Scan this QR code for the latest PACK EXPO Las Vegas news collated by PMMI Media Group’s roving team of editors. Find videos of the latest innovations and technologies directly from the show oor. ■

If your badge says, “First-Time Attendee,” you’re welcome to enjoy a networking breakfast tomorrow, Sept. 30, from 8:00 to 9 a.m. in the First-Time Attendee Lounge (Room S-220), sponsored by ProMach (Booths W-1500 and W-1524) Connect with peers and talk shop with fellow rst-timer attendees. RSVP not required. First-come, rst-served. ■

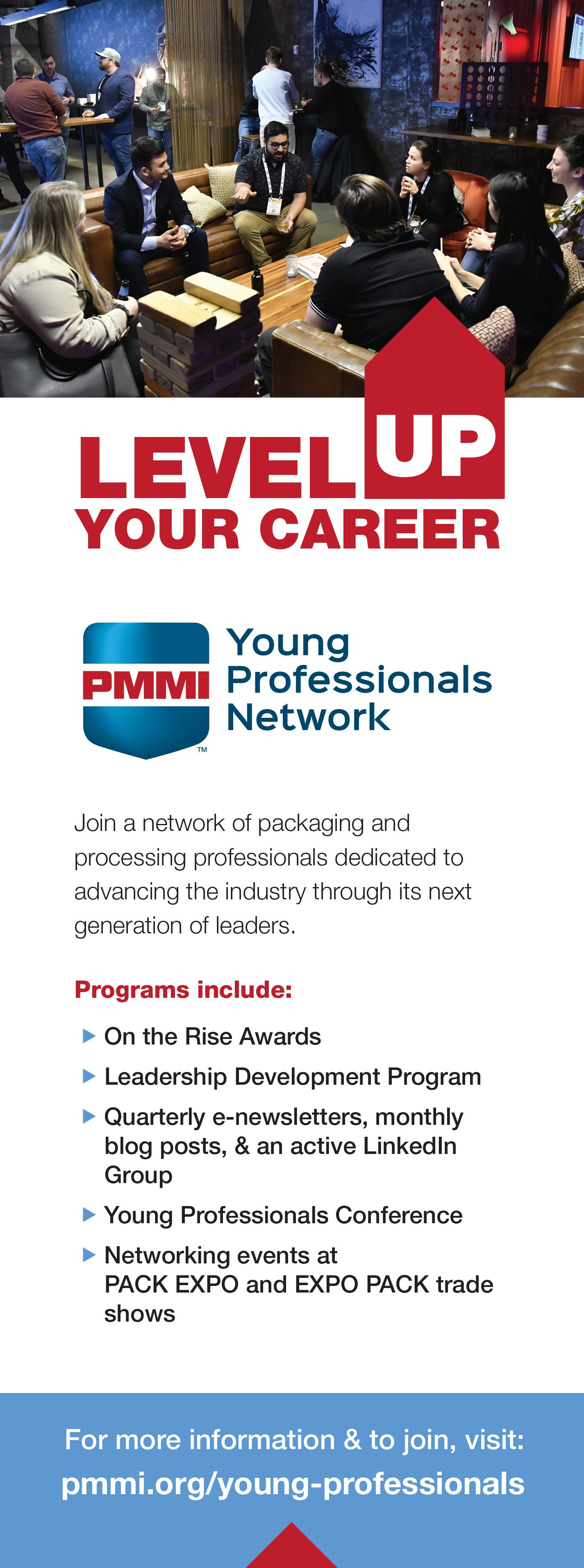

For rising stars in the packaging and processing world, tonight’s event from 7:30 to 9:00 p.m. at The Cove Bar & Arcade (Treasure Island Hotel) is the chance to unwind, meet peers, and make connections that help shape careers. Organized by the PMMI Young Professionals Network and sponsored by Beckho Automation LLC (Booth SL-15047), this reception promises a night of fun and opportunity. Free with registration, but RSVP is required at packexpolasvegas.com. ■

30th Year welcomes biggest show yet.

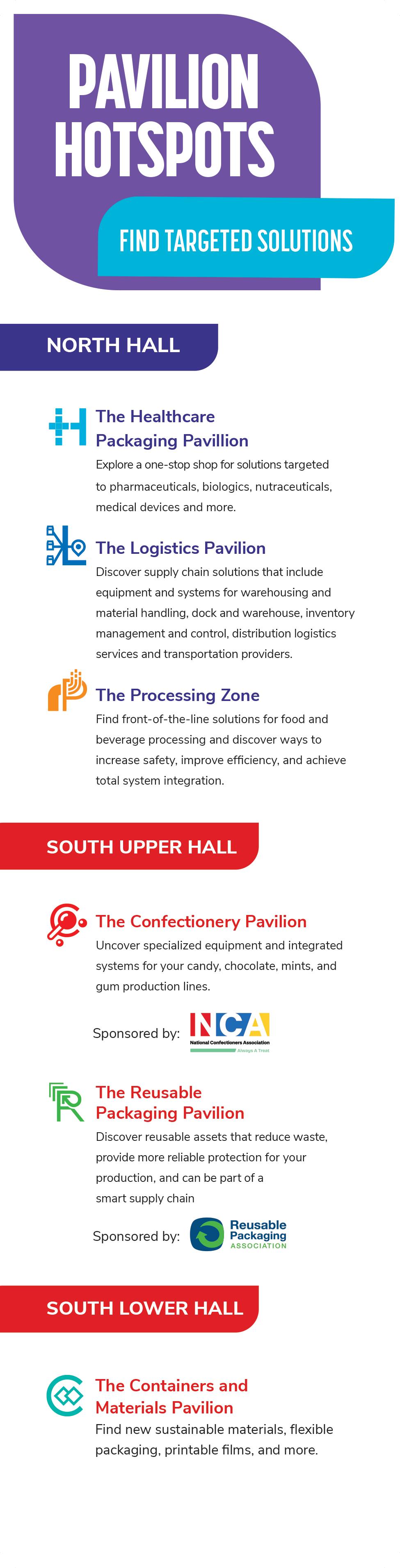

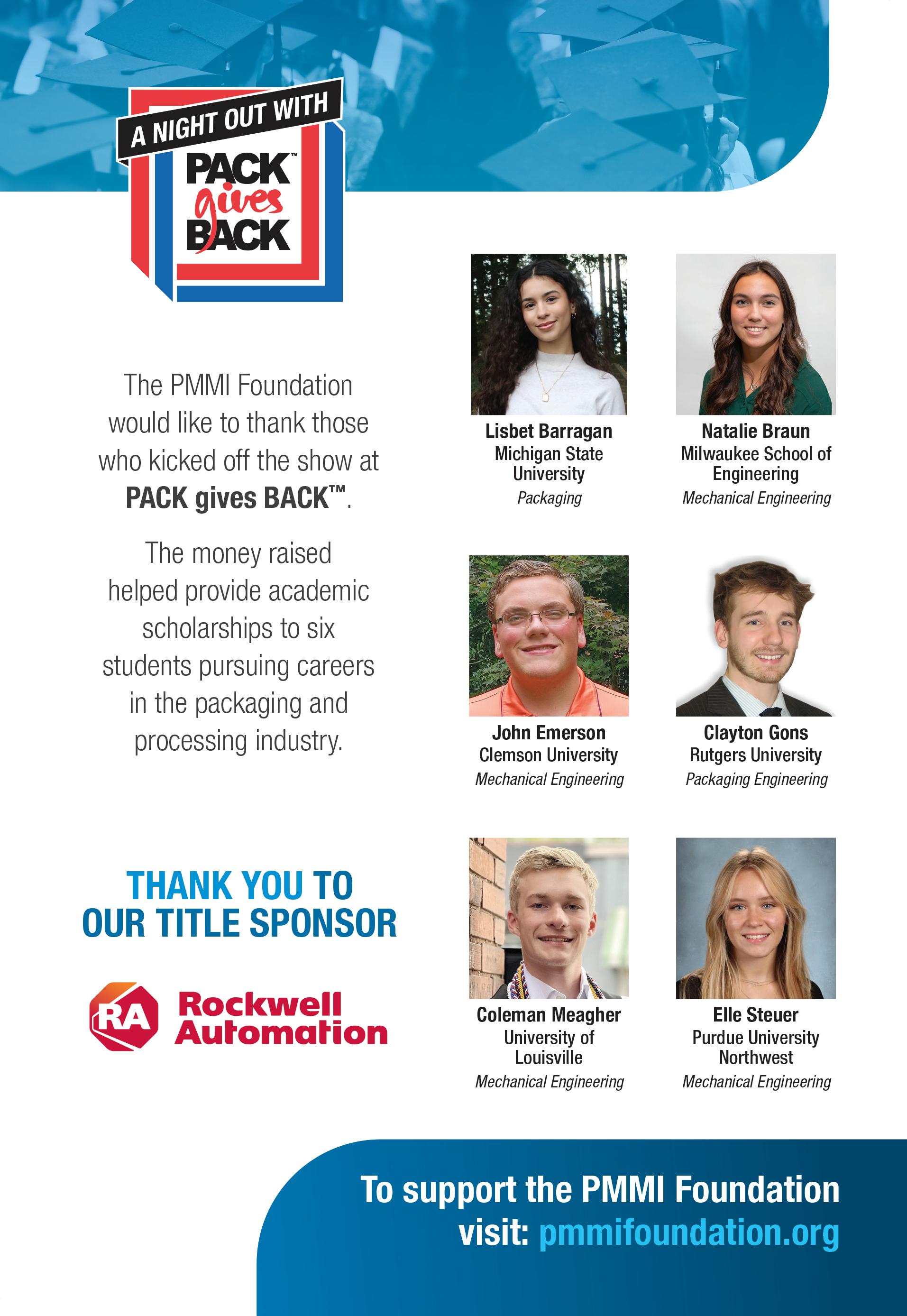

ings kicked o yesterday with two incredible events that truly set the tone for this year’s show. ank you to everyone who supported the PMMI Foundation Golf Tournament and PACK gives BACK™, sponsored by Rockwell Automation (Booth SL13028). Your participation helps us give back to the industry and invest in the future workforce. is year marks a historic milestone for PACK EXPO Las Vegas, celebrating 30 years of bringing the packaging and processing community together. e show reached a new record with more than one million net square feet of exhibit space. In addition, all six pavilions have expanded with more solutions to meet the industry’s needs, including:

• e Logistics Pavilion (North Hall)

• e Processing Zone (North Hall)

Voting is open for the Technology Excellence Awards. Showgoers may select winners in four categories: Food/Beverage, General Packaging and Processing, Personal Care/Pharma and Sustainability. Don’t miss the chance to check out each nalist (see p. 16 for all the nalists) and determine this year’s winners. ere are three ways to vote—onsite, on the o cial show mobile app, and online at packexpolasvegas.com

All attendees are encouraged to cast their vote for their favorite product in each category. is is a great way to have your opinion heard and to drive innovation for the future of the packaging and processing industry. ■

• e Healthcare Packaging Pavilion (North Hall)

• e Containers and Materials Pavilion (South Lower Hall)

• e Confectionery Pavilion, sponsored by the National Confectioners Association (South Upper Hall)

• e Reusable Packaging Pavilion, sponsored by the Reusable Packaging Association (South Upper Hall)

And that’s just the beginning. From Sustainability Central (Booth S-35000) and the Innovation Stages (Booths W-4300, W-4310, and W-4318) to the Processing Innovation Stage (Booth N-9100),

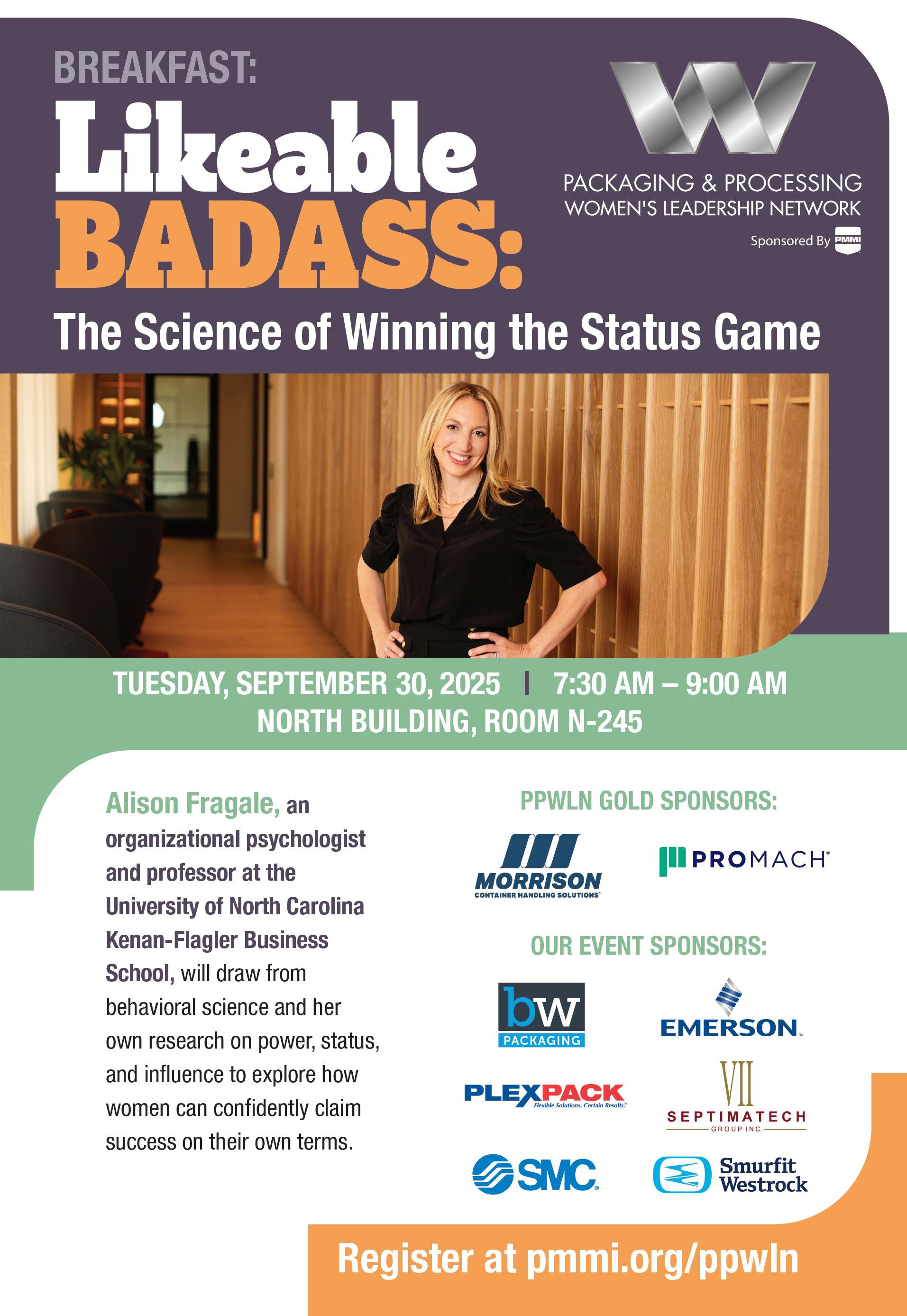

e annual Packaging & Processing Women’s Leadership Network (PPWLN) networking breakfast will be held tomorrow (Sept. 30) from 7:30 to 9:00 a.m. in Room N-245. e event is free, but attendees are encouraged to rsvp at packexpolasvegas.com is year’s featured speaker, Alison Fragale (pictured), an organizational psychologist and professor at the University of North Carolina-Chapel Hill, is a nationally recognized negotiation, communication, and workplace dynamics expert.

