Affective Rail and Plant’s new Track Remover and Carrier System, the Bravo, delivers powerful performance in a compact package.

Queensland line gets a facelift

PAGE 22

New locomotives hit the tracks

PAGE 31

A historic decision

PAGE 42

Published by:

379 Docklands Drive

Docklands, VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chairman

John Murphy E: john.murphy@primecreative.com.au

CEO Christine Clancy E: christine.clancy@primecreative.com.au

Managing Editor Lisa Korycki E: lisa.korycki@primecreative.com.au

Editor Kayla Walsh

E: kayla.walsh@primecreative.com.au

Business Development Manager

Arron Reed

M: 0466 923 194 E: arron.reed@primecreative.com.au

Client Success Manager

Ben Sammartino

E: ben.sammartino@primecreative.com.au

Head of Design

Blake Storey

E: blake.storey@primecreative.com.au

Designer Apostolos Topatsis

Subscriptions subscriptions@primecreative.com.au

www.RailExpress.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the Publisher.

Kayla Walsh Editor - Rail Express

It’s been another busy month for the rail industry, with major progress made on Victoria’s level crossing removal project, Inland Rail, and more.

Two of KiwiRail’s shiny new DM locomotives have officially completed their trial journeys phase and are getting amazing feedback – we caught up with the operator’s Chief Metro and Capital Programme Officer, David Gordon, to find out more.

But sadly, it hasn’t all been good news for the sector recently, with the announcement that Gold Coast Light Rail Stage 4 has been canned. We share the rail industry’s reaction on page 35.

This month includes a special Plant and Equipment feature, with our cover stars Affective Rail and Plant stealing the show with the launch of the innovative new Track Remover and Carrier System, the Bravo.

Meanwhile, one of Liebherr’s happy customers, Pilbara-based operation Finmec, shares its satisfaction with its new A 922 Rail Litronic railroad excavators, and Loram opens up about its ground-penetrating radar technology.

We find out more about how Allworks combines fleet, skills, and experience to solve complex rail challenges, plus Salix shares the benefits of its next-generation Infinity Composite Sleeper, made from 100 per cent recycled plastics.

With AusRAIL PLUS fast approaching and 7000 rail professionals gearing up to descend on Melbourne from November 25–28, I look at what to expect from the biggest industry event of the year.

Also in this issue, Downer launches its brand-new safety consulting service, Safe+, which is helping rail operators and high-risk industries elevate their safety standards through proven strategies, systems, and cultural transformation.

I had a fascinating interview with Martin Katzmann, Head of Sales at the Early Warning Network (EWN). I learned about the cost of severe weather events to Australia’s rail networks, and how EWN is helping to mitigate the risks.

I also caught up with Yvette Griggs, an inspiring female engineer from Alstom who has recently finished work on a signalling upgrade on Queensland’s North Coast Line.

There's something a little different in this issue too, as I shared a coffee with “Melbourne’s happiest tram driver” Bruce Whalley – a true local character. Plus, I got the chance to speak to David Luketic, a station master with Metro Trains Melbourne, with an incredible passion for making models.

With Australia’s infrastructure and transport ministers making significant decisions on a national signalling pathway, rail governance and speedier approvals for rolling stock, the National Transport Commission does a deep dive on why these represent such major milestones for the industry.

We’ve also got updates from the Australasian Railway Association and the Rail Industry Safety and Standards Board. Happy reading!

kayla.walsh@primecreative.com.au

Leveraging Australia’s leading rail business to empower your safety performance.

At Downer, safety isn’t just a priority; it’s embedded in everything we do.

With over 155 years in rail, we’ve built a reputation for delivering safe, reliable, and efficient transport solutions. Now, we’re putting that expertise to work with industry through Safe+, our Safety Consulting Services business.

We help rail operators, infrastructure providers, and high-risk industries lift their safety performance. Cultural Transformation

The Gippsland Line upgrade is complete, after a 55-day winter construction blitz to install a new train control system between Drouin and Traralgon in Victoria.

It means passengers are benefiting from more than 80 extra weekly services, with

trains set to run approximately every 40 minutes between Melbourne and Traralgon from 8am to 9pm, seven days a week.

As of 14 September, 55 new weekday services and 32 new weekend services have been added to the line, with 14 of those on

Saturdays and 18 on Sundays. Crews worked more than 80,000 hours during the final construction blitz to install new rail signalling equipment and safety-test the new system, before V/ Line completed driver training.

The new train control system will also enable the new platforms at Morwell and Traralgon stations to operate.

Upgrades to Morwell Station include a new second platform, an enclosed waiting room and improvements to accessibility, while Traralgon’s second platform has been rebuilt to allow for more frequent and reliable services.

The Gippsland Line upgrade previously enabled second platforms to be built at Bunyip and Longwarry stations in 2024, and modern VLocity trains to travel to Bairnsdale for the first time in 2018.

Sydney will get its first new heavy rail station in more than a decade, as the abandoned Woollahra Station is set to be resurrected.

Crews started to build the station in the 1970s, but construction was never completed.

The new station will be located on the Eastern Suburbs train line, an eight-minute trip from Sydney CBD.

The New South Wales Government announced that land around Woollahra and Edgecliff stations will also be rezoned, enabling up to 10,000 new homes to be built.

Affordable housing will make up a proportion of the development, with the amount of affordable housing required to be decided as part of the rezoning process. The New South Wales Government said these

areas are suitable for housing as the area is within walking distance of green spaces including Cooper, Trumper, Rushcutters Bay and Centennial parks.

They added that there is also existing capacity for “hundreds” of additional students at public and high schools, and Sydney Water and Infrastructure NSW have confirmed the water and wastewater systems will be able to accommodate the proposed 10,000 dwellings without any major upgrades.

The Eastern Suburbs train line between Bondi Junction and Sydney CBD currently has the lowest passenger usage rates during the AM peak of any line on the Sydney network, with only 43 per cent of operating capacity during the AM peak currently being uetilised by passengers.

The rezoning process is expected to take about two years, with construction on the station to start in 2027, due to be completed in 2029.

New South Wales Premier Chris Minns said the government is committed to delivering new homes in areas with existing infrastructure, in a bid to keep young people in Sydney.

“For too long, young people and families in New South Wales have been forced to choose between moving away from the Sydney CBD or not being able to afford a home at all,” he said.

“This new train station will allow us to deliver up to ten thousand new homes right here in the heart of Sydney, close to jobs, public transport, green space and essential services.”

The Beams Road rail level crossing in Carseldine, Queensland has officially been removed, with traffic switching onto the new overpass.

It marks the first level rail crossing removal in South East Queensland in more than 10 years, according to the Queensland Government.

Westbound traffic (towards Bridgeman Downs) moved onto the new bridge in early September and was followed by eastbound traffic (towards Boondall) and pedestrians/ cyclists later in the month.

The level crossing was permanently closed and decommissioned.

In the past five years, there have been 25 near misses recorded at the level crossing involving pedestrians and vehicles.

Overhead wires were also struck by a heavy vehicle carrying overweight equipment.

In late September, construction

north of the first, which the Queensland Government said will enhance traffic flow and connectivity. Once the second bridge is finished, the completed overpass will comprise four lanes, two lanes going east and two lanes going west.

The Federal Government has committed $56.24 million towards the project, with

In the past five years, there have been 25 near misses recorded at the Beams Road level crossing involving pedestrians and vehicles.

the Queensland Government contributing $138.76 million and $40 million committed by the Brisbane City Council.

Queensland Minister for Transport and Main Roads Brent Mickelberg said: “This project was due to start in 2021, so it has been a long time coming from the communities across North Brisbane, and we’re glad to be delivering this infrastructure to help improve safety and reduce congestion for commuters.

“The removal of the level crossing not only benefits the tens of thousands of motorists who use this important route every day but also makes travel safer for pedestrians and bike riders, who will be able to cross the rail line on a dedicated shared pathway as part of the overpass.

“This is about boosting travel reliability for both road and rail users – and in turn future-proofing this vital roadway in

Extreme weather events like flooding, fire, cyclones and heatwaves cause rail operators unplanned downtime, infrastructure damage, and safety risks which cost millions.

