Efficient filtration in PET recycling –How the new COBRA filter is setting new Standards

Conversation with Matthias Schmitz, Head of Engineering

Recycling Technology at BB Engineering

Editorial

Efficient filtration in PET recycling –How the new COBRA filter is setting new Standards

Conversation with Matthias Schmitz, Head of Engineering

Recycling Technology at BB Engineering

Editorial

BBEngineeringatK2025:ClosingtheLoop,OpeningPotential

OpenHouse:InnovationinAction

Barmag&Neumag:PoweringInnovationandSustainabilityatITMAAsia+CITMESingapore2025

SNCKherib,Algeria,orderscompletespunlacelinefromANDRITZ

Mistra-Autex,Estonia,ordersnewneedlepunchlinefromANDRITZ

Exportgrowth…MissionIndia!!!

Enhancesustainabilitywithemtec'sTactileSensationAnalyzerattheAmsterdamTextileShow2025

Retech–SwissPrecision–AppliedWorldwidefor50YearsPrecisionandInnovationin ProductionMonitoring

FrommicrosurgerytoaircraftwingswiththeBTMA

EngineeringExcellence,EmpoweringFutures:AUTEFASolutions atITMAAsia+CITMESINGAPORE2025

CinteTechtextilChina2025:Innovation,Collaboration,andaVisionfortheFuture

Nonwovens:TheSilentRevolutionPoweringModernLifeandInfrastructure

"BeyondRecycling:Everlane'sBlueprintforMicroplasticMitigationandCircularFashion”

RespondingtomarketdemandwiththenewMonfortsVertiDry

EfficientfiltrationinPETrecycling–HowthenewCOBRAfilterissettingnewstandards

ANDRITZatITMAASIA:Focusontextilerecyclinganddurablenonwovenproductiontechnologies RisingStronger:The‘Right’HygieneConferenceIgnitesaNewEraofInnovation

editor-in-chief

Prakashkinny contributor

ThomasChang circulation PamelaJones administration JoePereira accounts

RameshJain photography

TonyFernandes

RetailPrice:Rs.100.00 InsideIndia

Annualsubscription:Rs.400.00 OutsideIndia

AnnualSubscription:US$30.00

editorial office

TECHNICALTEXTILESINNOVATION

House No. 157, Satpala, Bhandra Lee Post:Agashi, Tal: Vasai

Dist: Palghar (401 301) State: Maharashtra, INDIA

Mobile: +91-7798189485/09892723562

Email:info@timesinternational.in prakashkinny@yahoo.com techtexin@gmail.com

www.timesinternational.in

JAPAN

KatsuhiroIshii

MediaRepresentative ACEMEDIASERVICEINC.

12-6,4-chome,Nishiiko,Adachi-ku, Tokyo121-0824Japan

Tel:81-3-5691-3335Fax:81-3-5691-3336 amskatsu@dream.com

TAIWAN,R.O.C

Kenlychang

BUILDWELLINTERNATIONALENT.,CO.,LTD.

HeadOffice:No.120,Huludun2ndSt., FongyuanCity, TaichungCounty42086,Taiwan,R.O.C

Tel:886-4-25123015Fax:886-4-25122372

E-mailaddress:buildwel@ms23.hinet.net

India,Pakistan,Bangladesh,Srilanka,Vietnam,Indonesia,Thailand, China,HongKong,USA,Germany,Spain,Italy,U.K.&France

ITMAAsia+CITME2025:ACatalyst forNonwovensandTechnicalTextiles

The upcoming ITMAAsia + CITME 2025, taking place from 28–31 October 2025 at the Singapore Expo, is poised to be a defining event for the textile machinery industry. Its expansion to Singapore underlines its growing international scope, drawing exhibitors and visitors from acrossAsia, the Middle East,andbeyond.

Forthenonwovensandtechnicaltextilessector,the exhibition holds special importance. Rising demand inhealthcare,hygiene,automotive,construction,and geotextiles is driving innovation and investment.At thesametime,globalemphasisonsustainabilityand circular economy practices is reshaping production methods. ITMA Asia provides a unique platform where these needs intersect with cutting-edge technologyandsolutions.

Covering19productsectors,theeventwillshowcase theentirevaluechain—fromrawmaterialprocessing and web formation to bonding, finishing, and recycling.Thisensuresbothvisibilityandknowledge exchange for stakeholders eager to embrace futurereadytechnologies.

Ultimately,ITMAAsia+CITME2025ismorethana trade fair. It is a catalyst for transformation, empowering the nonwovens and technical textiles industry to innovate, collaborate, and build a more sustainableglobalfuture.

