Editorial

Editorial

DrivingInnovation,Collaboration,andGrowth

Groz-BeckertShowcasesPrecisionSolutionsforTechnicalTextilesatTechtextilIndia2025

GermanTechnology,GlobalVision:VDMAStrengthensIndustryBondsat ITMAASIA+CITMESingapore

GlobalConfidenceRestored:VDMAMembersHailITMAASIA+CITME2025 asaMilestoneforTextileMachinery

ItalyWeavestheFuture:Innovation,Sustainability,andPartnershipShineat ITMAASIA+CITME2025

DILO:PioneeringNonwovenExcellencefortheEraofSmartManufacturing

SINCE2025:ShowcasingtheFutureofNonwovenInnovationinAsia

WeavingTomorrow:DORNIER's75YearsofExcellenceandthe NewEraofIntelligent,SustainableWeaving

INDAAnnounces2026AdvocacyandFly-InSummitinPartnershipwith ISSACleanAdvocacySummit

FromCarbontoConscious:ZymoChem'sVisionforaFossil-FreeTextileFuture

®RISE 2025:WhereInnovationMeetsImpact—RedefiningtheFutureofNonwovens

® IDEA27:IgnitingInnovationandIndustryConnection—INDAOpensExhibitSpaceforthe World'sPremierNonwovens&EngineeredMaterialsEvent

editor-in-chief

Prakashkinny contributor

ThomasChang circulation PamelaJones administration JoePereira accounts

RameshJain photography

TonyFernandes

RetailPrice:Rs.100.00 InsideIndia

Annualsubscription:Rs.400.00 OutsideIndia

AnnualSubscription:US$30.00

editorial office

House No. 157, Satpala, Bhandra Lee Post:Agashi, Tal: Vasai

Dist: Palghar (401 301)

State: Maharashtra, INDIA

Mobile: +91-7798189485/09892723562

Email:info@timesinternational.in prakashkinny@yahoo.com techtexin@gmail.com

www.timesinternational.in

JAPAN

KatsuhiroIshii

MediaRepresentative ACEMEDIASERVICEINC.

12-6,4-chome,Nishiiko,Adachi-ku, Tokyo121-0824Japan

Tel:81-3-5691-3335Fax:81-3-5691-3336 amskatsu@dream.com

TAIWAN,R.O.C

Kenlychang

BUILDWELLINTERNATIONALENT.,CO.,LTD.

HeadOffice:No.120,Huludun2ndSt., FongyuanCity, TaichungCounty42086,Taiwan,R.O.C

Tel:886-4-25123015Fax:886-4-25122372

E-mailaddress:buildwel@ms23.hinet.net

India,Pakistan,Bangladesh,Srilanka,Vietnam,Indonesia,Thailand, China,HongKong,USA,Germany,Spain,Italy,U.K.&France

ThestoryofIndia'stechnicaltextileindustryisoneof vision, resilience, and boundless innovation. As Techtextil India celebrates its 10th glorious edition from 19–21 November 2025 at the Bombay ExhibitionCentre,Mumbai,itstandsasabeaconfor the future of performance and functionality in textiles.

Sinceitsinception,TechtextilIndiahasevolvedinto the most influential B2B platform uniting manufacturers, innovators, and buyers across 12 diverse application sectors—from Medtech to Geotech and Agrotech. Each edition has not only showcased cutting-edge materials and technologies but has also inspired new collaborations and global connections that drive India's march toward becomingaUSD22billionpowerhouseintechnical textiles.

With a renewed focus on sustainability, advanced materials,andcross-sectorsynergies,TechtextilIndia 2025promisestobemorethanjustatradefair—itisa celebration of creativity meeting purpose, where innovationthreadsthefabricofthefuture.

Beyond innovation. Beyond boundaries. Techtextil India—where ideas take shape and industries transform.

th 15AnnualGeneralMeetingofIndianTechnicalTextileAssociation-FY2024-2025

The IndianTechnicalTextileAssociation (ITTA) th successfully concluded its 15 Annual General th Meeting (AGM) on 19 September 2025 at the Orchid Hotel, Mumbai. The meeting was conducted under the Chairmanship of Shri. Avinash Misar, with a large presence of ITTA members, special invitees, and press media representatives. Dr. Anup Rakshit, Executive Director of ITTA, warmly welcomed the distinguished guests, members, and press representativestotheevent.Shri.MaheshKudav, Vice Chairman conducted the Business Session. TheAGMwashonouredbythepresenceofShri. Kartikay Dhanda, Secretary, Textile Committee, as the Chief Guest and Dr. T. V. Sreekumar, Director, The Bombay Textile Research Association(BTRA)asaGuestofHonour.

Shri Kartikay Dhanda addressed the ITTA members,highlightingthecriticalrolethatITTA has played over the years as a dedicated

associationinupliftingthetechnicaltextilesector and serving as a vital link between the industry and the government. He acknowledged ITTA's significant contributions in driving innovation, sustainability, and growth within India's textile industryandappreciatedtheMinistryofTextiles, through NTTM and PLI schemes, for working towards the sector's development by implementing such initiatives. He further emphasizedthevastgrowthpotentialoftechnical textiles and commended ITTA for fostering industry interactions. Addressing the delegates, healsounderlinedtheneedtoreducebottlenecks, enhance facilitation processes to make exports more competitive, and seize opportunities for joint ventures and innovations to bridge technologicalgapsinthesector.

Dr. T. V. Sreekumar expressed his gratitude to ITTA for the invitation and acknowledged BTRA's close association with the technical

textiles sector. He highlighted the strong collaboration between ITTA and BTRA, noting that ITTA's presence on the BTRA campus has fostered knowledge exchange, research collaborations, and industry outreach, benefiting stakeholders.HesharedthatBTRAisengagedin major projects such as Carbon Fibre precursors and emphasized the importance of innovation, capacity building, and continuous awareness to strengthen India's global competitiveness. Appreciating ITTA's efforts in conducting seminars, workshops, and training programs, he reaffirmed BTRA's commitment to supporting ITTAand the industry through research, testing, training, and technology development, and encouraged members to actively participate in ITTA's initiatives.

Shri Avinash Misar, Chairman, ITTA, thanked Shri Kartikay Dhanda, Secretary, Textiles Committee;Dr.T.V.Sreekumar,Director,BTRA; and other dignitaries for their gracious presence. HehighlightedITTA'ssteadygrowthoverthepast 15 years, noting that the industry has achieved a 12% CAGR since 2021, with turnover reaching USD 27 billion and exports rising to USD 2.4 billion in 2024–25. With projections of USD 45 billion by 2030, he expressed confidence in the

sector's strong future while acknowledging challenges such as raw material imports, GST anomalies, QCO issues, and the need for greater MSME support under schemes like PLI. He appreciated the Ministry of Textiles' initiativesNTTM,PMMITRA,andsustainabilityprograms which have positioned technical textiles at the forefront. He also underlined ITTA's role in developing BIS standards, representing industry on key committees, promoting training and skill development, evaluating NTTM projects, and driving awareness across India. With over 400 members,ITTAremainscommittedtosupporting the sector in close collaboration with the government to overcome challenges and achieve sustainedgrowth.

Dr.AnupRakshithighlightedthatsincelastyear, ITTA has introduced the Innovation Awards to recognize members who are doing outstanding work in developing innovative products and machinery.Thisyear,thejuryselected4awardees from 6 applications, whose names will be announced during the ceremony. He further shared that ITTA's Executive Development ProgramsandTrain-the-Trainerprogramsonkey segmentsof technicaltextiles.

Shri. Avinash Misar continues to be the exmemberoftheBoardandwillbeaguidingforce

The AGM concluded with the formation of the new Board wherein Shri. Mahesh Kudav, Managing Director, Venus Safety & Health Pvt. Ltd.,formallytookoverastheChairmanofITTA andDr.NandanKumar,ManagingDirector,High PerformanceTextiles Pvt. Ltd. was unanimously electedastheViceChairmanofITTA.

oftheassociationalongwithShri.AmitAgarwal (Ex-OfficioMember).

A notable moment during the meeting was the presentation of the “Lifetime Achievement Award” to Shri. Pankaj Kapoor, Managing Director of Park Non-Woven Pvt. Ltd., for his outstanding contributions to the technical textile industryandhislastingimpactonthefield.Shri. Kapoor was inducted into the 'ITTA Hall of Fame', in addition to Shri. Pramod Khosla of Khosla Profil, Shri. Yogesh Kusumgar of KusumgarCorporatesandShri.MohanKavrieof SupremeNonwovens.