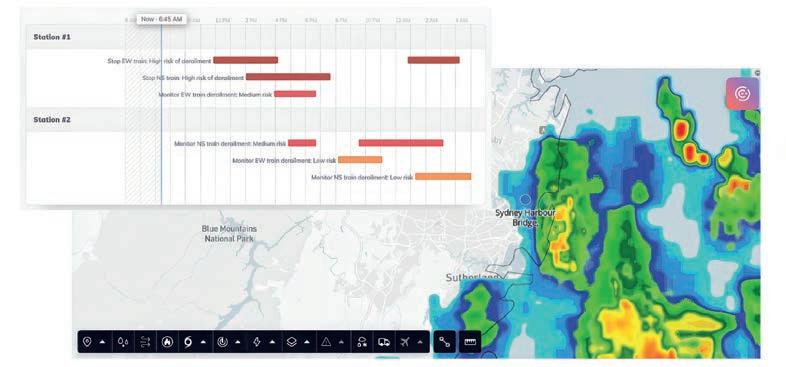

RailAWARE from Early Warning Network brings together leading weather and hazard technology in one solution for rail operators, empowering them to make faster, safer decisions and build long-term resilience against Australia’s most severe weather risks.

To mark the 160th anniversary of rail in Queensland, the State Government has announced a community grants fund for rail heritage organisations.

The $160,000 fund will support notfor-profit groups in their bid to preserve rail history.

Grants of up to $20,000 will be given to eligible rail heritage operators that can demonstrate a clear need for financial support for maintenance and repairs to rollingstock or community rail infrastructure.

Operators must have an Australian Business Number (ABN) or Australian Company Number (ACN).

Minister for Transport and Main Roads

Brent Mickelberg said the new scheme is an opportunity to acknowledge the essential role rail has played in shaping Queensland’s communities, economy, and identity over the past 160 years.

“This grants program is a great way to give back to the heritage organisations that work tirelessly to keep Queensland’s rail legacy alive,” he said.

“We’re proud to celebrate this incredible milestone by supporting those who share

in our passion for rail and its place in Queensland’s story.”

Queensland Rail Chief Executive Officer

Kat Stapleton said the grants will allow heritage rail organisations to continue their meaningful work.

an important and ongoing role to contribute to the social and economic wellbeing of local communities that host our operations,” she said.

The grants program is open to applications via the Queensland Rail website, closing on

A major project to replace rail level crossings in Takanini and Glen Innes in New Zealand with eight new bridges has started.

Pre-construction works kicked off in September, with main construction of new bridges at Takanini, Te Mahia and Glen Innes stations commencing in summer.

Auckland Transport said the project will support more frequent trains while improving safety, keeping traffic moving and enhancing urban areas.

“Level crossing removals are part of Auckland Transport and KiwiRail’s plan to be able to carry increasing numbers of people on quicker, even more frequent, easy train services during the 30 years after City Rail Link opens,” a spokesperson said.

Between 2013 and 2025 a total of 1242 level crossing collisions and near-miss events were recorded in Auckland. Of these, barrier arm collisions accounted for 68 per cent of all incidents.

Auckland Council and the government, through the New Zealand Transport Agency, have brought forward funding to allow the

delivery of the Takanini and Glen Innes level crossing removal projects.

Auckland Transport is also planning how best to replace level crossings on the Western Line, to prepare for more trains to support future passenger growth.

In addition to work starting on station bridges, essential work on the road bridges is underway.

This includes property acquisition, geotechnical investigations, further developing designs of the new bridges, tendering for a construction contractor and further community engagement in the coming months.

Auckland Transport Chief Executive Dean Kimpton said a number of level crossings have been, or will be, removed to be ready for more frequent trains when City Rail Link opens.

This means the average traffic wait time at a level crossing will be similar to an intersection with traffic lights.

Queensland's railways have a rich history. Auckland Transport said the project will support more frequent trains.

“We’re now getting on with the next stage of level crossing removals in Takanini and Glen Innes to support future increases in train frequencies,” he said.

“Auckland Transport has progressed from funding approval to breaking ground for the projects in just six months, there’s a lot of work to get done but people can now see things are happening.”

Adelaide’s trams are back in public hands for the first time since 2020, with the first services owned and operated by the South Australian Government resuming.

The city’s light rail services had been privatised by the previous Marshall Government but were bought back by the Malinauskas Government in February 2025.

A government press release stated 97 per cent of Torrens Connect (Adelaide Metro Operations/AMO) staff have accepted jobs with the government, and a “trained and skilled workforce will deliver a smooth transition for tram customers”.

Premier of South Australia Peter Malinauskas said the return of the tram services to public ownership will benefit all South Australians. “Our trams hold a special place in the hearts of South Australians,”

he said. “We all benefit from the sense of community fostered by a publicly owned and run tram service from the City to the Bay.

“We are acting on principle, and as promised, to reverse the privatisation of essential public transport services.”

All operational earnings will be reinvested into the tram network, and the government will continue to carry out upgrades through the Tram Grade Separation Projects.

Works include removing three level crossings where the Glenelg tram line crosses Marion Road and Cross Road, Plympton and Morphett Road, Morphettville.

The South Road Tram Overpass is also being rebuilt to accommodate the lowered motorway as part of a Non-Stop South Road. The Glenelg line is currently closed for the

works and on track to reopen before the beginning of the 2026 school year.

Minister for Transport and Infrastructure

Tom Koutsantonis said: "Every dollar from rail operations will be returned into our rail network – our trains, trams and people.

"The State Government will continue to make improvements across the tram network."

The previous Marshall Government awarded tram operator AMO and train operator Keolis Downer Adelaide (KDA) separate, initial eight-year contracts with options to extend to 10 and 12 years, respectively.

AMO will continue to maintain tram fleet and infrastructure until 2035. No contract break-fee was paid for the return of rail services to the government.

with the designs revealing a modern new station and vehicle underpass that it said will “transform the town’s railway precinct”.

Inland Rail is modifying the station and building a new vehicle underpass to provide sufficient clearance for double-stacked freight trains.

The visualisations show a bright station with a leafy forecourt opening to the centre of town, a new station platform, two accessible pedestrian underpasses, carparks and green spaces.

adds more trees and seating within the station forecourt, integrates the Euroa goods shed stone foundations in garden beds and retaining walls, and adds a new footpath at Anderson Street, connecting Nelson and Hinton streets.

It also changes the Railway Street carpark layout, to add more green space without losing parking spaces.

Construction at Euroa is progressing with the Anderson Street bridge removed, the Handbury Street pedestrian underpass

new station platform and lift shafts.

Early construction works will focus on the new platform, new west track and carpark on the Elliot Street side of the station, before work begins on the pedestrian and vehicle underpasses, station forecourt and carpark on the Railway Street side.

Pedestrian paths across the rail corridor will change during construction, and the community will be informed in advance.

In June this year, we learned how Affective Rail and Plant’s innovative Track Remover and Carrier System (TRACS) is making work sites safer and more efficient with its ability to move prefabricated track panels with minimal on-site assembly.

The innovative machine, designed in-

times and improved worker safety, as well as having the ability to build new turnout panels where they have enough real estate to do so and bring them onto track where they traditionally wouldn’t be able to in these locations,” he said. “At the same time, some customers operating on narrower or

more constrained networks told us they needed a smaller machine that could deliver the same benefits.

“That input directly influenced the Bravo’s size, design, and transportability.”

Jordan said the Bravo is ideal for narrow gauge systems such as those in regional Queensland or Perth in Western Australia, where prebuild of large panels can’t always be constructed next to the install point.

“It also suits urban or industrial settings with tight access points, tunnels, or yards where traditional equipment is too large to manoeuvre effectively,” he added.

It’s not the first time that Affective has innovated to fill a gap in the Australian rail market – this is also how the Alpha version of the TRACS machine came to be.

“Many of us at Affective Rail and Plant come from operational or project delivery backgrounds, so we’ve experienced firsthand the inefficiencies and safety risks of traditional methods,” Jordan said.

“In the case of the TRACS machine, we saw that turnout installation was labourintensive, time-consuming, and heavily reliant on large cranes.

“That sparked the idea of a self-contained, track-guided unit capable of delivering and placing turnout sections safely and quickly.”

From there, the team prototyped, fieldtested, and refined the TRACS machine in close consultation with end-users, putting real-world functionality first.

“We ensured it not only met engineering benchmarks but delivered genuine on-site value,” Jordan said.

The Alpha model was designed to accommodate long turnout bearers of up to 6.5 metres in length, while the Bravo handles bearers measuring up to 5.3 metres long.

Apart from size and track gauge adaptability, the key difference is transportability, with the Bravo’s compact frame allowing easier mobilisation between sites.

Crews can build turnout sections beside the install point and side shift them into position, or track them in from a nearby location, without the need to have track sections to run on.

