ALSO INSIDE:

• SATAJET X 5500 CLEARCOAT EDITION

• READY FOR A CAREER @ PPG?

• GETTING YOUR PARTS PROCESS RIGHT

• THE ADVANTAGES OF ACTIVATING BASECOAT

ALSO INSIDE:

• SATAJET X 5500 CLEARCOAT EDITION

• READY FOR A CAREER @ PPG?

• GETTING YOUR PARTS PROCESS RIGHT

• THE ADVANTAGES OF ACTIVATING BASECOAT

PPG’s automated paint mixing system, PPG MoonWalk, replaces manual paint mixing processes to deliver greater efficiency with less wasted product, a cleaner work environment for technicians, and reduced environmental impact.

This revolutionary system features a high-accuracy scale and precision mixing to ensure quality and consistency in every paint mix. Automated processes also help to reduce labor time and minimize human error, which means that PPG MoonWalk can significantly boost the productivity and profitability of your body shop.

PPG MoonWalk is part of the PPG LINQ™ digital ecosystem. Visit PPGLINQ.com for more information.

Featuring an eye-catching PPG paint job, a sleek miniature racing machine, designed and built by a group of Year 9 students from Blue Mountains Grammar School, has powered its way to the national title (Development Class) at the Australian F1 in Schools STEM Challenge. Billed as the foremost student competition for Science, Technology, Engineering and Mathematics (STEM), the annual competition involves around 22,000 students in Australia, while on a global scale, it reaches over 17,000 schools in 51 countries. Mimicking the world of a Formula One team, groups of students have to follow a pathway of engineering and manufacturing disciplines to design, analyse, test, construct and race a miniature F1 car capable of 0-80 km/h in under 1 second. Competing under the Xpeditious Racing banner, the Blue Mountains Grammar School team has now set its sights on the world F1 in Schools finale later in 2024.

Plans are in place to use PPG’s state-of-the-art ENVIROBASE® High Performance waterborne basecoat system to give the team’s car a slick, professional appearance as it takes on the rest of the world. Good luck! R

The opportunity to see, touch and get the lowdown on the very latest industry technology has seen record visitor numbers flood into the Auto Aftermarket & Collision Repair Expo. Over three days, 13,282 people streamed through the doors to have the Melbourne Convention & Exhibition Centre really humming, particularly at

the PPG stand where the main attraction was the MoonVan. Kitted out with ground-breaking PPG LINQ technologies, it took a short break from travelling around Australia, visiting repairers and distributors, to make a special stop at the Expo where it drew crowds throughout the event. Indeed, it proved so popular, visitors often had to queue up for their turn to see

these incredible time and material saving tools in action. After taking a reading with the next-generation DigiMatch™ spectro, visitors could see how simple it was to use the VisualizID™ 3D colour visualisation software to select the closest colour match. It was then easy to send the chosen formulation to the MOONWALK® automated dispensing system which produces a precise mix each and every time. If you were not able to get to the Expo but would like your own demonstration of PPG LINQ technologies, simply speak to your PPG representative. R

Haveyou had the chance to check out PPG’s MoonVan yet? Throughout the first half of the year, it has been travelling the length and breadth of Australia, including stopping off at various major events such as Summernats and the Collision Repair Expo, and everywhere it goes it seems to be a huge hit. The concept of fitting PPG LINQ technologies into a high roof van actually came from our PPG colleagues in Europe but it’s perfect for a big country like Australia. It gives us the ability to reach both regional and metro customers who might otherwise not get the opportunity to see PPG LINQ technologies in action. In particular, it’s an ideal way to understand how the next-gen DigiMatch

PPG continues to be recognised for the way it does business with a burgeoning list of honours that identify it as a trusted, high performing company that aligns its business strategies around employees. “Our employee culture and alignment with our purpose

– We protect and beautify the world – is something we pride ourselves on at PPG,” said Brenda Broad, PPG Global Head of Talent.

“We recognise the value of engaged teams and understand that to generate the most success we must first create a nurturing environment with opportunities for growth and engagement.” An impressive list of awards has been received over the past year:

• Newsweek: America’s Greatest Workplaces for Diversity

• Forbes: America’s Best Large Employers

• Newsweek: America’s Greatest Workplaces for Women

• Newsweek’s ‘Most Trustworthy Companies in America 2024’

• Barron’s 100 Most Sustainable U.S. Companies

• JUST Capital: America’s Most Just Companies

• Disability Inequality Index: Best Places to Work

• TIME Magazine: World’s Best Companies

• Forbes: Best Employers for Veterans

• FORTUNE World’s Most Admired Companies

• Computerworld: Best Places to Work in IT

• Gallup Exceptional Workplace Award

• Corporate Knight’s Clean200 R

spectro, VisualizID 3D colour visualisation software and MoonWalk automated dispensing unit work together to create the backbone for the paint shop of the future. Make sure to follow its journey on PPG socials – LinkedIn, Facebook and Instagram – and take a look when it’s in your neighbourhood. Look at the ongoing rise in energy costs, along with the need to be more sustainable and it’s clear that collision centre operators need viable solutions and PPG is ready to supply them. We are currently putting the finishing touches to a variety of exciting new products that will provide customers with the opportunity to work more efficiently, with a smaller carbon footprint and reap cost-saving rewards at a time when it’s most needed. Stay tuned – they are set to hit the market in around Q4 2024!

The show halls at MotorEx 2024 were once again packed with incredible machinery and gobsmacked fans and it was PPG painted vehicles that again featured heavily in the major awards. Notable winners included Ron Barkley’s gorgeous ’67 Chev Camaro taking out Superstars Best Paint and Craig McKenzie’s ’67 HR Holden which cleaned up with a string of awards culminating in the highest accolade of all – Superstars Grand Master! R

By introducing a series of clever, hi-tech solutions, the PPG LINQ™ suite of integrated digital technologies is bringing an unprecedented raft of benefits to the modern paint shop

For many years, the refinish paint shop environment remained fairly stagnant but the arrival of PPG LINQ has changed all that in one fell swoop. Led by a high-profile trio of technologies – MOONWALK™ automated dispensing technology, next generation DIGIMATCH™

PPG MagicBox™ the key to connectivity

spectrophotometer and VisualizID™ 3D colour visualisation software – it has altered the landscape by ramping up productivity, minimising waste and rework, and making life easier for painters. On top of this, PPG LINQ is offering a further series of innovative solutions for paint shops to take advantage of.

Consisting of just a small plastic box, MagicBox can appear a bit dull. However, it’s actually packed with clever electronics that have the ability to transform the paint shop. By configuring it to the collision centre’s router or WiFi system, it becomes a gateway that wirelessly connects the paint shop computer, spectrophotometer and scales so information can seamlessly flow between them. It means that only the scales need to be in the mixing room, thus offering the opportunity to remove clutter and free up space on mixing benches. You are then free to place the spectro and computer in any convenient location outside the mixing room. MagicBox streamlines workflow by wirelessly transferring any spectro readings to the computer and, after the colour formulation has been chosen on the computer, that information is also wirelessly transferred to the scales for mixing.

MagicBox is available via a very reasonable monthly subscription and, in most instances will not require an upgrade to the mixing room computer, scales, etc. However, it’s important to note that it does require a decent WiFi connection or being hardwired into the shop’s ethernet system. These days, no one would put up with a dodgy WiFi connection in the office and it’s

the same for the paint shop. Upgrading the WiFi capability is generally inexpensive and, with PPG LINQ, it allows for significant advantages.

