NEXT GENERATION medical implants manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> Exit planning for businesses 32 Additive manufacturing for WA 29 JULY 2023 Developing augmented reality from Australia 34 Official Industry Partners

twitter.com/Manmonthly facebook.com/Manmonthly linkedin.com/showcase/manufacturer’s-monthly/

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Josh Farrell joshua.Farrell@primecreative.com.au

Journalist: Mignon D’Souza mignon.dsouza@primecreative.com.au

Production Coordinator: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Kerry Pert, Tom Anderson, Louis Romero

Sales/Advertising: Danny Hernandez

Ph: 0431 330 232 danny.hernandez@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST)

Overseas prices apply

Ph: (03) 9690 8766

Copyright

Manufacturers’ Monthly is owned by Prime Creative Media and published by John Murphy. All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office 379 Docklands Drive

Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 3.06,

Chandos Street

Leonards NSW 2065, Australia

Manufacturers’ Monthly Contents

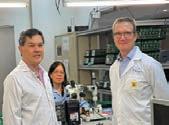

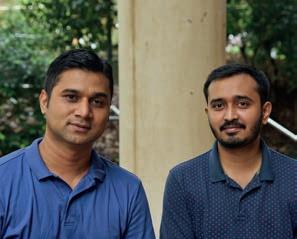

In the July edition of Manufacturers’ Monthly we unpack a variety of trends and challenges facing Australian manufacturing, from tax incentives to securing supply of critical parts. An incredible development in the medical implants space is this months engineering focus. University of Queensland researchers have created a gold sensor for implants which

promises to drastically improve efficiency and reliability of implantable medical devices. We sat down with the two reserachers behind the development to learn more about it and how it is expected to be used.

Elsewhere, RSM breaks down exit planning for manufacturers and what owners often forget when setting up a succession plan.

4 Editor’s Note 6 Comment 14 News 24 Engineering Focus 29 Additive Manufacturing 32 Financial Services 34 Augmented Reality 37 AMW Wrap 40 What’s New 42 Last Word For daily news visit manmonthly.com.au Inside JULY 2023 24 Behind the cover NEXT GENERATION medical implants manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> Exit planning for businesses 32 Additive manufacturing for WA 29 JULY 2023 Developing augmented reality from Australia. 34 Official Industry Partners T&C Only organizations with relevant use cases qualify for the Complimentary 3D Printed Part at the discretion of the Markforged Application Engineer. By subscribing to the Complimentary 3D Printed Part campaign you agree for Markforged to use the part for marketing purposes. Offer valid in Australia. Get your Complimentary 3D Printed Part* Are you looking to innovate faster and reduce supply chain issues by 3D printing everything from prototypes to end-use parts? We got you covered! At Markforged we are on a mission to bring industrial manufacturing to the point of need. To help manufacturer reduce lead time we are offering a Complimentary 3D Printed Part*, for a limited time only, to encourage manufacturers to improve their production processes. See for yourself the unmatched surface finish, strength and precision of our 3D printed parts in metals and continuous-fiber reinforced composites. Claim your Complimentary 3D Printed Part by simply scanning the QR code and filling out the form. Our Engineers will be in touch!

37

1-9

St

P:

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

+61 2 9439 7227

manmonthly.com.au

2 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

CAPS’ NEW RANGE OF ENERGY EFFICIENT ROTARY SCREW COMPRESSORS

Introducing our new BMF range of rotary screw compressors with variable speed drive and permanent magnet motors. Enjoy maximum energy efficiency and performance while reducing operating costs.

• 15 to 45 kW

• Kubota engine

Editor’s Note

JOSH FARRELL – Editor, Manufacturers’ Monthly

Looking to the future

IT has been an exciting time for the manufacturing community. I was lucky enough to attend all four days of the Australian Manufacturing Week, where I was introduced to a range of industry professionals, all sharing similar verve for manufacturing innovation and progress.

It was recognised by a range of manufacturers that it is important to invest in fresh initiatives to better support its employees and solidify their businesses.

Maria Christina,

national manager manufacturing and wholesale at Commonwealth Bank shed light to the AMW crowd on CBA’s annual publication examining the key trends shaping the manufacturing sector.

The Manufacturing Insight Report highlighted the resilience of our industry for a range of challenges it has faced over recent years. Eighty four per cent of manufacturers involved believe they adapted well or extremely well to pandemic induced opportunities and challenges. These challenges included a drop in revenue during the pandemic along with labour shortages but also an opportunity for a number of manufacturers to supply more of the local market, with supply chain issues impacting across the board.

Manufacturers invested in an average of 5.1 initiatives in their businesses. The most common were employee engagement, strengthening relationships with suppliers and partners to bolster supply chains, and investing in manufacturing or processing equipment and technologies to support growth.

The report took the opportunity to survey the expectations of the industry for the future, too.

The majority of manufacturers expect domestic and global economies to strengthen over the coming 12 months, with the largest businesses by far the most optimistic. Against this constructive backdrop, 65 per cent of manufacturers will concentrate on growth in the coming year, and 32 per cent seek to maintain revenues.

Manufacturers have implemented a broad array of sustainability initiatives,

and plenty more are in the pipeline. Several strategies have clear economic and efficiency benefits, while others extend beyond the organisation to encompass the supply chain, such as ethical procurement practices and using more sustainable materials in production.

However, it is manufacturers’ workplaces and people that are the most significant focus. More than 75 per cent of manufacturers are improving workplace safety and supporting employees’ well-being while also promoting an inclusive and diverse culture. The largest manufacturers are leading the way in extending the people-related initiatives to addressing and eliminating social issues within their organisation and across their supply chains.

The report uncovers a number of trends for manufacturers but there is a clear focus on people. As all industries struggle with a labour shortage, manufacturing is particularly hamstrung when compared to other sectors due to a lack of flexibility for employees,

employers will have to get clever to retain good staff.

It will be an interesting 12 to 24 months as businesses become increasingly resourceful with finding ways to retain employees. Hopefully, will see the industry as a whole grow.

I want to take the opportunity in my first editor’s note to show my appreciation for outgoing editor, Billy Friend and his tireless work and dedication to growing the Manufacturing space and diligently reporting on it in his time as editor of this magazine.

He has been an incredible advocate to the wider industry and his knowledge has been invaluable in setting up what will hopefully be a seamless transition of editors, allowing me to continue his fantastic work.

This magazine plays a pivotal role in sharing information within the manufacturing space while also advocating for the growth of the industry as a whole; I will strive to continue this tradition with every story that is put on these pages.

