Scan this QR code for the latest PACK EXPO Las Vegas news collated by PMMI Media Group’s roving team of editors. Find videos of the latest innovations and technologies directly from the show oor. ■

Mini Motor SPA’s (Booth SU-30056) Andrea Franceschini is recognized by PMMI Vice President Andrew Dougherty on the company’s 60th year in business. ■

PMMI Vice President Andrew Dougherty (second from left) awards Bayley Wright, Christina Sirek, Jason Moore, and Zak Netting on Stellar’s (Booth N-6850) 40th Anniversary. ■

It’s been an incredible show, and Day three is just as high-energy. There’s still time to find the solutions you’re looking for and get actionable insights from the educational sessions. ese are powerhouse sessions on trending topics like tari s, automation, sustainability, robotics, and workforce. Take advantage of on-site resources, such as Ask the Experts (West Hall Lobby and South Lower Hall) and the Attendee Solutions Center, to help you nd exactly what you need before the show wraps.

inspire innovation, foster collaboration, and deliver real business impact:

As we look ahead to 2026, the packaging and processing industry stands at an exciting crossroads. Rapid advancements in automation, AI, sustainability, and workforce development continue to reshape how businesses operate. PMMI is proud to lead the way in connecting professionals with the insights, technologies, and solutions that matter most.

Next year, we’re bringing the industry together at three powerful PACK EXPO events designed to

e people have spoken, and the 2025 Technology Excellence Awards are in.

A er tallying thousands of votes cast in person, on the o cial show mobile app, and online at packexpolasvegas.com, PACK EXPO attendees and exhibitors chose the best of the best in four categories: Food/Beverage, General Packaging and Processing, Personal Care/Pharma, and Sustainability.

PACK EXPO Las Vegas Show Producer PMMI would like to thank all exhibitors who submitted innovative and cutting-edge products for consideration. See page 4 for this year’s winners.

PACK EXPO East 2026 (Feb. 17–19, Pennsylvania Convention Center, Philadelphia) is regional show is all about a personal, focused experience. With professionals from 40+ vertical markets, 500 exhibitors, and over 8,000 attendees, it’s designed for meaningful conversations and e cient solutions. You’ll get hands-on access to the latest trends, uncover actionable insights, and nd opportunities to drive business growth. Not to mention, the debut of the Containers and Materials Pavilion. Simply put, it’s the must-attend event for anyone needing to stay ahead in packaging and processing.

EXPO PACK México (June 2-5, Expo Sante Fe, Mexico City)

Latin America’s leading packaging and processing trade show brings together industry professionals,

on page 6

A packed house numbering well into hundreds gathered yesterday for the annual Packaging & Processing Women’s Leadership Network (PPWLN) networking breakfast

Attendees took advantage of the free opportunity to network among their peers while hearing from featured speaker, Alison Fragale,

The method to our madness is simple:

Build ultra-rugged labelers to withstand your actual working environment. (Hint:They're BEASTS)

Infuse them with cutting-edge technology that makes bad operators good. ( e even built in HMI videos to teach the newbies how it's done. Yep!)

Support every system to ensure you are always running! (NitaCare connected internet login servicing. Consider your problem resolved)

The T ULY O IGINAL 100% Servo Synchronized labeler that dramatically reduces operator touch-time, speeds up changeovers beyond your wildest dreams and eliminates costly downtime on your line.

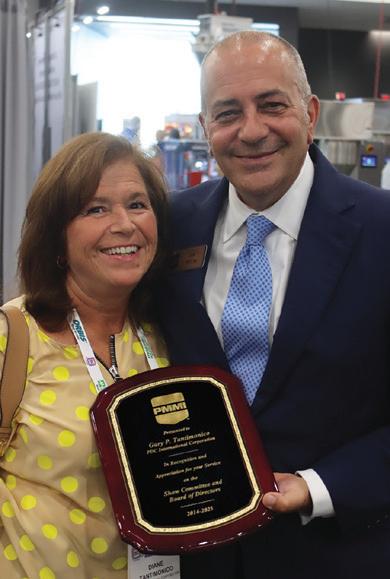

PMMI VP Trade Show Laura Thompson, PMMI President and CEO Jim Pittas and retired PMMI CEO Chuck Yuska gathered to celebrate PDC International (Booth W-3722) President Gary Tantimonico (second from right) and his wife Diane on Gary’s pending retirement. Gary was a staunch supporter of PMMI, serving on various commitees as well as the Board of Directors. ■

OCTOBER 1, 2025 4

Voting closed at noon yesterday for the Technology Excellence Award (TEA) competition, which honors technology never seen before at a PACK EXPO. Voters narrowed the eld of 12 nalists down to four winners, one in each category. Congratulations to the winners!