LINQ™ Color – convenience of the Cloud

With the launch of the LINQ Color digital colour platform, PPG’s market leading colour management system steps up to an all-new level as it becomes a thoroughly modern, easy to access and use, cloudbased solution. It’s the same concept as internet banking or many of today’s collision centre management systems. Therefore, it’s available 24/7, allowing you to make confident colour selections anytime, anywhere. Because it’s no longer a software program loaded onto a desktop computer, LINQ Color requires no installation. After going through the straightforward registration process, accessing this effective, accurate and easy to use colour management system is as simple as logging in on the LINQ Color website.

LINQ Color comes as part of the no cost support package for PPG customers and the basic workflow will be familiar to current PAINTMANAGER® XI users which should

make for a very short learning curve. There is a logical workflow that is very intuitive to use and there are nice, rich graphics throughout. Crucially, because LINQ Color data is held in the Cloud, all colour formulations, variants, specials, etc are up to the minute at all times. It also removes the need for a PPG Territory Manager to visit and perform updates. Another important advantage of LINQ Color is that it interfaces with MagicBox, allowing wireless communication between the spectro, the paint shop computer, the mixing scales and even the MOONWALK automated dispensing system. LINQ Color also supports the innovative VisualizID 3D colour visualisation software and DigiMatch spectrophotometer.

LINQ Color’s cloud-based technology minimises downtime. Because it’s accessible on any suitable, Internet capable device – including a PC, a tablet or a smart phone – if Internet access goes down for any reason, LINQ Color can still be used on a smart phone via the mobile network. In addition, LINQ Color’s cloud-based solution is isolated from frustrating computer issues, such as hardware failures or a Microsoft Windows update which could cause mysterious glitches. Any potential

technical issues can be easily resolved with support from the remote PPG helpdesk.

This small but highly effective device is mounted in the paint application area –typically, the spray booth – where it monitors the temperature and humidity of that room. Where it becomes especially handy is when you are using products that have different hardener and thinner combinations depending on the temperature in which they are being applied. MagicSensor transmits temperature and humidity (via MagicBox) to LINQ Color in real time. As a result, when preparing a particular product Ready For Use (RFU), LINQ Color can automatically recommend the best hardener and thinner combination (fast, normal, slow, etc) to use for those specific application conditions. By providing precise data, MagicSensor takes away the guesswork and helps avoid the potential of costly rework. It gives technicians the information they need to make smarter choices which makes the product easier and more efficient to apply, more productive to use and produces a better end result. R

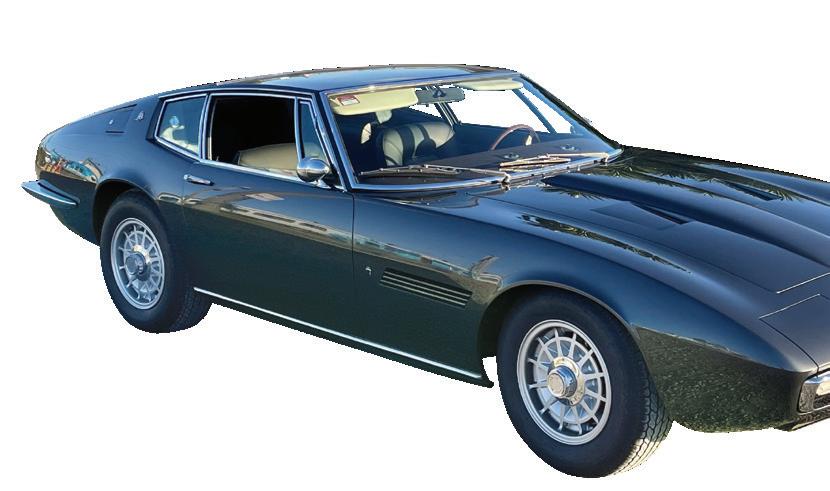

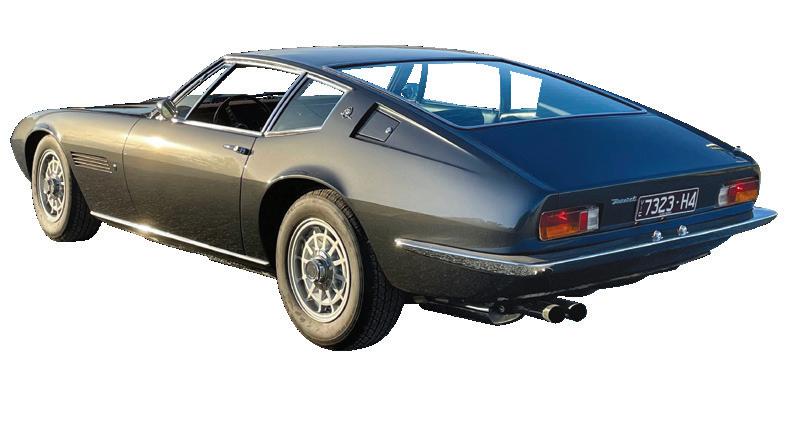

Leading vehicle designer, Julian Quincey, has restored a timelessly classic piece of automotive artwork that continues to tug at the heartstrings and get the pulse racing.

When it unveiled the original Ghibli, back in 1966, Maserati had pretty conservative sales targets, estimating a production run of just 100 vehicles. However, despite being the company’s most expensive model at the time (similar in price to a Ferrari Daytona or a Lamborghini Miura), a total of 1,170 coupes and 125 Spyders ended up rolling off the production line. Striking styling played a key role which is a credit to a young Giorgetto Giugiaro, then at Ghia, who would go on to become a design legend. It can be seen as the peak of Italian grand touring design language from the era, says Julian Quincey. And he should know, having been a vehicle designer all his life, notably as HSV Chief Designer from 2003 and now as Chief Designer at the Walkinshaw Group, where the busy design studio, in the

Melbourne suburb of Clayton, does work for clients across the globe.

“For me, the Ghibli has always represented one of Maserati’s most glamourous road cars and, as a car designer, it represents one of Giugiaro’s finest works and a stunning avant-garde design statement for 1966. It’s very much an early transition point between the rounded cars of the ’60s and the more modern, sharper lines of the ’70s. A very low, long two-seater that made every other Maserati at the time look old fashioned. It has fantastic proportions, with a long bonnet and raked windscreen that make it look fast just sat stationary.

It was a wide car for the time and the popup headlights are a typical ’60s cliché that would have been pretty breathtaking at the time of its launch in 1966.”

As he was coming towards the end of a two-year restoration project on his Maserati Merak SS, the thought of a Ghibli wasn’t even on Julian’s radar until he stumbled across an ad on eBay. “It was rather a sad looking 1968 Ghibli so what could possibly be the harm in looking at it? The car had some obvious problems that would have put most people off – sills you could put

panel damage on the back of the front wing and front of the driver’s door. However, it was a complete, two-owner car with matching numbers and it was remarkably unrusty in a lot of the problem areas.”

