North Sea Port and Promotion Council North Sea Port will be in attendance at various events and trade shows. Below you’ll fnd a snapshot of the upcoming events that might be of interest to you.

North Sea Port and Promotion Council North Sea Port will be in attendance at various events and trade shows. Below you’ll fnd a snapshot of the upcoming events that might be of interest to you.

Over the past year, we observed a 0.7% increase in seaborne cargo in our port, while inland navigation saw an impressive rise of 4.4%. This indicates that, in terms of cargo handling, our port made slight progress last year.

In 2024, we announced and realised numerous investments. For the coming year, we anticipate a land allocation of 30ha, just as we did last year. Investments in our port area continue to be recorded, and this issue highlights several examples. This demonstrates that despite turbulent geopolitical times, the port continues to develop and remains a credible investment area. Naturally, we must also keep an eye on what Europe will bring in the coming months with the Clean Industrial Deal.

In the coming months, the completion of the New Lock in Terneuzen will take place. At the request of future nautical users, test sailings will frst be conducted under the supervision of the Department of Waterways and Public Works after the handover. This will allow boatmen, pilots, tug services, and operators to gain experience with the New Lock. These test sailings are expected to last about two months. If everything goes according to plan, the New Lock will then be fully operational for ships that currently use the Western Lock. Following this, test sailings will begin with ships up to 38.5m.

Previously, as North Sea Port, we expressed our strong desire for a deeper channel with a draught of up to 15m up to the Massagoedhaven in Terneuzen as soon as possible. This would eliminate the need for

seagoing vessels to lighten their load on the Western Scheldt River before passing through the New Lock, making the process safer and more cost-effective. The port authority is also looking forward to enabling 43m wide ships to sail from the New Lock to the Kluizendok and Rodenhuizedok in Ghent as soon as possible — ensuring the New Lock is utilised to its full potential.

Peter Van Parys COO of North Sea Port

In its role as port authority, North Sea Port has a duty to ensure safety. This sounds like a clear task. However, its implementation is less straightforward than it seems. PortNews discusses this with Jolijn Delissen, advisor port safety & security at North Sea Port.

“Many people associate port safety primarily with safe navigation,” Jolijn Delissen states. “This is logical because it is indeed an important task of North Sea Port. Through our port service, we ensure that ships can navigate in and out of the port safely.” “But,” she explains, “a safe port encompasses much more. It also includes infrastructural safety, industrial safety, incident and crisis management, security, and, something closely related and increasingly common these days, subversion. Within security, cyber security is becoming an important issue as well.” (also see text frame ‘Fighting cybercrime together’ on page 7).

Jolijn Delissen continues, “When we talk about safety, it’s not just about maritime traffc but also safe infrastructure. Within our port area it is our responsibility to ensure that all infrastructure is safe in terms of construction and that they can be used safely through proper design. Of course, it will also be the responsibility of the owner of the infrastructure itself. A quay, for example, must be well-maintained to be safely used, but to allow cyclists to move safely through the port area, we also invest in bike paths. This too is safety. Additionally, we play a role in maintaining safety. We are not the party that can directly

North Sea Port supports the ‘The Hague 2025’ conference of the European Youth Parliament the Netherlands. This year, 5-13 April, the conference of the European Youth Parliament the Netherlands will take place in The Hague. The theme of the conference is Young Visions of Peace and Security. North Sea Port is one of the partners of this event. Consequently, young people will discuss safety in relation to port activities and ultimately make recommendations to the European Parliament and North Sea Port.

point out issues compromising safety to companies, but we can infuence the types of businesses allowed to settle through our establishment policy. This way, we can still steer safety. Furthermore, we play an important role in incident and crisis management, providing practical solutions, such as placing oil boom containers in the port, and collaborating with the Veiligheidsregio Zeeland (VZR; Zeeland Regional Safety) and its Flemish counterpart, the Brandweer Zone Centrum (BZC), to prevent and, in the worst-case scenario, act as liaison for VZR and BZC because of our knowledge of the port and the companies within. Regular exercises are also part of this, in which our port service plays a signifcant role.”

Another important aspect of safety is security. After the attack on the World Trade Center (WTC) in New York, ISPS was implemented worldwide to counter terrorism, espionage, and sabotage. These threats still exist. However, nowadays, other issues also play a role, such as human traffcking and drug smuggling. Particularly from the latter, subversion has become a phenomenon that businesses in seaports may face. Jolijn Delissen explains, “Subversion means that criminal organisations try to infltrate legal businesses, for instance, by bribing or pressuring employees at terminals to cooperate in drug traffcking. Due to these new developments, the Port Security Act in Belgium has already been expanded to include human and drug traffcking. This is not yet formally the case in the Netherlands, but seaports, including North Sea Port, are taking steps to tighten ISPS rules. After all, criminals always seek the easiest route for smuggling.”

“We cannot ignore that North Sea Port, as an important logistics hub, is attractive to criminals,” Jolijn Delissen elaborates.

The fence and accompanying information sign clearly mark where public areas ends and the port area begins. This makes it possible to exclude individuals who have no valid reason to be in the port area and tackle criminal activities

“Criminals increasingly use legal companies and services for illegal activities, blurring the lines between the ‘underworld’ and the ‘upper world’. Subversion is a real problem threatening the safety of businesses and employees in the port. This starts with the obvious fruit terminals with intensive connections to Central and South America, but other terminals are also becoming targets. When one door closes, criminals always look for another that is still open. Today, subversion is part of our license to operate,” Jolijn Delissen states. “We have come to realise that, next to for example the public authorities and companies, it is also our task to fght this social issue as it is a joint fght with all parties concerned against organised crime. We want to be a safe port for ourselves, the businesses and their employees, and the surrounding community. By the way, this applies not only to security and subversion but to safety in general.”

While there is a distinct difference between safety and security, both are equally important for North Sea Port. Both infuence a good establishment and a good workplace. They also play a role towards the surrounding community. “Just like the businesses and their employees, residents also beneft from a port that is safe on both fronts,” says Jolijn Delissen. “As previously mentioned, we have increasingly come to believe that we must take even more responsibility for this. We are currently expanding our visibility in the port with employing a new team of supervisors. They drive around the port as the eyes and ears

Security, in the broadest sense of the word, is an important theme for North Sea Port. Nowadays, cyber security is playing an increasingly important role in this theme.

We spoke with Els Verfaillie, IT manager at North Sea Port, and her colleague Paul van de Vijver, cyber security advisor, about this current topic. “North Sea Port is a rather unique organisation,” Els Verfaillie says. “We are a relatively small organisation but one that is connected in many ways to many domestic and foreign entities. This means that we must be extra vigilant about cyber threats. Not just for ourselves, but certainly also for the organisations we are connected with. Because you certainly don’t want logistical and nautical processes to be put at risk.”

Paul van de Vijver adds, “When we talk about cyber security within our company, it involves two things. Firstly, we need to ensure that our hardware and software are in order to protect us from cyber attacks. That sounds logical, but in fact, you are continuously engaged in a cat-and-mouse game in which you risk quickly falling behind the facts.” According to Paul van de Vijver, cyber security plays an increasingly signifcant role in the acquisition and implementation of new systems. “At the moment, work is underway on a new port portal, which also presents various challenges. With the new port portal, various applications need to be linked together. This involves questions such as, do they ft technically, do they comply with privacy legislation, but certainly also, do they meet the security requirements we set? It shows that we work much proactively, together with our suppliers.”

Paul van de Vijver continues, “Secondly, and just as important as the aforementioned task, is the role we, as the IT department, play at the policy level. What security measures are necessary, and how far do you want to go and at the same time alignate with effcient processes? After all, as a company, you must be able to continue functioning optimally. It’s also crucial to continuously keep the employees aware of the cyber threat. At North Sea Port training in digital skills is provided to our entire workforce. Naturally, people are becoming increasingly alert to digital threats, yet as an organisation, you always run the risk that someone overlooks something, causing things to go wrong. At all levels within North Sea Port, there is a focus and awareness that we need to act against cybercrime together.”

