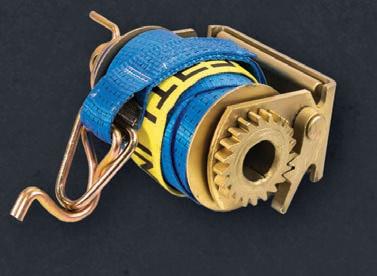

Bulk and Rural Carriers Association (LBRCA) of NSW, Wade Lewis, has condemned the actions of those behind the recent vandalism of two

The peak NSW livestock body issued a warning to livestock operators around the country following two alleged acts of animal activism in southern NSW.

The incidents occurred while the livestock trailers were parked and unattended – one at Goulburn on Saturday March 8 and another on the Olympic Highway near Wagga Wagga on Monday March 10.

Both operators were left with a hefty repair bill as a result.

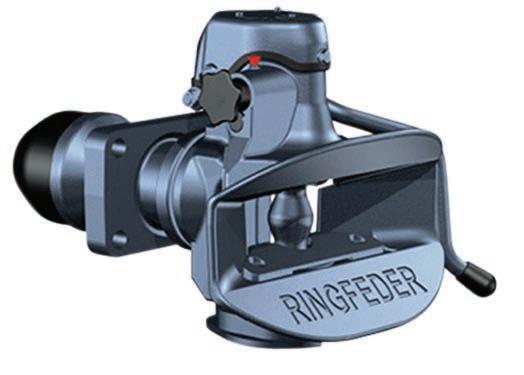

“The damage was extensive and included derogato-

adding there was also significant damage to cabling.

“They’re doing things like cutting airlines, which is a major safety issue for the operator.”

Lewis says this sort of behaviour not only impacts operators financially but can also have a psychological impact too.

“It has a flow-on effect,” he said. “These operators couldn’t go and pick up their loads, so the livestock is sitting around waiting to be transported. What these activists have done is counterproductive.

“In Australia, we have some of the highest standards in the world when it comes to livestock transport. Our industry contributes $5 billion to the economy each year –and then you have these people who contribute nothing to

society and are causing these sorts of issues, with no consequences.”

According to Lewis, one of the operators targeted is a young owner operator in his twenties. “He’s doing his best to try and make a go of it and make a living for himself. He’s also a member of our association and is committed to contributing to the betterment of the industry,” explained Lewis.

The operator commented, “As an owner operator, I depend on my equipment to earn a living. I’m looking at a repair cost of around $1015,000.”

Lewis added that the statebased livestock animal associations and the national body – the Australian Livestock and Rural Transporters Association (ALRTA) – work closely with various animal

welfare organisations includ ing RSCPA and Animal An gels.

Lewis says the actions of those responsible for the trail er damage is not only coward ly, but also totally misguided.

“They’ve targeted trailers on an isolated part of the highway – and they’ve totally missed the mark. All they’ve done is make more people angry with them rather than making any sort of difference.

“Instead of coming to the table with sensible discussion, they’ve chosen destruction to try and get their message across – and it has failed miserably.

“We’re seeing this sort of thing happen more regularly now. It’s not coming from the established animal welfare groups, it’s the smaller splinter groups.

“We’re asking livestock operators right across Australia to just be vigilant and make sure they do their pre-start checks.”

ALRTA President Gerard Johnson also slammed the actions of those responsible, “While peaceful activism is a cornerstone of democratic societies, illegal activities that harm small businesspeople and their property is completely unacceptable.

“These actions are not only unlawful but deeply harmful to the livelihoods and emotional wellbeing of those affected. Hard working rural Australians need to be pro-

tected from such groups.”

LBRCA shared a photo of an emblem spraypainted on the back of one of the trailers, resembling the same one used by the Animal Liberation Front (ALF), suggesting that the damage may have been carried out by this group.

The Animal Liberation Front is reportedly an international, underground “leaderless resistance” that engages in illegal direct action in pursuit of animal liberation.

The Australian faction has a Facebook group with 5500 followers where it also spruiks t-shirts sporting the logo “gives businesses a fright”. The site hasn’t been active since 2020.

Lewis is calling on police to help find the culprits. “If livestock operators are experiencing this sort of vandalism, we also encourage them to let us know so we can get as much information as we can to the authorities to help put an end to this sort of behaviour.”

THE rst anyone knew something was amiss was at 4.30am on March 6 when truckie Danny Martin checked in with his after-hours manager at Beerwah-based Armesto’s Transport.

Martin told the o ce he was “helping a new guy”, according to the widely circulated social media post by the Queensland operator later that same day, also asking for industry help to locate Martin.

But Armesto’s also said that didn’t make any sense because there were no breakdowns in the area at the time, the company added.

Martin had been on his usual run from Brisbane to Melbourne at the time of his disapperance.

Later that same morning, police went to the parking

bay at Widgiewa rest area, just south of Narrandera and found Danny’s truck parked in “an odd way”. “ e sleeper air-con was running, keys in the ignition,

tools sitting on step, Danny’s nowhere to be seen.”

NSW Police media released a statement the same day saying that shortly before 9am on March 6 o cers from Murrumbidgee Police District – with the assistance of the SES and VRA – commenced a search of bushland o the Newell Highway, Morundah, for a 50-year-old man.

“Inquiries have established that the man may have suffered a medical episode and walked into bushland about 4am after stopping the truck he was driving along the side of the road,” the police statement read.

It took another 24 hours, or so, before Martin was found, much to the enormous relief of family, friends and the outpouring of support from industry on social media plat-

forms all around Australia.

“He’s alive and well and is just being taken to hospital for precautionary measures – it’s a good result, Inspector Jason Dunn told Big Rigs on the morning of March 7.

“He’s been out in the elements for a day and a half, but he’s alright.”

An Armesto’s spokesperson con rmed to Big Rigs via email that Martin was suffering from dehydration but otherwise okay.

“How good is this news,” wrote Ian Drury on our Facebook page after reading that Martin was found safe and well, a sentiment shared by thousands of other well-wishers.

“Proud of the industry at the moment for their help in trying to nd ol’ mate too, well done all.”

Added Luan Berry: “Well done to Armesto’s Transport for picking it so quickly and raising the alarm. What a great company to work for.”

Armesto’s General Manager Teresa Armesto said Martin was released from Narrandera District Hospital just under a week after he was found.

She couldn’t elaborate on what caused the incident, other than to say she believed it was a medical issue.

Armesto also thanked the emergency services who

found Martin – and the industry for an overwhelming response to the company’s call for help on social media.

“It was just so out of character that we thought something untoward had happened, that was the concern, but I honestly didn’t realise it [the post] was going to go like it did. It was crazy.

“It’s sad that the industry has lost some of that banding together over time, but it’s good to see at times like this that they still can.”

CRIPPLING bridge assessment fees for operators that can run into the tens of thousands will soon be scrapped under a new permit scheme in Victoria.

Known as the Heavy Vehicle Structural Assessment Permit System, it will automate up to 85 per cent of structural assessments for Class 1 and 2 heavy vehicles, signi cantly reducing assessment and response times, and eliminating all fees for industry.

It is expected to be available from January 1, 2026, nally bringing Victoria into line with other jurisdictions which already have a similar system in place.

e cessation of the fees will result in easier access pathways for many heavy vehicle combinations, including innovative B-doubles, A-doubles, Performance

Based Standards (PBS) vehicles, quad-axle semi-trailers, and combinations featuring next-generation low- and zero-emissions trucks.

Victorian Transport Association (VTA) CEO Peter Anderson said the news this week is a big win for industry and the collaboration between the VTA, Heavy Vehicle Industry Australia (HVIA) and NatRoad which lobbied the state government for the change.

“We’re very grateful for the [roads] minister to understand the issues within the industry and to respond so positively and so quickly,”

Anderson said.

“It just shows we have a progressive roads minister in Victoria who is doing the best for our industry.”

Anderson said it’ll take a lot of costs out of getting permits

and running large vehicles on the state’s roads: “It’ll mean we get safer trucks on our roads and means our industry will get greater opportunity to do a better job than what they do today.”

In 2021, leading enginner Robert Smedley told Big Rigs that Victoria is seeing bridge assessments as a “cash cow”, charging anywhere from $5000 to $20,000 per bridge, and sometimes up to $80,000 for a single route, and taking six months to do it.

Other states, meanwhile, are providing the same service for free and turn around applications in less than four weeks.

Anderson agreed that the industry is currently drowning in red tape and unnecessary costs, putting operators under undue nancial pressures.

He cited the example of one VTA member who re-

cently copped a ne from the National Heavy Vehicle Regulator of $54,000 on one load because they were one tonne over on the steer axle and 20kg over on the drive.

