ALSO INSIDE:

• HELMET ART FROM

r STAR DESIGN

• A LOOK AT ELECTROSTATIC APPLICATION

• MEET A QUARTER

MILE HERO

The best refinish system on the planet gets even better! s

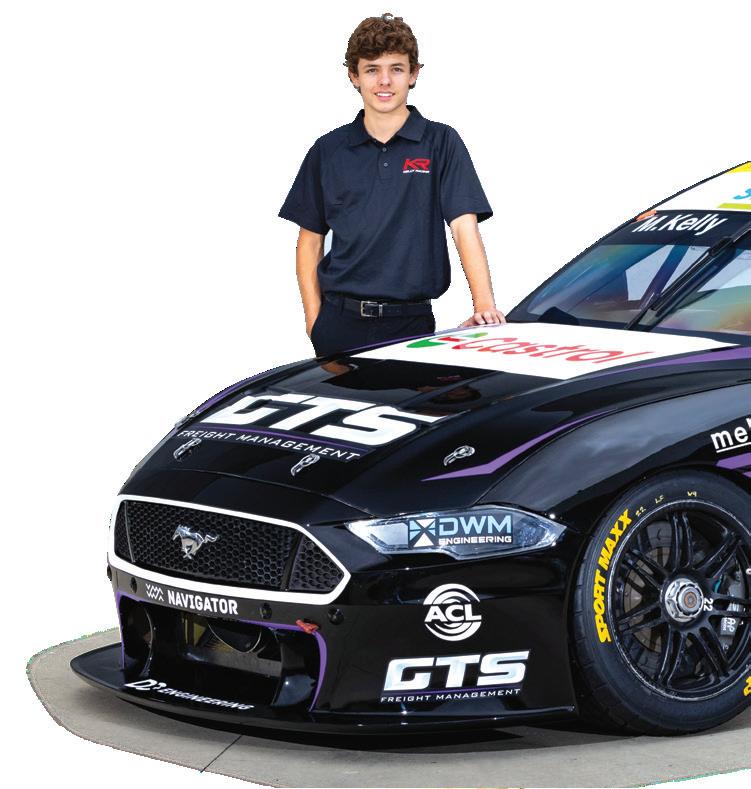

Kelly Racing 2.0 ...hits the track with PPG

ALSO INSIDE:

• HELMET ART FROM

r STAR DESIGN

• A LOOK AT ELECTROSTATIC APPLICATION

• MEET A QUARTER

MILE HERO

The best refinish system on the planet gets even better! s

Kelly Racing 2.0 ...hits the track with PPG

PPG’s automated paint mixing system, PPG MoonWalk, replaces manual paint mixing processes to deliver greater efficiency with less wasted product, a cleaner work environment for technicians, and reduced environmental impact.

This revolutionary system features a high-accuracy scale and precision mixing to ensure quality and consistency in every paint mix. Automated processes also help to reduce labor time and minimize human error, which means that PPG MoonWalk can significantly boost the productivity and profitability of your body shop.

PPG MoonWalk is part of the PPG LINQ™ digital ecosystem. Visit PPGLINQ.com for more information.

The best just got better! If you thought you knew Envirobase, think again

Process driven

A collision centre where SOPs rule

Hands-on approach

Todd Kelly has a long and storied driving career but he is arguably most at home when he is getting stuck in behind the scenes. Nowadays, that includes supporting his son, Mason, in his quest to become a fulltime Supercars driver

Sustainability hand-in-hand with profitability Introducing the PPG SUSTAINABILITY CO2NCEPT system

and effect

pays to choose your spray gun wisely

The SEM brand is well known for its innovative, no-nonsense products and now the local market gets access to two more creative SEM solutions which are locally manufactured and can be trusted to get the job done with ease and efficiency. You will find a range of high quality SEM products at PPG distributors and PPG Paint Powerhouse stores.

Forget traditional powdered guide-coats – SEM Guide Coat Black provides all of the performance you need with none of the frustrating downsides. Thanks to its super convenient aerosol application, it avoids the potential issues of fine, guide-coat powder spreading around the workshop.

At the same time, it also minimises wastage because you only use as much as you need for each job. Simply give the can a thorough shake and apply a number of light mist coats to achieve the required coverage over the job area. Any overspray simply wipes off. SEM Guide Coat Black dries instantly and is ready to sand immediately. The fine spray is

perfect for effectively identifying low spots, pinholes and other surface defects when sanding primer, yet it will not clog abrasives.

In order to return vulnerable areas, such as inner body panels, body cavities and body channels, to original factory condition after a repair, they require special protection

and that is where the new SEM Rust Preventer Cavity Wax comes in. The semi-transparent black internal panel compound is perfect for restoring OEM levels of corrosion protection and it comes with a number of special features that deliver excellent performance and ease of use. Even in tight, out of the way places, the 360° application wand provides a spray pattern that achieves a true 100% coverage with no patchy areas or missed places. In addition, the non-hardening SEM Rust Preventer Cavity Wax formulation ensures that it flows quickly over surfaces to fill any seams and provides superior wicking performance and adhesion. R

2024 competition. In recognition of Kynan’s achievements and passion for his work, German precision spray gun manufacturer, SATA, presented him with a set of premium SATA spray guns, including two SATAjet X 5500 models, all housed in a protective carry case. Terry Noble (PPG Refinish Business Support Specialist) handed over the special SATA package at Kynan’s workplace, Ultimate Vehicle Refinishing. In addition, Kynan spent a day at PPG’s NSW Training Centre learning a range of valuable tips and trick, including the best spray gun setups, to ensure he is well prepared for the WorldSkills final in Lyon, France, in September 2024. Best of luck, Kynan! R

Hasit gotten to the stage where you cringe every time a power switch is turned on or a booth is fired up? However, there is no alternative if you want to get jobs out the door, right? Or is there … What if you could quickly and easily explore different solutions and pick those that work best for you? It sounds too good to be true but the local PPG team is excited to launch a very cool new technology that lets repairers do just that. The PPG Sustainability CO2NCEPT was the brainchild of our European colleagues after that region was particularly hard hit by energy price increases. Suitably tweaked for this market, it’s ready to help local repairers make more informed choices – see page 24.

Of course, the Sustainability CO2NCEPT only works if you have viable alternatives to switch to in order to save on energy usage or production time and that is something we have also been working on. Starting on page 6, you can read about the major updates to the ENVIROBASE® High Performance system, headlined by new air-dry or low energy cure products that can slot right into your repair processes with a minimum of fuss. Not only do they offer energy and time saving alternatives and add perfectly to the existing PPG LINQ solutions (DigiMatch, VisualizID, MoonWalk, etc), our expert technical team, customer service and sales representatives, they also combine to help meet another significant industry target by reducing your carbon footprint. Operating more sustainably, with reduced costs and improved cycle-time is a win / win all around!