As a speaker, author, and educator, Fragale is known —Continued on page 4 —Continued on page 4

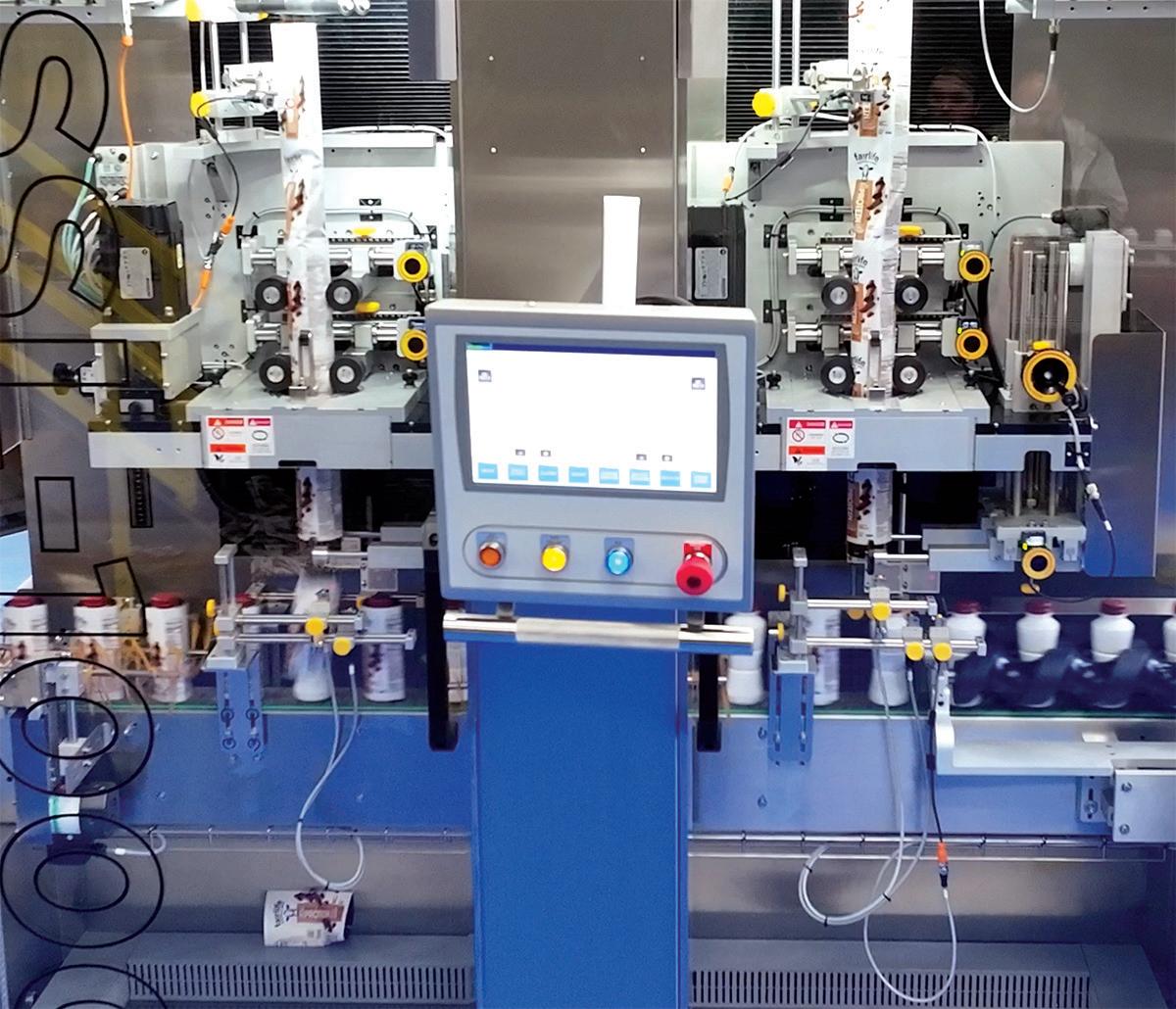

The method to our madness is simple:

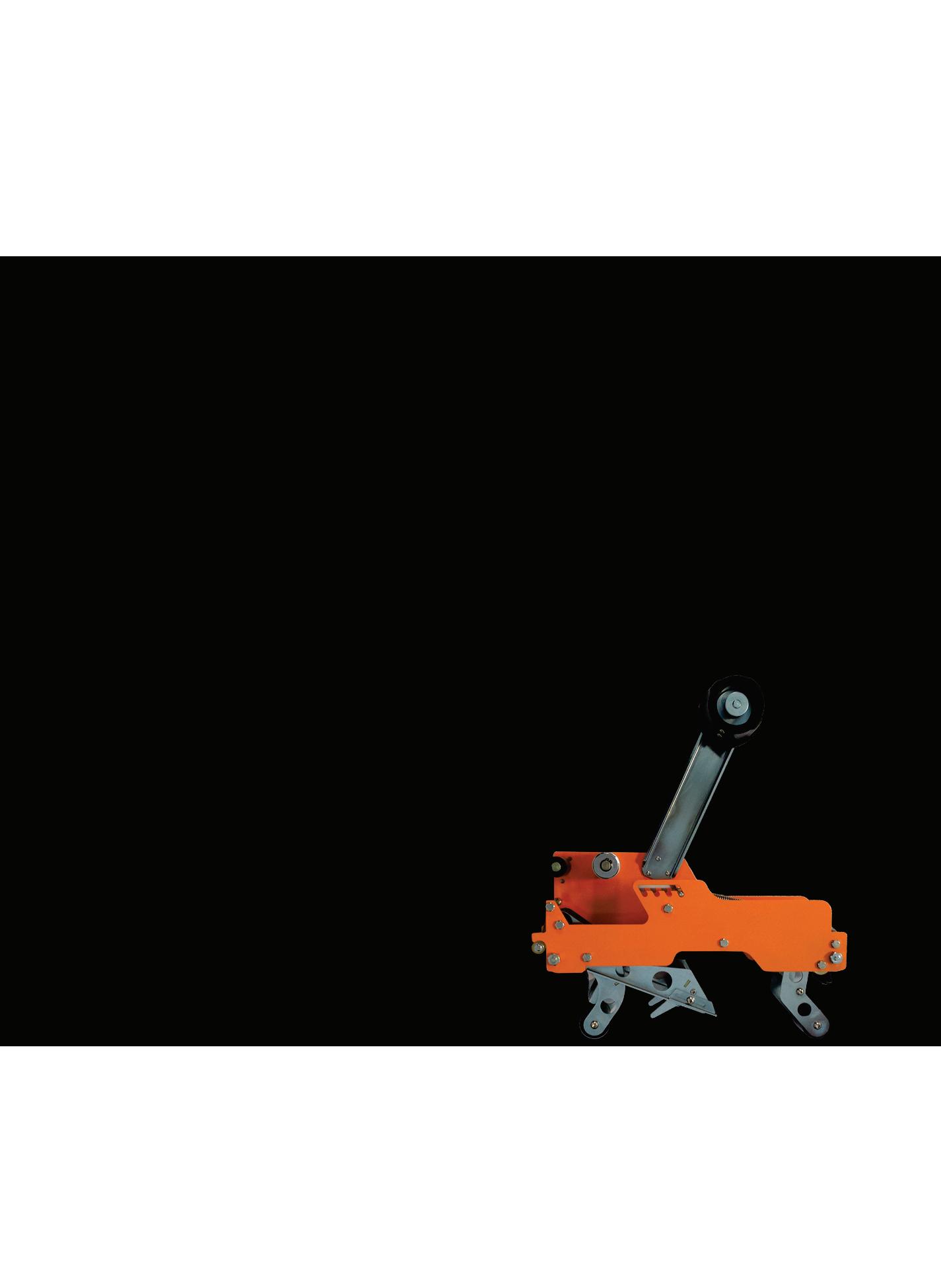

Build ultra-rugged labelers to withstand your actual working environment. (Hint:They're BEASTS)

Infuse them with cutting-edge technology that makes bad operators good. ( e even built in HMI videos to teach the newbies how it's done. Yep!)

Support every system to ensure you are always running! (NitaCare connected internet login servicing. Consider your problem resolved)

The T ULY O IGINAL 100% Servo Synchronized labeler that dramatically reduces operator touch-time, speeds up changeovers beyond your wildest dreams and eliminates costly downtime on your line.

SEPTEMBER 29, 2025 4

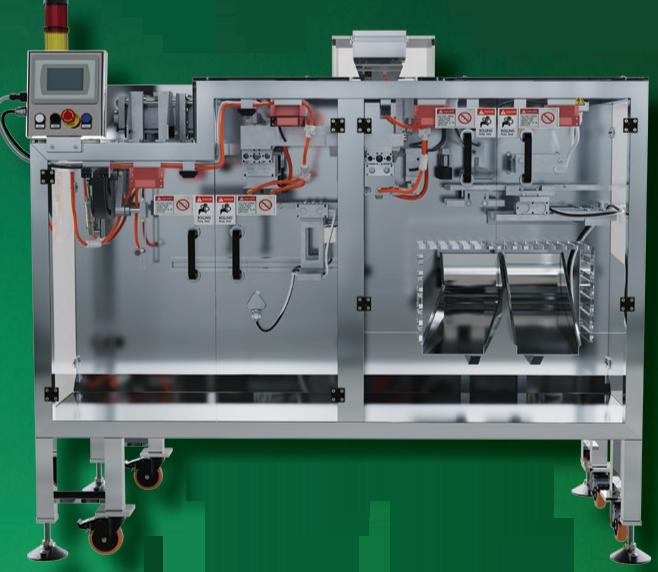

ALLIEDFLEX Technologies, Inc. (Booth SL-15021) has entered into an agreement with NEXES CONTROL, Barcelona, Spain, as its North American Partner (including Canada and Mexico) for the sales and marketing of

its NEXES series Premade Standup Pouch Packaging Machinery Program. NEXES technology provides a unique patented alternative to traditional rotary or in-line premade pouch “fill seal” packaging technology. ■

The PMMI Foundation Silent Auction returns to PACK EXPO Las Vegas, giving attendees the chance to bid on exclusive items and unforgettable experiences—all while supporting a meaningful cause. Items for bid are displayed in the North Hall Lobby, the West Hall by the W2 entrance and South Upper Hall Lobby. Proceeds from the Silent Auction directly benefit PMMI Foundation programs, including scholarships, educational initiatives, and workforce development efforts designed to inspire and prepare the next generation of packaging and processing professionals. ■

Education at PACK EXPO Las Vegas occurs across seven stages and content centers, where attendees will explore the latest trends, technologies, and strategies to drive

business success. See page 32 for an exploration of over 100 free educational sessions directly on the show floor, featuring insights from industry leaders, innovators, and solution providers. ■

Industry Speaks (Booth W-4324), and the Reusable Packaging Learning Center (Booth SU-34000), we’ve designed an immersive experience with 100+ educational sessions packed with valuable insights and solutions.

Debuting this year, the PACK EXPO Discovery Tours and PACK EXPO Sustainability Tour give attendees a guided path to the show’s most exciting innovations—spotlighting cutting-edge technologies and forward-thinking suppliers that could reshape the future of your operations.

It’s going to be an unforgettable week of discovery, connection, and inspiration. Explore everything PACK EXPO Las Vegas has to offer!

To make the most of your time, start with My Show Planner and the PACK EXPO Las Vegas mobile app, sponsored by ProMach, Inc. (Booth W-1500). Need extra guidance? Stop by the Attendee Solutions Center, Ask the Experts (West Hall Lobby and South Lower Hall) kiosks, or the PMMI Booth (West Lobby) for hands-on assistance.

Tonight, join us for the Young Professionals Networking Event at The Cove Bar & Arcade, sponsored by Beckhoff Automation (Booth SL15047), and don’t forget to cast your vote for the Technology Excellence Awards (p. 16). While you’re on the floor, download the show’s mobile app and

—Fragale Headlines PPWLN Breakfast, Continued from page 1

for blending research with relatable stories that help professionals better understand power, confidence, and leadership. Her keynote at the PPWLN Breakfast will offer attendees new perspectives and tools to grow personally and professionally.

Held each year at PACK EXPO Las Vegas, the breakfast has become a standout event, welcoming hundreds of women and allies from across the packaging and processing industries. Attendees gather to share experiences, build meaningful connections, and hear from influential voices in leadership and workforce development.

“PPWLN continues to provide valuable opportunities for networking and career development,” says Tracy Stout, vice president, marketing & communications, PMMI. “The PPWLN breakfast is a space where professionals from across the industry can come together to learn from each other, reflect on their paths, and feel encouraged in their careers.”

The PPWLN Breakfast is open to all PACK EXPO Las Vegas attendees, regardless of gender, and is designed to welcome everyone who supports the development of a diverse and inclusive industry.

PPWLN was established in 2016 to support the recruitment, retention, and advancement of women

participate in the Scavenger Hunt for a chance to win one of three $1,000 gift cards!

Be sure to visit the Future Innovators Robotics Showcase (North Hall, NL-1, Lobby), cheer on students competing in the Amazing Packaging Race, sponsored by Emerson Discrete Automation Group (Booth SL-15009), and stop by the Silent Auction (North Hall Lobby) to support the PMMI Foundation and its scholarships.

Finally, make tomorrow morning count by joining one of our featured networking breakfasts:

• Packaging & Processing Women’s Leadership Network Breakfast*, 7:30–9:00 a.m., Room N-245. RSVP required.

• First-Time Attendee Breakfast, sponsored by ProMach, Inc. (Booth W-1500), 8:00–9:00 a.m., Room S-220. First-time attendee badge required.

• International Networking Breakfast, 7:00–9:30 a.m., Room N-240

It’s going to be an unforgettable week of discovery, connection, and inspiration. Enjoy Day 1, explore everything PACK EXPO Las Vegas has to offer, and don’t forget to tag #PACKEXPO in your photos to share your experience with the world! Here’s to another 30 years of innovation—it all starts today. ■

* Gold Sponsors: ProMach (Booth W-1500) and Morrison Container Handling Solutions (Booth W-3522); Silver Sponsors: Plexpack (Booth W-2906), SMC (Booth SL-13034), Smurfit Westrock (W2300), Emerson (Booth SL-15009), BW Packaging (Booth W-3100), and Septimatech (Booth W-762); and PMMI Benefactor Sponsor: Schneider Electric (Booth N-214).

in the packaging and processing workforce. Through ongoing programming, in-person events, and industry partnerships, the network works to foster leadership and build community across all career levels.

The PPWLN Breakfast is proudly supported by PPWLN Gold Sponsors: ProMach (Booth W-1500) and Morrison Container Handling Solutions (Booth W-3522); Silver Sponsors: Plexpack (Booth W-2906), SMC (Booth SL-13034), Smurfit Westrock (W-2300), Emerson (Booth SL-15009), BW Packaging (Booth W-3100), and Septimatech (Booth W-762); and PMMI Benefactor Sponsor: Schneider Electric (Booth N-214) ■

Dive deeper into the resources available from the Contract Packaging Association’s (Booth W-101) during the CPA’s presentation at the Industry Speaks (Booth W-4324) stage on Tuesday at 10:30 a.m. The session, “How CoPack Connect® Links Brand and Contract Manufacturer: AI-Powered RFQ Tool” will highlight how both SOIR and CoPack Connect can help brand leaders sharpen their strategies, vet partners, and stay ahead of disruption. ■

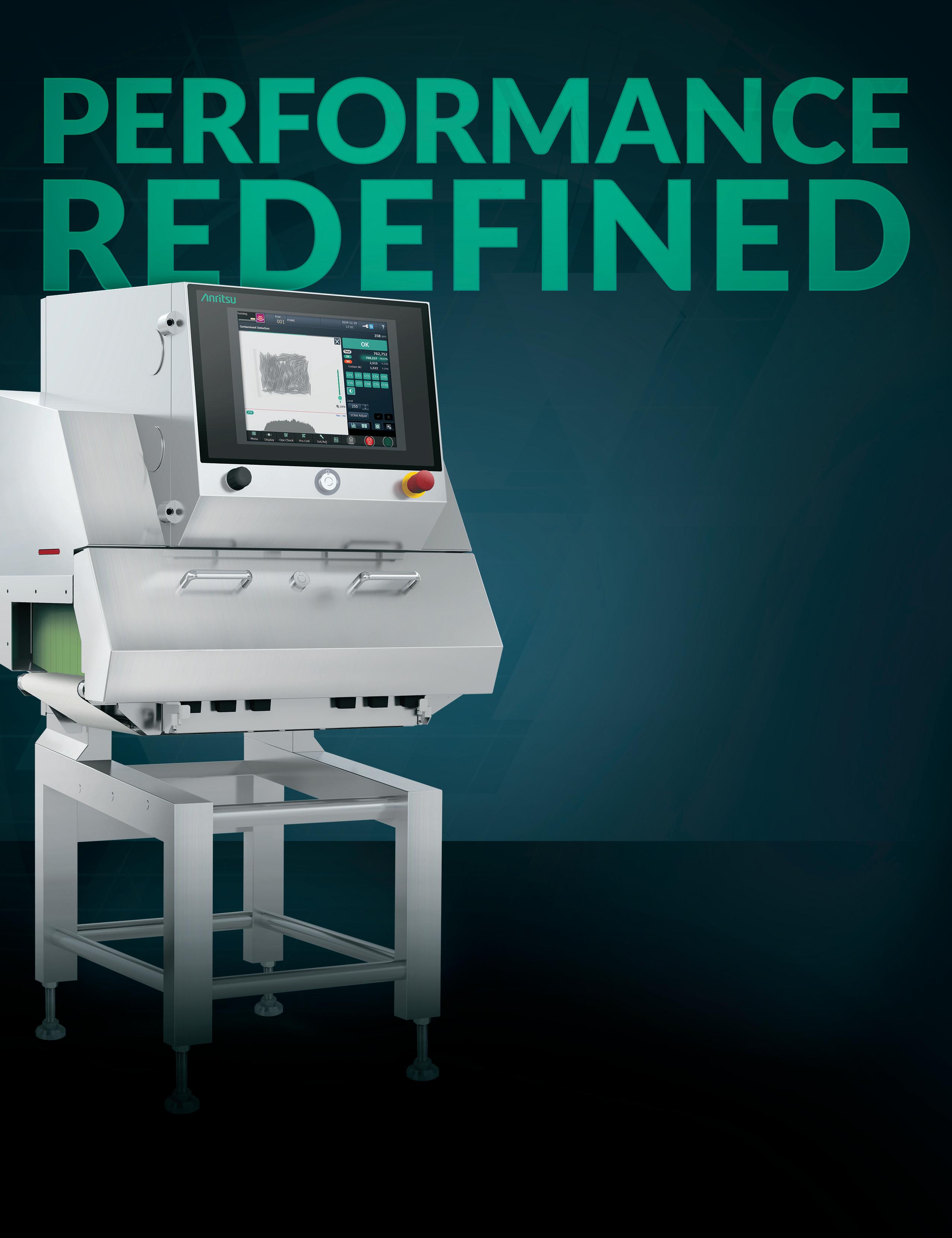

This year, Anritsu proudly marks its 130th anniversary of pioneering technology that has shaped industries and supported a safer, more prosperous society. Founded in 1895, Anritsu has advanced alongside the evolution of modern communications, expanding its expertise into fields such as healthcare, energy, and food safety. As part of this global legacy, Anritsu’s Product Inspection and Detection Division has been innovating and building on the parent company’s heritage. We continue to deliver advanced checkweighers, metal detectors, and X-ray inspection systems that set the standard for quality assurance worldwide.

