Discover the Power of Prestige with

PRESIDENT

3

The flagship of our fleet. Designed for long-distance travel with premium features, spacious interiors, and unmatched passenger comfort.

PRESIDENT

2

A sleek and stylish all-rounder, ideal for touring, school runs, or charter work — where versatility meets comfort.

PRESIDENT 10

Sophisticated modern midi coach at a competitive price.

BYD Designed, Proven in Australia.

Technology is central to BYD’s DNA, and its ongoing research & development ability is vital to BYD’s rapid development. BYD’s cutting-edge technology can transform lives and improve the world thanks to “technology-based, innovation-oriented” development philosophy. BYD has successfully built an industryleading suite of platforms, and its world-leading advanced technologies are tried and tested in the world’s most demanding environments before market launch.

BYD COMMERCIAL VEHICLES

BYD’s dedicated Commercial Vehicle Research Institute engages in extensive R&D of the whole vehicle and chassis for the pure electric bus and vehicle fleet use in public transport globally.

BYD Commercial Vehicles are available in Australia, sold and distributed directly by BYD.

BYD Commercial Vehicles has streamlined service and support to keep your fleet running with minimal downtime. Our industry-leading electric buses and trucks are backed by BYD’s global expertise and innovation.

Faster connection

Kwetta technology can accelerate your grid connection approvals with network providers by more than 60%.

Smaller footprint

A single fully integrated solution takes up less than half of your depot space - compared to traditional solutions.

Easy scaling

Traditional solutions require overinvestment or hit you with high costs when you upgrade. Kwetta provides you with a one-time grid connection and modular upgrades without rework or regret.

Bus operators face complexity everywhere they turn. Whether it’s space, grid delays or cost overruns. We asked ourselves, ‘What if we could electrify a bus depot with a single piece of hardware, from grid-to-plug.’

Bus operators face constant pressure to electrify quickly, reliably, and cost-effectively—but complexity strikes from every angle. Grid connections, fleet and grid modeling, oversized equipment, and inflexible upgrades threaten timelines, budgets, and your depot operations.

“When we started Kwetta in 2021, we spent a lot of time inside bus depots, speaking directly with operators, says Dustin Murdock, CEO and Co-founder. It quickly became clear how critical—and how incredibly complex—these depots are.

Operations run down to the minute; there’s no room for error or delays. Traditional electrification

meant dealing with nine separate designs and managing more than ten different contractors, then somehow jamming all that equipment into an already crowded depot with zero extra space.

It was clearly too complicated. So, we asked ourselves, ‘What if we could electrify a bus depot using just two equipment vendors and a single contractor?’

Then we built exactly that solution. By December this year we’ll have 17 charging sites operating across Australia and New Zealand.”

— Dustin Murdock, CEO and Co-founder, Kwetta.

Start your depot assessment at kwetta.com

Pictured right L—R Dr Robert Turner, Dustin Murdock, Mike Lazelle, Co-founders at Kwetta.

Full plate

As we start a new financial year, an array of news sets the Australasian bus and coach industry on a reshaped trajectory full of change and progress

The Australian bus and coach industry is full of news currently, with a raft of changes and updates keeping the wheels turning at a high rate. In Victoria, the switch over to new MZF contracts has dominated attention, with various family operators having to sadly farewell their final government contract runs in the lead-up to the new financial year. This means Dyson Group, CDC Victoria and Kinetic have the power in Melbourne and its suburbs as the trio usher in a new era of zero-emissions transport. July 1 also saw these operators be required to only order new zero-emissions vehicles. At the same time, bus driver strikes continue to rear their head in the state, while a lifeline for bus orders was granted by the state government.

Continuing on the Australian operator trend, it was a pleasure to sit down with Busways’ new CEO Will O’Neill to chat about the NSW giant’s future. While Will signals a shift away from the famous Rowe family’s day-to-day leadership, our in-depth chat on page 34 highlights the growth strategy that remains as consistent as ever for the largest fully Australian owned bus operator.

The Australian bus and coach industry is full of news currently, with a raft of changes and updates keeping the wheels turning at a high rate

Whether it be Ryan Bros Bus Service, Kastoria Bus Lines, Broadmeadows Bus Service or Panorama Coaches, the bus industry recognises the contribution and wonderful services these operators have all offered to Victoria’s public transport network over the years. June 30 served as a sad day as yet another Australian state farewelled popular public transport route operators from service, with Victoria following New South Wales in privatising the network and narrowing the pool of local family-owned companies in the game. Our coverage of the events that unfolded in early July can be read from page 48 as the final government contract runs of longstanding Victorian operators went ahead.

While some family operators had to bid farewell to their government runs, the July edition of ABC Magazine shines a spotlight on the other existing local operators who are continuing to provide valuable transport services to communities around the country. Our cover story encapsulates this spirit, with BLK Auto and Bundaberg Coaches working together to provide high-quality transport to a range of customers in Australia’s north. From page 22, traverse the ever-expanding world that Bundaberg Coaches is working in, from Queensland mines to interstate charter trips to the snow, and the valuable role that BLK’s tailor-made coaches are playing in these unique operations.

On the vehicle technology side, ABC ’s resident bus reviewer Paul Aldridge was in full swing in July as he headed to Sydney’s outer suburbs to take Yutong’s D7E, courtesy of VDI Australia, for a ride around the block. Whether it be the complete lack of noise or the comfortable ease of charging the electric bus, Paul provides his thoughts from page 27. Be sure to check out the video via the QR code too!

The July edition has a special segment for zero-emissions bus infrastructure and safety, with the likes of Fire Protection Technologies (page 30) discussing how its products are helping protect motorists, passengers and drivers safer during the rare instances of thermal runaway. The special focus also led to ABC finding out about E-T-A’s latest tech on page 32.

All of this and more is part of another vibrant edition of ABC, with another highlight being our interview with incoming BusVic executive director Peter Kavanagh on page 51 about his goals for the state association moving forward. As the industry sits on a new horizon, we hope you enjoy the array of stories before you in the July edition of ABC Magazine

Sean Mortell EDITOR, ABC

in the know

08. editorial | ignition FULL PLATE

As we start a new financial year, an array of news sets the Australasian bus and coach industry on a reshaped trajectory full of change and progress

12. news | all aboard

Check out the latest news from around Australia and the world

features

21. column | bic BUS SAFETY: NOT EXPENSIVE, PRICELESS

The BIC is continuing to focus on making buses safer for passengers of all ages, including recent seatbelt education campaigns

22. cover story | blk auto BUNDABERG BEACONS

Bundaberg Coaches’ two new BLK coaches are putting a popular north Queensland town on the map for a whole new reason

27. bus review | vdi NEW KID ON THE BLOCK

In ABC ’s latest test drive, Paul Aldridge took Yutong’s D7E around Sydney to see how the nifty electric bus works in suburban and community applications

30. feature | fire protection technologies TIME TO TICK ALL BOXES

Fire Protection Technologies is stepping up to provide effective fire suppression solutions that suits the evolving electric transition

32. feature | e-t-a SWITCHED ON

E-T-A ElectroTechnical Applications’ newest innovations are silently powering the transition to zero-emission vehicles

34. feature | busways DRIVER’S SEAT

Since January, Busways has been led by a new CEO. But Will O’Neill is quickly proving that he’s up to the challenge of leading the longstanding operator

38. feature | yutong DRIVING REAL IMPACT

Yutong has had its eye on bringing over its electric bus technology to Australia. Its partnership with Tropic Wings allows it to be at the forefront of sustainable change

40. feature | bci SUPPORT ON THE MOVE

As a regional WA hospital undergoes a major transformation, BCI and GoWest are stepping up to ensure frontline healthcare workers get to and from work safely

42. feature | byd BEYOND THE BUS

While Australians may only know BYD for its buses and cars, the global manufacturing giant has been making its mark on the EV space for decades

44. feature | scania DRIVING FORWARD

Scania Australia’s revised line-up is gearing up to become a favourite for operators on the roads

46. feature | volvo ELECTRIFYING WITHOUT COMPROMISE

Volvo Bus Australia’s electric range is building on the trusted models that have been serving Australia’s roads for years

48. feature | industry issue FINAL RUNS

Local Victorian operators have had to say goodbye to longstanding runs as the MZF contracts began operating at the start of July

51. column | busvic NEW BEGINNINGS

The new financial year sees BusVic welcome a new executive director, with Peter Kavanagh laying out his goals for the state association

55. competition | best bus MATARIKI MARVEL

Grady Weatherley-Connell has come back with vengeance, taking out the Best Bus title for a second time

departments

58. factory facts | bus deliveries JUNE DELIVERIES

Check out the latest bus and coach supplier sales data collected and recorded for you to review and see how the market fared in June