“Cooperation is essential to be adequately protected in a much broader context,” Els Verfaillie continues. “Due to the digital interconnectedness of many systems, you must work together to keep doors closed. In the feld of IT and cyber security, we focus on partnering within our sector. That is why, at the end of last year, we developed a joint approach with other Dutch seaports united in Branche Organisatie Zeehavens1 (BOZ; Dutch Seaports Organsation), the Ministry of Infrastructure and Water Management, and the National Coordinator for Security and Counterterrorism. With this

At the end of last year, a joint approach was initiated by the Dutch seaports united in Branche Organisatie Zeehavens, the Ministry of Infrastructure and Water Management, and the National Coordinator for Security and Counterterrorism. From left to right: Marijn van Schoote (CISO Port of Rotterdam), Boudewijn Siemons (CEO Port of Rotterdam), Cas König (CEO Groningen Seaports), Peter van Parys (COO North Sea Port), Paul Dirix (CEO Port of Moerdijk) en Koen Overtoom (CEO Port of Amsterdam).

‘Cyber Strategy Dutch Seaports,’ a joint and national approach has been formed to prevent digital attacks on nautical and logistical processes.” Paul van de Vijver explains, “For this joint approach, the FERM foundation, which has been active since 2021 for the ports of Rotterdam and Moerdijk, is transformed into a national cyber security platform for the BOZ. For this purpose, FERM’s activities are expanded and extended to the other Dutch seaports. FERM aims to raise awareness among companies about cyber risks and promote cooperation in this area by exchanging threat information, sharing knowledge, and providing the necessary training for companies in the port area. The beauty of this cooperation is that every port is different and works with different systems. Risk assessments that we make together will be worked out individually by each port into tailored solutions. Every port will also keep its own locks and keys.”

“The cooperation does not stop at the Dutch border,” emphasises Els Verfaillie. “We also have good contacts and consultation structures in Belgium regarding a joint response to cyber threats. The Port of Antwerp-Bruges is a respected partner from this perspective. Of course, and it has been said in various other contexts, the challenge for us remains that we are a cross-border port dealing with two different national legislations. Finding the right path here continues to play a signifcant role, but by collaborating extensively with the various governments, we consistently fnd good solutions. Thus, there is also an awareness that fghting cybercrime requires the effort of multiple parties – cross-border – making us all stronger together.”

1 Branche Organisatie Zeehavens: the Branche Organisatie Zeehavens (BOZ) unites the fve seaport authorities of national importance in the Netherlands: Groningen Seaports, North Sea Port, Port of Amsterdam, Port of Moerdijk, and Port of Rotterdam. BOZ focuses on themes that transcend individual seaports, represents the interests of our affliated ports and promotes knowledge exchange and networking between seaport organisations.

Funds, allocated by the Dutch Ministry of Justice are used to raise awareness among companies and employees, implement physical security measures, conduct research and innovation, and increase enforcement and investigation. This has already resulted in so-called resilience-proof and security awareness trainings for port employees in recent years.

of our organisation. They can spot things that are not right and address people’s behaviour, for instance, when parking unsafe, creating awareness that a safe port is everyone’s responsibility. Our supervisors will also be working closely with the municipal supervisors. It is also our duty to familiarise our governments with our problems. Representatives of national governments are regularly invited to learn about what is happening in the ports.”

Jolijn Delissen continues, “Of course, we do not work alone on this subject. As well as the collaboration with Veiligheidsregio Zeeland already mentioned, we cooperate with the provincial and municipal authorities, Police, and Customs. We also regularly partner with Port of Rotterdam and Port of AntwerpBruges to raise awareness of these issues at the national and international levels. The increasing urgency has led the Dutch Government to join the fght against subversion and smuggling. As a result of this, the Dutch Ministry of Justice has designated fve key logistical hubs and allocated resources to combat drug smuggling and undermining. One of these hubs is Mainport Zeehavens Zeeland-West Brabant. The allocated funds are used to raise awareness among companies and employees, implement physical security measures, conduct research and innovation, and increase enforcement and investigation. This has already resulted in so-called resilienceproof and security awareness trainings for port employees in recent years. It has also led to the creation of the Seaport Police, a team dedicated to North Sea Port (for its Vlissingen, Borsele and Terneuzen sub-areas), and the Port of Moerdijk. The Seaport Police consists of personnel patrolling the ports,

investigators conducting investigative work, and information offcers performing analyses.In our view, guarding safety and security is, next to own responsibilty, a partnership of the whole ecosystem.”

Jolijn Delissen continues, “To use government resources effectively and to collaborate more on safety, the foundation Veilige Zeehavens Zeeland (safe seaports Zeeland) was established in 2023, where the municipalities Vlissingen and Borsele and North Sea Port collaborate with entrepreneurs on securing the port area. The foundation carries out concrete projects and develops a vision and policy on security for the public areas in the port. Of course, the terminals have their own responsibilities for security. Initially, the focus is on securing the Bijleveldhaven in Vlissingen because many fruit ships from Central and South America are handled there. Traditionally, these are targets for drug smuggling. However, the goal is to eventually involve the entire port area.” The focus of the foundation lies on the creation of barriers. “This year,” Jolijn Delissen states, “initiated by the foundation, a new fence was installed around a part of our Vlissingen port area. The fence and accompanying information sign clearly mark where public areas ends and the port area begins. This makes it possible to exclude individuals who have no valid reason to be in the port area and tackle criminal activities. Enforcers, such as Police and Customs, can act more strictly against individuals with malicious intent, making it easier to enforce area bans. This makes the port area safer without disrupting legitimate activities and logistical processes. In the future, the physical fencing will be expanded with a closed network of cameras. ANPR cameras will also be installed at all port access roads this year. These cameras recognise license plates and record who enters the port.”

Although much effort is being made to ensure a safe port, Jolijn Delissen acknowledges several challenges. “One of the biggest challenges lies in the differing legislation within Europe, and particularly within North Sea Port, where we deal with both Belgian and Dutch laws. In Belgium, for instance, all port employees are screened. This is not yet the case in the Netherlands, which naturally poses risks. Therefore, it is crucial to constantly exchange information. And consider the previously mentioned adjustment of ISPS regulations. In the overarching lobby message towards The Hague, we state a legal framework within which requirements can be set for the security of companies with a high-risk concerning drug smuggling is lacking. We advocate for an amendment to the Port Security Act that would allow such requirements to be imposed on these companies. Of course, we realise that this can be a challenge for many businesses. With our communication and available resources, it is essential that everyone in the port understands that the measures are taken not because they must be, but because they are crucial for everyone’s safety. Besides these measures, companies and their employees also need to become aware of the importance of safety. One cannot compete with safety, but safety does go hand in hand with the commercial interests at stake. For this reason, we all beneft from a safe port in many aspects.”

I. NORTHSEAPORT.COM

On Thursday, 13 March, the Multimodal Transport Expo will take place in Breda, the Netherlands. It is the event where transport and logistics companies from both the Netherlands and Flanders come together. It is therefore only logical that North Sea Port participates in this event.

“Everyone in the feld of logistics and transport will be present on this day,” says Jean Ruinard, commercial manager of North Sea Port. “That’s why we don’t want to miss this event. Since the creation of North Sea Port, we have been working hard to increase our brand awareness, but that doesn’t change the fact that many parties looking for logistics solutions often frst think of Rotterdam or Antwerp. We are slowly but surely breaking through this.”

“Although we do not provide transport and storage ourselves, we do play an important role in this as a multimodal port,” adds Fred Baert, commercial manager and colleague of Jean Ruinard. “That is why we offer a platform during the fair

to various companies in our port that provide these facilities. In addition, as a port company, we are of course relevant. For example, because we often act as a sparring partner, helping companies to fnd a suitable solution. This will certainly also be a role for us at this fair. Although we are a relatively small port compared to Antwerp and Rotterdam, we distinguish ourselves positively from these ports by processing a large diversity of goods and hosting various parties with the necessary storage and transshipment facilities. In that sense, we actually have a solution for every logistics need. As a port company, we know our port and the companies like no other, and together with the companies in our port, we always fnd the right solution for every logistical challenge.”