Guided by our vision of “Beyond Testing, Beyond Limits, for a Sustainable Future Together,” Anritsu remains committed to providing solutions that protect brands, ensure safety, and create lasting value for our customers. Stop by Booth SL-11019 to celebrate this milestone with Anritsu ■

While on the show floor, be sure to journey through 10 key locations, and you could win $1,000. The Scavenger Hunt opens on September 29 and runs through the close of the show on October 1. Winners will be announced via email the week of October 6.

How to Play:

1. Download the Mobile App—Select “Scavenger Hunt” for a listing of all required destinations. To participate, you must log in to your My Show Planner. You can create an account for free.

2. Discover Key Stops—Find signs at each location and enter the unique codes. Then, enter all codes into the mobile app.

3. Win Big—Complete all 10 stops to enter the drawing for one of three $1,000 Gift Cards. ■

SEPTEMBER 29, 2025

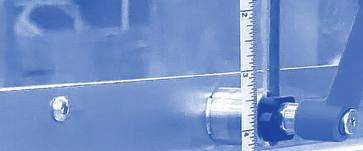

(Booth W-2356) promises to walk customers through practical moves to make coding a reliable step on their line

with fewer touches, fewer errors, faster changeovers, and calmer ops.

MMS expands its laser portfolio with Fiber, Fiber Film, and UV systems that deliver high-precision codes at line speed across metals, engineering plastics, films, and more. Innovations like Vibration Correction and OptiBeam (UV) help stabilize code quality on fast lines, while the MPERIA® controller centralizes setup, changeovers, and vision verification. Eliminate consumables and mark permanently with the right wavelength for most substrates.

The CT1000™ all-in-one thermal inkjet printer installs in under 30 minutes and delivers crisp date, lot, and barcodes on cartons and cases with a simple UI and a low total cost. Ideal for seasonal lines and frequent changeovers, CT1000™ brings bigsystem capability to compact footprints.

See the new MPERIA Axian Inkjet AX1000 Series, a breakthrough for primary packaging that combines

the flexibility of continuous inkjet (CIJ) with the clean, hassle-free operation of thermal inkjet (TIJ). Axian delivers industrial-grade reliability, quick start-up, and plug-and-print simplicity, with no clogs, unscheduled downtime, or solvent additives. Print multiple lines of text and 2D codes at speeds up to 200 ft/min, all with the intuitive MPERIA® interface. Maximize efficiency and lower total cost of ownership. ■

Sean Riley | Senior News Director

Kim Overstreet | Director of Content

David Bacho | Creative Director

sales@pmmimediagroup.com

Courtney Nichols | Director, Client Success & Development, cnichols@pmmimediagroup.com

Lara Krieger | Senior Manager, Print Operations, lkrieger@pmmimediagroup.com

Janet Fabiano | Financial Services Manager, jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

David Newcorn | President

Elizabeth Kachoris | Vice President, Digital

Jen Krepelka | Senior Director, Digital Media

Amber Miller | Director of Marketing

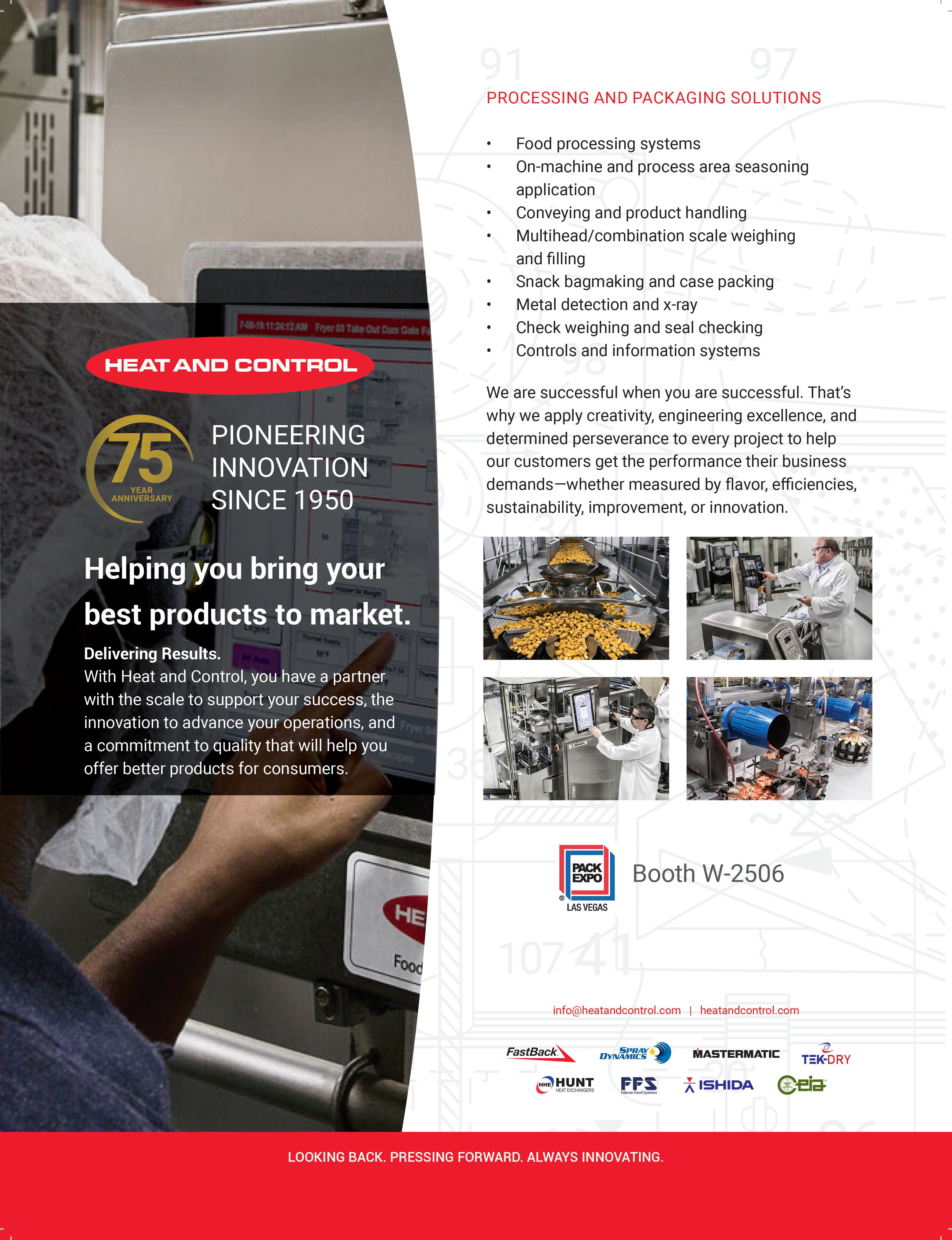

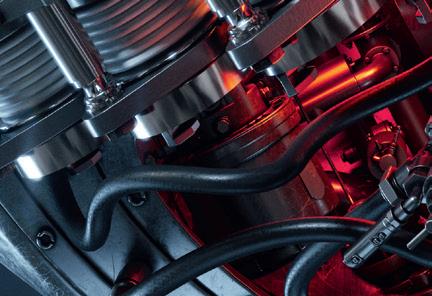

Metal detection, X-ray, vision inspection, and checkweighing are four inspection technologies that are revolutionizing how the food industry approaches production and regulatory compliance.

Previous approaches and models used to boost food production to meet the rising global demands are no longer able to keep pace. This has made it even more imperative for the food industry to explore innovative technology and tools that maximize space utilization, minimize waste, enhance productivity, and optimize costs.

Over the next 20 years, the world’s population is predicted to reach almost 10 billion people. Historically, the global food supply has been able to keep pace with this demand. However, the world now consumes three times more food than it did in the 1960s. Additionally, food supplies are not evenly spread, with one in seven people unable to access sufficient amounts and going hungry.

and facilities, and taking action to reduce food loss and waste. Finding more sustainable manufacturing practices that boost food safety will be imperative.

Research analyzed by the World Resources Institute points toward two major solutions: increasing food production without expanding land

When approaching the needs of our future food supply chain, there is an overall understanding that

Processors are already using digital reporting tools and data features extensively to support reporting and to ensure food safety is not compromised. Image courtesy of Fortress Technology Inc.

simply increasing food production without ensuring the food is safe for consumption would be counterintuitive, wasteful, and pose a risk to the health and safety of consumers. For food manufacturers, physical space restraints, production cost challenges, and sustainability agreements also need to be factored in when expanding production yields.

As modern and automated as many of today’s food factories are, they are entirely governed by increasingly tighter food safety, weight control, labeling, and quality assurance regulations.