While the Bravo is smaller and lighter than the Alpha, it maintains the same lifting capacity per machine as its predecessor.

The Bravo, like all TRACS machines, uses Affective Rail and Plant’s patented centre lift technique.

This design greatly reduces the risk of overturning compared to conventional cranes or excavator-type machines, making lifting operations far more stable.

“In addition, operators control the machine remotely rather than being seated inside it, so in the unlikely event of a failure, no one is near the suspended load,” Jordan added.

“Together, these features significantly lower the risk of accidents on site.”

Minimising the need for workers near moving loads not only boosts safety, but can reduce costs and simplify site logistics, particularly on busy or remote networks.

A suite of complementary accessories and attachments are also available for all TRACS machines, including adjustable hydraulic H beams, for handling different turnout geometries.

Jordan said Affective Rail and Plant always tries to provide a complete system, not just a standalone product.

“This ensures our clients can integrate the equipment into their workflows smoothly and efficiently,” he said.

The machines are designed and purpose-built in Australia, to suit the unique requirements of the environment and customers’ project demands. This reduces modification costs and ensures full compliance.

Affective consults closely with field crews and project teams during development to address specific pain points, particularly around manual handling, transport logistics, and speed of installation.

Currently, a prominent Australian operator is using the Alpha TRACS model for turnout installations on a major project.

“Early feedback has been extremely positive, especially around safety improvements and reduced installation

narrow-gauge lines to deliver the same benefits in tighter settings.”

Jordan also expects rapid uptake of the Bravo among other operators of narrowgauge networks in Queensland, mining companies, and regional rail authorities.

“Urban transit networks with restricted work sites are also likely to see immediate benefits,” he continued.

Affective Rail and Plant is gearing up to officially launch the Bravo at AusRAIL PLUS in Melbourne from November 25–28, 2025.

“AusRAIL is the premier rail event in the region, so unveiling the Bravo there puts it in front of the entire industry,” said Jordan.

“It’s a major opportunity to showcase how TRACS technology is evolving to meet diverse rail network needs.”

Jordan said the release of the Bravo won’t affect the popularity of the Alpha as they are complementary models.

“Many projects may ultimately require a combination of both for maximum flexibility,” he said. “Together, the Alpha and Bravo offer an efficient solution for modern turnout installations across a range of railway settings.”

Looking to the future, Jordan has big plans for the business.

“We’re exploring models optimised for different track conditions, transport methods, and even full integration with digital worksite planning tools to further streamline installation and maintenance

Downer is channelling its extensive expertise into a new safety consulting service.

As one of Australia’s leading providers of rail and transit systems, with expertise in delivering whole-of-life asset management, Downer knows the rail industry inside out.

Through its Rail and Transit Systems (RTS) business, it is a prominent supplier of rollingstock asset management services with proven capabilities in designing, building, maintaining and overhauling rollingstock across both passenger and freight rail.

Downer maintains nearly 2000 passenger rail cars (including contracted work) across Queensland, New South Wales, Victoria, and Western Australia. If you’ve travelled by train in these states, chances are Downer was behind the safety, comfort, and reliability of your journey.

In Victoria, Downer designed, built, and maintains the High Capacity Metro Train (HCMT) fleet – the largest single train order in the state’s history, which will be the only fleet operating in Melbourne’s Metro Tunnel when it opens later this year.

In New South Wales, Downer was responsible for the design, build, and ongoing maintenance of the country’s largest passenger fleet: the 119 eight-car doubledecker Waratah trains. A completely different design and maintenance regime from the HCMTs, expertly managed for over a decade.

In Queensland, the team has built over 1200 train cars and locomotives – including those operating in Perth – and will begin constructing 65 six-car trains for the Queensland Train Manufacturing Program.

RTS now maintains four fleets across two states, soon to be five across three states.

“To say Downer RTS knows rollingstock is an understatement,” said Nick Mountford, Executive General Manager of Health, Safety, Environment and Quality at Downer RTS. “And at the heart of every project? Safety.

“From cultivating a high-performance safety culture to navigating complex legislation, partnering with regulators, conducting audits and driving continuous improvement – Downer lives and breathes safety.”

Now, that expertise is being offered to the industry. Safe+ is Downer RTS’s new Safety Consulting Services arm,

helping rail operators and high-risk industries elevate their safety standards through proven strategies, systems, and cultural transformation.

LEADING BY EXAMPLE

“At Downer, safety isn’t just a priority; it’s embedded in everything we do,” said Mountford.

“With a 155-year history in rail and operations across 15 sites, our capabilities span rollingstock, infrastructure, systems integration, engineering innovation and digital solutions.

“We’ve built over 3000 train cars and locomotives, maintain more than 2000, and have overhauled 3000 more (including contracted work). That’s a lot of rollingstock – and a lot of responsibility.”

Mountford explained that safety in rail is non-negotiable.

“From the use of Personal Protective Equipment to shunting, site inductions, isolation protocols, exclusion zones, and working at heights, rail demands rigorous safety standards.

“These are large, powerful, and sometimes unforgiving machines operating in highly complex environments.”

Mountford said RTS's goal is simple: every one of its 1500 rail employees and other

Working with internal and external operations, engineering, delivery, and professional services teams, Downer offers strong support. The company also maintains close relationships with regulators and industry bodies.

“Whether it’s the Office of the National Rail Safety Regulator, the Rail Industry Safety and Standards Board, or the Australasian Railway Association – we have great, active relationships with all of them.

Mountford explained that RTS’s approach to safety isn’t top-down, but grassroots.

One example of this includes hosting forums where apprentices come together regularly to discuss operations and safety.

“Since embedding the apprentice forums across the business, we’ve seen a 50 per cent drop in the number of incidents involving apprentices,” Mountford said. “Storepersons from across the different training modules.”

Mountford said that safety culture is so embedded at RTS that his team has now turned its attention to extending safety training and messaging to the whole self –safe at work and safe at home.

“While these might sound like nice-tohaves on the surface, they’re the exact opposite,” he said. “They’re engaging, practical tools that we have strategically and systematically placed within the business to

Two years ago, RTS recognised that its workers needed a better understanding of their duties, obligations and authorities.

“As part our governance framework improvement review, we recognised this need,” said Mountford.

“We mapped the systems of safe work and formulated a plan to communicate and facilitate duties and diligence knowledge share to ensure industry best practice was adhered to.”

After developing a program, RTS partnered with a renowned industry expert to ensure its senior leaders were fully across their legislative responsibilities.

“We also rolled out targeted training for more than 120 frontline leaders – including leading hands, operations staff, and engineers – to refresh and reinforce their understanding of safety obligations.”

In 2025, RTS celebrated two major milestones: eight years of rail regulator audits/inspections with no major non-conformances raised, and five years of receiving a clean bill of health from International Organisation for Standardisation (ISO) external audits.

“As anyone in the rail industry knows, completing nearly a decade of audits is no small feat,” said Mountford.

“Audits are rigorous, necessary, and incredibly important. To come through without any major issues raised from both the rail regulators and ISO auditors is a phenomenal achievement – one our senior leadership team takes very seriously.”

But passing an audit isn’t just about doing the right thing every day – it’s about proving it. That means going back into the business, systematically pulling together evidence, and demonstrating consistent delivery across every site and team.

“With over 1500 employees in our rail business, even for a company of our size and scale, audits are challenging,” Mountford said.

“Now imagine being a smaller operator, or a business where rail is just one component. You might be doing everything right; but gathering and presenting the evidence to satisfy auditors can be a real struggle.”

That’s one of the key reasons RTS launched Safe+.

dedicated professionals who are passionate about rail and safety, and we recognised that not every company has access to that level of internal resourcing,” Mountford said. Safe+ offers just that; helping businesses not only meet safety standards but demonstrate them with confidence.

“I joined Downer in 2021, stepping into a business already delivering safe, reliable, and accessible transport solutions, with a strong safety culture and a robust safety team,” Mountford said.

“One standout example: every Downer rail site remained operational throughout the Covid-19 pandemic, thanks to comprehensive health and safety plans that protected both our on-site and remote teams.”

From there, the focus was on building momentum.

“We launched strategic Improvement Programs and broadened our Community of Practice initiatives to include business partners.

and rail safety improvement programs. These initiatives were not just symbolic, they were strategic, and they have delivered results.”

In 2024, RTS recorded a 78 per cent reduction in notifiable rail safety incidents and a 60 per cent drop in lost time injuries compared to 2020.