The Innovation Awards on outstanding contributions and advancements in theTechnical Textile industry, introduced by ITTA, were presentedtothefollowingFivecompanies-

1.Prashant West Point Machinery Pvt. Ltd.Shri. Apurva Kapadia and Ms. Amoli Shah, Director on the “Intelligent Direct Warper for FibreGlassYarn”.

2.Tarasafe International Pvt. Ltd. + High PerformanceTextilesPvt.Ltd.-Shri.AnaveerB. Telasang, Vice President & Business HeadMarketingandMerchandising&Shri.Mahendra Kushwaha,Manager-NewProductDevelopment,

Tarasafe and Dr. Nandan Kumar, Managing Director,HPTonthetwoinnovationsi.e., “Light Weight&BreathableMulti-FunctionalProtective Wear Sleeve, Apron, Bib-Trouser and ChapTrouser and TaraHeal - Reduce: Reuse: Recycle! NowinFR!”.

3.Garware Technical Fibres Ltd. - Shri.Yogesh Padule, Assistant Manager - R&D on the “Bio Aqua Rock Bag - An Eco-Friendly Solution for ErosionControl”.

4.Northern India Textile Research Association (NITRA) -Dr.M.S.Parmar,DirectorGeneralon the“DevelopmentofFireEntrySuit”.

The AGM also featured a Knowledge Sharing Sessionaimedatprovidingvaluableinsightsand industryexpertisewithinsightfulpresentationon “Recent Advances in Carbon Fibre Precursor development under NTTM” by Dr. T. V. Sreekumar,Director,BTRA.

ShriAnilKumarVasupillai,AdditionalExecutive Director, ITTA, extended a heartfelt vote of thanks to all members, guests, participants, and dignitaries for their presence and for making the ITTA AGM a success. He reaffirmed ITTA's commitment to being the voice of the Indian technical textile industry and to working closely with the government on policy initiatives. He further emphasized that ITTAremains dedicated

to facilitating the needs and aspirations of its membersandsupportingtheminachievinghigher growthandbusinessdevelopment.

Groz-Beckert, a global leader in industrial machine needles, precision components, and textile system solutions, will participate at Techtextil India 2025 from November 19–21, 2025,attheBombayExhibitionCenter,Hall4, Booth E31, Mumbai. The company will showcase innovations across four key product areas: Nonwovens, Weaving, Warp Knitting, andSewing,withadedicatedfocusontechnical textiles and high-performance material processing..

At Techtextil India, Groz-Beckert will highlight its for nonwoven wear-optimized solutions production,designedtoincreaseprocessstability, improve material consistency, and reduce operationaldowntime.

Keytechnologiesondisplayinclude:

Ÿ Felting Needles with Enhanced Barb Geometry

Optimized for abrasive and mineral fiber blends,thelatestbarbdesignsensure:

Ÿ Reducedneedlewear

Ÿ Lower clogging tendency in materials like bentonite

Ÿ More uniform surface appearance at high throughputrates

Ÿ InLineCardClothingSolutions

™ Featuring SiroLock plus worker and doffer wires:

Ÿ Improvedfibercontrolandwebuniformity

Ÿ Extendedservicelifeandmaintenanceintervals

Ÿ Higherandreproduciblecardingqualityacross productionruns

These solutions support demanding sectors such as automotive interiors, geotextiles, filtration, hygiene,andinsulationmaterials

Groz-Beckert will also present its weaving preparation systems and high-precision accessories, engineered to enhance quality and machine productivity in both apparel and technicaltextileweaving.

Exhibithighlightsinclude:

Ÿ Heald Frames, Healds, Drop Wires, and WarpStopMotions

Designed for durability, consistency, and compatibility across major weaving machineplatforms.

Ÿ High-PerformanceReeds

Deliveringprecisethreadguidancefor:

Ÿ High-speedweaving

Ÿ Finefilamentfabrics

Ÿ Complexmulti-layerandtechnicaltextiles

Ÿ KnotMasterWarpTyingMachine

Featuring:

Ÿ Intuitivetouchscreenoperation

Ÿ Automaticknottingadjustment

Ÿ Supportfordiverseyarntypesfromcottonand polyestertoaramidandglassfibers

This ensures , efficient warp changeovers minimized downtime, and improved mill productivity.

For the sector, Groz-Beckert will warp knitting showcase its ongoing developments in loop formation components for high-performance textileapplications.

Highlightsinclude:

Ÿ GuideNeedlesandModuleSystemsfornet, mesh, spacer, automotive, footwear,base fabric, andmedicaltextileproduction

Needle ApplicationField

Airbags,filtration,coated textiles,composites

Ÿ New Guide Needle Solutions for PiezoJacquardMachines,providing:

Ÿ Enhancedbendingresistance

Ÿ Preciseloopformation

Ÿ Longer component lifespan under dynamic load

Thesecomponentssupportmanufacturersaiming for consistent fabric geometry, repeatability, andhigh-speedefficiency

The Sewing Division will spotlight two ™ specialized SAN (Special Application Needles) designed for technical textile processing:

KeyAdvantages ™SAN 5.2 ™SAN 17

Automotiveseating,luggage, heavywebbing,safetytextiles

Highdimensionalstability,secureloop pick-up,optimizedseamintegrity

Reducedfrictionandheatathighspeeds, minimizedneedledeflection,smootherstitch formation

With a strong network of local technical service experts, sales offices, and warehousing across India, Groz-Beckert continues to support Indian textile manufacturers with application knowledge, process consulting, and lifecycle support.

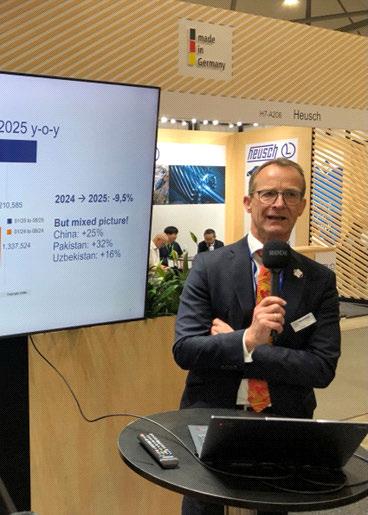

VDMAmembersatITMAASIA+CITMEinSingapore

Dr. Janpeter Horn, Chairman VDMA Textile MachineryAssociationatthepressconferencein Singapore

Imagesource:VDMA

With 69 exhibiting member companies, ITMA ASIA+ CITME 2025 is once again marked by a strongpresenceofVDMAcompanies.Altogether 82companiesfromGermanyexhibitattheshow, coveringabout3,500squaremetersofexhibition space, topped only by China and Italy. VDMA initiatedaGermanPavilionwithtwogroupstands (spinning in hall 4 and finishing in hall 7) with a totalof30exhibitors.

OntheoccasionofaVDMApressconferenceat ITMA ASIA + CITME, Dr. Janpeter Horn, Chairman of the VDMA Textile Machinery Association and Managing Director of August Herzog Maschinenfabrik explained: “The geopolitical and economic conditions are currently difficult. This makes the strong presenceofVDMAmembercompaniesatITMA ASIA+CITME,whichisbeingheldinSingapore for the first time in twenty years, all the more gratifying. The show offers VDMA members a key opportunity to showcase their latest technologies and connect with the ASEAN marketsaswellasothermarketsinAsia.”

Dr. Harald Weber, Managing Director of the VDMATextileMachineryAssociationadded:“It is no surprise, that most visitors to the ITMA ASIA + CITME shows in Shanghai came from the People's Republic. My expectations of the trade fair in Singapore are that the audience will bebroader.Ihopewewillseenumerousvisitors fromtheASEANregion,fromIndia,Pakistanand BangladeshandfromtheCentralAsiancountries, justtomentionafew.”

The VDMAmembers in Singapore cover nearly all different machinery chapters along the textile value chain including spinning and man-made fibres,nonwovens,weaving,braiding,knitting& warp knitting, finishing & dyeing as well as technologies for textile recycling and processing of recycled material. The companies remain focused on developing innovative, sustainable solutions that reduce production costs while upholding the high standards of European machinery — a commitment captured in their

sharedsloganinSingapore:'ExperienceLeading Technology'.