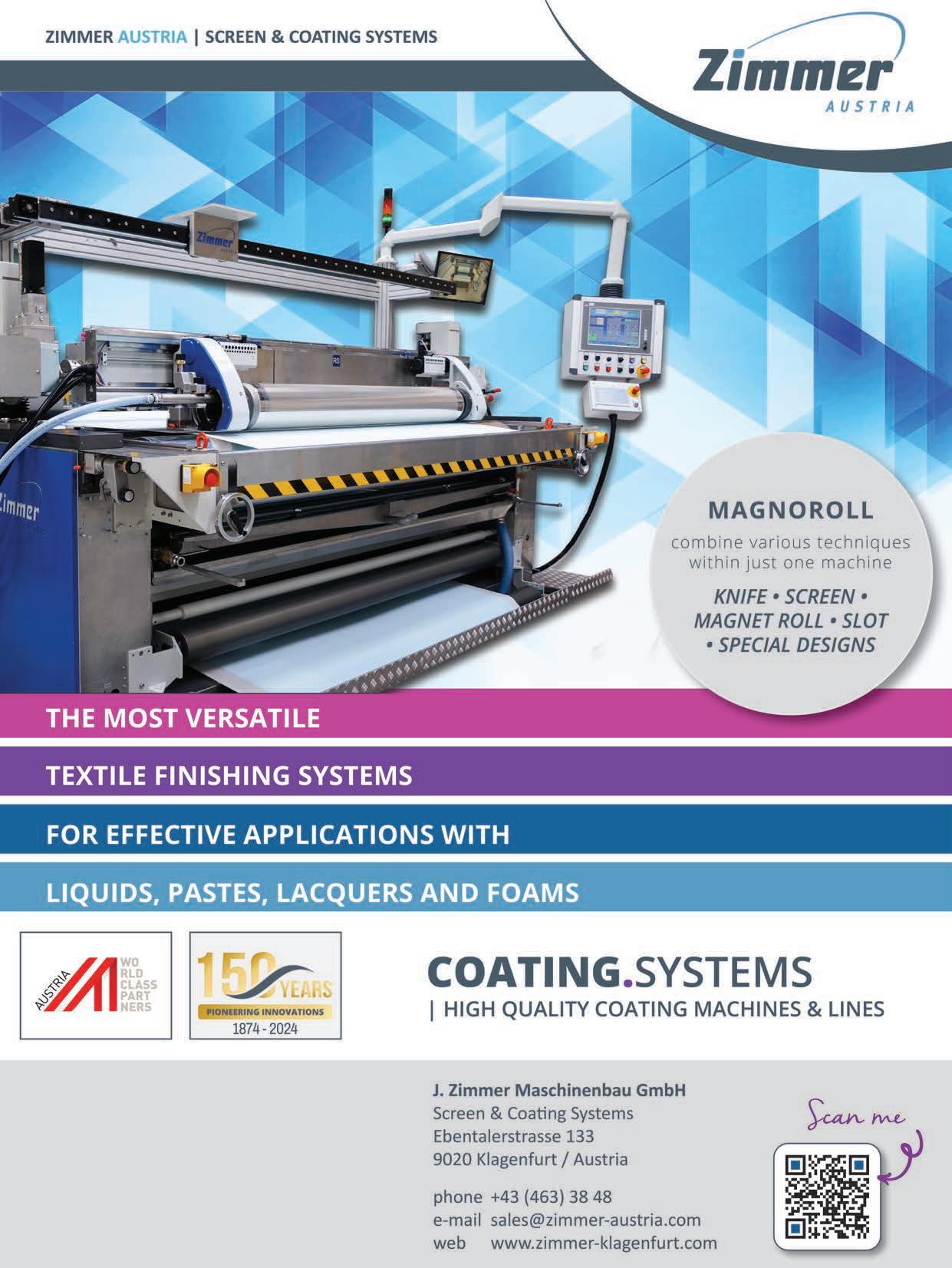

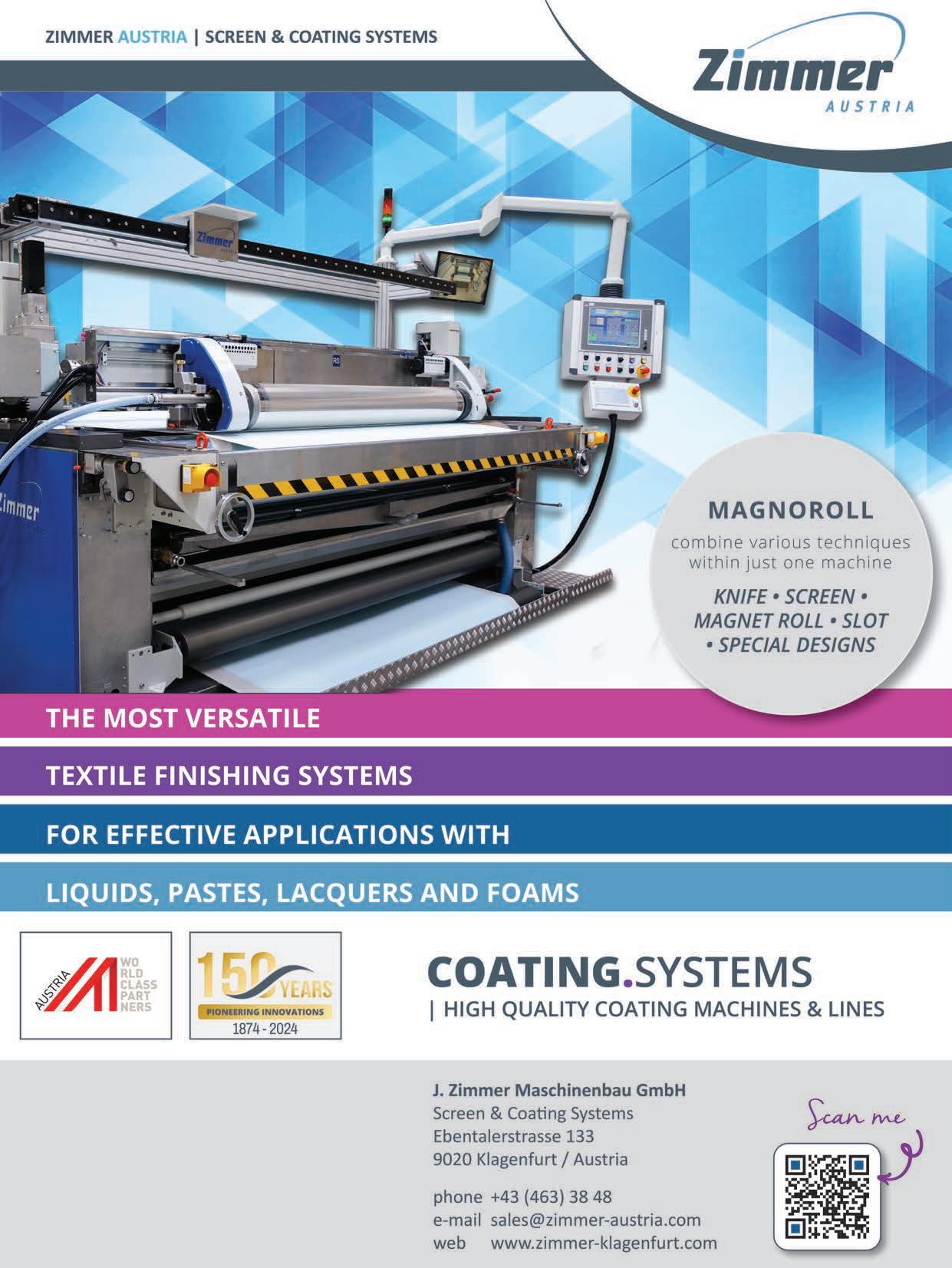

nder the motto Closing the oo O ening Potential, BB Engineering BBE , together with its parent company Barmag, will showcase pioneering technologies for PETrecycling and plastics processing at . isitors can meet the e pert team at the oint booth in Hall , Booth H , where innovation meets sustainable profitability. Proven E cellence in E tr sion

ith decades of e pertise and thousands of systems delivered, BBE continues to set standards in e trusion. Its single-screw e truders handle a wide range of polymers PP, PET, rPET, PA, and PE with throughputs from to , g h. or high-output operations, e trusion cascades ensure quality and efficiency, making BBE a trusted partner for film, fiber, and recycling industries.

Brea thro gh iltration forP re Melts

BBE snewproduct theCOBRAfilter,a continuous and automated large-area fine filter with self-cleaning function.

Ahighlight is the COBRAfilter, which redefines continuous polymer filtration. ith automatic valve switching, inline cleaning, and a ma imum throughputof , g h ,itguarantees uninterrupted,stableoperation criticalfor recycled plastics with variable input qualities.

ntegrated PETRecycling Sol tions

BBE also presents ac il , a fully integrated systemforPET recyclingvialiquid-state polycondensation. Its heart, the isco nit, allowspreciseI ad ustment,producing homogenous, high-quality rPETmelts suitable for fibers, films, and packaging. ith capacities ranging from to , g h, acu iloffers fle ible solutions tailored to diverse recycling needs.

ingle-screw e truder by BB Engineering

The core component in the acu ilrecycling processisthe isco liquid-state polycondensation unit.

Parallel to the trade fair, BB Engineering is hosting an open house with live demonstrations. The event was well attended in 2022. Image from 2022

uring 2025, BBE will host a s ecial O en Ho se at its Technical Center in Remscheid October 10 1 . ere, visitors will witness PETwaste transformed into high-quality yarn and e perience the COBRAfilter live, alongside the eTe air te t rizing system with auto-doffing.

BB Engineering at 2025 promises not ust technology,butavisionof rofita le s staina ility for the future of plastics.

With Bico yarns, rPET, Full Dull and Semi Dull, Cationic Dyable and dope dyed, as well as other specialty products, the range of Oerlikon Barmag's WINGS FDYFLEX is unique in the WINGS family.

Productivity and sustainability are no longer choices they are imperatives. At TMAAsia C TME Singa ore , Oerlikon s trusted brands Oerlikon Barmag, Oerlikon eumag and Oerlikon onwoven are stepping forward with solutions that not only meet this demand but redefine the future of yarn production. rom – Octo erin Singa ore, visitors at all , Booth C20 will witness innovation with purpose.

At the heart of the showcase is atmos io the intelligent operating system for smart yarn production. Imagine every bobbin carrying its own digital identity, every decision guided by real-time data, and every process seamlessly

connected. atmos.io makes this vision a reality, enabling manufacturers to cut waste, improve quality, and ma imi e profitability all while securing cyber-reliable data flows.

The future of filament s inning shines with S E , delivering unmatched fle ibility and even enabling recycled polyester processing. or te turing, the e EvoSmart sets a new benchmark by reducing energy use up to25 perkilogramofyarn,doubling maintenance intervals, and ensuring smoother operationsacrossweaving,knitting,and finishing.

The EvoSteam process for manufacturing synthetic staple fibers is superior to conventional processes in terms of efficiency, sustainability, and performance, while delivering significantly higher fiber quality.

Oerlikon eumag raises the bar in sta le fi er rod ction withits EvoSteam rocess , deliveringhigherqualitywithlessenergy.

Complemented by innovations like Evo ct, EvE , and automated spin pack wiping, fiber makersachieve efficiency, consistency, and environmental responsibility.

With Oerlikon Neumag's hycuTEC hydrocharging technology for the production of highly efficient electret filter media, the pressure loss of a typical FFP2 filter medium can be reduced to less than a quarter.

Carpet producers gain new opportunities with B CO BC technology and i er ard BC , ensuring higher performance, reduced waste, and sustainabilityineverystrand. eanwhile, onwoven s hyc TEC revolutioni es filtration with record-breaking efficiency.

Together, these innovations embody Oerlikon s mission technologythatdrives rogress, rotects reso rces, and em owers the te tile world to thrive in a ra idly changing f t re

SNC Kherib et Cie. has awarded ANDRITZ an order to supply a complete spunlace line for its plantlocatedinBejaiaCity,Algeria.Thestart-up isscheduledfortheendofQ32026.

ThiswillbetheveryfirstANDRITZspunlaceline installed on the African continent. The line will process both viscose and polyester fibers, enabling SNC Kherib to produce high-quality spunlace roll goods for the wet wipes markets to meet the growing needs of African consumers. This project marks a significant step in the development of the spunlace industry in Africa andopensthedoortonewopportunitiesforlocal converters.

The project is a family investment, with each member of the Kherib family actively involved.

AsapioneerintheAfricanmarket,SNCKheribis leadingthewayinintroducingadvancedspunlace technologytotheregion.

FaridKherib,founderofSNCKherib,states:“We are proud to collaborate with a global leader like ANDRITZ. This partnership highlights our commitment and passion for developing innovativesolutionstailoredtothespecificneeds of the African market using state-of-the-art equipment.”

The value of the order will not be disclosed. It is includedinANDRITZ’sorderintakeforthefirst quarterof2025.

BasedintheBejaiaareaofAlgeria,SNCKheribis a family business dedicated to a wide range of activitiesincludingtheproductionofnonwovens

(viscose and cotton cleaning cloths, polyester wadding for mattress and pillows, etc.), PVC clingfilm,PPwovenbags,aswellasPVCdoors andsandwichpanels

ContractsignatureatKheribfamilly'sfacility inBejaia,Algeria.Fromlefttoright:Caterina Potenza(SalesAgent),FaridKherib(Founder of SNC Kherib), Nicolas Canas (ANDRITZ Area Sales Manager), Smail Kherib (General Manager of SNC Kherib), Arnaud Laroche (ANDRITZHeadofSalesSpunlace)

Mistra-Autex AS has awarded ANDRITZ an ordertosupplyacompleteneedlepunchlineforits plant in Raasiku, Estonia. The new line will produce various types of nonwovens for surface applications, 3D molding, and other technical materials, primarily for the automotive industry. Start-up is scheduled for the end of the third quarterof2026.

Thescopeofsupplyincludesallmachineryfrom the carding stage to the end-of-line section. The line features the patented ANDRITZ ProWin™ web optimization system in a closed-loop configuration. This system will enable MistraAutex to achieve high end-product quality by ensuringoptimalfiberdistributionacrosstheline.

With this investment, Mistra-Autex is taking its production to a new level, as productivity is expected to increase more than fivefold. At the same time, the company is reinforcing its commitmenttoinnovation.

Priit Tamm, owner of Mistra-Autex, said: "We trust ANDRITZ to renew our needlepunch equipment and value its expertise throughout this

important project. As we share the same strong culture of innovation, we are confident that this will be the beginning of a successful long-term collaboration."

Mark Raja, R&D Director at Mistra, stated: "ANDRITZ's technology ensures excellent product quality while increasing line speed and reducingoperationalcosts.TheProWin™system reduces fiber deposits at the web edges and optimizes the CV ratio. This results in up to 10% fiber savings and higher production speeds, providingafasterROI."

The value of the order will not be disclosed. It is included inANDRITZ's order intake for the first quarterof2025.

Founded in 1986, Mistra-Autex AS is a leading Europeansupplierofhigh-qualitynonwovenand tuftedcarpetproductsfortheautomotiveindustry. Its technological expertise enables the company to offer comprehensive services, including design, engineering, and production of systems for passenger cars, trucks, and heavy-duty industrialvehicles.

