Editorial

ArchromaLaunchesTheFirstTrulyDurableSiliconeSoftenerForCottonThatStays SilkySoftForLonger

Stable&SustainableAdditivesforCoatingsandInksManufacturing

LucasMeyerCosmeticsadvancessustainabilitywithdualmilestoneachievements

Clariant'sHAIRMONISTconcept-anewwayforpersonalizedhaircareformulations

BeyondCarnauba:Clariant'sreliablebio-basedwaxforresilientprintinginksand premiumapplications

SustainableFinishingRevolution:HowArchroma,BWConverting&MonfortsAre ShapingtheNextEraofTextiles

Arvind,H&MGroup,andDevenSupercriticalsinaugurateIndia'sfirstsupercriticalCo₂ dyeingmachine,abreakthroughinsustainabletextilemanufacturing

Archromawins2025ITMFSustainability&InnovationAwardfor distresseddenimbreakthrough

WithitsFR3compounds,KRAIBURGTPEissettingnewstandards

SyensqolaunchesEasysoftPA,abio-basedadditivedesignedtoenhancethesensorial experience

byfabricsofteners

editor-in-chief

Prakashkinny

contributor

ThomasChang

circulation

PamelaJones

administration

JoePereira

accounts

RameshJain

photography

TonyFernandes

RetailPrice:Rs.150.00

InsideIndia

Annualsubscription:Rs.600.00

OutsideIndia

AnnualSubscription:US$30.00

editorial office

DYESCHEMICALSANDCOLOURTECHNOLOGY

House No. 157, Satpala, Bhandra Lee

Post: Agashi, Tal: Vasai

Dist: Palghar (401 301)

State: Maharashtra, INDIA

Mobile: +91-7798189485/09892723562

Email:info@timesinternational.in prakashkinny@yahoo.com

www.timesinternational.in

JAPAN

KatsuhiroIshii

MediaRepresentative

ACEMEDIASERVICEINC. 12-6,4-chome,Nishiiko,Adachi-ku, Tokyo121-0824Japan

Tel:81-3-5691-3335Fax:81-3-5691-3336 amskatsu@dream.com

TAIWAN,R.O.C

Kenlychang

BUILDWELLINTERNATIONALENT.,CO.,LTD.

HeadOffice:No.120,Huludun2ndSt., FongyuanCity, TaichungCounty42086,Taiwan,R.O.C

Tel:886-4-25123015Fax:886-4-25122372

E-mailaddress:buildwel@ms23.hinet.net

India,Pakistan,Bangladesh,Srilanka,Vietnam,Indonesia,Thailand, China,HongKong,USA,Germany,Spain,Italy,U.K.&France

India'sDyes,Chemicals&ColourTechnology: BuildingtheNextGlobalChapter

India's dyes and colour chemicals industry today standsatadecisiveturningpoint.Withalegacyrooted intextileexcellenceandascalethatplacesthecountry amongtheworld'stopproducersofreactive,disperse, andvatdyes,thesectorcontinuestoplayavitalrolein poweringIndia'stextilevaluechain.Strongdomestic demand,risingexportcapabilities,andthepresenceof integrated chemical clusters across Gujarat and Maharashtra have positioned India as a dependable global supplier. Yet, the industry is navigating a rapidly changing landscape shaped by sustainability mandates, global compliance requirements, and the shifttowardsgreenermanufacturing.

Recentadvancementsincolourtechnology—suchas low-liquor-ratio dyeing, digital print inks, and highperformance auxiliaries highlight the sector's readiness to innovate. Indian manufacturers are increasingly investing in R&D, automation, and effluent-reduction technologies to meet the growing expectations of brands and regulatory bodies Collaborativeinitiativesaroundzero-liquid-discharge systems, bio-based dyes, and circular chemistry models are helping the industry reimagine its environmentalfootprint.

Lookingahead,Indiahasthepotentialtoemergeasa globalcolourinnovationhub.Thenextdecadewillbe defined by cleaner chemistry, AI-driven colour prediction systems, and stronger integration between dyes producers, textile mills, and sustainability technology providers With the government encouraging scale, compliance, and exports, the industry is well-placed to capture opportunities arising from China+1 sourcing strategies and global textileexpansion.

India's dyes and colour technology sector is not just evolving—itispreparingtolead.

®

Industry-firstbreakthroughdeliverslonger-lasting softnesssogarmentsremaininactiveuseforlonger.

Archroma, a global leader in specialty chemicals towards sustainable solutions, today launched

®SILIGEN D2WLIQC,theindustry'sfirsttrulydurable silicone softener for cellulosic as well as cotton-lycra blended knits. Designed to keep the fabric soft and elastic for an extended usage, it is ideal for textile and fashion applications where long-lasting comfort and breathability are important, from undergarments and sleepwear to baby and children's clothing, dresses and trousers,activewear,T-shirtsandtowels.

Strongandabsorbent,cottonandothercellulosicfibers are among the most widely used premium materials in thetextileandfashionindustry.Toachievethesoftand luxurious handfeel that consumers expect, manufacturers commonly have to add a silicone softener during fabric finishing. In the past, it was necessary to choose between a durable softener that negatively impacted the natural absorbency of the cotton fiber or a softener that preserved the fiber's ability to hold moisture but also soon washed off throughhomelaundering.

® Archroma'snewSILIGEN D2WLIQCwasdeveloped to overcome these challenges and produce fabrics that maintain their absorbency and their silky smooth feel

® for longer, extending their use life. SILIGEN D2W LIQCimpartsanexcellent,andhighlydurablehandfeel while maintaining the natural absorbency of cotton. It alsohasminimumsideeffects,includingnoyellowing orphenolicyellowing,andisalsocompatibleevenwith anioniccomponentsandeasy-careresinsextendingthe range of possible combinations for functional finishes includingcrease-resistance.

DhirendraGautam,VPGlobalMarketingandStrategy, Archroma,said,"Archromaiscommittedtoinnovation thatfurthersourplanetconsciousvisionofthefutureof the apparel and textile industry As our brand partners increasingly design for longevity, they want to offer garmentsthatremainluxuriousandcomfortabletowear ® over a longer life. SILIGEN D2W LIQ C is a breakthroughinnovationthatenablesanewapproachto softening. By enhancing both durability and cotton handfeel,itreducestheneedforfrequentreplacement ofgarmentstoconserveresources,minimizewasteand lessentheenvironmentalimpactoftheindustry."

®SILIGEN D2W LIQ C is based on a new patent-

pendingchemistryfromArchromacalledmicro-x.Itis a cross-linkable microemulsion that forms a stable silicone network within the cellulosic fibers, ensuring moreuniformdistributionofthesoftenerandlockingit intomaintainsoftnessovertimewhilebringingwashresistance.

Inadditiontodevelopingthenewsiliconesoftener,the Archromaresearchersalsohadtofindawaytomeasure thedurabilityofhandfeelinanobjectiveway.