“ is is how absurd it is in terms of trying to run a transport business, and how hard it is.

“ e costs that the [federal] government puts on us are absolutely huge.

“So for the Victorian state government to not try and grab every cent they can and to actually acknowledge what the industry has asked them and say we’ll do something to help you is just a remarkable achievement.”

HVIA CEO Todd Hacking said the new permit system is an “absolute win” for industry.

“And also for the wider Victorian community, who

will enjoy the bene ts of a greater number of safer, more productive and more e cient trucks in the years to come.”

NatRoad CEO Warren Clark agreed that this is a great outcome for road transport operators.

“We acknowledge the Victorian Government’s commitment to reducing red tape and improving the e ciency and productivity of our industry.”

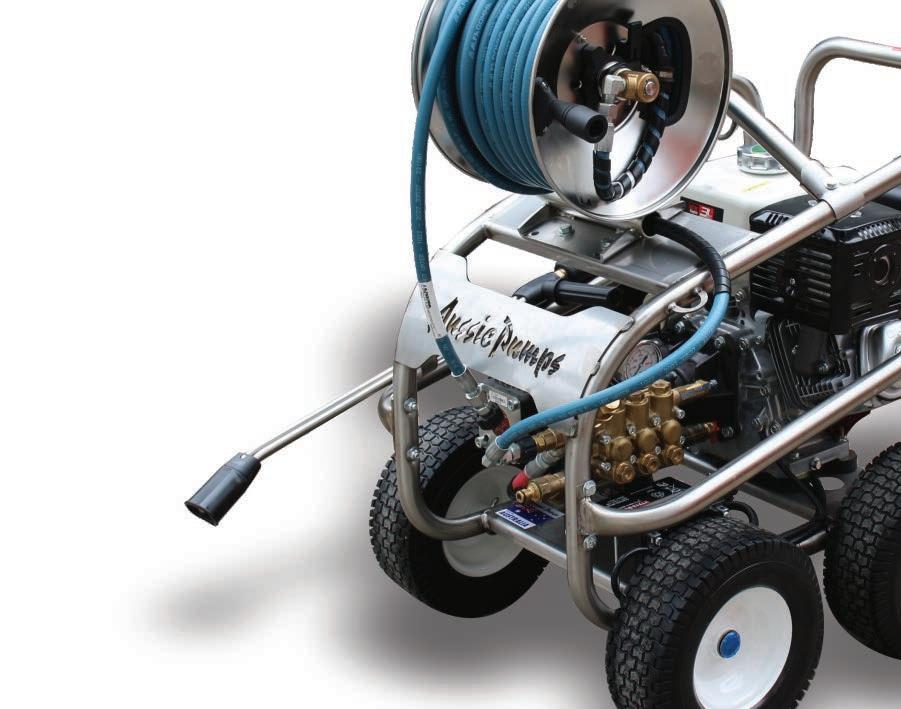

To expand its capabilities, Armoury has opened a new workshop in Melbourne, Victoria. Located near the Kenworth factory, this workshop is able to service dealers Australia-wide.

Contact our team to discuss your requirements.

DURING a month-long blitz across three states, targeting heavy vehicles during grape harvest season, the National Heavy Vehicle Regulator (NHVR) says 38 per cent of those intercepted were found to be “non-compliant”.

‘Operation Forti ed’ occurred across New South Wales, Victoria and South Australia, with more than 270 heavy vehicles intercepted.

NHVR Acting Director of Southern Region Stephen Bryers said Safety and Compliance O cers (SCOs) concentrated compliance and enforcement e orts on strategic locations across these states, providing education to drivers on how to meet their safety obligations in 88 of the intercepts conducted.

“We detected a non-compliance rate of around 38 during this year’s operation,” he said. e NHVR con rmed that mechanical issues were the leading cause of non-compliance during this year’s operation. SCOs also recorded low levels of non-compliance with fatigue, permits, mass and dimension.

“ is is the fth time Operation Forti ed has been undertaken in both SA and Vic, and each time the NHVR has led this operation we have seen the rate of non-compliance steadily decrease,” Bryers added.

“ is is down from a non-compliance rate of 42.2 per cent in 2023, 59 per cent in 2022, and 61 per cent in 2021 – this is a true testament

to industry’s collective e orts in driving continuous improvement.”

NHVR Chief Operations

O cer Paul Salvati said Operation Forti ed was critical to ensure the smooth and safe de-

livery of grapes and local produce, from vineyard to shelf.

“Heavy vehicles are currently hitting the road in force as the grape harvest season peaks, however it’s important to remember that safety is always in

season,” Salvati said.

“SA alone produces more that 50 per cent of Australia’s wine, and in 2021-2022, the state’s industry produced more than 800,000 tonnes of grapes valued at $622 million.

“ is just goes to show what a major contributor the industry is to the national economy, and with this kind of scale, it’s vital that the transport of these valuable crops is as smooth as ne wine.”

Operation Forti ed focused on fatigue management, monitoring and identifying potential grape spillage incidents, and mechanical inspections to ensure compliance.

“We know this is busy time of year for the agricultural sector, but we can’t a ord to let

any lapses in safety spoil what should be a very productive season,” Salvati added.

“Some of the primary risks related to grape harvest transportation include driver fatigue, particularly at the end of night shifts or from wait times to either load or o oad, in addition to spillage due to overloading.

“Grape spills have a significant impact on the safety of other road users, creating slippery surfaces that can lead to a vehicle losing control and increasing the risk of catastrophic accidents occurring.”

Salvati said this operation was a crucial step forward in the regulator’s ongoing e orts to reduce crashes and ensure the safety of everyone on the road.

THE liquidator of a national truck repair group has raised concerns in a recent report about undeclared company shares and vehicles and said the company may have traded insolvent from mid-2022.

Truck Repair Group (TRG) went into voluntary liquidation in December owing more than $3.9 million - most of that to the ATO - but is still being operated in ve different locations by the same family under a di erent name, TRG Heavy Vehicle Smash,

owned by TRG Group of Companies.

e liquidated company was solely directed by Scott Hunter, who used to work for the previous owner, Russ Hill, as the General Manager.

Big Rigs spoke to Hunter, but he declined to comment on record. He said his only role was to help the administrators with the closure of the old business.

According to a detailed report sighted by Big Rigs from liquidator Nick Combis of

Vincents, the new company had agreed to pay $117,243 for TRG’s business operations and assets, an amount which should have been $262,543 as “a best-case scenario”.

e liquidator said he had requested funds from the new company, including a $70,000 instalment already due under the existing sale agreement on March 9 and “possible further amount of $192,559”, due by March 17, to cover the shortfall.

e report said the collapsed

company owned shares in related company, TRG Parts & Accessories, which were not declared by the director and had been transferred after the liquidator had been appointed.

“My investigations of this matter are continuing,” Combis said.

Hill said he’s more concerned about the impact the liquidation will have on the smaller operators than recovering what he’s owed by TRG, his long service leave entitle-

ment of $38,000.

“A lot of the people have been ringing me asking what’s going on,” said Hill who sold the business in 2020.

“I have to remind them that I’m on that [creditors’] list too remember, and I haven’t been there for four or ve years.” Creditors have been asked to submit proof of debt forms with the liquidator as soon as possible and also to cast their votes in relation to the payment of liquidation costs by 6pm (AEST) on April 4.

BY JAMES GRAHAM

TRUCK parts bosses are urging customers to be on guard after a spate of online scams have eeced unsuspecting buyers.

Fraudsters are setting up fake websites and Facebook pages, impersonating legitimate truck parts suppliers, and tricking online users into paying for goods that never arrive.

Ben, the General Manager at Rocklea Truck Parts in Queensland, has been at the forefront of battling these con tricks.

“ ey’ve copied our name, our logo, everything,” Ben told Big Rigs

“Customers ring us thinking they’ve placed an order with us, only to nd out they’ve been scammed. It’s infuriating.”

e scammers are using Facebook business pages as their main point of operation, creating cloned versions of legitimate truck parts businesses to deceive customers.

According to Ben, Facebook has been largely ine ective in tackling the problem, despite multiple reports from victims and a ected businesses.

“Facebook could shut this down in a heartbeat, but nothing happens. ere’s a reporting function that just seems to be there to make people think action is being taken when in reality, it isn’t,” he said.

pattern: victims come across a seemingly legitimate truck parts supplier on Facebook, place an order, and are then instructed to transfer money to a bank account.

Once the money is received, the scammers disappear, often blocking their victims from further contact.

foreign accents, suggesting the operation may be based oshore. e nancial losses incurred by customers are signi cant. One unsuspecting buyer lost $4000, while Ben estimates that the total amount scammed

on the fake Rocklea Truck Parts pages could be upwards

“Customers are getting stitched up. It puts a bad taste in people’s mouths when they think they’re dealing with us, only to realise they’ve been scammed,” he said.

