Visibuild isn’t following the blueprint – it’s crafting a bold new approach to construction quality management. Directors Damien Quinn and Ryan Treweek reveal how they’re driving change.

Visibuild isn’t following the blueprint – it’s crafting a bold new approach to construction quality management. Directors Damien Quinn and Ryan Treweek reveal how they’re driving change.

out efficiency

Find out how Topcon technology is boosting productivity for Universal Civil Contracting Brisbane.

8 Laying the foundations of quality

Visibuild outlines its mission to make quality the cornerstone of every construction project.

44 Hala Taouk: Embracing authenticity

Discover how Hala Taouk, senior commercial manager at CIMIC Group’s UGL, embraced authenticity to carve her path in the construction industry.

ASSOCIATIONS

46 Collaboration over conflict

The Australian Constructors Association announces the return of its groundbreaking forum.

48 Streamlining excellence

The National Precast Concrete Association Australia highlights Ozcast’s contribution to the Princes Highway Upgrade.

50 Let’s do this

Empowered Women in Trades prepares for a transformative 2025, championing progress and opportunity.

52 A year of advocacy

The National Association of Women in Construction reflects on a huge year of advocacy achievements.

54 Building dreams

Learn how NexGen’s primary program is shaping the next generation of construction pioneers.

56 Grounded self-leadership

Dr Gretchen Gagel explores how understanding purpose, values and self-awareness shapes the foundation for effective leadership.

Certified to perform

Hobson Engineering underscores the importance of European Technical Assessment approvals in construction.

Pumping possibilities

Jacon Equipment presents its concrete pumping and shotcrete solutions, designed to tackle every construction challenge.

A true supporting act

Light gauge steel framing made from TRUECORE steel shapes The Round performing arts centre’s striking masonry façade.

Building beyond boundaries

Komatsu details how merging technology and smart machinery with expertise enhances productivity, sustainability and safety on worksites.

Winslow shares its sustainable construction innovations and insights to drive broader change across the industry.

Viva Energy showcases the practicality and environmental benefits of renewable diesel.

A blueprint for the future of urban living

Upper House, a 5 Star Green Star rated multi-residential tower, introduces a new way of inhabiting cities. 58 Instrumentation sector joins Converge

VEGA Australia reveals the measurement solutions and expertise it will showcase at Converge 2025.

As 2025 unfolds, the construction industry stands poised at the intersection of innovation, sustainability and quality.

It is time to build on the progress made in 2024 – a year defined by growth in equality, safety, productivity and a commitment to a greener future.

Reflecting on these milestones, the Inside Construction team applauds the collective efforts of industry leaders who tackled challenges headon, driving meaningful change. Now, the focus shifts to what lies ahead – the bold ideas, transformative projects and emerging technologies that will shape the next chapter in construction.

Sustainability remains the cornerstone of industry conversations, and its momentum continues to grow. As a media partner of the Green Building Council of Australia’s flagship conference, TRANSFORM 2025, this edition takes a closer look at how organisations are reshaping construction’s environmental footprint.

Among the highlights, we feature an Australian energy company breaking ground with renewable diesel, helping contractors cut emissions and take practical steps toward decarbonisation. A civil construction firm shares its journey of embedding sustainability into practice, and we explore a 5 Star Green Star rated multi-residential tower that is redefining urban living with its forward-thinking design.

The shift toward greener construction extends to equipment innovation. From electric excavators to hydrogen-powered machinery, a global manufacturer is unveiling solutions to meet the demands of a changing world. Simultaneously, advancements in concrete pumping, spraying and transportation are driving efficiency and sustainability across the sector.

Quality, often overlooked, takes centre stage in this edition. One

technology company shares its mission to elevate quality as the foundation of every construction project, challenging long-held assumptions and positioning it as a core pillar of industry progress.

This issue, we also highlight the inspiring journey of a senior commercial manager working on a transmission project delivering renewable energy to Australian households. Her story celebrates authenticity and leadership, illustrating how standing out can create meaningful impact.

Our Association Partners are also gearing up for a big year. The Australian Constructors Association announces the return of its influential forum; the National Association of Women in Construction continues its advocacy work; and Empowered Women in Trades pushes toward its ambitious vision of 30 per cent female participation in trade-based roles by 2030. NexGen shares insights on its primary program, and the National Precast Concrete Association Australia highlights a landmark highway upgrade.

Inside Construction is proud to be part of these conversations and innovations shaping the future of the industry. We hope this edition inspires, informs and energises you as we embark on another year of progress together.

Chief Executive Officer John Murphy

Chief Operating Officer Christine Clancy

Managing Editor Mike Wheeler mike.wheeler@primecreative.com.au

Editor

Ashley Grogan ashley.grogan@primecreative.com.au

Sales Director

Brad Buchanan bradley.buchanan@primecreative.com.au

Design Caterina Zappia

Head of Design Blake Storey blake.storey@primecreative.com.au

Business Development Manager

Nhung Nguyen nhung.nguyen@primecreative.com.au p: +61 0412 845 608

Client Success Manager Louisa Stocks louisa.stocks@primecreative.com.au

Cover image credit Kristoffer Paulsen

Head Office

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 Australia p: +61 3 9690 8766 enquiries@primecreative.com.au www.insideconstruction.com.au

Subscriptions

+61 3 9690 8766 subscriptions@primecreative.com.au

Inside Construction is available by subscription from the publisher. The rights of refusal are reserved by the publisher

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Copyright

Inside Construction is owned by Prime Creative Media and published by John Murphy. All material in Inside Construction is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Construction are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Queensland is in focus this month, featuring a luxury residential development and a transformative highway upgrade.

Bruce Highway Upgrade (Cooroy to Curra) Section D2 (Gympie Bypass), Queensland

Contractor: CPB Contractors

Current value: $380 million

Details: The Bruce Highway Upgrade – Cooroy to Curra Section D2 (Gympie Bypass) project, located between Woondum and Curra, was delivered by CPB Contractors for Queensland’s Department of Transport and Main Roads in October 2024. The project included the construction of 18 kilometres of new highway, 19 bridges and a new interchange at Curra, as well as realignments of local roads.

Status: Completed in October 2024.

Initiatives: Local employment, skills development, Indigenous engagement and sustainability all benefited from the project. Outcomes included more than 80 per cent local participation, with 2,362 workers inducted and 393 subcontractors and suppliers engaged. A total of $239 million was spent locally, directly benefiting Gympie and its broader communities. There was also formal recognition of, and ongoing connection to, the Kabi Kabi Traditional Owners. The project exceeded CPB Contractors’ Stretch Reconciliation Action Plan target of 4 per cent by achieving 5.7 per cent First Nations employee representation. Additionally, seven Indigenous businesses were engaged with more than $8.7 million spent. A total of 50 trainees and apprentices were engaged, and 176,000 training hours were delivered, including almost 100,000 for new entrants to the construction industry. The project also provided flood clean-up assistance in Gympie following severe and historic floods in 2022. The project upheld industry best practices across health, safety, environment and quality, including more than two million hours worked lost time injury free; the removal of 82,000 truck movements during construction due to the installation of a 6km pipeline providing a reliable construction water supply; and the planning, design and construction of 106 erosion and sediment control basins to manage all stages of construction, from clearing and bulk earthworks to final pavement works.

Contractor: Laing O’Rourke

Current value: Approximately $82.5 million

Details: In February 2023, Laing O’Rourke was awarded the contract by Transport for NSW to deliver a new footbridge and pedestrian plaza at St Marys Station as part of the Sydney Metro – Western Sydney Airport project. The footbridge will enable commuters to transfer between the new metro platforms and suburban trains on the T1 Western Line. It will also link to a new pedestrian plaza at the northern end of the footbridge, providing access to the existing station and improving connectivity in St Marys. The space will feature green areas, kiss-and-ride facilities, bicycle storage, and provide potential for future development. The design prioritises safety, durability and aesthetic appeal, complementing the surrounding urban environment.

Status: The project is currently in the construction phase. Recent onsite activities have included excavation, concrete works and steel reinforcement. Progress is tracking well, with the team focused on achieving key milestones, including completion of foundations and precast pier walls, with works coming out of the ground in the coming months.

Initiatives: The project team collaborated with subcontractor AnewX to trial the use of hydrotreated vegetable oil (HVO) in plant and equipment. Positive results have been reported, with consistent engine performance and seamless transitions between fuel types. Derived from vegetable oils and waste-based feedstock, HVO reduces greenhouse gas emissions compared to fossil diesel.