"Handfeel was previously evaluated through human perception and expert opinion, but this does not align with our efforts to improve the transparency of the textile value chain and support mills and brands in meeting their sustainability goals," Michael Schuhmann, Global Marketing Manager Finishing, ArchromaTextileEffects,said."Wediscoveredthatwe can measure the elastic recovery added to the knitted fabricbythesiliconefinishandtrackitthroughmultiple launderings to prove its durability. This enables mills and brands to more accurately quantify handfeel durabilityforthefirsttime."

Watch the video on the first truly durable silicone softenerforcotton.

Archroma launches the first truly durable silicone softener for cotton that stays silky soft for longer:

®SILIGEN D2WLIQC. (Photo:Shutterstock)

® Trademark of Archroma registered in many countries.

©2025Archroma

Beyond carnauba: bio-based waxes redefining stabilityandsustainabilityincoatings&Inks

Globaltradeconditionsarechangingrapidly.From seasonalcropriskstonewtariffsandsupplychain constraints,thereliabilityoftraditionalwaxessuch ascarnaubaisdecreasing.Thisvolatilitycomesata costforcoatingsandinksmanufacturers.

"When trade conditions change, your wax supply shouldn't,"saysMarianoSuarez,Clariant'sHeadof MarketingforAdditives."Ourbio-basedsolutions, ™ built on the innovation-driven Licocare RBW Vitaplatformandenhancedbynewdevelopments ™ such as Ceridust 1150, deliver stability, sustainability, and high performance. Together, they offer our customers a reliable choice in coatingsandinks."

Q1:What macro shifts are putting pressure on traditionalwaxsupplychains?

MarianoSuarez:Traditionalwaxsupplychainsare under growing pressure due to concentrated sourcing,seasonallimitations,andevolvingglobal trade dynamics. Carnauba wax, for example, is harvested almost exclusively in Brazil. Its availabilitycanfluctuateduetoclimateconditions and regional factors.As tariff frameworks change inkeymarketssuchastheUS,manufacturersface greater complexity in planning and costs. These changes are prompting many manufacturers to reevaluate their material strategies and seek more stableandscalablealternatives.

Q2: How is Clariant helping manufacturers within the coatings industry manage volatility whilealsoadvancingsustainability?

Mariano Suarez: We've invested in stable, highperforming alternatives that address supply chain challengesdirectly OurLicocareRBWVitawaxes

aresourcedfromnon-ediblericebran,anabundant agricultural byproduct with a secure, diverse supply chain across Asia. They deliver the performance customers expect while offering a renewable carbon index of over 98%, zero PFAS content,andupto80%lowercarbonfootprintthan fossil-based waxes. Because they avoid the seasonal, location-specific risks of carnauba, manufacturers not only gain measurable sustainability benefits but also a more consistent andscalablesupplybase.Inanenvironmentwhere tariffsandmarketrealitiescanshiftovernight,that combination of stability and sustainability makes allthedifference.

Q3: Ceridust 1150 is a new addition to your portfolio.Whatdoesitbringtothetable?

MarianoSuarez:Ceridust1150,ourlatestricebran wax-basedadditive,combinesreliablesupplywith high performance for coatings and ink applications. It supports the transition away from fossil and montan waxes while avoiding the volatilityofotherwaxeswithoutcompromisingon functionality. The product delivers excellent scratchresistance,glosscontrol,andanti-blocking properties, exactly what customers expect from a high-end wax additive. And for those who want more information, our technical experts are ready toshareinsightsintotheuniqueadvantagesofrice branwax.

Q4: Are customers ready to move away from traditionalwaxes,andwhat'sdrivingthatshift?

Mariano Suarez: Absolutely. There's strong momentum behind this shift. Customers are looking for sustainable, reliable, long-lasting ingredients. They understand that supply chain uncertainties are becoming the norm and want to proactively reduce risks. Meanwhile, growing

regulations surrounding PFAS and emissions are propelling the industry toward more transparent solutions, exactly where Clariant's expertise and innovative wax alternatives come into play to supportasmoothtransition.

Q5:AnyfinalthoughtsonhowClariantseesthe futureofperformancewaxes?

Mariano Suarez: Performance alone is no longer enough. What matters is purposeful performance thatisdeliveredreliably,sustainably,andatscale. That'spreciselywhatweofferwiththeestablished Licocare RBW Vita range and our new Ceridust 1150. We're not waiting for the next disruption. We'redevelopingsolutionsthatwilloutlastit.

Readytofuture-proofyourwaxsolutions?

Ÿ Explore Licocare Rice Bran Waxes for Coatings&Inks

Ÿ LearnmoreaboutCeridust1150

Ÿ Discoverhowricebranwaxesarereplacing carnaubainhigh-performanceapplications

Clariant is a focused specialty chemical company led by the overarching purpose of "Greater chemistry – between people and planet." By connecting customer focus, innovation, and people, the company creates solutions to foster sustainability in different industries. On 31 December2024,Clarianttotaledastaffnumberof 10465andrecordedsalesofCHF4.152billionin thefiscalyearforitscontinuingbusinesses.Since January 2023, the Group conducts its business through the three Business Units Care Chemicals, Catalysts,andAdsorbents&Additives.Clariantis basedinSwitzerland.

Theproductsdescribedhereinareforcoatingsand inksuseonly.