After some negotiations, the purchase was done and, within a few months, Julian had sold his beloved Merak SS to pay for what would be his biggest project. Max Hayes, from Vintiquemoto, was handed the task of restoring this incredibly original, a-grade classic. Some parts were off-theshelf, such as the wiper jets which came from a Fiat 124 Spider and the original early fuse box which is actually a VW Beetle part. In many cases, rusted original parts had to be used as templates for the fabrication of new items. At the same time, this needed to be done with extreme care

as it became clear that this was a bespoke, hand-built machine. Eventually, with the bodywork better than it left the factory, it was time to choose a colour and hand it over to Rankin Panels for preparation and painting. This is where Julian’s longstanding relationship with PPG came in. “PPG was always going to be my choice for paint and I chose the period-correct Maserati colour, ‘Grigio Flemington’, for several reasons. Firstly, the Ghibli is a big car and I wanted to shrink it a bit visually so a darker colour helps. Typical of the period, it uses chrome around windows and for bumpers and I wanted this to really contrast strongly with the body colour. Grigio Flemington is

also quite a tasteful, classy colour which emphasises the sharp horizontal features of the car. PPG paint is outstanding and it was used from bare metal upwards. Paul Rankin is a first-class painter and he spent many hours in preparation, including stripping any remaining under-seal and the suspension so the whole car, inside and out, could be painted in PPG epoxy primer to provide rust protection well into the future. It has all paid off with a finish as smooth as glass, with a super lustrous shine.”

Around two years ago, Julian’s Ghibli finally made its return to the road where it immediately turned heads, including being displayed at Motorclassica and winning best Maserati awards at a couple of other events. However, like any Italian thoroughbred, it’s built to be driven.

“The Ghibli is still a fairly rapid car with long legs for touring. It accelerates fairly briskly (0 – 100kph in under 6.8 seconds) but with a heavy mechanical gearchange.

Power steering, electric windows and a fifth gear make it easy to live with and it sounds great with a classy V8 burble and plenty of lowdown torque. It’s taken seven years but it’s been immensely rewarding to bring this beautiful classic back to its former glory!” R

Through a culture of continual upskilling and doing the job right the first time, Tony Farrugia Bodyworks has become the go-to place for even the toughest of repair jobs.

It’s easy to tell that Tony Farrugia is incredibly proud of his team. You can clearly hear it in the way the prominent, longstanding Canberra repairer talks in glowing terms about their skills, their loyalty and their willingness to embrace the philosophies which have driven his business from the start. Indeed, many of his current staff have been on the long-term journey with him, right through to the opening of the beautifully presented new home for Tony Farrugia Bodyworks in the Fyshwick suburb of the ACT, in August 2022. Tony didn’t need to go through the time, hassle and expense

of creating a new facility. After coming to an agreement to lease his previous premises to growing MSO, RepairHub, Tony could have slipped quietly into retirement but that is not his style.

“I love the industry but, more importantly, I looked at the people who work for me and a lot of them have been here for 20 or even 30 years or more. I didn’t need to do this but I thought if I build a nice little boutique shop, it would be nice to keep this team together as a family. I had 36 staff at the old shop but it was too big and hard to control. Now we have about

20 staff and it’s about making the shop more manageable and with a better flow. This is a team of very good tradespeople who are very particular and take real pride in their work. I built this shop to give them something back for what they have done for me. They have been very loyal.”

The 12-month build process tapped into Tony’s vast industry knowledge base to produce a state-of-the-art result.

The reception area is classy, comfortable and spacious and adjoins an undercover quoting area. A corridor leads to a series of stylish offices, a boardroom, toilets and a staff lunch room that wouldn’t look out of

place in a trendy housing unit. Staff even have the choice of a second ‘alfresco’ lunch area, if they wish. However, it’s the workshop that really sets the bar high. Beautifully laid out and fitted out, the team say that it’s a joy to work in. There are clever features wherever you look. Such as the low central divider which has been set up for extra storage, as well as supplying air, power, etc. The limited space out the back has been maximised

by installing a vehicle stacking system that stores 16 vehicles in the footprint of eight and even includes a roof for weather protection. Tony has also made use of the odd sized dimensions of the building by installing partition walls and hiding equipment behind them in specially fabricated, easyaccess, storage racks. Eighteen months down the track, the immaculate facility still looks like it opened yesterday!

During the build process, the arrival of the advance PPG LINQ™ technologies grabbed Tony’s attention. “I heard about PPG’s new MOONWALK® automated dispensing system and I thought to myself, we are building a new shop with all the latest gear and MoonWalk would fit perfectly. I spoke to Darryle Browne (PPG Business Manager NSW) about what PPG could offer and from that we sent one of our painters to PPG’s Training Centre, at Eastern Creek, to trial ENVIROBASE® High Performance. As a result, we fitted a MoonWalk unit and the paint team started using Envirobase on everything except one vehicle brand and they love it. PPG has been very supportive of me and the team. When we had a new painter start, Chris Kerr (PPG Territory Manager) organised for a PPG trainer to come in and

spend time to bring them quickly up to speed. In all my years, I have never been treated so well by a paint company – PPG has ticked all the boxes!”

Even as an elder statesman of the collision repair industry, Tony still enjoys getting hands-on in the workshop. Indeed, it’s been his refusal to do anything but the best possible job, that has helped establish the reputation of Tony Farrugia Bodyworks since it started in Canberra in 1983.

“Back in the early days, we were given the job to repair a badly damaged SAAB for a well-known local businessman. When he dropped the car off, he said ‘f**k this job up and I will f**k your business’. After we repaired it, he said the car was actually better than when he bought it. From then on, there was only one place that everyone wanted to bring their car. That means we do a lot of big stuff and if there is a nasty repair where the cost of a panel is expensive or it’s not available, the insurers will bring it to us.”

“I have never been an ‘office person’ – I still get on the tools. It’s a passion – I love it. Recently we repaired an immaculate, early model Lexus LS400 for a woman who had bought it new with her late husband. A side swipe had left the front guard almost flat and we couldn’t get a new or second hand one,

even overseas. Even my team thought it couldn’t be fixed but 212 shrinks later the guard was back in shape, file finished and painted and we returned it to her as good as new.”

It’s not just vehicle owners and insurers who recognise the advantages of dealing with Tony Farrugia Bodyworks, a substantial number of vehicle OEMs have also beaten a path to the door. “The first OEM badge

Tony Farrugia Bodyworks

Owner: Tony Farrugia Staff: 20

PPG Product: Envirobase High Performance

Territory Manager: Chris Kerr

I ever got was Volvo and now we have the highest number of OEM badges in Australia. It’s a big cost but it means we get all the technical data, equipment and training from the manufacturers. It means that the job isn’t stale here – the team are constantly learning. We even have an office set aside for team members to do training. I think it gives us a little leverage with insurance companies – not in terms of more money but they know it’s a specialised field and that we have the tools, data and skills to do the repair to the manufacturer’s specifications and return the vehicle to pre-accident condition. We do get a lot of audits so we document everything. For example, when we are doing things like gluing panels, the technicians will write down the date the glue was manufactured and the date it expires before running a bead of glue, letting it dry and putting it on file. If there are any queries down the track, we have the sample and details to back up what we did.”

Although Tony generally still comes in every day, he has a trusted team in place who run the business like clockwork. Eventually, he sees himself retiring to a small shop where he has “a heap of cars to restore”. At that point Tony plans to hand the reins over to his team. “This new shop has allowed us to keep the team together, do quality work and look after the badges that we have. I am proud of my staff and together we have achieved a lot. We are actually at the stage now where we are doing cars for the grandkids of our early customers. Every job we do is our advertising.” R

SATA is helping painters take clearcoat application to the next level with the specially developed SATAjet X 5500 Clearcoat Edition.

When it comes to refinish work, clearcoat application is the step that literally puts the finishing touch on the job and makes your work look good. It’s here that SATA spray guns have always given painters a significant advantage by offering exceptional control, atomisation and transfer efficiency. Now the industry leading spray equipment manufacturer has taken clearcoat application to the next level by creating a gun specially designed for the task – the SATAjet X 5500 Clearcoat Edition. Based on SATA’s premium SATAjet X 5500 spray gun and the popular and innovative I-nozzle technology, this new specialised version features a fresh new take on the nozzle geometry concept which is identified by an additional ‘cc’ designation – SATAjet X 5500 RP 1.3cc.

