16 minute read

Salvagnini at FABTECH 2025: a strategic opportunity for the North American market

Salvagnini, leader in sheet metal working innovation, will participate in FABTECH 2025 to showcase its latest technological solutions to the North American market. The company offers integrated systems combining machinery, automation, and software designed to tackle key industry challenges: labor shortages, production flow optimization, and cost reduction. With its Generation 4 (G4) solutions, Salvagnini empowers manufacturers to maximize productivity and final product quality.

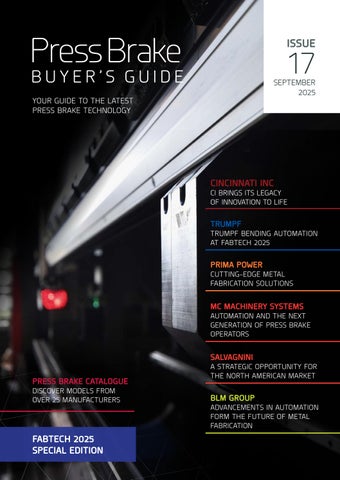

Flexible Smart Job Shop: Competitiveness guaranteed for dynamic workflows

The star that can be admired at the Salvagnini booth at FABTECH 2025 is a Flexible Smart Job Shop. It is the combination of three different stand-alone systems which are able to work together, when required, to manage convergent production jobs. The various systems are connected through the software, as well as by transfers and AMRs. Flexible Smart Job Shop can also integrate an intermediate store or other machining stations both upstream and downstream.

This FSJ consists of:

• the new L3.G4 laser with fully automated configuration, with LTWS store-tower, MCU sorting device and belt transfer; its distinctive artificial vision applications are based on neural networks;

• P-Robot, the application combining a P2-2120.G4 panel bender and a 6-axis robot; it includes the innovative RVS artificial vision system: P-Robot recognizes the incoming parts, whatever their position, and loads them without operator intervention and without centering;

• the B3 press brake, ideal for kit jobs, equipped with new parametric programming.

Full automation and neural networks for the new L3.G4

A new architecture that combines high accessibility with high rigidity, an 8kW high power density that reduces consumption and achieves the typical performance of 10kW sources: these are just two of the key features of L3.G4, the new Salvagnini fiber laser cutting system.

In the configuration proposed in Chicago, L3.G4 is fed by an LTWS 10-tray store-tower, equipped with automated loading/unloading. The MCU automatic sorting device completes the layout and is used to easily stack parts of different shapes, sizes and weights. But the cutting system offered by Salvagnini also features a wide range of advanced process control and efficiency solutions, which further improve the performance and make it a highly productive and versatile laser, with reduced power consumption and competitive running costs. Cutting has never been easier.

L3.G4 changes the architectural paradigm of Salvagnini laser systems with an innovative high-accessibility gantry solution. This solution offers unique and innovative design features guaranteeing full accessibility to the working range, high rigidity and precision machining, all to the advantage of performance on medium and thin thicknesses, 15% higher than in the past.

The high-efficiency 8 kW high power density source, a distinctive feature of Salvagnini lasers, guarantees cutting speeds higher than any other traditional 8 kW source, and at thicknesses of up to 6 mm achieves cutting speeds even greater than those of 10 kW sources. Its energy efficiency, above 50%, makes it extremely advantageous in terms of financial sustainability: reducing the power while keeping the cutting speeds high means reducing energy and gas consumption for the same performance.

