BUS & COACH

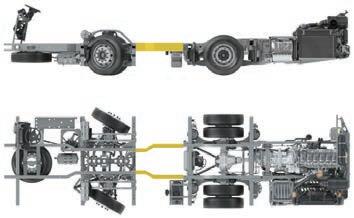

Technology is central to BYD’s DNA, and its ongoing research & development ability is vital to BYD’s rapid development. BYD’s cutting-edge technology can transform lives and improve the world thanks to “technology-based, innovation-oriented” development philosophy. BYD has successfully built an industryleading suite of platforms, and its world-leading advanced technologies are tried and tested in the world’s most demanding environments before market launch.

BYD’s dedicated Commercial Vehicle Research Institute engages in extensive R&D of the whole vehicle and chassis for the pure electric bus and vehicle fleet use in public transport globally.

BYD Commercial Vehicles are available in Australia, sold and distributed directly by BYD.

BYD Commercial Vehicles has streamlined service and support to keep your fleet running with minimal downtime. Our industry-leading electric buses and trucks are backed by BYD’s global expertise and innovation.

Change is the best way of describing 2025 – from leadership to regulation and technology, the industry isn’t staying still as it heads towards another hectic Expo year

This time last year it felt like 2024 had come to a rapid close. Fast forward 12 months and 2025 has set new records for pace, with the latter months of the year rushing upon us. While for many it may lead to feelings of anxiety or panic, for the bus industry this means we’re all closer to another edition of ABC ’s Bus Search Buyer’s Guide. And here it is for 2026.

It comes at a fine time, for one theme that’s defining the Australasian bus and coach industry as of late is change. From changing regulations on the way in 2026 to evolving technologies across the board and an improving number of people boarding bus services across the country, there’s no standing still. Throw in a new-look operator launching in November and there’s plenty happening in bus and coach as we speak.

We look forward to a bright collaborative future!”

To add to the changes, new National Heavy Vehicle Regulator CEO Nicole Rosie has outlined her latest approach to regulation and enforcement, with risk-based approaches set to be the flavour of her tenure at the body. In the same breath, leadership changes at the likes of Ventura in Victoria and Busways in NSW throughout 2025 highlights perhaps a changing of the guard within the industry at a variety of levels.

There’s plenty happening in bus and coach as we speak

It’s a fun exercise to imagine what the industry may look like in a year’s time. In just the past couple of months, Australasia’s largest operator in Kinetic has been acquired, its subsidiary SkyBus has launched in various new states, global force FlixBus has started its maiden runs across the country and new public transport ticketing systems are being developed, implemented and switched on across numerous states’ services.

All of this occurred around the Bus Industry Confederation’s (BIC) National Conference to end the year, with a major story hidden within these proceedings. The return of the Bus Association of Victoria (BusVic) to the BIC fold as a state association member allows for the harmonising of the major bodies, ensuring the theme of unity is in practice for the sector.

“We’re just pleased to be in the BIC camp again,” recently announced BusVic executive director Peter Kavanagh told ABC

“We plan to participate fully to support the national bus industry in all of its endeavours.

One thing that hasn’t changed drastically is our Bus Search Buyer’s Guide. It’s always a wholesome exercise to chat to the numerous vehicle manufacturers, HVAC, seating, door and parts suppliers at the turn of every year to recap their latest and greatest achievements within the local industry and cast our eyes ahead to 2026. With a milestone Bus & Coach Expo set to get underway mid-year in 2026 in Sydney, there’s a greater sense of urgency than ever before when it comes to product innovation and releases.

It all poses as a breakneck yet blossoming time for the sector. We hope you enjoy this year’s Bus Search Buyer’s Guide – a definitive bible for bus lovers. Stay safe over the holiday period and we’ll see you again in 2026, thanks for supporting ABC

Sean Mortell EDITOR, ABC

06. editorial | year in review RESOLUTE FOCUS

Change is the best way of describing 2025 – from leadership to regulation and technology, the industry isn’t staying still as it heads towards another hectic Expo year

11. column | bic POWERING ON

In the wake of a busy BIC Conference and AGM in Perth, BIC is preparing for a milestone year in 2026

bus search buyer’s guide

12. overview | bus search buyer’s guide WELCOME TO BUS SEARCH 2026

This year’s Bus Search Buyer’s Guide continues to grow, with an exciting twist of the latest bus and coach technology on display

14. chassis | byd BUILDING MOMENTUM

After a year that involved numerous milestones and a special initial electric bus delivery to a Victorian operator, BYD is continuing to evolve its local commercial vehicles division

18. chassis | man MAN-AGING GROWTH

After a productive 2025 that saw the brand grow both in market and internally, MAN Truck & Bus is ready to launch in multiple spaces in 2026

24. chassis | scania SUPER FUTURE

From growing its hybrid-electric and alternative fuel options to releasing an exciting new engine range, Scania is continuing to evolve its bus and coach technology for local operators

32. bodies | irizar GROWING ACROSS THE BOARD

The past year has seen Irizar emerge in more bus and coach body markets locally, with the global company preparing for another hectic year in 2026

34. chassis & bodies | challenger BUILDING SUCCESS

After another positive year that included the appointment of a new general manager, Challenger is preparing for a milestone 2026 with new products on the way

40. chassis & bodies | fuso REVOLVING AROUND THE ROSA

It might be a new year, but the same practical benefits of the FUSO Rosa remain

42. chassis & bodies | yutong BUILT TO LEAD

After a year of building its product range and expanding its national network, VDI Australia is preparing to continue strengthening the Yutong brand in the local market in 2026

48. hvac | qtk COVERING ALL OPTIONS

QTK has evolved its diesel HVAC products in 2025, with the refreshed brand looking to reinvigorate the zero-emissions space in 2026

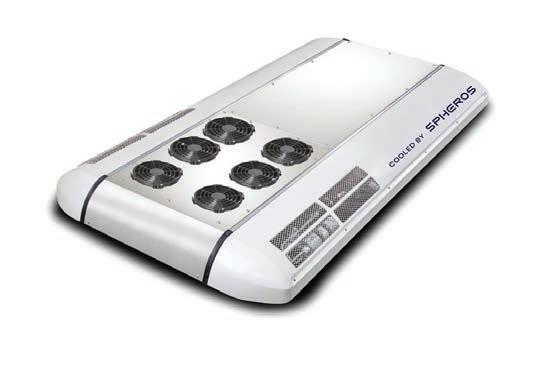

50. hvac | spheros

COOLER SERVICE AND SUPPORT

As operators shift to electric bus air conditioning, Spheros says the real differentiator won’t just be cooling capacity, but the strength and reliability of the service wrapped around it

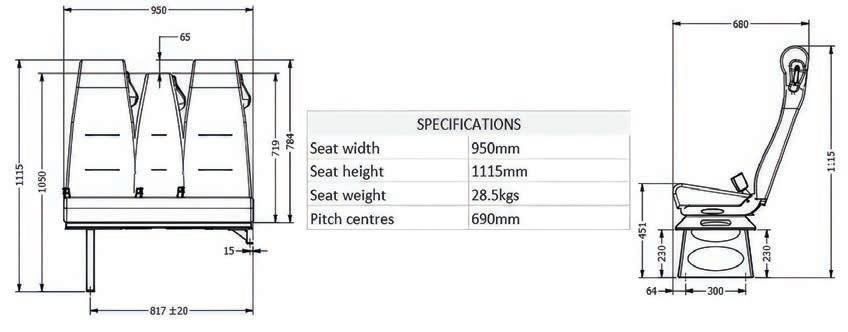

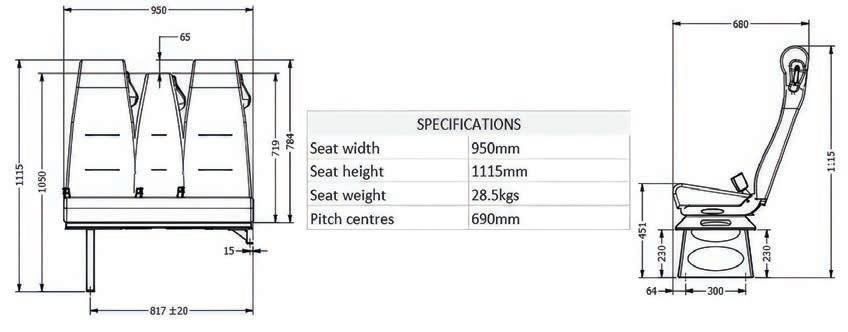

52. seating | sege STRIVING FOR SUCCESS

A year of innovating and enhancing the brand will see Sege Seats tease an exciting new bus seating concept in 2026

54. seating | styleride SUPERIOR SERVICE

After a year spent focusing on its internal processes, StyleRide is now looking to grow once again in the local bus and coach seating market

58. doors | ventura VISIONARY FUTURE

Having grown its presence in Australia, Ventura Systems is now looking to lead the way in door technology and set the tone for industry regulation