But for Mountford, improvement must be sustainable.

“Safety isn’t static – it evolves,” he said. “Six years ago, working from home was rare. Then came Covid. Suddenly, we had to ensure our remote teams were physically and psychologically safe.

“Safety trends shift, risks change and if we, as the safety team for Australia’s leading rail business, aren’t adapting and improving, we are not achieving our remit.

“I might be biased, but I have the best safety team in the business, and I’m proud to offer their expertise to the industry through Safe+.”

Learn more and contact the team through www.downergroup.com/scs

Building the #NextGenRailways of tomorrow

With more than 7000 delegates gearing up for the biggest rail event of the year, we take a look at what you can expect at AusRAIL PLUS 2025.

The largest rail event in the Southern Hemisphere is fast approaching, with more than 7000 industry professionals expected to descend on Melbourne’s Convention and Exhibition Centre for AusRAIL PLUS from November 25–28, 2025.

The conference is returning to Victoria for the first time in a decade, welcoming rail leaders from Australia, New Zealand and around the world for a comprehensive program covering the major challenges, opportunities and emerging trends in the sector.

This 2025 event will feature more than 120 speakers, 600 exhibitors, and six networking events.

A larger version of the AusRAIL conference, AusRAIL PLUS takes place every second year, with attendees including representatives from across passenger rail, freight rail, heavy haul, rollingstock manufacturing, consulting, industry bodies, the government, contractors and suppliers.

of the Australasian Railway Association,

said the event offers thought-provoking presentations, meaningful discussions and education on new products and services.

“AusRAIL PLUS 2023 smashed several AusRAIL PLUS records and was awarded ‘New South Wales Association Event of the Year’ at the Meeting & Events Australia Awards, Australia’s most prestigious event industry awards program,” she said.

“In 2025, we will build on this success, unveiling new features to maximise these opportunities for our delegates, exhibitors, and visitors.

“Our popular technical streams will also return, providing something for everyone across the three-day program.”

Attendees this year can expect informative sessions on everything from trends shaping the future of public transport to decarbonising passenger rail and the case for

Dinner (where everyone wears a splash of yellow) to networking drinks.

There’s even a guided fun run or walk around Melbourne’s scenic surrounds on the Friday morning, and a “Flavours of Melbourne” Street Party, new for 2025, with a wide selection of food stations, drinks, and entertainment.

We caught up with some of the exhibitors at last year’s AusRAIL to find out what they thought of the event.

“It’s been a very successful show for us,” said Alfie Hunziker, Managing Director of MATISA Australia. “We’ve had the opportunity to have discussions with our customers, with potential customers and with the interested public in general.

“The show has really assisted us in capitalising on our momentum and showing off our brand throughout Australia.”

James Elliot, Director of Strategy and Growth, Infrastructure and Transport at DTI Infrastructure, said AusRAIL 2024 was a fantastic opportunity to reconnect with clients and peers and hear more about some of the exciting innovations and developments in the sector.

“Rail in Australia is changing rapidly, with greater investment in modernising our infrastructure and embracing advanced technology,” he said.

“Our networks are becoming safer, more efficient, and more sustainable.

DTI is excited to be a part of some of the amazing projects going on across the country and looking forward to those on the horizon.”

Paul Warren, Sales Director at rail technology company KeTech, had travelled to the Gold Coast from the United Kingdom to attend the conference.

“It’s been great to meet so many people from all over Australia,” he said.

“We’re here to learn more about aspirations, some of the challenges and the requirements [in the rail industry here], and generate opportunities to take discussions forward when we get back home.”

For more information and to register for the event, visit ausrail.com.

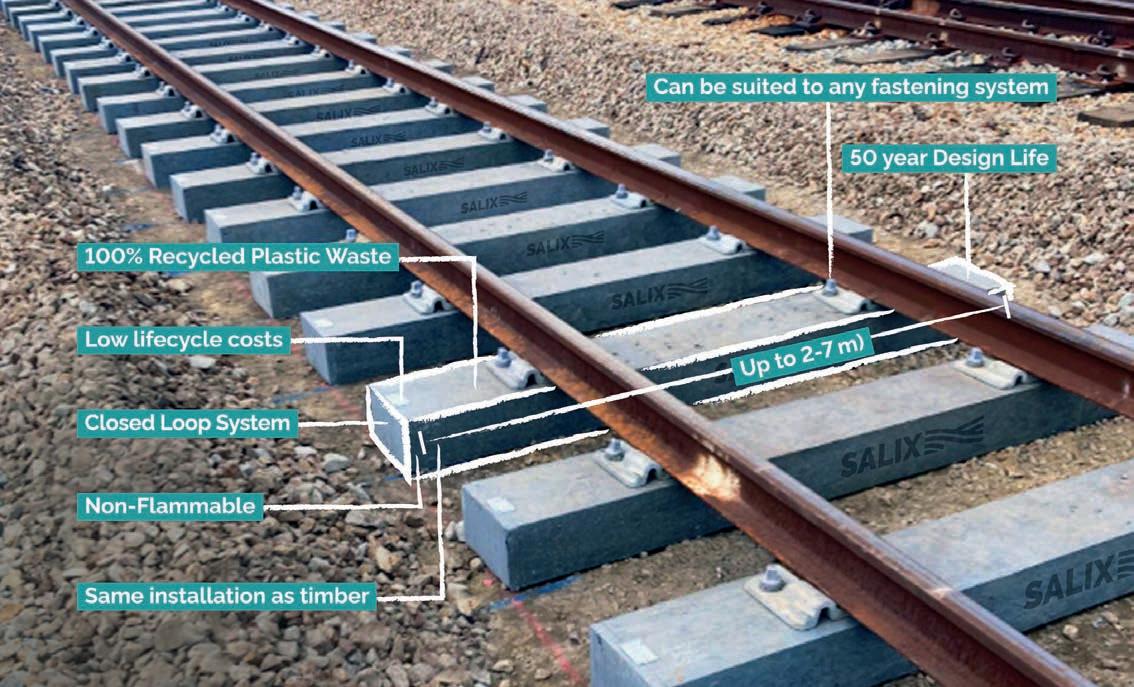

We look at Salix’s next-generation Infinity Composite Sleeper, made from 100 per cent recycled plastics.

Australia is committed to a target of net zero greenhouse gas emissions by 2050, and the rail industry has a major role to play.

The transport sector is currently the country’s third largest emitter, with 60 per cent of those emissions coming from cars and light commercial vehicles alone.

A major mode shift will be key to a greener future – with more passengers and freight on rail rather than roads.

But the rail industry’s role in decarbonisation doesn’t stop there, with companies increasingly turning to solutions such as recycled materials.

Australian owned and operated business Salix is a leader in this field.

In 2022, Salix launched its green range, a selection of innovative low carbon and sustainable products for the rail market.

A highlight from the range is the Infinity Composite Sleeper, a next-generation sleeper that is made from 100 per cent recycled mixed plastics – mostly household waste – and is fully compostable.

Developed in 2015 by Pioonier, Salix is the exclusive licensed partner for Australia and New Zealand.

It is the only sleeper in the world

consumer plastic waste, helping eliminate a major landfill problem. It is processed and reinforced through a patented manufacturing method that guarantees consistency. The system is also a fully closed-loop, meaning that once the sleeper reaches the end of its life, it can be recycled to create a new one.

With carbon dioxide savings of 300 kilograms per sleeper and landfill reduction of 113 tonnes per kilometre of track, the Infinity Composite Sleeper is a sustainable choice.

The product can also be designed to any network specifications, from passenger rail to freight and heavy haul.

It’s not just suitable for mainline rail but also for turnouts and bridges, and it comes with a lifespan of up to 50 years – saving operators time and money on maintenance and replacements.

The Infinity Composite Sleeper has been successfully used across multiple rail networks around the world. It has demonstrated outstanding performance in rigorous testing, including a three-point bending test, dynamic track test in ballast, and thermal expansion assessments. The

and by MXV. They meet – and exceed — the standards of the American Railway Engineering and Maintenance-of-Way Association (AREMA).

MXV granted its seal of approval after conducting wear and abrasion tests at temperatures as low as minus 40 degrees Celsius. The sleepers also withstood testing at 60 degrees Celsius for 3,750,000 cycles at 35 tonnes per axle.

Tested to 37.5-tonne axle loads and speeds of up to 160 kilometres per hour, the sleepers have proven to be both durable and high-performing. Additionally, the Infinity Composite Sleeper can be used with any fastening system, is fully customisable and can be installed with ease.

