06 From the Editor

Avoiding the humanoid robot hype trap.

30 New Product Solutions

October’s new product solutions highlight:

Pressure, Temperature, and Level Measurement

Electrical Components

Stainless Steel Piping and Fittings

Color-Coded Tools

42 Packaging Technology

A business launched out of a food truck is supplying restaurants with frozen french fries thanks to automated packaging equipment.

44 Smarter Line Utilization

Getting more from the lines you already have.

Five Strategies for Workforce Engagement

A company’s workforce is the nucleus; without it, the company won’t be able to produce product. Here are five ways food and beverage manufacturers can improve workforce engagement on the frontlines.

08 Tech Today: Water Conservation

More sensing on the plant floor and dedicated workforces are evaluating applications to reduce freshwater consumption and implement water recycling technologies to lower costs.

16 Project Profile: Kettle & Fire

The opening of a new 167,000-sq-ft facility in Lancaster, Pa., will allow the company to unlock e ciencies.

34 Café Spice

The need to improve precision, throughput, and flexibility leads to an automated RaaS solution that o ers greater profitability.

38 Dry Processing

Increasingly e cient equipment is helping manufacturers to maximize savings and get a quick ROI.

Pneumatically conveyed materials heat up, releasing moisture that can cause sweating on storage surfaces.

Xchanger has proven designs that will cool conveying air and eliminate the problem.

n For Gases & Liquids Talk Directly with Design Engineers! n Over 25,000 Units

n Over 25,000 Units

EDITOR-IN-CHIEF DERRICK TEAL dteal@pmmimediagroup.com

ASSOCIATE EDITOR CASEY FLANAGAN cflanagan@pmmimediagroup.com

ASSISTANT EDITOR CHRISTOPHER SMITH chris.smith@pmmimediagroup.com

DIRECTOR OF CONTENT KIM OVERSTREET

CONTRIBUTING EDITORS GRANT GERKE, BRYAN GRIFFEN, MARINA MAYER, PAT REYNOLDS

ART DIRECTOR KATHY TRAVIS

CREATIVE DIRECTOR DAVID BACHO

ADVERTISING sales@pmmimediagroup.com

PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com • 610/251-2579

DIRECTOR, CLIENT SUCCESS & DEVELOPMENT COURTNEY NICHOLS cnichols@pmmimediagroup.com

ACCOUNT EXECUTIVE BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com • 440/564-5920

SENIOR MANAGER, PRINT OPERATIONS LARA KRIEGER lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER JANET FABIANO jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

PRESIDENT DAVID NEWCORN

VICE PRESIDENT, DIGITAL ELIZABETH KACHORIS

SENIOR DIRECTOR, EVENTS TREY SMITH

SENIOR DIRECTOR, DIGITAL MEDIA JEN KREPELKA

DIRECTOR OF MARKETING AMBER MILLER

DIRECTOR, AD TECH AND SEARCH JOAN JACINTO

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI JOSEPH ANGEL

n 75 Countries

n 75 Countries

n Customize to your specs.

n Customize to your specs.

PMMI Media Group

n 10 Std. Models.

n 10 Std. Models.

n For Gases & Liquids

500 W. Madison, Suite 1000, Chicago, IL 60661 Web: www.pmmimediagroup.com

PMMI, The Association for Packaging and Processing Technologies 12930 Worldgate Drive, Suite 200, Herndon, VA 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

CONNECT WITH US @ProFoodWorld www.linkedin.com/ showcase/profoodworld

DERRICK TEAL | EDITOR-IN-CHIEF

There are some robots that are ready for work in F&B, but the hype that surrounds humanoid robots makes it tough to tell the difference between what’s real and what’s fantasy.

According to the hype of 2018, there shouldn’t be a steering wheel in my car right now because our electric vehicles should be autonomously ferrying us around. We can clearly see that hasn’t happened, but it brings up an important point about hype and recognizing what’s immediately available and what’s still yet to come, especially as it relates to robots in food and beverage manufacturing.

The problem is that hype outpaced capability. Though there have been significant advances in robotics, having one working alongside humans or on its own in food and beverage is still at least 5-10 years away. The main reason for this could be any one of the following: cost, safety, capability, availability, but there’s probably an even better reason: intuition.

That was made abundantly clear while on a recent OpX Leadership tour to Boston Dynamics. You’ve probably seen the company’s dog-like robot. During a demonstration, Spot opened and went through a door, which had a lever instead of a knob. While it’s a simple task for a human, we were told that the fairly cumbersome process for Spot took many engineers many, many lines of code to achieve.

In addition to the gripper arm, Spot also has sensors— vision, infrared, lidar, and acoustic—that enable it to scan a facility for potential faults in a line or in the facility itself, essentially working as an inspection robot. But most people probably haven’t seen them in use.

The reason for that is because even though some technology has been worked out, the cost is still a barrier for many small and midsize companies. So even if a humanoid robot had answered all the questions regarding capability and safety (which they haven’t), cost would still be a problem for most. So, there needs to be early adopters for that technology, so why not let the aforementioned auto industry take the lead? I’m sure they’ll get around to removing those steering wheels.

