ripe for expansion

AI the first responder

Safer future for waste and recycling

PROUDLY SUPPORTED BY:

APR Plastics is on the verge of opening its groundbreaking soft plastics recycling facility in Victoria.

POWERING A CIRCLE

Inside the revival of Australia’s rst food waste-to-energy plant.

New

Birth

Groundbreaking

“WE HAD TO FIND A SOLUTION FOR SOFT PLASTICS. WE’VE DONE THAT. NOW WE’VE JUST GOT TO GET THE FIRST ONE GOING AND THEN SCALE UP METHODICALLY.”

Darren Thorpe, APR Plastics Managing Director

Unlocking a

Industry leaders call for

e

Preventing

Ignore

Transformation underway in the Organics-to-Energy sector.

Inside the revival of Australia’s rst food waste-to-energy plant.

Revolutionising South Australia’s agricultural compost space.

From heavy industry to carbonneutral manufacturing success.

Tana Australia doubles down on service excellence and expansion.

100,000

still going strong.

Stubborn

Launch of world’s largest secondary shredder for

42 UNIVERSAL FIT

Caterpillar’s journey in the waste sector.

Unique system engineered for scrap and auto-shredding.

New perspective on how to tackle the challenges of tyre pyrolysis.

Giving old street banners a second life.

Why the NHVR Code of Practice matters.

Can global innovation extinguish the battery re risk?

Turning point for plastic From the Editor

e Australian waste sector is moving past the soft plastics crisis with a new wave of innovation focused on circularity.

e imminent launch of APR Plastics’ pyrolysis facility in Bacchus Marsh, Victoria, is a major step. After two years of planning, the plant will convert complex, multilayered soft plastics into synthetic crude that will be re ned and fed back into packaging.

APR Plastics Managing Director Darren orpe has a vision to “turn this humble, little confectionery packaging into the same product without using 100 per cent fossil crude.” In this edition’s cover story, he shares his excitement at seeing his vision take shape.

Simultaneously, Monash University researchers are tackling the end-of-life problem by using food waste. ey’ve further developed a process where bacteria convert food waste sugars into PHA biopolymers – a compostable plastic alternative for lms and agricultural wrap.

Underpinning these e orts is the Advancing Plastics Recycling in Australia (APRA) Project, which is quantifying the economic and environmental value of using Australian recycled content. is vital evidence will help strengthen domestic markets and ensure technologies like APRs and Monash’s can successfully scale.

Also in this edition, we address the critical issue of res in waste and recycling facilities – from AI rst responders to risk assessments and a unique challenge that pairs problem-solvers from around the world with Australian industry leaders to tackle the crippling issue.

is focus on re prevention is essential to protect a facility’s sta , productivity, safety and commercial viability, not to mention the thousands of dollars of plant and equipment that are the backbone of any modern waste facility. ese machines – from heavy-duty compactors and excavators to specialised shredders and sophisticated sorting lines – are not just tools; they are core assets, some of which are highlighted in a special plant and equipment section in this edition.

We also meet a leader determined to take an equipment manufacturer to the next level and cement itself as an industry partner, not just a supplier.

Happy reading

Lisa Korycki

CEO

Christine Clancy

christine.clancy@primecreative.com.au

PUBLISHER

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Jennifer Pittorino jennifer.pittorino@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGN

Laura Drinkwater

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia P: +61 3 9690 8766 info@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. e rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COVER Cover image: APR Plastics

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Fire safety: producers pay

New South Wales is mandating battery producer responsibility to combat fire risks, forcing brand owners to fund safer disposal.

New South Wales has become the rst Australian state to mandate producer responsibility for batteries, following a surge in battery-related res, which have already accounted for 241 incidents this year.

e State Government has released draft regulations that seek to ensure battery brand owners take greater nancial and environmental responsibility for their products.

e regulations proceed under the recently passed Product Lifecycle Responsibility Act 2025, which provides the framework for mandatory product stewardship. Batteries are the rst product class to be regulated.

Under the new regulations, battery brand owners who supply products for sale across New South Wales will be mandatorily required to participate in a product stewardship scheme and pay a fee on their products. is measure applies to small, removable, or rechargeable batteries under ve kilograms and those used in e-bikes and e-scooters.

ird-party delivery groups will then be required to use these funds to create safer processes for battery disposal and handling.

Proposed safety actions include maximising recovery to keep batteries out of land ll, rolling out public

education campaigns on battery risks and safe disposal, establishing dedicated collection points for safe disposal and recycling and mandatory reporting on the number of batteries supplied in New South Wales each year.

e State Government states that shifting from a voluntary scheme to a mandatory, regulated approach will ensure integrity and accountability, reducing the rising number of batteryrelated res. Brand owners who fail to comply with stewardship requirements, reporting, or action plan obligations face penalties up to $880,000.

Environment Minister Penny Sharpe said the regulations are crucial given

The New South Wales Government says shifting from a voluntary scheme to a mandatory, regulated approach will reduce the rising number of battery-related fires. Image: Desintegrator/shutterstock.com

the increasing number of lithium-ion powered devices.

“ ese res are hot, fast and incredibly di cult to put out,” said Sharpe.

“ is regulation is crucial to reduce the risks batteries can pose when damaged, mishandled or improperly disposed of.

“By acting now to make product stewardship mandatory for certain batteries, we can keep potentially dangerous products out of the general waste system – protecting people, the environment and the waste and resource recovery sector from further harm.”

e Association for the Battery Recycling Industry (ABRI) has welcomed the State Government’s action, recognising it as a milestone for producer responsibility.

Katharine Hole, Chief Executive O cer of ABRI, called the move a pivotal moment.

“Mandatory producer responsibility is essential to address Australia’s growing battery waste, re and safety risks. Importantly, long term it is about critical minerals and secondary metals production,” said Hole.

She stressed that regulation is the essential tool for change:

“ is regulation is the mechanism by which we can move from voluntary goodwill to enforceable, nationwide action.

“We commend the New South Wales Government for leading this agenda. But the success of the scheme will depend on strong, transparent regulation that gives industry certainty and safeguards community safety.

AUSTRALIA’S NO.1 WHEELED EXCAVATOR

Timely implementation is an absolute necessity to rapidly drive improvements in battery disposal safety.”

Under the framework, brand owners and stewardship organisations must submit action plans, maintain records, and be subject to audits. ABRI believes that because New South Wales is the rst state to regulate batteries, its framework will set a crucial precedent for other jurisdictions.

“To support streamlined implementation, it is critical that a cookie cutter model is adopted across Australia,” Hole said. “By moving swiftly and collaboratively with a clear commitment to harmonisation, we can build a robust, safe and world-class battery producer responsibility system.”

JCB HYDRADIG WASTEMASTER

ENGINEERED FOR WASTE INDUSTRY EXCELLENCE

The JCB Hydradig Wastemaster sets the standard for material handling in the waste and recycling industry, offering maximum productivity and safety. While operators benefit from unmatched visibility around the machine, enhancing situational awareness and operational efficiency.

Designed for demanding environments, its low centre of gravity ensures stable lifting even when working at full reach. Manoeuvrability is a key highlight, with two-wheel steer, four-wheel steer, and crab steering capabilities, allowing for ultimate usability even on the most confined job sites.

The Hydradig Wastemaster is built for the rigors of the waste industry with heavy-duty guarding, a higher cab height for superior viewing into skips and containers, and solid tires to prevent punctures. Its robust design minimises downtime and maximises operational uptime in challenging waste management applications.

Hope in action

What began as one mother’s response to a child’s plea for environmental change has grown into a grassroots sustainability movement that’s now recognised both within the local community and across Australia’s waste management sector.

On the second Saturday of every month, a quiet corner of the City of Melville in Western Australia transforms into a vibrant, bustling hub of community action.

Local volunteers arrive early, setting up bins, banners, and a themed mini expo room. By midday, families, school groups, and curious residents arrive carrying bags of plastic lids and hard-torecycle items, to what is a ectionately known as Bottle Top Hill Day.