Major topics of the show will be automation, sustainabilityandcirculareconomy.Herearejust a few examples of exhibitors that stand for the entire industry: Automation is a way to address the challenges of labour-constrained textile operations. On display in Singapore is an automation solution for the sliver transport in spinning. The topic of recycling is becoming increasingly important in the textile industry, for example due to corresponding government regulationsthatareaimingatacirculareconomy. At ITMAASIA+ CITME a system can be seen, thatautomaticallysortsgarmentsbycomposition and colour and prepares materials for further processing. It enables the recycling of postconsumer and post-industrial textile waste into fibresforspinning,nonwovensandcomposites.

Recycling is just one example for the broader topic sustainability. One way to produce sustainably is to make processes more efficient. Sustainable dyeing technologies reduce the consumption of water, energy, chemicals, and dyeswhileensuringsuperiorproductqualityand shorterproductiontimesbyintegratingflexibility and speed. That is another example of how economyandecologycanmeet.

Exportfiguresshowamixedpicture Asiahasbeenthenumberoneproductionlocation for textiles and clothing in the world and will retainthispositionforalongtimetocome.So,itis no surprise thatAsia is the most important sales market for the VDMA member companies. Between January and August 2025, German exports of textile machinery and accessories worldwidesummeduptoalmost1.2billioneuros,

a decrease of 9.5% year-on-year. Half of the exports went toAsia. Nevertheless, a closer look revealsamixedpicture:GermanexportstoChina (plus 25%), Pakistan (plus 32%) and Uzbekistan (plus16%)sawstrongincreases.

Asurvey among the VDMAmember companies in the beginning of October showed that 50% of the responding companies assess their current business situation as satisfactory. Around 30% expectthebusinesssituationtoremainunchanged in 2026, while 60% anticipate a deterioration in business prospects. For the current year, 60% of companies in the textile machinery manufacturingsectorexpectsalestostagnate.For 2026,74%continuetoexpectstagnation.Atleast 19%ofcompaniesanticipatesalesincreasesofup to20%.

According to the VDMA survey, the member companiesseebettersalesopportunitiesinAsian markets for the coming year than in 2025. SoutheastAsia, CentralAsia and SouthAsia are ratedmuchbetterfor2026.Theseexpectationsare in line with IMF forecasts, which predict a GDP growth of over 6% for India and growth rates of justover4%forChinaandtheASEANregionin 2026.

“The Asian markets are offering great chances thatEuropeanmachinerymanufacturerscantake with their innovative and sustainable solutions andthehighqualityofmachinerythatcustomers rightlyexpect.TheVDMAmembersarelooking forward to welcoming numerous visitors from various countries to their booths in Singapore”, summarised Dr. Janpeter Horn, Chairman of the VDMATextileMachineryAssociation.

+CITME

VDMAmembershighlysatisfiedwithITMAASIA+CITME2025inSingapore

Withmorethan840exhibitorsfrom30countries and thousands of visitors from more than 100 nations ITMAASIA+ CITME 2025 was a truly international show. Visitors came with clear project ideas, leading to many inspiring and fruitfuldiscussions.

Numerous VDMA members reported closed orders and deals – a positive sign for the machinery sector. “Better than expected”: this was a frequent statement from exhibiting companies.

The testimonials from VDMA member companiesreflectasuccessfultradefair:

"ITMAASIA + CITME 2025 in Singapore has been a real INTERNATIONAL Textile Machinery Exhibition inAsia, attracting visitors from more than 100 countries. The numbers and quality hoped for have been exceeded. In this friendlyandwellorganisedcity,smileswerealso very much seen at the EXPO during the exhibition.”

Dr. Janpeter Horn, Chairman, VDMA Textile MachineryAssociation

“ITMAASIA+CITME2025inSingaporewasa great success also for Mahlo. The show brought together the right people, the right ideas, and the right energy. A truly international event that delivered valuable insights and confirmed the

industry's commitment to innovation. We could discuss specific challenges and solutions with numerous industry professionals from across Asia.”

ThomasHöpfl,SalesDirector,Mahlo

“ITMAASIA+CITME2025inSingaporewasa great success for Trützschler. The event brought together an international mix of visitors and offered high-quality discussions with customers andbusinesspartners.”

Alexander Stampfer, CSO, TRÜTZSCHLER Group

“SingaporewastheidealstageforITMAASIA+ CITME 2025, drawing a highly engaged global audience. The exhibition proved to be an outstandingplatformformeaningfuldialogueand networking. The strong visitor presence and the depth of discussions underscore the industry's commitment to innovation and sustainability. With automation and future technologies taking centre stage, the event exceeded expectations by creating an environment where visionary ideas andpracticalsolutionsconverged.Customersare once again ready to invest, signalling renewed confidence and growth opportunities. This positive momentum encourages us and strengthensouroutlookforthefuture.”

Werner Volkaert,

Managing Director, Sedo Treepoint

"ITMAASIA+CITME2025inSingaporeproved to be a truly global platform, bringing together a remarkably international audience. The high visitor numbers, the quality of discussions, and the strong focus on innovation and sustainability reflectedtheindustry'sevolvingpriorities.Forus, the event reaffirmed the importance of personal dialogueinshapingthefutureofnonwovensand textiletechnology.”

Tobias Schäfer, Vice President, ANDRITZ Nonwoven&Textile

“We were impressed by the high quality and diversity of visitors at ITMA ASIA + CITME 2025 in Singapore. The event proved to be an excellentplatformformeaningfuldiscussionsand new connections across the entire Asian textile market.Singapore'sdynamicandwell-organized setting provided the ideal environment to exchange ideas, explore innovations, and strengthen partnerships throughout the region. Focustopicsweredefinitelyincreasingefficiency in the textile production at currently uncertain times.”

KathrinPleva,ManagingDirector,PLEVA

“ITMAASIA+CITME2025Singaporewaswell attended and attracted qualified visitors. It's strategic geographic location connected the SoutheastAsian region and positioned the event

asacentralmeetingpointforthetextileindustry.”

Riccarda Dilo, Member of the Executive Board, DILOGroup

“Choosing Singapore as the location for ITMA ASIA + CITME 2025 was absolutely the right decision.Ourexpectationswereexceededbothin terms of the quality and the number of internationalvisitors.”

TorstenvonKoch,SalesDirector,GeorgSahm

“ITMAASIA + CITME 2025 in Singapore was worth a visit. The location was excellent for visitorsfromtheASEANcountriesandSingapore offers an excellent infrastructure. We were impressed by the numbers of visitors and the quality of meetings with customers, who came mainlyfromPakistan,IndiaandBangladesh.The focusofvisitorswasonthefinishingofouterwear, denim and automation. Many customers plan to realizetheirprojectsinthecourseof2026.”

Hans-Gerhard Wroblowski, Sales Manager SEA,A.MonfortsTextilmaschinen

From16to22September2027,ITMAwillreturn to Germany for the first time in 20 years. The leading international trade fair for textile machineryandclothingtechnologyisexpectedto attractover100,000decision-makersfromalmost all textile-producing countries. Companies interested to exhibit in Hannover can already registerhere:http://www.itma.com./

Italian textile machinery brings the spirit of “Experience Leading Technology” to Singapore, reaffirming its leadership in sustainable innovation.

With a legacy built on creativity, precision, and engineering brilliance, Italy once again takes centre stage at ITMA ASIA + CITME 2025. More than 100 Italian textile machinery manufacturers, coordinated by ACIMIT (Association of Italian Textile Machinery Manufacturers) and supported by the Italian Trade Agency (ITA), are showcasing groundbreaking technologies across 4,000 square metres of exhibition space — making Italy one of the largest and most influential exhibitorsatthisyear'sevent.

ThisreturntoSingaporeaftertwodecadescomes at a momentous time, coinciding with the 60th anniversary of diplomatic relations between ItalyandSingapore—acelebrationofenduring partnership,innovation,andsharedprogress.

The Italian textile machinery industry, comprising around 300 manufacturers and employing12,500professionals,continuestobe a cornerstone of the global textile ecosystem. With a turnover of €2.1 billion and 86% of production exported to more than 130 countries, Italian machinery embodies the hallmark values of creativity, sustainability, reliability,andquality.

“The strong presence of Italian exhibitors in Singapore underlines the vitality of our industry andourcommitmenttosustainability,innovation, and efficiency. Italian manufacturers continue to combine a centuries-old textile heritage with the technological excellence that defines modern manufacturing.”