We at Suvin are on the verge of completing 15 yearsofconsultingservices,witnessingtheswing ride of our textile industry as it jumps high, falls back, and again rises to the very top. I thought it wastimetosharethewisdomIhavegainedwith my dearest textile industrialists about the extraordinary businesses that are growing today by taking the leap and trying out-of-the-box strategies.

The geopolitical dynamics, UK FTA, upcoming UStariff,inpipelineEUtradepolicy,sustainable solutions,andthepragmaticChineseimpact,etc. areallthephenomenathatareexpectedtochange the tides for favourable manufacturing in India. New opportunities are opening up. In case of textileindustry,shiftingofmanufacturingunitsto India has not yet materialized into a scalable opportunity, or are we lagging in grabbing the opportunity?

Todaywehavethebestofthetechnologiesatour disposal, there is no longer a dry patch as far as innovationisconcerned.Acceleratingproduction, cutting-edge technology, Innovative product portfolio, circular economy, 360 degrees of sustainability,traceabilityandCustomerfocusare thefewmostlookedattermsfortextilestoday.So, what's holding us back? I feel as textile entrepreneurs there is always a risk associated withtryingnewandbeingpioneersthatiswhere ourbigfootfallsshort.

We are simply the best at following innovation and finding practical multiple uses for these innovations. However, the monopoly fear of beingtheFirsttofallisalwayswhatkeepsthefoot small.And the strategy has played in our favour fordecades.Butnowtheeraisdifferenttodaybe thechangeandinvestinappropriatestrategyand decideyourproductportfolio.

The Indian government is introspecting the risk factor and has taken right steps to go a long way and bring in favourable FTAs. These FTAs are goingtobeourshieldintryingoutsomethingnew withacalculatedriskfactor.Thegovernmenthas come up with a solution for safeguarding the interestsofthetextileIndustry.

India's first FTA with a European bloc (Iceland, Liechtenstein,Norway,andSwitzerland)-IndiaEFTATEPAis thefirst to includecommitments on trade and sustainability, investment, and employment generation. India has also recently signedanFTAwiththeUK,thisagreementaims to double bilateral trade to $120 billion by 2030 and includes tariff reductions on 90% of British products,with85%becomingtariff-freewithina decade.TheagreementisexpectedtoboostIndian exportsinsectorsliketextiles,toys,jewellery,and auto parts.Apart from this Indian government is alsocurrentlynegotiatingFTAswithseveralother regions and nations, including New Zealand, the

US,theEU,Oman,Peru,Qatar,andSriLanka.All these FTAs will be our express ticket toward the growthandincreaseourexportssubstantially.

As an entrepreneur, one should always be on the watchtoventureintoaproductwithattractive& consistent demands that reap high profit margins at minimum project cost. Many times, instead of looking around and exploring what the market demands, we tend to oversee things that are trendinginthemarketandfollowthetrendthatis already flourishing. Just take the example of sustainability; for many years there have been talksaboutadoptingsustainablepractices,butitis today that everyone is on their foot to get things donetobeasustainableproducer.Takingforward this attitude of doing at the bare necessity, we mightstayintheracebutneverbethefrontrunner tograbthegoldenopportunity.

Let us talk about trends of today with great potential.Todaybio-basedfibres,revolutionizing Meditech innovation, traceability, and global standardizationaretheconceptsthatarecreatinga spaceforthemselves.Itisstillanicheareaasfar as the production scale is concerned. But today's nichespaceistomorrow'sbiggestmarket.

RecycledFibres:

Globalbrandsareencouragingtheircustomersto wear/use recycled products through a buy-back mechanism. Recycled fibres are being promoted bybrandsintheirhigh-rangeproductportfolioas their policy for commitment to Mother Earth. It also reduces operating cost for manufacturing same product as in most of the cases recycled fibresarecheaperthanthevirginfibresCurrently,

thereisalotoftabooforusingpetbottlefibres,but thedynamicsofcircularityhavestrongquestions onitsrecyclabletagsinceitisnotinitiallypartof the value chain and also the endless dump of textiles remains untouched with it. So, the true textilerecycledfibreswillhavescopenotonlyfor readymadegarmentsbutalsoinhomefurnishings and many upcoming technical textile applications. Many innovative & cost-effective productsalsocanbegeneratedbyusingrecycled fibres.Thewaythereiscurrentlyabigdemandfor recycledfibresintheclothingindustrytherewill beagreatdemandforrecycledfibreseveninthe technicaltextileindustryinfuture.

Standardization&QCOMandates:

Though the pandemic has seen many emerging players in Meditech there were no clear-cut specificationsmaintainedbymanyplayerswhich resultedinpoorqualityofusabilityoftheproduct beitaPPEkitorasimplemaskshield.Thisiswhy harmonized standards for hygiene products are beingdevelopedbytheEDANA.Ithasdesigneda program that lists the requirements the industry mustmeet.ThegovernmentofIndiahasalsoled many QCOs for technical textile products in recent times.Also, the Ministry of Textile under Govt of India has prepared a Quality Control Order in respect of the 12 textile goods for compulsoryuseofStandardMarking.Thereisno going around way for it and best practices often create exceptional products giving you the open marketaccessforhigh-qualityproducts.Henceit isimportanttolookaround,think,andintrospect tograbandadoptthetechnology,andinnovation thatwillbethedrivingforceforthefuture.

Traceabilityandaccountabilityarethecomplete packagetoday.Theyaretobefollowedforexport marketsandadoptionisthebestwayforward.

Theuseofnonwoventechnologyinhometextiles willgiveadifferentdimensiontothissegmentby reducingextensiveuseofdyesandchemicalsand we can use mechanical patterns produced by nonwoventechnologieslikeneedlepunchingetc. Disposabletextilesusingnodyes&chemicalscan be used especially in Hospitals, hotels & offices thus contributing a small share for saving the environment.

Similarly, spunlace curtains can take care of the aesthetic look of the fabric having the inherent capability of creating various structures & patterns that can be embossed on the fabric. Thereby the manufacturing cost of the curtains can be minimized drastically by using spunlace technology. So, the curtains which were once being used for years can now be replaced after identified occasions or events due to the price benefitsandevenadditionalsetofcurtainscanbe kepttoreplacethemalternativelytherawmaterial required for producing curtains using spunlace technology can also be the by-products of textile industrylikespinningwaste.So,thecostincurred on raw materials using spunlace technology is much lower as compared to woven curtains. Similarly, the entire spinning weaving & then fabric processing i.e. bleaching & dyeing technologies will be eliminated as the fibres will

be directly converted to fabric by using the spunlacetechnologies.

Theyhavebeeninthenichemarketforalongrun but some promising technologies being developed year on year are driving its growth. Noble Biomaterials' Circuitex range of yarns, fabrics, tapes, foam, and wallpaper provides lightweight, flexible conductivity and EMI shielding. This enables additional protection to military personnel allowing them to remain virtually undetectable to enemy advanced sensors.Manysuchinnovationsarehappeningall around us. Some might be the best fit with our existing product portfolio; some might not be. Somemightbeareplacementforourproduct.So, to look, observe, and introspect should be our continuousmantrabeforegoingforward.

Today there is a lot more to branding than the conventionalwaysofobtainingcelebrityfootfall and mere advertisements. Today the branding dynamicsarefarsuperiorandcomplex.Itisabout talking, making your presence heard in every situation world around. Positive Branding can take you a long way and similarly, one single negative narrative can tear you down hence it is the game of being committed to your loyal customer base, community, society, and Mother Earth. Also, branding can take mere products to iconic style statements. Take the example of the recentfashionshowstopper“IndianJhoolabags”. A high-end American department store, Nordstrom,isnowsellingwhatitcallsthe“Indian

Souvenir Bag” for a staggering $48 (approximately ₹4,100). Produced by Japanese brand Puebco, the product is advertised as a creative,repurposedpiecewithaglobalflair.This is the classic example of creating brand talk for everyday products and taking the utmost opportunityfromit.

Indiahastounderstandthingshappeningnoware different from the way things happened in the past. All brands are eyeing getting the final product. All technical textile products are the demands of not just the global market but of our domesticmarketaswell.However,justproducing apartofthefinalproductandlettingtheWestern world grab the higher margins on the finished products will not take us anywhere. We need to identifyproductswithourexperienceandkeepan eye on the complete development of the textile value chain. We need to take care of not just the technology, but also all aspects from production, quality, and social compliance to competitive marketing with certifications. Also, look at the scale of operation and select the appropriate technology,wherewecanbecompetent.

Now I think the time has come to introspect ourselvesandthinkon

• What am I doing Differently? Am I producingproductsforthefuture?

• Which are the opportunities right now in frontofme?

• HowIcandosomethingdifferentnotfrom the mere point of view of earnings and more profitsbutalsoalong-termrecognitioninaniche areaandwithsustainability.

• WhichmarketIamcurrentlycateringand whichmarketdoIwishtocapture?

• Have I done market research properly? WhatismySWOTanalysis?

Ÿ Let us take an example if at all I am a regularspinner,

Ÿ HaveIovertheyearsintroducedsomething newtomyproductportfolio?

Ÿ Whether I am trying something different? Whatmycustomersareusingmyyarnfor?

Ÿ Whatismycustomerdemandingadditionally?

Ÿ Isituseofrecycledfibres?ifso,doIhavethe technicalcapabilitytoproducethem

Ÿ FinishesfortechnicalperformancecapabilitycanIstraightwayintroduceit?

Is there any possibility of introducing the innovative practice, product, or process to my regularways?Thisisessentialbecauseifthereis anotherwayandsomecompetitorisalreadydoing it then doing extremely hard work to control operatingcostsandjustcompetewillbetheonly optionavailablewithasimpleyarnmanufacturer. Simply following the four generations' products and being in the market or scaling up the production capacity is not enough. When many spinners are producing the same yarn as I am doing then it is difficult for me to survive in the long run. Simple and small innovations if not looked out for can soon lead one to be out of the raceverysoon.

