Editor-In-Chief Paul Galea

Editorial Co-ordinator Chelsea Hilsberg Editor John M Stanley Creative Director Dean Parrott

Published for and on behalf of PPG Industries Pty Limited by

Editor-In-Chief Paul Galea

Editorial Co-ordinator Chelsea Hilsberg Editor John M Stanley Creative Director Dean Parrott

Published for and on behalf of PPG Industries Pty Limited by

Kisschasey Creative Pty Ltd

Unit 113, 91 Murphy St. Richmond, Victoria, 3121 Telephone (03) 9421 3311

Australia Head Office

Locked Bag 888, Clayton South, Victoria 3169. McNaughton Road, Clayton, Victoria, Australia, 3168 Telephone: 13 24 24 www.ppgrefinish.com.au

New Zealand Head Office 5 Vestey Drive, Mt Wellington, Auckland, New Zealand. Toll Free Telephone: 0800 320 320 Victoria 104-106 Woodlands Drive, Braeside, 3195 Telephone (03) 8586 0000

New South Wales 10 Peter Brock Drive, Eastern Creek, 2766 Telephone (02) 9854 6600 Queensland 18 Breene Place, Morningside, 4170 Telephone (07) 3823 8000

South Australia 97-105 Bedford Street, Gillman, 5013 Telephone (08) 8346 6870 Tasmania 136 Invermay Rd, Invermay, 7248 Telephone 1300 305 699

Western Australia Unit 2/6 Colin Jamieson Drive, Welshpool, 6106 Telephone (08) 9256 3920

Why Advanced Driver Assist System should be on your radar

Small, regional repairer becomes a MoonWalk leader Centre of attention

Toyota Australia’s A$40-million-dollar new ‘Product Centre’ is not just an incredible facility where homegrown engineering and design talent can thrive. It also continues the strong global contributions to some of Toyota’s most iconic and bestselling models.

Behind the scenes in PPG’s Clayton Colour Lab

How the light source affects accurate colour matching

Thanks to an incredible response around the globe, PPG’s exclusive MoonWalk automated paint mixing technology is dramatically altering the way collision centres operate. MoonWalk’s astonishing popularity actually saw it pass a major milestone recently when the 1,000th unit was installed at Group Perez Rumbao’s facility, in Spain. Along the way, MoonWalk’s

ability to precisely mix even small volumes, while saving labour and reducing waste, has seen it honoured with a growing list of prestigious awards. This includes the 2019 Special Innovation award from Equip Auto International Grands Prix for Automotive

Innovation; the 2020 Bodyshop Equipment of the Year award from Décision Atelier Magazine; the 2020 Technology and Innovation award from Bodyshop magazine, and the 2021 Sustainable Innovation award from the British Coatings Federation.

For more information and to see a video of MoonWalk in action, go to: www.ppgrefinish.com.au/products/consumables/moonwalk

The Refinish Marketing team at PPG’s Clayton headquarters recently took timeout to get hands-on with some of the products and processes that go into a typical repair job. The full day of training at the PPG Victorian Training Centre, in Braeside, saw the six team members start by preparing two panels using MIRKA electric power tools and abrasives. Later, SATA spray guns were used to apply a range of PPG products under the guidance of a PPG technical expert. This included Wet-On-Wet primer, DELTRON® solvent borne basecoat and ENVIROBASE®

High Performance waterborne basecoat. The final touch was LVC-136 EN-V Performance Clearcoat. The overall aim was to get a better understanding of PPG’s customer base, says Chelsea Hilsberg, Senior Marketing Specialist. “It was great to actually use products I have been so

involved with when creating marketing materials and promotions. My biggest take away was the obvious difference between solvent borne and waterborne technologies. I can totally understand why Envirobase High Performance is the region’s most popular refinish system!”

Despite all the roadblocks put in place by the COVID pandemic, a massive effort from the PPG organising team and TAFE facilities around the country has seen the 2021 PPG Colour Matching Competition successfully completed. Although a little later than anticipated, the final placings were recently announced via a special video presentation at: https://youtu.be/nY-vuDP9Xp8. Congratulations to everyone who participated throughout the year! R

For cyclists, being seen is part of staying safe, especially at night. For this reason, Lyft E-bikes is taking advantage of the world’s first commercial retroreflective powder coating – PPG’s Envirocron LUM. Indeed, the American transport service support provider is set to use PPG Envirocron LUM technology on a whole fleet of e-bikes, under the company’s DIVVY bike-share program. Using a formulation with embedded glass beads, the groundbreaking, single-layer

coating refracts light and retroreflects it directly back to a vehicle’s driver to enhance visibility. While liquid-based retroreflective coatings are commonly used to increase visibility on road markings and street signs, PPG Envirocron LUM is the first-ever retroreflective powder coating. It also features high transfer efficiency and exceptional scratch and mar resistance in a non-solvent solution, says Paul Bradley, PPG Technical Manager, Industrial Coatings. “PPG has been at the

Regardless of the industry or segment, you typically see periods of stagnation, along with slow and steady incremental change. However, occasionally the foundations are rocked by a truly game changing development. In the collision refinish segment, colour has become a specific focal point as we have seen vehicle OEMs rely more heavily on sophisticated colours to launch and differentiate new models. In meeting those challenges, I would say the segment has seen some good incremental improvements over the past few years, predominantly based on pigment development and more intense training.

However, a series of game changing, PPG developed technologies are about to shift things up a few gears very quickly. In isolation, each of these innovations bring an impressive range of efficiencies but, when they come together, they will radically change the game when it comes to colour selection and matching. They come under the ‘PPG LINQ’ umbrella and it began with the launch of the MOONWALK® automated mixing system (see page 10). Whilst PPG has been relatively secretive about the final end game, make no mistake, the developments don’t stop there.

On June 22nd, PPG globally announced the rollout of ‘DIGIMATCH’ and ‘VisualizID’ –individually these are significant innovations but together they are true game changers for the modern paint shop. I recommend taking the time to absorb the information about DIGIMATCH and VisualizID to get a clear understanding of how they transform the colour matching process. Then get set for the next batch of innovations that are set to flow out of PPG’s technology pipeline! R

forefront of retroreflective powder coating technology for several years as part of our commitment to innovation and sustainability. We are proud to partner with Lyft in its efforts to produce high-visibility e-bikes as part of our shared commitment to enhance on-road safety.” R

Advanced Driver Assist Systems (ADAS) are not new but, as they have become more commonplace, correctly dealing with them in the repair scenario is posing new challenges.

Although ADAS technology started out on high-end vehicles, today it’s very much mainstream. Indeed, a variety of ADAS components are now fitted to an ever-widening selection of vehicles, right down to budget models. In basic terms, ADAS is designed to scan the vehicle’s

surroundings to help the driver navigate a safer, smoother path on their journey. However, this generally means that ADAS sensors are located on the extremities, such as on or behind bumper facias, where they are especially vulnerable to typical accident damage.

Current ADAS sensor technology covers four main categories:

Ultrasonic – Uses reflected sound waves to calculate the distance to objects at a relatively short range. Mostly used to aid parking but can also be found in more complex functions, such as park assist, self-parking and some blind spot monitoring applications.

Radar (RAdio Detection And Ranging) –

Transmits radio waves and detects objects by measuring the time it takes for the waves to reflect back from any object in their path. Widely used for a variety of functions, including adaptive cruise control, blind spot detection, cross traffic alert, lane change assist and for parking.

Cameras – Although they have their limitations, cameras are the only sensors able to identify colour and contrast which gives them the ability to capture road sign and road marking information. Cameras also offer the resolution to help classify objects, such as pedestrians and cyclists, and are often used in conjunction with radar.

LiDAR – Seen as a key solution for future ADAS, it has so far only seen very limited applications. It works by transmitting a laser beam and then measures the reflected

light to generate a highresolution 3D image of the surrounding environment.

One issue is that LiDAR doesn’t reflect back from all colours equally, meaning darker coloured objects, including vehicles, are not as visible to the sensor. PPG is working on coatings technologies to overcome this.

For pretty much every collision repairer in the region, ADAS should now be very much on the radar (pun intended). At the very least, that means educating yourself on the basic workings of each system and how it should be treated before, during and after a repair. Having done this, Lloyd Taylor, from Precision Collision, in the northern

WA town of Karratha, went looking for the best method for his business to deal with ADAS.

