PPG’s automated paint mixing system, PPG MoonWalk, replaces manual paint mixing processes to deliver greater efficiency with less wasted product, a cleaner work environment for technicians, and reduced environmental impact.

This revolutionary system features a high-accuracy scale and precision mixing to ensure quality and consistency in every paint mix. Automated processes also help to reduce labor time and minimize human error, which means that PPG MoonWalk can significantly boost the productivity and profitability of your body shop.

PPG MoonWalk is part of the PPG LINQ™ digital ecosystem. Visit PPGLINQ.com for more information.

Next level protection Get a gladiator on your side

Welcome to the jet age

The all-new SATA jet X is the gun that ‘works for you’

A privilege, not a right

The Baum Cycles passion, precision and performance

Apex predator

When Cam Waters entrusted his 1974 Ford Falcon XB Coupe to Rob Zahabi and his team at Rides by Kam, it was a match made in heaven. The result is a blockbuster piece of resto-mod machinery with fiery performance and smouldering good looks.

your epoxy primers Use the right one for the right job at the right time

When planning your visit to Summernats 2025 (2nd to 5th January) leave plenty of time to take in all the attractions at the PPG stand. Located at ‘PPG Corner’, it showcases this year’s theme of a ‘PPG Summer’ complete with hot colours, wicked custom machinery on display and the opportunity to pick up some very cool and exclusive PPG Summer merchandise.

Features include an all-new version of the crowd favourite, ‘Colour Wall’ display that brings to life some of the legendary PPG VIBRANCE COLLECTION® finishes, along with the opportunity to meet and chat with

industry legend, Howard Astill. There is also activities for the kids, giveaways and demonstrations, as well as the ability to take advantage of hot, Summernats-only deals on MIRKA tools and abrasives, SATA spray equipment and Vibrance products. More than ever, the PPG Summernats stand is a perfect place to get inspiration for your dream build and chat to a PPG expert about bringing it to life. The PPG Summer is going to be hot, hot, hot!

R

Newly appointed PPG Refinish National Training Manager ANZ, Trevor Duke, has hit the ground running as he and the regional PPG training team, plan a variety of exciting initiatives designed to further enhance training opportunities. Trevor says, the revamped training syllabus will provide best practice solutions covering each individual step from job preparation right through to the final buffing stage. “PPG’s training activities cover the full spectrum –paint technicians, TAFE students and teachers, as well as motor manufacturer and dealership staff and insurance company

personnel. Our aim is to deliver clear messages that really hit home and create a positive impact with each and every participant. I have been in training roles for a large part of my career and I really enjoy being able to work with a variety of people in the industry and pass on the latest PPG has to offer in products and processes and immediately see benefits. It’s particularly satisfying to work with such a knowledgeable and professional PPG training team which is on-hand to support customers across Australia and New Zealand.” R

Arecent Caterpillar Supplier Excellence Recognition event in the U.S. saw PPG walk away with a coveted Supplier Excellence Award 2024, demonstrating the company’s excellence in meeting customer commitments. The sought-after award showcases PPG’s unwavering commitment to its customers, says Kevin Wozniak, PPG Global Accounts Director, Industrial Coatings. “Caterpillar relies on PPG to provide innovative, high-quality products that exceed their standards. PPG is proud of its partnership with Caterpillar, which enables the company to supply products and services to a variety of customers all over the world.” R

As we wind up the 2024 business year, it can be a great opportunity to stop for a moment and reflect on all that has been achieved throughout the past 12 months. While it’s great to celebrate any successes, it’s also important to ensure all the planning for 2025 is in place so you can really hit the ground running in the new year. That plan could include exploring extra work streams, updating equipment or refining processes and PPG has the resources to help you with all of these and more. Some of the articles in this issue could be helpful, including the Talking Training article (page 20) on epoxy primers, the launch of Gladiator XC Matte Extreme Coating (page 6) and SATA’s all-new jet X spray

gun (page 8), as well as a thought provoking look at potential solutions for the skill shortage. And when it comes to working safety, we should all be asking ‘What’s your Why?’ (page 14).

Of course, for extra support to prepare your 2025 plan, feel free to lean on PPG. For example, your Territory Manager can help with product solutions and best practice process charts and the PPG Training Managers can help with specialised training to upskill your team. On top of that, the MVP Business Solutions team can work one-on-one with you to supercharge any area of the business. Accessing any of this is as simple as asking.

Finally, I would like to wish all of our customers, distributors, suppliers and the incredible PPG team all the best for a relaxing and enjoyable festive / holiday season.

Launch events for PPG’s new-age low energy cure solutions couldn’t have gone much better, says John Hristias, PPG Sales Director Australia. Introducing LVP-565 Air-Dry Primer, LVC-177 Rapid Performance Air-Dry Clearcoat and LVC-131 HS Clearcoat Low Energy Cure, has given PPG customers the opportunity to alter the modern paint shop landscape. “Gas and electricity costs are rising and that trend is mirrored in major

TTo tackle the toughest applications with smooth, effortless efficiency, never-say-die strength and durability and long-lasting good looks, you can’t beat GLADIATOR™ XC!

here are plenty of coatings applications out there that are forced to cop a constant barrage of knocks, bumps, abrasions and general abuse over their (often short) lifetime and finding an efficient solution that is going to last is a real challenge. What is needed is a next level protective coating that not only serves up long term abrasion durability and chemical resistance but is also easy to use, cost effective and retains its quality appearance long into the future. By invoking the spirit of its legendary namesakes to deliver on all these criteria and more, the new Gladiator XC Matte Extreme coating is set to win itself a legion of local fans.

Market leading protection, manufactured in Australia SEM Products is a PPG business unit that has built a global reputation on using its extensive research and development strength to formulate best-in-class product solutions and Gladiator XC is a prime

From there it was a matter of carefully ticking off each criterion. The result is a complete, market leading package of characteristics that make this high-tech new product an

kits, in a choice of either 1 litre or 4 litres sizes. The 1 litre kit comprises a short filled 1 litre can of material and a 250ml can of hardener – the 4 litre kit is effectively four 1 litre kits in one. As a result, using Gladiator XC is as simple as pouring the 250ml hardener into the 1 litre can, giving it a shake and starting to spray using the SEM Products applicator gun (sold separately). Alternatively, this versatile product can also be brushed or rolled on or applied with a recommended HVLP spray gun setup, if you wish. Having the option of purchasing Gladiator XC in 1 litre kits make it convenient and cost effective for small jobs, touch ups or for adding to a 4 litre kit to tackle slightly larger jobs. As well as being available in a pre-tinted black, Gladiator XC also offers the ability to be tinted to a wide range of colours to better suit the application. Existing PPG customers can do this using PPG 2K / DG tinter systems, such as Deltron DG, Paraglaze, Delfleet or Selemix. For anyone else, simply speak to your local PPG distributor or PPG Territory Manager about colour possibilities. Whichever option you choose, you will benefit from a product that is designed for easy application, has excellent adhesion, a rapid cure time, superior fade resistance and incredible toughness. As if that is not enough, all the many advantages of Gladiator XC are available at very competitive pricing.

On the local market, perhaps the most obvious application for this ultra tough coating is as a convenient protective layer on ute trays or truck beds however, its

outstanding product characteristics make it versatile to use pretty much anywhere that extreme scratch / chemical resistance is required. This is supported by excellent flexibility that allows Gladiator XC to be used across a wide range of different substrates and surfaces. Common uses and benefits include:

• Ute trays and truck beds – Excellent alternative to traditional bed liners thanks to the extreme protection it offers, combined with terrific long-term appearance that helps retain vehicle value.

• 4WDs and off-road vehicles – Allows you to quickly and effectively protect almost any area impacted, including underside components, bumpers, bull-bars, running boards, etc.