Contractor: Multiplex

Current value: $160 million

Details: The Mantaray by Gordon Corp is situated on the foreshores of the Gold Coast’s iconic Broadwater. Located on The Spit’s Seaworld Drive, the residential development will be home to 24 luxury two-, three- and four-bedroom apartments and villas, along with a 67-berth superyacht marina.

Status: Construction is underway, with all eight stair and lift cores installed using precast concrete. This method has allowed suspended slabs to progress uninterrupted while the remaining basement raft construction is completed.

Initiatives: An activated retail plaza

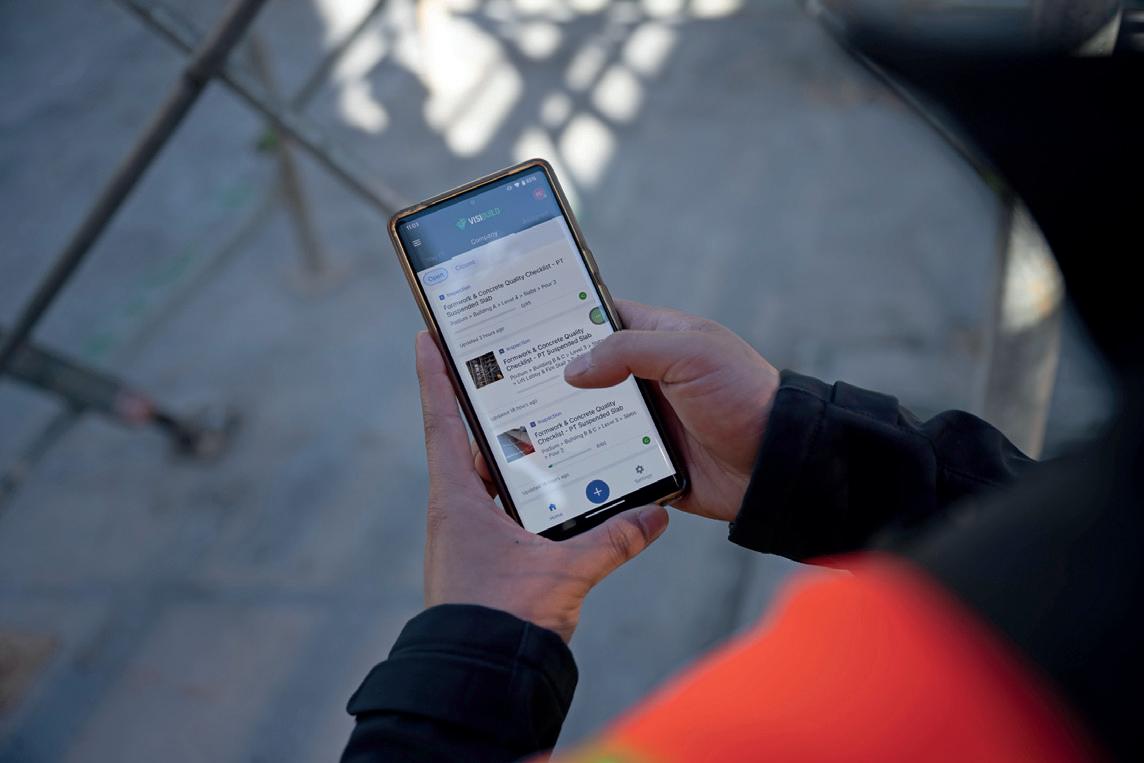

Visibuild isn’t just following the blueprint – with a clear vision, expertise and a strategic edge – it’s carving out a new approach to construction quality management.

“We need to build quality into the process from the start.”

In the construction industry, quality control has often been relegated to an afterthought – a task to tick off the list once a project is nearing completion. But what if quality wasn’t just something to inspect at the end? What if it was the foundation of every decision, every task and every project from day one?

This is the shift championed by Visibuild, a quality assurance platform developed by members of the Australian construction industry. Visibuild is on a mission to challenge the status quo and position quality as the cornerstone of every construction project.

Quality as a culture, not a checklist

In an environment where speed, efficiency and productivity have long been prioritised, quality control has often been viewed as

a cumbersome add-on. It’s easy to see why. In the race to meet deadlines, quality checks were frequently sidelined, treated as secondary to the pressing demands of construction schedules.

For Visibuild director Ryan Treweek, who has spent 17 years in the industry, this mindset was never the answer.

“Quality has always been left in the background,” says Treweek. “Being overlooked for so long, it requires a real cultural shift to move people away from the mindset of treating it as an afterthought.”

The tide, however, is turning. As buildings grow more complex and regulatory demands increase, the push for better quality has become inevitable. Changing an industry steeped in tradition is no small task, but

Visibuild’s leadership has embraced the challenge. United by a collective vision to make “quality the foundation of construction,” the company aims to drive cultural change through innovation.

Visibuild is using technology to not only digitise existing systems, but to transform how construction projects are built and how quality is managed.

“Technology has advanced significantly in the past decade, and the industry is starting to recognise that compliance and quality can no longer be checked off post construction,” says Treweek. “We need to build quality into the process from the start.”

Fellow company director Damien Quinn emphasises that technology alone cannot solve the problem.

“Unless you understand the underlying drivers of how projects are built and the motivations of the people involved, you’ll never be able to change the culture and mindset needed to implement quality control effectively,” he says. “Without this shift, attempts to integrate technology into quality control will be counterproductive.”

Visibuild’s software is designed with this cultural shift in mind. It moves quality from a passive, reactive process to an active, real-time one. By embedding quality checks throughout

“It’s no longer just about compliance – it’s about unlocking efficiency across the entire project lifecycle.”

Visibuild connects quality control to real‑time project progress.

(Image: Ned Meldrum)

“Being overlooked for so long, it requires a real cultural shift to move people away from the mindset of treating it as an afterthought.”

the project lifecycle, Visibuild aims to reduce errors, prevent costly rework and set a new standard for the industry.

From vision to execution

The COVID-19 pandemic served as a turning point. It gave the founding team the time to assess their careers and confront the frustrations they had experienced. They realised that addressing construction’s biggest challenges required a new approach in how projects were managed, rooted in quality.

Founded in 2022 by Quinn, Renee and Shaun Phelan, and Dave Allie – with Treweek leaving an executive post to join the team in 2023 – Visibuild has rapidly gained traction. But introducing cultural and technological change to a staunch industry has been no easy feat.

The basis for Visibuild stemmed from the team’s combined experiences in construction. After working more than a decade for the same contractor, they encountered recurring issues: rushed jobs, costly mistakes, and a quality control system that lacked the data and insights to enable meaningful change.

“Lessons learned” discussions were common, but past mistakes were often repeated as new projects began without time for reflection. Treweek likens this cycle to a hamster wheel – a constant race with little opportunity to improve processes.

“We knew that just introducing a piece of software wasn’t enough,” says Treweek. “We had to change the culture. You can’t just push a new tool onto a team without changing how they think about the process.”

Turning data into decisions

Visibuild’s strength lies in how it connects quality control to real-time project progress. The software doesn’t merely track errors; it identifies them as they occur, enabling immediate corrective action and preventing issues from mounting, which can ultimately delay projects or cause legacy quality issues.

“Historically, measuring quality control or compliance was almost impossible,” says Quinn. “Audits were infrequent, covering only a small fraction of projects. That left a huge gap in visibility and a lot of room for errors.”

Visibuild has turned this on its head by offering real-time visibility into quality control,

systems compliance and project outcomes. Its database categorises quality control data in granular detail – whether related to concrete, finishes or safety features – allowing for deeper insights and better decision-making.

The value of this data extends beyond individual projects. By feeding insights back into the system, Visibuild helps prevent recurring problems and drives continuous improvement. Treweek highlights the importance of using data not just to document issues but to create measurable impact.

“People often accept error as something that just happens, part of the chaos of constructing a building,” he says. “But in reality, if everyone followed the old adage, ‘measure twice, cut once,’ there would be fewer errors and delays.”

One project team in Melbourne experienced this firsthand. Whilst constructing a loading platform suspended several stories in the air, a team member was preparing to unload 200 cubic metres of concrete onto a temporary slab. When checking the mix details through Visibuild, he discovered the wrong mix had been sent and prevented the error by sending the trucks back.

“That moment completely changed his outlook,” says Quinn. “He went from being a sceptic to a firm believer in the system. This is the mindset shift we’re trying to create in the industry.”