dteal@pmmimediagroup.com

EDITORIAL ADVISORY BOARD

CHRISTINE BENSE

CHIEF SUPPLY CHAIN OFFICER

Turkey Hill

GREG FLICKINGER

CEO American Botanicals

JOHN HILKER

SENIOR VP, OPERATIONS Kite Hill

VINCE NASTI

SENIOR VP, OPERATIONS

Frozen Assets Cold Storage

TRAVIS POWELL

ENGINEERING TEAM LEADER Schreiber

JIM PRUNESTI

SVP, ENGINEERING Conagra Brands

SCOTT SPENCER

CEO

Quality Harvest Foods

TONY VANDENOEVER

PRINCIPAL CONSULTANT

Waterfall Ventures

DIANE WOLF

INDEPENDENT FOOD AND BEVERAGE CONSULTANT

BROOKE WYNN

SENIOR DIRECTOR, SUSTAINABILITY

Smithfield Foods

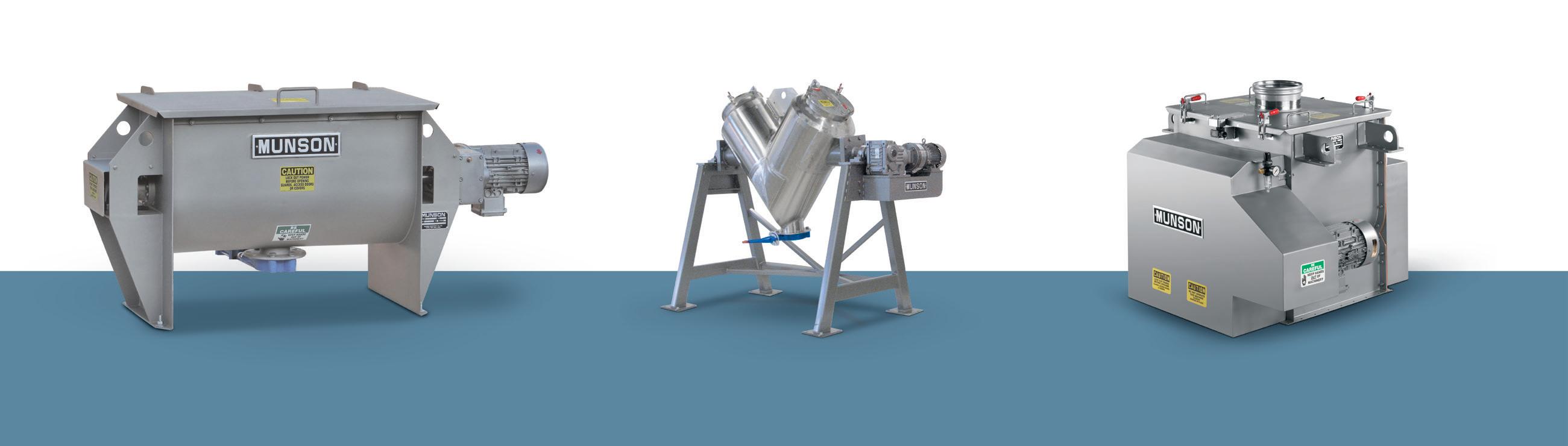

RIBBON/PADDLE/PLOW BLENDERS HANDLE POWDERS TO PASTES

Agitators forced through stationary materials impart shear needed to reduce agglomerates and blend pastes and slurries. Basic industrial units to state-of-the-art sanitary designs with heating/cooling jackets, liquid spray additions, and high-speed choppers/intensifiers. Capacities from 1 to 1,150 cu ft (.03 to 32 m3).

SANITIZE ULTRA-FAST, THOROUGHLY

Smooth internal surfaces free of baffles, shafts and bearings allow unobstructed material flow, plus complete discharge through a gate valve for rapid cleaning or sanitizing of the easy-access interior. Uniform blends are typically achieved in as little as 15 minutes with equal efficiency at fill volumes from 100% to 25% of capacity. Ideal for dry and granular materials.

n 100% Uniform blending and/or liquid additions in one to 2–1/2 minutes

n Total discharge with no segregation

n Ultra-gentle tumbling action (versus blades forced through batch)

n Ultra-low energy usage

n Equal efficiency from 100% to 15% of capacity

n No internal shaft or seals contacting material unlike other rotary mixers

FLUIDIZED BED MIXERS BLEND ULTRA-FAST, GENTLY

MUNSON® Fluidized Bed Mixers feature two shafts with paddles that counter-rotate at high speeds to fluidize material, achieving homogeneous blends in 10 seconds to 2 minutes. Low shear forces minimize friction with little or no degradation and insignificant heat generation. Drop-bottom gates provide rapid discharge. Capacities from 0.21 to 283 cu ft (6 L to 8 m3).

LUMP BREAKERS REDUCE AGGLOMERATES, FRIABLE MATERIALS

Remove lumps and agglomerates from bulk foods. Dual rotors with three-point, singlepiece breaking heads rotate with minimum clearance inside a curved, perforated bedscreen. On-size material exits through bedscreen apertures from 1/32 to 2–1/2 in. (0.8 to 63.5 mm) in diameter. Fits tight spaces between upstream and downstream process equipment.

PIN MILLS REDUCE FRIABLE SOLIDS IN CONTROLLED SIZE RANGES

Coarse to fine grinding of friable powders, flakes and granules into controlled particle sizes at high rates per HP/kW. High-speed rotation of the inner disc creates centrifugal force that accelerates bulk material entering the central inlet of the opposing stationary disc through five intermeshing rows of pins. Desired tight particle size distribution obtained by controlling the rotor speed.

GRANT GERKE | CONTRIBUTING EDITOR

Food manufacturers are adding digital tools and real-time data analytics to find water reuse opportunities.

More sensing on the plant floor and dedicated workforces are evaluating applications to reduce freshwater consumption and implement water recycling technologies to lower costs.

is expected to grow at a 9.25% CAGR from 2025 to 2032, according to Stats N Data. This report encompasses the water/wastewater market; however, water reuse projects have been progressing in the food and dairy industries since 2021. Food manufacturers are adding digital tools and real-time data analytics to find water reuse opportunities. In 2025, the ways food and beverage companies are leading with automation investments and adding new equipment are as follows. Options for dairy and food plants include water reuse solutions through reverse osmosis and membrane bioreactors or monitoring o take to water/ wastewater facilities. Sustainability programs may have driven the first wave of these projects, but food

producers are now leaning on data analytics tools to get more approvals.

Many dairy and food producers see the writing on the wall and are committed to the idea that consumer behaviors for protein and other clean label products are not a mirage. With this confidence, automation investments and digital tools are coming to a legacy or greenfield plant near you.

Jason Pennington, Director of Digital Solutions at Endress+Hauser, was cited in a recent ProFood World feature, stating that food manufacturers are crossing the chasm from digitizing operations to a complete digital transformation of their operations.

IMAGE

While workforce challenges exist in the food and beverage industry, a comprehensive team approach is necessary to identify opportunities.

“When the math was run on the capital price and operating expenses, it came to $13 million total cost of ownership over a 10-year period, which would save the customer about $7 million over 10 years.”

— Shane Wiercinski, Director of Wastewater Solutions, Complete Filtration Resources

“The food industry is undergoing a gradual digital transformation,” said Pennington. “Upstream and downstream processes benefit from connected technologies to solve challenges and aid in track and trace applications, digital documentation for performance verification, and lab record streamlining.” Implementing and acting on data analytics is gaining momentum at an operations level in food and dairy plants.

So, how do food and dairy processors empower staff to evaluate water use? “Spend time reviewing and adding meters to document water users within the facility. This baseline data is essential for water reuse planning,” says Rachel Kloos, Water/ Wastewater Group Leader at ISG . “Detailed tracking leads to 100% accountability for water utilization, often leading to the discovery of leaks or other opportunities for immediate improvement.”

ISG offers consulting services to assist food and

beverage processors with reducing water consumption and initiating water reuse. Once a baseline is established, operations must recognize the low-hanging fruit and avoid any food safety issues.

“Food and dairy processors should begin by identifying which water streams are most suitable for reuse, typically non-product contact streams such as cooling water, boiler blowdown, or rinse waters,” says Michael Ahmadi, Business Development and Water Reuse Specialist at Siemens. “The right technology choice—ultrafiltration (UF), reverse osmosis (RO), membrane bioreactor (MBR)—comes after a clear mapping of risks, hygiene requirements, and potential savings.”

While workforce challenges exist in the food and beverage industry, a comprehensive team approach is necessary to identify opportunities. “Communication is critical,” says Marne Rasinen, Director of Regulatory Affairs at Ecolab. “Water reuse efforts tend to involve multiple teams—quality, operations, sustainability, regulatory—and success depends on all of them working from the same playbook.”

Hormel is an example of teams coming together to implement a water management project at its Dubuque, Iowa, plant. The food giant implemented a reverse osmosis concentrate (ROC) solution in this plant, reusing water from boilers and replacing cold, soft water from a municipal water/wastewater plant for all of its retort cooking.

“At the plant level, we developed strategic energy management teams that promote our goals, our mission, which is energy conservation and cost savings projects,” said Randy Thole, manager of plant engineering for Hormel Foods during a ProFood World webinar.

The water reuse project did have risks and challenges. “Water pressure was always there with city water,” said Thole. “Now, using a pump system, supply control is critical, and additional control helps monitor the system continuously. We added multiple backup systems in case one would fail.” For Hormel, the ROC project paid off by reducing water use by 7.28 million gallons per year in the first phase, representing an 8% reduction for water and a 10% reduc-

pinch of

Too many cooks spoil the broth. That’s why our level and pressure measurement technology focuses on the essentials: reliability, efficiency and knife-edge precision. With the latest technology, you always get the values you need, wherever you are. So that you can concentrate fully on your personal recipe for success. Everything is possible. With VEGA.

tion for wastewater.