4 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

Comment

How industry can realise the benefits of advanced technology

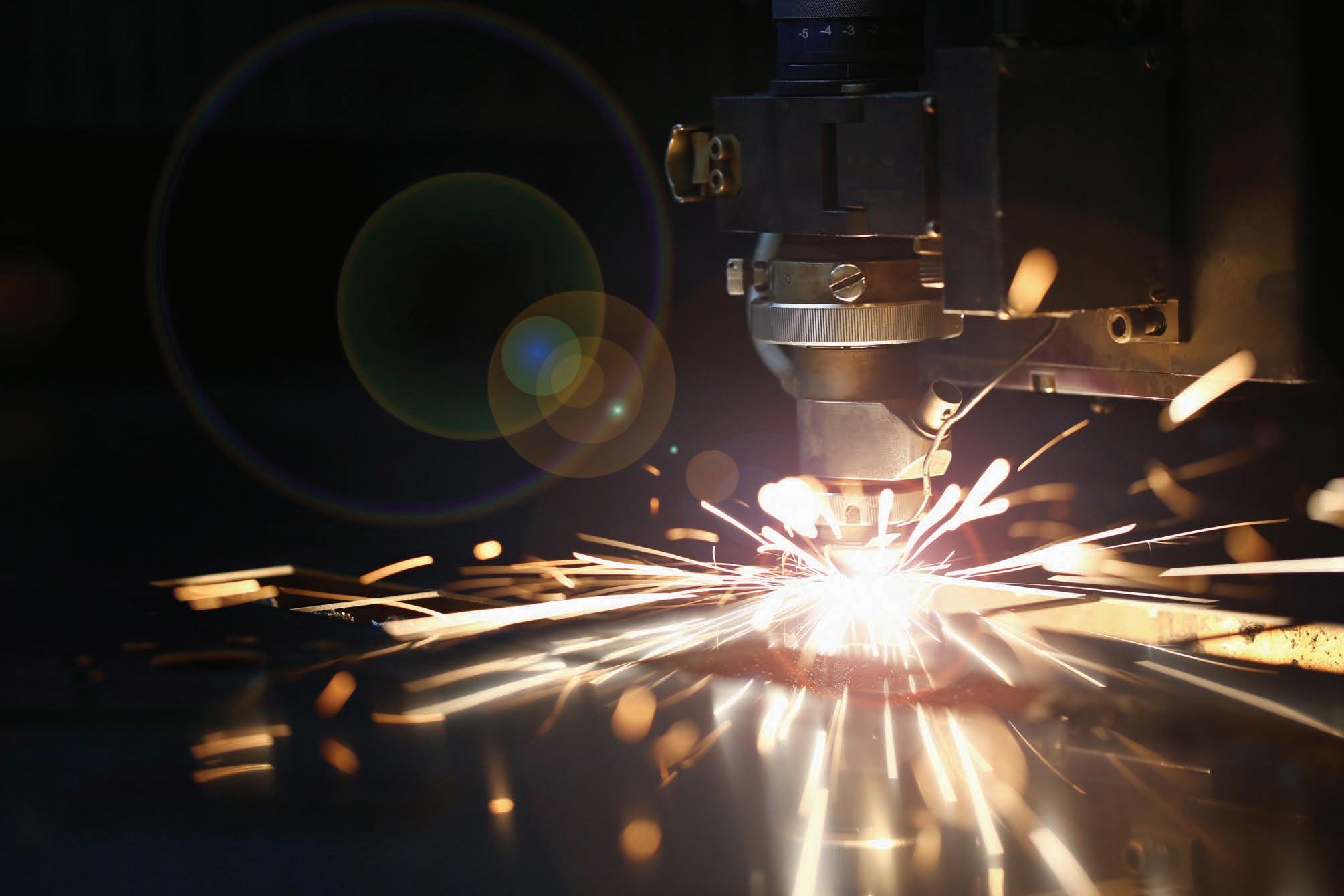

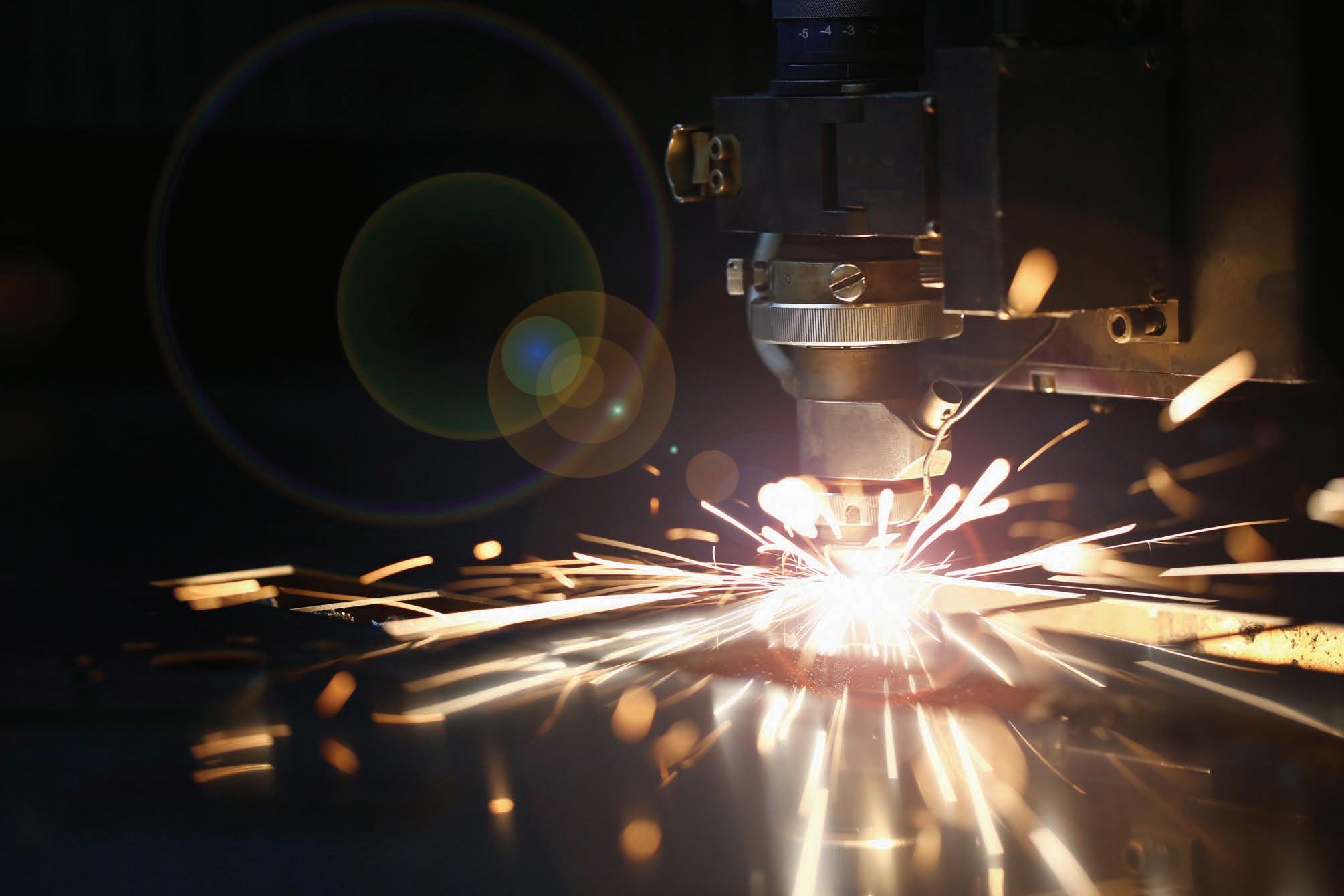

THE trade of welding conjures up images of dirty, dark workshops full to the brim with traditional tools and machinery prone to throwing off sparks and fumes.

But, with the advent of automation, robots, cobots and a range of other advanced welding technologies and techniques, this perception is becoming more and more outdated. Welding is a far less dangerous and arduous job than ever before. Increasingly, Australia’s worldclass welding workshops are light and bright, and fitted-out with some of the most advanced technology available. Weld Australia—the peak body representing the welding industry in Australia—can help welders and fabricators realise the benefits of these advanced welding technologies.

The power of industry 4.0, robots and cobots

Automation, Industry 4.0, robotics and collaborative robots are changing the way the welding and manufacturing industries work.

Cobots are specifically designed to share the workspace with human beings, making automation easier for businesses of all sizes, particularly SME’s. Cobots are generally versatile, smaller, lightweight, require relatively little space, and are much easier to program than their industrial counterparts. They can also capture large volumes of data that can be deployed in areas such as predictive maintenance. Weld Australia can help fabricators connect with cobot suppliers, and provide training related to the integration and use of cobots.

All these technologies offer a raft of benefits, from improved productivity, quality and repeatability, through to safer working conditions and greater job satisfaction. Increasingly, advanced technology is becoming a critical factor in the success of globally competitive welders, fabricators and manufacturers. And yet, Australia’s adoption rates lag well behind other advanced economies.

Improved productivity and profitability

To ensure their global competitiveness, businesses are investigating ways to save money and reduce their overheads. The best way to do so is by undertaking operational efficiency improvements that help reduce or eliminate redundancies, errors, bottlenecks and waste.

Industry 4.0 methodologies, robots and cobots play an essential role in creating lean manufacturing processes. The right type of technology can help eliminate workflow delays and duplications and accelerate entire processes through the automation of individual tasks.

Superior quality and repeatability

The integration of automation into production processes is proven to deliver superior quality outcomes and higher repeatability. Any process that improves weld quality and repeatability is worthwhile. Welding is not just a commodity, or a simple, straightforward process. When welds fail, the results can be disastrous. A poor-quality weld can be

6 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

GEOFF CRITTENDEN – CEO, Weld Australia

hugely expensive, and can cause massive damage, injuries, and even fatalities.

Growth in domestic and export markets

With increased productivity, quality and repeatability, manufacturers are able to leverage new domestic and export markets. Increases in productivity enable manufactures to deliver on changing customer needs and mass customisation, while maintaining a sustainable competitive advantage.

Safer working conditions

The use of robots and cobots has the power to improve safety for welders and manufacturing workers. According to Safe Work Australia, there were 6.9 million work-related injuries and illnesses

that occurred between 2008 to 2018, an average of 623,663 cases each year. This caused a 2.2 million full time equivalent (FTE) productivity loss between 2008 to 2018, and on top of this $37.6 billion in costs were incurred by the health system and $49.5 billion in employer overheads.

Fewer work-related injuries or illnesses would accelerate our transition to a knowledge-based economy, and create more higher-skilled, safer roles.

As automation reduces routine, dangerous manual work, workplace injuries are expected to drop by as much as 11 per cent. For instance, the use of robots and co-bots (particularly in confined spaces) helps to remove welders from immediate exposure to welding fumes, ultraviolent radiation, heat and sparks.

Greater job satisfaction

A move towards the use of Industry 4.0, robots and cobots will unburden the average Australian of two hours of the most tedious and manual work each week over the next ten years. Approximately 62 per cent of low-skilled workers will experience improved job satisfaction, and wages for non-automatable work will increase by around 20 per cent.

Introduction of cobots into production lines allow businesses to make better use of human skill and innovation, with machines taking over mundane tasks so that employees can focus on critical thinking, quality and creativity. This opens up new opportunities for businesses to improve and optimise their operations.

It can also result in other, more indirect, payoffs. For instance, using a plasma welding machine or a Microsoft HoloLens, or programming a cobot, can be more interesting than traditional MIG or TIG welding. Several Weld Australia members that have invested in advanced technology have reported marked improvements in recruiting, training and retaining staff long-term as a direct result.