Food/Beverage

Senzani Brevetti SPA

Technology: Senzani U-Seal

Booth SU-26041

General Packaging & Processing

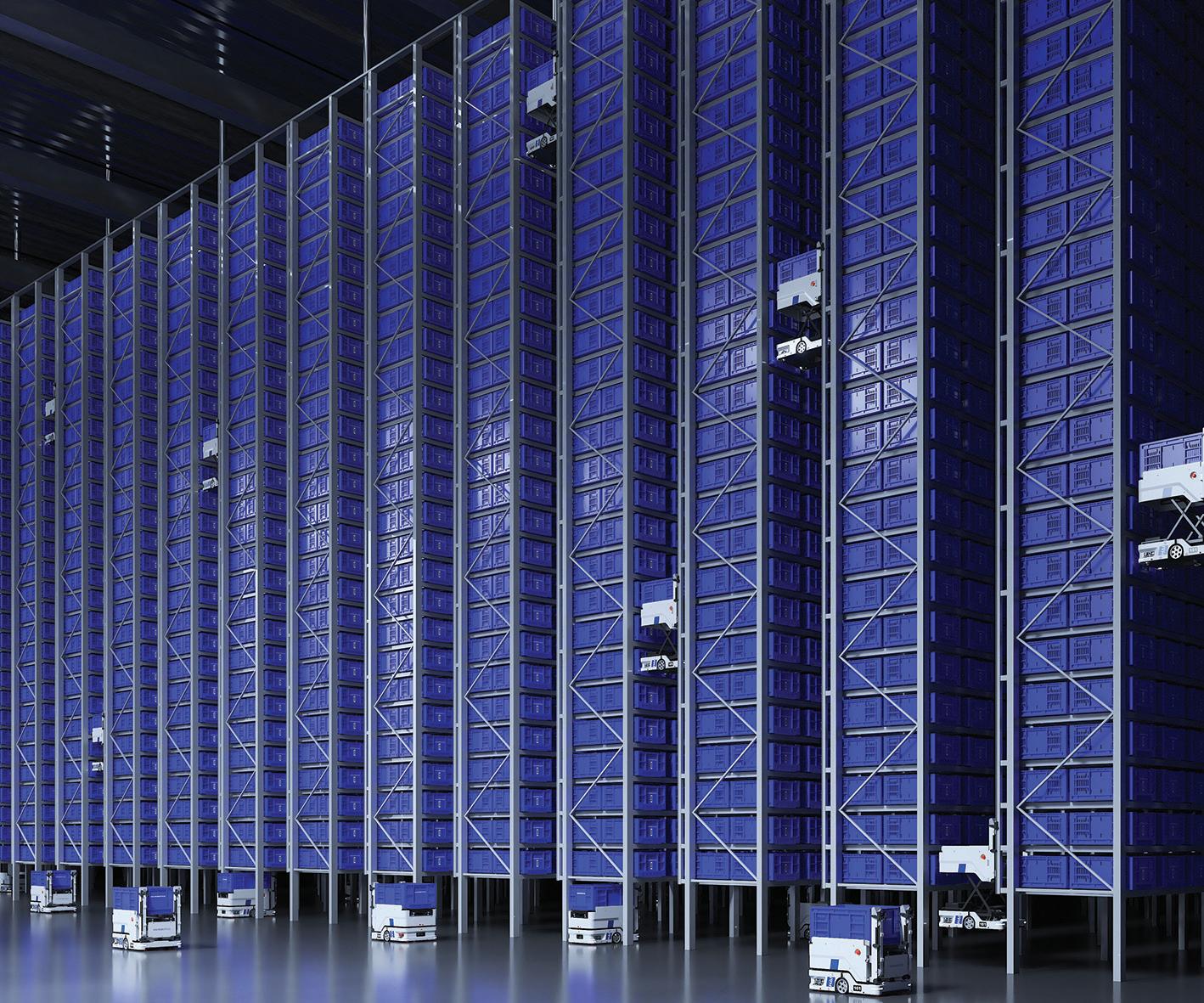

Hai Robotics USA

Technology: HaiPick Climb Booth SU-25090

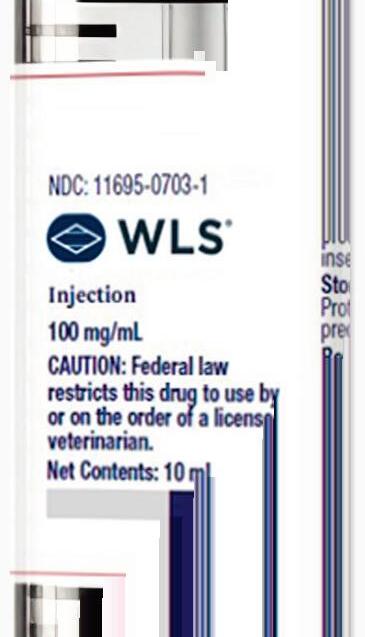

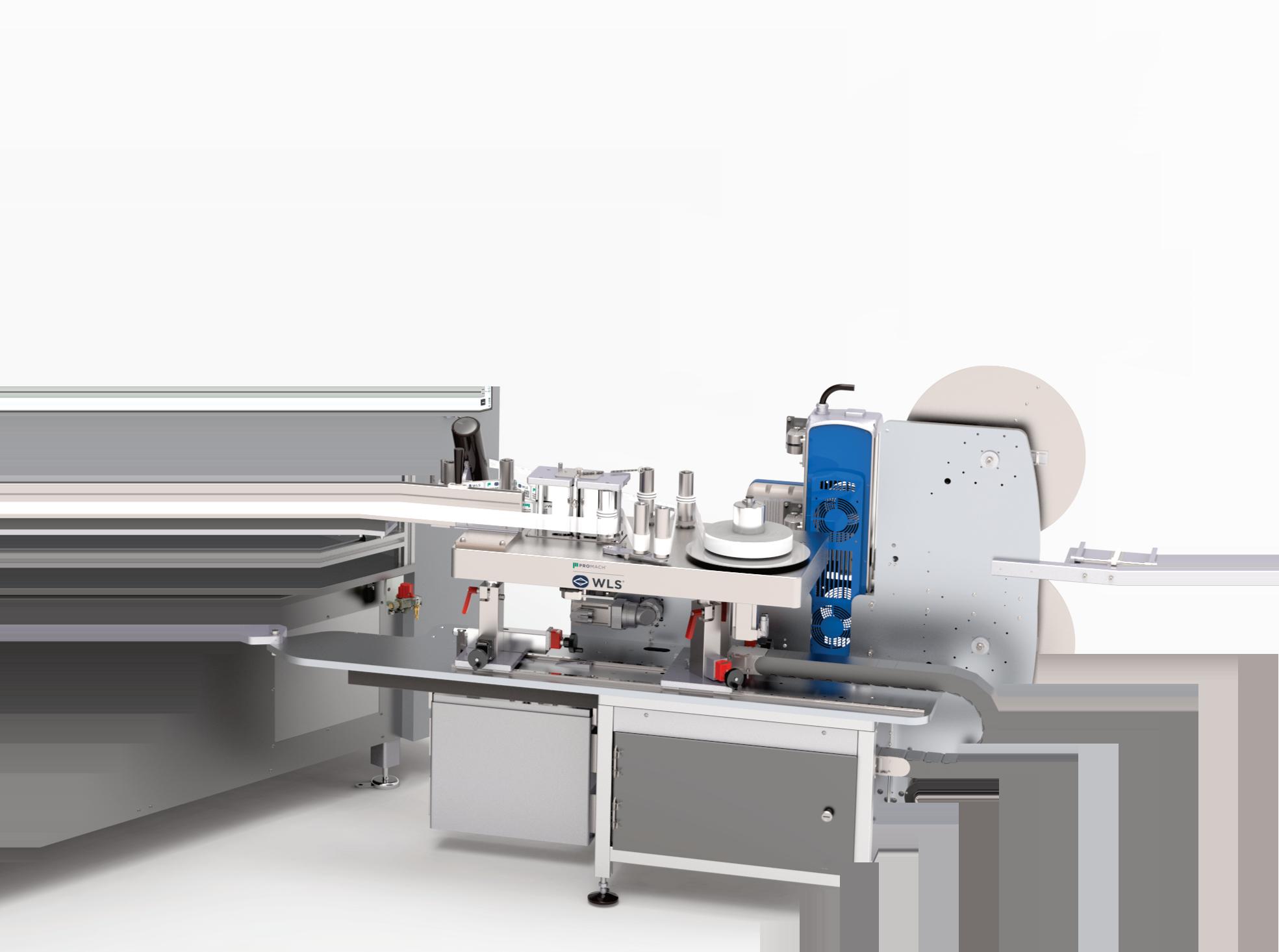

Personal Care/Pharma WLS

Technology: WLS PR-12 and PR-24 Plunger Rod Insertion and Labeling Machine for Syringes Booth W-1152

Sustainability

Floco Process

Technology: Comprex North America, LLC Booth N-6760

PMMI unveils 2025 State of the Industry report

Economic uncertainty persists in today’s business world, according to a special Media Luncheon on Monday, where PMMI Vice President of Market Development Jorge Izquierdo o ered insights into PMMI’s 2025 State of the Industry Report.

Major capital expenditures have declined somewhat across various sectors, and looking to the end of the year, uncertainty is expected to linger, contributing to equipment orders remaining delayed or on hold as companies reassess their plans in this economic environment. While a market contraction is not expected, 2025 is projected to be a low-growth year, with a modest 2.2% increase over 2024.

Overall, packaging machinery makers are tasked with designing compact equipment to t existing plant footprints, which can handle delicate materials without damage, and is easy to operate and maintain.

Other factors a ecting the industry include labor challenges, arti cial intelligence (AI), sustainability, and changes in U.S. government policies.

“End-user customers are also increasingly challenged by high SKU counts, innovative packaging formats, and the need to minimize downtime,” states Izquierdo. “Solutions for all the pressing challenges identi ed in the 2025 State of the Industry report can be found at PACK EXPO Las Vegas.”

Sustainability also continues to play a huge role for end users seeking to boost e ciency and pro tability. Still, priorities are shi ing as these companies strive to balance environmental goals with cost realities. Athe same time, tari s and changing U.S. policies are causing market volatility, making planning di cult.and changes in U.S. government policies. ■

Murrelektronik Inc. (Booth W-3964) President Markus Keller was very happy to receive an award from PMMI Vice President Andrew Dougherty celebrating Murrelektronik’s 50th Anniversary. ■