“As a port, we are increasingly fulflling a hub function for Rotterdam and Antwerp,” explains Jean Ruinard. “These ports often face congestion on roads and waterways, something we don’t suffer from. That is why more and more inland waterway container services are being set up via our port to or from Antwerp and Rotterdam. As a result, we have seen the share of inland shipping in our modal shift increase signifcantly in recent years to around 58% (2023). This has already allowed us to take a lot of freight traffc off the roads.”

“Inland waterway transport may not always be the fastest solution as such,” explains Fred Baert, “but in the end, it often turns out to be cheaper. For example, transporting containers by road from Ghent to Antwerp. All those loose containers often have to be stripped and stuffed again. This costs time and money. The delay that container transport by truck often encounters due to traffc jams and waiting times when entering the port and terminals often costs a lot of money. Inland waterway transport may be slower, but all those containers that are transported by truck can be loaded onto an inland vessel at once, and the transport and arrival at its destination can be better planned. Ultimately, this eliminates costly waiting times. In addition, as a port, we have border inspection points, which means that goods such as food, feed, and veterinary goods can already be inspected and cleared in our port. This eliminates the need to do this in Antwerp, for example, which also saves time and money.”

“With our hub function, in addition to road and inland waterway transport, shortsea and deepsea is also an important factor in our port,” emphasises Jean Ruinard. “More and more regular liner services are departing to and from North Sea Port to various destinations within and outside Europe. This not only includes coastal shipping but also intercontinental connections to Central, North, and South America, as well as to and from West Africa.

For setting up these liner services and inland waterway services, it is, of course, important to continuously seek the right fnancially viable combinations of cargo packages in collaboration with the business community. For this, volume is needed, and it is crucial that people know where to fnd us. We must try to become even more top of mind with the parties looking for a logistics solution.

A fair like the Multimodal Transport Expo offers an excellent opportunity for this.”

North Sea Port also has the necessary kilometres of rail for freight transport by train, and a lot will be invested in this in the coming years. “Rail transport does not really compete with inland waterway and truck transport,” explains Jean Ruinard. “Companies often consciously choose rail transport because it is simply the most suitable form of transport for their goods. Our advantage over other ports is that we have relatively long staging tracks, allowing terminals with rail transshipment facilities to receive really long trains at once for loading or unloading.”

We often hear from our customers that we are always willing to think along with a great solution.

North Sea Port’s efforts to profle itself as a multimodal port have ensured that the port is recognised by many parties.

“The location of our port between Antwerp and Rotterdam, with various congestion-free connections by land, water, rail, and pipeline, offers many advantages that are increasingly recognised by various parties. It is not for nothing that various project developers such as DHG, Heylen, and more recently Panattoni, choose our port. They dare to invest in their new construction projects in advance with the conviction that their potential customers can be convinced of the benefts that North Sea Port has to offer,” concludes Jean Ruinard.

more information

“A modality often forgotten but becoming increasingly important is pipeline transport. We can also provide well for this, which is certainly a strong advantage of our port, especially with regard to developments around, for example, ammonia and green hydrogen,” adds Fred Baert.

“Whatever the benefts and possibilities are and however multimodal North Sea Port is as a port,” continues Fred Baert, “we must not forget that North Sea Port is part of a larger interconnected transport system. As part of this system, it is crucial that every link and every hub is aligned. It is, therefore, important to keep talking to as many parties as possible to see how you can help and strengthen each other, and for that, it is important to be open-minded. Fortunately, we often hear from our customers that we are always willing to think along with a great solution.”

North Sea Port

Fred Baert, commercial manager

E. fred.baert@northseaport.com

North Sea Port

Jean Ruinard, commercial manager

E. jean.ruinard@northseaport.com

I. NORTHSEAPORT.COM

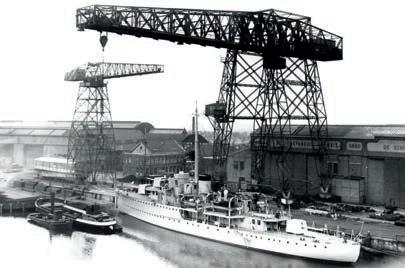

This year, Damen Naval is celebrating a double anniversary. October 2025 will mark 150 years since the company began as Koninklijke Maatschappij De Schelde (the Royal Schelde). It also marks 25 years since De Schelde – as it became popularly known – joined the Damen Shipyards Group. While marking this milestone moment in its history, the company is looking forwards.

Naval tradition in Vlissingen has a long and proud history, thanks in large part to its strategic location at the mouth of the River Schelde with direct access to the North Sea. As early as the Dutch Golden Age in the 17th century, the government gave instructions for the construction of a harbour in Vlissingen where the naval feet could overwinter. The naval activities at the time were concentrated on three locations; the Dokhaven (Dock Harbour), Dok van Perry (Perry’s Dock) and on a piece of land then known as Het Eiland (the island). Years later, in the 19th century, naval shipbuilding activities in Vlissingen were experiencing the same decline as in the rest of the country.

Fortunately, a naval engineer working in Vlissingen at the time stepped in. Bruno Joannes Tideman had already submitted a proposal for the creation of a new, large, modern shipbuilding yard in the city. Finally, after tireless lobbying, and with the support of Dutch King William III, permission was granted for a new yard. In 1875, Koninklijke Maatschaapij De Schelde opened its gates for the frst time.

Within a year, the new yard was employing hundreds of local workers. It would go on to become the largest employer in the region, and a major source of income for Zeeland’s economy.

Originally, the yard was engaged not only in naval shipbuilding, but also in the construction of merchant vessels that were to be found in operation all over the world. At the turn of the 20th century, however, it received

a number of orders from the Dutch Government for the construction of ships for the Royal Netherlands Navy (RNLN). There was, for example, the construction of the armoured carrier HNLMS Evertsen in 1896, followed by cruisers HNLMS Zeeland and HNLMS Brabant in 1898 and 1900, respectively, as well as two torpedo boats in 1905. De Schelde reached a milestone moment with the construction of the frst Dutch built submarine in 1905. It would go on to deliver a total of nineteen submarines for the RNLN. As the century progressed, orders for naval vessels increased, interrupted by the outbreak of hostilities in 1940. After the end of the Second World War, the trend continued.

However, around this time, Dutch shipbuilding was hit hard by unfair competition from a state-subsidised shipbuilding cluster in Asia and began to rapidly lose market share. There were a lot of bankruptcies and lay-offs and, by 1983 and under government supervision, De Schelde was the last remaining shipyard in the Netherlands to specialise in naval shipbuilding.

The response from Dutch industry was to consolidate into a compact, but highly innovative and competitive industrial cluster. This trend is illustrated by De Schelde’s transition, at the turn of this century, into the Damen Shipyards Group. Since then, the company has continued to specialise in complex and high-end naval shipbuilding, combining the experience and innovation of De Schelde with Kommer Damen’s series building concept to deliver complex, modern vessels to navies all over the world.

This was then a necessity since the so-called peace dividend slowly but gradually decimated armed forces throughout Europe after the end of the Cold War. The number of frigates in the RNLN, for example, dropped from more than 20 in the early 90s to only six units some ffteen years later.

Here we are, 150 years later, still in the business of building and designing complex ships.

“Here we are, 150 years later, still in the business of building and designing complex ships,” says Damen Naval’s director strategy and innovation, Richard Keulen. “Today, we’re very focused on restoration of naval capabilities, in the Netherlands, but also in European projects. Along with this focus we invest in innovation, taking onboard new technologies that are relevant for the navy ships of tomorrow.

We frstly need to ensure that our naval men and women at sea can prevail with our navy ships. We secondly need to retain our relevancy, as national naval shipbuilder in the Netherlands, and in Europe.”

As may be expected, there is a sense of celebration at Damen Naval at the achievement of this historic milestone.

“The frst moment of celebration is coming up very soon,” he says. “We will host the Christening Ceremony of the Combat Support Ship (DSS) Den Helder in Vlissingen Oost on 22 February. This will be the frst Christen of a Dutch naval vessel in over ten years and just happens to coincide with our anniversary year. We are additionally proud and grateful that HRH The Princess of Orange will christen the ship.” In addition to this, Damen Naval is planning a special summer celebration for employees and their families, as well as an event to mark the occasion closer to the actual anniversary date, which is 8 October.