Queensland Truck Spares has also been a ected, with

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

co-owner and director Nick Wirth con rming to Big Rigs that they had managed to get one fraudulent Facebook account shut down after extensive e ort.

However, he remains skeptical about whether this will have a lasting impact.

“With a lot of back and forth, requiring people to individually report posts and accounts, we had the scammer successfully removed from Facebook - for now.

“But we know this is only a temporary x. Facebook’s platform has aws in preventing these scams.”

Wendy Berry, co-owner of Rocklea Truck Spares, said it’s an ongoing battle to stay one step ahead of the scammers.

A few weeks ago, she successfully got a fake page removed from Facebook after three months of daily reports, only for it to reappear four days later with Sean back at the helm.

Berry said her scammer now operates on Facebook’s Marketplace platform advertising truck wrecking under their business name.

“He sends them a message back saying it’s going to cost this much money, this much freight, you need to pay this much deposit, then he sends them an invoice.

“Our advice is to never buy o Marketplace if they want a deposit, or you can’t check out

the item rst. If he was a real company you’d also be able to ring his business.”

NQ Truck Wreckers is another Queensland company impacted by the scammers who is urging customers to stay alert.

“Yes people, double check your facts,” the company posted online. “We have had a Facebook ‘impersonator’ for almost two years now! So hard to get them taken down!!!!!” Ben suggests that a deep dive into advertisements can sometimes reveal inconsistencies, as scammers often copy marketing material from multiple sources, including international truck parts dealers.

“If you look close enough, you’ll see that the ads show products from multiple locations.

“But most customers don’t notice these details,” he said. As the scam continues to evolve, industry members are calling for increased vigilance and stronger intervention from authorities and social media companies.

“At the end of the day, customers need to do their due diligence before making payments online,” Ben advised.

“Check the legitimacy of the business, con rm contact details, and avoid direct bank transfers when possible.” Facebook has been contacted for comment.

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

BRISBANE NORTH

1/259 Cullen Av, Eagle Farm QLD 4009 Ph 1300 11 4774, email: seats@isrinb.com.au, www.isrinb.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106 Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

NEWCASTLE/HUNTER VALLEY

Ph 02 4932 0600,

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 email: sales@hvss.com.au www.isri.com.au

BY JAMES GRAHAM

WHEN Jim Foody’s truck was pulled over on the Kennedy Highway near Mareeba, he expected a routine inspection.

What unfolded instead was an incident he said raised serious questions about the National Heavy Vehicle Regulator’s (NHVR) understanding of Dangerous Goods (DG) compliance – questions that could have had severe safety implications.

Foody, the owner of Bamaga Transport and star of the popular Outback Truckers, TV series, runs a demanding freight operation between Cairns and the tip of Cape York, often carrying LPG gas cylinders for BOC.

Given the nature of his cargo, he ensures his team is wellversed in DG regulations. In December, both he and his driver completed DG licensing to stay updated with the latest safety and compliance requirements. He said that knowledge, however, was ignored when NHVR o cers made a surprising demand.

“ ey pulled my driver over and asked if the gas bottles were empty. When he said yes, they went o , consulted someone over the phone, and came back saying we needed to remove the DG placards,” Foody explained.

“ at’s completely against the law. An LPG cylinder is still classi ed as Dangerous Goods unless it has been purged with nitrogen and certi ed as empty.”

According to Australian DG laws, gas cylinders - whether

full or empty - must remain placarded unless they’ve been professionally purged.

Ignoring this regulation could lead to severe consequences in the event of an accident. Yet, Foody said the NHVR o cers insisted the placards be removed, under the reasoning that emergency services needed to know the cylinders were empty.

“ is wasn’t just a simple misunderstanding - it was dangerous,” Foody emphasised.

“Had my driver been involved in an accident while descending the Kuranda Range, emergency responders would have had no way of knowing they were dealing with LPG. at’s beyond serious – it’s reckless.”

e NHVR didn’t issue a ne, which Foody believes indicates uncertainty on their part.

“If they were con dent in their decision, they would’ve ned us,” he said. “But they didn’t, which tells me they weren’t sure themselves.”

Foody said he’s become increasingly concerned about the knowledge and training of NHVR o cers since the regulator took over compliance and enforcement duties in the state in early 2024 - especially when it comes to DG compliance.

“I’ve tried reaching out to them, but no one’s interested in discussing it,” he said.

“I’ve heard similar complaints from others in the industry. It seems like they’re sending out undertrained ofcers who don’t fully under-

stand what they’re enforcing.”

Bamaga Transport operates in one of Australia’s toughest environments. Roads are brutal, and a single trip can take a severe toll on vehicles. Foody, who has expanded from a small truck-and-dog operation in 2020 to running triple road trains, understands the importance of compliance and maintenance.

“We run up to Bamaga every 12 days in the dry season. e terrain is unforgiving. ere are stretches where it takes us six or seven hours to cover just 12 kilometres,” he explained.

“As well as routine maintenance every trip, we do full maintenance every wet season, going over everything to ensure our trucks are in top condition. You can’t take shortcuts up there - it’ll come back to bite you.”

His Isuzu truck, pulled over just 70km from its home depot after a 1000km return trip from Bamaga, was already scheduled for repairs. While he had no issue with the defect notices issued he was frustrated by the o cers’ approach.

“ ey told my driver to drive the truck [with DG placards removed] 70km to the Kenny St Transport Inspection Facility in Cairns so it could have a pit inspection and brake test. All the major defects found were already known to us and occurred on the current trip. But some of the so-called defects they found were absurd.

“ e truck is a 2004 model, and they defected it because the dashboard lights didn’t come on when the key was turned to accessory mode.

at’s not a fault – it was never designed to do that.”

“We were then told to drive the truck to a repair facility and get it re-inspected before we could use it again, which I have no issue with.”

Foody, who has worked with NHVR o cers in the past, has noticed a decline in knowledge and professionalism.

“ e rst NHVR guys I dealt with were great. ey understood compliance and appreciated operators who did their best to stay within the rules. But now, it feels like we’re dealing with a whole new crew who don’t have the training they need.”

e incident on Australia Day, January 26, was the nal straw.

“I usually let these things slide, but this time, it felt bigger. If enforcement o cers don’t understand the Dangerous Goods Act, they’re putting people at risk.”

He has compiled the exact clauses NHVR o cers ignored and is willing to provide them to authorities – if they’re willing to listen.

“I even consulted with the expert who trained us in DG licensing, and he con rmed we were in the right. But NHVR doesn’t seem interested in that.”

Foody isn’t against regulation. In fact, he believes a well-run NHVR bene ts the industry.

“When done right, NHVR simpli es things – permits, compliance, and wide loads are all much better managed now. But enforcement needs

to be consistent and knowledgeable. Right now, that’s not happening.”

Despite the frustrations, Foody said he remains committed to running a compliant operation, regardless of the challenges posed by regulators.

“We take our responsibilities seriously, but we need regulators who do the same.”

An NHVR spokesperson told Big Rigs that as a safety and customer-focused organisation, the National Heavy Vehicle Regulator is committed to resolving complaints in a timely and professional manner.

“Should an individual have

feedback about our service delivery, we encourage them to get in touch.”

e spokesperson said more information about how to make a complaint can be found on its website at nhvr. gov.au/contact-us. Meanwhile, the National Transport Commission (NTC) is currently conducting the rst comprehensive review of the Australian Dangerous Goods Code in 15 years.

Over the coming months, the NTC will host regular webinar ‘drop-in’ sessions to keep stakeholders informed about the feedback received and how it is being incorpo-

NSW-BASED electric truck converter, Janus Electric, should soon be a publicly listed company with backing to rapidly scale up its expansion plans.

e Central Coast start-up has struck up a reverse takeover deal with the ASX-listed ReNu Energy, an Australia-based company that delivers clean energy products and services.

Instead of going through a costly and time-consuming listing process itself, Janus will use the shell of ReNu Energy which already has all the ASX structure in place. ReNu divested itself of its hydrogen interests last month to reposition itself as a heavy transport electri cation business.

ReNu will acquire 100 per cent of Janus’ issued share capital in exchange for ReNu shares and be renamed Janus Electric Holdings Limited when the acquisition is nalised. e new company is expected to start trading on the ASX on April 22. To support the transition, ReNu released a Capital Raising O er (CRO) at 20 cents per ordinary share to raise between $8 million and $10 million.

e deal will also see a new management structure with Ian Campbell, a former Citigroup Australia banker as managing director, and co-founder Lex Forsyth taking on the chief operating ofcer duties.