The Infinity Composite Sleepers are built to withstand all climates, from Melbourne’s cold winters to Perth’s scorching summers. They are currently being installed across multiple networks in Australia and New Zealand, with type approval processes still underway.

Silvana Kinninmont, Sales Manager at Salix, said Infinity Composite Sleepers have proven to be a “game-changer”.

“They offer the strength and durability we need, while delivering long-term savings

processed under a patented manufacturing process to guarantee consistency.

decay can lead to premature failures, and there are limited end-of-life solutions for the sleepers,” Kinninmont explained.

Allworks

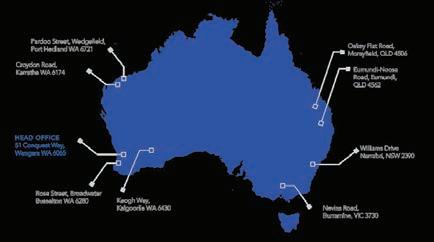

From emergency derailments to large-scale maintenance works, Allworks combines fleet, skills, and experience to solve complex rail challenges.

Allworks has built a reputation as a trusted provider of wet and dry hire plant and equipment for the rail industry, growing from its Western Australian roots into a national operation. Expansion onto the eastern seaboard in recent years has opened new opportunities and challenges – cementing Allworks as a partner of choice for rail projects across Australia.

General Manager Nick McLoughney said the company’s success is grounded in its people.

“The strength of Allworks lies in our team,” he said. “Our management group understands the industry beyond their individual roles. That means we can respond quickly, adapt to project demands, and support customers with the right solutions.”

The business was founded in 1999 by Angelo and Robin Sarich, with Angelo drawing on years of rail operations experience in Western Australia. His early career with Western Australian Government Railways and subsequent contracting roles shaped the practical knowledge that continues to guide the company today.

McLoughney said this background translates into customer-focused delivery.

“We know rail projects don’t always go to plan, so we build in contingency and

keep resources on standby,” he explained. “If equipment is needed urgently, we’ll do everything we can to make it happen.”

This approach has helped Allworks foster long-term relationships with Tier One contractors and project teams across Australia. Repeat business, he added, often comes down to reliability and trust.

“Customers know that when they call Allworks, we’ll make it happen,”

McLoughney said. “Even if they’ve moved to a new company, they maintain relationships with us because they know the quality of service is consistent.”

With more than 300 assets in its fleet –including excavators, trucks, and specialised rail equipment – Allworks supports projects across greenfield, brownfield, maintenance and emergency works. Its modern plant, sourced from trusted suppliers such as Hitachi, Volvo, Isuzu and John Deere, is kept up to date through a proactive replacement program.

“We often deploy machines on critical shutdowns or emergency derailment works,” McLoughney said. “By refreshing our fleet regularly, we reduce breakdown risks and give customers confidence their project can stay on track.”

Asset and Compliance Manager Tom Butcher plays a key role in ensuring the fleet is accredited for use across multiple networks, including the Australian Rail Track Corporation, Queensland Rail, Arc and the Pilbara operators. With more than a decade at Allworks, Butcher ensures machinery is compliant and ready to work wherever it is needed.

“Having someone dedicated to compliance across all networks is essential,” McLoughney said. “Each network has its own standards and requirements.

Tom’s knowledge means our machines meet regulations and are ready for immediate deployment.”

The move into eastern states brought new challenges, particularly in balancing fleet allocation between long-established Western Australia projects and new contracts on the east coast.

“Whilst historically the majority of our fleet serviced Western Australia, we’ve now got equipment working across multiple networks on the east coast, from Weipa in Queensland to Metro Melbourne,” McLoughney said.

To support this, Allworks has invested in nationwide backup systems and logistics

planning, ensuring customers in any region can rely on consistent service and technical support. The company also prioritises rapid redeployment of equipment and staff, minimising delays in critical projects from its depots in Brisbane, New South Wales and Victoria.

“If a client has a short shutdown window or an emergency worksite, our ability to redeploy assets quickly can make all the difference.”

While plant and equipment hire is its core offering, McLoughney emphasises that

Allworks’ value lies in the expertise it brings to projects.

“We don’t just supply machines – we help customers choose the right plant for their job and flag potential issues before they arise,” he said.

That expertise extends to planning for diverse rail projects, from heavy maintenance to greenfield track works. By understanding both the technical and operational requirements of each project, Allworks can anticipate problems and deliver practical solutions.

“Sometimes that means saying no if we can’t meet expectations. Customers value

that honesty because it helps them plan effectively,” McLoughney said.

The company also focuses on workforce training, ensuring operators and maintenance staff are highly skilled and familiar with the latest equipment. This not only enhances safety on site but also maximises productivity.

Rail projects often involve unpredictable circumstances, from extreme weather to urgent maintenance needs. McLoughney said Allworks thrives in these environments.

“Rail is unpredictable at times,” he said. “But our job is to make sure customers’ projects are on track and on time – every time.”

The company has developed systems to respond quickly to derailments or equipment failures, drawing on its broad fleet, mobile teams and extensive operational knowledge. By maintaining close communication with clients and planning for contingencies, Allworks ensures that challenges are managed efficiently and safely.

“Our reputation comes from being reliable, especially under pressure,” McLoughney said. “We combine the right equipment, the right people, and the right processes to deliver results – no matter what challenges arise.”

As rail investment continues across Australia, Allworks is positioned to keep building on its foundation of responsiveness, technical knowledge and industry relationships, proving that in the rail sector, experience and expertise remain the most valuable assets.

Alstom has extensive experience in delivering the European Train Control System (ETCS) in an Australian context. Senior Signalling Engineer Yvette Griggs provides an update on the upgrade of signalling equipment along Queensland’s North Coast Line.

Ever since she was a child, Yvette Griggs has been curious about how things work.

“My dad was an electrical engineer, and he was a great role model for me,” she said.

“I have a very mathematical brain, and I love problem-solving, and he always encouraged me to think about things more deeply.”

Griggs decided to follow in her father’s footsteps, studying maths and science in high school before going on to complete a degree in computer systems engineering.

She then applied for a general electrical engineering job at Queensland Rail.

“I interviewed with them, and they told me: ‘You’d be really great in signalling,’” she said. “So, I looked into it, and realised I absolutely agreed!

“One of the activities I quite enjoyed at university was where you had Field Programmable Gate Arrays (a type of integrated circuit that can be programmed) and its instantaneous logic – very similar to signalling, where you have a model of relay-based interlocking. It clicked in my brain as something familiar.”

After a graduate year at Queensland Rail, Griggs switched to the mining industry but

soon realised signalling was her calling, and returned to work for Aurizon.

“There are a lot of things about signalling that I enjoy,” she said. “From problemsolving to making systems that suit how they’re going to be used, there’s a degree of creative freedom that isn’t possible in other areas of engineering.”

Griggs now works as a Senior Signalling Engineer at Alstom, where she has recently finished delivering an upgrade of signalling equipment at stations between Caboolture to Gympie North along the North Coast Line.

The line’s signalling system was given an upgrade, with European Train Control System (ETCS) Level 1 overlayed on the previous system.

“One of the reasons I joined Alstom was to work on this specific project,” said Griggs.

“Having previously worked for Queensland Rail and Aurizon, I have an understanding of their traditional interlockings, how they operate, and what equipment they use.

“That gave me a great opportunity to be a bridge between the old system and the new.”

For this project, the customer already had in place a mix of relay-based interlockings and processor-based interlockings. Rather than completely removing the previous interlocking system and starting from scratch, the team delivered more of a “refresh” an upgrade to the existing network.

Griggs explained: “Our approach was to add-on ETCS to the older system, rather than bulldozing everything.

“It might be tempting to start from scratch and to have everything new, but it’s also great to recognise the value in what’s already working well and to incrementally improve existing networks through technology like ETCS – an area where Alstom is an expert. These interlockings are functioning smoothly, so it’s a lesson in building on a solid foundation rather than reinventing the wheel. No project has infinite funding and these interlockings are all functioning well; it’s not time to replace them yet.

“You always adapt to the budget, listen to the customer and work together to find the right solution together.”

Griggs said this kind of flexibility is a necessary part of signalling.

“Our signalling solutions can be tailored to suit requirements,” she said. “In fact, they often have to be, because a lot of the time the biggest cost in a project will be your civil works.

“For example, you can’t change the landscape – like where a mountain is –you just have to be expert in working with others to find the best solution together.

