-RECHARGES ITSELF WITH RRT -UP TO 1500A CLAMP POWER -STARTS JUST ABOUT ANY ENGINE -ULTRA-SAFE LiFePO4 BATTERY -LIGHTWEIGHT & PORTABLE

INTELLI-START INDUSTRIAL JUMP STARTERS IS3000 & IS5000 2 YEAR WARRANTY

Repair industry’s night of nights celebrates the best Giving everyone a fair go at MPSR Group MAY 2024 www.nationalcollisionrepairer.com.au

PROJECTA ROUNDS OUT ITS REVOLUTIONARY JUMP STARTER LINE-UP

PROJECTA.COM.AU J005938 PRO-IS Print & Digital Front Cover NCR May FINAL.indd 1 15/4/2024 11:32 AM INSIDE

Featuring Projecta’s patented Rapid Recharge Technology, Intelli-Start Lithium Jump Starters recharge themselves in 40 seconds once a vehicle is started, elimiating the need for regular docking or mains charging.

They’re compact, lightweight, ultra-safe, and provide up to 4 times the lifecycle of Lithium Cobalt alternatives, making them perfect for workshops, roadside assistance and fleet vehicles.

• Starts 7.0L Petrol or 5.0L Diesel vehicles

• Suited to 12V or 24V vehicles (IS2000 only)

Visit intelli-start.com

PROJECTA INTELLI-START LITHIUM JUMP STARTERS KEEPING WORKSHOPS MOVING PROJECTA INTELLI-START

IS1400 IS2000 projecta.com.au ASK AN AUSSIE POWER EXPERT ON 1800 422 422 THE ONLY JUMP STARTER THAT CHARGES ITSELF.

to find out more

TICKETS ON SALE NOW

com.au 0413 672 403

GET

TICKETS

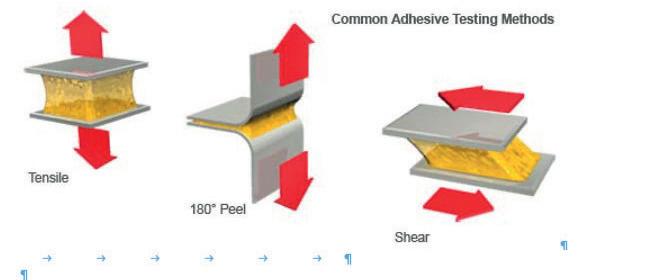

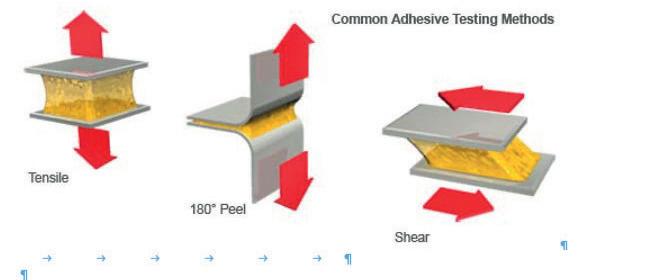

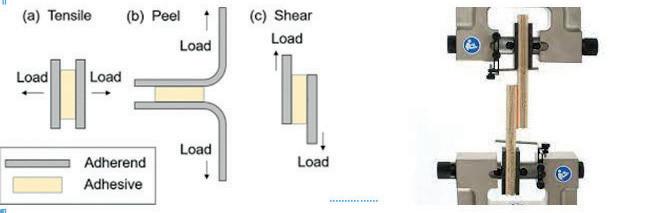

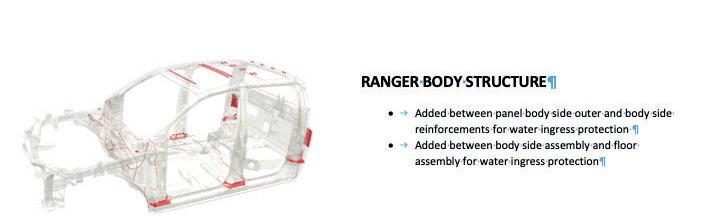

The National Collision Repairer Symposium will provide an opportunity to discuss key issues facing the collision repair industry, and how we can address these to ensure industry longevity and success. Sponsorship provides a unique chance to position your business as a leader in this sector and connect with decision makers. SYDNEY 19 JUNE 2024 Platinum sponsor Symposium sponsors www.ncrsymposium.com.au Latest News Special Reports Regular Features 6 Product Showcase 36 Local News Automotive industry news and information from around the country. 46 Global News Keep up to date with a selection of industry news from across the world. 52 Tech Talk Insight into adhesives. 10 Start me up Reliability in the workshop. 14 ‘Resounding success’ The colour, learnings and highlights from the industry’s biggest expo. 22 Lifetime Achievement Awards All the winners and the fun from the big night. 35 More benefits Capricorn wants members to use tax time to supercharge benefits. 42 Crash Course A look at the special US report. 20 Talking Shop MPSR Group set for growth. 34 Synposium24 Big industry ideas and big speakers. 44 Stateside Changing up for success. 48 OEM Snapshot More developments from the world of automotive manufacturers. 22 10 48 CEO John Murphy john.murphy@primecreative.com.au COO Christine Clancy

SALES DIRECTOR Brad Buchanan

EDITOR

Du y

0412 821 706 BUSINESS DEVELOPMENT MANAGER Kerri McCauley kerri.mccauley@primecreative.com.au 0404 898 362 PUBLISHED BY Prime Creative Media 379 Docklands Drive, Docklands, VIC 3008 03 9690 8766 www.primecreative.com.au DISCLAIMER The National Collision Repairer magazine is owned by Prime Creative Media and published by John Murphy. All material in National Collision Repairer magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published. The opinions expressed in National Collision Repairer magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated. © Copyright Prime Creative Media, 2023 Articles All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format. Head Office 379 Docklands Dr, Docklands VIC 3008 P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au Sydney Office Suite 3.06, 1-9 Chandos Street Saint Leonards NSW 2065, Australia P: +61 2 9439 7227 Contents

christine.clancy@primecreative.com.au

bradley.buchanan@primecreative.

Eugene

eugene.du y@primecreative.com.au

Time to consider

The pace of technological change can be unnerving.

In the automotive industry, fuelled by innovations to be ever safer, cleaner and more comfortable, this pace appears to be accelerating. Nevertheless, it is worthwhile to take a moment to pause and refl ect.

I recall some utopian thinking back in 2015 which predicted the young adults of the time would be the last generation to ever have to sit a driving licence test, so rapidly was the pace of automated driving moving. Fast forward a decade and despite the prospect of many a young person relishing the idea of not having to listen to their parents tell them how to drive, that level of confi dence in the technology still seems a long way o . One report from the US, where automated driving is considerably more advanced than in Australia, predicts this level of automation will not be ready until 2035. Whatever the date may be when robot cars are fi nally malfunction free and ubiquitous, one major stumbling block remains overcoming public perception. As highlighted by recent Swinburne University of Technology research, people like the idea but are not quite ready to fully trust that autonomy.

Even electric vehicles, which as a form of alternative power source are much further down the path of accepted new technology, retain some signifi cant barriers to being more universally embraced. In many ways some of these barriers are not new. Functioning hybrids on our roads are now more than twenty-seven years old and as one informed mechanic pointed out to me, the fi rst electric cars are more than 120 years old. Nevertheless, the trust factor has often stood in their way.

In Australia, this confi dence in pure EVs comes

down to three stumbling blocks: price, range and power. Technology is making great inroads into the range problem. Hopefully the future ability to reach 700 or even 1000km in range can outstrip the already lagging charging infrastructure. Power too will be an interesting point of contention. It will be fascinating to watch the US market, where numerous electric utes that can meet the Australian obsession with towing, are already available.

But for EVs this still leaves the price factor, a major sticking point for many. Even the lure of saving on fuel as petrol creeps over $2 per litre is not enough for many families to make the large initial outlay. Or at least not yet.

Nevertheless, the gradual trend for EVs to win public trust is unquestionably occurring, as the growing sales numbers of new vehicles from the FCAI show. When it is convenient and cost e ective, these cars can become a consumer’s fi rst choice. However, despite fi gures nearing ten per cent of new vehicles, EVs are still less than two per cent of the total car parc. That means on a rough average that two cars in a hundred repair shops are likely to see will be EVs. This will change and increase, so tracking the point in time where they reach a tipping point in the automotive industry will be interesting. The year 2035 will certainly be a milestone in Europe as they end production of ICE vehicles. All eyes will be on how far Australia has reached by then.

All this is not to promote inaction but rather for the industry to take a considered and informed approach as the change occurs. As such, the e orts in education, training and legislative review are extremely valuable and should be considered by everyone who wants a future in the industry. Naturally early adopters will stand to benefi t, accumulating expertise and loyal customers before they turn into the anticipated fl ood. But so far Australians have the advantage of time.

If change appears like an onslaught, the best defence is to stay informed. Agility and action will better serve the individual business and the wider repair industry than panic.

Eugene Du y Editor The National Collision Repairer

4 www.nationalcollisionrepairer.com.au Editorial

To receive our weekly e-newsletter sign up at www.nationalcollisionrepairer.com.au

The RAPTOR evolution is here

Since its introduction into the automotive scene, Raptor products from U-pol have developed an industry reputation for ultra-durability across a surprising diversity of applications and temperature resistance.