• Caravan and recreational vehicle manufacture –Offers a lightweight alternative to aluminium checker plate and other shielding materials, yet still achieve a high level of protection from stone impact and other types of damage.

• Trailers – A perfect way to protect the load carrying area or entire trailer with a finish that is going to hold its quality appearance long into the future.

• Agricultural equipment, industrial and commercial vehicles – Provides a quick, cost-effective solution to protect components and surfaces in vulnerable areas from impact, abrasion, chemicals, etc.

• Marine (above the waterline) – Great alternative to protect surfaces in high wear situations. R

More than 100 years of SATA experience has been poured into the next generation ‘jet X’ model, ensuring it brings out the very best in every painter who pulls the trigger.

When it comes to the modern refinish process, it pays to have all the odds in your favour. That means supplementing your own hard-won skills and experience with the best spray gun technology available and that is the new jet X from SATA. With its innovative nozzle technology, advanced digital functions, cutting edge ergonomics and unique detailed solutions, the jet X is the gun that ‘works for you’.

SATA is recognised as the industry leader for atomisation and transfer efficiency and the innovative ‘labyrinth airflow system’ sets an all-new benchmark. Using precision designed passageways, it guides the air in the nozzle in such a way that it exits each orifice at exactly the same pressure, as well as being free of turbulence and pulsations. The result is exceptionally fine and consistent atomisation. For painters, it delivers unprecedented control and ease of use thanks to optimised material distribution and an even spray pattern with clearly defined fade-out zones. Painters have the choice of HVLP or RP technology that

come in SATA’s ‘I’ (control) nozzle system which features a longer spray pattern with an even material distribution. Regardless of which nozzle you choose, the fan dimension remains constant across the full spectrum of nozzle sizes. Only the material throughput varies – it changes in a linear fashion, along with the size.

Along with maximising gun performance, SATA’s R&D team has also designed the jet X to be easy to clean. For example, the trigger is made from technical polymer and can be removed in one easy step, without tools and without snap rings. This makes the maintenance process quicker and easier, as well as making cleaning more thorough. As a clever added feature, the trigger has

an integrated tool moulded into it which is ideal for loosening or tightening the fluid tip.

Along with its fresh and sophisticated new styling and high quality, low sheen black finish, the new jet X DIGITAL is a substantial 50 grams lighter than its predecessor, the SATAjet X 5500. The ergonomically designed gun body sits comfortably in the hand and is finely balanced so that it doesn’t become top-heavy, even with a large, full cup. The result is a gun that is a pleasure to move around the job and get into tight or intricate spaces. In addition, the air micrometre adjustment has been moved to the bottom of the handle where it’s more natural and convenient to access and use.

Over the years, the DIGITAL versions of SATA’s premium spray guns have been extremely popular across Australia and New Zealand and, with the jet X going more digital than ever, customers have the choice of the jet X DIGITAL or the highly featured, jet X DIGITAL Pro. Because the display now faces back towards the painter, information is very easy to read and the unit can be easily removed for cleaning by simply swivelling it 90 degrees. Both units come with a range of functions designed to give painters more valuable information and options that help them achieve standardised and repeatable results.

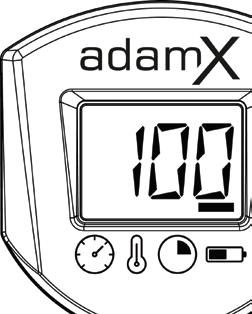

The jet X DIGITAL comes fitted with the new adam X digital unit which includes:

• Dynamic inlet pressure readout, switchable between bar and psi

• Ambient temperature indicator, switchable between °C and °F

• A reading for elapsed operating time

• Battery status indicator

The jet X DIGITAL Pro features a more advanced adam X Pro which steps up the depth of information available via a diverse range of functions tailored to the needs of professionals who work with the jet X day-in, day-out. It’s divided into two levels with the main screen appearing each time the device is activated. The main screen shows the most important parameters in a clearly organised display that includes:

1 + 2 = 3 WARRANTY

By simply registering your jet X on the SATA website, SATA will extend the warranty out to three years of coverage!

The ‘settings’ are found on the second level. The digital dashboard allows you to analyse and store the most important parameters of the paint process on a PC or smartphone.

The jet X is set to arrive at ANZ SATA distributors early in 2025. Be sure to keep an eye out and be one of the first to get your order in! R

Despite decades building some of the most exclusive bikes on the planet, Darren Baum takes nothing for granted. He pours passion, precision and performance into each and every one.

Do you remember your first bicycle? For many it’s a milestone memory that represented a first taste of freedom, giving the ability to truly travel some distance under your own steam. Often this can create a powerful connection that lasts a lifetime. Darren Baum feels that emotional connection and he has converted that passion into a life’s work via Baum Cycles. Based in Geelong, just south of Melbourne, the company manufactures between 100 and 150 beautifully crafted, bespoke bikes per year and attracts customers from all over the world, says Darren. “Probably the easiest way to define our typical customer, is a selfmade person who is ‘best in their field’. It’s still hard for me to wrap my head around it but Baum owners seem to seek each

other out. For example, I got a text recently from an owner. They were at the Monaco Grand Prix, in the McLaren hospitality suite, where they got talking to someone else about cycling and found they both buy Baum bikes and they both have the same paint job. I actually got a selfie of the two of them! Doing this is a privilege, not a right. I have built bikes for world champions and Tour de France winners, as well as Australian Prime Ministers, and Baum Cycles has ended up on an Australian postage stamp. Some of our customers fly here from the other side of the world in their own aeroplane and, so far this year, we have dealt with four billionaires.”

Although Baum Cycles attracts people prepared to pay for an exclusive piece of bicycling artwork and precision performance, it doesn’t mean they are out of reach of the average person, says Darren. “Our business

model has changed from the early years after I started doing commercial work in 1996. Rather than being a pure custom build, we are ‘made to measure’. We have a range of models that allow a certain amount of time for us to tailor that bike to your requirements. At the same time, we also have an ‘off menu’ option where, if you can name it, we will build it. Currently, our prices start at around the $15,000 mark and get up to around the $40,000. That actually makes a Baum bike one of the cheapest luxury items going around. Some people will say ‘you can buy a motorbike for that price’ but if you compare the technology and the high-end materials we use, you are at MotoGP levels!”

In contrast to many sports, Darren points out that cycling is a great equaliser. It’s an activity where a world

class athlete and an average cyclist can actually ride together for an hour or two and both will get something out of it.

That brings people to Baum Cycles’ doorstep from a wide variety of backgrounds and for an assortment of different reasons.

“If you like our body of work and you come here to buy a bike, the first thing we do is sit down, have a coffee and work out what you need. Sometimes it’s because their anatomical shape is such that they need a bike that is longer or

shorter or lower or taller. Sometimes it’s because a Baum Cycle is Australian made or that we build out of titanium and steel. Sometimes we have customers come and buy a bike because they love the colour.”

Indeed, Darren has found that the colour and finish applied to a Baum bike can create a highly emotional connection. This led to a partnership with PPG that now spans over two decades.

“When we looked at paint, I didn’t start with colour – I started with chemistry. PPG gave me the opportunity to work with the technical team at Clayton to work through the chemistry of the products we use, the film thickness, spray techniques, etc. Over the years, PPG has helped us consistently review our products and process to ensure we achieve the best possible result. We have had our own spray booth since about 2004 and during that time we have painted about 2500 bikes. We paint the frames on a rotisserie where we start with a Wet-On-Wet primer, before building the colours and applying clearcoat. Every job gets flow-coated and we are definitely looking for

gloss straight-off-the-gun because we don’t cut and polish.”

