AUTONOMY REVOLUTION CATALYSING THE manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS INSIDE >> MAY 2023 EOFY tax considerations 36 Official Industry Partners Training program for chains and hoists 34

manmonthly.com.au twitter.com/Manmonthly facebook.com/Manmonthly linkedin.com/showcase/manufacturer’s-monthly/

CEO: John Murphy

Chief Operating Officer: Christine Clancy

Managing Editor: Syed Shah

Editor: Billy Friend billy.friend@primecreative.com.au

Journalist: Mignon D’Souza mignon.dsouza@primecreative.com.au

Production Coordinator: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Kerry Pert, Tom Anderson, Louis Romero

Sales/Advertising: Danny Hernandez

Ph: 0431 330 232 danny.hernandez@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST)

Overseas prices apply Ph: (03) 9690 8766

Manufacturers’ Monthly Contents

Copyright Manufacturers’ Monthly is owned by Prime Creative Media and published by John Murphy. All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive

Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 3.06, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia

P: +61 2 9439 7227

Behind the cover

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

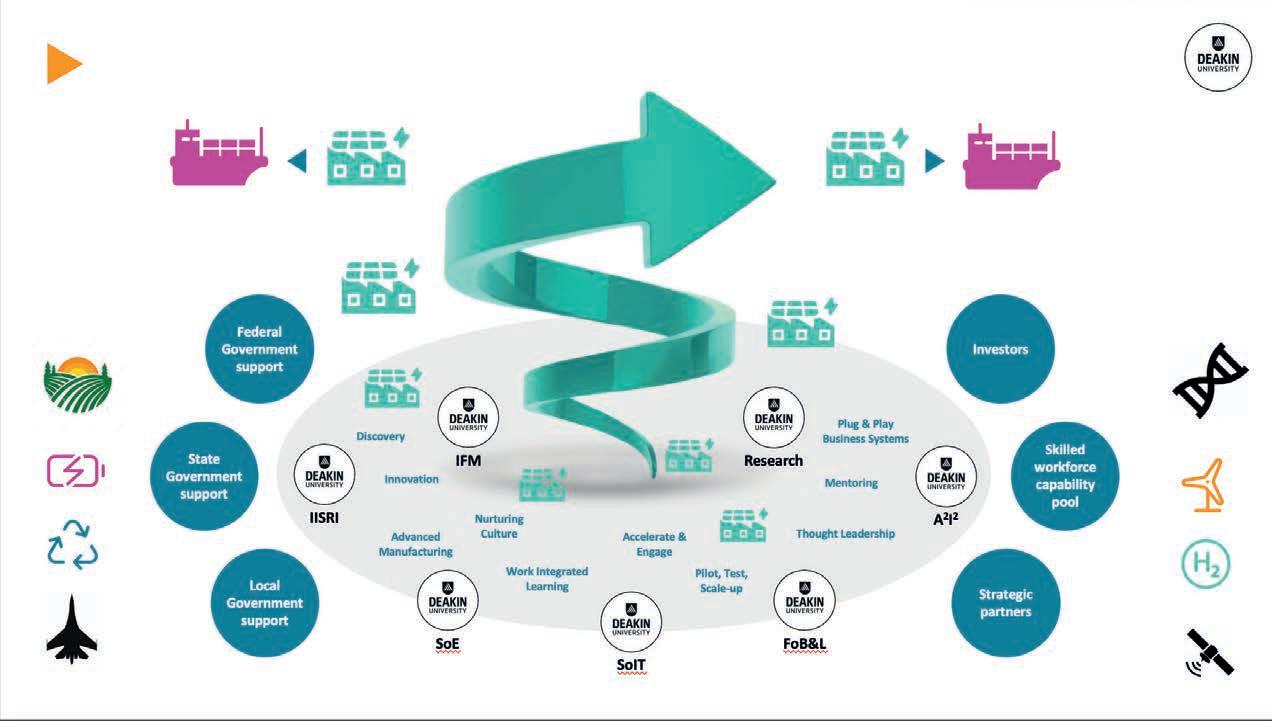

In the May edition of Manufacturers’ Monthly, we unpack a variety of trends and challenges facing Australian manufacturing, from tax incentives to securing supply of critical parts. Training the next generation is critical to our prosperity as an industry, so we hear from the team at Deakin University about the ManuFutures Hub. The project is designed with the aim of promoting innovation and collaboration between different stakeholders in the manufacturing ecosystem. This approach is not just about providing the latest equipment but also fostering a culture of collaboration, knowledgesharing, and innovation.

The facility is part of the university’s broader

strategy to create industry-academic partnerships that drive innovation and support the growth of the advanced manufacturing industry in Australia. The goal is to create an environment that supports the translation of research outcomes into practical, commercially viable solutions.

Elsewhere in the magazine, Kito PWB has launched a new training program, which educates buyers and operators about its extensive product line and safety procedures.

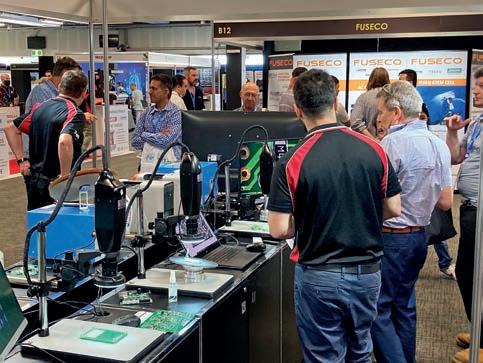

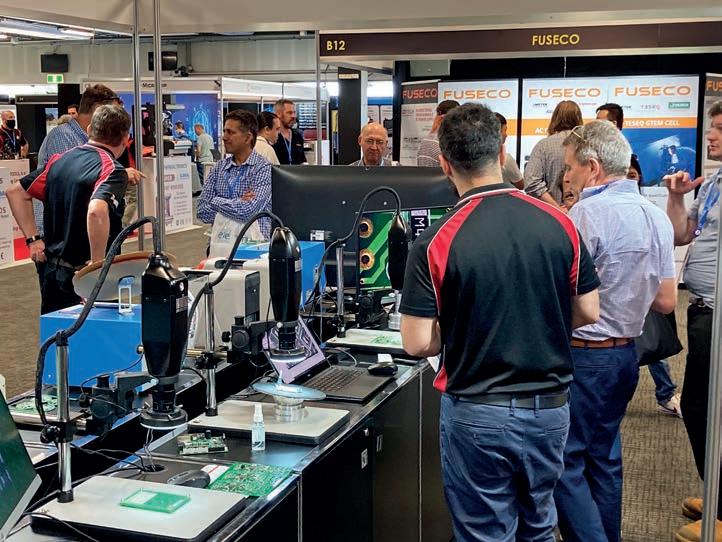

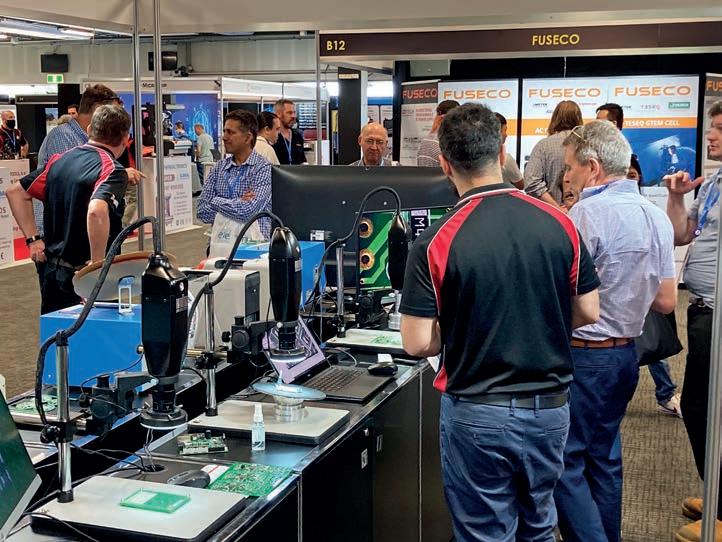

We also learn about two major events impacting manufacturing – the largest electronics expo in the country, Electronex, and the 2023 Workplace Health & Safety Show.

4 Editor’s Note 6 Comment 8 News 18 Manufacturer Focus 22 Engineering Focus 26 Additive Manufacturing 28, 44 Compressors 31, 42 Events 38 Industrial Gases 40 Aluminium Capability 46 Welding Gases 48 What’s New 50 Last Word 2 MAY 2023 Manufacturers’ Monthly manmonthly.com.au Inside MAY 2023 18

AUTONOMY REVOLUTION CATALYSING THE manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> MAY 2023 EOFY tax considerations 36 Official Industry Partners Training program for chains and hoists 34 Your single source steel and aluminium product, processing and service solutions provider National aluminium routing solutions As one of Australia’s leading national steel and aluminum distributors, BlueScope Distribution has the product range, processing capability, and technical expertise to deliver on your project requirements. shapes with precision, ease and accuracy. Combined with our we work closely with your business to deliver aluminium solutions Talk to our team about your aluminium processing requirement milling, holes, material labelling and coding, and much more! 13 72 82 Steel. Aluminium. Knowhow. Sydney Albury

22

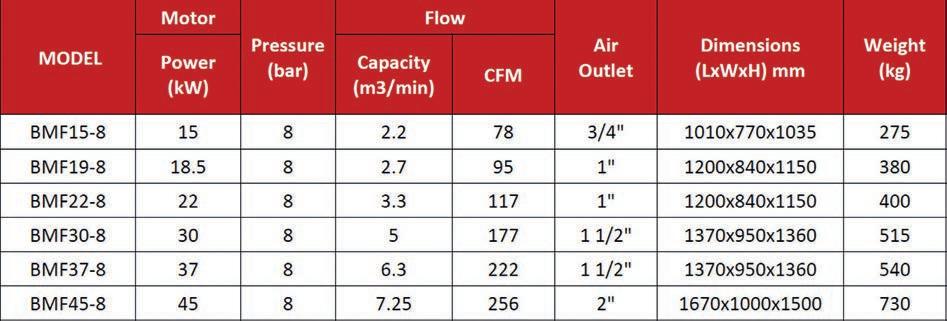

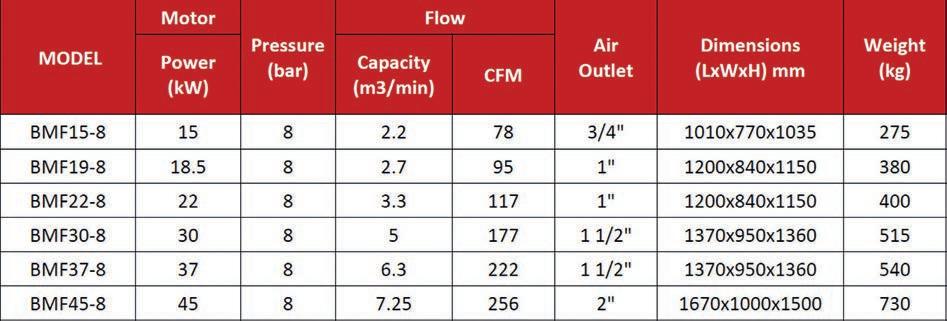

NEW BMF RANGE ENERGY EFFICIENT ROTARY SCREW COMPRESSORS

Introducing our new BMF range of rotary screw compressors with variable speed drive and permanent magnet motors. Enjoy maximum energy efficiency and performance while reducing operating costs.

• 15 to 45 kW

• Kubota engine

• 2 year warranty on the complete unit and a lifetime warranty on the airend (conditions apply)

Editor’s Note

Showcasing the art of engineering

WATCHING Melbourne’s Grand Prix event in early April, I reflected on the engineering expertise which is the cornerstone of the event. Having observed days earlier the Alfa Romeo team inside the garage work on a car which will travel over 300 kilometres per hour with relative ease, I gathered perspective for how remarkable advanced manufacturing can be. Formula One is a shiny example for the world to see, but so much of manufacturing has the same fascination, albeit from behind a public curtain.

As we head deeper into 2023, the Australian manufacturing industry contemplates what a proposed industrial

transformation might look like. The current government has made significant investments, including creating a $1.5 billion Modern Manufacturing Strategy and a $1.3 billion Manufacturing Modernisation Fund. How this all plays out largely remains to be seen, but success stories are already emerging of local manufacturers using government funds to grow their local business and compete on the world stage.

After being introduced in the budget last year, the historic passing of laws to establish the $15 billion National Reconstruction Fund (NRF) was recently announced by prime minister Anthony Albanese. Australia has demonstrated

advantages and ability in areas such as clean energy, automation and artificial intelligence, and the NRF is a platform for that to blossom over the next decade. Having the right skills in the workforce, a viable pipeline of companies ready to invest and potential blind spots in the policy are all challenges, but it is an exciting time for new technology.