—Continued on page 10

—Continued from page 8

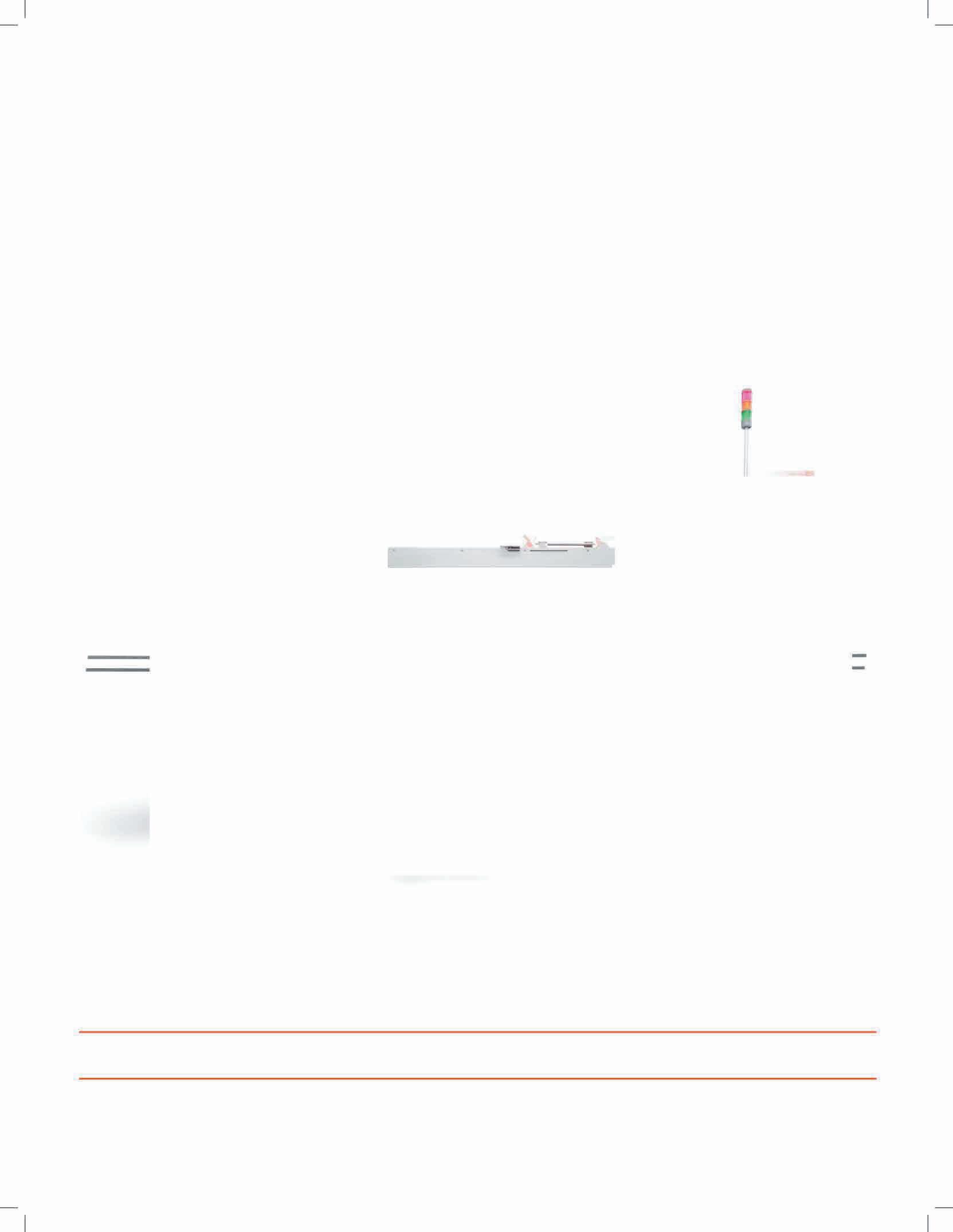

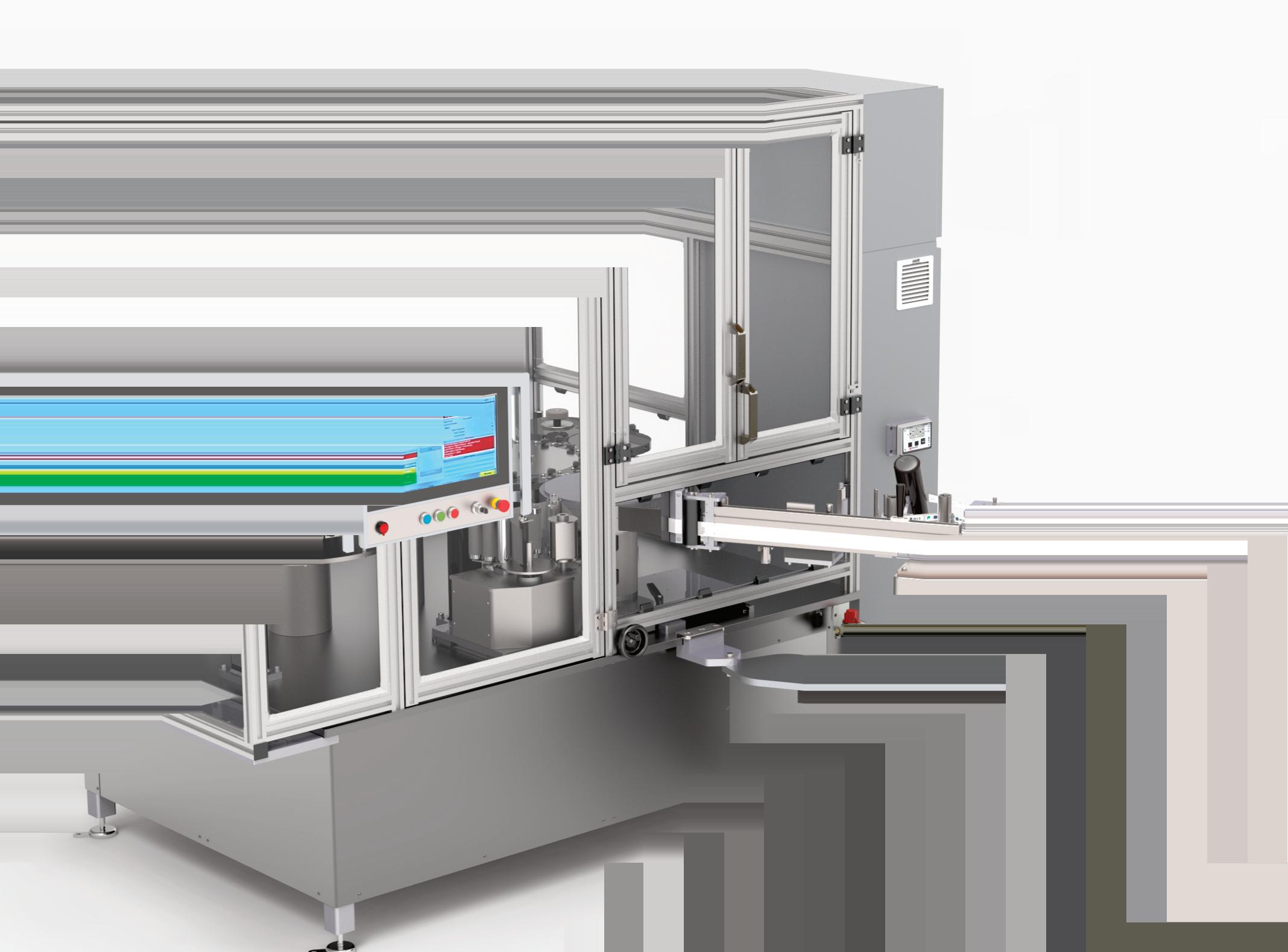

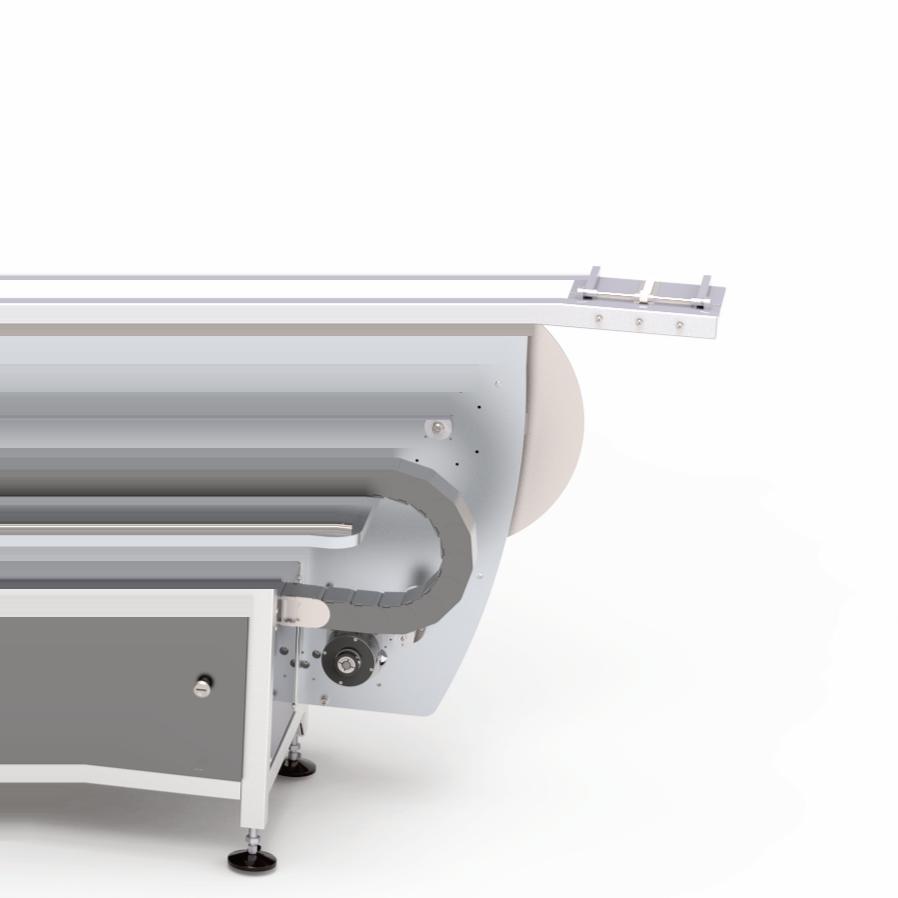

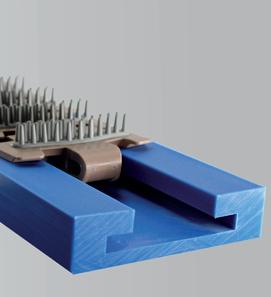

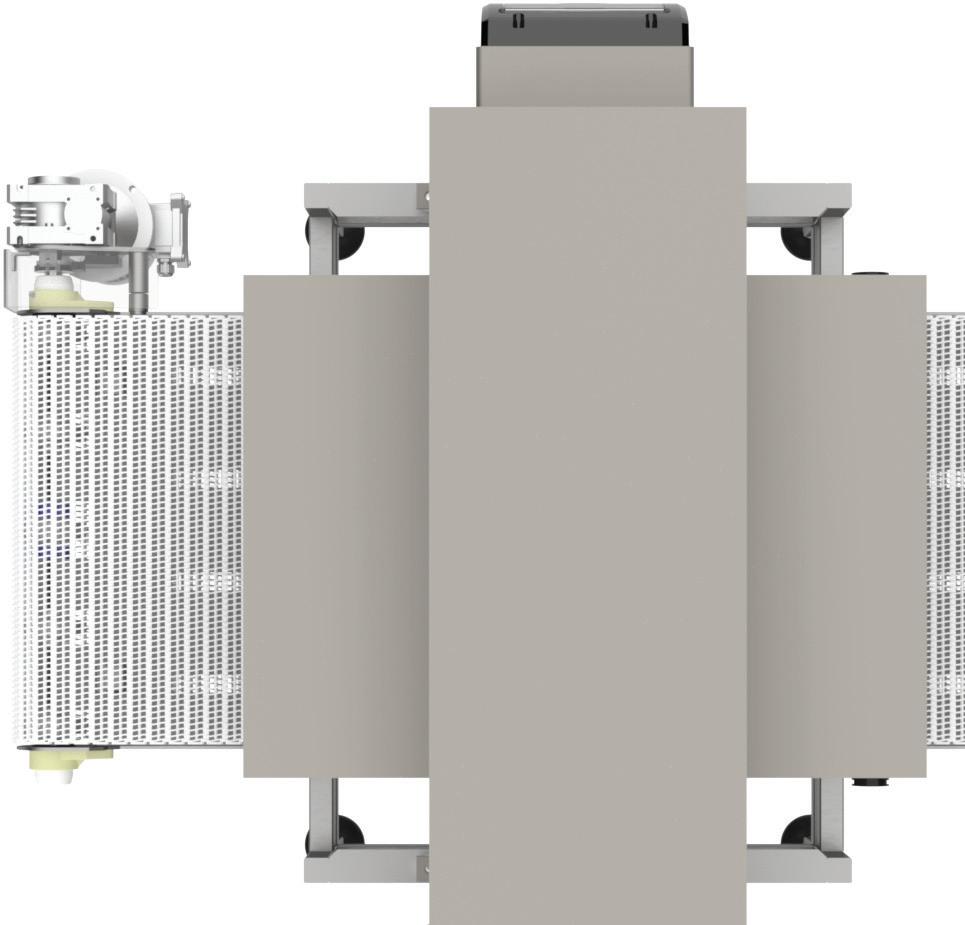

Integration of metal detection, X-ray and checkweighing is feasible and can more than halve the footprint compared to installing individual machines. Image courtesy of Fortress Technology Inc.

New productivity levels are not attainable without innovative equipment solutions.

Metal detection, X-ray, vision inspection, and checkweighing are four inspection technologies that are revolutionizing how the food industry approaches production and regulatory compliance.

Although it is commonplace to see two of these technologies in combination inspection units or even multi-lane con gurations, Fortress Technology (Booth W-3670) eventually anticipates wider adoption and integration of all four in food production environments at the end of HACCP/HARPC processing and packaging lines. By doing this, the industry could see each technology’s respective performance synergistically enhanced, particularly when utilizing vision, data analysis, and AI tools.

Not only do combination systems signi cantly reduce equipment footprint, but every aspect of that footprint provides value to the company.

Many of the perceived limitations of combination systems can usually be overcome with smart design considerations, customization and con guration exibility, regular training, and localized support. e most important thing to note is that the performance and sensitivity of any technology in a combination system should never compromise the others.

For example, vision inspection could be applied to improve X-ray technology by providing a visual context to the pack being inspected. Vision systems could also help to enhance checkweigher performance by reading weight labels and providing physical information about pack separation. Additionally, metal detection and X-ray could work in tandem to inspect for all types of physical contaminants. Where an X-ray can only detect higher-density metals, metal detectors can detect both at and “spherical” metal contaminants.

The choice of equipment depends on the most prevalent risks identi ed through HACCP or HARPC planning. Image courtesy of Fortress Technology Inc.

In more advanced systems, machine vision is likely to feature more strongly by the time the FDA nal rule is applied at the start of 2026. For example, vision could be integrated more into a combination of metal detection and/or X-ray and checkweighing systems.

When compared to purchasing multiple individual inspection systems, the faster ROI, smaller footprint, and operational savings of a single inspection unit can be equally bene cial. As well as sales, services, parts, and technical support coming from one supplier, training and operating the equipment becomes easier and safer when there is only one user interface. Other cost savings are gained from faster installation, reduced training time, and increased operational e ciency.

With the future of food supply chains reliant on optimizing manufacturing spaces and food safety to their fullest extent, AI-driven All-In-One systems could very well be the single solution that elevates production and quality standards to a groundbreaking new level. ■

These dedicated spaces make it easy to navigate the show floor, zero in on solutions, and compare options side by side.

PACK EXPO Las Vegas is a massive showcase of cutting-edge technology and solutions, but finding exactly what you need is simple in distinct pavilions. These “shows within a show” feature solutions that address many industry challenges, making it easy to navigate the show floor, zero in on targeted solutions, and compare your options side by side. All of the pavilions have expanded, reflecting the tremendous market growth in packaging and processing.

The Logistics Pavilion (North Hall):

With the rapid expansion of e-commerce, this pavilion features cutting-edge supply chain solutions, including warehousing, fulfillment, distribution logistics, and transportation providers.

The Processing Zone (North Hall):

This area showcases the latest processing innovations, including homogenizing, heat treating, forming/sizing, and coating solutions.

The Healthcare Packaging Pavilion (North Hall):

Focused on life sciences, this pavilion showcases packaging innovations for pharmaceuticals, biopharmaceuticals, nutraceuticals, and medical devices.

The Containers and Materials Pavilion (South Lower Hall):

From paperboard to films and foils, right-sized containers and all kinds of consumables, this pavilion houses solutions to increase sustainability, enhance usability, and improve convenience.

The Confectionery Pavilion (South Upper Hall):

Sponsored by the National Confectioners Association (Booth SU-26000), this pavilion delves into the latest trends in candy, baking, and snack production.

The Workforce Development Pavilion (North Hall Lobby):

The ultimate resource hub for strengthening the existing workforce and nurturing the future workforce.

The Showcase of Packaging Innovations (West Hall Concourse, Level 2):

Sponsored by Smurfit Westrock (Booth W-2300), this attendee favorite displays award-nominated packaging solutions.

The Reusable Packaging Pavilion (South Upper Hall):

Sponsored by the Reusable Packaging Association (Booth SU-34000), this area explores sustainable, reusable transport packaging that reduces waste, improves material handling performance, offers superior product protection, and improves the freshness and quality of perishable foods.

The Association Partner Pavilion (West Hall):

Serves as a vibrant hub for industry collaboration, connecting attendees with the foremost organizations across the packaging and processing spectrum.

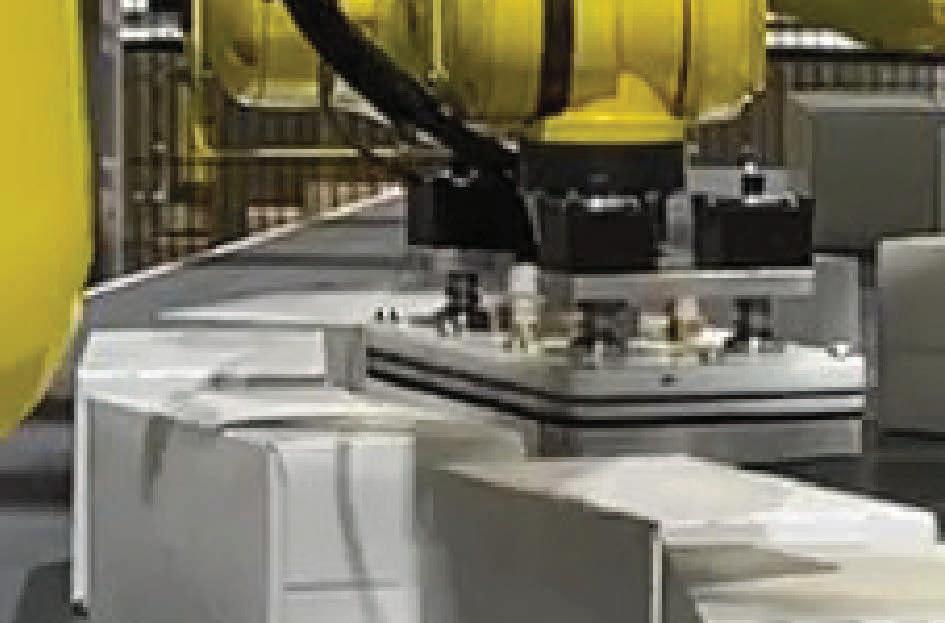

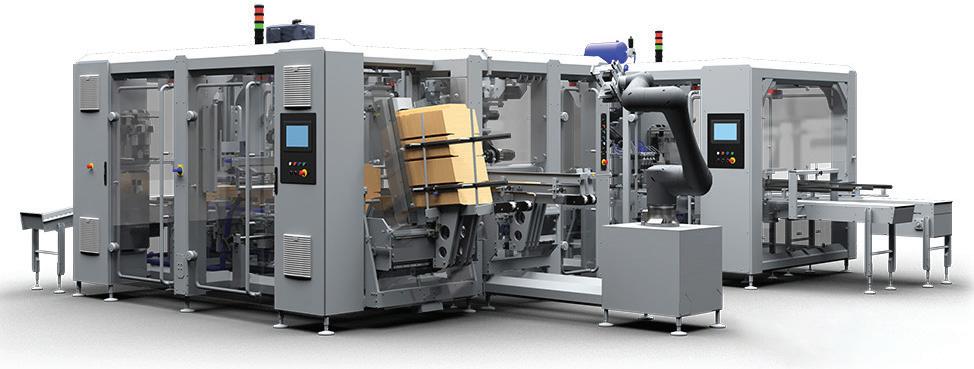

SMART AUTOMATION FOR MIXED-PRODUCT PALLETIZING

Streamlined palletizing: RI20 with industrial robot arm handles 15 kg at 12 cycles/min.

Compact and mobile: adapts easily to recipe or line changes.

AI-driven palletizing: Mixed Palletizer handles various box sizes without preset patterns.

Easy-to-use: unique hardware and HMI ensure smooth operation.

PACK EXPO Las Vegas newcomers benefit from the First-Time Attendee Lounge (Room S-220), sponsored by ProMach, Inc. (Booth W-1500), a dedicated space offering guidance and networking, ensuring everyone leaves with valuable connections.

The First-Time Attendee Lounge is a hub for starting the day right and maximizing the PACK EXPO experience. Holders of a First-Time Attendee badge can access this exclusive lounge offering and receive:

• Personalized guidance: Knowledgeable show staff are on hand to help locate exhibitors, recommend sessions, and create a plan to tackle the show floor.

• Product locators: Quickly find the solutions and suppliers that align with your goals.

• Comfortable seating and refreshments: Enjoy free coffee, tea, and charging stations to recharge yourself and your devices.

• Special Sessions:

How to Navigate the Show Like a Pro

(Monday -Tuesday, 8:30 to 9:00 a.m.) Kickstart the day with helpful insider tips and strategies to help navigate the exhibit halls and make the most of the show experience. Plus, plenty of Q&A opportunities with show staff.

First Time Attendee Breakfast

(Tuesday, 8:00 a.m. – 9:00 a.m) Connect with peers and talk shop with fellow first-timer attendees while enjoying a complimentary breakfast. It’s a great way to kick-start the day. Your First-Time Attendee badge is your ticket. Spaces are limited, first-come, first-served.

Simplify Supplier Sourcing With ProSource

(Monday - Wednesday, 12:30 to 1:00 p.m.) Find trusted suppliers, explore features, and simplify the sourcing process all in one place. PMMI ProSource is a searchable directory that can help you find suppliers year-round. ■

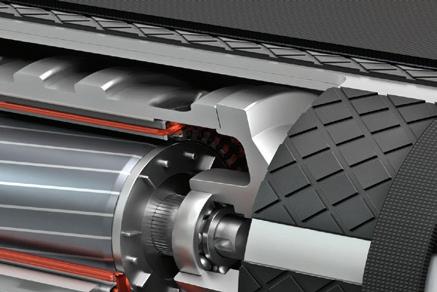

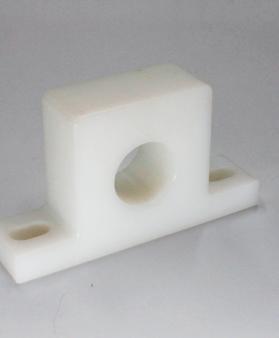

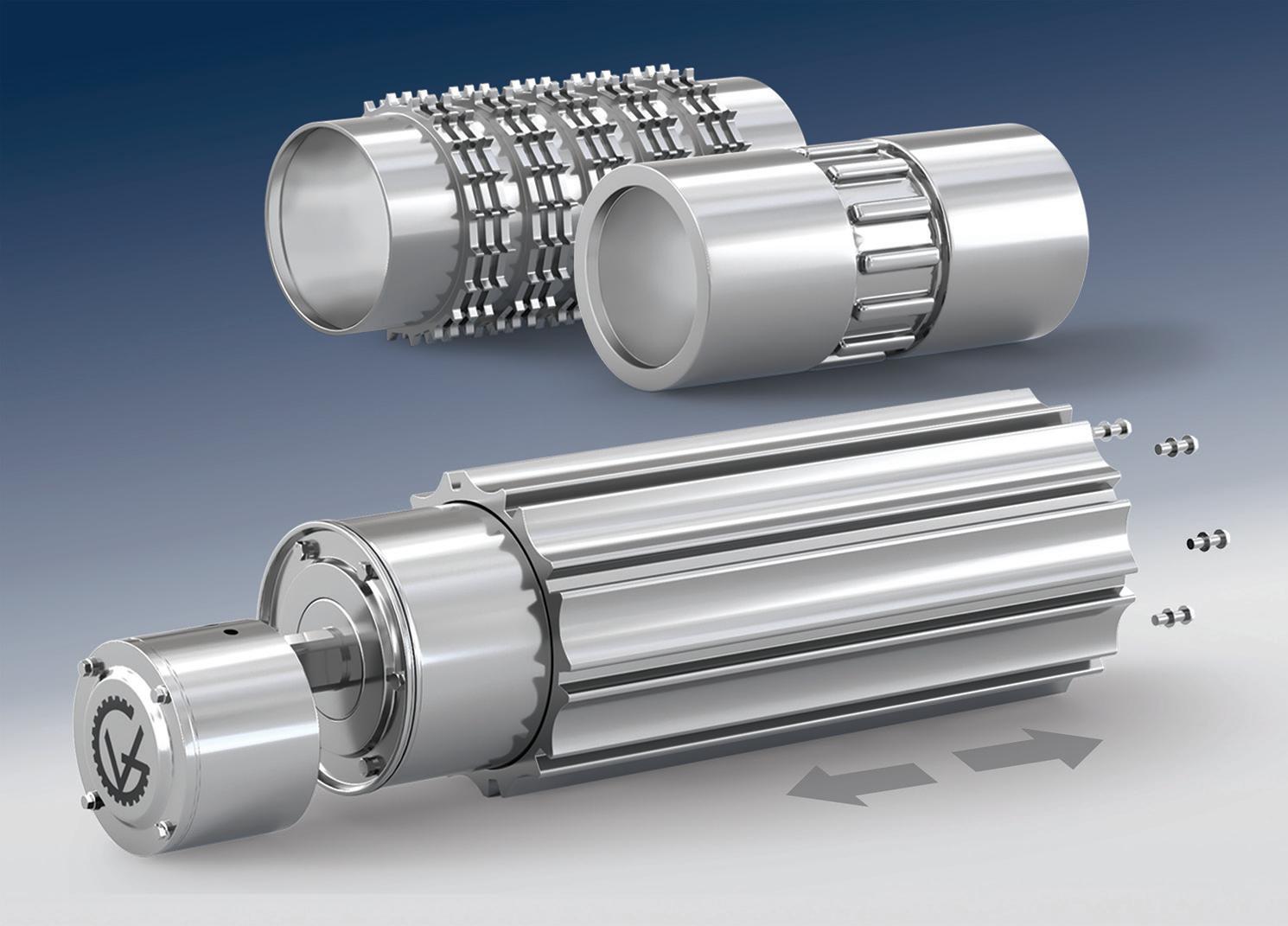

All drive components of the VDG Drum Motor, including the premium-efficiency electric motor, gear reducer, and bearings, are enclosed and protected inside the drive drum and maintenance-free for 80,000 hours of continuous operation, reducing operational and maintenance costs while increasing throughput.