“We will also be underlining the anniversary throughout the year at the many seminars, exhibitions and conferences we attend or organise,” says Richard Keulen. At the same time, though, as it refects on the past 150 years, Damen Naval is looking ahead.

“While this is very much a year of celebration for us,” Richard Keulen continues, “it is also a year of urgency. This is a time of revolution in naval shipbuilding against the background of urgently needed restoration and bolstering of military capabilities to make the EU more autonomous and ft to withstand the growing number of threats and disturbances in the world.”

Recently, there has been an increased governmental focus on the Dutch shipbuilding industry as a whole and this has, he says, implications for naval shipbuilding, and for Damen Naval.

A key development was the release of the Sectoragenda Maritieme Maakindustrie (Sector Agenda Maritime Manufacturing Industry). This governmental report was stimulated by a desire to halt a decline in Dutch shipbuilding and restrengthen the industry for the future.

“At frst glance, the Sector Agenda doesn’t appear to have a connection to naval shipbuilding,” states Richard Keulen. “However, on closer inspection, we see it addresses the sector specifcally, mentioning Vlissingen as national hub and touching

on a lot of the same issues we are facing; calls for increased innovation and sustainability, for example, as well as for more cooperation with neighbouring states. The naval shipbuilding sector has a very important part to play in these areas.”

As the Sector Agenda thus makes clear, the core of this naval shipbuilding lies is Vlissingen and, specifcally, at Damen Naval as OEM (original equipment manufacturer) to the Ministry of Defence and for its operational user, the Royal Netherlands Navy. As such, the city is home to a unique set of skills and knowledge, amounting to the ability to design, engineer, construct, integrate and care for a naval vessel throughout its lifecycle.

“From the Sector Agenda we saw then in succeeding Defence related initiatives and publications the frst mentioning of a so called ‘war economy’. It was the frst step in acknowledging our defence weaknesses after relentless and repeated budget cuts and the awareness of the need for urgent repair and bolstering of our armed forces’ capabilities in the Netherlands and in the EU. It calls for a much more strategic cooperation with the defence industry, resulting in a European Defence Industry Strategy (EDIS).

“We saw the numbers game coming back. We simply need more ships. We also saw the growing importance of topics such as unmanned technology, vessel autonomy, etc., looking at what is happening in Ukraine, new technology and concepts of operations will call for shorter and more responsive innovation cycles. As a whole, we have to engage in meaningful cooperation within Europe.

“Due to the changing geopolitical situation, there is broad support for more military spending. For example, in parliament and in society, there is consensual commitment to the NATO budgetary requirement of 2% of GDP and voices already pushing to go beyond it.”

Recently, the growing strategic cooperation led to a very meaningful national Defence Whitepaper (Defensienota) 2024 which has impacted signifcantly on the way Damen Naval operates.

“The paper stated that, in view of all the accelerations, necessary investments and efforts to be made, there should be strategic cooperation between industry and the Ministry of Defence. As

Where you might have seen one naval vessel every ten years, in the coming years, there may be three or four new navy vessels simultaneously quayside at Vlissingen-Oost.

OEM for naval shipbuilding that has signifcant implications for Damen Naval.”

The company has signed a letter of intent (LOI) with the Ministry that laid out a way ahead for a series of feet replacement projects over the coming twelve to ffteen years.

The most prominent of these projects include the replacement of the M-frigates of the Belgian and Netherlands navies with new Anti Submarine Warfare (ASW) frigates. Production of the vessels will begin this year, with the frst vessels delivered in 2028. There are presently two ASW frigates on order for each of the navies, with more orders anticipated.

Another project will see the introduction of amphibious transport ships to the Royal Netherlands Navy to replace the current Holland Class and the Landing Platform vessels. The coming years will also see the construction of a total of eight auxiliary vessels able to take on a wide variety of support tasks. Damen Naval will lead the project as OEM, working together with numerous other organisations in the realisation of this 100% Dutch project.

Furthermore, two innovative Multi-Role Support Ships will be developed. These innovative vessels will support marine operations with loitering ammunition, as well as conducting intelligence, surveillance and reconnaissance duties in the North Sea.

Finally, there is a plan to replace the current Seven Provinces Air Defence and Command Frigate Class with a new class of frigates currently named the Future Air Defender.

“To be able to dedicate ourselves to this very ambitious replacement programme we, and our supply chain are going to require a stable business environment with stability of demand. That is why, for the entire set of projects, we need to explore a

strategic plan together with the Ministry of Defence, RNLN and Command Materiel and IT (COMMIT).”

The close collaboration between Damen Naval and the Dutch Government has implications for wider cooperation in Europe, also, Richard Keulen says.

“There is a lot of pressure, not only in the Netherlands, but also in Europe. We are not the only member state now having to address feet replacement and replenishment. Having this level of focus between one customer and one OEM, with a robust supply chain provides the means for us to have relevance at the European level. This can be seen, for example, in the ASW frigates for Belgium, as well as our F126 project for the German Navy. In the latter we involve many German partners, but also work together with Thales Nederland.”

As Damen Naval sets itself towards the future, there are also clear implications for the situation more locally. With the increased levels of activity, Damen Naval is going to be on the look out for talented employees to join its team. To those ends, the company is looking to strengthen its links to local organisations.

“We’re talking to the local education establishments, for example, about how we can help improve the transition from education to industry. There are certainly going to be a lot of employment opportunities here in the coming years. In fact, the feet replacement activity will be of considerable beneft to the local economy.”

The work taking place will also be highly visible in North Sea Port, he says.

“We will certainly see a lot more activity in the harbour. Where you might have seen one naval vessel every ten years coming for outftting, in the coming years, there may be three or four new navy vessels simultaneously quayside at Vlissingen-Oost.”

I. DAMEN.COM/COMPANIES/NAVAL

Sustainability is a topic that is top of mind at LBC Tank Terminals right now. Amongst the numerous initiatives the business is currently pursuing in this direction is a new project in North Sea Port. Late last year, LBC took over Evolution Terminals, a green energy hub development in Vlissingen-Oost. Here, the company’s new general manager for the location, Alexander Fokker, discusses LBC’s commitment to a greener future.

In recent years, LBC has driven signifcant growth by expanding capacity at its terminals, all located across two key regions: Antwerp-Rotterdam-Amsterdam (ARA) in Europe and the US Gulf Coast. This strategic focus enables the company to meet rising demand while advancing innovation and pushing forward with its sustainability initiatives.

The company has set out a series of ambitions for the coming years. These involve operating best-in-class in terms of safety, service, effciency and, crucially for this story, sustainability. Within this feld, LBC has turned its attention to a number of markets including hydrogen, ammonia cracking, CO2 and pyrolysis oil. It has also set itself some serious goals for its own performance; LBC aims to be CO2 neutral for both scope 1 and scope 2 emissions by 2030.

That the company has enjoyed considerable successes in its work towards the transition is evidenced, for example, by its achievement of Platinum EcoVadis status two years running, and its GRESB (Global Real Estate Sustainability Benchmark) 5 Star rating and sector leadership.

While multiple expansion projects are currently underway, availability of land at LBC’s existing locations is limited,

prompting the search for new opportunities for growth. It was this, combined with its sustainability ambitions, that brought LBC’s attention to North Sea Port and Evolution Terminals.

The Evolution Terminals project aims at the development of a green energy hub for the import, storage and handling of renewable energy products, hydrogen carriers and low carbon fuels. In order to realise the full potential of the project, its owners were on the lookout for a terminal operator to step in to further develop the site. In December 2024, LBC took over.

“The terminal is located in a prime position in the ARA region,” Alexander Fokker, general manager for LBC Vlissingen, says. “The site enjoys availability of land and direct access to the major shipping lanes of the Western Scheldt River and also benefts from its access to the European Hydrogen Backbone (EHB) pipeline network.”