L3.G4 features a wide range of advanced process control and efficiency solutions, which improve performance and make it a highly productive, versatile and easy-to-use laser, with reduced power consumption and competitive running costs. The ACUT option allows L3.G4 to cut with suitably treated compressed air. Depending on the source power, ACUT is used to cut thicknesses of up to 20 mm, with productivity similar to that of cutting with nitrogen at significantly reduced costs. Cutting with compressed air is cheaper than with nitrogen, and this is even truer when the cost per m3 of nitrogen increases: the higher the cost of nitrogen, the more cost-effective cutting with compressed air becomes, while maintaining the same cutting quality and accuracy. Also contributing to the sustainability of ACUT is APM2, the new compact, turnkey device which connects directly to the pneumatic system of the factory and ensures the pressure values required for the cutting process. In order to further simplify some activities which are potentially time-consuming or could generate errors or waste – and therefore reduce the overall efficiency of the system – L3.G4 is also equipped with a number of artificial vision applications based on neural networks. These are simple solutions that increase the flexibility of the system and broaden its field of application. NVS checks that the laser beam is centered, and uses the machine learning algorithms to monitor the state of the nozzle and reduce waste. SVS recovers sheet metal leftovers, responding to urgent needs or replacing any waste in downstream machining activities. With the new multisheet feature, SVS can organize a production list, positioning more than one sheet metal format on the worktable and associating different production programs with a simple drag & drop.

All the programs and nests with L3.G4 are done with STREAMLASER, the Salvagnini software for the laser world, part of the STREAM software programming suite. STREAMLASER improves material efficiency and reduces costs due to its distinctive features. The OPTI nesting algorithm optimizes the use of the sheet metal, minimizing scrap. SAFE GRID automatically optimizes part positioning on the grids, reducing wear and maintenance costs and improving machining quality and laser reliability.

Modular, scalable automation for regaining efficiency

The Salvagnini laser automation range has always been extremely vast and modular: each system can be configured differently to meet various production needs. Such a wide range of solutions satisfies practically all layout and configuration requirements, and above all helps to reduce loading/unloading times.

LTWS is designed for unmanned loading, unloading and storage of material. It is compact in size and has extremely short cycle times, up to 50 seconds. Its loading and unloading devices are independent, increasing the process efficiency even in extremely rapid cutting programs. The configuration on display at FABTECH, with trays without wooden pallets and MCU automatic sorting device, is a perfect summary of Salvagnini’s expertise in the field of automation. LTWS makes different materials and thicknesses available for just-in-time production, reducing waiting times for sheet metal feeding, and operator dependency. Its autonomy is guaranteed by the availability of material and the STORE software, which identifies the empty loading trays on which to stack the machined material. The optional mixed tray management function available on the storetower exhibited in Chicago is also used to manage any sheet metal packs on wooden pallets. It also exploits the available spaces in the best possible way, in any case with the possibility to manage materials on pallets, delicate materials, or a few sheets in a tray, when needed.

The store-tower is also equipped with AB, an optional brush which allows the pallet changer grilles to be cleaned in masked time and which replaces, on request, the traditional brushes of the fork-structure of the unloading device.

The MCU automatic sorting device is used to easily stack parts of different shapes, sizes and weights. It can work in multigripping mode, picking up several parts in sequence with the same gripping device, or in double picking mode, where two gripping devices descend at the same time to pick up two independent parts, reducing the part pick-up time by over 25%. Automatic sorting facilitates the work of the operators, who can pick up the parts already stacked without having to separate them, thus greatly reducing the waiting times between the end of cutting and the start of the next phase. Making the individual cut parts immediately available on a conveyor belt that acts as a buffer, in the case of the Flexible Smart Job Shop in Chicago, the MCU ensures the physical integration of the laser with the downstream technologies.

LTWS and MCU feature AVC, adaptive vacuum control, technology. Constantly monitoring the vacuum degree in the gripping suction cups, AVC activates the vacuum generation only when required, reducing compressed air consumption by up to 90%.

Easy and flexible sorting with NEXUS

NEXUS is the Salvagnini software for programming MCU automatic sorting devices. Its algorithms optimize grips and movements and minimize stacking times. With NEXUS, it is not necessary to select a specific production strategy in the design step as it manages diversified production scenarios with extreme flexibility. These features make NEXUS the ideal sorting software for both subcontractors and OEM manufacturers.

NEXUS has the same design as FACE, the Salvagnini HMI, making it simple and easy to use. Its first strength is simplicity. All the MCU features can be used according to need, reducing intermediate waiting times and assuring maximum reactivity for sorting automation. NEXUS reduces operator entry barriers: minimum training is required to use it, ensuring rapid production start times. This feature makes it easy to manage any unforeseen situations relating to staff availability or turnover.