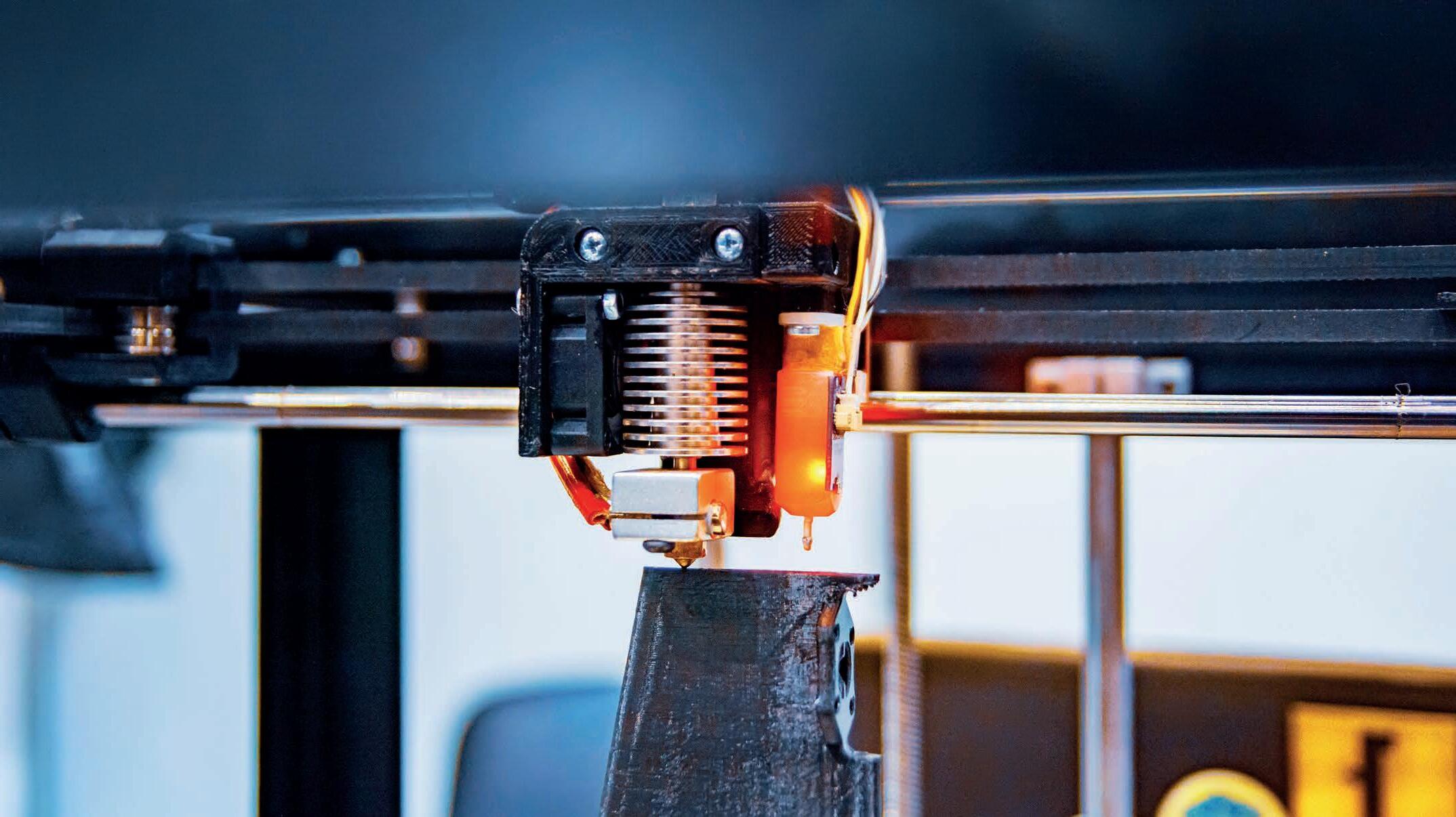

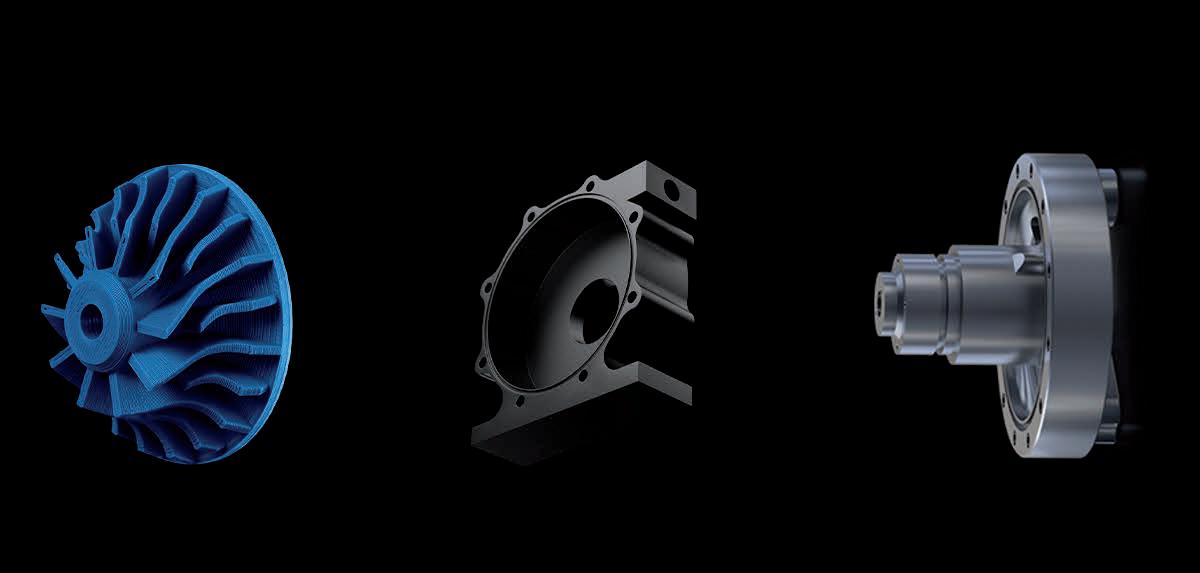

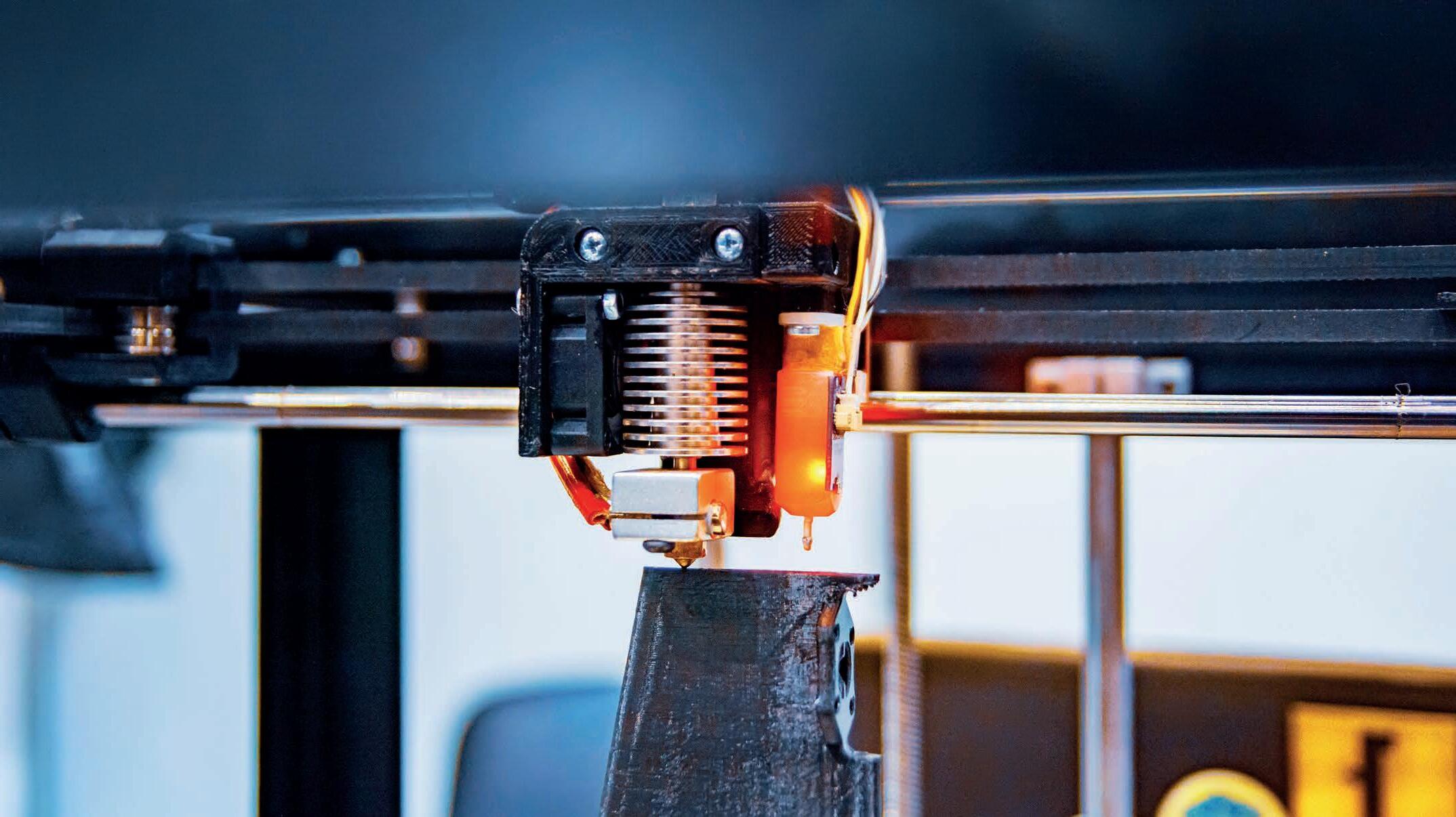

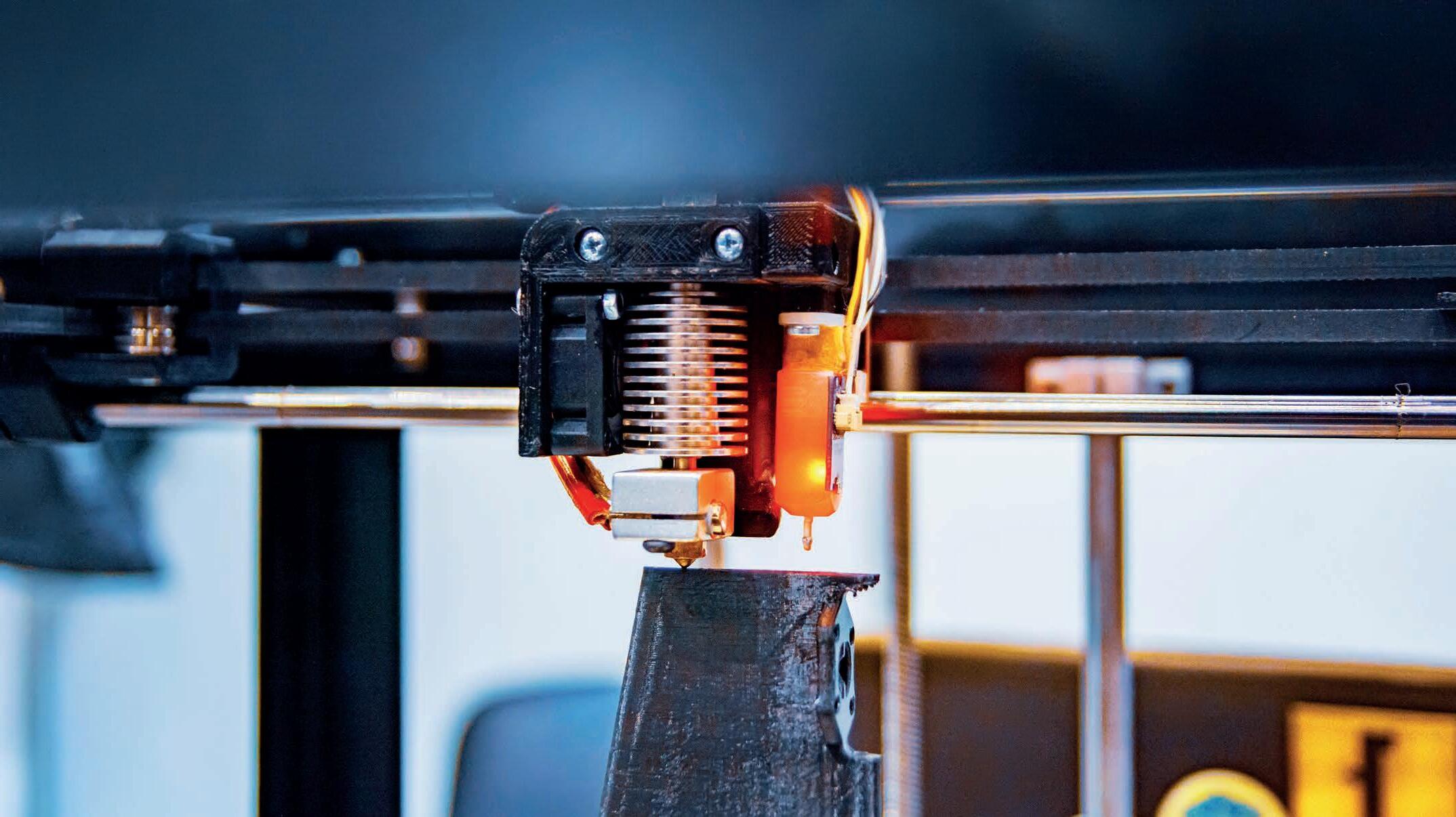

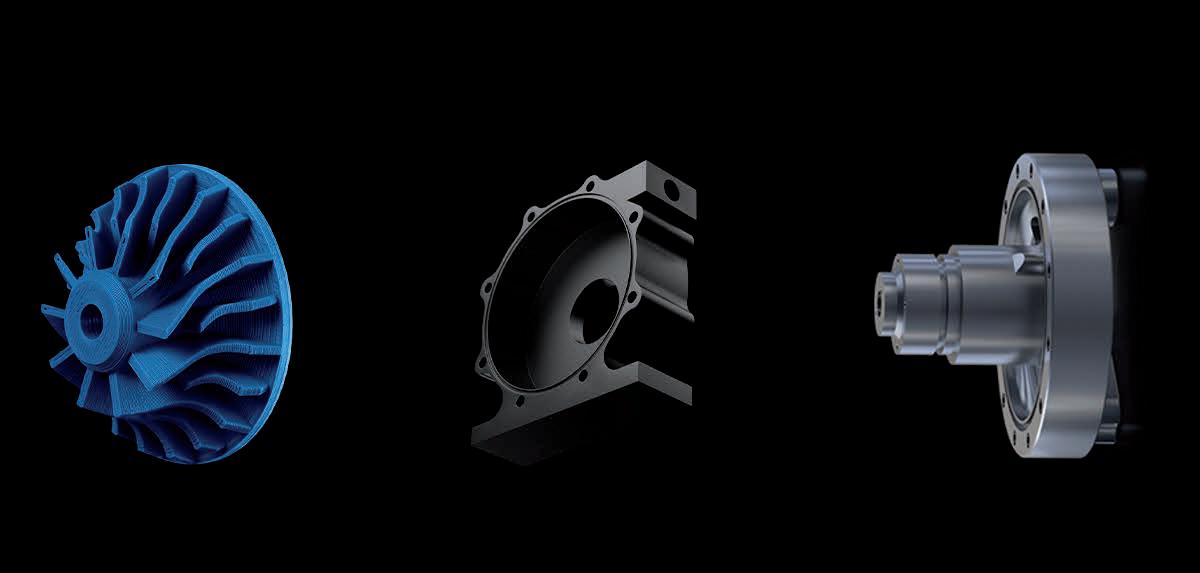

Metal 3D printing or additive manufacturing

Metal 3D printing, also known as additive manufacturing, is a rapidly evolving technology that is revolutionising the manufacturing industry. This technology allows for the production of complex geometries using processes familiar to any welder, such as submerged arc welding,

TIG welding, and electrobeam welding. However, 3D printing goes beyond traditional welding by using a computercontrolled system to precisely deposit metal layer by layer, allowing for precise control over the final product.