According to Darren, bikes are an emotional purchase and colour plays a key part. PPG’s colour accuracy and versatility has helped Baum Cycles cater to customer needs no matter how outside the square they are. “Currently, we have 60 standard colours and within those we match our pearls and metallics. On top of that, we have 15 designs for customers to choose from – some are two colours, while others run to four or five colours. The other thing to understand is that we don’t use any stickers –everything you see on a Baum bike is paint. We do lots of different logos. It could be corporate, for tax purposes, or it could be kid’s artwork or something else significant that gives the rider motivation and takes them to their happy place.”

“With the help of PPG, we will also match specific colours for customers. We have matched any number of famous car colours –Ferrari, Porsche, Bugatti or whatever - as well as coffee cups, socks, beanies, aeroplanes. You name it we have

matched it. This is where it can get very emotional. For example, we have had people match their mother’s birth stone after she passed away so that colour really means something to them.”

Interestingly, as a custom car fan himself, Darren sees lots of similarities across the two genres. It means that many Baum Cycles customers are also 100% car people. “Our paint work and level of finish is probably closer to what you see in the custom car scene. For example, when I am out riding one of our bikes, it’s not unusual for a complete stranger to wind down their window at a set of lights and say ‘nice bike’. It’s something that took me a long time to accept. One of our mantras is ‘passion, precision, performance’ when building our bikes and that is no different to the amazing custom car builders you see out there. This is my passion and, after 25 years of commercial work, I am fortunate to have customers drawn to us who are likeminded people. It means that we are lucky now that Baum Cycles stand for something and I can build what I like to ride. It’s a bit like the custom car world – if you get to build what you really like, you end up with better relationships with your customers.”

Over the past two decades, Baum Cycles has been instrumental in raising the profile of Australian bike manufacturing across the globe. Indeed, during a recent bicycle show tour in the US, Baum Cycles was invited to display at a high-profile bike shop, says Darren. “We are strong enough that we were asked to exhibit at what is probably the best bike shop in America and maybe the world. We were amongst three Australian bike builders and one wheel manufacturer. Interestingly, all of those products were painted in PPG.”

As NASCA works with young indigenous people to help to expand their understanding of career opportunities on offer, Geoff Richards Panel Beating and PPG are lending a hand.

‘What are you going to do when you finish school?’ It’s a question teenagers often hear but how can they give an accurate answer if they never get a clear view of the career paths on offer? It’s a particular challenge for young indigenous people in isolated communities which is where the non-profit organisation, NASCA, comes in by offering support services designed to help them thrive at school and beyond, says Courtney Richards, a NASCA Pathway Senior Manager, based in Dubbo, NSW.

“Global multinational, Cummins Inc., kindly funded Pathways as a pilot program about two years ago. It’s given us the opportunity to work with young women and men from Year 9 to 12 to show them career options that are out there that they might not automatically consider. From there, we help them create a ‘post-school plan’ so they can pursue their career aspirations. Out of Dubbo, we work with remote communities right across Western NSW, as far as Brewarrina which is around four hours’ drive away.”

To support the NASCA program, Courtney’s husband Lewis Richards, from long-term PPG customer, Geoff Richards Panel Beating in Dubbo, began running

workshops to showcase the various career options in the collision repair industry.

To further build on that, Lewis reached out to Adam Hogg, PPG Regional Sales Manager (far right) who was happy to utilise PPG state-of-the-art training facility at Eastern Creek, Sydney. He and PPG National Training Manager, Trevor Duke (right), prepared a one-day familiarisation session which the first NASCA group took to with enthusiasm, says Adam.

“The group was engaged and enthusiastic from the moment they arrived. The whole day was focused around giving these kids a go at spray painting and hoping it inspires them to look at a trade career and the PPG training centre was the perfect way to do it. The set of PPG LINQ technologies onsite – including

a MoonWalk automated dispensing machine, DigiMatch spectro and VisualizID 3D colour visualisation software – really showcased an exciting paint shop environment. Each of the kids got a panel which they sanded, painted and finished off and the results were very good considering they had never picked up a spray gun before. They all loved it and I reckon at least one of them will end up chasing an apprenticeship.”

With further sessions planned at the PPG training facility and elsewhere, the NASCA Pathways Program is already achieving outstanding results, says Courtney. “It’s broadened the horizons of these young people so it’s a program that can literally change lives.” R

PPG’s latest safety campaign makes it personal by asking the question, ‘What’s Your Why?’ It’s a powerful tool that can have a positive impact in any workplace.

Logic tells us that safety should be front of mind at all time because it plays such a key part in our everyday working life. Unfortunately, it’s often when people are lulled into a false sense of security where they stop actively considering safety during their working day that they open themselves up to the potential for disasters. It could be pressure to get a job done quickly, the complacency of doing a routine task that you have done ‘a thousand times’ before or just daydreaming or thinking of something else rather than the job at hand.

So how do you get everyone in the workspace to consider safety as part of everything they do? Whether you have employees across the world, like PPG, or you are a small collision repair centre with employee numbers in single digits, it’s still a crucial question. It’s something PPG’s Environmental Health & Safety (EHS) organisation has devoted a lot of energy to and the result is a thought-provoking safety campaign called ‘What’s Your Why?’. It’s about using a simple question to connect

people through safety with the overall aim of fostering a stronger safety culture. To do that it makes it personal by encouraging each individual to discover, embrace and share their personal reasons for prioritising safety in the workplace.

“I firmly believe that safety is not just a set of rules to follow; it is a way of life,” said Lyndee Brassieur, VP, EHS at PPG. “It is about protecting ourselves, our colleagues and our loved ones. It is about ensuring that we all return home safely at the end of each day, ready to embrace the joys and challenges that lie beyond our workplace.”

The crux of the campaign is for each employee to take a moment to form their own answer to the question – What’s Your Why? What drives you to prioritise safety? What is the deeper purpose behind your commitment? The important thing to remember here is that there is no right or wrong response because every individual can have a different perception of what it means and they are all legitimate. It could be

that you don’t want your family to have to deal with your loss or injury. It could be the effect an injury might have on your participation in a favourite sport or activity. It might be the fear of having to deal with a life changing injury. It might be having to deal with the pain and disruption caused by an injury. It could be having to deal with the financial impact an injury might have. The point is that it’s personal and it has to have a clear meaning to the individual.

The theme of the ‘What's Your Why’ campaign is designed to help each of us connect with the deeper purpose behind our commitment to safety. It’s about finding our individual ‘why’ – the reason that drives us to work safely every single day. When we understand why we work safely, it becomes personal. It becomes a part of who we

are and what we stand for. It reminds us that safety is not just a statistic but a way of life. Once they understand their ‘why’ individuals are encouraged to embrace it and let it guide their actions, both at work and in their personal life. By going through this process together, the aim is to make safety a way of life at PPG.

Although ‘What's Your Why’ is an internal PPG EHS campaign there is no reason why it can’t be used to ignite a stronger safety culture within any organisation, including collision repair centres. These days, there is

an extra incentive to keep your team safe because an injured staff member isn’t just bad for them, it leaves the team a person down with a subsequent negative impact on production numbers. Asking the question at, say, a morning toolbox meeting is an easy way to find out the ‘why’ that drives each member of your team. Alternatively, you can simply get each team member to read this article. Understanding the why is the first step to building a strong, ongoing safety culture within your business. After that, don’t keep it to yourself – share the concept of ‘What’s Your Why’ with your family, friends, colleagues and customers. The more individual ‘whys’ that we share, the more we spark meaningful conversations around the importance of safety in the workplace. And that can only be a good thing for everyone. R

Working like a well-oiled machine, Cam Waters and Rides By Kam have created a totally wicked XB Falcon Coupe resto-mod, complete with Supercars engine and epic PPG paint!