The second distinctive feature of NEXUS is the automatic processing of sorting programs, which the operator can change manually in each action to obtain full flexibility. This assures full process control, the third strength of NEXUS. If necessary, the operator can edit the gripping, unloading sequences, stacks, stacking strategies and table changes proposed automatically by the software. The control therefore covers the whole production sequence, it can be fine-grained even acting on single sheets, at precise moments of the production cycle. This is a distinctive feature used to organize even extremely variable scenarios and batch ones, standing NEXUS aside from other sorting software available on the market, which generally organize only single sheets as they are designed for series production of large batches.

NEXUS is therefore extremely flexible in managing diversified production scenarios, and this is its fourth strength. On one hand, programming can be carried out in the office, on board the machine, or in both environments, to meet all needs and requirements as efficiently and effectively as possible.

On the other, NEXUS can adapt its operating logics to dynamic industrial contexts and the production strategy chosen for the specific job, stacking by production order, kit, downstream processing station and so on. It is not necessary to select a specific production strategy in advance, and different needs are met - large batches, small batches, kits, batch ones - according to need. NEXUS is the key to managing MCU automatic sorting devices, optimizing performance, bridging skills and resources gaps which often do not allow the automation to be exploited to the full.

At FABTECH, Salvagnini presents another evolution of NEXUS, which exploits the integration with the STREAMLASER programming software to combine the classic operating mode for defining sorting strategies after having defined the nesting program with that for defining sorting strategies before defining the nesting program.