Hormel utilized an outside firm to assist with the Iowa project; however, applying reuse solutions across multiple dairy plants is not always feasible. The distance between the retort cooking equipment and ROC technology for Hormel in the Iowa plant was ideal. “The starting point for food processors is conducting a comprehensive water mapping exercise—identifying where water enters and how it’s used in various operations,” adds Rasinen.

The Hormel application reveals how to reduce water usage and also achieve cost reduction by avoiding water/wastewater treatment. “It’s not uncommon for dairy plants to be paying upwards of $100,000 to $200,000 a month or more in municipal wastewater surcharges due to high organic loading,” said Shane Wiercinski, Director of Wastewater Solutions at Complete Filtration Resources, Inc. in a recent webinar.”

Wiercinsk advocates for RO, MBR, or anaerobic MBR co-located solutions for high-volume dairy and food processing plants. Complete Filtration Resources, Inc., a designer and manufacturer of membrane systems, showcased a feasibility study on a company that incurred water discharge costs of $2

According to ISG, recycled water is often used as makeup water for cooling towers and boilers. However, these streams are frequently unmetered, making it hard to measure usage and build a strong case for the feasibility of reuse.

s

The most effective organizations are those that integrate water data into their broader ESG reporting and operational dashboards to drive decision-making, identify investment opportunities and engage internal stakeholders across departments.

million per year.

“We ran an economic analysis to compare anaerobic MBR versus outsourcing treatment to the city,” said Wiercinski. “The MBR solution would treat the waste, wastewater, and get it below their surcharge limits, and simultaneously give them the opportunity to generate valuable biogas.” The study captured capital equipment, the cost of chemical consumption each year, sludge, haul-outs, and any additional costs associated with wastewater treatment. Also included in the feasibility study was the creation of biogas for a combined heat and power (CHP) unit to generate electricity for the wastewater plant application.

“When the math was run on the capital price and operating expenses, it came to $13 million total cost of ownership over a 10-year period, which would save the customer about $7 million over 10 years,” cited Wiercinski.

Additionally, drying volatile solids in wastewater is an energy-intensive process. “One important aspect is the integration of water and energy management,” says Siemens’ Ahmadi. “Water reuse is not only about saving water but also about reducing the energy demand associated with treatment and heating.” Siemens is utilizing digital twin technology

Employee-owned and operated with a legacy spanning over 180 years, ROSS is synonymous with innovation and quality in manufacturing mixing, blending, drying, and dispersion equipment.

Our commitment to excellence is evident in our five state-of-the-art manufacturing facilities across the U.S.A., complemented by an 8,000 sq. ft. Test & Development Center and three international plants, ensuring we serve customers worldwide with precision and reliability.

From standard models to custom solutions tailored to your unique processing needs, ROSS mixing equipment is engineered for decades of trouble-free operation, empowering industries and fostering economic growth.

Proudly engineered and fabricated in the USA, we’re driving the future of manufacturing, supporting American jobs, and fortifying supply chains for generations to come.

to connect water treatment directly with energy systems, enabling customers to measure, optimize, and scale their reuse strategies.

In addition to energy monitoring at the system software level, advanced automation and controls are being added to equipment in the craft brewing segment. For brewers, chilling equipment is integral to the yeast fermentation process and must be carefully controlled; excessive heat can lead to unwarranted flavors during fermentation.

G&D Chillers partnered with Siemens to integrate advanced controls into its line of vertical and horizontal chillers, and recently Barnum Mechanical Inc. recommended this solution to Russian River Brewery in Windsor, Calif. Barnum Mechanical installed a custom-designed G&D chiller at the brewery, which would reduce water consumption at a facility producing as many as 35,000 barrels annually.

The chiller at Russian River Brewery is a hybrid system that utilizes both air and reclaimed water from the facility’s MBR, which removes 99% of all contaminants from industrial wastewater. The reusable water is used throughout the plant, including in clean-in-place (CIP) systems. The new chiller also reduces energy consumption by up to 40% com-

pared to other similarly sized systems.

“The chiller’s control system constantly economizes the evaporative condenser,” says Jared McClintock, Business Development Engineer at Barnum Mechanical. “It has the difficult challenge of using as much free cooling from the Cambrian MBR water while still outputting the targeted temperature setpoint. The better the control system is at doing this, the greater the amount of energy saved.”

While significant capital investments yield substantial results, an engaged workforce is crucial to identifying reuse opportunities. “It’s helpful to think in terms of complete water circularity, not just wastewater reuse,” says Ecolab’s Rasinen. “There’s a lot of value to be gained upstream—reducing rinse steps, using more effective cleaning solutions or optimizing CIP cycles through digital tools.”

Small investments in digital tools and the addition of meters can initiate a program. According to ISG’s Kloos, “Accurate and detailed tracking leads to 100% accountability for water utilization, often leading to the discovery of leaks or other opportunities for immediate improvement.”

The new 167,000-sq-ft facility in Lancaster, Pa., will allow the company to unlock e ciencies.

KETTLE & FIRE announced the opening of KettleWorks, a new state-of-the-art manufacturing facility in Lancaster, Pa., the company’s first self-manufacturing venture. The company says that KettleWorks will allow it to unlock significant e ciencies that will lead to higher levels of service while maintaining high quality.

Kettle & Fire partnered with High Real Estate

Group to bring KettleWorks to Lancaster’s Greenfi eld development. KettleWorks is a new build designed to meet Kettle & Fire’s standards and help accelerate growth and innovation in the larger broth category. Central Pennsylvania was chosen for the new 167,000-sq-ft facility because of its manufacturing environment, qualifi ed labor pool, and logistics and supply chain e ciencies.

s

Founders Nick Mares (with scissors at left) and Justin Mares (with scissors at right) cut the ribbon to open KettleWorks.

KettleWorks is Kettle & Fire’s first self-manufacturing facility, and it is expected to provide the company with significant efficiencies.

The development comes during a significant growth period for Kettle & Fire, including having recently secured a $43 million secondary buyout— led by strategic partner Colter Ventures—focused on growing consumer demand, strengthening resources in innovation, and strategically investing in supply chain capabilities, including self-manufacturing.

Kettle & Fire secured a $43 million secondary buyout to grow consumer demand, invest in supply chain, and self-manufacture.

Since its inception, Kettle & Fire has created bone broths, broths, and soups that “maximize nutrient density and flavor while positively impacting the food system.”

“In the decade since we first introduced Kettle & Fire, we’ve seen exciting changes in the bone broth and broth category,” says Justin Mares, Co-founder of Kettle & Fire. “More than ever, consumers are taking their health into their own hands and looking for options they can trust to be part of that journey. Because health is in our bones, Kettle & Fire has

“Self-manufacturing is one of the most important steps an emerging brand can take to ensure consistent service for its customers and improve its ability to partner with retailers, distributors, and other partners. By opening KettleWorks, we unlock signi cant capabilities which will enable us to deliver higher service levels and quality.”

— Brian Hack, CEO of Kettle& Fire

Founded in 2014, Kettle & Fire is a shelf-stable bone broth brand on a mission to make foods that nourish people and the planet.

Project Owner: Kettle & Fire

Location: Lancaster, Pa.