This is a gun that is designed to do just one job and do it extremely well. Utilising almost 100 years of spray gun design experience, along with feedback from customers, SATA’s research and development team have created a precisely tuned nozzle that delivers a large, even fan, fine atomisation and optimised distribution for clearcoat products. For collision centre owners it minimises product wastage, while for painters it provides an ideal tool that allows for easily controlled application and helps them achieve a final finish which mimics the original factory clearcoat appearance.

Navigating your way along a pathway to a fulfilling and rewarding career means keeping an open mind to all of the opportunities.

Where do you see your career path taking you in the future, be it in six months, five years, ten years or the rest of your life? Given time at work takes up such a large portion of life, it’s an important question. As the old adage says, ‘find a job you love and you will never have to work a day in your life’. The spread of opportunities available on today’s jobs market means that what we start out as doesn’t necessarily mean it’s where we will finish. Often, opportunities crop up that allow us to utilise current skills but in a different role while, at the same time, adding new skillsets to our repertoire. It can be perfect for breathing new life into a stagnating career.

With more than 50,000 employees spread across the globe, PPG is a big company. It’s also a diverse company in terms of the different roles it takes to run it. Although PPG’s refinish business is probably the part that most readers recognise, there is also a variety of other business categories where PPG is a major player, including architectural coatings, light and heavy industrial coatings, aerospace coatings and protective & marine coatings. With so many career pathways on offer, it begs the question, ‘have you considered a career at PPG?’, says Paul Galea, General Manager Refinish ANZ.

Around three decades ago, Paul himself charted a career path from a refinish paint technician on the workshop floor, through a variety of steps to his current high-profile role.

“When you look at the breadth of roles at PPG, there really is a lot of choice. On the refinish side of the business, the most common one we think of is tradespeople choosing a different pathway and bringing their skills to PPG. When you look at the management structure throughout the PPG refinish business across Australia and New Zealand, most people in those roles actually have a trade background behind them. Having said that,

there are plenty of opportunities at PPG for non-tradespeople, whether it be marketing, forecasting, customer service, IT, admin or even on the factory floor as part of the team who manufacture many of our products locally.”

Switching a familiar, workshop floor environment for a totally new role can be daunting but the reality is quite different, Paul explains. “A lot of people in the trade think that joining a paint company is all about selling but it’s not – it’s exactly the opposite. If I think back to my nervousness about transitioning to a Territory Manager role, I had a belief that to sell products you had

Here are just some of the opportunities:

Customer Service

Using your technical skills to provide customers with over the phone technical information and support.

Technical Demonstrator

Using your technical skills in a hands-on role where you are able to demonstrate the capabilities of PPG products or processes directly with a customer.

Territory Manager

to have the gift of the gab and talk people into it. We don’t want to sell anything that someone doesn’t want. Typically, it’s about combining your technical skills and people skills to support customers. While it’s true that you need good communication skills, a large part of our customer facing roles are about listening, listening, listening. In that way, we can identify what the customer’s needs, problems or issues are and what PPG’s portfolio of products and services can offer to help them achieve their goals. The way I see it, most of our refinish roles are not sales roles, they are solutions roles. It’s about facilitating solutions to help them on their journey.”

Contrary to the popular industry myth, this is not about selling and cold calling. The main portion of the role is looking after a group of existing customers – usually in a geographical area – to provide them with whatever support they need on a day-to-day basis.

Business Development Manager

Although this role is about following up on opportunities to secure new business, it’s still about providing solutions that help customers achieve their goals.

“The important thing to remember is that you don’t do it alone – most roles at PPG are very much team based. As a result, there is a support network to provide training, guidance and whatever else you need at each step along the way. For paint technicians coming off the workshop floor, you will have your technical skills but you can build on those with specific PPG product and process knowledge, communication skills, organisational skills, etc.”

From wide-eyed young fan to living her dream behind the wheel, Brooke Newson is taking her loyal fanbase on an exhilarating journey aimed at the front of the sprintcar pack.

At 180-odd km/h, the corner arrives at a frightening pace. Your sensors are assaulted by a highly tuned V8 bellowing at 7,800rpm, as the car bucks, shimmies and dances on the edge of grip. A pack of similarly angry machines swarm around, all jostling for the best position while peppering your vision with pellets of dirt and track debris. The fast approaching 180-degree dirt turn appears to offer little in the way of grip and the unforgiving concrete wall that surrounds it is ready to punish any mistakes so every fibre of your being screams at you to back off and brake. Instead, you keep the throttle nailed wide open, while feathering the brakes and applying a subtle left then right steering input.

As the weight gets thrown onto the huge right rear tyre, the enormous roof wing catches the wind to create downforce and the car pirouettes into a finely balanced power slide that arches sweetly around the turn. After missing the wall by a whisker, you transition to max speed on the back straight where the process starts all over again. Welcome to Brooke Newson’s world!.

From a very early age, Brooke Newson was bitten by the Speedway bug. Back when her age was measured in single digits, the family would regularly go to events at Perth’s Cleremont Speedway. Although she often fell asleep before the feature race, the shear love of the spectacle stayed with her into adult life. Despite dabbling in powerboat racing and tarmac circuit racing, it was a call from her father that restoked the passion for sprint cars.

Oneadvantage of being a woman in the male dominated sprintcar world, is that Brooke’s journey has sparked huge interest on social media. A consistent flow of quality content has allowed her fans to follow her along the way ‘warts and all’ and this has seen her gather a legion of followers. Interestingly, statistics show that around 50% are from Australia while most of the remainder come from the home of sprintcar racing, the US. While maintaining a regular presence on platforms, such as Instagram, YouTube and FaceBook, eat into what little spare time she has, it definitely has its advantages. “Potential sponsors like to see a large social media following because, for them, it’s about advertising their products and services. In the end, my social media presence has actually helped me secure sponsorships and those partnerships

“Dad said, ‘I’ve bought a sprintcar – let’s go racing!’. The thought of driving a fully-fledged sprintcar was terrifying but the very first time I got behind the wheel it was an incredible feeling I had never had before and I knew I was going to love it. I remember thinking ‘why did I not start doing this ten years ago!’.”

Not prepared to do anything in half measures, Brooke and her father, Matt, set up Brooke Newson Racing and, in January 2020, that saw Brooke’s sprintcar journey begin when she hit the speedway circuits along the length and breadth of Western Australia. “There are four of us in the team. Dad is the transporter driver and crew chief, then there is John Krikke, who is a household name in sprintcars and an amazing wealth of knowledge and Tim who helps keep everything in the pits running smoothly. After a race meeting, it takes a good four or five hours just to clean the car so you can get into the maintenance.”

Inan effort to accelerate her on-track experience (and have more fun!), Brooke also competes in the Outlaw Karts class. She says these pintsized speedway weapons are often misunderstood by those new to the sport.

“An Outlaw Kart looks like a tiny sprint car so people will say ‘that’s cute, it must be for kids’. It’s basically a go-kart frame with a wing and a 450cc KTM dirt bike

On race weekends, Brooke swaps her day job handling contract management at a multinational energy corporation but brings along her attention to detail and determination to be thoroughly prepared.