Run by the Kolich family, Weststar Prestige, in the Melbourne suburb of Sunshine, is a Mercedes-Benz, Tesla, Peugeot and Suzuki authorised repairer with a reputation for quality and service over its 53 years in the industry. One of the factors that has set Weststar Prestige apart is its willingness to embrace the latest in repair technology and recently this saw it install a trio of ground-breaking PPG LINQ™ technologies. This includes a MOONWALK™ automated dispensing system which, at just the touch of a button, measures out ENVIROBASE® High Performance waterborne basecoat tinters with incredible accuracy. It’s joined by a next generation DIGIMATCH™ spectrophotometer, with its built-in colour camera, and the VisualizID™ 3D colour visualisation software which streamlines the colour matching process. By generating a 3D colour spray-out of the target vehicle colour it can quickly and easily be compared to the closest variants to help make an accurate choice without using a drop of tinter. R

Sustainability matters to all of us. More than ever, it’s important to find new ways to navigate through this world we all live in while leaving the lightest possible carbon footprint and this includes the collision repair industry. When talk turns to sustainability it often raises concerns about the impact any changes might have on business performance and, therefore, profitability but PPG has come up with readymade solutions that let repairers effectively meet these challenges. PPG has put ESG, or Environment, Social and Governance, at the core of its strategy. As well as committing to reducing its own energy consumption on a global scale, PPG is also providing customers at the local level with a set of user-friendly options to help them do the same without reducing business performance. Indeed, in many instances, these PPG developed technologies have the ability to actually increase profitability. Combined with PPG SUSTAINABILITY™

CO2NCEPT (see page 34), it gives collision repairers a set of easily implemented tools that lets them understand where they are now, while helping them choose a clear pathway to what they want to achieve.

Today, over 40,000 collision centres around the globe trust the ENVIROBASE® High Performance waterborne basecoat system. That remarkable success story is repeated in Australia and New Zealand, where it has become clearly the most popular choice in the refinish market. However, it’s important to note that the Envirobase High Performance system that was released locally, back in 2006, is not the same as what is on offer today – it’s so much better! While it may not always be obvious, there has been a constant stream of additions and improvements over the years to help retain its position as the most advanced waterborne basecoat system available. Now a new package of enhancements takes it another significant step forward with improvements at every step of the process. Not only does it make Envirobase High Performance versatile and flexible enough to suit the preferences of virtually every painter, it also offers products that help collision

centres to be kinder to the environment while at the same time saving on energy costs and improving productivity to help maximise profitability.

New additions to PPG’s low energy repair solutions:

• LVP-565 Air-Dry Primer

• LVC-177 Rapid Performance Clearcoat

• LVC-131 UHS Clearcoat

As well as sustainability, efficiency and energy saving benefits, these low energy repair solutions offer a terrific option for dealing with the growing list of Hybrid Electric Vehicles and full Electric Vehicles, by helping to minimise or eliminate the potential to generate unwanted heat in the battery cells.

As the collision repair industry has evolved and changed, so has Envirobase High Performance. It actually started life with

very clever PPG developed chemistry that gave it huge advantages over other waterborne basecoat systems and it retains many of those advantages today. It still has the unique, PPG developed waterborne technology (the third generation from PPG’s laboratories) which consists of latex resin particles suspended in a gel-like state. It’s one of the key reasons why it’s able to offer users market-leading colour strike, speed of drying and ease of use. In addition, there are little features, such as the ability to tack-rag and de-nib between stages to easily correct potential faults. Nowadays, Envirobase High Performance is a complete paint system that includes a versatile range of primers and clearcoats so collision centres can select products to best suit their processes. There is even a matt and semi-gloss clearcoat option, along with an Engine Bay

Converter which makes it super easy to recreate the factory finish in places such as under bonnets, boots and door jams. As if that is not enough, Envirobase High Performance is also fully compatible with the trailblazing PPG LINQ digital technologies that are helping drive the transition to the paint shop of the future. This includes the next generation DigiMatch™ spectrophotometer and VisualizID™ 3D colour visualisation software, that enable fast and accurate colour matches without using a drop of tinter, and the MOONWALK® automated dispensing technology which measures out volumes of the chosen colour formulation with extreme accuracy time and time again.

As rising energy costs and the need to work more efficiently continue to put pressure on collision centre operations, LVP-565 Air-Dry Primer offers a highly versatile solution. Whether you are looking for speed, energy savings, increased efficiency, a more sustainable option or any combination of these, this advanced primer technology provides the flexibility to choose the mode that best suits your individual production processes.

The best refinish system on the planet gets even better, thanks to a bucket list of updates that deliver unparalleled flexibility, allowing you to produce sustainable, profitable repairs.

Whether you are looking to slash energy costs or reduce your carbon footprint, LVP-565 Air-Dry Primer offers an instant impact thanks to the ability to air-dry in just 30 minutes @ 20°C. At that point, it’s ready to sand and continue on with the next steps in the process. Imagine the booth bake time this frees up, as well as the reduced CO² output and energy bills. What’s more, unlike some other air-dry primers, this PPG developed primer surfacer does not rely on humidity conditions to enhance the speed of drying. Not only that, the exceptional versatility means you can easily accelerate the drying time, by using infra-red technology or conventional baking, if a job needs to be pushed through.

It's not just with its drying options that LVP-565 Air-Dry Primer offers outstanding benefits – there is also impressive outright application speed and excellent sanding properties. For example, the application process is achieved in a rapid, singles visit mode where absolutely no flash-off is

required. In addition, the specialised characteristics of this high-tech primer have been tuned to deliver excellent film build and the ability to lay down a super smooth film that is fast and extremely easy to sand. Best of all, zero investment is required to take advantage of this unparalleled versatility, efficiency and sustainability.

Rapid air-drying – Instant ability to slash energy costs and reduce CO² emissions

Drying modes: air-dry, IR, bake –

Versatility to choose the best option for you

Advance PPG technology – Fast drying process not dependant on humidity

No flash off, one visit application – Boost process efficiency

Super smooth laydown – Fast and easy sanding process

Reduce repair cycle-time – Improved productivity

Hybrid and EV friendly – minimises potential impact on battery cells

clear

By offering three different drying modes – airdry, low temperature cure or high temperature cure – LVC-177 Rapid Performance Clearcoat give you the freedom to choose the best fit for your repair process. Thanks to nextgeneration air-dry technology, it’s a highly versatile way to save time and reduce energy usage and emissions without compromising on ease of use and an outstanding finish. Air-dry mode is perfect for maximising savings on energy costs and minimising CO² emissions. Using this method, LVC177 Rapid Performance Clearcoat is dust free in 20 minutes and ready to fit up in just 60 minutes. Best of all, unlike older air-dry technologies, it does not suffer from humidity

Formulated using PPG’s premium Ultra High Solids (UHS) clearcoat technology, this is a simple, flexible, user-friendly product that inspires confidence and helps build paint shop speed and productivity, while delivering a high-quality end result.

related issues. Alternatively, you can choose a short, low temperature bake cycle and the job is ready to handle in as little as 20 minutes. If a job needs to be pushed through a bit quicker simply switch to the ultra-fast, high temperature bake mode where the job is ready to fit up in just five minutes!