Introducing the RAPTOR High Temperature range, six new RAPTOR products formulated to perform in temperatures from 120°C to 1000°C. 5 times tougher than ordinary paints*, RAPTOR High Temperature products provide superior protection from heat, impact, and corrosion. Easy to use, fast drying, and with an attractive smooth finish. There’s a RAPTOR High Temperature product for almost any job.

Professional quality RAPTOR Wheel Paint is ideal for extending the life of worn or damaged wheels, supplying protection from impact, heat, stone chips, brake dust, and corrosion. It’s chemically resistant to oils and tra c film. Suitable for use on all types of primed metal wheels including steel, aluminium, and alloys. Available in gloss and satin black. For roll bars, chassis, or any vehicle

surface that needs extra protection, there’s RAPTOR Roll Bar & Chassis. Available in gloss or satin black. Heat resistant up to 120°C. Self-priming with exceptional adhesion, it can be applied directly to most prepared metal without primer.

Heat resistant up to 300°C, RAPTOR Engine Enamel is perfect for engine blocks, engine accessories, and other surfaces in the engine compartment. Available in Primer Grey, Bright Red, Gloss, Satin and Flat Black and Gloss Clear. Containing ceramic resins that provide superior protection from heat, oil, and other automotive fluids. Suitable for all type of primed metals.

RAPTOR Caliper Enamel contains ceramic resins that resist temperatures up to 500°C. Provides brake calipers with superior protection from impact,

heat, brake dust, automotive fluids, and corrosion. Available in Satin Black and Real Red.

For protection against extremely high heat there’s RAPTOR Flameproof. Formulated with advanced ceramic technology and high heat-resistant pigments, RAPTOR Flameproof can withstand temperatures up to 1000°C. Ideal for use on exhaust manifolds, headers, exhaust systems and other areas that require protection from very high heat as well as oil and other automotive fluids. Suitable for use on all types of primed metals including steel and alloys. Available in Primer Grey, Satin Clear, Flat Black and Flat Red.

For more information or to find a distributor of RAPTOR products go to u-pol.com/au

6 www.nationalcollisionrepairer.com.au Product Showcase

RAPTOR products can perform in a temperature range from 120°C to 1000°C.

Image: U-pol.

Reliability when you need it most

There’s nothing worse than a dead battery just when you need it most. Dependability is one of the hallmarks of Projecta equipment, whether it is in the workshop, the home or the home away from home and their INTELLI-IQ Smart Display is one more example of this innovation in automotive electronics

The Projecta INTELLI-IQ Smart Display (IQD2) makes the dreaded scenario of a flat battery at the end of the day a thing of the past. The smart display has multiple applications in professional and recreational motoring scenarios or wherever a driver wants to have full knowledge of charge rates and retain control over their 12V system IQD2 is the communication hub for the Projecta DC system, enabling users to create a smart home on wheels. It provides complete control of the DC System, including charge rate and battery voltage. IQD2 is the first of five phases of the Projecta Internet of Things (IoT)* System, and it ensures both scalability and allows the integration of future products and technologies. Projecta’s IQD2 links connected products within the Projecta ecosystem, with new ways

of connecting and controlling devices without being physically hardwired or using Bluetooth®.

Don’t get stuck in 2024

IQD2 and the IDC25X DC to DC charger are designed for the future and will seamlessly integrate with the upcoming phases of Projecta IoT. This means that as technology advances, the IQD2 and the IDC25X are prepared and ready to adapt and upgrade the smart home on wheels.

Projecta Senior Brand Manager, James Pearson, said the new INTELLIIQ Smart Display unlocked the full potential of the IDC25X DC to DC charger and other Projecta equipment.

“When paired with the IDC25X charger, the INTELLI-IQ Smart Display further elevates the charger by o ering total and convenient control – in combination, the technology is unique and industry-leading for the segment,” Pearson says.

“Many competitor systems feature Bluetooth® control where the appliance connects directly to the smart device. These systems can be subject to functionality issues with range and connectivity; this is often because the

appliance is mounted in the engine bay or another area shielded by layers of metal, causing a barrier for the Bluetooth® signal. In comparison, the IQD2 o ers automotive grade communication meaning no dropouts along with an easy set-up,” he said.

The IQD2 takes the award-winning DC DC charger IDC25X to the next level and allows for both scalability and implementation of future products and technologies. The IDC25X can charge any battery chemistry that is currently on the market, but with the IQD2 and the INTELLI-IQ App, defined profile settings can be changed and allow for not yet invented battery chemistries to be charged. This also allows scalability when the user needs additional power.

Mount it anywhere

The INTELLI-IQ Smart Display unit features a 2” display screen. It can be mounted anywhere the user deems suitable due to its single-wire connectivity, and the cable is easy to manipulate around a vehicle or a caravan. Owners can also extend, shorten or even run their wire through a trailer plug. The unit itself can be mounted flush, at an angle, or even upside down.

Further information go to www.projecta.com.au

The National Collision Repairer 7

Projecta have brought their innovation and dependability to an even wider range of applications.

Images: Projecta.

Images: Projecta.

The display can be mounted almost anywhere.