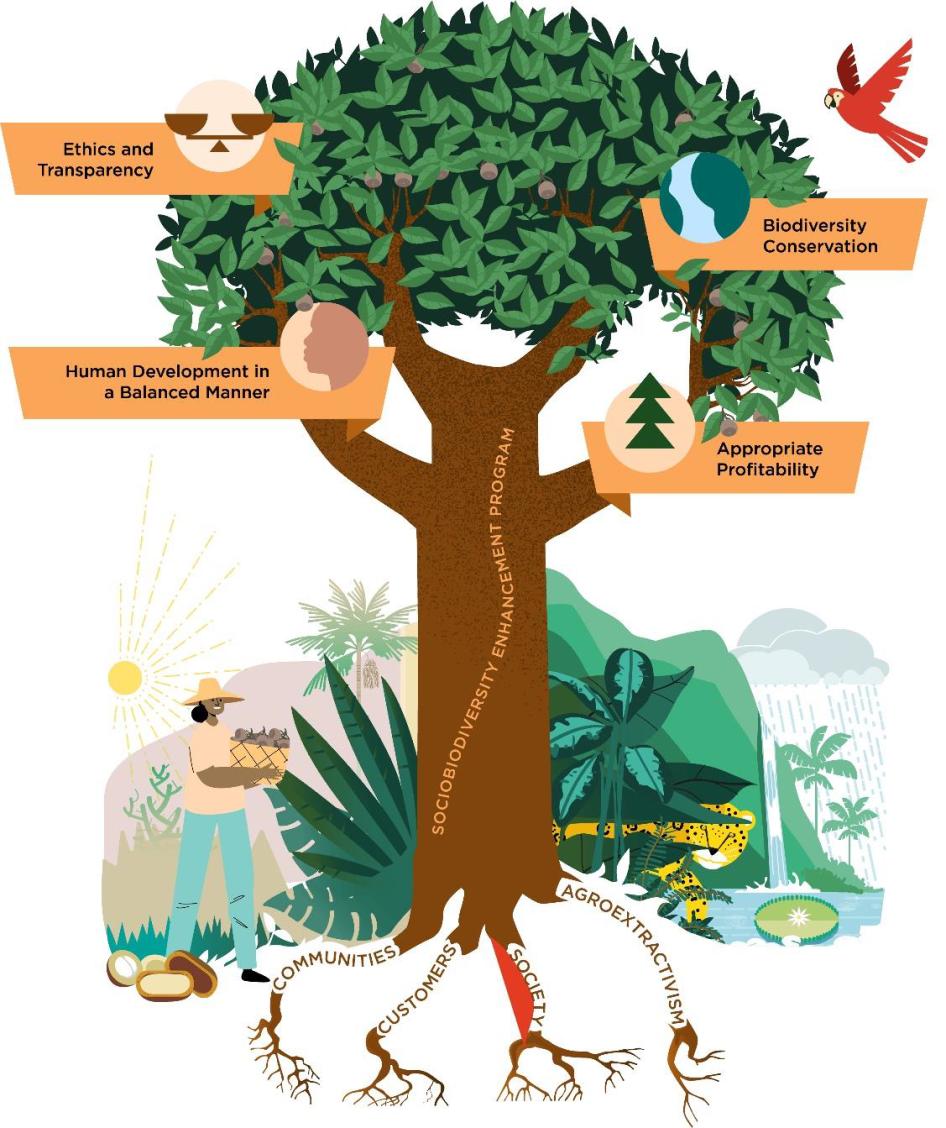

Ÿ Lucas Meyer Cosmetics by Clariant unveils ambitious2030sustainabilitygoalsforitslecithin platform, targeting 100% non-GMO soy derivativesandzerodeforestation

Ÿ Company celebrates 25th anniversary of ™ pioneering Beraca Socio-biodiversity EnhancementProgram,supporting14,000families across36Braziliancommunities

Ÿ Both initiatives demonstrate Clariant's longterm commitment to responsible sourcing and environmental stewardship in the cosmetics industry

FromtheAmazonrainforesttolaboratorybenches, Lucas Meyer Cosmetics by Clariant is transforming the cosmetics industry with two sustainabilitymilestonesthatblendenvironmental protection with community empowerment. The company is reinforcing its enduring commitment to responsible sourcing and environmental stewardship with ambitious new 2030 sustainabilitygoalsforitslecithinplatformandthe celebration of 25 years of the pioneering Beraca Socio-biodiversityEnhancementProgram.

Clariant is celebrating the 25th anniversary of the BeracaSocio-biodiversityEnhancementProgram, a pioneering initiative that has been creating positive socio-biodiversity impact and empowering communities across Brazil for a quarter century. Since acquiring Beraca in 2021, Clarianthascontinuedtostrengthenthisprogram, which now operates in 11 Brazilian states and 36 communities, supporting approximately 14,000 families.

"The Beraca Socio-Biodiversity Enhancement Program exemplifies how business success and environmentalprotectioncanworkhandinhand," said Flavia Igreja, Product Line Manager for Beraca at Clariant. "After 25 years, this initiative continues to demonstrate that economic empowerment is fundamental to conservation efforts."

The program has created sustainable economic opportunities for local populations by providing alternativeincomesourcesthatreducerelianceon deforestation-related activities.This approach has

successfully bridged local communities with global markets while conserving Brazil's rich biodiversity The 25th anniversary of this groundbreakingprogramwillbehighlightedatincosmeticsLataminlateSeptember2025.

Atthesametimethenewsustainabilitystrategyfor Lucas Meyer Cosmetics' lecithin platform builds on 25 years of expertise in cosmetic ingredients derivedfromlecithin.

By 2030 the business has committed to offering 100%soy-basedderivativesfromguaranteednonGMO soy and ensuring at least 80% of its soylecithin-based ingredients are obtained from responsibly sourced soy backed with 3rd party certification.Critically,theinitiativealsoincludes a zero-deforestation commitment, striving to ensuretheentiresoysupplychainoriginatesfrom areaswhereforestsremainprotected.

"This commitment represents a significant step forwardinoursustainabilityandlecithinplatform journeys," said Isabelle Lacasse, Head of Global Marketing, Product Line Management & FormulationatLucasMeyercosmeticsbyClariant. "We'vealreadyadaptedourproductionandsupply chains capacities to achieve this objective, demonstrating our dedication to raising industry standards."

The lecithin platform strategy focuses on enhancing supply chain transparency and traceability while systematically reducing environmental and social risks. Lucas Meyer Cosmetics and its suppliers are committing to responsible practices and encouraging third-party certifications such as ProTerra. This initiative builds on Clariant's broader supplier engagement program, which for example includes the membership in the Action for Sustainable Derivatives(ASD).

Lucas Meyer Cosmetics' lecithin expertise spans both functional and active ingredients, supported by a specialized formulation team that helps customers successfully incorporate these responsiblysourcedingredientsintotheirproducts. This technical expertise, combined with the

company's sustainability commitments, positions Clariant as a leader in responsible cosmetic ingredientsourcing.

These dual initiatives underscore Clariant's ongoing commitment to sustainability as a core strategic pillar, continuously improving processes and sourcing practices to deliver cosmetic ingredients that exceed industry standards for responsible and ethical sourcing. By focusing on

both environmental protection and community empowerment, Clariant demonstrates that m

comprehensive approach that addresses both ecologicalandsocialdimensions

Visitorsto in-cosmetics LatinAmerica 2025 can learn more about Beraca and the programs firsthandatboothno.L30.

Ÿ Clariant launches HAIRMONIST, an innovative hair care concept combining personalization, wellness, and natural hair movement

Ÿ Ingredient portfolio including ™ ™ GlucoTain and Genadvance lines enables brands to create customized formulations that meetdiverseconsumerneeds

Ÿ Official debut at in-cosmetics Latin America 2025 showcases how Clariant's solutions empower formulators to develop personalizedhaircareexperiences

Clariant has unveiled HAIRMONIST: The Hair Symphony, a new hair care concept that harmonizes personalization, sustainability, and sensory experiences to meet evolving consumer demands.DevelopedbyClariant'sLatinAmerican team, this new approach demonstrates how the company's specialized ingredients enable beauty brandstocreatecustomizedhaircaresolutions.