Flexible application characteristics are another feature of this advanced formulation. Either choose single visit application mode (a light closed coat immediately followed by a full wet coat) or go with the traditional two coat method – it’s up to you. Whichever application or drying mode you choose, LVC-177 Rapid Performance Clearcoat delivers a superior, mirror-like finish.

Sustainability – Reduce energy bills and CO² emissions

Ultra flexible – Choose the drying mode that fits your repair process

Single visit application –

Saves time and material

Air-dry mode – Helps minimise energy usage

Dust free in 20-minutes

@ 20°C air-dry – Quick cycle-time with reduced energy usage

Low temp and high temp cure options

– Fast process time and potential to reduce energy costs

No compromise performance – Excellent drying properties deliver a superior finish

Hybrid and EV friendly – minimises potential impact on battery cells

It terms of applications, LVC-131 UHS Clearcoat offers the versatility to be used on a wide variety of jobs – anything from a single panel, right through to a full respray. Thanks to a short, 15 minute (@ 60°C) conventional bake cycle, there is the opportunity to shorten process cycle time, while also making a saving on energy costs. Alternatively, this thoroughly modern clearcoat also produces excellent results when using gas-infrared curing technology. When it comes to application, there is the choice of a single visit mode (a light closed coat immediately followed by a full wet coat) or the traditional two coat method. Whichever option you choose, LVC-131 UHS Clearcoat is easy to work with and produces a very fine peel finish which is favoured by many painters. In addition, it features a long pot life and excellent polishing characteristics.

Multipurpose – From a single panel to a respray

15-minute bake @ 60°C – Fast process time and potential to reduce energy costs

40-minute bake @ 40°C – Flexibility to choose the bake cycle that best suits your process

Single visit application – Saves time and material

Excellent finish and polishing – Fast detailing and high-quality end result R

Standard operating procedures are everything at Sommerville Smash Repairs where they have proven to be great for the team, great for the end result and great for profitability.

In the 30 years that Chris Agnew has been running Sommerville Smash Repairs, located in Nerang, on Queensland’s Gold Coast, it has only once failed to increase annual revenue and even then, it didn’t go backwards, it just remained stagnant. While there are a number of factors involved, Chris is adamant that one of the driving forces is having across the board procedures.

“We are extremely heavily process driven. We have written Standard Operating Procedures (SOPs) for absolutely everything. My technicians love it because their job is very organised and structured. Driving the business with SOPs has meant that our average cycle-time, across all types of repairs, is just under four days. I have been told that, outside of some of the big MSOs, we have the quickest cycle-time in the country. It means we are wound exceptionally tight so we could potentially

Having said that, we have it very well structured. One building is geared up for heavy collision and the Tesla repair side. The latest shop, I bought about 3.5 years ago, handles the main throughput of the business and mostly does small to medium look to take the pressure off a little by moving it back to four days average cycle-time and still be well under the insurer’s requirements.”

Today, Sommerville Smash is a bustling collision repairer with 32 staff but when Chris and his brother, Carl, bought the business in 1994, it was just a two-person operation, in a small shed in Southport. As demand grew, they moved to a bigger facility before taking the opportunity to purchase a building, around 20km away in Nerang. Since then, the two adjoining buildings have been purchased to grow space to around 2500m² under roof. About four years ago, Chris bought out his brother to become sole operator of the business, along with wife, Shari.

“My preference would be to have everything in one big shed, under one roof but that is not the way it’s gone.

jobs. In the third building we have invested heavily in a new paint shop.”

In 2023, Sommerville Smash split with its paint supplier of 24 years and went looking for a company that aligned with its philosophies and needs. Chris says, he is only interested in premium paints and that lead to PPG. “We are all about doing the job quickly and efficiently and doing it once which is why we have gone with Envirobase High Performance. The colour accuracy and the way PPG’s PaintManager colour retrieval system works were key factors and the DigiMatch spectro and VisualizID 3D colour visualisation software are also definite advantages. I like the idea of the MoonWalk automated paint mixing machine to the point where we are going to trial it to make sure it’s exactly where we want to be.

PPG has also helped in regards to their SOPs for preparing and painting vehicles. A constant focus on SOPs is something we do across the whole business – we never let it go. After all, you are working with human beings and human being forget and get complacent so it’s a case of constantly reinforcing.”

From the many long-term employees, through to the newest apprentices (there are currently three), the 32-person Sommerville Smash team is the businesses biggest asset, according to Chris. “The most important thing in the business is looking after our people and the key is the culture we have built up.

We are extremely protective of the culture. If I interview for a new employee and I think that person could cause trouble, it doesn’t matter if they are the best tradesperson in the country, they won’t be working here.

The biggest thing we do is provide a good workplace – it’s always squeaky clean. The team love this type of environment and everybody plays their part.

For example, the expectation is that when a panel beater finishes a job, they pack their things away, make sure there is no big debris on the floor and then move onto the next job. After he has allocated the next job to the technician, the production manager moves the car out and sweeps and washes

the floor. We make our money by selling our labour and renting our floorspace and we maximise that by having technicians working on cars. I am not paying them to clean up.”

Chris says, the business used to have 36 to 38 people but, with the current 32

staff, it’s actually managing to produce the same output, if not more. Rather than try to micromanage ever detail, he has put in place a motivated management team that are trusted to get the job done. “We have an office manager, an operations manager who controls the whole site and managers in both the panel and paint departments. Then we have my wife, Shari, who has worked fulltime in the business for 27 years. In a lot of ways, she is more valuable to the business than I am – you would go a long way to find someone who is more across the bookwork and office side of the business. I am not really out in the workshop that much anymore. I do float around out there but this place is so busy there is always something that requires my attention. One thing I make sure I do every day is to say g’day to each staff member. It helps

me keep connected to the team and work out who is on a high, who is on a low and who has issues going on so we might be able to support them.”

Apart from the difficulty in finding skilled staff when needed, Chris reckons another

Sommerville Smash Repairs

Owner: Chris and Shari Agnew

Staff: 32

PPG Product: Envirobase High

Performance

Territory Manager: Tahlia Riini

key challenge is the growing complexity of the industry. “People from outside the trade will say we don’t panel beat anymore, we just replace parts but, in fact, it’s completely opposite to that. For example, late model cars are much more advanced and technical, with ADAS, electric vehicles, composite materials, etc, it’s a different ballgame. That is why I am happy to organise appropriate training to keep the team upskilled. As part of that, we were the 19th shop in the country to earn I-CAR Gold Class and we continue to maintain that every year. We choose the direction and path we need to train our people and we lock in a schedule of those training courses in January each year.”

Sommerville Smash has become even more of a family affair in recent years, with Chris and Shari’s son, Corey, now seven years into a panel beating career and daughter, Hayley, recently joining the business to work with her mum on the admin side.