Metal 3D printing enables the generation of on-the-go components for industries like defence and aerospace, or spare parts for assets like cranes and armoured vehicles. Businesses are able to create a digital inventory of parts rather than holding a physical inventory, eradicating overheads like storage and transport.

Metal 3D printing allows for rapid prototyping and the ability to produce custom, one-of-a-kind parts quickly and easily. It has led to the development of new materials and applications that are driving innovation in the industry. For example, metal 3D printing is being used to create lightweight parts for the aerospace industry, reducing fuel consumption and emissions.

Traditional manufacturing methods often result in a significant amount of waste material, while metal 3D printing allows for precise control over the amount of material used, reducing waste and material costs.

Weld Australia is in the process of establishing an Advanced Manufacturing Industry Group. This Group will facilitate technology transfer across the additive manufacturing industry, and share technical knowledge to enhance safety, manage risk, reduce cost, and optimise operating efficiency. Our Industry

groups also provide access to a unified peak industry body that can advocate to government on behalf of members.

How Weld Australia can help

Weld Australia can provide businesses with access to this highly specialised and cutting-edge technology. We have a thorough understanding of the concepts, design and process integration of automation and robotic solutions. Our team members are at the forefront of welding technology and techniques and are involved in ISO Standards Committees that oversee the standardisation of various technologies. For instance, Cornelis Van Niekerk, our Business Manager for Defence Welding, serves on two ISO Standards Committees: one for metal 3D printing and the other for friction stir welding. These Committees are focused on issues such as safety measures, implementation, and quality control.

If your fabrication business is keen to improve its productivity, profitability and working conditions for its employees, Weld Australia can help with feasibility studies, conceptualisation, integration of advanced technology and techniques, system verification and demonstration, project management, development of welding procedures and welder qualification.

If you need help or further information on any of the above, please contact Cornel is Van Niekerk (Business Manager - Defence Welding, Weld Australia) on c.vanniekerk@weldaustralia.com.au.

manmonthly.com.au Manufacturers’ Monthly JULY 2023 7

Embracing technology like 3D metal printing in the welding space can create a range of benefits for businesses.

Weld Australia is in the process of establishing an Advanced Manufacturing Industry Group.

Comment

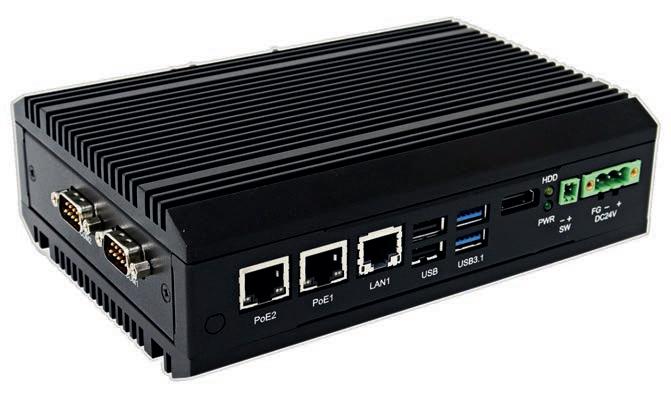

CSIRO to assist automated system innovators with an enhanced development platform

DURING more than two decades with CSIRO I’ve witnessed and been part of numerous digital innovations across Australian manufacturing and other industries. In the majority of cases, I’d class these as being part of what is known as the third industrial revolution – computerisation. We are now in the midst of the fourth industrial revolution – Industry 4.0. Robotics and automation are central to Industry 4.0 and are major CSIRO R&D priorities because we’re both a voracious user and a cutting-edge developer of them. Globally and domestically the manufacturing industry is at a challenging point. Imperatives for companies, industries and countries include achieving net zero emissions, improving sustainability, and contributing to a circular economy. Robotics, autonomy and Artificial Intelligence (AI) are key for ongoing business competitiveness, and for establishing more sustainable manufacturing systems. Pertinent examples of robotics, autonomy and AI in the manufacturing and logistics context are autonomous ground or aerial vehicles, intelligent assistive cobotics, and AI-assisted machine and process controls. These can underpin step changes in competitive advantage. They are also complex innovations requiring dependable hardware and software components. I’m a strong advocate for using Robotics Operating System (ROS) as the software platform upon which to base many of these kinds of innovations.

What is ROS?

Some in the manufacturing industry will be familiar with ROS and its current version ROS2. ROS is a major open-source software initiative which emerged out of Stanford University in the USA during the mid-2000s. Additional to operating robotics and automation, ROS is a useful toolkit for complex sensing, computer vision, data fusion and real-time AI. ROS is applied in scientific, industrial, and aerospace domains.

ROS or ROS2 is not actually an operating system in the standard sense of computer operating systems such as

Windows or Linux. ROS is a software framework and suite of libraries used for controlling and coordinating robotics system elements. The software executes within a mainstream computer operating system on any device capable of running it, including cameras, robot arms and machine controllers, within a centralised, distributed and/or edge computing manner.

ROS2 is now the preeminent open-source option for programming robotics, automation and sensing. It is predicted that 55% of commercial robots shipped in 2024 will have at least one Robot Operating System package. (Source: ABI Research, 2019).

At CSIRO we have used ROS and ROS2 within autonomous vehicles, robots constructed from flexible materials, real-time distributed video streaming, and real time object recognition systems.

We have also used it in integrated laboratory robotics and sensing systems, additive manufacturing robotics control

and real-time sensing, and multicamera high precision measurement systems.

ROS2 can handle greater volumes of larger and/or more complex data in closer to real time compared to the MQTT-based systems that are popular for Industrial IoT (noting also that ROS2 can interoperate with MQTT, e.g., for ROS2 nodes to exchange MQTT messages with IoT sensors). ROS2 offers a non-proprietary and expanding development platform, efficient and effective solution creation, and longterm support from a large pool of international practitioners.

Taking on ROS2

In a manufacturing context, CSIRO is using ROS2 to integrate robot arms, cameras and scanners, additive manufacturing and machining tools, and computer vision and other AI. ROS2 enables us to manage chemical and materials laboratory automation,

process sensing and control, and the pre-commercial development of new robotic additive manufacturing work centres. We are also pursuing many other ROS2 applications within CSIRO in agriculture and other domains besides the manufacturing domain.

In our experience, and from what others have written, we know that understanding and using ROS2 can be challenging. This is especially the case for smaller teams using the platform for the first time. The learning curve can be very steep. Within CSIRO there are many ROS2 success stories but also many burned fingers from insufficient assistance in the initial stages of adopting ROS2.

Kick-starting a journey by contracting or hiring ROS2 developers is a great option. Accessible and professional sources of expertise and help around ROS2 are indeed available. However, few companies in Australia have been long-term adopters of ROS2, and experienced ROS2 engineers are now in great demand globally. The creates

8 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

SIMON DUNSTALL – Principal Research Scientist, CSIRO Data61

The CSIRO will work closely with industry to develop automated systems.

a workforce undersupply issue, and I see this as having three critical dimensions.

Firstly, a lack of people with practical ROS2 knowledge leads to a continued reliance on proprietary, legacy, and out-of-date approaches to automation, sensing and robotics. This constrains Australia’s manufacturing innovation success in terms of technical performance, interoperability, and product longevity.

Secondly, it locks the available robotics software engineering labour force into a low productivity regime. The old ways require more intensive effort in developing and (especially) maintaining solutions. Moreover, they put out of reach the opportunity to freely leverage the vast global capacity which is directed at open platforms including ROS2.

Thirdly, the Australian robotics community is probably too small to properly support unduly divergent and proprietary approaches to robotics. Australia needs workforce mobility between projects, products, and employers. Similarity and familiarity of solutions that are developed across the manufacturing sector and the Australian innovation system is also required. We need to be able to concentrate our education and upskilling effort.

It expected that some elements of these dimensions will be addressed or dissipate in future. For now, for a practical ROS2 journey, this puts the emphasis back onto developer communities and selfeducation approaches.

The global online developer community is a great asset for any development team, but not sufficient to ensure initial or ongoing success. Vibrant geographic and sector-specific communities are crucial. Resources such as do-it-yourself ROS2 project kits, designed to deliver early wins, are also required.

To the best of my knowledge, a community for ROS2 in Australia mainly exists among R&D institutions. A broad and national ROS2 community is only nascent in Australian advanced manufacturing. I know of many advanced manufacturing robotics and machine developers, Industrial IoT product innovators, and system integrators in Australia who are aware of ROS2. The majority however are presently deferring ROS2 adoption for want of stronger innovation support and better entry points that assure success.

The ROSella initiative

CSIRO is seeking to play its part in turning this around via an initiative that we have named ROSella. Initially incubated inside CSIRO as a stepchange in how we approach robotics and automation development, we are launching ROSella nationally in the second half of 2023. ROSella is intended as an open national community around ROS2 with a strong advanced manufacturing applications focus.

Curating and maintaining a subset of ROS2 and other software modules that interoperate and address major use cases in manufacturing is a key plank of ROSella. In our experience, ROS or ROS2 can become difficult to get up and running when third party software (proprietary or open) is needing to be integrated with it. Getting Windows deployments of ROS2 to work has also been troublesome on occasion. Commercial developers in particular need confidence that teething troubles and core platform interoperability is assured, hence ROSella’s focus is on a core ROS2 subset.

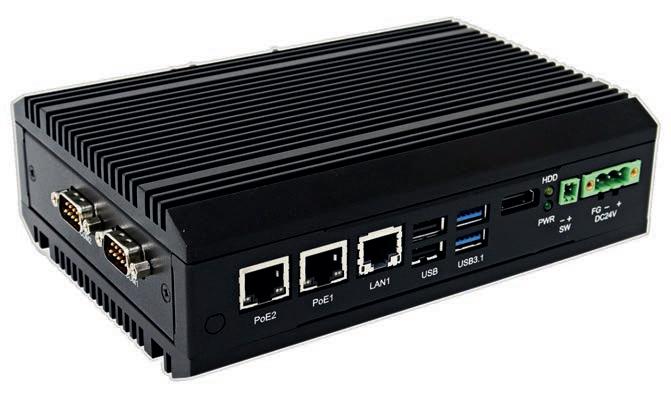

Easing the adoption barrier is helped by the availability of hardware and software starter kits that get ROS2

working out-of-the-box. These are demonstrators, confidence builders, and seeds for more complex systems. At CSIRO we have developed a low-cost computation box and camera kit that allows a ROS2 demonstrator to be built and operated by “newbies” in a single afternoon. Several such units are being made available across our organisation for hire by R&D teams beginning ROS2 journeys. Extending this service to others in the innovation system is part of ROSella’s brief.