The HAIRMONIST concept addresses the growing consumer desire for personalized beauty experiences that combines individual values and needs. With Clariant's extensive portfolio of ingredientswithahighshareofrenewablecontent, formulators can now develop tailored hair care productsthatdeliverbothexceptionalperformance and environmental responsibility One example in ™ this range is Plantasens Olive LD & SP ECO whichservesasnaturalalternativestosilicones.

"Today'sconsumersexpecthaircareproductsthat are as unique as they are," said Diana Gaitan, Marketing Manager Personal & Home Care at Clariant "With HAIRMONIST, we are showcasing how our ingredients can be orchestrated to create personalized formulations that deliver outstanding performance and answer the growing demand for natural beauty solutions. Beyond functionality, this concept embodies our commitmenttohelpingbrandsdesignproductsthat forge a deeper emotional connection with consumers."

At the heart of the HAIRMONIST concept is Clariant's comprehensive range of renewable-

basedingredients,includingtheGlucoTainlineof mild surfactants, which offers excellent cleansing properties while maintaining the natural moisture balance of hair and scalp. The Genadvance line provides targeted conditioning and protection benefitsthatcanbecustomizedtoaddressspecific hair types and concerns, from damage repair to colorprotection.

"Theversatilityoftheseingredientsystemsallows especiallyregionalformulatorsinLatinAmericato createproductsfordiversehairtypesandconcerns. ™ Innovative combinations of Aristoflex and Genadvance create unique sensory experiences that enhance the emotional connection between consumers and their hair care routines, transforming daily hair care into moments of wellness," explained Luciana Rodrigues, Head of Application Development Personal Care at Clariant,Americas.

Visitorstoin-cosmeticsLatinAmerica2025will experiencetheHAIRMONISTconceptfirsthandat booth no. L30, with technical experts available to discuss formulation challenges and help brands translateconsumerinsightsintoinnovativeproduct concepts.

Clariant'sHAIRMONISTconcept-anewwayfor personalized hair care formulations. (picture: AIgenerated)©Clariant

Howcanyouachieveflawlessaestheticsandhighperformance functionality in inks and coatings while meeting the world's demands for greater sustainability, transparency and supply chain resilience?

For decades, carnauba wax and its blends, often combined with polymers, have been the trusted choice for delivering high-quality finishes in printinginksandpackaging.However,asanatural, seasonal material, carnauba wax is subject to unpredictable supply fluctuations that are increasingly challenging production schedules, particularly in the US market where tariffs are furtherexacerbatingavailabilityandcosts.

The pressure is now on manufacturers and formulators to urgently find reliable, highperforming and sustainable alternatives. This growing uncertainty is driving a wave of innovation,unlockingnewbio-basedsolutionsthat meet performance demands while reducing environmentalimpactandsourcingrisk.

This market situation highlights the critical importance of reliable, high-quality, bio-based ™ alternatives such as Ceridust 1310, which can help businesses maintain performance and continuity amid economic and regulatory pressures. Ceridust 1310, a bio-based wax compound, that comes in the form of micronized ricebranwaxandachievesameltingpointofover 120°C and excellent rub resistance. It encourages the potential of rice bran wax to offer greater consistency,andClariantisworkingtostrengthen

thisfurther.

"It's about expanding formulation options with a reliable, bio-based alternative to help ensure consistent quality despite market fluctuations," explains Simon Bodendorfer, Application DevelopmentManagerofCoatingsandInks.

Ceridust1310isahigh-performancewaxadditive based on a carefully selected blend that includes rice bran wax: a renewable, non-food-competing byproductofagriculture.Designedtomeetmodern formulationneeds,itoffersareliablecombination of sustainability, consistency, and process efficiency, helping formulators reduce variability andenhancetheenvironmentalprofileofcoatings andinks.

Ceridust 1310 ensures stable, batch-to-batch quality that supports consistent performance and minimizes material waste. With its renewable content, it contributes to reducing reliance on fossil-basedmaterials.

Applications across premium printing and packaging

The versatility of these new wax technologies makesthemsuitableformanyhigh-enduseswhere appearanceandperformancematter:

Ÿ Premiumpackagingwithmattefinishes

The matting properties create the elegant, understatedlookluxurybrandsexpect.Consistent quality ensures packaging meets strict standards acrossbatches.

Ÿ Glossymagazines

For publications that demand sharp images and durability, these additives offer excellent rub resistance at low doses (0.2–1%), protecting vibrantvisualswhilekeepingproductionefficient.

Ÿ Specialtylabels

Labels need to withstand handling, shipping, and various environments while staying visually appealing. Advanced waxes provide durability withoutsacrificinglook.

Ÿ Water-basedtopcoats

Astheindustryshiftstowardwater-basedsystems,

these waxes perform well in formulas that require strongscuffresistanceandclarity

Easytoformulate,easiertoadopt

Transitioning to new additives doesn't have to mean reworking entire formulations or disrupting production. Ceridust 1310 is designed for easy integration. It works effectively in common systemsatlowdosagelevels(0.2–1%forprinting inks and up to 4% for coatings). Its compatibility allowsformulatorstoadoptitgradually,replacing carnauba or synthetic waxes without significant changes to existing processes while gaining flexibilityandsustainabilitybenefits.

What'snext?

Bio-basedwaxadditivesarepartofabiggershiftin the industry. Rather than simply replacing old ingredientswithnewones,Clariantiscontinuously developingsmartersolutionsthatperformwell,are moresustainablethanfossil-basedalternativesand can be produced on a large scale. For formulators seeking control, supply security and stronger environmental alignment, the future isn't about compromise; it's about achieving greater chemistry.

Youcanaccesstheaudioversionoftheblogatthe officialwebsiteofClariant.

BeyondCarnauba:Clariant'sreliablebio-basedwax forresilientprintinginksandpremiumapplications.©Clariant

RedefiningtheFutureofTextileFinishing:From Resource-IntensivePasttoSustainablePathways

AGlobalDialogueonChange

On 18 September 2025, the VDMA Textile MachineryWebtalkbroughttogetherinnovators, sustainability leaders, and technology providers from around the globe. With participants from morethan40countries,thesessionspotlightedthe urgentneedtorethinktextilefunctionaliza tionandfinishing—movingawayfromwaterand energy-intensive legacy systems towards modern,resource-savingconcepts.

Speakers from Archroma, BW Converting, and Monforts shared practical solutions that blend performance, sustainability, and costeffectiveness—laying down a vision for a textile industry aligned with the world's climate andcircularitygoals.

Responsibility

Archroma's Michael Schuhmann emphasized that textiles must deliver comfort, durability, and protection, but not at the expense of the environment.Traditionalfinishingreliesonheavy water consumption, high energy loads, and residual waste, particularly in forced impregnation(padding)methods.