62. back seat | bus restoration FORMER GLORY

Driven by passion, Hamish Withington is on a mission to rescue and restore vintage buses to keep Australia’s transport history alive

EDITORIAL & DESIGN

Managing Editor: Geoff Crockett

e-mail: geoff.crockett@primecreative.com.au

Editor: Sean Mortell

e-mail: sean.mortell@primecreative.com.au ph: 0468 577 166

Assistant Editor: Tiarna Condren

e-mail: tiarna.condren@primecreative.com.au

Art Director: Daz Woolley

Designer: Apostolos Topatsis

PRINTING

Brougham Press

ADVERTISING

Sales Manager – South:

Courtney Burton ph: 0481 736 890

e-mail: courtney.walker@primecreative.com.au

Business Development Manager – Bus: Sylvie Hanlon ph: 0466 545 664

e-mail: sylvie.hanlon@primecreative.com.au

SUBSCRIPTIONS

www.busnews.com.au/subscribe ph: +61 (0)3 9690 8766

Mon-Fri 8am-4.30pm (EST) e-mail: subscriptions@primecreative.com.au mail: 379 Docklands Drive, Docklands VIC 3008 Australia

Annual subscription rates (12 issues): Australia: $99* Overseas: $A170 (Australian air-mail only) *price includes GST

Cover image: BLK Auto

ISSN

Image: Yutong

Victorian veteran exits bus industry

The retiring bus operator is a well-known member of both the Victorian bus industry and the state’s political history

A popular member of Australia’s bus and coach industry is preparing to leave the sector, with Ken Jasper AM announcing he will exit the industry mid-year.

At age 87, he has enjoyed many years in the sector as well as a thriving political career.

Originally from Wales, there have been four generations of Jaspers in Rutherglen operating a range of enterprises from bus transport to petrol stations and cafes.

An 1892 photo of his great grandparents and staff showcase when the family first started business that resulted in Jasper Bros Buses in Rutherglen as coachbuilders, blacksmiths and undertakers.

Based in Victoria’s north-east, Jasper Bros has run school buses for nearly 75 years, with Ken now

selling the company to Wangaratta Coachlines as he exits the industry.

The bus operation started in 1952 when Ken’s father and uncle bought the first school bus business in Rutherglen in 1952. Since then, Ken has operated three school bus contracts and done charter work for the schools the operator services.

Throughout this time Ken remembers

Western Melbourne scores major transport boost

The new and improved bus services in Melbourne’s west aim to connect communities to key local destinations

The Victorian government is delivering a significant boost to public transport in Melbourne’s growing western suburbs, with 470 new weekly bus trips rolling out in July.

From Tuesday, July 1, four major routes – 170, 180, 190 and 192 –offer more frequent services and extended operating hours, allowing buses to run later into the evening most days of the week.

The upgrade is improving connections to key train stations including Werribee, Tarneit and Wyndham Vale, while also making it easier for locals to reach shopping centres such as Pacific Werribee, Manor Lakes Central, Tarneit Central, and Wyndham Vale Square.

Whether it’s late-night shopping, heading home after work, or returning from the footy on a Saturday night, the expanded timetable is designed to better fit around people’s lives and support shift workers and weekend travellers alike.

Public and active transport minister Gabrielle Williams says the improvements reflect the changing needs of Melbourne’s growing outer suburbs.

“We understand the importance of buses to local communities which is why we’re getting on with improving routes and adding new services, especially in our growing suburbs,” she says.

“More evening and night services on our busiest routes reflect changing

White branded buses in 1948 through to Bedfords, Isuzus, Mercedes-Benzs and now two new Scanias.

Alongside this, Ken’s father and uncle also became GM Holden dealers in 1929, running the local dealership before selling it in 2012.

The Jasper family’s rich automotive history can still be seen today, as behind the café sits a free motorcycle museum with a couple of dozen bikes and other machinery, memorabilia and photographs.

During this time, Ken was also the Nationals member for Murray Valley in Victorian Parliament from 1976 to 2010.

He was awarded a Member of the Order of Australia (AM) at the Queen’s Birthday Honours in 2012 for his services as a member of Parliament for 34 years and to the community in general.

travel patterns, including the increase in people travelling to and from the city in the evening for our major events, hospitality and work.”

The extra services are part of a broader $162 million investment in new and improved bus services, announced in the Victorian Budget 2025/26.

In Werribee South, Kings Leigh Estate is connected to the public transport network for the first time, with services also increasing to the new Wyndham Law Courts and Employment Precincts.

A new Route 140 bus from Rockbank to Tarneit is offering a vital cross-suburban link through Truganina and improving connectivity between Melton and Wyndham.

Below: Ken Jasper (middle) has sold Jasper Bros to Wangaratta Coachlines. Image:

vdiaustralia.com.au

Love the journey

Empower your city with our next-gen buses – available in both diesel and EV versions. Built for safety, innovation, and reliability, our BCI Citiriders come equipped with the most advanced features to ensure a smooth, secure ride for every passenger. With a streamlined production and logistics system, we deliver faster than anyone else –because your city’s progress can’t wait.

Contact our team for further information on 1300 289 224 or visit bcibus.com.au

Head Office Perth: 08 9353 9000

Melbourne: 03 8787 2100

Brisbane: 07 3275 6900

Adelaide: 08 8182 3888

Free travel and bus services retained in WA

Free travel has been extended for Armadale line commuters and popular services retained as the WA government invests in public transport

The Western Australian government has announced an additional $1.4 million to be invested to continue free public transport for regular passengers still affected by the ongoing Armadale line closure.

The announcement ensures commuters who were previously receiving free travel, including those

using stations between Kenwick and Armadale, will continue to do so until their local stations reopen.

WA transport minister Rita Saffioti says the decision reflects the government’s commitment to supporting the community while delivering one of the most significant rail upgrades in Perth’s history.

Keppel sells 25 per cent stake

in Ventura to Samsung

Samsung will now own almost a quarter of the bus operator, forking out approximately $130 million for