To be part of a ROS2 system, each intelligent device in the system needs to implement a ROS2 software interface, which is only sometimes natively implemented out-of-the-box. Furthermore, the international ROS2 community can lag in developing ROS2 software interfaces for newly released devices, most notably for cameras of various kinds. In-silico device representations are also necessary for simulating systems (e.g., in ROS’ own Gazebo simulator) prior to building them and this extends the interface development effort. CSIRO is equipping the ROSella community with tools and resources to speed up the device interface and in-silico

emulator development process.

ROSella is also a channel for advanced IP developments out of CSIRO and elsewhere to reach mainstream robotics, automation and sensing applications. Key present examples are in new methods for multi camera system calibration and control, and in enabling real-time video streaming and object-detection AI through coupling ROS2 with the popular GStreamer libraries.

Nucleating an energised and distinctly Australian innovation community around ROS2 is another major aim of ROSella. We have learned from experience and observation that community building is not a simple task. Facilitating the open exchange of ideas and value, at selfsustaining scale, takes careful curation and significant resourcing. For ROSella this will come in part through the activities like the ROS2 starter kits. It will also need incumbent ROS2 devotees, including CSIRO, to come together and co-invest the time, money and energy that is needed to support Australia’s ROS2 adoption.

If this collaborative approach speaks to your business, then contact Simon Dunstall or Christian Ruberg on 1300 363 400, or email fdmf@csiro.au

manmonthly.com.au Manufacturers’ Monthly JULY 2023 9

Having recognised a number of challenges, the CSIRO has implemented the ROSella program to help industry.

Comment

TIM ODOKEYCHUK – President,

People-centric leadership: Unlocking your continuous improvement culture

AS many of those reading know, developing a mature culture of Continuous Improvement (CI) is a journey which some may feel is one they have been on for a lifetime.

Those who have well established CI systems will have likely developed a daily management system – integrating their work with improvement for employees, leaders and in turn specialised support resources ensuring stable processes, allowing a team to acheive sustained performance.

Many of those businesses would have performance metrics that are timely and meaningful, with clear targets aligned with business plans and strategies to deliver success.

They go about exception-based or observational reviews to uncover opportunities for improvement, while employees use systematic methods of root cause analysis and problem-solving to address challenges.

Perhaps in less mature environments, there are only a few key people that can describe what is happening in a process and whether it’s meeting the needs of the customer. Management launches into erratic bursts of effort to ‘figure out’ what just happened and why the owner, customer or other department is unhappy with recent work.

There are likely issues related to turnover of people, less standardisation in the systems and generational loss of knowledge during staffing changes.

It can be uderestimated the role that leaders play in the systems described above.

Many leaders will deliver a basic awareness in continual improvement to their teams and expect them to simply take the idea on board.

This give and watch approach is like providing our team a car and asking them to drive it while we sit in the grandstand. The team is bound to fall short of the

desired results, regardless of the good intent.

Instead, an organisation who is truly wishing to strive for excellence must ensure their leaders practice, live and learn alongside their teams. They should be close enough to the process to feel the strength or fray within and to know where to hem, patch or tailor the next curve.

Achieving a bond is a matter of trust and confidence that the journey is on a shared pathway. At the heart of this journey lies respect for people.

Respect for people: connected cooperation

We hear the term respect for people often in our CI journeys. It often shows up in the ‘values statement’ of organisations – but what does it really mean?

Does it mean that everyone’s getting along and that there’s no conflict in

the team? Does it mean that everyone gets a bonus if we meet our targets?

Does it mean that we celebrate work anniversaries and birthdays at monthly updates? It’s likely a little more than this.

Perhaps respect for people means that employees understand the organisation’s direction and their role in contributing to its goals.

Individuals are well-informed, capable, fulfilled, and self-reliant, bringing out their best for the the team.

Most likely they are valued for their skills, knowledge, and experience, and have autonomy to make decisions and implement simple improvements.

Differences aren’t seen as defects but instead perspectives to leverage and opportunities to support each other along the way.

Ultimately, the team embraces a culture of experimentation and learning from practice and failure, where together they have the ability to challenge ideas

10 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

People-centric leadership sets a positive tone for the whole organisation.

AME Australia

and policies for the sake of improvement towards common goals.

In my experience, the above is not always the starting point however, achieving an underlying state of respect for people is the ‘grease between the gears’ that allows the methods, tools and continuous improvement thinking to thrive.

Over time, this state creates highly effective teams that can overcome great barriers, who reject negativity, dishonesty and defeatism all the while learning and building their capability, solving more and more complex problems together.

This connected cooperation sounds good, doesn’t it? So why isn’t it the norm in our industry?

The importance of people centric leadership:

Leadership sets the tone for the entire organisation.

Through action or inaction, directive or suggestion, by praise or by punishment – ripples in the pond can become the behavioural waves that

come back from the other shore to make changes to an organisation for the better.

At the root of things, employees who feel valued and empowered are more likely to contribute their best ideas, proactively identify improvement opportunities, and embrace change, fuelling the organisation’s growth and success.

This type of respect is needed as a constant from leaders within an organisation. When continual improvement efforts move from being an initiative; to a shared a way forward; then ultimately a culture through repetition and resilience that protects the underlying thinking and values of the group.

This can stem from a people centric leadership approach which recognises that employees are the foundation of continuous improvement.

Those practicing people centric leadership involve employees in decision-making processes, encourage collaboration, and provide opportunities for growth and development both

one-on-one and in group development sessions.

They do so systematically but responsively in a way that’s understood and transparent - think ‘leader standard work’ which is highly proportioned to being where the work is happening and coaching with on-the-job learning where a shared perspective is created and mutual trust is rooted.

Through this approach, leaders can create an environment where individuals feel valued, motivated, and empowered to contribute their best. They also become better advocates for investment and system level change needed across the organisation to improve operating conditions and effectiveness of the work being done.

Unfortunately, traditional management creates the opposite effect.

Whether intended or not, a less people-centric approach stifles the potential of continuous improvement by disempowering employees and inhibiting their creativity.

Be on the lookout if decisions are typically made at the top and cascaded

downward without meaningful involvement or input from the workforce.

This hierarchical approach often leads to a lack of ownership and resistance to change where it’s need most as no preparation or context of how this helps them secure longer-term opportunities for themselves, their families and their colleagues has proceeded the proclamation that from tomorrow we’re going to follow “a new way”.

Perhaps this contributes to how often we hear that someone has left their boss, not the company? As manufacturing leaders, I’m sure we all know which type of leader we’d rather be.

We should therefore do everything in our power to enable, not hamper our organisation’s ability to become better today than it was yesterday.

If we want to truly excel, we need to ensure we nurture and support one of the greatest appreciating assets in our company – our people, and only through building the mutual respect that comes from weathering storms and climbing hills together, would we truly have earned the privilege to lead others.

Sydney

Olympic Park Wednesday 20 - Thursday 21 September 2023 whsshow.com.au SCAN TO REGISTER FREE manmonthly.com.au Manufacturers’ Monthly JULY 2023 11

Showground

Comment

Northern Territory leads the way

MANUFACTURERS’ Monthly sat down with managing director of the Advanced Manufacturing Growth Centre (AMGC) Dr Jens Goennemann to break down the Northern Territory’s Advanced Manufacturing Ecosystem Fund and this year’s federal budget.

The budget announced in May was the first-full Labor budget handed down in 10 years and it will see a widening of support provided to small to medium sized manufacturers according to AMGC.

Through matched-funding and mentorship, Australia’s new Industry Growth Program has the potential to expand the pipeline of investment-ready projects for the $15 billion National Reconstruction Fund to consider in coming years.

Through loans, guarantees and equity investments, the National Reconstruction Fund will partner with the private

sector to invest in priority areas that leverage Australia’s natural advantages and strategic priorities in renewables and low emissions technologies, medical science, transport, value add in agriculture, forestry, and fisheries, value add in resources, defence capability and enabling capabilities.

Utilising Australia’s natural resources for the manufacturing industry is something that Goennemann believes can make Australia competitive on a global scale.

“I will encourage every Australian government, past, present or future to focus on areas of strength that we have or areas of strength that we want to have,” Goennemann said.

“We have one of the strongest health systems and that came from choices made by government, they should be utilising a similar framework for the country’s manufacturing capabilities.”

Goennemann states that as an

industry, manufacturing should look to leverage the abundance of natural resources available to grow itself.

AMGC has identified and advocated for a need to support small businesses as they enter the Industry Growth Program and later the National Reconstruction Fund to prepare them for success.

“The projects announced in this budget will take time to deliver,” Goennemann noted.

“For this budget to see a reallocation of funds, for example, from the Entrepreneurs’ Programme to an Industry Growth Program, gives the government the opportunity to curate companies to be investment ready including but not limited to manufacturers for them later to be picked up by the National Reconstruction Fund.

“The National Reconstruction Fund, just by sheer size of its organisation will struggle to reach SMEs. We believe the IGP

offers an opportunity to get manufacturers investment ready and absorb the larger funds that will flow from the NRF, how that will look remains to be seen but I anticipate AMGC could play a role in helping to maximise the impact of the program,” Goennemann explained.

“The realities of the industry structure in Australia are that we have 47,000 manufacturers and around 90 per cent employ less than 20 people. It will take time for them to be ready to take a cheque from the National Reconstruction Fund and we already support some that may.”

In September 2021, the Northern Territory Government partnered with the AMGC to launch a $7.5 million Advanced Manufacturing Ecosystem Fund (AMEF), in response to local manufacturing successes in the Territory.

The Fund delivers on the recommendations from the Territory Economic Reconstruction Report and

12 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

The AMGC believes what is happening in the NT is a shining example for the rest of the country.

DR JENS GOENNEMANN – Managing director, Advanced Manufacturing Growth Centre (AMGC)

successfully increasing Australia’s manufacturing capability. With a focus on expanding manufacturing in the Northern Territory, co-investments will target local projects that seek to: grow an advanced manufacturing ecosystem and capability in the Northern Territory across the Territory’s priority sectors; and increase investment in advanced manufacturing activity in the Northern Territory, and secure a greater number of advanced manufacturing jobs located in the NT.

commercialise new products and processes, including transitioning a new product or process from pilot/ prototype stage to full commercial operations; and/or

support early-stage small scale and pilot research projects in advanced

more quickly move to larger-scale commercialisation.

Goennemann spoke to the importance of this fund and said that it is important to the Northern Territory and is a shining example for the nation as a whole.

“The Northern Territory is the first sub-national jurisdiction that came on board and worked with AMGC together in the advanced manufacturing ecosystem function,” Goennemann said.

“We jointly curate the ecosystem of manufacturing capability and help Northern Territory manufacturers to advance. Eventually we hope to advance, grow and allow manufacturers to be investment ready for an uptake of NRF or other sources of capital.

While it is important for us to have national funds which flow through seven key areas, each jurisdiction has its own unique strengths. For example,

capabilities, there is only so much you can do at a national level so focusing in at a sub-national level is imperative.

“That is what the Northern Territory leaned in on heavily – how we can supplement what’s being done on a federal level and really help local projects to succeed and tackle local challenges,” Goennemann added.