Facility Size: 167,000 sq ft

Product Types: bone broths, broth, and soups

Investment: $43 million

Strategic Partner: Colter Ventures

Focus of expansion:

• growing consumer brand

• strengthen resources in innovation

• investing in supply chain capabilities

been a trusted partner for health and wellness seekers since day one. Now, by owning and operating our production facility, we can continue to position the brand for strong growth while delivering products to nourish our consumers.”

At KettleWorks, Kettle & Fire products will be made by following a process that includes slow simmering bones and nothing artifi cial to deliver nutrient-dense products. The company says it sources only the highest-quality ingredients and performs rigorous quality checks before, during, and after the slow simmering process.

“Opening KettleWorks marks a signifi cant milestone in our company’s history,” says Brian Hack, CEO of Kettle & Fire. “Self-manufacturing is one of the most important steps an emerging brand can take to ensure consistent service for its customers and improve its ability to partner with retailers, distributors, and other partners. By opening KettleWorks, we unlock signifi cant capabilities which will enable us to deliver higher service levels and quality.”

ustom-built. Family-owned. uilt to perform. Let’s find the right belt for your line!

A company’s workforce is the nucleus; without it, the company won’t be able to produce product.

PRIORITIZING RECRUITMENT and onboarding are paramount when it comes to workforce engagement. Closing the skills gaps is important. Providing the right training programs are necessary. Even implementing emerging technologies like AI can make an impact.

That’s because a workforce who feels valued in turn becomes more productive. And with more productivity comes the ability to produce quality food in a safe and e cient manner.

Here are five ways food and beverage manufacturers and solutions providers can improve workforce engagement on the frontlines.

in employees also emphasizes

operations and toolkits.

Employees want to feel supported, valued, and coached. They want to be heard and be given opportunities to grow. They want to know they matter.

That’s why Redzone’s worker-first technology empowers employees to take pride in their work and make a significant business impact.

“Younger people are used to managing almost all of their lives on smartphones or tablets, so when they are given a clipboard and a radio, it feels like stepping back into the stone age. Younger people—the future—want to work similarly to how they would book a flight, call an Uber, communicate with friends,” says Blake Strickland, VP of Product, Redzone from QAD

Investing in employees also emphasizes imme-

diate productivity, connects teams digitally, and simplifies daily operations and toolkits.

Investing in the workers includes providing predictable schedules, clear feedback and recognition and a safe and respectful work environment.

Manufacturers can also boost engagement through investing in the knowledge of their employees. Is a certain employee looking to advance in his/her career and may want additional training in another area of the facility/company? Is a newer employee looking to be mentored? Or is a certain employee just looking for any sort of feedback to improve his/her skillsets? Getting to know your workers on a personal level and understanding their wants, needs, and goals is one of the greatest investments management can make.

Taking care of your employees today and investing in their future is key to ensuring a fully engaged workforce.

Gone are the days where the CEO just sits behind a desk. High-performing CEOs are visible and can sometimes be seen walking the production floor. It’s these leaders that exhibit the ultimate in workforce engagement.

“When managers and executives spend time on the floor, listening actively, and following through on concerns, employees feel seen and heard,” says Bryan T. Gri en, President, Gri en Executive Solutions LLC. “Engagement thrives in environments where people feel that their voice counts.”

Oftentimes, companies will implement technology to hire, onboard, and train employees. Depending on the technology, it may be di cult to understand, may not be available in the right language, or may only cover certain parts of the training but not all.

Emerging technologies like AI and generative tools such as ChatGPT have a dual impact on workforce engagement, Gri en says.

“On one hand, they can enhance engagement by reducing repetitive tasks, streamlining communication, and improving access to information. For example, frontline workers can use AI-powered interfaces to troubleshoot equipment, access SOPs instantly, or even generate real-time reports, saving time and boosting confidence,” he adds. “But on the other hand, there’s growing anxiety about how these technologies will reshape jobs or potentially reduce the human element in manufacturing. If companies adopt AI without engaging employees in the conversation, without upskilling or involving them in the change process, it can erode trust and drive disengagement.”

However, emerging technologies are not a standalone solution.

“AI-powered tools can answer so many questions and give support material for operators and technicians but are not able to instill the tactical training that is needed for these roles,” says Ashley Donohoo, VP of Sales, Multi-Skill Training Services. “Conversational bots like ChatGPT can serve as instant support coaches, explaining safety steps or equipment procedures in plain language—this tool works extremely well within our blended training approach.”

For its part, Redzone’s upcoming launch of Champion AI is designed to give frontline teams even more autonomy with a suite of digital agents.

“The Productivity Champion can predict a run’s top loss and create an action to address it, empowering teams to solve problems on their own. This is like having a full cross-functional team in every employee’s back pocket, constantly working to make things better,” says Strickland. “If your workforce only has access to outdated technology while performing their jobs, they will become disengaged and may even seek a new employer that utilizes more advanced technologies.”

At the Little Potato Company, transformation started with visibility. For the potato processor, it was about providing real-time targets or clear overall equipment effectiveness (OEE) metrics.

The Little Potato Company implemented Redzone Software from QAD, where in just weeks, the team saw 13-point and 18-point OEE improvements across plants, reduced overfill by tracking weights, and streamlined compliance by eliminating paper checks, driving a 4% productivity uplift and a 5% reduction in overfill potatoes.

Likewise, Taffy Town implemented QAD Redzone Connected Workforce Solution, which reduced production lead times from 10 to 3 weeks over 9 months; drove production output by 33% and achieved an overall equipment effectiveness uplift of 48%. It also reduced overtime to 0%, saving $360,000; increased staffing by 20%; decreased equipment downtime from 3-4 monthly breakdowns to zero over the past three months; and reduced food safety audit timeframes from 3 to 1.5 days.

“[A main challenge is] old legacy reporting systems (either poor digital or paper-based) that make it feel like you are disconnected from the overall goal. How does the person know if they are on target to the expectation of the leadership group? Most people want to do a good job but never know if they make the finish line,” says Strickland. “Encourage managers to create environments where people want to win, not just come in, punch a clock, and go home.”

For some solutions providers, it’s about equipping leaders—from the shop floor to the C-suite—with practical tools and coaching that foster stronger engagement.

For example, the New Manager Training Series, developed by Gri en Executive Solutions, helps emerging leaders build confi dence and consistency in their day-to-day leadership, Gri en says.

“We also o er customized leadership workshops that tackle communication, feedback, trust-building, and accountability, all key elements for frontline engagement,” he adds. “For companies seeking broader cultural impact, we provide executive coaching and organizational development programs that align leadership behavior with workforce expectations. I’ve also developed practical morale tracking tools and onboarding frameworks tailored specifi cally for food and beverage manufacturers.”

Customization of training is pertinent to an individual’s position.

“We’ve found companies using in-person training accompanied by support video snippets for reference are far more e ective than generic online modules,” says Donohoo.

That’s why, for Multi-Skill Training Services, it’s about keeping it simple but e ective. As a result, it created focused training solutions that directly relate to the skills needed to perform the job, using real-world components on simulators that can be taught both virtually and in person. The goal is to identify the tasks, assess the current knowledge and create direct training to fill those gaps.

“We have launched a blended training approach that allows technicians to learn ‘the why’ on a modular digital training platform with mobile-friendly micro-lessons in multiple languages, followed by in-person, hands-on training that reinforces these skills and confirms the skill has been obtained,” says Donohoo. “A customized assessment tool that allows each client to build the framework for paths-to-progress, where employees can chart clear advancement routes by obtaining more technical skills.”