Forsyth told Big Rigs that

he’s excited about the di erence the deal will make to the growth at Janus, which has not been without its teething problems in the early stages.

One of the biggest setbacks was a re in one of its trucks on the West Gate Freeway in 2023, which was a caused by a rogue battery cell issue.

Forsyth said 30 per cent of the CRO allocation had already been picked up by day one and he is con dent that the initial o ering will be closed out quickly.

“It’ll see us scale production and assembly of trucks and lift our build rate quite signi cantly,” said Forsyth when asked about what di erence the new funds will make.

“It will also lead to an infrastructure and battery fund

that will scale the volume of batteries within the business as well.”

Janus already boasts 23 converted trucks with high-prole clients that include Fennell Forestry, Cement Australia, Qube Bulk, NewCold and Symons & Clark Transport.

Forsyth said the company also has another 142 contracted orders on the books.

“I think it’s a an extremely well-valued o er,” Forsyth said of the deal with ReNu.

“I know the under-pinning value in the business. I’ve reinvested into the business and so has my family.

“We are a big believer in what we’re achieving, and I know what the future holds and where energy is going as

a whole for the transport industry.”

Campbell said there were 80,000 prime movers that were less than 15 years old on Australian roads, and these were the main target market

for conversions which cost around $175,000.

“ ere is room for disruption. is is one of those events where there is a market large enough for a disrupter,” he said.

Driving Concepts Pty Ltd, an entity controlled by Ron Finemore Transport, has snapped up 28 million shares in Lindsay Australia.

e deal was announced earlier this week for $0.6200 per share, resulting in a 8.89 per cent interest in Lindsay for the Wodonga-based company.

Lindsay Australia has a $227 million market value

and made a $15.8 million underlying net pro t for the six months to December.

e Brisbane-based giant recently revealed an acquisition of its own with the purchase of WA operator GJ Freight, an operator that generates more than $20 million in annual revenue.

Lindsay Australia also has a new Perth depot due for completion later this year.

is development is expected to deliver operational eciencies and synergy bene ts with the GJ Freight acquisition.

Late last year, Ron Finemore hired former Australia Post executive James Dixon to become chief executive.

Dixon declined to comment about the Safe Driving Concepts buy-up of Lindsay Australia shares and what it

might mean for Ron Finemore Transport when approached by Big Rigs With 280 prime movers and 900 sta , Ron Finemore Transport provides regional and inter-capital city linehaul road transport services across two major operating divisions – food, produce (either ambient or temperature controlled) and manufactured goods and bulk liquids.

EDITOR JAMES GRAHAM

It proves that drivers are still looking out for each other when it matters most, as we also saw recently in the North Queensland floods.

We can only hope that transport ministers have the same empathy for truckies when they see the first draft of the new-look Heavy Vehicle National Law later this year.

Our columnist Jodie Broadbent wasn’t holding out much hope in her well-read column in out last issue, ‘Why can others make mistakes without consequences while truckies are fined?

It got a phenomenal response online and also inspired this issue’s cartoon on the right by Ryan-Lee Taylor.

It’s no wonder we have a driver shortage with the ever-present threat of losing a week’s wages for an issue that doesn’t affect anyone’s safety.

JODIE Broadbent’s column in our last issue about disparities in penalties for truckies compared with other roles and industries touched a raw nerve amongst readers.

“Yeah, what other industry in Australia can you get fined some stupid amount for forgetting to tick a box on a page? Absolute BS, nothing to do with safety at all,” wrote Ryan Edwards.

John Klye said police should stay out of drivers’ logbooks: “It’s not their job any more. They can look after the road rules only - like speeding. And going after the REAL

road safety problem - car drivers . They’re not qualified to manage fatigue regulation.

I’ve seen one copper ignore an NHVR officer’s ruled line and go back further to find something to issue a ticket.”

Joy Burns believes the only way to solve the issue is if the industry stopped.

“It would be sorted in about three weeks to a month. Hurt the bulk of the population. No fuel, food, medicines, etc. The problem is the big companies won’t do it, and the little blokes can’t do it on their own.”

Operator Sally Tipping said

Covid was the time to push for an image change for the industry.

“I pushed this to the big end but they could not/ would not see the potential in promoting our industry.

Now we see a floundering industry, with multiple start-up companies lasting a year or two while stripping the hell out of rates.”

Chris Cartwright said it’s all about attitude: “Been fined plenty of times, and not one of them I didn’t earn by my choices…change your choices and you change your outcome.”

NEWS that NSW will ick the switch on cameras to capture speeding light vehicles on sections of the Paci c and Hume Highways was met with resounding cheers by online readers.

“I love how everyone gets upset when they do stuff like this car drives but don’t care when it is happening to truck drivers I say if it good for one it is good the other,” wrote Glenn Smerdon.

Rod Leven also had little sympathy for car drivers.

“Not getting enough money from truck drivers because of speed limiters or from the NHVR for defective or

overloaded vehicles, those poor politicians aren’t getting enough money. Poor Buggers, I feel sorry for them NOT!”

Added Davos Trading:

“What better time to bring up the subject of how dangerous speed limiters are.

“They have several bad flaws that cause significant danger ous and regular safety risks. More so to a new operator.

“So, before they encourage more accidents, they should at least understand how they ac tually cause them now, first.”

Chris Kohen joked that the government is now considering logbooks for car drivers as well so they can better manage

ANDY Hughes also stirred up plenty of debate with his column in the February 28 issue about the role driving instructors play in keeping roads safe.

Truckie Niell Graham told us that he’d stumbled across a company in Victoria advertising for a driver-trainer and you only needed to have had your truck licence for 12 months.

“I would’ve thought you would need a minimum of five years because you learn nothing in 12 months.”

Paul Warren said driver instructor training is the key.

“They need to be trained and shown how to do the job properly. If they can’t read, write, and

their fatigue, and cars towing caravans will be directed to weighbridges for checks.

“I suppose that’s fair; same rules for everyone.”

THE Australian Trucking Association’s pre-election plea for the government to do more to support trainee drivers and their employers was another hot button issue for our Facebook followers.

“Employers want fully trained drivers with 50 years’ experience at 21 years of age, they don’t want to train them,” said Bruce Skelton.

“You start in the yard and work your way up, but today’s drivers want the big shiny banners with all the bells and whistles straight away.”

Adrian Bates said it’s a licence holder’s reasonability to know

speak English, and they can’t reverse, then no licence should be handed out.”

Ross Boothby agreed that instructors have a major role to play to get new drivers ready, confident and competent with all aspects of driving.

“But nowdays the drivers only see trucking as a job, they don’t see it as a craft. Like anything in life, you need to learn your craft in order to become better. That’s where I feel we fall off the wagon in this industry.”

Ash Anderson said she’s a Queensland-based instructor where an RTO’s only involvement is for an MC licence.

“But I do find it shocking that there is no set standards for the

all rules and regulations pertaining to the class of license they hold and to the class of vehicle they are driving.

“A one day driving courses and $700 gets a driver a license but no knowledge. “Where would a new heavy vehicle driver be able to find the information, they need to know to be safe out on the road. The driving schools need to do more to inform their students when training them.” Added Brendan Callon: “Since when does one need to undertake an apprenticeship to drive a truck, you bloody twits! There is already too much BS

lower license classes. It is up to us instructors to get the students to test standard so that they will pass, where there is no requirement for discussion or education on load restraint, using a work diary or fatigue management.”

red tape and ‘training’, cough, cough.”

Brad Dean said this system is already in place. “Plenty of large companies sign their drivers up as trainees, and the government subsidises their wages.”

True

to form, Darren Nolan took the burden away from distraught family members to talk about their loss

BY TIM GILES

THE funeral for trucking industry identity, Darren Nolan, of Nolan’s Interstate Transport, took place at Saint Mary’s Catholic Church, in Gatton, Queensland on March 15.

Darren sadly passed away on March 6, aged 54, after a prolonged battle with cancer, the same cancer which his father, another industry icon, Terry Nolan, had died from.

In what was described as a “truly unique and heartfelt gesture”, Darren, true to form, had actually prepared his own eulogy on video for the packed funeral service, a video that left most of the mourners in attendance in tears.

Organising this video was a typical Darren thing to do, taking the burden away from distraught family members to talk in public about the man and their loss, handling it himself.

e attendance showed the a ection for Darren and his family in the trucking industry, and the importance of this large family-run trucking business in bringing progress across a wide range of areas, for the Gatton community and the trucking industry as a whole.

“I’m doing this eulogy to take the pressure o of making someone t years and

years of my lifetime into 15 minutes and feel incredibly nervous about doing it,” said Darren on video.

“Sit back, relax and enjoy the show.”