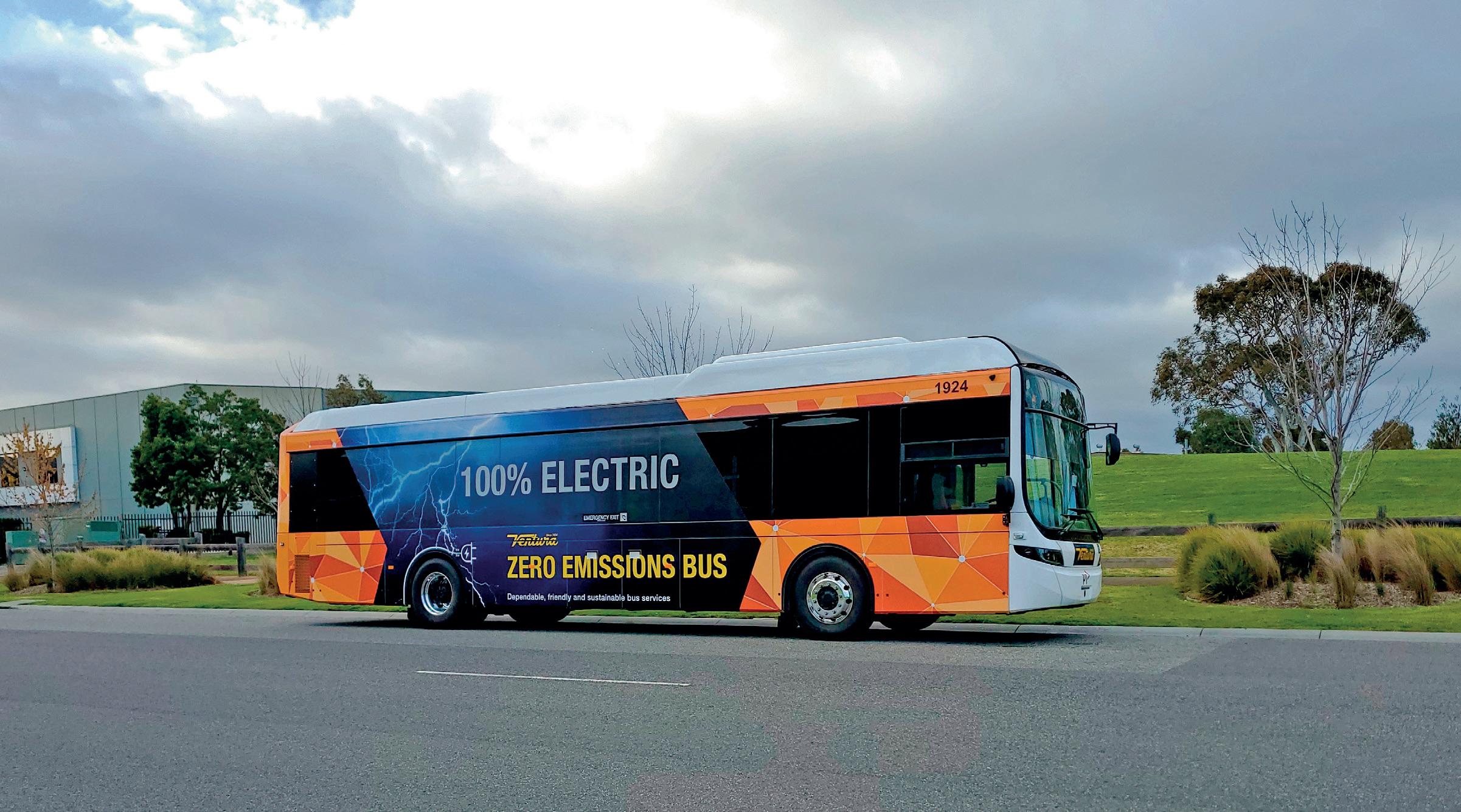

Keppel Infrastructure Trust (KIT) has divested a 24.62 per cent stake in bus operator Ventura Motors to private investment funds managed by Samsung Asset Management (Samsung).

Costing $130 million, the transaction is 19 per cent higher than the amount paid by KIT at acquisition for the relevant stake.

KIT acquired approximately 97.68 per cent interest in Ventura back in June 2024 for $600 million.

Post transaction, KIT and Ventura CEO Andrew Cornwall will continue to hold stakes of 73.06 per cent and 2.32 per cent respectively in Ventura.

“As part of KIT’s value creation strategy, we are pleased to be able to realise the upside in Ventura’s value through the divestment of a partial stake to Samsung,” Keppel Infrastructure Fund Management (KIFM) CEO Kevin Neo says.

“This divestment, coupled with our earlier divestment of our 50 per cent stake in Philippine Coastal Storage & Pipeline Corporation, both amounting to approximately S$301 million, will bolster KIT’s financial strength and agility, and enhance KIT’s ability to capture further opportunities through strategic capital recycling.”

“We committed to providing free public transport to regular passengers during this closure,” she says.

The retained routes include: Route 529 linking Armadale Station to Cockburn Central Station, Route 51 from Cannington Station to Perth Busport via Orrong Road and Route 36.

the stake

Ventura has a fleet of about 900 buses and 12 strategically located depots and has the largest market share of public bus services in Victoria, operating approximately 530 routes out of Melbourne’s 1,200 total routes and transporting more than 42 million people annually.

“As a provider of essential services, Ventura has continued to deliver market-leading performance in metrics such as punctuality and reliability,” Neo says.

“KIT is committed to work with the

Ventura management to strengthen and grow the business over time so as to generate stable, recurring and predictable cash flows for the Trust.”

The transaction is expected to be completed in the third quarter of 2025, subject to conditions and customary approvals from the relevant regulators and authorities.

KIT says the transaction is not expected to have any material impact on the distribution per unit and net tangible assets per unit of KIT for the financial year.

Above: Part of Ventura will now be owned by Samsung. Image: Ventura

Who is Transit Systems’ new NSW managing director?

The operator has appointed a new Sydney born and bred leader to run its NSW bus service operations

Sydney-sider Rino Matarazzo stepped in to lead Transit Systems’ network on May 26, his first day as the new managing director of the business.

Matarazzo brings more than four decades of leadership experience in the public transport sector to the role alongside a wealth of neighbourhood and industry knowledge.

Transit Systems group executive general manager of business operations Mark Peters says Matarazzo has built a “distinguished career” across rail, bus and government operations while demonstrating a focus on customer experience, stakeholder engagement and service delivery excellence.

“Rino is a highly respected and people-focused leader with a reputation of operational excellence.

Below: Rino Matarazzo.

His experience navigating complex environments and driving customer-first transformation makes him the ideal person to lead our NSW network into the future,” Peters says.

“Combined with our global team of transport experts and insights, Rino has the resources, capabilities and intel to raise the benchmark for what is possible in the NSW landscape.”

The appointment comes in the aftermath of Transit Systems achieving a record-breaking year of commendations from the community in the Sydney contract Region 6.

Matarazzo says this is a motivating benchmark.

“We are in the business of keeping cities moving, and if we are doing that with compliments from the

right track,” he says.

“I join Transit Systems at a dynamic time, and I’m passionate about delivering services that customers can truly rely on. I look forward to working alongside the talented Transit Systems NSW team to continue building a safe, efficient and people-centric network.”

Transit Systems has also extended its gratitude to Rachel Byrnes, who served as acting managing director over the past five months.

“I want to sincerely thank Rachel for stepping in during this interim period, and acknowledge the broader NSW team for their dedication and hard work,” Peters says.

“Their efforts have laid a strong foundation for Rino to build on as we

Hundreds of jobs at risk as Alexander Dennis plans site closures

The company says a “competitive imbalance” was partly to blame for the plans to move production down to England and close the Scottish sites

Up to 400 jobs are at risk after bus manufacturer Alexander Dennis announced plans to move operations to England.

The OEM, which has factories in Falkirk and Larbert, says it is considering moving manufacturing to a site in Scarborough in an effort to lower overall costs, deliver clearer responsibilities and increase efficiency.

Its Scottish based manufacturing in Falkirk, which has already been

reduced in recent years, would be discontinued and the site closed. Production lines at Larbert would be suspended upon the completion of current contracts.

The consultation puts up to 400 roles at Alexander Dennis at potential risk of redundancy, around 22 per cent of the company’s whole workforce.

Alexander Dennis president and managing director Paul Davies says the company must take significant

action to drive efficiency to allow its operating model to be competitive.

“It is extremely regrettable that as part of this, we must place jobs at potential risk of redundancy and propose to cease manufacturing operations at some of our facilities,” Davies says.

The company, which manufactures single and double decker buses, says the new proposed structure would lower costs and increase efficiency.

The company says it is facing strong competition from Chinese electric bus manufacturers, whose share of the market has risen from 10 per cent to 35 per cent.

“The stark reality is that current UK policy does not allow for the incentivisation or reward of local content, job retention and creation, nor does it encourage any domestic economic benefit,” Davies says.

“We have warned of the competitive imbalance for some time and would like to see policy and legislative changes that incentivise the delivery of local benefit where taxpayer money is invested.

“We strongly believe funding that supports public transport should lead to investment in local jobs, domestic supply chains, technology creation and a recurrent tax base.”

Above: Alexander Dennis may shift its manufacturing to England. Image: Alexander Dennis

Greater Wellington secures new site for bus depot

The council says by controlling depots, it is removing barriers for new bus operators to enter the market and thrive

Greater Wellington Regional Council has purchased a one-hectare site in Happy Valley for the development of a new bus depot.

The depot, set to open in mid-2028, will support the continued operation and future growth of Metlink services, including the transition to a zero-emissions fleet.

The council takes possession of the site in May 2026.

The acquisition was strongly backed by the community, with 86 per cent of respondents supporting the strategy during consultation on Greater Wellington’s 2024–2034 Long Term Plan.

Greater Wellington Transport committee chair Thomas Nash says owning depots is key to encouraging competition and ensuring value for money.

“Value for money for residents and public transport users through open and fair competition is a key plank of our strategy, which also aims to improve the passenger experience as we transition to a zero emissions fleet,” Nash says.

“This purchase gives us a base for growth by encouraging bus operators that do not have depots to bid for

to make long term investments in charging infrastructure for electric buses, at a location that will help us deliver a more planned, responsive and efficient network.”

Council chair Daran Ponter says that the depot’s location will enhance service efficiency across key routes.

“We need the right infrastructure in the right places,” Ponter says.

“The depot will be near the start of several bus routes – including the high frequency route 1 – and will support the expansion and electrification of north to south services.”

With the future of the earthquake-prone Kilbirnie depot in doubt beyond 2030, and space constraints at the existing Rongotai depot, the council is also planning further investments.

“That’s why Metlink is also exploring opportunities for another depot north of Wellington, and breaking ground on a new depot by the airport to buttress east to west buses –including our most popular service, the route 2,” Ponter says.

Deputy Transport committee chair Simon Woolf described the Happy Valley acquisition as “sensible future

“Happy Valley depot will eventually strengthen bus services between Wellington’s south coast and growing areas in the north,” Woolf says.

“It will initially stable up to 80 diesel buses, until sufficient energy is connected and battery chargers installed to power our expanding electric fleet.”

South Wellington bus user and regional councillor Yadana Saw says Metlink is committed to being a good neighbour and responsible member of the Happy Valley community.