Bottle Top Hill (BTH) was established in April 2021 by Em Charlton, a local advocate for environmental sustainability, with a background in adventure training and education.

Entirely volunteer-run, BTH operates as a monthly pop-up recycling club that collects over 20 consumer and common litter items too tricky for kerbside recycling, most notably plastic bottle lids.

Charlton created BTH to provide a recycling solution for the “lids o policy” across the state which requires all plastic lids to be removed from bottles and containers before recycling, due to the small size of lids and the di culty in processing them in automated sorting machinery.

“ e general rule is to remove them, place them in your general waste bin, or take them to a local collection point, and I wanted to create a local collection point with a di erence,” Charlton said.

“Our mission statement is to engage and assist the public on issues relating to environmental sustainability –my passion.”

e moment Charlton knew she wanted to be a part of the circular economy movement came from one of her children.

“For me, this project was born from a really raw moment,” she re ects. “One of my children remarked, ‘Your generation has really stu ed it up for mine.’ at moment lit a re in me. I could no longer wait. I felt I needed to act to provide some form of hope for the future.”

From that sense of urgency, BTH was built around three core values: sustainability, community, and legacy.

“I believed that action could come from everyday people, and if we can learn together and share knowledge, we can form a positive wave of behavioural change,” she said.

“I knew this would be an adventure like I’ve never had before, I said ‘let’s see what we can do’.”

RESULTS ARE IN

Since its inception, BTH has hit many major milestones, both in terms of community engagement and tangible waste recovery.

More than 4.5 million plastic lids have been collected and returned to BTH, diverting more than 22.5 tonnes of plastic from land ll.

e lids are then transported and processed by local plastic recycler, CLAW Environmental, where they are pelletised and returned to industry and made into new products.

roughout the journey, Charlton has received numerous accolades in recognition of her contribution to the local community and environment, including the West eld Local Hero Award in 2022 in the City of Melville; an Auspire Australia Day Award from the Australia Day Council of Western Australia, for both individual and group achievements; and was Highly Commended twice in the WasteSorted Western Australia awards in 2023.

“ ese accolades prove the project is resonating with the industry and the community, which is the whole purpose,” she said.

Beyond the numbers, Charlton said the project has brought a sense of

The monthly Bottle Top Hill pop-ups are entirely volunteer run. Image: The BTH Project

belonging and action to the broader community. Every visit to Bottle Top Hill is more than just a drop-o , it’s an educational experience.

“When people come in, they don’t just leave their recycling and go,” she said. “ ey learn from guest speakers and volunteers, and they walk away feeling empowered.”

THE BTH 12R’S

BTH operates through Charlton’s own authored guide, e Twelve Rs of Sustainability, a citizen-focused climate action plan designed to take people from awareness to action on a “collaborative journey of hope.”

e guide is sectioned in 12 chapters or months, with each focusing on one of Charlton’s 12Rs methodology which expand on the traditional ve; refuse, reduce, reuse, repurpose, recycle, and include repair and regenerate.

Each August, the spotlight is on Reduce. Aligning perfectly with Keep Australia Beautiful Week.

“Each month, we host a mini expo alongside our collection day, and in August we dedicated it to reducing litter, preventative

action and community beauti cation,” said Charlton.

“It’s all about action, picking up rubbish, reducing single-use plastics, and changing behaviours at the source.” is is just another way Charlton works to drive behaviour change from a grass roots level.

“Not only does BTH stand for Bottle Top Hill but also for Be e Hope,” she said.

“My hope is that the 12 Rs maintain their relevance and impact and ultimately encourage others to act sustainably for the future.”

SUPPORTING KEEP

AUSTRALIA BEAUTIFUL

Laura Carrazza, Head of Community Programs at Keep Australia Beautiful, describes Bottle Top Hill as a perfect alignment with the not-forpro t organisation.

“Initiatives like the BTH project help extend our mission of inspiring Australians to create a litter-free and sustainable environment, by collecting and recycling materials, like bottle tops, that might otherwise end up in land ll,” she said.

“In doing so, they not only reduce waste but also create tangible community bene ts. eir work aligns perfectly with KAB’s mission, turning potential waste into valuable resources and engaging people in handson solutions.”

Although KAB Week runs once a year, Carrazza said people don’t have to wait for a big clean-up day.

“Small, consistent actions, such as picking up litter on your walk, reducing single-use plastics, joining your local KAB committee, or even starting a recycling initiative at work, make a huge impact over time,” she said.

“We also run year-round programs and campaigns, so you can volunteer, donate, or advocate whenever it ts your life.”

For those thinking about getting involved, Carrazza said now is the time.

“Caring for the environment isn’t someone else’s job. It’s ours, collectively. Every action, no matter how small, contributes to a cleaner, greener Australia.”

“Whether it’s your street, your local park, or a stretch of coastline you love, your e ort matters.”

Keep Australia Beautiful Week clean-up 2025. Image: KAB

Plastic’s new life

After years of planning, APR Plastics is on the verge of opening a groundbreaking soft plastics recycling facility in Victoria.

The saga of Australia’s soft plastics has been a headline-grabbing story of crisis and collapse, with the abrupt closure of a national recycling scheme leaving thousands of tonnes of material without a home.

Yet, amid the headlines of stockpiles and stalled progress, a quiet revolution has been unfolding in Victoria’s west. For years, a company has been methodically working to build a complete end-to-end solution,

proving that the dream of circular soft plastics is not just possible, but imminent.

At a new facility in Bacchus Marsh, Victoria, the nal pieces of the puzzle are coming together, promising to

APR Plastics Managing Director Darren Thorpe is determined to create a circular outcome for soft plastics. Images: APR Plastics

transform a national problem into a viable, circular solution.

APR Plastics Managing Director Darren orpe is a man of vision. For more than two and a half years, he has navigated the complex regulatory landscape to secure a development licence for the pyrolysis plant.

at licence, approved earlier in 2025 by the Victorian Environment Protection Authority (EPA), is the critical rst step in what has been a long and arduous journey.

A pilot trial at APR’s Dandenong South facility in 2022 was a success but reinforced the need for a solution at a

much larger scale to handle the sheer volume of soft plastics.

“It’s been really, really frustrating, but also very exhilarating, because it’s here,” Darren says.

“It’s starting to gain real momentum.”

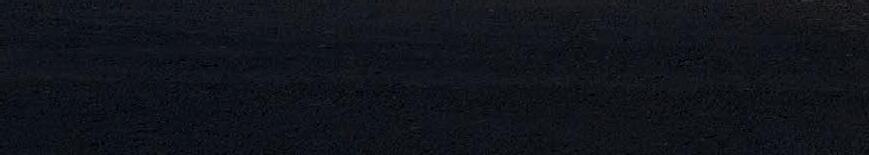

e facility, located at Bacchus Marsh, was partly funded by a $250,000 Sustainability Victoria grant. It will house a 10-tonne-a-day unit, giving APR Plastics the operating knowhow to expand elsewhere.

e technology at the heart of the plant is pyrolysis, a process that uses heat to break down soft plastics in the absence of oxygen. e result is pyrolysis oil, a synthetic crude that can be further re ned and processed into feedstock for the packaging industry, creating a truly circular loop.

“I want to be able to turn this humble little confectionary packaging into the same product without using 100 per cent fossil crude,” Darren says.

“ e driving force is to be able to take these items that are non-recyclable right now and turn them into a recyclable outcome. Circular is what I want.”

For Darren, the mission is to stop using 100 per cent fossil crude for soft plastics packaging by providing a viable, recycled alternative.

e company’s vision for a full-scale operation would produce 35 million litres of synthetic crude annually. And while Darren describes it as a “drop in the ocean” he sees any o set of fossil crude as a win.

“ at means there’s at least 35 million litres of fossil crude we don’t have to manufacture.”

Australia uses about 70 billion pieces of soft “scrunchable” plastics such as food wrappers each year, according to the Department of Climate Change, Energy, the Environment and Water (DCCEEW).