“Once you have your track layout confirmed, you can tailor the signalling solution to suit it.”

The advantages of installing ETCS include improved interoperability, with Alstom’s trackside system working in tandem with Hitachi’s onboard system.

“Because ETCS is a standard, everyone who provides something that's branded as ETCS should be able to work together,” Griggs said.

“So, you can have Alstom’s brand of onboard ETCS and another company’s trackside ETCS or vice versa, and it can all talk to each other.”

ETCS also offers safety and efficiency benefits.

“It's got driver supervision, so the system knows when the train should be stopping next, and it has an in-built profile of how it should slow down, following a braking curve.

“If the train starts deviating from what the system knows to be safe, it will intervene. Particularly with higher levels of ETCS, it also allows for more efficient driving of the trains, because the driver has a more advanced view of the route rather than what they can see with their own eyes out the window.”

Griggs said she enjoys working with Alstom for many reasons.

“It’s a great place to work,” she said. “I've been over to Canada and to our

headquarters in France, as well as our Centre of Excellence in Belgium, which have been amazing opportunities for me.

“As a market leader in Australia and New Zealand and one of the world’s leading pure play rail businesses, the company has unparalleled focus on the rail segment that others simply don’t have.

“Alstom has its own product line that it’s aligned to rather than being a floating consultant, which appeals to me.”

As a woman engineer in a maledominated industry, Griggs is passionate about levelling the playing field.

She is the Employee Resource Group Leader for Alstom’s gender diversity group in Australia and New Zealand, and said the company doesn’t just talk the talk.

“We have five different diversity, equity and inclusion pillars in Alstom Australia with many global initiatives aimed at making a difference,” she said. “Alstom doesn’t have the corporate facelessness that you might expect from such a large company. It really cares about its people.”

task

When Pilbara-based company Finmec needed some new railroad excavators to support a major client, Liebherr’s A 922 Rail Litronics were the obvious choice.

When Western Australian equipment hire and maintenance company Finmec decided to expand its capabilities in rail, its requirements were clear: versatility, reliability, and the ability to support customers in some of the harshest operating environments in the country.

The answer came in the form of Liebherr’s A 922 Rail Litronic railroad excavator, a machine designed from the ground up to service the needs of the rail industry.

For Finmec, which is based in Port Hedland, acquiring several A 922s means more than simply having new, high-performing equipment on the books – the machines will create many opportunities in rail construction and maintenance for the company.

We spoke to Finmec’s Managing Director, Daniel Finch, to find out more.

Finch said Finmec’s decision to add A 922 Rail Litronic railroad excavators to its fleet was driven by a key customer.

“We bought the machines to support one of our clients in rail maintenance who will be dry hiring them,” Finch explained.

“What stood out to us was the fact that the A 922 Rail are built ‘rail ready’ from the factory, with ease of use for the operators

and a hydraulic system designed to handle attachment use without lag.”

That “rail ready” capability is one of the A 922 Rail Litronic’s calling cards.

Unlike standard excavators modified for rail use, Liebherr’s purpose-built design integrates road-to-rail conversion, dualaxle rail guidance, and industry-leading safety systems.

Safety features include load torque, height and sway limitation, as well as “virtual wall” technology that limits the space that the machinery can move within.

“The virtual walls are a very big factor for us when our customer is working on dual track and needs to set limits in place,” Finch added.

He said the ability to switch between road and rail easily was a critical factor when Finmec was choosing what machines to buy.

“The scope changes daily, and to have the ability to switch between road and rail keeps the operation going,” he explained.

The A 922 Rail is compatible with a large selection of attachments, from quick coupler systems to digging tools and grabs for a wide variety of applications.

Finmec has installed an Engcon head, which Finch said enables the team to change its work tools quickly and operate in narrow spaces.

“Having the quick hitch couplers is critical for the work tool that we use on these machines, as it offers a quick ability to change attachments,” he added.

“We have also ordered a selection of Harry Bilt work tools to assist our operation, including tampers, threaders, cribbing buckets, plus more.”

Finch said he’s confident the A 922 Rail will stand up in the rugged conditions of the Pilbara.

“From Liebherr’s quality, engineering and support, these machines will perform to a very high standard.”

The latest generation of the A 922 Rail Litronic builds on the strengths of its predecessor while introducing a series of upgrades to boost performance and efficiency.

With an operating weight of 20,400 to 23,400 kilograms and powered by a new 120-kilowatt construction machine engine, the new railroad excavator delivers higher working speeds and smooth operation. The machine can be configured to meet country-specific emissions regulations to meet with different working conditions and requirements.

A redesigned heavy counterweight boosts load-bearing capacity through better weight distribution, while a more compact rear radius of just 2000 millimetres makes it easier to work in narrow or restricted areas.

The performance of handling attachments has also been improved, with the proven dual variable displacement pump now providing two independent control circuits with delivery rates of 220 litres per minute each. This allows operators to run high-demand attachments without compromising responsiveness, and the system can still combine both hydraulic circuits when maximum output is required.

Customisation is one of Liebherr’s key strengths, offering the A 922 Rail in various

undercarriage versions with different track widths and rail wheels.

An independent variable displacement pump powers the rail undercarriage, delivering strong traction and safe propulsion, while standard integrated brakes in the rail wheels shorten stopping distances, adding an additional layer of safety.

The A 922 Rail’s spacious double cab with a modern design and standard rollover protective structure offers more comfortable and safer conditions for operators, with entry lighting easing access to both seats.

The operator’s seat, the touchscreen colour display and other control elements

are also ergonomically designed for a better operator experience.

As Australia’s rail industry continues to expand and modernise, equipment such as the A 922 Rail is giving contractors and maintenance providers the versatile tools they need to stay productive and safe.

For operators such as Finmec, the investment means they can deliver for clients across Port Hedland and the wider Pilbara region, and keep projects moving –on track and on time.

For more information, visit: www.liebherr.com.au

Early Warning Network’s new RailAWARE system is helping operators stay prepared, protect crews, and keep freight and passenger services moving when the weather turns.

Australia’s passenger and freight networks play a crucial role in keeping the country connected, but they are becoming increasingly vulnerable to the effects of severe weather events.

Disruptions are happening more often, lasting longer, and bringing significant repercussions – costing operators millions of dollars, damaging assets and even leading to loss of life.

But many rail operators are still relying on weather apps, the news, or even social media for their weather updates, which mean they are often working with generic, outdated or inaccurate information.

Early Warning Network (EWN), a business that provides cutting-edge weather forecasts, real-time data and climate risk analytics to safeguard organisations around the country, wants to spread the word that better options are available.

EWN has a long history of working with prominent Australian rail companies but has recently taken its offering to the next level, launching its RailAWARE package.

RailAWARE is a dedicated solution designed to help rail operators minimise disruption, protect crews, and improve resilience against extreme weather – from floods to dangerous winds to bushfires.

We spoke to Martin Katzmann, Head of Sales at EWN, to learn more.

Since 2011, EWN has worked closely with leading rail operators such as Aurizon and UGL, helping to keep its customers’ networks safe, resilient and moving.

Katzmann said it has particular expertise in providing real-time intelligence to freight operators – however, it has recently signed a contract with Yarra Trams and is looking to expand its partnerships with passenger rail operators.

Building on its years of expertise, EWN’s RailAWARE offering brings together advanced forecasting and monitoring technologies developed specifically to address the severe weather and natural hazards that disrupt rail operations.

The package includes:

• FloodAWARE: brand-new technology that provides accurate flood extent and depth

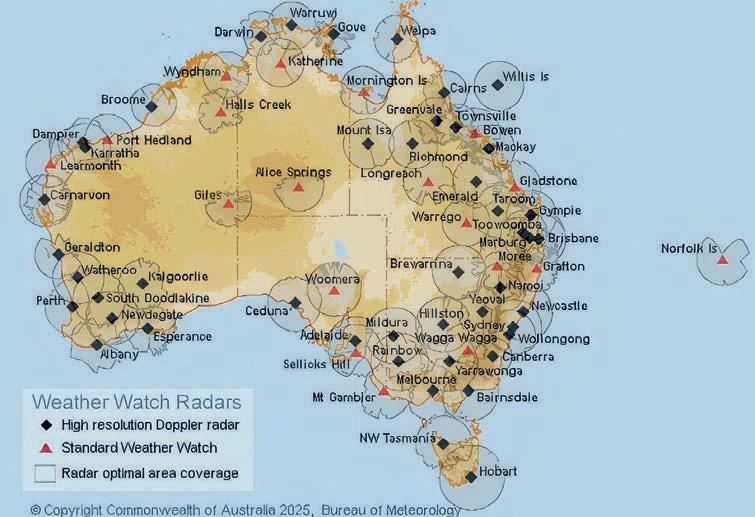

Vast areas of Australia are not covered by ground-based radar –which is where Early Warning

forecasting, real-time monitoring and post-flood analysis.