As a gun Supercars driver, Cam Waters’ day-job sees him pilot the latest Gen3 Tickford Racing S650 Ford Mustang GT. And his latest off-track ride actually shares a couple of features with his ballistic on-track weapon – both have Supercars V8s under the bonnet and both are finished in eye-catching PPG paintwork. It was the 30-year-old’s soft spot for older cars, particularly Aussie muscle cars, that led to him purchasing a 1974 Ford Falcon XB Coupe bodyshell which is where the adventure began.

“I have always loved old cars and custom cars and the XB Coupe has real character. However, from factory it was not finished that nicely so the plan was to give the body a bit of love, fit some modern running gear and get it back on the road without going too crazy. That plan changed as I started ticking off boxes and the project just evolved to be something special.”

Waters’ father, Chris, had built many of his own race cars during his speedway career so the initial aim was for the XB Coupe to become the ultimate father and son project. Unfortunately, when the primer layer was removed from the shell, what it revealed meant it quickly outgrew their skillset. The upside was that it brought the project into the orbit of Rides By Kam, a family-owned, specialty custom shop headed by the highly experienced Rob Zahabi and located at Burleigh Heads, on Queensland’s Gold Coast.

“I saw some of the work from Rides By Kam and I was impressed so I reached out to Rob”, says Waters. “He is super creative when it comes to building cars. Rob would throw ideas at me and I would tell him about different things l liked from other builds. It all came together and I was very happy to have him build my XB Coupe.”

Growing up in Sydney, Rob Zahabi was drawn to the custom car scene as an extension of his love of art. As he built custom cars with close friends, he began to learn and absorb new skills from wherever he could, to the point where his skillset now includes everything from fabrication, panel work and paint, through to interior trimming and even wiring. These days, Rides By Kam is very much a one-stop-shop family affair with Rob having been joined by his three sons, Mitchell, Cooper and Tyler.

Agood custom build is all about artistic expression and Rob believes his artistic side has played a major role in his current line of work where the ability to think outside the square often results in award winning solutions.

"In this day and age, there is a lot of visual art in cars, especially in fabrication work. Growing up drawing every day has given me the ability to freehand draw something and then visualise what it would look like in three dimensions. When we were growing up, some mates and I actually got paid to do some murals. It got you used to putting paint

“People come in with a budget in mind and we can design a car to suit that. Cam was able to give us a lot of accurate information on what he wanted which always helps. Like many projects, it started out as a basic muscle car build and just evolved to where it ended up. It’s a very cool thing! The logic behind it was to make it look like this was an XB Coupe that Ford built today. Having said that, this is a bloody old car so we had to start by fixing a lot of nasty steel work. That took about six months before we could get into the bodywork stages.”

With regular input from Waters, Rob and his sons began an extensive program of modifications, including deleting the drip rails, fitting flush-fit front and rear glass, flush-fit door handles, tucking the bumpers inwards and backwards into the car and leaving consistent, tight panel gaps throughout. A lot of time was spent on the front end which retains the original grille but

colours, shapes and designs together to create a piece of artwork. It means that I don’t go looking at other people’s work for inspiration – I try to be the innovator. Ultimately, I want my boys to be the new age innovators. When they were growing up, they use to sit down and draw with me. Now they are all working in the business, you can see that they all have their own qualities. I want them to suck all the knowledge they can out of me and then perfect it and make it even better. At the end of the day, they are super passionate about getting a top-quality end result."

replaces the separate eyebrows on the front guards with fabricated steel items and fits halo-style LED headlights. The sophisticated, full Alcantara interior features a very cool looking Haltec digital instrument cluster and individual Ford FG Ute seats front and rear. What makes this build even more special is that Waters was able to raid the old parts store at Tickford Racing for a Supercars V8 which was then built by former Tickford Racing engineer, Jon Grove. While the choice of engine gives this XB Coupe a key point of difference, it also created some headaches for the Rides By Kam team. For example, a Supercars engine doesn’t have any provision for mounting air-conditioning. As a result, an electric air-conditioning compressor has been packaged cleverly and neatly into the passenger side inner guard. The other side houses the dry sump oil system and the electric driven power steering pump. To ensure it turns and stops as well as it goes, there is upgraded suspension and brakes throughout, along with billet PRISM wheels (19-inch front and 20-inch rear). In a build full of challenges, one of the biggest was creating the bespoke engine airbox, says

Rob. “We had to work in with the engine builder to design and then fabricate an airbox that looked good, worked for him and was realistic. I got the tolerances around the trumpets and it took me about six weeks just to design and build the airbox!”

When it came to trusted, bare-metal-to-clearcoat products to give this project the protection and finish it deserved, both Rob and Waters were unanimous it had to be PPG. “I could use any paint company but I am loyal to PPG because of all the support they give me, especially from Mark Heywood (PPG Training Manager QLD). I still get Mark involved in each project and ask lots of questions because I don’t want to guess the answers, I want to learn from the experts. We have kicked some big goals with the cars we have built and they have all been PPG cars.”

RidesBy Kam has an incredible back catalogue of work – many featuring PPG paintwork – that is genuinely renowned on the global scale, explains Rob. "In 2010, we thought we would give

It won the SEMA Show Stoppers Award and featured on the cover of Popular Hot Rodding magazine, along with other accolades. In 2015, we went back with a twin supercharged Chevy Nova and it got into the top ten for the Barrett-Jackson Cup which is pretty prestigious. We built a ’70 Dodge Challenger, called ‘HAVOC’, in 2019. It was completely hand-built and so ahead of its time we actually filmed the entire build to give people an insight. We took that to The States in 2021 and it kicked ass by beating them all to win the Barrett-Jackson Cup ‘Ultimates Best in Show’. This tiny shop in Burleigh Heads took on the best of the best in America and won!"

While it was always going to be PPG, Waters agonised over choosing the colour.

“I have had a strong relationship with PPG since I started at Tickford Racing ten years ago. I got to know the people at PPG and the products are awesome. When you are building a car to a certain quality standard, you need to use the best products and that makes PPG a no brainer. Choosing the colour was nearly the hardest part – I wanted something different. Our social media guy suggested this Porsche GT3 colour, called Amethyst metallic, so I got a render done with it and I really liked it – it suited the car.”

Despite COVID putting the brakes on the project, it was finally completed and became one of the most anticipated unveilings at Motorex 2024. Now the show crowds have faded away, Waters can get down to what he really wants to do – drive it!

“So far, I have only driven it about one kilometre.

We need to get it on the dyno, get the engineering certification done and get it registered. I just want to be able to take it on Sunday drives and, if there is a cool car show, put it on display.”

Rob looks back on the project with a lot of pride and satisfaction that he and his team were able to think outside the square to come up with innovative solutions.

“This was a fun project for us. I really enjoy the creative side of it and I think that all stems from art and being artistic. Each step of the way it challenges you to learn new skills and come up with solutions and, at the end, you build something really cool like this. The best advice I can give anyone looking to make their way in the industry is that you should never stop learning.”

R

Despite their versatility, epoxy primers are not one-sizefits-all products. Like other priming solutions, each one is purpose-designed to perform specific tasks.

Acrucial element for any bare metal upwards process is choosing the correct primer technology to achieve the desired result, with no downsides. That means eliminating some misconceptions surrounding the various products and understanding the advantages and limitations, according to John Hristias, PPG Sales Director Australia.

Technicians should be careful not to see the name, ‘epoxy’, and just assume the technologies are the same – they may not be! There are actually two PPG epoxy technologies – amine cured and isocyanate cured. Before starting a process – whether in collision repair or restoration – it pays to get all the required products and understand each choice, rather than wait until the last minute when mistakes tend to be made. Read the Product Data Sheet and, if needed, get advice from the paint company – not from anyone else!