So, the mindset needs to be developed wherein small changes matter, the next generationshould especiallylookoutfortherightsmallchangethat will make a huge difference in the not-so-far future. The conventional textile players should

also eye the big avenues i.e. technical textiles which are available right in front of us. How, when,inwhat,andhowmuchinvestmentarethe key questions for which answers must be sorted out.Especiallylookoutforinvestmentsthatareto be made only for introducing new product lines, innovations,ornewprocessesthatwillaltogether change the efficiency scale. Time is “now” or never…

A few of the things that are easily available for bringing into practice are the adoption of techniques for recycling fibres introducing new product variants, and adopting renewable energy resources this will make a huge difference in marginsasitbringsdownthecostofproduction, thorough retrospection of what one is doing. Changeistheanswerforallofus.

All of the textile entrepreneurs are well aware of the above needs, however, out-of-the-box thinking needs to be practiced, great minds are alsoonthelookouthoweverwhatismissingisthe “Implementation”Twomorestepsarewhereitall fallsshort.Ofcourse,thisisbecausetheexisting knowledgebasehasmanyotherjobrolestolook out for, the usuals have them all packed up, and alsoastheworldknowstherearelimitationstothe knowledge. But to be the front runner complete out-of-boxthinkingisneededfurtherthanthis.It is a must to have a market study that backs the thinkingapproach.

Adetailedstudythatanswers

Ÿ DetailedSWOTAnalysis

Ÿ The demand and supply needs of domestic andglobalmarkets

Ÿ The techno-commercial analysis of the existingsetup

Ÿ Adopting“AtmanirbharBharat”asagolden mantra

Ÿ Newinnovativemarketsegmentadaptation

Ÿ Introduction to Social compliance, green culture

Ÿ Profitabilityprojectionsforfuture

Ÿ Newproductionportfolio

Ÿ Roadmapforsuccess

These are the areas that we need to look into for better prosperity and long-lasting business philosophy.

We are ready to hand hold you for all your requirements to grow your exports in this changing global scenario. Our specialised advisory services will certainly help you in achieving your dreams in the global horizon. Pleasedonothesitatetocontactus.

-AvinashMayekar, ManagingDirector,Suvin

avinash@suvinindia.co.in +919322906199 www.suvinindia.co.in

emtec Electronic m H will showcase its innovative Tactile Sensation Analyzer TSA at rd the nternational Amsterdam Te tile Show

, ta ing lace from Se tem erto Octo er At ooth no in Hall , Ale ander r ener lo alB siness

evelo ment Manager and Phili Sievers

Sales Manager will demonstrate how the TSA transformsthewaythete tileind stry

eval ates and comm nicates fa ric hand feel

Traditionally, assessing fabric hand feel and wearing comfort has been highly sub ective, making collaboration along the te tile supply

chaindifficult.TheT Achangesthisby delivering ob ective, reproducible data on key parameters such as surface softness, surface smoothness, compressibility, stretch, friction, and thermal behavior. This enables manufacturers, mills, and brands to establish a common language for fabric quality, ensuring consistency and reliability.

By digiti ing tactile data and linking it to the cloud-based irtual aptic ibrary, the T Ahelps te tile developers

Ÿ Save time and costs in R by reducing sample shipping, iterations, and approval delays

cutting development cycles from up to 20 weeks to as little as two.

Ÿ m rove efficiency across sourcing and production workflows through digital comparison instead of costly lab dip submittals.

Ÿ Boosts staina ility byminimi ing sample waste and reducing transport-related emissions.

Ÿ Ens re ality consistency by detecting subtle variations between fabric batches that are otherwise nearly impossible to recogni e by touch.

The system also integrates seamlessly with Product ifecycle anagement P , Enterprise Resource Planning ERP , and quality

management systems, supporting the te tile industry s shift towards digiti ation, automation, anddata-drivendecision-making. Turning subjective impressions into objective data is a critical competitive advantage, says Ale ander ruener. With the TSAand our Virtual Haptic Library, we provide a scalable solution that acceleratesdevelopment,improves communication, and supports sustainability goals across the global textile supply chain.

isitors to the Amsterdam Te tile how 2025 will havetheopportunitytoe periencelive demonstrations of the T Ain all 11 at booth no. 10 and learn how emtec Electronic is shaping the future of digital fabric evaluation.

RetechAktiengesellschaft,Switzerland,byRalphvonArx,www.retech.ch

Highendheatedgodetrolls,suitedforupto350°Candultra-highdrawforces

High-quality synthetic fiber production requires uncompromising precision and process stability. Godet rolls play a key role in ensuring exact temperature control and maximum reliability. As a Swiss pioneer in thermal treatment for filament fibers, Retech has been setting benchmarksforfivedecades–withtechnologies that make production processes smarter, more efficient,andmoresustainable.

At ITMAAsia + CITME Singapore 2025, our team will be on site to share insights, discuss ideas, and show how our solutions can support yourspecificproductionrequirements.

Smart Control Technology – Predictive, Not Reactive

Retech's godet technology combines precise temperature control with intelligent sensor systems:

Ÿ UTR-6ATemperatureMeasurement& Transmission–contactless,continuous,reliable

Ÿ UCR-6 Temperature Controller – realtimecontrolandanalysisforstableprocesses

Ÿ Bearing&VibrationMonitoring–early deviationdetection

Ÿ Optional Induction HeaterMonitoring –addedsafety

Result: reduced downtime, longer component life,improvedefficiency–withsolutionstailored toeachcustomer'sneeds.

50YearsofSwissEngineering

Retech stands for Swiss engineering in heat treatment, yarn tension monitoring, and process control. We combine decades of experience with continuous innovation – delivering sustainable, energy-efficient, and future-ready production solutions.

Fromourcustomers'perspective:

"Your high-speed inline drawing equipment has been invaluable to our R&D efforts and it continues to be a strong supporter of our work. Thank you once again for providing such excellent equipment and I look forward to continuingourcollaborationandcommunication withyou."

– Dr. Wan-Gyu Hahm, Korea Institute of IndustrialTechnology(KITECH)

SustainabilityasaDriverofInnovation

Our solutions are designed not only to increase efficiencybutalsotoconserveresources.Precise process control reduces energy consumption, minimizes material waste, and extends componentlife–benefitingbothbusinessandthe environment.

Meet us at ITMA Asia + CITME Singapore 2025 28–31October2025 Hall4,StandC203

Join us for valuable conversations, knowledge exchange, and exploring collaboration opportunities.

At the forthcoming TMAAsia C TME e hi ition in Singa ore, s ecialists from a strong delegation of British Te tile Machinery Association BTMA com anies will e on hand to disc ss some of the highly advanced ind stries they are now actively s orting

The manufacture of medical sutures, for e ample, is a very specialised process and because these items are implanted directly into the human body, every stage of production is tightly controlled to ensure safety, sterility and reliable performance.

Absorbable suturesare usuallymade from polymers that degrade safely within the body, such as polyglycolic acid, polylactic acid or polydio anone, while non-absorbable sutures use durable materials like nylon, polypropylene, polyester, silk or even stainless steel. All of these must be of medical grade and fully biocompatible.

The s ibre E trusion Technology ET is a world leader in both the fibre selection and production technologies behind this industry and in ingapore will highlight a groundbreaking new parallel technology for the medical sector based on supercritical CO2. urther developments in the field of automation and control in advanced fibre productionwillbehighlightedbyBT A membersincludingAutofoam, ames eal, Roaches, trayfield, erivideand ira Instrumentation.

A Pand AT

rom the micro to the macro, sophisticated aerospace technologies such as automated fibre placement A P and automated tape laying AT meanwhile involve the precise placement of carbon fibre tapes or tows on a mould surface, which are then cured to form lightweight yet strong components.

A Pallows for comple geometries by steering individual tows, making it ideal for fuselage sections, wing skins and other curved structures.

AT , on the other hand, is more efficient for larger, flatter surfaces such as wing covers or stabilisers, where wider tapes can be laid down at high speed with minimal gaps or overlaps. Together, these technologies significantly reduce material waste, improve repeatability and deliver structural performance beyond what traditional hand lay-up methods can achieve.

The s Cygnet Te kimp has developed a new technology to greatly assist this industry which will be unveiled in ingapore.

Colla oration

ighvalueindustriessuchasaerospace, defence, renewable energy, automotive and the medical sector are areas of high growth and opportunity and an important factor underpinning the success of our companies here is the strong collaboration between industry and the many universities and institutes in the , says BT A CEO ason ent. achine builders can also be important in driving material developments as well as technologies.

A good e ample of this is the fle ible new process for manufacturing ultra high molecular weight polyethylene PE that will be introduced in ingapore by ET.

PE is pri ed in many industries due to its e traordinary properties, being for e ample, ten times stronger than steel by weight. It is increasingly used in medical implants, but the current systems for manufacturing it are on a huge scale, with very comple processing routes.

This restricts the opportunity for new product development a disadvantage that is fully addressed with ET s series lab and small scale gelspinningsystem,whichisalready industrialised.

ET is a world leader in oth the fi re selection and rod ction technologies ehind medical s t res

e have supplied many e trusion systems to the biomedical market and in e ploring what else we could do for the same customers it became clear that there was a need for smaller quantities of PE fibres in bespoke si es. e plains ET anaging irector Richard lack. e believe our introduction of a patented batch system for solvent e traction e ploiting supercritical CO2 is a game changer.

Cygnet Te kimp has meanwhile ust introduced a ne t-generation, production-scale prepreg tape slitting machine at its Innovation Centre in orthwich.