One million tonnes of that annual plastic consumption are single-use plastics, 84 per cent of which is

The Bacchus Marsh facility under construction. When complete the plant will house a 10-tonne-a-day unit to process soft plastics.

sent to land ll and only 13 per cent is recycled.

e collapse of in-store collection service REDcycle in November 2022, which uncovered thousands of tonnes of soft plastic stockpiled in warehouses across two states, forced the packaging and recycling industries, and government, to look at how to build ongoing sustainable pathways for soft plastic.

Darren says one of the greatest challenges is the public’s perception of plastic recycling. e REDcycle collapse has created a trust de cit, and he’s determined not to repeat those mistakes.

“ e community wants to do the right thing,” he says.

“A soft plastics drop-o day in my municipality earlier this year attracted about 800 cars, so we know communities want soft plastics recycling, but they’ve lost trust.

“We want to rebuild that trust. We just have to make sure that we’ve got everything in place, so it doesn’t fall over.”

at has meant a meticulous and collaborative process to build a complete supply chain from collection through to remanufacture, ensuring the produced oil has a home.

APR’s kerbside division receives soft plastics from voluntary stewardship programs and subscription platforms. at material is then transported to the company’s new sorting facility to be separated into the correct feedstock for the pyrolysis plant.

Darren says a methodical, line-by-line approach to sorting ensures the purity of the feedstock, which is essential for producing high-quality pyrolysis oil.

Most soft plastics, such as chip packets and chocolate wrappers, are multilayered. e outside is polypropylene (PP), but the inside is metallised PP lm acting as a barrier that protects the integrity of the food. Traditional mechanical recycling processes cannot separate the layers, so soft plastics have been considered a contaminant.

APR’s process will separate the polypropylene from the barrier lm. e PP will be turned into a vapour and then condensed into an oil, which will be sent to a re nery to be further processed so it can be reused in foodgrade plastic products.

is attention to detail has also been applied to securing a market for the end product. In May, APR announced a Memorandum of Understanding with Aster Chemicals and Energy, Taghleef Industries Group and Pro-Pac Group.

Aster will process the pyrolysis oil into ole ns, which will then be converted into PP resin before Taghleef manufactures it into PP lm. Pro-Pac will complete the circular value chain by manufacturing the lm into snack food wrappers.

While the initial 10-tonne plant is set to begin operations and produce sellable oil by the rst quarter of 2026, the company is already focused on phase two, which will dramatically expand production capacity. is, in turn,

A 3D render of the soft plastics recycling line.

“The driving force is to be able to take these items that are nonrecyclable right now and turn them into a recyclable outcome. Circular is what I want.”

Darren Thorpe, APR Plastics Managing Director

will be a stepping stone to 100-tonne-aday operations.

Darren’s dedication is fuelled by a singular vision: to create a circular economy for soft plastics that are currently considered non-recyclable.

e goal is to prove that these products, which are t for purpose and essential for reducing food waste, have a valuable second life.

is, he says, will require signi cant infrastructure and, crucially, a mandatory packaging reform for all brands.

In 2024, DCCEEW consulted on future regulations to reduce packaging

waste, with potential mandatory reforms such as Extended Producer Responsibility (EPR) being considered.

“We’re going to need the packaging reform to be made mandatory,” Darren says. “ e 85 per cent of brands that are now sitting back could potentially go on a free ride, and we need them all to be saying, ‘we’re in’.”

“We’re in” is an ethos shared across the APR group which includes Australian Paper Recovery and APR Kerbside.

Darren acknowledges the dedication of his team for the success so far and

says while it’s often been a “long hard slog”, they are united in the belief that this is an opportunity to make a di erence.

“ is is a family-run business, and the values that people bring to our business are important; they’re critical to the strength and the development of where we’ve come from.”

But the mission is about more than just a single plant; it’s about building a national framework.

Darren believes that by demonstrating a viable, pro table, and truly circular solution, the wider industry will be compelled to follow suit. e APR Plastics facility is not just a plant; it is a proof of concept, a blueprint for the future of soft plastics in Australia.

“We had to nd a solution for soft plastics,” Darren says. “We’ve done that. Now we’ve just got to get the rst one going and then scale up methodically.

For more information, visit: www.aprplastics.com.au

The pyrolysis process was tested during a pilot trial at APR’s Dandenong South facility in 2022.

With more than 80 years of magnetic expertise, Eriez designs and manufactures industrial solutions like the PokerSort, helping to improve ferrous recovery for recycling operations.

Food-safe green light for plastics

For years, the conversation around plastic recycling has focused heavily on the PET (polyethylene terephthalate) bottle, but as global directives push for recycled content across all packaging types – including polyole ns – the need for advanced cleaning technology has become critical.

A new partnership between Austrian technology leader Starlinger viscotec and local market heavyweight Applied Machinery promises to deliver a solution.

Starlinger viscotec, celebrating its 20th anniversary this year as a business unit of Starlinger & Co GmbH, has built its reputation around a philosophy of “food-grade without compromise.”

It o ers top-tier, green solutions for plastic recycling, creating new packaging sheets entirely from recycled PET that’s globally proven to be 100 per cent safe for food packaging.

Its advanced cleaning process for plastics such as polypropylene (PP), polystyrene (PS), and high-density polyethylene (HDPE) beats the highest international safety standards set by regulators such as the US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA).

e collaboration with Applied Machinery is being driven by the extensive background of Peter Koueik, the Sales Manager for Applied Machinery’s recycling department.

Peter’s close working relationship with Starlinger’s recycling technology

division, dating back to 2016, provided the foundation for establishing Applied Machinery as the o cial representative for Starlinger viscotec in Australia and New Zealand.

Peter says local customers now bene t from local expertise and faster response times from representatives operating within the same time zone, enhanced after-sales support via Applied Machinery’s established service department, and targeted marketing initiatives aimed at better promoting advanced technologies across the region.

He says the addition of viscotec complements the company’s established partnerships with other global brands such as Genox and YVO Shredding Technology, further strengthening its position as a trusted partner for complete, endto-end recycling systems across the Australasian market.

new partnership promises to unlock a new recycled plastic economy ‘Down Under’.

e capabilities of Starlinger viscotec were on show at the recent K Show 2025, a world-leading trade fair for the plastics and rubber industry, held in Düsseldorf, Germany, where the viscoZERO technology was presented in detail.

e melt phase decontamination reactor is designed to super clean post-consumer HDPE, LDPE, PP and polystyrene to food-contact quality.

Peter says the technology is a gamechanger, ushering in plastics recycling in food-grade quality that goes beyond “just PET bottles.”

e technology gives manufacturers an edge by letting them create recycled plastics that meet the toughest food-safety standards and positions companies to easily meet, and beat, new rules, such as the European Union’s 2030 mandate for using a minimum of 10 per cent recycled material in non-PET packaging.

A

The viscoZERO system is available as a complete turnkey solution or can be installed as a retrofit onto existing recycling lines.

e technology’s cleaning e ciency and lasting odour reduction capabilities are a major feature, with Starlinger exhibiting many examples of end products across sensitive industries such as food, cosmetics, and automotive.

Markus Neudorfer, Managing Partner at PETman, a recycler and converter, stated that after evaluating multiple technologies for polyole ns and polystyrene, the company chose viscoZERO technology because of its “outstanding decontamination e ciency and a lasting odour reduction.”

e core technology behind viscoZERO is its ability to perform a deep intrinsic cleaning of used plastics in the melt phase.

e process e ectively removes volatile contaminants, which is crucial for allowing recycled plastics to be used in sensitive applications such as foodcontact packaging.

For plastics such as polyester, a major bene t is the quick increase of intrinsic viscosity (iV), a measure of material quality.

Essentially, the technology allows for genuine “recycling” instead of “down-cycling”,it avoids PP, PE, and PS plastics from being limited to lowgrade products.

e viscoZERO system is available as a complete turnkey solution or can be installed as a retro t onto existing recycling lines.