Archroma presented spray-based, non-contact applicationtechnologies,which:

Ÿ Cutwaterdemandbyupto60%

Ÿ Reduce energy consumption and CO₂ emissions

Ÿ Enable functional finishes—softening, moisturemanagement,flameretardancy,andwater repellence—withoutharmfulchemistries.

Their next-generation products, such as ® ® SILIGEN for softness, SMARTREPEL PFAS-free repellents, and zero-formaldehyde easy-care resins, prove that sustainability and performancecancoexist.

BW Converting: Precision Spray as a GameChanger

RickStanfordfromBWConvertingunveiledhow precision spray technology isreplacingoutdated “dip-and-squeeze” methods. Traditional padding often wastes over 10% of finishing chemicals, drives high effluent volumes, and requires heavy energyfordrying

BW'sTexCoatG4systemintroduces:

Ÿ Non-contact, uniform spray with zero contamination

Ÿ Upto71%chemicalsavingsand26%water reductioncomparedtopadding

Ÿ 20–30% faster production speeds with lowergasandelectricityusage

This leap demonstrates how efficiency and ecofriendliness reinforce one another, offering millsbothsustainabilitycredentialsandsignificant costsavings.

Monforts: Energy Efficiency & Hydrogen Horizons

Monforts,representedbySaskiaKuhlenandHans Wroblowski, outlined new ways in textile finishing with innovations designed for integrationintoexistingplants

Highlightsincluded:

Ÿ Eco Applicator & coaTTex systems –enabling water and energy savings through kisscoatingandknife-coatingtechniques.

Ÿ MONTEX stenter frame upgrades – from optimized nozzles to insulation and heat recovery systems, delivering higher speeds and reduced energydemand

Ÿ Hydrogen trials at Monforts ATC (Aug 2025)–pioneeringtheuseofhydrogenburnersin textile finishing, a breakthrough towards carbonneutraloperations.

Ÿ

Thisforward-lookingstrategycombineseconomic and ecological goals, positioning Monforts as a catalystfortheindustry'sgreentransformation.

From Archroma’s chemistry innovations to BW Converting’s precision spray and Monforts’ hydrogen-ready finishing frames, the message is clear:

Ÿ Sustainabilityisnolongeroptional—itis thefoundationofcompetitiveness.

Ÿ Resourceefficiencymeansprofitabilityas wellasresponsibility.

Ÿ Innovation must serve both performance andplanet.

These groundbreaking technologies will take center stage at ITMA ASIA + CITME 2025 in Singapore (28–31 October), where around 70 VDMA members will showcase their solutions across spinning, finishing, and technical textiles halls.

This convergence of innovation underscores the beliefthatthetextileindustry'sfutureliesnotin I n c r e m e n t a l s t e p s , b u t i n b o l d leaps—embracingmodernfinishingpathwaysthat save water, cut emissions, and unlock new performancepossibilities

In response to unprecedented market demand, BW Converting, a member of TMAS, the Swedish textile machinery association, will provide details about its new Baldwin TexChroma digital spray dyeing system at ITMA Asia + CITME in Singapore from October28-31.

“We are excited to launch TexChroma because spray dyeing is the future and many of our customers are already seeing the benefits,” says Yiannis Vasilonikolos, BW Converting Sales Leader for Textiles, who has many years’ experienceintextiledyeingtechnology.“Wehave conducted successful trials of TexChroma with pigment, reactive, acid and disperse dyes on both cottonandsyntheticfibres.”

From production data to date, TexChroma can achieve savings in energy, dyes and chemicals of more than 30% compared to conventional continuouspadbatchdyeingusingsteam,andupto 50%comparedtoexhaustreactivedyeing.

It also benefits from an advanced technology enabling reactive dyestuffs and alkali fixation chemicals to be mixed just seconds before spray application, in order to completely eliminate any ‘tailing and listing’– uneven dye application or colourvariations.

® TheTexCoat G4Legacy

The introduction of TexChroma follows the runaway success of BWConverting’sTexcoat G4 finishingsysteminthepastfewyears.

“TexCoat G4 spray technology was developed in Swedenfromouroff-setprintingbusiness,andwe initially focused on installing units in Europe and the USA,” explains Vice President of Global BusinessDevelopmentforTextilesRickStanford.

“Inthepasttwoyears,however,wehavebeenvery active in Asia, with 35 units sold – and many of these customers have been asking for a similar technologyforthedyeingprocess.”

ThefirstTexChromawillbeinstalledattheplantof averywell-knownItaliancontinuousdyerwhichis part of a larger textile manufacturing group, in order for it to be fully industrially tested before goingintoseriesproduction.

“Our first customer is close by our facility in Sweden, has the practical dyehouse skills we can learn from, and is a satisfied TexCoat G4 customer,” Stanford says. “We believe a major benefitofTexChromawillbeineliminatingmuch reworkwhichiscommonindyehouses,butwe’ve been very cautious about providing details on TexChroma too early. The dyeing process is unforgiving,andwemustgetitrightthefirsttime. The market has been ready for quite some time. Andnow,soarewe.”

BWConvertingisatstandB201inHall8atITMA Asia+CITME2025.

TMASmembersinSingapore

In further new developments from TMAS membersattheSingaporeshow,KinnaAutomatic (Hall 6, stand D106 in Singapore) will provide details of its complete robotic lines for the production of pillows and duvets for the home furnishings sector and introduce the new Hector industrial sewing machine designed for the heavy duty circular and point stitching of filled textile components.

Eltex (Hall 2, stand C203) has made an important breakthrough on its EyETM tension monitoring system for the heat setting, tufting, warping and winding sectors, with the addition of

electromagnetic brakes in combination with the latest advanced sensors. These enable tension variationtonotonlybedetected,butautomatically adjusted in real time during operation, rather than manuallychangedaspreviously

The company’s ACT-R unit can further significantly reduce the selvedge yarn waste from the weft insertion systems of rapier weaving machines, while at the same time maintaining equalandsteadytensionacrossallpre-winders.

Advanced weaving control is also the bedrock of businessforVandewieleSwedenAB(Hall2,stand D301e), which supplies weft yarn feeding and tension control units for weaving looms to the majority of the leading weaving machine

manufacturers, as well as for retrofitting in workingmillsaroundtheworldThecompanywill present its latest X4 yarn feeders with integrated accessory displays and has recently further strengthened its product portfolio with IRO Gaugepart modules. These are applied to tufting looms to determine the appearance of a carpet in termsoffeelandstructure.

Finally, the colarette machines of Svegea (Hall 6, stand D109) set the standard throughout Asia for the high speed production of tubular apparel components such as cuffs, collars and neck tapes andinSingaporethecompanywilldemonstrateits EC 50 and EC 200 with E-Drive II models, in additiontolinkedcuttingsystems.

As a leader in colour measurement and management solutions, Verivide will showcase its latest DigiEye imaging system at the forthcomingITMAAsia+CITMEexhibitionin SingaporefromOctober28-31.