This enables organisations to trial the slitting of continuous thermoset, thermoplastic and ceramic prepreg tapes for A Pand A processes in realworld conditions using their own materials or those produced on Cygnet Te kimp s in-house R prepreg machines on the machine. The technology can slit tapes at speeds of up to 0 metres per minute, sub ect to the input material.

e re pleased to be able to offer partners the opportunity to engage with us at an early stage in process development, to test out their concepts, e plore machine parameters, assess output quality and validate performance with support from our e pert team, says raeme ones, wide web product director at Cygnet Te kimp.

Also providing back up services to the aerospace industry is Airbond, with splicing technologies whichensureresourceefficiencyinthe processing of e tremely e pensive carbon and aramid fibres. Pneumatic yarn splicing is a process established in the te tile industry for oiningyarnsandworksbyintermingling individual filaments closely together, to make oint which are stronger and flatter than knots.

e are continuing to find new partners in the wind turbine, hydrogen and aerospace industries and are doing a lot of developmental work with researchinstitutesanduniversities, says technical director Carwyn ebb. This is leading to us e panding our portfolio and we are currently working on systems for carbon tape splicing, for e ample, as well as an automated system for full weaving beams.

urther developments for the technical te tiles and composites sectors will be showcased by BT Amembers including arnett Controls, Roaches International, lack Parr and Tatham.

any BT Amembers are currently developing new technologies, either in-house or increasingly through oint pro ects, and we have much to reveal

in ingapore, says ason ent in conclusion. There s a new spirit of openness and adventurous interaction in the right now especially in the fields of advanced fibres and technical te tiles which is very encouraging for the future.

BT Acompanies taking part in IT AAsia

CIT E 2025 are Airbond stand A202, all 2 , Autofoam B 0 , all , A ACA /Cam C210, all , Cygnet Te kimp B , all , ibre

E trusion Technology B 0 , all , ames eal B 0 , all , C A20 , all 5 , Roaches A112 all 2 , aurer ibrevision C 01c, all , C Enterprises B10 , all , ellers B20 , all , helton ision B 0 , all , lack Parr 05, all , ociety of yers and Colourists B20 , all , trayfield B50 , all , Tatham 205, all 2 , The Te tile Institute B105, all , erivide B201, all , ickers

Oils B102, all 5 and ira Instrumentation

A10 , all ,

ounded in 1 0, the British Te tile achinery Association actively promotes British te tile machinery manufacturers and their products to the world. The non-profit organisation acts as a bridge between its members and the increasingly diverseindustrieswithinthete tile manufacturing sector.

At IT AAsia CIT E 2025 2 1 October, ingapore E po, all 2, Booth 201 , A TE A olutions will once again demonstrate why it stands at the forefront of te tile machinery innovation. As a global partner for complete production solutions, A TE AunitesitsthreeBusiness nits onwovens,BalingTechnology,and oollen Carding Technology to deliver tailor-made systems thatdriveperformance,efficiency,andfuture readiness.

Positioning itself as a f ll line s lier, A TE A s e pertisespansfiberopeningandcardingto crosslappers, needle looms, spunlace, thermobonding, and Airlay technologies. At the heart of this portfolio, the ineO E series delivers cost-efficient yet robust solutions for a wide range of applications.

The star attraction at IT AAsia will be the Styl s O E needle loom, designed for smart investment and sustainable performance. ith up to , stro es er min te and proven durability, tylus O E embodies the perfect balance of productivity, reliability, and cost efficiency settingnewbenchmarksfor manufacturers seeking e pansion and moderni ation.

Sha ing lo al Partnershi s – irst Orderto China

Asignificant milestone underscores A TE A s global leadership he iang Heading ilterMaterial Co , td has invested in two fiber preparation lines, seven tylus O E needle looms, and advanced end-of-line equipment. This trust in A TE A highlights not only technological e cellence but also the company s commitmenttodelivering integrated,practical solutions for demanding production environments.

riving Efficiency Across the i erChain

In Baling Technology, A TE Ais redefining the fibersupplychainwithfullyautomated systems from transport to wrapping and storage. By integrating automation into every step, manufacturers gain ma im m rod ctivity, streamlined logistics, and nmatched o erational consistency

TraditionReinvented oollenCardingwith OCT R

iththeOCTIRbrand,A TE Ashowcases modernized woollen carding machines featuring advanced drives, inverter AC and brushless servo motors, and recipe-based controls. The result faster set-ups, minimal material waste, and cost-effective production even for small lot si es proving that innovation can honor tradition while paving the way for the future.

In a rapidly evolving industry, moderni ation is essential. A TE Aoffers customi ed grades, retrofits, and system assessments, ensuring e isting installations evolve with market demands delivering enhanced performance and optimi ed costs for today s competitive environment.

E

isitors to IT AAsia 2025 are invited to discover state of the art technologies, ractical sol tions, and ins iring innovations live at A TE A s booth. Every machine, every upgrade, and every solution reflects the company s mission O rTechnology for o rS ccess

oin s at the Singa ore E o, Hall , Booth –and e erience the f t re of te tile technology with A TE ASol tions

Shanghai, Se tem er – ,

Cinte Techte til China 2025 officially concluded afterthreeremarkabledaysofinnovation, dialogue, and collaboration in the field of nonwovens and technical te tiles The event once again affirmed its reputation as one of the industry s most influential platforms, bringing together thought leaders, technology providers, and business professionals from across the globe.

ithvibrantenergyontheshowfloor, participantsengagedin gro nd rea ing rod ct resentations, the m ch tal ed a o t Econogy To rs, insightf l seminars, and a m ltit deof sinessnetwor ing o ort nities that set the stage for the industry s future growth.

At all 5, Booth A02, A TE ASol tions presentedits f t re roofnonwovens machinery ortfolio, featuring needle nching lines, aerodynamic we forming, s nlace, and thermo onding technologies

Ahighlight of ay 1 was the distinguished visit by

formerMinisterofTe tiles zho , President S n R izhe of the China Te tile nd stry ederation, President i ingshen, and President i imei They were warmly received by itian ang, eneral Managerof A TE ASol tions i, who shared the company s ourney of combining E ro ean technology with e anded Chinese rod ction ca acity The recognition and appreciation from industry leaders underscored A TE A s pivotal role in shaping nonwovens innovation.

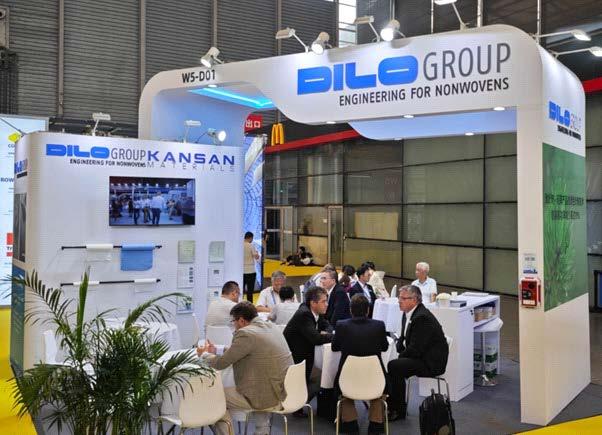

or ilo ro , in partnership with ansan Materials, Cinte Techte til China 2025 was a resounding success. At Hall , Booth , the groupshowcaseditsgloballeadershipin needle nch,wetlaid,andengineered nonwoven rocesses underthemotto “Engineering for Nonwovens.”

Overthethreedays, ilo roup sbooth witnessed

Ÿ Strong isitorRes onse Asteady flow of professionals and decision-makers, eager to e plore advanced machinery solutions.

Ÿ Technology oc s emonstrations

highlighting innovative nonwoven production methods designed to improve sustainability and efficiency.

Ÿ Colla orative m act The partnership with ansan aterials offered visitors integrated solutions for machinery and materials.

Ÿ lo alReach Thepresenceof

international buyers and industry stakeholders highlighted ilo roup s global influence.

The event further reinforced ilo ro s role as a ioneer in com ining engineering e cellence with s staina le innovation to lead the future of nonwovens.

Ÿ OR ER Hall , Booth B howcased the latest te tile weaving innovations, reinforcing their reputation as a trusted innovator in technical fabrics.

Ÿ orafin Booth emonstrated technicalte tilesolutions,withspecial appreciation e tended to their local partner Henry Hao for support.

Ÿ lo alEngagement International leaders, including Andr ang and os an Hatt m, highlighted the fair s relevance as a global meeting point for technical te tiles.

CinteTechte tilChina2025reaffirmed hanghai s position as a hub of te tile innovation and glo al trade ith strong participation from globalmachinerymanufacturers,material innovators, and thought leaders, the e hibition

provided a platform for nowledge e change, siness colla orations, and a vision of a s staina le te tile f t re

Theenthusiasm,scale,andqualityof participation highlighted a clear direction the future of nonwovens and technical te tiles will be definedby innovation,s staina ility,and cross ordercolla oration

ith this successful edition behind us, the industry is already setting its sights on Cinte Techte til China Promising an even broader scope, it will continue to serve as a bridge for technology,s staina ility,andglo al artnershi s

Ase hibitorsandvisitorsbidfarewellto hanghai, they carry with them not ust new businessconnections,butalso ashared commitment to sha ing the ne t cha terof technical te tiles

SinceArthur Julius introduced his original WetNap food wipe in 1958—later adopted by Colonel Sanders for Kentucky Fried Chicken restaurants—nonwoven wipes have transformed fromasimpleconvenienceintoaglobalnecessity. Today,theyareintegraltoeverydaylife,touching sectors as diverse as personal care, healthcare, household cleaning, and industrial manufacturing.

By 2024, the wipes industry has grown into a powerhousevaluedat$18.8billioninconsumer marketsand$4.3billioninindustrialmarkets With annual growth forecast at 6.2% and consuming 1.5 million tons of nonwovens per year,wipesarenolongerjustcommodities—they are high-performance solutions engineered for specificneeds.

ConsumerWipes–ComfortandCare

PersonalandBabyCare

Nonwoven wipes are beloved for their softness, absorbency,andskin-friendliness.Widelyused infacialcareandbabyhygiene,theyoftencontain moisturizing and soothing agents such as aloe vera, enhancing comfort while maintaining effectiveness. These attributes have made wipes indispensableinmodernroutines,particularlyfor parentsandskincareenthusiasts.