• Radar-derived rainfall: high-resolution rainfall intelligence which alerts for heavy rainfall between rainfall gauges.

• Severe weather alerts for track sections: location-specific risk notifications for heat, lightning, wind et cetera.

• Tropical cyclone services: detailed forecasting, monitoring and alerting for cyclone effects.

• Observational rainfall gauges and culvert monitoring: on-the-ground verification of rainfall and water movement to protect network assets.

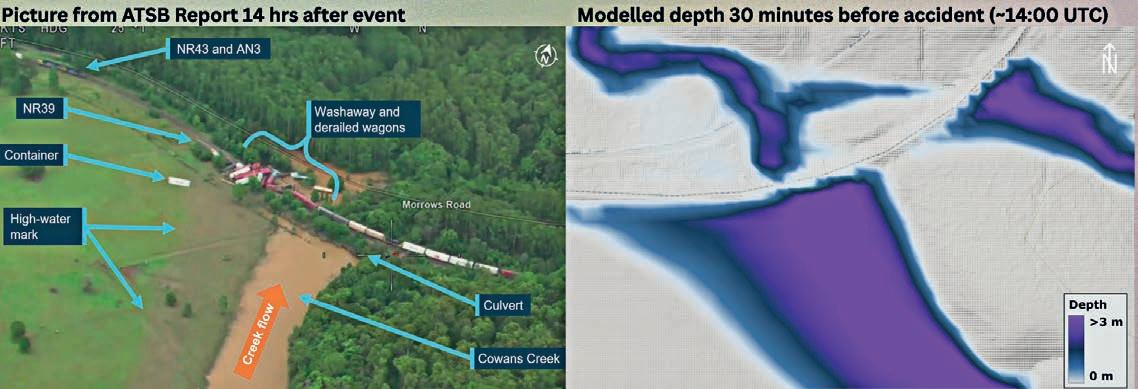

Modelling EWN did in FloodAWARE against the Nana Glen Train Derailment on Feb 25, 2021. This shows the precision forecasting that FloodAWARE can offer organisations.

Katzmann said that where EWN excels is in closing the weather forecasting gap in parts of Australia that are not covered by groundbased radar. These are not just remote areas, but vast swathes of the country.

“If you look at a map of Australia, you can see there are massive black spots in Western Australia, where a lot of the mining operations are,” he said.

“There’s usually about 200 kilometres around a ground-based radar that we can monitor, but the ground-based radars don’t always intersect. Port Augusta in South Australia is a prime example.”

EWN is Australia’s reseller of Tomorrow. io, a space-powered predictive weather intelligence platform that is eliminating these radar blackspots.

“With Tomorrow.io, we can provide hyperlocal predictions for rainfall, wind temperature and storm impacts across specific rail corridors,” Katzmann said.

“It includes tools to model ‘what if’ weather scenarios and address potential impacts on rail schedules and infrastructure, as well as dynamic monitoring, with continuous updates as conditions evolve, turning forecasts into actionable decisions for operators.”

THE COST OF NOT BEING PREPARED

According to Katzmann, the biggest hazard operators need to be concerned about is heavy rain.

“The most important hazard for rail operators to monitor is rainfall, to start with, and then the subsequent flooding,” he said.

“Whether that is flash flooding or riverine flooding, they are equally dangerous.

“As soon as the culverts are overwhelmed, that’s when buckling occurs or there is a risk of the rail track being inundated.”

He said wind is another major risk factor, especially when it comes to double stacking.

“If operators double stack and they don’t know what wind is forecast, they are at high

risk of toppling over,” he said. “If there are strong, convective winds affecting their network, they can’t drive the trains.”

He gave an example of an operator loading coal in Darwin for a four-day journey to Adelaide.

“They need to know which wind or rainfall is going to impact them on that four-day journey,” he said.

“So, we need to forecast up to seven days in advance for them, because if they load in Darwin and then there’s strong convective winds or intense rainfall affecting them near Tarcoola or south of Alice Springs, they have to stop the train.

“The cost of stopping the train has a massive impact.”

The financial consequences of operators being inadequately prepared for severe weather events don’t stop there.

As an example, in New South Wales alone, rail disruptions can cost up to $392 million a year in cancelled deliveries, shortages and repairs.

“When you consider that hundreds of millions of dollars can be lost, investing in severe weather risk mitigation is like a little drop on a hot stone,” Katzmann said.

Another benefit of investing in EWN’s services is maintaining supply chains to remote communities.

“If we’re talking about the line between Darwin and Adelaide, freight rail is the main way communities receive goods,” he said.

“If the trains can’t run, those communities are majorly impacted.”

But the most serious risk that comes from operators working with outdated or inaccurate weather information is the risk to the lives of passengers and crews.

Katzmann said that many of the derailments that have happened in Australia in recent years – several of which sadly led to crew and passengers being injured or killed – could have been avoided with operations-specific alerts

that enabled them to anticipate risks and act early to protect both their assets and their people.

“When EWN started out as a business, it was all about protecting lives,” Katzmann said.

“We still offer free alerting functionality to State Emergency Service volunteers.

“Loss of life is the highest cost there is, and that’s our main focus.”

With Australia’s changing climate conditions increasing the risks to rail network resilience, Katzmann said it’s never been a better time for operators to invest in weather intelligence.

“On the East Coast, rainfall and flood events will most likely increase in frequency, while in the central part of Australia, we might be looking at bushfires and drought impacts,” he said.

“We want rail operators to be aware of what technology is out there, because whoever doesn’t jump on board is going to be left behind.”

By combining Ground Penetrating Radar, Lidar scanning and its Rail Doctor analytics platform, Loram is reshaping rail maintenance by giving operators valuable insight into track condition – and the tools to act on it.

In today’s rail industry, the ability to anticipate, plan and execute maintenance with precision is central to safety, performance and cost efficiency. Loram’s analytical track condition tool combines advanced Ground Penetrating Radar (GPR), Lidar scanning and intelligent data analysis to deliver the most accurate and actionable information available.

The fundamental indicator of track condition is track geometry. Track geometry refers to the lines, curves, profiles and gauge that define the railway’s alignment. When geometry deteriorates, ride quality suffers, safety margins diminish and maintenance costs escalate. Inspection vehicles measure geometry roughness and, when assessed over time, this data reveals the performance trends and deterioration rate of the track.

A well-maintained geometry is directly dependent on the condition of ballast and drainage. By analysing successive inspection runs, Loram can determine how ballast and drainage are performing, and whether deterioration is accelerating in particular segments of the network.

While track geometry gives a performancebased view, it cannot explain the underlying causes of degradation on its own. This is where Loram’s integrated technologies step in.

Ground Penetrating Radar provides continuous, high-resolution insights into the subsurface. It identifies fouling levels within

The machines are built to industry-leading standards of productivity and reliability.

whether geometry issues are driven by ballast contamination, weak formation or drainage deficiencies.

Complementing GPR, Lidar scans provide detailed corridor information, mapping surface features, drainage paths and surrounding terrain. When precisely aligned with GPR and track geometry data using differential GPS, Lidar enhances understanding of both track and corridor health, enabling engineers to see the full context of deterioration.

At the centre of Loram’s capability is Rail Doctor, a proprietary analysis platform that integrates track geometry, GPR, Lidar and historical performance data. Rail Doctor goes beyond raw measurement, it transforms disparate datasets into intuitive visualisations and actionable insights, highlighting root causes of poor track performance.

This integration allows railways to quickly assess ballast condition, drainage effectiveness and the relationship between geometry roughness and substructure health. With this clarity, maintenance decisions can be made with confidence.

Accurate diagnosis is only valuable if it leads to effective action. Loram’s analytics directly inform maintenance planning by identifying where tamping will deliver results, where ballast cleaning is required, or where drainage interventions such as ditching should be prioritised.

Rail Doctor enables railway operators to prioritise work, optimise budgets and build long-term renewal strategies. The outcome is a shift from reactive maintenance to a predictive and proactive model, reducing both risk and cost.

Once the analysis highlights the necessary work, Loram delivers execution with precision. Its fleet of specialised equipment includes:

• TrackVac for fouled ballast removal.