This benefits from 100% LED illumination, improving the accuracy of colour assessments while supporting environmentally responsible practicesincolourmanagement.

Designedforefficiencyandreliability,theDigiEye includes integrated dust filtration and a fully enclosedcameraforaddedsecurity

Unlikeitspredecessor,thenewDigiEyenolonger requires annual fluorescent lamp changes, thanks to its 100% LED light source. The system also includes software-integrated lighting controls and lighting geometry checking, enhancing its precisionandeaseofuse.Additionally,itnowhas the ability to auto-capture images upon door closure, making it ideal for imaging multiple samplesquicklyandefficiently.

The new DigiEye offers significant upgrades, including a 67% larger imaging area and a 112% largermeasurementarea.Itsdrawerloadratinghas increased by 55%, and the LED light source lasts tentimelongerthanbefore.

As part of the VeriVide ecosystem, the DigiEye integratesseamlesslywithUltraView,VisionView andtheVeriVidePortal,offeringacomprehensive solutionforallcolourmanagementneeds.

Verivide will be part of a 20-strong delegation of UK companies present in Singapore, as active membersoftheBTMA(BritishTextileMachinery Association).

“Our members have been very active in 2025 to date and have plenty to shout about in Singapore, including new technologies for the production of technical fibres and fabrics, as well as the introduction of AI and machine learning into processcontrolsystems,”saysBTMACEOJason Kent. “Areas in which British companies are particularly strong, however, are in testing and preparation,aswellastotalprocesscontrol.”

Martindale testing needs little introduction to textilemanufacturers,beingwellestablishedasthe industry standard for abrasion and pilling testing since its initial development and introduction by JamesHealbackinthe1940s.

For 2025, however, James Heal's development team have taken a fresh look at this classic instrument and the result is the new Martindale Motion.

This redesigned nine-station Martindale instrumentwithindividualliftingheadsnowoffers theflexibilitytoruneachstationindependentlyfor carryingoutdifferenttextiletestssimultaneously

Multiple textiles can be tested at the same time through to conclusion without intervention. Once set up, the Martindale Motion can be left running withthesampleholdersautomaticallyliftingatthe required evaluation points, freeing up the operator'stimetodootherworkwithouttheneedto return until the abrasion or pilling test is fully completed,includingovernight.

Each sample is kept in-tact at the end point for evaluation and checking, reducing queries on grading and the potential need for re-testing. Furtherrefinementsincludeanewhingedaccessto changetheself-aligningdrivepins,allowingquick andsafeswitchingbetweentests.

Designed and manufactured in the UK, the James HealMartindalerangehasseennumerousupdates, models and innovations over the years, such as touchscreen and user-friendly software, best-inclass safety features combined with the signature near silent running of this staple lab instrument. Added to this have been the introduction of the DurAbrasionmulti-functiontestingmachine,later followed by the market-leading evolution, the AquAbrasionwetabrasiontesterlaunchedin2019.

The Martindale Motion, however, is now taking productivity and efficiency to a higher level than everbefore.

Total control of textile drying is meanwhile enabled with the advanced radio freqency (RF) technology of Strayfield, which has over 4,000

installations worldwide and provides solutions tailored to diverse textile applications such as cotton, wool, polyester, nylon, silk, acrylic and specialityblends.

Strayfield technology enables consistent quality, superioroutputandsustainabilitybenefitsthrough gentle and uniform drying, ensuring even results and moisture removal across entire batches and preserving fibre integrity, colour vibrancy and softnesswithoutyellowingorshrinkage.

Adaptive electrodes regulate power delivery according to product height and moisture, maximising efficiency and eliminating energy waste and unlike conventional rod systems, Strayfield's full-area plates deliver consistent energydensityforgentledryingwithouthotspots.

BTMA companies taking part in ITMA Asia + CITME 2025 are Airbond (stand A202, Hall 2), Autofoam(B309, Hall7),AVACAD/Cam (C201, Hall 6), Cygnet Texkimp (B403, Hall 8), Fibre ExtrusionTechnology(B306,Hall4),JamesHeal (B306, Hall 3), MCL (A203, Hall 5), Roaches (A112Hall3),SaurerFibrevision(C301c,Hall3), SDC Enterprises (B203, Hall 3), Sellers (B207, Hall 7), Shelton Vision (B308, Hall 7), Slack & Parr (D305, Hall 4), Society of Dyers and Colourists (B107, Hall 3), Strayfield (B509, Hall 7), Tatham (D205, Hall 2), The Textile Institute (B105, Hall 8), Verivide (B201, Hall 3), Vickers Oils (B102, Hall 5) and Wira Instrumentation (A108,Hall3).

Total

Arvind,H&MGroup,andDevenSupercriticalsinaugurate India'sfirstsupercriticalCo₂dyeingmachine,abreakthroughin sustainabletextilemanufacturing

Arvind Limited, one of India's leading textile-toretailconglomerates,incollaborationwithleading fashionbrand,H&MGroupandIndianinnovation start-up Deven Supercriticals Pvt. Ltd., today announced the inauguration of India's first supercritical CO₂ dyeing machine at Arvind's facilityinAhmedabad.

This pioneering technology, globally patented ® undertheSUPRAUNO brand,reducestheuseof water in the fabric dyeing process by using supercritical carbon dioxide. At a commercial scale, it delivers up to 76% water savings, ~67% energy savings, and ~90% reduction in chemical usage within the coloration stage compared to conventional dyeing methods, while also significantlyreducingeffluentdischarge.

The inauguration marks the culmination of a unique three-way partnership: Deven Supercriticals bringing cutting-edge Indian innovation,Arvind enabling large-scale industrial deployment, and H&M Group supporting the

adoption of disruptive solutions in line with its sustainability ambitions. This is a first of its kind approachtoenablescalingofInnovationfromLab toBulkscale.

Speakingontheoccasion,Mr.PunitLalbhai,Vice Chairman, Arvind Ltd., said, “This inauguration representsadefiningmomentfortheIndiantextile industry. By hosting the world's first commercial® scale SUPRAUNO machine at Arvind, we reaffirmourcommitmenttopioneeringsustainable solutions and setting global benchmarks. This collaboration is proof that innovation, scale, and sustainabilitycangohandinhand.”

Mr Omang Narang, H&M Group's Production Manager for India, added: “We recognize that electrification is essential for making the textile industry fossil-free. Wet processing is the single most impactful area in the value chain for fashion brands like ours, and water- and energy-efficient technologies like this one make further electrificationmorefeasible.Weareproudthatour

supporthelpsdrivetheentireindustryforward.”