“It is a practical tool that supports the environment while creating new business opportunities for local recyclers and plastic processors by delivering odourless, high-quality, and food-safe recycled materials,” says Peter.

Starlinger viscotec also o ers the viscoSHEET line, a cutting-edge sheet extrusion system designed to make quality PET sheet using up to 100 per cent recycled material. is system guarantees that the recycled

content is fully decontaminated and approved for food contact by strict regulators. It also ensures the nal sheet has excellent physical strength and consistent quality, making it suitable for food packaging and thermoformed products.

Features such as autoSTART, autoGAP, autoGAGE, and autoDIE make its operation simple and highly automated.

For more information, visit: www.appliedmachinery.com.au

rPET sheet using up to 100 per cent recycled material.

Starlinger viscotec’s technology creates new packaging sheets entirely from post-consumer recycled PET. Image: Starlinger viscotec

The economic case for recycled plastics

A new analysis will quantify the economic, environmental, and social benefits of using Australian recycled plastic to push for urgent packaging reform.

Australia’s leading recyclers, resource recovery companies, and brand owners have joined forces to commission a crucial analysis, demonstrating the urgent need for packaging reform and highlighting the economic, environmental, and social bene ts of using Australian recycled plastic.

e Advancing Plastics Recycling in Australia (APRA) Project, led by the Australian Council of Recycling (ACOR) and the Australian Packaging Covenant Organisation (APCO), aims to directly inform governments on strengthening domestic recycling and manufacturing capabilities, fostering resilient markets, cutting reliance on virgin and cheap imported plastics, and ensuring plastic waste is managed responsibly.

is project is key to boosting domestic manufacturing while improving Australia’s circular economy.

Speci cally, the project will quantify the environmental and economic value of a strong local plastic recycling industry to incentivise the use of domestic recycled content in the Federal Government’s upcoming National Packaging Laws.

“Packaging reform is long overdue, and the stakes are high,” says Suzanne Toumbourou, Chief Executive O cer of ACOR.

“Without strong domestic markets for locally recycled plastic, Australia risks repeating Europe’s experience, where falling demand and cheap imports have

forced plant closures and left recycling capacity stranded.

“With a ban on the export of plastic waste, and signi cant investment in recycling infrastructure through the government’s Recycling Modernisation Fund, Australia must now ensure that locally recycled plastics can compete with virgin and cheap imported material.”

She says the APRA Project will measure the real bene ts of using Australian-made recycled plastic in packaging and show how it can be a win for jobs, the environment and the economy overall.”

In 2018 Australia established the ambitious National Packaging Targets to create a new sustainable pathway for how packaging is managed in Australia. e targets apply to all packaging that is made, used and sold in Australia and include 100 per cent of packaging being

reusable, recyclable or compostable, 70 per cent of plastic packaging being recycled or composted, 50 per cent of average recycled content included in packaging, and the phase out of problematic and unnecessary single-use plastic packaging.

Earlier this year the Department of Climate Change, Energy, the Environment and Water, said progress is being made toward the target but more work is required to increase the volume of plastic packaging being recycled and the amount of recycled content in plastic packaging.

Chris Foley, APCO Chief Executive O cer, says that building strong, lasting demand for Australian recycled plastic packaging is essential to achieving packaging targets and circular outcomes.

“By quantifying the economic and environmental value of Australian plastic recycling, this project can provide the evidence backbone for policy and investment decisions that deliver stronger domestic markets and support much-needed national regulation of packaging.”

Strategic consultancy rm Rennie Advisory has been commissioned to undertake the APRA Project. e results will be vital for government and industry as they nalise national packaging reform processes and investment frameworks aimed at reducing plastic waste and enhancing domestic recycling capability.

Industry leaders say the project is key to boosting domestic manufacturing and improving Australia’s circular economy. Image: Sergey Ryzhov/shutterstock.com

Applied Machinery

Australia is bringing in a monster singleshaft shredder from its exclusive partner, YVO! The H30 will be displayed at Applied Machinery’s showroom soon.

The H30 shredder is a high-strength equipment capable of continuous operation in various harsh working environments. Different types of feedstock can be processed to desired size by a single pass. The equipment operation has significant characteristics such as low noise, low dust, low energy consumption, low maintenance costs, high reliability and high output.

This shredder is mainly designed for the following applications:

•Aluminum profile

•Various type of cable

•Domestic waste

•Commercial waste

•Bulk waste

Specifications

Quantity of rotor 1 pc

Rotor operation lengthApprox 3,000mm

Rotation diameter Approx 1,000mm

Type of rotor blade Crown type

Size of rotor blade 100 x100mm

Quantity of rotor blade50pcs

Quantity of counter blade26pcs

Rotation speed 10-41RPM

Type of ram Swing ram pusher

•Industrial waste

•Waste wood

•Green waste

•Cardboard or paper

Main drive 2 x 210kW Baumueller synchronous permanent magnet motors and corresponding inverters

Hydraulic drive 15kW

Gearbox Rigianna Riduturi Drive LEOG

Dimension Approx 8,360 x 2,470 x 5,360mm

Weight Approx 39,000kg

Bacteria brews bioplastics

Forget landfill: our food waste is about to become the next generation of plastic packaging

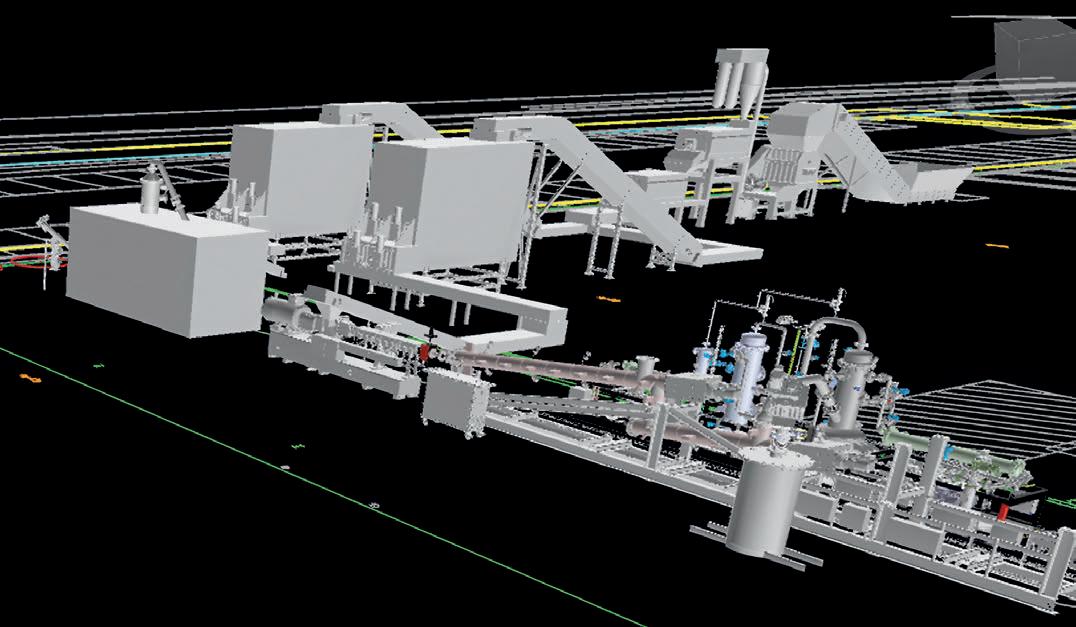

Anew Australian study shows food scraps could hold the key to a fully compostable, sustainable alternative to petroleum-based packaging.

Monash University researchers, led by Edward Attenborough and Dr Leonie van‘t Hag, have optimised a process to convert the sugars in food waste into polyhydroxyalkanoates (PHA) biopolymers – a natural plastic that performs just like its conventional counterpart. is breakthrough o ers a potential, compostable solution for

products from food lms to agricultural silage wrap.

Edward’s involvement in the research stemmed directly from his chemical engineering background and a desire for real-world impact. He started his PhD in 2021 speci cally to tackle challenging waste streams.