Premium-Efficiency Electric Motor

Eliminate Routine Maintenance

Low Cost of Ownership

INCREASE ELIMINATE REDUCE

For sanitary applications, SSV Series Drum Motors are manufactured in all-stainless steel, feature an IP69K-rated sealing system, withstand pressure washdown up to 3,000 psi, and drive modular, wire mesh, and monolithic thermoplastic conveyor belts without using sprockets.

Conveyor Hygiene Drive Sprockets Water Usage & Time for Washdown

Recognize PACK EXPO debuts by selecting winners in four categories.

PACK EXPO Las Vegas Show Producer PMMI (West Lobby) would like to thank all exhibitors who submitted innovative and cutting-edge products for consideration for the 2025 Technology Excellence Awards. e Technology Excellence Awards recognize the best innovations in packaging and processing, being shown for the rst time at a PACK EXPO event. ere are three ways to vote—onsite, on the o cial show mobile app, and online at packexpolasvegas.com. Voting closes Tuesday at noon, and the winners will be announced via a press release on Tuesday a ernoon. All attendees are encouraged to cast their vote for

HyperBarrier® Paper

their favorite product in each category. is is a great way to have your opinion heard and to drive innovation for the future of the packaging and processing industry. ank you to the Technology Excellence Awards reviewers who reviewed the submissions and narrowed them down to three nalists in each category:

• Bob Larkin, Owner, BL.PKG LLC

• David Smith, Principal, David S Smith & Associates

• Diane Wolf, Independent Consultant, Food & Beverage Consultant

• Robert Champion, President, InnoFlex Solutions, LLC

COPAR SMART PACKAGING (Booth SU-30098A)

Hyper Barrier™ paper by Copar, developed with Smart Planet Technologies, is a packaging innovation engineered speci cally for food and beverage applications. It replaces multilayer plastic laminates with a single-layer nanocomposite barrier coating on paper, using commodity polymers (HDPE/LDPE) to achieve 200–400x better oxygen barrier and 5–7x better moisture barrier than traditional PE coatings—without using costly EVOH or foil.

Food products like sliced meats, cheese, co ee, dry mixes, and frozen items demand strong barrier protection—but current high-performance laminates are expensive, hard to recycle, and o en overengineered. Hyper Barrier™ delivers the “just-right” level of protection for these applications, keeping food fresher for longer while signi cantly reducing packaging complexity and plastic content. Its performance is matched by practicality: Hyper Barrier™ is a drop-in solution that runs on existing converting and lling lines without special handling. It is commercially scalable and designed to reduce material costs while improving shelf life and sustainability metrics.

Hyper Barrier™ is recyclable through standard recycling streams—meeting the dual need for performance and environmental compliance. It helps food brands meet plastic reduction goals, avoid packaging taxes, and comply with EPR and recyclability regulations across global markets.

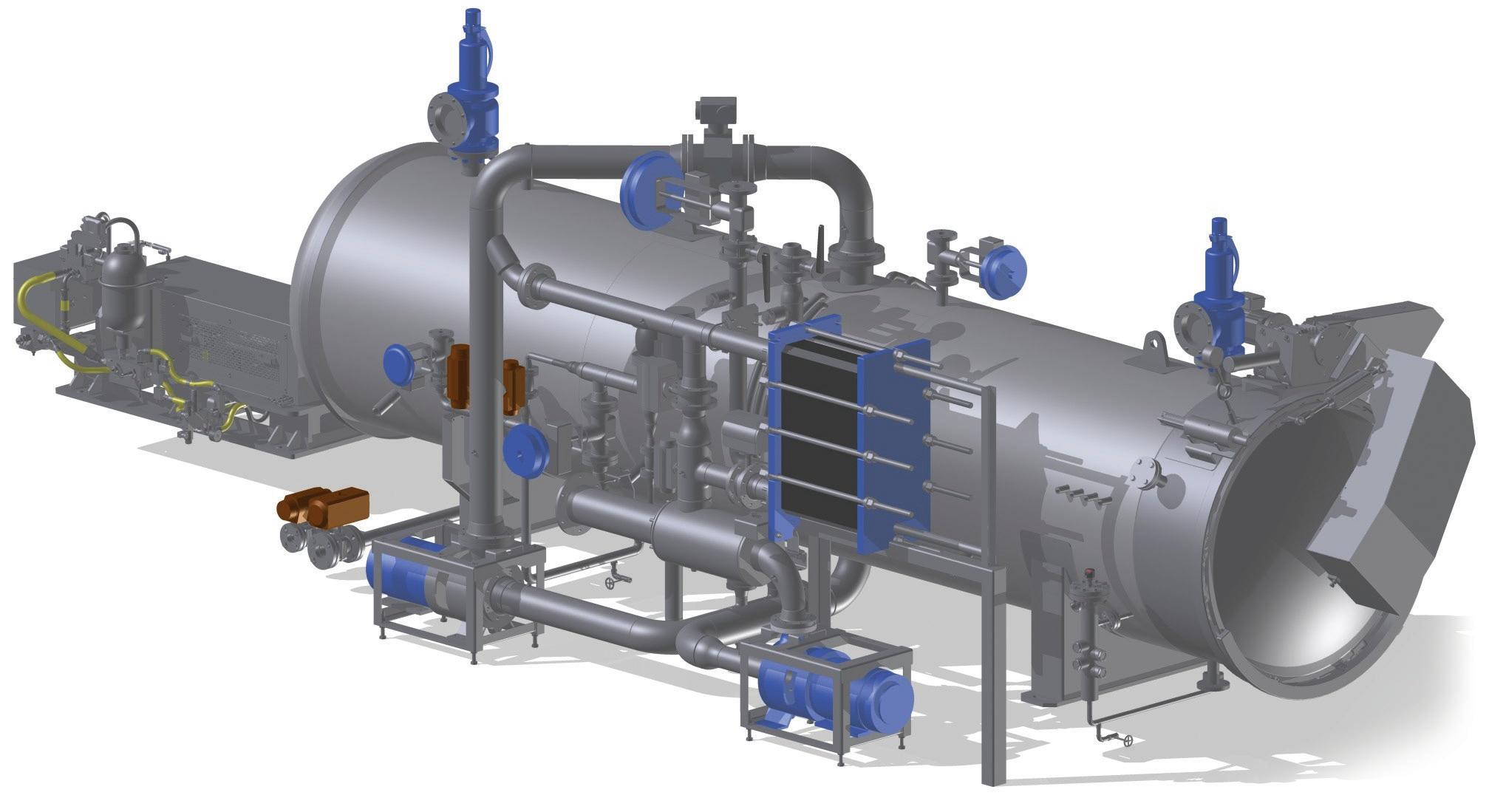

JBT Corporation (Booth N-8612)

JBT Marel’s one-of-a-kind EA Retort rede nes retort agitation with its perfect balance between static processing and agitation.

e patented technology of the EA Retort surpasses traditional retort agitation by o ering more packaging exibility and quicker heating capabilities, resulting in ready-to-eat and drink products that are better in quality from a taste and texture standpoint. Unique advanced linear agitation technology is used to produce more consistent results than traditional retort agitation, while reducing sterilization cycle times by up to 43% for shelf-stable goods.

e EA Retort brings goods to FDA-required temperatures up to 30% faster than traditional retort agitation, and can speed cooling times by up to 34%. is reduces utility costs and the number of retorts required for production, while contributing to sustainability bene ts by lowering energy usage in facilities using the technology.

is product o ers both a unique solution for manufacturers and several bene ts for the end-consumer. Shorter sterilization cycles result in higher-quality packaged goods with fresher tastes and textures.

JBT Marel’s EA retort is gentler on sustainable food packaging systems than

traditional rotational agitation, and the technology’s in nitely customizable programming adjusts to a variety of packaging options, from pouches, aluminum cans, bottles, cups, and bowls, giving users the option to pursue more sustainable solutions. ese packaging choices also allow consumers to take advantage of local recycling programs.

—Continued from page 16

Senzani Brevetti SPA (Booth SU-26041)

Senzani U-Seal combines cutting-edge technology, high performance, and sustainability, while allowing for complete creative freedom in pack design.

e core of this solution is the patented cold sealing technology, which signi cantly enhances operator safety and allows for quicker machine access in case of downtime, compared to conventional heat-based technologies.

At the same time, U-Seal supports eco-friendly practices. e system’s ability to produce tightly sealed packs using fully recyclable cardboard aligns with modern sustainability goals. Moreover, producing all packs starting from at blanks reduces logistical footprints through e cient storage and transport, consequently reducing environmental impact.

From a technical standpoint, U-Seal delivers exceptional speed and precision, packaging up to 330 units per minute with exceptional sealing quality. Its modular design gives manufacturers the exibility to scale and adapt to their production needs.

Finally, U-Seal o ers a level of functional and aesthetic customization that sets it apart from any other solution on the market. Its ability to form and seal packs in a wide range of outstanding shapes and sizes makes U-Seal a marketing powerhouse. Additionally, U-Seal supports advanced packaging features such as transparent windows, tamper-evident systems, dosing lids, custom printing both on the inside and outside of the pack, and product-speci c barrier levels, making it adaptable across diverse sectors, including food, pet food, home and personal care, and more.

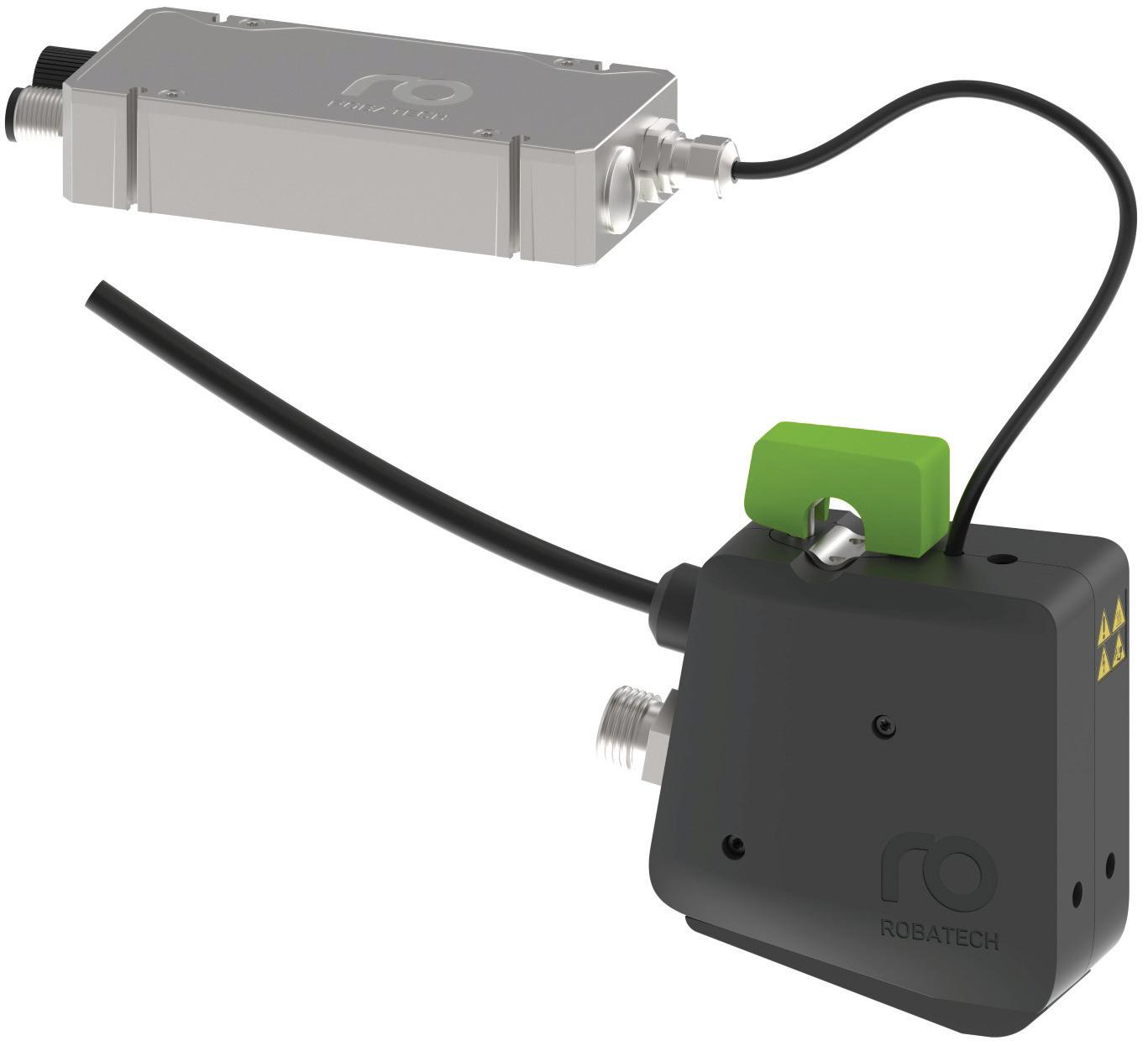

New Volta All Electric Adhesive Jetting Head

Robatech USA, Inc. (Booth N-8447)

Robatech’s innovative Volta electronic adhesive jetting head is distinguished by its impressive warranty covering two billion lifetime cycles, underscoring both its durability and reliability. Additionally, its all-electric design eliminates the need for compressed air, thereby promoting signi cant reductions in energy consumption and enhancing sustainability in industrial processes. Energy savings by as much as 60% have been observed compared to pneumatically operated heads.

e new Volta head also introduces an innovative integrated pattern control, allowing for direct programming on the head itself—a signi cant advancement in adhesive application technology. For instance, if a customer wishes to switch from applying beads to dots of adhesive on their packaging, the head enables programming the speci c number of dots without relying on the adhesive melter, which has been the conventional approach. is advancement not only enhances the versatility of the Volta head in relation to Robatech adhesive melters but also extends its applicability to any adhesive melter available on the market, highlighting its importance in streamlining and improving operations.

SEPTEMBER 29, 2025

—Continued from page 18

HaiPick Climb

Hai Robotics USA (Booth SU-25090)

e HaiPick Climb System simpli es automation while expanding what can be expected from automated storage and retrieval systems (ASRS). e system is operated by the rst warehouse climbing robot, HaiClimber, with the ability to easily navigate low-precision environments, making inventory automation possible for more businesses and helping companies get more from their existing facilities. It frees facilities of the burden, time, and costs typically required of robotic solutions, breaking down barriers to warehouse advancement and lowering the cost of automation ownership for all facilities.

HaiClimb Systems can be constructed of almost any industry standard racking and storage containers, eliminating the high cost, extreme precision, and limitations that are typical of historic ASRS solutions. Totes and racking can be sourced locally around the world, simplifying implementation and making local compliance even easier.

e compact robot climbs on two channels connected to one side of the racking, half the connection points of typical ASRS climbing

technology, creating a more reliable climb and simplifying maintenance.

Traveling at extreme speeds of 4 m/sec, and with direct access to each bin at all times, orders can be delivered to picking stations in only two minutes a er order intake—34% faster than typical ASRS. Each HaiClimber robot is able to freely navigate under reaching in any direction, allowing each robot to take the most e cient path to inventory and workstations, preventing robotic “tra c jams” caused by aisle-only travel and ensuring consistently fast operations.

