6 minute read

Bridging the Gap: Automation and the Next Generation of Press Brake Operators

One of the biggest challenges facing modern manufacturing is finding qualified machine operators. As veteran operators retire and younger workers enter the field, many shops are struggling to train new staff quickly and safely. The solution for a growing number of shops? Smart automation.

Older machines can present a major obstacle. They often require years of hands-on experience to run efficiently, and learning the ins and outs, what tools to use and when, the best bend sequence, how to handle parts safely, can eat up valuable time and resources. That kind of training investment is tough to justify and is often regulated to on the job learning in today’s fast-moving production environment, especially when skilled labor is in short supply.

However, press brake technology has come a long way. Innovations in machine design, control software, and automation have dramatically shortened the learning curve. With these tools, shops can get new operators up to speed quickly while maintaining high levels of safety, repeatability, and accuracy.

At MC Machinery, our goal is to help shops modernize without sacrificing quality or usability. We design our equipment with both seasoned pros and brand-new operators in mind, intuitive controls, automation options, and smart tech that make it easier to bend parts right the first time. Whether it is your first week on the floor or your twentieth year, the machines should work with you, not against you. Our systems not only boost productivity but also make the transition smoother for newer workers stepping into skilled roles.

Making Setup Fast and Foolproof with ATCs

Tool setup is often the most time-consuming part of any job, especially in high-mix environments. Depending on the job complexity, material type, and tool organization, shops can spend 15–25 minutes, or more, on a single setup. Multiply that by 20 or 30 setups a day, and the lost time adds up fast. That has not just lost production, its lost momentum, focus, and profitability.

Automatic Tool Changers (ATCs) address this problem head-on. They drastically reduce setup time, often to under 5 minutes, and eliminate the risk of incorrect or inconsistent tooling. With automated loading and exact tool placement, ATCs increase repeatability, reduce human error, and improve overall part quality. They allow shops to switch from job to job with minimal downtime and maximum confidence.

Our BH Series press brakes, ranging from BH13530 to BH25040, are all available with ATCs. These use New Standard style tooling and come standard with 32 meters of tool storage. Each ATC is integrated with our Videre Operator Support System, which projects a 3D model of the final part, a live bend sequence animation, 1:1 top-down view, tool locations, and even supports PDF and DXF files, right onto the ram. Think Minority Report for your press brake, but real, and built for daily production. Faster setups, cleaner runs, and a more confident operator on every shift.

Sheet Followers: A Smart First Step into Automation

For shops not ready to jump into full robotics, sheet followers offer a simple and affordable way to ease into bending automation. They are especially useful for large or heavy parts, or whenever a second set of hands comes in handy. If you have ever watched an operator struggle to handle a long panel solo, you know exactly how valuable a sheet follower can be.

Our Diamond Series offers two models: the SF70 (a 70kg follower mounted on a front rail) and the SF150 (one or two 150kg capacity units mounted via removable pin with caster or rail mobility). Both can be easily repositioned and parked when not in use, adding flexibility without cluttering your floor. What really sets our followers apart is the vacuum or magnetic assist and the unique third axis. This third axis lets the follower track J-bends around gooseneck tooling, keeping parts clear of the ram on ascent, perfect for complex geometries, odd-shaped flanges, or heavy gauge material that would otherwise require two operators.

For heavier applications, our Adira press brakes offer follower options rated at 100kg, 200kg, and even 400kg. No matter the size or shape of your parts, we have a solution to improve handling, precision, and safety, without jumping straight to robotics.

The Robotic Revolution in Bending

Robots are not just for the big guys anymore. What used to be the domain of large OEMs is now showing up in small and mid-sized shops across the country. Robotic bending cells take on the repetitive, physically demanding work, freeing up your team for more valuable tasks. That means less fatigue, a safer work environment, and a completely new level of consistency on your shop floor.