“Being in a fairly remote area, we have a very limited dealer support network. Sometimes, a post-repair ADAS calibration meant putting a vehicle on a tow truck for a 1600km trip to Perth. It was horrible – in total, it took at least a couple of weeks and then there was the potential damage the vehicle could collect on the way. Even if the brand was serviced by a local dealer, it could still take a couple of weeks to book a vehicle in and get a calibration done. Overall, we recognised that dealing with ADAS was one of the main things holding up our key-to-key cycle-time and, on top of that, we hate losing control of a repair to a third party. As we started exploring our options and looked at what was happening in the US and Europe, aftermarket ADAS calibration systems began popping up but they seemed very complex. That is when we came across ADAS Solutions Australia. With their help, we identified the main brands we work on – Toyota represents about 60% – and the main ADAS sensors we deal with which is front radars and blind spot monitors. As a result, I sent our Workshop Manager, Glen May, to visit ADAS Solutions Australia in Brisbane to get a feel

for the equipment and do some training. Following their recommendation, we decided to invest in a package of ADAS calibration equipment.”

According to Adrian Parkes, founder of ADAS Solutions Australia, ADAS technology represents a revolutionary step for the automotive industry so it’s no surprise that it’s taking some time for collision repairers to get their head around it. Although just two years old, the business is thriving with eight staff and a range of services on offer.

“There is really no part of the industry that is not impacted by ADAS. For example, we have a team of technicians who, on a daily basis, conduct ADAS calibrations and diagnostics for smash repairers, windscreen replacement outlets, mechanical shops and auto elecs.

At the moment, it’s predominantly covering south east Queensland and Adelaide but we intend growing the business to a national footprint for calibration services. We also have all the other boxes ticked,

including technical support, equipment supply and training. We believe our expertise puts us in the best position to consult with and guide customers through the process of choosing the best investment in equipment. Rather than sales people working for a particular brand, we are an independent organisation who understands the wider market.”

“By asking a lot of questions, such as where are you geographically, what is your vehicle park, what are you looking to achieve, what is your investment level, etc., we build a clear picture of what that repairer needs. From there, we can recommend a package of equipment. Typically, businesses might buy a kit that allow them to do 60% to 70% of vehicles that come through and send the remainder to us if we are nearby or to the traditional dealer network. The investment can range between around $10,000 up to $70,000 or even more. Precision Collision is a really good example. Lloyd’s investment for the tailored package of equipment has been relatively small but his return on investment has been really good.”

After consulting with ADAS Solutions Australia, Lloyd Taylor says he is very happy with the outcome. “Our aim was to control the repair as much as possible without sending vehicles to a third party at a local dealer or to Perth. The scan tool that drives the calibration is used every day and it lets us do pre and post repair scans. The pre-scan protects our company by alerting us to any existing faults and the post-scan lets us calibrate the ADAS sensors and check that everything is plugged in and working correctly. I feel really confident having a trained, senior staff member controlling calibrations, as opposed to someone at a dealership who may or may not be as trained and committed. If we have any issues, ADAS Solutions Australia remotely supports us by dialling into our scan tool and guiding us through the calibration.”

ADAS technology is not going away – it’s only going to get more complex, says Adrian Parkes. “The overwhelming response from our customers is satisfaction, security and trust that they have found someone who can support their needs. We have built the ADAS Solutions Australia business around integrity and I think they appreciate that. Whether you are one of our customers or not, we encourage people to use the ‘Data’ set on our webpage https://adassolutions.com.au/. It’s updated monthly and you can use filters to get a better understanding of the types and percentage of vehicles that are requiring a post repair calibration.”

ADAS (along with autonomous driving functions) feeds off a continuous stream of information from sensors which monitor the vehicle’s surrounding environment. Obviously, the ability of these sensors to do their job without interference is crucial.

As a result, repairers need to familiarise themselves with the various ADAS technologies and have a process in place to safely and effectively deal with each one.

OEM warnings and recommendations – A steady stream of OEMs have issued warnings around the refinish or repair / replacement of areas containing ADAS sensors so it’s important to keep up-to-date with these and follow any recommendations.

Scan before and after – While it’s crucial to scan ADAS following any repairs, it’s also important to scan before starting the job.

By including ADAS as part of the general vehicle system pre-repair check, you will know exactly what you are faced with, identify any potential hidden damage and avoid nasty surprises when the job is done.

Body filler and plastic repairs – Because it can block outgoing or return signals, no body filler or plastic repairs should be used on external surfaces around ADAS sensor locations.

Film builds – All refinish paint layers can impact on ADAS radar signal performance but the reflective properties of aluminium pigment make it a particular issue if the film build is too high.

The local PPG technical team has done a lot of research on this issue, resulting in a recommendation that the upper limit for basecoat silver colours, in both waterborne and solvent-borne, should be no more than 40 microns. Note that three coats of ENVIROBASE® High Performance waterborne basecoat equals around 12 to 14 microns and three coats of DELTRON® basecoat equals around 20 to 25 microns. No extra colour – When repairing painted parts, no extra colour should be applied over the areas where radar sensors are located (eg, in a blend area). Instead, remove the paint back to the substrate and reapply the coatings layers. Remember to check film build.

Radar cruise control sensor – This sensor should be masked off before painting and care should be taken when using drying lamps (eg, infrared) – don’t exceed 60°C object temperature.

Ultrasonic parking sensor – Remove sensors from the bumper cover before painting as any additional paint will affect their performance. Paint them separately, with minimal paint or avoid painting, if possible – for example, if the bumper skin is being replaced but not the already painted sensors. Care should be taken when using drying lamps (eg, infrared) – don’t exceed 60°C object temperature.

R

One of the first businesses in Australia to install PPG’s groundbreaking MOONWALK® automated mixing technology is actually far away from the bright lights of a big city. In fact, Lakes Entrance Smash Repairs is located in the sleepy fishing / tourist town of Lakes Entrance, around 320km east of Melbourne. It’s home to just over 8500 people, including Paul Theologou and his son, Steven. When he bought Lakes Entrance Smash Repairs, around 20 years ago, Paul says it was pretty rundown but he has since made consistent upgrades and investments, as they have become affordable.

PPG’s ENVIROBASE High Performance waterborne installed – they said, ‘you don’t need it’. That was over ten years ago and we were the first shop in Eastern Victoria to do that but going with Envirobase is one of the best decisions we ever made thanks to the colours and the amount of time we save. It was the same when we had the gas infrared arch fitted in the booth – it makes a huge difference to the quality of work, as well as the speed and the much lower gas usage.”

“When I saw in The Refinisher magazine that MoonWalk was coming, I called Rowan Kenny (PPG Territory Manager). He thought I was mucking around but I convinced him

Steven joined the business as an apprentice painter around 16 years ago, at the tender age of 15 years old. Today, he runs the paint shop and has inherited his father’s drive to keep up with the latest technology. According to Steven, MoonWalk has made a significant contribution to paint shop operations.

“To be honest, for a shop our size, the MoonWalk is a bit of a luxury but it’s a great tool to have and I love it. As a painter, MoonWalk takes the stress out of mixing, particularly when it’s a small amount, it doesn’t make mistakes. And I have noticed that colours are even better than

actually afford to mix a little less. If after the first coat you find it’s not going to be enough to finish, you just get MoonWalk to mix another, say 50ml, while the first coat is flashing off.”

“Using MoonWalk means we know exactly how much paint has been used for each job and we have found that our paint stock is lasting longer,” Paul explains. “Because the tinter bottles sit upside down in the machine, you get to use every last drop instead of throwing away the bottle with a little left in it.”

shop, two panel beaters and a mechanic, as well as Steven’s wife, Janita, in reception.

“I enjoy seeing the nice equipment we have to look after customer cars – it gives me a sense of pride,” says Paul.

“Occasionally, an insurance company representative will drop in to check out where they are sending work. I think they expect some dingy little shop but they find we have lots of the latest tech. They see that we are investing so we must be serious. When you look at the MoonWalk investment, you actually get quite a lot for the money – you get the MoonWalk machine, a spectro and a full set of Envirobase tinters. We also took advantage of the (Australian Government) instant asset writeoff which really helped to minimise the cost.”

As the town continues to grow and the workload increases, Paul sees the need to add another painter in the not-too-distant future. It’s here that MoonWalk gives an unexpected benefit.