AtITMAASIA+CITME2025,Italiancompanies are not just displaying machinery — they are showcasing the future of textiles. From automationanddigitalizationtorecyclingand resource-efficient dyeing technologies, their solutions reflect a deep understanding of the globalindustry'sevolvingneeds.

Among the highlights are innovations in automatedslivertransport,AI-drivenprocess controls,andsmartrecyclingsystemscapableof sorting garments by composition and colour — advancing the vision of a circular textile economy. Italian technology also leads in lowimpact finishing processes, minimizing water, energy, and chemical use while enhancing fabric qualityandproductionspeed.

For Italy, sustainability is not a trend — it is a tradition renewed through technology. Across generations, Italian manufacturers have refined the balance between artistry and automation, maintaining uncompromising quality while embracing environmentally responsible production.

Giorgio Calveri, Director of ITA Singapore, affirmsthisvision:

“Asia remains the most important market for Italian textile machinery, accounting for nearly half of our exports. ITMAASIA+ CITME 2025 offers a strategic opportunity to reinforce Italy's role as a trusted partner in sustainable and competitivetechnologies.”

Italy's strong representation in Singapore underscores its strategic engagement with Southeast Asia, South Asia, and Central Asia — regions that are shaping the textile future. Markets such as China, India, Pakistan, and Bangladesh continue to drive demand for highquality, energy-efficient machinery, reaffirming the importance of Italian innovation in Asia's industrialgrowthstory.

Despite global uncertainties, Italian manufacturers remain optimistic. Their strength lies in adaptability, customer collaboration, andcontinuousR&Dinvestment,makingthem preferred partners for industries seeking excellencewithconscience.

WhatdistinguishesItaliantextilemachineryisnot only technology — it is passion. Behind every innovation lies the craftsmanship of engineers, designers,andentrepreneursunitedbyavisionto transformtextilesintoasustainable,smarter,and morehuman-centricindustry.

As ACIMIT and ITA lead this remarkable participation,Italy'spresenceatITMAASIA+ CITME2025standsasalivingexpressionofits values — where tradition meets transformation,andinnovationbecomesart.

“Made in Italy” continues to weave a story of global excellence — one thread of innovation, collaboration,andsustainabilityatatime.

Exhibitor Spotlight – SINCE 2025 | Booth 1A23

Inanindustrydrivenbyconstantinnovation,Dilo Systems GmbH continues to define the benchmarks of excellence in nonwoven technology. As the global leader in complete nonwoven lines, the DiloGroup's presence at SINCE 2025 (Shanghai International Nonwovens Conference & Exhibition) underscores its enduring commitment to empowering smart, sustainable, and highperformancetextileproduction.

Engineering Precision Across the Nonwoven ValueChain

The DiloGroup integrates over a century of engineering heritage with cutting-edge innovation. Its group companies — DiloTemafa (BergischGladbach)DiloSpinnbau(Bremen) , , and — collectively DiloMachines (Eberbach) deliver end-to-end expertise spanning fibre opening and blendingmechanical and , aerodynamic web formingcrosslapping , , and needling

This holistic approach allows Dilo not only to supply individual components but to deliver complete, intelligently synchronized nonwovenlinesthatdefinethegoldstandardfor efficiency,reliability,andproductuniformity.

1. Fibre Opening and Blending: The FoundationofQuality

Every great nonwoven product begins with impeccablefibrepreparation—andthisiswhere Dilo'sprecisionmachinerysetsthetone. DiloTemafa systems ensure optimal opening, cleaning,dosing,andblendingforawiderange of fibres — from synthetic to natural (including flax, hemp, and kenaf). The company's feeding

equipment for cards and web-forming machines enhances uniformity and throughput, while its solutionsforrecyclingedgetrimmingsandoffquality material embody the brand's sustainability-firstphilosophy.

AtSINCE2025,Dilohighlightsitsuniversaland specialtycardingsystemsdesignedforflexibility, width,andperformance

The product range includes single and double doffer cardsdouble main cylinder cards , , random and airlay cardswide-format , and designsupto6000mm

This suite of machinery ensures precise fibre orientation and uniform web formation — essential for industries demanding technical consistency such as automotive, filtration, and geotextiles.

Dilo's reputation for crosslapping excellence

remains unmatched. Its high-precision crosslappers enable exact layering even at high infeedspeeds,deliveringconsistentwebstructure andthickness.

For different production needs, Dilo offers tailoredsolutions:

Ÿ DLAAlpha Line The deliversefficiency at lower speeds, ideal for cost-optimized operations.

Ÿ Hyperlayer The technology caters to ultra-lightweight felts with the finest fibres, ensuring uniform layering even with minimal layers.

Throughthesesystems,Diloreinforcesitsroleas the go-to partner for precision layering technologiesinthenonwovendomain.

DiloMachines' range of stands as needlelooms thebeatingheartofmodernnonwovenprocessing —availableinworkingwidthsfrom0.6mto16 mstroke frequencies up to 3,500 strokes , and perminute.

Their versatility covers the entire needling spectrum — from one-sided pre- and finishneedlingdouble needling systems to for dual-

sidedprocessing. The model introduces elliptical Hyperpunch needle beam kinematics, achieving high-speed needling with minimal draft, enhancing both strengthandsurfacequality.

Dilo's and technologies DI-LOOPDI-LOUR bring new design and texture dimensions to the field, while circular and endless needling systems (RONTEX and BELTEX) offer unmatched uniformity for roll goods and tubular fabrics.

AmongDilo'smostforward-lookinginnovations, MicroPunch technology represents a paradigm shifttoward .greenmanufacturing

This process is designed for lightweight nonwovens (30–150 g/m²) with up to 75% reduction in installed power, offering remarkable energy savings without compromisingperformance.

Withaneedledensityupto45,000needlesper meter per boardX22 needle module and the system for effortless insertion and exchange, MicroPunch redefines productivity while reinforcing Dilo's commitment to low-impact, resource-efficientproduction

This technology exemplifies how sustainability and industrial performance can coexist harmoniouslyinnext-generationmanufacturing.

Perhaps the most visually striking of Dilo's innovations, the 3D-Lofter – Sliding Colors system introduces a new dimension of functionalityandcreativity.

This aerodynamic web-forming technology enablesthe3Ddistributionofadditionalfibres on a flat needlefelt, producing locally variable thickness,stiffness,andstrength—allwithout compromisingtheintegrityofthebasematerial.

The result is a material with engineered performance zones automotive , ideal for interiors,upholstery, mattresses, apparel, and flooring. Moreover, the system's ability to create colored patterningduringtheformingprocessopensnew aestheticpossibilitiesfortechnicalanddecorative applicationsalike.

Inaworldseekingpersonalizationandprecision, the 3D-Lofter stands as a symbol of manufacturingintelligenceinmotion.

Dilo's exhibit at SINCE 2025 is more than a machinery display — it's a showcase of integratedsmartmanufacturing.

Each of its technologies contributes to a connected production environment where data, design, and performance converge. From fibre openingtofinalneedling,everystageoftheDilo process is optimized through digital control, energyefficiency,andmodularadaptability.

InnovationRootedinResponsibility

What distinguishes Dilo is not just technological leadership, but a responsible innovation philosophy

In an age where sustainability is no longer optional, the company continues to pioneer energy-saving, waste-minimizing, and resourceoptimizingsolutions.Whetherthroughrecyclingoriented fibre systemsenergy-efficient or needling, Dilo's machines demonstrate that productivity and planet can indeed progress together.

ThisethospositionsDiloasa fortrustedpartner nonwoven manufacturers navigating global transitions — from the demands of e-mobility to thesustainabilityimperativesofcirculartextiles.

By seamlessly linking all production stages — from to opening and blendingfinal needling and finishing — Dilo delivers unmatched processcontrolandreliability.

Its vertically integrated systems ensure not only mechanicalcompatibilitybutalsoaunifieddigital backbone,allowingcustomerstomonitor,adjust, andimproveperformanceinrealtime.

This system-level thinking defines the Dilo Difference—transformingstandalonemachines

This aligns perfectly with the global movement toward ,wherereal-timemonitoring,Industry4.0 processoptimization,andpredictivemaintenance ensure not only but also quality consistency operationalresilience

intointelligentecosystemscapableofresponding to evolving material needs and sustainability goals.