A company’s workforce is the nucleus; without it, the company won’t be able to produce product. Taking care of them today and investing in their future is key to ensuring a fully engaged workforce.

ProFood World Half Page Ad_3.pdf 1 9/3/2025 6:08:35 PM

Our LTH (Large Tube Housing®) is a powerful magnetic separator that incorporates 3 inch diameter rare earth tubes into our proven Drawer-in-Housing configuration for optimum ferrous metal separation for difficult flowing products.

JAX Halo-Guard FG-PM is an NSF H1 grease for heavily loaded, slow-moving equipment, like pellet mills. Formulated with a calcium sulfonate thickener and heavy base fluid, it delivers extreme pressure and anti-wear performance as well as advanced rust and corrosion protection. It maintains mechanical stability under severe stress, resists shear breakdown, even in extended high temperatures, and offers superior thermal and oxidative stability. Micronox technology provides additional microbial protection to the lubricant.

JAX, Inc. | jax.com

Nationwide Boiler’s mobile steam plants provide rapid and reliable temporary steam solutions for industrial and commercial facilities. These self-contained units, ranging from 47.5 to 1,000 HP, are preengineered, fire-tested, and maintained for reliable operation, with ultra-low NOx models pre-permitted for expedited use in strict air quality districts. Built for fuel flexibility and quick connection, the plants ensure uninterrupted operations for planned maintenance, increased capacity, or unexpected outages.

Nationwide Boiler | nationwideboiler.com

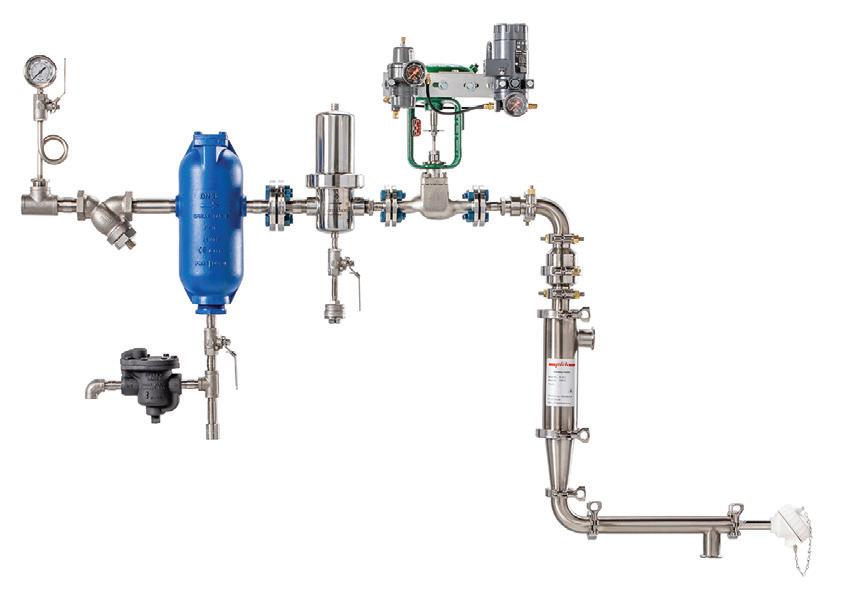

The ThermOmegaTech ITV is a self-operating, easy-to-install valve designed to address the challenge of high-temperature effluent discharge in industrial settings. Utilizing a proprietary Thermoloid thermal actuator, the ITV automatically injects cold water into drain lines when effluent temperatures exceed a pre-set point, preventing damage to PVC piping and ensuring compliance with plumbing codes. As temperatures drop, the valve modulates to shut off cold water flow, conserving resources and minimizing water waste.

ThermOmegaTech thermomegatech.com

Vibra Screw’s Bulk Bag Unloader series offers hygienic, dustfree handling and discharge of food-grade bulk bags, available in eight models to suit all bag styles and installation types. Features include a bulk bag support hopper that seats and seals bags for safe access, integrated two-point dust collection, and a no-spill collection hopper to prevent contamination. Options include vibrating discharge systems or pneumatic massaging paddles for difficult-to-flow materials and models with load cells and batch weighing capabilities for precise measurements.

Vibra Screw | vibrascrew.com

The Pick Sanitary Heater/Jet Cooker provides continuous cooking with direct steam injection, which delivers rapid, uniformheating, reduces energy costs, and minimizes maintenance. The system instantly achieves set-point temperature and gently cooks products, such as starches, using its low-velocity, variable-orifice steam injector and helical flights, ensuring intimate blending of steam and product without shear or degradation. Designed to meet 3-A sanitary requirements, it provides precise temperature control, 100% energy efficiency, and reliable in-line heating for food and dairy processors. Pick Heaters | pickheaters.com

PSR Automation’s PI5000 Pump Inserter is an efficient, servocontrolled machine designed for automatically inserting and partially tightening pumps and triggers onto bottles. Built for robust, high-volume production, it features an automatic pump sorter and integrated bottle detection sensors, ensuring consistent operation. With a moderate throughput of 70 bottles per minute, its 15-minute changeover system minimizes downtime, which enhances overall productivity and reduces manual labor in bottling lines.

PSR Automation Inc. | psrautomation.com

The Gericke USA FEEDOS M is designed for versatile and accurate feeding of a wide range of dry solids, including powders, pellets, and granules. Its interchangeable feed screws can be swapped quickly without tools to match the specific properties of the material being processed. The feeder o ers three screw designs: the Helix for light materials like cocoa powder, the Helix with Center Shaft for heavier materials such as salt, and the Full Flight for hygienic applications. This adaptability allows the system to handle various flow rates and material types.

Gericke USA gerickegroup.com

Designed for complex, high-viscosity materials, the ROSS VMC-300 integrates three independent agitation systems: a 30 HP anchor with scrapers for systematically wiping the vessel walls, a 50 HP high-speed disperser for e cient powder wet-out, and a 50 HP axial flow turbine for intense blending. Constructed from stainless steel 316, it has a 300-gallon capacity and operates under full vacuum and pressure up to 300 degrees. A userfriendly touchscreen o ers precise control over mixing parameters, and a dual-post lift system with safety interlocks ensures safe operation.

Charles Ross & Son Company mixers.com

Key Technology’s COMPASS is designed specifically for potato chips, tortilla chips and similar snack foods. The belt-fed system uses an advanced sort engine with multispectral sensors to identify and remove defects like dark spots and foreign material to protect food safety and product quality. The sorter is engineered for easy operation, with a user-friendly interface and automatic belt tracking, and its sanitary design allows for quick cleaning and extended run times. Data analytics software provides insights into production, helping to optimize line operations.

Key Technology | key.net

DERRICK TEAL | EDITOR-IN-CHIEF

The need to improve precision, throughput, and flexibility leads to an automated RaaS solution that offers greater profitability.

CAFÉ SPICE , a manufacturer of premium ready-to-eat meals, has built its reputation on authentic flavors, strict quality control, and presentation standards that match its culinary ambitions. But by 2023, its production model—especially at the company’s New Windsor, N.Y., facility—was straining to meet demand.

“Even before COVID, labor was a big challenge, and post-COVID it became even harder to source and retain talent,” explains Virgilio Felix, Chief Operating Officer at Café Spice.