Product Showcase

Handling the future safely

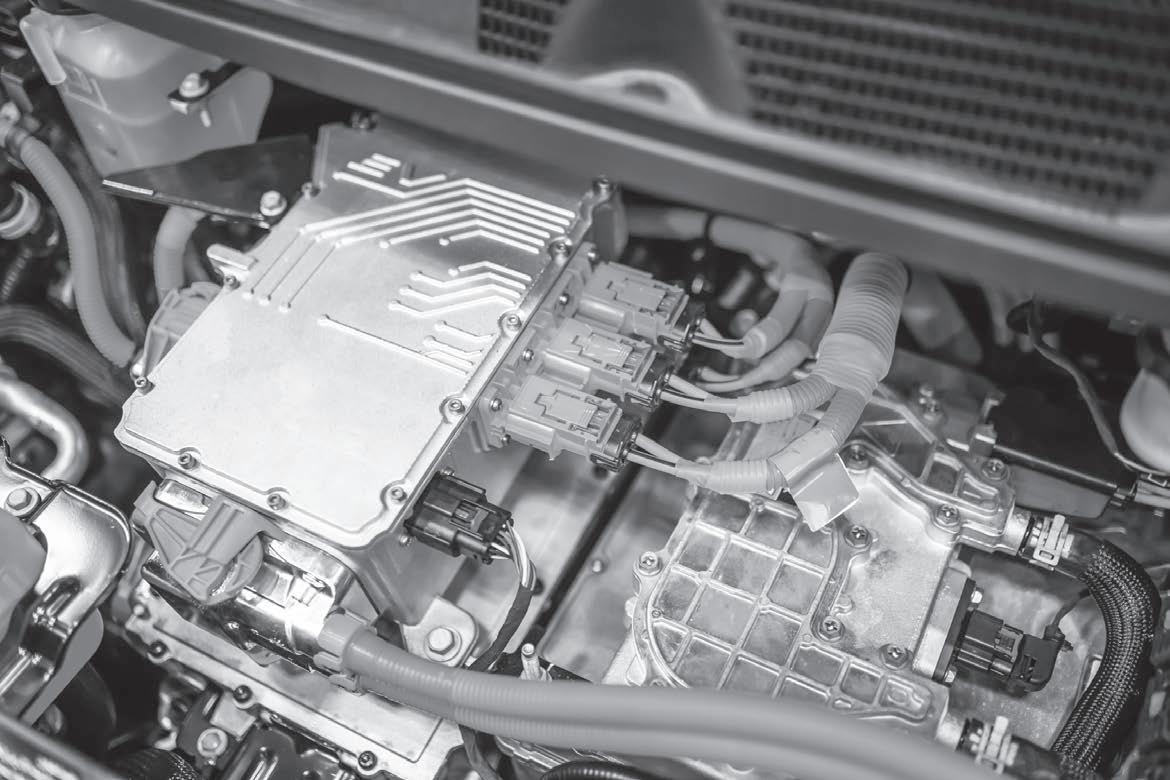

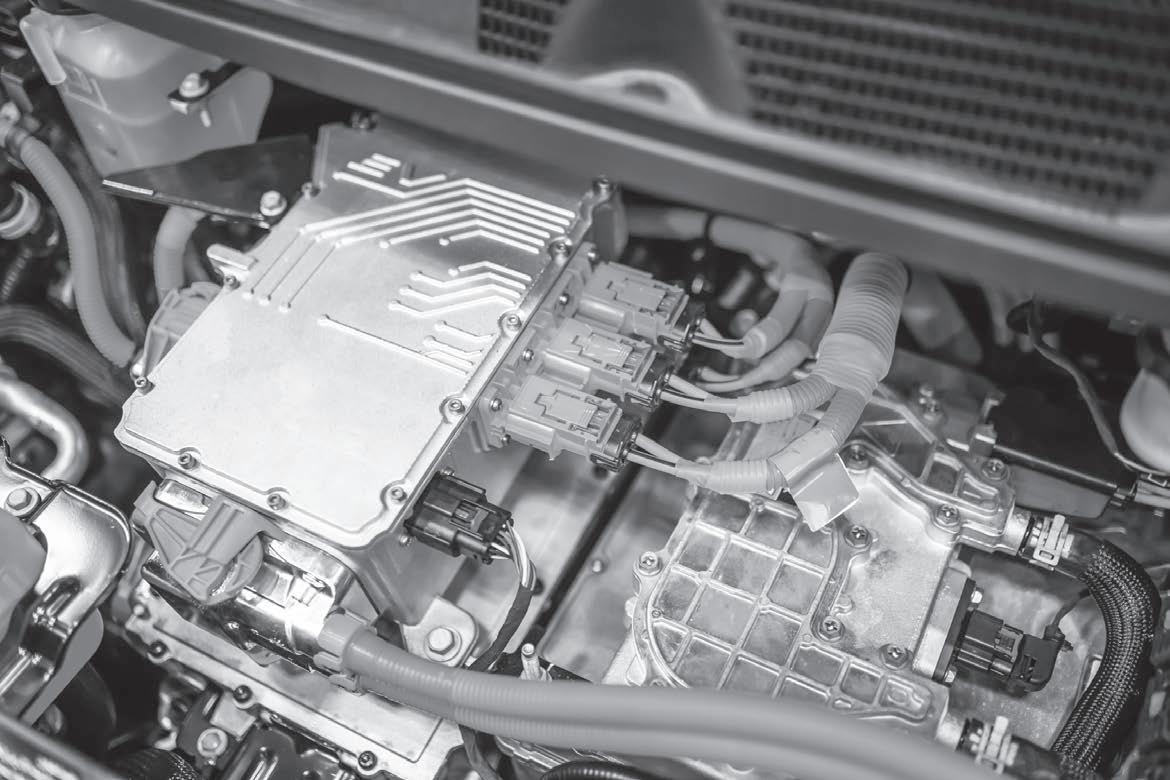

Recent figures show almost one quarter of new vehicles are made up of hybrids and EVs and it is only a matter of time before their presence is felt on the repair shop floor.

The question for many collision repair businesses is how to get ready to and how to ensure any workplace can deal with them safely.

Safe Working on Electric and Hybrid Vehicles

Unquestionably there are new and inherent risks associated with the maintenance and repair of Electric Vehicles and Hybrid vehicles in contrast to conventional vehicles such as:

• Short circuits creating explosions and fires

• Exposed connections and the presence of high voltage cable which has the potential for electric shock, resulting in serious death or injury

• Components that may retain a dangerous voltage even when a vehicle is switched o

• Harmful gases and liquids released when batteries are damaged

• Vehicles silently moving and people not aware

• Components that may move unexpectedly due to magnetic forces

Obtaining additional skills, appropriate training through registered training facilities and following the car manufacturer’s guidelines will be necessary to allow technicians to work safely with these vehicles.

Having a proper procedure to depower and reinitialise battery electric vehicles, incorporating a lockout procedure so the vehicle can’t be re-energised until technicians have completed their tasks is also essential for safe work practices.

Going in equipped

But there is also the indispensable gear

a workshop needs to tackle EVs and hybrids safely.

AS 5732:2022 “Electric Vehicle Operations- Maintenance and Repair” lists necessary personal protective equipment (PPE) depending on the task and level of risk involved.

Some of these last line of defence measures include:

Electrical Insulating Gloves with an appropriate voltage rating, commonly these are Class 0, that o er protection up to a working voltage of 1000V AC /15000V DC. These can be worn with a cotton under glove to reduce sweating and provide comfort. Leather overgloves are worn to protect the rubber insulated gloves from mechanical harm and also to provide protection against electrical arcing.

The use of Caution signage and

Warning steering wheel covers to alert others of potential risks and temporary exclusion zones to instruct non authorised people to keep away.

Using 1000V insulated rated tools when working on energised components to lessen the risk of shorting out the high energy source.

Wearing arc rated face shields and clothing to protect the face and body against the direct force of an electric arc incident.

Having an (AED) automated external defibrillator immediately available in the event of an electrical shock.

To get more information on product solutions that help technicians mitigate risk when electric and hybrids are worked on contact Electrical Factory Outlet. www.electricalfactory.com

8 www.nationalcollisionrepairer.com.au

High-quality equipment that ensures the safety of workers in the modern EV workshop.

EFO has everything needed for technicians to safely work on EVs.

Images: EFO.

Developing specialised products

As the rapidly developing electric car market evolves, EFO is continually searching for creative yet workable solutions that are simple to implement in mechanical workshops.

One of the elements that makes Electrical Factory Outlet stand out from many suppliers is their commitment to innovation and maintaining an edge over competitors.

They do this by developing products that solve problems or provide improved work practices for any technicians working in automotive electronics. They work with utility companies, electricians, and their supply partners, to design products to comply with Australian Standards and meet the demands of the specific tasks the customer wants.

Electrical Factory Outlet collaborates

Factory

with RTO’s, Industry Associations and TAFE Colleges across Australia that provide training for electric and hybrid vehicles. EFO provides product solutions that help keep workers safe when repairing and maintaining these vehicles.

The products are used and reviewed by qualified and operating electricians to ensure they meet the triple criteria of being safe, the highest quality and great value for money. The company also backs up its products by ensuring they are supported across Australia. Decades of accumulated knowledge in the industry, an agile approach to meeting any issue or problem are some of the other hallmarks of their service and advice.

EFO is a prominent supplier of high-grade 1000V rated Tools, Safety

Products, and Test Equipment. Providing a complete line of personal protective equipment, including covers, mats, and insulated gloves rated for a working voltage of 1000V AC/1500V DC. In addition, exclusion zone barrier kits, rescue crooks, automatic external defibrillators, caution signage, arc-rated clothes and face shields.

Electric & Hybrid Vehicle Safety Trolley

The trolley contains the basic safety equipment and signage requirements of AS 5732:2022 “Electric Vehicle Operations Maintenance and Repair.” Designed to be portable with locking wheels the trolley can be moved to any bay the EV or Hybrid vehicle is being worked on. The technician’s personal protective equipment, emergency equipment and tooling will always be near the potential risk area.

Part No. EVSTROLLEY

Ph: 07 3209 4333 E: sales@electricalfactory.com.au www.electricalfactory.com.au

Electrical Factory Outlet Pty Ltd

For further information contact Electrical Factory Outlet www.electricalfactory.com.au Electrical

Outlet

Image: xioalange/ stockadobe.com.

More EVs mean workshops need to be equipped to work safely.

The art of reliability

If there is one quality repairers cherish in the workshop, it is dependability. And when it comes to getting cars started, there is one product name workshops love to rely on: Projecta.

With vehicles frequently sitting idle in the workshop for some time, often with varying degrees of battery life and quality, jump starting is a part of everyday life for mechanics and repairers. This is why they turn to equipment they trust. The name of Projecta is one that is repeatedly raised by technicians for the equipment’s features, safety and ability to get things moving time after time. The National Collision Repairer magazine spoke to several workshops about what they are like to work with.

Trusted

For Josh Jones owner and manager of Quick Spark Automotive his view of Projecta Intelli-Start range of jump starters all comes down to one word: “Quality”.

His successful Sunbury business services a wide range of clients in the growing area on the outskirts of Melbourne and he cannot speak highly enough of the quality and dependability of their equipment and how it keeps his business moving.

“If you bring a car in and leave the ignition on for example, you’re doing a service and it’s sitting there for a couple of hours and the battery goes flat; you bring the Projecta in and it will jump start it every time.

“If something comes in with a faulty alternator or dead battery or on the back of a truck, we can go out, jump start it and bring it into the workshop.”

The Rapid Charge technology in Projecta units means they can recharge themsleves if left connected to a vehicle. The Intelli-Start Jump Starter can fully replenish the energy that was discharged during the starting process in just 40 seconds.

Jones sees the application for the starters as potentially even more crucial for collision repair shops, to avoid time wasted over flat batteries and ensure workshop e ciency.

“Sometimes they have cars sitting around for ages. This IS3000 should be a best seller for panel shops, who would be able to jumpstart anything.”

Mechanic Martin Lanza at Revesby Motors, another busy automotive repair shop based in western Sydney, highlights the wide range of cars that can need jump starting from depleted batteries.

“Modern cars are never really o , there are a number of circuits consuming electricity, the remote keyless entry system for example,” Lanza says

“Sometimes after major mechanical work a car is reluctant to start, the battery can quickly become depleted and a jump starter is required. With older cars, often collectors’ showroom items, the battery goes flat through age, these also need to be jump started.

“Cars that break down and are not repaired quickly often flatten the battery or cars being sent to us on a tow truck

Cover Story 10 www.nationalcollisionrepairer.com.au

For Quick Spark Automotive owner Josh Jones and his team, the Projecta IS jump starter range o ers dependability for years of operation.

Image: Prime Creative Media.

also often need to be jump started.”

In all these scenarios it is the dependability of the Projecta IntelliStart range that stands out for Revesby Motors.

“We’ve been using the IS1500 for 18 months and IS2000 for 6 months. Both the IS1500 and IS2000 have excellent performance in all three start-up scenarios,” Lanza says

“We use the IS1500 on a wide range of vehicles from small cars to large vans. The case construction is rugged and has survived a number of accidental falls. The IS2000 is a new addition to the workshop. It’s very impressive, more powerful and has more features.”

“Prior to these we used a large battery on a trolley. Portability was poor and the operator had to be very careful as the jumper leads were always live.”

Jones agrees it is hard to look back at old systems once a workshop has come to rely on Projecta Intelli-Start jump starters.

“The worst thing about the old set ups was they were huge, and you had to drag them around on wheels, and if you had anything outside it was a pain but with the Projecta you just grab it, carry it out and get the vehicle started.”