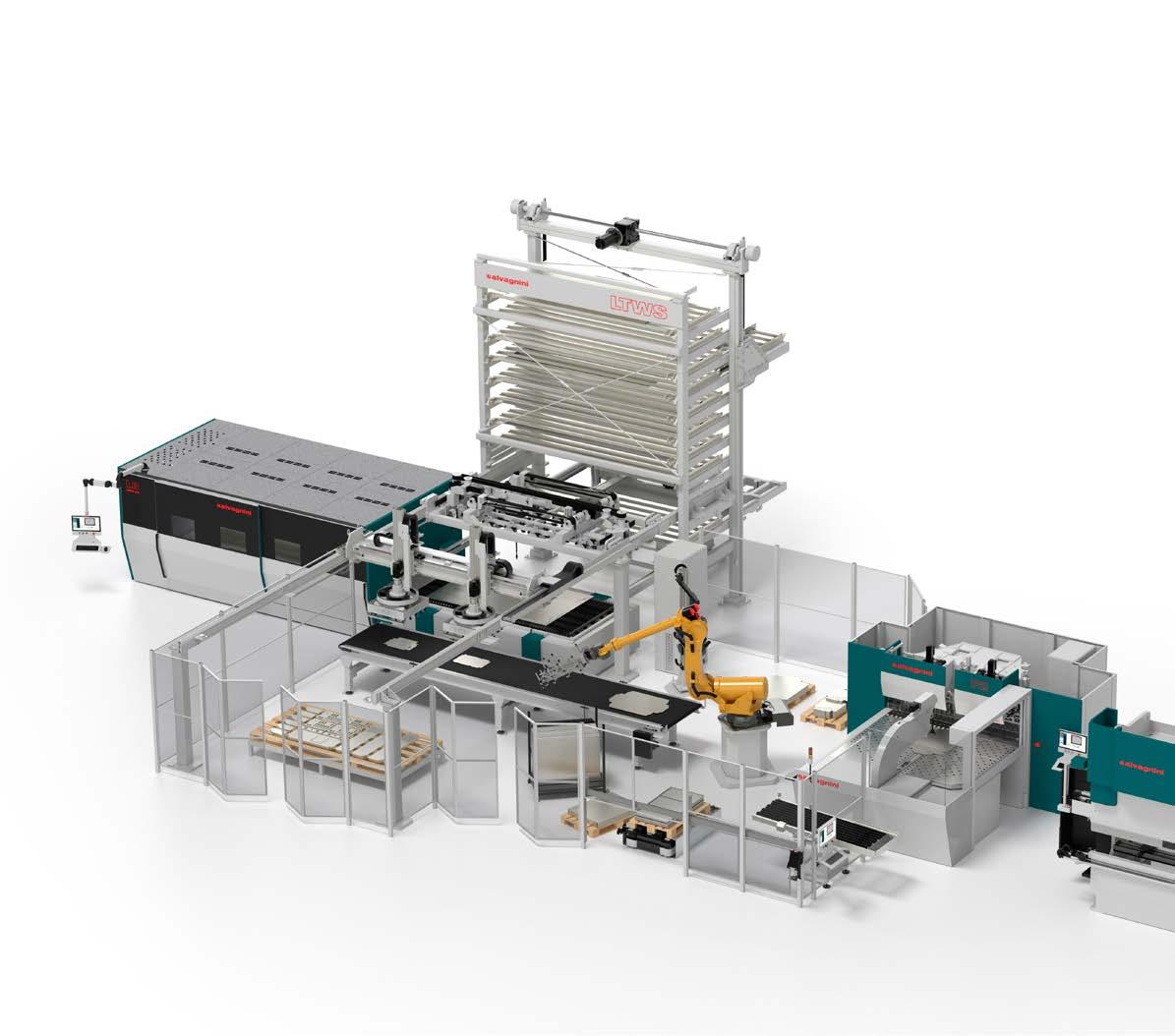

P-Robot. 100% flexible production strategy.

P-Robot is the Salvagnini application which combines a panel bender with a robot to produce kits, batches and single parts. At FABTECH, it is presenting the innovative RVS artificial vision system, for full process efficiency.

P–Robot is Salvagnini’s answer to an industrial context marked by high item turnover rates, quick lead-times and constant personnel shortages. Automation and robotization extend production beyond the traditional manned work shifts, while operators can spend time on activities with high added value.

P-Robot is a smart solution, much simpler than those already on the market: it is easy to program and use, and is able to exponentially improve the flexibility and productivity of the panel bender.

The P-Robot configuration can be customized: Salvagnini proposes simple production flows, with loading/unloading assistance only, and more complex systems including, for instance, automatic pallet handling or third-party integrations such as work centers for corner forming, labeling, laser marking, riveting and welding.

The flippable gripping device adapts automatically to the size of the part being handled. It is equipped with suction cups on both sides used to pick the finished part from the worktable of the panel bender, and in masked time, replace it with a new part to be bent. All this helps to optimize the sheet metal loading/unloading times, improve the production rate and substantial reduction in idle times.

P-Robot is used to choose the most suitable strategy for current production needs. On unmanned shifts, or in production contexts where a single operator monitors numerous systems, P-Robot naturally works in R2R (robot to robot) mode, loading, unloading and, if necessary, stacking the parts. But this is not an exclusive strategy: the same P-Robot can work in different modes, seamlessly and without re-tooling. In R2H (robot to human) mode, it is responsible solely for loading the flat part, whereas the operator is responsible for unloading the panel. This is an advantageous strategy if the operator must complete the processing of the panel on a different workstation – for example with a press brake or a welding machine.

In H2R (human to robot) mode, it is the operator who will load the flat part onto the working area, and the robot will unload the panel at the end of the cycle: this strategy is useful for managing extremely diversified batch-one productions. Without forgetting that the panel bender nevertheless remains available for any work managed completely by the operator.

The panel bending program is done with STREAMBEND and can be used without the need for changes on both the P-Robot and on the standard robotless panel benders.

On board the machine, the MOVE software receives the panel bending program, generates the dimensions of the flat part and the finished panel and uses it to automatically generate the robot trajectories. MOVE also manages the intermediate robot movements independently, and the operator is only required to make a reduced set of movements: it is an authentic smart teaching system, that makes offline robot programming pointless.

RVS – Artificial intelligence serving the cell.

The P-Robot on show in Chicago also presents another key innovation, the RVS (Robot Vision System) option. RVS exploits an artificial vision system, the only one of its kind on the market, to further simplify the use of the technology, optimize the production flows by accelerating the intermediate recognition, handling and programming steps – and maximizing the value of the finished part with the quality control system.