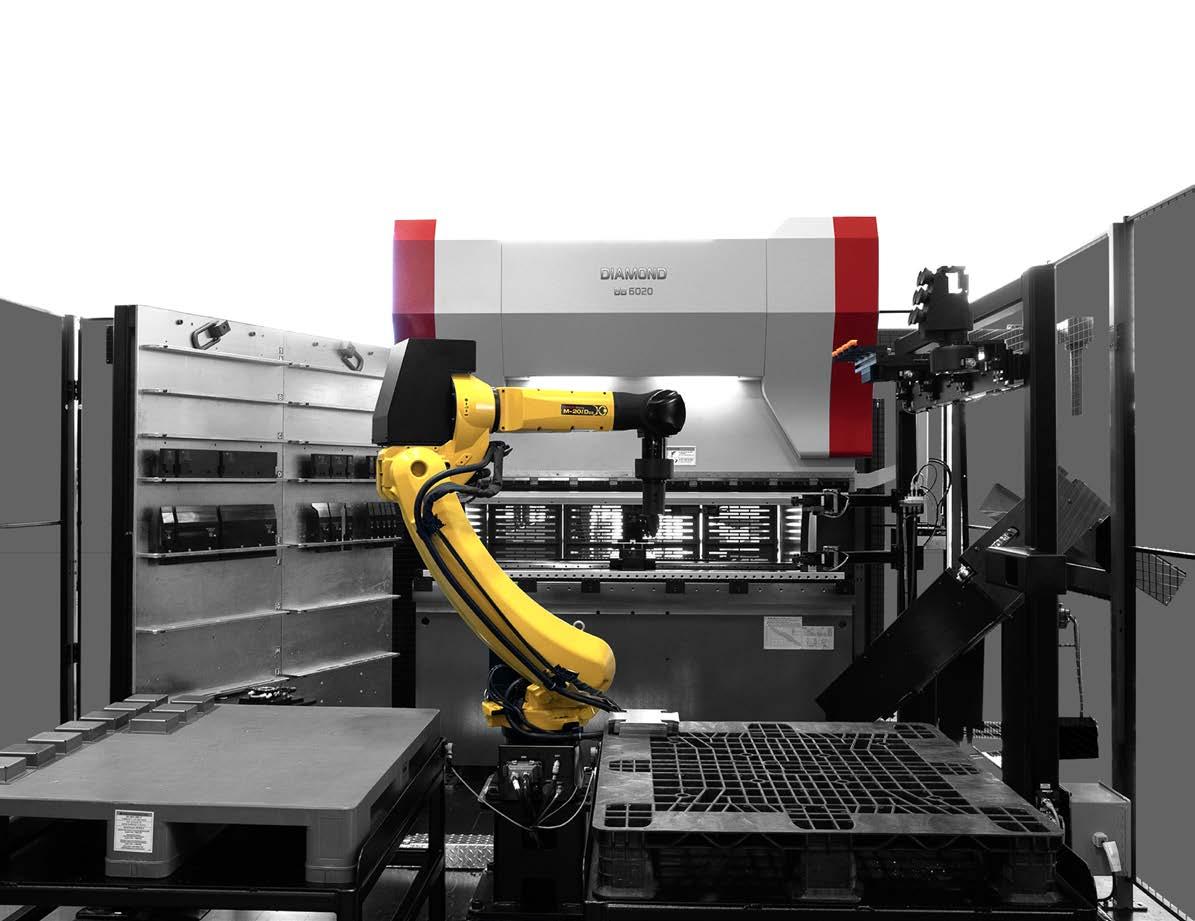

MC Machinery has partnered with Acieta, a U.S. leader in robotic automation and integration, to offer a range of solutions for nearly any shop size or production goal. Our FastBend robotic bending cell pairs our BB Series all electric press brake with an m20iD Fanuc robot capable of handling parts up to 25lbs, and up to 4ft x 3ft in size. Complete with automatic tool change and automatic gripper change, this cell is designed for unattended fulltime production, all within a surprisingly compact footprint suitable for most shops.

For heavier applications, our BH Series Press brake with RIBS (Robotic Integrated Bending System) is a powerhouse. With Brakes up to 275 Tons, and Fanuc robots with part capacities up to 700LBS, these systems can be tailored to handle everything from batch runs to lights-out manufacturing. One example we will be showing at Fabtech 2025 is our BH13530 Paired with a Fanuc robot that can handle parts up to 165LBs, complete with automated material loading and unloading. These cells can be tailored to the most complex and unique processes, be it welding operations, fastener insertion, or even inline packaging systems to help you get parts out the door faster.

These robotic cells will consistently deliver high-accuracy bends, minimal scrap, lower cost-per-part and more predictable and consistent output, enabling manufacturers to improve cycle times, reduce handling error, and allow for true 24/7 operation. Whether you are running small batch production, or your largest orders, robotic bending is no longer just a nicety, it is a must-have in today’s competitive landscape.

Smarter Bending Starts Here

Automation is not about replacing people, it is about empowering them. By simplifying training, reducing manual handling, and improving repeatability, modern press brake automation paves the way for the next generation of operators while boosting shop performance across the board.

In a labor market where skilled operators are hard to come by, these systems act as force multipliers, helping your current team do more with less stress, less risk, and better results. Whether you are looking to streamline setup with an ATC, ease operator strain with sheet followers, assist new employees with the Videre Operator Support System or make the leap into full robotic bending, MC Machinery offers the tools, tech, and support to help you thrive in today’s competitive landscape.