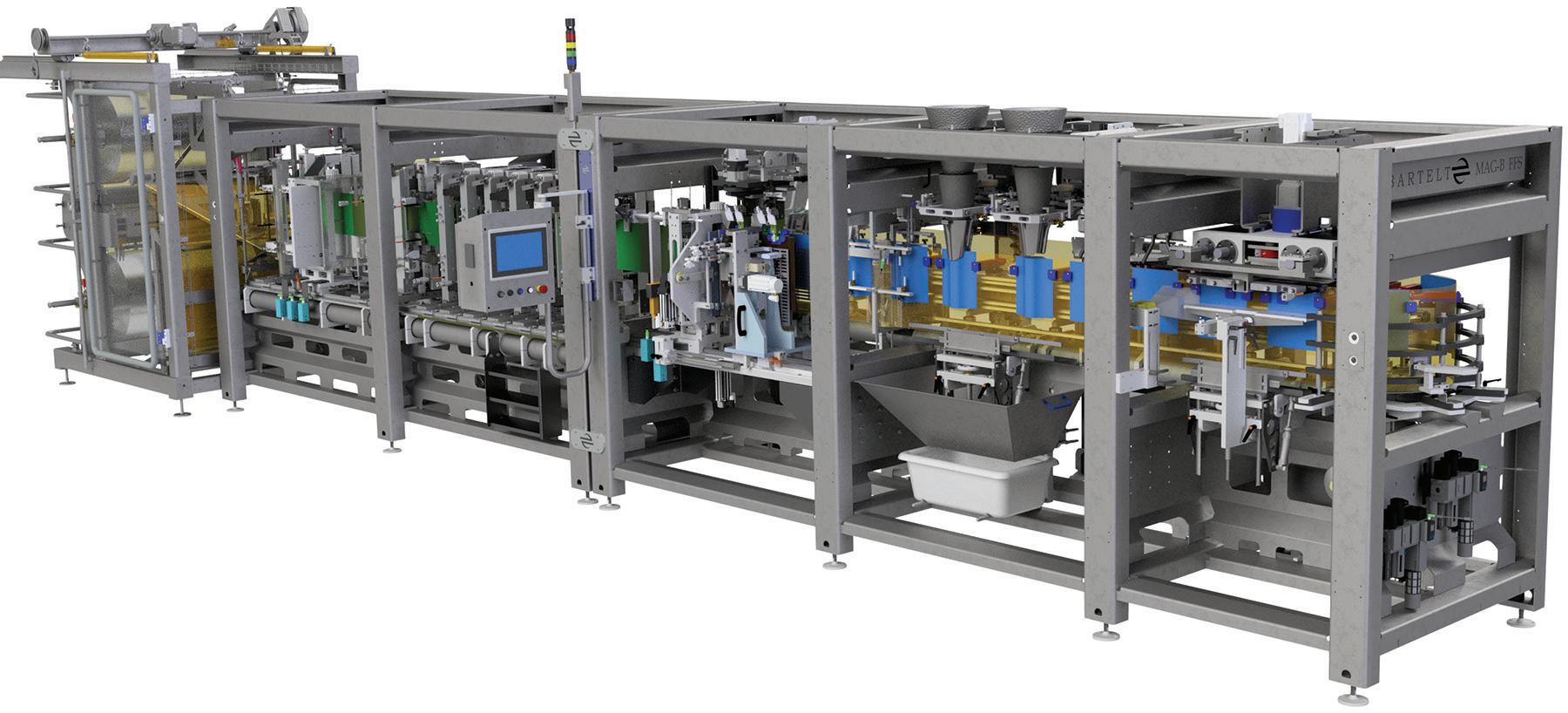

Bartelt MAG-B

Horizontal Form/Fill/Seal

Bartelt Packaging

(Booth W-1130)

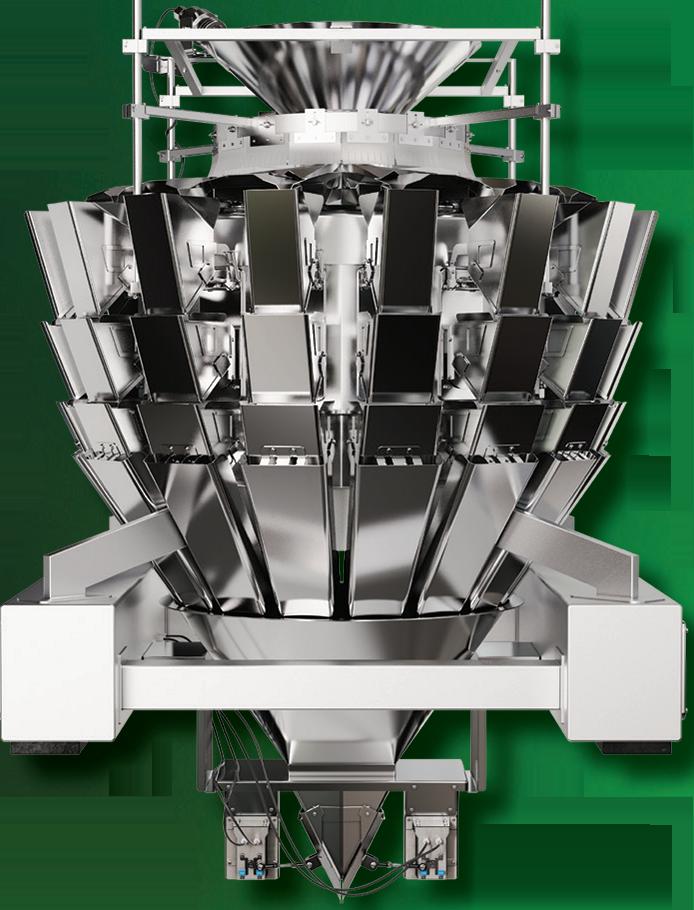

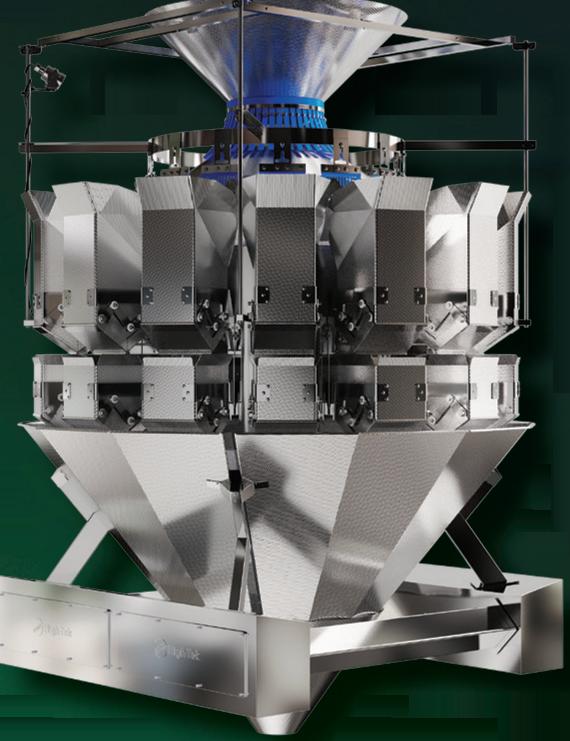

Bartelt’s MAG-B rede nes what’s possible in HFFS pouching technology through three industry- rst innovations: a space-e cient magnetic track system, a patented, maintenancefree pouch clamp design and Adaptive Sealing Control which automatically adjusts sealing and cooling assemblies during changeover, including compensation for lm stretch.

Traditional pouching machines rely on xed mechanical drives, timing chains, and manual adjustments, limiting exibility and creating wear points, increasing downtime and maintenance. Additionally, they lack the exibility to quickly adapt to di erent product con gurations.

Bartelt’s MAG-B allows one operator to perform a changeover on the y without mechanical adjustments

in less than 15 minutes. Additionally, the MAG-B is con gured to utilize the front and rear of the track, providing world-class functionality in a compact footprint and cycle rates that can exceed 150 PPM. e magnetic track allows an exclusive product settling “shake” feature at lling and purging, which reduces O2 levels and obtains better product settling. ese capabilities, combined with Bartelt’s patented maintenance-free pouch clamps, result in a machine platform uniquely designed to meet your current and future production needs. When future requirements require di erent sizes, faster production, or the integration of mono-materials and/or thin-gauge substrates, the MAG-B is designed with the capability to adapt quickly and e ciently.

• Up to 40% sensitivity improvement

• Rejects reduced to 1/7 of previous model

• 30% lower power consumption

• Intuitive, smartphone-style user interface

Anritsu’s new XR76 is the next evolution in X-ray inspection . Advanced imaging enables better detection of metal and low-density contaminants while lowering false rejects that result in costly downtime. Simple, touchscreen operation is easy to use for your whole team, reducing training time.

Visit PACK EXPO booth SL-11019 www.anritsu.com/product-inspection

—Continued from page 20

Syntegon (Booth N-5244)

e MLD Advanced meets the increasing requirements of pharmaceutical manufacturers for high output with 100 percent in-process control (IPC).

e automatic bag and tub openers, well-known from many syringe lines, use no-touch transfer to ensure the aseptic transfer of the syringes into the lling area. e Pharma Handling Unit developed by Syntegon denests the syringes automatically without glass-to-glass contact and places the containers into the pitch adjustment station. Here, the syringes are moved into the machine pitch and then placed in the clips of the machine transport.

e empty syringes are weighed using 100 percent IPC before they are transferred to the lling station. e subsequent lling and stoppering process is based on the proven FXS series for syringes: the lling needles are mounted on the Pharma Handling Unit and allow for exible redosing if required. anks to IPC, the lling weight is controlled precisely.

Customers bene t from this innovative combination of proven technologies in several ways: in addition to achieving an output of up to 400 syringes per minute, they also receive safe and proven processes.

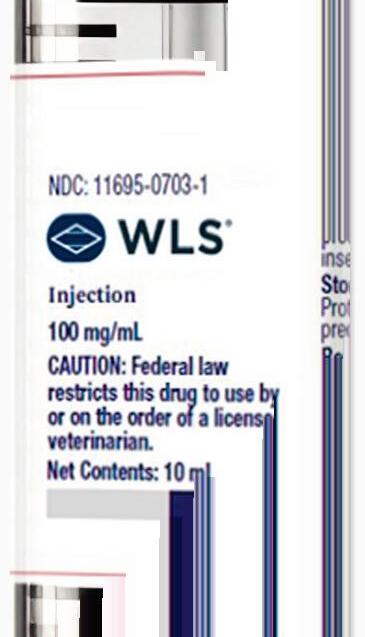

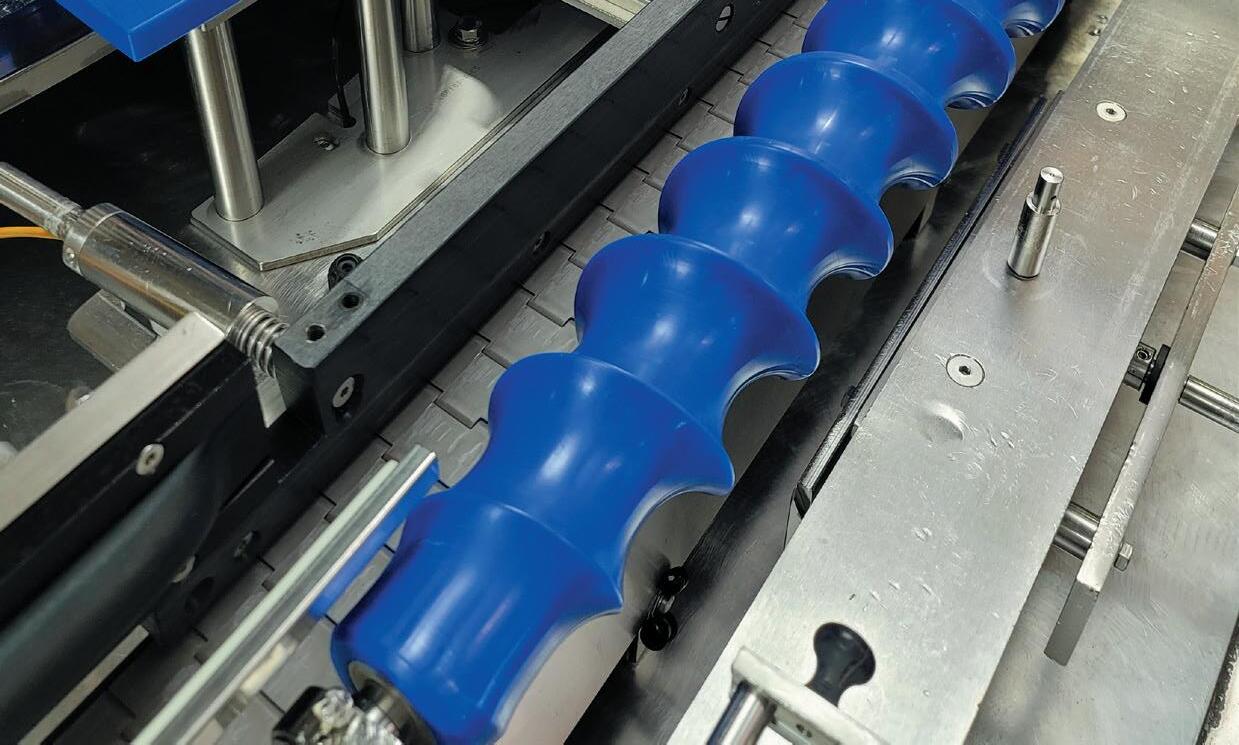

WLS (Booth W-1152)

e patented PR-12 and PR-24 from WLS perform highspeed, high-control plunger rod insertion and syringe labeling in one single, compact-footprint unit. e PR-12 is designed to run 300 bulk syringes per minute, and the PR-24 is designed to run 600 bulk syringes per minute. e system can run the following syringe sizes: 0.5mL. 1mL short, 1mL long, 2.25mL, 3 mL and 5mL. Featuring patented ATR Technology, the system will not disrupt the plunger height or seal while inserting the plunger rod. e unique, automated regulation of torque makes this plunger rod insertion machine a generational leap forward over prior plunger rod insertion technology.

e system is designed to compensate for a plunger placement tolerance of +/- 5mm, ensuring the plunger rod is fully seated into the plunger every time. is provides greater control and greater protection of the aseptic seal created by the plunger.

SEPTEMBER 29, 2025 24

—Continued from page 22

BK-4 Precision Belt Capper with EM-980 Inline

Torque Control

Kaps-All Packaging Systems, Inc. (Booth W-820)

While many cappers rely on disc-based mechanisms that struggle with closure variability

or risk damaging high-end packaging and limited contact with the caps, the BK-4 uses a patented 4-belt system that gently yet precisely grips each closure, minimizing scu ng while achieving consistent torque across cap styles from standard caps to child-resistant caps and beyond. is exibility is critical for brands seeking to maintain aesthetic integrity in luxury cosmetics and dosage integrity in pharma.

What truly sets this system apart is the EM-980 Torque Monitor, an inline, electronic quality control unit that measures and records cap torque in real time on every bottle. Unlike traditional torque testers that rely on o ine sampling, the EM-980 provides 100% inline veri cation, immediately alerting operators and/or rejecting under-/over-torqued closures. is not only ensures 100% torque compliance but also streamlines operations, reducing manual inspection and rework.

e BK-4 also incorporates on-board inspection for veri cation of missing cap, missing foil, crooked cap, etc. is is incorporated into the on-board reject system that is standard to this model. Its compact design and seamless integration with the capper allow it to t into space-constrained production lines. e result is a high-throughput, data-driven, operatorfriendly capping solution that delivers premium results both in quality and appearance.

Comprex North America, LLC

Floco Process (Booth N-6760) Comprex e ectively dislodges residues without chemicals or mechanical intrusion. Paired with Viridivis, a biodegradable and low-foaming cleaning uid optimized for rapid rinsing, it achieves superior cleaning with up to 90 percent less water, dramatically reduced downtime, and no reliance on traditional caustic or acid-based chemicals.

Sustainability Bene ts of Comprex:

• Traditional CIP (Clean-in-Place) systems o en use thousands of gallons per cycle.

• Comprex uses short, high-e ciency air and water impulses, o en reducing water usage by up to 90%.

• Ideal for water-scarce facilities or those paying for puri ed water.

Comprex can clean without relying on harsh chemicals. is reduces:

• Chemical costs

• Chemical e uent

• Worker exposure risks

• Environmental discharge treatment

• Faster cleaning means less equipment idle time.

• Plants can run more e ciently, reducing waste from o -spec product starts or delays.

Non-invasive, low-pressure impulses reduce:

Metal

Booth # W-3350

At RYCHIGER, we bring precision, flexibility, and innovation to packaging automation. From filling and sealing to cartoning, case/tray packing, and palletizing, our solutions are engineered to adapt to your production demands, no matter the format, speed, or complexity. With fast changeovers, compact footprints, and seamless integration, we help you reduce downtime and scale with confidence. Backed by decades of expertise and in-house support, our systems deliver the reliability you need to stay ahead.

See the future of packaging automation at PackExpo Las Vegas, Sept. 29–Oct. 1, Booth # W-3350. Experience live demos of the VRC-60 Cartoner and RCP-10 Cobot Palletizer, and learn how RYCHIGER makes packaging performance come together.