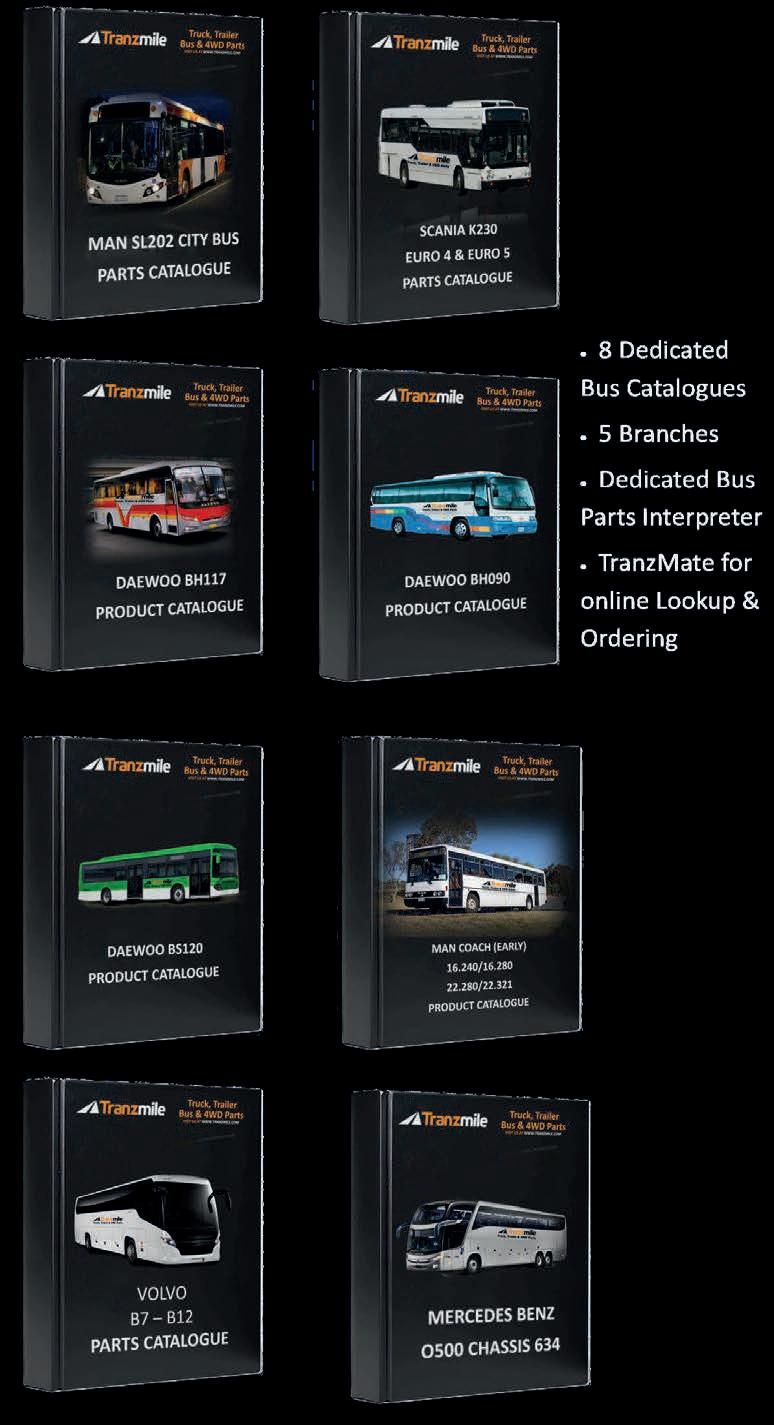

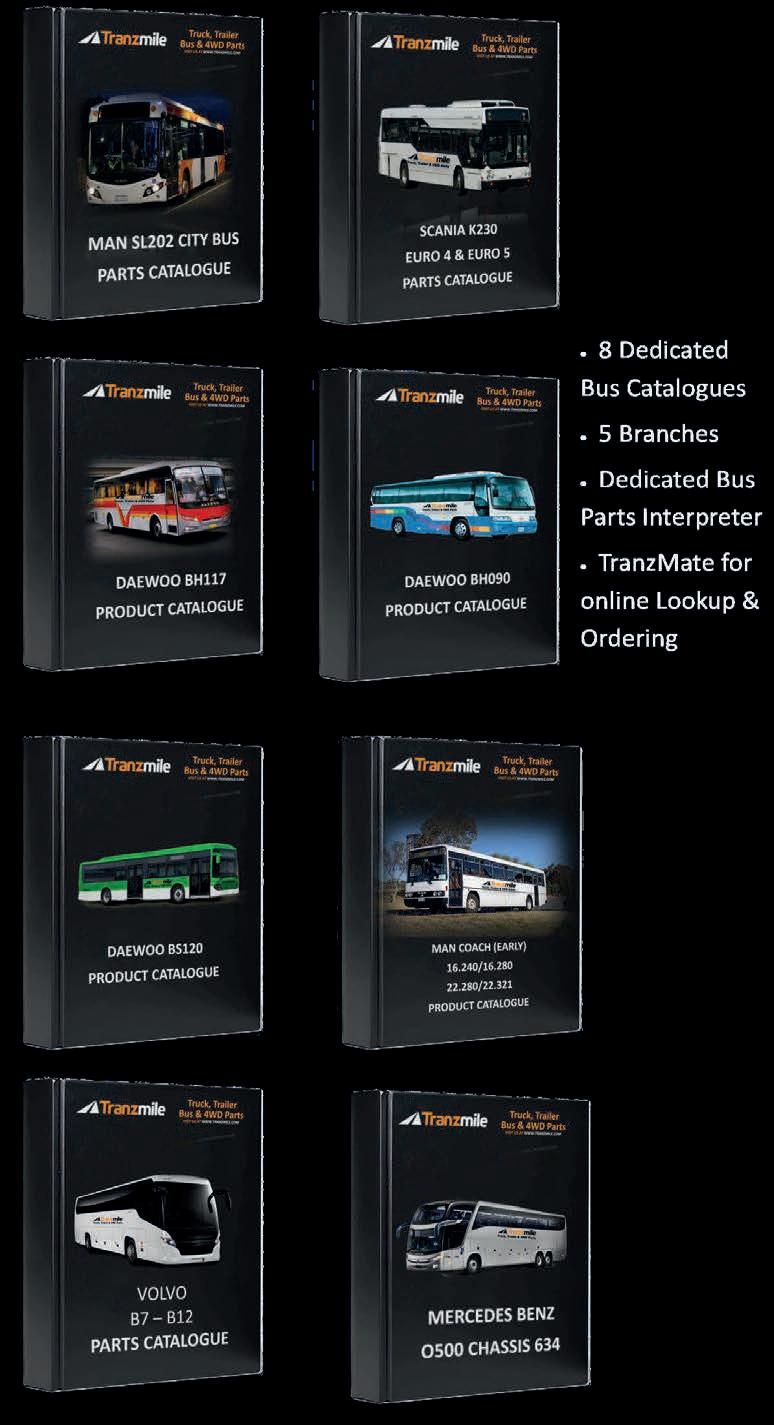

60. parts | tranzmile TRUSTED PARTNER

Through an expanded bus parts catalogue and new fleet management software, Tranzmile is increasing its standing as an important bus and coach parts supplier

62. feature | custom auto glass KEEPING IT LOCAL

In a market where bus, coach and motorhome parts are often turning to overseas supply, Custom Auto Glass and BCM Windscreens are ensuring tailored glass manufacturing remains close to home

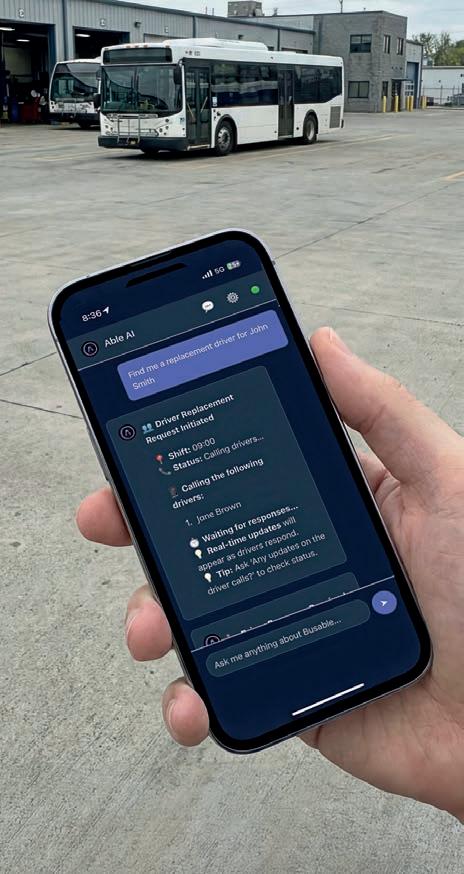

64. feature | busable LAYING THE FOUNDATIONS

Innovative technology is central to the future of the bus and coach industry, with Busable’s software reshaping bus operations with intelligent software

66. feature | australian car audio AUSSIE PUSH

In just over a year since the North American tech was released in Australia, several local operators have already installed the Ready2Talk range onboard their buses

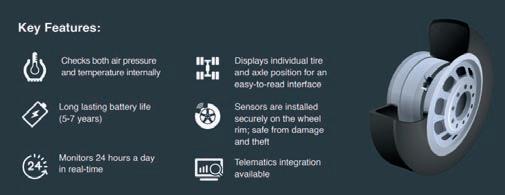

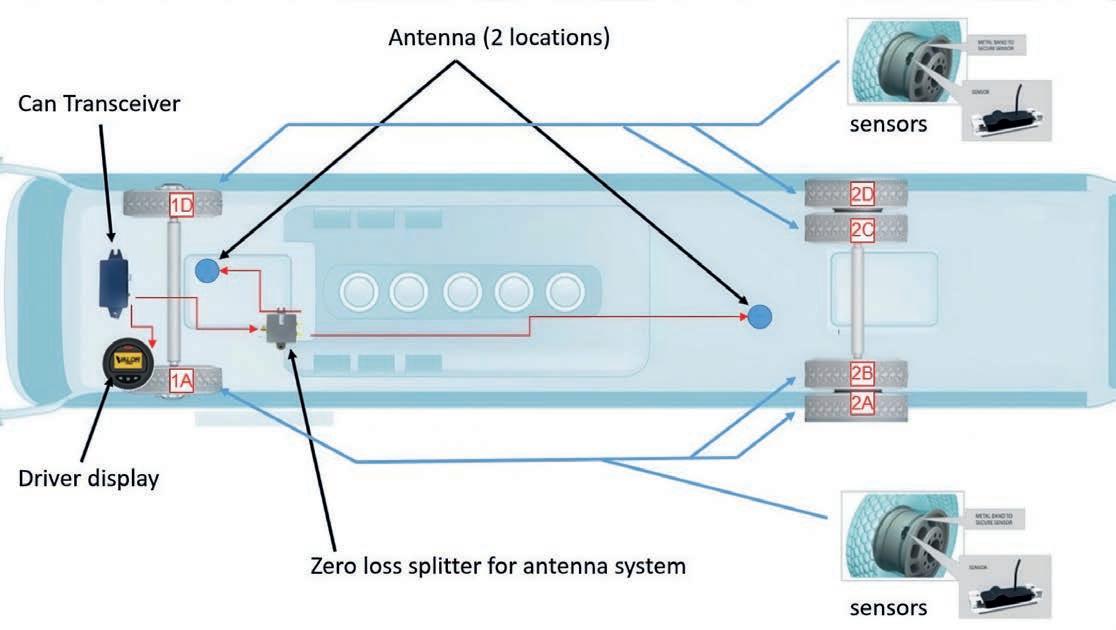

68. feature | spartanlync SAFETY SPECIALISTS

As an important modern piece of bus safety technology, SpartanLync’s tyre pressure monitoring system is leading the way locally

EXECUTIVE GROUP

CEO: Christine Clancy Chairman: John Murphy

Head of Customer Experience: Regina Fellner

EDITORIAL & DESIGN

Managing Editor: Geoff Crockett

e-mail: geoff.crockett@primecreative.com.au

Editor: Sean Mortell

e-mail: sean.mortell@primecreative.com.au ph: 0468 577 166

Art Director: Daz Woolley

Designer: Apostolos Topatsis

PRINTING

Brougham Press

ADVERTISING

Sales Manager – South:

Courtney Burton ph: 0481 736 890

e -mail: courtney.walker@primecreative.com.au

Business Development Manager – Bus: Sylvie Hanlon ph: 0466 545 664

e-mail: sylvie.hanlon@primecreative.com.au

SUBSCRIPTIONS

www.busnews.com.au/subscribe ph: +61 (0)3 9690 8766

Mon-Fri 8am-4.30pm (EST)

e -mail: subscriptions@primecreative.com.au mail: 379 Docklands Drive, Docklands VIC 3008 Australia

Annual subscription rates (12 issues): Australia: $99*

Overseas: $A170 (Australian air-mail only) *price includes GST

Cover image: VDI

Empower your city with our next-gen buses – available in both diesel and EV versions. Built for safety, innovation, and reliability, our BCI Citiriders come equipped with the most advanced features to ensure a smooth, secure ride for every passenger. With a streamlined production and logistics system, we deliver faster than anyone else –because your city’s progress can’t wait.

Contact our team for further information on 1300 289 224 or visit bcibus.com.au

Melbourne: 03 8787 2100

Brisbane: 07 3275 6900

Adelaide: 08 8182 3888

Secure the safest coach chassis, powerful and quiet hybrid-electric drive, and reduce CO2 emissions by up to 92%.

The Scania Irizar i6 Hybrid offers the best of both worlds, providing a low-emission solution that reduces your carbon footprint without requiring costly infrastructure investment or range restrictions.

Switch between battery and diesel

360 hp (265kW) Euro 6 engine

12-speed Scania Opticruise Gearbox

Alcoa Durabrite alloy wheels

Ideal for:

Remote regions with limited grid access

Mining operations requiring robust, low-emission solutions

Long-distance travel where range and refuelling flexibility are critical

In

the wake of a busy BIC Conference and AGM in Perth, BIC is preparing for a milestone year in 2026

ost organisations use this time of the year to power down.

However, the Bus Industry Confederation (BIC) continues burning the midnight oil right across the east to west. The annual AGM, held on October 29, 2025 ahead of the BIC National Conference in Perth, returned the official announcement that a new Constitution was endorsed by the membership. In addition, the change to a Company Limited by Guarantee was also formally adopted.

The new Constitution – representing a major step forward in strengthening the governance, accountability and operational integrity of the BIC –offers a comprehensive framework for the effective management and oversight of the new Board’s activities. It replaces the previous governing document and reflects the evolving needs and priorities of the organisation and its stakeholders. BIC Council members for 2026, as well as the Chair and Vice Chair, were also locked in for the year ahead at the AGM.

reviews from those present. Check out the key takeaways online on Day one concluded with a scenic dinner and entertainment at Kings Park, which also played host to the 2025 National Industry Awards presentation. As a member benefit for BIC members, along with those from the individual state bus associations,

Below: Award winners included Bus Stop’s

One of the biggest highlights was the return of the Bus Association of Victoria (BusVic) as state association members of BIC, setting the year ahead up for long-awaited progression and productivity as a wholly unified industry in 2026.

An industry-wide contingent of over 450-strong attended the biggest bus and coach event of the year, the BIC National Conference (BNC25), in Perth, with new faces turning up to register on day one.