Kate Pounder, CEO of Tech Council Australia, said the NRF can complement private sources of funding for building long-term strategic, emerging technologies and industries.

“This is a long-term, landmark investment that will help build Australia’s tech industries in strategically important

areas like quantum, AI, robotics and cyber security.

“The $15 billion investment in Australia’s industrial and technological capabilities has only become more important as we face global economic headwinds and continued geopolitical uncertainty.” There’s nothing revolutionary about this sort of role for government. Emerging industries and technologies have always been funded by a mix of private and public capital.”

In this month of Manufacturers’ Monthly, we continue to celebrate Australian Made by showcasing companies with a storied history in this country as well as new kids on the block. Happy Reading!

4 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

Formula One demonstrates the beauty of advanced engineering.

Image credit: EvrenKalinbacak / Shutterstock.com

BILLY FRIEND – Editor, Manufacturers’ Monthly

AIR LIQUIDE EXELTOP™ Trust in performance

Discover How.

Air Liquide’s new patented cylinder top will help you work safely, gain greater performance and save you time and money.

ESSENTIAL SMALL MOLECULES FOR MATTER

Comment

Renewable energy: challenges and opportunities for Australian manufacturing

THE Australian Government has legislated emissions reductions targets of 43 per cent (on 2005 levels) by 2030 and net zero by 2050. These targets are enshrined in law in the Climate Change Act 2022.

These targets will play a key role in limiting global temperature increases and ensuring Australia’s transition to a low carbon future, consistent with our commitments under the Paris Agreement.

Importantly, these targets will necessitate the construction of new infrastructure on a massive scale. Australia’s existing renewable energy generation of 64GW is forecast to grow to over 218GW by 2050. This will comprise 90GW of wind, 39GW of solar, 18.7GW of water, and 35.9GW of battery storage.

According to the Clean Energy Council, there are currently 106 renewable energy generation projects that are either under construction or due to start construction soon around Australia.

For example, it is expected that over 11,000 wind towers will need to be

produced, each requiring 500 tonnes of plate steel (for onshore wind towers) or 750 tonnes (for offshore wind towers). The annual production of plate steel in Australia is currently 400kt.

According to Australian Energy Market Operator’s (AEMO) 2022 Integrated System Plan, demand for steel from the electricity sector (NEM-wide) is likely to increase by approximately 50 per cent from 2021 to 2027. These demands equate to 8% of Australia’s annual crude steel production, most of which is needed for wind turbine towers.

To connect all this new generation to consumers, AEMO estimates that more than 10,000km of new transmission lines and 25,000 transmission towers (at 30 to 60 tonnes of steel per tower) will need to be constructed around the country.

To support this, the Government established the Rewiring the Nation project in the 2022-2023 Budget as part of the Powering Australia plan, with $20 billion in low-cost finance to expand and modernise Australia’s electricity grids at lowest cost.

A skilled clean energy workforce

However, while funding has been made available for the infrastructure itself, little consideration has been given to the skilled workforce that will be required. The only initiative announced so far is the New Energy Apprenticeships program.

The Federal Government has committed to spending over $95 million to support 10,000 new apprenticeships under the New Energy Apprenticeships program, and another $1 billion on a 12-month Skills Agreement that promises to deliver 180,000 Fee-Free TAFE places to priority groups in 2023.

The Federal Government recently added an extra 39 occupations to the Australian Apprenticeships Priority List. The list has grown to encompass 111 occupations, as Australia continues to struggle with skills shortages across a range of different sectors—particularly welding and fabrication.

Several occupations related to welding and fabrication were added to the Priority List, including Welder, Pressure Welder, Fitter, Metal Fabricator, Metal Machinist,

Metal Casting Trades Worker, Sheetmetal Trades Worker, and Blacksmith. In fact, 11% of the occupations included in the Priority List are now related to welding. Occupations on the Priority List are eligible for financial support through the Australian Apprenticeships Incentive System. A wage subsidy of 10 per cent is provided to businesses in the first and second year, and then it drops to 5 per cent in the third year. Up to $5,000 in direct payments is made to apprentices across two years.

While these initiatives will provide welcome financial incentives for both employers and their apprentices, this is just one small piece of the puzzle. These initiatives alone will not solve the skills crisis.

A veritable army of skilled workers

All this the renewable energy infrastructure will require a veritable army of skilled workers, including welders.

Australia’s renewable energy

6 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

GEOFF CRITTENDEN – CEO, Weld Australia

industry will need a raft of additional resources to deliver on these ambitious projects, including: manufacturing and fabrication capacity, raw materials (particularly steel), and contracting and contractor resources. Plus, new technologies will need to be developed and deployed.

The renewable energy industry will require huge volumes of fabrication in the coming years. While this represents enormous opportunities for Australia’s welding, fabrication and manufacturing industries, there are also enormous challenges ahead.

While our governments can wish, and hope, and make public pledges about Australia’s transition to renewable energy, we simply do not have the sovereign manufacturing capability to make this a reality.

The Federal Government and state governments can wish their renewable energy policies into existence, but without a massive investment in fabrication and steelmaking facilities, and skills and training in each state, it will not be achievable.

Local content policy

The main competition for Australian wind tower manufacturers are overseas suppliers from Vietnam, China and Indonesia. The issue is that the quality of imported wind towers is appalling. They do not adhere to Australian Standards. Local fabricators comply to internationally recognised Australian Standards and are certified by the relevant Australian authority. In this way, Government and private clients can ensure the quality and safety of projects. Imported steelwork, which does not meet these requirements, is often of inferior quality and may not meet the Australian safety requirements.

These quality and safety issues will only be exacerbated by increased global demand. The whole world is looking to transition to renewable energy.

Countries like Scotland, New Zealand and Sweden are all investing in wind power. Not only will increased global demand likely reduce the quality of wind towers manufactured overseas, it will also increase scarcity of supply. There are already global supply chain issues— imagine how these will be magnified.

& Hayward cannot win jobs on their doorstep when governments and multinational companies place a premium on price over and above quality and safety.

The Federal Government must commit to building sovereign manufacturing capability for renewable energy—in the same way that it has for shipbuilding. The Federal Government must legislate local content policy. This will create a capacity mechanism that generates a clear, longterm signal for investment by private equity and local manufacturers. The Federal Government must also mandate that all wind towers are constructed, erected and inspected according to Australian Standards.

To overcome the established overseas supply chains and generate investment into fabrication capability, local manufacturers need certainty of demand. This demand must stem from government, project investors and developers, and OEMs. Local manufacturing companies must be assured of the security of sufficient orders to enable them to invest in the necessary plant and equipment to deliver high quality, cost effective wind towers.

Our governments must support macro demand generation. For example, the Victorian Government’s Victorian Renewable Energy Target (VRET) legislation has helped to support the domestic manufacturing industry. In addition, local content policy must

be legislated. Given the huge scale of potential demand, local content need not be 100 per cent—VRET required 64 per cent local content and 93 per cent locally milled steel. With this long-term demand a reality, local manufacturers will have the confidence improved production efficiencies and stability of supply can improve competitiveness.

Only with this commitment in place will industry have the confidence to invest. Unless industry and governments come together now to formulate a plan of attack, when the time comes to manufacture the assets needed for a clean energy transition, there will be no fabrication facilities, no skilled workforce, and no regulatory frameworks in place. There will be no sovereign manufacturing capability.

National Manufacturing Summit

Given the sheer volume of challenges and opportunities on the horizon in the renewable energy industry, Weld Australia, in conjunction with the Australia Institute’s Centre for Future Work, will host the National Manufacturing Summit at Parliament House in August.

With the theme of Renewable Energy: Challenges and Opportunities, the aim of the Summit is to help industry leverage the opportunities currently available in the renewable energy sector, and translate these into action.

The Summit will gather industry leading representatives from all the major stakeholders in Australia’s manufacturing sector—business, unions, universities, the financial sector, suppliers, and government—to discuss the sector’s prospects, and identify promising, pragmatic policy measures designed to support an industrial turnaround. Government Ministers and international experts will delve into the challenges and opportunities of the renewable energy revolution.

Stay tuned for further information, including registration via the Summit website: https://manufacturingsummit. com.au.

Renewable Energy Infrastructure Group

Weld Australia is also proposing to establish a Renewable Energy Industry Group. It will bring together existing generators, new players, manufacturers, suppliers, specialists and consultants to: Share knowledge experience, and learnings

Discuss and workshop renewable energy issues Network and collaborate with likeminded industry colleagues

If you’re interested in joining the Renewable Energy Industry Group, please contact Andrew Davies (Manager Technical Industry Networks, Weld Australia) on a.davies@weldaustralia.com.au.

Local manufacturers like Keppel Prince Engineering and Crisp Bros.

Local manufacturers like Keppel Prince Engineering and Crisp Bros.

manmonthly.com.au Manufacturers’ Monthly MAY 2023 7

Weld Australia says government initiatives alone will not solve the skills crisis.

What AUKUS means for manufacturing

Prime minister Anthony Albanese has announced the biggest industrial undertaking in Australia’s history alongside British PM Rishi Sunak and US president Joe Biden.

Together in the US, the three leaders emphasised the industry-building aspects of the tri-lateral plan to jointly develop and build nuclear-powered submarines.

In total, Australia will end up with eight of the new nuclear submarines, called SSN-AUKUS.

The current price tag for the entire submarines plan is between $268 billion and $368 billion over the next 30 years.

That includes $8 billion to upgrade the naval base HMAS Stirling in Western Australia as well as $2 billion over the next four years to upgrade the Osborne shipyards in South Australia.

The Federal Government has said the phased approach will result in $6 billion invested in Australia’s industrial capability and workforce over the next four years, creating around 20,000 direct jobs over the next 30 years.

Prime minister Albanese said AUKUS is a historic investment in Australian people and would strengthen the nation’s national security and deliver a superior defence capability into the future.

“We will partner with the United States and the United Kingdom to build the next-generation submarine. They’ll be built by Australians, commanded by the Australian Navy and sustained by Australians in Australian shipyards. In the meantime, we’ll be training and upskilling our people through increased visits and rotational presence from US and UK submarines,” he said.

“With construction beginning this decade, we’ll train more engineers, scientists, technicians, submariners, administrators and tradespeople. Already, Australian personnel are upskilling on nuclear propulsion technology and stewardship alongside British and American counterparts.”

The South Australian Submarine Construction Yard created for the build of the next-generation nuclear-powered submarines will be almost three times larger than the yard forecast for the Attack class program.

At its peak, up to 4,000 workers

will be employed to design and build the infrastructure for the Submarine Construction Yard in Osborne, South Australia.

A further 4,000 to 5,500 direct shipyard jobs are expected to be created to build nuclear-powered submarines in South Australia when the program reaches its peak. This does not include the additional jobs created in the supply chain for the construction or sustainment of submarines.

“The significance of this moment cannot be overstated,” said SA premier, Peter Malinauskas.

“The AUKUS submarines will be the most complex machines that have ever been built in human history. But it is not just the thousands of workers to be employed at Osborne who will benefit. This is a transformational opportunity to increase our economic complexity. We now have a massive task ahead of us to prepare the highly skilled workforce to capitalise on this historic opportunity.”

Innes Willox, chief executive of the national employer association Ai Group said, “Delivering maximum benefit for Australia from this historic agreement will require the highest level of cooperation

between governments, defence and industry.

“Now the deal has been inked, the next major priority for the AUKUS governments will be to work to reduce the trade, regulatory, and bureaucratic barriers that could hinder the historic partnership, to create a cohesive industrial base and build the required workforce. These are among the important issues that must be addressed to underpin AUKUS success,” he explained,

“The AUKUS partnership is much more than submarines. Australia is making a massive technological commitment as part of the agreement. There will be extensive spill-over benefits in technological advancement and technology sharing including around artificial intelligence and quantum technology with its promise of major developments in weapons, communications, sensing and computing technology.”

Willox said it was vital that strong benefits from the AUKUS collaboration are captured for domestic industry.

“We will be looking closely at the details around the local build and

The submarine plan will cost between $268 and $368 billion.

domestic supply chain aspects of the overall program to ensure that these benefits are realised.”

AUKUS industry associations –consisting of Ai Group and the US Aerospace Industries Association (AIA) and ADS, the UK trade association for aerospace, defence, security and space organisations – have agreed on the following priorities for the agreement:

1. 1Enhancing trade and technology transfers;

2. Eliminating bureaucratic and regulatory barriers impeding the timely delivery of capabilities;

3. Building shared, robust, and resilient trade and contracting systems; and

4. Sharing workforce talent and expertise and strengthening international collaboration Greens leader Adam Bandt took to social media to say the $368 billion for nuclear submarines could be used for other priorities.

“Politics is about priorities and choices. With $368 billion we could get: free childcare, mental and dental healthcare into Medicare, fully free public schools, student debt wiped.”