The compact nature of the units is enhanced by their portability, with shock proof casing, comfortable carry handles and modest weights for even the most powerful units, 10.6kg and 13.5kg for the IS3000 and IS5000. Jones is impressed by the versatility of the larger units, especially with the larger IS2000, 3000

and 5000 range that have the flexibility to do 24V charges.

“We’ve had a IS1500 for four or five years and it has been brilliant,” Jones says.

“But this IS3000 is the next level; the big one. This is probably a good all round workshop unit because it has the capability of starting anything; trucks and cars and look how small it is, you put this in your little car, run out and you can jump start anybody.”

Jones says this dependability and flexibility adds to workshop e ciency and in turn saves time and money. He says he uses it for a couple of jump starts a day in his workshop after which the unit goes back into its convenient desktop 5V cradle to recharge and is always on hand, fully charged when needed.

“But with the Projecta you wouldn’t have to recharge this for ages, you probably get ten starts out of it.”

“The Rapid Charge technology is beneficial, on busy days where we can jump start multiple vehicles multiple times,” Lanza says.

“Without Rapid Charge we may have had to put some jobs to one side and wait for an overnight charging operation. We really appreciate the smart charge feature, after starting a car the IS2000 will recharge o the car’s alternator. This is an excellent feature because it ensures the jump pack is always in a high state of charge. On a busy day with multiple jump starts this avoids the jump pack becoming discharged and unusable before charging.”

Safety First

“The safety features provide total peace of mind for both the operator and the business owner,” Lanza says.

“Batteries have high energy levels and mistakes can harm people, vehicles and equipment. Factoring out these risks carries a lot of weight with us.”

For Jones at Quick Spark Automotive the simplicity of the units and their intuitive controls makes them largely mistake proof, a valuable safeguard for the safety of sta and vehicles.

“With the old school jump starters, if you jump started something backwards you could blow the main fuse, or the alternator or even the computer. The Projecta units have a safety feature, if you put the clamps on backward it won’t power,” Jones says.

Jones also cautions mechanics and repairers about relying on many other modern jump starters that lack the

The National Collision Repairer 11

The team at Revesby Motors rely regularly on Projecta jump starters to get all kinds of vehicles running.

The IS3000 Intelli-Start comes in a sturdy and portable carry case.

Image: Projecta.

Image: Projecta.

power and dependability of Projecta units, particularly some cheap units sold to motorists.

“Those little ones, you’ve got to connect them up then let them power up because they have capacitors inside and then it gives you one big bang and that’s it. But if the vehicle doesn’t start, you’re screwed because you only have the one charge.”

By contrast both workshops agree the investment in Projecta jump starters is an investment in long term dependability.

“The cheap ones, they just don’t last but with the Projecta, it has been at least four years and I don’t know how many starts. Over the years I have sold I don’t know how many. When people learn about Projecta, they just want these units.”

Lanza agrees, “The IS1500 model has been our “go to” jump starter for the last 18 months. It’s compact, powerful and very easy to use. Our business depends on these devices.”

Features

A further benefit of the latest models is their ability to jump start vehicles and machines that use a variety of battery types including Lithium, Wet, AGM, Gel and Calcium.

The Intelli-Start range is equipped with premium LiFePO4 batteries, the safest lithium technology available. The range also utilises an advanced all-inone protection system that prevents surges, short circuits and overheating. The display will also alert the user of an incorrect connection and advise when they’re ready to use.

Common to units are premium sparkfree clamps, ‘no solder’, high current connections for added longevity and performance, intuitive LCD display with real time updates, in-built LED work light, EVA storage case, USB charging port and the ability to be used as a powerbank.

Projecta’s jump starters also provide more starts with up to 2000 battery cycles – around four times more than competitor Lithium Cobalt based jump starters. This range delivers a substantially longer operating life and provides a smooth

and reliable start, time after time.

Added durability comes from the range’s rubber moulded impact and drop resistant housing and IP-rated dust and water ingress protection.

The top of the range; IS3000 and IS5000 jump starters are ideal for use on large industrial and commercial equipment including heavy-duty trucks, tractors, and agricultural equipment.

The IS3000 is suitable for both 12V and 24V electrical systems and provides 1000A clamp power for 12V systems and 850A for 24V electrical set-ups, along with 3000 peak amps – it’s enough to start petrol and diesel engines up to 12L displacement in 12V machines and all 24V engines.

The IS2000 model is a compact model providing even further versatility, with its auto sensing clamp connections making it convenient for use on both 12V and 24V electrical systems. The

IS2000 will jump start 12V petrol vehicles with engines up to 8.0L and up to 6.0L for diesels. It can also jump start 24V vehicles – both petrol and diesel –with engines up to 7.0L.

The IS1400 is suitable for 12V electrical systems and o ers 500A clamp power and 1400 peak amps, more than enough to start petrol-powered vehicles up to 7.0L displacement and diesel engines as large as 5.0L. These capabilities along with a compact design makes the IS1400 an ideal choice to carry in the glovebox, for stowage with 4x4 recovery gear, or to keep on hand at workshops or car yards.

Other Projecta Intelli-Start models in the existing line-up include the IS920, IS1220 and IS1500.

For more information go to projecta.com.au

12 www.nationalcollisionrepairer.com.au

Story

Cover

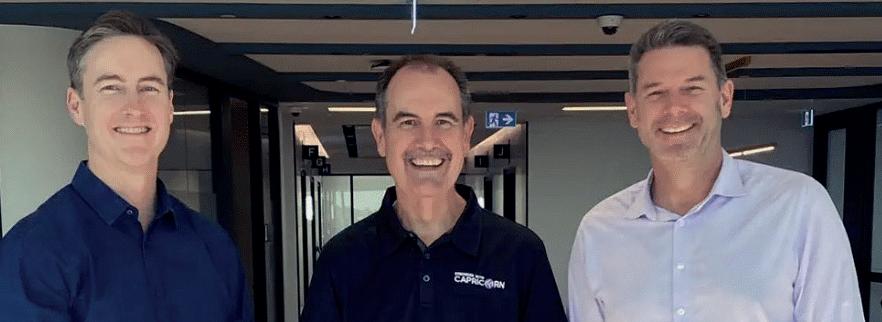

Josh Jones, Daniel Penny and James Carr speak highly of the Projecta starters they have used for years.

Image: Prime Creative Media.

www.nationalcollisionrepairer.com.au Promoting businesses, growing the industry Reaching more than 2500 recipients across the industry, our weekly newsletter is also a great opportunity to promote your company. For advertising details contact kerri.mccauley@primecreative.com.au National Collision Repairer Our weekly newsletter delivers the latest news, views and product information direct to your inbox. STAY UP TO DATE WITH THE LATEST INDUSTRY NEWS

Expo breaks records for ‘incredible industry’

Australia’s biggest aftermarket expo has lived up to its name, breaking records in attendance over the three-day event and opening the door to many future opportunities for the repair industry.

The combined Australian Auto Aftermarket & Collision Repair Expo saw 13,282 visitors pass through the Melbourne Convention & Exhibition Centre in April.

Australian Automotive Aftermarket Association CEO Stuart Charity described the biennial event as a resounding success with the range of training, innovations and product o ers giving visitors the incentive “to charge into the future” with new skills, ideas and opportunities.

“I am incredibly excited about the success of the 2024 Auto Aftermarket Expo and Collision Repair Expo. The vibe was electric in the packed halls, and feedback from visitors has been o the charts. The number and quality of exhibitors was amazing, as was the popularity of our expanded training programs and features. Expo ’24 was a truly remarkable and extremely valuable trade event,” Charity says.

The Expo was o cially opened on Thursday 11th April by Dr Andrew

Leigh MP, Federal Assistant Minister for Competition, Charities and Treasury and was joined by Stuart CharityAAAA CEO, Wayne Bryant – AAAA Board Chairman, Bill Hanvey – CEO Auto Care Association (USA) and Gino Ricciuti – APMEC Chairman. With over 400 exhibitors representing the entire automotive aftermarket supply chain, attendees were treated to a showcase of the latest tools, technology, parts, and services.

14 www.nationalcollisionrepairer.com.au

Repair

2024

Collision

Expo

More than 400 exhibitors packed the exhibition centre.

Image: AAAA

“Our objective was to show visitors how incredible our industry is and give them access to new skills, products, equipment, experts, o ers and opportunities - all under one roof,” Charity says.

“The tradeshow floor encompassed renowned brands, sought-after training, and avenues for career and business advancement. This is a fundamental role of the AAAA, and we are very proud of our contribution to fostering industry growth through this event. The Expo has exceeded expectations across all our key measurables and the feedback we have received has been overwhelmingly positive,” Charity says.

The Expo Electrified Zone and ADAS Technology Zones proved to be valuable additions to the Expo. With all scheduled training sessions for each zone fully booked ahead of the event, it demonstrated the hunger the industry has for these emerging and critical

areas of the automotive aftermarket.

Training was a central feature of the 2024 Expo, with the delivery of comprehensive training sessions covering advanced diagnostics, EV training, business management and collision repair.

The Business Education Program covered the most important automotive business topics, led by many of Australia’s leading aftermarket voices and respected subject matter experts, as well as Auto Care Association USA President and CEO, Bill Hanvey. Subjects covered the latest aftermarket trends, how to address the industry skills shortage, marketing and much more, with many sessions filled to capacity.