Meet Dilo at SINCE 2025: Experience InnovationinAction

Visitors to at Booth 1A23SINCE 2025 (Shanghai, December 3–5, 2025) will experience Dilo's hallmark of innovation firsthand.

From the MicroPunch line's sustainability promise3D-Lofter'svisualcreativity tothe ,the company's display embodies the synergy of engineering precision, environmental responsibility,andmanufacturingintelligence

The exhibition will also serve as a platform for discussing future-focused solutions — from lightweight compositesfunctional textiles and to that cater to smart nonwoven architectures evolving mobility, filtration, and medical applications.

For Dilo, every innovation is more than machinery — it's a contribution to shaping the nextchapterofnonwovenevolution

Editorial Perspective: Dilo and the Future of Nonwovens

From an editorial lens, Dilo's consistent leadership in nonwoven machinery represents a rare blend of technical mastery and visionary purpose

Itsinnovations—especiallytheMicroPunchand 3D-Lofter — redefine the parameters of sustainability, efficiency, and creativity in textile production.

Asglobalmanufacturingmovestowarddigitally intelligent and circular ecosystems, Dilo's role extends beyond equipment supply. It becomes a technologyenablerandsustainabilitypartner, guidingtheindustrytowardsmarter,cleaner,and moreadaptiveproductionparadigms.

At SINCE 2025, Dilo's showcase is not just a displayofmachinery—itisablueprintofwhat responsible innovation looks like in the age of smartmanufacturing.

VisitDiloSystemsGmbHatSINCE2025

Ÿ BoothNo.:1A23

Ÿ December3–5,2025|Shanghai,China

Ÿ http://www.dilo.de/

Discover how Dilo continues to shape the future ofnonwovens—oneinnovationatatime.

By the Editorial Desk, Technical Textiles Innovation

Inthedynamicworldofnonwovenmaterials,few platforms have stood the test of time and transformation like the Shanghai International Nonwovens Exhibition (SINCE). Since its inceptionin1986,SINCEhasevolvedintoAsia's most influential and comprehensive nonwovenstradeandtechnologyevent,driving innovation,collaboration,andsustainablegrowth acrosstheglobalnonwovensvaluechain.

Nowenteringits21stedition,SINCE2025isset to take place from December 3–5, 2025, at the Shanghai World Expo Exhibition and Convention Centre (SWEECC) — once again reaffirmingShanghai'sstatusasthebeatingheart ofthenonwovensindustry.

Co-organizedbytheChinaTechnologyMarket Association (CTMA), China Nonwovens TechnicalAssociation (CNTA), CNTAScience &TechnologyCo.,Ltd.,andInformaMarkets, theSINCEexhibitionhasgrownfromaregional trade fair into a global innovation hub for nonwovensandtechnicaltextiles.

The last edition — SINCE 2023 — achieved remarkablesuccess,featuring:

Ÿ 25,000squaremetersofexhibitionspace

Ÿ 335exhibitorsfromChinaandabroad

Ÿ 12,259 professional visitors recording over 35,000visitsacrossthreedays

The exhibition brought together leading players from hygiene, filtration, medical, automotive, apparel, home furnishings, wiping, and upholstery sectors, making it a comprehensive convergence point for end-to-end nonwoven solutions.

A hallmark of SINCE has always been its completecoverageofthenonwovenecosystem. Theexhibitionspanstheentirevaluechain,from

raw materials and production machinery to roll goods, testing equipment, and converted products.

Visitorscanexpecttoexploreadvancementsin:

Ÿ Nonwovenrawmaterialsandfibres

Ÿ Productionmachineryandaccessories

Ÿ Testing, inspection, and quality control systems

Ÿ Converted products for hygiene, filtration, automotive,apparel,andhomeapplications

Thisholisticapproachensuresthateverysegment ofthenonwovenindustry—fromfibresuppliers and machinery manufacturers to converters and end-users — finds its place within SINCE's exhibitionfloors.

A Platform for Sustainable and Smart Transformation

In alignment with global sustainability trends, SINCEhasbecomeakeyplatformforpromoting eco-friendly, energy-efficient, and smart manufacturingtechnologiesinnonwovens.

The SINCE 2023 Nonwovens Sustainable DevelopmentForumandExhibitors'Technical Presentations provided thought-provoking insightson:

Ÿ Recyclableandbiodegradablematerials

Ÿ Low-impactmanufacturingprocesses

Ÿ Circulareconomymodels

Ÿ Automationanddigitalisationinnonwoven production

These knowledge-sharing sessions positioned SINCE not just as a trade fair, but as a collaborative think-tank for sustainabilitydriven innovation. The upcoming SINCE 2025 promisestoexpandthisdialogue,focusingonthe synergy between smart manufacturing, material science, and environmental stewardship.

SINCE'sstrengthliesinitsabilitytoconnectthe globalnonwovenecosystem—fromtechnology developers to converters and end-users. Its Shanghai venue strategically bridges Asia's manufacturing powerhouses with international markets, facilitating business expansionandtechnicalexchange.

For international participants, the exhibition offers:

Ÿ Direct access to China's rapidly growing nonwovenmarkets

Ÿ Networkingwithregionaldistributorsand technologypartners

Ÿ Insights into emerging Asian consumer trendsandsustainabilitymandates

Atthesametime,Chineseexhibitorsbenefitfrom global exposure, presenting their innovations to an audience of buyers, engineers, and investors from across Europe, the Americas, and SoutheastAsia.

DrivingtheFutureofNonwovens

With industries such as healthcare, mobility, construction, and filtration demanding higherperformance materials, SINCE 2025 is set to highlight next-generation nonwoven technologies — including advanced fiber engineering,digitalwebformingsystems,and functionalsurfacetreatments

Visitorscanlookforwardtolivedemonstrations, product launches, and technical seminars that emphasize automation, material circularity, and new applications for technical nonwovens. ExhibitorslikeDilo,Truetzschler,Andritz,and A.Celliareexpectedtoshowcasehowhigh-speed precision machinery and intelligent production lines are reshaping nonwoven manufacturing worldwide.

WhySINCE2025Matters

In an era where sustainability and smart manufacturing are reshaping industrial priorities, SINCE serves as the strategic platformwheretechnologymeetspurpose.Itis wherecompaniescan:

Ÿ Benchmark innovations and evaluate new machinery

Ÿ Discovermarket-readysustainablesolutions

Ÿ Forge partnerships for research, production, andtrade

Ÿ Stay informed on regulatory and market developmentsimpactingnonwovens

As the industry continues to recover from global supplydisruptionsandacceleratestowardcircular models,SINCE2025willplayapivotalrolein setting the agenda for the next decade of nonwovenadvancement.

AGlobalGatheringofIdeasandInnovation

Beyondtheshowfloor,SINCE2025willcontinue to host technical forums, product showcases, and B2B matchmaking sessions, providing a dynamic space for knowledge sharing and strategiccollaboration.

For professionals across R&D, manufacturing, sustainability, and business development, the exhibition offers a 360-degree view of industry trends — from bio-based raw materials and smart fiber systems to AI-driven quality controlandnext-genfiltrationmedia.

With the continued backing of CTMA, CNTA, and Informa Markets, the event ensures global standards, strong industry participation, and valuabletradeoutcomes.

TheEditorialPerspective:FromInnovationto Impact

From an editorial viewpoint, SINCE stands as a beaconofindustryevolution —aplatformthat consistently balances technological progress withmarketrelevance

The 2025 edition is poised to reinforce the exhibition's role as a driver of innovation in Asia's nonwoven sector, particularly as the industry pivots toward sustainability, automation,andhigh-performancematerials

Inanincreasinglyconnectedindustriallandscape, SINCE's true achievement lies in how it brings together vision, technology, and people — shaping a collaborative future for the global nonwovenscommunity.

By the Editorial Desk, Technical Textiles Innovation

Whenhistoryandinnovationintertwine,progress finds its strongest thread. At ITMA ASIA + CITME2025,heldin SingaporefromOctober 28–31,LindauerDORNIERGmbHmarkedits 75th anniversary with an exhibition that celebratedbothlegacyandleadership.

In Hall 2, Stand B401, DORNIER presented a compelling vision of sustainable, digitalised, and automated weaving — proving once again why “Made in Germany” continues to stand for excellence in textile machinery. The company unveiled its latest developments in rapier and air-jet weaving machines, along with advanced IoTsolutionsfornetworkedtextileproduction and systems for fibre composite manufacturing,settinganewbenchmarkforthe futureofintelligentweaving.