While he doesn’t go out of his way to look for praise or industry accolades, Chris is very happy for his team when it does come. Indeed, in recent years Sommerville Smash has been recognised with nominations for a number of major industry awards. “Knowing that we are at the top of our game and held in high regard within the industry is a good thing, not just for me but for the whole team. You really are nowhere without your people!” R

After originating in the USA in the 1960s, ‘street art’ has steadily transitioned from a rebellious form of expression into a legitimate worldwide art movement. Originally created in the urban landscapes of large cities, many artists have turned street art into a recognised artform that is often used to send and immortalise social and political messages in the form of eye-catching murals. From the streets of New York, to the Berlin wall or one of Banksy’s thought-provoking works, street art has become an uber cool attraction, with cities such as Melbourne actually offering guided street art walks to better appreciate them.

When it comes to making a statement in the refinish paint shop, street art combines perfectly with SATA’s premium spray gun to create the limited edition SATAjet X 5500 Street Art. Featuring a beautifully crafted, precision engineered body covered in sophisticated street art motifs and offset with black accented nozzle and gun controls, this latest SATA special combines energy and creativity with the outstanding qualities that have made SATA an industry leader. Behind the vibrant graphics, you will find all the high value features of the regular SATAjet X 5500, including the unique X-Nozzle System. This innovative range of nozzle options makes it easy to perfectly tune this spray gun to suit a painter’s personal spraying preferences, the paint brand being used and application conditions that can range from a cold, dry

SATA’s latest special edition, the SATAjet X 5500 Street Art, pays special homage to the global movement that literally sees artists take their work to the street.

Art is available in your choice of RP or HVLP technology, as well as selected nozzle sizes, and the extremely popular digital version with a handy air pressure readout integrated into the gun handle.

Past SATA limited edition models have proven extremely popular with paint technicians looking for a little individuality, as well as the growing number of collectors looking to add to their display cabinet and the SATAjet X 5500 Street Art is sure to be the same. Stock is strictly limited so to avoid missing out speak to your SATA distributor, across Australia and New Zealand, for more information.

For gun driver, Tony D’Alberto, a helmet is more than just protection – it’s a high-profile way to showcase his sponsors and personality and that is where rStar Design comes in.

Skid lid, stack hat, brain bucket, call-it-what-you-will, a quality helmet is a crucial piece of a race driver’s kit. However, it’s not all about safeguarding the wearer. In a grid full of cars and drivers, helmet colours and design actually become a key point of difference that can help to quickly identify individuals. Creating these works of art is a specialised skill and one of the best in Australia is Frank Stivala who

an eclectic mix of clientele from racing categories all over the world, encompassing go-karts to Supercars, IndyCar and NASCAR. One of rStar Design’s long-term customers is Tony D’Alberto who recently purchased two new helmets –one for his Supercars duties with DJR Shell V-Power Racing and the other for when he is behind the wheel of his TCR Honda Type-R or in GT racing. The next step was to pass them on to Frank to transform them from dull carbon fibre to

your creativity and personality. You need to ensure that your sponsors are prominently surface, you can put your own personal flair

Over the past few years, I have kept a similar design and just evolved it each time. It’s featured a lot of red, white and blue and the line work has been pretty consistent. My wife, Stephanie, is very good in the design space so she helps me with some of the initial mock ups to give Frank a bit of guidance. He then makes that design work on the 3D shape of the helmet. Frank also adds extra touches, such as with one of the new helmets where he has included a really nice black pearl which looks amazing.”

time we do a new one we just make little tweaks to evolve it.”

rStar Design has long painted helmets for Kiwi star, Scott McLaughlin, and that sparked the connection to PPG, says Frank. “It’s one of those things where you don’t realise what you are missing until you try it. When I started working with PPG products, they worked so well for what I do, it was like night and day different. It dries quickly and smoothly which is important to me because I am constantly masking to do different layers. As far as productivity goes, PPG has definitely made a massive change to my day-to-day operations. It just makes life so much easier. I also utilise the PPG Vibrance Collection of specialty finishes and I have a couple of SATA Minijet spray guns I use for basecoat and clearcoat application.”

Even when dealing with the pressure of

Todd Kelly is in his element when fully immersed in a project, whether it’s developing a racing V8, running a family business or helping son, Mason, on the pathway to Supercars.

Between the ages of eight and 44, Todd Kelly has had precisely one year away from the relentless intensity of motor racing. After starting out spending pretty much every weekend honing his skills in go-karts, he progressed through the various motor racing categories to reach the pinnacle of Supercars where he drove for prominent teams, including Holden Racing Team, Perkins Engineering and Kelly Racing. After becoming the youngest driver to reach 100 starts in Supercars, Todd went on to amass a total of 541 Supercars starts, 19 race wins and 58 podiums by the time he retired from driving at the end of the 2017 season. He continued to run Kelly Racing with his brother, Rick, until the team was sold at the end of the 2021 season. At this point, Todd was content with stepping away, taking a well earnt breather and exploiting the skills learnt during his long racing career.

“That whole block of 20 years of Supercars racing is just a bit of a blur. It’s funny but a lot of drivers just live and breathe racing and they seem to be able to remember every lap they drove. I am not like that – I don’t remember it. Because racing is so cutthroat and intense, I put absolutely everything into that moment and, when it was over, I could tick that box and move on. On the other side of the coin, when we ran Kelly Racing there was also the commercial side and the engineering / manufacturing side to take care of which was a whole new aspect. Racing is such a hard game, it teaches you a lot. If you can get through being a professional driver or a team owner for a long period and you don’t come out the other end as one of the most resilient people on the planet there is something wrong. After doing professional sport for so long, running a business in the ‘real world’, as I call it, is quite easy.”

With racing commitments off the table for the first time in 35 years, Todd was free to pursue a whole range of other interests. For example, with the family buying the Steeline Mildura business and putting it through a major transformation. This included finding a green-field site and building a bespoke facility which was fitted out with brand new, state-of-the-art machines from around the globe for rolling and forming steel. Now, the 35 staff are kept busy supply the Sunraysia region with a range of steel building materials. When it comes time to carrying out periodic servicing and maintenance on these giant machines, the person you typically find at the coalface is Todd. Rather than being a point of stress, he says getting his hands dirty is actually something that relaxes him.

“If I am getting smashed in the office or whatever, a few hours in the fabrication shop, the paint shop or on one of the Steeline Mildura machines, is a bit of therapy. Looking back, probably my fondest memories are of developing the Nissan Altima Supercar and developing the Nissan Patrol V8 engine into a competitive Supercars engine. These were ‘world first’ engineering tasks and, back in 2012, we had 75 staff working on the project. I was immersed in every aspect of the development of the Nissan aero package and engine. To me, that is really cool! I was there helping to fabricate exhaust systems and working on inlet and exhaust port design and inlet manifolds. When you look around the workshop now, there are still test pieces and remnants everywhere. At the time, it was the biggest team, running four cars, with the most amount of manufacturing being done in-house that has ever happened in this country. Looking back, we really took on way too much but we didn’t realise it at the time. That was a period where you still had real racers / engineers, such as Larry Perkins, Glen Seton and Ross and Jim Stone who were out on the workshop floor looking for ways to make the cars faster. The way Supercars is setup nowadays you can pretty much buy a car and all the parts and go racing without having to do any major design engineering.”

