3 minute read

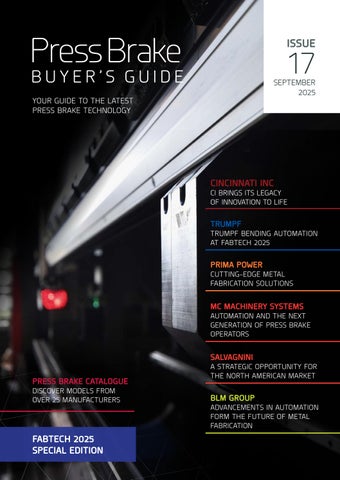

Better Bending - TRUMPF Bending Automation at FABTECH 2025

At FABTECH 2025, TRUMPF Inc. will be demonstrating a variety of bending solutions, including new, standalone press brakes, panel benders, mobile bending cells, and automated bending cells that integrate custom robotics.

One highlight of the booth is TRUMPF’s fastest mobile bending cell: Flex Cell automation connected to a TruBend 7050. The Flex Cell will be shown as part of a Smart Factory in the booth that’s designed to showcase the efficiency and flexibility of smart manufacturing solutions.

TRUMPF’s Flex Cell automation solution offers highly efficient bending in combination with a TruBend 7050 press brake. In just a few simple steps, operators can dock the mobile robot cell to the bending machine and operate it automatically. The machine can run autonomously for several hours. This automation solution helps companies handle order surges and combat labor shortages. The combined footprint of the Flex Cell and the TruBend 7050 is under 107 square feet, compact enough for any production environment.

“The Flex Cell gives fabricators a quick and easy way to automate the TruBend 7050, which is TRUMPF’s fastest bending machine,” says TRUMPF Inc. Head of Product Management for Automation Bend & Material Flow Sebastian Leeb. “This is another great example of how TRUMPF is focused on customer needs and feedback-driven solutions.”

Easy to program, safe to operate even "lights-out" production

The Flex Cell has a large material buffer that ensures it has enough material to feed the TruBend 7050 throughout a night shift. A vacuum combination gripper on the robot arm enables fast and safe loading, bending and unloading. Using the proven TRUMPF TecZone Bend software, a bending program for the TruBend 7050 press brake can be created in just a few seconds. The operator is then able to program the robot by means of an app and the teach panel. This makes the solution quick and easy to set up. Thanks to automatic double-sheet detection, the Flex Cell is also able to recognize if unprocessed material has stuck together during loading and then eject it. This reduces defects and saves resources and adds process reliability.

Designed for small and simple parts

The Flex Cell is suitable for components up to 23.6 by 15.75 inches in size. It can process sheet metal of between 0.03 and 0.23 inches in thickness. Combined with the TruBend 7050, the Flex Cell is ideal for companies seeking a solution to problems caused by a shortage of labor and that would like to increase productivity through costeffective automation. Companies with fluctuating orders of small and simple parts are particularly suited to benefit from this solution.

The Flex Cell is just one of the automated bending solutions in TRUMPF’s extensive portfolio of machines available to suit different applications.

TRUMPF offers TruBend machines to produce simple and complex parts in any format, precisely and cost-effectively. At the FABTECH show, TRUMPF will demonstrate production of high-quality parts, increased flexibility, innovative tools, sophisticated automation solutions and intelligent software. Bending capabilities are just part of the story. The company will also showcase new capabilities for connected and automated Smart Factory technology using real-life production to show the connected and customer-driven ecosystem of automated products and services designed to solve problems related to material flow, production capacity, process transparency, flexibility, efficiency, quality control, and more.

The innovative Smart Factory technology presented by TRUMPF at FABTECH emphasizes the point that automated processes – including bending -- and connected manufacturing can be successfully implemented at any size production facility.