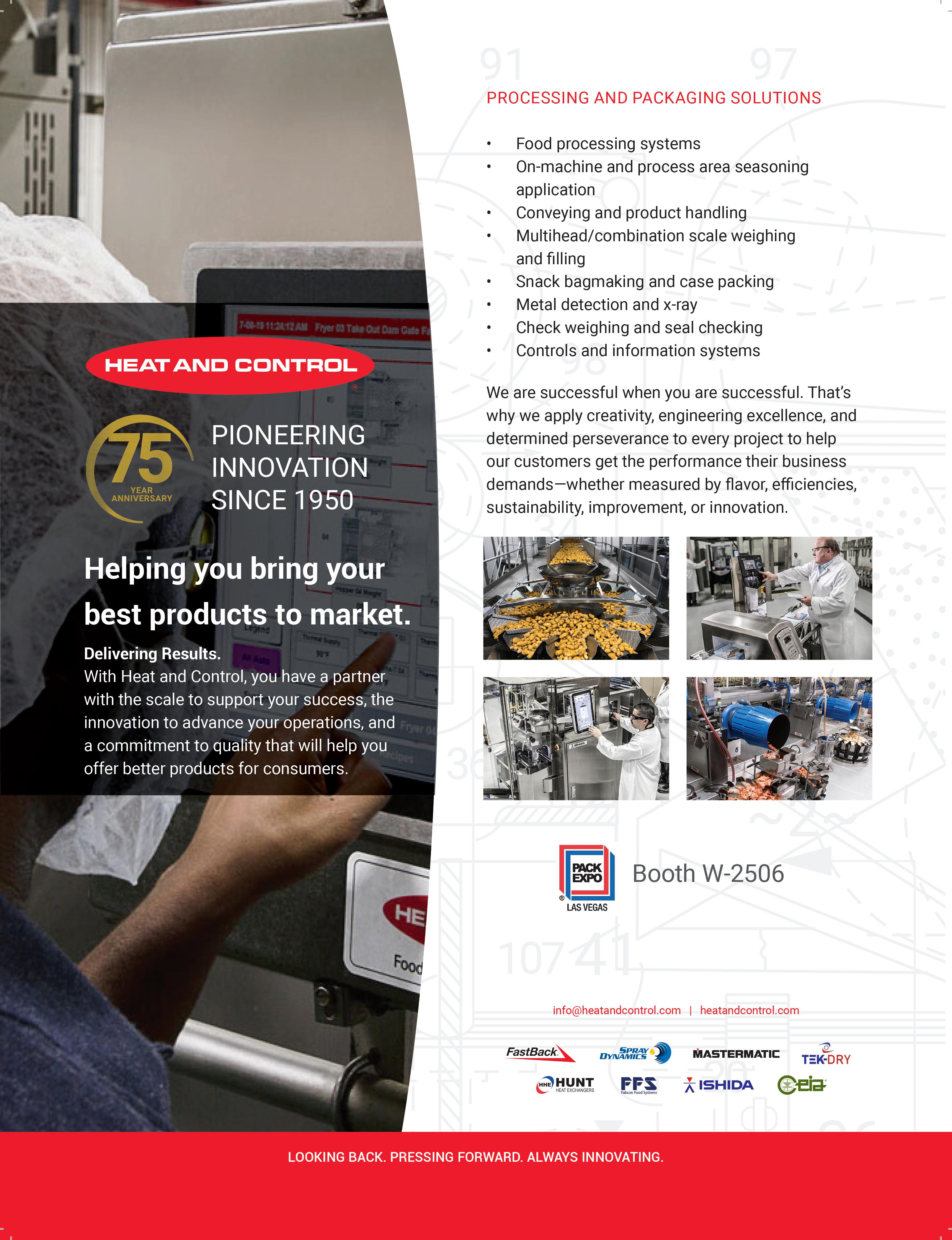

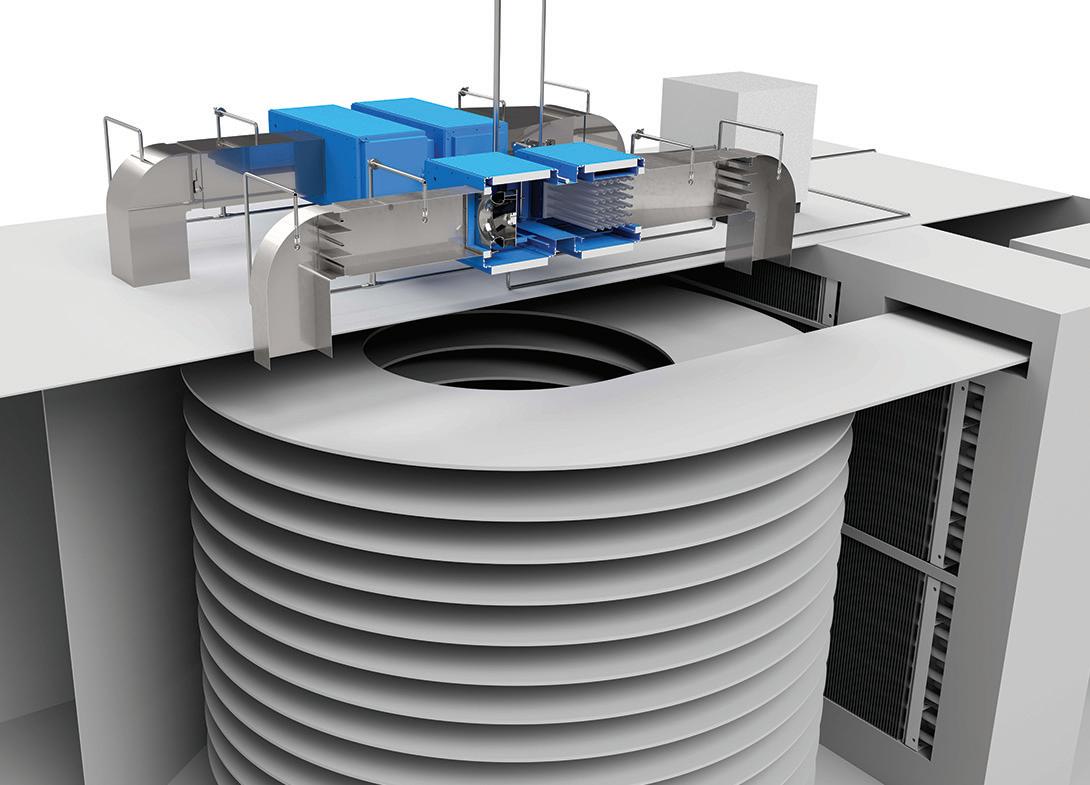

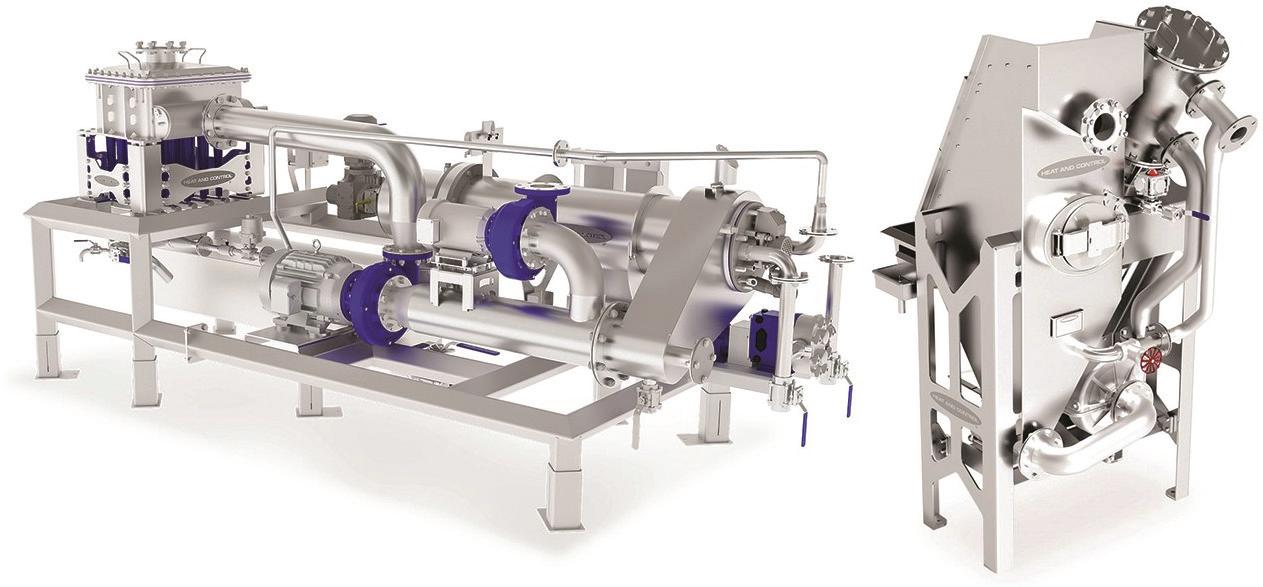

Heat and Control, a global manufacturer of food industry equipment, is pleased to announce the acquisition of Tek-Dry Systems Ltd. and Hunt Heat Exchangers, two providers of thermal processing and heat transfer equipment.

This strategic acquisition reinforces Heat and Control’s commitment to providing customers with innovative, customized solutions that set the standard for yield, e ciency, and safety across a wide range of industries. ■

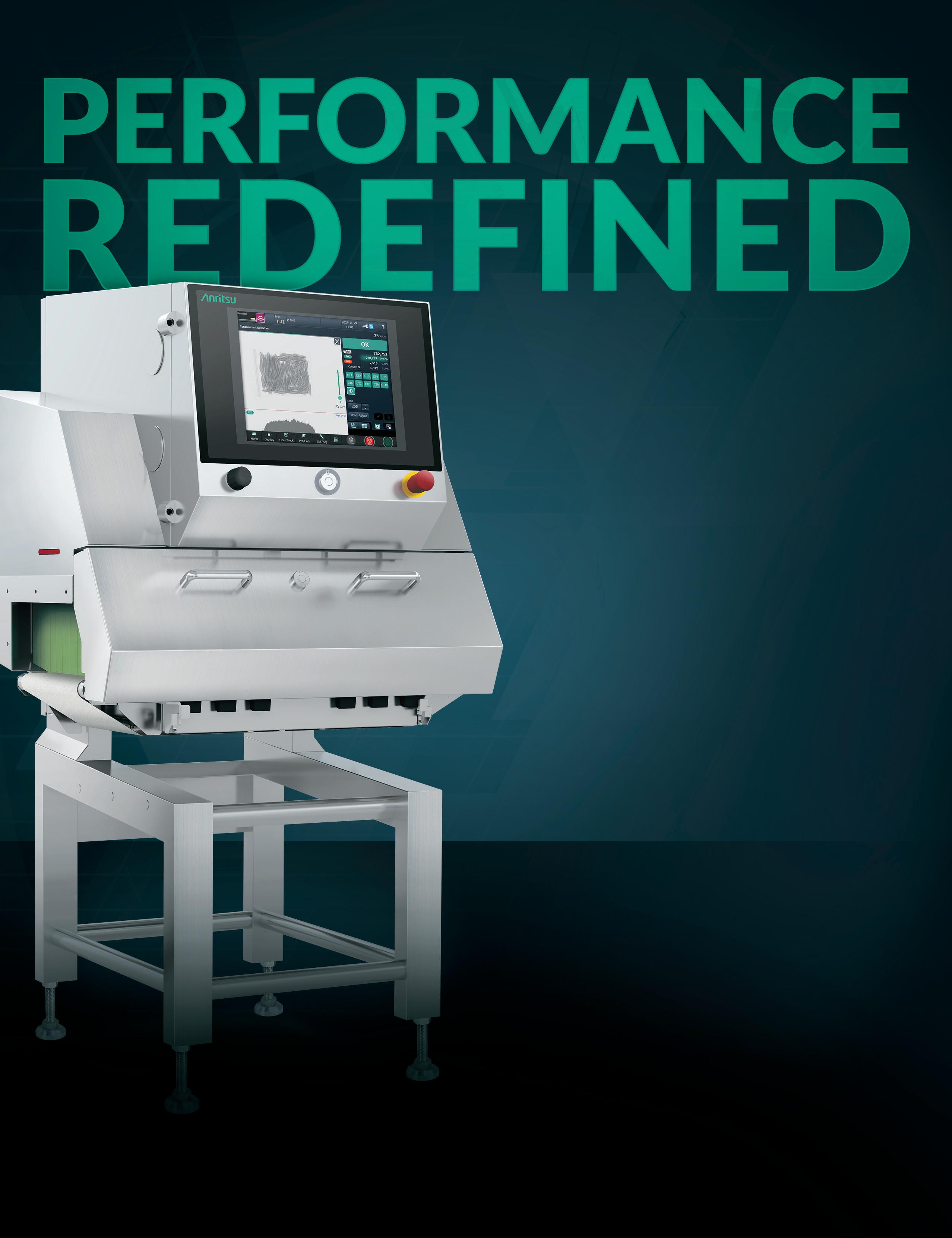

Experience Anritsu’s advanced inspection technology without leaving your facility. Anritsu’s Demo Vans travel across the U.S., fully equipped with the latest X-ray Inspection Systems, Metal Detectors, and Checkweighers. These mobile showrooms give manufacturers a handson opportunity to see how Anritsu solutions improve detection sensitivity, reduce false rejects, boosts production e ciency and enhance quality control. Stop by Booth SL-11019 to schedule a Demo Van visit and see Anritsu’s innovative inspection equipment in action. ■