The international flavour of the Expo continued in an exclusive Collision Repair Training Program. US based EV expert Dirk Fuchs, CEO of Electric Mobility Consulting held multiple

sessions covering EV service, repair and workshop fundamentals.

“I want to sincerely thank all of our incredible exhibitors, our world-class speakers who came from across the globe and around Australia, and the record number of visitors who showed their commitment to the future of our industry by taking time out of their businesses to attend - the passion and dedication shown by everyone involved has been brilliant,” Charity said.

“I’d like to acknowledge and express my gratitude for the support of Auto Aftermarket Expo Major Sponsor Repco, and Collision Repair Expo Major Sponsor SAPE Group, and all of our valued partners and sponsors who helped us to deliver this amazing industry event.

The next Australian Auto Aftermarket Expo and Collision Repair Expo will take place in 2026.

The National Collision Repairer 15

Major suppliers like Car-O-Liner are a big part of the Collision Repair Expo.

Images:

Prime Creative Media.

Demonstration crowds were often three to four deep.

On floor demonstrations were an ongoing attraction.

Collision Repair Expo 2024

Insights from a global industry leader

This year’s Collision Repair Expo had a special guest from ‘across the pond’.

Bill Hanvey, the President and CEO of Auto Care Association (ACA) USA made his way to Australia to speak at the Melbourne Convention and Exhibition Centre.

Hanvey represents the entire supply chain of the independent automotive aftermarket in the United States.

With a jam packed schedule, Hanvey presented on panels across three

seminars, including the Right to Repair, Global Automotive Aftermarket Trends and Skills Shortages.

NCR sat down with Hanvey at the Expo to gain further insight into Hanvey’s extensive knowledge in the automotive aftermarket.

“I feel very honoured to be brought here to talk about the United States and pass on our knowledge,” Hanvey says.

Hanvey is a strong advocate for unifying the industry through solid communication and collaborative work.

“The key thing that we can learn together, whether you are in Australia, or in the States, or New Zealand, is that our industry’s similarities are much more aligned than our dissimilarities.

“And that we can work collectively on the issues that face our industry is more productive.”

With over 35 years in the automotive industry, Hanvey broke down three keys pillars in pushing the sector to the next level.

“The key pillars are identifying good talent to work in the industry, elevating the image of the industry, and thirdly, understanding the issues that are in play on both sides of the pond,” Hanvey says.

“The main message from me, is that if we collaborate and work on these issues together it is much more e ective.”

Identifying good talent also means finding good talent to support the industry. Hanvey, the ACA, and the AAAA are focussed on lifting the image of automotive careers, one that is not just about ‘getting your hands dirty’.

The high-tech industry is something to be celebrated, however, public perception still needs improvement.

“Unfortunately, the perception of the industry has not changed as quickly as the technology has in the industry. That is something that the AAAA is working on in Australia, and Auto Care in the United States is also working on.”

“It is really important to communicate to young men and women when making career choices how technologically advanced the industry is.”

“Education is a crucial mechanism to ensure our industry is sustainable and continues to grow.”

Hanvey outlined how Australia’s industry di ers from the United States, with diversity being a key di erence.

“Australia has a much more diverse vehicle population than the United States. There are a lot of di erent players. New Zealand also has tremendous diversity in their vehicles in operation. So yes, I think that the Australian automotive industry is an agile one.”

Despite the di erences in the aftermarket and legislation, Hanvey is dedicated to collaborating with Australia and New Zealand in growing the capacity of the automotive industry.

“We can all learn from each other.”

16 www.nationalcollisionrepairer.com.au

Bill Hanvey, President and CEO of Auto Care Association USA.

Images: AAAA.

Lectures proved a vital part of the Collision Repair Expo whether they were on business insights or technical subjects like ADAS.

What to do: skills shortages

The skills shortages is a complex issue that requires a unified approach, according to industry leaders. The Collision Repair Expo gathered four experts to talk about while there may be no easy, quick solution, there are key strategies that workshops can implement to find and retain sta .

The panel gave pragmatic advice on the proven tactics to find new team members and keep them engaged in your business. The panel included Lesley Yates from the AAAA as MC, Bill Hanvey from the Auto Care Association USA, Adam Pay from MyCar Tyre and Auto, and Fred Molloy from Konnecting Group.

Bill Hanvey - Auto Care Association USA

Hanvey outlined the work that is being done in the United States, and how there is a push for more to be done in encouraging young people to enter the automotive career pathway.

“We are working with members of Congress to promote apprentice programs. We also do it on the state level. We are far behind in terms of where we are in terms of the apprenticeship programme. But it is near and dear to our heart, and we are really trying to promote that in the US,” Hanvey says.

Relationships and connections with schools and university are key strategies to broaden the potential for gaining workers in the industry.

“Make it a point to establish a relationship with technical schools and high school programs so you are aware of one another. This will make it easier to recognise talent at an earlier stage,” Hanvey says.

Adam Pay - MyCar

Pay highlights the multifaceted issue of keeping sta and of recruiting new people.

“A few years ago, we decided to measure retention instead of turnover. So instead of asking why people leave, we are asking why people stay. Measures for success are a key focus for us,” Pay says.

“At My Car, we have a retention goal of 85 per cent. At the moment, it is at 75 per cent, so there is still work to be done.”

Pay emphasises the importance of shifting your focus onto the environment of your workshops.

“Where you apply your focus, is where you have the best result,” Pay says.

“We have 460 apprentices right now, which is a good number. However, we do still lose too many first years. I think we have a solid apprenticeship programme.”

Changing with the times is also essential for keeping up to date with the latest technologies, and the retention of sta .

“As the world is changing, it is a good opportunity to rethink and reimagine what the apprenticeship program could look like.”

“Gone are the days where you advertise on Seek. You have to start way further down the chain now. We have had some really good success with partnering with schools. It is so easy to do. You are pushing on an open door.”

“It doesn’t matter if you are a MyCar with 280 stores or an independent operator with one store, schools greet you with open arms,” Pay says.

“We aim to attract, develop and retain the very best team and when you get them, to support them, encourage them, and keep them engaged.”

Fred Molloy Konnecting Group

The demand for labourers is at an alltime high. Registered migration agent from Konnecting Group, Fred Molloy emphasised the need for not only gaining and retaining sta in the industry but foreseeing issues and planning ahead.

“The amount of calls I get from workshops saying can we get any technicians, can we get any panel beaters, or can we get any spray painters. The skilled migration piece is part of the proposal. It is normally the last desperate resort,” Molloy says.

Molloy stated that forward planning is essential in seeking international workers.

“Workshop owners need to be strategic. Getting skilled labour from overseas is a process that takes anywhere between 3 – 12 months. It can be done, but you need to get your ducks in a row.”

The National Collision Repairer 17

Image: Prime Creative Media.

The Skills Shortages panel on stage.

A ‘Right to Repair” score card

The Right to Repair: Fair and Open Competition – Are We There Yet? Seminar was held at the Collision Repair Expo 2024 as part of the Business Education programme.

The seminar was led by Lesley Yates as MC from the AAAA, Bill Hanvey from the Auto Care Association (USA), and Stuart Charity from the AAAA.

Stuart Charity outlined the history of the Right to Repair movement in Australia, the highlights of the law so

far, and areas that need improvement.

In Australia, the Right to Repair became enshrined in law in 2022 after a decade-long campaign. Despite this, there are still multiple hurdles in car owners’ way when repairing their cars, including missing information and the navigation of OEM websites.

Charity gave the audience a ‘Score Card’ on the Right to Repair law so far.

“There wasn’t a major issue with right to repair in the industry in 2009, but we knew it was coming because we have international linkages. There was already a lot of activity overseas at that time,” Charity says.

“We also knew it was going to take a long time to get a law in place. We got the ball rolling very early.

“The campaign got the Government to take on the recommendations of the ACCC. This engagement, grass roots campaign got everyone involved, from workshops to both sides of Parliament on board.

“By the time the legislation was

introduced into Parliament in 2021, it changed our competition laws.”

Charity’s Right to Repair Score Card

The green ticks:

• Functioning sustainable AASRA

• Dedicated enforcement: ACCC Motor Vehicle Information Scheme (MVIS) unit

• Registered technicians/data is flowing.

• Complaint and referral process

• Dispute resolution.

• Learning and continuous improvement

Areas for improvement:

• Untested legislation with no precedent

• No visible enforcement action to date

• Separation of EV from non-EV.

• EV training requirements

• Scan tools and third party data providers

• Low awareness

• Telematics is not included.

“The right to repair law is principle based. It means that any independent repairer operating in our market can access full dealer information. However, the law isn’t too descriptive on how that information is delivered,” Charity says.

“This is a blessing and a curse. It is blessing that there is flexibility in changing the scheme to suit the market conditions if it is not working. The curse, however, is that there is a lot of grey area in the legislation and a lot of that will have to be tested by precedent.”

“AASRA is up and running and doing a fantastic job.”

18 www.nationalcollisionrepairer.com.au Collision Repair Expo 2024

The ground floor of the Expo.

Bill Hanvey’s presentation on the ACA’s Right to Repair initiative.

Images: Prime Creative Media.