Additionally, the company was losing money because workers would over-portion meals to avoid filling an underweighted tray that would get rejected. “One ounce over per 16-oz meal doesn’t sound like much—until you calculate it annually. That’s hundreds of thousands of dollars literally given away,” says Felix.

When Café Spice opened its newer facility in Beacon, N.Y., the company saw an opportunity to go beyond typical end-of-line automation and target portioning and pre-packing.

Before automation, workers at Café Spice portioned food by hand into trays moving slowly down the line, pausing to weigh deposits to ensure accuracy. While effective for consistency, this method kept throughput low and created bottlenecks. Placement precision was critical: The company’s signature two-compartment tray separates rice from curry to maintain freshness and shelf life. Overfilling could cause curry to spill into the rice compartment, requiring rework and adding labor touches.

To start, Café Spice added a conveying system into its process. This initial step allowed the integration of Chef Robotics’ machines into the line, which changed both the speed and quality of production.

The automated system had to match the dexterity of a skilled worker, handle a wide range of ingredients, meet hygiene standards, and allow for rapid changeovers in a high-mix environment.

For example, each Chef robot occupies roughly the same space as a human worker and fits directly into the line without costly retrofits. Robots meet ISO 10218 standards for safe operation alongside human workers, enabling blended work cells.

The system enables rapid changeovers because it requires only 120V AC power and a pneumatic quick-disconnect for operation. Each unit is on castors that allow it to be moved where needed on the line with leveling feet to secure the unit in place. Café Spice can use a proprietary quick utensil changer to switch between SKUs in under 10 minutes. This is essential for a high-SKU manufacturer where downtime directly impacts output. Chef also engineered a custom utensil to handle varying curry densities and suspended proteins without breaking down textures or damaging rice grains.

This means Café Spice can deploy robots quickly; Chef’s units were running in production within two weeks of conveyor installation.

Stainless steel strength. ±0.20% accuracy.

Built to perform season after season.

AI-based perception courtesy of a dual RGB and depth camera system creates a “topographical map” of food in pans, allowing the robot to choose optimal scoop points. This is critical for handling ingredients like chicken tikka masala with large protein pieces or dal with lentils suspended in sauce. Integrated scales weigh each deposit in real time, making adjustments in as little as three seconds without halting the line.

The robots then place food into multiple compartments within a tray, ensuring clean separation of rice and curry. This preserves Café Spice’s visual presentation and reduces the need for manual cleaning before sealing.

The continuous weighing feature eliminated the need for periodic spot checks, while ingredient-level data analytics gave Café Spice real-time visibility into every deposit, accessible from anywhere. Says Felix, “It’s hygienic, accurate, and gives us insight into every deposit for trend analysis.”

Instead of a traditional capital purchase, Café Spice adopted Chef Robotics through a robotics-as-a-service (RaaS) subscription. This model includes hardware and software, all upgrades, field support, and maintenance for a flat monthly fee. It also allowed the company to start small— deploying four robots—before scaling to eight and now sixteen across two fully automated lines.

The RaaS approach reduced financial risk, avoided large upfront costs, and provided the flexibility to expand capacity in stages. This incremental rollout also gave Café Spice time to integrate automation into its workforce culture, redeploying rather than replacing staff.

The impact went beyond the numbers. Automating portioning removed one of the biggest sources of repetitive motion injuries. The mobility of Chef robots gave production managers the ability to reconfigure lines as demand shifted, without expensive reengineering.

Chef Robotics Founder and CEO Rajat Bhageria emphasizes that this kind of flexibility is key in food manufacturing. “Many plants have the demand; they just lack the labor,” he says. “By increasing throughput 2–3x without more people, you not only meet demand but often create more jobs anyway.”

For Felix, the transformation is about resilience: “Automation wasn’t about replacing people; it was about scaling our business, protecting our workers, and ensuring product quality at every step.”

By integrating AI-based robotics upstream, Café Spice has shown that high-mix food production can achieve the same precision, flexibility, and throughput as more uniform manufacturing without compromising the standards that define the brand.

• THROUGHPUT: Increased from 10–15 trays per minute to an average of 30, with the capability to reach 40.

• LABOR PRODUCTIVITY: Staffing per line reduced from 8–10 to 3–4, delivering a 60% increase in productivity and freeing workers for other roles.

• FOOD GIVEAWAY: Reduced from 9.19% to 3.05%, a 67% improvement.

• ACCEPTANCE RATE: Improved from 75% for human-assembled trays to 91% for robot-assembled trays.

MARINA MAYER | CONTRIBUTING EDITOR

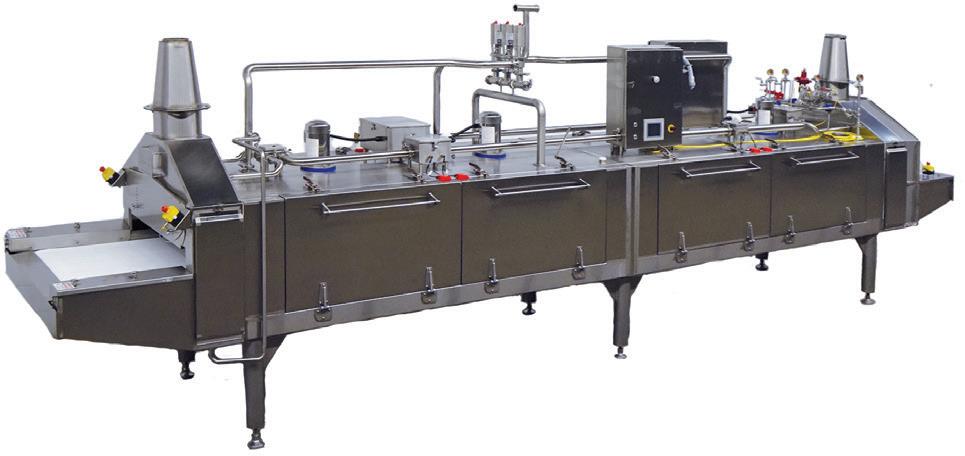

Increasingly efficient equipment is helping manufacturers to maximize savings and get a quick ROI.

IT COMES

, there are some common challenges dry food processors face. For instance, where in the line can you be more energy efficient? How do you become more energy efficient without impacting other areas of the line/plant? And what does the overall return on investment look like?

All challenges aside, achieving—and maintaining—energy efficiency of any kind is paramount. Not just because customers are paying more attention to how their food travels through the chain, but also because certain rules and regulations are coming down the pipeline, leaving manufacturers with no choice but to become more energy efficient.

The Witte Company, for instance, manufactures Fluid Bed Dryers, which are considered one of the most energy-efficient types of dryers available.

“The drying process is often one of the more

energy-intensive steps in dry food processing; any efficiency gains found here can go a long way,” says Tyson Witte, President, The Witte Company. “The first step in addressing dryer efficiency is to do a thorough examination of current sizing and operation to be sure that basic measures are not being overlooked. Many times, older pieces of equipment are used in a process they were not necessarily designed for, and time was never taken to evaluate proper equipment settings. When specifying new equipment, increased energy efficiency can be found with exhaust air stream heat recovery. Heat recovery can be achieved by recycling warm exhaust air as well as utilizing fresh air heat exchangers to heat incoming air to the dryer, lessening the load on the inlet air heaters.”

To drive maximum energy efficiency in a fluid bed drying process, features such as adjustable product retention time and exhaust air heat recovery can be both used to drive overall dryer efficiency, Witte says. That’s because maximizing product retention time inside a dryer allows more heat to be transferred from the heated air stream to the product, increasing efficiency.