“From the moment I get to the track, I am in the zone. It’s a different level of focus. We make sure the transporter is fully organised so we know exactly where all the spare parts and tools are. And in the lead up to a race, I actually have checklists for myself so I don’t forget anything. Every track is different so we usually roll out with a base setup from last time we were there. Then we work to finetune the setup using adjustments and tweaks, such as shock tuning, tyre pressures, wing angles, that affect the balance of the car and the way it handles the track. Depending on the length of the straight we adjust the gearing to get the engine in the right rev range – typically, it maxes out at around 7,800rpm. One of the things that makes the car so exciting to drive is the throttle response.

It’s absolutely instantaneous and when the car takes off it compresses you into the back of the seat.

engine and the power-to-weight is incredible. Believe it or not, they are actually so much harder to drive and physically handle than anything else I have ever driven. There is no suspension, your butt is less than 10cm off the track and you feel ever single bump so I go home with quite a few bruises. It also takes a lot of upper body strength so I work hard in the gym. Twenty-five laps in an Outlaw Kart is insane – I can’t compare it to anything else!”

It means you have to be super smooth with throttle inputs and that has taken me a while to get used to. Race day is intense and I don’t relax until the moment I get back after a feature race.

To prepare for it I do a lot of exercise, including sessions with a personal trainer at one of my sponsors, Culture Fitness, in Wanneroo. I do a lot of HIIT (High Intensity Interval Training) to give me the endurance to cope with a 30 lap feature, as well as strength training and exercises to improve my reaction time. It takes a lot of mental strength, as well as physical strength, so when I finish a race meeting, I am absolutely exhausted!”

Even as an amateur team, sponsorship is important to help pay the sizable racing bills so presenting a professional image is crucial. In the pits, matching race attire helps crew members stand out, while on track, the team has a secret weapon, says Brooke. “PPG has pretty much followed my entire racing career and that gives us an edge in professionalism. Out on track amongst a pack of other cars, you want your sponsors to stand out but getting the right balance of colours can be super difficult. The colours and quality of our PPG paint scheme not only look amazing, it also helps showcase all of our sponsors. We are currently building a new car and PPG is helping us take the paint scheme to the next level. It features the same colour scheme but we have added a PPG pearl tinter to each one so it really ‘pops’ in the sun or under lights on the track!”

Although she is well respected by the other competitors both on and off track, Brooke is a sprintcar rarity simply due to her gender. As a result, she embraces opportunities to encourage young women looking at taking up the sport. “I definitely want to be a role model and I love being an advocate for young women in motorsport. I always take the time to coach / mentor any young female drivers coming through because I think it’s so important. I was one of those kids who would collect posters, stickers and photos from my sprintcar heroes and now I am that person. It’s one of the best things when you see a young face light up after you offer them the chance to sit in the car. I think, OMG that used to be me!”

is on the right track. “I am really hard on myself. Being a high achiever in the workplace also fuels my drive for success in my racing. Although I am running at the pointy end of the field, I am not where I want to be just yet but I have to remind myself that I am up against guys who have literally been racing sprintcars all of their lives. In the short term, I want to get my first podium in a feature

In a relatively short time, Brooke has managed to get a handle on sprintcar racing and has begun forging a solid foundation of results. Despite admitting to being her own worst critic, Brooke acknowledges she

Newson is in fact named after Aussie speedway royalty, Brooke Tatnell. The pair actually met back in Newson’s first season of racing in 2020 and Tatnell was blown away to learn that the young racer had been named after him. The funning thing is, says Newson, if you were to Google ‘Brooke sprintcar’ today, it’s just as likely bring up Brooke Newson material as it is content about the legendary Tatnell.

When using a solvent borne system in a multi-coat scenario or when tackling a larger job, activating the basecoat helps achieve a quality result while avoiding the pitfalls.

While it’s true that PPG’s solvent borne basecoats, including the DELTRON® refinish system and the DELFLEET® Evolution commercial transport paint system, are formulated to allow them to be applied in an un-activated state, without hardener, there are definite limits that need to be understood and carefully followed. Naturally, the primary job of the basecoat layer is to provide colour. However, it’s also important to remember

that the basecoat layer is essentially encased in a sandwich between the inner primer layer and the outer clearcoat layer. Therefore, to achieve a durable, long-lasting finish it’s vital that there is a strong adhesion bond between all the paint layers, says Trevor Duke, PPG Training Manager NSW.

Whether it’s being used in a primer, a basecoat or a clearcoat, the basic function of the hardener is to create

the chemical crosslinking within the paint film. As a result, this process is incredibly important when it comes to the adhesion properties that help produce a strong, durable finish. When it’s used to activate the basecoat, the hardener also helps with better lay down during application and improved gloss retention for the finished job.

There are a variety of scenarios where switching to an activated basecoat is the difference between a quality job and a disaster waiting to happen:

Multiple coats – If the job requires more than four coats of basecoat, it should be activated. For example, on a three layer pearl you might apply two or three coats of colour, followed by two or three coats of pearl. This means four to six coats in total and film builds that are increasing and not in a good way. Adding hardener ensures that each of these layers is able to key into the neighbouring layers and achieve good adhesion.

Large jobs – When tackling big jobs, incorporating hardener into the basecoat formulation helps it stay wetter for a little longer to give you time to move around something like a truck cabin or a large van and still wet back into the proceeding layer. This gives the paint film – particularly metallics – the chance to laydown nice and smoothly and evenly, as well as achieve the required adhesion properties. In the commercial transport sector, we actually recommend activating the basecoat as a matter of course because ever job tends to be large. Indeed, we find that some CT repairers / refurbishers, using the Delfleet Evolution paint system, actually choose to activate the basecoat on every single job, even if it’s a smaller one. Sticking to this standard is only a small cost penalty per job but it means that it leaves no room for error. Generally, these operators have also picked up on significant benefits they get in terms of better basecoat laydown, better gloss from the clearcoat and increased stone chip resistance.

work

– Activating the basecoat is something we definitely recommend for custom work. Typically, this is where we see multiple coats being applied, particularly when there is striping or lines being included in the paintwork. Even if a custom job has a normal amount of basecoat, it will often have a lot of clearcoat layers added over the top in an effort to make the paintwork look really deep so you need to take that into consideration and add hardener. The aim is to produce a finish that looks amazing, yet also has the durability to match. If I am doing my own custom car with a solvent borne system, I am activating the basecoat every time, without a doubt!

High impact areas – What we are talking about is all those areas on a vehicle which come under attack from stones and other debris, including wheels, sills and other lower parts. Activating the basecoat gives these vulnerable locations the extra protection that can keep them, and your paint job, looking better for longer.

Generally, a check of the Product Data Sheet will provide the recommendations for when to activate the

basecoat. The beauty is that switching to an activated basecoat is very straightforward. The spray gun setup, application technique, etc. is all the same. Usually, the only difference is that hardener is substituted for a portion of thinner. Using RFU (Ready For Use) mode, PPG’s PAINTMANAGER® XI colour management system can guide you through the exact proportions to add for each colour formulation and volume being mixed. R

Before the arrival of photography, paintings and sculptures were used to immortalise certain people or mark points in history so it’s crucial to retain those that remain. Katrin’s clients are museums, galleries, private collections, churches and public institutions and they come to her for a wide range of

By using exceptional skills, remarkable patience and superb tools to restore and conserve ancient artworks, Katrin Etringer, is helping to give us a snapshot of a bygone era.

services which are all about preserving works of art. It could be about ensuring optimal storage and exhibition conditions, accompanying artworks while they are being transported, preparing appraisals or, often, it’s about restoration.