“Mason got some good results in go-karts but he was not able to do it enough to get into a rhythm. When he got into Hyundai Excel racing it was scary for Kristy and I. He was just a little tacker, racing with a whole field of Hyundai’s around places like Sandown, Winton and Phillip Island. However, he did really well, especially with his limited experience. Then a friend offered Mason a drive in a V8 sports sedan and he ended up driving it at a few races, including at Bathurst. He did a really good job – he was lapping at Supercars pace! – I thought, he probably needs to jump into one of my Supercars. He did well at that and, in the blink of an eye, we had our old staff back and we were running a three car team in Super3! From there, he stepped up to Super2 for 2024.”

According to Todd, establishing Kelly Racing 2.0 was relatively easy as the facilities, including engine shop, fabrication shop, paint area and workshop, were ready to go, as were a couple of Mustang race cars. Because running a team takes a decent budget, it also gave Todd the opportunity to reconnect with long term sponsors, such as PPG. With all the razzle dazzle of motor racing, one thing people don’t see is the extraordinary amount of work and determination that goes into funding a team, says Todd.

one thing that sticks in my mind is those friendship and partnerships, like the ones we have made with Sally Atkinson (PPG Executive Assistant), Paul Galea (PPG General Manager Refinish ANZ) and everyone at PPG.”

“There is a lot of knockbacks. You might visit 100 companies looking for team sponsors / partners and get just one. Then you come across partners, like

Just as Todd learnt to maintain his own equipment back in his go-kart and Formula Ford days, Mason is also keen to be hands-on. It started with a father and son COVID project, explains Todd. “We had an old red Massey Ferguson tractor rusting away up in Mildura so we hooked into that. We stripped and sandblasted it and Mason learnt how to paint on it. He has always maintained his Excel but he has also gotten into the painting side with advice from some really good painters who help us out and some PPG training. Now Mason is at the point where he does all the prepping and painting himself which is really cool.

I want him to understand the work that goes into fixing the car after it gets on-track damage.”

Painting the cars also pays off elsewhere, says Mason. “Painting our cars is something a bit different because most of the other cars in

is to be a fulltime Supercars driver but my goal this year is just to get as much experience out of the season as I can. Obviously, Super2 is a really high level of competition and it’s quite easy to turn up at a track and be half a second or a second off the pace. You need to be able to find that time in the car setup and within yourself in order to be really fast. One of the biggest things to learn is to be able to concentrate on driving fast but, as the same time, to also be thinking about what the car is doing and what does it need to make it better. Doing those two at the same time is one of the hardest things.”

As well as being team manager, Todd is doing his best to help speed up Mason’s development by passing on his extensive experience. “Mason has been properly thrown in the deep end. I am able to talk him through different challenges, what to expect and what to do. He is very good with his mindset and how he goes about his racing. Mason has shown that he has the talent and he can drive the car fast but he is having to learn race craft. In the meantime, our 16-yearold daughter, Alex, has decided she wants to drive the Hyundai Excel so she might be racing soon!”

It seems there is no rest for Todd and he would not have it any other way. “It’s those times when I have been on the tools that I end up feeling completely unstressed and content at the end of the day!” R

Tother words, choosing from the wide variety of different product technologies and then using specific, step-bystep processes that allow the paint team to efficiently reproduce the same highquality finish every single time, while avoiding wasteful rework. As part of this, paint technicians need to understand the different spray gun technologies and setup options and, using that knowledge, be prepared to switch to suit different application tasks, according to Mark Haywood, PPG Training Manager QLD.

In basic terms, a spray gun works by flowing high velocity compressed air over a fluid control device, known as the fluid tip. This creates a negative pressure area that draws liquid into the stream of turbulent air which impacts on the surface of the liquid film, causing it to collapse into droplets of widely varying sizes. Controlled air flows from small holes in the air cap to further reduce the droplet sizes. This cylindrical atomised stream is then shaped into the required pattern by introducing air from the air cap horns. Directly opposite streams of lower velocity air push against each other to flatten the cylindrical stream into a fan pattern. The more air introduced, the wider and narrower the pattern becomes. If too much air is fed from the horns, it will split the pattern in two, making it top and bottom heavy, with less paint in the centre.

While spray guns work on the same principles, it’s important to understand that there is no such thing as a universal spray gun – the modern refinish process if far too specialised. As well as different spray gun brands, they are typically available in different technologies (HVLP and RP), as well as different nozzle setups. As a generalisation, High Volume (of air) Low Pressure (of air)

In today’s refinish paint shop, the right spray gun, with the right nozzle set and the right setup for each application task, is crucial to being consistent, productive and profitable.

is better suited to the application of lower viscosity materials, such as basecoats, which are easier to atomise. As a result, its greater transfer efficiency reduces material consumption and the fan and delivery assist with blending

and help to control mottle. On the other hand, Reduced Pressure (of air) technology tends to be better suited to higher viscosity products, such as primers and clearcoats.

Once the gun technology has been selected, it’s time to choose the best nozzle set and this comes down to the product being applied. For example, a 1.2 tends to be good for newer generation ‘ultra high solids’ clearcoats, whereas for ‘medium solids’ and ‘high solids’ clearcoats, a 1.3 is better. Then, for wet-on-wet primers

you want something a little larger, such as a 1.4, because the product is thicker and for regular primers which are thicker again, you would be looking at something larger.

Spray fan shapes

Another crucial factor is to get spray gun setting (fan, material and inlet air pressure) that work and then stick to them. You can’t do that if you don’t have the means to measure these accurately. For example, it’s impossible to setup a gun by listening to the sound of air when you pull the trigger. A SATA DIGITAL model, with the gauge built into the gun handle is ideal, as is a SATA adam 2 digital air micrometer. Alternatively, you can attach a gauge to the base of the gun which will do the job but I find that this upsets the gun balance.

This is where it’s important to get advice from your paint manufacturer. They should be able to provide guidance on best nozzle size and other gun settings to suit each of their products. For example, the local PPG technical team has done exhaustive testing with different products, different nozzle sizes and different gun setting to come up with comprehensive recommendations for nozzle setups and gun setting (particularly for SATA models), including when operating in hot / humid conditions or hot / dry conditions. This helps to consistently get the best from each and every product and application. Best of all, accessing them is as easy as asking your PPG Territory Manager or Training Manager.

Recognising the importance of choosing the correct nozzle setup for each application, SATA actually created the SATA Nozzle Finder App (free from Google Play Store or the Apple Store). By answering a few simple questions, such as your current brand of spray gun, nozzle size and paint material being used, the App will recommend the best X-Nozzle option for your SATAjet X 5500. R

in a hall full of show cars as it is pulling eight seconds down the quarter mile.

As people dropped in to visit the PPG stand at Motorex 2024, many took the time to admire a very tough looking 1971 Holden Torana XU-1, with classic drag car stance and a menacing black finish. Although it was not a show car, the outstanding build quality and paint work marked it out as more than just a machine built to be thrashed down the drag strip. The backstory that brought this epic machine to life starts with 17-year-old Peter Di Petta buying his very first car.