“Securing this site safeguards public transport assets in public ownership. It enables genuine engagement with people working and living nearby and strengthens our partnership with mana whenua Taranaki Whānui and Ngāti Toa Rangatira – bringing us together on any sites of significance,” Saw says.

BigAir Gym will continue to operate on the site, and other tenants will be given time to relocate.

When development begins, Metlink will work to protect Ōwhiro Stream from any stormwater run-off that comes from the section.

Valley site will stabilise bus services in the region. Image: Metlink

Bus safety: Not expensive, priceless

The BIC is continuing to focus on making buses safer for passengers of all ages, including through recent seatbelt education campaigns

The Bus Industry Confederation (BIC) continues to advise and support governments across the country in the revision of bus safety requirement policies — particularly on dedicated school bus services.

The BIC has developed a suite of operator guidelines and industry advisories on fire, passenger door, roll-over and seatbelt safety, for example, as well as submitted numerous papers to key government stakeholders and reviews. Its Safety Initiatives Paper details key topics and matching recommendations, including implementing a national harmonised approach to bus safety awareness aimed at education in schools and the general public.

Of recent focus are education and awareness campaigns to encourage seatbelt use, which have traditionally focussed on cars with little or no reference to buses. It’s generally accepted that seatbelts should be worn if present, though the lack of focus on buses over the years meant that it hasn’t been automatically adopted by passengers and especially not school children. Various state-based approaches to seatbelt safety in buses have always existed, yet they’ve varied in their promotion in the classroom.

Following its official national launch last year, the BusSAFE school program extended its reach beyond South Australia into Queensland and Tasmania.

By term two of 2025, BusSAFE presenters had opened the program in regional Queensland with school visits in Gympie, Emerald and Beaudesert, and further south in

the Tasmanian north coast. Term three will be moving into regional hubs like the Gold Coast, Toowoomba and outer suburban Hobart.

The BusSAFE message remains clear: stay alert at the bus stop, don’t distract the driver or other passengers, be prepared for emergencies and use seatbelts, headphones and phones responsibly.

Teaching students how to safely cross the road around buses, with a focus on blind spots, is also key.

One student reported that the most important thing learnt during a BusSAFE session was that “there are lots of spots (outside the bus) where the driver can’t see you”.

Bus drivers transporting students from the first schools in Launceston to take part in the program also noticed the change in their young passengers, such as reminding others to wear their seatbelts and to remove earbuds around buses. These are the kinds of early interventions that create safer journeys for everyone.

BusSAFE will move into New South

Wales, Victoria and Western Australia later in the year.

In January this year, through the BIC’s advocacy efforts, a new Australian Design Rule (ADR) to improve seatbelt wearing rates in buses and coaches was finally introduced to help save lives on our roads following consultation with the states, territories and industry.

Coming into effect from November 1, 2026, the new requirements include visual and audio alerts on buses and coaches – similar to those featured on air travel – which aim to encourage usage where three-point seatbelts are present. It also removes a loophole that allowed some coaches not to be fitted with seatbelts.

While current data shows bus and coach travel remains one of the safest forms of transport, their size and passenger capacity can result in a greater number of fatalities and serious injuries in the event of an incident.

This victory, then, is highly welcomed. Both this outcome and the success of the BusSAFE program point to the ongoing commitment to bus safety and co-operation with industry, states and territories by government. It also represents the next step toward encouraging all passengers, including our kids, to protect themselves while travelling by bus and coach.

For more information on BusSAFE, visit bussafe.com.au or email info@bussafe.com.au.

For more on bus safety, visit: bic.asn.au or email communications@bic.asn.au.

schools across

Above: School bus safety is a key focus in various ways. Image: AGDER/ stock.adobe.com

Bundaberg beacons

Bundaberg Coaches’ two new BLK coaches are putting a popular north Queensland town on the map for a whole new reason, Sean Mortell writes

For many Australians, Bundaberg is an iconic place.

As home to the popular rum distillery and brand of beverages, the town north of Queensland’s Sunshine Coast is a household name.

It’s not just the well-known label that is now making Bundaberg a popular stop for many travelling through Queensland’s north. For more than half a century, Bundaberg Coaches has been a touring giant in the area, providing a crucial link to the breathtaking countryside, stunning greenery and pristine beaches that encapsulate the region.

“I bought the business in 2011 from Mick and Carol Foley – they had developed a really strong touring following in the area,” Bundaberg Coaches director Jason Beresford told ABC

“The Foleys had scaled it back

from several to two vehicles to make it more manageable to sell, and I’ve slowly grown over time.”

The Beresford name is now driving the historic operator forward in north Queensland. The Burgess family initially established the business in 1972 before the Foleys took over roughly a decade later. Now, the Beresford leadership has seen Bundaberg Coaches further enhance its reputation in the region while driving the charter and mining sides of the enterprise.

The latter is a particular source of growth for the business – while Bundaberg Coaches has always been synonymous with tour and charter trips in the area, the mining transport avenue is allowing the popular local business to add more strings to its bow.

“We have steadily expanded into the mining game, starting with a contract we won to run vehicles to

Above: Bundaberg Coaches has welcomed unique BLK models to its expanding fleet

and from Middlemount Coal Mine,” Beresford says.

“We permanently run two buses from the mine site to the camp, while we also run two return services a week from Bundaberg, Rockhampton and Mackay to the camp and mine site.”

On top of this, Bundaberg Coaches has also secured a contract to run services at Rolleston Mine near Emerald. It’s resulted in the most diverse operations to date for the ongoing transport operator. With these various requirements comes the need to buy unique and tailor-made vehicles.

This is where BLK comes in. Since emerging in the Australian market in 2006, BLK Auto Bus & Coach Sales has emerged as one of the leading luxury bus and coach suppliers to the local industry. With Bundaberg Coaches currently completing tour and charter, mining transfer and

rail replacement runs in its daily operations, the operator has trialled its fair share of bus brands.

It has landed on BLK as its supplier of choice on its latest delivery of two 14.5m coaches.

“The idea behind these coaches was that we didn’t previously have vehicles that were specifically tailored to certain tasks in our operations,” Beresford says.

“We needed vehicles that we could trust to go to mines one week and then complete rail work or school charter or tours elsewhere the next.

“We decided to go to BLK for this –they are the third and fourth deliveries from the brand into my fleet, with the previous models having performed really well to date.”

The recent delivery of two BLK President 3 coaches join the Bundaberg Coaches fleet, ready to complete a range of runs. However, these models aren’t your usual buses. Instead, Beresford has worked with BLK to produce two unique vehicles that differ from a standard three-axle coach.

“We’ve spec’d these coaches in a luxury style – I call it a charter spec, as it includes longer range due to extra fuel,” he says.

“We’ve added large fuel tanks into the design and we’ve introduced new diamond stitched leather seats

to create a more upmarket look. Then throw in the standard stuff – a bullbar, driver lights and USB charging built into the seats.”

The two coaches, which are also trialling Starlink to allow for streaming and Wi-Fi for passengers, have been designed to ideally fit the demands of running to and from Roleston Mine and Middlemount.

“When we run out to these two mines, we do go through black spots, so Starlink will allow us to remain in communication with the vehicles too,” Beresford says.

“We made sure we have also included the biggest motor that we can get to provide the largest amount of fuel possible. They are very nice vehicles.”

During the build process of the BLK President 3 vehicles, Beresford sourced two used vehicles as a “stop gap” which will now continue to be used in the mining and charter and tour operations.

“I always liked to have at least four buses in the yard at all times, as it meant we could cover the majority of our charter work, but now it’s more like 12 in the yard,” he says.

“We’re doing more work for new customers and our charter side is continuing to grow, while our mining operations are steady.”

The two BLK Presidents signal

Below: The coaches will

a change for the operator. The delivery is the first time Beresford has sat down and designed two vehicles specifically suited to the mining task. While they follow in the suit of previous buses and coaches that can handle a variety of long distance transfer operations, these BLK Presidents can also be put to use when Bundaberg Coaches completes contract work for Queensland Rail replacement services.

“We handle all the breakdown and rail replacement work for the local area, and it requires us to have wheelchair accessible vehicles,” he says.

“That’s just one of many specs that we needed in these vehicles, which BLK helped us out with.”

On the BLK side, the two President coaches join a duo of Senator 8 models at 37 and 33 seats respectively that the supplier first delivered to Bundaberg Coaches. On this latest delivery, BLK sales and special projects manager David Jiear says the company was keen on ensuring every detail of the unique coaches was spot on for Beresford’s team.