Building relationships, not just software Visibuild’s success is also underpinned by its commitment to relationship-building. In an industry driven by trust, maintaining integrity has been central to its approach.

“Having spent years in the industry, we’ve worked hard to build a reputation for integrity across Australia,” says Treweek. “Maintaining that trust is essential to us.”

Visibuild involves customers in the platform’s development journey, regardless of their business size. Quinn believes that collaboration and authenticity are key to fostering trust and aligning with clients’ needs.

“It’s about bringing people along on the journey and showing them how their input aligns with a bigger, more meaningful goal,” he says. “That sense of alignment and shared purpose is critical for balancing day-to-day execution with our larger goals.”

Driving the shift

Visibuild’s goal is to raise the baseline for quality and compliance across the construction industry. By positioning its platform as the “central nervous system” for construction data, it is helping businesses harness information to drive efficiency and transparency.

“When people realise the value of knowing, with certainty, that tasks have been done properly, it transforms their understanding of quality assurance,” says Treweek. “It’s no longer just about compliance – it’s about unlocking efficiency across the entire project lifecycle.”

In a rapidly changing world, where regulatory shifts, sustainability concerns and digital transformation are reshaping industries, Visibuild is prepared. Its approach may have

started with a singular focus on quality, but it has grown into something much greater: a movement to embed process into every decision, action and project.

Both Quinn and Treweek are optimistic about Visibuild’s potential to raise quality assurance standards globally.

“With an extensive development pipeline of new features and modules underway, we will continue driving cultural change in the construction industry through our innovative approach to quality management,” says Quinn.

Visibuild is redefining how quality is perceived and practised in construction. By combining technological innovation with a focus on cultural transformation, it is creating a new paradigm where quality becomes an intrinsic part of the industry.

“Technology has

advanced significantly in the past decade,

and

the industry is starting to recognise that compliance and quality can no longer be checked off post construction.”

A hybrid generator powered by biodiesel and solar, paired with stormwater harvesting from site sheds for toilet use. (Images: Winslow)

Sustainability is part of Winslow’s DNA –through a blend of innovation, collaboration and long-standing values, it has always been more than compliance.

For Winslow, sustainability isn’t just a box to tick – it’s a responsibility to embrace.

While the civil construction company has championed sustainable practices for years, it hasn’t always been vocal about its efforts.

Dean Lal, Winslow’s group environment and sustainability manager, says the company’s focus has always been on delivering results, not seeking recognition.

“We’ve realised that sharing what we’ve learned can drive broader change across the industry. It’s not about saying, ‘look at us.’ It’s about fostering collaboration and empowering others to join the journey,” says Lal.

Winslow recently raised the bar by securing an IS v2.1 Ecology credit (Eco-1) for the Sunbury Road and Lathams Road Upgrades under the Infrastructure Sustainability Council’s (ISC) rating scheme. The IS Rating Scheme evaluates economic, social and environmental performance across all phases of infrastructure projects.

“This was our first time pursuing these ratings, and we secured three excellent outcomes. It’s a testament to the expertise and collaboration across our teams and with Major Road Projects Victoria (MRPV),” says Lal.

“We’ve realised that sharing what we’ve learned can drive broader change across the industry.”

With more than 25 years of environmental sustainability expertise, Lal understands the power of collective action. Winslow’s projects are designed with sustainability in mind, but the company is now stepping up to forge deeper partnerships with government and private clients to amplify its influence.

“Our sustainability strategy doesn’t just align with government requirements – it exceeds them,” says Lal. “We’re driving innovation on major infrastructure works, setting new standards, and helping lead the industry forward.”

“While Tier 1 contractors have been working in this space for years, we’ve proven that we are now on par with these industry leaders, a fact that has been acknowledged by MRPV.”

Tackling challenges like brownfields environments and rigorous compliance head-on, Winslow’s efforts didn’t just meet expectations – they exceeded them. Tools like SoilFlo, which tracks soil movements, enabled high spoil reuse rates while hitting environmental benchmarks. Meanwhile, Aqua Prep, a hydro-demolition method using 100 per cent recycled non-potable water, reduced

reliance on potable water and eliminated the need to transport contaminated water offsite, minimising environmental and logistical impacts. These initiatives align with ecologiQ, a Victorian Government program that promotes the use of recycled materials and a circular economy approach in transport infrastructure projects.

Another game-changer, the Guard Dog Drain Filter, safeguarded waterways by trapping sediment at stormwater grates, outperforming traditional solutions like silt logs.

“This approach is more reliable, sustainable and lasts up to six months with minimal maintenance,” says Lal.

While these tools have delivered impressive results, Lal highlights that collaboration with clients and stakeholders is the cornerstone of success when it comes to sustainability.

“Engaging with clients early in the process is crucial. We cannot achieve these outcomes alone; everyone involved needs to be aligned,” he says. “Innovation during the design phase opens up far more opportunities to implement sustainable solutions. Waiting until the delivery phase makes meaningful changes much harder to achieve.”

Lal notes that Winslow’s use of SoilFlo, Aqua Prep and the Guard Dog Drain Filter on the Sunbury and Lathams Road Upgrades marked their first application in Australia – a testament to the company’s proactive approach to innovation.

Building a culture of leadership

Winslow’s sustainability efforts are powered by its core values – Family, Accountability, Commitment, Empowerment and Safety (FACES). Empowerment, in particular, plays a crucial role in enabling every team member to take ownership of sustainability initiatives.

“This isn’t just about leadership at the top,” says Lal. “From the CEO to construction crews, everyone is driving change. Our CEO’s unwavering commitment to sustainability has united the entire organisation behind this vision.”

This leadership and teamwork were recognised when Winslow’s Sunbury Road Upgrade team won the 2024 Civil Contractors Federation (CCF) Earth Award for the best project over $150 million, further

solidifying the company’s commitment to environmental excellence.

Also in 2024, the Winslow Environment and Sustainability Team was awarded the CCF Industry Award for Sustainability Excellence.

The team was recognised for exemplifying excellence in initiative, capability and subject matter expertise, demonstrating a commitment to learning, supporting delivery teams and advancing broader sustainability initiatives across Winslow.

“Collectively, the team has shown immense capability in leading cultural change within Winslow while transforming the planning, design and delivery processes and practices across both MRPV and other projects,” says Lal.

“These awards underscore what can be achieved when you equip your team with the right resources, empower them to innovate and provide clear direction. It’s all about enabling individuals to excel and contribute meaningfully. Our success stems from our people.”

With new legislation requiring sustainability reporting from 2025, Winslow is ahead of the curve, with sustainability already embedded

“Our sustainability strategy doesn’t just align with government requirements –it exceeds them.”

“Our success stems from our people.”

identifying associated risks, as well as financial

accounting. Reporting will begin with Scope 1

year. By the fourth and fifth years, Scope 3 reporting will expand and require external verification by auditors.

“Given that Scope 3 emissions involve activities related to assets not owned or controlled by Winslow, collaboration with stakeholders is critical,” says Lal. “Many stakeholders are already engaged due to their experience in this area, but others will need to adapt. This will be a highly collaborative process, and those who fail to keep up risk being left behind.”

Winslow is also laser-focused on setting long-term goals, especially around emissions reduction. “Right now, our priority is gathering baseline data. Once we have that data, we can establish realistic, achievable goals,” says Lal.

“We aim to set incremental targets that allow for steady progress and acceleration over time, rather than committing to unrealistic aspirations.”

From groundbreaking innovations like SoilFlo and Aqua Prep to earning top-tier ratings, Winslow is not only addressing industry challenges but also demonstrating what it means to build responsibly for the future.

On the 4th of January 2020, Penrith in Sydney’s West was the hottest place on earth, with an extreme high of 52 degrees.

Terroir architects specified COLORBOND® steel Surfmist® in a Classic finish for the expansive, visually striking roof on the Penrith Anglican College Performing Arts Centre, knowing the choice of a lighter colour would lower solar absorption and in turn lower the buildings ongoing HVAC costs. Not only can the roof help toward creating a cooler environment for its students by lowering heat absorption, but also by creating a positive impact on the surrounding community environment by helping to reduce the effects of Urban Heat Islands.

With 11 COLORBOND® steel cool roofing colours featuring low Solar Absorptance values of less than or equal to 0.45*, architects and specifiers now have a wide colour choice that achieves deemed-to-satisfy compliance within the National Construction Code (NCC) Section J energy efficiency provisions.