“I bought the car because I fell in love with it. Back in 1983 the car was 12-yearsold and someone had already removed the original six-cylinder engine and put a 253 cubic

inch V8 under the bonnet. Through friends, I met some drag racers who were building high performance engines and it just snowballed from there. It was like they threw out the drag racing bait and reeled me in!

We built a really hot 308 cubic inch V8 for it and, although the engine bay is small, it actually fitted quite well, along with a Turbo 400 auto. I drove it on the street for a couple of years before I had the brainstorm idea to go drag racing. We freshened up the engine and added a rear half-chassis, a nine-inch diff and big back tyres, as well as a paint job. Back in the early to mid ‘90s, it ran 10.5 seconds down the quarter mile at 125mph.”

brother, Charlie. Initially, the pair did regular smash repairs but then transitioned into restoration work. They still do that today, along with fitting canopies and roller covers for Bodyline Automotive Restyling and a little smash work for existing customers. For more than a decade, the Torana sat neglected in a corner.

“In mid-2010, I said to my wife, I have to get this car back on the track or I never will. I got in touch with my friend, Mike, from Chris Alston’s Chassisworks in the US, who could supply a lot of the parts I needed so he packaged everything up and shipped it here. When I first built the car, it was still the original floor with the back half modified to fit the nine-inch, ladder bars and coil-over shocks. Now, using a chassis kit I got

from the US, it’s a full chassis car – basically a space frame. The bodyshell is still steel but the floor is aluminium and pretty much everything else is fibreglass. It now runs a 400 cubic inch small block Chev with two speed Powerglide auto and nitrous oxide injection. All of this wouldn’t have been possible without the support from my family, friends, John and Jay from Pro Matic Transmissions and Stef from Westernlink Automotive.”

Although it was never meant to be a show car, Peter’s passion and determination meant that he couldn’t allow himself to do anything but the best job possible. “When I was doing the body, people kept asking why I was being so fussy – it’s only a drag car. I said, it’s because this is my trade and I want to show off the quality of workmanship and attention to detail that we do.”

The colour choice came down to keeping the status quo but the choice of paint material was always going to be PPG, says Peter. “I was actually using PPG from before Charlie and I started this business in 1988. Thirty-five plus years later we are still using PPG. The car was always black from when I built it the first time. I toyed with the idea of doing it in the original factory silver with black accents but everyone knew my car as being black. When it’s done in black, everything has to be absolutely straight so I spent about 12 months of weekends, etc, just doing bodywork.

It’s all been finished in straight black tinter –the car is always going to cop little nicks here and there and it will be easy to touch up.”

With his beloved Torana back at the strip, Peter is getting to know this latest version. “It has gone from an engine that made maybe 450 to 500hp, to now having 1020hp in a car that weighs just over a tonne with me in it. The first two meetings I ran it without nitrous and it was like I had never even left.

The next time out I turned on the nitrous and it was like someone belted you in the back of the head! To date it’s recorded 8.09 seconds down the quarter mile at 167mph so it’s quick and a real buzz to drive.” R

As repairers navigate the tricky path to reduce their carbon footprint without impacting profits, the new PPG SUSTAINABILITY CO2NCEPT system offers tailormade solutions.

Today’s collision repairers can quite rightly feel like they are caught in a squeeze. On one side there is the growing pressure from customers, work providers and society in general, to operate in a more sustainable way in order to reduce their environmental footprint. At the same time, the inexorable rise in energy costs is throwing operating budgets out the window and putting a sizable hole in overall profitability. With this in mind, PPG has created the Sustainability CO2NCEPT. It consists of a suite of products, processes, digital tools and consulting services and offers unique opportunities to embrace sustainability and reduced energy consumption as a pathway to sustained long term profitability.

For individual repairers, the secret to thriving in this environment, is having a clear understanding of the current situation, followed by clear directions on exactly what alterations are needed to reach their goals. That makes the Sustainability CO2NCEPT Calculator an extremely powerful tool that not only lets repairers get a handle on

current energy efficiency, it also lets them easily explore the available options to determine what works best for them.

a baseline

The process begins with an individual collision repairer working with a PPG representative to input a variety of the business’ parameters into the app-based Calculator. This information includes:

• The price the business currently pays for gas and electricity

• Estimated spray booth gas usage per cycle

• Estimated electricity current draw for lights, motors, etc

• Average ambient temperature for the area. This is important because in a cooler climate a higher amount of energy is used to heat the incoming air

• Booth airflow

• Product bake times

With all the available information plugged in, the Calculator is able to generate an estimate of the current energy efficiency and carbon emissions. As well as providing a

handy starting point, it’s also a springboard to exciting improvements.

Check before you change

In the past, if a collision centre wanted to make changes in the workshop, it meant going through the rigmorale of introducing a new product or process and then monitoring it to check its impact. This is not only time consuming, particularly if you are working through a number of different options, it also tends to disrupt workflow. Rather than making actual changes, the Sustainability CO2NCEPT Calculator offers the unique opportunity to make virtual changes to test out potential scenarios. Best of all, it gives immediate results. For example, by simply inputting the parameters for a different product or process into the Calculator, you get to see the impact that change would have on cycle-time, energy usage, waste and the collision centre’s carbon footprint.

No matter where you are across the region or what size your business is, this

innovative PPG concept offers a remarkable catalyst to drive changes for the better, according to Greg Tunks, MVP Business Solutions Manager ANZ. “When you are looking at minimising electricity and gas costs, reducing cycle time and being more sustainable, you are talking about practically every collision centre, across the board. Of course, the more booth cycles per day, the bigger the potential savings but even small shops can make good savings by using the Sustainability CO2NCEPT Calculator. Image if you could simply switch out one product for another and see significant savings in energy usage and carbon emissions – in today’s business environment, that is a no brainer.”

“Although it was born out of the PPG team in Europe, the Sustainability CO2NCEPT Calculator available to local repairers has been thoroughly tuned to this

market. That means the data that drives it has been updated with all the latest local information. For example, this includes the latest PPG products that are available for local customers to choose from.”

By using the simulations on offer through the Sustainability CO2NCEPT Calculator, it becomes easy to ‘test run’ what would happen if you were to use one of the many different products or processes that are on offer to PPG customers. For example, what opportunities could it offer to switch to:

• Using UV8080 UV Cured Primer Surfacer which cures in as little as three minutes under an approved UV lamp and frees up booth space.

• Curing with InfraRed (IR) which avoids running the booth bake cycle

• Using a Wet-On-Wet primer, rather than batch priming

• Using an air-dry primer or clearcoat to reduce energy consumption

• Using a shorter bake clearcoat to reduce booth cycle time and energy consumption

Whichever options you choose, the PPG team is there to support you along the journey with crucial services, such as training to bring your team quickly up to speed and guidance from your MVP Business Solutions Manager to give you peace-of-mind that you are making the most of your opportunities.

For more information about the PPG Sustainability CO2 NCEPT, speak to your MVP Business Solutions Manager, your PPG Territory Manager or the PPG Customer Service Hotline 13 24 24 (Aust) or 0800 320 320 (NZ). R

After leaving school, Sharon decided to take up a customer service role as a job to do until she worked out what she really wanted to do. 30 years later she has held pretty much every customer service role you can think of, including Training & Quality, Team Leader, Compliance, Project Lead & Customer Service Manager. Around seven years ago, Sharon was looking for a change of scenery when she accepted the role of Customer Service Manager at PPG Clayton.