“I wanted to do something that had an ongoing impact on reducing our pollution and our waste materials,” Edward says. “ is seemed like a fantastic way to combine Biochemical

Engineering, Polymer Engineering, and chemistry altogether to try and create a solution to the big problem of fossilbased plastics reliance, and how we can try to make a circular version of that.”

e team’s “secret weapon” is a pair of soil-dwelling bacteria, which are fed a balanced “diet” of waste sugars, salts, and nutrients. Once the microbes fatten up, they stockpile natural plastic inside their cells. is PHA plastic is then extracted and cast into superthin lms.

Edward Attenborough and Dr Leonie van’t Hag are creating smarter bioplastics for packaging and medical films to cut down single-use waste. Image: Monash University

e Monash research advances bioplastic development by showing how blending the material from two di erent bacterial strains allows scientists to tune the lm’s properties, controlling its melting point and crystallinity for speci c applications. Crucially, the nal material is truly compostable.

“ ese polymers are fully biocompatible, and they can be broken down by most microorganisms,” Edward says. “ ey break down within 180 days, so they meet the home-compostable standard.

e really exciting thing about these polymers is they’re completely marine biodegradable.”

Edward describes the research as the third generation of bioplastics, moving beyond earlier concepts such as PLA (polylactic acid) – a biodegradable and compostable bioplastic derived from

renewable plant-based sources such as corn starch, sugarcane, and cassava.

While the rst generation focused on industrial composability, and the second on using sustainable bio-based sources, this new frontier focuses on waste material. Globally, large-scale production facilities in countries including China and South Korea are already proving the concept, though the a ordability of petroleum plastics remains a major hurdle.

Edward sees this as a de nitive shift towards circularity in bioplastics.

“ is third generation is looking at how we can take a waste material, use bacteria to ferment it, and create polymers that fully compost and don’t create microplastics. at is what’s so exciting,” he says.

e team is collaborating with industry partners such as Enzide,

through the Australian Research Council’s research hubs for Carbon Utilisation and Recycling, and ValueAdded Processing of Carbon Waste, to develop biodegradable packaging and medical solutions with potential commercial applications. Enzide is an Australian unlisted company that o ers alternatives to fossil fuel and single-use plastic, with patented, scalable technology.

Edward will also travel to the United States to continue his research, having been awarded a Fulbright Scholarship.

“ is research demonstrates how food waste can be transformed into sustainable, compostable ultrathin lms with tunable properties,” Edward says. “ e versatility of PHAs means we can reimagine materials we rely on every day without the environmental cost of conventional plastics.”

AI, the first responder

Imagine a fire suppression system designed to detect, verify and extinguish fires faster than human response. Enter, FlameSmart.

This is essentially a rst responder – a reman on the wall – that prevents a small incident from becoming a disaster.”

It’s a powerful statement from Nick Boyd, Founder and Chief Executive O cer of FlameSmart, as he highlights a core issue facing the waste and resource recovery sector – the speed at which res can spread.

By the time emergency crews arrive, a small thermal event has often escalated, resulting in millions of dollars in losses and operational downtime.

“Fire ghters have told me that by the time they arrive at blazes at waste

facilities, it’s already a write-o ,” says Nick. “ e re spreads so quickly that even the most dedicated re brigade e ort is often too late.

“First response is critical.”

e FlameSmart system is designed to act exactly as a human re ghter would, but with 24/7, Arti cial Intelligence (AI)-driven response.

“It thinks and acts the same way a re ghter would, which is a new approach based on AI image recognition,” Nick says.

e concept for FlameSmart was born out of a moment of personal urgency during the Black Summer bush res,

which burned across several states in 2019-20.

Nick and his wife were watching the news and seeing countless stories of people being forced to evacuate their properties, their homes unprotected and often lost to the ames.

Having worked at the University of Tasmania setting up an Internet of ings (IoT) course, Nick realised that using sensors to detect re and an autonomous system to extinguish it was technologically feasible.

Initially, the idea was focused on protecting individual households. However, the focus quickly shifted

The system is capable of delivering a firefighter-grade flow of up to 2800 litres a minute in a focused jet. Images: FlameSmart

to where the risk and nancial loss were highest: large industrial sites such as waste and resource recovery facilities.

is provided the business case for developing a powerful, sophisticated, and always-on system – a kind of permanent, digital re ghter capable of preventing small thermal incidents from becoming total write-o s for businesses.

e system operates by coordinating high-grade vision and powerful action. FLIR thermal cameras provide the vision, detecting a re’s earliest heat signature and feeding data to the AI “brain”, which then triggers Elkhart Brass re monitors, or water cannons, as well as alerting re authorities and other critical contacts. Even if communications are down, the system continues to suppress the re independently.

Nick says this setup allows the system to put out a typical re in as little as 25 seconds after the rst ignition.

“ e system connects directly to the site’s local industrial re mains, capable of delivering a re ghter-grade ow of up to 2800 litres a minute in a high-pressure jet, projected to a maximum distance of 65 metres,” he says.

Developing a technology that needs to be right every single time requires intense, real-world validation. FlameSmart underwent a gruelling 10 months of extensive live re trials at a Victorian waste transfer station to iron out every detail and edge case.

One surprise challenge demonstrated the technical precision required.

“ e thermal camera was set up so that it could see just outside the building,” Nick recalls.

“We started getting false alarms every evening at a certain time. It turned out that it was being triggered by the sunset. We cropped the thermal camera image to ignore those pixels

outside the building. Boom, it’s gone. No false alarm.

“It was fascinating conducting the trial because you learn so much about the details of the equipment. It’s highly precise equipment, and it does a great job.”

e system’s fast response is essential even during working hours. Nick cites a case, before FlameSmart was installed, where paint thinners, crushed by a bulldozer, caused a small re that “crawled rapidly up to the top of the waste pile”.

While the onsite team quickly dealt with the chemical re, the incident demonstrated the speed with which a ame can climb an unseparated waste pile, a massive vulnerability that only a machine capable of a near-instant, highow response can mitigate.

For the growing threat of lithiumion battery res, Nick says the system’s role is slightly di erent but no less critical.

Since lithium res can only be extinguished by submerging the material, FlameSmart aims to stop the spread to surrounding, combustible fuel sources, protecting the building until the battery burns out or the re brigade can safely isolate the material.

When the re brigade does arrive, the system seamlessly integrates.

FlameSmart works with local re brigades to include the system in their pre-incident plan, allowing them to either easily switch o the autonomous system to take over, or in highpressure situations, even run the systems in parallel.

Nick says the response from emergency services has been positive: “ ey are happy to turn up and see that the critical rst battle has already been fought and won.”

But the argument for FlameSmart goes beyond re safety.

e technology is a critical investment in business continuity and nancial risk mitigation.

“A catastrophic re can put a business out of operation on that site for potentially two years during a rebuild,” Nick says.

“ e second major impetus is insurance. e interest from the insurance industry has been signi cant, validating the technology as a genuine risk reduction tool that translates into reduced premiums and, crucially, reduced risk to capital.”

For more information, visit: www. amesmart.com.au

The FlameSmart system can put out a normal fuel fire in as little as 25 seconds after the first ignition.

A catastrophe waiting

Ignoring small, frequent fires is the fastest way to lose an entire waste facility. Jill Lethlean, Director of Lethlean Fire and Environment, explains.

Minor re incidents are an unfortunate reality across the Australian waste industry. For many facility managers, a small, quickly extinguished re in a pit, processing line, or stockpile is a cost of doing business – an inevitable nuisance that is swiftly contained.

is mindset, however, ignores the “hazard pyramid”: the principle that if a consistent log of small res ensures, eventually, one will become uncontrollable.

According to Jill Lethlean, Director of Lethlean Fire and Environment, this tension between routine containment and catastrophic loss is one that the industry must address.