FOR ENQUIRIES: (02) 9772 9013 OR VIEW THE IRT RANGE ONLINE AT SAPEGROUP.COM.AU CONNECT, FOLLOW AND HAVE A CONVERSATION WITH US 3-2 PCD CURING SMALL SIZE REPAIRS & PRIMERS 4-2 PCD IR CURING HIGH OUTPUT IR MOBILE DRYER IRT 1 PREPCURE HANDHELD DRYER WITH 1 LAMP IRT 2 PREPCURE HANDHELD DRYER WITH 2 LAMPS IRT UV SMARTCURE BATTERY POWERED UV CURING IRT UV SPOTCURE POWERFUL HANDHELD UV CURING IRT SINGLE RAIL SYSTEM RAIL MOUNTED IR CURING ADAPTED FOR THE PREP AREA IRT POWERCURE ARCH INSTALLED IN A SPRAY BOOTH TO GREATLY SHORTEN CURING TIMES IRT I-CURE ROBOTIC DRYER ROBOTIC IR AND UV CURING FOR THE SPRAY BOOTH AND PREP ZONE SAVE

WITH A WIDE SELECTION OF INNOVATIVE HIGH-QUALITY, USERFRIENDLY, SPACE-SAVING SHORT-WAVE INFRARED (IR) AND ULTRAVIOLET (UV-A) IRT DRYERS - AVAILABLE EXCLUSIVELY THROUGH THE SAPE GROUP!

SPACE, TIME AND MONEY

Collision Repair Expo 2024

The world on show

Exhibiting at the Collision Repair Expo is a major investment in time and resources, but the returns come in the form of high exposure to eager businesses and the opportunity to showcase the best that automotive innovation has on o er.

Long a fixture at the Collision Repair Expo, the SAPE Group is not only a major exhibitor but again took up the key role of principle sponsor to the show.

The massive SAPE Group stand, strategically placed near the entrance to the Collision Repair Expo, was one of the highlights of the diverse event and the biggest they have mounted yet.

The SAPE Group aimed to showcase the best on o er in collision repair and drew experts from around the globe to showcase a range of cutting-edge equipment and materials.

SAPE Group CEO Paul McMartin says the diverse o ering of innovative products showcased SAPE’s unwavering dedication to excellence within the industry.

McMartin said the multiple presentations and sections, all with easy access and experts on hand, allowed visitors to the SAPE stand to celebrate innovation and excellence in the industry.

The Weilander + Schill Workbay WS Arena Plus was just one of the show pieces of the stand. Integrated

with other key equipment, it o ered the potential for increased bodyshop e ciency including with the increased demands of new automotive materials, such as working with aluminium and carbon fibre.

The system comes equipped with protective spark curtains and special daylight lighting that meets the industry requirement of 1000 lumens at one metre height.

Weilander + Schill product manager Stefan Knappe said the flexibility it adds to a workshop gives it the capacity to work with aluminium in a multipurpose booth without having to build a dedicated space solely for a new material, often impractical in an existing business or any location where space is at a premium., But critically it allows the workshop to do that work safely with key preventative equipment for any ignitions.

“The special extractor unit means they can work on aluminium, clean the

space and then work of steel without any danger of ignition that can come from working with both materials,” Knappe says. “The unit also has a special spark filter that ensures the safety of the workspace.”

These safety requirements are now mandated by a range of European OEMs potentially giving the wellequipped workshop the capacity to work on a range of cars including VW, Audi’s and Porsche.

SAPE Group’s Tony Maher who has more than 30 years’ experience in the industry, said the cutting-edge equipment meant a business could meet the increasing sophistication of the industry.

“This investment unlocks so much potential in the workshop,” Maher said.

Elsewhere, sophisticated coatings solutions where on display at the consumables stand, including a delegation from German company Vosschemie showing o Carsystem

20 www.nationalcollisionrepairer.com.au

Pepijn Woerdman, Maximillian Voss and Steven Luck demonstrated the beautiful finishes of Carsystem.

Images: Prime Creative Media.

Nick McDonald, Adrian Albany, Lachlan McMartin, Tony Maher, Joakim Gorsberg and Stefan Knappe show o a Spanesi bench in the Weilander + Schill Workbay.

with live demonstrations of repairs.

“My father met Ray McMartin (Father of SAPE Group Director Paul McMartin) more than forty years ago and the partnership is still going strong,” Vosschemie head of automotive Maximilian Voss says.

“They were both family businesses, so it was a very good fit.”

Another partnership for SAPE group on display was HB BODY, leading supplier of coatings and automotive repair solutions in Europe and across the world.

The company, originally founded in Thessaloniki, Greece had its paint mixing technology on display and along with a range of top-level coatings.

Consistency is one of the major strengths of the technology, o ering dependability for the workshop, HB Body’s Christos Demertzis explained.

“One of the most important things is ensuring batch consistency,” Demertzis says.

“Imagine if you are dealing with 90 pigments and only one of them is slightly o , the result can be a disaster.”

This is why experts at HB BODY and other suppliers for the SAPE Group want to ensure they are providing the highest quality and services to equip the modern repair workshop. Other highlights of the stand included renowned brands such as Spanesi, Celette, Gys, Jollift, Irt, Kamatec, Drester, Scangrip, and Carbon Plus along with consumables stand like Juice, Por-15, Sika, Roar, Cam and Scangrip.

For more information go to www.sape.com.au

THE ULTIMATE PH NEUTRAL CLEANER THAT IS HIGHLY EFFECTIVE IN REMOVING BRAKE DUST AND FALLOUT FROM WHEELS.

IT HAS A DEEP CLEANING ACTION THAT EFFECTIVELY REMOVES DIRT LEAVING A BRIGHT FINISH.

PLASMA DOES NOT MARK CERAMIC BRAKES, CHROME, GALVANISED METAL, ALUMINIUM OR POLISHED ALLOY.

AVAILABLE IN 500ML, 5L aND 20L.

The full team were on hand to help visitors at the massive SAPE group stand. Image: SAPE Group

Experts were always on hand at the SAPE group stand to demonstrate the benefits of investing in great equipment.

Christos Dermetzis and George Kazepis from HB BODY are proud of their cutting-edge products.

JUICEPOLISHES.COM.AU

Lifetime Achievement Awards

Celebrating the best

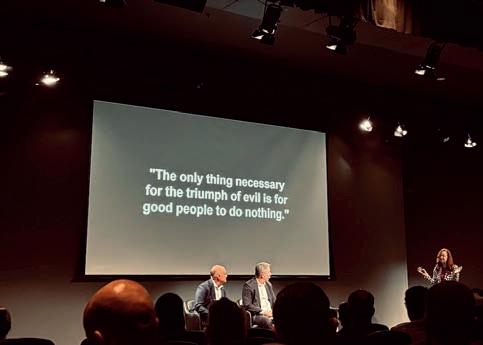

The National Collision Repairer Lifetime Achievement Awards kicked o a special week in Melbourne with the gala event celebrated on the eve of the 2024 Collision Repair Expo.

About two hundred industry leaders, innovators, suppliers, services and supporters gathered to recognise outstanding achievements in the repair industry on a night designed for fun and networking opportunities.

The evening was hosted by AFL legend and media personality Dermott Brereton, who revealed his talents extended even further, having run a panel beating business himself in Melbourne for several decades.

Brereton, or “Dermie’ as he is a ectionately known, regaled the room with stories from that era in the industry, including some amusing mishaps with fellow Hawthorn legend Robert “Dipper” DiPierdomenico.

But after the fun and banter, the order of the night lay with its key purpose; to recognise and celebrate the role models in the collision repair industry.

The Lifetime Achievement awards, which began in 2007, were created to acknowledge the dedication and commitment of the men and women who have contributed to the collision repair industry over and above their “day job”.

The criteria for induction are a minimum of 20 years in the collision repair industry, with contributions to the industry beyond the scope of their local area and their direct employment.

The gathering represented a who’s who of the repair industry, including sponsors, collision repairers, suppliers, insurers, and previous inductees who gathered to celebrate the people that make the industry strong, innovative and supportive.

National Collision Repairer magazine editor Eugene Du y says the awards were a vital part in how the industry rewards success.

“For almost two decades this award has been a great tradition for the best in the industry and with many great winners over the years,” he said.

“These are the first awards since NCR magazine’s acquisition by Prime Creative Media and in many ways, we are the custodians of this great tradition. Prime Creative Media’s values align well with the collision repair sector because it is dedicated to showing the best in that industry and to help it grow. That is why we wanted to ensure it was a gala event that becomes a red-letter day in the repairers’ calendar.”

In 2024, the Lifetime Achievement Awards also reflect the changing nature of the industry and have incorporated two new awards, one for women in repair and one for future leaders.

In 2024 The Lifetime Achievement Award, proudly supported by Platinum sponsor Repairify, celebrated an individual who has made significant contributions to, and achievements in, the collision repair industry over the course of their entire career. The award recognises an individual who have demonstrated excellence, innovation, and a lasting impact in the industry.

The new Women in Automotive award, proudly sponsored by PPG, is an important new inclusion and gives recognition to women in repair businesses alongside the prestigious accolade for lifetime achievement.

The Next Generation Leader award, sponsored by Capricorn, was also celebrated on this special night and showcased the valuable contributions made by up-and-coming achievers in the industry.

22 www.nationalcollisionrepairer.com.au

LA Award winner Craig Carey celebrates with family and friends.

Sarah Karavasilias enjoys the evening and her award with her husband Johnny, also a nominee on the night.