The specifications of the President 3 coach consist of the usual in a vehicle of this calibre, such as a rear toilet and wheelchair loader over the rear axle so not to encroach over the rear bin space, with the other options added

by Beresford including driving lights and a larger fuel tank of 800 litres.

The success in all of this, along with the X12 engine and steerable tag axle with the modest tare weight, is that it provides peace of mind when refuelling and loading the large luggage bin area. All of this is giving Jason and the Bundaberg team the perfect coaches for their operations.

Another key factor in BLK’s design that piqued Beresford’s interest was the brand’s use of all-American running gear. With the Cummins X12 engine being joined by an Allison transmission, Beresford says the American running gear is durable and efficient.

“These new models have already started working – one has done a mine run while the other has gone to the snow in Canberra,” Beresford says.

“The first runs are showing really good fuel efficiency, but we’ll continue looking at the data to see just how efficient they are.

“We always like to use the Allison and Cummins combination, as we think they work very well together. We have a good relationship with both companies and we get great local support from them.”

These latest unique deliveries are a highlight of a productive year for BLK. Whether it be school buses, charter vehicles or mining coaches, BLK has seen its order bank grow in 2025.

“Traditionally, our President 2 model has been our bread and butter coach, but we’ve also seen an increasing interest in our smaller President 10 model and our 14.5m President 3 that Bundaberg Coaches has received,” Jiear says.

“We’re continuing to expand off the back of this – we’ve put on more staff throughout the business and have expanded our sales and aftersales presence around the country. We

to have nearly $2 million in parts stock for a wide range of manufacturers.

“There’s a mix of vehicles we’re pushing through currently, and we’re also looking at what we will introduce at next year’s bus expo. It’s busy times for BLK.”

Despite the hectic nature of business for the brand, Beresford is grateful that BLK was still able to sit down with him and produce two ideal coaches for Bundaberg Coaches. One of the deliveries will continue working a “pretty demanding run” on rotation to and from Roleston Mine, while the other model will join the 15-bus fleet to complete a wide range of tour and charter activities.

Much like BLK, Bundaberg Coaches is continuing to experience a boom in demand. With meticulously designed vehicles like the two unique BLKs, Beresford is confident that Bundaberg and BLK can continue forging a strong reputation in Queensland.

“We’re looking to continue enhancing our charter capabilities –our distance to Brisbane sets us up as an ideal long-distance operator,” he says.

“I have faith that these vehicles will continue working well, which will allow us to offer leading travel options

Below: The all-American running gear is a

Above: The Sege diamond stitching pattern seats is a stand-out with the interior

Need Australian Made aluminium extrusion? Capral can do.

As Australia’s largest supplier and extruder of aluminium, Capral is committed to supporting Australian manufacturing with high-quality, locally produced aluminium extrusions. Our state-of-the-art facilities provide precision-engineered solutions for the transport industry nationwide.

Choosing Capral is an investment in reliable supply, shorter lead times, and a stronger Australian manufacturing sector.

When you need Australian-made aluminium, Capral can do.

New kid on the block

In ABC ’s latest test drive, Paul Aldridge took Yutong’s D7E around Sydney to see how the nifty electric bus works in suburban and community applications

Over the past decade, the Yutong D7 (originally introduced under a different badge) has become a popular member of Australia’s bus and coach market.

In the past year, the emerging success of the D7 has included a new element. VDI has introduced an electric version of the much-loved model to the local market. On a pleasant Sydney day last month, ABC ’s resident bus reviewer Paul Aldridge got to hop behind the wheel of the D7E and put it to the test.

In 2022 he was driving the D7 –while it may not be that long ago, plenty has changed since Paul last got his hands on Yutong’s smallest bus model in Australia. All of these updates are reflected in the D7E, which mirrors its diesel older sibling but is creating its own path forward with a range of nifty improvements that only a zero-emissions driveline can offer.

Being able to introduce an electric counterpart to the D7 has been a source of great pride for the VDI Australia team. The seven-metrelong Yutong bus now comes with the latest electric and overall safety features to make the D7E Yutong’s safest and most secure model to date in Australia.

“We’re proud to have this fully electric model in Australia with an advanced driver assistance system and a raft of other leading safety packages,” VDI Australian national sales manager Sara Clark told ABC

“It’s a fully integrated product that comes with Yutong’s electric architecture and YESS safety standards, creating five layers of protection for the entire bus and its systems. The overall build quality of the D7E is fantastic.”

In the years that have passed between VDI introducing the D7 and the D7E to the local industry, a lot has changed. However, Paul

Above:

While it may feature a different power source, the quality is the same on the D7E compared to the D7

immediately noticed that safety still remains paramount for the local Yutong distributor.

“With the D7 diesel variant, a big selling point of this bus was safety, safety, safety,” he says.

“The D7E is no slouch in this area, featuring cameras all around the bus to provide a 360-degree visual for drivers to see pedestrians and other vehicles.

“I’m very impressed – the D7E lacks nothing when it comes to safety, even including automatic sounds for when it travels under 20km/h to alert vulnerable passengers.”

Alongside these updates is a refreshed dashboard that better displays the driver warning system and the mobile eye camera technology. Outside of this, expect the D7E to be as similar to its diesel variant as it can be, with the usual increased electric safety features onboard ensuring the electric battery is kept safe and protected.

Images: Paul Aldridge

“This includes 24/7 battery monitoring, nitrogen injections into battery packs, crash barriers, pack protection, fire blankets and base cell level cell monitoring of temperatures and voltages,” VDI Australia national service and technical manager Luke Edwards told ABC

“With disc brakes as standard, the regenerative braking on the D7E allows the bus to not use the brake pads while creating its own power.

“We’ve also added a hill start assist to ensure the electric bus doesn’t roll back on a hill when you’re going to take off.

“We kept development on track with the previous D7 when building this – it’s literally an electric version of the diesel bus.”

One key tweak Paul notices as he goes to hop into the D7E is the remote control door opener, labelling it “fantastic”. Upon climbing the two steps into the bus and then towards the driver’s area, the lack of an engine cover creates more space.

“It’s nice and accessible to drop into this area, and the visibility as a driver is fantastic,” he says.

“The driver compartment area is more spacious. With a screen, A/C controls and buttons for doors and steering wheels, it makes life easy.”

While the D7E may run on completely different power technology when compared to its diesel older brother, the VDI team says the drive and feel of the bus closely mirrors the D7. Instead, it’s just a quieter and smoother ride for passengers without the noise of the diesel engine.

The noise is so quiet on the D7E that VDI has had to install a pedestrian warning system so that pedestrians can hear the bus coming when it travels under 20km/h. Over that speed the D7E meets the 50db of noise cut-off, mainly due to the sound of the tyres.

“Realistically, people wouldn’t know that it was electric until you point it out to them. It’s a really different experience, for the better,” Clark says.

When Paul begins driving, he agrees – if he didn’t know it was electric prior to taking it off, he thought it could be a diesel bus that is very well insulated.

“It drives very well and is so easy to manoeuvre – it’s very car-like,” he says.

“I can negotiate it through any tight space with confidence, and the 360-degree camera means it’s very difficult to hit anything unintentionally.”