This year’s proceedings included a mini expo which attracted positive comments from supplier members, operators and delegates, as did the Scan2WIN QR code hunt. The collection of keynotes and special guests also received impressive

As one of the biggest conferences and successive overall wins in recent years for the BIC, be sure to keep a keen eye out for the full details on

CHASSIS DIMENSIONS:Length(m)

Wheelbase(mm)

FrontOverhang(mm)

Overhang(mm)

ChassisFrontOverhang(mm)

ScaniaDC09140

....and read about manufacturers and brands. Find out what has changed with the latest chassis, bodies and completely built vehicles, as well as air-conditioners, seats, doors and parts as we head into 2026

or years, the ABC Bus Search Buyer’s Guide has been a leading guide when it comes to the latest bus and coach products, providing in-depth details on existing and fresh chassis and body models. After last year becoming more than just a bus and coach vehicle guide, the 2026 edition includes a wider range of vehicle technology than ever before.

Last year, the Bus Search Buyer’s Guide included specifications on

certain HVAC, seats and door models, widening its scope to include more than just chassis and bodies. At the turn of every year, the guide now features products from various emerging and solidified markets. The 2026 edition of Bus Search Buyer’s Guide continues down this path, maintaining the focus on chassis and bodies, as well as completely built units, while also featuring an even broader range of HVAC, seating, doors and parts. Now,

after this section, enjoy some of the latest software and technological innovations that are leading the way in bus and coach evolution in Australia.

Starting with the chassis section, the guide then drifts to the body area before transition to completely built chassis and bodies models. Outside of vehicles, the HVAC and seating sections are covered, as is the door side of the industry, while parts also come into play in another major edition of the Guide.

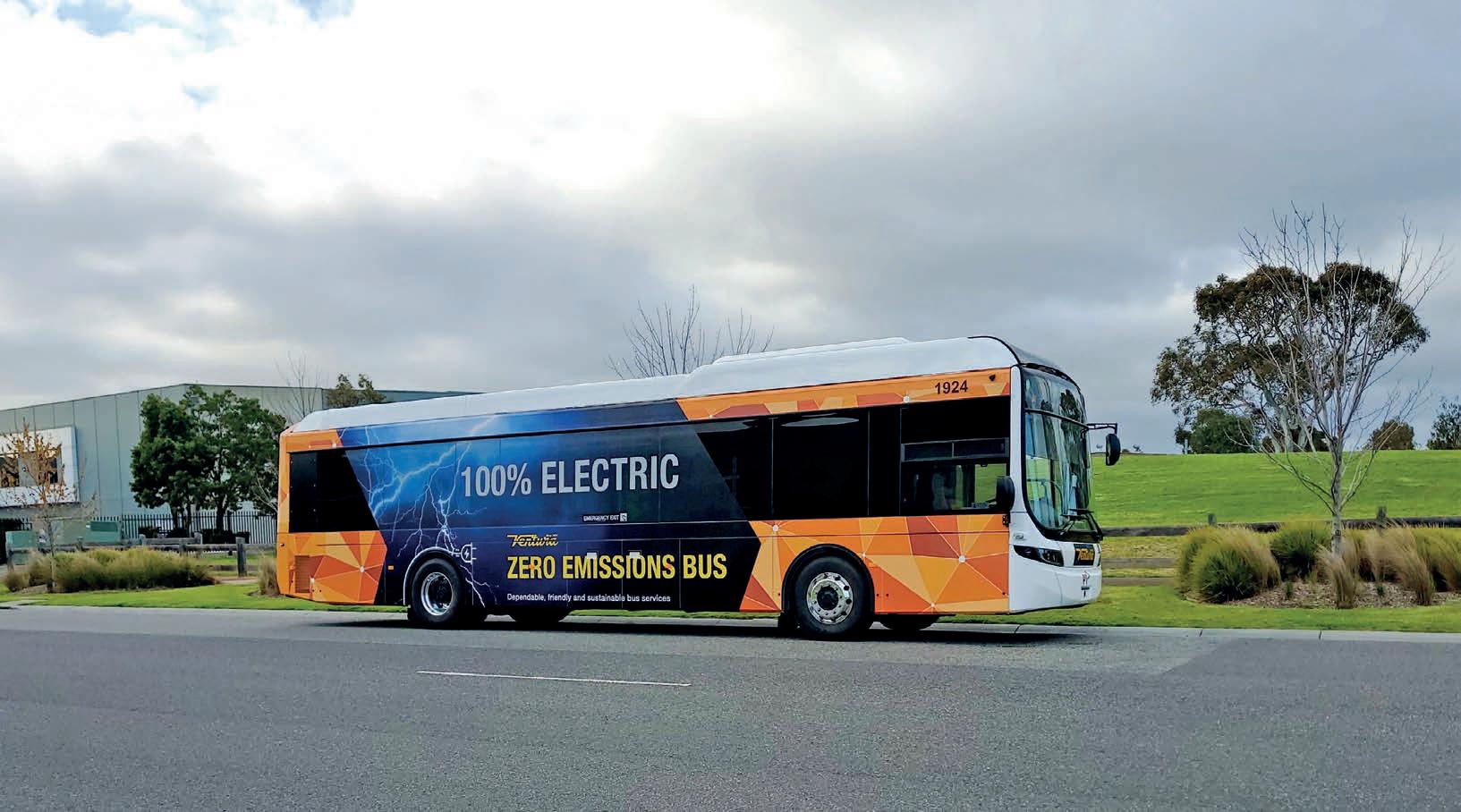

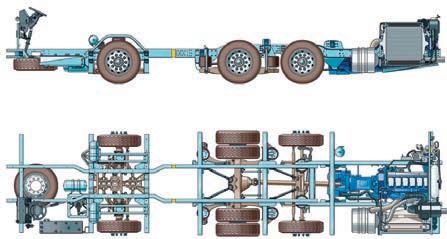

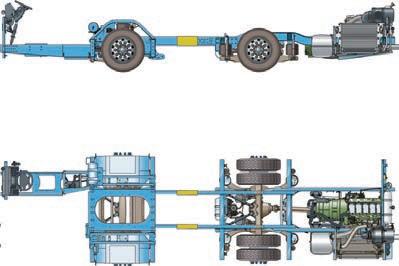

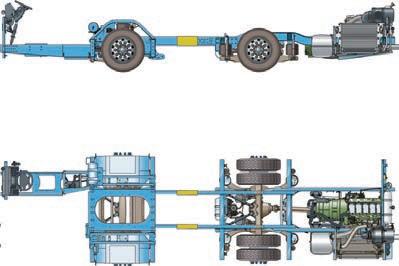

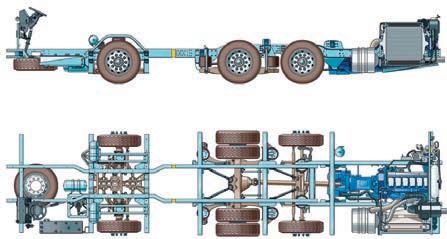

After a year that involved numerous milestones and a special initial electric bus delivery to a Victorian operator, BYD is continuing to evolve its local commercial vehicles division

For BYD, 2025 has been all about milestones. After committing to its customer base in the Australian bus industry with an investment in its aftersales servicing processes and staff, the manufacturer enjoyed numerous local and global achievements.

In July, the international brand celebrated 60,000 vehicles delivered in Australia, while its continual focus on its global prowess and capabilities resulted in the delivery of BYD’s 5,000th electric bus in Europe in late September.

By the end of the year, the very first BYD electric bus as part of a new wave of zero-emissions vehicles was delivered to Dyson Group in Melbourne’s north.

“There’s been plenty of changes made since we first formed the commercial vehicles division in Australia,” BYD commercial vehicles director Jon Tozer told ABC “We first sought to repair our reputation in the local sector as

a respected bus manufacturer, investing in our aftersales team and product support to help local customers.”

These milestones came in short time, as BYD decided to establish its own commercial vehicles division in Australia just under three years ago. This move to build its own full factory backed commercial vehicle division for buses and trucks in Australia and New Zealand is paying off, with Dysons’ milestone electric bus order

Above: With improved servicing behind the scenes, BYD is continuing to evolve in Australia

heralding a new era for the local transport sector.

During this period in 2025, BYD’s commercial vehicles team has grown, bolstered by spare parts and aftersales staff, while BYD also established its very own national parts distribution centre in Melbourne alongside a Sydney parts centre.

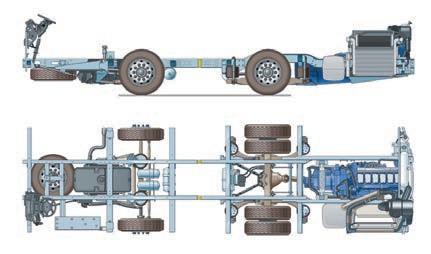

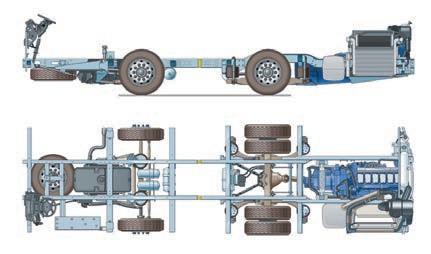

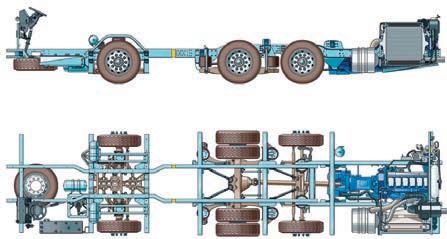

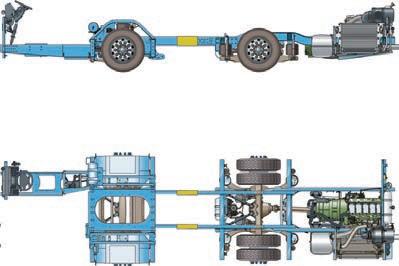

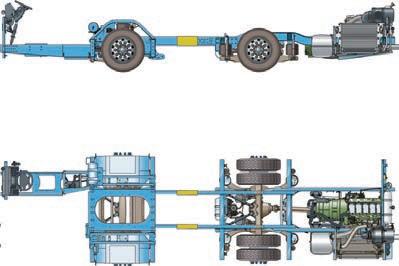

“The BYD chassis is the only electric chassis on the market with a fully integral E-driveline – we’re the only manufacturer that manufactures the

full drive system from the electric batteries, motors and the control systems for our chassis,” Tozer says.

“It means the chassis is a one-stop shop solution.”

Throughout 2025, the brand built on its existing electric bus chassis range. This included the release of its articulated electric bus model, innovating the longer-bus market. Alongside this, the recently unveiled B70 and revamped BC12B1 are highlights of BYD’s local commercial vehicles department.

In a market first, BYD now offers 10-year/3,300 cycle greater than 80 per cent of original capacity warranty on the BC12A05 city bus chassis, providing operators with greater surety on battery life expectations.

These developments in the commercial vehicle sector added to BYD’s overall vehicle dominance in Australia, with the manufacturer surpassing 60,000 vehicles sales in Australia in just under three years throughout 2025. In June, the brand finished in a record fifth place as one of Australia’s highest-selling automotive brands.

Globally, the delivery of its 5,000th electric bus in Europe resulted in a special ceremony, as BYD members converged on Danish public transport operator Umove to unveil the BYD eBus B12.b.

The manufacturer says the BYD eBus B12.b is a groundbreaking model, equipped with BYD’s industry-leading Blade Battery integrated with CTC (Cell to Chassis) technology, specifically tailored for the European market.

The best milestone for BYD was left until last from a local perspective, as Dysons’ first major step in its large-scale transition to zero-emissions transport, which includes a redeveloped new depot, was to receive the first of its BYD electric buses.

These vehicles form the first of more than 168 electric buses that will enter the operator’s Melbourne network over the next nine years, with training programs already underway to familiarise staff with the new technology and maintenance teams preparing workshops for electric vehicles.

What to look forward to in

With an Expo on the horizon, 2026 serves as another important year for BYD. Despite market challenges, the global manufacturer is looking to continue enhancing its spare parts and aftersales development locally while also delivering more electric buses to innovative operators like Dysons in Victoria.