Images: nicrobertsmedia.

Next Generation Leader winner Nick Batey with supporters.

The National Collision Repairer 23

The gala awards night was a who’s who of people in the repair industry ranging from suppliers like SAPE Group, PPG, BASF, Saint Gobain, Car-O-liner, industry services like Repairify and Capricorn to a whole range of repair workshops from Car Craft, Sheen Group, Fix Auto, the AMA Group, Western General Bodyworks Group, MPSR Group, Walker Crash Repairs and Carllision Group to name a few.

Images: nicroberts_media.

Lifetime Achievement Awards

Support when you need it

The 2024 Lifetime Achievement Awards would not have been possible without the generous support of its sponsors and leading the group was diagnostic specialist Repairify Australia, platinum sponsor of the evening.

Repairify Australia General Manager Tristan Sender says he was thrilled to a be a platinum sponsor of the 2024 Lifetime Achievement Awards.

“The collision industry wouldn’t be the innovative, cutting-edge industry it is today without the people in it,” Tristan told the industry gathering at the gala night in Melbourne.

“We’re proud to support the prestigious Lifetime Achievement Award and celebrate the outstanding work and meaningful impact of long-serving industry experts.”

“In my opinion, the collision repair industry doesn’t get all of the recognition it deserves. It’s an essential part of our economy and in so many ways, it’s what keeps our nation moving. Nights like these that recognise leaders in the industry that have dedicated their lives to it are so important.”

But Tristan also said beyond the great nominees and worthy winners the awards were also about celebrating the wider industry and its future.

“Creating a culture of recognition and holding up examples of people who

have had successful careers is essential to encouraging people of future generations toward joining us,” he said.

“Collision Repair is going through a period of change in terms of technology as it develops and becomes an increasingly important part of the repair process. Whilst change can be challenging and create new and rewarding careers and jobs for people entering our industry, the changes in technology will also provide new opportunities for savvy repair businesses to generate new revenue streams.”

“Repairify is new to the Australian market but has been helping the collision and aftermarket repair businesses navigate these changes in technology and profit from them. We are a large employer in America, Mexico, UK and in Europe and we intend in the future to provide many people with long and rewarding careers within the broader repair industry.”

Repairify is driven by the fundamental industry objective; to get damaged cars back on the road, safely and e ciently.

Since launching with their cuttingedge diagnostic tools in Australia late in 2023, Repairify has seen a rapid uptake of their services as technology increases in vehicles and automotive repair shops turn to experts to unravel the complexity or overcome secure gateways.

Repairify o ers a diagnostic tool, a tablet-based device known as the “Allin-One” which enables the workshop to complete local diagnostics, performed at the car side by a technician from the workshop. But critically when gateways or new technology prevent the technician from going further, Repairify’s services allow them to undertake remote diagnostics with the help of their experts.

Without this access workshops may be faced with repair jobs that require extra expense and can inflate the repair time such as having to transport the vehicle for calibration or wait for a time it can be booked in at a third party or dealer.

Repairify’s Remote Services allow the technician to plug into the vehicle, access coding, calibrating and diagnosing the car using the Original Equipment Manufacturer’s tool and Repairify’s qualified technicians giving workshops a crucial time advantage.

The benefits for the workshop to have this added flexibility are many, including workshop revenue as it allows them to retain the allowances insurers have for calibration.

“The beauty of it is that you don’t need to take it to a dealership to have that job done,” Tristan told NCR. “There are two major advantages. The first is speed. Key to key time is massively sped up because you basically do it there and then in your workshop. The second is you also keep that revenue directly inside your shop because you can complete the whole job from start to finish. Importantly, by being able to access secure gateways using our OEM tools you can keep jobs in house that you would previously have been unable to complete.”

He says the whole industry benefits, from the satisfied customer to the insurance company that is covering the cost.

“It’s a win-win situation for the insurance company, body shop and customer. The time that the car is o the road is lower, which is good for customer service and customer retention and time saved results in reduced repair costs.”

24 www.nationalcollisionrepairer.com.au

Repairify can help in finding diagnostic solutions with their highly experienced team. Image: Repairify.

Repairify Australia GM Tristan Sender congratulates award winner Craig Carey on the night.

Image: nicrobertsmedia.

Proudly Sponsored by:

The National Collision Repairer magazine would like to thank its generous sponsors of the 2024 Lifetime Achievement Awards.

Platinum Sponsor

GoldSponsors

Evening Sponsors

Lifetime Achievement Awards 26 www.nationalcollisionrepairer.com.au

Fostering success

Self-e

acing and down-to-earth, the long career in collision repair of Craig Carey is anything but ordinary and sets a model in the industry for dedication and growth.

Former AMA Group leader and industry veteran Craig Carey is the latest inductee in the prestigious National Collision Repairer 2024 Lifetime Achievement Award.

The Lifetime Achievement Award, sponsored by Repairify, is one of the industry’s most prestigious awards and celebrates those involved in the sector for more than 20 years who have made outstanding contributions to the wider industry.

With more than forty years in the industry before his retirement in 2023, Craig Carey is a well-known collision industry leader who has forged a strong legacy in Tasmania and across the repair sector.

Over these decades, Craig has shown a commitment to the industry, to developing the next generation of leaders and tradespeople and a passion for quality and achieving OEM accreditation.

In the judges’ comments they noted Craig’s long commitment to the industry and his professionalism.

“Craig’s Carey’s career is marked by a series of strategic advancements and leadership roles that have significantly contributed to the industry’s evolution. Craig’s journey exemplifies dedication, innovation, and excellence. His leadership

skills are evident through his ability to mentor, guide and inspire his team. He has fostered a culture of success and growth within his organisations.

His ability to navigate through changes with foresight and adaptability underscores his exceptional capacity as a leader as a leader in the industry. Craig stands as a beacon of professional integrity and visionary leadership, making him a distinguished leader in the collision repair sector and an absolutely worthy recipient of this year’s Lifetime Achievement.”

More than two hundred peers and leaders from across the industry cheered the 2024 winner at a special gala night at South Wharf in Melbourne in April.

“It’s really humbling to be recognised by your peers after such a long time and when there are so many of them in the room,” Craig Carey said.

“I’ve made some lifelong friends both in the panel beating and paint industry and the insurance industry and there are some super close friends in the room.”

But Craig saved his especial thanks for his wife, Deanne of 39 years, who he said had been a great support during the highs and lows of his long career.

Craig has championed many initiatives

and changes across his career spanning 40 years. In his roles prior to retirement, he drove improvements and initiatives across the business. This included a review of the Capital SMART business as well as driving operational and profitability improvements in (what is now) AMA Collision.

Darren Wales, EGM of Heavy Motor Division AMA Group says in his submission: “In the time I have known Craig and working with him within the AMA Group, he has led various successful initiatives within the AMA Group and Capital SMART. He has implemented and managed multiple projects that have enabled change within the business. He has provided a “handson” mentoring role to his team and is respected by those around him.”

The Centre Manager at Craig’s original Micra Repair Centre in Breadalbane, Josiah Casboult says that “even when he wasn’t running the site, he always knew what was going on at site level and industry level. He always knows the question and the answer before I’ve asked it. He is really switched on.”

“I worked for Craig for 12 years. He taught me everything, from my time as an apprentice, through to being a qualified tradesman, then as an estimator.” Josiah says.

Craig is very disciplined leader, known for keeping his workshops in order and coaching others to do the same. He is a courageous leader who is not afraid to say what he thinks. Those who have worked directly with him say that nothing phases him, and he’s always taken everything in his stride.

Craig began a qualified panel beater and spray painter before starting his first collision repair business, Longford Bodyworks, with his father-in-law in 1989.

The National Collision Repairer 27

Craig Carey with his family as he enjoys the accolade of one of the repair industry’s highest awards.

Image: nicrobertsmedia.

Lifetime Achievement Awards

Young leaders shine

Young role models in the collision repair industry are critical for a future workforce and NCR ’s Next Generation Leader Award celebrates some of the best.

From six finalists to one winner, the Next Generation Leader Award was awarded at the special gala event to rising star, Nick Batey from Fix Auto Port Melbourne.

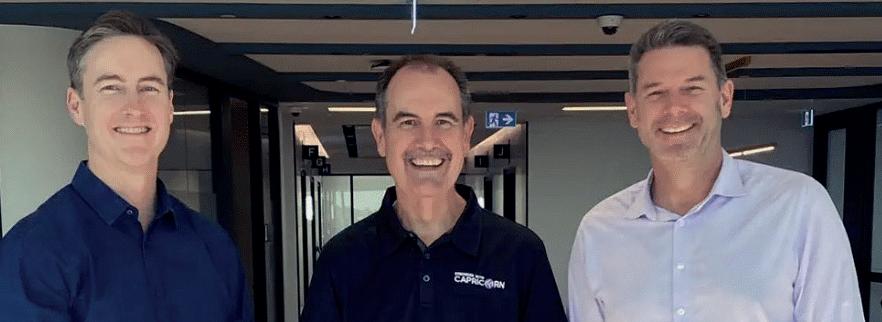

The Next Generation Leader Award was proudly sponsored by Capricorn.

The award promotes the younger generation of auto specialists rising in the ranks. It aims to recognise an individual who has impressed their colleagues and counterparts with their contribution, along with making an impact to their organisation and excellence in service.