OCTOBER 1, 2025 6

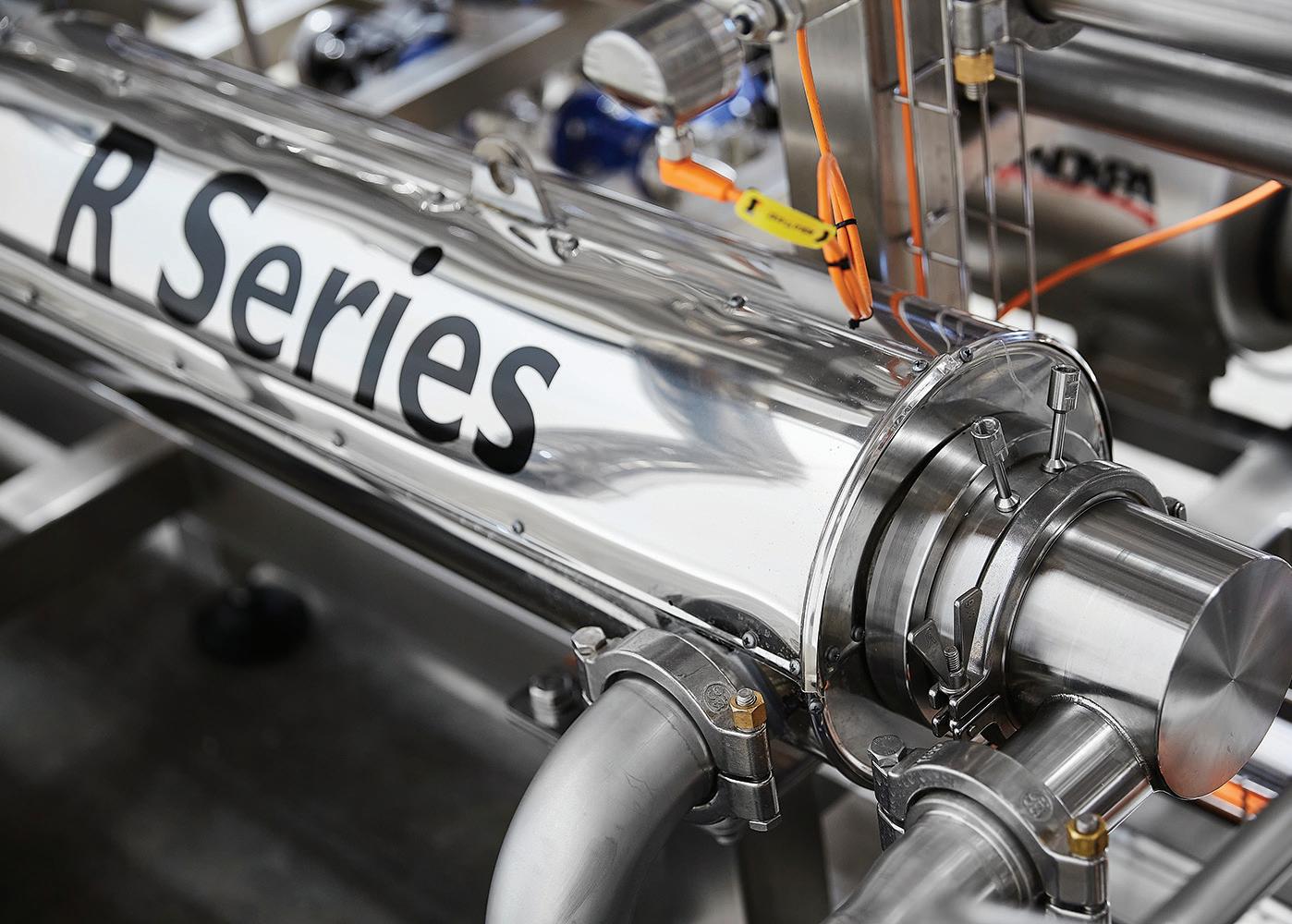

Join SPX FLOW (Booth N-5164) experts for a special rst look at the soon-to-be-released APV® SteamRecycle System, a rst-of-its-kind innovative solution that recovers and reuses 100% of the steam used during the infusion UHT process. Traditional Infusion UHT systems average about 47% steam recovery while indirect tubular UHT systems reach 80%. SteamRecycle captures and repurposes 100% of steam, helping direct systems match or outperform indirect systems in e ciency while preserving

—One Last Day for PACK EXPO Las Vegas, Continued from page 1 innovators, and decision-makers from across the region. Packed with cutting-edge technologies, sustainable solutions, and hands-on learning opportunities, the show helps brands stay competitive in a fast-changing market. It’s the go-to platform for networking, discovering the latest innovations, and driving business growth across Mexico and beyond.

PACK EXPO International 2026 (October 18-21, McCormick Place, Chicago)

As North America’s largest packaging and processing event in 2026, PACK EXPO International brings together industry leaders, innovators, and decision-makers from around the globe. You’ll experience cutting-edge technologies, game-changing insights, and unmatched opportunities to build relationships that drive growth. For anyone wanting

—Fragale Inspires at PPWLN Event, Continued from page 1

an organizational psychologist and professor at the University of North Carolina-Chapel Hill. Fragale blended her research with relatable stories to help professionals better understand power, con dence, and leadership. Her keynote at the PPWLN Breakfast o ered attendees new perspectives and tools to grow personally and professionally.

“PPWLN continues to provide valuable opportunities for networking and career development,” says Tracy Stout, vice president, marketing & communications, PMMI. “ e PPWLN breakfast is a space where professionals from across the industry can come together to learn from each other, re ect on their paths, and feel

premium product quality. Less steam used in the UHT process creates cost savings without sacri cing product quality, o ering processors energy savings and carbon dioxide emissions reductions of up to 1,000 tons annually (calculated based on 6,000 operating hours per year) compared to traditional Infusion UHT systems. It also reduces cooling water usage by up to 33 m³/h.

e SteamRecycle is expected to launch in the coming weeks. ■

to stay ahead of the curve, this is the place to see the future of packaging and processing in action.

Across each event, PMMI is committed to enhancing the attendee and exhibitor experience through smarter tools, curated networking opportunities, and robust educational programming. Whether your goals involve exploring automation, navigating sustainability, or addressing workforce challenges, the PACK EXPO shows are where the industry comes to learn, connect, and lead.

We invite you to be part of these de ning moments for our industry.

We look forward to seeing you in 2026. ■

encouraged in their careers.”

PPWLN was established in 2016 to support the recruitment, retention, and advancement of women in the packaging and processing workforce. e PPWLN Breakfast is proudly supported by PPWLN Gold Sponsors: ProMach (Booth W-1500) and Morrison Container Handling Solutions (Booth W-3522); PPWLN Breakfast Sponsors: Plexpack (Booth W-2906), SMC (Booth SL13034), Smur t Westrock (W-2300), Emerson (Booth SL-15009), BW Packaging (Booth W-3100), and Septimatech (Booth W-762); and PMMI Benefactor Sponsor: Schneider Electric (Room W-214) ■

While on the show floor, be sure to journey through 10 key locations, and you could win $1,000. The Scavenger Hunt opens on September 29 and runs through the close of the show on October 1. Winners will be announced via email the week of October 6.

1. Download the Mobile App—Select “Scavenger Hunt” for a listing of all required destinations. To participate, you must log in to your My Show Planner. You can create an account for free.

2. Discover Key Stops—Find signs at each location and enter the unique codes. Then, enter all codes into the mobile app.

3. Win Big—Complete all 10 stops to enter the drawing for one of three $1,000 Gift Cards. ■

Education at PACK EXPO Las Vegas occurs across seven stages and content centers, where attendees will explore the latest trends, technologies, and strategies to drive

business success. See page 40 for an exploration of over 100 free educational sessions directly on the show floor, featuring insights from industry leaders, innovators, and solution providers. ■

The PMMI Foundation Silent Auction returns to PACK EXPO Las Vegas, giving attendees the chance to bid on exclusive items and unforgettable experiences—all while supporting a meaningful cause. Items for bid are displayed in the North Hall Lobby, the West Hall by the W2 entrance and South Upper Hall Lobby Proceeds from the Silent Auction directly benefit PMMI Foundation programs, including scholarships, educational initiatives, and workforce development efforts designed to inspire and prepare the next generation of packaging and processing professionals. ■