“Efficiency, energy savings, and intelligent process monitoring — these define the next chapteroftextilemanufacturing,”saidWolfgang Schöffl, Head of theWeaving Machines Product LineatDORNIER.

This philosophy was reflected across every innovation on display. DORNIER's newgeneration machines are engineered not just for performance,butforpurpose—respondingtothe industry's growing demand for resource efficiency, digital integration, and precision weaving

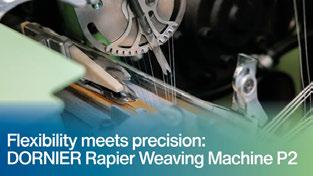

At the heart of their showcase stood two groundbreakingweavingsystems:theP2Rapier Weaving Machine with PIRO technology and the A2 Air-Jet Weaving Machine — both representing quantum leaps in control, sustainability,andproductivity.

DORNIER's PIRO (Pic-a-Pic Release Optimization) system for the P2 Rapier WeavingMachineisaninnovationthatredefines precision.Eachindividualweftinsertioncannow be digitally adjusted with pinpoint accuracy, ensuring optimal release times even for yarns of varyingfinenessandelasticity.

Theimpactisprofound:

Ÿ Reduced weft waste, resulting in material savingsandlowercosts.

Ÿ Enhanced fabric quality, with fewer faults andhigherstructuralintegrity.

Ÿ Fasterarticlechangeovers,asPIROdatacan bestoredandrecalledforeachfabricstyle.

Formanufacturersoftechnicalfabrics—from industrialfiltersandconveyorbeltstogeotextiles and metallic meshes — the benefits are transformative. The system improves reproducibility, reduces downtime, and raises overallproductivity.Availableasaretrofit,PIRO

enables existing P2 machines to evolve seamlesslyintosmartweavingsystems.

“WithPIRO,precisionbecomesprogrammable,” says Frank Seifried from DORNIER's TechnologyCenterWeavingTechnique.“Itisthe nextsteptowarddigitalweavingintelligence.”

DORNIER'snewA2Air-JetWeavingMachine marks a generational shift toward energyoptimized weaving. Based on the company's modular design principle, the A2 integrates electronic air control and intelligent process monitoring to deliver superior efficiency and reducedresourceconsumption.

Keyfeaturesinclude:

Ÿ Redesigned main and relay nozzles, achievingremarkableairandenergysavings.

Ÿ ServoControl-2 touch panel, providing real-time process visualization and air-pressure management.

Ÿ Modular system architecture, offering flexibilityacrossapplications.

From awnings and airbags to tyre cords and carpets, the A2 ensures precision weaving with lowerenergycostsandminimaldowntime.

“Intelligent process monitoring ensures that energy is used purposefully — not wasted,” explains Volker Janke, Product Manager,

WeavingMachines.“TheA2makeseverybreath ofaircount.”

Composites Reinvented: From Fibre to Function

Looking beyond traditional textiles, DORNIER also showcased its advancements in composite production systems — a rapidly growing domain where lightweight strength meets materialintelligence.

Keyhighlightsincluded:

® Ÿ PROTOS TPTapeProductionSystem–for manufacturing unidirectional, fibre-reinforced tapesusingcarbon,glass,oraramid.

® Ÿ PROTOS TWTapeWeavingMachine–for weaving semi-finished thermoset and thermoplasticcompositestructures.

® Ÿ TRITOS PP3DWeavingMachine–enabling three-dimensional composite architectures withunmatchedstructuralstability.

Thesesystemsenableserialproductionofhighperformance composites, driving innovation acrossaerospace,mobility,sports,andmedical industries

By merging DORNIER's precision weaving expertise with the structural demands of modern composites,thecompanypositionsitselfasakey enabler of next-generation materials engineering.

ExpandingHorizons:StrengtheningServicein Asia

In parallel with its technological showcase, DORNIER reaffirmed its commitment to the Asianmarket—aregionthatcontinuestodrive textile modernization and smart manufacturing investments.

Its Chinese subsidiary, ChinDO, now oversees sales and service operations across Southeast Asia, supported by an expanded regional team.

This strategic realignment ensures closer customer engagement, faster response times, and localized support for both weaving and compositesystems.

This initiative underscores DORNIER's longtermvision:tobenotonlyasupplierofmachines butapartnerinindustrialtransformation.

ALeadershipTransitionMarkedbyLegacy

ITMA ASIA + CITME 2025 also marked an emotional milestone for DORNIER's weaving division.

After a decade of leadership, Wolfgang Schöffl willretireattheendoftheyear,passingthetorch to Yvonne Schuberth, a seasoned textile specialistwhopreviouslyledinternalsalesforthe weavingmachinedivision.

Schöffl's tenure witnessed several major innovations — from digital integration to ecoefficient machine design — and his farewell coincides fittingly with DORNIER's 75th anniversaryyear.

“Looking back, we are proud not only of our machines but of the trust our customers have placed in us. DORNIER's legacy is woven from partnerships,progress,andpurpose,”hereflected.

Founded in 1950 by Peter Dornier, son of aviation pioneer Claude Dornier, the company hasconsistentlystoodattheforefrontofmachine andplantengineeringexcellence.

Itslegacymilestonesinclude:

Ÿ 1950s:LaunchofthefirstDoTexloom,setting thefoundationformodernshuttlelessweaving.

Ÿ 1967: Introduction of the world's first shuttleless rapier weaving machine, revolutionizingthetextilelandscape.

Ÿ 1980s: Breakthrough in air-jet weaving technology, integrating Jacquard systems and

enhancing productivity for airbags and technical textiles.

Ÿ Today:Globalleadershipinrapierandair-jet weaving systems for fashion, home, and technicalapplications.

From fine wool suiting to high-strength industrial fabrics, DORNIER machines have become the global benchmark for quality, reliability,andinnovation.

From an editorial standpoint, DORNIER's presence at ITMA ASIA + CITME 2025 exemplified the perfect balance of heritage and forward-thinking innovation. The company's message was clear — sustainability, precision, andintelligencearenolongerseparategoals,but wovenelementsofasinglevision.

As the textile world enters a new era of smart manufacturing, DORNIER's advancements in digital weaving systems and composite technologies reaffirm its role as an industry pioneer — a company that doesn't just build machinesbutbuildsthefutureoffabricitself

“The beauty of weaving lies not only in threads, but in the thinking behind them,” the DORNIER team noted. “And that thinking continues to evolve — intelligently, sustainably, and collaboratively.”

Made in Germany. Designed for the World. DrivenbyPurpose.

As DORNIER celebrates its 75th anniversary, it redefines what precision, partnership, and progressmeaninthemoderntextileera.

Fromthehumofitsrapiermachinestothesilent strength of its composite systems, every innovation echoes a legacy of engineering excellence — and a promise of a smarter, cleaner,andmoreconnectedtextilefuture.

Event Will Amplify the Nonwovens Industry's Voice Amid Legislative Uncertainty in Washington

INDA,theAssociationoftheNonwovenFabrics Industry, is proud to announce the third annual INDAAdvocacy and Fly-In Summit, co-hosted with ISSA, the Worldwide Cleaning Industry Association's Clean Advocacy Summit, taking place March 23–24, 2026, at the Royal Sonesta Washington,D.C.CapitolHill,locatedstepsfrom the U.S. Capitol and Congressional office buildings.

The 2026 event will unite leaders from INDA, ISSA, IICRC, and WSA for two days of highimpactdiscussions,advocacytraining,anddirect engagementwithpolicymakers.

The first day will feature advocacy training sessions, policy briefings, and nonwovensspecificbreakoutdiscussionsdesignedtoprepare INDA members to effectively communicate the industry'sprioritiestolegislatorsandregulators.

On day two, INDA member groups will participate in a “Hike the Hill”, meeting directly with congressional offices to discuss key legislative, trade, and regulatory issues shaping

thenonwovensindustry'sfuture.

“With so much uncertainty happening on Capitol Hill, it has never been more important for INDA members to have their voices heard,” said Tony Fragnito, INDAPresident. “The 2026 Advocacy and Fly-In Summit gives our members a unique opportunity to engage directly with policymakers ontheissuesthatmattermost—fromtheWIPPES Act and tariffs to PFAS and extended producer responsibility proposals. By participating, INDA members help ensure the nonwovens industry's perspective is represented in the decisions that willshapeourfuture.”