On the product side, Tozer is teasing the introduction of new bus models across the market ahead of the Expo in Sydney, with the industry set to benefit from the global OEM’s latest technology in the coming year.

“We have so many products to get excited about, but we’re also focusing on continuing to improve our aftersales service offerings,” Tozer says.

“There’s plenty more to come from us, including the introduction of BYD trucks into Australia and New Zealand, so stay tuned.”

ADDRESS:

PHONE: 0407 048 097

WEB: www.bydglobal.com/en/ CommercialVehicle.html

EMAIL: jon.tozer@byd.com

ADDRESS:

WEB: www.bydglobal.com/en/ CommercialVehicle.html EMAIL: jon.tozer@byd.com

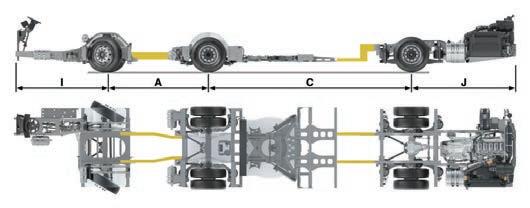

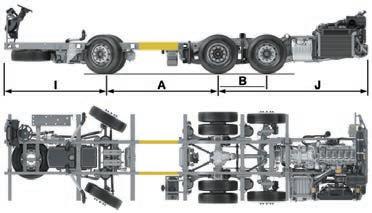

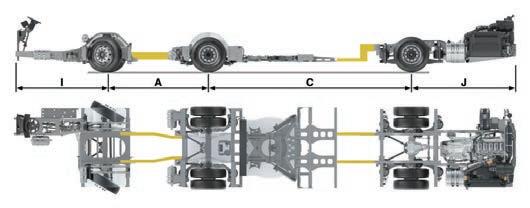

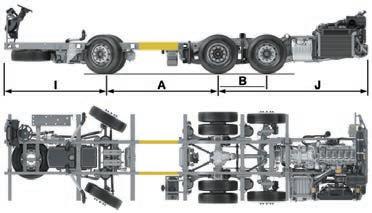

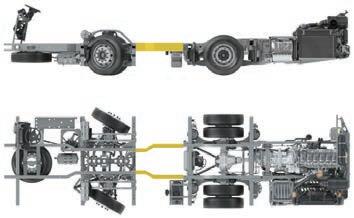

DIMENSIONS

(mm)

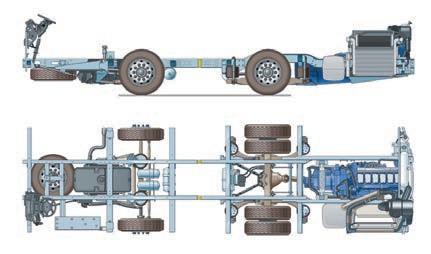

After a productive 2025 that saw the brand grow both in market and internally, MAN Truck & Bus is ready to launch in multiple spaces in 2026

Imported and distributed by Penske Australia, innovation is an apt descriptor for MAN Truck & Bus’ 2025 as the brand has come out the side of plenty of change. Both internal and product evolution has headlined the year, with MAN welcoming staff changes while engaging in exciting developments with its product range.

“It’s been an exciting year for MAN,

with our first two battery electric buses in build,” MAN Truck & Bus head at Penske Australia Derek Schroff told ABC

“One is in build at Gemilang in Malaysia that will head to the New Zealand market, while one is with Global Bus Ventures to come over to Australia once it’s done the final stages of build. We expect this model to be shipped before the end of the year.”

For the Global Bus Ventures-bodied model, MAN is on the front foot, having opened the unit to pre-sale for local customers. Schroff says MAN is excited to bring these new electric models out to the local market and demonstrate their capabilities in both Australia and New Zealand.

“These are also models that we have ready to purchase, readily available in the local market today,” he says.

“We’re keen to get our footprint in the battery electric vehicle side of the business involved in Australia.

“It’s been a good year overall for our bus business – while we have gone through some internal changes within the business, we have a fantastic bus team ready to support the product.”

The tweaks to MAN’s staff include the addition of Warren Young as the New South Wales and Victorian account manager, while Jason Jovanovic has joined the team to look after Queensland sales.

“We’re very excited to have both of them join us, they’ve integrated into the business so well,” Schroff says.

“Jason has been with Penske for a period of time and has experienced down to the production of our chassis. Both he and Warren, who is well known in the industry, bring plenty of passion to the business.”

Adding to these two staff boosts is Jesse Smith, who is in charge of bus supply as national fleet delivery manager. These appointments come at a critical time as MAN’s focus is primarily on increasing its customer engagement to support the new generation of products entering the local bus market.

From a sales perspective, Schroff has been left impressed by the growth seen within the city bus market segment as MAN continues to drive vehicle sales.

“Heading into 2026, we’re going to have our largest order intake for MAN buses since Penske took over the distributorship of MAN more than a decade ago,” Schroff says.

“We’re focusing more now on the coach side of the business, as we want to engage or re-engage with customers on that side. We believe diesel coaches are a great fit for that market, and we’ve experienced great success in that space before, so we want to regain that customer engagement that we had previously.”

German engineered product being appreciated in Australasia,” he says.

“It features the latest German technology and is the latest and greatest battery electric bus on offer to the market – we’re very fortunate to be able to bring that product to Australia.

“The quality is second to none –operators understand our reliability and quality and should expect the same with this electric product too.”

From the Penske side of the partnership, Schroff is looking to expand on a long and storied history with MAN buses in Australasia.

Central to this is the new-look team that is pushing the brand to new heights locally.

“Our major focus is all about the customer – it’s a major part of what we’ve tweaked in the past year, so we’re now ready to push this approach to market,” he says.

On the city bus side, Schroff says the global MAN battery electric chassis will become the focal point of the brand’s line-up in the local market.

“We’ll follow the same MAN battery electric chassis that is popular worldwide, with the

Much like 2025, Schroff admits there’s “a lot on the go” for MAN and Penske in the year ahead. The primary focus may be about customer engagement, but on the product side, Schroff is expecting the brand to display some exciting innovations at the upcoming 2026 Bus and Coach Expo in Sydney.

“We’re in the works of finalising some plans – unfortunately we missed out on showcasing our latest products at the

last Expo, so we’re now in great shape to showcase our units in Sydney,” Schroff says.

“We have our new model range that we’re welcoming and our new wiring architecture that’s a nice upgrade to better integrate with our bodybuilder partners. We’ve also brought in the D15 engine for the MAN chassis, so we’re excited to have a couple of different things in market in both the diesel and zero-emissions space.”

YEAR: 2026 MAKE: MAN APPLICATION: CITY – ROUTE

LE 19.330 RC2 AND LE 19.290 RC2

DIMENSIONS

Circle Diameter (m) Dependent on wheelbase. 52 degree front inner wheel cut angles.

ENGINE

Make/Model MAN/D1556 LOH17 E6e MAN/D0836 LOH91 E6e Configuration Inline 6-cyl.

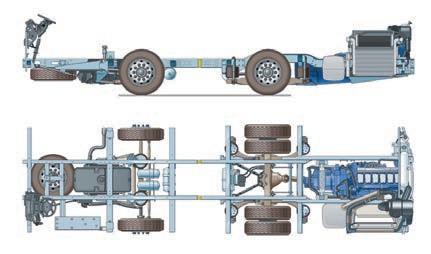

YEAR: 2026 MAKE: MAN APPLICATION: CHARTER, SCHOOL, MINING

MODEL: IC 19.330 RR8 AND IC 19.290 RR8

DIMENSIONS

(mm) 4,000 Buggy form Front Overhang (mm) Provisional Rear Overhang (mm) 3,400 (3,250 opt) 3,150 (3,400 opt)

Turning Circle Diameter (m) Dependent on wheelbase. 56 degree front inner wheel cut angles.

ENGINE

Type – Front

7,200kg. Cast cranked rigid front axle with stabiliser and steering damper. Type – Rear MAN/HY1350-B03/13,000kg. Stabiliser bar. TRANSMISSION

SUSPENSION Type – Front Air (ECAS) Type – Rear Air (ECAS) AXLES

Service Brakes Air/Disc Retarding Brake System Integrated hydraulic retarder EBS Yes

FUEL TYPE

TRANSMISSION

AXLES

Type – Front MAN/VOS-08-B-01/ 8,000kg. Rigid front axle (opt: Independent Inter City or Inderpendent Coach).

Type – Rear

SUSPENSION

MAN/VOK-08-B/8,000kg. Rigid front axle.

MAN/HY1350-B03/13,000kg. Stabiliser bar.

Type – Front Air (ECAS)

Type – Rear Air (ECAS)

BRAKES

Service Brakes Air/Disc

Retarding Brake System Integrated hydraulic retarder

EBS Yes

ELECTRONIC SYSTEM

Alternator 2 x 120A

WHEELS & TYRES

72 Formation Street, Wacol, Qld, 4076 Queensland: (07) 3271 7777

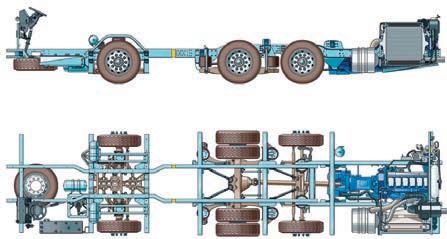

RR2 APPLICATION: CHARTER, COACH , LONG DISTANCE, MINING YEAR: 2026 MAKE: MAN

DIMENSIONS

Length (m) 11.0 to 13.2

Wheelbase (mm) 4,000 Buggy form

Front Overhang (mm) Provisional

Rear Overhang (mm) 3,400

Turning Circle Diameter (m) Dependent on wheelbase. 52 degree front inner wheel cut angles.

ENGINE

Make/Model MAN/D2676 LOH52 E6e

Configuration Inline 6-cyl. 12.5ltr turbo. Up to 520hp available. Power (kW) 316/353/382 Torque (Nm) 2,200/2,450/2,650

Capacity (L) 42

FUEL TYPE

Type Diesel E6, Bosch EDC 17 common rail

Capacity (L) 480 (opt: 2 x 220)

TRANSMISSION

Auto Model / Type ZF/MAN Tipmatic 12OD automated with retarder 12-speed. Opt: ZF 6AP2520 Ecolife 2 (440/480hp only) 6-speed

AXLES

Type – Front

MAN/VOS-08-B-01/8,000kg. Independent front axle with stabiliser (opt: Rigid axle).

Type – Rear MAN/HY1350-B03/13,000kg. Stabiliser bar.

SUSPENSION

Type – Front Air (ECAS)

Type – Rear Air (ECAS)

BRAKES

Brakes

ELECTRONIC SYSTEM

Alternator

WHEELS & TYRES

CO

WEB: man.com.au EMAIL: bussales@man.com.au YEAR: 2026 MAKE: MAN MODEL: CO

COACH, LONG DISTANCE , DOUBLE DECKER

RR4

DIMENSIONS

Length (m) 12.8 to 14.5

Wheelbase (mm) 4,000 Buggy form

Front Overhang (mm) 2,005 mm temporary

Rear Overhang (mm) 1,470 mm + 3,100 mm

Turning Circle Diameter (m) Dependent on wheelbase. 52 degree front inner wheel cut angles.

ENGINE

Make/Model MAN/D2676 LOH52 E6e

Configuration Inline 6-cyl. 12.5ltr turbo. Up to 520 hp available.

Power (kW) 316/353/382

Torque (Nm) 2,200/2,450/2,650

Oil Capacity (L) 42

FUEL TYPE

Type Diesel E5, Bosch EDC 17 common rail

Capacity (L) 480

TRANSMISSION

Auto Model / Type ZF/ MAN Tipmatic 12OD automated with retarder 12-speed Opt: ZF 6AP2520 Ecolife 2 (440/480hp only) 6 speed.

AXLES

Type – Front

MAN/VOS-08-B-01/8,000kg. Independent front axle with stabiliser.

Type – Rear MAN/HY1350-B01/13,000kg. Stabiliser bar.