8 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

News @MM

Battery manufacturing key for Australia’s transition to net zero

Minister for industry and

science

Ed Husic said large-scale uptake of battery storage and battery manufacturing will be vital in the nation’s transition to net zero and to Australia becoming a world leader in clean energy.

Husic said the CSIRO Renewable Energy Storage Roadmap released yesterday shows major investment in storage technologies is needed to meet the growing demand for cheaper renewable power.

“The Government recognises the pivotal role that cheap, widely available energy storage will need to play in the transition to renewable power. That’s why the Government is delivering the Australian Made Battery Plan, spearheaded by the development of Australia’s first National Battery Strategy.

“By 2030, the battery manufacturing industry has potential to be worth nearly $17 billion and create more than 61,000 jobs, according to the Charging Ahead report from the Future Battery

Industries Cooperative Research Centre.

“As the CSIRO roadmap emphasises, we need a pipeline of projects using diverse technologies to unlock the full potential of our renewable energy resources.

“That means there’s a huge opportunity for new systems and technologies to be developed here to manage the production, storage and use of renewable energy.

“The private sector is keen to invest in these innovative storage projects crucial for Australia’s energy transformation, and we’re committed to supporting efforts to bring these projects forward.

“That’s why we are working closely with the states and territories, and consulting widely with industry, the community, academia and experts to shape the National Battery Strategy.”

In welcoming the CSIRO roadmap, Minister Husic added “this report is a great example of the sort of work the CSIRO should be undertaking –

harnessing Australia’s science and research capabilities to tackle major national challenges and grow new industries.”

The Government said it continues to implement other initiatives focused on bringing cheaper renewable energy to homes and businesses and meeting Australia’s international emissions obligations.

This includes reaching 82 percent renewables in Australia’s energy grid by 2030, which will be achieved through the $20 billion Rewiring the Nation Fund through deals with states and territories, as well as unlocking around $10 billion of investment in clean dispatchable power through the Capacity Investment Scheme.

To equip businesses with the skills and technology they need to locally manufacture renewable energy technologies such as batteries, the government is creating a Powering Australia Industry Growth Centre.

manmonthly.com.au Manufacturers’ Monthly MAY 2023 9

News @MM www.boge.net.au or (03) 5940 5913

High pressure piston and booster up to 40 bar(g)

Oil free scroll compressors Medical, instrument, dental

NEW generation series-4 screw compressors up to 160kW

For sales and service support contact your nearest

partner NEW refrigerant

air

with sustainable, efficient and

From 15-6,000

NEW full feature oil injected screw compressors 4-22kW

BOGE

compressed

dryer

smart operation

cfm

Ed Husic wants Australia to become a world leader in clean energy.

News @MM

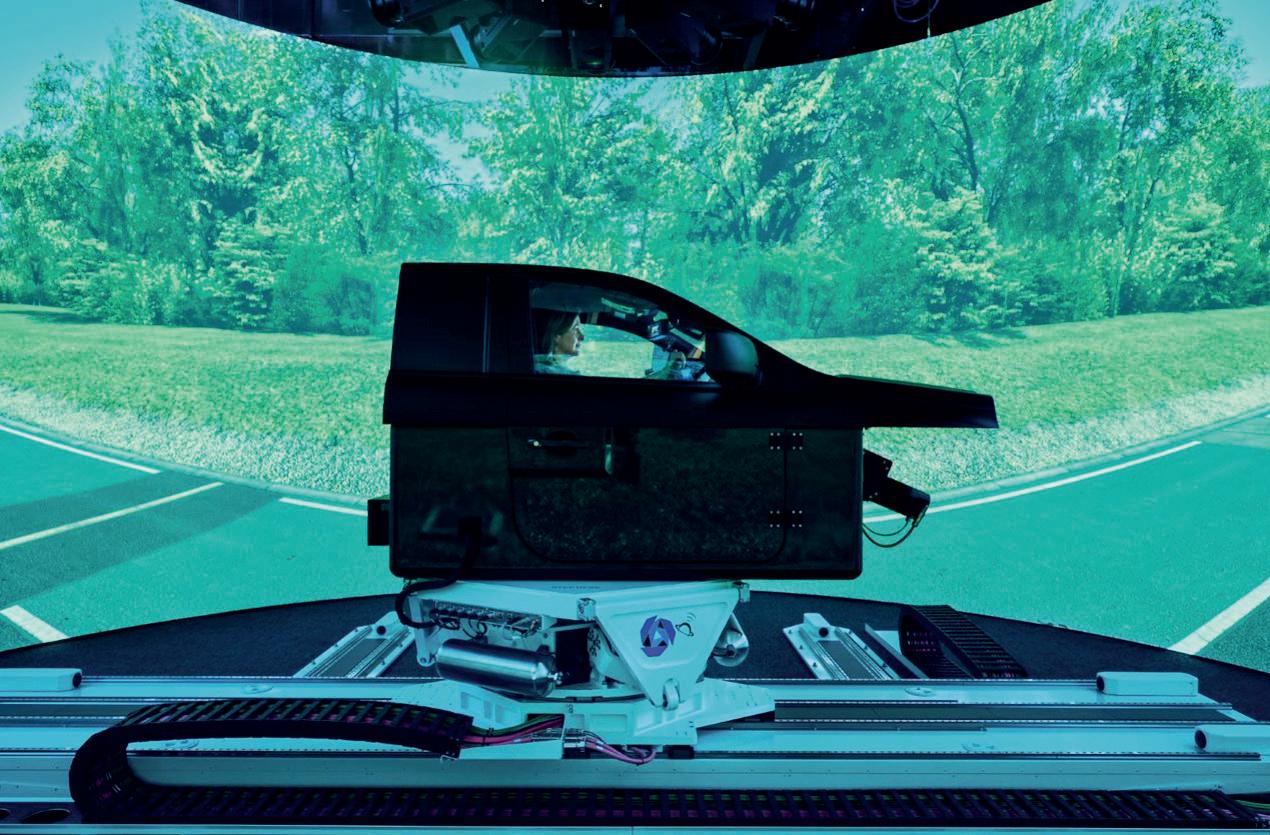

Deakin launches Australia’s most advanced motion simulator

The $9 million simulator is designed to provide advanced research and innovation opportunities for mobility technologies and industry sectors.

Minister for higher education Gayle Tierney today unveiled the simulator at Deakin University’s Institute for Intelligent Systems Research and Innovation (IISRI).

The Genesis Simulator is one of the most advanced mobility simulators in Australia and the only one of its kind in a university in the world.

The simulator will fast-track transport prototyping and improve driver safety and training by supporting complex research into mobility and industry needs, automotive testing and design.

The five-metre-tall 360-degree screen

creates an immersive and realistic experience for researchers to assess how different environmental and vehicular conditions affect specific driving conditions.

This advanced technology will boost training opportunities for students, researchers and industry across Victoria –supporting the pipeline of skilled workers ready to build the future manufacturing industry.

The state government has said it backs Geelong as a global innovation centre of automotive-based research and innovation, with this new project supporting more than 20 jobs, internship opportunities and Higher Degree by Research projects.

The Genesis Simulator was funded by the government’s $350 million

Victorian Higher Education State Investment Fund (VHESIF), developed to help universities respond to the significant impact of the COVID-19 pandemic. The Victorian state government will invest $5 million in the simulator as part of the fund.

The fund supports universities with capital works, applied research and research infrastructure focused on boosting Victoria’s productivity.

“The new Genesis Simulator will boost our existing skills and knowledge in vehicle manufacturing – driving innovation and creating world-first solutions,” Tierney said.

“This will lead to ground-breaking research partnerships with companies and industry bodies across the automotive sector, emergency services,

transport companies, and health bodies.”

Minister for manufacturing sovereignty Ben Carroll said, “Victoria is Australia’s manufacturing state –employing more than 260,000 people. That’s why we’re making sure our local workforce have the skills they need to power our economy.”

Deakin University deputy vicechancellor research Professor Julie Owens, said, “IISRI has more than 15-years’ experience in motion simulation research and is home to Australia’s biggest multi-disciplinary team of world-class mobility researchers and PhD students. Deakin University is excited to launch our new Genesis simulator to support new industry partnerships, research and innovation.”

10 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

The Genesis advanced mobility simulator.

Glyde Metal Industries wins bid for 2023 Australian Grand Prix

The Australian Grand

Corporation required a wide variety of parts and assemblies to be locally manufactured and supplied in

preparation for the Grand Prix in Melbourne

The Australian Grand Prix attracted thousands of visitors and international attention this year.

For the event, Glyde Metal Industries brought its expertise and experience in steel fabrication, supplying debris fences, poles for timing equipment, bridge upgrades, and on-site fabrication. With 25 years of continuous ISO9001 accreditation, Glyde Metal Industries said it is proud to have been chosen for this major project.

“We are thrilled to have been chosen as the supplier for the 2023 Australian Grand Prix,” said general manager, Mark Wood.

“We take pride in our ability to provide high-quality steel fabricated components and services, and we are confident that we can meet the needs of this prestigious event.”

manmonthly.com.au Manufacturers’ Monthly MAY 2023 11 → Cobot welding and cutting systems. → NEW intelligent gas mixer analyser. → Gas supply options from VIPR cylinders to POD portable on-site vessels and beyond. → High-performance laser gases, shielding gases and gas management systems. → The Xnet welding quality management system → The latest range of high-quality German welding machines from ewm. → The total welding emissions management portfolio. BOC Limited 10 Julius Avenue, North Ryde NSW 2113 BOC is a trading name of BOC Limited, a Linde company. © BOC Limited 2023. MP23-0628-2 FDAUS | 0323 Making you more productive. Visit us at Australian Manufacturing Week 9–12 May, stand WA340. To find out more call 131 262 or visit www.boc.com.au 26424 MM Half Page AMW Advert D2.indd 1 29/3/23 2:46 pm News

Victorian manufacturer Glyde Metal Industries were the successful bidder to supply steel fabricated components and services to the Australian Grand Prix Corporation.

@MM

Prix

Steel fabricator Glyde Metal Industries supplied this year’s Melbourne Grand Prix.

News @MM

Senate passes $15 billion NRF bill

Prime minister Anthony Albanese announced that the National Reconstruction Fund (NRF) bill has passed the upper house, calling it “one of biggest-ever investments in Australian manufacturing”.

The Federal Government’s $15 billion National Reconstruction Fund will now be established in law, after passing the House of Representatives earlier this month.

“Australia has all the resources that go into solar panels, batteries and other finished products. We should be making them here. And that’s what this investment is all about. It will mean more secure jobs and more world-class products made in Australia,” Albanese said.

“Recognising that during the

pandemic, our vulnerabilities at the end of supply chains were exposed for all to see. We’ve been very good at exporting our resources and should continue to do so.

“But where possible, we should be value-adding, creating jobs here, particularly in our regions and in our outer suburbs. And this is about manufacturing. It’s about making sure that we make more things here, that we’re less exposed to the supply chain issues which we continue to see placing pressure on inflation,” the prime minister added.

The NRF was announced by the government in the Federal Budget for October 2022 and will invest $15 billion across priority areas of the economy including renewables and

low emissions technologies, medical science, transport, value-adding in resources, value-adding in agriculture, forestry and fisheries, defence capability and enabling technologies.

Minister for industry and science Ed Husic said it is a big day for Australian industry and for Australian jobs, from our outer suburbs through to the regions.

“We want to create good, secure work for Australians and being able to rebuild Australian manufacturing. It’s time for us to get up off the mat.

“This fund, the National Reconstruction Fund, is about Australians backing Australians in terms of pursuing those ideas. It’s from the factory floor to the lab bench to the boardrooms of this country,

making sure that we’ve got that huge growth capital available to unlock what is really important for the economy and jobs long-term. And the National Reconstruction Fund will be the greatest investment in manufacturing capabilities in living memory.”

Minister for finance, Katy Gallagher, said, “After a decade of uncertainty, the National Reconstruction Fund will support Australian innovation and industry. More things being made here means more jobs for Australians.”

The NRF will be administered by an independent board making independent investment decisions. It is modelled on the successful Clean Energy Finance Corporation.

Senate amendments will now return to the House of Representatives.

12 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

The NRF aims to build Australia’s sovereign capability across multiple sectors.

News @MM

Professor Alex Brown joins CSIRO Board

The Australian Government has appointed Professor Alex Brown to CSIRO’s board of directors, becoming the first Indigenous scientist to serve on the national science agency’s board.

An internationally recognised clinician and researcher with a background in Aboriginal and Torres Strait Islander health, Professor Brown is the Professor of Indigenous Genomics at the Telethon Kids Institute and the Australian National University.

A proud member of the Yuin nation, Professor Brown is the first Indigenous

scientist appointed to the CSIRO Board, bringing a wealth of experience in understanding and overcoming health inequalities and bridging connections across science ecosystems.