OCTOBER 1, 2025 8

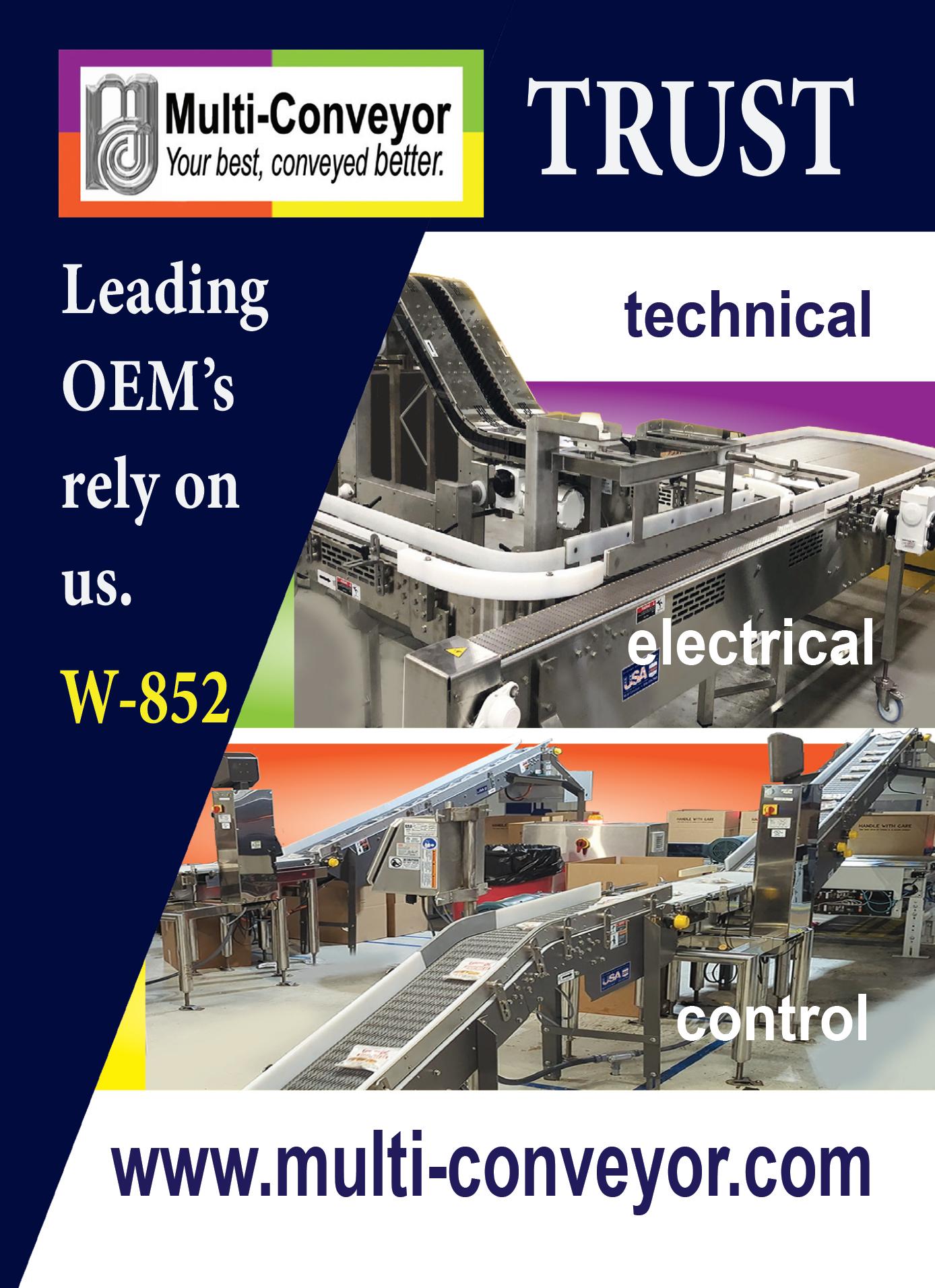

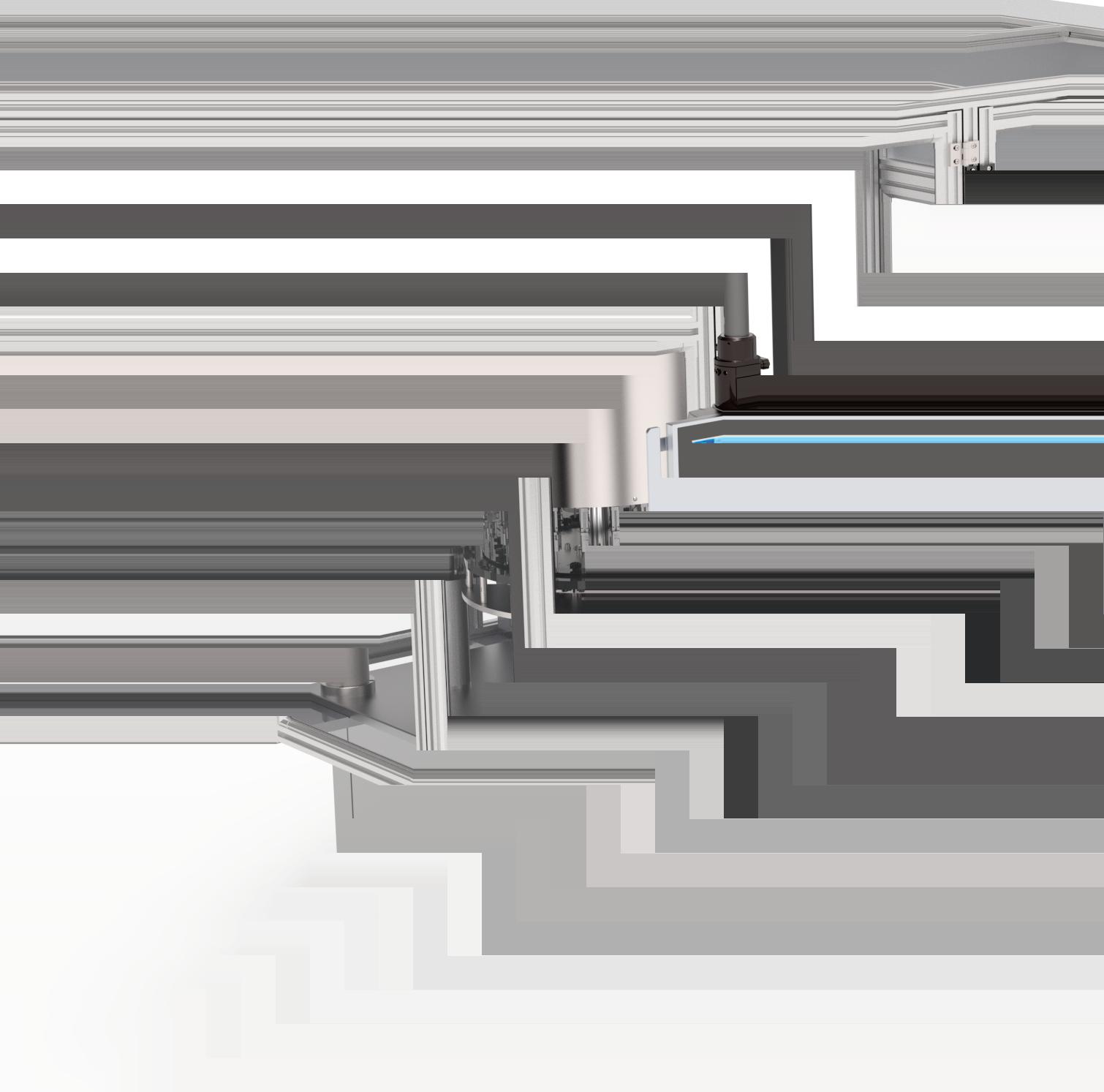

Simplistic 180-degree C-chute conveyor reorients cases to assist multiple palletizer configurations.