Katrin says she developed an interest in art and antiques from an early age. Later, she trained as a gilder, making picture frames for valuable works of art. However, picture frames were not enough. “I was fascinated by the technology behind paintings, sculptures and furniture and wanted to learn more about it. The conservation / restoration study course combines science with art history in a wonderful way. It was just right for me.”

The oldest works of art Katrin has worked on came from the 15th century and, indeed, she can often be found working on objects from around the year 1500 AD. Whatever its age or where it came from, she says it’s important to respect every item entrusted to her.

“Every painting is unique and there are always new types of damage and problems to solve. As a first step, I examine the painting and draw up a detailed plan of action. For example, do I ‘only’ conserve it as it is or do I restore it completely? What often makes the whole thing tough is the constant back and forth with all the parties involved. Communication at every level is key. The reward is being able to spend time with the artwork and get as close to it as hardly anyone else. You always get a little closer to the people and the past. And, of course, being part of the history of an object and helping to preserve it.”

Although every job is different, there is a basic step-by-step process to follow. The first is to analyse the support. If it’s a canvas, deformations may need to be levelled and, for example, this can be done with the help of heated metal plates. A heating spatula and interfering glue can be used to smooth out raised layers of paint. Older repairs may need to be removed and defects in the paint layer filled. If there are tears or punctures in the textile support, it’s sometimes necessary to attach threadby-thread in the fabric and re-sew the area. It’s often necessary to clean the surface of paintings or to remove an old layer of varnish. In traditional painting, a varnish coating was usually applied as the final layer. Over the centuries, this layer darkens and yellows, so fine details are

lost in a grey haze, the colours lose their intensity and the artistic statement is literally clouded. Working millimetre-by-millimetre, aged varnish is painstakingly removed with a cotton swab soaked in ethanol. New varnish gives the work back its depth of light and the colours shine in new or, rather, old brilliance. This brings the greatest visible change, allowing the viewer to look at the painting with different eyes. It’s a step Katrin really enjoys: “You can see the result of your work straight away and have an 'aha' effect. When varnishing, the restored painting regains its depth of light and the colours shine in their true brilliance.”

When it comes to the important task of applying the new layer of varnish, Katrin chooses the SATAminijet 4400 B. “If retouching has been applied to the

painting by us, it’s advisable not to overstress it with a brush. Under certain circumstances, the retouching would dissolve and roughen again or in the worst case even remove it completely.” Just like in the refinish environment, the SATAminijet 4400 B’s fine, even atomisation, controlled material transfer and optimum handling make life easy for the painter. “With the SATAminijet, I can also work partially and, if necessary, apply more material to a few individual areas of the painting without creating edges and noses.” Katrin also appreciates the easy maintenance and cleaning, as well as its high level of reliability.

You can check out Katrin’s amazing work at https://kunstkonservierung.de/ or on Instagram: @kunstkonservierung.

R

Want to eliminate a key point of frustration and a roadblock that

perception is very different on the shopfloor. Almost universally, technicians from both panel and paint will identify ‘parts’ as their biggest frustration, according to Greg Tunks, MVP Business Solutions Manager ANZ. He points out that when you look at ‘parts as a percentage of sales’ (up towards 50% in Australia and around 40% in New Zealand), it makes having an effective parts process an absolute priority when looking to boost profitability.

In general, technicians want to work efficiently but to do that they need to be supported with a good parts process. That encompasses everything to do with the parts needed to repair a damaged vehicle, including ordering parts at the correct time, ensuring all the parts are available to the technician before they start the job, ensuring the parts that arrive are correct, etc. In other words, putting systems in place that allow the technicians to work on the job uninterrupted by any issues with parts.

it’s perhaps no surprise that one of the most common requests the MVP Business Solutions team gets is for help with this crucial area. And when changes are made, we typically see immediate improvements.

Your MVP Business Solutions Manager can offer a full set of best practice process that cover the entire step-by-steps method of dealing with parts, as well as helping to implement them and support your team through the process. Here is just a sample of some of the issues and solutions.

A good parts process starts with estimating. Rather than quickly knocking up a quote to get the job into the system, the aim is to capture all of the parts required to complete the job. As well as allowing all the parts to be ordered at once, it minimises the need for supplementary adjustments that are an unnecessary drain on admin resources.

This is where the X-Ray Repair Planning method, from MVP Business Solutions, provides a powerful tool.

Stripped bare – When it comes to stripping the vehicle for repairs, make sure the process is detailed and thorough from the start. For example, when replacing a damaged bumper, don’t just remove it and place it on the parts trolley. Go one step further by removing components, such as

Mirror matching – These days, all parts tend to come in a box or a packet but anyone who has been in the trade for a while knows that the label on the outside doesn’t necessarily represent what is inside. Mirror matching is the process of putting the broken part and new part together to be sure they definitely match. At a glance, parts can appear the same but it’s only when checked side-by-side that slight differences are noticed. Once the match is confirmed, you can throw the old part away and put the new one on the parts trolley ready for the technician to fit. This often-overlooked process is crucial for avoiding issues later in the repair process. If you don’t pick up issues until the assembly process, it can cost you the price of the part, the labour cost for production and painting and a very annoyed customer.

sensors, lights, grilles, etc. Not only does this pick up unseen damage to these items, it also means that if something breaks while it’s being removed, another one can be ordered early. This helps prevent almost completed jobs sitting around waiting on one part so they can be returned to the owner.

– This is about providing easy to understand visual aids to help technicians understand what stage the parts process is at. There are various different options. For example, a simple but effective solution can be to have a clipboard on the parts trolley with two pieces of paper. One has a picture of the vehicle so technicians don’t just rely on the job number. The other contains a parts list where individual parts are highlighted after they arrive to provide a quick, easy reference. Another option is a red, yellow and green traffic light system, either on the parts trolley or the vehicle. Red is used to indicate that the job is not ready to start because major parts have not arrived. Yellow signifies all the key parts have arrived but you might be waiting on something minor, such as a badge. Green is used when all the parts have arrived and the job is good to go. R

For further information or to access the wide variety of support services on offer, contact the MVP Business Solutions team at mvp.anz@ppg.com.

Little did Sally know that an urgent request to fill in at PPG for one day would see her still with the company

administration role with PPG Access, she progressed to working in the PPG Clayton warehouse and then became a refinish marketing assistant, before settling into her current role in 2009.

“The PPG role came at the right

it’s organising. I help to organise the schedule for Paul Galea, Refinish General Manager ANZ, and other members of the executive team, as well as organise events, marketing stuff and other things. Since 2006, I have managed our motorsport partnerships, particularly PPG’s sponsorship arrangements with Supercars teams. It’s quite interesting educating the different teams on what PPG is all about, maintaining those strong connections and seeing so many PPG logos and paint on cars up and down

“I think it’s important to be surrounded by people who you get along with and you can work well with. For example, Paul Galea and I always seem to be on the same wavelength and that makes my role really enjoyable. For me, the autonomy of my role is a big factor –people trust me to get the job done and

Favourite hobbies/pastimes? Olympic style weightlifting (clean and jerk, snatch) –I’m obsessed. Also CrossFit Salmon

A really good coffee, preferably an almond milk latte Favourite music / band? Anything

Favourite car / motorcycle? I used to own an original Holden EJ Premier, complete with venetian blind Favourite holiday destination? Fiji.

Thanks to an unrivalled combination of exceptional speed, superb colour accuracy, no-fuss ease of use and effortless blending and mottle control, this is simply the best refinish technology on the market. Backed by a range of primers and clearcoats featuring advanced low-VOC technology, it’s the eco-friendly choice which really delivers on outright speed. With everything a modern, fast-paced collision centre needs to slash cycle-time while boosting productivity and profitability, Envirobase® High Performance is engineered for excellence!

