6 minute read

Advancements in Automation Form the Future of Metal Fabrication

The next generation of metal fabrication is at our doorstep – and it doesn’t look like the last. Manual machines are being replaced by integrated systems, and paperbased processes are being replaced by digital workflows.

Machines are not only being monitored and controlled remotely – entire shop floors soon will be as well. Metal fabricators are looking for solutions not only for their challenges, but for their customers’ challenges – all amidst a skilled and experienced workforce that is quickly approaching retirement age. The industry needs All-In-One integrated machine and equipment solutions that are accessible by people of any level of skill and experience.

“Customers are looking for high-quality parts for the lowest price,” said Israel Arenas, Press Brake and Sheet Laser Product Specialist at BLM GROUP USA, regarding the press brake world.

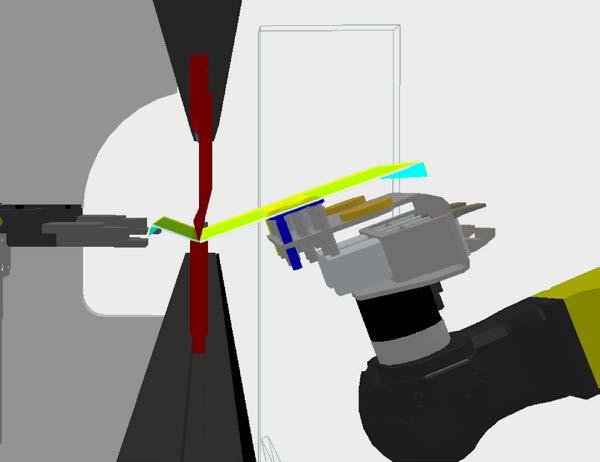

“The way to achieve that is by investing in automation – the simpler the better. This is difficult to achieve, and only a few manufacturers have managed to meet this repeatability. The game changer moving into the future is a press brake automated system that can be custom built to support all parts that need to be formed. We have achieved this with our new ProBend HBS line of press brake automation cells.”

However, compatibility is the key ingredient to the automated press brake cells Arenas mentioned. No single fabricator has the same needs, so there is truly no one-size-fits-all automation solution. The automation system must be able to support all different kinds of part lengths and thicknesses as well as compatibility for any size brake – including tandem options. “The biggest challenge here is addressing high operator rotation,” Arenas continues. “What good is an automated system if your skilled operator has just retired and you can’t find someone who is able and willing to learn how to program it? This is where state-of-the-art software comes into play. The software must be user friendly for operators of all experience levels, and easy to use –the only way to make that possible is if a single software can program both the robot arm and the press brake simultaneously.”