Funding for the AMEF ranges from $25,000 up to $500,000 (or more based on scale and impact), but must be equally matched by industry in cash.

AMGC’s Perceptions of Australian Manufacturing Report has evidenced that Territorians support for, and knowledge of, manufacturing is the highest of anywhere in mainland Australia, rising by 33 per cent, to 83 per cent over the pre-pandemic survey.

Dr Goennemann explained that the fund in the Northern Territory is not a test of its capability but in fact an example

level can reap rewards

“We are way beyond the testing stage of this, we are mid-program. It’s [AMEF] an example which has worked on the federal level, it’s an example which works on a sub-national level, and it is an example which works in other countries who have a deliberate industry policy to develop this strength and not leave it up to market forces alone,” he said.

“The important part for us is making sure that manufacturing in the Northern Territory does not just consist of what happens in Darwin but includes places like Alice Springs and Katherine. Our projects happen everywhere in Australia, not just in our big five cities. By expanding where manufacturing occurs it boosts communities resilience, competitive jobs, helping manufacturers get a leg up helps communities get a leg up – it means we can all grow together.”

manmonthly.com.au Manufacturers’ Monthly JULY 2023 13

It is an exciting period for the AMGC as they work with manufacturers across the country.

Combat systems agreement boosts sovereign shipbuilding capability

BAE Systems, Lockheed Martin, Saab, and the Department of Defence have signed a new agreement to integrate the Navy’s existing guided missile destroyers and Hunter class frigates in Australia.

The Combat System Integration (CSI) Collaboration Agreement (CCA) will grow a long-term, cost-effective and agile CSI sovereign industrial capability for the Navy’s major surface combatants.

The agreement is another significant step towards the development of continuous naval shipbuilding in Australia.

Specifically, the collaborative relationship will support CSI in surface vessels fitted with the US Navy’s Aegis combat management system – produced by Lockheed Martin and with an Australian Interface developed by Saab Australia.

Through the CCA, BAE Systems

Australia, Lockheed Martin Australia, Saab Australia and Defence have established the Combat System Integration – Integrated Project Team (CSI-IPT).

The CSI-IPT team will comprise professionals from the Department of Defence and an equal mix of combat systems integration professionals from each of the industry organisations, facilitating a ‘one team’ approach.

As part of the CSI-IPT, all four organisations will work collaboratively as a united combat systems team to design, integrate, test and deliver the integrated combat system for the Hunter class frigates and the major combat systems upgrade to the Hobart class destroyers.

Managing director of BAE Systems Australia – Maritime, Craig Lockhart, said, “Key to delivering the high-end warfighting capabilities for Australia’s

naval surface fleet is the design, installation and integration of the combat management systems into a warship, and that’s why we worked so hard to secure this collaborative arrangement with Defence, Lockheed Martin Australia and Saab Australia.

“Through close collaboration, we will establish an enduring Combat Systems Integration sovereign industrial capability for our nation.”

Vice president of operations Lockheed Martin RMS Australia and New Zealand, Steve Froelich, said, “As the manufacturer of Aegis, the world’s most advanced combat system, Lockheed Martin Australia is proud to integrate, deliver and sustain this key maritime capability that safeguards our nation together with our valued partners –Defence, BAE Systems and Saab Australia.

“Working together makes us stronger.

The CCA aligns all four organisations on a joint path of success to ensure Australia’s security, economic growth and ongoing military interoperability with the US and allied partners across the Indo-Pacific.”

Managing director, Saab Australia, Andy Keough CSC said, “Saab looks forward to working with our collaboration partners to build on the decades of combat system integration work we have successfully performed in partnership with the Department of Defence,” Keough said.

“Through this collaborative partnership, and as the nation’s sovereign combat management system provider for the Royal Australian Navy’s Surface Fleet, we are strengthening Australia’s sovereign defence capability and jointly developing the skilled workforce we need to deliver future programs.”

News @MM 14 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

This announcement will see Australia improving its shipbuilding processes.

News @MM

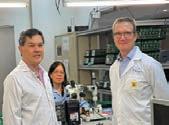

New innovation centre to advance transport technology

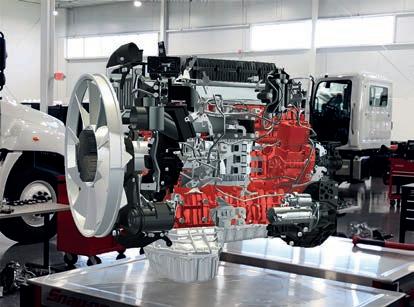

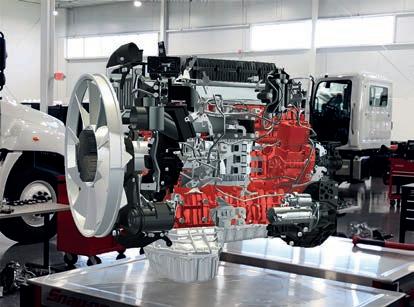

Victorian minister for small business Natalie Suleyman officially opened Directed Technologies’ $1.5 million Connected Mobility Innovation Centre for smart technology in fleet vehicles.

The centre, which is located within Directed Technologies’ new $15 million headquarters in Tullamarine, is expected to create nearly 60 new jobs over three years and allow the company to expand its export markets

Directed Technologies designs and manufactures navigational systems for the transport industry and fleet vehicles such as freight and emergency services trucks.

The company’s system considers a vehicle’s dimensions, weight and clearance when planning routes to help its driver travel safely and efficiently to their destination.

The new centre will enable Directed Technologies to expand its transport technology by developing smart sensors that can keep track of important safety

metrics including driver fatigue, tyre pressure and temperature of refrigerated cargo.

This means clients such as Australia Post can know exactly what is happening to their vehicles on the ground, improving safety and service reliability.

Victoria’s manufacturing sector is one of the state’s largest employers, contributing around $31 billion to the economy each year and providing around 30 per cent of Australia’s manufacturing output. Manufacturing also supports small businesses and local jobs in their supply chains.

The Victorian state government’s Made in Victoria 2030: Manufacturing Statement outlines its vision and actions to ensure Victoria continues to be a place for advanced manufacturers to grow and thrive, including in key sectors such as digital and advanced technologies.

“We support businesses like Directed Technologies because they bring skilled jobs and investment to Victoria, which

further cements our status as the nation’s advanced manufacturing hub,” Suleyman said.

“Our advanced manufacturing industry supports many small businesses along their supply chain – boosting the economy and creating local jobs.”

Directed Technologies executive director Brent Stafford said, “We’ve built a world-class facility right here in Victoria

thanks to the assistance of the Victorian Government and developed innovative solutions for the world’s biggest transport companies that have allowed us to compete against global competitors –and win.”

Member for Sunbury Josh Bull said investing in innovation today will increase Victoria’s competitiveness and help create the industries and jobs of the future.

manmonthly.com.au Manufacturers’ Monthly JULY 2023 15

The new facility should create close to 60 jobs.

News @MM

QLD green jet fuel industry set to soar with Qantas partnership

The Queensland State Government has signed an MoU with airline giant Qantas to unlock the state’s potential to manufacture sustainable aviation fuel (SAF) locally.

The partnership will include exploring how to fully leverage sugarcane and agricultural by-products for biofuel production and the potential for developing new feedstock sources and processes.

More broadly, the parties will focus on developing a Queensland-based SAF supply chain.

SAF is yet to be manufactured in Australia at a commercial scale.

Qantas currently uses green aviation fuel sourced overseas and is targeting 10 per cent SAF in its fuel mix by 2030, and about 60 per cent by 2050.

The announcement, made during Australian Renewable Fuels Week, is the latest in a series of SAF wins for Queensland.

In March this year, the State Government, Qantas and Airbus

announced support for Jet Zero Australia to commence a feasibility study for a new biorefinery in Queensland, which could produce up to 100 million litres of SAF a year.

The State Government has also partnered with Ampol and ENEOS, which will assess the feasibility of delivering an advanced biofuels manufacturing plant at Ampol’s Lytton site.

Oceania Biofuels also plans to build a commercial aviation fuel biorefinery in Gladstone, which could generate up to 350 million litres of SAF and renewable diesel each year.

“When it comes to decarbonising our skies, Queensland is the place to invest,” said deputy premier Steven Miles.

“Growing our SAF industry is one of those opportunities that will fuel Queensland’s economic future and contribute to decarbonisation targets.

“With our rich supply of feedstock and skilled workforce, Qantas, and the world, has recognised Queensland

as an ideal location to establish an Australasian SAF supply chain.”

“Partnerships like this one with Qantas, position Queensland as a SAF hub, along with the right mix of investment, government support and policy, and industry collaboration,” he added.

“Importantly, growing industries that will be in demand in a decarbonising world will create more good jobs for Queenslanders and new export opportunities.”

Qantas Group chief sustainability officer Andrew Parker said, “Air travel is a critical industry, especially in a state as big as Queensland with an economy that benefits so much from tourism. Having a clear plan to decarbonise air travel so we can keep connecting Queensland and Australia in the decades ahead is key for the future.

“Sustainable fuels are the most significant tool airlines currently have to reduce their emissions, particularly given they can be used in today’s engines

and fuel delivery infrastructure with no modifications.

“Qantas will be the largest single customer for Australian-made SAF, so it’s fantastic that the Queensland Government is seeking to partner with us so we can work together on establishing the industry from the ground up.” Queensland produces significant feedstock needed to make SAF, including tallow, sugarcane waste pulp, cereal cropping residues and pongamia.

SAF can be used in existing aircraft engines and airport refuelling infrastructure to cut carbon emissions typically by up to 80 per cent on a life cycle basis.

An Australian SAF industry could be worth $3 billion annually by 2030 and could create up to 15,600 jobs – mostly in regional areas – nationwide by 2050.

The new partnership with Qantas is further progress towards growing a local SAF industry under the Queensland Biofutures 10-Year Roadmap and Action Plan.

16 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

The partnership is a step forward in sustainable aviation fuel manufactruring ability in Australia.

@MM

New Melbourne centre to advance manufacturing training

Minister for Training and Skills and Higher Education Gayle Tierney officially opened a new $3.2 million Advanced Manufacturing Centre of Excellence at Melbourne Polytechnic’s Heidelberg campus.

The new centre will train Victoria’s next generation of engineers to enter the workforce equipped with the skills and knowledge that will keep students at the forefront of the advanced manufacturing market.

The latest industry-grade technology in robotics, 3D printing, and computer design will support a range of industries including biomedical, defence and aerospace and food technologies.

In partnership with Apprenticeships Victoria, the new centre will promote engineering career opportunities to secondary students and boost hands-on training for entry-level engineers across the state.

The Victorian state government has invested $1.4 million in the project

through Apprenticeships Victoria.

Manufacturing employs more than 261, 000 people and contributes almost $31 billion to the state’s economy each year. This centre will help address an

industry need for more engineering tradespeople identified in the Victorian Skills Plan.

Free TAFE has saved students around $340 million in tuition fees since the

state government introduced it in 2019 – removing the barriers to training for a great new career for around 137,000 students – according to a government media release.

Since 2014, the government has made a record $3.5 billion investment to rebuild TAFE and support higher education to ensure Victorians have access to high quality education and rewarding career pathways.