• Shoulder Ballast Cleaners and Full Section Undercutters to restore ballast quality and stability.

• B adger Ditchers, Slot Machines and Self-Powered Slot systems to address drainage, cutting ditches, and directing water away from the track. These machines are built to industryleading standards of productivity and reliability, ensuring that prescribed maintenance translates into measurable track improvements.

Loram continues to advance its solutions through automation and artificial intelligence. Automated data collection is reducing inspection time, while Artificial Intelligence-driven analysis accelerates the speed and accuracy of diagnostics. These developments further enhance Rail Doctor’s ability to provide near real-time recommendations for track maintenance.

Suited for all types of railway track

Environmentally sustainable

100% circular - the next generation in high performance composite sleeper

Two of KiwiRail’s shiny new DM locomotives are officially in service – we find out more.

KiwiRail has marked a major milestone with its first two DM locomotives completing their trial journeys phase and officially joining the fleet.

The locomotives, which were built in Spain by rollingstock manufacturer Stadler, will operate the route from Christchurch to Timaru on New Zealand’s South Island.

In total, KiwiRail has purchased 66 new DM class locomotives. These will be used for freight transport and will gradually replace the ageing DX fleet, which is 48 years old, on average, and expensive to maintain.

The first two DM locomotives completed their 5000-kilometre trial running period in August, and locomotive engineer training is now being rolled out on the South Island.

KiwiRail’s Chief Metro and Capital Programme Officer David Gordon said the trial journeys were fault and failure free, which is a “huge success for a first-inclass locomotive”.

The modern locomotives even held up well in the challenging Otira to Arthur’s Pass section of the route.

“Extensive simulations and calculations were done prior to the DMs arriving, but it was still reassuring to see them clear all structures and tunnels throughout our

South Island network as they are the largest locomotives in our fleet,” Gordon said.

“The current consist of DX locos for the Otira tunnel are in a bank of six and the expectation with the DM is that we will need less than six for the same task.

“But with only two in the country so far, we will need more DMs in the fleet to carry out full testing before we can assess the number required.”

Tests during the seven-month testing phase for the DM locomotives included tuning up the traction and braking systems, checking the performance of the locomotives with a load, and checking

the compatibility of the DMs with legacy locomotives in the fleet.

Justin Young, mechanical engineer at KiwiRail, said: “Regulatory-wise, the DMs fall into this category where it’s a new vehicle to New Zealand.

“We have to satisfy the regulator, really making sure that they’re doing what the current standards around the world are doing. We’ve done our best to ensure that the locomotives are safe and fit for purpose.”

Young said the first two DMs had to undergo rigorous testing so problems could be ironed out before the rest of the DMs are shipped to New Zealand.

“It’s really easy to fix two locomotives while they’re in New Zealand, but it starts to become a challenge when there’s up to ten locomotives at once,” he explained.

With two different testing teams on different sides of the world, you might think it would be difficult to collaborate – but Young said this was actually quite handy.

“Due to the big time difference between New Zealand and Spain, what we were finding is we could send issues across in the late afternoon and show up the next morning and have some

Rectifications were also made to the likes of anti-climbers, cab doors, vigilance software behaviour and engine mounting.

“As expected with a new model locomotive, we did experience some small teething problems, but in the case of the DMs these were minimal,” Gordon added.

The operator has specified that each new locomotive must have a low emissions profile, meeting the European Union Stage V emission standard with a diesel engine 3000-kilowatt output.

It’s also targeting a 25 per cent reduction in nitrous oxide emissions, and a 30 per cent reduction in particulate matter emissions.

The locomotives must also have an

Dual cabs provide operational flexibility, and the locomotives are also equipped with a Driver Energy Reduction and Advisory System to support the locomotive and drivers to achieve optimal energy performance.

Each locomotive is also equipped with an auto engine start stop (AESS) system which can switch off the engine when the locomotive is idling, saving fuel, as well as a Train Handling System to manage asset fatigue and energy performance.

Meanwhile, a Remote Diagnostic System allows KiwiRail to receive instantaneous fleet geographical location, speed, fuel tank status and battery main switch status, a summary indication of mileage, energy consumption for each locomotive, fault records (automatically logged for each locomotive), locomotive condition and trending of key parameters.

Borja Rozalén Valcuende, Project Technical Leader in Design and Development Engineering at Stadler, said it was at times challenging to achieve KiwiRail’s expectations, but he is proud of the final product.

“The locomotives’ performance is going to be great here on the KiwiRail network,” he said. “Working with KiwiRail has been fantastic. The facilities are great, the help we have been receiving from KiwiRail is great, and I think we have built a very good and strong thing together.”

Gordon said KiwiRail’s locomotive engineers have given very positive feedback so far and have played a pivotal role in the development of the locomotive’s cab and overall functionality.

One such engineer, Kyle Swainson, said the switch from DXs to DMs was like going from a 1960s car to a modern 2020 vehicle.

“It’s a lot more comfortable, it’s a lot quieter,” he said. “The air con is a big thing for us – we’re not used to having air con!

“The creature comforts, from a loco engineer point of view, are amazing.

“The computer systems in the locomotives are also stand-out, compared to what we’re used to.”

Two additional locomotives are scheduled for delivery in late October or early November 2025, while the rest will be delivered in groups of five or six, starting in January 2026, at intervals of every few months until they have all arrived.

KiwiRail Chief Executive Peter Reidy previously said in a statement that the modern machines will be a “huge benefit”, especially for the operator’s customers

in the South Island, where 47 of the 66 locomotives will be based.

“As the new machines enter service, it will mean greater reliability for our freight customers, which is crucial for growing rail,” he said. “Rail is already a lower emissions transport mode, producing 70 per cent fewer emissions per tonne carried compared with heavy road freight.

“The DMs are built to the leading European emissions standards and are fuel efficient, with potential to further reduce emissions from our South Island fleet by 20-25 per cent.”

He said the more efficient locomotives will help New Zealand towards its overall

climate change targets.“Not only do they h ave a cab at each end, reducing some of the need to run two locos on freight trains, but they also have modern traction control, to better utilise the more powerful high-speed engine,” he said.

“Being more powerful, the DMs will be able to pull larger trains, which will help to future -proof us for the freight growth expected over the long term.

“A modern standardised, locomotive fleet has been on KiwiRail’s wish list for a long time and these first two locomotives are a tangible sign that the significant investment in rail by successive governments over the past years is bearing fruit.”

The Australasian Rail Directory is a comprehensive, all encompassing rail services directory, available both online and as a traditional hardcopy publication.

The Rail Directory is an industry driven project to provide a complete listing of all businesses involved in the Australasian, Oceanic and Asian rail industries.

This year’s rail directory will be revamped to become even simpler to use. Listings will be sorted into categories allowing users to easily find businesses working in each area of the rail industry.

With over 1000 listings from areas as manufacturing, signalling and maintenance, make your listing standout with a frame advertisement.

To ensure you are in prime position in this year’s rail directory contact Arron Reed today.

Free Listing

To ensure that the Australasian Rail Directory is comprehensive, we offer all businesses who operate or trade in the region one free listing in the directory.

Premium Category

Listing Available

From $600 (+gst)

Double page, full page, half page and quarter page advertisement space also available.

To discuss the advertising opportunities available, please contact: Arron Reed on 0466 923 194 or email: arron.reed@primecreative.com.au

The decision to scrap the planned extension to the Gold Coast light rail network has disappointed rail industry representatives.

The Queensland Government’s recent decision to cancel Gold Coast Light Rail Stage 4 has drawn much criticism from rail industry associations and supporters.

The next phase of the light rail was a proposed 13-kilometre dual track extension from Burleigh Heads to Coolangatta via the Gold Coast Airport.

However, the project has been axed due to “overwhelming local community opposition”, the State Government said.

Instead, plans will be drawn up for a rapid bus service, with the Department of Transport and Main Roads to undertake a multi-modal transport study for the region.

Australasian Railway Association (ARA) Chief Executive Officer Caroline Wilkie hit out at the extension’s cancellation, saying it will hold the Gold Coast back from future growth opportunities.

“It is disappointing to see the cancellation of Gold Coast Light Rail Stage 4 given the significant economic, community and sustainability benefits this project would deliver,” she said.

“The certainty of ‘tracks in the ground’ would have delivered increased economic

A 13-kilometre extension of the light rail had been planned to run from Burleigh Heads to Coolangatta.

growth opportunities for the region and supported long-term development along the corridor.”