“When we go to hire someone, MoonWalk and the other technologies we have will be an attractive thing. It’s hard to find good staff so high-tech tools are something we have in our favour. We believe that, with a good flow of work and by continuing to keep up with technology we can employ more

Market leading coatings aren’t the only way that PPG works to ‘Protect and Beautify the World’ – PPG Teslin EMI/RF shielding material is helping to win the battle against identity fraud.

There is an unseen battle going on. Notorious individuals and organisations are trying to ‘skim’

more than 75 nations around the globe currently rely on PPG TESLIN® substrate to secure and protect embedded electronics in their passport covers due to the material’s tamper-evidence capability, cushioning and durability.

Part of PPG’s Specialty Coatings and Materials business, Teslin is a singlelayer, polyolefin-based material that is in a category of its own among synthetic papers and printable plastics. This is because it’s engineered with a microporous matrix that allows it to absorb and create strong interlocking bonds with inks, adhesives, coatings and laminating films. As well as making Teslin substrate breathable and lightweight, this microporosity also lets it combine insulation, cushioning and other exclusive performance

benefits in a way that no other synthetic substrate can equal.

PPG Teslin EMI/RF (Electro Magnetic Interference/Radio-Frequency) is the key technology when it comes to a shielding material that offer enhanced RF-shielding performance for electronic passports (e-passports) and other electronic security documents. Recent improvements have introduced new options that enhance the substrate’s RF signal blocking and detuning performance over greater distances, enabling e-passports fabricated with the material to more effectively protect the personal data of travellers – even when their passports are slightly opened. Other benefits include high-definition colour photos, laser-engraving capabilities, built-in tamper evidence and flexible production and issuance options.

“This improved shielding material is a great example of how our products can fulfill PPG’s commitment to protect and beautify the world,” said Pierre Scaglia, PPG Global Segment Manager, ID and Security. “Whether through new physical or digital technologies, our customers are always looking for innovative ways to increase document security in the never-ending battle against identity fraud. Customer response to our RF shielding material has been very positive since the product adds value and a complementary option to their document security toolboxes.”

In fact, PPG Teslin EMI/RF is generating global interest as a shielding solution that is ideal for a variety of products which can benefit from its signal-blocking capabilities or that require shielding or a durable grounding path to function properly. Examples include credit card pouches, electronic toll pass containers, grounding tapes, wearables, circuit boards, antennas and consumer electronics devices. R

To learn more about PPG Teslin EMI/RF shielding material, visit teslin.com/RFshield.

Aspray gun is a precision piece of equipment and how you treat it will directly influence the way it operates. Treat it properly and will be a real asset that makes a painter’s life easier or treat it poorly and it can result in poor work standards and even reworks. This is especially true when it comes to cleaning operations and it’s where the new SATA Multi Clean 2 can give you a significant advantage. Whether it’s a rinse after each paint application task or a deep, thorough clean at least once a day, the SATA Multi Clean 2 gives you the option of a powerful, yet gentle, automatic washing cycle or a hand washing mode. It’s driven by a high performance, robust, low-wear double diaphragm pump that delivers a long lifespan of efficient and effective gun washing. Internally, there are two separate storage container systems – one for the cleaning phase and another for the rinse cycle. Because fresh cleaning solution is only used for the rinsing process, this ensures an impressively low solvent consumption of just 200ml of pure

cleaning solution for each cleaning cycle.

In addition, a replaceable filter inside the cleaning system container helps to capture coarse residue from the washing process and, therefore, keep it out of the cleaning fluid containers.

The automatic cleaning cycle is the easy way to get thorough cleaning of all material passages of the spray gun. Because it’s crucial to protect other internal parts of the gun, a low-pressure air connection prevents the cleaning solution from penetrating the air passages of the spray gun

during the cleaning and rinsing process. The manual cleaning mode is perfect for things like pre-cleaning of the gun and cup. It features a pedal activated flow of cleaning fluid to the brush and is a closed system that is VOC compliant. No matter which mode is being used, an automatic fume extraction system protects the operator from harmful vapours whilst the lid of the cleaning chamber is open.

SATA may be best known for its precision, German engineered spray guns but its latest SATA Multi Clean 2 benefits from the same attention to detail. For cleaning with economy, power and simplicity, it has all the answers. R

The SATA Multi Clean 2, along with a range of SATA spray equipment, is available from authorised SATA distributors across Australia

Economical, powerful and simple to use, the SATA Multi Clean 2 gives your SATA gun (or any other spray gun) a thorough clean that keeps it at peak performance.

On the 20th December 2020, Luke McCue made a fateful decision. This seemingly simple choice is one that many would be familiar with at some point in their lives – he drove while fatigued. Following a shift as an apprentice auto-electrician, the 18-year-old went on to complete a shift at his second job at Bunnings, before heading home. He didn’t make it. Not far from the family farm near Crookwell, in country NSW, Luke’s car ran off the road, hit some farm machinery, and he

was tragically killed. For his parents, Glenda and John, and his wider family and friends, it was a heartbreaking end to a young life that held so much promise. As well as being a talented sportsman and school captain, Luke was working hard to pay for his passion for cars and fishing, says John McCue.

“Luke had already done-up a WB Holden One-Tonner and had started on a HZ Holden Sandman Panel Van. After he was killed, I couldn’t stand looking at it in the shed. I didn’t know what to do but, somehow, I got hold of Greg Maskell who took on the project and created the unbelievable car you see now.”

When John’s phone call came out of the blue, Greg Maskell and his team at Maskell’s Custom and Classics, in the northern Victorian city of Shepparton, already had a couple

of years of work booked in. Not wanting to give a flat ‘no’, Greg started to delve a little deeper.

“The bloke on the phone (John) said he wanted us to do a resto on a Holden Panel Van but I was struggling to see how we could fit it in. To get a better picture, I asked what he wanted to do with the car. John said, ‘I want to sit in it and cry’. He explained about how Luke had passed away just a few weeks before and that changed the ballgame. I knew I was going to struggle to say no but I had a problem – at our Christmas breakup, I had told the team that I was not going to increase the

After the tragic loss of a young life, a tsunami of support has come together to complete an iconic build that helps spread awareness about the dangers of driving when fatigued.

workload by taking on any extra projects over the year. After John and Glenda drove around six hours to visit us, I showed them the workshop and introduced the team. They are really good people who have been through a hell of a time but, if we were going to do it, it had to be okayed by the team. At lunchtime, I explained the story and said if anyone of them says ‘no’, we won’t take on the project. Every one of them said ‘yes’ we have to do it!”

From the very first social media post Greg made, support for the project went

ballistic. “I posted a thanks to John and Glenda for giving our team the honour of doing the restoration and almost immediately our suppliers contacted us to offer products. One of the first was Dale Parkinson (Territory Manager Victoria) who said PPG would love to support the project with whatever they could. In the end, we had 23 different supporters! Originally, we were doing a regular, good quality restoration but as the products continued to roll in, we needed to up the ante even further.”

When it came to the colour, it was actually Luke who made the choice, according to Greg. “In Luke’s bedroom, John and Glenda had found two printed pictures of what the van was to look like when it was finished and both were Windsor Blue which is a factory Holden colour. We got PPG to mix it for us and the final result looks very cool.”

As well as pushing the envelope in terms of quality, the biggest challenge was to hit the deadline of completing the car for Luke’s birthday on 12th November 2021. In the end, the job took exactly six months from start to finish and it was only COVID restrictions that saw it delivered slightly behind schedule.

As the project rolled along, the social media buzz in the background was phenomenal, leading to a groundswell of interest to see this iconic tribute to Luke in person. The result was a request from Street Machine magazine to appear at Summernats 2022 and an invite from PPG

to display the car at the Showcars Melbourne PPG Showdown in February, says John.