Darren’s parents, Terry and Daphne Nolan, had seen their eet grow fast at the same time as road transport became such a major factor in the Australian economy.

In the 90s, in the aftermath of the Grafton and Clybucca truck and bus crashes, there was an increased emphasis on safety in eets and new accreditation schemes were being developed.

One of the eets involved was Nolan’s. e workshop manager at the time, Craig Roseneder, was a pioneer in creating a robust system to ensure safe trucks on our roads, and Nolans’ membership number for TruckSafe is 001, as a result.

Terry Nolan insisted that his children had to work outside of the business, before working in the Nolans enterprise.

For Darren this was a period of working in the hospitality industry and overseas in Norway.

When he did return to the trucking game, Darren was given a number of roles before settling into one assisting Craig Roseneder. e task at hand was to be part of the pilot scheme,

with a video that left mourners in tears.

developing an improved regime, which would enhance fatigue management in the trucking industry, but also enable productivity levels to

be maintained.

is was a process of rewriting and re ning the standards of the time, putting processes in place and working out what kind of paper trail was needed. an important part of this was developing new ways of recording various aspects of truck maintenance.

is was the template used to develop AFM, BFM and standard hours, as well as the Trucksafe scheme we have

After Craig’s passing Darren took on more of the compliance role and developed the ideas they had developed

He also became an advocate for safety and compliance systems, ending up on the Trucksafe board for several years, and speaking nationally and internationally on the

Until last year, Darren continued his roles within the family business, working with his brother, Flea, to steer the continuing upward trajectory in the Nolan’s Interstate Transport business. Darren will be remembered, both for his genuine thoughtfulness towards others and his passion and vision to bring improved outcomes into the trucking industry.

He was also a gure who could present a positive and considered argument to those legislating and regulating the trucking game.

“ e many people that I

Industry tributes

I’m saddened by this news. Darren was an amazing individual, someone who would always be ready to lend a hand if it meant that industry would be the eneficiar a s thin in for the enefit of a arren as an in str cha pion an honest carin individual and my friend. I will miss him dearly and o r tho hts are ith arena e ai e an the No an family. RIP my friend.

Jacquelene Brotherton, Chair Transport Women Australia Limited

tre e sa ne s con o ences to the fa i arren as s ch an a a in a ocate for the in str

Gary Mahon, CEO Queensland Trucking Association

We were saddened to hear the news of Darren’s passin after a on att e ith cancer On eha f of the oar an staff offer eepest con o ences to arren s ife arena an a hter e ai e the entire No an fa i an the No an s nterstate ransport fa i arren as e no n to an in the in str for his or in the safet an co p iance area a on stan in oar e er of r c safe as e as an other oar s an co ittees

Ben Maguire, former CEO Australian Trucking Association con o ences to the No an fa i arren as s ch a professiona an s ch a in an

Steve Shearer, Executive Officer, South Australian Road Transport Association he in str has ost one of its est On eha f of R o r e ers an a in the in str ho ha the pri i e e to or ith or no arren e e press o r eepest con o ences to arren s fa i an or co ea es He a e a si nificant contri tion to the in str an to an peop e s i es One of the nicest an ost sincere so s e er to race this in str

Todd Hacking, CEO at Heavy Vehicle Industry Australia ncre i sa ne s n a so te ent e an tte

worked with were exceptional people, very skilled at what they did,” said Darren in his eulogy.

“ ey would probably call me a hard boss to work with.

I suppose I have pretty high expectations, you might have to ask them, but I couldn’t have done what I do without the group of people that I worked with and a huge amount of assistance from my mum.

“Quite often she doesn’t get the credit that she deserves. She’s looked after everyone, from her sister who was ill, to her mother, to all these people, she’s always put them rst. She’s had to go through the aches and pains, and she managed that without whinging once about the situation.

“I believe that she’s the cement, the glue, that holds everything together for the family. What she’s been able

to do in her lifetime is phenomenal, she’s an extraordinary woman.”

On a personal note, I would like to add that I had the privilege of working with Darren in writing a book about the history of the Nolan’s business, back in 2007, for the operation’s 100th anniversary.

I can attest to the qualities many others recognised in him. He was great to work with, considerate and reliable. He was also hot on getting the details right and, surprisingly, a pretty damn good photographer, and we used many of his shots in the book.

“How would I like my life to be celebrated?” said Darren via his farewell video. “Well, French champagne is number one.”

Darren is survived by wife Sarena and their daughter Adelaide.

Mack is more than a truck. From uptime services to parts and maintenance, Mack is an indispensable part of your business.

Mack. By Australia’s Side.

The first 780hp Mack Super-Liner in New Zealand couldn’t have gone to a better home than Golden Contracting, specialists in cartage and aggregate supply.

MARK ‘Skip’ Golden reached a major milestone in his long career in the transport industry when he rst laid eyes on his brand new Mack Super-Liner at the manufacturer’s Brisbane HQ earlier this month.

“When I heard about the 780hp Super-Liner from a conference call, I thought ‘imagine getting the rst one o the line for New Zealand?’” said Skip, who is also celebrating 25 years since he bought his rst truck.

“I initialled an agreement without even asking the purchase price.”

As a proud Mack owner, the boss of Golden Contracting, based in Silverdale, 30km north of Auckland, said there was never any question about his decision.

“ is wasn’t just about the horsepower, it’s the conventional look of the Mack, especially with the commemorative big hood Mack o ered to t on this truck.

“It’s a numbered truck, I want it to be remembered, and Taite who will be pedalling it, is Mack through and through himself.”

But while it might sound like an emotion-based acquisition to the eet, Skip said there’s some hard business logic behind it as well.

“I rate trucks by their cents-per-kilometre over the life of the vehicle, and the Macks have consistently outperformed other brands when it comes to durability, reliability and fuel e ciency,” he said.

“We had a Trident that we ran for 550,000km before it went for a mid-life, and that cost us a fraction of what we were expecting.”

Skip’s drivers also love the Macks, something he attributes in part to the mDRIVE automated transmission.

“No other transmission gets near it,” Skip said. “Just when you’re thinking you might need to change gear it does it. It’s so intuitive, it knows exactly when to shift and it’s very smooth on the pedal. It’s peace of mind in the gnarly terrain.

“Some people may call me soft for not using a manual, I just say, ‘What are you doing to yourself? Why get fatigued driving when the mDRIVE can just drive you around, and with better fuel e ciency?’”

Skip said the Super-Liner’s 780hp Euro 6 engine is also something he’s looking forward to driving.

“It’s not like we need that much power, but it gives even better fuel e ciency, and you know if you really want to let the Big Dog out to eat then it’s there,” he said.

“We are more than happy to be passed on the ats, but you’d want to be checking your mirrors on the climb!”

Golden Contracting, specialists in cartage and aggregate supply, work their trucks hard, doing double shifts, supporting roading, commercial projects and rural farms around the upper North Island for over 800 customers.

“You need a mixed eet for the di erent things we do, and the Macks give us impressive tare weight, good ground clearance, great visibility and a tight turning circle. e Macks t us like a glove really,” Skip said.

Skip’s association with Mack goes back to the days when he was working as an engineer, and his friend Dale Fenton had a R Model and a 440 Super-Liner in a yard across the road.

“I was into anything with moving parts, and I just formed a bond with these trucks, I was really drawn to them,” Skip said.

“It was 2015 when our rst bulldog entered the eet, a Mack Trident. Word went out I was in the market and salesmen turned up from every brand, but I took that Trident around the block just once and I was sold.”

After 15 years in the game, Skip nally had a Dog out the front.

He also once bought a Trident at such a good price that he kept in the shed for six years until he needed it. He nicknamed it ‘Not Ready’.

Skip also now has a 100year anniversary Super-Liner with the bonnet badge ‘ ird Wife’, as he said “it’s cheaper to marry a Mack”, and another Trident named ‘Born Ready’.

“Even now we’re looking at the next acquisition, and we’ll keep buying them.

“I’ve always been a bit of a bulldog myself, so the Mack is the ideal truck for me, but there’s more to it than that.

“We go into some pretty rough o -road terrain: forestry skid-sites, farm tracks, loose metal, you name it, and the traction and high torque curve on the Macks is ideally suited for this work.

“If I go into some of the rough country up the top of the North Island in a Mack, I know I’m coming home that night, they’re dependable.”

is dependability is something he’s come to expect not just from his trucks, but from Mack as a company.

“Mack take things seriously,” Skip said. “You’ve heard people talk about being part of the Mack family? Well, it really is like that.

“It’s a unique community you join when you buy a

Mack. It’s a bit like rugby; there’s a lot of camaraderie beyond the business.”

At this month’s handover, Tony O’Connell, Vice President Mack Trucks Australia, said he was thrilled to be able to deliver this example of Mack’s engineering skills to Golden Contracting.