The EHB aims to accelerate European decarbonisation via cross-border collaboration in the supply and demand of hydrogen, based on existing and new pipelines. In the Netherlands, the plan is to convert the extensive network of gas pipelines and infrastructure already in place to the purpose of transporting hydrogen. The developments in Vlissingen will see the pipeline extended right up to the Evolution Terminal, enabling the transfer of hydrogen around the Netherlands, as well as to neighbouring states such as Belgium, France, and Germany.

“In addition to this, the port boasts an impressive concentration of large industry – companies who are going to require access to clean energy and CO2 reduction in the coming years.” It is expected that, in the coming years, demand for hydrogen will exceed the volume of renewable energy available to carry out sustainable electrolysis. Therefore, imports will be required,.

Alexander Fokker joined the company at the beginning of this year, after seventeen years at VOPAK. During the last few years, his work, which included responsibility for the company’s

Vlissingen operation, was focused on the transition to cleaner energies.

“I was keen to undertake a role that allowed me to focus all my energy on the transition. I wanted to be involved in something that contributes to society’s shift towards a more sustainable future, and this project at LBC is 100% aligned with that.”

Right now, LBC is busy with developing the terminal with the aim of being operational by 2028 with the cracker following shortly.

“Most ammonia production facilities are scheduled to come online around that time, so we will be ready for the frst seaborne volumes,” Alexander Fokker says.

When LBC took over the development, work was already at a relatively advanced stage. The terminal is located on a former

industrial site, which required that soil sanitation be carried out. This is now completed. Additionally, the previous owners had already applied for the necessary permits.

“In the coming time, the frst step will be to complete the permit applications, with the main uncertainty related to nitrogen, stemming from recent court rulings. In parallel we will be looking at the engineering and the design, and talking to clients to get commercial coverage. At the same time, the cracker is being developed for the conversion into hydrogen, which is a key part of the project.”

“Despite such challenges, however, I am confdent that the energy transition will ultimately take place. We already see a lot of commitment to it from governments, and industry within Europe.

“There is still a big push from the European Commission for climate neutrality by 2050. This is combined with initiatives at the national level, for instance the Netherlands’ Hydrogen Strategy. This gives me great confdence that the transition is going to happen. Governments are being forced to make decisions. There may be delays along the way, but I frmly believe governments will fnd a way forward.

This will be backed up by the efforts to create a more energy independent Europe, which is very topical at present. Given the relative absence of fossil fuels here, if we want to be more independent, then we are going to have to move towards energy sources such as hydrogen, solar and wind power.

The infrastructure we are building here in North Sea Port is an essential part of that process. I am confdent that, by 2030, this terminal will be up and running and we will be putting hydrogen into the backbone – a signifcant frst step for the growth of this industry.”

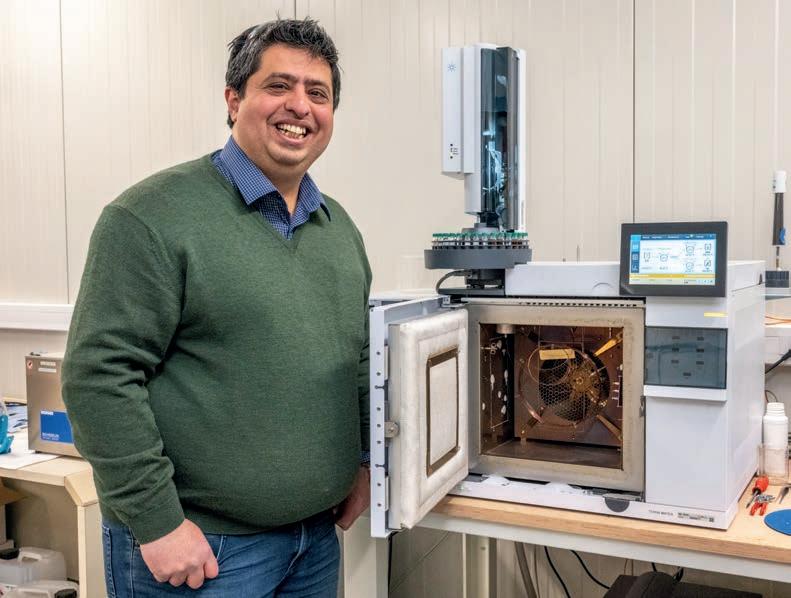

Within the new Ghent Renewables site at Kluizendok lies the pilot plant and laboratory of Terra Mater, a joint venture of Ghent Transport & Storage (GTS) and Dr Kapil Shyam Lokare. Dr Lokare is a world-renowned doctor of Chemistry who, with the support of GTS and North Sea Port, has developed a new technology to create renewable fuel that can drastically reduce worldwide carbon emissions, as it quite literally takes crude oil out of the equation.

No, not your average Chardonnay or gin and tonic, but ethanol and a variety of chemically modifed alcohols are the backbone of almost any product you know: plastics, coatings, soap, cosmetics, and of course, fuels. These alcohols are manufactured from what most people know is the basis of these products: crude oil. This is a problem, as the crude oil reserves will eventually run out, and more pressingly, refning this oil requires a high amount of energy and makes for high carbon dioxide emissions. Producing these alcohols from sustainable, renewable sources instead of crude oil would mean a giant leap forward in reducing carbon emissions and a more sustainable economy. And that is precisely what Terra Mater does.

“So far, Terra Mater is the only company on the planet that can make biobased alcohols for the chemical industry,” says Dr Kapil Shyam Lokare, Co-founder and CEO of Terra Mater. “We manufacture alcohols used by the chemical industry to create all sorts of common, everyday products such as soap or cosmetics. For instance, we are currently in the trial stages of creating surfactants for a well-known producer of ecological soaps and detergents used throughout Europe.”

“If you look at the way these alcohols are being produced today, starting with crude oil, it’s a very lengthy process with a high carbon footprint,” Dr Kapil Shyam Lokare says. “Heating alone must be done non-stop, 24/7, to temperatures of up to 500°C. It’s ridiculous how much energy the chemical industry needs for this, which is why many chemical companies are struggling with the high energy prices. We can offer these companies an alternative, as we have the technology to produce these alcohols, the feedstock for their chemical products, in a green, sustainable way. Not only will this drastically lower the energy costs for these companies, it will also signifcantly reduce their carbon footprint.”

Another absolute game changer is Terra Mater’s fuel technology. Dr Kapil Shyam Lokare explains, “Imagine your current gas station for your everyday cars. You have diesel and two types of gasoline: 95-E5 and 98-E10. Figures 95 and 98 represent the octane-heptane ratio, which both come from crude oil, whereas the E5 and E10 stand for the amount of ethanol used: maximum 5% or maximum 10%. This ethanol is added as a biocomponent in the fuel as it comes from green and sustainable sources instead of crude oil. The amount of ethanol as a biocomponent in gasoline is currently limited because petrol engines cannot run on gasoline with higher percentages of ethanol. However, with our technology, we can create fuel consisting of 100% ethanol. Any petrol-powered engine, old or new, can run on this fuel, and it is all green, as the ethanol comes from sustainable sources such as sugar, beetroot, corn or wheat. Sometimes the ethanol is even recovered from waste streams. Imagine the environmental impact of all gasoline cars running on this green fuel.”

Although Terra Mater’s patented technology can be used for any vehicle running on petrol – cars, trucks, ships, aeroplanes, … – Terra Mater currently focuses on the aviation industry. This is in part due to the Paris Climate Agreement. Following this agreement, the aviation sector has set itself a net-zero carbon emissions goal by 2050. For this ambitious goal to be met, the

industry is in dire need of new technologies.

Terra Mater’s patented 2X Alcohol-to-Jet technology might just be the solution they are looking for, as the facts and fgures of their already biobased, green fuel – as opposed to petrol-based kerosine – are astonishing, as Dr Kapil Shyam Lokare clarifes, “Our fuel weighs less, but has more power. Take for example the fight from Brussels to Sao Paolo in Brazil. That’s a twelvehour fight. If you were to use petrol-based fuel, you would need about 140 litres to fy this distance. With our fuel, you would need 17,000kg less. That translates roughly to 40t less CO2 in the air. And that’s one fight, one way. If you multiply that by the number of fights each day worldwide, you end up with a signifcant reduction in carbon emissions.