Isocyanate cured epoxy – Generally featuring an isocyanate hardener, these epoxies are designed to seal off bare metal areas. Used correctly, they achieve good adhesion and corrosion protection in a wide range of applications.

• The correct epoxy option to use both under and over body filler.

• Can be used in Wet-On-Wet mode with PPG 2K primers, spray-polyesters or hand applied body filler.

• Applying primer under body filler prevents corrosion and rust creep around filler repair, unlike body filler directly applied to bare metal.

Fun fact – 410 48248 Epoxy Urethane Primer is an isocyanate cured technology which was specifically developed in the PPG Clayton R&D laboratory to cater to the needs of the restoration market.

Amine cured epoxy – Generally identified by a 1:1 mixing ratio using a catalyst, these epoxies tends to achieve a smoother finish but don’t typically dry to the same hardness as isocyanate cured epoxy, tending to have a more rubbery feel, particularly when sanded. A number of factors make it less versatile than isocyanate cured epoxies.

• After application, the job can be stored for up to around six weeks as long as it’s kept dry and out of any weather.

• Unless stated by the paint manufacturer, should not be used on external surfaces exposed to high levels of UV radiation as it will penetrate the topcoat and attack the amine cured epoxy causing paint degradation. If used in these circumstances, it should be overcoated with a PPG 2K primer, such as LVP-219 or a WOW primer, such as LVP-205 EnviroLOCK, which is

Can be used in WOW mode with topcoats (subject to the above conditions). For example, in an application like a chassis or undercarriage of a vehicle, UV is not an issue which makes an amine cured epoxy a good option.

• Tends to achieve a smoother, off-the-gun finish than isocyanate cured epoxies.

• Should not be used with body filler as the active agent in the filler hardener tends to attack the softer amine cured epoxy.

Fun fact – PPG actually offers the convenience of an aerosol epoxy primer. OneChoice® 1K Epoxy Rub Thru Primer quickly and effectively deals with small bare metal sanding rub throughs to achieve good adhesion and corrosion protection.

• Always wear rubber nitrile gloves when working with bare metal – it protects you and the substrate.

• Don’t use high build 2K primers directly on large areas of bare metal unless specified and warrantied by the paint manufacturer. USE THE RIGHT EPOXY – that is what it’s designed for!

• For bare metal, start with Deoxidine metal conditioner. It’s extremely thin five-micron crystalline coating gives a first layer of corrosion protection from sweaty hand prints, moisture in the air, etc.

• Before using epoxy primer on aluminium, first apply acid etch primer over bare surfaces (preferably treated with Allodine). It’s particularly effective on aluminium substrates and will ‘etch’ into the metal to promote adhesion and corrosion protection.

• Don’t apply body filler directly to bare metal or to acid-etch primer because the acid activator will affect the body filler. Apply an isocyanate cured epoxy over acid-etch primer before applying body filler, then apply the same epoxy to seal off the body filler.

• Don’t use amine cured epoxy primers with body filler – the two are not compatible and can result in coatings failure.

• When preparing a bare metal substrate, don’t sand to too rough a finish – P120 to P180 maximum will leave sufficiently deep scratches for the primer to bite into.

• Plan the job – Take the time to understand what you are trying to accomplish and the steps needed to achieve it.

• Always check the Product Data Sheet, rather than guess or go by memory.

• Your PPG Territory Manager is not just a great source of technical advice, they can also provide you with full ‘best practice’ processes that list products and easy to understand guidelines for dealing with bare metal substrates.

• Don’t be tempted to take short cuts or mix product brands, particularly when dealing with an expensive, bare metal upwards restoration or custom job.

• If you are unsure, ask your paint company representative, not your mate up the road!

Sometimes, no matter how much you try, it’s just not possible to find a piece of equipment that fits your criteria. This is the predicament Rod Glue found himself in back in the late-1990s when he needed a new vacuum truck for his septic tank business in the beautiful but isolated town of Mansfield, at the foot of the Victorian Alps, around 210km northeast of Melbourne. His solution was simple – he built his own. The result was so good, when a contractor from Gippsland saw it, he convinced Rod to sell it to him.

With almost three decades of experience built into every model, Vacuum Truck Supplies is all about making messy jobs easy and looking good while you are doing it.

Each time he built a new one, it was quickly snaffled by someone else looking for a high-quality piece of equipment, to the point where Rod created Vacuum Truck Supplies (VTS) in 1998. Today, it’s arguably Australia’s premier specialist manufacturers of vacuum trucks, says National Sales Manager, Mike Fischer.

“VTS pretty much concentrates on specialist equipment that deals with liquid waste. Dealing with septic tanks is an obvious one but it can also be sewage, grease traps and what they call ‘oily water’ which is basically where water is contaminated

with an oily substance, such as a sump in a petrol station or the liquid in the bilge of a ship. These days, we build the equipment on rigid trucks of any size, we have two semi-trailer versions, small portable units for the port-a-loo market and other specialist models. We have also just introduced a range of hydro excavation equipment. This is where high pressure water is used to blast out a trench and a much more powerful vacuum system is used to suck up the water and dirt. These days, hydro excavation is often used, rather than an excavator, because it’s much safer around infrastructure, such as fibreoptic cables, power cables, gas lines, etc.”

While production numbers started off small, they have accelerated over the years as word-of-mouth spread Vacuum Truck Supplies’ reputation around the country. From the beginning, each unit that rolled out the door received a sequential number, with the 1150th unit recently heading off to a happy customer. According to Mike, each VTS unit goes through a tightly scheduled build process.

“On our busy production line, jobs are allocated down to the day. From our point of view, paint is the middle step of the process. After the components are fabricated, they go to the sandblasting booth and then for painting in one of the two large spray booths, one of which is large enough to fit a full semi-trailer. It then returns for assembly where all the technical aspects are fitted, such as electric, hydraulic and pneumatic systems.”

Part of the close attention to detail lavished on every VTS piece of equipment is a durable, high quality paint finish and recently this has seen VTS strengthen its partnership with PPG. When a new painter arrived, VTS asked PPG for support and local Territory Manager, George Syder, was happy to help out. “The new painter had a good skillset so it was really just a matter of doing some onsite coaching to quickly get him up to speed on the VTS way of doing things. At the same time, I was able to help VTS in terms of looking for more efficient ways of doing things, reducing waste and improving EH&S. VTS use a variety of PPG Commercial Performance Coatings primers, along with 625 Polythene as the topcoat, all suppled out of our Paint Powerhouse store in Albury. VTS are very proud of the finish

they put on their equipment and PPG is proud to give them the best solution to help them do that.”

Establishing VTS in Mansfield has its pros and cons, says Mike. “As with many small towns, there is not a huge labour pool. For many, coming here is very much a lifestyle thing. The staff in Mansfield are made up of people who grew up here, others who moved for a ‘tree change’ and some who came here specifically to work for VTS. Of course, there isn’t a big housing pool available in the town so the company helps out wherever it can. The good thing is that, although we are in an isolated location, you can find our trucks all over the country.”

Although COVID created some supply chain issues, it actually saw VTS get even busier which has blown out wait times. The challenge is on to bring them down to reasonable levels, says Mike. “For our rigid trucks we are booked out about six months in advance but for a custom truck you are looking at far longer. We actually created our premium range as an alternative to a custom truck. The standardised production process makes it much quicker to build and in the majority of cases it’s a great fit for the customer. We have invested 28 years of experience into our premium truck range so it lets us give our customers all the features they need in one package.” R

The industry skills shortage continues to impact repairers right across the region. It’s a complex issue that requires a range of solutions.