“We are not into car showing but doing these events has introduced us to a different world and the support we have received gives you more faith in humanity. We are happy to do these events for anyone who supported the project. It has given us the opportunity to get the message out, particularly to younger drivers, to look at their lifestyle and not take the risk of driving when fatigued.” R

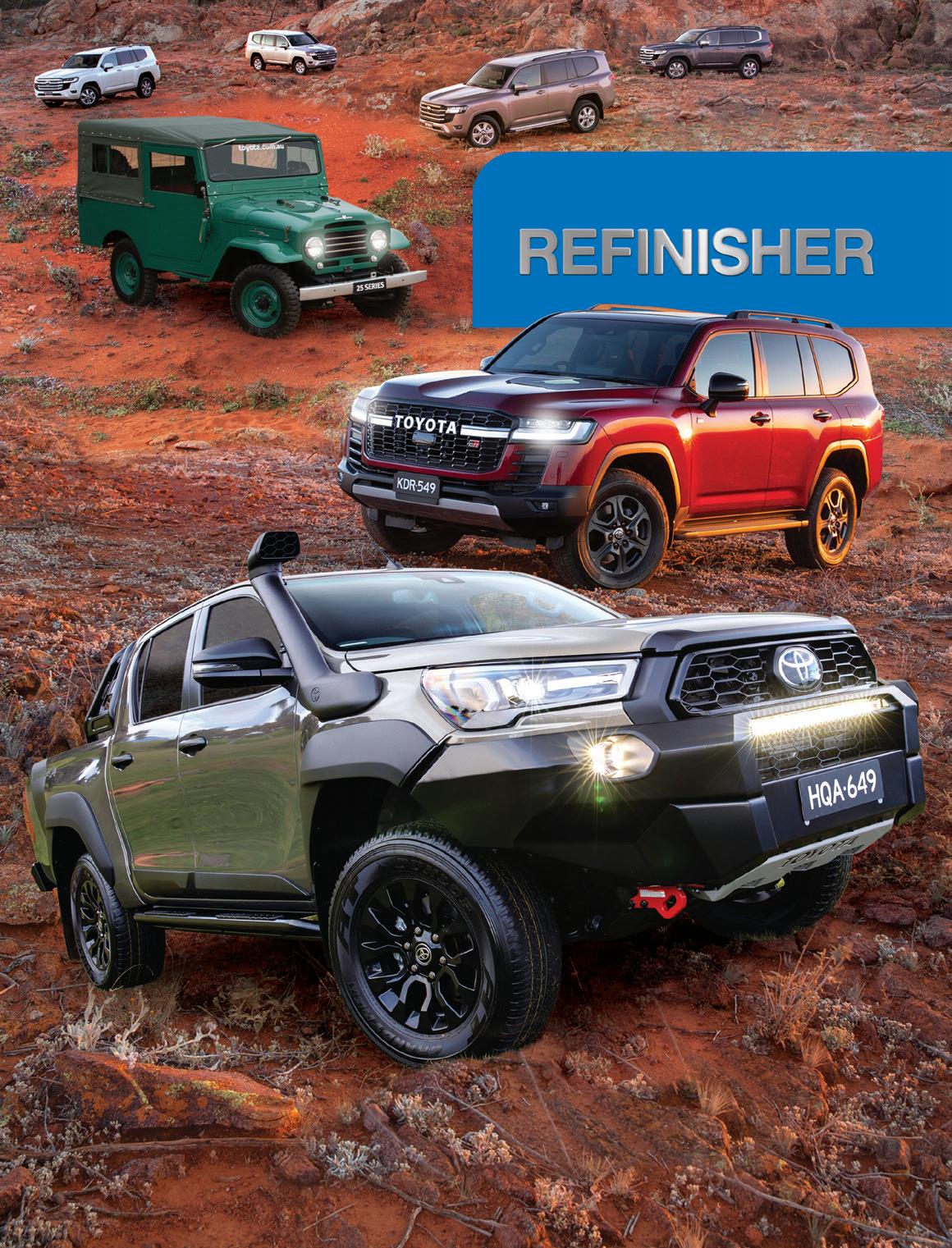

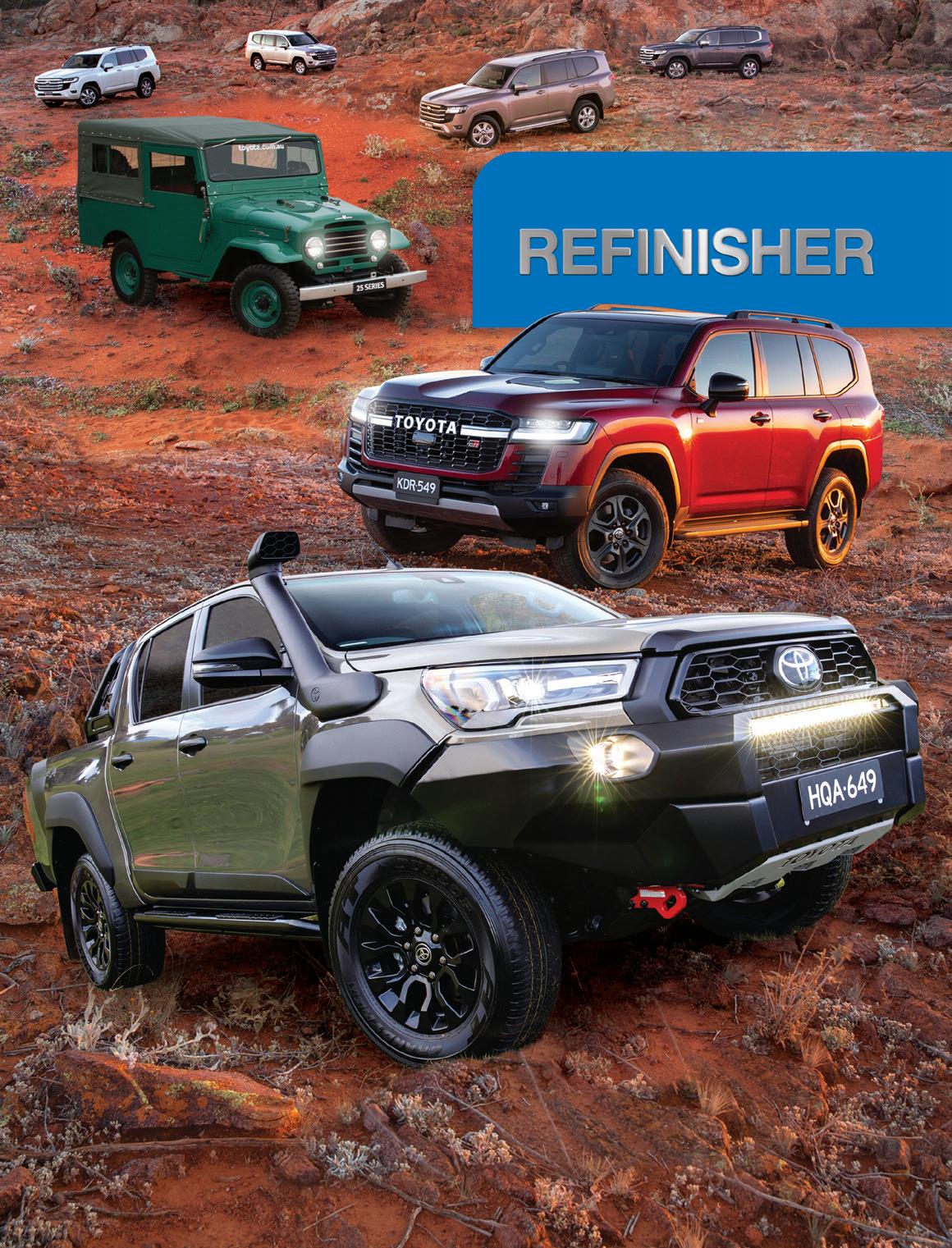

Australia is ‘LandCruiser country’, with people across the nation relying on the iconic 4WD to get them home across varying landscapes and tough conditions. While it’s sold in approximately 170 countries and regions, when global all-time LandCruiser sales passed the 10 million vehicle milestone in September 2019, it was the Australian sales tally that led the world with a 10.6% share or in excess of 1.065 million vehicles. This included LandCruiser Prado, 70 Series and 200 Series and their predecessors, back to the birth of the nameplate. What’s more, 2021 sales figures confirmed Toyota’s long running HiLux as Australia’s best-selling vehicle for the sixth straight year. In addition, HiLux has been the leading vehicle of choice in the Northern Territory for an unbroken 21 years, as well as racking up 15 years of sales leadership in Queensland and 14 years in WA.