With the integration of RVS, P-Robot recognizes and processes the parts fully autonomously. With cameras and sensors, the artificial vision device acquires an image of the surrounding environment and interprets it using artificial intelligence. RVS recognizes the parts, distinguishes the single sheets, and identifies the position of pallets and stacks without references. All this information is shared in real time with the panel bender and the robot, which adapt autonomously to ensure that the sheet metal is handled and positioned precisely.

With the introduction of RVS P-Robot can produce in Single Piece, Joblist or Autorun mode. Whatever the mode, RVS optimizes the cycle times, eliminating the sheet metal centering prior to production. The option increases the flexibility of P-Robot and is used to handle parts with complex shapes or that cannot be centered using gravity centering devices.

P2-2120.G4: the flexible panel bending solution

The P-Robot exhibited at FABTECH includes a P2 panel bender: one of Salvagnini’s most successful models. P2 natively combines productivity, with its automatic bending and handling cycles, with an average of 17 bends per minute, and flexibility, with its universal bending tools. It doesn’t need re-tooling, because the upper and lower blades, the counterblade and the blankholder are universal tools that are able to process the whole range of thicknesses and machinable materials. The ABA automatic blankholder adapts the tool length according to the size of the part being produced in-cycle, without machine down times or manual re-tooling. P2 is really the ideal solution for kit or single batch productions. P2 guarantees zero waste production, adapting completely autonomously to the variations in the mechanical and geometrical characteristics of the sheet metal being machined, thanks to MAC3.0.

The P2 exhibited in Chicago comes highly configured with many options that increase its field of application. APL, for example, is used to compose the auxiliary P-tool to produce parts that have to be produced in sequence, due to their shape or with different lengths and widths.

B3: the press brake combining productivity and flexibility

B3 is the ideal Salvagnini press brake for dynamic production, perfectly combining productivity and flexibility. Designed combining the features and benefits of the electric and hydraulic solutions available on the market with the in-depth business skills of automation, software, mechanics and electronics, B3 is available in 20 models, from 2 to 6 meters long and from 80 to 400 tons.

The B3 press brake presented by Salvagnini at FABTECH to complete its Flexible Smart Job Shop is 3 meters long with 135 tons of force.

What makes the Salvagnini B3 press brake particularly interesting are the adopted technical solutions, including Direct Drive and KERS, which help to respect humans and the environment without reducing productivity. With Direct Drive technology, the ram movements are driven by two independent direct drive brushless motors, which allow to achieve both fast approach and fast return, with speeds as high as 250 mm/s. The KERS energy recovery system, on the other hand, is used to recover energy waste and reuse it in subsequent steps, accelerating and reaching higher speeds with the same consumption.

All the B3 press brakes are equipped with MAC3.0 – a set of integrated adaptive technologies that make the system intelligent and cancel out waste and corrections. S-Crowning is the intelligent crowning system that ensures consistent bending angles along the entire bending length: as the parameters – material, thickness, length and therefore the required bending force – change, the effective curvature of the lower table is measured and compensated in real time, without any operator intervention. TFC2.0, Total Frame Control, prevents deviations in the bending angle using an algorithm derived from the FEM study of each model. TFC2.0 compensates any in-cycle deformations of the press brake structure according to the variations of the characteristics of the part being processed. AMS is a laser angle measurement system that detects and corrects variations in the bending angle due to sheet metal springback. Regardless of the length of the press brake and of the part being bent, the angle is always measured in one single point: this approach helps reduce the cycle time without compromising on precision.

B3 can be programmed on the machine, but programming in office is what maximizes its efficiency: the STREAMFORMER software automatically creates the bending sequence, set-ups, and bending stations integrating perfectly with ATA devices, enhancing the performances. Programming in the office also increases productivity, as while the programmer deals with the programs in the office, the operator continues to bend. STREAM maximizes the performance of the press brake, allowing it to communicate with the other systems in the Flexible Smart Job Shop.