The Xchanger model shown is used to cool, dehumidify, reheat, and filter low-pressure conveying air.

For its part, Coperion K-Tron expanded its state-of-the-art test center at its Niederlenz, Switzerland, facility. This strategic move is designed to enhance the company’s capabilities, particularly for tests involving materials that require containment, and will be equipped with the latest technology and equipment, ensuring the highest standards of safety and efficiency.

Added equipment will feature advanced containment systems for handling all types of materials,

Certain rules and regulations are coming down the pipeline, leaving manufacturers with no choice but to become more energy efficient.

including an airlock system with filtration, ensuring the safety of both the testing process and the staff as well as the environment.

Coperion also enhances energy efficiency in plastic processing through new process designs, such as an energy-efficient ABS blend extrusion process using its ZSK twin screw extruder. To date, Coperion extruders are said to provide energy savings of between 8-14%, on average.

Herbold Meckesheim, a brand of Coperion, debuted the SMS 80-200 Granulator, which integrates energy-efficient double cross-cutting action and pre-adjustable rotor and bed knives to produce a high-quality regrind with minimal fines and consistent particle size distribution.

• The U.S. Department of Energy (DOE) issued a final rule on new energy conservation standards for Commercial Refrigerators, Freezers, and Refrigerator-Freezers (CRE), with the compliance date of Jan. 22, 2029. U.S. commercial refrigeration and cooling for dry processing facilities involves specialized temperature and humidity control to protect shelf-stable ingredients and finished goods. Similarly, new efficiency standards for Walk-In Coolers and Freezers (WICFs), based on the updated Annual Walk-In Efficiency Factor (AWEF2) metric, follow this same timeline, with compliance by Dec. 31, 2028.

• Under California Climate Investments, the Food Production Investment Program (FPIP) continues to support food producers in improving energy and emissions performance through grants. For fiscal years 2022–2024, more than $26 million has been allocated.

• As it pertains to the European Union regulatory landscape, the Industrial Emissions Directive (IED)—amended in 2024 by Directive 2024/1785—continues to require use of Best Available Techniques (BAT) to reduce emissions across industrial processes, including dry food processing.

Coperion’s test center expansion will allow the company to conduct more comprehensive and diverse testing, providing customers with a broader range of solutions for their specific material handling needs.

The Xchanger system from Xchanger Companies, Inc. is an energy-efficient solution that saves buildings 19.3% in HVAC electricity and 25.2% in gas yearly with its extra pressure drop and 37.4% in HVAC electricity and 7.7% in gas without added pressure drop, according to research conducted at the University of Maryland’s Maryland Industrial Partnerships (MIPS).

Meanwhile, Choice Organic Teas installed the stainless-steel Munson blender from Munson Machinery to eliminate waste. The Munson blender uses a gravity-driven mixing process that employs internal mixing flights to produce a tumble-turn-cut-fold mixing action said to yield 100% batch uniformity in less than three minutes using minimal energy.

When it comes to energy efficiency overall in relation to impending regulations, equipment manufacturers are still challenged with how to invest in the equipment needed to keep up with customer demand alongside meeting all of the potential energy savings possible.

“In an ever-evolving processing environment, making sure drying equipment is properly matched to its current process and operating at its maximum potential can go a long way towards increasing energy efficiency,” Witte says. “Taking the time to ensure that basic steps are not being overlooked is often all that is needed to make a big impact on a dry food processors bottom line.”

PAT REYNOLDS | CONTRIBUTING EDITOR

A business launched out of a food truck in Phoenix is now supplying restaurants galore with 5-lb bags of frozen french fries thanks to automated packaging equipment.

ADECADE AGO Flip Isard started selling Belgian-style fench fries on the streets of Phoenix out of a food truck. Appropriately enough, he called his operation “Frites Street”—i.e., “pomme frites” (French for “french fry”) that are sold on the street. Turns out his fries were so darned good that local restaurants wanted them, so by 2018 he sold the food truck and began selling frozen 5-lb bags of gourmet fries, cottage fries, and breakfast potatoes to foodservice institutions, restaurants primarily. Demand grew so steadily that by 2024 some kind of automated weighing and bagging was essential. So in the second quarter of 2024, his Scottsdale, Ariz., facility put into production an MFT 7 Ultimate Range vertical form/fill/ seal machine integrated with an MHW 14-head combination scale. Both are from Maxpack

“Before partnering with the Maxpack team, we

were manually packaging everything,” says Isard. “That meant using hand-held heat sealers, scales, and pre-made bags—one at a time. It was slow and labor-intensive, and it made scaling up nearly impossible. Now we’re running a 14-head combination scale that consistently packs 5 lbs per bag. And running at about 15 bags per minute, that’s faster than we’re able to get them into cases. It’s the best kind of problem to have. On top of that, we’ve integrated batch/lot numbers and QR codes for full traceability, which has helped us pass SQF audits [certification managed by the Safe Quality Food Institute] with confidence. This setup gives us the foundation we need to grow and scale up further.”

High on the list of reasons Isard selected the Maxpack equipment was that firm’s established expertise in handling frozen food. It didn’t hurt any, either, that the Maxpack MFT 7 was a finalist in the 2022 Technology Excellence Awards sponsored each year by PMMI, The Association for Packaging and Processing Technologies.

Packaging at Frites Street begins as french fries exit the freezer. A vibrating conveyor drops the frozen product onto a flighted incline conveyor that brings the fries up to the combination scale. Maxpack’s Julio Ulich points out that the conveyors, also supplied by Maxpack, are designed for full washdown, which comes in handy in the frozen food arena in which Maxpack frequently operates.

Once the scale has selected which combination of 14 buckets comes closest to the desired 5-lb weight, those buckets release the french fries down the chute leading to the forming tube that pulls roll-fed flexible film around a forming collar. Heat-seal jaws close to form the top of the filled bag making its exit and the bottom of the next bag. Finished bags ride a short distance up an incline conveyor, through a Sesotec metal detector, and then to a station where operators manually case pack them.

This 14-head combination scale drops 5-lb portions of frozen french fries into a vertical form/ fill/seal system below.

Current production at Frites Street involves only 5-lb bags. But should the firm choose to branch into other sizes, the MFT 7 is known for being able to handle a broad range of bag sizes, says Ulich. “A lot of our customers are co-manufacturers, so we are very familiar with applications where maximum versatility in bag size is important,” he says.

As for the 4-mil flexible film used to package the product, it’s a two-layer adhesive lamination of a freezer-grade kraft and a nylon/PE lamination that brings good seal strength and tear resistance. It’s supplied by LK Packaging.

Date coding, of course, is part of the package, and in this case Maxpack integrated a Videojet thermal-transfer printer. As for throughput, the improvement has been impressive. When all of it was done by hand, it took three or four employees eight hours to package 6,000 lbs of product. The same three or four employees now package up to 20,000 lbs of product in four hours.

“This equipment has truly been a dream come true for our operation,” says Isard. “The system packs faster, works smarter, saves labor, and eliminates common problems. It gives us the confidence to say yes to big orders and the capability to back it up. Plus it brings consistency to every bag and makes our brand look and feel like we are the major player we’ve become.”

A lot of our customers can’t talk about their secret to safe, smooth, gentle conveying but everyone knows the secret is Volkmann. Our patented pneumatic vacuum conveyors automatically transfer powders and other bulk materials from one point to another in fully enclosed, dust-tight, explosionproof systems.