Given the way LandCruiser and HiLux are equally at home in an underground mine in WA, a cattle station in outback Queensland or ferrying the kids to school in suburban Melbourne, it’s almost as if they were designed specifically to suit the ‘wide brown land’. While that is not entirely accurate, it is true that plenty of local design and engineering talent has made strong contributions to these and other Toyota models over the decades.

The LandCruiser story began in 1951 when Toyota developed the BJ four-wheel-drive (4WD) for use by Japan’s National Police Reserve. Australians got their first glimpse in 1959 when the Thiess organisation imported a small number of LandCruisers to help on the rugged construction-site trails of the original Snowy Mountains Hydro-Electric Scheme. The construction crews were merciless and, like other 4WDs onsite, the LandCruiser had some issues. However, it was Toyota’s response that set the company apart from other

brands. Not only did it take notice of the mechanical issues and fly in replacement parts, Toyota even sent two engineers from Japan who lived onsite to analyse the problems and find solutions. It's this commitment to Toyota’s kaizen (continuous improvement) culture which continued to this day.

In 2021, Toyota officially opened its state-of-the-art Product Centre, located within the sprawling 22-hectare Altona Centre of Excellence (CoE). Having previously been based at multiple facilities around Melbourne, it brings together all of Toyota’s local planning, design, engineering and evaluation teams under the same roof. The A$40-million-dollar investment is about giving these world-class local teams the tools to continue designing and developing unique products for the Australian and global markets, according to Toyota Australia Vice President Product, Guest and Aftersales Operations, Mike Rausa. “We wanted to retain and build on the capability developed during our long history of vehicle manufacturing, providing a highly collaborative environment that would allow Australian design and engineering expertise and know-how to be utilised within the broad Toyota family. The new Product Centre delivers just that, keeping jobs, skills and career paths grounded in Australia."

After relocating from its previous home in Port Melbourne, the Product Design department, and its 42 staff, have settled into purpose-designed digs within the CoE. As it has done in the past, the team not only works on local projects, it actually partners with Toyota Technical Centres around the globe. As a result, Toyota products which were styled in

Australia can now be found in most corners of the globe. Moving to the Product Centre offered a fresh, cutting-edge environment to really get the stylist’s creative juices flowing freely. One of the keys is a spacious, indoor viewing area with three vehicle turntables. Complete with studio-quality diffused lighting and high, curved ceilings, the vast space lets people view cars from 11 metres away which is ideal for evaluating new designs. A secure outdoor viewing area also allows styling elements to be assessed under natural daylight. The new design studio, itself, features two full size modelling plates where creative designers, studio engineers, clay and digital modellers can work together to create enhanced designs. To get the best of both worlds, the team actually intertwines traditional, hand-based design methods with state-of-the-

Despite ceasing full scale local manufacturing in 2017, Toyota Australia continues to invest in Australian innovation and expertise with its new state-of-the-art Product Centre.

Before any new vehicle component or accessory makes it to production, it needs to be prototyped and this is where Cameron Brimelow’s (Manager Prototyping & Operations, Product Design) team comes in. The 16-year veteran at Toyota, says there is no such thing as a typical day.

“We have quite a fun role, in that we look after all the prototyping for new vehicles and accessories. We might be tasked with creating a prototype of a new wheel design, a piece of styling trim or even different scale models of a complete vehicle. What it means for local Toyota buyers is that, because we get the opportunity to design global products that are sold around the world, we can put our own local flavour into the mix.”

At its disposal, the team has a vast array of cutting-edge capabilities, combined with traditional handcrafting skills. Two highly automated, full size,

machines bring incredible speed and versatility to the prototyping process. Typically, the final stage is the paint department where Colour & Coatings Technician, Will Taylor, is responsible for literally adding the finishing touch.

“Compared with refinishing in a traditional smash repairer, this work is far more interesting. I could be painting anything from small parts, right up to a complete vehicle and it can be all different substrates. For example, a new wheel design might be machined out of tooling board so I have to use paint to make it look like, say, an alloy wheel. Equally, it could be 3D printed plastic or modelling clay or even vinyl sheets – I have pretty much painted everything. Even after 17 years at Toyota, I still pinch myself that I am able to do all these different jobs.”

“One of the challenges is time pressure to get jobs done for our internal customers but using PPG ENVIROBASE® High Performance has made my job very easy. There used to be a lot more colour matching but, with Envirobase, the colour strike rate is just so good and on the odd occasion you do need to tweak, it’s simple. Then there is the fast-drying time that gets jobs through nice and quickly. PPG’s way of doing things really ties in with Toyota’s way of standardising processes. For example, I do everything by the book and use a SATA gun with PPG’s recommended set up. Because the process is clearly set out, I know that myself, or another painter, will get the same result every time. As well as great PPG products, we get great technical support whenever we need it.”

“My specialty is getting the surface finish to mimic the grains and textures of the sample. It’s about using the paint system to the limits and being very creative. I really enjoy it when I see people happy with the job. Then, when they put that component on the car, people think it’s a production component when, actually, it’s made from modelling clay or 3D plastic, etc. PPG’s products help make me look really good! It’s a proud moment when you see one of these Toyota models going down the road and you know the local team

As one of 13 global centres for Toyota Genuine Accessories, the Conversion & Accessories (C&A) team produces a wide range of tough and durable accessories for multiple models, including the recently launched LandCruiser 300 Series.

The team’s high-tech equipment includes an environmental chamber that can simulate extreme hot and cold temperatures, as well as high and low humidity conditions. Other test rigs record millions of cycles of vibrations, mimicking road corrugations to ensure accessories, like bullbars, nudge bars and antennas, can cope with the physical rigours of outback travel. With nearly 40 employees on site, C&A developed accessories are not just for Australia but are exported to other markets, including New Zealand, Europe and South Africa.

With 80% of global road conditions available within Australia’s borders, Toyota Australia’s Vehicle Evaluation and Development (VED) group is heavily relied on to provide evaluation and real-world testing for Toyota’s global engineering teams. This helps shape models, such as the LandCruiser, HiLux and Prado, and ensure Toyota’s 4WDs can stand the test of time in the harshest of Australian environments, according to Ray Munday, Toyota Manager Research, Evaluation and Training. “Undertaking development of these heavy-duty 4WDs in Australia, in a number of different usage conditions, is the ideal testing and development environment. Being one of the oldest

geological countries on the planet, we have conditions that are some of the most unique in the world and these are hard to replicate in a test lab.”

The LandCruiser 300 Series is a good example. Local work on it actually began all the way back in 2014. The VED team was tasked with ensuring this all-new model follows in the footsteps of its illustrious forebears and handles everything customers throw at it, including off-road driving and towing in high temperatures.

Where some companies might plan five to ten years in advance, Toyota has a much longer term horizon and the new Product Centre and the CoE at Altona fit neatly into that strategy, says David Cadzow, Toyota Australia Product Planning and Development General Manager. “Our design and engineering teams are highly utilised by Toyota affiliates around the world, thanks to their exceptional ability to create products that resonate with customers across the

One factor Peter Sadler particularly enjoys about his role as MIRKA Business Development Manager ANZ is getting face-to-face with users and showing them what the company’s wide range of products can deliver in the real world. Whether it’s at the Collision Repair Expo, one of PPG’s region-wide training centres or onsite at a customer’s premises, it never fails to impress, says Peter.

“Industry people know who MIRKA is but they don’t often get to see our products in action. When we conduct a demonstration, the thing we really enjoy is the MIRKA ‘Wow’ factor that we get. You finish the demonstration and invariably people go ‘Wow!’ Then we let them play with the products themselves and you get another ‘Wow’. The more demonstrations we do, the more people we convert to MIRKA. It’s a lot of fun.”

“For that reason, the recent Collision Repair Expo was a very successful event for us. Not only was it a good platform to launch new MIRKA products, it was also a great opportunity to catch up with people who we have not seen face-to-face for a few years. People still buy from people so relationships are very important.”

If you weren’t able to make it to the Collision Repair Expo, getting your own personal MIRKA demonstration is easier than ever. There is now a dedicated, four-person MIRKA team covering Australia and New Zealand who will be happy to help, as well as the region-wide PPG team to provide support for customers in sectors, such as automotive refinish and Commercial Transport (CT). It means there is never a dull moment, according to Peter.

“Despite originally being a spray painter from the refinish trade, I find I am able to take those skills into a variety of other sectors where MIRKA has an excellent reputation for the return on investment it can provide. It means I could be dealing with customers in the marine industry, wood industry, refinish, etc, all in one day. The beauty is, MIRKA has ready-to-go technologies capable of making an instant difference in all these sectors.”