“We’re making sure Victorians can go to their local TAFE and get a great qualification for our state’s most indemand jobs,” Tierney said.

“This centre is just one of the ways we are ensuring that we have the highly skilled, sustainable workforce needed to secure Victoria’s future prosperity.”

Member for Ivanhoe, Anthony Carbines, said, “We’re investing locally so that every student has the skills and high-quality training they need to power our future.”

PA RT OF THE GROUP News

manmonthly.com.au Manufacturers’ Monthly JULY 2023 17

The new centre will support the biomedical defence and aerospace and food technologies

News @MM

PM Albanese launches new rocket at Gilmour Space Technologies

Gilmour Space Technologies welcomed prime minister Anthony Albanese to its Gold Coast factory to formally unveil and ‘launch’ the Eris rocket – Australia’s first home-grown orbital launch vehicle.

“This is a great Australian success story. A company that began eight years ago but now employs 200 people here at the cutting edge of innovation, science, new technologies, and new jobs,” said the prime minister as he toured Gilmour Space’s sovereign manufacturing facility, and started a new tradition of signing Australian rockets before launch.

“You’re looking at the first Australianmade rocket that will attempt orbital space launch. Their hybrid rocket engine

technology is one of the first in the word to use a combination of solid and liquid propellants.

“When this rocket goes into space, it will carry 300 companies with it. Australia will become the 12th country in the world to be able to have access to this technology – designed, manufactured and built right here (on the Gold Coast) and creating high quality jobs.”

“This is one of the companies that we’re looking at when we have our National Reconstruction Fund and that whole agenda about a future here made in Australia – making use of an Australian procurement policy to buy Australian and making sure we back Australian

science and innovation,” Albanese added.

“Australia can compete with the rest of the world,” he said.

“What we need to do is to back our businesses that are doing it. This is truly an Australian manufacturing success story, and we want more of them.”

Adam Gilmour, CEO of Gilmour Space, said, “We are proud to have the Prime Minister come see our Australian-made orbital rocket and space manufacturing facility.

“Australia must have its own sovereign launch and satellite technologies if we are serious about growing our capabilities in defence, communications, and advanced

manufacturing. Gilmour Space is at the leading edge of these technologies.

“Both the State and Federal governments have been great supporters of the space industry here in Queensland, and we appreciate their ongoing support for Australian innovation, high-tech jobs, and manufacturing.

“The team is working hard toward the first test launch of our Eris rocket later this year from the Bowen Orbital Spaceport in north Queensland. Only 11 nations have launched their own rockets into orbit, and our efforts will help to build a significant dual-use capability for Australia.”

18 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

Gilmour Space Technologies will launch the first orbital space rocket from Australia.

Mars Petcare invests $112.6 million to bolster regional capabilities

Construction of the new facility at the Wodonga factory has commenced and is set to be fully operational by mid 2025.

Supported by Regional Development Victoria, Mars Petcare has announced a significant investment in its Wodonga factory to expand its pet food manufacturing capabilities and create more than 60 new jobs in regional Victoria.

Leading pet food manufacturer Mars Petcare Australia has announced it will be investing $112.6 million to expand pet food manufacturing capabilities at its Wodonga factory.

Proud to have been manufacturing at the site since 1967, this project builds on more than $55.8 million invested at the Victorian facility over the past five years and will enable the company to future-proof its local operations for years to come by creating over 60 new jobs through the on-shoring of pet food production.

The investment will support the development of a 7,800sqm manufacturing facility dedicated to the production of single serve pouches, including two additional lines with a combined yearly capacity of 25kT – around 290 million pouches of cat food initially.

The new facility will primarily serve the Australian and New Zealand markets and the growth of both existing and new product ranges across the company’s well-known Whiskas, Advance, Optimum, and Dine brands.

Craig Sargeant, general manager at Mars Petcare Australia, spoke about the announcement.

“As a market leader, we are committed to bolstering our local operations by sourcing and making most of our portfolio right here in Australia. This significant investment will allow us to respond to pet trends including the continued rise in cat ownership – growing at nearly 4 per cent per year – more than twice as fast as our dog population,” he said.

“We’re also seeing increased demand for convenience, with pouch products representing half of the Australian wet cat food market and growing at nearly 10 per cent per year.”

As a result of the project’s contribution to the local economy, Mars Petcare Australia’s investment has been supported with grant funding from the Victorian government’s Regional Development Victoria.

Harriet Shing, Minister

for

Regional

Development Victoria, celebrated the announcement.

“As pet ownership continues to increase there are enormous opportunities for businesses like Mars to expand. We’re continuing to work

Visy completes major upgrade to Gibson Island recycling centre

Australian recycling giant Visy unveiled a $48 million upgrade to its recycling and remanufacturing campus on Gibson Island with Queensland premier Annastacia Palaszczuk and deputy premier Steven Miles.

The upgrade is part of Visy executive chairman Anthony Pratt’s commitment to invest $2 billion over the next decade – $700 million of that in Queensland – to reduce landfill, cut emissions and create thousands of green-collar Australian manufacturing jobs.

“This is a very proud day for our company because we’re not only manufacturers, we’re actually in the landfill avoidance business which is good for greenhouse gas reduction as

well because as things decay in the landfill they produce methane gas which is 84 times worse for climate change than carbon dioxide,” said Pratt.

“So recycling is an important weapon against climate change.”

The project will divert up to 39,000 tonnes of material from landfill – covering the equivalent of approximately 2,500 Suncorp stadiums – using a new state-ofthe-art paper optical sorting plant.

Instead of going to landfill, Visy will recycle and remanufacture this kerbside waste from hundreds of thousands of Queensland homes into 100 per cent recycled paper and corrugated boxes for the state’s farmers, and iconic food and beverage companies.

The upgrade was made possible thanks to co-investment support from the Queensland Government and is set to reduce landfill by up to 20kg per Queensland household annually.

The 100 per cent recycled paper will then be sent to Visy’s corrugated box plants, including the new one at Hemmant.

“We are transforming Australia’s recycling and manufacturing sectors through these initiatives,” said Pratt.

Pratt also praised premier Palaszczuk and her Government “for their foresight and dedication to practical environmental reforms.”

“You, premier and Deputy premier Miles, are champions of Queensland

with rural and regional producers to support investment in growth industries, to cement Mars Petcare’s long-term operations and workforce in Wodonga and its place in a strong market.”

manufacturing and under your leadership, Queensland has become an economic powerhouse” he said.

The Gibson Island project created hundreds of jobs during construction and has established even more green-collar manufacturing jobs on site.

Visy operates in more than 140 sites throughout Australasia and has trading offices across Asia and Europe. With over 7,000 employees, the company‘s innovative approach provides endto-end solutions for customer needs across paper, primary packaging, fibre packaging, packaging supplies and consumables, point of sale displays, automation, materials handling, logistics and recycling.

News @MM

manmonthly.com.au Manufacturers’ Monthly JULY 2023 19

Mars Petcare will add 60 jobs to its facility in Wodonga.

News @MM

New Bushmasters for the Australian Defence Force

The Australian Government has signed a $160 million contract with Thales Australia to deliver an additional 78 Bushmaster protected mobility vehicles for the Australian Defence Force.

The contract for the new Bushmasters was signed at Thales Australia’s Bendigo facility in the presence of member for Bendigo Lisa Chesters. The Bushmasters will continue to be manufactured in Bendigo, Victoria, with the first delivery expected in 2024.

Bushmasters are integral to Australia’s military capabilities – supporting security and stabilisation activities, including humanitarian assistance and disaster relief, both at home and abroad.

The Bushmaster is world-renowned for

innovative design features which protect its crew and passengers from landmines and other explosive devices, and small arms fire.

Minister for Defence Industry, Pat Conroy said, “I am delighted to be in Bendigo to announce this $160 million investment in regional Australia, securing more than 200 local defence industry jobs for the city.

“The iconic Bushmaster vehicle is supporting defence industry jobs in Australia, as well as saving lives in military operations around the world.

“The workforce at Thales Australia should be proud of the important contribution they make to providing a world-class capability for our soldiers

and to strengthening Australia’s national security.”

Thales Australia CEO Jeff Connolly said the manufacture of new Bushmasters would directly support jobs at the Bendigo facility.

“This is a strategic industrial capability that is vital for the Australian Defence Force. Today’s contract signing is an important expression of support from the Government, not just for the Bushmaster vehicle, but also for the manufacturing capability and Australian supply chain that produces and sustains the vehicles.

“Work will begin immediately on the new vehicles, with a mix of troop-carrying vehicles and Command vehicles to be manufactured over the next 18 months.

“More than 1200 Bushmasters have

already been manufactured at our Bendigo facility and as well as proving to be a lifesaving vehicle for the Australian Army in operations in the Middle East, they have been exported to eight nations including the Netherlands, UK, Fiji, Jamaica, New Zealand, Japan and Indonesia.

“Bushmasters gifted to Ukraine by the Australian Government are currently in service in Ukraine and providing a vital capability to the Ukrainian Armed Forces as they fight the illegal Russian invasion.

“In addition to our direct employment on site in Bendigo, the manufacture of Protected Vehicles supports around 360 jobs in our Australian supply chain with many suppliers across regional areas of Victoria and New South Wales.”

20 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

Bushmasters are important to Australia’s military capabilities.