To find out more about COLORBOND® steel’s cool roofing colours, visit steelselect.com.au/coolroofing

Viva Energy is helping the construction sector make strides toward sustainability by showcasing the practicality and environmental benefits of renewable diesel.

The construction industry is at a critical juncture: balancing the demands of productivity with the need for sustainability. Diesel-powered equipment has long been the backbone of the sector, but with the growing demand for cleaner solutions, renewable diesel – also known as hydrotreated vegetable oil (HVO) – presents a promising alternative.

Australian energy company Viva Energy is making renewable diesel more accessible, enabling construction companies to reduce their carbon footprint and take a decisive step toward decarbonisation. Produced from renewable feedstocks like used cooking oils and animal fats, renewable diesel offers a reduction in carbon emissions compared to conventional diesel.

Robert Cavicchiolo, carbon solutions manager at Viva Energy, describes it as a “game-changer” for the construction industry.

“Renewable diesel offers the comparable performance as conventional diesel but with lower emissions,” says Cavicchiolo. “It’s a straightforward, drop-in solution that allows companies to continue operations while reducing their carbon footprint.”

The key advantage of renewable diesel is its seamless compatibility with existing diesel infrastructure. Its hydrocarbon structure is very similar to fossil fuel diesel, meaning construction companies can use it in their current machinery, fleets and generators without any costly modifications.

Produced using a hydrotreating process, renewable diesel turns feedstocks such as used cooking oils and animal fats (tallow) into a high-quality fuel. Not only does it reduce carbon emissions, but it also has the potential

to reduce particulate matter, nitrogen oxides (NOx) and carbon monoxide, improving air quality on construction sites and in surrounding communities.

“Renewable diesel can reduce emissions by 70 to 90 per cent compared to traditional diesel, based on a life cycle analysis basis, helping companies achieve their emission reduction targets,” says Cavicchiolo.

Seamless transition, immediate benefits

Switching to renewable diesel is straightforward. Companies don’t need to upgrade equipment or change infrastructure – simply switch the fuel supply. Equipment manufacturers, including Liebherr, Volvo, Kubota, JCB, MTU, John Deere, Cummins and Caterpillar now support renewable diesel in their service bulletins and fuel recommendations, providing businesses with the confidence that it won’t disrupt operations. It is always recommended to check with the equipment manufacturers before switching to renewable diesel.

Viva Energy also ensures a reliable supply of renewable diesel, sourcing fuel from certified sustainable feedstocks under the International Sustainability & Carbon Certification (ISCC) standard.

This certification guarantees the fuel meets environmental and ethical standards.

Renewable diesel’s compatibility with existing storage and refuelling infrastructure and its ability to reduce emissions make it a practical solution for companies looking to transition to greener operations.

considerations

While renewable diesel offers clear benefits, there are some factors companies should consider before making the switch:

1. Supply – renewable diesel, similar to conventional diesel, is currently imported into Australia and hence requires planning if companies want to convert over to its use. However, Viva Energy ensures consistent availability through a robust supply chain.

2. Cost – renewable diesel typically comes at a premium compared to traditional diesel. Despite this, the long-term environmental and regulatory benefits may justify the additional cost.

3. Transition – the transition to renewable diesel is simple and doesn’t require significant downtime or equipment upgrades, though companies should complement its use with their existing fuel

“It’s a straightforward, drop-in solution that allows companies to continue operations while reducing their carbon footprint.”

“For some off-road applications, where electrification or green hydrogen isn’t yet viable, renewable diesel provides an attractive interim solution.”

As the construction industry faces increasing pressure to reduce its environmental impact, renewable diesel offers a viable, drop-in solution. It helps companies stay ahead of regulatory requirements and lower emissions – all while continuing to rely on the machinery and vehicles they’ve already invested in.

Hydrocarbon Solutions team, we can help customers establish or upgrade fuel farms, project-manage tank installations and ensure reliable, on-spec supply.”

“We’re

here to guide construction companies through the switch to renewable diesel.”

“Renewable diesel is recognised under Australian Government legislation, such as the National Greenhouse and Energy Reporting (NGER) Scheme and National Greenhouse Accounts Factors (NGAF), for those facilities who are listed under the safeguard mechanism,” says Cavicchiolo.

“For some off-road applications, where electrification or green hydrogen isn’t yet viable, renewable diesel provides an attractive interim solution.”

Viva Energy isn’t just a supplier of renewable diesel; it’s a partner in the journey toward sustainability. From educational resources to technical support, the company is committed to helping businesses transition with minimal disruption and confidence.

“We’re here to guide construction companies through the switch to renewable diesel,” says Cavicchiolo. “Through our

The company’s Carbon Solutions and New Energies teams provide expertise in decarbonisation and collaborate with emerging technologies to explore future opportunities. As a technology-agnostic partner, Viva Energy stays forward-looking and adaptable, helping construction companies achieve sustainability goals while keeping pace with industry trends.

The construction sector is adopting renewable diesel as a transitional solution on the road to zero-emission technologies. Supported by a reliable supply chain and technical expertise, companies can confidently make the switch to a more sustainable future.

“Globally, renewable diesel has been in use for years in regions like Europe and the United States, and Australia is now following suit,” says Cavicchiolo. “With a well-established import model and a national supply footprint, we can serve customers across Australia.” By championing renewable diesel, Viva Energy empowers companies to make informed decisions that align with their sustainability goals, reduce emissions and maintain peak performance.

Topcon MC-Mobile

3-in-1 solution for excavators and compact track loaders

Excavators from $55K + GST installed

CTLs from $60K + GST installed

Measure, design and build with a single system! Powered by Topcon Pocket3D software, MC-Mobile is a versatile machine control and survey rover solution in one.

• Compatible with Tokara remote suppoprt

• Works with a wide range of attachments and accessories

• Hardwire and hire options available

Terms and Conditions apply, visit www.aptella.com for full details. Warranty for serialised components only Available now with

Situated in the social hub of South Brisbane, Upper House is a 5 Star Green Star rated multi‑residential tower that is inviting a new way of inhabiting cities.

From its dramatic architecture, inspired by the Moreton Bay fig tree, to its dancing balconies, Upper House embodies a modern design ethos – harmonising nature, wellbeing and environmental excellence in sustainable vertical living.

Designed by Koichi Takada Architects, the 32-storey building houses 188 apartments and features a five-storey artwork by Australian artist Judy Watson. Titled Bloodlines weaving string and water, 2023, the perforated metal, folded and backlit piece offers a cultural narrative, acknowledging the Turrbal people as the traditional custodians of the land.

With its striking exterior – evoking Moreton Bay fig tree roots framing the building and a canopy curling around the roof – it

celebrates the natural world while treading lightly on it. Davina Rooney, CEO of the Green Building Council of Australia, says the design and sustainable features of the 5 Star Green Star rated residential tower, along with the commitment to deliver homes designed for energy efficiency and resiliency, should be applauded.

“Upper House represents Australian excellence in sustainable design – a vision of sustainable urban living with high-quality apartments designed for efficiency, healthy living and low emissions,” says Rooney.

“They represent a future where apartment living is climate-resilient and comfortable, without sacrificing performance or architectural design.”

Urban high-rise living can sometimes feel disconnected from community and nature – a far cry from the classic suburban lifestyle so often associated with Australia. But according to architect Koichi Takada, this space was designed to bring people together.

“High-rise living can sometimes feel isolating, but we’ve designed spaces to bring people together and foster community,” says Takada.

“For example, on the rooftop, we created inviting amenities where residents can meet, relax and socialise. It’s like a shelter in the sky – a place where you’re encouraged to interact with your neighbours.

“When people love a space, they’ll not only enjoy it today but pass it on to future generations. That’s true sustainability.”

What makes Upper House sustainable For Aria’s development manager, Michael Hurley, pursuing the Green Building Council of Australia’s Green Star certification – Australia’s only national, voluntary, holistic rating system for buildings and communities – was about creating something for which they could be proud of.

“Our guiding principle is to create residential and retail spaces that we’ll be proud to walk past with our families in 20 years,” says Hurley.

“We also want to be proud of the decisions we’ve made during the construction, ensuring they consider our future generations.

“Upper House is fortunate to be developed within Brisbane City Council, which supports well-designed, green and energy-efficient buildings. Its Brisbane Green Building Incentive Policy assisted in offsetting the substantial investment in capital to achieve Green Star.”

The team behind Upper House designed and built with best practice sustainability in mind, focusing on key areas such as water, emissions, energy, transport, land use and ecology, materials, and indoor environment quality.