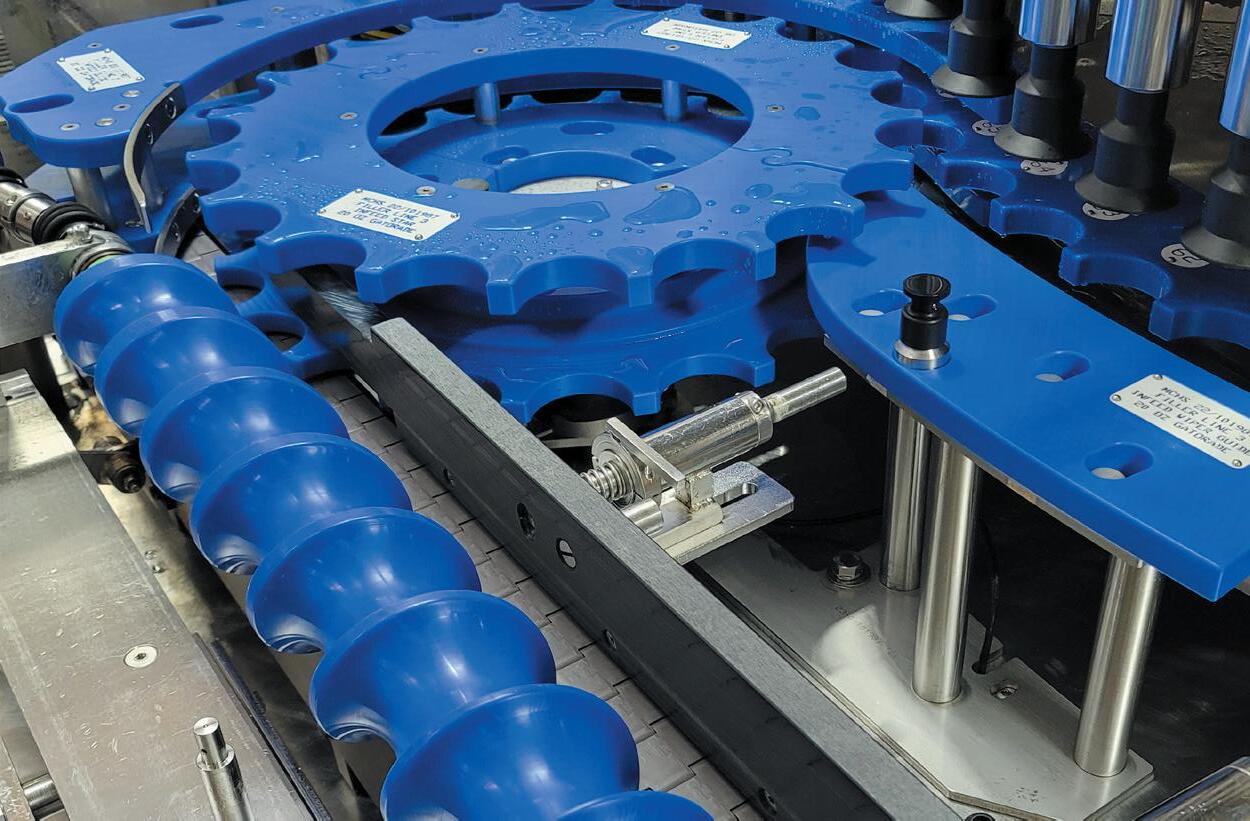

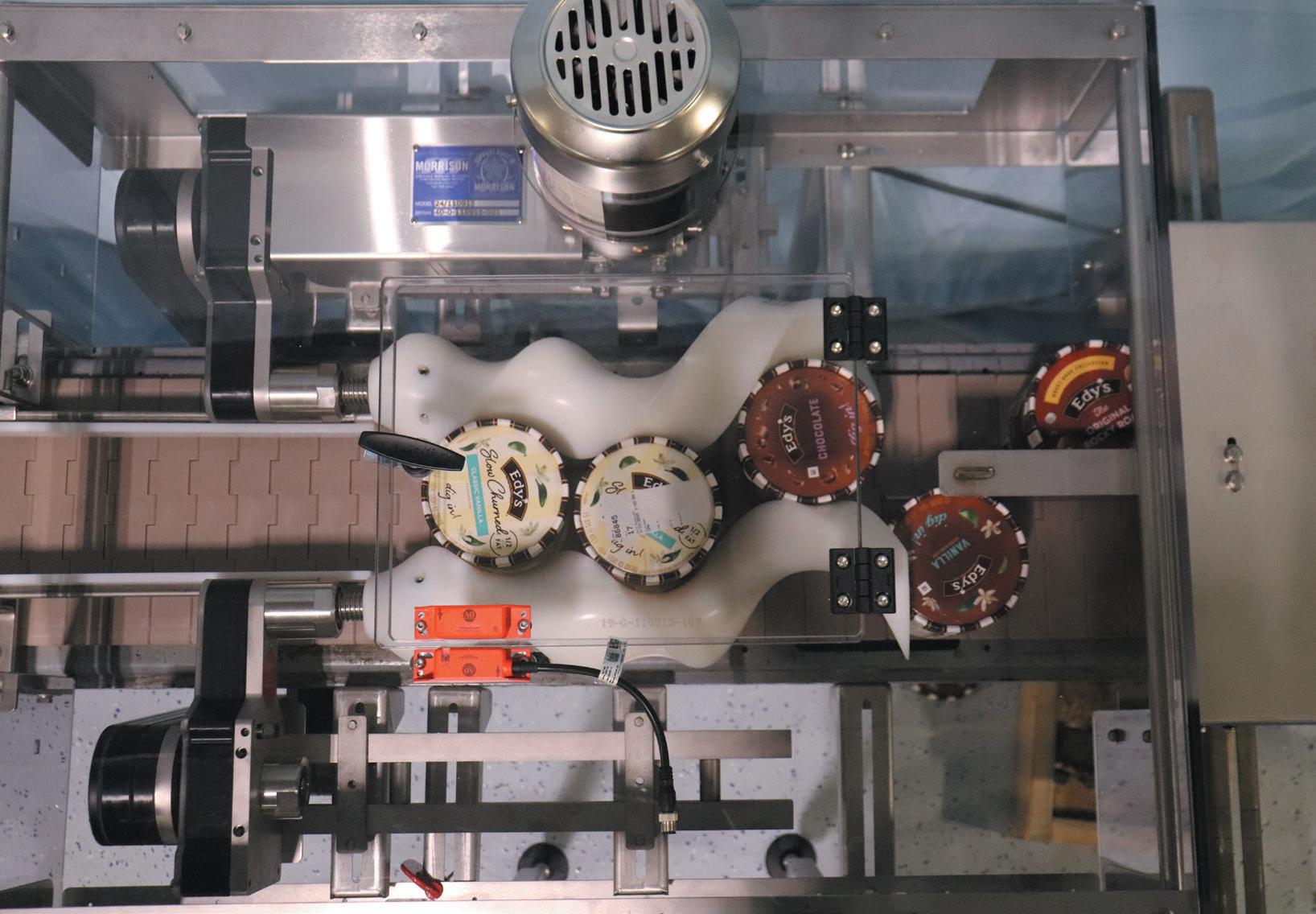

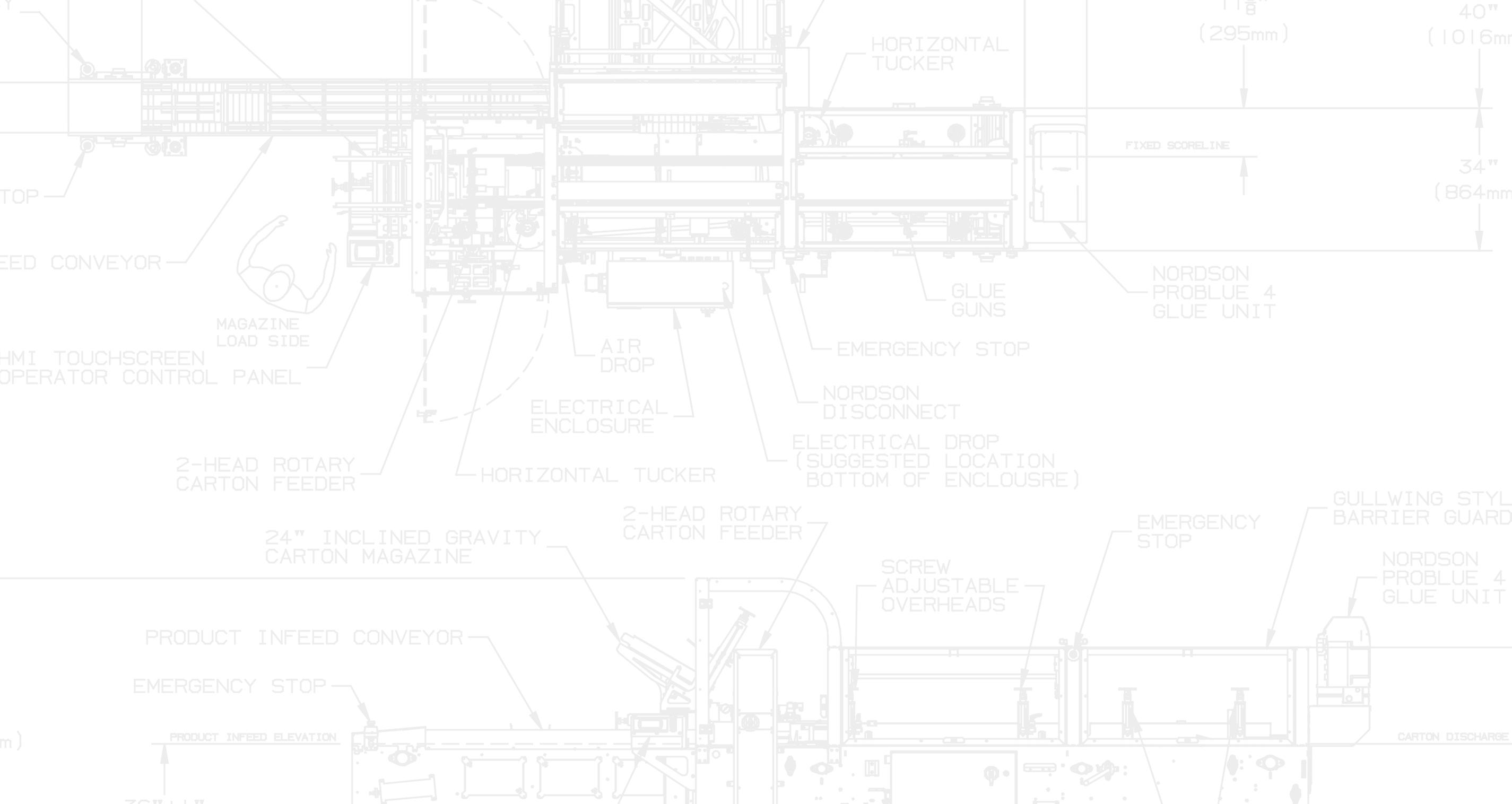

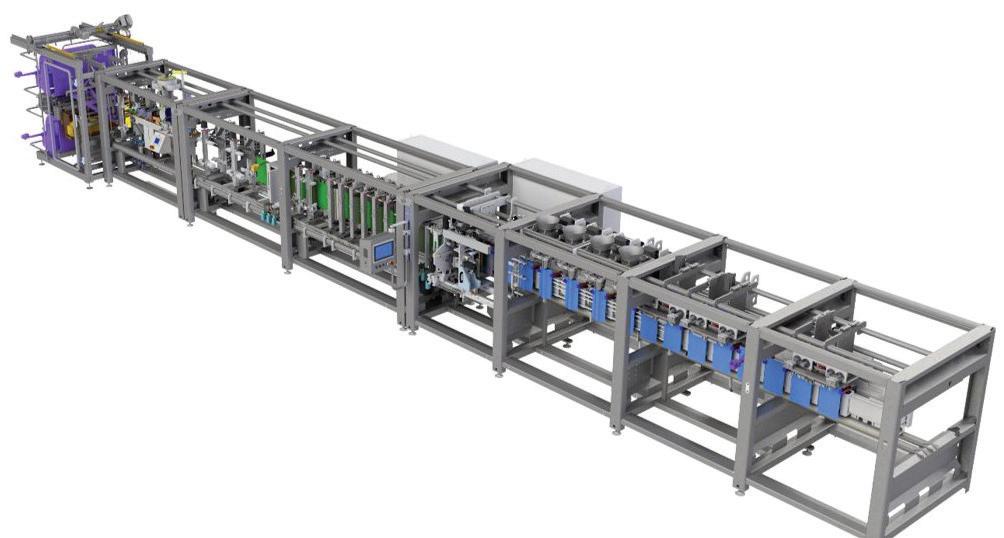

Multi-Conveyor (Booth W-852) recently built a conveyor system as part of a packaging line upgrade for a large dairy, at the request of one of its integration partners, Arrow Conveyor Equipment Inc.

The project’s scope required a conveyor system to move reverse-tapered dairy tubs from a multi-lane fill/seal/lid machine. The system then wrapped around the case packer and corrugated cases from the packer to an elevated tie-in point with an existing case conveyance system.

Case handling criteria required cases to change orientation, as well as an optional inversion of the case, to support multiple palletizing configurations, all within a very compact footprint. Food-grade stainless steel frames with wash-down compatible components were used throughout, built to customer specifications.

The corrugated cases are transferred from the tabletop chain onto a center-driven, bi-directional mat top belt, changing the orientation of the case from wide leading to narrow leading. The path to the left leads to a gravity C-chute that inverts the cases 180 degrees, while the path to the right allows cases to bypass the inverter and slide down a gravity roller transition onto the incline conveyor.

Gravity C-chutes provided an inversion solution, occupying minimal space without requiring elaborate electrical assistance. The C-chute guide rails provide optimal control, allowing for damage-free rotation during the inversion process. The manual pin-inplace gravity roller section easily pivots out of the way to make way for the inverted case path.

Following post-case manipulation, a 26-foot-long rubber top mat and top belt incline conveyor elevate the cases to the height of a case conveyor, allowing for seamless line reentry to a palletizer.

Due to the project’s complexity and small footprint, testing of the system was requested at Multi-Conveyor. Both video and on-site FATs were performed to eliminate on-site startup delays. ■

Sean Riley | Senior News Director

Kim Overstreet | Director of Content

David Bacho | Creative Director

ADVERTISING sales@pmmimediagroup.com

Courtney Nichols | Director, Client Success & Development, cnichols@pmmimediagroup.com

Lara Krieger | Senior Manager, Print Operations, lkrieger@pmmimediagroup.com

Janet Fabiano | Financial Services Manager, jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

David Newcorn | President

Elizabeth Kachoris | Vice President, Digital

Jen Krepelka | Senior Director, Digital Media Amber Miller | Director of Marketing

PMMI Media Group

IL 60661 • Web: www.pmmimediagroup.com

More than three-quarters of PMMI’s survey respondents are focused on productivity, with cost and automation priorities sharing second place.

Productivity ranks as the top priority among surveyed CPGs and industry suppliers, according to the 2025 Embracing Operational Readiness report by PMMI, e Association for Packaging and Processing Technologies (West Lobby), the producer of the PACK EXPO portfolio of trade shows.

is report summarizes key issues, industry insights, and recommendations from PMMI’s 2025 Top to Top Summit, held in February. e summit serves as a platform for OEMs and consumer packaged goods (CPG) companies to exchange perspectives, address shared challenges, and collaborate on practical solutions.

More than three-quarters (78%) of participants voted for productivity as their top priority, followed by cost and automation (both 47%). Growth (39%) and workforce (24%) also attracted signi cant proportions of the vote. While it is unsurprising that participants are focused on productivity and cost, the importance given to automation is interesting, particularly as it was a key theme of all three distinct, yet interconnected phases explored at the Top to Top 2025 Summit:

• Vertical startups

• Operator training

• IT-OT integration

According to the study, vertical startups are successful and achievable through clear communication and collaboration between OEMs and end users. Participants provided speci c details about strategies for e ective training, such as digital tools, follow-up assessments, automated systems, tailored learning formats, and digital solutions that include AI-driven troubleshooting, interactive manuals, and augmented reality.

Operator training highlights the need to account for diverse workplace realities, including language barriers, varying levels of technical skills, and high turnover rates. People-centric training is also needed to overcome the “shi phenomenon” and minimize performance uctuations across di erent shi s.

