3 minute read

New Delem DA-60S Series

The new Delem DA-60S series marks the next generation of modular control systems, fully succeeding the DA-60T series. Built on a powerful and scalable platform, the DA-60S series not only serves as the foundation for Delem’s ongoing innovation but also empowers customers to develop additional proprietary applications and functionalities. Designed specifically for press brake applications, this evolving system significantly enhances machine productivity and operator experience.

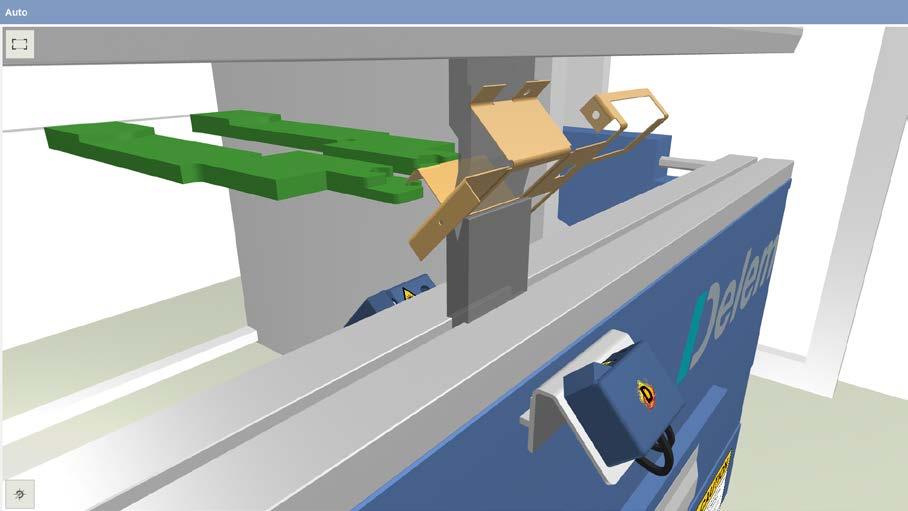

Advanced 3D Machine Visualization

The DA-60S series - which includes the DA-66S and DA-69S - introduces a completely redesigned 3D machine visualization system. This allows machine manufacturers to incorporate realistic representations of their machines directly into the control interface. These 3D models not only reflect the real-world design of the machine but also enhance the control’s ability to simulate operations accurately, preventing potential collisions between the machine and the product during production. The result is a highly realistic simulation that confirms feasibility before production begins.

Intuitive User Interface

The machine’s user interface, centralized on the control console, is designed to make machine setup and operation as straightforward as possible. Delem’s focus remains on delivering powerful functionality without adding complexity. The DA-60S continues Delem’s tradition of user-friendly design, guiding operators through the entire workflow—from selecting and executing existing programs to creating new ones based on sketches, technical drawings, or complete 3D models.

Seamless CAD Integration

The DA-60S series supports a wide range of CAD import functions, both at the control and through its offline software. Whether importing unfolded DXF files or 3D models in STEP or IGES formats, the system integrates seamlessly into the development and production chain— allowing operators to start from any point in the process.

Autonomous Guarding

The goal of integrating the safety system with the machine’s control solution is to ensure operator protection without compromising productivity. In today’s press brake technology, safety precautions are a top priority—reflected in the seamless integration of safety features within the DA-60S control system. This approach allows safety to become an integral part of the bending process, enhancing both efficiency and peace of mind for operators. With Autonomous Guarding, the system automatically determines optimal safety settings during a ‘Test Bend’ cycle, subsequently finding the desired settings in the first bend cycle — no manual programming required. The machine suggests the correct settings from the very first bend.

Smart bracket controls further enhance safety by automatically adjusting the system to the height and shape of the mounted tooling. Additionally, the exact sender and receiver alignment can be managed directly from the control interface. An integrated calibration function ensures accurate positioning and perfect alignment of the safety system.

Platform for Innovation

The powerful DA-60S platform enables machine manufacturers to build on top of the base functionality with advanced features such as angle measurement, which is increasingly in demand for its role in improving accuracy and productivity. Angle sensor visualization, real-time feedback on measurability, and full integration of setup systems within the bending program are just a few of the innovations being developed in collaboration with OEMs. These technologies lower the barrier to adoption and make it easier to expand functionality over time.