Under the bus, five batteries form a 175kW system for the D7E model, with

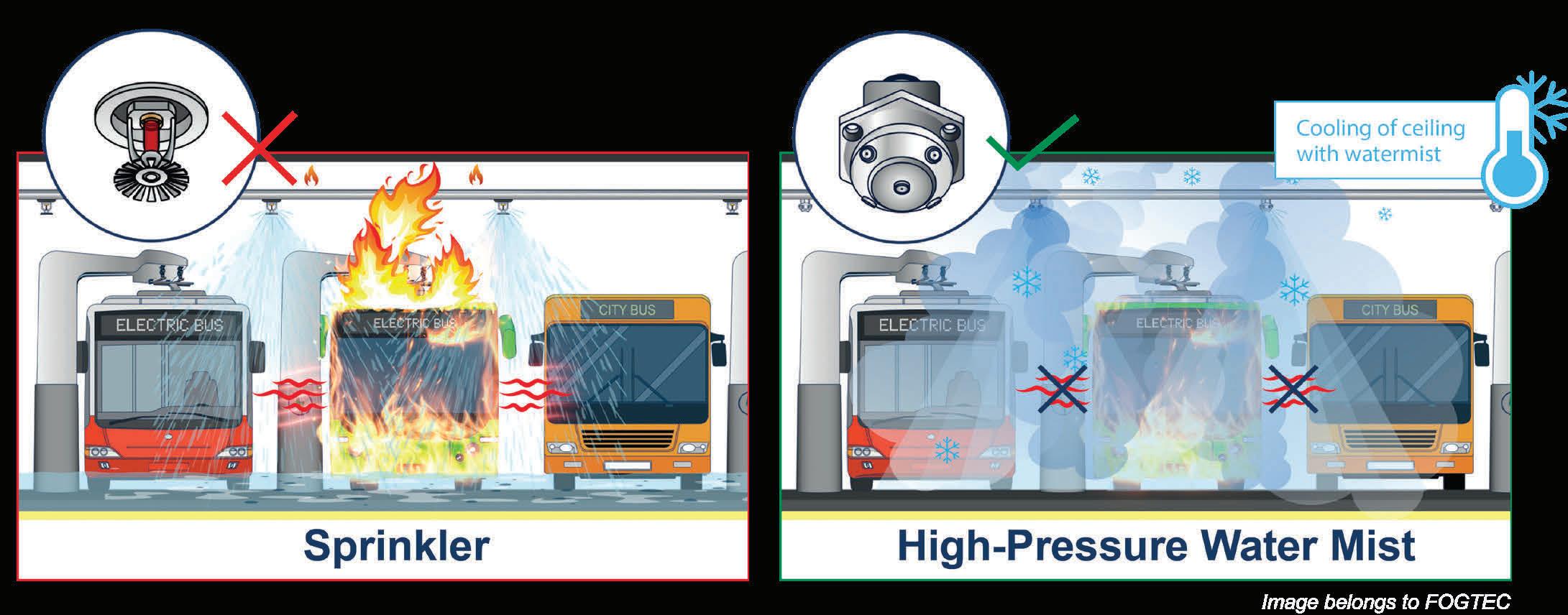

Time to tick all boxes

Fire Protection Technologies is stepping up to provide effective fire suppression solutions that suit the evolving electric transition, Tiarna Condren reports

The Australian bus and coach industry has spent years finetuning electric vehicles to be cleaner, quieter and, most importantly, safer than ever before. Introducing advanced battery monitoring systems, driver-assist technology and thermal imaging, it seems the industry has ticked all the boxes.

But while they’ve been busy making them safer on the road, there’s one

in the rearview mirror – what happens when something goes wrong and a fire breaks out?

With lithium-ion batteries powering a growing number of buses across the country, and new charging depots being built at scale, the risks involved with housing and operating electric bus and coach fleets are real and increasingly complex.

“The industry’s done a fantastic job making EVs reliable and safe,” Fire

Below: The dangerous effects a fire can

manager for water mist and oxygen reduction systems Barry Farrell told ABC

“But fire risk hasn’t been front and centre. With lithium-ion batteries, that’s not a box you want to leave unticked.”

Starting operations in the late 1990s as Halon gas systems were being phased out due to environmental concerns, Fire Protection Technologies founder Pat Harrington seized the opportunity to introduce specialist hazard products to the Australian market.

Specialist hazard products provide precise, effective fire suppression solutions that are customised to protect critical or sensitive assets where standard sprinkler systems could be too harsh or ineffective.

“Pat saw a gap and filled it,” Farrell says.

“He began importing alternatives to Halon from the US, partnering with companies like Fike and from there, the product range expanded into water mist and other advanced suppression technologies.”

Now, with electric buses and their infrastructure creating new kinds of risks that operators and OEMs alike must manage, the safety company is once again moving to fill a critical gap in the local market.

“Despite the rapid growth of electric buses across Australia, there are currently no national standards or requirements specifically addressing fire safety in EV buses, charging depots or maintenance facilities,” Farrell says.

“Traditional buses have long been covered under established fire protection codes, but with the evolving nature of EV technology, new risks aren’t yet reflected in legislation or building guidelines.

“This could lead to some problems for the industry.”

Overseas, the risks involved with

running these batteries are already being realised, as multiple depot fires have made headlines and safety guidelines have become more stringent.

Farrell says that these electric bus batteries, when damaged or faulty, can enter a volatile state known as thermal runaway which can cause intense, fast-spreading fires that are difficult to extinguish.

“When a lithium-ion battery goes into thermal runaway, it can spread rapidly, especially when buses are parked closely together in depots charging overnight,” he says.

“In Europe, where many bus depots are fully enclosed, that creates an even higher risk scenario.”

The introduction of electric buses into Australia has been slower than in countries like Germany, and while many will complain about the gradual adoption being seen locally, Farrell sees this as a blessing in disguise on the safety standard side.

together with the company for more than a decade.

“FOGTEC has the only tested system of this kind,” Farrell says.

“We’re in a unique position to learn from Europe’s experience and deliver evidence-based fire safety solutions for new energy carriers like lithium-ion batteries, hydrogen and biofuels,” he says.

One of the ways Fire Protection Technologies aims to do this is by continuing its work with German-based fire suppressant company FOGTEC. FOGTEC brings almost 30 years of experience in water mist fire suppression, with Fire Protection Technologies having tackled modern low and zero-emissions transport safety issues

“It has worked directly with the German government under the SUVEREN program to develop protocols for battery fire suppression. And this is not just about control, but true suppression that actively reduces the heat release rate of a fire.”

Instead of dumping lots of water on the batteries like a traditional sprinkler, the mist system sprays super-fine droplets that quickly soak up heat and turn to steam. This steam helps choke the fire by pushing away the oxygen it needs to keep burning.

Due to the droplets being so small, the system can cool a fire from over

500°C down to about 50°C in under a minute.

“It’s not about extinguishing the fire immediately, but buying time, limiting its spread and reducing risk to first responders,” he says.

The benefits of high-pressure water mist systems aren’t just limited to fire safety.

Due to high-pressure water mist systems using significantly less water than traditional sprinklers, they greatly reduce the amount of contaminated run-off that can carry hazardous chemicals, debris and pollutants into the environment, helping to protect nearby waterways and reduce clean-up costs after a fire event.

“It ticks both boxes,” Farrell says.

“It’s providing a way to safeguard assets and people, while also being mindful of your environmental footprint.”

As the company continues its work in providing critical systems for operators and their buses, Farrell is still left lamenting a lack of national standards for the industry to follow. He says now is the time for change and for pen to be put to paper to make electric vehicle safety guidelines official.

“We need collaboration between government, insurers, engineers and the fire protection industry to create a national standard for fire safety in EV bus depots or charging environments,” he says.

“We’ve seen what can happen when things go wrong, and it would be irresponsible not to act on that knowledge now.”

Above: Fire Protection Technologies product manager for water mist and oxygen reduction systems Barry Farrell

Switched on

E-T-A’s newest innovations are silently powering the transition to zero-emission vehicles

When it comes to electric buses, most of the focus tends to be on big, obvious innovations like battery technology or electric drivetrains. But behind the scenes, it’s the small, smart components that are helping drive real change.

German parts supplier ElectroTechnical Applications (E-T-A) is playing a quiet but crucial role in that transition, working with bus manufacturers to lighten the load and reduce emissions without cutting corners on safety or performance.

“We’re trying to reduce complexity, save weight and lower power draw,” E-T-A Australia managing director Andrew Skaltsounis told ABC.

“That’s what makes our components so valuable, especially in electric buses where every kilogram counts and every amp matters.”

At the heart of this effort is the EPR10, a solid-state electronic power relay designed for use in high-current applications on 12 and 24-volt electrical systems.

“In high-power battery circuits, especially in electric buses, the EPR10 can handle key switching operations without generating heat,” Skaltsounis says.

“That means no risk of overheating, no extra space taken up by heat sinks, and less weight overall.”

Unlike traditional relays that rely on mechanical switching and often generate heat that requires bulky heat sinks, the EPR10 operates silently and efficiently, with no need for external cooling.

Introduced to market around two years ago, the relay quickly earned a reputation for reliability. Available in two variants, the EPR10-N (a standard relay without protective functions) and the EPR10-P (a protective relay that monitors load current and thermal load), it offers continuous current switching of up to 200 amps at 24 volts DC.

Used for high-load systems in buses and utility vehicles for pumps, ventilations and cooling systems, the relays are vital to vehicle operation and passenger comfort.

With its advanced heat management, the EPR10 eliminates the need for extra cabling, fuses or bulky mounts. Instead, it’s cooled via its own connecting cables, and its compact size takes up to 80 per cent less space than comparable solutions.

By reducing internal resistance and holding power, it requires less energy to operate, particularly in standby conditions. That means lower energy demand from the battery and, over time, less strain on the entire system.

“People might say, ‘Well, if you’re only saving 500 grams on a component here or there, what’s the big deal on an 18 tonne bus?’” Skaltsounis says.

“But it’s not just the weight of the relay itself. It’s about reducing the entire system’s complexity – fewer cables, fewer components, less heat and ultimately, fewer failure points. That all contributes to better energy efficiency and lower emissions.”