EventDetails:

When:March23–24,2026

Where:RoyalSonestaWashington,D.C.Capitol Hill,20MassachusettsAveNW,Washington,DC 20001

To register, visit: https://www.inda.org/indaadvocacy-and-fly-in-summit-cohosted-withissa/

By the Editorial Desk, Technical Textiles Innovation

AttheITMFAnnualConference&IAFWorld Fashion Convention 2025 in Yogyakarta, one start-up captured the imagination of an entire industry. ZymoChem, led by Dr. Harshal Chokhawala,ispioneeringaquietrevolution— transformingthechemistryoftextilesfromfossildependenttofossil-free

Withtherallyingcryto“acceleratethetransition toareal-zeroeconomy,”ZymoChemhasbuiltone of the world's most carbon-efficient biomanufacturing platforms — a breakthrough that could redefine how fibres, coatings, and everydaymaterialsaremade.

Foroveracentury,textilechemistryhasreliedon petrochemicalfoundationsthathaveleftbehinda legacy of microplastics, PFAS, and greenhouse emissions. ZymoChem's approach replaces that legacy with plant-based, low-emission, and cost-competitive alternatives. Using patented microbesandproprietaryfermentationprocesses, the company is now producing bio-based

building blocks for Nylon 6,6, Spandex, and PTTfibres—withouta“greenpremium.”

This innovation holds immense promise for the technical textiles sector, especially for performance-driven applications in hygiene, filtration, and apparel. As global brands like Lululemon and leading fibre manufacturers begin partnerships with ZymoChem, the shift toward 100% plant-based Nylon 6,6 no longer feels like a distant dream — it's unfolding right now.

ZymoChem's impact extends beyond sustainability. Its distributed, scalable model eliminatesthecostbarriersthatoftendeterlargescale adoption of green chemistry. By designing materials “with the end in mind,” ZymoChem is enablingafuturewhereperformance,price,and planetfinallyalign.

From beverages to bio-based fibres, their philosophy is simple yet transformative: Fermentation isn't new — what's new is how it's changingtheworld.

As Dr. Chokhawala remarked, “We're not just replacing fossil materials; we're redesigning the foundationofmanufacturingitself.”

Thetextileindustryhaslongsearchedforawayto balanceinnovationwithimpact.InZymoChem's story, that balance is no longer theoretical — it's measurable,scalable,andinspiringlyreal.

Ÿ The future of textiles won't be extracted — it willbegrown

Editorial Feature | Technical Textiles Innovation | ITMF Start-up Award 2025 –ZymoChem: Building a Real-Zero Textile Future

® Keel Labs Wins RISE InnovationAward for ®Kelsun Fiber

® TheRISE (Research,Innovation&Sciencefor Engineered Fabrics) Conference 2025 brought together the brightest minds in the nonwovens industry — from pioneering scientists to visionary entrepreneurs — under one roof at North Carolina State University's McKimmon Center.Co-hostedbyINDAandTheNonwovens Institute (NWI), this year's edition ignited conversations that are shaping the sustainable, high-performancefutureofnonwovenmaterials.

Withafocusoncircularinnovation,renewable carbon, green chemistry, and breakthrough ® fiber technologies, RISE 2025 stood out as a livinglaboratoryofideas—wheresustainability isn'tjustagoal,butthefoundationofprogress.

® Keel Labs' Kelsun Fiber: A Seaweed RevolutioninSustainableTextiles

® ThecovetedRISE InnovationAward2025was ® presentedtoKeelLabsforitspioneeringKelsun fiber — the world's first high-performance, seaweed-basedfiberengineeredforcommercialscalenonwovenapplications.

® Plastic-free and tree-free, Kelsun sets a new benchmark for material sustainability. Its unique composition offers softness, strength, natural flame resistance, antimicrobial protection, and complete biodegradability — all without shedding microplastics. Designed to integrate seamlessly into existing nonwoven manufacturing, it symbolizes a future where performance and planet coexist in perfect balance.

Other finalists reflected the spirit of innovation ® thatdefinesRISE:

· EsterCycle by EsterCycle LLC — a low-cost, low-emission chemical recycling process capable of safely treating contaminated PPEandmixedpolyesternonwovens,closingthe loopforcriticalwastestreams.

· Fentanyl Detection Wipe by Rockline Industries—apotentiallylife-savinginnovation enabling instant identification of fentanyl traces, protectingfirstrespondersworldwide.

® (Last year's RISE Innovation Award was won by ™ Hempitecture, Inc. for its PlantPanel, a 100% biobased insulation material combining acoustic andthermalefficiencywithsustainability.)

Innovation Through Collaboration:

®HighlightsfromRISE 2025

The conference showcased how collaboration between academia, industry, and start-ups is accelerating the evolution of nonwovens into smarter,greener,andsafermaterials.

Key sessions delved deep into bio-based materials, renewable carbon pathways, circular economy frameworks, and advanced recycling technologies — alongside crucial insights into trade, tariffs, and policy trends shapingtheglobaltextileinnovationlandscape.

KeynoteSpotlights

· Dr. Lars Börger, CEO of nova-Institute GmbH, explored the power of moleculardesign in driving renewable materials and circular businessmodels.

· Dr. John Warner, CEO & CTO of The TechnologyGreenhouse,inspiredattendeeswitha vision for a renewable carbon economy — a system where chemistry and sustainability coengineeraresilientindustrialfuture.

“RISEcontinuestospotlightthetechnologiesthat are redefining what's possible in nonwovens,” said Dr. Matt O'Sickey, INDA's Director of Education & TechnicalAffairs.“From renewable carbon to AI-enhanced fibers, this year's conference showcased the creativity and collaboration shaping a more sustainable future forourindustry.”

Empowering the Next Generation of Innovators

®RISE 2025alsoservedasalaunchpadforfuture talent, with over 30 graduate students

presenting research that ranged from biodegradable composites to advanced filtration materials. Through poster sessions, tabletop exhibits, and mentorship dialogues, the event bridged the gap between emerging science andreal-worldindustrialapplication.

Complementing the conference was a charity golftournamentsupportingstudentparticipation in INDAevents, as well as a guided tour of The Nonwovens Institute's $65+ million pilot lines and analytical labs — where next-generation materials move from prototype to proof of concept.

®LookingAhead:RISE 2026

Asthe2025editionclosedonanoteofoptimism ® anddiscovery,attendeeslookedforwardtoRISE 2026, set to returnto the McKimmon Centerin Raleigh, North Carolina, on August 25–26, 2026.

® With each passing year, RISE continues to strengthen its position as the premier global platform for sustainable innovation in engineered fabrics — a place where science meets imagination, and where the materials of tomorrowareborntoday.

From seaweed-based fibers to molecular ® innovation, RISE 2025 was not merely a conference — it was a movement toward a circular future. The breakthroughs unveiled in Raleigh reaffirm one truth: sustainability is no longer a trend; it is the new engine of competitiveness and creativity in the world of nonwovens

March 23–25, 2027 | Kansas City Convention Center, Missouri

The global nonwovens and engineered materials

® industryisalreadysettingitssightsonIDEA27, INDA'sflagshipinternationaleventthatpromises to redefine the boundaries of innovation, collaboration, and commercial success.

Scheduled from March 23–25, 2027, at the Kansas City Convention Center, this edition ® marks a milestone in the evolution of IDEA — where business, sustainability, and breakthrough technologyconverge.

Organized by INDA, the Association of the ® Nonwoven Fabrics Industry, IDEA27 stands

asthelargestandmostinfluentialgatheringfor professionals,innovators,andleadersshapingthe futureofengineeredfabricsacrossdisposableand durableapplications.

®“IDEA is where business gets done,” affirmed Tony Fragnito, INDA President & CEO. “Our move to Kansas City reflects INDA's commitment to listening to our customers — a world-class event in a world-class city that combines affordability, accessibility, and opportunity.”

Introducingthe“DurablesDistrict”—ANewEraforLong-Life Nonwovens

AdefiningfeatureofIDEA27isthelaunchofthe Durables District, a dedicated showcase spotlighting innovation in long-life nonwovens and engineered fabrics. Designed to connect manufacturers,machinerysuppliers,andsolution providers across automotive, construction, filtration, geotextiles, and industrial sectors, this new zone gives durable applications the attentionandvisibilitytheydeserve.