What has helped to keep MIRKA at the top of its game is a development team determination to think outside the square to create new and ground-breaking

MIRKA already has an outstanding reputation for surface preparation and finishing solutions but it’s seeing these products in action that really generates the ‘Wow’ factor.

solutions to benefit users. At the same time, local feedback goes back to head office in Finland to help drive product development, says Peter.

“I often get asked what it’s like working for MIRKA and I have to say that they really keep me on my toes with a stream of new products – it’s a phenomenal problem to have. Our pipeline of new products means there is always something new to talk about with new or existing customers. What really impresses me most about the MIRKA team is that they never rest on their laurels. Even if a product is already a market leader, they are never satisfied and are constantly looking at how further improvements can be made. Over the last couple of years, COVID has put many product launches back so now we are seeing a lot of new MIRKA technologies and product developments come through.”

MIRKA Pneumatic Belt Sander – This new tool builds on MIRKA’s reputation for ergonomic tools that move the performance benchmark and I reckon it will be a terrific solution for panel beaters, in particular. It even comes with MIRKA abrasive belts to maximise efficiency.

Abralon J3 – This new and improved version of Abralon will appear as a rolling change. Thanks to market feedback, it’s now thinner and delivers even better performance, yet at very competitive pricing.

Iridium SR de-nibbing discs – Our popular Polarstar SR discs have been replaced with

the latest Iridium SR technology in 5 micron and 7 micron configurations. Not only is Iridium SR a more robust product which holds its edge really well, it’s also long lasting and ideally suited to the latest clearcoat technologies.

Upgrades to Polarshine – To further improve speed and efficiency, the high performance Polarshine polish range has come in for an upgrade. For example, a new two step process now includes Polarshine 45 – a quick and aggressive polish which was originally designed for rejuvenating gel coat in the marine industry but has since proven to be perfect for quickly and effectively dealing with modern automotive clearcoats. In addition, black and other dark colours are now quicker and easier thanks to Polarshine 12B.

LEROS – The radically different LEROS (Long Electric Random Orbital Sander) was released during COVID so a lot of people in the automotive sector haven’t yet had a chance to see a demonstration. It was originally designed for sanding high walls and ceilings in the architectural sector but we see massive opportunities in the CT sector where it can dramatically slash sanding labour times. R

Accurately colour matching a vehicle on a collision centre paint shop floor can be very challenging but the colour matching tasks that land in the in-tray at the Colour Laboratory, within PPG’s Clayton, Melbourne headquarters, are on a whole other level. As one of PPG’s global epicentres of colour matching, it actually takes a particular talent for solving puzzles to thrive in this environment, according to ANZ Colour Lab Manager, Richard Harvey.

“Having an ‘eye for colour’ is obvious but being a successful colour matcher at this level takes a really specific attitude.

You can’t be tunnel visioned – you have to be able to think outside the box because these colour matching puzzles often don’t have a straightforward solution. You need to have a real eye for detail and an almost perfectionist attitude to getting that colour

exactly right. On top of that, you also need to enjoy it because you are going to do a lot of it. The good news is that skills from the refinish paint shop can transfer to the Colour Lab. For example, of the current team, Manny Grillo and Adam Tully are spray painters from the trade and Chris Collin came via a paint distributor.”

For the Australian and New Zealand refinish community, the PPG Clayton Colour Lab fills a crucial set of roles. First and foremost, it ensures all vehicle colours are available to meet the needs of painters in the field. This means there needs to be a colour match for any vehicle that gets imported into ANZ, from any manufacturer, anywhere in the world. It starts with

matching to the OEM colour standard, called the prime match, then gets more complex, says Richard.

“The standard colour might be what the OEM intended but during the production process there are always some variations.

Through PPG’s colour auditing process which happens in markets right across the globe, we aim to identify any major variants. For example, ANZ Colour Auditor, Manny Grillo, visits new vehicle holding yards to determine what, if any, variations there might be. It’s about capturing them and making them available on PAINTMANAGER® XI before they even get to a repairer. That way, our customers are ahead of the game. In addition, we also match on demand for our Commercial Performance Coatings range and our Commercial Transport

Whether it’s new vehicle colours or variants or a special colour match, you can be thankful that the extraordinary skills of the Clayton Colour Lab team are on your side.L to R – Adam Tully, Arlene Ambler, Manny Grillo, Richard Harvey and Chris Collin

products, such as DELFLEET® Evolution. Typically, this is where a customer wants to match to a fleet branding colour.”

One of the most important members of the small Colour Lab team doesn’t even do colour matching. Arlene Ambler is effectively the gatekeeper who keeps the process functioning smoothly from start to finish. The steady stream of requests pass through her, where they are logged and scheduled for processing by the colour matchers. When it gets to the colour matchers, their specialist skills come into play, explains Richard.

“To get a starting point for a colour match, the team have a number of tools they can use, including very sophisticated spectrophotometers and a microscope to look closely at particle size and shape. Our colour matchers have a really in-depth understanding of all the tinters used in each of the PPG product ranges and they use that knowledge to work out which tinter is required to get the colour closer to the target. Afterwards, they can spray out the colour, bake it and assess it against the target colour using our light booth that

has a variety of different specialised colour matching light sources.”

Despite all the tools and knowledge at their disposal, some colours can be more challenging than others. PPG has very close relationships with vehicle OEMs around the globe and, thanks to this, it typically gets an early warning of any new tinters or technologies going into a new colour. However, OEMs don’t always provide this information so it can take some very creative colour matching, using application techniques, as well as tinter combinations, to get a precise match. It’s just one of the reasons why the Clayton Colour Lab is such an advantage for the local market, says Richard.

“It’s about offering direct customer support. With the skills and resources at our disposal, we can quickly provide a solution to a customer’s request. In contrast, if the colour lab is in another country, the sample colour needs to be sent by ‘snail-mail’ which not only takes time but can result in lost panels. It just introduces delays at every step.”

For anyone who accesses a quick, accurate colour formulation via PaintManager XI, it’s worth saying a silent thanks to the service the Clayton Colour Lab provides day-in, day-out. “You may not get excited about colour matching but we do. Technology continues to advance and we enjoy unravelling new challenges. I think we all get a buzz out of matching a challenging colour!”

R

When you think about it, the job title ‘Estimator’ doesn’t seem quite appropriate given that the aim is to always be as accurate as possible with each and every quote. Although the industry has taken a couple of different paths, with some repairers using the traditional quoting method while others use a fixed price or predictive repair cost model, the role of Estimator is a vital one that has the ability

While there are often time pressures throughout the collision repair process, estimating is one task where rushing can be particularly counterproductive. For the estimate to be as accurate as possible, the Estimator must be super thorough as they investigate

part and operation that is required. If not, the Estimator ends up having to revisit the quote somewhere down the track in order

Understanding the full spectrum of collision centre operations and costs gives an estimator the essential tools they need to write an accurate quote that avoids guesswork.

Generally speaking, the estimating process marks the very start of the repair process. Regardless of whether your collision centre is getting a fixed amount for the job or you are getting an individually quoted amount, it’s important to remember that the estimate turns into a job sheet. In essence, the Estimator is writing a plan for how that particular vehicle is going to be repaired. An inaccurate estimate evolves into an inaccurate repair plan which can lead to issues and delays further down the track during production. In contrast, writing an accurate estimate means the technicians receive an accurate repair plan where everyone clearly understands what needs to be done and what parts need to be replaced, etc. Not only does it make the job smoother and easier for the technicians, it’s less likely they will need to leave the job to ask for directions which gets the job done faster and more efficiently. Ultimately, that makes a valuable contribution to saving money on production costs.

Just like the technicians on the shopfloor, a good Estimator needs to have a certain level of skill and understanding that fits with their role. One of those skills which is particularly important is an understanding of what it costs to run the business and a key part of that is the real shop labour rate.

I’m not talking about the technician’s salary rate – I’m talking about the amount per hour of labour needed to ensure each job generates enough money for the business to make a profit.

A lot of detail goes into calculating the real shop labour rate but it has to be done properly otherwise you are really plucking a figure our of the air (or somewhere else!)

It includes:

– This includes everything from wages, insurance and superannuation to rent, utilities, depreciation and accountants fees.