SUSPENSION

Type – Front Air (ECAS)

Type – Rear Air (ECAS)

BRAKES

Service Brakes Air/Disc

Brake System Integrated hydraulic retarder EBS EBS

ELECTRONIC SYSTEM

Alternator

WHEELS & TYRES

x 120A

x 12V 225Ah

From

growing its hybrid-electric and alternative fuel options to releasing an exciting new engine range, Scania is continuing to evolve its bus and coach technology for local operators

The past year has been a time of difference for global heavy vehicle manufacturer Scania. Historic forays into electric hybrid bus and coach deliveries headlined 2025 for the European powerhouse, with plenty of innovation on the way for the local market in the near future.

The achievements for 2025 culminated in Scania’s first self-charging electric hybrid powered coaches, featuring an Irizar body,

arriving in Australia. Already the first two models are in service in Western Australia, with further stock on hand.

The self-charging electric system means operators don’t need to invest in more expensive charging infrastructure for more location work, as the electric-hybrid system can deliver greater range than pure diesel and use electric-only operation when required.

While Scania has offered this powertrain successfully on route

Above: Scania has further enhanced its technology in multiple spaces

bus products for several years, the brand is now working with Irizar to offer the technology in a luxury coach configuration.

“Scania continues to offer a range of modern and efficient vehicles through its bus and coach range that are configured to meet the needs of Australian operators,” Scania Bus and Coach national sales and contracts manager for WA, South Australia, Victoria and Tasmania Jamie Atkinson says.

“Our commitment to our customers through our expansive network of company-owned and independent workshops provides a confidence that we can keep our customers moving. Our long-standing promise of maximum uptime puts dollars in the bank for customers who are able to deliver uninterrupted service to their customers.”

This innovation also includes the phased introduction of the updated Scania Touring and Scania-Higer

A30 school and charter coach alongside a range of electric and electric-hybrid route buses fitted with locally assembled bodies. The phased introduction of these models reiterates the benefits of these popular, mass-produced and affordable vehicles, all coming with the latest generation of safety focused Advanced Driver Assistance Systems. A highlight of this technology is the new digital dashboard that allows for easier manipulation of these extended safety and convenience features.

Within the route bus range, local assembly at Volgren for Scania’s electric-hybrid chassis is now well established with a good flow of vehicles emanating from the Dandenong factory. Fully electrified chassis are also in build, answering the demand from government fleets for zero-emissions vehicles.

A major focus for 2025 has also been to enhance Scania’s parts stock and maintenance capabilities to ensure Scania customers all over Australasia continue to enjoy the benefits of these models without any disruptions to uptime.

“With our newly expanded parts warehousing and our preventative maintenance knowledge that comes from a connected global fleet of more than 700,000 vehicles, we are reducing the potential for unplanned stoppages, which in the public transport world means more people reach their destinations on time,” Atkinson says.

“We have decades of experience operating in Australia providing the back-up that operators in big cities and smaller towns rely on for their day-to-day operations.”

This culminated in Scania’s 2025 Busworld Expo stand that included

new solutions on display like the PHEV plug-in hybrid model that serves as a new powertrain option for Europe.

“If there is demand, we can investigate adding it to our local offerings,” Atkinson says.

While this depth and range is more than sufficient for a large-scale OEM looking to continue evolving in

Australasia, Scania has no intentions to apply the brakes. Instead, its development is only set to fasten in the coming year as Scania Australia powers into 2026 with a modern and fresh range of fully-imported coaches in the Scania Touring and A30 alongside electric and electric-hybrid buses with locally assembled bodies.

The big news for Scania in the year ahead is the introduction of a range of new-generation six-cylinder SUPER diesel engines that promise at least an eight per cent improvement in fuel efficiency. This benchmark has been more than achieved by these engines when used in Scania trucks in Australia over the past couple of years, offering plenty of promise for local bus and coach operators.

The focus for 2026 will be on the roll-out of the new SUPER generation engines while also further enhancing its fully electric route buses, providing additional supplies of electric hybrid buses and coaches and fulfilling market demands for the Scania Touring and A30 coaches alongside its array of trusted Euro 6 emission diesel chassis. Where market demand exists, Scania is also looking to supply battery electric chassis as well as other alternative and renewable fuel vehicles from its wide range of options, including diesel engines that can run on B100

renewable diesel offering a more than 80 per cent reduction in CO2 emissions.

“For those running high horsepower engines in charter and touring routes, the new generation 13-litre six-cylinder SUPER engines will make a significant impact on their daily running costs, as well as a welcome reduction in exhaust emissions,” Atkinson says.

“We see the arrival of the SUPER engine as a significant step forward in efficiency, but also continuing Scania’s legendary reliability and durability, and importantly, driveability, also.

“As we look to the future, our colleagues in Sweden have been developing further alternative and renewable fuel solutions for public transport, many of which will in time have direct application for Australian operators. But for the here and now, the solutions we are offering meet the needs of our customers, particularly with regard to commercial viability.”

ADDRESS:

PHONE:

VEHICLE DIMENSIONS:

Chassis Length (m) 12.3

Chassis Wheelbase (mm) 5850

Chassis Front Overhang (mm) 2810

Chassis Rear Overhang (mm) 3350

Chassis Turning Circle Diameter (m) 25

ENGINE:

TRANSMISSION:

Make / Model Scania 12-speed gearbox with Opticruise and Retarder; ZF Ecolife 2 6-speed automatic gearbox

ABS & ADAS

Retarding Brake System Scania retarder / ZF retarder

EBS Yes

APPLICATION: CHARTER - LONG DISTANCE

CHASSIS DIMENSIONS:

Chassis Length (m) 13.3

Chassis Wheelbase (mm) 5925

Chassis Front Overhang (mm) 2810

Chassis Rear Overhang (mm) 4565

Chassis Turning Circle Diameter (m) 25

ENGINE:

Make / Model Scania / DC 13 165

Configuration 6 cylinder Power (HP / kW) 500/368 @ 1800 ( SCR ONLY)

Torque (Nm) 2550 @ 925-1340 Oil Capacity (litres) 43

FUEL SYSTEM:

Type / Max Speed (km/h) Diesel /1 00 Capacity (litres) 410 (usable volume)

TRANSMISSION:

Make / Model Scania 12-speed overdrive gearbox with Opticruise and Retarder / GRSO895R

AXLES:

Type - Front Scania AMI580SA Independent Type - Rear Scania AD400+AM661

SUSPENSION:

Type - Front Independent - 2 x airbags

Type - Rear 6 x airbags

BRAKES:

Service Brakes Disc brakes with EBS, ABS & ADAS

Retarding Brake System Scania retarder

EBS Yes

CLUTCH:

Model/Type K432/ Pull

Diameter (mm) N/A

Control SACHS

ELECTRONIC SYSTEM:

Alternator 2 x 150 A

Starter 5 Hp Batteries 2 x 12v 230aH

ADDRESS:

Scania Australia 212-216 Northbourne Road, Campbellfield, VIC, 3061

PHONE: 03 9217 3300

MAKE: SCANIA MODEL: K360C

SERIES: A6X2/2LB

APPLICATION: CHARTER - SCHOOL

CHASSIS DIMENSIONS:

Chassis Length (m) 12.3

Chassis Wheelbase (mm) 5850

Chassis Front Overhang (mm) 2810

Chassis Rear Overhang (mm) 3550

Chassis Turning Circle Diameter (m) 25 MAKE: SERIES:

ENGINE: Make / Model Scania DC 09 140

FUEL SYSTEM:

TRANSMISSION:

Make / Model ZF Ecolife 2 6-speed automatic gearbox/ ZF 6AP1620B

Type / Max Speed (km/h) Diesel, HVO / Diesel, HVO, Biodiesel/100 Capacity (litres) 275 (usable voume) AXLES:

Type - Front Scania AM660S I-Beam

SUSPENSION:

Type - Front I-Beam - 2 x airbags Type - Rear 4 x airbags

& TYRES:

Durabright polished alloy

BODY SPECIFICATIONS:

Seating Capacity Up to 57 seated No. Of Doors 1 Passenger Capacity 57

BODY DIMENSIONS:

Seating Make Customer choice

Seating Model NS Seatbelt Yes

Length (m) 12.3

Body Floor Height (mm) 1317 Body Weight (kg) NS

STORAGE:

Internal 7 m3 thru bins, manual operated pantograph doors External Open overhead luggage racks

AIR-CONDITIONING:

Air-Conditioning Standard Yes

Air-Conditioning Make Konvecta

Air-Conditioning Model SL800

OPTIONS:

Cd-Pa-Radio, Dvd-Tv, Individual Reading Lights, Individual Ac Vents, Reverse Camera Yes Additional Body Options NS

APPLICATION: CITY – ROUTE

CHASSIS DIMENSIONS:

Chassis Length (m) 9 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2500

Chassis Rear Overhang (mm) 3080

Chassis Turning Circle Diameter (m) 25

ENGINE: Make / Model Scania DC 09 141 Configuration 5 cylinder

(HP / kW) 360/262 @ 1900 (SCR only)

Torque (Nm) 1700 @ 1050-1475 Oil Capacity (litres) 31

FUEL SYSTEM: Type Diesel, HVO, Biodiesel

(litres) Body Builder

TRANSMISSION:

/ Model

AXLES: Type - Front

SUSPENSION:

Type - Front I-Beam - 2 x airbags Type - Rear 4 + 4 x airbags

Retarding Brake System

CLUTCH:

ELECTRONIC SYSTEM:

WHEELS & TYRES:

ADDRESS:

PHONE: 03 9217 3300

MAKE: SCANIA MODEL: K320C / K360C / K370C SERIES: B4X2NB

APPLICATION: CHARTER – LONG DISTANCE, SCHOOL

CHASSIS DIMENSIONS:

Chassis Length (m) 9 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2075-2500

Chassis Rear Overhang (mm) 3280

Chassis Turning Circle Diameter (m) 25

CHASSIS DIMENSIONS:

Chassis Length (m) 10 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2075 - 2500

Chassis Rear Overhang (mm) 4385

Chassis Turning Circle Diameter (m) 25

TRANSMISSION:

TRANSMISSION:

AXLES:

SUSPENSION:

BRAKES:

ADDRESS:

Scania Australia 212-216 Northbourne Road, Campbellfield, VIC, 3061

PHONE: 03 9217 3300

Chassis

(mm)

Chassis Front Overhang (mm) 2500 - 2700

Chassis Rear Overhang (mm) 3280

Chassis Turning Circle Diameter (m)

FUEL SYSTEM: Type Diesel, HVO, Biodiesel

AXLES: Type - Front Scania AM 580 I-Beam

- Rear Scania AD400

CLUTCH:

WEB: www.scania.com.au

MAKE: SCANIA MODEL: K410C SERIES: B6X2NB

APPLICATION: LONG DISTANCE

CHASSIS DIMENSIONS:

Chassis Length (m) 10 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2075 - 2500

Chassis Rear Overhang (mm) 3990

Chassis Turning Circle Diameter (m) 25

ENGINE:

Make / Model Scania DC 13 163

Configuration 6 cylinder

Power (HP / kW) 410/302 @ 1800 (SCR only)

Torque (Nm) 2150 @ 900 - 1340

Capacity (litres) 43

FUEL SYSTEM:

Type Diesel, HVO, Biodiesel Capacity (litres) Body Builder

TRANSMISSION:

Make / Model Scania 12-speed gearbox with Opticruise and Retarder

AXLES:

Type - Front Scania AM660 I-Beam

Type - Rear Scania AD400 + A450

SUSPENSION:

Type - Front I-Beam - 2 x airbags

Type - Rear 6 x airbags

BRAKES:

Service Brakes Disc, ABS, ADAS

Retarding Brake System Yes EBS Yes

ELECTRONIC SYSTEM: Alternator 2x 150 amp Starter 5 Hp

2x 12 volt 230Ah

WHEELS & TYRES: Type Polished Alloy Rim

Size 8.25 x 22.5

MAKE: SCANIA MODEL: K360C / K370C

SERIES: B4X2NI

APPLICATION: CHARTER – LONG DISTANCE

CHASSIS DIMENSIONS:

Chassis Length (m) 9 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2075 - 2500

Chassis Rear Overhang (mm) 3280

Chassis Turning Circle Diameter (m) 25

ADDRESS:

PHONE: 03 9217 3300

MAKE: SCANIA MODEL: K240E SERIES: B4X2LB

APPLICATION: CITY-ROUTE

DIMENSIONS

Chassis Length (m) 9 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2500 - 2700

Chassis Rear Overhang (mm) 3280

Chassis Turning Circle Diameter (m) 25

ENGINE:

TRANSMISSION:

SUSPENSION:

BRAKES:

The past year has seen Irizar emerge in more bus and coach body markets locally, with the global company preparing for another hectic year in 2026

In the aftermath of its new site opening in 2024, Irizar has continued to build its presence in the local bus and coach market. With another impressive bank of consistent deliveries and growing success in various sectors, Irizar’s numerous highlights from 2025 include ongoing orders under New South Wales’ Panel 4.