“An added advantage is the freezing point of our fuel. It freezes at less than -90°C, whereas traditional kerosine freezes at -47°C. This means that aeroplanes can fy higher with our fuel. If you fy higher, there is less air resistance, which means the aeroplane can fy further with even less fuel. Furthermore, the current worldwide production of ethanol per year is more than suffcient to cover the yearly worldwide demand for jet fuel for the aviation industry. We will never run out, and it is renewable and green. So, now that our technology is ready for large-scale production, our next goal is to achieve a 10% market share in worldwide aviation fuel by 2035. This is why the agreement with the company Petrom is so important, as they will supply the necessary volumes of biobased ethanol.”

The agreement with chemical giant Petrom was signed last November in Sao Paolo, as Dr Kapil Shyam Lokare joined delegates of North Sea Port and the Belgian Royal family on their trade mission to Brazil.

“Brazil is a major trade partner for North Sea Port,” Dr Kapil Shyam Lokare states. “Not only for fruit juice but for feedstock for biofuels as well. Brazil is the number one ethanol producer in the world. With Petrom we have signed a fve-year agreement. They provide the ethanol and fusel alcohols, and in return, they receive our patented technology to produce signifcant amounts of sustainable aviation fuel for local use in Brazil. The volume of ethanol Petrom can provide is large enough to use locally as well as send some produce back to Belgium, where it can be used at Brussels Airport, for example. This deal puts Belgium and Brazil together at the forefront of the Paris Climate Agreement in reducing carbon footprint.”

Whilst also planning to build their very own plant at North Sea Port, Terra Mater is in the process of fnding multiple partners worldwide; established chemical companies that use the technology in return for royalty fees and/or fnished products or feedstock. And there is a very good reason for that, as Dr Kapil Shyam Lokare explains: “This technology can have a huge impact on carbon emissions, not only in Belgium and Brazil, but

worldwide. But there’s only so much I could do in my lifetime if we were to limit productions to future Terra Mater plants only.

The current pilot plant at North Sea Port can produce 1,000l per day, which is not nearly enough to even reach our goal of a 10% market share. But it already took me twelve months to build.

Building a much bigger plant would take about three to four years, taking into account the securing of the land – incidentally, we are hoping that North Sea Port will support us by providing additional land for our project – getting all the permits in place, and fnding a construction company to construct the plant.

Add to this the signifcant amount of money it would take to complete such a project, then you see that I would not be able to build that many plants in the next two decades.

Now compare that to a recent test run we had at the plant of another partner, a chemical company in Antwerp. In December we upscaled our technology for a much larger volume to be produced with their installation. We made 25t of product – very successfully I might add, the chemistry went so smoothly. The entire process took us only fve days, at a much lower cost than building our own installation. Furthermore, the parameters used at our partner’s installations and the results obtained from them give us valuable information, which we can use to keep improving our chemistry and technologies. Moreover, Terra Mater will also receive royalty fees, which we can use to invest back in the company, hire more people, and develop more processes. This way of working enables us to achieve things much faster and go further.”

In the pursuit of realising his vision, Dr Kapil Shyma Lokare has moved around the globe. So how does an Indian-born,

USA-educated, world-renowned Doctor of Chemistry end up founding a company in Belgium? The story behind the technology is quite incredible indeed. “I always wanted to be an academic,” he explains. “I was born in India to a family of textile traders. But going into the family business was not what I wanted. I knew that I wanted to contribute and make a difference in the world, and that to do so, I had to study. After I got my Master’s Degree in Chemistry in Bombay, I moved to the United States and got my PhD at Michigan State University. “It wasn’t until after I had obtained my PhD in Chemistry that the idea for this technology began to form. The frst spark came to me while driving around in Pasadena, California. That year, we saw an immense rise in fuel prices, even by US standards. Driving around in my petrol-fuelled car, I remember thinking: there has to be a better way to do this. Create fuel, that is. I worked at Caltech and Scripps Research Institute at that time, which is such an enabling, stimulating environment for a scientist.

“As the idea for my technology began to grow, I started looking for investors while working for several universities around the globe, in Leiden, Sydney, Berlin … During this time I was trying to fgure out where I could start my company. Before moving to Belgium with my family I must have talked to about 16,000 companies worldwide, and I had gotten 16,000 no’s. But I persevered until fnally, I found my partners here at North Sea Port. One yes was all that was needed, and it came from Yves Bienfet of GTS. We founded Terra Mater in 2020, and then one week later, the COVID-19 pandemic broke out and Belgium went into lockdown.

“Looking back, COVID did enable me to work in solitude and peace on my pilot line, which was not necessarily a bad thing. I made good progress, both on this and in driving here on the empty roads. But it was so diffcult to get components for my installation. In fact, the reactor I used, and am still using now

in the pilot line, was brought to me by my good friend and esteemed advisor Professor Dr Nicola Pinna. I had worked together with him and Professor Dr Joachim Sauer, Angela Merkel’s husband, at the university of Berlin. If it wasn’t for this support the whole project would have been delayed.”

“We are now fnally ready to take off and bring our technology into the world. But there is still quite a bit of work to be done here at the pilot line and in our laboratory, which is in full expansion,” Dr Kapil Shyam Lokare says. “We are continuously theorising, testing and improving our products and processes. As our laboratory – and company – grows, we’ll need more team members. We welcome all applications from those who want to contribute to our cause. We need good engineers, process engineers, but also skilled marketeers. Luckily, North Sea Port has been a great partner to our company. “In fact, North Sea Port has been a big supporter of Terra Mater from the start,” he adds. “I am so very grateful to North Sea Port, GTS and the other investors for believing in me and my dream, and for their support in realising it. This project has been 20 years in the making, from the frst time I had the idea for this technology to signing this deal with Petrom and being ready to use this technology on a large scale. Twenty years ago nobody cared about sustainable energy, and investors ignored my ideas. Now, of course, everybody is rushing to fnd sustainable solutions. People I talked to ten years ago, contact me now to ask if I’m still working on the ideas I pitched back then. But I tell them that if they want to work with me, it has to be with Terra Mater, the company I founded with GTS. North Sea Port will always be the home base of Terra Mater and my technology.”

I. TERRA-MATER.BE

Marifex provides custom on-site fltration and pumping services for a wide range of liquid bulk products, including molasses, de-bunkering, and other viscous liquids. Our experienced team delivers fast, tailored solutions to minimize downtime, whether for onboard pumping, de-bunkering operations, or liquid transfer.

We offer reliable equipment, including pump sets, hydraulic power packs, and centrifugal or positive displacement pumps. Our fexible solutions are available both onshore and onboard vessels, ensuring smooth and safe operations for chemicals, edible oils, biofuels, and petroleum products.

With Marifex, you get reliable service, project coordination, and expertise—tailored to meet your specifc pumping needs.

24/7 Operational Support

As of 1 January of this year, John Dane has started as the new chairman of the Promotion Council North Sea Port. In this article, we get to know him, his vision, and his plans.

For many people in and around North Sea Port, John Dane is not an unfamiliar face. That doesn’t take away from the fact that we are curious about his motives for taking on the chairman role. But frst, an introduction for those who don’t know him yet.

“Many people in the North Sea Port area know me from Kloosterboer (now Lineage Logistics) where I worked for twenty years in Vlissingen,” John Dane explains. “What many people don’t know is that before that, I had worked for about twelve years for what was then called PTT (Post Telefoon Telegraaf; the former government owned Dutch postal service). So, I’ve had a logistics background for quite some time. I started at PTT in 1983 in a role within management & control. In the last four years, until early 1994, I was a policy controller for PTT Post region South West Netherlands. During that period, I got in touch with Jack Kloosterboer, whom I knew from the football feld. He asked me to come work at his company. At that time, Kloosterboer in Vlissingen was still a young company with about 30 employees. I started there as a fnance manager and in 2004 became general manager. Over the years, through acquisitions among other things, the company grew into a successful international player in the feld of handling and storage of mainly fresh, chilled, and frozen products.”