Minister for industry and science

Ed Husic said Professor Brown’s appointment puts First Nations representation at the heart of Australia’s national science agency.

Minister Husic said Professor Brown’s appointment would bring a wealth of experience to the Commonwealth Scientific and Industrial Research

Organisation (CSIRO) and signals generational change on the Board.

“Professor Brown has dedicated his research career to understanding and overcoming health inequalities experienced by Aboriginal and Torres Strait Islander Australians, particularly the burden of chronic conditions,” Minister Husic said.

“While he is the first Indigenous scientist appointed to the CSIRO board, I know he won’t be the last.”

The CSIRO Board is responsible to the Australian Government for the overall

strategy, governance and performance of CSIRO.

“His experience in working with Aboriginal communities and bridging connections across science ecosystems will strengthen the CSIRO’s leadership,” Husic said.

“The appointment of Professor Alex Brown will help address skills gaps identified by the Board, facilitate greater collaboration between research agencies and universities, and ensure CSIRO’s future direction benefits from being more inclusive.”

14 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

Alex Brown is the first indigenous scientist to serve on CSIRO’s board.

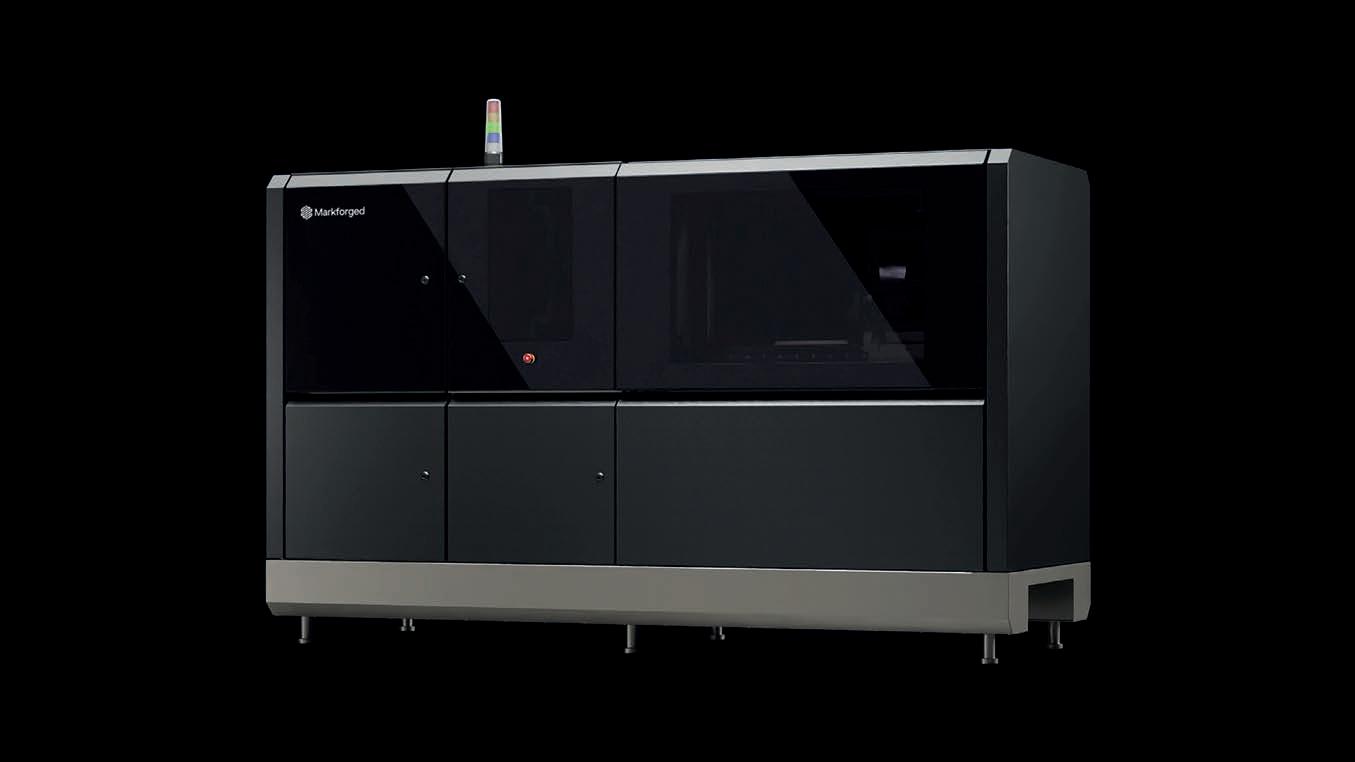

Get your Complimentary 3D Printed Part*

Are you looking to innovate faster and reduce supply chain issues by 3D printing everything from prototypes to end-use parts?

We got you covered!

At Markforged we are on a mission to bring industrial manufacturing to the point of need. To help manufacturer reduce lead time we are offering a Complimentary 3D Printed Part*, for a limited time only, to encourage manufacturers to improve their production processes. See for yourself the unmatched surface finish, strength and precision of our 3D printed parts in metals and continuous-fiber reinforced composites.

Claim your Complimentary 3D Printed Part* by simply scanning the QR code and filling out the form. Our Engineers will be in touch!

* T&C Only organizations with relevant use cases qualify for the Complimentary 3D Printed Part at the discretion of the Markforged Application Engineer. By subscribing to the Complimentary 3D Printed Part campaign you agree for Markforged to use the part for marketing purposes. Offer valid in Australia.

Space industry partners chosen for Australia’s first Moon mission

The AROSE consortium and the EPE and Lunar Outpost Oceania consortium will receive $4 million each from the Australian Government’s Moon to Mars Trailblazer Initiative.

Minister for industry and science, Ed Husic, along with dignitaries from the Australian Space Agency and the National Aeronautics and Space Administration (NASA) made the announcement earlier this week.

The two consortiums will design rovers for Australia’s first mission to the Moon in partnership with NASA. Each winning consortium is made up of a mixture of Australian industries, space start-ups, major resource companies, universities, and other research partners.

The rover will collect lunar soil from the Moon and deliver it to a NASA payload which will attempt to extract oxygen from the sample.

The rover is part of the NASA Moon to Mars mission which will be a major step

towards a sustainable human presence on the Moon and supporting future missions to Mars. It aims to launch by 2026.

In a continuing sign of the close cooperation between Australia and the United States, NASA administrator Bill Nelson and deputy administrator Pamela Melroy are visiting Australia, the first visit of a sitting NASA administrator since 2014.

“It is great that, with this announcement, Administrator Nelson will get to witness first-hand the extensive knowledge and capability in our space sector, as well as robotics and automation more broadly,” Husic said.

“From those selected to be part of the Trailblazer program, to other industry success stories and our impressive universities and research organisations, Australia has much to be proud of. Programs like Trailblazer are important to growing our space sector, as well as our know-how in robotics and

automation. It also has an important role to play in inspiring more young Australians to consider STEM careers.”

Nelson said he was excited to be working with Australia on this important lunar mission.

“It’s cooperation like this that will enable NASA and our international partners to uncover more discoveries. In this new era of space exploration, every advancement is not an achievement for one country – but for all of humanity.”

Head of the Australian Space Agency Enrico Palermo said this announcement is another step toward Australia’s first mission to the Moon.

“From those selected to be part of the Trailblazer program, to other industry success stories and our impressive universities and research organisations, Australia has much to be proud of. Programs like Trailblazer are important to growing our space sector, as well as our know-how in robotics

and automation. It also has an important role to play in inspiring more young Australians to consider STEM careers.”

The Trailblazer program will help further develop Australia’s robotics and automation capability, aligning with the development of the Australian Government’s National Robotics Strategy.

The EPE and Lunar Outpost Oceania consortium’s lead organisations include BHP, Northrop Grumman Australia, RMIT University’s Space Industry Hub, and University of Melbourne’s Space Laboratory. University of Adelaide, Inovor, Australian National University, Element Robotics, Colorado School of Mines and Saber Astronautics will provide specialist contributions, and Australian Industry Collaborators include Titomic, One Giant Leap, VI AROSE’s consortium is led by Fugro and Nova Systems, with additional support provided by Woodside Energy and Rio Tinto and the Western Australian Government.

16 News @MM

The Moon to Mars Trailblazer Initiative seeks to progress Australian space exploration with remotely operated and autonomous Australian robotic lunar assets.

Cremorne Digital Hub boosts digital innovation in Victoria

The Cremorne Digital Hub is entering a new phase in its development, with the appointment of a new CEO and board, building on Cremorne’s transformation from a manufacturing centre to a magnet for high-tech businesses and innovation jobs.

The Hub aims to strengthen Victoria’s tech offering by encouraging

cross-industry collaboration, growing investments and nurturing the state’s talent and skills. Over 700 businesses and around 10,000 workers are already based in the precinct.

Cremorne contributes more than $4 billion to the state’s economy each year and is already home to some of Australia’s most successful tech

companies, including Carsales.com, SEEK, REA Group and MYOB.

Through its $50 million Cremorne Venture Fund – to be managed by Artesian – the Hub will also play an active role in commercialisation by investing in exciting new digital companies that can take Victorian innovation to the world.

International business leader Mark Sims has been named as CEO and prominent corporate executive and investor Monique Conheady will serve as inaugural chair of the Hub – which was established with support from the Victorian state government.

Sims has worked for numerous Fortune 100 companies and previously served as chief operating officer for Hong Kong-based EdTech company Xccelerate.

Conheady is the co-founder of Australia’s first carshare service Flexicar and chair of JET Charge, provider of electric vehicle charging infrastructure.

Joining her on the board are chief executive of the Melbourne Chamber of Commerce Scott Veenker and cofounder of Artesian and Boab AI Matthew Clunies-Ross.

Shareholders Carsales.com, investment firm Artesian and Melbourne, RMIT and La Trobe universities will also work together on the Hub’s development to boost collaboration between academia and industry.

Minister for Industry and Innovation

Ben Carroll said, “Cremorne is at the heart of Victoria’s digital boom, and we’re backing the Hub to play a critical role in boosting up our tech sector and attracting more investment and jobs to Victoria.

“We welcome Mark Sims and the other highly experienced business and tech leaders to the Cremorne board, knowing they can champion our state’s tech sector and propel Victoria to the forefront of digital innovation.”

News @MM

manmonthly.com.au Manufacturers’ Monthly MAY 2023 17

The Cremorne Digital Hub helps commercialise new digital companies.

Manufacturer Focus

Navigating the future

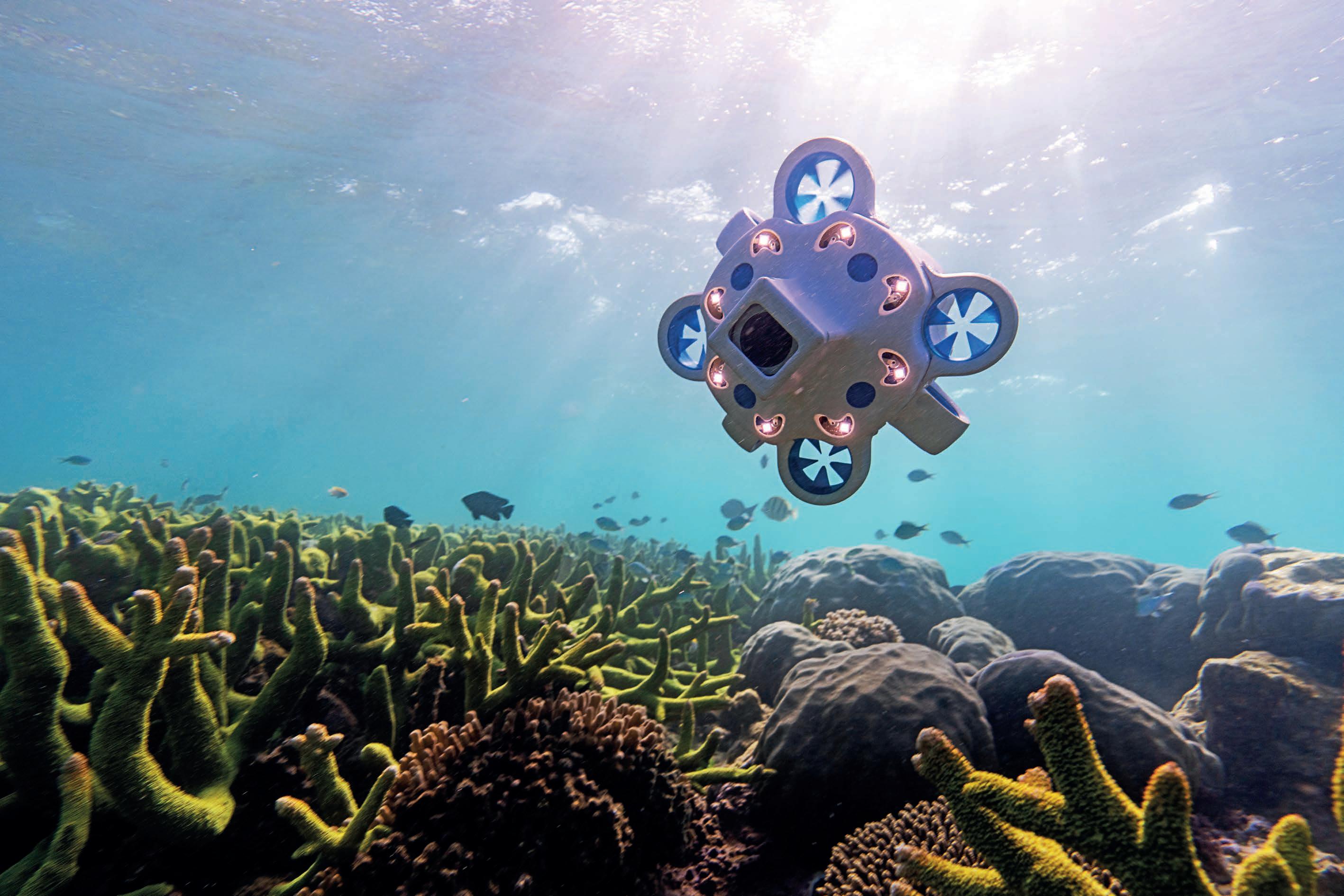

Advanced Navigation is building on its reputation for making ground-breaking inertial navigation systems for land, sea and air. Billy Friend catches up with CEO and co-founder Xavier Orr to learn about the company’s core products and how AI research at university led to deals with Google, Apple and Airbus.