The EPR10-P also includes built-in

current and thermal monitoring. If a circuit overloads, the device automatically disconnects the load and issues a group fault signal, helping to prevent overheating, fires or further electrical damage, which is especially valuable in demanding operating conditions.

With sealed circuitry, the EPR10 is highly resistant to dust, moisture, vibration and mechanical stress, making it a natural fit for vehicles that operate all day, every day, often under punishing conditions.

“If you’re building out a panel and need a reliable, compact component that won’t overheat or rattle loose, this is the one,” Skaltsounis says.

The company is also continuing to evolve its product range, including the MPR20 series of relays and the SCS switching systems, which are used for lower-power circuits.

Each of these developments, whether big or small, feeds into a broader goal of helping bus manufacturers meet sustainability targets without adding complexity or sacrificing performance.

And that’s exactly where E-T-A shines, behind the scenes, helping to power the future of transport.

Above: The EPR10 is available in two variants. Image: E-T-A ElectroTechnical Applications

Driver’s seat

Since January, Busways has been led by a new CEO outside of the Rowe family. But Will O’Neill is quickly proving that he’s up to the challenge of leading the longstanding operator

Growing up in the Sydney suburb of West Ryde, buses have always been an integral part of Will O’Neill’s life.

“My mother didn’t drive, so buses were our main means of getting around when I was a kid,” he told ABC “Whether it was going to the dentist or heading to Parramatta to do special shopping, buses were always important.”

Now, decades on, buses form an even larger part of Will’s life. Since January, 10 years since he first started

at the company, Will became the chief executive officer of New South Wales operator Busways.

Will is proud to be in the bus industry, to have the sector coursing through his veins. However, that doesn’t mean being the CEO of Busways is always rosy for him and his family.

“I have seven children, a number of which are school aged, and they catch our buses to school,” he says with a chuckle.

“It’s nice being the boss of the company that delivers their school

Above: Will O’Neill is the new CEO of Busways, with Byron Rowe the new executive chair

bus services but the downside is when a bus happens to arrive late and everyone knows to come to me.”

Will hasn’t stepped in to just any old local bus company. As the largest Australian-owned bus operator, Busways has a rich legacy in both the NSW and national industry. For the past 82 years, since Dick Rowe founded the company, Busways has been led by the Rowe family, with Dick’s grandson Byron the latest managing director.

The move to handing over the reins to someone outside of the Rowe family is a massive step, with Byron

assuming the role of executive chair of the Busways board following his seven year stint as managing director that saw the operator double in size. While it’s sizeable shoes to fit into, Will is ready to continue the successful Busways history.

“It’s a great privilege to be leading Busways as CEO,” he says.

“As a business, it has such a great heritage and legacy as a family-owned company. While it is still family owned, Busways has never been about the family that owns it –it’s been about the business family and the wider Busways team.

“It’s been a consistent theme for decades that continues to this day that Busways is never about the singular person, but instead the wider collective.”

So who is the new leader of Busways, and what does he bring to the table? Will’s experience speaks for itself, with more than 30 years spent in senior executive leadership, corporate finance and strategic planner roles. This includes being a director at Pitcher Partners, the Australian strategy manager of ORIX, a partner at KPMG and an executive director of accountancy firm Kelly+Partners.

His involvement in the bus industry may not have been as pronounced during this time, but in 2014 he returned to the sector that was so pivotal in his childhood. It started with the group manager of strategy role at Busways before Will became the chief financial and commercial officer in 2018. Now, as the CEO, he’s prepared to take over the likes of Byron and Dick to continue the Rowe family business’ rich legacy.

“I’ve spent a couple of decades in consultancy and accounting, working across a broad range of businesses and industry sectors,” he says.

“That’s allowed me to bring a kitbag of insights into Busways. I’ve received wonderful tutelage from Byron and Richard on the bus business that has more or less prepared me for the role of CEO.”

Will’s experience at Busways in his decade at the NSW operator has included playing an active role in tendering. It’s a sector that has proven critical to Busways’ longevity – in the

1970s there were approximately 40 private bus operators in the Sydney metro area alone, making it the most challenging and competitive markets in the country. Now there’s only one – Busways – and it serves 20 per cent of the market. Tendering has proven crucial to adjusting to this drastic change in operating conditions.

Will also played a major role in developing the on demand services in The Ponds, north-west of Sydney’s CBD.

“The on demand service has been hugely popular and is very much up there with some of the best on demand services in the world,” he says.

“That was my baby, and the experience has put me in good stead to take on the role of CEO and cover all aspects of the business.”

Since stepping into the role in January, Will has already had to tackle a fast-amassing pile of industry issues that are challenging operators. From driver shortages to the increasing

Above: Will has capped off a long history around buses with the role of CEO of Busways

difficulty of contract tendering, Busways is in the midst of change in the Australian bus industry.

“The challenges that we’re facing as an industry have been a great stimulus for me to kick into gear in this role,” he says.

“It has also allowed me to very quickly establish myself and create a bond with the leadership team. We’ve forged a closer and more collaborative working relationship that has had to work through changes that have occurred.”

This new look leadership team also includes the promotion of Helen Wong to Chief Financial Officer in

January, with Helen mirroring Will in starting at Busways around a decade ago. As part of this latest operating model that Busways has created at the top, Will leads the entire company while Byron now looks at bigger picture topics from his position as executive chair.

“It’s very important to have someone out of the daily operations who can have an overarching view of where the industry and where our business is at – that’s what Byron is doing,” Will says.

“He looks at the more strategic elements, while a large part of my focus is on our day-to-day operations

and our execution.

“Byron is an exceptional professional and has an outstanding understanding of the industry – he continues to add a huge amount of value to the business in his new role.”

Under this evolving leadership structure, what does the future look like for Busways? Will says it’s all about growth – the nature of tendering and contracts means operators have to continue building their operations to a size that makes organisations resilient to contract changes.

With a “clear aspiration” of reaching 3,000 buses in the fleet by 2034, Will says this growth can be reached in a variety of ways.

“We’re in the fortunate position that we haven’t had to re-direct our business in a different way,” he says.

“My focus is on continuing the evolution of the business that Byron has established while continuing to improve on our execution each and every day.”

It may seem like any usual year, but 2034 is a key number for Busways. All eyes are focused on reaching this audacious bus fleet goal. While this happens, the NSW and wider Australian industry continues to consolidate. Will is adamant this process is ongoing, and that Busways needs to be on the right side of consolidation.

“Our goal is to ensure we’re one of the consolidators, and not a business being consolidated,” he says.

“We need to do this without losing what makes us special. We’ve established ourselves as pioneers in numerous sectors, particularly with zero-emissions buses. We’re making a clear focus on trying to establish best practice in that space and become a leader.”

Recently, Busways has also signalled its intention to grow into different areas. When Dick Rowe first founded the operator, it was based in the beating heart of Sydney’s suburbs. Now, Will has aspirations to bring the Busways badge to more Australian states in the near future. In NSW alone, Busways is operating all over Sydney and the Central Coast, the NSW north coast and in South Australia. The goal is to not stop there.

Above:

The new leadership structure sees Will oversee the day-today operations

“We want to be the go-to operator for our clients, including transport authorities in South Australia, New South Wales, Victoria and Western Australia,” he says.

“On the technology side, we also want to have 50 per cent of our fleet be electric buses by 2034. We’re well on track and have a clear pathway to achieve this. While doing so, we’re keeping an eye on other advancements in bus technology.”

This doesn’t mean the present is filled with joy and success – Will admits Busways is continuing to work through industry challenges. While he feels that Busways “is on the other side” of the driver shortage, he is leading the operator through a bus crisis and a slower electric bus roll-out in NSW than predicted.

“We’re working closely with Transport for NSW to achieve the deployment of more electric buses as soon as possible,” he says.

“One side benefit to this challenge is

it allows us to work more collaboratively in the market with other operators – collaboration is key and we now look to the government to come to the party and achieve better solutions.”

For the immediate future, Will is committed to delivering the best services each and every day for passengers. This includes supporting an ever-growing team that he is immensely proud of. It’s this culture that he wants to foster and build on as Busways searches for more success around Australia.

“I’m so proud of our team of 2,800 people who withstand all of our challenges, from increased congestion to bus shortages and a rise in anti-social behaviour – they try and do their best job every single day,” he says.

“My favourite part of the role so far has been getting out to depots and talking with our drivers, mechanics and depot staff to understand what is happening on the coalface. They’re

very passionate, invested and resilient – this underpins Busways’ success to date and will do so going forward.”

As Busways casts its eyes on the lofty goals it has placed in front of itself, it is also calling on the industry to continue supporting local operators. While Busways may be the largest 100 per cent Australian owned operator currently, Will knows the industry needs to continue giving local operators the chance to shine.