Get two or more repairers together and the main topic of conversation invariably turns to the difficulty of finding skilled staff. While PPG’s region-wide MVP Business Solutions team is on-hand to deliver a range of support service to help alleviate the effects, it’s only a part of the solution, says Mindy Roberts, MVP Business Solutions Manager Vic/Tas.

“To help navigate the changing industry landscape, we work with individual repairers to implement streamlined processes that

let them process jobs more efficiently and produce more work from their existing team by working smarter, not harder. While this helps keep profitability up, many repairers still struggle without enough staff to process the amount of work coming through the door. For repairers, the question often comes down to, what other options are there? As a result, at our recent Vic/Tas MVP RoundTable meeting we invited Jim Damatopoulos, from Body Shop Recruitment (BSR), to do a presentation about some of the options they offer repairers. It got people thinking outside-the-square.”

BSR was founded around 10 years ago by CEO Ash Jardine and is made up of some serious real life industry expertise. Today, there are three parts to the business – overseas recruitment which is looked after

by former I-CAR Australia CEO, Mark Czvitkovits, remote estimating services which is run by Jim Damatopoulos, and body shop consulting (estimator training, workshop efficiencies, workshop design, etc). In addition, newly appointed Rebecca Witt is looking after a new program the BSR team is working on to help the admin side.

One age-old solution to the skills shortage has been to bring in staff from overseas countries. However, doing this is extremely difficult for an individual repairer which means leaning on businesses, such as BSR. According to Ash, a thorough understanding of the Filipino culture and lots of contact have helped set up a robust, in country recruitment process, which is run by Mark Czvitkovits.

40 hours per week

$880 plus GST Remote estimating Remote estimating PART TIME

20 hours per week

$540 plus GST

“We have a facility in the Philippines capital, Manilla, where panel or paint technicians come in to do some basic trade testing. Those that pass go onto a comprehensive technical interview which is recorded. That recording, along with the trade test results and their CV can then be passed onto prospective Australian employers who can use it to select the candidates they think will best suit them. From there, we refer them to a visa agent or they can choose their own, and we facilitate the rest of the process. It’s an extremely difficult, frustrating and expensive process that takes around 12 months even if everything goes right!”

Recent developments indicate this is also becoming a less viable option, says Ash. “Over the past 12 months we are seeing a lot of candidates not wanting to come to Australia. Due to the cost of living and difficulty in getting good accommodation, as well as the upfront government costs, Filippino workers would rather go to New Zealand, Canada or the UK. It’s a massive problem.”

Another BSR service which has really taken off, is the ‘remote estimating’ option, according to Jim. “For many repairers, finding skilled estimators is a massive problem. What our solution offers is overseas based, fully trained estimators for Australian repairer to take advantage of. The model is that a remote estimator works solely for one repairer so you get to know them and build a relationship with them, just like having a person working for you. However, unlike employing an estimator, you don’t need to worry about things like payroll tax, superannuation payments, Work Cover payments, training, etc. When one of our remote estimators wants to go on holiday, another estimator from our team will cover for them – that is something that is very difficult to do with a local estimator. It’s essentially built around taking advantage of modern software capabilities. With the remote estimator, you would go to the vehicle, triage and photograph it and then upload straight to whichever Cloud-based program you are using and task your estimator to do the job. We see it as a convenient, cost-effective service that helps to take the load off repairers.

For a fulltime, remote estimator, working 40 hours per week, the cost is $880.00 plus GST and it’s billed fortnightly – that is approximately one third of the price of employing a fulltime local estimator! Alternatively, repairers can choose to have a part time remote estimator for 20 hours per week which is $540.00 plus GST. Currently, we have one team of remote estimators in Sri Lanka and another in the Philippines. To ensure this all happens smoothly we have been busy writing Standard Operating Procedures, along with a training regime which each of the remote estimators goes through. Making this concept work has been a great journey. Eighteen months ago we started with one remote estimator and we are on target to have 50 operating by the end of 2024.” R

For more information about Body Shop Recruitment go to: https://bodyshoprecruit.com.au/ve/

To access the wide variety of support services on offer, contact the MVP Business Solutions team at mvp.anz@ppg.com

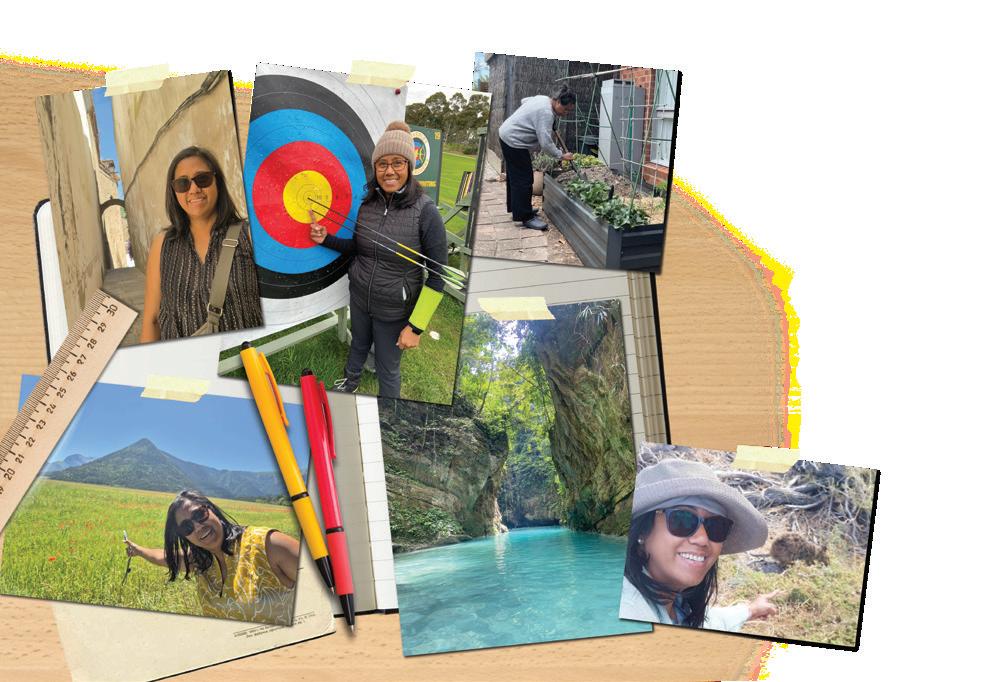

To make informed business decisions and plan successful strategies, PPG relies on a rich stream of market specific information and Bing is one of the specialists who sift through a mountain of data in order to provide it. However, this is just the latest in a diverse variety of roles she has taken on since joining PPG as part of an acquisition in her native Philippines, over 20 years ago. On top of that was a transfer to Singapore, where she met her

future husband, and then to Australia in 2008. Whether it was HR, sales, customer support, event organising or her current role, Bing says the ability to build on her skillset has been a major motivator.

“I love to learn and I continually push myself to learn. That is where PPG is a great place to work because there are lots of knowledgeable people that you can learn from.”

While Bing acknowledges that her current role is challenging, that is exactly the way she likes it.

“The part I really enjoy is the challenge – I love it! The key challenge is to be able to access the right information to help us analyse what is going on in the market. We are aiming to get good quality, independent market information from different sources which is as accurate as possible. Using market analytic processes, we can then examine the data in order to identify trends, better understand where PPG currently fits into the market and what opportunities there may be which we can use to help plot strategies. It’s all about solving problems and that is my happy place.” R

• Favourite hobbies/pastimes? Gardening, planting and harvesting vegetables, working on crafts

• Favourite food? I miss Filipino foods. In Australia, it’s mainly roast

• Favourite drink? Sparkling wine

• Favourite music / band? 70s music is my go-to

• Favourite car / motorcycle? My Dad’s Peugeot when I was young – I have fond memories

• Favourite holiday destination?

El Nido, Palawan, in the Philippines.