The amounts should represent expenses incurred over a year. Although the method of breaking down expenses is not that important, it’s important to be able to

monitor performance over a long period of time to ensure it is meeting set targets.

Real wages – This is not simply the gross weekly salary or hourly rate staff are paid, there are other factors including, payroll taxes, superannuation, holiday pay, etc. Although employees are typically paid for 38 hours per week, 52 weeks per year, this doesn’t directly equate to the number of productive hours that are available to devote to chargeable jobs – that requires an additional calculation.

Desired profit – Are you looking to generate a ‘break even’ figure or one with a reasonable profit for the business owner built in? After all, the owner is making a significant investment in terms of both time and money and should expect to receive a reasonable return on that investment in addition to a wage.

Whether you are an Estimator or a business owner, your MVP Business Solutions Manager will be happy to guide you through the process of calculating your real shop labour rate.

When a customer drops in for a quote, don’t forget that estimating is also a sales process. Explain the advantages of your collision centre, describe the quality management process and show them a vehicle under repair so they can relate it to their own. When done correctly, it’s actually an opportunity for your shop to differentiate itself from the competition and win extra business. This is certainly the case with private work and it also applies to insurance work where the customer has the choice of repairer.

R

As well as thriving in a collaborative work environment, Chelsea says she enjoys a consistent stream of different challenges and she has found both of these at PPG.

The Adelaide native moved to Melbourne where she followed a Diploma of Graphic Design with a Batchelor of Arts in Interactive Media and Animation – both at RMIT. After winning a scholarship to spend six months in South Korea, Chelsea returned to focus on her career path which headed in the direction of PPG.

Favourite hobbies /pastimes? Lots – video games, travelling, editing holiday videos and studying other languages

Favourite food?

Korean Favourite drink? Green rose tea from T2 Favourite music / band? K pop

Favourite car / motorcycle? Nothing fancy – I love the Hyundai i30 hatch

Favourite holiday destination? I like travelling Asia

“I started as a contractor simply changing the GHS information on the labels for literally thousands of products. A three-month contract was extended to six months before a 12-month maternity

leave position came up in the Refinish Marketing Department at PPG Clayton. After that I was offered a permanent position and I have now been with PPG for around six years. My current role, as Senior Marketing Specialist, is a bit of everything, from planning product launches, through to preparing for events such as the Collision Repair Expo. I am also on a lot of global PPG teams working on upcoming innovations. Experience in that global environment is great but it’s also about putting my ideas forward in a collaborative environment.”

“Why I have been with PPG for so long is that I enjoy the challenge of my job. My job title has changed a few times and even with my current role, there is something new every day. I also enjoy working with the people in the PPG team. The challenge now is to delve into what else we can do with our brands in this market. It’s about better understanding the needs of our customers and using technologies, such as social media channels and video content, to help get the message out.”

Here at PPG, we work to develop and deliver the paints, coatings and materials that our customers have trusted for more than 135 years.

Have a career with us & you will find meaning in your work every day! You will engage in opportunities that will shape you both personally and professionally. We make it happen and seek candidates of the highest integrity and professionalism who share our values, with the commitment and drive to strive today to do better than yesterday – everyday.

PPG provides equal opportunity to all candidates and employees. We offer an opportunity to grow and develop your career in an environment that provides a fulfilling workplace for employees, creates an environment for continuous learning, and embraces the ideas and diversity of others If you are passionate about the automotive and refinish industries, then PPG could be for you!

Humans can’t see colour in the dark so it’s obvious that we need light. However, when it comes to distinguishing between colours, light sources are definitely not equal. In particular, during the refinish colour matching process, it’s crucial to use the light source that gives you the very best means of making an accurate choice, says Richard Harvey, PPG ANZ Colour Lab Manager.

Whether it’s fluorescent, halogen, incandescent, LED, natural sunlight, etc, each light source has its own ‘light signature’ which is made up of elements of the visible spectrum of light. Some incorporate more wavelengths than other and that is the key. Because it contains all of the visible wavelengths, natural sunlight is the best choice for colour matching. The recommended time to view colours in sunlight is around the middle of the day – avoid times when the sun is low or directly overhead. I would also recommend that technicians check in different daylight conditions, including direct sunlight (single source) and indirect

sunlight (diffused source), such as in the shade or overcast skies and, preferably both. This is done for a very specific reason – any issues may not surface if checked in just one light source and this has a lot to do with the difference in the way ‘pigments’ and ‘effect pigments’ reflect light. For example, say a wrong variant is chosen and then adjusted to be lighter using white instead of aluminium. Because white scatters light from any direction, it becomes dominant. Although the match might look perfect in bright sunlight, it will show up as very light on-the-flip when viewed in shade or diffused conditions. It can be a very frustrating issue to nail down, particularly on greys and silvers.

Fun facts: We see the sky as blue during the day because the atmosphere scatters the blue spectrum of light. Temperature also has an effect which is why the sky looks redder on a hot day. In the evening the sky tends to be orange because blue wave lengths find it harder to get through the atmosphere.

It’s important to understand that the light source, itself, doesn’t change the colour of an object, it just changes the available wavelengths the object can reflect. No matter whether it’s labelled as ‘cool’ or ‘warm’ or what technology it uses (incandescent, fluorescent, LED, halogen, etc), virtually all common artificial light sources are missing parts of the full spectrum of wavelengths we see in sunlight. As a result, this is going to affect how you are able to perceive any colours we view under them. For example, a green colour

looks green because it’s reflecting the green wavelengths and absorbing the redder wavelengths. However, if you view it under an artificial light source that is missing some or all of the green wavelengths, it’s impossible to see the true green colour

Recognising that it’s not always practical or possible to check a colour match in direct or diffused sunlight, lighting technology has been used to create various alternatives light sources. For example, in PPG’s Clayton Colour Laboratory we use a D65 light source which is an industry standard around the world. It means that, no matter where you are in the world, you can view a colour match under exactly the same consistency of light. In the same way, technological advancements have also allowed for the development of specialised, portable colour matching light sources for collision repairers. For example, SATA’s recently launched trueSun LED Lamp utilises LED technology which has been especially finetuned to produce a full spectrum of lighting wavelengths to closely mimic natural sunlight. Like other SATA products, it’s a

For humans, colour is subjective. The fact is, we are very susceptible to the environment we are viewing a colour in and that especially includes the light source.

precision tool that has lots of features but, the most important thing is, it gives you convenient access to a handheld device with an almost perfect reproduction of daylight for accurate colour matching inside the paint shop, or anywhere else indoors.

Observing colours has traditionally come down to three factors – the colour itself, the light source and the human eye. Unfortunately, it’s the last element that can be the limiting factor. It has been estimated that the average healthy, untrained human eye can decipher between around a million different colours. Just to show how diverse and individual we all are, some people might only be able to detect just a few hundred colours, while others can distinguish up to 10 million variations in colour. We also know that our colour perception declines as we get older. This is where a leading spectrophotometer, such as PPG’s RAPIDMATCH® GO which reads colours from five angles, is such a big advantage for the modern industry. Apart from requiring regular calibration, a spectro ticks all the boxes – it controls the lighting, it doesn’t lose performance with age or suffer from retinal fatigue and it eliminates background effects while accurately measuring and storing the data. It’s about using the best available resources to achieve the best possible colour match. R

people in person. It’s not just about getting the message across about the features and benefits of SATA products, it’s also an ideal place for us to learn from the people we speak to and get a better understanding about what is going on in the industry here. Listening to end users is paramount with anything SATA does. When I say end users, that means painters, managers and bodyshop owners but equally important is the constant exchange with the paint industry, such as with PPG. I refer to it as a symbiotic relationship – paint is nothing without a spray gun and a spray gun is nothing without paint.”

While acknowledging it can be very difficult to find new improvements and innovations for spray guns, air-hoods and filters which are already at the cutting edge, the SATA R&D team always rise to the occasion, says Jörg.

feedback where painters wanted more choice and it resulted in the I-shape and O-shape spray patterns. For each nozzle size, painters can choose between the O-shape, for a little higher, more traditional SATA application speed, or the I-shape, for a slightly slower, more controlled application. The tendency was for the O-shape to be used for basecoat but we are now seeing more and more painters choosing the I-shape for both basecoat and clearcoat.”