“2025 has been another solid year for Irizar with good deliveries and a solid order bank in place going into 2026,” Irizar Asia Pacific managing director Steve Heanes told ABC

“We’ve gone well with Panel 4 in NSW in 2025 and will continue to grow that side of the business. Our coach segment is also going strong, while our mining sector in Western Australia has been going well too.”

The building popularity under Panel 4 has allowed Irizar to make an impact on NSW’s school bus network, with Irizar delivering up to 16 high-floor i6 3700 school buses over a couple of months in the back half of 2025.

A further 12 rolled out prior to the end of 2025, forming an impressive milestone for the bodybuilder.

“The i6 3700 is a workhorse and has proved itself in many applications and

remote areas,” Heanes says.

“We’ve worked hard to really position the product into the TfNSW panel contracts. As we all know, it’s the highest spec and has the most stringent supply conditions for a school bus in the country.”

Outside of the NSW procurement program, Irizar’s coach segments have also grown courtesy of a new entrant to the nation’s tour and charter market. With international operator FlixBus launching its very first Australian services alongside Deanes Coaches Group and Sunbury Coaches, Irizar has been able to provide bodies for the new coaches entering these innovative services.

“The other major part of growth for us is our business with Flix –we’ve managed to score a fair bit of their business as part of the brand’s introduction into Australia,” Heanes says.

On the service side of the business, Irizar has continued to evolve through its service vehicle network. However, a recent update to its iService portal has led to Irizar offering a one-stop shop for Australian customers.

“Customers love the iService portal because it makes their lives easier

Above: Service and leading product have defined Irizar’s 2025. Image: Irizar

What to look forward to in 2026

when it comes to maintaining their buses,” Irizar procurement and spare parts manager Luke Walker told ABC

“It’s basically a one-stop-shop for them, providing them with maintenance, technical and parts information in one place.”

While there has been plenty of innovation made to Irizar’s diverse range in recent years, Heanes and the Irizar team are remaining tight-lipped about what 2026 has in store for the fleet. Ahead of what is set to be a popular 2026 BusNSW Bus & Coach Expo in Sydney in July, Heanes is teasing some product updates that will be made clearer in the new year.

Outside of the excitement, the brand will maintain its focus on escalating its customer service capabilities across the country.

“On the product side, we’ll be launching updates at the 2026 Expo – we’ll have a fairly big stand on display,” Heanes says.

“We’ll also continue to grow our service team and have recently added a second person to our service network in Western Australia. We’ve started completing service contracts with customers for body servicing and we want to grow that part of our business.”

ADDRESS:

WEB: www.irizar.com.au EMAIL: sales@irizar.com.au

ADDRESS:

ADDRESS:

CHASSIS

CHASSIS

ADDRESS: Scania Australia 212-216 Northbourne Road, Campbellfield, VIC, 3061 PHONE: 03 9217 3300

MAKE: SCANIA MODEL: K410C

SERIES: B6X2NB APPLICATION: LONG DISTANCE

CHASSIS DIMENSIONS:

Chassis Length (m) 10 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2075 - 2500

Chassis Rear Overhang (mm) 3990

Chassis Turning Circle Diameter (m) 25

ENGINE:

WEB: www.scania.com.au

MAKE: SCANIA MODEL: K360C / K370C

SERIES: B4X2NI APPLICATION: CHARTER – LONG DISTANCE

CHASSIS DIMENSIONS:

Chassis Length (m) 9 (transport)

Chassis Wheelbase (mm) 3000 (transport)

Chassis Front Overhang (mm) 2075 - 2500

Chassis Rear Overhang (mm) 3280

Chassis Turning Circle Diameter (m) 25

ENGINE: Make / Model Scania DC 09 141 / Scania DC 13 162

TRANSMISSION:

SUSPENSION: Type - Front I-Beam - 2 x airbags Type - Rear 6 x airbags

BRAKES: Service

TRANSMISSION:

/ Model Scania 12-speed gearbox with Opticruise and Retarder; ZF Ecolife 2 6-speed

SUSPENSION: Type - Front Independent - 2 x airbags

After another positive year that included the appointment of a new general manager, Challenger is preparing for a milestone 2026 with new products on the way

side, the addition of a maiden general manager revitalised the brand’s future aspirations.

“Our biggest change in 2025 saw Challenger employee Paul Fagg become our very first general manager, which was a real turning point,” Challenger Bus and Coach CEO Greg Sloan told ABC

“Having Paul on board has provided the team with an even greater skillset and has seen each of our sales team members grow.

“We are always evolving and finding ways to ensure that we can provide the best service possible. Paul has demonstrated a real passion for the bus industry after multiple decades in the truck industry, so we couldn’t be happier that Paul has joined the team.”

When it comes to Challenger’s premier fleet options for Australasian operators at the end of 2025, the ever-popular V12 and V10 continue to lead the way. As soon as the V12 lands in the country, it is quick to leave the depot and head off to eager new owners.

“The V12 is our premium workhorse – it’s one of those buses that fit straight into the fleet and keeps on going,” Paul Fagg told ABC

“Its strong stainless steel frame, flat glass panels and windows, as well as a premium Cummins engine, make it a lucrative option for many operators around the country.

As another year has passed for emerging supplier Challenger Bus and Coach, more milestones continue to tick over. Just a couple of years ago, the brand’s fleet included two primary models in the V10 and V12. Fast forward to the end of 2025 and Challenger has added

the Callibar and electric low-floor bus variants to its suite while also upgrading and refining its initial two leading models. Outside of enhancing its trusted V10 and V12 and developing new models for the local market, the main highlight for Challenger in 2025 was delivering its 50th unit. On the team

“A few new features have been upgraded on the V12 in 2025, including fitting a new multimedia touch screen system and a new saloon style door, and these have all been a real hit.”

Being one of the smaller manufacturers in the local bus and coach market, Challenger’s major focus has been on growing its brand and its identity. While people may have heard of Challenger, Fagg says

sometimes people may not know exactly who or what the brand is about. Spreading its identity has been a primary move for Challenger in 2025 as the emerging force continues to show customers the design flexibility it has when compared to other manufacturers.

“We’re able to customise the vehicle to exactly what the customers wants. If someone needs a wheelchair lift, toilet or kitchenette, we can include it,” he says.

“If someone wants to use the bus as a teaching classroom or convert it into a premium corporate coach, we can do any of these things to any of our models.”

Heading into a defining year that should see continual expansion, both in terms of vehicle range and market coverage, Challenger’s message is simple. Challenger is an Australian brand, suited perfectly to the local market’s needs for the future.

“We aren’t a dealership –Challenger Bus and Coach owns all of our own intellectual property for the design and construction of our vehicles, so we’re an Australian bus and coach manufacturer,” Fagg says.

“Yes, we build in China, but that doesn’t mean we are a Chinese bus. We’re an Australian bus, built the Australian way and to the Australian standard.”

Above:

It’s bright horizons for Challenger in the next year as the ever-growing bus and coach brand continues to search for evolution and development. The brand is ready to have a major presence at the 2026 Bus and Coach Expo in Sydney, showcasing its latest developments to its four-vehicle strong fleet.

What to look forward to

This includes two new models that are slated for a 2026 release in a three-axle coach and a tweak to the small and dynamic Callibar model that will be built on a four-wheel drive chassis. While this is enough to excite the industry, Fagg teases that this may only be the tip of the iceberg for Challenger in 2026 and beyond.

“The three-axle coach is built to the impressive Challenger standards, and it comes equipped with 52 passenger seats, a wheelchair lift, toilet and two disability friendly spaces,” he says.

“The Callibar on a four-wheel drive chassis is one of a kind in the market and is highly sought after. The option came as there was a gap in the market, with lots of regional tour operators and mine sites using a truck cab with a ‘cabin’ on the back, while our vehicle will be an all-in-one unit with a 4.5L Cummins Euro 6 engine.

“We’re also evolving our electric range in 2026. Watch this space, we’re saying that anything is possible.”

ADDRESS:

39A Chelmsford St, Williamstown, VIC, 3016

WEB:

www.challengerbusandcoach.com.au

EMAIL: sales@challengerbusandcoach.com.au

MAKE: CHALLENGER MODEL: V12

APPLICATION: SCHOOL/CHARTER/DAY TOUR

CHASSIS DIMENSIONS:

Chassis Length (m) 11.88

Chassis Wheelbase (mm) 6550

Chassis Front Overhang (mm) 2030

Chassis Rear Overhang (mm) 3300

Chassis Turning Circle Diameter (m) <24

ENGINE:

/ Model / Fuel Type Cummins L9 EVIE340

(litres) 26 Emissions Euro 6

TRANSMISSION:

ADDRESS:

39A Chelmsford St, Williamstown, VIC, 3016

WEB:

www.challengerbusandcoach.com.au

EMAIL: sales@challengerbusandcoach.com.au

DIMENSIONS:

TRANSMISSION:

CHASSIS DIMENSIONS:

Chassis Length (m) 12

Chassis Wheelbase (mm) 5900

Chassis Front Overhang (mm) 2695

Chassis Rear Overhang (mm) 3395

Chassis Turning Circle Diameter (m) 22.5

Description/ Battery

TRANSMISSION: Auto Trans Make/ Model/ Description Automatic ELECTRIC BUS SPECIFICATIONS:

SUSPENSION:

BRAKES:

BODY

BODY DIMENSIONS:

Body Length (metres) 12

Body Width (metres) 2.5

Body Height (metres) 3.3

Body Weight (GVM) 18000 (Gross)

BRAKES:

ADDRESS:

39A Chelmsford St, Williamstown, VIC, 3016

WEB:

www.challengerbusandcoach.com.au

EMAIL: sales@challengerbusandcoach.com.au

MAKE: CHALLENGER MODEL: 4WD CALLIBAR APPLICATION: CHARTER/ TOURING/ MINING

CHASSIS DIMENSIONS: Chassis

Chassis

(mm) 4200

Chassis Front Overhang (mm) 1350

Chassis Rear Overhang (mm) 2200

Chassis Turning Circle Diameter (m) 20

It might be a new year, but the same practical benefits of the FUSO Rosa remain

he Rosa’s steadfast dependability and flexibility has made it an icon on Australian roads.

The FUSO bus boasts unmatched flexibility with both 22-seat and 25-seat variants available. It is the only Japanese light duty bus with 25 seats. Given the average primary school class size in Australia is 23, it’s a very important fact.

With buses often operating in high pedestrian traffic areas, safety of buses is paramount and something that FUSO and its parent company, Daimler Truck, takes very seriously.

The Rosa has the advantage of a fully integrated active safety system. The Advanced Emergency Braking System uses both radar and a camera, while it can perform full emergency braking in the event of a potential collision. This advanced radar-based system can even detect, and begin braking for, moving pedestrians.

Rosa also has a Lane Departure Warning System as standard, along with Electronic Stability Program, driver and front passenger airbags, height adjustable LED headlights, Hill Start Assist, disc brakes all round and a reversing camera.

There are also four exits and three-point lap sash seatbelts for passengers in the Deluxe model. The latest generation Rosa also features a transom window on the passenger side to further enhance its excellent visibility.

Part of the latest Rosa offering is the upgraded eight-inch multimedia unit with Apple Carplay and Android Auto compatibility. A reverse camera is also fitted as standard, with the option available to install five additional cameras.