HouseholdCleaning

Theconvenienceofready-to-usepre-moistened wipes has revolutionized household hygiene. Whetherfor:

Ÿ Dustingfurniture

Ÿ Disinfectingkitchensurfaces

Ÿ Scrubbingbathroomstains

…nonwoven wipes offer speed, efficiency, and peace of mind. Many variants also integrate antimicrobial agents to combat bacteria and viruses, raising hygiene standards where it

mattersmost.

Medical and Healthcare Wipes – Hygiene at theForefront

The fight against infection has elevated nonwoven wipes into vital tools within healthcare:

Ÿ Patient care wipes ensure hygiene and comfort

Ÿ Surface disinfecting wipes reduce contaminationrisksinclinicalsettings

Ÿ Instrument-cleaning wipes withstand sterilizationandchemicaltreatments

Theirrolewasparticularlyunderscoredduringthe COVID-19 pandemic, where wipes helped safeguardfrontlineworkersandpatientsalike.

IndustrialWipes–BuiltforPerformance

ManufacturingandAutomotive

Industrial-gradewipesmustbedurable,solventresistant,andhighintensilestrength.Theyare usedtoclean:

Ÿ Machineryandtools

Ÿ Assemblylines

Ÿ Automotivesurfacesandcomponents

Theirengineeredabrasionresistanceensuresthey performreliablyunderdemandingconditions.

ElectronicsandOpticalEquipment

In sensitive environments, lint-free wipes are crucial.Designedtoleavenoresidue,theyensure precision cleaning for delicate devices such as circuitboards,cameras,andlenses.

KeyPropertiesofNonwovenWipes

Ÿ Absorbency: Quickly soaks up liquids withoutdripping

Ÿ Softness and skin-friendliness: Gentle forpersonalcare

Ÿ Durability: Engineered tensile strength andabrasionresistance

Ÿ Chemical and solvent resistance: For industrialuses

Ÿ Antibacterial and disinfecting properties: Essential for hygiene and infection control

Theversatilityofnonwovenwipespositionsthem as a growth engine in nonwovens.As lifestyles shift towards hygiene, convenience, and sustainability, demand is set to rise across all

categories:

Ÿ Eco-friendly wipes with biodegradable substrates

Ÿ Advanced healthcare wipes with improvedsterilizationperformance

Ÿ Smart industrial wipes for high-tech applications

Nonwoven wipes will continue to evolve—provingthatfromasimplefoodwipein the1950stotoday'smulti-billion-dollarindustry, theirjourneyisfarfromcomplete.

Conclusion

From baby care to automotive factories, nonwoven wipes embody comfort, protection, and reliability. They are the quiet partners in everydayhygiene,thehiddentoolsofhealthcare, andtheruggedaidsofindustry.

Asthemarketexpands,wipesarenotjustcleaning tools—they are symbols of safety, efficiency, andmodernliving.

The COVID-19 pandemic revealed to the world what the healthcare community had long understood—nonwoven fabrics are indispensable to modern medicine. When personal protective equipment (PPE) shortages made global headlines, nonwovens emerged as

lifesaving materials, providing the only effective barriers against viral transmission. From the frontline battle against infection to everyday wound care, nonwovens have become silent protectorsofhealth,hygiene,andsafety.

Facemasks–TheFirstLineofDefense

During the pandemic, multi-layered nonwoven facemasks with meltblown inner layers were recognized as the only effective shields against airborne viral particles.Their fine fiber structure provided high filtration efficiency while maintaining breathability, making them the gold standardforprotection.

SurgicalGowns,Caps,andDrapes

Nonwovens are the material of choice for PPE

suchasgowns,caps,anddrapesduetotheir:

Ÿ Barrier properties against fluids and microorganisms

Single-use sterility, reducing crosscontaminationrisks

Ÿ Lightweight comfort, ensuring ease of movementduringlongprocedures

In operating rooms, these nonwoven products combine protection with functionality, safeguarding both patients and healthcare workers.

The sterility of surgical instruments is nonnegotiable. Nonwoven sterilization wraps and packagingareengineeredfor:

· Durabilityandpunctureresistance

· Breathability,allowingsterilizingagents topenetrateeffectively

· Compatibility with steam, ethylene oxide,andgammaradiation

These properties ensure instruments remain sterileuntilthemomentofuse,reinforcingpatient safety.

Modern hospitals increasingly rely on customized surgical procedure trays, containing up to 5,000 single-use nonwovenbasedcomponents.Benefitsinclude:

· Reduced preparation time—cut by more thanhalfcomparedtotraditionalmethods

· Significanttimeandcostsavingsforboth majorandminorsurgeries

· Organized, ready-to-use sterile packaging,improvingworkflowefficiency

This innovation demonstrates how nonwovens not only protect health but also enhance hospital efficiency.

Nonwovens are central to wound dressings, bandages,andsurgicalsponges,offering:

· Highabsorbencytomanageexudates

· Breathability for a moist healing environment

· Antimicrobial treatments to prevent infection

· Softness and conformability for patient comfort

Even in the simplest plaster or band-aid, the nonwoven center patch safeguards cuts, speeds recovery, and reduces infection risks—an everyday reminder of their silent role in healthcare.

Beyond conventional products, nonwovens are advancing into innovative medical technologies, including:

· Coldandheattherapypacks

· Drug delivery patches for controlled medicationrelease

· Tissue scaffolding in regenerative medicine

Their combination of strength, elasticity, and biocompatibilitymakesnonwovensadaptableto theevolvingfrontiersofmedicalscience.

Ÿ High barrier performance against fluids andpathogens

Ÿ Absorbencyandmoisturemanagement

Ÿ Softnessandelasticityforcomfort

Conclusion

Ÿ Strengthanddurabilityforreliability

Ÿ Breathability to balance protection with usability

Fromshieldingfrontlineworkersinthepandemic to quietly protecting small household injuries, nonwovens are woven into the very fabric of healthcare. They save lives, safeguard surgical environments,streamlinehospitaloperations,and even contribute to cutting-edge medical innovations.

In a world that demands resilience, sterility, and comfort, nonwovens are not just materials—theyaretheguardiansofhealth.

Infrastructure is the foundation of modern civilization—roads, airports, railways, coastal defenses, and urban landscapes all depend on engineering solutions that ensure stability, longevity, and sustainability.Among these silent enablers, nonwoven geotextiles—typically produced from polypropylene (PP) or polyester (PET)—haveemergedasindispensablematerials.

With their versatility across separation, filtration, reinforcement, protection, and drainage, nonwoven geotextiles are playing a critical role in both traditional and nextgeneration infrastructure projects around the globe.

1.RoadsandRailways

For decades, nonwoven geotextiles have been applied beneath stone layers forming the base of highwaysandrailwaylines.Withoutthem,water flow and heavy traffic gradually destabilize the soil beneath. By allowing water to drain while maintaining soil separation, geotextiles prevent contamination, settlement, and long-term damage.Thisensures:

Ÿ Enhancedroadlifecycle

Ÿ Reducedmaintenancecosts

Ÿ Greater safety for millions of daily commuters

2.CoastalandMarineDefense

Tidal action and erosion are persistent threats to coastlines. Beneath rock armors and pre-cast concrete blocks, robust nonwoven geotextiles form a protective shield, ensuring soils are not leachedaway.Thisunseenlayerhasbeenvitalin strengtheningcoastaldefensesinprojectsranging from European seawalls to Middle Eastern artificialislands.

3.IconicGlobalProjects

Ÿ Palm Jumeirah, Dubai: The world's largest artificial island, built using 90 million cubic meters of sand and rock, relies on engineered nonwoven fabrics to separate rock bases from sandy beaches and stabilize roads

acrossitspalm-shapedfronds.

Ÿ Hong Kong International Airport (ChekLapKokIsland):Intheworld'sbiggest reclamation project, over 7 million m² of nonwoven geotextiles ensured stability as the islandexpandedfrom3to12squaremiles.

4.GreenRoofSystems

Ascitiesmovetowardssustainability,nonwoven geotextiles have found a growing role in green roofing.Theselayers:

Ÿ Actasagrowingmediumforvegetation

Ÿ Distribute and store water within root zones

Ÿ Prevent root penetration into building structures

Ÿ Provideinsulationandreduceheatloads

Ÿ Enhancebiodiversityandurbancooling

This dual benefit of structural protection + ecological enhancement is positioning geotextilesattheheartofgreenarchitecture.

Nonwoven geotextiles are engineered for durability and adaptability, with critical propertiessuchas:

Ÿ Soilseparationandreinforcement

Ÿ Effectivefiltrationanddrainage

Ÿ Erosionresistance

The demand for nonwoven geotextiles is accelerating,drivenby:

· Sustainableurbanization–eco-friendly greenroofsandstormwatermanagementsystems.

· Mega-projects in Asia and the Middle East–airports,ports,andartificialislands.

· Climateresilience–coastaldefensesand floodprotection.

From holding together sand in Dubai's Palm Islands to supporting planes at Hong Kong's Chek Lap KokAirport and greening rooftops in megacities, nonwoven geotextiles are silent guardiansofglobalinfrastructure.

Ÿ Hightearandpunctureresistance

Ÿ Superiorstrength-to-weightratio

Ÿ Permeability and water absorption balance

Ÿ Chemical,bacterial,andfungalresistance Long-termrot-proofstability

· Next-gen mobility – durable bases for high-speedrailandhighways.

™

AshighlightedbyINDEX 2026inGeneva,the world's leading nonwovens exhibition, geotextiles are no longer auxiliary—they are mission-critical materials for 21st-century infrastructure.

They embody the future of construction: strong, resilient, sustainable, and invisible, yet indispensable.