“Fires might be small, but they are never insigni cant,” Jill says. “ e thing is that if you have enough small

res, sooner or later, one will get away from you, and you’re going to end up with a very large re, and you could lose your whole facility. So, it is worth taking seriously.”

e expense of a major re is not limited to the loss of a facility itself. It includes loss of licence, reputational damage, lengthy downtime, and enormous remediation costs.

Compared to this potential nancial fallout, a thorough re risk assessment is one of the most cost-e ective investments a facility can make.

Jill, a specialist in re safety engineering with a background in the waste sector, says generic re safety measures are often insu cient in the waste industry.

Her approach involves evaluating waste facility designs right from the

start, providing an understanding of how di erent waste materials behave in a re, ensuring designs minimise re spread and maximise suppression. e threat of lithium-ion batteries is a textbook example. Unlike conventional waste res, battery res are chemically driven and notoriously di cult to extinguish. ey are creating a new, severe category of re hazard that demands updated response readiness.

Jill says that as the use of lithiumion power has exploded, batteries are nding their way into every type of waste stream imaginable. Facilities that historically considered themselves low risk must now factor in this hazard.

“If they’re collecting waste from kerbside, chances are there’ll be a battery there at some stage,” Jill

Understanding how different waste materials behave in a fire can help minimise fire spread and maximise suppression. Image: Tongpool Piasupun /shutterstock.com

“Fires might be small, but they are never insignificant.”

Jill Lethlean, Director, Leathlean Fire and Environment

says. “Batteries are in everything, inside vapes, electric toothbrushes, power tools, and even ashing children’s shoes.”

She says if facilities are not prepared for a battery-related thermal runaway event, which requires unique suppression agents and isolation procedures, a minor incident can quickly escalate, rendering standard equipment useless.

Waste facilities are complex environments with highly speci c materials, processes, and stock control methods that vary from site to site. A re plan for a construction and demolition facility is useless for an organics plant, and vice versa.

Jill says that too often, facility managers expect a re engineer to walk the site and intuitively understand all the operational nuances. She advocates for a speci c, tailored assessment that requires deep engagement from the operators.

“ e waste operator must act as an active partner in the assessment, clearly explaining material ows, processing points, peak stockpile volumes, and speci c hazard zones,” she says.

“It is important to actually engage with a re engineer and explain what’s going on. is ensures the resulting re safety system, be it water cannons, monitoring technology, or operational procedures, is truly t for purpose.”

For many facilities, a review of re readiness is only initiated under duress, typically driven by a development application (DA) requirement or a condition attached to their licence.

Jill says facilities that have been operating for years without signi cant changes often have obsolete re systems that do not account for modern waste streams, increased volumes, or evolving regulatory compliance standards.

She says the expertise o ered by specialists who understand both the engineering standards and the

operational realities of a materials recovery facility or transfer station is invaluable. It provides certainty that the system will perform under pressure, protecting the facility’s assets, licence, and employees.

“If the waste facility has been there for a long time and hasn’t changed anything, then there’s a pretty good chance that the re system is out of date,” Jill says.

“A risk assessment is not that expensive, especially compared to the cost of actually losing a facility.”

For more information, visit: www.lethlean reandenvironment.com.au

Energising organics

A transformation is underway in the Organics-to-Energy (OtE) sector, spearheaded by environmental technology solutions provider NALG. Philip Parekalam, NALG Founder, explains.

As Australia steps into an era where environmental responsibility and circularity is crucial, NALG’s upcoming ground-breaking projects in Australia and New Zealand are leading the charge to revolutionise organic waste management and expand processing infrastructure.

From mid-2028 onwards, NALG, in cooperation with global cleantech company Kanadevia Inova, is set to build and operate facilities capable of treating more than 260,000 tonnes of organic waste annually.

Philip Parekalam, Founder, Chief Executive O cer and Managing Director, says the organics industry is critical to the foundation of achieving net-zero goals and climate change mandates.

However, the limitations of traditional composting, often mired by contamination and evolving environmental regulations concerning PFAS (poly uoroalkyl substances)/ PFOA (per uorooctanoic acid), necessitate a more advanced approach.

NALG is answering the call with its Hybrid Processing Solution (HPS) – a state-of-the-art, proven technique that goes beyond composting.

NALG began as a company supplying technology to the organic industry and has transformed into a fully integrated Design Build Own Operate company with its own engineering, procurement and construction (EPC) team and inhouse technology.

It is also an exclusive collaborative technology partner with Kanadevia Inova for all organics-to-energy (OtE) technology and research and development.

NALG’s HPS synergistically integrates Kanadevia Inova’s advanced dry anaerobic digestion Kompogas technology with NALG’s proprietary in-vessel tunnel composting technology, complemented by a modern carbonisation plant.

Philip says this innovative framework aims to convert organic materials into not just compost, but valuable resources – including biochar and biogas – while reducing the mass by up to 85 per cent.

“In a world where urban populations are rising and real estate is at a premium, HPS provides a sustainable solution that alleviates the burden on ratepayers and the environment,” he says.

NALG’s pioneering facility, the Midcoast Regional Organic Processing Solution (MC ROPS) in New South Wales, is poised to handle 146,000 tonnes of organic waste annually, including food organics and commercial food by-products.

is initiative aligns with the state’s 2030 FOGO (Food Organics Garden Organics) rollout and showcases NALG’s commitment to innovative solutions in organic waste management.

Philip explains that while there’s a push for composting across Australia, emissions challenges, processing limitations, changing weather patterns and rising energy costs present signi cant hurdles for councils and operators.

NALG aims to rede ne these narratives with modular, proven technologies that foster greener operations and substantial waste reduction.

e company vision transcends the role of a technology provider to a design, build, and operations company for sustainable waste management.

“ rough a strategic partnership with Kanadevia Inova – built on more than a century of expertise and the success of more than 100 renewable gas projects – NALG is driven by a passion for energising organics.

“Our mission is forti ed by a team of more than 3000 engineers across the globe, ensuring we do not merely experiment with potential solutions but instead leverage extensive, real-world experience to deliver and operate our facilities,” Phillip says

Philip Parekalam, Founder, Chief Executive Officer and Managing Director of NALG, with Marc Stammbach, Managing Director and Country President at Kanadevia Inova Australia. Images: NALG

e essence of NALG’s integrated approach lies in fostering a circular economy where the right technologies are adapted to e ectively convert organic waste into essential resources. is not only promotes environmental sustainability but also enhances resource e ciency.

“By transforming organic waste into valuable products, we are re-envisioning waste materials as vital components of an environmentally responsible future,” Philip says.

He further explains that the potential of centralised regional processing cannot be overstated; larger plants with capacities exceeding 100,000 tonnes per annum and processing diverse feedstock signi cantly lower capital expenditure and operating costs.

As urban areas grow, OtE services are best co-located where these

valuable products are consumed. is also supports the NSW Environment Protection Authority’s plan for locating processing infrastructure away from densely populated centres.

“By using biomethane as a diesel fuel replacement, NALG o sets fossil fuel emissions, making projects environmentally bene cial, despite the transport required to consolidate and transfer organic waste to regional processing sites,” he says.

“It’s clear that innovative processing sites are pivotal to advancing OtE in

Australia. OtE should be regarded as a cornerstone of successful circular resource recovery precincts.”

With NALG’s agships now spreading outside of Australia to New Zealand, the focus is to establish a standalone HPS (technology supply and integration) business for the wider organic sector, with o ces planned in the Netherland and Middle East to support the growing global organics sector.

For more information, visit: www.nalg.com.au

A concept view of the proposed Midcoast regional facility.

Powering a circle

Sydney’s waste management landscape has received a boost with the revival of Veolia Australia and New Zealand’s pioneering EarthPower facility in Camelia, New South Wales.

For years, the closure of Australia’s rst food waste-to-energy plant left a critical gap in the nation’s organic waste infrastructure. Its reopening in 2025 represents more than just a refurbishment; it’s a statement about the viability of anaerobic digestion and a renewed commitment to circular economy principles.