Whether planning your own special paintjob or you just have a keen interest, the ‘Muscle Car Respray’ YouTube series provides an inspirational, in-depth guide from start to finish.

Agood quality street car paintjob is not what it used to be, says Howard Astill. With a career spanning over four decades, the revered elder stateman of the Australian custom car scene is adamant that the bar is set much higher today. Bringing this to the foreground became the catalyst for a ‘tell all’, behind the scenes ‘Muscle Car Respray’ series, in conjunction with PPG and MIRKA, which roll out on the Astill Design YouTube channel in the second half of 2023. The fascinating 14-episode series follows the step-by-step processes involved in taking a 1971 Camaro body from bare metal, all the way through to a quality, ‘street car’ paint finish, says Howard. “Some people will say this is better than a street car paintjob. However, the level of expectation from customers is way higher today than 10 years ago. When they go to paint shop to get a job done, it needs to be at what used to be ‘show’ standard.”

Over a 25-year partnership, Howard credits PPG with helping him produce some of the best paint finishes in the country and this new initiative further evolves the relationship. “Our target audience is primarily the small custom / restoration business who often find it difficult to keep up with the latest trends, as well as DIY people who have enthusiasm and basic skills but are looking for some

expert guidance. As we progressed, stage by stage, through the job, we also looked for opportunities to take advantage of some of the latest PPG refinish technologies that allowed us to eliminate certain steps and shorten the process. For example, using a Wet-On-Wet primer eliminated a whole sanding step and PPG has so many product options. One of them is F4949 CT

Productive Chassis Primer Binder, from PPG’s Delfleet Evolution commercial transport range, which was perfect for the chassis and engine bay. And to finish it off, we just used a satin black from the Delfleet range.”

Howard also took the opportunity to introduce some of the latest MIRKA technologies. “I have used a MIRKA dustless sanding system for 10 years – I don’t do any wet rubbing. Recently, I upgraded to the new MIRKA Galaxy self-sharpening abrasive range and I trialled the MIRKA DEROS electric sanding block. It’s a nice tool to use because it takes away some of the wear and tear on the body so I will definitely be adding it to my process.”

Throughout the series, Howard was joined by various PPG experts. “I am really pleased to be able to do this series in conjunction with PPG and MIRKA and I have had lots of

positive comments about the PPG professionals coming in. People really liked the way I was able to quiz them about exactly what they are doing with each process and why it’s being done in a certain way. They were also able to drop in handy tips and tricks that make life easier or help get a better result.”

Judging by the statistics, the ‘Muscle Car Respray’ series has been an outstanding success. “As of January 2024, we have had over 200,000 views which is very good. While some people will watch every single episode, some just drop in to watch certain parts so the viewing numbers tend to go up and down. One of the most popular was when we put the actual paint on. The most surprising episodes was when we showed different ways to remove paint runs. Comments came from around the world – some saying you should never get runs, while others defended me by saying if you have never had a run, you are not trying hard enough.”

One of the more interesting statistics is what types of devices people are watching the content on – phone, PC, tablet, TV, etc. It shows that almost 50% of viewing is

done on a TV. Rather than watch traditional broadcasts, people are actually sitting down in the evening to watch the Astill Design YouTube channel through their TV.

As a sidenote, although his YouTube channel has not yet made Howard a household name, it has at least made him more recognised. Whether it’s Los Angeles airport, a convenience store on the way to Las Vagas or just at a local café in Wollongong, he is getting used to hearing ‘Hey, Howard!’, as fans come up to say hello or get a selfie.

The outstanding success of this latest collaboration between Astill Design, PPG and MIRKA, is set to resume in 2024. Covering a wide range of subjects, from specialised masking and spray guns, through to surface finishing, painting and a host of other thoughtprovoking subjects, the aim is to drop a fresh video every second week. R

The Astill Design YouTube channel https://www.youtube.com/@AstillDesign is the place to look for the latest episodes, along with Howard’s vast back catalogue of videos.

Built with clever PPG chemistry, the revolutionary SELEMIX® tinting system is a super versatile colour solution for almost the entire Commercial Performance Coatings range.

The typical refinish paint system, whether it’s solvent borne, waterborne, hybrid, etc, has just one dedicated range of tinters in order to provide the vast number of vehicle colours required. However, this approach was never going to cut it for PPG’s Commercial Performance Coatings range. Rather than being focused on the single task of refinishing vehicles, this super versatile system has to cater to a customer base that has a vast number of applications and outcomes they want to achieve. They could be looking to coat anything from agricultural and construction equipment to trailers, business equipment, concrete floors, structural steel and much, much more. Providing all these coatings solutions is a Commercial

Performance Coatings portfolio consisting of well over a dozen different products offering single pack and two pack options, along with different technologies, including alkyd, acrylic, epoxy, enamel and urethane. The result is an incredible number of choices and coatings with different abilities to meet the needs of a vast cohort of customer requirements. The question is, how do you smoothly service all these many and varied products with just one tinter system?

Selemix – the locally developed solution

No matter which technology it’s created from, each Commercial Performance Coatings product comes as an colourless opaque or clear binder. This is where the clever SELEMIX® Tinting system comes in. Developed by PPG’s R&D Laboratory in Milan, Italy, the components of this ‘universal’ tint system are made up of a special alkyd non-drying resin which shares compatibility across a whole range of binder chemistries. With the world-class Selemix tinting system in hand, it was up to the local paint chemists at PPG’s Clayton R&D Laboratory to take the steps necessary to ensure it worked across the Commercial Performance Coatings range. That came down to a lot of chemical juggling to get the desired outcome, says Scott Mandragona, PPG ANZ Refinish Technical Manager.

“For the technical team, it was a very comprehensive program to put the Selemix tint system together. On one hand we could draw on PPG’s huge global technologies database but we are also aware of the potential pitfalls of simply launching an overseas product here.

For example, products from other markets typically don’t have the durability to cope with Australian conditions. For the

Selemix tinters that meant adjusting the actual pigments to improve the durability characteristics. As we were developing the various Commercial Performance Coatings primers, topcoats, etc. specifically to suit this market, we realised the benefits of being able to offer a ‘universal’ tint system with particular properties that make it fully compatible with the whole binder range, from 1K products right through to premium 2K polyurethane topcoats.

“Developing such a flexible tint system around such a complex range of binder technologies was a challenging but very rewarding exercise for the technical team. It’s about achieving a balance for every single product, in terms of colour and opacity, while maintaining the necessary performance qualities and the user-friendly aspects, such as ease of application. Afterwards, each product goes through a thorough testing program which starts in the laboratory and then gets more in-depth at our Braeside Training Centre in Melbourne,

before we bring in our technical sales team and even selected customers. Bringing the benefits of the Selemix universal tint system to local customers has been a real team effort and the colour capability it offers is something that everyone is very proud of.”

The Selemix / Commercial Performance Coatings project highlights the significant advantages of having a skilled team and the PPG R&D laboratory, at Clayton, on-hand to support the local market. In addition, virtually 100% of Commercial Performance Coatings are manufactured locally, at PPG’s Clayton, Melbourne production facility.

Thanks to the chemical compatibility of Selemix tinters, it’s very straightforward to mix exactly the same colour across each of the Commercial Performance Coatings technologies and be confident they will match each other. In fact, the Selemix system is capable of formulating around 10,000 colours in any gloss level, from full gloss, through semi-gloss to a matt finish.