Dr. Swapneshu Baser, Founder, Deven Supercriticals Pvt. Ltd., said, “We are immensely ® proud to see our patented SUPRAUNO technologybeinginauguratedatcommercialscale in India. This machine is not just a technological milestone but also a step towards safeguarding water,energy,andhealthforfuturegenerations.We are grateful to H&M Group and Arvind for their faithinthisinnovationandformakingthisvisiona reality.”

The Ministry of Textiles has also strongly supported the initiative. This milestone strongly supports the Government of India's vision of building a sustainable, circular, and globally competitive textile sector showcasing Indian innovation at the forefront of global textile transformation.

Arvindisatextiletoretailconglomeratewithfocus on textiles, apparels, advanced materials, environmental solutions, telecom and Omnichannelcommerce.ArvindLimitedisanintegrated solutions provider in textiles with strong fiber to fashioncapabilitiesforaglobalcustomerbase.Itis also a design powerhouse implementing innovative concepts and generating intellectual property It ranks amongst the top suppliers of fabric worldwide.The company strives every day to create opportunities beyond conventional boundaries and believes that the possibilities are endless.

AboutH&MGroup:

H & M HENNES & MAURITZAB (PUBL) was foundedinSwedenin1947andislistedonNasdaq Stockholm.H&M'sbusinessideaistoofferfashion and quality at the best price in a sustainable way. The group's brands are H&M (including H&M HOME, H&M Move and H&M Beauty), COS, Weekday (including Cheap Monday and Monki), & Other Stories, ARKET, Singular Society and Sellpy. The group also includes several ventures. Forfurtherinformation,visithmgroup.com.

Deven Supercriticals, is an innovation driven companydedicatedtostate-of-the-artSupercritical Fluid (SCF) technology, leading for more than 2 decades. Deven's flagship innovation, ®SUPRAUNO , is a globally patented, waterless dyeing technology that transforms textile manufacturing using supercritical CO₂ as the mediuminsteadofwater.It'sthefirstintheworldto enabletheuseofconventionaldyesandtri-chrome recipesinsupercriticalCO₂,dyeingawiderangeof fabrics—Cotton, Polyester, Nylon, Viscose, Silk, ® Linen, Acrylic, and their blends. SUPRAUNO eliminates the need for salt in cotton dyeing and reduction clearing in polyester, cuts auxiliary chemical use by up to 90%, and reduces dyeing batch times—cutting energy loads by 67% and waterusageby76%.

Archroma, a global leader in specialty chemicals, has won the International Textile Manufacturers Federation (ITMF) 2025 Sustainability&InnovationAwardforDENIM HALO, a revolutionary denim pretreatment and dyeing process. It gives brands and mills a simple way to produce highly sought-after distressed denim looks with a significantly reduced environmental footprint and cleaner chemistries.

“Archromabelievesinchallengingthestatusquo. Under our planet conscious roadmap, we seek solutions that not only advance sustainability but also nurture the creativity and profitability of textile manufacturers,” Dhirendra Gautam, Vice President Commercial, Archroma said. “DENIM

HALO exemplifies this approach, and we're honored that it has been recognized by ITMF. In partnership with mills across the globe, we're proving that world-class sustainability and worldclass products aren't trade-offs – they're the same goal.”

Aconsumerfavoritefordecades,distresseddenim is more popular than ever But achieving the covetedwornandfadedlookremainsproblematic, involving manual scraping, hazardous potassium permanganate sprays or energy-intensive stonewashing. Traditional indigo and sulfur dyeing processes add to the burden, with high water and energy consumption and significant effluent discharge.

DENIM HALO is a breakthrough alternative. It ® draws on a unique new chemistry, DIRSOL RD, and a broad portfolio of textile dyes based on decades of advanced research to produce laserfriendly denim with outstanding contrast on intenseblackandindigoshades.

®DIRSOL RD p is a new viscosity-modifying and patented pretreatment that enables superficial dyeing while also reducing water, energy, and greenhousegasemissionsinprocessingandwashoff. In DENIM HALO, it is combined with a tailoredArchroma dye solution according to millspecificproductionneeds:

® Ÿ DENISOL pre-reducedindigodyes,including aninnovativeaniline-freeformulation;

® Ÿ DIRESUL pre-reducedsulfurdyes,including anenergy-savingblackformulation;and

®

Ÿ EarthColors , biosynthetic earth-tone dyes madefromagriculturalwaste.

Impact assessments usingArchroma's ONE WAY

Impact Calculator demonstrate substantial environmentalbenefitsforDENIMHALOversus standard processes with ZDHC Level 3 MRSL compliance. Results include water savings of 40-

56%, energy reductions of 30-36%, and CO2 emission cuts of 33-34% depending on the dye formulation used [See infographic: DENIM HALOEnvironmentalImpactResults]

Thebenefitsextendbeyondsustainabilitytosafety, and economics. Mills can produce distressed effects without modifying standard dye recipes or equipment setup. The process enhances worker safety by enabling high-contrast laser etching, eliminating potassium permanganate and manual scraping.DENIMHALOalsoreducescausticsoda consumption in sulfur mercerizing and enables easier washdown. Technical advantages include reduced yarn shrinkage and improved garment tensile strength, especially on black denim, with lowerchemicaluseindyeingandfinishing.

The ITMFAwards celebrate achievements in two categories: Sustainability & Innovation and International Cooperation. Winners were honored at the ITMF Annual Conference, held in Yogyakarta,IndonesiafromOctober24-25,2025.

® Trademarks of Archroma registered in many countries.

©2025Archroma

WithitsFR3compounds,KRAIBURGTPEissettingnew standardsformeetingthehighestfiresafetyrequirements

WiththenewFR3series,KRAIBURGTPEhas now developed the third generation of compounds for use in environments that place the highest demands on fire protection. All requirements of the European standard for railwayapplicationsDINEN45545-2havebeen met. In addition to their fire protection properties, TPE compounds in the FR3 series have othermaterial properties that make them ideal for use in demanding environments, such as very good compression set values and improved tear resistance. Since power cables areofteninstalledwithmulti-componentplastic parts, excellent PP adhesion and processing in standard injection molding and extrusion processesarealsoimportant.

Effectivefirepreventionisessential,especiallyin places where large numbers of people gather in rooms within buildings or on public transport—even more so when escape routes are limited. High safety standards therefore always applytopassengertransportbyrail.Thefiresafety requirements imposed on manufacturers of train parts and components are correspondingly high. Particularattentionispaidtomaterialsusedinthe field of energy supply, for example for cable managementsystemsandcableglandsorforseals.