Batey proudly accepted his award and was quick to thank the automotive industry for the opportunities it o ers.

“Firstly, I would like to say thank you to everyone here tonight. To the National Collision Repairer magazine, thank you for putting

on this lovely night,” Batey says.

“Thank you to Fix Auto for giving me the opportunity to be here in this category.”

Batey’s 10-year career in the automotive industry has taken him to di erent places. He began as a young man, doing three years of an apprenticeship and followed that with multiple jobs within the industry, including with Capital SMART, RPM Somerton and Repairhub.

“When you’re young, you always do a bit of everything. Panel shops are normally good at this and show you around and give you a taste of what all the di erent jobs are, especially at Fix Auto. They want to give you a taste of everything to learn what you are good at,” Batey told NCR.

Capricorn – Australia’s largest

automotive cooperative that has more than 29,000 members representing all forms of the automotive industry, has been a strong supporter of the NCR awards.

The Award was presented by the CEO Automotive at Capricorn, Bradley Gannon.

“Capricorn are thrilled to be a sponsor of the Lifetime Achievement Awards in 2024,” Capricorn Group CEO David Fraser said.

“This year we’re also sponsoring the Next Generation Leader Award to show our support for the up-andcomers who will drive the industry into the future.”

“These awards recognise some of the most experienced individuals in collision repair and we are proud to play a part in acknowledging the contribution they have made to the iwndustry.”

28 www.nationalcollisionrepairer.com.au

Capricorn CEO automotive Bradley Gannon Celebrates with Nick Batey. Images: nicrobertsmedia.

Fix Auto Port Melbourne’s Nick Batey took out the Next Generation leader award.

Bringing diversity to the industry

Sarah Karavasilias from MPSR Group was announced as the first ever winner for the National Collision Repairer ’s ‘Woman in Automotive’ Award. The category was proudly sponsored by PPG.

Sarah Karavasilias who holds multiple management roles at MPSR Group in Marrickville NSW brought a decade in criminal law to the family business. She highlights the industry as having good support networks which enables her to keep challenging herself and her sta .

During her acceptance speech, Karavasilias expressed her gratitude towards her husband, Johnny, who also works at the MPSR Group.

“Without Johnny I wouldn’t be able to receive this award and he enables me to be a trailblazer in the industry,” Karavasilias says.

“And of course with Johnny and the MPSR Group by my side we really want to help the automotive industry to continue and thrive.”

Karavasilias acknowledged how her prior career in law helped her navigate the auto motive industry.

“I’ve only been in the industry for a short time, starting in 2022. Previously I was doing criminal law, so a male dominated industry. It wasn’t much of a shift coming into the automotive industry.”

Karavasilias and the MPSR Group have their sights set on the future, with aims to improve the perception of the automotive industry.

“I am really focussing on trying to get the word out there to young people to get them into the industry. We have a lot to o er.”

New to 2024, the Woman in Automotive Award seeks to honour a female professional in the industry who has been a promoter of positive change.

Recipients not only showcase their own contributions to diversity and inclusion but also exemplify the skill to inspire more women to embrace opportunities in the field.

“That’s one of the benefits of being a female is that you have that sympathetic ear and you’re able to manage personal interests with business interests as well,” Karavasilias told NCR during a recent forum about life in the repair industry.

“You’ve got to have a thick skin. I always, try and challenge myself and lead by example. But we are at work more than we are at home, so you’ve also got to really enjoy it as well.”

Global coatings giant PPG is a Gold Sponsor of the awards night and a special sponsor of the category.

Presenting the Woman in Automotive Award was PPG’s Paul Galea.

“On behalf of PPG it is an honour to sponsor the Woman in Automotive Award,” Galea says.

“I first stepped into automotive industry at 15 years of age which was a long time ago. I have had the pleasure of meeting and working with many amazing women in the automotive industry. The winner and the nominee’s tonight are no exception.”

PPG Sales Director Australia with John Hristias said the awards were an important recognition of outstanding figures in the repair industry.

“Today’s robust, tech savvy collision repair industry has been made possible by people across the country who have literally put their blood, sweat and tears into it,” Hristias said.

“To help recognise that, PPG is proud to support the National Collision Repairer Lifetime Achievement Awards. As one of the longest serving suppliers to the local industry, PPG has built its success on establishing long term relationships and that has brought us into contact with individuals who have dedicated themselves to making the industry stronger. Whether these industry achievers are front and centre or operate quietly in the background, the National Collision Repairer Lifetime Achievement Awards provide a valuable way to recognise them.”

The National Collision Repairer 29

Images: nicrobertsmedia.

Sarah Karavasilias is the proud inaugural winner of the Women in Automotive award.

PPG’s Paul Galea presents Sarah with the award.

Limitless growth

Johnny and Sarah Karavasilias from the MPSR Group are shining examples of the di erent pathways that can lead you towards a successful career in the automotive industry.

With Johnny starting o as a panel and refinish technician at his family workshop, and Sarah working as a solicitor in criminal law, the unified business partners (and couple) prove there are many diverse career pathways in the automotive industry that can cater to any background.

Johnny and Sarah have ensured that the MPSR Group is a family run and centred business. This mentality also spreads to their attitude towards their employees, with a fair-go attitude at the forefront of their ethos.

Not a pair to shy away from hiring people with little experience, Johnny and Sarah’s can-do attitude embraces newcomers and apprentices with open arms. All the MPSR Group require is a willingness to work and learn.

The original repair shop that started the MPSR Group was founded by Nick

and Elias Karavasilias in 1980. It wasn’t until 2019 that Johnny Karavasilias branched out from his father and uncle’s business and opened the MPSR Group in Marrickville, New South Wales.

Johnny’s wife, Sarah Karavasilias joined him three years later in 2022, which proved to be an asset to not only the family business, but the automotive industry as a whole.

The MPSR Group is based in the heart of Sydney’s Inner West, Marrickville. The site is situated on 5,500 meters squared with the capacity to repair 150 vehicles a week.

A smart system

As an award-winning automotive repair business, the MPSR Group have the latest technology to boost not only their business, but the experiences

and opportunities for their sta .

“It’s not so easy to finish 150 cars in a week, but I always like to be on the floor and always want to improve our process and how we do things. I’m always investing in equipment, so the speed of our repairs is e cient. We’ve got two Lowbake Gas IR arches, one Lowbake Alpha spray booth and one Gas IR combination spray booth. They allow us to do between 35 to 40 cars a day,” Johnny says.

“At any given time, there is about 70 people on the workshop floor, so there is always something going on,” Johnny says.

“About a month ago we had training with the MTA for EVs. We had 10 of our sta do that course. The course was on depowering and repairing electric cars,” Sarah says.

The shift towards a streamlined

30 www.nationalcollisionrepairer.com.au

Talking Shop

Johnny and Sarah Karavasilias (front and centre) with their team.

Images: MPSR Group.

system and consistent training, was a result of the boom in business after the COVID pandemic.

“Our workload exploded coming out of COVID. In 2022 the workload just went through the roof and we were essentially catching our tail towards the end of the year. Now we’re starting to optimise what we have. We’re taking time to implement leadership training and making sure that the workshop is e cient,” Sarah says.

“We’re trying to streamline everything, so onboarding is an easy process.”

Embracing electrical

As a workshop on the path to I-CAR Gold Class, the MPSR Group is dedicated to upskilling and continuously improving their workshop and customer experience.

The Group has also invested in Lowbake equipment, which incorporates Rapid Air Drying System (R.A.D.S) that saves 80 per cent on energy costs and a 70 per cent reduction in baking time.

“About 30 of the 150 cars we repair each week are usually EVs, and that is growing every month” Johnny says.

The Karavasilias’ have made contributing to a greener future a

priority for the Group. With a Tesla accreditation received at the start of 2021, and a BYD accreditation that followed, the Group has trained sta to fix the changing car parc.

“There were little add ons when becoming Tesla accredited. There was a lot of new equipment we had to buy. Before we only had two EV chargers on site, now we have a few more to keep up with charging the customers vehicles,” Johnny says.

Risk taking and expansion

The ability to take risks has paid o for Johnny, resulting in an

The National Collision Repairer 31

Working together since 2022, Johnny and Sarah make a great team.

The MPSR Group are dedicated to upskilling their sta .

A core value at MPSR Group is giving people a fair go.

additional warehouse.

“I think one thing that sets me apart from others, is my ability to take risk. For instance, I made the commitment to invest in millions of dollars’ worth of equipment to fill out a state-of-the-art workshop without guaranteed work,” Johnny says.

“This investment, although stressful, has now brought in several contracts of insurance work and improved the overall customer experience. I work long hours to get the job done and give my other sta motivation, I love my job. I still learn new things each and every day.”

“We work well with the insurers and with the OEMs. We try our best to keep a happy medium,” Sarah says.

A fair go

Giving everyone a fair go and a chance to succeed sets the MPSR Group apart from their competition. Sarah and Johnny choose to take an informal route when looking for sta .

“I think a strength that we have is that we give everyone a go. If someone is looking for work, we call them in. I haven’t seen a CV in two years. So, I will just give them a go, give them a trial and see how they do. And then we work out if they’re going to stay on board with us. We will give everyone a chance if they want to work with us,” Sarah says.

The breadth of opportunities in the automotive industry is a topic that

Sarah is particularly passionate about. Sarah identifies the di erent career paths within the industry as a great opportunity to get your foot in the door.