During the refurbishment process, Veolia leveraged expertise from its local and international technical teams to implement state-of-the-art technological upgrades that make the anaerobic digestion process stable, safe, and e cient.

Carmen Loecherer, Veolia’s General Manager Resource Recovery in New

South Wales, says the company is delighted with the upgrade of the landmark facility, which creates signi cantly more capacity for processing food waste in Sydney.

“We’re already servicing a number of customers in both the commercial and municipal sectors, and it’s great to be open for business again,” she says.

e upgraded “plate to paddock” facility, with a total capacity of 62,500 tonnes (65 per cent dedicated to food waste), will produce 1500 tonnes of soil improver and generate green electricity, potentially powering 4000 local homes.

One of the most signi cant upgrades is a new ‘bu er tank’ system that helps manage the ow of waste coming in. is acts as a staging area, controlling the ow of feedstock so it doesn’t overload the system.

e facility can now gradually introduce di erent organic waste streams while maintaining the critical bacterial balance.

“For optimum performance, we carefully manage our bacteria – keeping them at around 38 to 40 degrees, maintaining the right pH levels and feeding them the right mix of materials to keep them healthy and productive,” Carmen says.

“We’re taking it slow with introducing new waste types. Right now, we’re sticking to food waste that we know our bacteria can handle well.”

Carmen emphasises the precision required: “You need to keep an eye on everything – the acid levels, the gas we’re producing, the methane content.

The facility can now gradually introduce different organic waste streams.

We want about 55 to 65 per cent methane for good energy production.

“It’s all about balance – too much waste and you get too much acid, too little and you’re not being e cient.”

EarthPower’s specialised capability to handle liquid waste sludge also addresses a critical market gap.

“Liquid waste is trickier than solid food waste,” Carmen notes. “We have to screen it rst, remove any grit, and then carefully mix it with other materials.

e key is getting the right carbonto-nitrogen ratio and making sure everything mixes properly in the tanks.”

e methane produced during digestion is converted into green energy through combined heat and power units.

Carmen says the facility is producing about 350 to 400 cubic metres of biogas from each tonne of waste, about 60 per cent of that is methane.

“Our generators convert that to electricity at around 35 to 40 per cent e ciency, which means we can power ourselves and still have energy left over for the grid.”

Veolia views EarthPower as a proof of concept for strategic replication.

“ e technology is quite sophisticated – we have automated systems,

continuous monitoring of temperature and gas composition, all sorts of controls,” Carmen says.

She says the technical achievement of the rebuild represents more than operational success.

“When you understand how the bacteria work – what they need, how they break down waste, how they produce methane – you can

really optimise the whole process. We’re basically creating the perfect environment for these microorganisms to turn waste into something valuable.

“It’s like being a farmer, but instead of crops, we’re growing bacteria that eat waste and give us energy.”

For more information, visit: www.veolia.com.au

The upgraded facility has a total capacity of 62,500 tonnes.

Veolia’s refurbished EarthPower facility was reopened in 2025. Images: Veolia

Can-do compost

Mulbarton Compost is revolutionising the agricultural compost space in South Australia.

With a mission to produce the best possible compost and improve soil health, Mulbarton Compost is taking the organics world by storm.

What started as a small family venture in Padthaway, South Australia more than 30 years ago, has grown into a successful business with a focus on soil improvement and education.

Before taking on a range of varied waste streams, Mulbarton Compost primarily worked with local wineries on composting grape mark.

“It was the wineries that introduced us to composting because they wanted

us to transform their vineyard waste into compost,” says Phil Giles, CoFounder of Mulbarton Compost.

“Now we focus largely on biological and nutrient improvement, working with our customers to ensure we are producing a premium product to meet their needs.”

With two sites and a nishing pad, Phil and the team are well equipped to work with viticulturists, farmers and croppers across South Australia and neighbouring states. Phil says distance is not an issue – having run road trains up

“We focus on quality over quantity and service a niche market by providing the farmers with products they wouldn’t normally utilise,” he says.

ENDLESS POSSIBILITIES

All waste can be turned into a resource, according to Phil, who says there is an endless scope for turning organic material into useful pro table products.

“So much of the material has the potential, with the right inputs, to be repurposed and put back into the

The team carry out multiple trials per year across its two sites.

Images: Mulbarton Compost

Using natural biological processes and products, Mulbarton Compost works to heal soils that are causing problems for farmers.

“Our team will assist the customer in identifying what the soil needs and develop a tailored solution to suit the goals of the customer,” Phil says.

“Some farmers are told by agronomists to use chemical processes or products to x certain issues, but we prefer to use a unique blend of natural organic products composted to Environment Protection Authority (EPA) standards.”

Incorporating years of study and development, Mulbarton Compost aims to produce a product with biological diversity and activity that aids soil development and production yield.

Bene ts of using the product can include improved soil biology, an increase in weed suppression, improved soil friability, plant health and soil structure, which leads to improved soil performance.

To continue learning about the everchanging organics landscape, Mulbarton Organics Compost frequently oversees trials on both of its sites.

Currently, the team is working on several compost and biochar trials with Landscape SA.

Comprising eight regional landscape boards and the Green Adelaide Board, Landscape SA works with the Department for Environment and Water to manage South Australia’s land, water, pest plants and animals, and biodiversity.

Phil says these trials will involve planting various multi-species crops into a farming environment, followed by the use of compost and bio-char to improve soils. Plant growth and animal performance will then be measured.

While current trials allow the team to learn about potential new processes, past trials have shown the importance of passing on knowledge to clients.

“One trial we were involved in, using compost in a fertiliser comparison, could have gone better if everyone involved had more information on the process,” says Phil.

“Our trial partner required the fertiliser to go out on a certain day, which happened to be 40 degrees and very windy. is wouldn’t have been a problem if our compost wasn’t full of live biology!

“Unfortunately, the trial had a limited e ect initially before ultimately doing really well. But if they had been aware that working with compost is like working with living animals, which need to breathe and have moisture, we could have avoided a lot of damage.”

EDUCATION MATTERS

An in-house agronomist on site is part of the company’s holistic approach to providing the best service and educational process.

“We work really hard on educating our customers where possible,” says Phil. at education comprises several initiatives, including free educational courses and eld days.

For ve years, the courses and eld days have proven a success, earning Phil and the team positive feedback and a returning customer base.

“ ere’s big potential out there for everyone to branch into the education side, because many people are unaware of what’s involved with the compost process. Most of the time people are willing to learn if it will mean better results,” he says. “If we can continue to educate our users to recognise

that compost needs to be treated di erently than fertiliser, everyone will be better o .”

In future, Phil and the team are excited about doubling the sites to allow for more opportunities and capabilities, as well as installing more equipment and growing the company.

AORA’S SUPPORT

John McKew, National Executive O cer for the Australian Organics Recycling Association, visited Mulbarton Compost in late August, and was instantly captivated by discussions with Phil.

“What stood out for me from the visit with Phil is the focus and commitment to providing bespoke organic solutions to farmers,” says John.

“What started o as a focus on local wineries in the Padthaway region has now expanded to farmers who want a solution to their soil health problems.”

John says the introduction of compost, in application with traditional fertilisers, is important work being undertaken by Mulbarton Compost.

“Compost applications in agriculture is extremely important to the organics recycling sector and to our farmer endusers,” he says.

“Producing quality compost is just the start of the process for Mulbarton, its stance on education and applications in order to nd solutions to organics problems will continue to grow.”

For more information, visit: www.aora.org.au

Mulbarton Compost, located in South Australia, has one mission – to produce the best possible compost and improve soil health.

Steel’s greener future

Tasmania’s oldest foundry is transforming into a modern, carbon-neutral manufacturing success story.

Afoundry is perhaps the ultimate symbol of heavy industry: smoke, molten metal, and a heritage stretching back centuries.

In Australia, this traditional manufacturing sector has long wrestled with the pressures of global competition and the need to modernise. On the outskirts of Launceston, a business with roots tracing back to 1834 is proving that tradition is not a barrier to innovation.