The building is designed to achieve more than an 11 per cent reduction in potable water consumption compared to a standard build, while a 40-kilolitre rainwater harvesting tank is used for irrigation, collecting an average of 170 kilolitres annually – reducing the demand for irrigation water, particularly during increasing periods of extreme heat.

Upper House was designed and constructed with a focus on reducing greenhouse gas

“High-rise living can sometimes feel isolating, but we’ve designed spaces to bring people together and foster community.”

along with 60 electric vehicle charging stations and 194 bicycle parking spaces for tenants. A rooftop designed for living, working and leisure further reduces the need for external travel.

Upper House, once an entirely hardstand site, has been transformed to maximise green space and environmental sustainability, with native plants and indigenous landscaping enhancing its ecological value. The site’s ecological value has increased 100-fold, with landscaping, shading and water elements now covering 75 per cent of the area, helping mitigate the urban heat island effect.

The materials chosen impact the environment at every stage of a building’s lifecycle. For this reason, responsible material selection and waste management are key strategies for reducing carbon emissions and addressing the high percentage of waste generated by construction and demolition, which accounts for 40 per cent of all waste in Australia.

All building materials went through an assessment for environmental impact throughout their lifespan, ensuring sustainability.

“When

people love a space, they’ll not only enjoy it today but pass it on to future generations. That’s true sustainability.”

During construction and demolition, 93.4 per cent of waste was diverted from landfill, with 2,141,882kg recycled. The team conducted monthly waste reporting during construction to ensure the implementation of waste initiatives.

The team behind Upper House worked to reduce CO2 emissions and achieved improvements compared to reference projects. With the aid of solar panels, CO2 emissions dropped by 21 per cent, and fossil fuel consumption decreased by 19 per cent.

The building was also constructed using responsible and sustainable materials, all verified by third-party certifications. Green concrete was used, along with recycled water and aggregate. Fly ash, a by-product of coal

combustion in power stations, served as a binding agent, supplementing 30 per cent of the concrete used in this project.

When it comes to sustainable buildings, the indoor environment quality – including thermal comfort, indoor air quality and indoor pollutants – comes into play.

Harmful pollutants were minimised at Upper House through the selection of low-VOC paints, adhesives, sealants and carpets. This approach reduced volatile organic compound emissions by 95 per cent, improving indoor air quality and occupant wellbeing.

The apartments feature acoustic insulation, including windows, walls, ceilings and floors, minimising both internal and external noise disturbances for the comfort of residents and neighbours.

Along with thermal comfort, the apartments offer energy efficiency, with an average NatHERS (Nationwide House Energy Rating Scheme) rating of 8.4 stars, surpassing best practice standards. The 3-metre-high ceilings and double-glazed glass optimise natural light and reduce the need for air conditioning.

For Hurley, the certification is a result of staying aligned with sustainability goals and not cutting corners – achieved through clear reporting and communication with the team, from subcontractors to consultants. The project also reflects a dedication to pushing boundaries, incorporating organic, living elements rarely seen in high-rise buildings.

“The journey of Upper House, 5 Star Green Star took more than three years of dedication, perseverance, and a substantial investment in capital. When we finally received the 5 Star Green Star Design and As Built rating, it was a huge relief and a moment of immense pride,” says Hurley.

“Furthermore, knowing the residents of Upper House will experience the long-term benefits of the decisions we made as a collective team is incredibly rewarding.”

Green Star certification not only delivers environmental excellence but also creates healthier, more connected and resilient communities. We invite developers, architects and policymakers to follow Upper House’s lead and join us in shaping a sustainable future for urban living. Together, we can create a legacy of buildings that inspire, endure and tread lightly on the planet.

Topcon technology is igniting a surge in productivity for Universal Civil Contracting Brisbane.

Universal Civil Contracting Brisbane has built a strong, enduring partnership with Aptella over the past 15 years, beginning with the purchase of its first Topcon lasers. From the outset, Universal Civil recognised the value of Topcon’s technology, remaining a loyal advocate ever since. This long‑term relationship has been instrumental in supporting the company’s growth and maintaining its position at the forefront of the construction industry.

As a foreman at Universal Civil, Mark Smith oversees a range of large scale construction projects across Brisbane and the Gold Coast, including new schools, shopping centres and logistics facilities, such as the Australia Post distribution centre at Brisbane Airport.

Smith explains that to ensure smooth operations and deliver the best outcomes, Universal Civil relies on top t ier technology, including Topcon’s machine control systems.

As technology has advanced, Universal Civil has embraced Topcon’s machine control solutions to enhance the precision

and efficiency of its operations. The company initially adopted the MCR3 system, followed by the MC I platform, and is now utilising the MC Max system across its fleet of graders, dozers, excavators and other heavy machinery. The integration of these machine control systems has improved the accuracy of grading, excavation and earthworks on complex projects, ensuring positive results with minimal rework.

“At Universal Civil, we use the Topcon MC Max platform across a variety of our equipment, including excavators, graders, compactors and scrapers,” says Smith.

“The MC Max system offers exceptional accuracy and control, allowing us to achieve precise grading, excavation, and earthworks with minimal rework. This is particularly important on large, complex sites like the Australia Post distribution centre, where every centimetre counts.”

In addition to the MC Max system, Universal Civil relies on a suite of Topcon products and software to support its operations. The Topcon HiPer VR receiver

and Pocket 3D software play a key role in enhancing site positioning and providing real t ime data, further streamlining the company’s workflows and increasing overall productivity. Together, these technologies ensure that Universal Civil’s projects – ranging from large infrastructure developments to logistics facilities – are completed with high precision and efficiency.

Smith highlights that the support from Aptella has been invaluable, noting that the team not only supplies the best in Topcon technology but also offers exceptional after‑sales service: “Aptella’s technical team truly sets them apart.”

“They’re always just a phone call away, and whenever we encounter an issue – though they’re rare – it’s always minor and quickly resolved,” he says.

“Their deep knowledge of Topcon’s systems ensures we receive expert advice and real‑time assistance whenever needed. This integration of Aptella’s support with Topcon’s advanced positioning technology gives us the confidence to operate with complete reliability and efficiency.”

Smith says Topcon’s machine control technology, combined with Aptella’s service, is second to none. He highlights the systems’ ease of use, reliability and robustness as factors that have enhanced Universal Civil’s

“Aptella’s technical team truly sets them apart.”

The Topcon MC-Max system improves the accuracy of grading, excavation, and earthworks operations.

workflow. With Aptella’s support, Universal Civil is able to minimise downtime and maximise the productivity of its machinery, ensuring superior outcomes on every project.

Smith strongly recommends Aptella to anyone in the construction industry, emphasising that its products and support

“The MC-Max system offers exceptional accuracy and control, allowing us to achieve precise grading, excavation, and earthworks with minimal rework.”

have been crucial to the success and efficiency of Universal Civil’s projects. Thanks to systems like the MC Max platform and Aptella’s support, Universal Civil consistently maximises productivity and achieves positive results, no matter the scale or complexity of the project.

Universal Civil Contracting Brisbane deploys the Topcon MC-Max platform across its fleet of excavators to enhance operational efficiency.

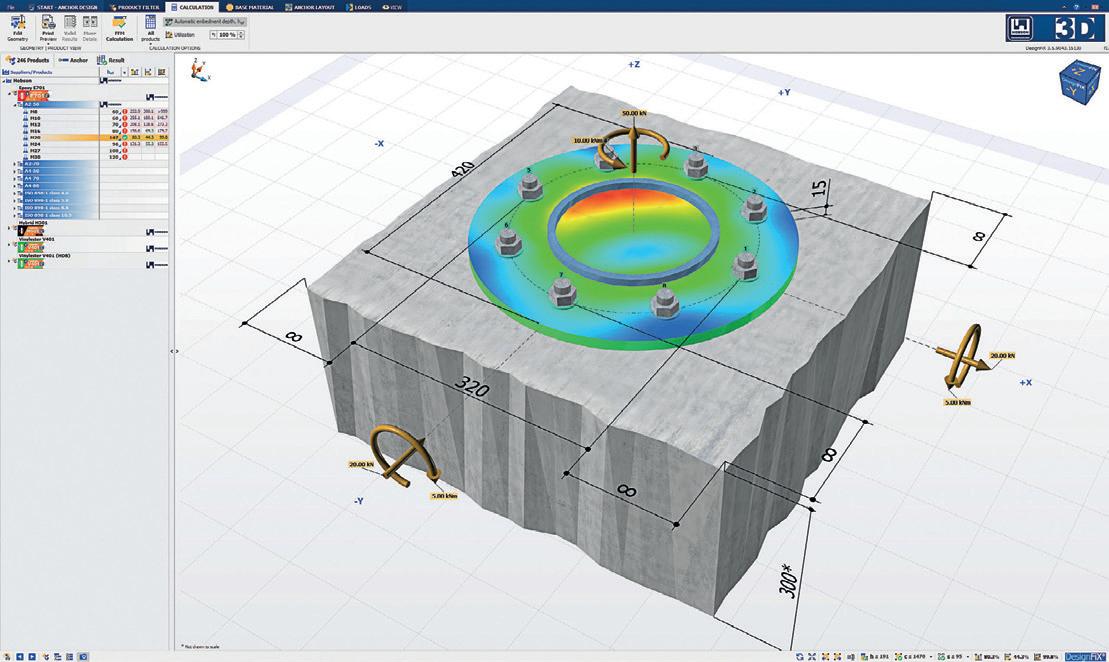

Hobson Engineering, an Australian supplier of fasteners and XCHEM adhesive anchoring systems, is underscoring the importance of European Technical Assessment approvals in construction.