Modern buildings are no longer just bricks and mortar—they are complex systems designed to balance comfort, energy efficiency, durability, andsustainability.Behindwalls,underfloors,and beneath roofing tiles lies an unsung hero:

nonwoven fabrics. Though hidden from view, these engineered materials quietly ensure that buildingsbreathe,staywarm,resistmoisture,and protectoccupantsfordecades.

Nonwovens are widely used as breathable insulation layers placed behind walls, ceilings, andunderfloors.Theyhelp:

Ÿ Retain heat in winter and cool air in summer

Ÿ Absorb sound, reducing noise transmissioninhomesandoffices

Ÿ Improve indoor air quality by filtering

dustandparticlesinventilationsystems

HVACSystems

In heating, ventilation, and air-conditioning (HVAC) units, nonwoven filter media trap contaminants while allowing optimal airflow. These silent filters contribute to healthier indoor environments by cleaning circulated air of dust, allergens,andbacteria.

Nonwoven housewraps have revolutionized exterior protection by replacing traditional tar paperandasphaltfelts.Theiradvantagesinclude:

· Lightweight and easy installation comparedtooldermaterials

· Moisture resistance, keeping rain and wateroutofwallassemblies

· Breathability, allowing trapped water

CarrierMaterialsforMembranes

Nonwovens are engineered as carriermaterials for bituminous roofing membranes. These layers:

vapourtoescape

· Energy efficiency, by reducing air leaks whenseamsaresealed

By preventing mould, rot, and moisture-related degradation, housewraps extend the life of buildings and protect the effectiveness of insulation.

Ÿ Retain moisture while also promoting vapourrelease

Ÿ Act as insulators, lowering heating and coolingcosts

Ÿ Improve durability of roofing systems throughsuperiortearstrength

Modern airtight building envelopes, while excellentforenergysavings,createcondensation risks. Everyday activities—cooking, bathing, or laundry—release water vapour. Without ventilation, moisture condenses on cooler

Beneath floors, nonwoven carpet underlays enhancecomfortwhileoffering:

· Thermal insulation for improved energy efficiency

surfaces,damagingwallsandceilings. Nonwovenroofingmembranesmitigatethisissue by enabling high airflow and moisture vapour transport,makingcondensationunlikely.Unlike filmsthatdependonairtightness,thesebreathable nonwovensprovidelastingreliability.

· Acoustic dampening to reduce noise betweenlevels

· Structural stability for carpets and flooringsystems

Ÿ Roofingmembranesandunderlays

Ÿ Interiorandexteriorinsulationsolutions

Ÿ Superiortearandtensilestrength

Ÿ Highmoistureandvapourpermeability

Ÿ Multi-directional elongation for flexibility

Ÿ High UV resistance for durability under harshconditions

Ÿ Energy absorbency to withstand environmentalstress

As construction shifts towards sustainable, energy-efficient, and healthier buildings, nonwovens will play an even more critical role. Their adaptability enables integration into smart buildingenvelopes,greencertifications,andnet-

Though unseen, nonwovens underpin the reliability of homes, offices, and infrastructure across the globe.They protect against weather,

zero housing. From reducing energy costs to ensuring breathable indoor environments, nonwovens are the invisible foundation of moderncomfortandsustainability.

prevent condensation, insulate interiors, and clean the air—all while quietly driving sustainability.

Aconcise overview of the technology rocesses sed e g , rPET rPAso rces, mechanical vs chemicalrecycling, artners,and micro lastic mitigation ste s

Ÿ Technology rocesses

Ÿ Everlane has been on this ourney since 201 , whenwelaunchedour o ewPlastic commitment in con unction with launching our performance outerwear category. Our rPETand rPAsources today are primarily mechanically recycled,thoughsomerPAcomesfrom chemically recycled sources all are certified to the R standard to ensure process verification and content claims. icroplastic-mitigation steps

Ÿ etakeanapproachthatmirrorsthe precautionary principle from strategy through sourcinge ecution,focusedon1 reducing/minimi ing our use of synthetics to start less than 10 of our volume across apparel, footwear,andaccessoriesisattributedto polymers like rPET, rPA, and elastane , and 2 actively participating in research and partnerships with leading institutions that are helping us reduce microplastics upstream in the supply chain as well as at finished product level.

1. inimi ing use of synthetics focusing on tightly woven fabric structures e are particularlyfocusedonmitigatingplastic microfibers, the most harmful source of pollution

in our waterways. The best way we can do this is to minimi e polymer use even recycled in our products.

Ÿ As a rule of thumb, we will only add polymers to a product where there is a clear performance or durability need, and when no other alternative provides the same attributes. Today, less than 10 of our fibers by volume are polymers, half of which are used e clusively in durable, tightwovenproductslikebags,outerwear,and footwear all products that have a low likelihood of being washed frequently, if at all, and therefore lower-risk for shedding harmful microplastics.

Ÿ The remainder of our polymer use is relegated toproductcategoriesthathaveaclear performance need, such as activewear. In these cases, we suggest and recommend that our customersusemicroplasticmitigatorsfor washing,evenpointingthemtoavailable solutions such as the uppy Bag and Cora Ball.

Ÿ Back in 2021, we also launched a fellowship program called The e t Collective, investing in 5 early stage innovators at the forefront of cleaning up the fashion industry, focused on eliminating virgin plastics. The initial e t Collective fellowship targeted entrepreneurs with early-stage ideas to reduce the use of virgin plastics while also using an equitable approach to drive positive social and environmental change

across the fashion landscape. any of these innovators have gone on to have meaningful series A/B rounds of funding and operate successful business ventures at the intersection of fashion and innovative plastic removal.

2. Partnershi s with research leaders e are also keeping tabs on the latest scientific and industry research from organi ations such as 5 yres Institute, The ature Conservancy, and the icrofibre Consortium, all who we call partners to inform our approach and mitigation strategies from capture systems in wet processing units in the supply chain via ature Conservancy and microfiber testing standards via icrofiber Consortium . e also support organi ations doing the work such as urfrider and Oceana to research and remove plastic pollutants from our oceans and waterways. In addition to this, we are taking a keen interest and strategic approach to government affairs, staying up to date on state and national legislation, providing critical feedback to legislators,andpubliclysupportingkey legislative activity whenever possible. Bills we ve

publicly supported related to this topic are

Ÿ CA B 5 Packaging EPR bill passed 2022

Ÿ CA B 0 Te tile EPR bill passed 202 , and the first te tile EPR law passed

Ÿ Everlane com ines re se first circ larity via ebrand , traceability tech for rPET/rPA supply chains, regenerative cotton programs ibershed, eed2 hirt ,andsupplier decarboni ation partnerships Aii, CAP all while advancing policy, industry coalitions, and microplasticmitigationthroughdesignfor durabilityandresponsibleend-of-life management.

Ÿ icroplastic Environmental itigation Circular ashion Coalition oined in 202 to e change best practices and scale recommerce, reuse, and recycling efforts.

egislative Action upported and informed California Responsible Te tile Recovery Act B 0 , the first . . te tiles E tended Producer Responsibility EPR law.

ar re aration rocess for Everlane s Renew recycled olyester yarn

Everlane s Renew, recycled olyesteris rocessed thro gh a melt s inning system where olymerchi s are melted, e tr ded into filaments, and wo nd onto o ins, forming the fo ndation foryarn sed in weaving

Collected PET ottles are com ressed into ales and re ared for rocessing into Everlane s Renew recycled olyesterfi er, which is then e tr ded, s n, and transformed into yarn for fa ric rod ction

a ric made from recycled olyester yarn ndergoes ins ection and handling

Any data sheets certifications e g , RS, OE O TE ,ECO relevanttothe collection Our polymers are certified to the R standard. e also use safe chemistry standards like bluesign and Oeko-Te , and work with branded fibers like Econyl for specific applications like swim .

At the forthcoming TMAAsia C TME te tile machinery e hi ition in Singa ore this Octo er, Monforts will introd ce the new erti ry,averticaldryerfor sein com ination with coating machines, adders orMonforts EcoA licator nits in the s ecial finishing of technical te tiles

The fully contactless and energy optimised convectiondryerisintendedforusein combination with a stenter, either before or after it, depending on the specific application, for the essential pre-drying of sensitive fabrics, as well as after the coating of airbags, denim fabrics and glass-fibresubstrates.Otherenvisaged applications include the finishing of sportswear, outerwear, carpets, geote tiles and tarpaulins.

The erti ry can be integrated into both new and e istingfinishinglines.Asingleunitcan accommodate appro imately eight metres of fabric at any given time and multi-storey versions are also possible. This makes it very adaptable to finishing line configurations.

In addition, the erti ry can be powered by all available heating sources, or combinations of heating sources depending on the most economic route for the individual mill. The unit is further equipped with an integrated e haust air duct and can also be connected to a heat recovery system such as the onforts Energy Tower.

ifferent no le types are available for the unit which will be supplied pre-erected for shortest installation times.

The new erti ry has been designed in response to demands from the market for a space and energy saving vertical dryer to fulfil the demand in terms of CO2 reduction and the need to integrate into special processes, especially in the treatment of technical te tiles, says onforts arketing anager icole Croonenbroek. ith its contactless drying it will help our customers to produce a wide range of high-quality, added value fabrics efficiently and economically.

To learn more a o t the new vertical dryer erti ry lease visit s at TMAAsia H

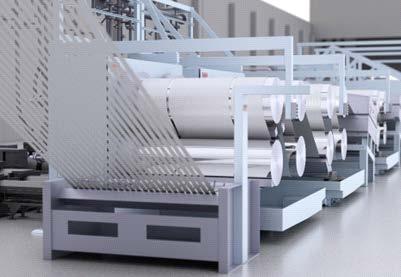

Rapidly rising recycling rates, fluctuating input qualities and high demands on product purity pose ma or challenges for recyclers especially in filtration. BB Engineering mb is responding to this with an innovative filter system the COBRA filter. This combines large-area fine filtration with inline cleaning and promises not only increased efficiency and low operating costs, but also noticeable cost reductions. In this interview, atthias chmit , eadofEngineering Recycling Technology at BB Engineering, talks about the development goals, technical features and practical benefits of the new solution.