FUSO has a reputation for strong

customer support and is backing the recently upgraded Rosa with a generous five-year/200,000km warranty, giving owners real peace of mind.

It has also introduced longer service intervals, now 15,000km, which, when combined with the added assurance of a guaranteed buy back, help increase the time the bus spends on the road.

The Rosa features an efficient 3.0-litre four-cylinder turbo diesel common rail engine with the most power and torque in its class – 129kW and 430Nm. This advanced unit, which features a variable geometry turbocharger, is light but powerful. The Rosa has also been Euro 6 compliant since 2020, when it became the first

light duty bus to do so. It has since proven the durability of this technology out on the road.

FUSO also boasts an advanced DUONIC Automated Manual Transmission that features six gears. This advanced dual clutch transmission delivers fuel efficiency improvements as well as fast and smooth shifts. It also features a handy creep function for easy low-speed manoeuvring.

A new flat-floor design not only makes it easier for passengers to get in and out of their seats, but also allows for simpler aftermarket wheelchair lift installations.

FUSO says one of the things Rosa buyers appreciate is how easy it is to drive and part of this is due to its independent front suspension for optimum comfort and handling is complemented by a class leading turning circle of 12.6m (22 seat) and 14.2m (25 seat) that helps navigate tight spots.

FUSO recently freshened the interior and exterior design of the Rosa, giving it a stylish and modern look due to new design language.

It is available in Standard and Deluxe trim levels to help customers have the ability to choose the Rosa that is right for them.

fuso.com.au

MAKE: FUSO MODEL: 25-SEAT SERIES: ME OMNIBUS

DIMENSIONS:

ENGINE:

BRAKES:

SCHOOL, CHARTER VARIANTS

After a

year of building its product range and expanding its national network, VDI Australia

is preparing to continue strengthening the Yutong brand in the

Sometimes, the best way to express growth is through numbers, cold hard data, facts and figures. In recent years, VDI and Yutong have emerged as a leading partnership in Australia’s bus and coach market. Reaching the milestone of 2,000 Yutong buses in service marked a significant moment in the brand’s local expansion.

“From a product point of view, VDI and Yutong are in the strongest position we have been in since entering the market,” VDI Australia national sales manager Sara Clark told ABC

VDI now offers a model range across small, mid and large size buses, spanning Euro 6 diesel and battery electric options in both high-floor and low-floor applications. With multiple interior layouts and safety configurations, the line-up reaches far beyond the core bus industry, supporting schools, community transport, mining operations and local government fleets. Backed

by Yutong’s global engineering capability, the brand is confident in its ability to meet the needs of diverse operators across Australia.

Outside of its vehicle range, VDI has continued to build its national team, growing staff numbers by more than 30 per cent throughout the past year to now employ 125 bus professionals. Over the past two years, the supplier has strengthened its sales and aftersales capability in every state while investing in a Brisbane hub to match its Western Australian presence.

Alongside deepening its technical support for both diesel and electric fleets, VDI’s culture remains grounded in its family ownership and long involvement in Australian transport. However, now it sits on top of a much larger fleet and a more mature national network.

“In simple terms, we finish 2025 with a milestone moment in our heritage – 2,000 Yutong buses on the road, a strong pipeline of product development and a team

local market in 2026

that understands the local conditions those buses operate in. That is a good platform for the next phase of growth,” Clark says.

To create this blossoming picture, Clark says 2025 has been a “very solid year” of growth and consolidation for both VDI and the Yutong Australia brand. The focus has been on turning a growing national fleet into long-term value for operators rather than chasing new model headlines.

This has resulted in a fleet that is diverse in applications and capabilities, reflecting where Australian operators are seeing the most demand and where Yutong’s global platforms, adapted locally by VDI, add the most value.

On the smaller end, the D7 and D7E remain key products for school, community transport, mining villages and regional route work. Clark says they give operators the choice of proven Euro 6 diesel or battery electric on familiar Yutong underpinnings, with options such

as two for three seating, CCTV, 360 degree cameras and school bus safety packages.

“The newer E7S sits slightly differently again,” Clark says.

“It is a compact, purpose built solution for demand responsive, last mile and local shuttle work where zero-emission operation, tight turning circles and good accessibility are all important. It shows how Yutong’s electric experience globally can be tailored very specifically to Australian use cases.”

On the larger end, the C12 and C12E continue to anchor VDI’s school, charter and mining offering. The C12 gives operators a robust Euro 6 coach platform with the kind of luggage, seating and safety options local fleets expect. The C12E builds on that with a full electric driveline, long range capability and the flexibility to be specified for school, mining or touring work, all while backed by the same parts and service network.

While 2025 saw VDI strengthen its current offerings and support network around the nation, 2026 should see VDI strengthen the whole Yutong model range in Australia and prepare for new local introductions.

“This includes refining both our Euro 6 and battery electric ranges for specific use cases and giving operators clearer pathways through the line-up,” Clark says.

“It also includes preparing for the Australian introduction of the Yutong U18, a high capacity articulated electric bus that will sit at the top end of the range for busy routes where additional capacity is required.”

When it comes to the 2026 Expo, Clark says the emphasis will be on reinforcing the broader fleet story, establishing a strong presence that reflects its model range and support capabilities without giving away too much in advance.

“There will be plenty for operators to see first-hand at the event,” she says.

“Across the wider calendar, operators can expect to see more targeted trials, regional events and customer partnerships. The aim is to give fleets practical, local evidence of how Yutong products, delivered

and supported by VDI, perform in their environment, whether that is a compact bus on a town shuttle or a high capacity coach working hard in demanding regional conditions.”

Clark acknowledges the industry is under pressure on multiple fronts – to reach the milestone of 2,000 deliveries takes loyalty and plenty of commitments to help customers long into the future.

“With the delivery of our 2,000th Yutong in Australia, the main message is one of appreciation. None of those milestones happen without operators who are willing to try new product, give honest feedback and hold suppliers to account,” Clark says.

“Our commitment, as Yutong’s long term Australian partner, is to stay focused on practical, reliable solutions that work in real fleets, backed by local people who understand the environments those buses operate in.

“If we keep working together in that way, we think the next few years can deliver real benefits for passengers and operators, whether they are running a single school bus or a large mixed fleet.”

“Across all of these, the common story we want to highlight is choice,” on, Clark says recent highlights include broadening the range in service, refining the existing models to improve performance and reliability, and introducing standard enhancements such as telematics across the line-up. We listen to our customers and use their feedback to continually improve our offerings.

“Euro 6 and battery electric Yutong models are now working in school, route, charter, mining and community transport applications right across the country,” she says.

“Independent reviews and operator feedback have reinforced what we see internally, which is that the combination of Yutong’s global product depth with local Australian assembly and support is resonating in

“Alongside the product story, 2025 has also been a year of investing behind the scenes in parts, service, telematics and training. That work is less visible than a show stand, but it is critical to supporting a large and growing Yutong fleet in daily operation and making sure existing customers feel just as supported as

MAKE: APPLICATION:

CHASSIS DIMENSIONS:

Chassis Length (m) 7.73

ADDRESS:

ELECTRIC ELECTRIC

Chassis Wheelbase (mm) 4350

Chassis Front Overhang (mm) 1250

Chassis Rear Overhang (mm) 2130

Chassis Turning Circle Diameter (metres) ≤ 16

ENGINE:

Make / Model Yutong TZ330XSYTB56

Configuration Full Electric

Power (HP / kW) 161/120

Torque (Nm)

BATTERY:

Description Lithium Iron Phosphate

Capacity 175kWh

Location Under vehicle

Charging System CCS2

Charging Voltage 750v

TRANSMISSION:

Automatic Trans N/A

Manual Trans N/A

CLASS: SMALL BUS CLASS: LONG DISTANCE CHARTER BUS

MAKE: YUTONG MODEL: C12E FULL ELECTRIC APPLICATION: SCHOOL/CHARTER/TOUR/MINING

CHASSIS DIMENSIONS:

Chassis Length (m) 12.37

Chassis Wheelbase (mm) 6450

Chassis Front Overhang (mm) 2600

Chassis Rear Overhang (mm) 3320

Chassis Turning Circle Diameter (metres) ≤ 24

ENGINE:

Make / Model Yutong TYZ400XSYTB49

Configuration Full Electric Power (HP / kW) 288/215

Torque (Nm) 1260 Continuous / 3200 Peak

Emissions ZERO

BATTERY:

Description Lithium Iron Phosphate

Capacity 350kWh

Location Under vehicle

Charging System CCS2

Charging Voltage 750v

TRANSMISSION:

Automatic Trans N/A

Manual Trans N/A

ADDRESS:

ELECTRIC

MODEL: E12 FULL ELECTRIC APPLICATION: CITY ROUTE

CHASSIS DIMENSIONS:

Chassis Length (m)

Chassis Wheelbase (mm) 6300

Chassis Front Overhang (mm) 2740

Chassis Rear Overhang (mm) 3430

Chassis Turning Circle Diameter (metres) ≤ 23

BATTERY:

Description Lithium Iron Phosphate Capacity 434kWh/399kWh

Location Roof & Rear lower of vehicle

Charging System CCS2 & Pantograph

TRANSMISSION: Automatic Trans N/A Manual Trans N/A

CLASS: LOW FLOOR CITY BUS

CLASS: SMALL BUS

MAKE: YUTONG MODEL: D7 APPLICATION: SCHOOL/CHARTER/TOUR/MINING

CHASSIS DIMENSIONS:

Chassis Length (m) 7.73

Chassis Wheelbase (mm) 4150

Chassis Front Overhang (mm) 1250

Chassis Rear Overhang (mm) 2330

Chassis Turning Circle Diameter (metres) ≤16

ENGINE:

Make / Model Cummins D4 .5EVID190

Configuration Turbocharge, Intercool Power (HP / kW) 188 / 140

Torque (Nm) 700 @ 1200RPM

Bore and Stroke 107/124

Compression Ratio 17.1 : 1

Fuel Capacity (litres) 150

Oil Capacity (litres) 21.6

Emissions Euro VI

TRANSMISSION:

Automatic Trans Make/ Model/ Description Allison - 2100 5 Speed (optional 6 speed)

Manual Trans Make/ Model/ Description N/A

SUSPENSION:

Type – Front Parabolic leaf spring

Type – Rear Parabolic leaf spring

BRAKES:

Service Brakes Disc, ABS, ASR, ESC

Retarding Brake System Yes

EBS Standard

BODY DIMENSIONS:

Body Length (m) 7.73

Body Width (m) 2.41

Body Height (m) 3.17

Body Floor Height (mm) 710

Body Weight (kg) N/A

WHEELS AND TYRES:

Tyre Size 235/75

Rim Size R17

ADDRESS:

CLASS: MIDI BUS

CHASSIS DIMENSIONS:

Chassis Length (m) 9.985

Chassis Wheelbase (mm) 4830

Chassis Front Overhang (mm) 2290

Chassis Rear Overhang (mm) 2865

Chassis Turning Circle Diameter (metres) ≤ 18.5

ENGINE:

Make / Model Cummins D6.7EVID290

Configuration Turbocharge, Intercool

(HP / kW) 286 / 213

Torque (Nm) 1100 @ 1100-1600RPM

Bore and Stroke 107/124

Compression Ratio 17.1 : 1

Fuel Capacity (litres)

TRANSMISSION:

CLASS: MIDI BUS CLASS: LONG DISTANCE CHARTER BUS

CHASSIS DIMENSIONS:

Chassis Length (m) 12.37

Chassis Wheelbase (mm) 6450

Chassis Front Overhang (mm) 2600

Chassis Rear Overhang (mm) 3320

Chassis Turning Circle Diameter (metres) ≤ 24

ENGINE:

Make / Model Cummins L9EVID340

Configuration Turbocharge, Intercool Power (HP / kW) 337 / 251

Torque (Nm) 1600 @ 1000-1500RPM

Bore and Stroke 117/144.5

Compression Ratio 17.1 : 1 Fuel Capacity (litres) 400 Oil Capacity (litres) 32 Emissions Euro VI

TRANSMISSION:

Automatic Trans Make/ Model/ Description Allison T390R 6 speed Manual Trans Make/ Model/ Description N/A

SUSPENSION:

ADDRESS:

WEB: www.vdiaustralia.com.au

EMAIL: sales@vdiaustralia.com.au

CLASS: ULTRA LOW FLOOR MICRO BUS

CHASSIS DIMENSIONS:

Chassis Length (m) 7

Chassis Wheelbase (mm) 5190

Chassis Front Overhang (mm) 940

Chassis Rear Overhang (mm) 870

Chassis Turning Circle Diameter (metres) ≤ 17

ENGINE:

Make / Model Yutong TZ220XSYTC65

Configuration Full Electric

Power (HP / kW) 134/308HP / 100/200kW

Torque (Nm) 230/470

Emissions ZERO

BATTERY:

Description Lithium Iron Phosphate

Capacity 176kWh

Location Roof Mounted

Charging System CCS2

Charging Voltage 750v

TRANSMISSION:

Automatic Trans Make/

Model/ Description N/A

Manual Trans Make/

Model/ Description N/A

SUSPENSION:

Type – Front Two Spring Electronically Controlled Air Suspension - ECAS

Type – Rear Two Spring Electronically Controlled Air Suspension - ECAS

BRAKES:

AVAS, TPMS, LDW, DDAW

CLASS: ARTICULATED LOW FLOOR CITY BUS

CHASSIS DIMENSIONS:

Chassis Length (m) 17.97

Chassis Wheelbase (mm) 5900+5900

Chassis Front Overhang (mm) 2740

Chassis Rear Overhang (mm) 3430

Chassis Turning Circle Diameter (metres) ≤ 21.5

ENGINE:

Make / Model Yutong TZ330XSYTC33

Configuration Full Electric Power (HP / kW) 168*2 / 335*2HP 125*2 / 250*2kW

Torque (Nm) 1200*2 / 2400*2

Emissions ZERO

BATTERY:

Description Lithium Iron Phosphate

Capacity 528kWh

Location Roof & Rear lower of vehicle

Charging System CCS2 & Pantograph

Charging Voltage 750v

TRANSMISSION:

Automatic Trans Make/

Model/ Description N/A

Manual Trans Make/ Model/ Description N/A

SUSPENSION:

Type – Front Two Spring Electronically Controlled Air Suspension - ECAS

Type – Rear Four Spring Electronically Controlled Air Suspension - ECAS

BRAKES:

Service Brakes Disc, ABS, ASR, EBS Retarding Brake System Regeneration Braking EBS Standard

QTK has evolved its diesel HVAC products in 2025, with the refreshed brand looking to reinvigorate the zero-emissions space in 2026

When Queensland Thermo King customer solutions manager Allan

Lowes talks about how 2025 has been for the bus and coach HVAC brand, the word that first comes to mind is collaboration. Having spent the year working closely with bus and coach operators and suppliers, QTK has ensured its air-conditioning systems deliver not just comfort, but also operational efficiency and dependability.

This has come into the focus as the Australasian bus and coach market has undergone plenty of change.

“With uptake in zero-emissions buses slower than first expected, we’ve focused on reinvigorating our diesel unit offering to help our customers balance passenger expectations with energy efficiency and cost certainty,” Lowes told ABC “2025 has been a year of strong collaboration for us, balancing passenger expectations with the energy efficiency and cost certainty of our models.”

This industry investigation has resulted in the development and release of QTK’s new CF range of HVAC units for diesel buses. While models like the CF-1100A were first launched at the 2024 National Bus and Coach Show in Brisbane, these variants have offered a welcome new product for regional diesel buses and coaches.

“This one-piece unit is more compact and incorporates a full aluminium frame to remove the installation issues seen in other models,” Lowes says.

“It has a lower operating current and includes a weight reduction of 45kg, or 25 per cent. All of this means less power draw and load to the engine, therefore resulting in lower fuel consumption and operating costs.”

While variants of the range, like the

Despite QTK Group focusing its research and development on the CF range and its variety of diesel HVAC models, Lowes says the supplier is set to turn back towards the zero-emissions market in 2026. Ahead of the Bus and Coach Expo in Sydney, Lowes is teasing some new products that offer alternatives for operators wanting to veer towards the decarbonisation side of transport.

“We have some exciting things in development in readiness for the evolution of electric vehicles,” Lowes says.

“We recognise the important part that our systems and components play in this space, all with the view to enhance vehicle performance and operator uptime.”

CF-1100A, are ideal for regional diesel bus and coach operators offering a variety of services, the broader CF range is suited to buses and coaches running in urban, city, school and route bus operations.

“Our CF range is a great offering

In a broader space, QTK is looking to also proudly affirm its unwavering commitment to the local bus and coach industry. Lowes acknowledges that the QTK team has evolved over all times, but, like most leading businesses do, he says QTK’s focus has never shifted away from “this wonderful industry”.

“Our customers remain at the heart of everything we do – every innovation we introduce is done so with the full support of Thermo King with our customers front of mind,” he says.

“As we look ahead, our promise is simple – QTK will continue to be a trusted partner, providing dependable climate solutions that keep fleets future ready and passengers comfortable on every journey.”

Above: QTK is growing its local focus with its CF range. Image: QTK

for a variety of bus operators, while our flagship KRS models, which are popular in the coach market, never seems to waver,” Lowes says.

“The KRS unit’s slimline profile maintains the coach’s aesthetics while delivering first-class performance.”

PHONE: 07 3712 7777

EMAIL: sales@qtk.com.au

MAKE: THERMO KING MODEL: CF1100A / CF1200A

MAKE: THERMO KING MODEL: E-1200LW

STANDARD INFORMATION

Compressor

MAKE: THERMO KING MODEL: KRS BRUSHLESS / KRS TROPICAL

Rated Capacity (kW) 29 /36

Capacity (kW) 35 /42

Consumption (kW) 87A / 107A (maximum)

Heating Capacity (kW) 30

(m3/hr) 5100 Condenser (m3/hr) Variable speed

Unit weight & dimensions Weight (kg) 188

(mm) 4287 / 4274 Width (mm) 1827 /1900

As operators shift to electric bus air conditioning, Spheros says the real differentiator won’t just be cooling capacity, but the strength and reliability of the service wrapped around it

Electric bus air conditioning has advanced rapidly in the past few years, but Peter Mercer says the technology story is only half the picture. For Spheros’ technical sales manager, the real pressure point for operators is finding long-term, consistent support in a sector where skilled technicians are increasingly scarce.

After years “on the tools” before moving into sales, he knows the strain firsthand.

“Honestly, the biggest thing is support,” Mercer told ABC “Industry-wide, it’s struggling. Everybody is struggling to get the work done.

“You need to find the right technical people with the knowledge to sort it out. Higher-level technicians are very scarce on the ground.”

He says that “while customers can select any brand of air conditioner to install on a new bus”, the real test comes years later.

“With some units currently on the market, there is a risk that spare parts will be difficult to obtain once production ceases or the supply contract expires,” he says.

That scarcity is shaping Spheros’ strategy in Australia. While the company is known globally for its electric bus air conditioning systems, Mercer says Spheros has deliberately expanded its local presence to ensure operators are never left without help.

The company has established a new service department in Sydney and is building in-house capability rather than relying solely on third-party agents.

“We’re taking the steps to actually take the personal Spheros leap into the service world,” he says.

“We’re a relatively small team,

but by focusing solely on Spheros products, we’re making sure we’re not spreading ourselves too thin.”

premium brushless fans, accessible components and an upgraded electric compressor.

“It’s easier to work on. Even something like changing a dryer doesn’t need welding,” Mercer says.

Mercer and technicians travel statewide, and interstate when needed, stepping in for issues that “you can’t solve over a phone call”. Training also plays a major part in Spheros’ support model once vehicles leave warranty. Mercer says customer technicians are encouraged to take over servicing when appropriate, backed by systems designed for simplicity.

“Our units are quite simple overall. They do the job they’re intended to do,” he says.

Fault codes can be read directly from the unit’s control display and, in some cases, from the chassis instrument cluster or telematics when connected to CAN.

Parts availability is another area where Mercer feels operators need more confidence as the national fleet electrifies. Spheros stocks parts across Australia to minimise downtime.

“It’s a high priority to have spare parts readily available. We can generally get parts anywhere within Australia, overnight between Sydney, Brisbane and Melbourne,” he says.

The company’s electric bus air conditioning units are engineered for both performance and maintainability. The latest REVO-E global generation uses a single refrigeration circuit to reduce complexity, with

Long-term parts support, Mercer says, is where operators need to be particularly vigilant. Because Spheros engineers and manufactures its own units globally, components remain available well after a model’s lifecycle ends.

Unlike others in the market, where there is no direct link between the retailer in Australia and the factory producing the AC systems, Spheros owns its factories internationally, engineers and produces its units worldwide. This shows that Spheros is fully committed to the bus and coach air conditioning market in Australia now and into the future.

With major metropolitan electrification programs gathering pace, Mercer sees the next decade as a turning point, one where reliable support will matter as much as technology.

“Depots need to understand what an actual electric air conditioner is. They operate differently from diesel systems. They need to be treated with the respect that comes with an electric machine,” he says.

For Mercer, that’s the heart of the shift ahead: not just newer systems, but stronger support wrapped around them.

MODEL: CC355

MODEL: CC450-490 STANDARD

MODEL: REVO®-E GLOBAL GEN 2

MODEL: REVO GLOBAL 400 STANDARD

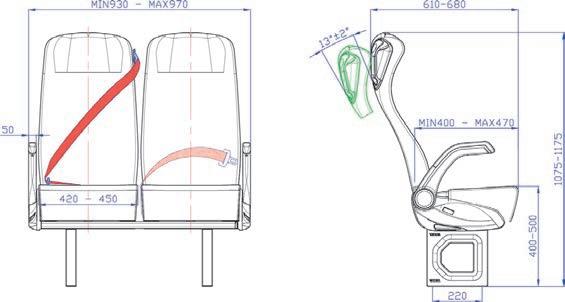

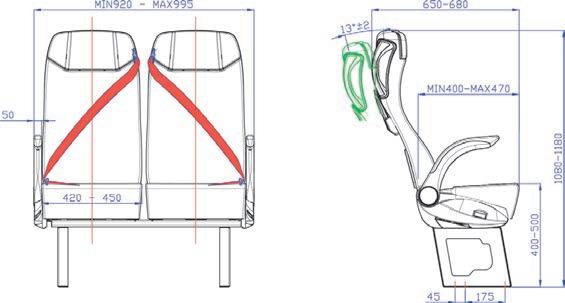

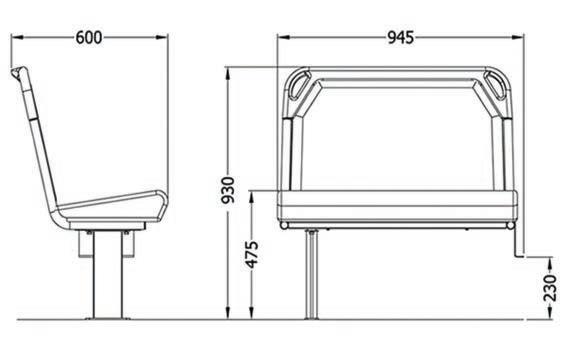

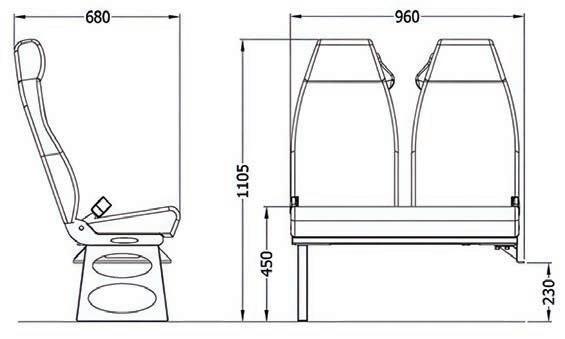

A year of innovating and enhancing the brand will see Sege Seats tease an exciting new bus seating concept in 2026

The past few years have been both busy and productive for Sege Seats, with the global seating manufacturer and supplier expanding across numerous regions. Now selling bus and coach seating models into more than 30 countries, the Australian division of Sege Seats has welcomed updates across both its product range and customer service capabilities.