For example, a customer might choose Performance Polyurethane Topcoat (which is a two-pack product)

to give the upper, more visible surfaces of a trailer a nice premium level finish in, say, Monza Red. For the chassis and other parts which are hidden away underneath, they can use a cheaper, single pack option, such as Rapid Dry Enamel, which will give them the durability they want but also the exact matching Monza Red, so the job looks cohesive and consistent. Another example could be a concrete floor and a piece of equipment which are exactly the same colour but painted in different Commercial Performance Coatings technologies. It’s the special chemical tuning process carried out by the local PPG technical team that ensure the Commercial Performance Coatings brand lives up to its tag line ‘Simplicity, consistency and capability’. R

Utilising the best of engineering, products, materials and manufacturing, A & A Di Medio & Son is aiming squarely at being

‘the’ one-stop-shop for

concrete agitators in Australia.

Made up of a mix of aggregate (sand, stones, etc), cement and water, concrete is the world’s most widely used building material. From a house slab or a footpath, through to massive infrastructure projects, concrete literally lays the foundations for our civilisation. However, once it’s mixed, concrete has a set

timeline before it becomes unworkable and eventually cures which means there needs to be a way to efficiently feed the insatiable demand for the product. As a result, any working day will see an armada of concrete agitator trucks transporting mixed product from suppliers to worksites. It’s a crucial supply chain role and, in Australia, that has seen a large proportion of concrete suppliers put their trust in one brand – A & A Di Medio & Son.

Based in the Melbourne suburb of Braeside, the company has worked hard to be a leading local manufacturer, says co-owner, Peter Di Medio.

“The A & A is for my parents – Alex and Anna – and I am the ‘Son’. They started the business back in the 1970s when dad was running a few concrete agitator trucks. He used to do his own repairs and maintenance and other operators started

asking him to do work on their trucks. From there it was a long progression from maintenance to making various parts, to manufacturing complete units. Today, the operation is run by myself and my business partner, Duarte Damas – thirty years ago it was just him, Dad and I, now we have around 60 staff. We are aiming for Di Medios to be a one-stop-shop for concrete suppliers where they can come to get maintenance, repairs, new parts, refurbished parts or complete new concrete agitator units.”

As demand continued to grow, Di Medios has steadily expanded operations. After starting in a single factory, it has spread to a spacious fit-out facility a couple of doors down and then another

premises over the road. According to Peter, every single customer started dealing with Di Medios when they were just one truck operations. Now they order two, three, four or even ten units at a time. It’s about delivering a combination of proven design and long-term reliability, says Peter.

“Our design has been refined and finetuned over a long period of time and it’s backed up with quality manufacturing and components. After a load of sand, stones and cement flow into the truck, it’s actually the agitator barrel that goes on to ensure it’s thoroughly mixed to Australian standards. The internal blades need to be tuned to the way we mix concrete in Australia and when it’s discharged, it’s about making sure it’s the right consistency. To suit the needs of different operators, we manufacture lightweight, medium and heavy agitator sizes. In a rigid chassis truck, you are talking up to eight cubic metres capacity, while there are also larger, semitrailer versions that carry up to around 11cubic metres. Because aggregate is constantly swirling around inside, an agitator barrel will

actually wear out after about four to five years. We fit new replacements to keep a truck going and we offer refurbished units, if that better suits the customer’s needs at the time.”

Like many manufacturing industries, imports from China are beginning to impact on the concrete agitator market. It’s where Di Medios long-standing reputation and ability to work closely with its customers is holding it in good stead.

“Over the last five years or so we have seen Chinese products brought in and it’s really about catering to those looking to

buy purely on price. What some operators don’t realise is that what you might save at the start, you end up paying for later on, in terms of more vehicle downtime and a product that either no one want to repair or they physically can’t be repaired. In contrast, Di Medios is about making products that continue to make money for our customers. When you do the sums, having a vehicle off the road for just one day could cost the operator $1000 in lost usage. When you add up those costs over the lifespan of the unit, it can be a big hit. Much better to have a reliable unit that stays on the job making money for you. It’s why the Di Medios motto is ‘Built to Perform’.”

The Di Medios manufacturing process is a credit to the skilled team who literally take raw steel sheets and craft them into the various sized agitator barrels and other components. On average, a new concrete agitator unit takes four weeks to manufacture from start to driving out the door. Right through the process there are inspections and quality gateways that must be passed before proceeding

high quality, easy to maintain appearance, explains Peter.

“Presentation is key because it’s about branding for the concrete company operators. Remember, their name is all over it. It’s why we have had a long-term partnership with PPG. It’s a really good quality paint and we are very happy with the results. Laurie Allen (Commercial Performance Coatings National Field Demonstrator & Account Manager) has been a very good contact for us – if we have a problem, he gives us solutions. We get very good support from PPG.”

to help them out with best practice processes and suggestions on what spray guns and application equipment will maximise their efficiency and quality of finish. It’s great to see a true, all Australian manufacturing company using PPG products that are almost all manufactured locally, at the PPG Clayton plant.

The Clayton Colour Laboratory also plays a big part by providing Di Medios with FleetSpec colour matches for the various fleets it works with.”

For his part, Laurie Allen says he has enjoyed supporting Di Medios’ drive for quality. “The four person Di Medios paint team are very good operators and a pleasure to deal with. I have been able

As Di Medios navigates the pathway to increased production to meet demand, one of the limiting factors is finding enough skilled staff, says Peter. “It’s a nightmare. You name it, we are looking for auto electricians, motor mechanics, labourers, welders, boilermakers, etc. We try to run a few apprentices but good ones are hard to find. If someone comes along who doesn’t quite have the skills we need, we will spend the time to teach them – it has become a big part of our job now. Without the skilled staff we need, it slows us down and limits our production numbers.”

In an effort to make Di Medios a one-stop-shop, the company has moved to open maintenance and repair outlets in strategic locations around the country.

“We are really trying to crack the Australian market. In order to offer our services closer to more of our customers, we have opened an outlet in Campbellfield, in Melbourne’s north, another in Wingfield in Adelaide and we are working on setting up joint venture operations in NSW and, eventually, right around the country. Our plan is to become ‘the’ concrete agitator brand for Australia. Even after all this time in the business, it still feels good to see an agitator with the Di Medio name out on the road.”

Where regular abrasives wear and fade during the sanding process, Galaxy has been engineered with unique, self-sharpening ceramic grains so they continue to cut long after others have given up. This new MIRKA developed technology means that every time the edge of an abrasive grain is broken off, the grains underneath simply form new cutting edges and the sanding process goes on. As well as a faster cut from edge-to-edge and excellent edge wear resistance, Galaxy abrasives continue to retain that sharp feel for longer which significantly extends the lifespan. As an added bonus, the scratch pattern of finer Galaxy grits is especially quick and easy to polish out.

Mirka® Galaxy – Non-sticking • Self-sharpening • Long-lasting.

The end-to-end digital ecosystem bringing advanced, game-changing technologies to your collision centre

Scan the QR code to see how PPG LINQTM can benefit your business! youtu.be/t4isZfVLwzw

Introducing the 3D digital sprayout

This advanced, 3D digital colour visualisation tool smoothly interfaces with the next-generation PPG DigiMatch™ camera-equipped spectrophotometer to totally transform the user experience of selecting the best colour match formulation from PPG’s extensive library.

Compact, fast, easy-to-use spectrophotometer

PPG’s high tech DigiMatch spectrophotometer features a digital colour camera to significantly boost performance. The camera’s six imaging angles combine with six reflective angles to provide additional texture information to help quickly and precisely retrieve the correct formula match.