With the FR3 series, KRAIBURG TPE has now launched the third generation of thermoplastic

elastomers that meet special fire protection requirements. All specifications of the European standard for railway applications – fire protection inrailvehicles(DINEN45545-2,inparticularR22 HL3andR23HL3)–havebeenmet.Inadditionto their specific fire protection properties, TPE compounds in the FR3 series have outstanding material properties that make them ideal for applications in this demanding environment, including very good tear resistance values for halogen-freeandflame-retardantTPEcompounds. Inaddition,thesoftandelasticTPEmaterialsofthe FR3 series have improved resilience properties compared to their predecessors. Especially in the temperaturerangebetween23°Cand70°C,these materials score highly in comparative tests with predecessorproductsandarethereforesuitablefor many sealing applications. Since current-carrying assembliesaremadefrompolyolefins(PP),among othermaterials,excellentPPadhesionisoneofthe important requirements for the new FR3 TPE. In addition, they can be processed using proven thermoplastic injection molding and extrusion processes. Due to the thermoplastic material structure, cold runner distributors and 1component defective parts, for example, can be shredded and added back into the in-process recyclingsystem.

One of the key requirements for comprehensive flame protection in this market is now that the materials used are halogen-free: this is one of the basicprerequisitesfortheuseofmaterialsintrain

parts and components. Unlike halogen-containing materials, the FR3 series guarantees significantly lowertoxicityintheeventofafirewhensmokeis generated,thusreducingtheriskofharmtopeople whocomeintocontactwithit.

While low smoke density and toxicity can be verified by railway standard tests, the UL94 vertical burning test ensures that the compounds reactinaself-extinguishingmannerintheeventof a fire. The FR3 series guarantees V0 flame retardant classification even with a sample thickness of 1.5 mm. The outstanding test results were confirmed by the UL certification program, which allows these FR3 products to be awarded a Yellow Card. Such a Yellow Card provides the necessaryprerequisiteforULlistingandservesas proof that the required safety, quality, and performance requirements for TPE are met. A

corresponding certificate is a strong selling point onthemarket.

Another important test requirement for flame retardancyistheglowwiretest.Sincethereisarisk that live cables may ignite even without direct contact with flames as a result of high temperatures, this test is particularly relevant for materials used in or in the immediate vicinity of powercables.TheFR3seriespassesthetestat960 degrees Celsius, the glow wire limit temperature, withoutformingflames.Thesespeciallydeveloped compounds therefore meet all railway-related requirements–inallcolorandhardnessvariants.

"Thanks to their low smoke toxicity, our halogenfree, flame-retardant TPEs improve safety and healthprotectionintheeventofafire,"summarizes Johanna Schmid, market specialist for industrial applications: "In addition, users of halogen-free solutionsbenefitfromeasierdisposalattheendof theproductlifecycle."

KRAIBURGTPEhasdevelopednewthermoplasticelastomersforhighly effectivefireprotection.(Image:©2025KRAIBURGTPE)

SyensqolaunchesEasysoftPA,abio-basedadditivedesignedtoenhancethesensorial experiencedeliveredbyfabricsofteners.

This advanced polymer technology enables fabric softeners to sustainably and effectively deliver long-lastingfragranceandsoftnessbenefits.

Syensqo expands its portfolio of bio-based solutions for home care with the launch of Easysoft PA, a novel fabric softener additive designed to enhance consumers' sensorial experience.

Fragrance has long been recognized as the top purchase driver in fabric care, shaping consumer loyalty and creating opportunities for differentiation.EasysoftPAaddressesthistrendby enabling efficient scent delivery and improving fragrance deposition from fabric softeners, ensuringthelong-lastingfreshnessthatconsumers desire.

“Easysoft PA is at the sweet spot of the cost–performance–sustainability equation,” says Max Chabert, Home Care Global Marketing Manager at Syensqo. “By enabling formulators to efficientlydeliversuperiorfragranceandsoftness, we are empowering fabric softener brands to respond to consumer demands while capturing opportunitiesforpremiumization.”

At the heart of Easysoft PA lies Syensqo's proprietary guar-based polymer technology, engineered to deliver exceptional benefits at low inclusion levels. This innovation enables formulatorsto:

Ÿ Reduce quat content while maintaining or enhancing softness, yielding both carbon and cost efficiency.

Ÿ Improvefragranceperformancefrombothoils and encapsulates, offering consumers a richer sensorial experience while providing consistent rheologyandstableformulations.

Versatility across concentrations is another key advantage. From low concentration to ultraconcentrated fabric softener, Easysoft PA is compatiblewithallformats,providingbrandswith a flexible solution adaptable to diverse market segments.

WithEasysoftPA,Syensqoonceagainreaffirmsits commitment to sustainable innovation that enhances everyday experiences for consumers whiledrivingefficiencyandvaluefortheindustry

™

ClariantlaunchesTexCare OneTerra,anewpolymer technologyforultra-concentratedlaundryformulations

ClariantlaunchesTexCareOneTerra,anewpolymertechnologyforconcentratedlaundry formulationsatSEPAWA2025.

Ÿ TexCare One Terra, a new multifunctionalsoilreleasepolymerspecifically designed for high-concentrate laundry detergent liquids and capsules, is presented at the SEPAWA Congress 2025 in Berlin, Germany,from15-17October2025

Ÿ High compatibility with concentrates combined with superior cleaning performance at low temperatures and reduced dosages supports energy-efficient washing and product compaction

Ÿ Innovative solution addresses growing consumer demand for convenient, more sustainable and high-performing laundry products

ClarianttodayunveiledTexCareOneTerra,an innovativemultifunctionalpolymerengineered toimprovetheperformanceofhigh-concentrate liquid laundry products, particularly laundry capsules. The latest addition to Clariant's established TexCare product range addresses the growing market trend toward compact laundry formulations while delivering exceptional cleaning effectiveness even at low temperaturesanddosages.

"With TexCare One Terra, we're responding directly to the industry's need for innovative solutions that support the evolution toward even more concentrated and compact laundry products without compromising on cleaning performance," said Dr Christine Oberbillig, Global Marketing Manager Home Care & Sustainability at Clariant. "This next-generation polymer helps our

customersdeveloppremiumlaundrycapsulesthat combine convenience, resource-efficient and superiorcleaningpower.”

TexCare One Terra features a novel chemical structure that provides high compatibility with concentrated capsule formulations, allowing manufacturers to create more effective laundry products. The polymer's multifunctional capabilities bring best-in-class next time cleaning benefits, detergency boost and whiteness maintenance into detergent capsules in a single ingredient.

The new polymer demonstrates remarkable efficiency at low dosages, requiring very low use levels in formulations to deliver significant benefits, supporting manufacturers efforts to further reduce capsule sizes with same effectiveness, even at low washing temperatures andinshortwashcycles.

The polymer supports sustainable formulations through high biodegradability and Renewable Carbon Index and the use of waste-based feedstocks, making it a strong contributor to Clariant's and its customers' sustainability strategies.Duetoitssuperiorperformancebenefits it enables more sustainable washing through energy and water savings, reduced plastic usage, and supporting lower carbon emissions along the value chain. The launch of TexCare One Terra marks a significant step in Clariant's broader commitment to addressing the needs of sustainability-consciousconsumersandbrands.