From next-generation geotextiles to smart filtration systems, exhibitors in the Durables District will be at the epicenter of conversations driving sustainable durability, circular materials,andhigh-performancedesign. StrongDemand,HighMomentum

® Excitement for IDEA27 is already surging — with 50,000 square feet of exhibit space

reserved during pre-sales. “Interest has been fantastic,” noted Dan Noonan, INDA's Director of Business Development & Membership.

® “ExhibitorsseethevalueinbeingpartofIDEA. We encourage companies to act fast to secure primelocationsbeforethefloorsellsout.”

Theenergyispalpableasbothglobalbrandsand emerginginnovatorspreparetounveiltheirlatest advancements in nonwovens, engineered materials,andmachinery.

In 2027, Kansas City, Missouri, will welcome ®IDEA for the first time — a move inspired by industry feedback for a more budget-friendly andconnectedhostcity.KansasCitydeliverson everyfront:

Ÿ Cost-Effective: Competitive rates for labor, hotels,anddining—enhancingexhibitorROI.

Ÿ CulinaryExcellence:Recognizedby Forbes foritsdynamicfoodandhospitalityscene.

Ÿ Walkability: Hotels, restaurants, and the convention center all within easy walking distance.

Ÿ World-Class Host City: Refreshed infrastructure following the 2026 FIFA World Cupand2027NCAASweet16&Elite8events.

Ÿ Vibrant Sports & Entertainment Hub: Home to the Kansas City Chiefs, Royals, and Jazz, ensuring visitors enjoy a complete experiencebeyondtheshowfloor.

® BuildingontheSuccessofIDEA25

® Thepreviousedition,IDEA25inMiamiBeach, attracted over 550 exhibitors and 5,300 professionalsfromacrosstheglobe—allunited by a shared vision of accelerating innovation in engineered materials. Participants praised its unmatched business value and access to senior decision-makers.

® IDEA27aimstotakethatsuccesstoevengreater heights — leveraging a new venue, a fresh industryfocus,andtheadditionoftheDurables Districttodrivestrongercollaborationsandmore impactfuloutcomes.

PlatformforaFuture-Driven Industry

With sustainability, circularity, and technology

® converging faster than ever, IDEA27 will serve astheindustry'slaunchpadforthenextgeneration ofmaterialsandapplications.

It's more than an exhibition — it's a movement shaping the future of performance, efficiency, andenvironmentalresponsibilityinnonwovens andengineeredfabrics.

® “IDEA27 is not just about showcasing innovations,” said Fragnito. “It's about creating theconnectionsthatmakeinnovationthrive.”

Withrecord-breakingdemandalreadyunderway, ® exhibit reservations for IDEA27 are open now.

Toreserveaboothorsecurepremiumplacement, visit http://www.ideashow.org/ or contact INDA'sexhibitionteamatsales@inda.org

From Miami's momentum to Kansas City's ® promise,IDEA27representsaboldstepforward — proving once again that when the nonwovens industry gathers under one roof, innovation doesn'tjusthappen;itaccelerates.

® IDEA27isn'tjustthenextbigevent—it'swhere the future of engineered materials will be imagined,built,andshared.

At the crossroads of science and sustainability, a newchapterintextilecircularityisbeingwritten —onedefinednotbywaste,butbyrenewal.

In a groundbreaking collaboration bridging TaiwanandFrance,FarEasternNewCentury Corporation (FENC), Carbios, and Salomon have joined forces to pioneer the world's first biological recycling of PET/polyester — a project that has earned them the ITMF InternationalCollaborationAward2025.

Together, they have proven that with the right chemistry — and the right collaboration — the textileindustrycanreimagineitsrelationshipwith plasticforever.

The Science of Circularity: Turning PET WasteBackintoPurity

Atthecoreofthispartnershipliesarevolutionary process: enzymatic recycling of PET — a method that uses nature's own tools to close the textileloop.

While traditional chemical recycling relies on heat, solvents, and catalysts to break down PET

into its monomers (PTA and MEG), biological recycling goes a step further — employing enzymestogentlydepolymerizepolyesterunder mild,water-basedconditions.

Ÿ High selectivity and purity of recovered monomers, suitable for reuse in textile manufacturing.

Ÿ Lower energy demand, no toxic byproducts,andasignificantlysmallercarbon footprint

This innovative approach allows discarded fabrics and plastic bottles to be reborn as new, high-quality textile fibers — without compromisingperformanceoraesthetics.

FromBottletoFibertoFashion—TheWorld's FirstFabric-to-FabricT-Shirt

The collaboration made headlines at TITAS 2020, where FENC unveiled its TopGreen® ChemCycleproduct—theworld'sfirstchemical recycling-basedT-shirtmadeentirelyfromused polyesterfabric.

But the real breakthrough came in April 2025, whenCarbiosandFENCannouncedtheworld's first batch of T-shirts created through enzymatic recycling of PET — a milestone in bothtechnologyandsustainability.

“This innovation demonstrates that circularity is achievable at scale when science and industry uniteforasharedpurpose,”saidDr.FannyLiao, ExecutiveVicePresidentofR&DatFENC.

From Apparel to Footwear: The Salomon Connection

The success of the T-shirt project sparked a new frontier — a partnership with Salomon, the French sportswear and outdoor performance

brandknownforitsinnovationandenvironmental responsibility.

Together, FENC, Carbios, and Salomon unveiled the world's first shoe uppers made fromenzymaticallyrecycledPET,showcasedat ParisFashionWeek(January2025).

And the innovation didn't stop there. Leveraging chemical recycling, FENC transformed PET bottles into rTPEE midsoles for Salomon's Solamphibian shoes — marking the first commercial launch of footwear components derivedentirelyfromrecycledpolymers.

This achievement signifies more than just technical success — it's a proof of concept that fashion, function, and sustainability can coexistbeautifully.

What sets this initiative apart is not just its technological brilliance, but its collaborative spirit

FENC brought its decades of polymer science expertise and large-scale fiber production capabilities.

Carbios contributed its cutting-edge enzymatic depolymerization technology — a solution that breaksPETintopuremonomersreadyforreuse.

Salomon,inturn,providedaplatformtotranslate theinnovationintorealconsumerproducts— closing the loop between science, industry, and lifestyle.

Together, the trio demonstrated a circular ecosysteminaction—fromdiscardedpolyester wastetonew-generationfashionproductsthatare infinitelyrecyclable.

The FENC × Carbios × Salomon collaboration

has redefined what's possible for the textile and apparel industry. It goes beyond recycling — it's aboutreinventingmateriallifecycles,restoring environmentalbalance,andrenewingindustry ethicsthroughinnovation.

By proving that biological recycling can operate atanindustrialscale,thesepartnershavelaidthe foundation for a global shift toward enzymepoweredcircularmanufacturing—onewhere textiles are not the end of consumption but the beginningofregeneration.

“Empowering possibilities and providing solutionsforabettertomorrow—thatisFENC's vision,”saidDr.Liao.

“We're not just recycling materials; we're redesigningthefuture.”

The 2025 ITMF International Collaboration Award recognizes a true milestone in textile innovation — one where science meets sustainability, and collaboration becomes the catalystfortransformation.

FENC,Carbios,andSalomonhaveilluminateda newpathfortheglobalfiberindustry—proving that the future of polyester is not petroleumbased,butbiology-based

Intheirstoryliesapowerfulmessagefortheentire textileworld:

When industries collaborate with courage and conscience, waste becomes a resource — and sustainabilitybecomesreality.

Editorial Report Inspired By The Presentation

By Dr. Fanny Liao, Executive Vice President (R&D & BD), Far Eastern New Century Corporation (FENC) — Winner Of The ITMF International Collaboration Award 2025 For Its Pioneering Biological Recycling Of PET/Polyester Project With Carbios (France) AndSalomon(France).

Technical Textiles Innovation is a leading quarterly magazine dedicated to the growing world of technical textiles. It offers in-depth coverage of innovations across segments like geotextiles, medical textiles, protective wear, automotive textiles, and smart fabrics. Each issue features expert articles, market trends, sustainability insights, and interviews with key industry players. Distributed globally at major exhibitions and directly to decision-makers, the magazine is a trusted resource for and innovators. With a strong focus on technology, sustainability, and market opportunities, Technical Textiles Innovationplaysakeyroleinadvancing thefutureofthetechnicaltextileindustry