“We believe Australian operators should have a fair representation in the market and have something to offer it more broadly,” he says.

“We have strong ambitions to expand into other states and we think we can add good value there, so when opportunities arise we’ll put forward our credentials.

“It will strengthen our business and allow us to become a larger and more diversified Busways that provides opportunities to our people.”

Driving real impact

For years, Yutong has had its eye on bringing over its electric bus technology to Australia. Its partnership with Tropic Wings allows it to be at the forefront of sustainable change

With zero-emissions deadlines and sustainability targets looming closer, operators across the country are faced with one important question. To electrify or to not?

For some, the decision is made for them, with state governments slapping down mandates with a timeline. For others, however, the choice to turn electric is one they embrace with open arms.

Among the latter is operator Tropic Wings. Leading a quiet revolution in Far North Queensland, the company’s daily tourism operations have been running cleaner, smarter and more sustainably for over five years due to its move to welcome zero-emissions technology into its operations.

Taking delivery of a Yutong E12 back in 2019, the Cairns-based company has been carving out a leadership role in sustainable transport ever since.

Now, the company boasts a fleet of almost 40 buses, with 36 per cent already electric models.

“Tropic Wings is showing how practical decisions today can shape a cleaner and quieter tomorrow for its passengers and community,” Yutong Queensland and Northern Territory account manager Clark Jingxin told ABC

“This commitment to electrification isn’t just symbolic. From scenic charters to daily shuttles through the Cairns Botanic Gardens, Tropic Wings has made electric buses a core part of its operations.”

The Yutong D7E and C12E models

Above:

Tropic Wings boasts a fleet of almost 40 buses, with 36 per cent already electric models

form the backbone of Tropic Wings’ electric fleet, with these particular buses selected for their range, comfort and proven performance in hot and humid environments.

Used across the operator’s tourism, school contracts, charter and long-distance work, the electric models have helped redefine the customer experience – with driver and passenger comfort a big selling point.

Standing by the operation philosophy of “putting customers at the centre”, the C12E boasts a new generation of luggage racks and semi-hidden brackets balancing aesthetics with practicality.

A spacious flat floor, new-style air outlet and high-quality seating round out some of the customer-fo -

Images: Yutong

cused details that make the model a popular vehicle for passengers to hop onboard of. For the drivers, the car-like layout and multi-functional steering wheel, coupled with fully automatic headlights and wipers, make for an improved driving experience.

The D7E combines innovative technology and thoughtful design, delivering an exceptional passenger experience that exceeds the needs of operators across Australia.

“Safety is paramount for us,” Jingxin says.

“The D7E is equipped with lane departure warning, blind spot monitoring and a range of other advanced safety technologies.

“These features work together to help prevent accidents and keep passengers safe.”

With the Yutong electric models providing a smoother, quieter and more environmentally responsible journey for passengers and drivers alike, Jingxin says none of it would be possible without the right technology behind the scenes.

Yutong’s Link+ Telematics platform powers the day-to-day efficiency of the operation, giving Tropic Wings real-time access to energy use, fault alerts and GPS tracking. Additional local driver training and 24/7 technical support from Yutong means the team can focus on running services, not solving problems.

“Working with Tropic Wings has been a true collaboration,” Jingxin says.

“They’ve helped us better understand regional tourism needs and we’re proud to support their push to make sustainable transport a real-world success.”

For Tropic Wings, the shift to electric has delivered practical business outcomes, with the company reporting a 30 to 40 per cent reduction in running costs per kilometre. Maintenance requirements are lower, vehicle availability is up and passengers are consistently enjoying the difference.

With more than a year of daily service under their belt, the electric fleet isn’t just meeting expectations –it’s raising them.

“It’s not just about saving money or going electric for the sake of it,” Tropic Wings general manager Colin Anderson told ABC

“Our passengers enjoy the ride more, and we know we’re helping keep Cairns clean for the next generation.”

Anderson says that the feedback from the local community has been just as rewarding.

“We’ve even had locals stop our drivers to ask about the buses. People notice the difference, especially around town where the quiet ride and lack of fumes really stand out.”

With fewer emissions and less noise, the impact of the new fleet extends beyond the depot.

Tropic Wings estimates its transition to electric has removed the equivalent of 2,954 tonnes of CO2 emissions annually, a figure comparable to planting 33,696 trees every year.

It also means clearer air and quieter streets around some of the region’s

most iconic tourism destinations.

Tropic Wings is now within reach of its goal of converting four in every five vehicles in its fleet to electric by the end of the decade, and that ambition is already influencing how other operators are setting their own fleet targets.

From operators on the Great Ocean Road to those in Central Australia, tourism businesses across the country are watching how Tropic Wings is committing to a more sustainable form of tourism transport.

The operator’s success isn’t just about being among the first to make the switch, but about making bold choices and pairing them with the right technology partner to support it.

In this case, that partner is Yutong.

“We’re having more conversations with operators who’ve seen what Tropic Wings has done,” Jingxin says.

“When they see it working in real-world conditions, it builds confidence and drives momentum.”

Below: Tropic Wings has reported a 30 to 40 per cent reduction in running costs per

Above: The operator says that the feedback from the local community on the Yutong models has been very rewarding

Support on the move

As a regional WA hospital undergoes a major transformation, BCI and Go West are stepping up to ensure frontline healthcare workers get to and from work safely

When the world shut down during the COVID-19 pandemic, there was one place that never slowed down. The hospital.

As fear and uncertainty gripped communities, it was nurses, doctors and hospital staff who stepped forward, often at great personal risk, to keep the community safe.

Working through exhaustion, isolation, interrupted mealtimes and loss, the pandemic pulled back the curtain on just how critical these professionals are. You see, hospitals don’t run on machines or medicine alone; they run on people.

Now, around five years since the first COVID-19 case was recorded, companies like Bus and Coach International (BCI) and Go West are still finding ways to support and uplift

the healthcare workers who carried us through.

Over in Western Australia, a $471 million redevelopment of Bunbury Regional Hospital is set to see the day-to-day life of workers altered forever.

“Once complete, Bunbury Regional Hospital will be the biggest in country WA, strengthening its role as a vital healthcare hub for the entire South West,” a WA government statement reads.

“The redevelopment will significantly expand capacity, delivering additional medical and intensive care beds, an expanded emergency department, increased operating theatre capacity, as well as new and expanded maternity, birthing and neonatal services.”

To make room for the new hospital footprint, staff parking was one of

Above:

The EV is a smart, zero-emissions solution that supports both the environment and the essential workers relying on it

the first casualties. Now, rather than parking on site, workers are being shuttled between the South West Health Campus and the nearby Hay Park precinct.

The distance, more than 20 minutes by foot and across a major highway, made safe, timely transport a necessity. That’s where Go West and its trusted partner BCI stepped in.

“Go West is a trusted, long-established bus operator with deep community ties, having served the region since 1994,” Go West general manager Brad Bunce told ABC

“Our reputation for reliable service and local commitment positioned us as a partner of choice to support the hospital’s transport needs.”

Go West is now operating a weekday shuttle service with services running every 10-30 minutes from 6am to 6pm.

When it came time to choose a bus model for the job, Go West had a clear set of requirements.

“Our key considerations included advanced safety features, innovation, vehicle reliability and strong aftersales support,” Bunce says.

“We wanted a solution that aligned with our quality and operational standards.”

The team assessed both diesel and electric models before choosing a zero-emissions solution that balanced environmental sustainability and reliability – BCI’s Fleetmaster EV.

“Our partnership with BCI has been built on flexibility, shared values and their commitment to innovation,” he says.

“They’ve consistently supported our growth by tailoring products to our specific operational needs.”

The Fleetmaster EV ticked every box. Originally developed to suit the rugged needs of WA’s mining sector, the model’s design proved just as capable in an urban hospital setting.

BCI Australia sales development manager Armando Baylon told ABC that electric vehicle technology has matured rapidly over the past few years, and with that, the applications have broadened.

“With EVs, it’s a very new technology that evolves so quickly, especially around battery efficiency,” Baylon says.

“Each batch we build improves on the last; lighter, more efficient

and better suited to real-world conditions.”

Once seen as the domain of city-based low-floor buses, zero-emission options are now being successfully rolled out across coaches, mid-size and even mini-bus formats.

“Initially the industry wasn’t quite ready, especially in terms of infrastructure and operator training on the new EV technology,” Baylon says.

“But now we’re seeing a much more diverse offering and more operators, including regional ones, are confident to make the switch.”

In Go West’s case, it was able to repurpose a Fleetmaster EV originally spec’d for mining use. The vehicle’s 53-seat layout and robust build proved a strong match for the hospital’s needs.