18 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

IN 2008, Xavier Orr was digging deep into the world of neural networks in his final year of artificial intelligence studies at the University of Western Australia. He discovered navigation systems in our phones, cars and homes were using an algorithm from 1967, known as the Kalman filter. This prompted the student to explore an alternative approach to the outdated technology – he completed his thesis on a neural network AI approach to navigation. Like any bright idea, it needs a whole lot of work before it is ready to be commercialised, so Orr spent the next couple of years honing in on the concept.

In 2012, Orr met with co-owner Chris

ManufacturerFocus

Shaw to commercialise the technology, and Advanced Navigation was born. Advanced Navigation began with inertial navigation systems and continued to broaden its scope to sonar and photonics. Today, the Australian-based company is making moves in the futuristic worlds of self-driving cars, aerial drones, space launch vehicles and robotics. The algorithm can be used with sensors in any environment, opening up a huge range of applications for the technology.

Advanced Navigation sensor products are sold into commercial and defence industries spanning sea, land, air and space. Two manufacturing facilities in Sydney as well as a larger factory in

Perth work in conjunction with subcontractors around the country to make the innovative range of products. The cCompany’s AI approach allows its solutions to have greater accuracy and reliability while maintaining a small form factor. Today, Advanced Navigation’s solutions are adopted by some of the world’s largest technology companies and defence prime contractors, including Thales, BAE Systems, Raytheon and Lockheed Martin.

“Defence is one of the many sectors we serve, our products are well suited because they are designed to aerospace standards,” Orr said. “They weren’t designed specifically for defence but the

applications of the products are where reliability is absolutely critical. They’ve been built to that extreme level which is why they’re suited to defence as well as commercial markets.”

From farfetched perceptions not long ago, driverless cars, ground robots delivering mail and air taxis are on the horizon. Solène Le Bris at Paris airports operator Groupe ADP recently announced ambitions to launch the first e-VTOL (vertical takeoff and landing) precommercial service in the world in time for the 2024 Paris Olympics. The initiative will use the existing helicopter route network to fly with one passenger and one pilot along two routes, taking short

manmonthly.com.au Manufacturers’ Monthly MAY 2023 19

Manufacturer Focus

rides from Charles de Gaulle airport to Le Bourget then to a new landing pad at Austerlitz Paris, and another route from Paris to Sans-Cyr.

As for driverless cars, predictions of the technology being more commonplace have been around for years, to which Orr noted that regulatory hurdles are the last bridge to cross.

“I think we’re going to see the regulatory walls come down in the next five years,” he said. “We’ll start to see strong adoption for driverless cars. Advanced Navigation supplies to pretty much all the fully autonomous cars right now, so we will obviously grow as the market grows.”

As for Australia, Orr said it’s an exciting time for automation and robotics.

“We are starting to adopt the technology more,” he said. “We’re seeing the drone delivery trials in Canberra. The Civil Aerospace Safety Authority (CASA) are starting to allow beyond visual line of sight (BVLOS) drone operations for the first time and we’re seeing driverless car trials across Australia. There’s a lot of government funded programs supporting automation and robotics, and we’re seeing a lot of uptake which is really exciting.”

Being at aerospace and automotive quality control level for its products, testing is of utmost importance. Orr explained that there can be anywhere up to 300 individual tests run on one component before it leaves the factory.

“A lot of the components in our factories and manufacturing houses areis automated all the way from manufacturing through to the quality assurance and testing. We want to minimise the handling time but also really increase the level of quality assurance through automation.”

At the core, Advanced Navigation is determined to be the catalyst of the autonomy revolution. Orr and his team have experienced a rapid rise, which was accentuated by a $108 million Series B funding round at the end of last year. Leading global investment firm KKR announced the funding included participation from new investors such as deep learning venture firm AI Capital and existing

investors, including Main Sequence and the Hon. Malcolm Turnbull AC. With the latest Series B raise, Orr said he expects to spend a significant amount of R&D funding working inhouse and with engineering experts, partners and global institutes on robotic, photonic and quantum sensing technologies.

“We’ve experienced 100 per cent growth for the last few years and seen really strong adoption,” he explained.

“With extreme levels of interest for products developed in the last year it felt like the right time to do a big expansion to grow our international sales and support the disruptive products we have in development.

“This next phase of growth is to help us be a driving force in the autonomy revolution. KKR has significant experience investing in emerging technologies, so we are thrilled to have them lead our Series B funding round and work alongside our team to advance our product and technology innovation and development.”

The funding follows a $20 million Series A round in 2020 led by Main Sequence Ventures’ CSIRO Innovation Fund, which supported a global expansion for Advanced Navigation to accelerate research and development programs for transformative new robotics, navigation, and sensor technologies.

“We are really excited to be pushing forward on our mission to catalyse the autonomy revolution,” Orr added. “There’s a lot going on in Australia right now with autonomy and robotics and Advanced Navigation is really at the forefront of a lot of that. This funding allows us to really turbo charge us on our mission.”

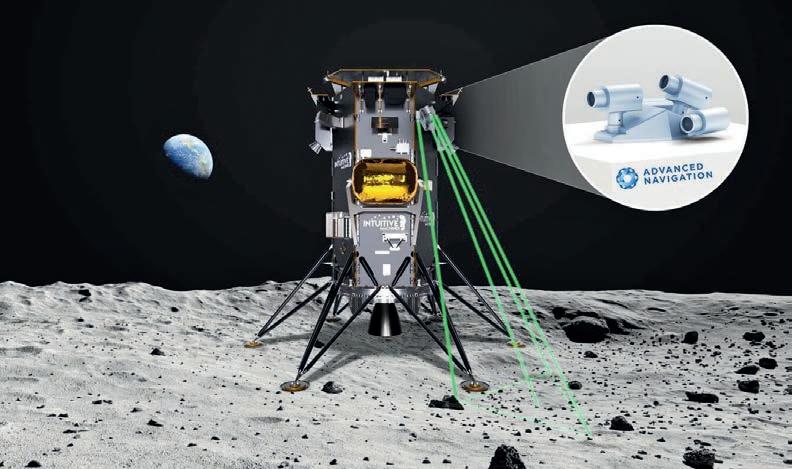

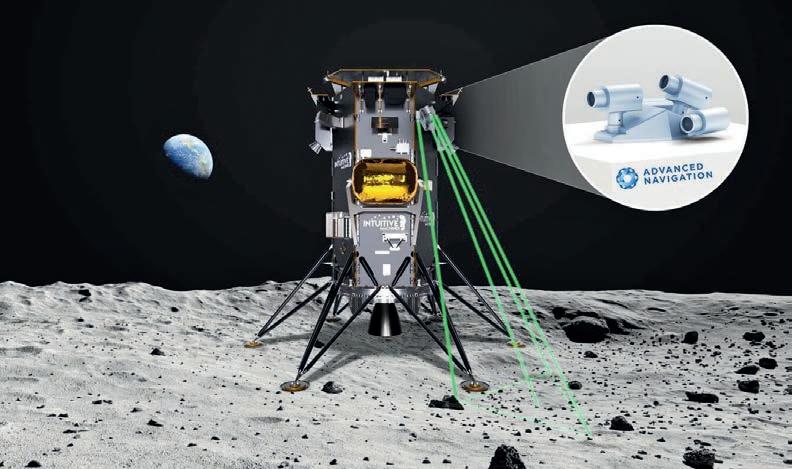

The mission to the moon

The demand for autonomous spacecraft is increasing as space exploration becomes more commercialised, and the push for easier engagement of the cosmic frontier continues. Given the harsh environmental conditions that come with space exploration, the Guidance, Navigation and Control (GNC) system of autonomous crafts have to make rational decisions onthe-fly.

Advanced Navigation has developed its patent-pending light detection altimetry and velocimetry (LiDAV) technology – a revolutionary sensor package for space exploration offering accuracy and reliability several orders of magnitude over current industry standards.

LiDAV uses photonics technology to provide accurate and instantaneous motion information while being totally immune to interference at both the physical and software levels. When visual references are unavailable and cameras fail due to lack of light, dust and other obscurities, LiDAV will provide primary navigation input. The system provides far greater amounts of