With such a radical innovation, Jörg says the challenge can be to fully explain the concept so that everyone understands its benefits. This is where the close regional partnership with PPG pays dividends.

“It’s one thing to explain the differences between an I-shape and an O-shape on paper or in a video but actually feeling the difference is best.

Despite still being a family-owned business with just 280 employees, SATA is a global force in the field of spray equipment. As Head of Export, Jörg Göttling and his team of six Area Sales Managers, is responsible for a large chunk of that empire – basically, everything excluding Germany, Austria, the UK and Canada. According to Jörg, the opportunity to once again work with the local PPG team at the recent Collision Repair Expo was like a breath of fresh air.

“This is what we have missed for the past two-and-a-half years. It’s great to be here with SATA Asia / Pacific Area Sales Manager, Arnika Enderle, and actually meet

“There are some really good examples, such as the SATA air vision 5000 air-hood which is so practical and comfortable that painters actually want to wear it. Another is the X-Nozzle system found on our premium SATAjet X 5500 spray gun. It was developed directly from customer

This is where PPG helps us convey that message to the market. Not only can the PPG trainers and sales team explain the differences, they can also let painters try a SATA gun themselves.

SATA’s reputation for pushing the performance envelope is based on customer driven improvements and the Collision Repair Expo offered an ideal place to re-connect.

“People tell us that our best marketing tool is a tour of our production facility at Kornwestheim, in Germany, where 100% of SATA spray guns are manufactured”, says Jörg. “We have a state-of-the-art manufacturing facility, production processes and precision measuring procedures that maintain SATA’s very strict tolerances. The guns are hand assembled by our skilled staff

and we still manually spray test every gun and every replacement nozzle set before it leaves the factory – this is what differentiates SATA from many other manufacturers. People leave here with a better understanding of what goes into a SATA spray gun. I hear the word ‘expensive’ used for SATA guns but, at the end of the day, you get what you pay for. Once you use a SATA gun

you realise it’s worth spending a little more to get the level of performance. If you are visiting Germany, we encourage you to contact SATA and schedule a tour – you won’t be disappointed!”

After trying a SATA gun, these painters typically become a SATA user for life.”

SATA also shares a similar philosophy to PPG – it’s about providing customers with an overall system that can be used to drive productivity in a modern paint operation, Jörg explains. “The key message is that we never try to sell just the product – we always propose that the SATA system be used to improve processes in terms of productivity, reliability and repeatability. It’s nice if someone uses a SATA gun but if they combine that with SATA RPS (Rapid Preparation System) cups, they get the benefit of using 100% of the material in that cup. Also, they can use SATA filtration to ensure the compressed air for the spray gun, as well as the breathing air for the painter, is top-notch quality. Finally, they can choose a SATA air-hood

which is comfortable and protects their health. My hope, and the hope of SATA, is that as the industry becomes ever more professional, our products will become more important because they offer something special to the professional end user.” R

Over 42 years in business, Daryl Hobbs has established an enviable reputation for his team’s ‘can do’ attitude and its ability to take on oddball work that others shy away from.

It could have been seen as a bad omen.

On the Friday night before the scheduled opening of their new panel and paint shop, Daryl Hobbs’ business partner pulled out. Fortunately, he says, in those simpler times, you just got on with it.

“It was stressful but I felt like I had no choice because I already had all this work booked in as soon as I opened the doors on Monday 20th October 1980. The situation would be a lot more serious today because of all the money and effort that goes into starting a business in the current climate. At that time, you just needed some basic tools and I rented an old army style ‘igloo’ shed in Port Kembla (a suburb of Wollongong, about 110km south of Sydney) I worked on my own for a couple of years until I started employing people.”

As business expanded, DJ Hobbs Panel & Paint moved to a large, new premises in the nearby suburb

of Unanderra, in 1989, before settling into an even more spacious workshop, complete with truck-sized spray booth, on the same property where it remains today. While Daryl sometimes regrets not having the opportunity to go the extra yard with a top-notch workshop, the big bucks to fund that investment were just not available. Nevertheless, it seemed to have had no impact on the wide assortment of customers who continued to flow through the doors.

“I believe it’s the variety of clients over the years, and my background with plant / machinery, that turned this business into what it is. Back when most shops were doing insurance work, we were doing all this oddball stuff that was private work. Even today, insurance work is just a small percent of our workflow. People who knocked on our door often wanted work done that was a little ‘different’. For instance, one customer

had just finished building a Jabiru ultralight aircraft in his home garage and asked could we paint it? I said, if you can pull it apart and get it here, I can paint it. I had a bad habit of not saying ‘no’! On another occasion, I was asked to repair some shipping damage on a crawler crane for the Lampson company which was imported from Seatle in the US. What started as one 10-day job working in and around Port Kembla harbour ended up being 18 months of work. We have done car fleets, civil works equipment for road laying and maintenance and we have a 30-year

relationship with NSW Fire Brigades. I think our mix of work and the people I meet have helped keep me interested in the trade. It has been rewarding!”

After starting his career as a panel beater, Daryl later added spray painting and body making qualifications to give himself a well-rounded skillset. products from PPG’s Commercial Performance Coatings range.

We use PPG on everything except for a very small percentage where a customer specifies something else. Even then, we have convinced some customers to try PPG and, they have been so impressed,

when Delfleet Evolution arrived on the scene – it’s the product that really does it for me. There is no point looking elsewhere for the best when you already have it. The other great thing about PPG is the backup service. I only need to make a quick call to Chris Rovere (National Specifications Manager, Commercial Performance Coatings) or Sam Minter (PPG CT Manager NSW) to get what I need. The PPG team has been fantastic to me over the years.”

In the past, Daryl has had as many as nine staff but, these days, he employs a more manageable three. Like many in the industry, he finds it difficult to obtain good, skilled staff so he’s thankful for his current team.

“I have been very fortunate over the years to have good staff and my current team is a good example. This is a place where there is a lot of opportunity for technicians to use current skills and learn new skills, rather than just remove and replace. For instance, we recently had an old UD truck that needed a new hinge pillar and we couldn’t get one new or second-hand. I walked in and one of my tradesmen, I respectfully call ‘John the genius’, had actually fabricated one from scratch.”

With so many different jobs coming through the doors, from family cars, trucks and planes to plant equipment and cranes, it’s vital to all be on the same page. “I might be the owner but I am always willing to listen. For example, when I show the team a new job, I give them an idea about how I would repair and paint it but I also let them have their say. Often, they come up with really good suggestions for doing the job better, smarter or quicker. For instance, a few years back I asked a young painter to mask up the internal hydraulic hoses and electrical wiring of a new machine we were painting and he asked if we had any aluminium kitchen foil. At that stage, I had been in business for 30 years and I had never heard of such a simple idea. The aluminium foil wrapped the hydraulics and electrics quickly and easily with no need for fiddly masking paper or tape.”

According to Daryl, the workshop team also play a key role in keeping customers coming back. “I think our customers feel at ease with the workshop culture. Even if

I am not here, I have good reliable people who can welcome someone and give them the information they want. We all get along and we are all on the same page. As well as quality work and service, the other key factor is on-time delivery. I have learnt over the years, if you commit to taking on a bloke’s truck, which is his business and livelihood, you need to commit to getting it back on the road so he can make a quid. When it comes to turnaround time, I explain to customers that I have booked in their job so we have the staff on hand to work on it and get it back to them in the agreed timeframe.”

Despite approaching his 67th birthday, Daryl says he has no plans to retire. “I know I can’t stay here forever but I still feel fit enough to do what I did years back so I reckon I have a few years left in me.

I am more concerned about the employees I have and making sure they are right before I retire. In business thus far, I am a man satisfied, however I do believe it needs to advance into the future of auto repair and paint by someone enthusiastic and willing to take it to the next level. At this point, I am happy just to cruise along the way I am. At the end of the day, I don’t live to work – I work to live!”

Thanks to an unrivalled combination of exceptional speed, superb colour accuracy, no-fuss ease of use and effortless blending and mottle control, this is simply the best refinish technology on the market. Backed by a range of primers and clearcoats featuring advanced low-VOC technology, it’s the eco-friendly choice which really delivers on outright speed. With everything a modern, fast-paced collision centre needs to slash cycle-time while boosting productivity and profitability, Envirobase® High Performance is engineered for excellence!