IT-OT integration explores the complexities of how end users and OEMs can work together to overcome barriers and ensure technical requirements, cybersecurity measures, and data integration needs are met. By prioritizing real-time data visibility, secure infrastructure, and early stakeholder involvement, organizations can achieve seamless IT-OT integration, future-proof their operations, and avoid costly setbacks. Justifying an IT-OT investment remains a key challenge. As a result, CPG companies must balance short-term, tangible bene ts, such as cost savings, reduced downtime, and immediate ROI, with long-term advantages, including a scalable, future-proof solution that enhances automation, provides real-time insights, and optimizes production processes.

“Technology is playing a growing role in all aspects of industry,” notes Jorge Izquierdo, vice president, market development, PMMI. He explains, “Used strategically and safely, it can provide the means to create more e cient production. Companies that re ne and streamline processes, develop skilled workers, and unlock the power of their IT-OT systems create an environment of operational readiness.”

Solutions for all aspects of operational readiness are available at PACK EXPO Las Vegas 2025 the premier packaging and processing event of the year. ■

The next evolution of OpX

The packaging and processing industry stands at a critical juncture, experiencing profound workforce transitions that challenge the foundation of operational excellence. Industry leaders are aware of the seismic shifts that created knowledge gaps, cultural disconnects and learning challenges on their plant floors:

1. COVID-Era Resignations and Retirements:

The unprecedented waves of resignations during the COVID-19 pandemic disrupted continuity across roles and generations. Now, an accelerating retirement wave is further compounding this disruption, as decades of frontline expertise, hard-earned intuition, and operational know-how are exiting the industry.

2. Emergence of a New Generation:

Simultaneously, a new generation of professionals is stepping in—driven, talented, and eager for relevance, rapid learning, and meaningful engagement. They demand training methods that connect and resonate with them and seek a current, inclusive workplace.

Addressing these challenges is paramount for maintaining and advancing operational efficiency. To address this, the OpX Leadership Network (West Lobby) is launching two new products for Fall 2025.

“Workforce transitions are inevitable, but they don’t have to disrupt performance,” says Carlos Quintero, director, industry services, PMMI. “The OpX Leadership Network’s new tools are more than resources—they’re a call to action. If we want to safeguard operational excellence, we must equip our teams now with training and data standards that inspire, connect, and prepare them for the future.”

The products aim to bridge generational knowledge gaps and foster a culture of continuous learning and data-driven decision-making.

1. Operator Training Standardization (OTS):

This modern, adaptable approach to onboarding and developing operators balances legacy wisdom with contemporary learning preferences. By incorporating fast, visual, mobile, and clear methods, OTS ensures that the incoming workforce connects with and retains critical operational knowledge.

2. Data Management Standardization (DMS): This initiative provides a unified structure for organizing, labeling, and utilizing data across OEMs and end users. DMS aims to close communication gaps, enabling consistent and effective data for informed decision-making, maintenance, and performance improvements.

OpX Work Products are not merely theoretical frameworks; they are real-world solutions engineered through OpX’s Joint Collaboration Process (JCP) between PMMI member OEMs and consumer packaged goods (CPG) companies that manage production lines daily.

“Work products are built through six months of bi-weekly meetings with 10–15 experts—each with 15–20-plus years of experience,” says Quintero. “The results are tools that capture the real capabilities, limitations, and possibilities of every topic.”

Over the past 15 years, the OpX Leadership Network has introduced over 20 tools—from hygienic equipment design to digital transformation—that give teams a common language, clear handoffs, and readyto-use checklists for faster startups, safer operations, and fewer changeover losses.

The new OTS and DMS offerings are grounded in this tradition, built to ensure smooth workforce transitions and long-term operational success.

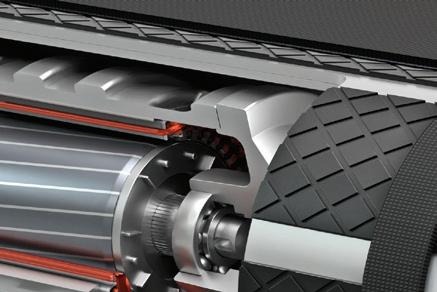

All drive components of the VDG Drum Motor, including the premium-efficiency electric motor, gear reducer, and bearings, are enclosed and protected inside the drive drum and maintenance-free for 80,000 hours of continuous operation, reducing operational and maintenance costs while increasing throughput.