Thanks to an unrivalled combination of exceptional speed, superb colour accuracy, no-fuss ease of use and effortless blending and mottle control, this is simply the best refinish technology on the market. Backed by a range of primers and clearcoats featuring advanced low-VOC technology, it’s the eco-friendly choice which really delivers on outright speed. With everything a modern, fast-paced collision centre needs to slash cycle-time while boosting productivity and profitability, Envirobase® High Performance is engineered for excellence!

With MIRKA’s industry leading Polarshine system you get a compact solution that lets you tackle everything from refinish to a show car with efficiency and an outstanding end result.

The surface finishing or polishing process is one where collision centres must aim to maximise speed and efficiency, particularly as the cost of this task is rarely funded as part of the repair quote. At the same time, the process must also leave a customer pleasing final finish. This is where MIRKA’s Polarshine surface finishing system outshines the opposition, according to John Hristias, PPG Sales Director Australia.

Choosing a polishing system for your workshop is not something you should do based on price or brand – it should be all about what that system can actually contribute to your workflow and quality of finish. As a result, the local PPG team invested significant time in physically analysing and benchmarking the best systems on the market so you don’t have to.

Not only did MIRKA’s Polarshine

system shine through against well-known traditional polish brands, it also created a platform that allowed us to create a special ‘Paint Rectification Process’ chart. Because polishing jobs are not one-sizefits-all, the Paint Rectification Process chart provides details on tackling pretty much any scenario you are likely to face. This best practice surface finishing system takes advantage of a compact range of specialised MIRKA products to keep jobs as small and fast as possible without compromising on end finish quality.

Whether it’s an everyday refinish job, right through to putting the finishing touches to a high-end show car, MIRKA’s Polarshine system has everything you need and nothing that you don’t. The Polarshine range has been deliberately keep compact to reduce the need for numerous bottles of product on the shelf. However, each item in the range plays a part which means it can cater to anything from the removal of dust inclusions and reviving dull paintwork, right through to the final detail on a high-end show car.

• Polarshine 45 Polishing Compound

– This coarse, fast cutting compound was developed to save on process time, yet achieve a deep gloss finish. Unlike compounds that simply fill scratches, it actually removes imperfections quickly and permanently.

• Polarshine 12 Polishing Compound – Specifically formulated for a perfect balance between speed of cut versus the effective removal of surface imperfections to avoid haze and hologram issues. Comes in a black compound for darker colours and white for lighter colours.

• Polarshine 5 Finishing Compound – Ideally suited to the last step in the polishing process (after Polarshine 45 and/or 12) to achieve a higher gloss level.

• Polarshine Liquid Nano Wax – Suitable for both machine and hand application, this product is excellent for buffing and sealing of surfaces and for hologram removal.

Tips and features for maximum efficiency

Keep it compact and quick – MIRKA’s Iridium Purple and Green de-nibbing discs let you focus on tiny inclusions that need to be removed. Following up with a 77mm buff head helps to further reduce polishing time.

Clean between stages – Use a 50:50 water methylated spirits solution (such as PPG’s super convenient SWX250 WaterMethylated Spirits Cleaner) to clean the panels after each polishing stage. This removes any built up polish compound and lets you clearly see if scratches have been removed or not. The only step where it’s not necessary is when all scratches have been removed and the final protective layer, such as Polarshine 5 or Polarshine Liquid Nano Wax, is being applied.

Don’t overload the pads – Less is more!

Rather than polishing out scratches, excessive compound just clogs the surface. Pads are designed to work best with small amounts of compound. Only add more when there is no compound left.

An easy cleanup is black and white – One of the challenges of buffing is the cleanup time afterwards. Available in either black or white, Polarshine 12 Polishing Compound lets you choose the best option to suit the colour of vehicle you are working on.

Apply the compound to the pad, not the surface – minimises spatter for a faster cleanup.

Use a low polishing speed – Avoids overheating the product.

Wash pads each day – Don’t let compound build up on buff pads. To keep them in peak condition, wash them in warm water at the end of each day and leave them to dry.

Finish off with Polarshine 5 – Typically, we finish the job with a wax but during our benchmarking process, I struggled to find one that didn’t make dark colours go cloudy. An excellent alternative is to finish by hand with Polarshine 5 and a microfibre cloth to leave a deep final finish.

Polarshine 5 produces such great depth of shine, it’s an excellent choice for the spectro reading process. Use it with a 77mm polisher to buff a particular spot and the minimised scratches and deep finish make for a more accurate spectro reading.

Microfibre – Only use microfibre cloths on paintwork, they are designed for the job. Never use shop rags as they put fine scratches back into the paintwork.

A full range of Polarshine products is available at your authorised MIRKA distributor.

For decades, PPG Clayton has been a global centre of excellence using precise chemical recipes to manufacture premium quality coatings tailored to the local market.

For tens of thousands of years our ancestors used available raw materials to make paints in order to leave their mark in history. Despite this primitive tech, many of those rock paintings have actually survived through the eons, allowing us to marvel at them today. Nowadays, PPG manufactures coatings on an industrial scale at production plants scattered right across the globe, including at the company’s local headquarters in the Melbourne suburb of Clayton. In fact, PPG Clayton is recognised as the largest industrial coatings manufacturing plant in Australia and includes Research & Development (R&D) facilities, quality control and a colour laboratory. Each year, PPG Clayton manufactures in the order of 22 to 24 million litres of paint in a multitude of technologies that are designed to cater to a wide variety of sectors, from architectural and coil coatings, through to Commercial Performance Coatings and refinish products.

No matter which PPG paint product you are looking at, it all started in the R&D laboratory. This is where the team of local PPG chemists are able to work their magic to finetune products in order to better suit the needs of local users. Things like the critical compatibility between the resin and any pigments is thoroughly tested and additive, such as UV absorbers, are added to build in the desired characteristics. Just like when cooking in a kitchen, it’s about creating

a precise recipe that can be accurately followed in the large-scale manufacturing setting to not only ensure quality paints but also consistency, consistency, consistency!

Resins are the key building blocks of each product so the process of chemically formulating them is a fundamental step in paint production. The process sees heat and catalysts used to create a chemical reaction that links small chemical molecules, called ‘monomers’, together to produce bigger and longer molecules, called polymers. Polymers are also called resins or binders and they play a number of important roles, including creating a chemical matrix that secures pigment particles in place, as well as supporting adhesion to the substrate.

To retain better control over quality, PPG Clayton manufactures the majority of the resins used at the plant.

Despite often playing widely different roles, just about every paint product, including tinters, is made up of a mixture of resin, solvent, pigment and additives. At PPG Clayton, the raw materials are precisely measured into either a ‘mixer’ or a ‘pot’. Both are essentially made up of varying sized vats which have a mechanism to stir the contents. Pots are portable and smaller, while mixers are typically much larger and are built into the factory infrastructure. Generally, the resin is added first, followed by the solvent and, if required, the pigment.

Each year, PPG Clayton manufactures in the order of 22 to 24 million litres of paint in a multitude of technologies

Although it comes as a fairly fine dry powder, the pigments need to be put through a ‘high speed dispersion’ process and some also go through a milling process. These processes are designed to break the pigment material down into a smaller and more consistent particle size which, when applied to a substrate, helps with the opacity of the paint. Because the smaller particles stack better and leave less void in between, it also produces better film build. As with every other step in the process, the amount of energy which is applied to these processes is accurately controlled to ensure a consistent result from one batch to the next. In particular, this really pays off in the refinish paint room where painters can rely on PPG tinters to match the required vehicle colour. Following the high speed dispersion and milling process, there may be remaining solvent and resin to add, along with further additives, such as UV absorbers. To ensure they retain their shape, size and effect, aluminium and pearl particles are also added after milling.