“Seven years at PPG is the longest I have ever been in one role!

Day-to-day, I manage a dedicated team of 24 people who support PPG customers and distributors across Refinish, Protective & Marine Coatings, General Industrial, Packaging and Export, around Australia and New Zealand, as well as visitors to our Clayton site.”

“This is a talented team who never know what the next call will be about so they have to be ready for anything. It could be something as straightforward as a general enquiry or placing an order, or it could be someone looking for product or technical advice, or perhaps checking on a discrepancy with an order. Active listening is really important in order to understand exactly what the customer needs and then you need to have empathy for each customer’s situation. Ideally, you want every interaction to be a win / win for the customer and PPG. I really enjoy the diversity of people I get to interact with as part of my role, as well as seeing team members learn and progress in their own roles.” R

• Favourite hobbies/pastimes?

Playing / watching sport, travelling

• Favourite food? Thai

• Favourite drink? A nice Shiraz

• Favourite music / band? Anything 80’s

Thanks to an unrivalled combination of exceptional speed, superb colour accuracy, no-fuss ease of use and effortless blending and mottle control, this is simply the best refinish technology on the market. Backed by a range of primers and clearcoats featuring advanced low-VOC technology, it’s the eco-friendly choice which really delivers on outright speed. With everything a modern, fast-paced collision centre needs to slash cycle-time while boosting productivity and profitability, Envirobase® High Performance is engineered for excellence!

More so than pretty much any other trade, a painter’s main tool – the spray gun – has a dramatic impact on their quality of work so it literally pays to choose wisely.

Whether you are an apprentice through to a seasoned tradesperson, what goes through your head when you are looking to purchase a new spray gun? Is it just buying the same brand again, is it about price, is it the brand your local distributor has in stock, is it a recommendation from your mate. In fact, the best thought process is ‘what can this gun do for me’. In other words – what is the return on investment I can expect from this gun. Given the spray gun is a painter’s primary tool of trade, it has a huge influence over the work they produce. Make the wrong choice and you are likely to regret it every time you pull the trigger. However, get the choice right and you will have something that is a joy to use every day, says John Hristias, PPG Sales Director Australia.

The purchase decision for a new spray gun should never be taken lightly and should never be made on price – it’s far too important for that. Most painters will accept that SATA is the premium spray gun technology on the market but then you get people making off-the-cuff comments that SATA is expensive. But is it?

I would argue that SATA’s premium price tag is because the familyowned German company isn’t aiming to the cheapest – it’s aiming to be the best. However, it’s when you look at what comes with the purchase experience that the return on investment comes into play.

For a start, nothing measures up to SATA in terms of performance. An average gun might produce reasonable results on a straightforward job but it’s when the going gets tougher that

SATA technology shines through and really becomes the painter’s friend. Particularly with more complex tasks, such as challenging colours or blends, the accuracy and precision atomisation you get from a SATA gun makes life so much easier and less stressful for the painter. At the end of the day, painters are judged by the finish they produce and SATA guns give you an edge, no matter what paint system you are using.

So how much would you be prepared to pay for that performance? Given that you can easily expect to get 10 years or more of service from a SATA gun – if it’s maintained and looked after correctly – the cost per year is a lot less than you might think. We have done the figures and it works out to around a few hundred dollars per year.

When considering a SATA gun against another brand, it’s important to make sure it’s an equal feature-for-feature comparison. For example, for many SATA guns there is the option of a DIGITAL version which has a digital pressure gauge built into the gun handle. Given that it’s crucial to be able to measure the inlet air pressure, if the gauge isn’t built in, you will need to purchase a separate inline gauge. Not only does that mean extra cost, it also adds extra weight and changes the balance of the gun so it’s more awkward to use. It’s perhaps no surprise that the DIGITAL versions are by far the most popular SATA models on the local market

SATA guns have a reputation for premium quality components and long-lasting performance but like any spray gun, they have parts

that wear and require replacement from time to time. However, one big difference is that SATA is committed to making those parts readily available long into the future, along with backup service. Rather than having to throw away the gun because parts are no longer available, you can keep your SATA gun in top working order. For example, I still have my first SATA gun that I got when I was an apprentice and it still works perfectly!

At the end of the day, is the ordinary gun really the one you want to own? Every painter should at least try a SATA spray gun just so they know what they are missing out on and the easy way to do that is to contact your PPG Territory Manager, your local PPG Training Manager or your SATA distributor. The whole PPG team use SATA guns because we know from long experience that they consistently produce outstanding results and make difficult jobs easier. They will also be happy to give you the

opportunity to experience the SATA advantage without actually shelling out your own money – what have you got to

Amagnetic poles repel, whereas ‘opposite’ magnetic poles are attracted to each other. However, it’s not just magnetic fields where this force is found. This principle also comes into play in the electrostatic force and that makes it possible to take advantage of these characteristics to create the electrostatic paint process.

Back in the early 1950s, the coatings industry was looking for a spray application process that could dramatically improve transfer efficiency in order to reduce product wastage and, hence, reduce production costs. Given that all matter is made up of electrically charged particles and these particles

was applied to paint particles and a positive charge to the substrate, the electrostatic forces made the two attractive to each other. Since then, refinements to electrostatic technology have seen it used in a wide variety of industries and applications. For example, vehicle OEMs typically utilise robotic electrostatic rotary bell application technology in their paint facilities and these units can reach transfer efficiencies exceeding 90%! For smaller scale painting operations, advances in electrostatic equipment means the technology is now easily accessible and very safe and easy to use. Best of all, it’s capable of producing a great finish, a faster application speed, reduced VOC emissions and lower hazardous waste disposal costs, as well as high levels of transfer efficiency.

By tapping into the principle of oppositely charged particles being attracted to one another, the electrostatic

with items that are difficult to paint in the traditional method, such as round bars, latticework, etc.

A typical electrostatic paint process begins with a specialised electrostatic spray gun. In terms of atomising paint, it works in basically the same way as a conventional gun. However, it also includes a charging electrode located at the nozzle which is electrically charged via a power supply.

As atomised paint material leaves the gun nozzle, it passes the electrode and is ionised – a process that causes the paint material to pick up extra electrons and, therefore, become negatively charged. At the same time, a positive charge is applied to the job substrate. As a result, the force of attraction between the negatively charged paint particles and the positively charged substrate is actually sufficient to turn around particles that would normally end up as overspray and draw them back onto the job surface. While the process is happening, it’s literally possible to see the paint particles curving in the air as they track their way to the job. However, there are limits to how much the electrostatic force can influence the path of the paint particles. For example, larger paint particles, sprayed at higher speeds, have greater momentum and, therefore, have the ability to overcome the electrostatic force and simply continue travelling past the job. In contrast, finely atomised paint particles, sprayed at a lower velocity have lower momentum which gives the electrostatic force a chance to take over and attract them to the job surface. As the negatively charged paint particles are deposited onto the positively charged substrate, it completes the electrical circuit.