“Our

product range has approvals to ensure performance and suitability for applications ranging from small-scale home projects to large infrastructure developments.”

In Australian construction, the demand for high-quality anchor products with the right certifications has become central to industry practice. At the forefront of this is the European Technical Assessment (ETA) – a certification evaluating construction products for performance and suitability in specific applications.

Gavin McPherson, lead engineer at Hobson Engineering, emphasises the need for construction professionals to understand ETA approvals and their implications.

“ETAs provide a consistent framework for evaluating products across various categories and suppliers,” says McPherson. “This standardised approach simplifies comparisons between products.”

Why ETA approvals matter ETAs ensure products, such as chemical anchoring systems, meet European Union requirements. In Australia, AS 5216 governs the design of post-installed and cast-in fastenings in concrete and is referenced in the National Construction Code (NCC). ETA-approved products are considered compliant with this standard.

“In our market, suppliers have two options: undertake the full suite of testing on a product or use a product with an existing ETA,” says McPherson.

“Most opt for the latter, as testing is rigorous and time-consuming.”

He notes one common misconception: the more ETA approvals a product has, the more a design is perceived to have.

“We often encounter situations where customers ask for additional approvals that are not considered in the design. This would, in effect, result in the end user paying more for a product they did not fully utilise,” he says.

“Extra approvals, like those for seismic or cracked concrete applications, require a reduction in the anchor’s characteristic load capacity. Assuming a higher rating equates to better performance can lead to suboptimal choices. Not considering load reductions for a required design case could result in the failure of the anchor.

“For example, many engineers assume seismic-approved anchors are required for their project without assessing actual risk factors. If the concrete substrate in the anchor location isn’t anticipated to crack during a seismic event, or if the importance or seismic class of the building is low enough, the highest seismic rating may be unnecessary. Careful risk assessment and an understanding of the concrete design are essential to selecting the right anchor for the job.”

The XCHEM range

Hobson Engineering’s XCHEM range of adhesive anchoring systems exemplifies how ETA approvals can help address diverse construction needs:

• XCHEM P201 Polyester – approved for non-cracked concrete, it is suitable for lighter loads in general-purpose and light-duty applications.

• XCHEM V401 Vinylester – approved for cracked and non-cracked concrete, masonry and reinforcing steel applications, with added fire ratings, making it a versatile choice for general-purpose engineered designs.

• XCHEM H501 Hybrid – features approvals for cracked and non-cracked concrete, masonry, seismic categories C1 and C2, and fire ratings. Its high load capacity and fast curing times make it suitable for urban projects.

• XCHEM E701 Pure Epoxy – offering all the approvals of the hybrid product, with the addition of a 100-year design life, it is designed for major infrastructure projects and warmer climates where a longer working time is required to set the anchor.

“Our product range has approvals to ensure performance and suitability for applications

ranging from small-scale home projects to large infrastructure developments,” says McPherson.

Software

Design to AS 5216 is complicated, which is why most suppliers have anchor design software. This software automates the design of chemical anchorages, offering precise results for any application. Chemical anchoring systems require meticulous attention to detail to ensure long-term safety and stability. Design software takes into account all necessary safety factors and provides designs with robust, reliable performance for even the most demanding structural applications.

Towards a deeper understanding

The adoption of ETAs in Australia is still in its early stages, with many engineers yet to fully grasp their implications.

“Careful risk assessment and an understanding of the concrete design are essential to selecting the right anchor for the job.”

“For instance, I recently spoke with an engineer who simply checks whether a product has an ETA and considers that sufficient,” says McPherson. “They rely on software to input loads but don’t evaluate the specific performance data or understand the approvals’ specific implications.”

“ETAs are invaluable for providing transparency and enabling like-for-like product comparisons. But to gain the full benefit, engineers must engage with the detailed performance data within these documents.”

meet extended design life requirements, such as 100 years or more for major infrastructure projects,” he says.

“Additionally, fatigue loading approvals, which assess a product’s performance under cyclic stress, are becoming increasingly relevant, particularly for infrastructure like bridges and tunnels. We’re going to see ETA approvals reflect these trends in the coming years.”

The Hobson Engineering team is dedicated to educating customers on the practical applications of ETAs. For Australian engineers and contractors, understanding and applying these certifications can lead to informed decision-making, cost savings and improved project outcomes.

Hobson Engineering’s XCHEM range highlights the importance of aligning product performance with evolving industry demands. By leveraging ETA-approved solutions and deepening their understanding of how these certifications impact projects, construction professionals are better positioned to achieve compliance and adapt to emerging standards.

As ETAs continue to influence industry practices, Hobson Engineering remains steadfast in supporting engineers and contractors with expert guidance and dependable products.

“ETAs

provide a consistent framework for evaluating products across various categories and suppliers.”

The strength of ETAs lies in their ability to level the playing field. They offer a consistent standard that allows engineers to assess product performance with clarity, understand the underlying testing and make straightforward comparisons. Critical performance data for anchors is detailed within the ETA document, making it an indispensable tool for informed decision-making.

As the industry advances, ETAs are set to evolve further. McPherson predicts the next wave of approvals will focus on fatigue loading and extended design lives.

“For instance, most buildings today are designed for a 50-year lifespan. If we think back 50 years to the 1970s, many of those buildings are now being demolished and replaced. As construction evolves, there will likely be increasing demand for products that

For more information or tailored advice on ETA-approved solutions, reach out to the Hobson Engineering team.

has the right approvals to meet diverse technical specifications.

Touch down with VEGA’s comprehensive range of accurate and reliable pressure measurement sensors for all applications.

PROCESS, HYDROSTATIC AND DIFFERENTIAL PRESSURE.

From slabs to skyscrapers, Jacon Equipment powers Australia’s construction projects with concrete pumping and shotcrete solutions tailored to every challenge.

“Our customers value the balance of usability, durability and value in our machines.”

Since 1978, Jacon Equipment has been at the core of Australia’s construction industry.

suburban driveways, reinforcing a high-rise tower or tackling ambitious infrastructure

Jacon’s impact stretches beyond its robust machinery. At the heart of the company lies a commitment to forging lasting partnerships with customers.

“We’re not just selling machines; we’re partnering with our customers, delivering tailored solutions that drive long-term value,” says Darryl Simms, product specialist at Jacon.

“Many customers come to us unsure of what they need. We guide them to the right solutions, helping their projects succeed while saving time, cutting costs and boosting efficiency.”

Jacon’s trailer-mounted and truck-mounted pumps exemplify flexibility, reliability and performance. With decades of engineering expertise, these workhorses adapt seamlessly to diverse construction applications.

The S-Series, for instance, offers trailer-mounted pumps with capacities ranging from 30 m3/h to Jacon’s flagship stationary pump, which delivers an impressive 100 m3/h. Available in diesel and electric configurations and with mounting options including trailer, skid or track, these pumps meet the unique demands of each job.

For contractors requiring more mobility, Jacon’s truck-mounted options, including the T60 and T100, provide a balance of power and versatility. The T60 delivers a capacity of 60 m3/h, while the T100 equals Jacon’s largest trailer-mounted models with 100 m3/h output.

“Our S-Series pumps are engineered with an ‘S’ valve that handles harsh mixes, low-slump concrete and fluid grout. They’re indispensable for applications ranging from concrete slabs and retaining walls to underground void filling, ground stabilisation and large-scale infrastructure projects,” says Simms.