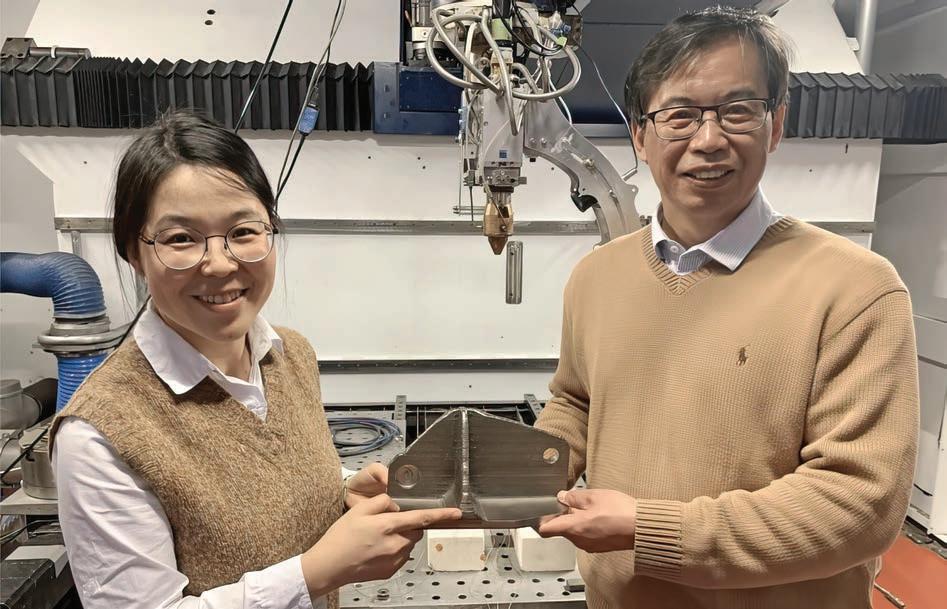

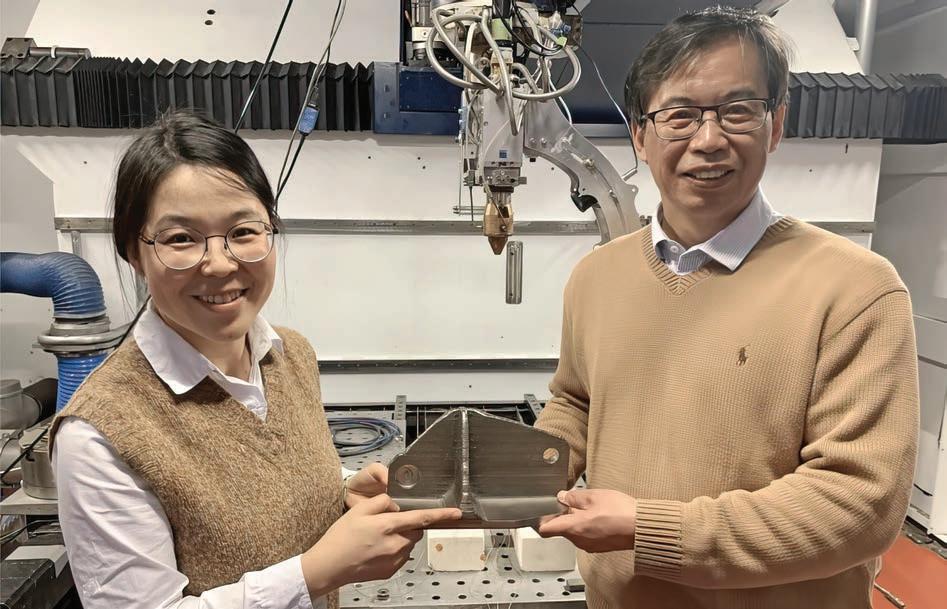

New ‘designer’ titanium alloys made using 3D printing

A team of RMIT and University of Sydney researchers have created a new class of titanium alloys that are strong and not brittle under tension, by integrating alloy and 3D-printing process designs.

The breakthrough, published in the top journal Nature, could help extend the applications of titanium alloys, improve sustainability and drive innovative alloy design.

Their discovery holds promise for a new class of more sustainable high-performance titanium alloys for applications in aerospace, biomedical, chemical engineering, space and energy technologies.

RMIT University and the University of Sydney led the innovation, in collaboration with Hong Kong Polytechnic University and the company Hexagon Manufacturing Intelligence in Melbourne.

Lead researcher Distinguished Professor Ma Qian from RMIT said the team embedded circular economy thinking in their design, creating great promise for producing their new titanium alloys from industrial waste and low-grade materials.

“Reusing waste and low-quality materials has the potential to add economic value and reduce the high carbon footprint of the titanium industry,” said Qian from RMIT’s Centre for Additive Manufacturing in the School of Engineering.

What type of titanium alloys has the team made?

The team’s titanium alloys consist of a mixture of two forms of titanium crystals, called alpha-titanium phase and betatitanium phase, each corresponding to a specific arrangement of atoms.

This class of alloys has been the backbone of the titanium industry. Since 1954, these alloys have been produced primarily by adding aluminum and vanadium to titanium.

The research team investigated the use of oxygen and iron – two of the most powerful stabilisers and strengtheners of alpha- and beta-titanium phases – which are abundant and inexpensive.

Two challenges have hindered the development of strong and ductile alphabeta titanium-oxygen-iron alloys through the conventional manufacturing processes, Qian said.

“One challenge is that oxygen –described colloquially as ‘the kryptonite to

titanium’ – can make titanium brittle, and the other is that adding iron could lead to serious defects in the form of large patches of beta-titanium.”

The team used Laser Directed Energy Deposition (L-DED), a 3D printing process suitable for making large, complex parts, to print their alloys from metal powder.

“A key enabler for us was the combination of our alloy design concepts with 3D-printing process design, which has identified a range of alloys that are strong, ductile and easy to print,” Qian said.

The attractive properties of these new alloys that can rival those of commercial alloys are attributed to their microstructure, the team says.

“This research delivers a new titanium alloy system capable of a wide and tunable range of mechanical properties, high manufacturability, enormous potential for emissions reduction and insights for materials design in kindred systems,” said co-lead researcher University of Sydney ProVice-Chancellor Professor Simon Ringer.

“The critical enabler is the unique distribution of oxygen and iron atoms within and between the alpha-titanium and beta-titanium phases.

“We’ve engineered a nanoscale gradient of oxygen in the alpha-titanium phase, featuring high-oxygen segments that are strong, and low-oxygen segments that are

ductile allowing us to exert control over the local atomic bonding and so mitigate the potential for embrittlement.”

What are the potential applications of the research findings?

Lead author Dr Tingting Song, RMIT Vice-Chancellor’s Research Fellow, said the team is “at the start of a major journey, from the proof of our new concepts here, towards industrial applications.”

“There are grounds to be excited – 3D printing offers a fundamentally different way of making novel alloys and has distinct advantages over traditional approaches,” she said.

“There’s a potential opportunity for industry to reuse waste sponge titaniumoxygen-iron alloy, ‘out-of-spec’ recycled high-oxygen titanium powders or titanium powders made from high-oxygen scrap titanium using our approach.”

Co-lead author Dr Zibin Chen, who joined Hong Kong Polytechnic University from the University of Sydney in the later stages of the collaboration, said the research had broader implications.

“Oxygen embrittlement is a major metallurgical challenge not only for titanium, but also for other important metals such as zirconium, niobium and molybdenum and their alloys,” he said.

“Our work may provide a template to mitigate these oxygen embrittlement issues

through 3D printing and microstructure design.”

Support for this research

The team’s work benefited from sustained, targeted investment in research infrastructure from national and state governments and from universities, Professor Ringer said.

“In many ways, this work showcases the power of Australia’s national collaborative research infrastructure strategy and sets the scene for extending this strategy into the realm of advanced manufacturing,” he said.

The Australia Research Council (ARC) through the Discovery Program and the Training Centre in Surface Engineering for Advanced Materials (SEAM) funded and supported this research.

The team acknowledges support from the Australia–US Multidisciplinary University Research Initiative program supported by the Australian Government; The Hong Kong Polytechnic University; the State Key Laboratories in Hong Kong from the Innovation and Technology Commission of the Government; and Hexagon Manufacturing Intelligence for its Simufact DED solution used in the L-DED process design.

The team’s research paper, ‘Strong and ductile titanium-oxygen-iron alloys by additive manufacturing’, is published in Nature (DOI: 10.1038/s41586-023-05952-6).

News @MM

manmonthly.com.au Manufacturers’ Monthly JULY 2023 21

The new titanium alloy is an exciting development by various institutions.

CSL Seqirus’ $800 million manufacturing facility nears completion

CSL Seqirus has announced that construction of its new state-of-the-art vaccine and anti-venom manufacturing facility in Tullamarine has reached its highest point, known as ‘topping out’.

The facility will use innovative technology to produce seasonal and pandemic cell-based influenza vaccines, CSL Seqirus’ vaccine adjuvant technology (MF59), the world’s only approved human vaccine for Q fever, and antivenoms for venomous creatures native to Australia.

The site in Tullamarine, Melbourne, will have a gross floor area of 28,400m2 across three key buildings. Topping out has been marked by the completion of roof laying on these buildings, which will be used for:

• Seasonal and pandemic cell-based influenza vaccine manufacturing

Antivenoms and Q-Fever vaccine manufacturing, and Administration and laboratories

It is on schedule to be operational in 2026 and will support Australia’s preparedness and responsiveness in a future pandemic crisis.

The new facility bolsters CSL Seqirus’ and Australia’s sovereign manufacturing capability and underpins a long term partnership with the Federal Government for the supply of seasonal and pandemic influenza pandemic vaccines, antivenoms and Q fever vaccine.

Jonah Smith, vice president and program lead for the CSL Seqirus Tullamarine Manufacturing Facility, says topping out is an important milestone in the journey to completing the world-class facility.

“This will be the only cell-based influenza vaccine manufacturing facility in the Southern Hemisphere and will provide access to Australian-made innovative vaccines and potentially lifesaving antivenoms,” Smith said.

“This facility will manufacture influenza vaccines for use in Australia and overseas, creating a supply chain worth more than $300 million annually to the Australian economy.”

“The site will support the future of public health in Australia and we’ve designed it to support a sustainable future

for our community,” Smith added.

“We’re incorporating on-site renewable energy generation, electrifying the plant to reduce our reliance on fossil fuels, conducting heat and water recovery. This is also one of the first local manufacturing facilities to pursue 5 star ‘Green Star’ and Gold WELL certification.

“The new site will also feature a digitally connected manufacturing environment, deploying advanced analytics that will drive innovation and optimise our manufacturing operations.

“This includes a fully automated and paperless manufacturing execution system that will support our highly skilled workforce to optimise production, improve quality control and reduce downtime.

Jonathan Anderson, CSL Seqirus executive medical director –international regions, says the innovative technology at the facility will form a key part of Australia’s preparedness for seasonal and pandemic influenza.

“Cell-based vaccines are a significant innovation in influenza vaccine manufacturing as they address several limitations associated with traditional technologies. By making vaccines in cells, we can eliminate the introduction

of egg-based mutations that can impact influenza vaccines.

“We’re seeing influenza return to pre-COVID levels and we’ve experienced early flu seasons in both the Northern and Southern Hemispheres recently. Reducing the burden of influenza is a key focus for public health strategies and meeting demand for vaccines is an important aspect of those strategies.

“Over 200 million doses of cell-based influenza vaccines have been distributed worldwide by CSL Seqirus, with demand doubling in the last two years. Australia will soon be a major contributor in meeting this demand.

“In the event of an influenza pandemic, this facility would quickly switch to manufacturing strainmatched cell-based pandemic influenza vaccines. Cell-based technology offers scale and production time advantages over the traditional influenza vaccine manufacturing process, an important consideration for pandemic preparedness.”

Dr Anderson also says that producing antivenoms will be an important part of how the facility contributes to the health of Australia and its neighbours.

“Australians love the bush and the beach but unfortunately over 3,000

Australians are hospitalised annually due to injuries caused by venomous creatures. While there are relatively few deaths, it’s important that we’re prepared for venomous bites and stings.

“We have been producing antivenoms since the development of tiger snake antivenom in 1930 and through this facility we will continue to help protect Australians in the event of a venomous bite or sting from snakes, spiders and marine life.

CSL has invested over $800 million to construct the facility, reinforcing Victoria’s globally significant medical research and biotechnology community.

“This facility will form a key pillar in our world-class influenza vaccine manufacturing network that includes sites in the US and UK. The investment signifies CSL’s strong support for Australia’s biotech manufacturing capabilities and reinforces our confidence in the skills and expertise of the Australian workforce,” says Jonah Smith.

This facility is CSL’s largest capital project underway and is part of the company’s investment of over two billion in Australia which includes the new plasma fractionation facility in Broadmeadows and new global headquarters in Melbourne.

22 JULY 2023 Manufacturers’ Monthly manmonthly.com.au

News @MM

The facility bolsters CSL Seqirus’and Australia’s sovereign manufacturing capabilities.

UNSW to help build AUKUS workforce with funding boost

The Federal Budget funding of $128.5 million to create 4,000 student places at UNSW aims to build a future STEM workforce with strong defence and nuclear technology capabilities.