Automated, hygienic and quiet

Easy to use, easy to clean

No tools disassembly

Stainless steel as standard

Fast lead times, easy to install

BRYAN GRIFFEN | PRESIDENT, GRIFFEN EXECUTIVE SOLUTIONS LLC

The path to resilience isn’t always about building new lines; sometimes it’s about finally unleashing the potential of the ones we’ve had all along.

IN TODAY’S UNPREDICTABLE economic environment, food and beverage manufacturers face increasing pressure to deliver more with less. We need more product, more output, more reliability, but with less budget, less labor, and less room for error. This demand isn’t new, but it has taken on greater urgency as supply chain disruptions, inflationary pressure, and labor shortages stretch operations thin. With capital projects harder to justify and new equipment lead times growing longer, many processors are asking a critical question: Are we truly maximizing the lines we already have?

That question lies at the heart of smarter line utilization. It’s a concept that challenges manufac-

Bryan Griffen is the President of Griffen Executive Solutions LLC. He was previously Senior Director of Industry Services for PMMI: The Association for Packaging and Processing Technologies, and he held a number of roles for Nestlé during his many years there.

turers to increase throughput, reduce downtime, and eliminate inefficiencies without adding equipment or headcount. It requires us to think differently about the assets on the floor—not as fixed-capacity machines, but as flexible, optimizable systems capable of more than they’re currently delivering.

In most processing facilities, there’s a gap between what the line is doing and what it could be doing. That gap may be caused by inefficiencies in changeovers, unplanned micro-stoppages, inconsistent material flow, operator variability, or lack of real-time visibility. But that gap represents opportunity, and in many cases, a significant one.

In a large milk processing plant, managers discovered that frequent, extended changeovers were quietly eating away at daily production volume. Though each changeover seemed efficient in isolation, the cumulative time lost added up to hours of idle equipment each week.

By engaging the line team and applying lean tools, they began measuring actual change -

WITH AI SEARCH & CHATBOT!

Tired of dead-end searches? PMMI ProSource’s AI-powered search fills in the gaps, delivering relevant supplier matches instantly— even for complex searches like “beef jerky.”

Need help?

Just ask! Our AI chatbot is available 24/7 to guide your search and connect you with top suppliers.

Search results for “Beef Jerky”

Did you mean?

No more wasted time— just smarter, faster sourcing. Try it today at ProSource.org.

By integrating visibility into daily operations—not as a policing tool, but as a team motivator—plants are seeing more proactive ownership and faster responses to performance dips.

over durations, identifying sources of variability, and standardizing best practices. Visual tools such as center-lining (which indicates optimal settings directly on the equipment) and laminated changeover guides were developed to assist operators in quickly restoring settings after cleaning or format changes.

Additionally, targeted One Point Lessons (OPLs) were created—not for the full changeover process, but to address particularly tricky or error-prone tasks like aligning a filler valve or resetting a digital controller that often led to extended troubleshooting. These bite-sized, visual SOPs were displayed near the relevant equipment and helped reduce learning curves for newer team members while reinforcing precision for seasoned operators.

The result was a significant reduction in average changeover time and a measurable increase in cases produced per shift, without any capital investment or added labor.

This story illustrates a central truth in smarter utilization: The key isn’t always automation or high-tech upgrades. Sometimes it’s about empowering the people already on the floor, connecting them with clearer processes, better data, and visual tools that help them make the right decisions faster.

That said, there’s also no denying the role of technology in unlocking hidden capacity. Today’s modern processing plants can benefit from a growing set of tools designed to expose inefficiencies and drive action.

Visibility is the catalyst for improvement. When frontline teams can see how their line is performing in real-time, they can take immediate action and feel more connected to the outcome. In recent years, digital tools like Redzone, LineView, and FactoryIQ have grown in popularity for tracking productivity and displaying performance dashboards at the line level.

Beyond these, many facilities are finding renewed value in simple, effective tools like Andon displays. These real-time visual boards show metrics such as cases per minute, current output, downtime occurrences, and performance against the shift record. When used correctly, they foster a healthy, competitive spirit among crews and create a shared sense of purpose. Operators begin asking, “Are we on pace to break the record?” and supervisors can coach in the moment when performance slips.

By integrating visibility into daily operations—not as a policing tool, but as a team motivator—plants are seeing more proactive ownership and faster responses to performance dips.

What’s important is that these tools are most effective when paired with a culture that’s ready to use the data. In high-performing plants, we often see frontline teams reviewing performance dashboards during shift huddles and using real-time alerts to identify and resolve problems on the spot. In one facility, teams use live dashboards during shift meetings to pinpoint which steps in the prior shift’s changeover created bottle -

necks and adjust their plans accordingly. The combination of visibility and empowerment is where the real power lies.

To be clear, none of these platforms are silver bullets, they’re enablers— part of a broader strategy to make line utilization more transparent, more responsive, and more team-driven. They also don’t require massive capital investment. Many platforms are subscription-based or can be piloted on a single line, making them accessible even in tight budget cycles.

As I’ve worked with manufacturers of all sizes over the years, I’ve come to believe that one of the most valuable roles in a plant is what I call the “linker.” This is the person—often a team leader, engineer, or tech-savvy operator—who sees the whole system and knows how to connect people, processes, and tools to drive improvement.

Smarter line utilization thrives when these linkers are empowered. They spot patterns in downtime data and bring the right teams together to solve them. They help bridge the gap between what the machine can do and what it is doing. They translate real-world operator feedback into improvement projects that actually stick. And they do it by helping the organization move as a cohesive system, not just a set of machines. If your plant is serious about increasing output without expanding headcount or footprint, find your linkers and support them. Give them access to real-time data. Give them time to work on improvements. Give them visibility with leadership. The ROI will follow.

It’s tempting to think that meaningful capacity increases require major investments. But smarter line utilization is built on the opposite idea: Many small changes, applied consistently, add up to big results.

That might mean tightening changeovers by 10%, eliminating the extra 30 seconds it takes for materials to reach a staging point, or improving startup procedures so the first 20 minutes of every shift are actually productive. In aggregate, these micro-improvements can be the difference between meeting a production goal or falling short, especially when demand spikes or downtime events push your system to the limit.

One processor shared with me that after implementing a visibility platform and retraining operators on daily performance goals, they were able to produce an additional day’s worth of product each month—without changing the equipment, layout, or staffing. It wasn’t flashy. It was just good operational discipline, grounded in data and executed consistently.

As we continue our “Doing More with Less” series, smarter line utilization stands as one of the most impactful levers available to food manufacturers. In a world of constrained capital and uncertain demand, getting more out of what you already have isn’t just a cost-saving measure, it’s a competitive advantage.

The tools are within reach. The knowledge is already inside your operation. The key is bringing it together by empowering your people, standardizing your processes, and using data to make better decisions faster.

And while the industry continues to evolve, one thing remains clear: The path to resilience isn’t always about building new lines. Sometimes, it’s about finally unleashing the potential of the ones we’ve had all along.

Tackle new projects early in the year and be ready for whatever 2026 brings. At PACK EXPO East, you’ll find solutions for all types of packaged foods—all in one trip to Philadelphia.

See live demos of processing and packaging equipment and materials in person.

Explore creative ideas from 500 exhibitors and insights for 40+ verticals.

Discover advances in safety, efficiency and sustainability.

Learn about the latest food industry trends in free on-floor sessions.