“Our larger pumps are a mainstay in infrastructure projects across Sydney and Melbourne,” he added, underscoring their critical role in urban development.

Shotcrete solutions shine

When it comes to ground stabilisation and tunnelling, Jacon’s shotcrete rigs are game-changers. Two standout models, the MJ4.5 Midjet and the Maxijet MX3-M KII, demonstrate the company’s focus on innovation and functionality.

“The Midjet thrives in tight spaces,” says Matt Finn, another product specialist at Jacon. “Its compact design and AWD skid steering make it ideal for navigating narrow tunnels. Powered by diesel and equipped with a 10-metre vertical reach, it excels in challenging underground environments.”

For heavy-duty operations, the Maxijet MX3-MKII steps up. With a pumping capacity of 30 m3/h, its nozzle technology enables 360-degree rotation and 180-degree tilt for precise shotcrete application. Features like hydrostatic transmission, an enclosed

cab and an optional hybrid diesel/electric design further enhance its versatility.

“These machines are essential for securing slopes, reinforcing tunnel walls and stabilising construction ramps,” says Finn. “They prevent collapses, creating safer environments for workers and equipment.”

To ensure accurate application, Jacon equips its rigs with pre- and post-scan (PPS) systems that measure shotcrete thickness. By aligning with Tier 4 emission standards, these rigs also contribute to a more sustainable construction landscape – particularly important given Australia’s evolving environmental regulations.

“We’re

not just selling machines; we’re partnering with our customers, delivering tailored solutions that drive long‑term value.”

Jacon’s commitment to quality extends to every aspect of its operations, ensuring

state-of-t he-art facility in Vietnam, designed with standardised components that simplify maintenance and reduce downtime.

“Breakdowns are inevitable in this industry, but our machines are built to minimise their impact,” says Finn. “Clear schematics, accessible parts and interchangeable components ensure repairs are straightforward, keeping projects moving.”

The company also offers 24/7 breakdown support through offices in Sydney, Brisbane, Melbourne and Perth, complete with fully stocked parts inventories. Jacon’s training programs, including annual refresher courses, empower customers with both theoretical and practical expertise.

As the industry evolves, so does Jacon. The company is refining hybrid systems to reduce emissions while incorporating user-friendly, ergonomic features across its product line.

“Our customers value the balance of usability, durability and value in our machines,” says Simms. “While our standard pumps are robust and versatile, we also offer customised upgrades for specialised applications, ensuring every solution is tailor-made to meet specific project requirements.”

Central to Jacon’s ongoing success is its consultative approach. By understanding client needs, the company delivers machines engineered not just for performance but for

2024 – Victorian CCF People and Training Awards –Sustainability Excellence

2024 – Victorian CCF Earth Awards –Sunbury Road Upgrade project –Best project over $150 million

Thank you to our partners for sharing our vision and working together with us to achieve success.

We are thrilled that our commitment to sustainability is receiving industry accolades.

Winslow continues to be driven to find sustainable outcomes through innovative solutions.

Lathams Road Upgrade project:

Commendation IS Design Rating

Excellent IS As-Built Rating

Sunbury Road Upgrade project:

Excellent IS Design Rating

Excellent IS As-Built Rating

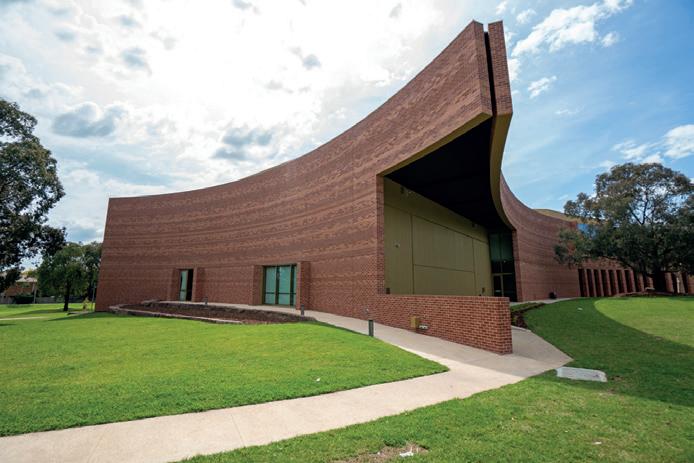

Lightweight, strong and versatile, light gauge steel framing made from TRUECORE® steel is a key structural component that enables this striking, curved masonry façade to take shape.

Project

The Round – Performing Arts Centre

Location

Nunawading, Victoria

Principal Steel Product

23 tonnes of light gauge steel framing made from TRUECORE® steel

Builder

Kane Constructions

Steel fabricator

CMG Frames

Architects

BKK Architects and Kerstin

Thompson Architects

Brick façade fabricator

Modular Masonry

Photography

CMG Frames, Modular Masonry and Derek Swalwell

Set in the Melbourne suburb of Nunawading,

The Round is a performing arts centre that was commissioned by the City of Whitehorse to provide local residents with a facility for community engagement, performance, entertainment and celebration.

The Round performing arts centre replaced the 30-year-old Whitehorse Centre and incorporates a new 626-seat proscenium theatre, a 203-seat black box theatre, rehearsal studios, function rooms, and a large foyer area for pre-event hospitality. Additionally, one of the building’s curved exterior elevations provides the basis for a ‘sound shell,’ extending the centre’s theatrical spaces to an open-air amphitheatre.

Designed by BKK Architects and Kerstin Thompson Architects, the building’s imposing, curved, red brick façade was created to respond to its surrounding residential environment. Its distinctive shape was derived from a contextual map of the site, with circles drawn around the surrounding community zones: sports grounds to the east, family homes to the north and northeast,

parklands to the west and southwest, and the Whitehouse Road and council buildings to the south. The area remaining between these circles inspired the building’s concave-shaped footprint and distinctive façades, with each face of the building addressing a different community zone of influence.

The ground floor brick façade was constructed in the typical manner, using full bricks with mortar. However, in order to improve the overall construction program and delivery timeline, Kane Constructions identified an opportunity to use brick slips for the building’s upper levels. Early-stage collaboration between Kane Constructions, CMG Frames and Modular Masonry enabled the realisation of this solution. CMG Frames was engaged to develop an engineered light gauge steel (LGS) framing system that would support ‘thin bricks’ without compromising the architects’ design intent for the façades. Large LGS frames made from TRUECORE steel were prefabricated to support the second-storey brick façade, which was installed over several weeks rather

than months, as required with traditional brick-laying. An additional benefit was that the mobile lifting equipment used to position the prefabricated panels eliminated the need for scaffolding, ensuring internal trades could work concurrently.

development manager at CMG Frames, “The build was a large-scale, complex project which combined multiple curved and straight prefabricated wall panels to deliver a dynamic articulated façade. It required custom-made

frames, bespoke fixing brackets and 3D shop drawings integrated into the project’s overall BIM model. The 3D modelling approach taken reduced the reliance on RFIs (‘request for information’ to clarify documents, drawings, specifications or other project issues), which

“The build was a large-scale, complex project which combined multiple curved and straight prefabricated wall panels to deliver a dynamic articulated façade.”

“We’re proud to have partnered with Kane Constructions and Modular Masonry to help deliver such an iconic civic structure.”

architects need innovative solutions. Our approach combines prefabricated LGS framing with our brick slip façade system, providing a practical and efficient solution to meet these challenges.”

Engineered by LD Consulting Engineers, the curved frames use laser-cut profiled

Each face of the building addresses a different community zone of influence.

(Image: Modular Masonry)

Converge is Australia’s premier event for Sub-Contractors, Project Engineers, Council Fleet Managers, and Large-Scale Construction Contractors across the municipal works, civil construction and infrastructure space.

Through a mixture of live demonstrations, equipment showcases, and conference spaces, Converge will bring industry experts together to share knowledge and deliver solutions for building and maintaining Australia’s future.

Komatsu is rewriting the construction playbook, merging technology and smart machinery with expertise to deliver productivity, sustainability and safety on worksites.

The construction industry is experiencing a seismic shift, driven by increasing demands for smarter and greener solutions. Leading this evolution is Komatsu, combining a century of expertise with modern technology to redefine what’s possible in project delivery. Through its expanding Smart Construction solutions, Komatsu is transcending individual machines to create smarter, more connected worksites. This holistic approach improves efficiency, lowers emissions and enhances safety – addressing the evolving challenges and priorities of major Australian projects.