John Dane continues, “After about nineteen years, it was 2013 by then, I thought it was time for a new challenge and that it would be nice to look outside the business world for once. That’s how I came across Hogeschool Zeeland (now: HZ University of Applied Sciences). I started there in 2014 as the managing director of two faculties, but after a few months, I was asked to join the executive board alongside Adri de Buck. In that role, I helped with the transition of the school, during which the organisation was restructured. After Adri de Buck stepped down as chair of the executive board, I remained as the sole executive board member. At the end of 2022, after building a new executive and management board, I resigned from the board.” Over the years, John Dane has built a large network within the region. Not only through his work at Kloosterboer and HZ, but also, he says, because he lives here and has always been involved in various initiatives. “In the years that I have been active, I have consciously sought contact with other people, companies, governments, the education sector, and other relevant organisations. For example, during my time at Kloosterboer, I was often present at the Promotion Council events, which was then called Zeeland Port Promotion Council (ZPPC). And via my role at HZ, I was the chairman of Zeeland Connect, a Knowledge and Innovation Table of Campus

Zeeland, in its early stages. I also participated in the Economic Board Zeeland, where I often met Daan Schalck (the former CEO of North Sea Port).”

Sitting still is not really something for John Dane, which is why he remained active in various supervisory and advisory boards after he resigned as president. And, the passion doesn’t fade away. Since this year John Dane has returned to the port as chairman of the Promotion Council North Sea Port. “Last year,” John Dane says, “I spoke to Henk de Haas, we know each other from Vlissingen, and he told me he was going to step down as chairman. He then asked if I was interested in taking over his position. After thinking about it for a while, I decided it would be nice to return to the port in this role. After a positive conversation with the other board members, in which it became clear what exactly they expected from their new chairman, I made the decision and agreed to step in.” I felt a good connection with the board. Moreover, I still know many people in the port, and the port has always held my attention. It is, therefore, a privilege for me to be able to contribute as chairman to the further development of the Promotion

It is a privilege for me to be able to contribute as chairman to the further development of the Promotion Council and the port area.

Council and the port area. That may sound a bit lofty, but that is what the Promotion Council stands for. Of course, the development of economic activities is primarily the responsibility of North Sea Port and the companies in the port area, but with our activities, we also make a valuable contribution to supporting their efforts. Think, for example, of the many networking events we organise, the role we play at trade fairs as representatives of our port and members, and of course as the publisher, together with North Sea Port, of this beautiful magazine.”

John Dane continues, “Collaboration is something I have always strongly believed in. Working together, the Council, North Sea Port, the companies in the port, and everyone else

involved in the port’s development, such as the education sector and governments, leads to quality and results. In this respect, it is nice to see that, following the merger between the Port of Ghent and Zeeland Seaports, more and more companies and organisations from the Belgian part of the port are becoming members of our council. They also seem to place importance on joining forces. These new members have helped us grow strongly in recent years. This growth certainly obliges us to our members, who all need to feel that they are getting something in return for their membership, but it also offers us opportunities to profle and strengthen ourselves further and more broadly.”

For at least the next four years, we will see John Dane as Promotion Council North Sea Port’s chairman. When asked what will change now that John Dane has become chairman, the answer is clear: not much. “As an organisation, the Promotion Council is already well-established. We are fnancially healthy, well-organised, and our events are appreciated and always well-attended. So, frst of all, I want to continue the policy as it was set by Henk de Haas and the current board. Of course, with my experience and knowledge, I will make some changes here and there, but it is not in me to change everything immediately. Why would I, if there is no immediate need for it? I have taken note of the pillars on which North Sea Port’s strategy is based. These are beautiful pillars full of ambition that we, as a council, would like to contribute to wherever possible. We do this based on our motto ‘Meet, Connect, Promote’. By organising meetings, bringing companies into

As

an organisation, the Promotion Council is already wellestablished. We are fnancially healthy, well-organised, and our events are appreciated and always well-attended.

contact with each other and with potential new parties, and by bringing our members and the North Sea Port to attention wherever possible. Naturally, as a council, we will move with the developments in the market. It is no coincidence that last year we focused on subversion and this year we had a presentation during our frst port and logistics networking event about AI and data science; current topics that we want to inform our members about. I know, in the past, the question was sometimes asked, ‘Is there a need for the Promotion Council?’ Of course, there is a need, if only because on the very day the council ceases to exist, a new similar initiative would emerge, simply because collaboration and working together always yield results. It’s a cliché, but in this case, one plus one still equals three, and I look forward with great pleasure and confdence to supporting the Promotion Council with its collaborative role and its objectives in the coming years.”

I. PC-NSP.COM

Promotion Council North Sea Port offers the parties concerned with the port area a platform to meet, do business and exchange information. It is a business networking organisation that wants to bring everyone involved in North Sea Port together and facilitate stronger connections.

Companies and institutions that have a direct or indirect interest in the enhancing North Sea Port’s position, can become members.

Interested in subscribing as a member? Please call or mail us via T +31 (0)118 491 320 | E info@pc-nsp.com

North Sea Port held its own last year. Seaborne cargo throughput slightly inched up, despite the geopolitical and economic tensions, and the port is counting on Europe to come forward with an Industrial Deal that will pave the way for new growth. Barge traffc reached a new high tide. The United Kingdom emerged as the main trading partner of the port.

Steady as she goes, an order for a helmsman to keep a ship’s current course, comes close to describing North Sea Port’s performance in 2024. Seaborne cargo volumes ended the year at 66.3t million, a notch up (+0.7%) from the 65.9t million recorded in 2023, when maritime traffc took a dive after hitting an all-time high of 73.6t million in 2022. “An encouraging increase, especially given current economic and geopolitical developments and North Sea Port’s distinctive profle as an industry port,” port offcials underlined at the presentation of the year’s results.

Dry bulk and breakbulk up

Dry bulk, the main pillar of port activity, went up 2.1% to reach 35.9t million, accounting once again for more than half – 54%, to be precise – of total transhipment. Breakbulk registered a solid growth of 7%, reaching 10.2t million and 15% of maritime throughput.

Ro/Ro traffc remained stable at 3.7t million and a 6% share. Liquid bulk and containers put a brake on the recovery of maritime throughput. Liquid bulk went down by 3.5% at 14.6t million, but still represents 22% of the total. Container

transhipment lost 18% at 1.8t million in volume (a 3% share of the total) and fell to 175,000TEU in units.

A further shift happened in the import/export balance. Imports still largely dominate the scene, but exports climbed to a record 31.5% share of total transhipment, continuing a slow but steady trend that has been visible over the past ffteen years (exports stood at about 25% in 2010). It is the very frst time outgoing fows pass the 30% bar. This refects the continuing diversifcation of port activities. Looking at commodities, North Sea Port saw increases in agricultural products (+4.9%), ores and metal residues (+5.8%), fertilisers (+5.7%), chemical products (+7%), vehicles and machinery, and other manufacturing goods like cellulose (+14.7%). Solid fuels remained static. Food products (-13%), petroleum products (-4%), crude minerals and construction materials (-3%), and steel products (-11%) decreased.

Among North Sea Port’s main trading partners, the United Kingdom leaped over the United States to take frst place in the ranking. UK trade jumped by no less than 1.2t million to a total of 6.0t million, gaining 26%. “The impact of Brexit seems to be a thing of the past in terms of tons of goods transhipment, and North Sea Port continues to strengthen its role as a port frmly positioned in the heart of Europe.”

The USA came in a strong second, at 5.1t million, despite a 6% loss in volume. Sweden (4.3t million, +8%) and Canada (4.2t million, +3%) jockeyed for third place. Brazil (3.6t million, -19%) took a hit but maintained its position in the top-5. Norway (3.4t million, +12%), Spain (3.2t million, +35%), France (2.9t million, +20%) and Turkey (2.6t million, +8%) all noted strong growth. Russia (2.8t million, -8%) continued to nosedive, still ending the year in the top-ten but at a level that lies 55% lower than the one this country generated in 2021, when it still was the most important trading partner of the port.

Together, the ten largest trading partners generated 38.1t million or 57.5% of maritime trade with North Sea Port. In that trade, globally, Europe accounted last year for 58%, North America and South America 14% each, Africa 7%, Oceania 4%, and Asia 3%.