Scan to learn how our solutions can streamline your end-of-line process

—Continued from page 24

Machine Stretch Film with 30 Percent PCR

Trioworld (Booth SU-34018)

Trioworld designs its highperformance stretch lms to meet the evolving needs of both its customers and the planet. What sets its products apart is the combination of reduced material usage, 30 percent Post-Consumer Recycled (PCR) content, and

exceptional performance, making it a leader in the circular economy for exible packaging.

Trioworld’s stretch lms are thinner and stronger, allowing for reduced material usage without compromising durability or load stability. is innovation helps businesses reduce plastic waste while still maintaining the necessary performance standards for their packaging needs. By o ering lms with PCR content, Trioworld not only reduces the dependency

on virgin plastics but also decreases carbon emissions, making a signi cant contribution to environmental preservation.

What truly makes the product innovative is the seamless integration of circularity into every step. Its Baled Film Collection program allows for used stretch lms to be collected, sorted, cleaned, and recycled back into the product line, closing the loop of the plastic lifecycle. is process results in the creation of highquality PCR regranulate, which can be reused, reducing waste and promoting a circular packaging solution.

ZeCycle Recycling Program: Closing the Loop on VCI Packaging

ZERUST Corrosion & Cleaning

Solutions (Booth SU-25054)

ZeCycle is an innovative closed-loop recycling program developed by ZERUST in partnership with RecycleMax, designed to help industrial manufacturers reduce plastic waste and carbon emissions. is program enables companies to collect and recycle used ZERUST VCI packaging and plain LDPE poly lms, which are then processed into post-consumer recycled (PCR) resin and used to manufacture new ZERUST ICT510-PCR30 VCI lm. By transforming end-of-life packaging into new corrosion-inhibiting lm, ZeCycle advances sustainability goals, supports a circular economy, and provides a measurable environmental impact, o setting approximately 1,480 lbs. of greenhouse gas emissions for every 1,000 lbs. of lm recycled. ■

The northeastern U.S. seafood producer has enhanced the quality of its products with metal detector inspection systems.

Boston Sword & Tuna (BST), a U.S. seafood distributor, is making use of Profile Advantage metal detectors from Mettler Toledo (Booth W-2122) on three packaging lines to help ensure final product quality.

BST processes a wide variety of frozen fish and seafood out of its 50,000-sq.-ft. Boston facility, and the company needed a quality system that could handle the challenges seafood poses to detectors.

“Inspecting seafood is particularly difficult for most metal detectors,” states Phil Tripoli, Maintenance Manager at BST. “Saltwater and ice put out a magnetic field that can confuse run-of-the-mill systems, so we needed something high tech that could reliably identify metal contaminants without triggering false rejects. Mettler Toledo is well regarded in the seafood industry, and their Profile Advantage is a great fit for our needs.”

BST installed its first Profile Advantage metal detector in 2020 and added two more in 2023 to other packaging lines.

The Profile Advantage metal detectors contain a large aperture used to inspect 10-pound corrugated cases of fresh and frozen products, including cod, salmon, haddock, crab, swordfish, scallops, and shellfish.

To help prevent false rejects and produce clearer results, the detectors use multisimultaneous frequencies to distinguish between metal contaminants and natural product characteristics. BST follows a quality assurance protocol that includes calibration tests done twice a day using certified test strips made from ferrous, nonferrous, and stainless-steel metals.

“Our new inspection systems deliver great detection sensitivity, which is

—Continued from page 28 imperative given how frequently metal objects turn up in wild-caught seafood,” says Tripoli. “Plus, these metal detectors are consistent. They stay within our required specifications during long production cycles without any adjustments.”

Furthermore, Profile Advantage can store up to 100 different recipes for fast recall changeovers. The detectors’ product clustering capability further simplifies operations by allowing similar products to share the same settings. New products receive optimal parameters from a single-pass auto-setup routine, which is done in a matter of seconds.

If the system detects metal, its conveyor automatically stops so the package can be removed from the line for further inspection.

“Any flagged cases undergo reinspection through one of our other metal detectors to confirm the finding,” Tripoli explains. “Fortunately, reruns are very rare, and the few we’ve had prove the accuracy of these systems.”

Boston Sword & Tuna found the Profile Advantage detector to be an effective solution for its quality needs, and the ease of buying and implementation reinforced the company’s decision to add more detectors to its lines.

“We were so impressed with our first Profile Advantage that going back for more was an easy decision,” states Tripoli. “The entire purchasing and startup process was seamless, thanks to excellent support from Mettler Toledo and our sales rep, Brian Vernet of Flo-Dynamics.”

Seafood inspection can be challenging due to the conditions of products, but the Profile Advantage systems’ quality capabilities aid BST’s food safety efforts and growth.

“As we continue to expand our operations and serve more customers across the country, maintaining the highest food safety standards remains our top priority,” Tripoli says. “Our Profile Advantage systems give us confidence that we’re protecting consumers and help us deliver the outstanding product quality that has defined our company for generations.” ■

Inserting the plunger rod, torquing it into place, and labeling the syringe using our new, patented ATR technology

The NEW, patented PR-12 and PR-24 from WLS perform high-speed, high-control plunger rod insertion, and syringe labeling in one, single, compact-footprint unit.

Scan the QR codes below or visit the show app sponsored by ProMach (Booth W-1500) for descriptions, times, and locations.

For up-to-the-minute content, head to the always-popular Innovation Stages (Booths W-4300, W-4310, and W-4318). Exhibitors and subject matter experts present packaging industry breakthroughs, new products, and best practices during fast-paced, 30-minute seminars presented on three stages.

Education session topics include:

• Be Future Ready: Advanced TIJ Technology for Enhanced Efficiency, Global Coding Standards Compliance, and Better TCO

• AI and Automation in Labeling and Artwork Management : Are You Ready?

• Building Traction with ERP and Gen AI

• Sustainable by Design: Energy-Efficient Packaging Machines Transforming the Industry

• Leadership and Change Management in the Age of Industry 4.0

Industry Speaks (Booth W-4324) features thought leaders from PACK EXPO Las Vegas Partner Associations, giving attendees a snapshot of the trends and issues shaping their specific industries and their effect on the marketplace. Explore diverse perspectives from representatives of all corners of the packaging and processing world for insights that make an impact on business decisions.

Industry Speaks Sessions at PACK EXPO Las Vegas include:

• How Smart Packaging Helps Grow Consumer Transparency

• Before You Buy: What Equipment Specs Really Matter?

• The Latest Trends in Robotics

• Top Packaging Policies Impacting Your Business

• Inside the Workforce Gap: Insights from PMMI’s Latest Research

• Ordinary But Extraordinary: The Tried-and-True Benefits of Corrugated Packaging

Got 30 minutes? Take a seat at the Processing Innovation Stage (Booth N-9100) to hear about the latest food and beverage processing breakthroughs and improvements to make in operations. Content is targeted to food and beverage manufacturers. Exhibitors and subject matter experts present packaging industry breakthroughs, new products, and best practices during fast-paced seminars.

Education session topics include:

• Advancing Sustainability Through Innovative Food & Beverage Factory Solutions

• Processing Foods without Preservatives

• Automation Solutions for HPP: Success Story by Bay Center Foods (Chick-fil-A)

• Packaging Line Startups: A Proven Blueprint for Success

• Scaling Quality and Efficiency Through Continuous Mixing: Three Bakery Success Stories

Within PACK EXPO Vegas’ Sustainability Central, attendees get different takes on sustainability from industry experts and gain insight into making brands more sustainable for the future.

Education session topics in Booth S-35000 include:

• Sustainable Packaging Impact on Consumer Behavior

• Packaging Waste, Circularity, and the EPR Mandate to Create ROI

• Legislation is Here—Is Your Packaging Ready?

• Driving Sustainable Savings & Circularity in Packaging

• Evolving E-Commerce Packaging Materials

• Driving Efficiency in Compressed Air with Data & AI

—Continued from page 33

Discover innovative ways to optimize logistics and make the supply chain more efficient and sustainable with reusable assets. In the Reusable Packaging Learning Center (Booth SU-34000), attendees hear from suppliers and their clients who’ve successfully transformed their operations to incorporate reusables. Sessions discuss enhancing supply chain performance, sustainability, and technology usage through reusable transport packaging.

Sessions at this year’s event include:

• Panel: When Products Are No Longer Reusable, Achieve Maximum Value and Sustainability

• Panel: Market Outlook: Sustainable Packaging Trends in the Fresh Produce Industry

• Optimizing the Cube: GPO strategies for Smarter Packaging

• State of the Industry: The Game-Changing Opportunity with ArtificialIntelligence in a Reusable Transport Packaging System

• Drive Warehouse and Storage Efficiency with Versatile Bulk Packaging

From rising talent to industry leaders, PACK EXPO is where packaging and processing professionals come together to share ideas, spark partnerships, and build the future.

One thing is certain: the connections made at PACK EXPO Las Vegas can change the trajectory of your business. With more than 35,000 attendees expected from over 40 vertical markets and 2,300 exhibiting companies, the networking opportunities are not just numerous—they’re unmatched.

PACK EXPO Las Vegas 2025 offers the largest gathering of industry professionals this year. With it comes the chance to meet decision-makers, thought

leaders, and peers who are driving innovation across the packaging and processing supply chain. Whether you want to exchange ideas, spark partnerships, or gain new perspectives, this show offers countless touchpoints to engage, connect, and grow.

Attendees will gain access to a dynamic mix of formal and informal networking events, including:

On Sunday night, PACK gives BACK™, sponsored by Rockwell Automation (Booth SL-13028), presented an exclusive, private performance of Mystère by Cirque du Soleil® at Treasure Island—an event just for PACK EXPO Las Vegas participants. Proceeds from this annual event support the PMMI Foundation

Monday is highlighted by The Young Professionals Networking Reception, sponsored by Beckhoff Automation LLC (Booth SL-15047), at The Cove Bar & Arcade at Treasure Island. The event offers upand-coming leaders an opportunity to socialize with their peers in a fun and relaxed environment, perfect for making new connections in the industry.

Tuesday morning brings the Packaging & Processing Women’s Leadership Network (PPWLN) Breakfast. Open to all registered attendees, this annual breakfast offers a unique opportunity to connect with like-minded professionals, share experiences, and gain valuable insights. This year’s featured speaker, Alison Fragale, an organizational psychologist, professor at the University of North Carolina-Chapel Hill, leadership expert, and bestselling author of Likeable Badass: How Women Get the Success They Deserve, will offer attendees practical strategies to navigate their career boldly and authentically.

The PPWLN Breakfast is supported by PPWLN Gold Sponsors: ProMach (Booth W-1500) and Morrison Container Handling Solutions (Booth W-3522); PPWLN Breakfast Sponsors: Plexpack Corp. (Booth W-2906), SMC Corporation of America (Booth SL-13034), Smurfit Westrock (W2300), Emerson Discrete Group (Booth SL-15009), BW Packaging (Booth W-3100), and Septimatech Group Inc. (Booth W-762); and PMMI Benefactor Sponsor: Schneider Electric (Meeting Room N-214). First time attendees can connect with peers and talk shop with fellow first-timers while enjoying a complimentary breakfast on Tuesday from 8:00 a.m. –9:00 a.m. in the First-Time Attendee Lounge (Room S-220), sponsored by ProMach (Booth W-1500). A First-Time Attendee badge is your ticket. Spaces are limited, first-come, first-served.

Daily through Wednesday

The First-Time Attendee Lounge (Room S-220), sponsored by ProMach (Booth W-1500), is an inviting space for new attendees to the show. This exclusive lounge provides first-time attendees with assistance on how to navigate the show, access product locators, talk to experienced show staff, and an opportunity to relax and recharge to help maximize their time at the show.

Throughout the show, Vision 2030 provides unparalleled networking opportunities among packaging and processing industry leaders. During these interactive sessions, industry professionals gain valuable connections, insights, and new perspectives around common operational challenges – while helping to develop innovative solutions. Four sessions are planned at PACK EXPO Las Vegas covering the following topics:

• The Dirty Work: Automation in Food and Beverage Equipment Sanitation of the Future

In addition, dedicated resource centers, such as the Association Partner Pavilion (Booths W-100W-130) and the Workforce Development Pavilion (North Hall Lobby), provide structured settings for meeting with industry organizations and talent development leaders.

“PACK EXPO Las Vegas is where the industry shows up—not just to see machines run, but to meet the people driving the industry forward,” says Jim Pittas, president and CEO of show organizer PMMI, The Association for Packaging and Processing Technologies. “It’s where conversations become partnerships and where ideas turn into real-world solutions.”

Find a complete list at packexpolasvegas.com. ■

• From Paper to Digital Intelligence - Knowledge Transfer for Machine Operators

• Securing the Future of Packaging and Processing: Collaborative Cybersecurity for OEMs and CPG companies

• Beyond Manuals: Setting the Right Expectations for Operator Training on Modern Packaging Lines

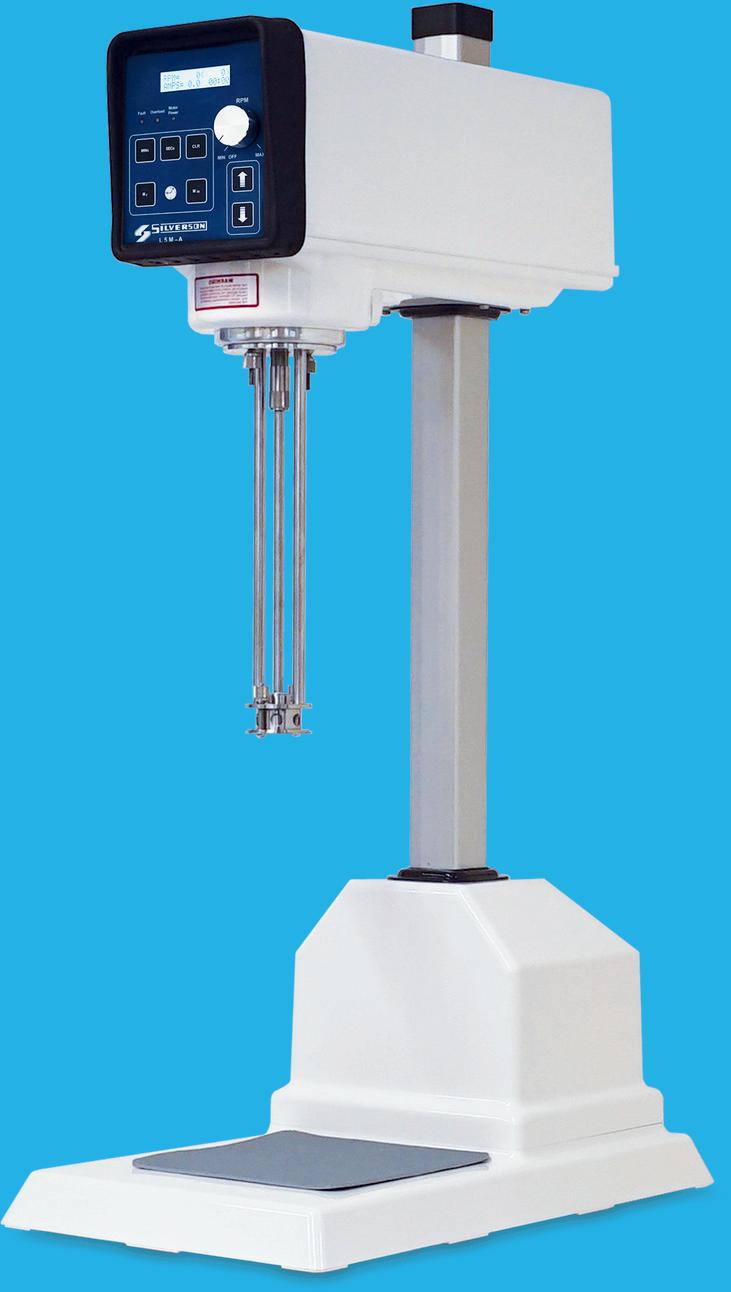

Obtain rapid results with mixing times reduced by up to 90%

Achieve effortless incorporation of even the toughest-to-mix ingredients

Scale from lab to production with consistent, reproducible results

btain imes chieve ven cale onsistent,

xplore our comprehensive mixing pplication guides & how-to videos to

Marchesini Group (Booth N-5820) creates value through digital transformation and Industry 4.0 tools

For over 50 years, Marchesini Group, a leading company in the design and production of packaging machinery for the pharmaceutical, animal health, and cosmetic industries, has been investing in new technologies to provide increasingly innovative machines and lines. The goal is to create value for customers through digital transformation and Industry 4.0 tools, investing in multiple areas and applications.

Marchesini develops technologies based on artificial intelligence applied to product quality inspection systems and especially to robotics. The latter, in particular, is designed, produced, and assembled internally within the company and has

the quality and integrity of pharmaceutical products have always been a central step in the pharmaceutical industrial process. By collecting images with highresolution cameras combined with specialized software algorithms, the inspection machines made by Marchesini Group can detect defects that are increasingly difficult to detect with the human eye, minimizing the possibility of error.