“ is is a company that understands the true value Mack o ers, not just in terms of our trucks, but the long-term relationships we build,” O’Connell said.

“We couldn’t be prouder to see the NZ Number One 780hp Super-Liner joining the Golden Contracting stable in New Zealand.”

Scott Holt, General Manager of MTD, Mack Trucks New Zealand’s distributor was also pleased to see the very rst 780hp Mack for New Zealand going into the Golden eet, alongside its other Super-Liner.

“ is is certainly a re ection of the strong relationship Skip has with our team and the outstanding quality and performance of Mack over the long term.

“ e handover of this unit at VGA in Brisbane is a pivotal moment for Mack in New Zealand, heralding the class leading MP11 Super-Liners and Titans as they start hitting the roads here.

“We are proud to have supported Skip and his team with this impressive Super-Liner that is purpose built for the job, and look forward to seeing it take pride of place on Skip’s Silverdale yard.”

A small two-man operation with just two trucks has quickly blossomed into a seven-day-a-week business that now employs 14 staff.

BY DAVID VILE

‘FROM little things, big things grow’ adorns the eet of vehicles owned by Mick Johnson of Cooma, and it sums up nicely the evolution of his family’s company, which has grown from a twoman operation in 2006 to one which today runs a number of trucks and employs 14 people.

Running under the banner of Monaro Milk and Juice, the company trucks cover the Snowy Mountains and South Coast regions of New South Wales, with the terrain covered some of Australia’s most picturesque and challenging for road transport.

With a number of his eet on show late last year at the bi-annual Cooma Motorfest, Mick gave Big Rigs a rundown on his company and in particular how the last few years has seen the business, and eet, expand.

“We bought a business called High Country Wholesale with two trucks, and in the last 4-5 years with the Snowy 2.0 project coming on we look after the essential food services for them - anything consumable we cart into the work sites including Lobs Hole and Tantangara,” Mick said.

“Over that time, we have gained ve new rigids and four prime movers as well. In addition, the company also services the ski resorts of Perisher Valley and redbo along with the South Coast towns of Bermagui, Bega, Merimbula and Eden.”

With the Snowy 2.0 construction in full swing, it makes for a busy work schedule for the eet, said Mick.

“Cooma is the hub with our depot at Polo Flat. Our rigids are 8-10-14 pallet units and with the semis we run slider-sides and pans.

“Carting into the work sites we run about four semis a week plus the rigids - generally we will have one truck in there a day so from Monday afternoon through the rest of the week it’s full on.

“From our association with

that work we also cart all the fruit and vegetables out of Sydney and the meat up out of Wodonga.”

Operating a eet of trucks in the alpine environment yearround has its own set of challenges, most notably in winter and with the Snowy project work continuing through the snow season.

Future Generation, who is overseeing the construction of the Snowy project on behalf of Snowy Hydro, also has a high priority on safety and compliance with Mick making the investment in equipment that is up to the task.

“If the winter weather is too bad Future Generation won’t have us going on site. [ e year] 2022 was a big winter and if our trucks have to go into redbo or Perisher they have to t chains, so in the last 12 months we have had a couple of trucks tted with RotoGrip chains.

“We try and use one of these

the chains do a great job. We also update the drivers each year with tting the chainswe have been lucky with our driver base; we have some really good sta .”

Mick said the Monaro operation has worked for Snowy Hydro for 18 years and they keep an eye on everything.

“Our trucks are tracked, which is handy as you don’t have to hassle drivers, you know where they are. Compliance has helped us get where we are today, as a lot of customers expect that now as a matter of course and you have to have the right gear for the right job.”

e Johnson eet is primarily PACCAR-oriented, running Kenworth K200s and a T909 along with DAF CF and LF rigid units across a variety of con gurations.

With a MAN also part of the eet, Mick has worked on standardisation across the

costs on track.

“We have looked at getting everything in the one stable, all vehicles bar one have the same tyre size and so forth. With our work out of Wodonga we can get the trucks serviced there (Twin City/ KenworthDAF Wodonga) and Monaro Trucks here in Cooma are really good to us with tune ups and so forth,” he said.

For Mick, the wheel has pretty much turned full circle. A lifelong Cooma local, he has been around transport all his life with a family association with both trucking and the original Snowy Mountains Scheme which was built between 1949 and 1974.

“Dad did a lot with the Snowy - he used to cart fruit and vegetables o the train to all the work sites - Eucumbene, Island Band, Cabramur-

there wasn’t much time o !

We have always had trucks.”

Coming o a stint in logging, Mick took on the High Country Wholesale operation in 2006 and it has been all go since then.

“Our accountant looked at it and said, ‘People need milk all the time’ and here we are today, we started with two guys. It was only meant to be four-days-a-week and now it’s a seven-day-a-week operation - we subbie a bit of stu out as the work doesn’t stop.

“ ere’s a couple of good transport companies we work with such as Murphys at Bombala, and we have good relationships with our suppliers, and we all work in together.”

Sitting at Mick’s home is the rst truck he bought, a C-Line International which is being restored as time allows.

“It was at a mate’s place for about 10 years, and we have been getting it going with a few parts - my wife Debbie bought it back for me. I have had a couple of panel beaters and so forth looking at it but for its age its pretty good.”

For Mick, the last few years have been busy ones and with the Snowy project ongoing it appears the Johnson trucks will be a regular xture throughout the Snowy Mountains and South Coast regions for some time yet. Mick reckons the investment made and the ongoing work means a bright outlook for the future.

“We have upgraded our eet in the last three years, and we have spent a lot of money getting to where we are now, but you have to have good gear to do the job. (Snowy 2.0) has certainly been a positive thing for our business.”

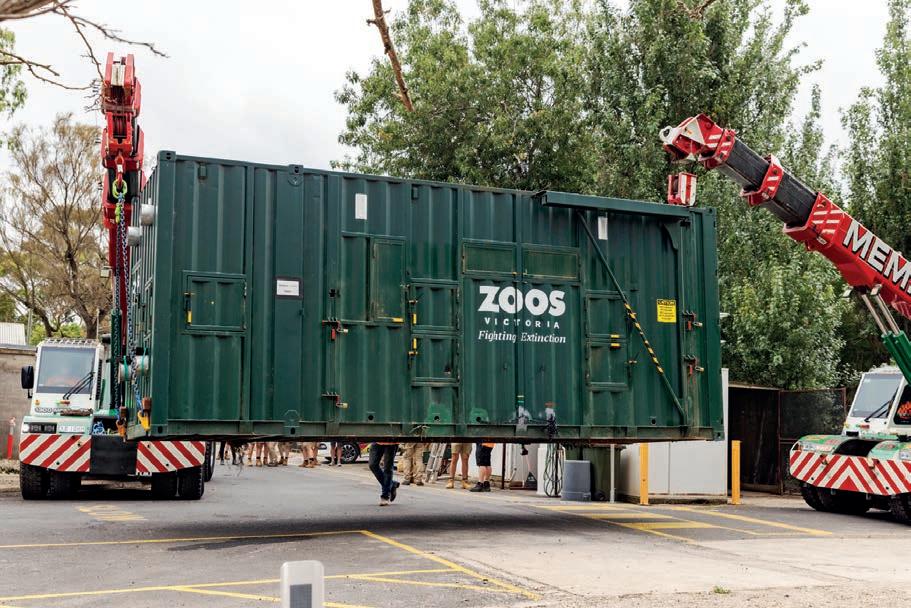

Thanks to a specialist team, an entire herd of Asian elephants recently hit the road to be safely transported to their new $88 million purpose-built home.

BY DANIELLE GULLACI

IN one of the biggest moves to ever be undertaken in the history of Zoos Victoria – both in terms of its complexity and the sheer size of the animals – all nine of Melbourne Zoo’s Asian elephants have been welcomed to their new home at Werribee Open Range Zoo.

Elephants have called Melbourne Zoo home for the past 160 years, so this move to their new habitat was quite the momentous occasion.

It took around two and half years of meticulous planning, including crate training for the elephants, to see this come to fruition.

e logistics team was made up of many, with Linfox and Membrey’s Transport and Crane Hire tasked with the logistics of moving the herd from Melbourne Zoo in the city’s inner north, to Werribee Open Range Zoo, around 40 kilometres away.

ey were assisted by the 21-strong team of elephant keepers, a team of veterinarians, the Department of Transport and Victoria Police.

ree moves took place across ve days, to get the entire herd to their new $88 million habitat at Werribee Open Range Zoo. e impressive 21-hectare space is the size of the entirety of Melbourne Zoo.

e space has been thoughtfully designed to replicate the elephants’ natural habitat, complete with huge open spaces to roam, deep-water pools, mud baths and more.