After falling back to 61.5t million in 2023, inland navigation rose to a new high tide, totalling 64.2t million (+4.4%), a volume very close to the record 64.5t million of 2022. “North Sea Port’s ideal location at the intersection of Western European inland waterways, our excellent port infrastructure, modal shift projects aimed at transporting more goods via inland waterways, and, not least, the distinctive nature of the products handled in the port – specifcally bulk goods – are boosting this sustainable form of transport,” the port states.

The main fow for barging is liquid bulk (34.5t million, +7%). Dry bulk reached 23.3t million (+5%). Breakbulk stood its ground at 4.0t million (-3%). Container volumes declined by 15% to 2,2t million. In units, the drop was 17% to 240,000TEUs. Ro/Ro contributed 0.1t million to the total.

The import-export ratio in inland navigation remained unchanged at 41%-59%.

“The challenges for the years ahead are many – with tensions on the geopolitical front, the slowdown in the energy transition, and possible trade barriers looming. There remains an urgent need for a level and competitive playing feld within Europe and a European Industrial Deal,” port offcals said, looking forward, but they saw no reason for gloom.

“Our cross-border port remains an attractive place for new developments. The new lock in Terneuzen will be fully operational soon and the raft of upcoming investments for 2025 in the energy, offshore, logistics, and circularity sectors – all-in line with our strategic objectives – offer the prospect of additional jobs, value added and fnancial security for the port authority. North Sea Port expects to release 30 hectares of land in 2025, the same amount as in 2024. Once industry regains its momentum – in the context of a European industrial and sustainability policy – the tide may turn, putting us back on a growth track as a leading European port.”

I. NORTHSEAPORT.COM

Sitting comfortably amongst the transitional metals on the periodic table, the naturally occurring chemical element molybdenum was frst isolated in 1781. Its byproduct rhenium was discovered in 1925; the same year, coincidentally, Molymet Belgium was founded. Molymet Belgium, which celebrates its 100th anniversary at North Sea Port this year, is the European leader in molybdenum production.

The extraordinary qualities of this chemical element combined with Molymet’s process expertise and efforts for sustainability put Molymet at the forefront of the energy transition and a greener future.

Molymet Belgium has had a long history with the processing of chemical compounds. Founded in Ghent on 31 March 1925, the company frst focussed on the production of calcium carbide. It wasn’t until the 1940s that the company started producing iron alloys such as ferromanganese. “We started processing molybdenum in 1965, at frst as the iron alloy ferromolybdenum,” says Nele Van Roey, CEO of Molymet Belgium. “We started producing RMC, or Roasted Molybdenum Concentrate, as of 1970. In 2003 the company was acquired by the Molymet Group – a Chilean company – and the processing of molybdenum and its byproducts have been our core business ever since. Our new roasting furnace was built in 2011 and expanded with two more foors in 2016. With its sixteen foors, it is the largest roasting furnace in the world. At full capacity it produces about 17,000t of molybdenum each year, making Molymet Belgium the European market leader.”

Molybdenum is an essential trace element in plants, animals and humans. Although it doesn’t occur as a free element in nature, it is found in mineral ores where it is bound to carbon dioxide and sulphide. Once isolated through oxidation, molybdenum is used for several applications: as a pigment, in electronics, for chemical applications, and even as a micronutrient. When used in metal alloys, molybdenum makes the material lighter, harder, stronger, heat-resistant and corrosion-proof.

“These extraordinary qualities mean the demand for molybdenum and molybdenum alloys is ever increasing

All images courtesy of Molymet Belgium.

worldwide,” Nele Van Roey says. “At Molymet Belgium, we produce technical-grade molybdenum oxide. This is used mainly for high-quality steel products that need to be heat-resistant, corrosion-proof or strengthened for mechanical use. Molybdenum alloys are used, for example, in stainless steel, piping, equipment and bridges, or steel plates used for house numbers. As molybdenum is a light element, it is also often added to construction materials as it strengthens the material. Furthermore, it is used for medical utensils and implants because of its anti-

allergenic properties. For this same reason, molybdenum is used as a substitute for nickel in metals for jewellery and piercings.”

“The molybdenum for chemical applications and electronics is produced by the Molymet Group as well,” she adds. “This is a more purifed product. One interesting application of this chemical-grade molybdenum, for instance, is your smartphone: the adhesive spray between the touchscreen of your smartphone and the actual phone itself contains high levels of molybdenum trioxide.”

“Our roasting furnace at North Sea Port produces molybdenum oxide, or Roasted Molybdenum Concentrate (RMC), with which we create three molybdenum end products for our customers,” Nele Van Roey explains. “The Roasted Molybdenum Concentrate is sold both as a powder as well as pressed in briquettes to avoid dust formation and product loss. In addition,

we use our RMC to produce ferromolybdenum (FeMo), a metal alloy with at least 65% molybdenum. This ferromolybdenum is produced in large blocks which are then crushed into various fraction sizes convenient for our customers.

“Our feedstock is molybdenite, which is the mineral molybdenum disulfde. We receive molybdenite from ores all over the world, but mainly from the US and Chile where it is found as a byproduct of copper ores. The mountain ranges stretching from the north to the south of the American continent –the Rocky Mountains and the Andes – are full of these ores. The copper and molybdenum fractions are separated already at the mines, so the ores we receive already contain a high concentration of molybdenum. We do, however, have the possibility to separate copper from molybdenite at our site, should this become necessary. This leaching installation is on standby and will only be used when needed by the market.”

“Our roasting furnace heats these fractions of molybdenum disulfde to 600°C to 700°C as they slowly pass through all 16 foors of the roasting furnace, while adding certain amounts of oxygen. This process takes the carbon dioxide and sulphur out of the metal. This is necessary as these elements create weak spots in the metal. Additionally, the sulphur that is released during this process is recovered and turned into liquid sulphuric acid, which we sell as a byproduct of our molybdenum production.”

“We have been focussing on recycling our waste streams and a circular production process for a long time,” Nele Van Roey states. “We started producing sulphuric acid in 1989, following the VLAREM II environmental legislation. This installation was meant primarily to reduce emissions of our roasting process by recovering the sulphur from the fue gasses. Over the years, our installation was optimised and now converts 99% of the sulphur from the fue gasses into liquid sulphuric acid. Since

“Molybdenum is a very important element in the green transition,” Nele Van Roey states. “It is used for the refning of biofuels and it makes materials lighter, harder and stronger, which means less material and energy is needed to build a solid structure. Molybdenum is also used for the construction of wind turbines and thin-flm solar panels. Furthermore, the process of isolating molybdenum out of the ores is in itself energy-effcient, as it is an exothermic reaction.” She explains, “The reaction is ignited at the top level of the roasting furnace, but after that, it generates enough heat to become self-sustaining. Sometimes we even have to cool so that the temperature in the oven does not exceed 700°C. Only at the bottom level of the furnace, we give it another blast to evaporate all remaining impurities from the molybdenum oxide.”

this installation always runs together with the roasting furnace, we produce 39,000t (maximum) of sulphuric acid each year, which can be used in chemical applications such as wastewater treatment. The sulphuric acid we produce is sold exclusively to our neighbouring North Sea Port company PVS Chemicals.”

“Aside from the sulphuric acid, this installation also recovers other elements from the fue gasses from the roasting furnace.”

Nele Van Roey says. “Another important byproduct we recover is rhenium, a very rare metal which is an impurity in the molybdenum ores. The rhenium we produce is sold exclusively to our parent company Molymet, which further purifes the rhenium. This valuable metal is used in small quantities in aerospace applications such as aeroplane engines, as it has extraordinary resistance to heat and corrosion.

“We try to recover all byproducts from all our production processes and where possible recycle them as useful feedstock for other applications. From the production of our ferromolybdenum blocks, we recover large amounts of slag, which is crushed into sand used for concrete and asphalt. We recuperate as much molybdenum as possible from our waste streams, and we have a water fltering system that selectively extracts this molybdenum and other impurities, such as selenium, for reuse.”