When manufacturing on a large scale, you don’t want to be making huge batches of a coating that is not used often, while on the flip side, you don’t want to be constantly manufacturing smaller batches of popular, high turnover products. It’s a balancing act which relies on lots of batch flexibility at PPG Clayton. During product development, the R&D lab team has the ability to produce accurate batches of as little as 250ml. Once the product formulation is locked in and moves to the production floor, the batch sizes can be scaled up to suit the manufacturing requirement for each product. While ‘pot’ sizes generally top out at about 900 litres per batch, a ‘mixer’ might be used to produce a batch of between 3000 litres, up to 10,000 litres! Typically, the product is decanted from the container it’s manufactured in, directly into the tin, flask, etc you pick up off the shelf at your distributor. R

A landmark collaboration between the Defence Science and Technology Group and PPG has created a groundbreaking waterborne system for Australian Defence Force projects.

For well over 20 years, PPG has quietly gone about the business of utilising its local technical team and laboratory resources to develop a range of specialised products which are specifically tuned to the needs of the Australian Defence Force (ADF). This has made PPG a reliable, trusted partner for a variety of major ADF projects and seen a wide variety of vehicles painted in PPG products, including the ‘Bushmaster’ protected mobility vehicle, the ‘Hawkei’ protected tactical vehicle and the M1 Abrams tank. During this time, the ability of the local PPG team to consistently work closely with the ADF and defence contractors to come up with effective solutions has been recognised by the Defence Science and Technology Group

(DSTG). As part of the Australian Department of Defence, the DSTG has an important role to play by bringing together wide-ranging expertise, from across Australia and around the world, in order to address defence and national security challenges. To do this, it works closely with the Australian science,

technology and innovation eco-system to deliver scientific advice and solutions that provide capability enhancement for ADF and the national security community. Recently, this saw PPG work with DSTG to create a cutting-edge waterborne coatings system designed specifically to meet the needs of the ADF.

Both the DSTG and PPG enjoy a longstanding reputation for driving technological innovation so it was perhaps no surprise that the pair have come together to create a cutting-edge waterborne coatings system –PPG Waterborne Defence. The aim was to formulate a thoroughly modern, eco-friendly and sustainable option for coating vehicles

in the iconic ADF camouflage pattern and the result has exceeded all expectations. Indeed, the low Volatile Organic Compound (VOC) credentials of PPG Waterborne Defence coatings place it dramatically lower than current regulations across global markets, including Europe and California. This eco-friendly coatings solution was developed in conjunction with Defence Science and Technology Group using core technology from DSTG. Over more than 12 months in development, the close collaboration helped overcome a host of technological challenges in order to continually finetune the system, as well as ensure it met Australian Paint Approval Scheme (APAS) standards. Along with being a global coatings specialist and a leading ADF supplier, PPG also has the unique ability to offer a comprehensive network of local resources. This includes a local team of paint chemists and other technical experts, along with the extensive facilities of its Research & Development (R&D) laboratory located within PPG Australia’s Clayton, Melbourne headquarters. It was an exciting but

intense project, according to Scott Mandragona, PPG ANZ Refinish Technical Manager.

“We have always had a good relationship with DSTG and, in the past, we have worked on a number of little side projects with them. Talk of a waterborne solution for the ADF actually came up in general conversation.

The DSTG team had spent a lot of time working on waterborne topcoat technology for aerospace applications but it was recognised that, with some tweaks, that same technology could work for landbased defence projects. Because the DSTG organisation doesn’t manufacture paint, it approached PPG to possibly do a joint development and, with support from PPG management, it was agreed. There was a lot of confidence in the main topcoat resin that DSTG had developed so the PPG team went to work with refinements to the additive selection to ensure its application characteristics and

performance were spot on and that it had everything necessary to achieve APAS certification. From there it was about tweaking the formulation to allow for manufacture at PPG Clayton, as well as incorporating PPG’s own near infra-red reflectance technology. In the R&D lab, we were able to make test batches of the new products so we were confident it could be translated to the main production facility. While this was all going on, the PPG team was also developing a waterborne primer that is applied underneath the topcoat.

When the ADF LAND 907 Phase 2 and LAND 8160 Phase 1 projects popped up, the production schedule ended up being ramped up dramatically. The technical team

The primary source of camouflage for ADF equipment comes via its disruptive, green, brown and black paint pattern which helps to disguise the equipment by assisting it to blend into its surroundings. However, modern warfare detection techniques incorporate more than what can be seen by using your eyesight. For example, heat signature detection using infra-red, is now a key method. As a result, ADF coatings are typically formulated with specific infra-red reflection levels in the green, brown and black colours. With these specialised coatings applied, the shape of the equipment can be disguised with the aim of avoiding infra-red detection, much like the disruptive paint colours do for visual detection.

in the PPG R&D lab worked unbelievably hard to get it completed in an incredibly tight timeframe and it included a PPG Australia team member travelling to the US to conduct training on the new products. Feedback from the ADF is that they are very happy with the results, to the point where a special citation was actually issued (see below) to thank the PPG team for its efforts.”

The eco-friendly, easy to use system starts with Waterborne 2K Epoxy Primer which lays down a strong foundation with outstanding adhesion, good build characteristics, excellent abrasion resistance and strong chemical resistance. It’s followed by Waterborne Polyurethane Camouflage Topcoat Colours– available in ADF camouflage colours of green, brown and black – which is applied over the top to achieve an extremely tough, durable and chemical resistant finish. In addition, the way the topcoat colours lay down smoothly and precisely make it very straightforward when it comes to applying

Thanks to a proven, long-term record for delivering exceptionally durable APAS approved formulations, PPG has established itself as a leading supplier for Australian Defence Force projects and this has been officially recognised via a special ADF issued commendation. In the prestigious citation, the local PPG team is singled out ‘for outstanding support to the LAND 907 Phase 2 and LAND 8160 Phase 1 projects’. This included the local manufacture and supply of the groundbreaking PPG Waterborne Defence coatings. In addition, the PPG team was also praised for its dedication, strong support, technical advice, training delivery and breadth and depth of logistic expertise.

Colours are available in a full spectrum of infra-red performance characteristics and the entire system has been fully tested to AP-S0502 specifications. As part of the exhaustive testing and refinement process, the development team were able to identity the best spray gun settings for each phase of application. Combined with the technical data sheet and application training from PPG’s dedicated training team (if required), this puts defence contractors in the ideal position to begin using PPG Waterborne Defence and immediately achieve first-class, repeatable results.

As well as being developed locally, PPG Waterborne Defence coatings are also manufactured in Australia at PPG’s Clayton, Melbourne production facility. It forms part of PPG’s light industrial coatings Commercial Performance Coatings brand which includes a specific range of products tuned to the needs of the ADF. Customers can also take

The end-to-end digital ecosystem bringing advanced, game-changing technologies to your collision centre

Scan the QR code to see how PPG LINQTM can benefit your business! youtu.be/t4isZfVLwzw

Introducing the 3D digital sprayout

This advanced, 3D digital colour visualisation tool smoothly interfaces with the next-generation PPG DigiMatch™ camera-equipped spectrophotometer to totally transform the user experience of selecting the best colour match formulation from PPG’s extensive library.

Compact, fast, easy-to-use spectrophotometer

PPG’s high tech DigiMatch spectrophotometer features a digital colour camera to significantly boost performance. The camera’s six imaging angles combine with six reflective angles to provide additional texture information to help quickly and precisely retrieve the correct formula match.

We have designed the ideal tool for the job. A spray gun that helps you achieve the highest quality finish - and makes it easier than ever before. A piece of equipment into which all our experience as well as the feedback of the painters have been incorporated.

The spray gun that works for you - COMING SOON.