Leading the on-road convoy for each of the three moves was veteran truck driver Mick Best, 75, who is no stranger to transporting these incredible gentle giants. Working for Linfox since 1992 – along with a threeyear stint with the company

back in the 1970s – Mick has seen and done some incredi ble things across his long ca reer, but he says this project was de nitely a highlight.

Mick was involved in this elephant move from the getgo, managing Linfox’s in volvement in the project and serving as primary driver.

“I’ve done lots of amaz ing stu in my career – I’ve transported elephants be fore, moved gira es, worked on the Olympics, bush re and ood relief, which were all wonderful experiences – but this is by far the most rewarding project I’ve had the privilege to work on,” re vealed Mick.

Along with the move itself, Linfox was involved in pro ducing the specialised con tainers used to transport the elephants. “After Linfox was approached by Zoos Victoria to assist in the move, I met with the zoo to discuss their requirements,” said Mick. “ en we started the pro cess of converting eight 20ft containers to facilitate the el ephant move. ey were pur posely converted. One was made higher to transport the bull elephant, Luk Chai, and the others were converted to take the females and their calves together.”

Zookeeper Lucy Truelson is project manager for the elephant herd. She told Big Rigs, “We moved nine elephants and three were young calves – so the crates had to be built to support that, so the mothers and calves could travel together and have contact with each other in the crates throughout the entire move.”

To ensure the comfort of the elephants while out on the road, the containers were also air conditioned. “Ahead of the move, it took about six weeks to produce these unique air conditioning systems. We used a quarter of a shipping container for each, then attached a fridge mo-

I’VE DONE LOTS OF AMAZING STUFF IN MY CAREER… BUT THIS IS BY FAR THE MOST REWARDING PROJECT I’VE HAD THE PRIVILEGE TO WORK ON.”

MICK

BEST

tor onto them, sealed them up and had tubes going into the elephant crates so the air was continually recycled,” explained Mick. Mick took part in his rst big elephant move back in 2006. Eight elephant calves had been brought into Australia from Bangkok – part of global conservation e orts for Asian elephants that aims to nurture genetically diverse populations of the endan-

three headed to Melbourne Zoo and ve transported to Taronga Zoo in Sydney.

“ e ones we brought over from overseas were all babies and they’d been nurtured individually with their handlers for the entire trip,” said Mick.

Interestingly, the 15-yearold male bull elephant, Luk Chai – who was the rst elephant to be transported to the new habitat at Werribee Open Range Zoo – was born to one of those elephants at Taronga Zoo. He was transferred to Melbourne Zoo to take part in a breeding program, where he had very great success, fathering three calves.

As Lucy explained, “When Luk Chai joined our herd, there was a plan to breed him with three viable females.

females and a male.

“With elephants, if they don’t breed regularly, they can become infertile, that’s why it was very important to breed them at Melbourne Zoo before we moved. ey were all born within a few months of each other. It was also important to know that they’d be 1-2 years old by the time of the move, so they’d be old enough to be trained in the crates. e calves are now all approaching 1 tonne.”

As Lucy revealed, the idea to move the elephants to Werribee has been many years in the making, “We already had the land but we needed the funding – and it was a pipe dream until we secured that funding from the Victorian Government.”

e whole basis of the new

habitat was to replicate how elephants would live and behave in the wild. “It was about going back to nature and looking at how elephants thrive – and that’s in a multi-generational matriarchal herd unit,” said Lucy. “All related females remain in the herd, with the matriarch being the oldest female – in this case 52-year-old Mek Kapah who weighs around 3.2 tonne. All the females then play a part in raising the calves. en the males move between herds.”

With this in mind, Luk Chai was brought to his new home by Mick and the Linfox team. Weighing in at a whopping 4.28 tonne, he is the heaviest in the herd.

Bringing him in rst was a deliberate decision. As a solo bull, it gave him the opportunity to explore his new habitat on his own, before

the rest of the herd followed. en two days later, the next group was transported – a mother and calf in one crate, and another female elephant in the other. en another two days later came the nal move, where two mothers travelled with their calves in two of the containers, and the matriarch Mek Kapah in another.

Linfox compliance manager Michael Stephenson worked with the relevant road authorities and road managers to obtain travel permits for the transport task.

“ is was a really coordinated e ort. Everyone was really focused on getting it done, and getting it done as safely and smoothly as possible. It’s not your usual oversize container move. Luk Chai is a big boy and the total combination ended up at 4.4 metres high,” he said.

“We worked with the NHVR and Department of Transport to con rm the best route. You’d think moving elephants would be a nerve-racking process, but the way it was all coordinated across all the teams, was just incredible and the move went smoothly.

“And when it came to moving the mothers and calves, we could see on the cameras that they were holding trunks.”

e elephants were transported by three Volvo FH prime movers, with three drivers involved. For two of the drivers, it was their rst

time working with Zoos Victoria. “ ey hadn’t been involved in zoo moves before but found it really rewarding – to get them all there, and to see the elephants all together, mixing in their new environment,” said Mick.

e team from Membreys also travelled in convoy with the trucks, keepers and police escorts, to be on hand in case there were any hiccups.

But thankfully, it all ran smoothly, with everything precisely coordinated down to the nest details.

VicRoads even assisted with tra c light control, to ensure that by leaving at the prescribed time, the vehicles would have green lights for the entire journey.

“A lot of work went on behind the scenes,” said Mick.

“It was one of the most professional teams I’ve ever had the privilege of working with – including the Linfox team, the zoo team and Membrey’s. To work with that group from the zoo, they just live and breathe their work.

It was an amazing sight.

“ ey had cameras in each container, and the person sitting with me in the truck was watching the elephants the whole way and letting me know they were all okay.”

Mick also spoke of the heartfelt moment when the elephants were reunited, “It was extremely emotional for me to see all the elephants back together in their new enclosure. A lot of us couldn’t look each other in the eye!”

e elephants will now be

given some time to explore their new space before the habitat is opened to the public. “ e elephants have settled in beautifully. We stand there and are in awe of them,” said Lucy. “It’s quite a thrill for all of us to watch them as they discover all these new spaces. ey’ve moved like a herd of elephants would in the wild, with matriarch Mek Kapah leading the herd through the landscape.

“And for Mek Kapah, what a journey she’s been on. She was brought into Melbourne Zoo as a young female in 1978. We’ve learnt and grown this herd around her. It’s an incredible sight to see her in this expansive environment, grazing on grass with all these calves around her – that’s exactly how it should be!”

e new larger space will also give Werribee Open Range Zoo the chance to continue to breed the elephants and grow the herd.

“We have our beautiful bull elephant Luk Chai, who will be able to wander in and out of the herd – and we can see biology run its course,” added Lucy.

She also praised the e orts of the logistics team. “It took a whole team to make this happen. e empathy and the care everyone showed for the elephants is something we’ll never forget. We are so grateful,” said Lucy.

“It was a highlight for everyone in this team to be involved in such an incredible event.”

Our Victorian correspondent strikes trucking gold when he heads to one of Australia’s most original mining towns for the weekend.

BY GRAHAM HARSANT

RECORD attendances at truck shows seem to be the norm so far this year and Clunes in Victoria was no ex ception, the grounds chock-ablock with a massive variety of brands on show.

Clunes Historic Truck Show for vehicles 25 years or older on March 9 o ered no awards, but similarly to Lance eld, was an opportunity to just park up and chat to other truck owners and interested members of the public.

ere’s an old Mack Elite amongst the throng with Av oca Transport painted on the doors, along with the name Steve Gleisner.

Steve’s father bought Avoca Transport in 1948 as an al ready established business. e Elite is now owned by Steve’s son, Fred, who also turned up with his 1966 B61.

On the Elite, Fred said: “Dad passed away two years ago from cancer, and I wanted to keep his name on it as a trib ute. At the time I had a West ern Star, which was a pretty good truck, but running two was not an option so I moved the Star on and this is my daily drive now.

“ e shed on the Western Star was a bit bigger, but I’ve still got 50” in this which gives me a lot more space than the Euros – important because I travel everywhere. It’s also a bit lighter and better on fuel.

e truck is a 1998 model, which was around the time Mack went from Renault to Volvo ownership.

“ e Elite name means it is all Mack running gear – engine, gearbox and di s. e old man bought it when it was about three years old and put 2.8 million km on it without

a spanner touching it. It was a Wednesday truck for sure.

“When I decided to use it as my daily it was getting long in the tooth, so we did a rebuild, which turned out to be a Friday job, unfortunately. It was back to the drawing board and now she’s pretty reliable again.

“I go everywhere in this truck. It’s been to every corner

of Australia since I’ve had it over the last three years. Darwin, Townsville, Perth and not just once either. I told you I do a bit of everything.”