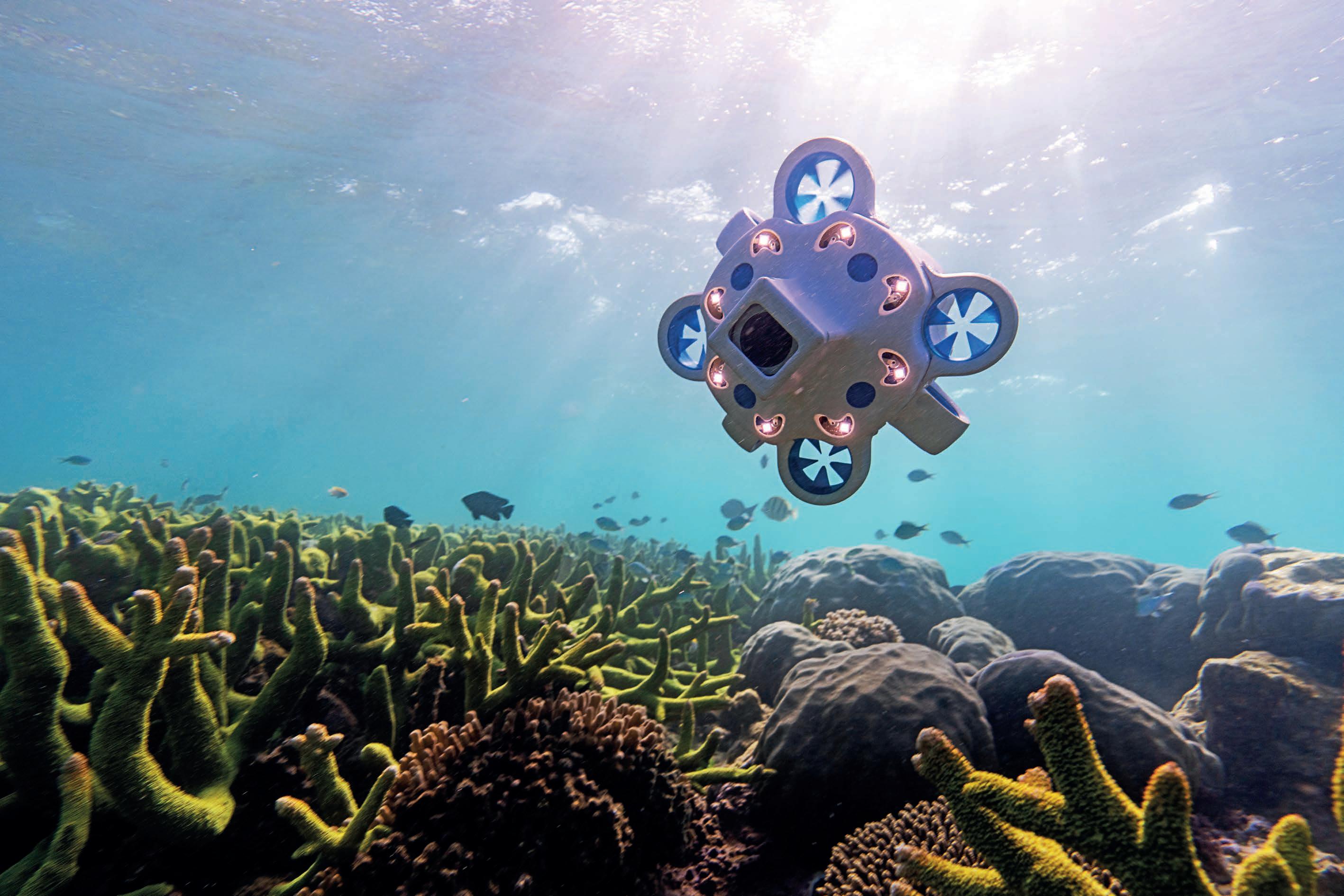

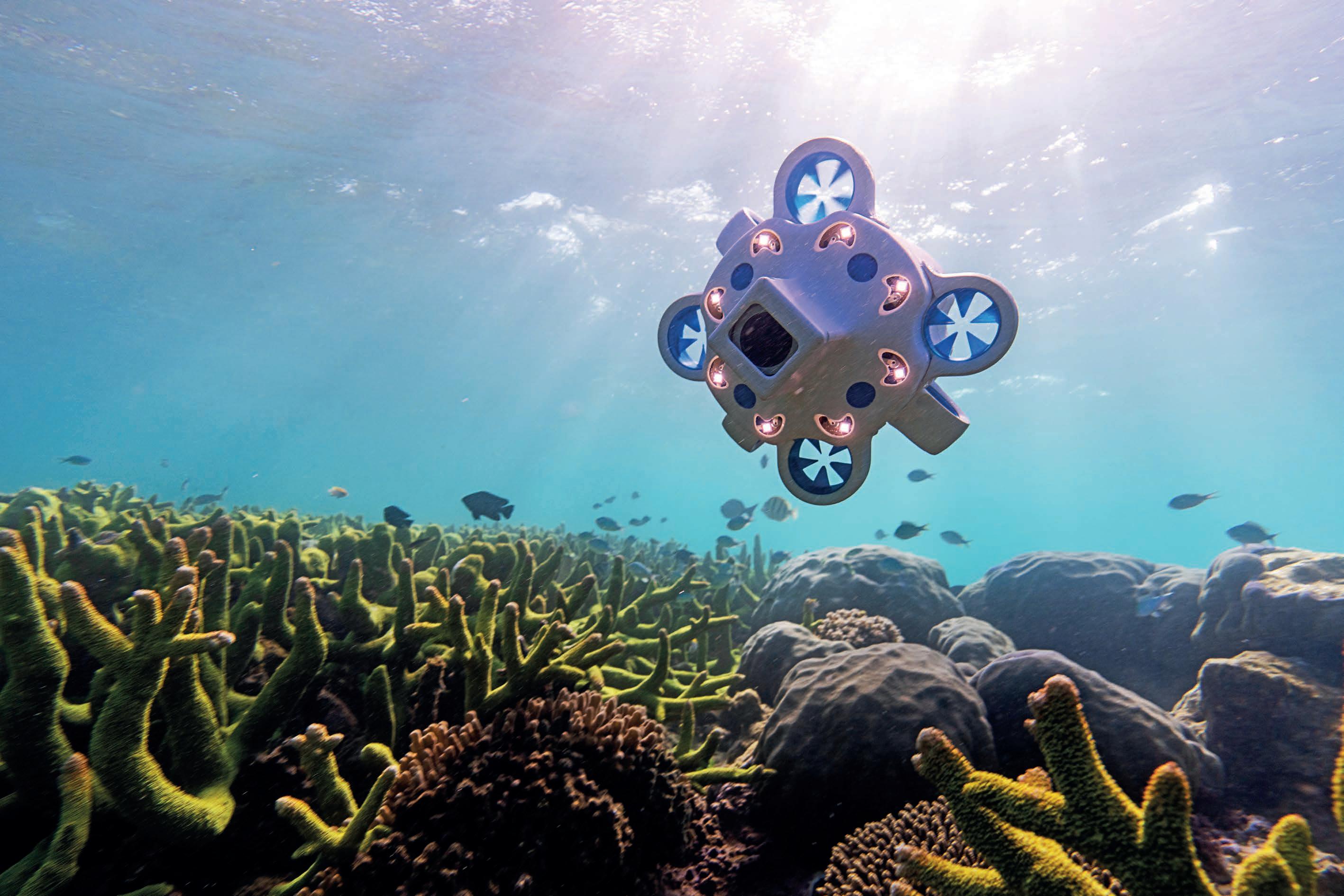

Hydrus takes the drone revolution underwater.

20 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

“The team is absolutely thrilled to see years of research in development progress into successful technology. We look forward to being the first Australian company to reach the Moon in early 2023 and 2024, this will be a huge milestone for us,” Orr said. “It has the ability to have quite profound impacts here on earth as well with things like plane navigation for take-off and landing, the flying taxi market, and even improving weather prediction.”

LiDAV is not the only system developed by Advanced Navigation for space exploration. The Boreas X90 is another patented technology which enables positioning and navigation capable of maintaining extreme precision without using relatively fixed references, such as stars, or requiring base station control telemetry. The strategic grade inertial

ManufacturerFocus

Underwater drones

A general trend in drone technology over the past decade has been an increase in autonomy, and more acceptance and trust from industry to deploy these autonomous solutions. In the subsea space, however, things are moving much slower, with only incremental changes made to vehicles which have been around for decades. Advanced Navigation is changing this, bringing the drone revolution underwater.

Solving this challenge was largely in part to Advanced Navigation’s ability to work with manufacturers of uncrewed and autonomous systems, as well as the customers of navigation positioning technologies and geospatial data. Standing next to industry helps to create more rapid solutions like its autonomous underwater robot, Hydrus.

Venturing underwater brings tremendous pressure without access to the internet or GPS – the best way to communicate is through sound. The idea for Hydrus stemmed from Advanced Navigation’s sonar and navigation equipment being sold to be installed on other underwater vehicles, which were cumbersome and difficult to use, requiring large ships and qualified crews to operate.

As a fully autonomous underwater drone, Hydrus is programmable straight out of the box, can venture 3000 metres below sea level, and is equipped with advanced sonar, navigation and communications systems. It has a web interface that makes it simple to plan and

execute underwater missions in three dimensions. Crucially, the drone is compact and lightweight enough to be launched by a solo operator, allowing for surveying wind farms, underwater mine detection and classification, routine surveillance and other activities.

“Users of subsea data don’t want to be dealing with these really complex systems to get hold of that data,” Orr explained. “Hydrus is a tool that will actually deliver the data that people want, and it really is the start of the drone revolution.”

Hydrus is equipped with a cinemagrade 4K 60fps camera combined with an AI engine that can analyse image quality and adjust lighting in real-time. Its compact size and minimal weight make it easy to launch and carry-on when flying, even by a single person.

Developing the drone involved significant challenges, including shrinking the technology down to fit within the small size of the drone and adapting to an underwater environment, requiring a significant change in mechanical engineering.

“Anywhere you want to capture data, it can go down and capture it far more quickly, cost effectively and safely than has ever been possible before,” Orr said. “Waterways such as the Sydney Harbour require inspections almost quarterly, surveying bridge footings, electric cables, water pipes and any infrastructure touching the water. This is the first teatherless, handheld device where all you need to do is grab it out of the water. It’s super easy, quick and safe.”

To make informed decisions about sustainable ocean resource use, data on a greater scale and magnitude is needed more than ever before. Hydrus has the potential to help discover why the most significant climate change events in the ocean are occurring, such as CO2 absorption, reef bleaching, new diseases, loss of sea life and biodiversity, coastal erosion, and fishery decline. It can monitor the Great Barrier Reef, build maps of world ocean heritage sites, inspect underwater infrastructure and fish farms, and identify new marine life. Mitigating against the complexity and cost of collecting underwater data can help to restore the health of our oceans.

Advanced Navigation co-founder Xavier Orr.

The LiDAV system can indicate a vehicle’s velocity and position relative to the lunar surface in three dimensions.

manmonthly.com.au Manufacturers’ Monthly MAY 2023 21

Engineering Focus

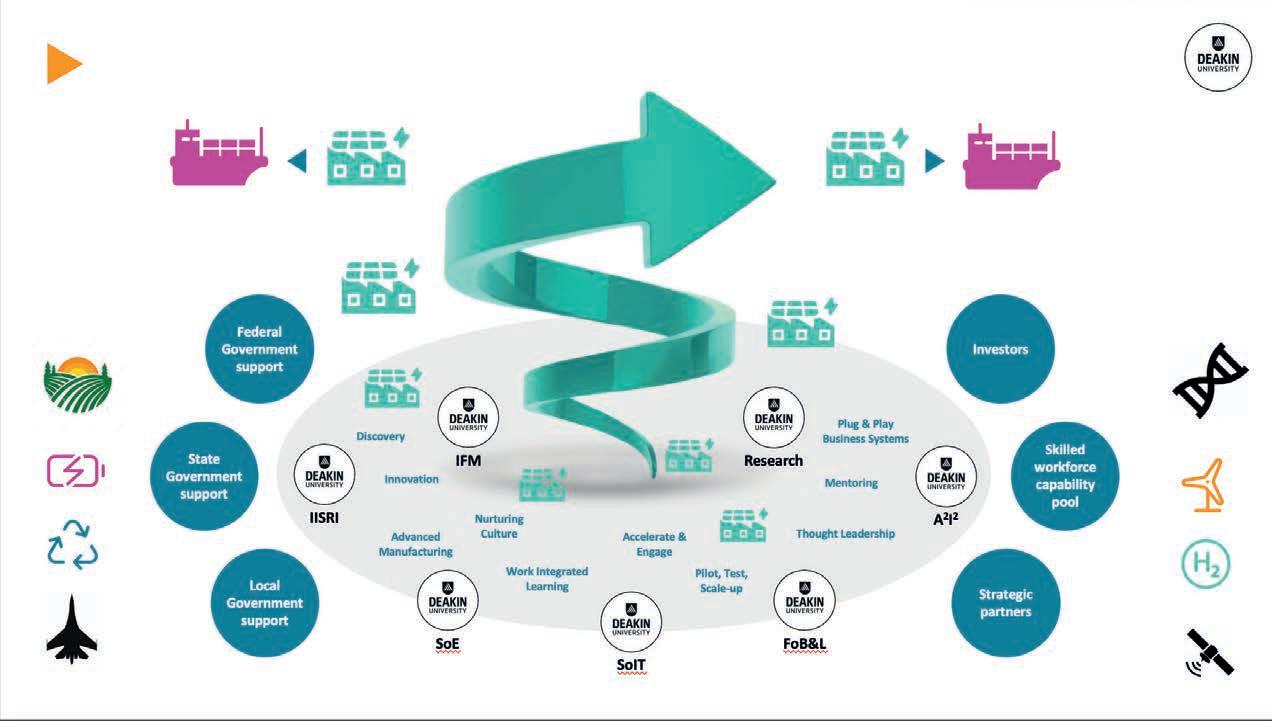

Research to commercialisation with ManuFutures

Deakin University’s research innovations regional manufacturing director Mark Curnow sits down with Mignon D’Souza to discuss how the university’s innovation hub ManuFutures works towards growing advanced manufacturing capability in regional Victoria and Australia.

MANUFUTURES is an advanced manufacturing and innovation hub located in Geelong, Victoria. The hub boasts a range of state-of-the-art facilities, including advanced manufacturing technologies, prototyping equipment, design studios, and collaboration spaces. This allows businesses to develop their products from concept to production, all under one roof.

Mark Curnow, research innovations regional manufacturing director at Deakin University said the hub was established in 2018 when Deakin University realised that it was time to progress the ideas that had been incubating within its institutes and faculties to commercialisation.

“The last few years since COVID have really ignited interest in manufacturing in Australia, particularly sovereign capability. With that in mind, the university went into establishing ManuFutures by wanting to transform research into commercialisation and advance regional manufacturing in Australia.”

ManuFutures has been designed with the aim of promoting innovation

and collaboration between different stakeholders in the manufacturing ecosystem. This approach is not just about providing the latest equipment but also fostering a culture of collaboration, knowledge-sharing, and innovation.

The facility is part of the university’s broader strategy to create industryacademic partnerships that drive innovation and support the growth of the advanced manufacturing industry in Australia. The goal is to create an environment that supports the translation of research outcomes into practical, commercially viable solutions.

ManuFutures is focused on supporting start-ups and entrepreneurs. The facility provides a range of resources and support to help entrepreneurs and small businesses to develop their ideas and bring their products to market. This includes access to funding, mentorship, and business support services.

“ManuFutures is a business accelerator. Typically, when a start-up business is in its initial phase, they’re very focused technically on its product and how it’s progressing. But they can probably lack fundamental business

elements and have questions like – how much cash do we need? What’s cash flow about? What sort of investment will we need? How do we create a pitch deck? How do we seek seed investment?” Curnow explained.