Castings Tasmania is forging a new path, using advanced automation and a commitment to the circular economy. It’s demonstrating how Australian industry can successfully transition from mere survival to global competitiveness, underpinned by environmental stewardship.

Castings Tasmania, which primarily manufactures large, technical steel castings for the rail, mining, and industrial sectors, has a history marked

by both boom and near-extinction. After operating under various corporate ownerships, the business was shuttered in 2016 and later revived by the EcoCycle Group, which saw the potential of the facility and its skilled workforce. at legacy, while rich, came with inherent challenges that required systemic change, especially in environmental and operational practices.

Dean Lalor, General Manager at Castings Tasmania, says the journey has been about much more than just staying a oat.

“We’ve not only survived the challenges facing the Australian manufacturing industry, but – through invigorating strategies, especially around automation and the circular economy, coupled with investment from our parent company – we’re now well positioned to transition from simply surviving to becoming a thriving success story,” Dean says.

“If we think about the business itself, it comes with tradition and heritage. A lot of old practices come with that, and not all of them good. ere is a multitude of history that we need to unwind and change at the same time.”

As part of the EcoCycle Group, which includes EcoCycle, EcoBatt, Eco E-Waste, Recycal, and ACL Metal Powders, Castings Tasmania has embraced evolution, targeting sustainability and operational excellence. e core of its transformation lies in the company’s

material sourcing and energy pro le. About 97 per cent of its product is produced using recycled steel. is immediately provides clients with signi cant Environmental, Social, and Governance (ESG) bene ts, a crucial metric for major industrial customers.

Compounding this advantage is the plant’s geographical location. Based in Tasmania, 85 per cent of the foundry is powered by the state’s hydroelectricity grid.

Newly installed pulsi ed gas burners use 50 per cent less gas. is means that the most energy-intensive part of the process – melting steel – is already largely decarbonised, positioning the foundry ahead of many international competitors reliant on coal- red power.

Beyond energy and steel, Castings Tasmania views every input as a resource that must be managed responsibly. is extends to the moulding sand, a non-renewable resource that is currently facing shortages in Australia.

e company is exploring ways to remove used casting sand completely out of the waste stream and into the circular economy, either by reclaiming it for repeated use within the foundry or by repurposing it into a component, such as concrete, for other industries.

Dean is a staunch supporter of the company’s approach to resource recovery, referring to the team’s role not merely as recyclers, but as stewards of the materials they use.

Castings Tasmania primarily manufactures technical steel castings for the rail, mining, and industrial sectors.

“ is circular economy is not just a buzzword. We need to own it, because we need to make the most of our resources that we currently have,” he says.

“We are just custodians of these resources. In the past, industry has been very good users. Now, all EcoCycle Group businesses are about recovering as much as we can, and repurposing and recycling. It’s stewardship of our resources.”

Embracing this philosophy has driven signi cant capital investment in automation and technology. e foundry is currently commissioning a rst-in-Australia prototype robotic cell designed for the nishing of castings. Traditionally, this laborious and high-risk work involved sta using grinders and oxygen cutters.

“By changing some of the processes, we can remove some steps that require energy consumption,” Dean says.

“Before, we used to heat up some of the castings to process them. By using a robot, we don’t need to heat them. erefore, we’re removing some energy costs, as well as ensuring we have consistent, repeatable processing. ere’s also a secondary bene t of improved productivity.”

is digital transformation strategy is deliberately aligned with the company’s people strategy. By automating physically demanding and repetitive roles, Dean says the business can focus on attracting and training personnel for high-skill, technical roles, ensuring the essential skill set remains in Australia.

He believes the future of Australian manufacturing must be built on a foundation of quality, accessibility and sustainability.

“What is our value proposition for people to buy from us, versus buying it from larger manufacturing places? It has to be around quality, delivery time, and ESG,” he says.

“When you get a lining to go to a mine site out of Castings Tasmania, and you contrast that with a lining coming out of

an international market, I know where the ESG value is going to be.”

Looking forward, the vision is ambitious. Castings Tasmania aims to transition from solely producing castings to manufacturing the nal, full product, complete with machining. is will not only capture more value in the supply chain but also reinforce Australia’s manufacturing sovereignty.

e ultimate goal, however, is a moonshot for heavy industry: carbon neutrality.

“ ere is no reason why we cannot get to that position,” Dean says. “ e carbon credits that we get from recycled steel coming through – that is a massive credit base to work from.

“ en, if we can start using thermal energy and solar, there is a lot of opportunity where we could end up being carbon neutral. Why shouldn’t we aim for that?”

For more information, visit: www.castingstas.com.au

Castings Tasmania is proving that tradition is not a barrier to innovation.

Images: Castings Tasmania

Service, support, and scale

Tana Australia is doubling down on service excellence and strategic expansion under new leadership.

In the high-stakes environment of a modern land ll or resource recovery centre, time is not just money – it is health, hygiene, and compliance.

When a critical machine stops, the entire operation grinds to a halt, creating a chain of risks that quickly moves beyond a simple production delay. e challenge for equipment suppliers is not just delivering highquality machinery but ensuring that downtime is minimised to near zero.

It’s this mandate driving the renewed focus and expansion plan for Tana Australia under its new Country and Sales Director, Al Garcia.

Al, who took the helm in July, brings a wealth of experience from a di erent, yet equally demanding, heavy industry: mining. He spent years in that sector, even founding his own family manufacturing business, which was built entirely on solving core industry problems: a crippling lack of reliable service and durable products.

“Whenever I visited a site, I always found out their pinch points, their problems, their issues,” Al says.

“Overwhelmingly, everyone was saying, ‘you know, getting service and support or a product that lasts is almost impossible’.” at singular focus on resolving customer pain points is the engine driving his transition to the waste and recycling sector.

Al’s attraction to Tana was twofold: he had long held the Tana product

in high regard from his earlier work selling heavy equipment, and he saw a rare opportunity to start with a “clean slate” backed by the full support of the factory.

He views the Australian and New Zealand market as ripe for expansion, provided the core customer promise, minimising machine downtime, is guaranteed.

In the 24/7 world of waste management, a broken piece of equipment has profound consequences that quickly cascade across the operation.

“ ese machines are a critical piece of equipment,” Al says. “I mean, downtime, you’ve got to minimise it to basically zero. If a machine stops,

the waste doesn’t stop; the waste keeps coming in.

“It creates a lot of downstream issues, both from a hygienic, production, and maintenance point of view.”

He says the industry needs a partner, not just a supplier. It’s this ethos that has Tana moving away from simple equipment sales to become an indispensable service and support network.

While Tana Australia is a small business, Garcia sees that as an asset, noting room for growth, particularly in maximising revenue from the service and spare parts division. is will be the main area of focus, underpinned by a comprehensive, proactive review of all existing customer sites, especially those in remote locations.

e new service model is built on two pillars: parts proximity and speed of response.

“With our remote customers, my vision is that we’ll have spare parts containers on their site,” Garcia says, detailing a plan to ensure critical components are already in place, mitigating the delays associated with freight to remote Australian locations.

Tana is also developing strategic partnerships with local service providers across the country. ese local mechanics will be trained speci cally on Tana’s unique equipment, giving customers access to specialised expertise far faster than Tana could provide from its central base.

Al Garcia, Tana Australia Country and Sales Director, sees huge potential for the company. Image: Tana Australia

“ is means that if an issue occurs, there will be someone quali ed and prepared to attend site within a matter of hours, rather than days,” Al says. is strategic focus is also fuelling geographic expansion. Tana is actively working to appoint a new distributor in New Zealand to o er better, localised support to customers across the Tasman. Similarly, the company is looking to grow its presence in Western Australia to ensure customers on that side of the country receive better service.

Al’s service focus is backed by Tana’s core product o ering, which he contends is unique in the market.

Tana’s engineering approach is to design machines that are purposebuilt for the extreme stresses of waste handling, rather than adapting construction or earthmoving equipment. e company’s shredders

and land ll compactors represent their technological advantage.