Productivity in construction is one persistent challenge affecting the sector. Labour productivity declined by 1.8 per cent during the 2022-23 financial year, according to the Australian Productivity Commission’s 2024 report. Disconnected equipment and siloed data have hindered progress, but Komatsu’s Smart Construction solutions are bridging these gaps.

James Muir, general manager of Smart Construction at Komatsu, says the company’s

success is driven by the agnostic nature of its technologies, which integrate with equipment from other manufacturers.

“Centralised data empowers customers to make informed decisions, ensuring compatibility with existing tools and solutions,” says Muir.

A standout innovation in Komatsu’s lineup is the Smart Quarry Site platform, a fleet management solution. By providing real-time data on machine performance, production and safety, it ensures materials are moved efficiently, reducing waste and fuel consumption. The platform supports machines from multiple brands, fostering a more connected and collaborative environment.

These operational efficiencies can translate into environmental benefits. The built environment is responsible for 40 per cent of global carbon emissions, with 22 per cent attributed to embodied carbon in construction and infrastructure, as highlighted in KPMG’s 2023 Embodied carbon in construction and

infrastructure report. Komatsu is tackling this challenge with a proactive approach to sustainability.

Intelligent Machine Control (iMC) technology helps operators avoid over-d igging or unnecessary rework, reducing fuel consumption by up to 30 per cent. On large-scale projects, these efficiencies quickly add up.

With Smart Quarry Site, the material distribution in truck trays is displayed via a digital spirit level indicator, ensuring even loads. This maximises capacity, improving loading efficiency while reducing the number of trucks and cycles required.

“By optimising loading cycles, our customers achieve greener outcomes while cutting operational costs,” says Muir. “For one company, Smart Quarry Site saved more than 80,000 litres of fuel and reduced CO2 emissions by 217 tonnes in just 12 months.”

Komatsu’s sustainability efforts surpass operational improvements. The company is advancing electric excavators, hydrogen fuel cell technology and power solutions

to meet environmental targets without compromising performance.

“We have released Tier 4 engines, reducing particulate matter and nitrogen oxides (NOx) emissions, even though Australia has not yet mandated this standard,” says Muir.

“In Europe, Tier 5 is already required and supplied by Komatsu, so as a country we are lagging. Still, we remain committed to delivering solutions that drive global environmental goals.”

While moving the needle on sustainability, Komatsu is equally focused on enhancing safety in one of Australia’s most hazardous industries. In 2023, machinery operators and drivers accounted for 37 per cent of all worker fatalities, according to Safe Work Australia’s 2024 report.

Safety is non-negotiable, and Komatsu prioritises people alongside sustainability and performance. Intelligent features like 360-degree KomVision surround cameras, payload measure and capture and aerial

“For one company, Smart Quarry Site saved more than 80,000 litres of fuel and reduced CO2 emissions by 217 tonnes in just 12 months.”

hazardous areas while increasing accuracy.

“Our iMC systems deliver survey-grade precision without putting workers at risk,” says Muir. “Surveyors no longer need to enter pits or traverse unstable ground because machines operate using real-time digital design data.”

Komatsu also employs training technology, such as machinery simulators that provide immersive learning environments. These tools allow operators to hone their skills in a controlled, risk-free setting before stepping onto live worksites.

Advancing autonomous construction

Komatsu’s technologies are accelerating the vision of more autonomous construction sites – a reality that is rapidly taking shape.

“Autonomous machines are not replacing people; they are creating new roles,” says Muir. “These machines can operate consistently,

24/7, without fatigue, enabling skilled workers to focus on tasks requiring oversight and expertise.”

Komatsu is partnering with engineering firms and contractors to ensure its innovations benefit entire project sites rather than isolated workflows. This approach delivers productivity gains across the value chain and reductions in resource waste.

Collaboration fuels innovation

Komatsu’s success thrives on a commitment to collaboration. Each new solution, from Smart Quarry Site to future iMC advancements, is shaped by customer input and real-world challenges.

“The voice of the customer drives everything we do,” says Muir.

“Our solutions are not about quick fixes –they are about delivering tools that provide measurable value today and scalable benefits tomorrow.”

While the construction industry is still years away from achieving autonomous worksites, Komatsu’s suite of smart solutions is laying the groundwork. From electric excavators to hydrogen-powered machinery, Komatsu is building a future where construction is safer, greener and more efficient. With iMC 3.0 on the horizon, the company’s 100-year legacy continues to evolve – its journey is far from over.

“The voice of the customer drives everything we do.”

Hala Taouk has traded fitting in for standing out, carving her path in the construction industry with authenticity and unwavering enthusiasm.

Speak with Hala Taouk, senior commercial manager at CIMIC Group’s UGL, and it quickly becomes clear: she is proudly herself – passionate about construction and a natural leader. But this sense of authenticity was hard‑won, honed over many years of perseverance and self d iscovery.

A civil engineering graduate from the University of New South Wales, Taouk wasted no time diving into the construction world. Her debut project – a high r ise building in Sydney – saw her stepping onto a site as the sole woman among 200. While many might have been daunted by such an environment, Taouk rose to the challenge, overcoming obstacles and emerging stronger in the process.

Reflecting on it now, despite its challenges, she says she enjoyed the experience.

“I started as a site engineer and, as I like to say, earned my stripes. The great thing about being on a construction site is the authenticity – there’s a level of genuine connection I haven’t seen elsewhere,” says Taouk.

“By the end of a project, it often feels like you’ve become a family because everyone is working towards a common goal every single day.

“Even though I graduated with a civil engineering degree, I realised I wanted to be part of that atmosphere. That, and I loved the smell of fresh concrete in the morning.”

testament to how the industry had grown to embrace individuality.

“Back yourself and be yourself,” says Taouk. “Don’t try to be one of the boys – your strength lies in doing things your way. That’s the key takeaway I want women to know.”

Taouk’s identity as a Lebanese Australian also plays a vital role in her story. Although born in Australia, she spent her teenage years in Lebanon before returning at 18 to study engineering on her own. This experience instilled a profound resilience.

“I’ve realised that embracing my whole self – both as a woman and as someone from an ethnically diverse background – is a strength,” she says. “Times have changed, and so has the way people appreciate diversity, both cultural and personal.”

At a company she previously worked for, Taouk experienced the power of diverse perspectives in an operations role within the company’s digital business. Collaborating with architects, engineers, software developers and user experience consultants reinforced the value of authenticity and confidence.

“Your personal brand is what sets you apart,” she says. “When you embrace it, you not only advance your career but also make a meaningful impact.”

“I’ve realised that embracing my whole self – both as a woman and as someone from an ethnically diverse background – is a strength.”

While Taouk looks back on the experience with fondness, recognising how it helped shape the leader she is today, she’s also grateful to see how the industry has progressed. Her male colleagues often struggled to know how to communicate with her, and she, in turn, found it challenging to connect with them.

“Fast forward 20 years, and I’ve seen significant progress,” she says. “People have become more aware, and with awareness comes understanding. I don’t see men resisting these changes. Quite the opposite – I see them actively promoting and supporting women, even with gestures like wearing pink shoelaces to show solidarity.”

A defining moment in her career came years later, when she shared a site office with a female engineer sporting fluoro purple nails and reading Vogue during lunch. It was a far cry from her early days – a

With a career spanning iconic projects like Sydney’s Darling Square, Taouk is now working on the HumeLink West transmission project being delivered by CIMIC Group companies, UGL and CPB Contractors for Transgrid Group. The initiative, which will deliver renewable energy to Australian households, holds special significance for her.

“This is a once i n a generation opportunity,” she says. “Being part of a project that powers homes with renewable energy is incredibly meaningful. It’s something I’m proud to share with my kids and friends.”

Taouk’s days are as varied as her career. Mornings begin early, juggling emails and family routines. Work often involves tackling procurement issues, managing teams and ensuring regulatory compliance.

“To excel as a commercial manager, you need to be a jack of all trades, master of none,” she says. “The role requires a combination of skills – part engineer or construction professional, part lawyer, part accountant, and, most importantly, an effective communicator.”

(Image: HumeLink West JV)

requires a blend of process d riven activities and reactive problem solving.”

She also takes pride in fostering seamless communication between her team and senior management, ensuring ideas are heard at all levels.

“As a manager of managers, I act as a conduit,” she says.

“Whether it’s the most junior team member or senior leadership, my aim is to create harmony and let the best ideas drive decisions.”