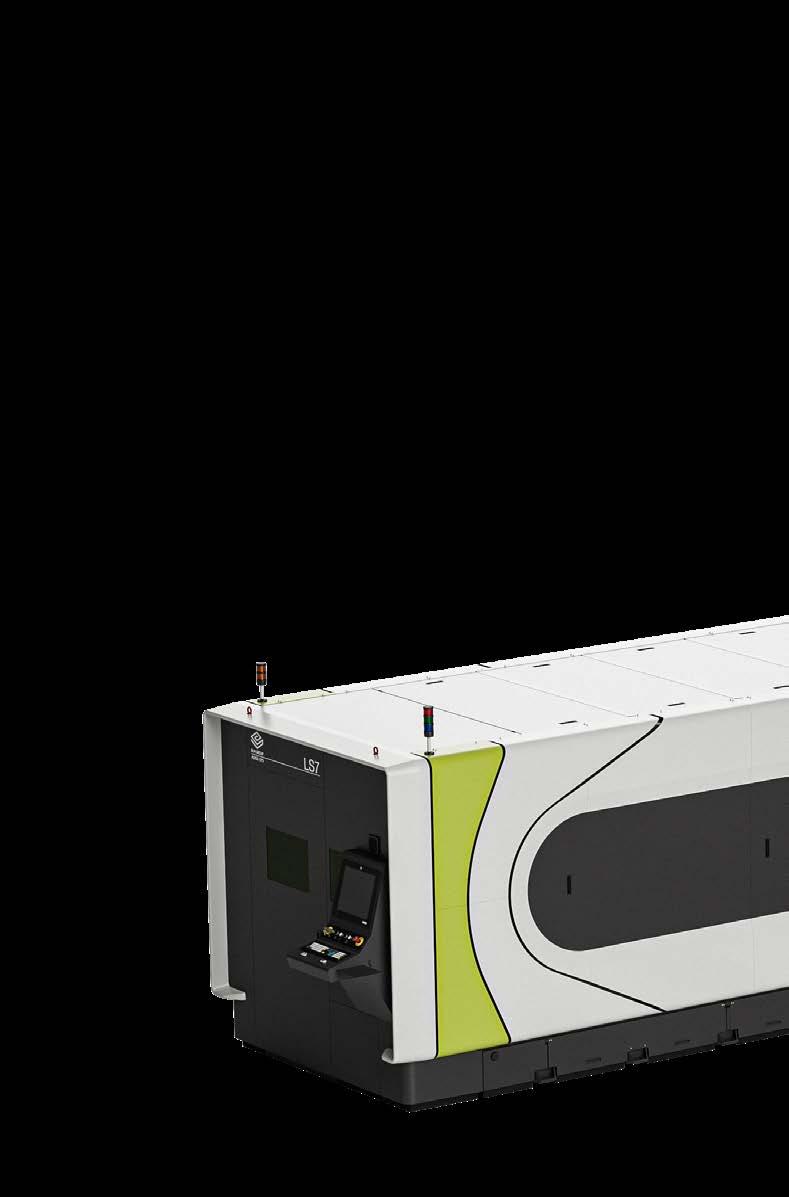

Sheet laser automation is a natural complement to press brake automation and can be a multipurpose solution with the right configuration. As laser cutting machines become more advanced, it is no secret that human processing speed has become one of the most prevalent bottlenecks in the world of sheet metal. Without proper handling, the surge from improvements in power and speed can yield higher production rates, but the operator’s own processing speed ultimately hinders the system’s overall performance more than any other factor.

Thus, the implementation and improvements around automation for sheet lasers is a major key to unlocking the machine’s true potential. However, humans are not the only bottleneck, as automation systems still struggle to maximize potential output.

“Industry experience has shown that maintaining stable and reliable production continuity is more valuable than sporadic, high-speed bursts,” says Luca Croce, Senior Business Development Manager at BLM GROUP USA. “These bursts can inadvertently introduce risks. In today’s manufacturing landscape, automating processes to minimize human intervention is crucial.

While human creativity and holistic vision are irreplaceable qualities, human factors can pose risks in the production process to consistency, quality, and even safety for health and life.”

Considering these factors, it’s clear that investing in material handling automation offers a compelling returnon investment. Although such systems might seem slower at first glance, their ability to operate continuously – day and night, including holidays – makes them far more impactful than the cutting speed alone. This approach allows for the installation of laser machines that don’t need to be pushed to extreme performance levels, resulting in more stable systems with lower maintenance requirements.

“Additionally, achieving these outcomes necessitates high-quality products, which pose challenges for lower-tier competitors entering the market,” Croce continues.

“Of course, some clients may still choose to venture into less reliable options, but they will soon realize the shortcomings of such decisions. For instance, modern laser cutting technology can achieve speeds exceeding 3,000 inches per minute. However, if the automated material handling system can’t keep up, the fabricator won’t be able to maximize uptime on the laser cutting machine.

Only by focusing on improvements through optimizing automation can we ensure that our laser systems operate at peak efficiency, delivering consistent, highquality results while minimizing risks associated with human intervention.”

Finally, the most important aspect of automation is keeping machines up and running continuously, and even the most advanced automation systems can go down. One way to ensure that machines are kept up and running at their full potential is through pre-scheduled maintenance and active machine monitoring. “BLM GROUP USA has a top-tier team of service technicians throughout the US and Canada,” says Croce.

“In addition, we have over eight million dollars of spare parts inventory on hand – keeping our customers’ machines up and running is critical to our mission. Our service team is able to review machine performance data directly from any location, so we are able to understand how machines are running as well as which parts may need maintenance in the near future.”

Where is the future taking sheet automation? “Now, operators are still interacting with robots and material handling,” says Arenas. “From incoming material to final product – for any product. This is already starting to take shape, but there are clear limitations in both accessibility and practicality. To achieve this, we need to be open to new ways of approaching challenges with flexibility. Considering the way that we develop our products and pursue R&D with an open mind at BLM GROUP, always listening closely to customer needs, I feel that we are on the right path to redefine the way press brakes are utilized.”

BLM GROUP will be showcasing its All-In-One product line of metal fabricating solutions, including load/unload sheet laser automation and the ProBend HBS II press brake automation cell, at FABTECH 2025, Booth #A2138.