MrSchmitz, what was the main motivation ehind the develo ment of the COBRAfilter

Schmitz The filtration requirements in PET recycling are high. The input material is often heavily contaminated, but at the same time the quality of the end product must be right. Conventional filter systems quickly reach their limits either they cannot achieve the necessary filtrationfineness,ortheyaree tremely maintenance-intensiveandcomplicatedto handle. And yet filtration plays a key role in recycling. Our motivation was to develop a system that could overcome these challenges efficiently, automatically and with as little waste of resources as possible.

The res lt is an a tomated large area fine filter with inline cleaning – a system that has never e isted efore Can yo tell s more a o t the COBRAfilter hat ma es it s ecial and how does it stand o t from e isting filtersystems

Schmitz E actly. Our COBRAfilter is a continuouslarge-areafinefilterwithan automated cleaning process directly in the filter anovelty in this form. e use pleated filter cartridges in two filter inserts so that COBRAcan produce non-stop. witching between the two filter inserts is automated, as is inline intermediate cleaning. hile one filter insert is in production, the other insert is cleaned. The whole system is closed and runs without manual intervention or cleaning chemicals. Our hite ilter Cleaning

technology works e clusively with superheated steam and restores the filter cartridges to an operational condition. This e tends the service life of the filter many times over and protects the materials.Insummary,ourCOBRAfilter achieves significant efficiency gains through integrated intermediate cleaning, requires only minimal operating effort thanks to automation, and is very safe in terms of both process stability and handling.

There are many e citing as ects to this et s first ret rn to the to ic of filtration itself COBRAisalarge areafinefilterwith cartridges hy do yo se this artic lar method and how effective is the filtration

Schmitz arge-area filtration has the stigma of high costs, high maintenance and time-consuming conversion and cleaning work.This is why many producers shy away from large-area filters. owever,theyofferthebestfiltration performance, which is essential, especially with increasing rPETproportions. That is why we have createdalarge-areafilterthatprecisely overcomes these known weaknesses. ith its pleated filter cartridges, COBRAoffers a filter area of up to 2 m2 with a fineness of up to 20 μm. COBRAtherefore filters more finely than screen changers or laser filters and can absorb a larger amount of contamination. This makes it perfect for recycling applications or other demanding filtrations tasks, such as synthetic fibre spinning and film production. In a filter test with rPET, the COBRAfilter with 20 μm showed a filter pressure value of 1,5 bar/kg/cm2, which corresponds to the quality of virgin material.

o ra roach to the high o erating costs associated with changeoverand cleaning is the intermediate inline cleaning How e actly does it wor

Schmitz e have been offering our hite ilter Cleaning C filter cleaning system as a standalone solution for several years now. This intermediate cleaning of filter inserts does not require any chemicals and uses only superheated

steam. This protects the components, is more costeffective and also significantly safer for operators and, of course, for the environment. The C system is now fully integrated into the COBRA and can therefore be used as a closed system with filtration to its full advantage. The filter control system signals when intermediate cleaning is required, switches production to the second filter insert and initiates cleaning. The filter insert remains in the filter and is automatically drained and then repeatedly e posed to superheated water vapour in several hundred cycles until it is ready for operation again. The cleaning process takes only 10 hours, whereas pyrolysis and chemical cleaning require several days.

hat advantages does this offer rod cers

Schmitz COBRAoffers advantages in many respects. Operators do not have to handle molten liquids or hot components, and there is no need to spendtimeonchangeoversandcleaning. urthermore, the consumables and materials have a longer service life because they are cleaned gently, without aggressive chemicals or the e tremely high temperatures of pyrolysis. The costs for chemicals and their disposal are eliminated. ltimately, COBRA s automation and intermediate cleaning lead to noticeable OPE savings in terms of personnel, energy, materials, and parts. owever, in our view, the biggest advantage is the significantly longer service life of the filter. Thanks to the intermediate cleaning cycles, the filter can remain in use appro . -5 times longer before it needs to be cleaned and inspected again. This means a significant increase in efficiency, especially in recycling, where service lives tend to be shorter rather than longer. This also applies to downstream processes.

To the downstream rocesses – in what res ect

Schmitz The high filtration performance of the COBRAfilter makes the melt so clean that downstream cleaning steps are significantly reduced or even eliminated. This saves time, material, and energy. In addition, there are fewer interruptions in the production chain due to residual particles in the melt. This is a decisive advantage, especially in demanding applications such as the packaging or te tile industry.

Arethereanya lications eyondPET

Schmitz efinitely. Although the COBRA filter was developed with a focus on PETrecycling, its modular design means it can also be used in other areas such as plastic spinning or the processing of technical plastics. herever high-purity melt is required, and contamination is to be e pected, COBRAcan demonstrate its strengths, even as a retrofit solution in e isting plants.

How do yo see the f t re of filtration in the conte tofthecirc lareconomyand s staina ility

Schmitz iltration already plays a key role in recycling and will become even more critical if we want to achieve really high recycled content in high quality products. To do this, filters have to perform well under high levels of contamination whileremainingefficient. hat smore, sustainability doesn t ust start with the product, but with the process design. I believe that solutions such as COBRAhelp to ensure that recycling remains economical, becomes more efficient and becomes even more widespread in industrial applications.

ill the COBRAfilter e on dis lay at coming trade fairs

Schmitz e will be at the show in sseldorf in October and will also be holding an in-house e hibition at our technical center at the same time. The COBRAfilter will of course be one of our main topics there. e will also be represented at the booth of our parent company Barmag at IT A Asia in ingapore.

mage Rendering of the new COBRAfilter from BB Engineering Asia in

International technology roup A RIT will bepresentingitsinnovativenonwovens production and te tile solutions at IT AA IA

CIT E 2025 in ingapore, from October 2 to 1,2025 all2, 10 .A RIT will showcase its C production plants, te tile sorting and recycling, bast fiber processing, needlepunch,airlay,andlife-cycleservice technologies,withafocusonsustainable solutions. iscover how these innovations can grow your business opportunities and support a greener future.

MMC

AtIT AAsia,A RIT introducesits competences in production plants for man-made cellulosic fibers C , namely lyocell a rapidly growing market driven by demand for sustainable materials. The solutions cover the full scope, from engineering to speciali ed equipment like flash dryers and pulp preparation systems. ith decades of e pertise in pulp and paper, A RIT also provides audits and upgrades for e isting plants. The lyocell process stands out for itsenvironmentalbenefitsandhigh-quality output, making it a key technology for the future of te tiles and nonwovens.

A RIT has always been a pioneer in providing industrially and economically viable solutions that bring the circular economy to the world of te tile fibers. Thus, A RIT is not only a reliable supplier but also a knowledge provider. The company offers everything from automated te tile sorting and te tile fiber preparation to mechanical and chemical recycling and combined processes.

Aparticular focus is placed on A RIT s automatedte tilesortingprocess,asthis represents the missing link in the true circular economy for te tiles. The unique process has been developedthroughacollaborationbetween ouvelles ibres Te tiles, Pellenc T, and A RIT .Thesystemsortsgarmentsby

composition and color, removes hard parts like buttons and ippers, and prepares materials for further processing. It enables efficient recycling of post-consumer and post-industrial te tile waste intofibersforspinning,nonwovens,and composites. The implementation of automated sorting technologies marks a turning point in the globalefforttoreducete tilewaste.By addressingthecorechallengesoffiber identification, color sorting, and contamination removal, A RIT is paving the way for truly closed-loop te tile recycling.

A RIT introduces the new -Pro crosslapper, a groundbreaking innovation in the crosslapping process for needlepunch and spunlace lines. This new machine sets unrivalled standards in speed, productivity, and quality, overcoming traditional limitations. Its unique -path design ensures precise fiber control, eliminating distortion and enabling flawless overlap regardless of web characteristics.Thesystemma imi es th roughputandfabrichomogeneitywhile maintaining superior quality. Additionally, it is fully compatible with A RIT s Pro in profile correction system, enhancing performance and efficiency to unprecedented levels.

E PA S O O EE E OOM PORT O O E E OOM OR ME M RA E CAPAC T ES

In the area of durable nonwovens, A RIT is pleased to present the new ne loom needleloom, specifically designed to meet the demands of medium-range production capacities across key markets such as synthetic leather, filtration, and automotive applications. Engineered for robust performance and cost efficiency, the ne loom combines the renowned A RIT quality with features that reduce operational and maintenance costs. The machine supports a random needle pattern for enhanced product characteristics and offers optional systems including automatic greasingandcooling,furtherimproving reliability and ease of use.

ith a speed range of 50 to 1200 rpm and a

stroke range from 25 to 0mm, the ne loom represents a strategic addition to the A RIT portfolio,reinforcingitscommitmentto innovation and customer-focused solutions in the nonwovens industry.

A RIT highlightsitstechnologiesfor processingbastfibers,whicharegaining importance across industries such as automotive, insulation, geote tiles, construction, and te tiles. nown for their low environmental impact and local sourcing potential, bast fibers support circular and ero-waste production models. One ma or trend is the use of industrial hemp in airlay applications. A RIT offers complete lines combining decortication and refining equipment with ne line airlay systems. These lines are designed for gentle fiber processing, compact layout, and low energy consumption, delivering high-quality fibers suitable for a wide range of applications.

oreover, A RIT offers a multi-technology, one-stop-shop approach for bio-based te tile fiber production. This includes automated sorting, mechanicalandchemicalrecycling,and decortication lines for fla , ute, hemp, and kenaf. Byuniquelycombiningthesetechnologies,

A RIT supportstherisingdemandfor sustainable products and empowers companies to achieve long-term economic success in a dynamic market.Thesesolutionsopenupn ew opportunities in both spinning and nonwoven markets, enabling the creation of value-driven, innovative products.