“Through ManuFutures, we’ve established a raft of training programs that support those early-stage businesses in developing their understanding and capability and accelerate their journey to commercialisation.”

22 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

ManuFutures has the equipment and facilities to help nurture young businesses.

ManuFutures has four training programs:

• Ignite: A pre-accelerator program strategically designed to help early-stage start-ups and start-up entrepreneurs.

• Accelerate: A program that helps startups to grow and scale-up, with a focus on product engineering.

Engage: A program that engages with small- to medium-sized enterprises (SMEs) for collaborations with Deakin for research and development, identifies gaps that need to be bridged within industry, and connects SMEs with internal and external technology experts.

• Connect: A unique product engineering service designed to leverage skills, capabilities, resources, assets and research outcomes across the university and support manufacturing businesses to maximise their competitiveness and create new global market opportunities.

“The journey of a start-up is not easy. It’s time and resource-consuming, which is why our we lay out the roadmap for start-ups through our training programs,” Curnow said, adding that the ManuFutures training programs were for both individuals and organisations.

“For instance, our Ignite program involves 12 days of training over 12 weeks at no cost to the participant. Here, we map out the start-up journey, the personal time investment needed, and the financial resources needed, so that people and start-ups completely understand what they’re getting into.

“Our Accelerate program is more focused on the business side of things. It could be a smaller business that has a product and needs help to take it from an early-stage product to scale-up ready.

EngineeringFocus

Here, we help them with many elements of product planning, and production line layout – we have full desktop 3D experience capability. So, we can digitally twin their process to help them along that journey.”

One of the several start-ups that has benefited from the resources and support provided by ManuFutures is FLAIM Systems, a company that has developed the world’s first multi-sensory firefighter immersive learning solution to replicate the stress and uncertainty of real-world emergency situations safely and costeffectively. FLAIM is ManuFutures’ first tenant, located at Deakin University’s Waurn Ponds Campus.

“FLAIM is one of our many successful graduates – they’re reaching a level of maturity now with growing global sales,” Curnow said. “And their product is phenomenal. It’s immersive learning for firefighter training, where Virtual Reality (VR) can put scenarios into a training environment.”

Over the last four years, FLAIM Systems has conducted over 141 training scenarios, sold over 500 systems, onboarded over 200 customers, and sold in 43 countries, generating over $10 million in total revenue.

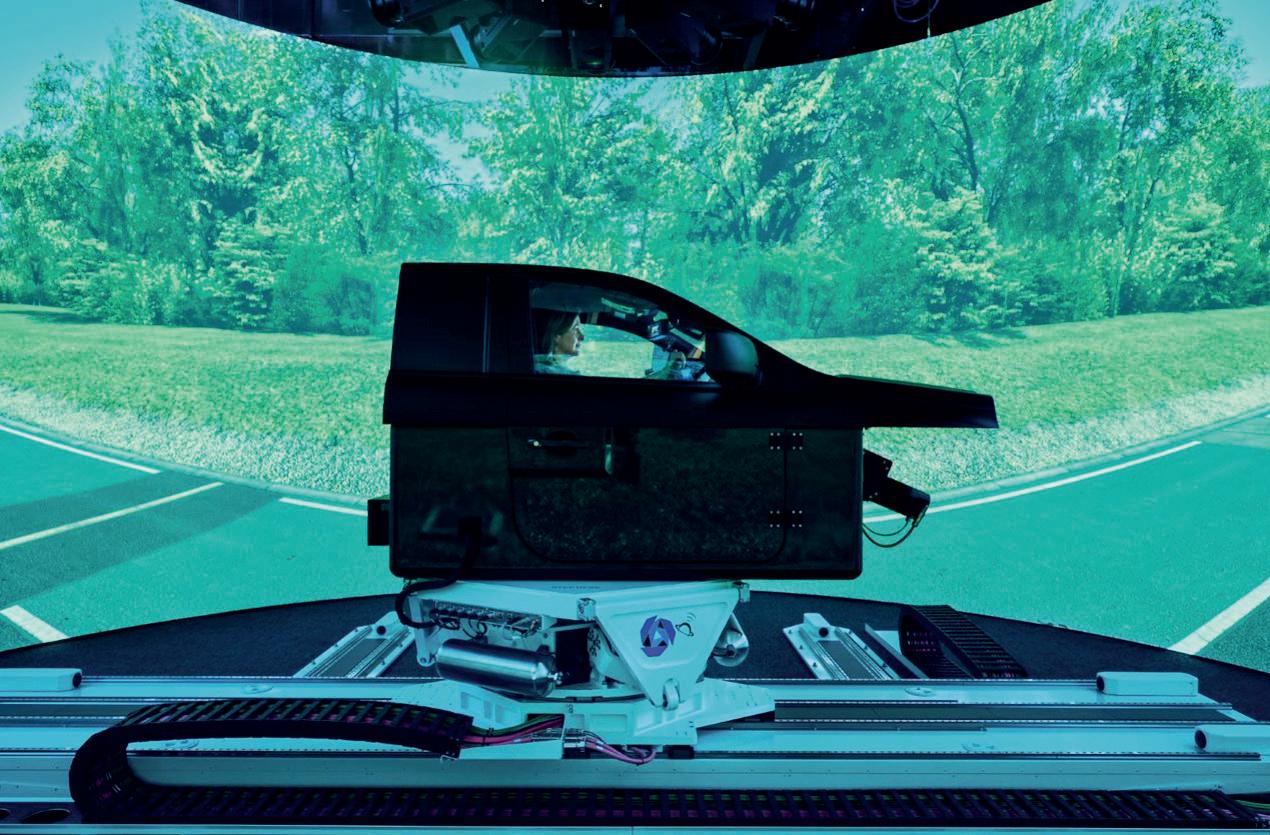

Another company that ManuFutures has supported is Universal Motion Simulation (UMS), which develops and manufactures turnkey reconfigurable driver training simulation solutions for armoured vehicles. The company’s core Reconfigurable Driver Simulator (RDS) is a highly dynamic motion platform consisting of a six-degree-of-freedom robotic arm, interchangeable replica vehicle cabins, haptically enabled control devices and immersive simulation environments featuring detailed vehicle dynamics and terrain modelling.

ManuFutures has helped create

more than $1 billion in company value, incubated more than 17 advanced manufacturing start-ups, helped companies establish export markets in over 45 countries, hosted 500 student placements, and created over 200 direct advanced manufacturing jobs, including in regional areas.

ManuFutures2 expansion

Recently, ManuFutures has expanded its operations with a newly completed $20 million ManuFutures2 building at Deakin University’s Waurn Ponds campus. The hub has doubled in size, offering more tenancy opportunities, product engineering services, training, and manufacturing incubator programs. The Victorian Government and Deakin University jointly funded the expansion with $10 million each, as part of the Victorian Higher Education State Investment Fund (VHESIF), which launched post-COVID.

Mark Curnow stated that the

manufacturing innovation.

“So back in 2020 – 2021, we received support from the state government in the form of the VHESIF grant. With that investment, we built the second ManuFutures facility that houses an additional six manufacturing businesses. Our new ManuFutures2 building includes collaborative working spaces, further rental tenancy bays for manufacturing businesses, and an Innoveering Centre that includes product engineering and development capability, and opportunities for research collaboration and integration,” he said.

“Four new manufacturing businesses have already moved into the new spaces as tenants, with room for two more. A total of 14 successful and emerging global manufacturing businesses now call Deakin’s ManuFutures home.”

With the new expansion further promoting the development of advanced

manmonthly.com.au Manufacturers’ Monthly MAY 2023 23

We’re trying to create a full circle experience within the university. While we’re developing manufacturing, we also want to create opportunities for students.

ManuFutures is Australia’s unique advanced manufacturing innovation hub.

Engineering Focus

manufacturing capabilities, ManuFutures has attracted new investment to regional Victoria, boosting the local economy and creating jobs.

“When the second ManuFutures hub was built, we were given a series of

criteria that we need to meet to support the grant we received. And one of them is to develop regional manufacturing and set up satellite operations that will provide education and training in regional Victoria,” Curnow explained.

“Therefore, we have established satellites in Warrnambool and Bendigo, and we are currently actively pursuing cohorts of entrepreneurs and start-up businesses so we can take our training packages to these regions.”

The next phase of ManuFutures will be three more factories of 2000 square meters in size with the key objective of supporting businesses to scale. The factories – known as ManuFutures4, ManuFutures5, and ManuFutures6 – will be constructed within the next two and a half years.

“Instead of a very successful business graduating and flying the nest, we will have the capability to retain them on campus in the future economy precinct at Deakin University’s Waurn Ponds campus. This will retain their connections to research, to students’ learning opportunities, and to graduate students’ work opportunities,” Curnow said.

Collaboration in the manufacturing ecosystem

Collaboration is extremely important to the work that ManuFutures does, according to Curnow. ManuFutures has fostered collaboration among different sectors and disciplines by bringing together industry, academia, and government, which has helped break down silos between different sectors and disciplines, leading to more effective problem-solving and innovation. For instance, in Bendigo, ManuFutures has

24 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

ManuFutures is located in the heart of Deakin’s Future Economy Precinct.

Deakin University’s Advanced Manufacturing Ecosystem.

experience within the university. While we’re developing manufacturing, we also want to create opportunities for students. So, we’re collaborating with the schools, faculties, and institutes, where we’ve got many specialists that can help with research or product development problems.”

Curnow added that they encourage their tenants and program participants to collaborate as much as possible with each other. The new ManuFutures building is designed and set up to provide opportunities to do so – from the lunchroom and the areas where they can co-mingle and enjoy their lunch or coffee break, to meeting rooms and collaborative workspaces where they can work together and create learning opportunities for each other.

One of ManuFutures’ targets for the year is to establish firm linkages with more established businesses like Hanwha Group to become part of its ecosystem.

“Let’s say, for Hanwha, we want to do some work in supply chain development. If we can raise their capabilities through

EngineeringFocus

we’re developing an industry-ready workforce, improving the supply chain for smaller start-ups, and helping the talltree businesses deliver what they want to do,” he said.

Education in engineering and manufacturing

Deakin University’s ManuFutures is helping to develop the skills and knowledge of the next generation of engineers and manufacturing professionals by providing access to training programs, research opportunities, industry collaborations, and industry events. Deakin University’s research and development capabilities have played a key role in contributing to the success of ManuFutures and the businesses it supports.

The relationship between ManuFutures and the students at Deakin University is a symbiotic one.

“To have start-ups or entrepreneurs, you need an innovation pipeline and a lot of our innovation pipeline to date has come out of the university,” Curnow said.

“We’d like to say we’re Australia’s unique, advanced manufacturing innovation accelerator. And the uniqueness comes from that connection with the university. It’s a closed-circuit activity where we can rely on each other to support businesses in growth.”

ManuFutures also provides workintegrated learning opportunities for PhD candidates, research assistants, and higher degree by research (HDR) students by connecting them with businesses, which in turn generates employment opportunities in their fields of interest.

This also completes the circle of ManuFutures’ key objective of research to commercialisation, according to Curnow.

“Research has many avenues of impact. While a lot of research occurs to educate people through papers, there’s also research that needs to be converted to commercial reality and has societal impact. Getting the research out of the university and into the commercial world is the piece of the equation that we’re working on.

“We are not landlords. We provide

complete that circle for our students.”

Discussing education in manufacturing in general, Curnow said that generating student interest in manufacturing and STEM careers is an important issue that the industry must come together to resolve.

“We need to teach the emerging workforce of the future that manufacturing is not in overalls and trudging around in boots with grease. Manufacturing is intelligent, challenging, and rewarding work.

“When I see some students today, the work they do in additive manufacturing, 3D printing is their hobby because they are so passionate about it. That’s a great capability that we need to tap into as an industry.

We also need to be well in touch with major industry sectors and employers in any given region and have a good understanding of their skills requirements, so that we can tune our education to suit that direction and focus on those needs. Because if you’re not preparing the students for the workforce, it’s all for nothing,” Curnow concluded.

manmonthly.com.au Manufacturers’ Monthly MAY 2023 25

The hub has facilitated more than 500 student placemnts since its establishment.