This technology is a key tool for increasing productivity and gaining greater knowledge of how to better operate and maintain equipment. How does it work? Thanks to the presence of sensors on the machine (IoT network) capable of performing accurate monitoring, as well as data collection and subsequent analysis tools using AI-based algorithms, customers can monitor the health status of their machines 24/7 and schedule maintenance in advance, thus avoiding potential breakdowns.

become a distinctive feature of Marchesini Group machines over the years. Thanks to a collaboration with the start-up Eyecan, a technology has been developed that allows the company’s robots mounted on the production line to become self-learning. Specifically, AI is involved in the robots’ picking applications, allowing the robotic arms to identify and pick up an object along the packaging line with the aid of a camera. With the help of machine learning algorithms, it is now possible to program Marchesini Group robots using another robot as a tutor, enabling them to autonomously recognize any object, in any condition, without the need for a human programmer to write new software. The benefits of this technology are greater flexibility, ease of use of the machines, and improved final performance.

Another area of application, in which Marchesini has been investing in recent years, is inspection, since

Marchesini Group has developed several solutions based on augmented reality to facilitate customers by communicating information and expertise related to the proper use of the machines. This simple and intuitive

technology allows pharmaceutical companies to train their technicians quickly and effectively, reducing the risk of errors. Workers who operate production lines can benefit from this technology and receive step-bystep guidance on required operations. ■

A launch pad for packaging and processing breakthroughs, the biennial event has experienced significant expansion and influence.

PACK EXPO Las Vegas is celebrating a milestone: 2025 marks 30 years since the show’s debut. Today, PACK EXPO Las Vegas remains a global hub for industry innovation and collaboration.

Show producer PMMI, The Association for Packaging and Processing Technologies (West Lobby), has elevated PACK EXPO Las Vegas from a regional trade show to a global industry force— expanding its scale, influence, and relevance across

international markets. This year, the show will span over 1 million net square feet, feature 2,300 exhibitors, and expects to attract 35,000 attendees from more than 40 vertical markets.

“PACK EXPO Las Vegas has always been more than a trade show—it’s where the future of packaging and processing takes shape,” says Jim Pittas, president and CEO, PMMI. “For 30 years, we’ve been proud to drive innovation, foster collaboration, and spotlight the technologies shaping tomorrow’s supply chains. As we look ahead, we remain focused on the forces transforming our industry: automation, AI, sustainability, and workforce development.”

Since its launch in 1995, each show edition has introduced cutting-edge technologies, from the earliest automation solutions to today’s advances in AI, robotics, and sustainable packaging solutions.

PACK EXPO Las Vegas has been at the forefront of innovations over the past 30 years, and continues to evolve like the industry it serves. For example:

• In 2015, the show brought a new focus on pharmaceutical and medical device manufacturing, eventually growing into today’s Healthcare Packaging Pavilion (North Hall) and highlighting the show’s diversification into specialized sectors.

• The growing demand for logistics solutions, driven by the surge in e-commerce and supply chain complexities, led to the introduction of the Logistics Pavilion (North Hall) in 2023.

• The Processing Zone (North Hall), featuring front-of-the-line solutions, and the Processing Innovation Stage (Booth N-9100), were added to provide everything food and beverage manufacturers need to improve production, all in one place.

• Las Vegas has become a destination where the entire industry converges, thanks to the addition of the Industry Speaks (Booth W-4324) learning stage, where thought leaders from the PACK EXPO Las Vegas Partner Program provide valuable insights and resources to their peers.

• Sustainability Central (Booth S-35000) debuted in 2023 and has evolved into a must-visit show floor destination with educational sessions covering

sustainability, one of the most multifaceted challenges the packaging and processing industry faces today. Expert-led sessions will help attendees navigate the complexities of this issue and what it means for their brands.

Also, in 2025, two new guided show floor tours offer attendees curated experiences. The PACK EXPO Discovery Tours, sponsored by Lantech (Booth W-2322) and Formic (Booths SU-26038, SU38084), are ideal for first-time buyers and senior-level decision-makers looking for automation solutions to streamline and optimize various stages of packaging and processing. The PACK EXPO Sustainability Tour, sponsored by Anchor Packaging (Booth SL-17000), is tailored for consumer packaged goods (CPG) brand owners seeking eco-conscious solutions.

PMMI proudly honors the PMMI Member Companies that were part of the inaugural 1995 show and continue to exhibit today by highlighting each company with a special PMMI legacy member exhibitor placard in their booths. A complete list of these members can be found at packexpolasvegas. com/exhibiting/legacy-exhibitor. Their support has helped shape the legacy of innovation and excellence that defines this industry and the continued growth of PACK EXPO Las Vegas.

“As the industry accelerates toward smarter, more sustainable operations, PACK EXPO Las Vegas remains the one place where it all comes together— technology, insight, and community. This year’s show reflects the momentum we’re seeing across the market, with record participation and unmatched opportunities to learn, connect, and grow,” says Laura Thompson, vice president, trade shows, PMMI.

The show is also a prime opportunity to build relationships that drive business growth and bring people together across all levels of the industry.

On Sunday, attendees enjoyed a private Cirque du Soleil® performance of Mystère at PACK gives BACK™, sponsored by Rockwell Automation (Booth SL-13028), supporting the PMMI Foundation.

Anyone who RSVPs can join the Packaging & Processing Women’s Leadership Network Breakfast on Tuesday at 7:30 a.m. in Room N-245 —backed by Gold Sponsors ProMach, Inc. (Booth W-1500) and Morrison Container Handling Solutions (Booth W-3522), plus Plexpack, Corp. (Booth W-2906), SMC Corporation of America (Booth SL-13034), Smurfit Westrock (Booth W-2300), Emerson

Discrete Automation Group (Booth SL-15009), BW Packaging (Booth W-3100), Septimatech Group Inc. (Booth W-762), and PMMI Benefactor Sponsor Schneider Electric (Meeting Room N-214). Future leaders in packaging and processing can connect with their peers and other industry trailblazers on Monday at the Young Professionals Networking Reception, sponsored by Beckhoff Automation LLC (Booth SL-15047), at the Cove Bar

& Arcade (at Treasure Island Hotel).

Newcomers also benefit from the First-Time Attendee Lounge (Room S-220), sponsored by ProMach, Inc. (Booth W-1500), a dedicated space offering guidance and networking, ensuring everyone leaves with valuable connections.

Additional networking and special events can be found at packexpolasvegas.com/the-show/ networking-and-special-events ■

PMMI Foundation showcases career-driven programs for the next generation of packaging and processing talent

The next generation of packaging and processing professionals take center stage at PACK EXPO Las Vegas 2025 through engaging student activities hosted by the PMMI Foundation (North Hall Lobby NL14), the charitable arm of PMMI, The Association for Packaging and Processing Technologies (West Lobby). With a strong focus on workforce development and industry engagement, the show offers high-energy programs that bring Science, Technology, Engineering, and Mathematics (STEM) skills to life and give future leaders a front row seat to the industry’s possibilities.

From high school robotic demonstrations to a fast-paced PACK Quest educational competition, students experience what makes the packaging and processing community so dynamic.

Returning to PACK EXPO Las Vegas is the Future Innovators Robotics Showcase (North Hall Lobby), where local high school robotics teams demonstrate their skills in automation design, engineering, and troubleshooting. This mentorbased program fosters STEM learning while building life skills such as communication, confidence, and teamwork. Each participating team’s high school receives a $500 grant from the PMMI Foundation to support their involvement. This year, the show welcomes FIRST Nevada teams to showcase their robot skills.

Students will take the spotlight on Wednesday, Oct. 1, during the Amazing Packaging Race, sponsored by Emerson Discrete Automation Group (Booth SL-15009). In this high-energy, hands-on competition, student teams race across the show floor to complete challenges at exhibitor booths, gaining realworld exposure to advanced technologies while making valuable industry connections. Participating exhibitors include:

• Beckhoff Automation (Booth SL-15047)

• Carleton Helical Technologies (Booth N-9010)

• CMCO Conveyance Solutions (Booth W-2744)

• Cold Pressure Council (W-103)

• Domino North America (Booth W-549)

• Econocorp (Booth W-2522)

• Encoder Products Company (Booth SL-11009)

• Fallas Automation Inc. (Booth W-2130)

• Formers International, Inc. (Booth W-2766)

• FOX IV Technologies, Inc. (Booth N-6800)

• HARPAK-ULMA Packaging, LLC (Booths N-5272, SL-13000, and W-1568)

• Hoosier Feeder (Booth SL-12026)

• IoPP (Booth W-100)

• Lenze Americas (Booth SL-13043)

• LinMot USA (Booth W-4144)

• Massman Companies (Booth W-2722)

• Morrison Container Handling Solutions (Booth W-3522)

• OMAC (Booth W-105)

• Pacteon Group (Booth W-2944)

• Pepperl+Fuchs, Inc. (Booth SL-16055)

• ProMach (Booths W-1500 and W-1524)

• Rinco Ultrasonics USA (Booth SU-30019)

• Shurtape Technologies (Booth SL-14015)

• SICK, Inc. (Booth N-8830)

• Siemens Digital Industries (Booth N-9230)

• Starview Packaging Machinery (Booth W-3344)

• Triangle Package Machinery Co. (Booth W-2200) FEBRUARY 17-19, 2026

The 2024 PACK Challenge winners, Spruce Packaging, will be showcasing their award-winning design, offering attendees a glimpse at the innovation coming out of today’s classrooms and into tomorrow’s plants.

Students are also encouraged to visit the Student Lounge (Booth N-237), where they can meet with HR professionals to discuss career paths, polish their resumes, and attend interview workshops. Sponsored by PMMI Foundation Visionary

Benefactor Schneider Electric (Booth N-214), the lounge provides a supportive, career-focused space just for students and will host a Meet and Greet with Schneider Electric on Tuesday from 11:00 a.m. to noon.

Students can connect with industry professionals, learn about their commitment to sustainability and innovation, and explore exciting career paths through internships and early talent programs.

To help students maximize their experience, PMMI staff will lead guided Student Tours daily at 10:00 a.m. and 2:00 p.m. Additionally, students are invited to attend the Packaging & Processing Women’s

Leadership Network (PPWLN) Breakfast, followed by a special PPWLN Student Tour led by members of the Executive Council, highlighting key exhibitors and empowering young women in the industry. The PPWLN Breakfast is supported by PPWLN Gold Sponsors: ProMach (Booths W-1500 and W-1524) and Morrison Container Handling Solutions (Booth W-3522); Silver Sponsors: Plexpack (Booth W-2906), SMC (Booth SL-13034), Smurfit Westrock (W2300), Emerson (Booth SL-15009), BW Packaging (Booth W-3100), and Septimatech (Booth W-762); and PMMI Benefactor Sponsor: Schneider Electric (Booth N-214).

“These programs are more than just exciting activities; they’re meaningful gateways to career discovery,” says Kate Torrence, director, workforce development, PMMI. “By engaging students early and immersing them in the show experience and demonstrating how they can help advance packaging and processing, we’re investing in the future of our industry.”

Something to benefit students and exhibiting companies is the Workforce Development Pavilion (North Hall Lobby)—the ultimate resource hub for strengthening the existing workforce and nurturing the future workforce. Colleges and universities will showcase their mechatronics and packaging and processing programs, while companies will have the opportunity to engage with students interested in pursuing careers in the industry.

Participating schools include:

• Brigham Young University - Idaho

• Cal Poly Packaging

• Clemson University

• Hennepin Technical College

• Michigan State University

• Purdue University Northwest

• Rochester Institute of Technology

• Rutgers Packaging Engineering Program

• San Jose State University

• Toronto Metropolitan University

• Tuskegee University

• University of Florida

• University of Maine

• University of Wisconsin - Stout

• Virginia Tech

The PMMI Foundation supports these efforts year-round by funding scholarships, student travel, and hands-on learning opportunities. A key fundraising initiative was the PMMI Foundation Golf Tournament, which took place Sunday, at Bali Hai Golf Club. In addition, a Silent Auction will be held during PACK EXPO Las Vegas featuring various entertainment, sports, and historical items up for bid. Proceeds from the Golf Tournament and Silent Auction directly benefit initiatives like student programming at PACK EXPO Las Vegas.

PACK EXPO Las Vegas is a launchpad for talent and a celebration of the next generation. ■

Cutting-edge packaging and processing solutions advance the circular economy and support corporate sustainability goals. Plus, new sustainability events and resources help attendees stay ahead of complex challenges facing the industry.

Show producer PMMI, The Association for Packaging and Processing Technologies, (West Lobby) is emphasizing sustainability, one of the most important topics in the packaging and processing

industry at PACK EXPO Las Vegas.

“PMMI is committed to reducing the industry’s environmental impact and improving sustainability in the supply chain,” says Jim Pittas, president and CEO

of PMMI. “PACK EXPO, its partners, vendors, and exhibitors are dedicated to driving meaningful change in packaging and processing.”

PMMI is proud to partner with Dow (Booth SL-17081 and SL-17082), the Official Sustainability Partner and Official Sponsor of ShowFloor Recycling. Dow will contribute its expertise in sustainable practices by sponsoring all recycling on the show floor, increasing the number of recycling bins, diverting as much waste as possible from landfills, and educating attendees and exhibitors on the importance of recycling.

Fostering awareness and efficiency, attendees will gain valuable knowledge that can be directly applied to their operations at the show’s Sustainability Central (South Upper Hall, Booth SU-35000)

Presented by Packaging World (West Lobby) and sponsored by Dow, Sustainability Central is the first show-floor stop for staying informed about the multifaceted challenges facing the packaging and processing industry. Expert-led sessions will allow attendees to navigate the complexities of sustainability and what it means for their brands.

“These free sessions will explore every aspect of sustainability,” says David Newcorn, president of PMMI Media Group (West Lobby). “Attendees will hear fresh perspectives from industry leaders and gain powerful insights to make their brands sustainability leaders.”

Session topics include:

• Streamlining Operations with Right-Sized Packaging Solutions for a Sustainable Future

• Building the Business Case for Sustainability

• Legislation Is Here — Is Your Packaging Ready?

• Driving Sustainable Savings & Circularity in Packaging

A list of all the Sustainability Central sessions can be found at packexpolasvegas.com/education/ sustainability-central.

In addition to the sustainability sessions held over all three days of the show, PACK EXPO Las Vegas is debuting industry expert-led PACK EXPO Sustainability Tours, sponsored by Anchor Packaging (Booth SL-17000). This new addition to the show provides a curated experience designed for consumerpackaged goods brand owners who are actively seeking sustainable solutions. The guided tours will

The Reusable Packaging Pavilion (South Upper Hall) showcases solutions that help companies implement sustainable transport packaging practices. By adopting reusable packaging, businesses can significantly cut waste, optimize their supply chains, and reduce their carbon footprint. Sponsored by the Reusable Packaging Association (Booth SU-34000), this pavilion is a must-visit for professionals striving to embrace a greener future. ■

provide valuable insights and exhibitors showcasing cutting-edge sustainability advancements, including:

• 15-minute overview to set the stage for the tour

• Headsets to ensure clear communication despite show floor noise

• Custom PACK EXPO Las Vegas Game Plan (a personalized booth itinerary), featuring the Sustainability Solutions Finder to help navigate sustainable solutions

• Exclusive networking reception with light snacks and beverages

Navigating sustainable solutions has never been easier for attendees with the Sustainability Solutions Finder, a powerful online resource directory that connects attendees with professionally vetted suppliers offering environmentally friendly solutions. Attendees can search by sustainability feature, package type, or “beyond the package” for additional criteria such as machinery and sustainable facilities at sustainability.packexpo.com. In addition, PACK EXPO Green Exhibitors are noted with the green logo in the exhibitor directory and on placards in their booths. These exhibitors feature sustainable packaging materials or machinery solutions.

Beyond the exhibits and new sustainability events, PACK EXPO Las Vegas offers more than 100 free educational sessions right on the show floor and eight specialty pavilions covering healthcare, confectionery, containers and materials, processing, logistics, education and workforce development, industry association partners, and reusable packaging.

Whether you need IP69K-rated components to withstand washdown environments, or advanced networking and RFID solutions to optimize throughput in your warehouse - Turck has the automation technology to power your packaging machines and lines.

Visit Booth # SU-30029 to learn more!

■ Improved shipping verification & traceability with RFID

■ Reliable sensors for metal cap detection & more

■ Rugged connectivity for extreme environments

■ Flexible I/O solutions for modular machine design

www.turck.us | 1-800-544-7769

The Partner Program returns to PACK EXPO Las Vegas 2025, where the entire packaging and processing industry will gather to explore breakthrough innovations, connect with peers, and experience machinery in action.

Now celebrating 30 years since its inception, PACK EXPO Las Vegas, produced by PMMI, The Association for Packaging and Processing Technologies, (West Lobby) will connect packaging and processing professionals from more than 40 vertical markets with over 2,300 exhibitors displaying the latest solutions across over 1 million net square feet of show floor. At the center of it all, the Association Partner Pavilion—located in the West Hall (Booths W-100 – W-130)—will serve as a vibrant hub for industry collaboration, connecting attendees with the foremost organizations across the packaging and processing spectrum.

“The PACK EXPO Las Vegas Partner Program demonstrates the importance of PACK EXPO Las Vegas bringing the entire industry together under one roof,” says Laura Thompson, vice president, trade shows, PMMI. “We’re thrilled to welcome back this impressive lineup of associations, including five new partners, each contributing expertise and connections that make this event truly unmissable. It’s a one-of-a-kind opportunity to discover solutions and build meaningful relationships that move business forward.”