Compared with a traditional spray-painting setup, going with electrostatic technology definitely requires a higher upfront investment. However, because of the advantages in production speed and reduced product usage due to higher transfer efficiency, the potential for a return on that investment is often measured in months, rather than years. When it comes to making the switch to an electrostatic application method, there are a number of other factors to consider, says Laurie Allan, PPG Commercial Performance Coatings National Field Demonstrator and Account Manager.

“Expert support is a must with any paint system but it’s particularly crucial with something like switching to electrostatic. We custom build the system to suit the customer’s application. That means the spray gun, the hose setup, the pump or delivery system, the needles and nozzles setups, the caps, etc, including having extra critical spare parts on hand should an issue arise. We also do tests with the paint products – such as monitoring the resistivity – to ensure it works perfectly in the customer’s application environment. Application training is absolutely paramount to the end result. Electrostatic is a different

type of painting. Some techniques are similar to conventional spray painting but it’s also quite different – it’s all about the angle of the gun to get the most wrap of paint product around the job. Most of all, once the decision to switch has been made, it’s about commitment – commitment from the paint shop floor and management so that everyone is on the same page. Then you can get the maximum advantage from electrostatic.” R

Photo credit: Wagner Spraytech Australia

After taking a chance to set up Roadmaster Trailers from scratch in 1991, the Rotorua-based manufacturer has become the byword for high quality, high productivity solutions.

every part of a trailer to suit their individual needs.

“We have a spec sheet that every customer fills out and there is many

multiple different combinations available for them to choose from. Some might only be slight differences, while others are big differences. That is why one of our sales team generally sits down with the customer to help fill out the spec sheet.”

down the busy production line is driven by customer demand and that is influenced by a number of factors, says Torsten.

Amongst the extensive Roadmaster range you will find curtain-siders, tippers,

“Up until about a year ago, we were predominantly building truck and trailer combinations with curtain-siders.

However, there has been a bit of a change to road usage charges in New Zealand which has altered what customers are ordering. Over the past year, about 40% to 50% of our business has shifted to B-trains (two trailers of the same size

behind a prime mover – commonly called a B double in Australia) which have become cheaper to run. The rest of our production is mostly made up of truck and trailer combinations.”

While Roadmaster is a thriving business today, just under 33 years ago it was merely an idea in the minds of four men – Pat Mear, Lyall McGee, Bill Lacey and Ross Bell. Using their existing experience in trailer engineering, manufacture, sales and finance, the group took the leap by taking a 25% stake each in this fledgling trailer builder. Things were very tight in the early days. Indeed, the first job was simply to lengthen the wheelbase on an existing trailer. The first two trailers built from scratch were a pair of tippers that were delivered inside four weeks. In the first year, Roadmaster built 28 trailers, boosting that to over 50 in the following year. A year later, production

was required for our paint shop and come up with a few ideas – that was PPG! They were very proactive and good to deal with and the partnership just developed from there. Today, the relationship has been going for nearly 25 years.”

numbers were into the 70s and they have not looked back. From the very early days, the Roadmaster team were determined to set the standard for design refinement and overall quality and this got the company noticed in the marketplace, says Torsten.

“Just prior to when I came onboard in 1994, Roadmaster was approached by truck and trailer rental specialists, TR Group, to see if it was interested in building roughly 100 trailers for them per year. In New Zealand, that is quite a big deal. At the time, we were considering setting up production facilities in Palmerstone North and that is where I got involved with the PPG team. I knew very little about paint so I needed someone who was prepared to help me understand what

Although it has a maintenance facility in Auckland, Roadmaster’s production facility is located around 225km south, in Rotorua. The city of around 77,000 people is ideal for manufacturing transport industry equipment, says Torsten. “Rotorua is probably the main transport manufacturing place in New Zealand and that includes different manufacturers

of running gear which allows us to source locally. We run a production line system where we literally go from raw steel to completed trailers. Up until 2007, we used to cut up all the steel in our cutting bay but we decided to outsource it to a specialist plasma / laser cutter in Auckland and leave our cutting bay for specialised jobs. All those different shapes and pieces of raw steel are virtually the building blocks of our trailers.”

“Production starts by fabricating and jig welding the beam deck which is the

rotators fitted at each end. These are like big wheels that create a rotisserie style function that allows you to rotate the whole trailer so the welders can easily weld in difficult to get at area without having to climb underneath. That way, you get some pretty beautiful welds! The assembly area is where it starts to really look like a trailer

Around 120 staff work at Roadmaster and like most industries skilled staff are difficult to find, says Torsten. “Welders are the number one priority but we also need skilled tradespeople, like auto electricians and painters. We usually have a few apprentices to help build a skilled team from within and we have had good success sourcing people from Sri Lanka, to the point where we have around 30 in our workforce.”

As with society in general, the COVID pandemic also threw a bit of a curve ball at Roadmaster. “In the past the longest we ever had orders blow out to was about seven to nine months. In other words, we knew what we were going to be building in seven to nine months’ time. Then COVID came. The effect was a little slow to begin with but it accelerated to the point where the number of orders rolling in blew delivery times out to just over two years. If you look through the workshop now you will see that we are very busy feeding through that backlog of orders. The challenge for the business going forward is to keep the momentum by getting consistent orders through the books.”

“The beauty of Roadmaster is that we keep high quality engineering and manufacturing in New Zealand and give local customers the ability to customise a trailer to exactly what they want. For example, we just finished a special trailer where each individual wheel, across all four axles, is able to turn in almost any direction you want. In fact, it can almost turn sideways. It means the customer can reverse the trailer quite close to a building without the truck having to do a lot of manoeuvring. It’s a special trailer which has a lot of engineering work in it but it’s what Roadmaster does. We are proud of every truck and trailer that leaves here.”

The end-to-end digital ecosystem bringing advanced, game-changing technologies to your collision centre

Scan the QR code to see how PPG LINQTM can benefit your business! youtu.be/t4isZfVLwzw

Introducing the 3D digital sprayout

This advanced, 3D digital colour visualisation tool smoothly interfaces with the next-generation PPG DigiMatch™ camera-equipped spectrophotometer to totally transform the user experience of selecting the best colour match formulation from PPG’s extensive library.

Compact, fast, easy-to-use spectrophotometer

PPG’s high tech DigiMatch spectrophotometer features a digital colour camera to significantly boost performance. The camera’s six imaging angles combine with six reflective angles to provide additional texture information to help quickly and precisely retrieve the correct formula match.

SATA’s latest special edition, the SATAjet X 5500 Street Art, pays homage to the global movement that literally sees artists take their work to the street. Featuring creative and expressive street art images, it’s sure to make an eye-catching statement in any paint shop or on display in a collector’s display cabinet. Behind the vibrant graphics, you will find all the high value features of the regular SATAjet X 5500, including the unique X-Nozzle System.

Stock is strictly limited so to avoid missing out speak to your SATA distributor, across Australia and New Zealand, for more information.

Follow us online!

PPG Refinish Australia & New Zealand