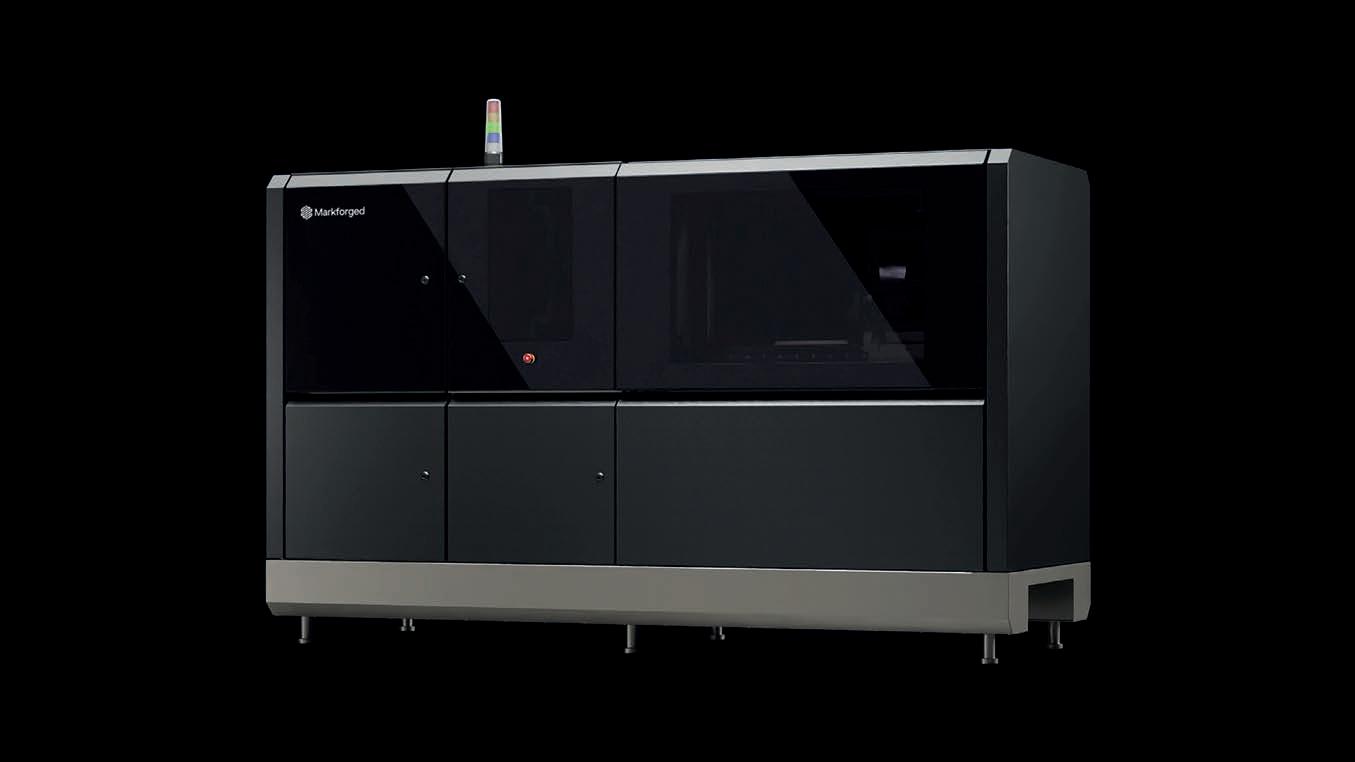

Additive Manufacturing

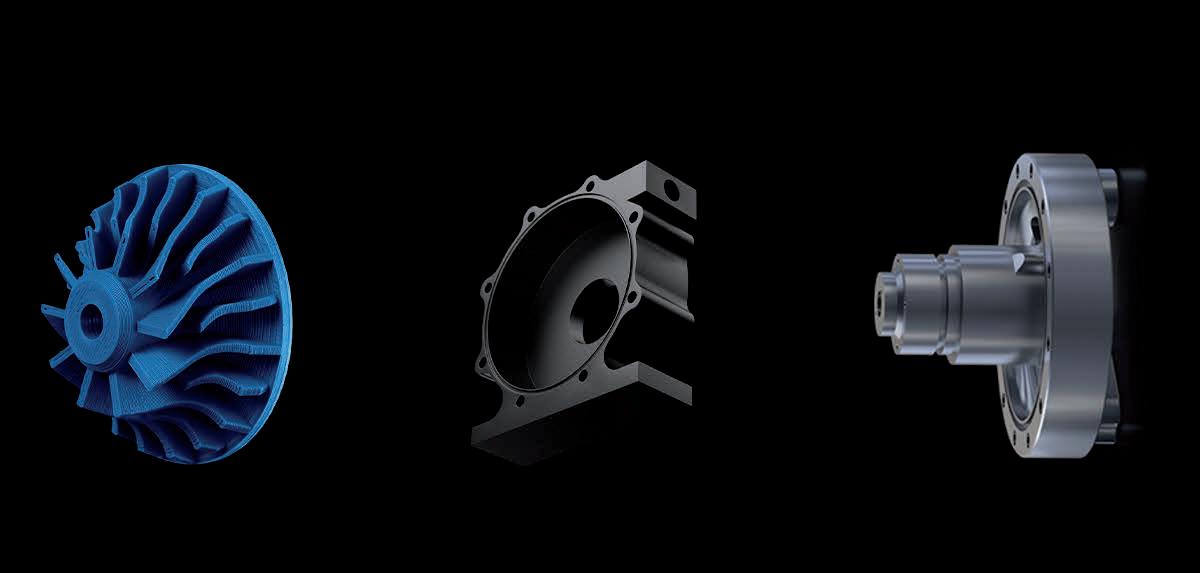

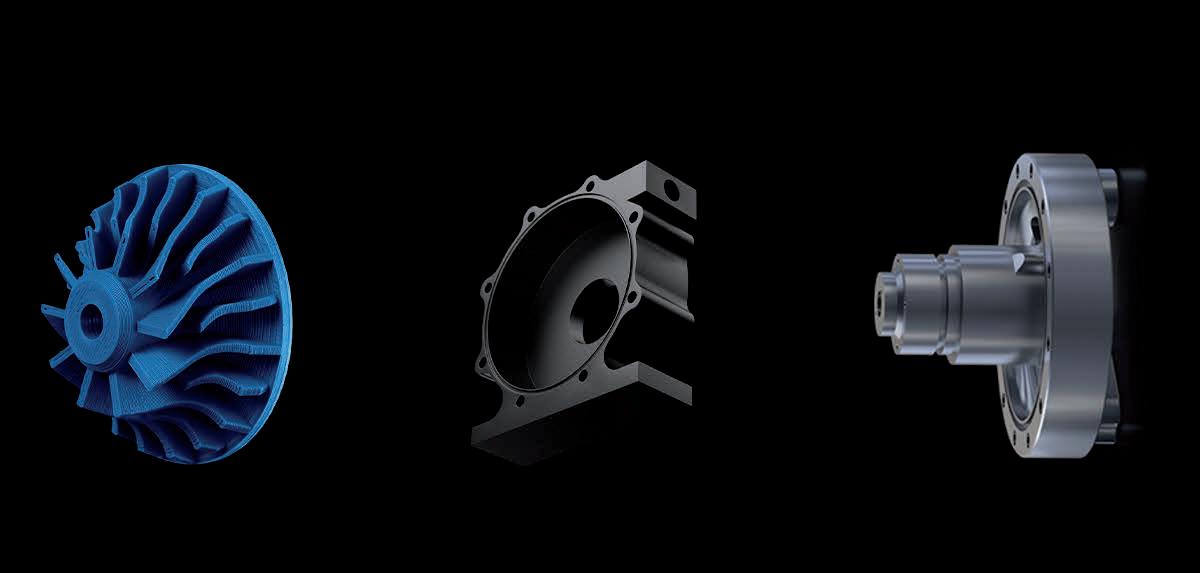

The technology behind serial production

Markforged’s serial producing printer – the PX100 Binder Jetting solution – enables manufacturers to build large quantities of high-quality metal parts. Manufacturers’ Monthly speaks with CEO of Digital Metal Christian Lönne during his recent visit to Australia about the capabilities of the printer and the future of the additive manufacturing landscape.

INITIALLY developed by a small team in Sweden, Digital Metal begun as a subsidiary of Höganäs AB as a relative unknown in 3D printing. When Christian Lönne joined the company in 2019, it had grown from its startup roots using completely new technology to having a presence in a number of industries. Digital Metal’s 3D metal printing machines with proprietary, high-precision binder jetting technology, required further commercialisation to get into the hands of industry.

“When I arrived, we were ready to scale,” he said. “I realised we had fantastic engineering capacity and we could see the inherent opportunities of serially producing additive manufacturing. We had mechanical engineers who refined the technology, but didn’t have the expertise in software.”

After many changes, Digital Metal’s biggest move came in July last year, when Makrforged – the creator of the integrated metal and carbon fibre additive manufacturing platform Digital Forge –entered into a definitive agreement with

Höganäs AB to acquire the company. This is what ‘the next step’ looked like for Digital Metal.

The acquisition fit both companies perfectly. Markforged is always looking to solve manufacturing challenges, and a huge problem is the months required for traditional production to move from design to manufacturing, with third party supplier risk and poor unit economics during ramp up and lower volume periods also concerns. Powder binder jetting is a highly scalable technology for production grade parts at the point of need with minimal setup required.

With Markforged’s experience and go-to-market scale, Digital Metal has been able to grow its technology on the mission to help more manufacturers produce the high-volume metal parts they need to drive highly productive and cost-efficient operations. Crucially, Markforged’s Digital Forge platform is helping take Digital Metal’s mechanical solutions to the next level – the easy-to-use platform, best-in-class software capabilities and material expertise felt like a natural fit

together. The now Markforged binder jetting technology brings new capabilities in Australia to the Digital Forge platform – a production system capable of fabricating thousands of complex end-use metal parts.

“We slot into that ecosystem of combining hardware, software and materials,” Lönne explained. “Coming from that more mechanical background where powder metallurgy is very intensive on the engineering side, we have widened our perspective to the bigger picture. I think this is where digital manufacturing is going and the vision which Markforged has is very appealing to become a part of, so we are integrating into that world.”

The keys to serial production

As a batch manufacturing process, metal binder jetting is the exciting technology in the additive manufacturing space with serial production capability. Most 3D printing technologies are built part-by-part, scaling by adding more or less printers, whereas this technology

allows many parts to be built at the same time. There becomes no real difference building one or one thousand parts, which is the magic of metal binder jetting. It has well and truly emerged as a powerful tool for manufacturers to reduce their time to market and increase flexibility. As Lönne explained, the technology enables designers to iterate their designs quickly and produce parts in a serial manner, without having to go through a long industrialisation phase. Markforged’s Metal Binder Jetting 3D printer – the PX100 – aims to bring manufacturing home, offering supply chain resilience and capabilities to manufacture small to large-scale serial production of metal parts at the point of need.

The new version of the PX100 has basically doubled its print-speed without losing the quality of the surface finish on the parts. The machine is also gas-tight, which is important for applications with reactive materials.

“It gives an ability to go from prototyping to production seamlessly,”

26 MAY 2023 Manufacturers’ Monthly manmonthly.com.au

The PX100 Metal Binder Jetting 3D Printer.

Lönne said. “You don’t have to do a lot of lower prototyping at the start to then find a way to produce your part. Once you’re happy with your design and iterations, you’re straight onto serial printing.”

Developed by Digital Metal over nearly 20 years, Digital Metals has made many incremental changes on the platform –including a new technology co-developed with an Australian company – but the base technology remains the same. The printer offers a unique combination of high precision and high throughput to ensure the user gets a robust production solution as well as being a future-proof platform to support manufacturing needs – both foreseen and unforeseen – in the future.

“One of the unique things with Digital Metal platforms is that the owner can upgrade the printer and modify it to the latest specs, so even if you bought your printer five, six years ago, you can upgrade it to the latest standard,” he said. “That means you can protect your investment because you don’t have to buy a new printer when technology updates.”

Simply put, the PX100 allows for change. When a business wants to change design, it can simply stop printing, make the necessary changes and start printing the new design, bypassing the tedious but necessary changes required in other manufacturing processes. For instance, in injection moulding operations, a new design can take up to six months and comes with a hefty added expense. This limits flexibility, as you need to make the same part over and over and do a large

AdditiveManufacturing

series to pay off that investment. Lönne noted how companies will adopt this technology in the future is one to watch, especially given the shorter product life cycles industry is experiencing.

“People are used to changing designs or changing formats much quicker, which is why it fits very well,” he noted. “I think it will become a mentality – people expect that if you need to change, you won’t have to go through different bottlenecks to reach the end result.”

As the pace of innovation continues to accelerate, more businesses are having to adapt quickly to changing market conditions. The increasing demand for customisation, speed, cost-effectiveness, and sustainability in manufacturing is expected to drive the uptake of additive manufacturing in the coming years. Lönne explained that it will take time to learn how to design components and learn the benefits, but there will be a massive impact on supply chains.

“The cool thing with additive manufacturing is it is mainly capital expenditure, so it negates the different expense of parts from different countries problem,” he said. “The production costs are more or less the same wherever the printer is in the world, which I imagine would be a huge deal for the more remote countries in increasing competitiveness and keeping manufacturing onshore.”

For now, Markforged’s focus is on providing real value, real products with customer applications and lowering total cost of ownership.