As well as the Elite, there’s that 1966 B61 with a 25C motor, quad box, Mack tandem drive and camelback rear end.

“I’ve had it about 18 years, and it’s been a toy; I’ve never

worked it. e previous owner used it as a farm truck out of Beaufort. It’s been a good toy and has kick-started a lot of conversations.”

Fred drove the old B61 the 100 or so kilometres to Clunes which is a feat in itself, given he was just a week out of hospital, where he’d spent three weeks.

“ at gave the guts a bit of a workout but we made it here. I’d had few stomach pains going on; actually, I was in the truck when I pulled up at Cooper Street BP and called an ambulance.

“I ended up in hospital and got diagnosed with stage IV cancer. I’ve just had a big section of my bowel removed two weeks ago and I’m looking at probably starting chemotherapy in four weeks. I have it in my liver as well so hopefully the chemo will take care of that.

“It’s a bit of a shock to the system to nd out that what you think is a belly ache is so much more.

“I’m 36 this year and it

wasn’t quite the news I expected to hear. But anyway, I’m staying positive. I have ve kids – I made the most of being at home when I wasn’t in the truck.” at Fred can have a laugh given what he’s been through shows his positive attitude towards his treatment and the future.

We at Big Rigs and we’re sure all our readers wish you the best of luck, Fred.

Clunes was a welcome change for the Cornwill brothers who are known throughout Victoria and beyond for their award winning T908, ‘Paradise’ and more recently their Legend #59 SAR, ‘Dynamite’. is time however, those trucks stayed at home, with Wayne Cornwill opting to bring an ‘old banger’ to the show.

“She’s just an old 1978 Kenworth K123 Slimline with a 400 Cummins and 15 overdrive,” said Wayne.

“We actually bought it some 10 years ago for the motor which we were going to transplant into another truck. But there was too much history in it so we put it on club plates and bring her out on the odd occasion. She’s here obviously, and we’ve taken her along to Castlemaine and Koroit as well.”

Wayne was the solo occupant of the truck on the drive up from Geelong.

“ ey were all scared to get in it because of how rough she is bobtail. Our mate, Fingers reckoned he wasn’t going anywhere in something that wasn’t air-conditioned. One hundred k’s per hour and wind the windows down and you get a bit of air in the cabin!”

Wayne commented that Clunes was probably one of the best truck shows he’d attended: “I’ve been able to spend the day chatting with folk instead of washing and polishing.”

Continued on page 20

From page 18

BILL Fitzpatrick was a legend down Charlton way and sadly passed away last year.

His last drive, a 2000 Kenworth cabover, showed up at Clunes, courtesy of his sons, Billy Jnr and Paul, along with grandson, Murphy.

“ is was the last truck that the old man drove, and we thought we’d bring it to Clunes so people can remember him.

“Ten years ago, we’d sent him to an auction to buy a stock crate and a T650 Kenworth, and he came home with this truck for himself.

“He didn’t worry about us. We asked about the one we’d sent him to buy and he replied that it wasn’t any good. Yeah, right!

“He worked it right until the week before he passed away. He was getting pretty old and doddery but at 91 he was still working. Mum tried to get him out of the truck on

more than one occasion but he wouldn’t listen to her.

“He didn’t listen to us either. He did what he wanted to do; he had learned to never listen to his kids.”

Will the truck stay in the family? “We reckon Murphy’s got his eye on it, so yes, it probably will.”

I walked past Bert Fagan’s truck and he asked me if I knew what it was. I said Dodge and he said no. I said an International and again he said no. Which goes to show how much (or otherwise) I know about trucks.

“It was built by Bill Norling of W&H Norling Engineering back in 1977 for Pakenham Blue Metal as an agitator.

“Bill’s son, Craig Norling told us that his dad only built six of them and this is number one out of the six.

“It has a di erent chassis to

an International although it’s made up of Inter stu . It used to have a Dodge bonnet and it did have a D line grill but I changed that because I don’t like ‘em. It has power steering, and a 653 GM. It’s an Alison automatic with a three speed Joey box and bogey on Hen drickson at the back.”

Bert has owned the rare beast for seven or eight years.

“If International got an or der from the truck and they couldn’t handle, it they would handball it on to Bill Norling to do the job.

“Originally it had a Norling badge on it but I never got it. A friend of mine has one for me which will be really cool. It is similar to a Chevrolet badge.”

is is a little part of history that few people in the indus try or out of it would know about.

And that’s the great thing about truck shows such as Clunes. You’ll always nd out something new.

MAXIMISE YOUR PROFITS WITH COMPLIMENTARY SERVICING FOR 3 YEARS.*

Start hauling with your new Cascadia knowing you’re already ahead, with complimentary Complete Servicing for three years or 450,000km (whichever comes first). Plus enjoy class-leading fuel efficiency, cutting-edge safety technology, and the ultimate in driver comfort. Available on selected models for a limited time.

It was the end of an era at this year’s event in Kyabram. Now everyone’s hoping someone will step up to take over the wheel.

BY GRAHAM HARSANT

RAY and Michele Grima insti gated the White Truck Muster at Kyabram, Victoria, 20 years ago. After 10 events Ray has had enough and feels that if it is to continue, others can step into the breach.

No one can argue that Ray has not given his all to the event.

“ at very rst Muster was done in conjunction with ATHS Australian Chapter, and was, in fact their rst event and the rst ATHS event any where in the world, outside the US,” said Ray.

“Now they have come to our aid again by e ectively staging this year’s show which allowed us to go ahead under their public liability insurance um brella, without which we could not have gone ahead.”

e American Truck Histori cal Society (ATHS) is seriously considering taking the White Muster into the future with a small sticking point being its timing – only three weeks after their Lance eld show.

We shall wait with bated breath because the White Muster has become a staple on the truck show circuit.

Ray has done a wonderful job over the past 10 shows, drawing people from near and far. “It brings people from all around Australia and around the world. ere are a lot of White tragic’s out there.”

One such tragic is Werri bee-based Craig Collins who owns CRX – Collins Road Express and brought along his mint 1980 Road Boss which has an interesting background.

“It had a 290hp, 12.7-litre Rolls Royce engine in it – one of only nine, I’m told,” said Craig.

“Apparently, they may have had some in Road Commanders as well. Originally we think it was a Caltex fuel tanker.

“I was using it every day with that motor for four or ve years but I couldn’t get parts for it. I’m a Caterpillar man so I repowered it with a 3406C PEEC. It’s a later model engine and I like the cruise control part which makes for easy driving with the super 10 overdrive.”

Craig’s had the truck for 30 years. “I bought it from John George’s at Campbell eld. He was selling up and moving his eet on.

“It was pretty much a wreck, and I just built it up over quite a few years. It had already been stretched by John George and had a tray on the back until I got the taught-liner built for it.”

Along with the Road Boss, Craig has two prime movers and CRX made a living delivering anything from clothes to toothpaste for K-Mart, Myer and Target to their country stores, with the prime movers hauling steel or anything else in between.

“ is truck hasn’t done much for the last 3 or 4 years as I’ve slowed down a bit and become semi-retired. I like taking it to truck shows like this and Castlemaine and Alexandra where it has won Best Rigid – not bad for an old girl.”

Craig was joined at e Muster by his mate, Andrew Senkinc who owns a 30-year-old Sprint Car daubed with Craig’s business colours.

“It’s a Buckley chassis, midbar and goes in vintage races,” said Andrew.

With a 360 cubic inch Chevy motor at 650Hp and weighing only 850 kilos, she has a pretty good power to weight ratio. And before you

ask, no, it doesn’t travel in his taut liner. He’s too tight to buy ramps.”

Yes, we know you’re only joking, Andrew.

TJ featured in a recent story on the Koroit truck show, with his Mack Muncher, so it was a surprise to see him at the muster with not one, but two Whites. To be more speci c, they belong to dad, John, or Spud as he’s known to friends.

“We wanted a farm truck,” said Spud. “And we found this old girl [a 1966, 2300 model] at a wrecker’s for $5000.

“Like TJ I’m a KW fan, but Kenworths are too good to be paddock wagons! Seriously

though, this had been sitting for 12 months, we hopped in, and she red right up.

“We’ve had her for 20 years now. Flick the isolator and she just goes. e poor thing gets ogged to death moving cattle, hay or silage.”

Spud res the truck up and the 653V motor is as sweet as new. He points me to the pedals in the cab and the brake pedal is bent at a 45 degree angle at the retaining pin.

“ at’s because it’s the accelerator, not the brake,” he tells me. e brake pedal in on the right-hand side.

“So, people get in it for a drive, forget it’s in the middle, go to brake and speed