Premium-Efficiency Electric Motor

Eliminate Routine Maintenance

Low Cost of Ownership

INCREASE ELIMINATE REDUCE

For sanitary applications, SSV Series Drum Motors are manufactured in all-stainless steel, feature an IP69K-rated sealing system, withstand pressure washdown up to 3,000 psi, and drive modular, wire mesh, and monolithic thermoplastic conveyor belts without using sprockets.

Conveyor Hygiene Drive Sprockets Water Usage & Time for Washdown

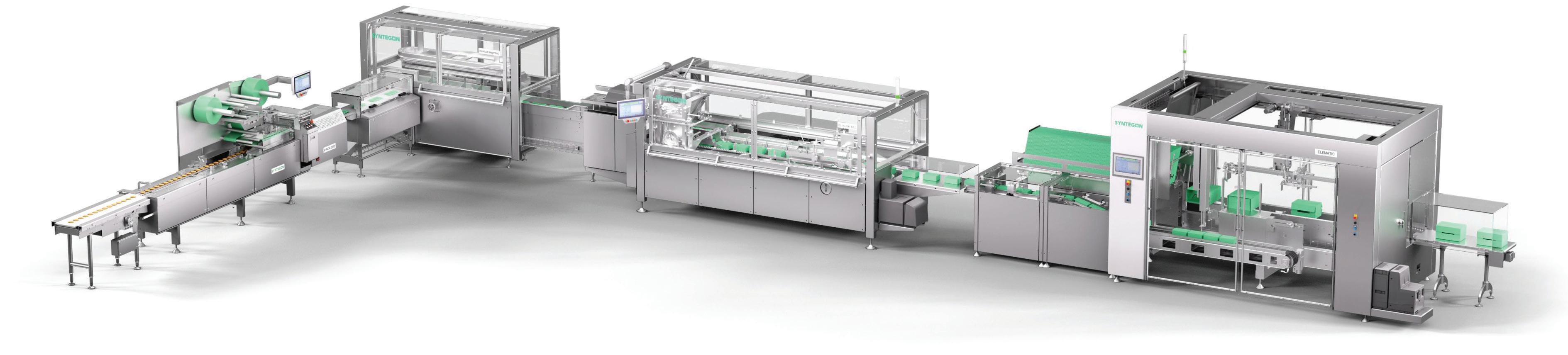

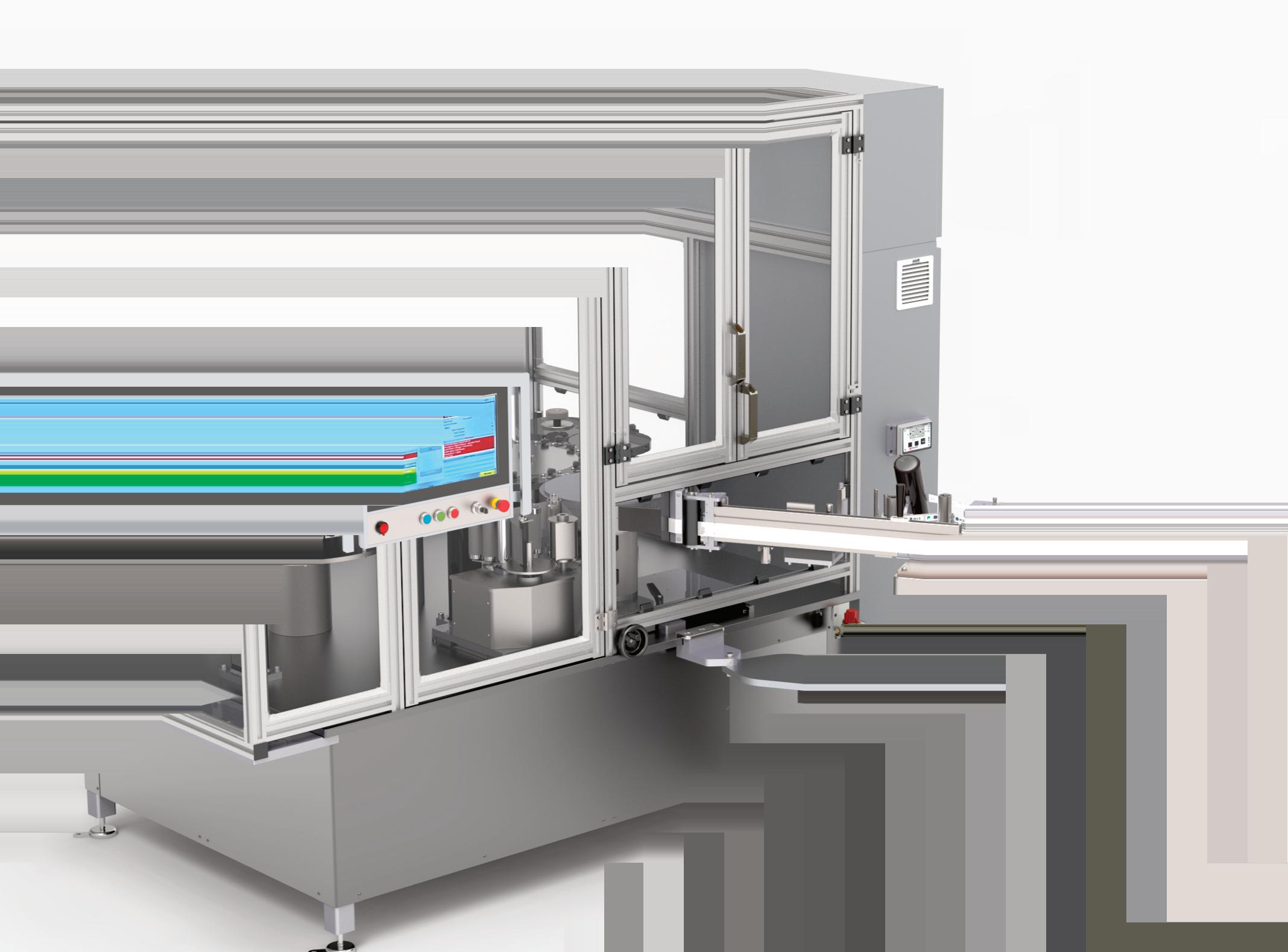

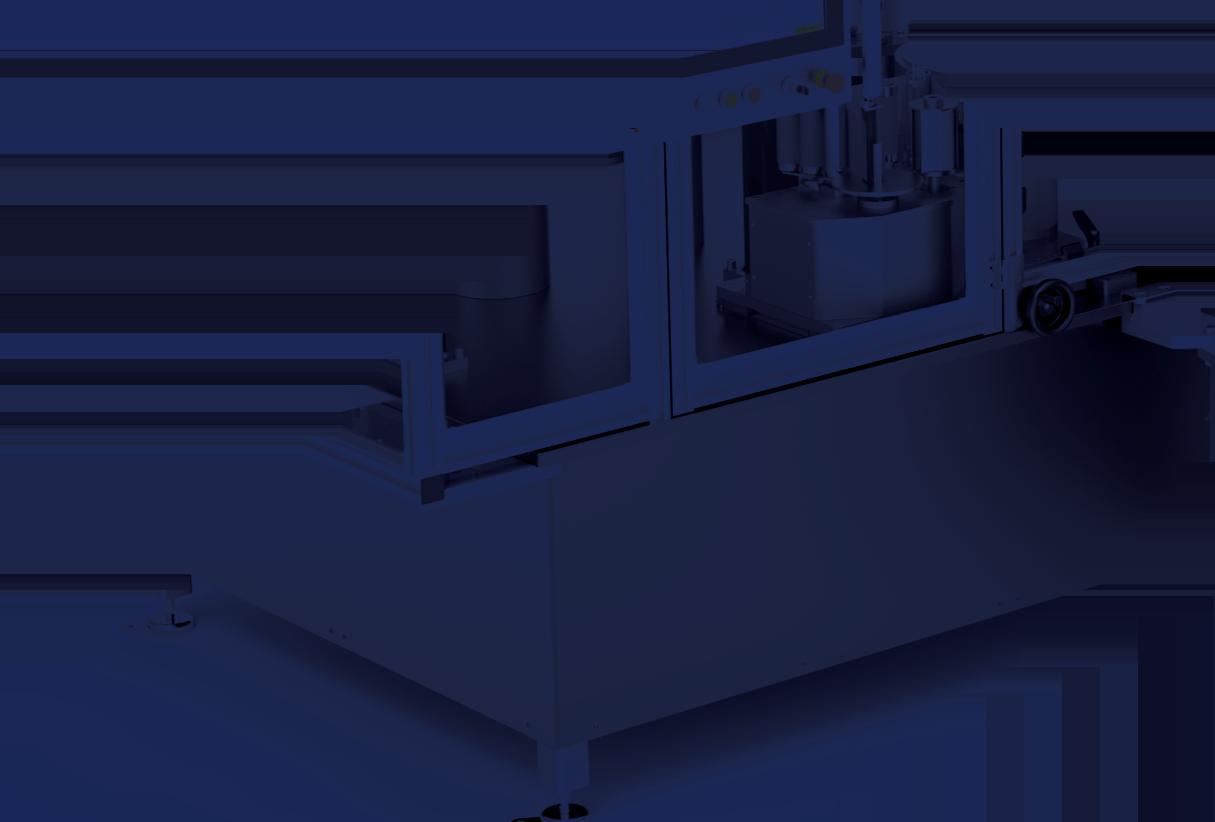

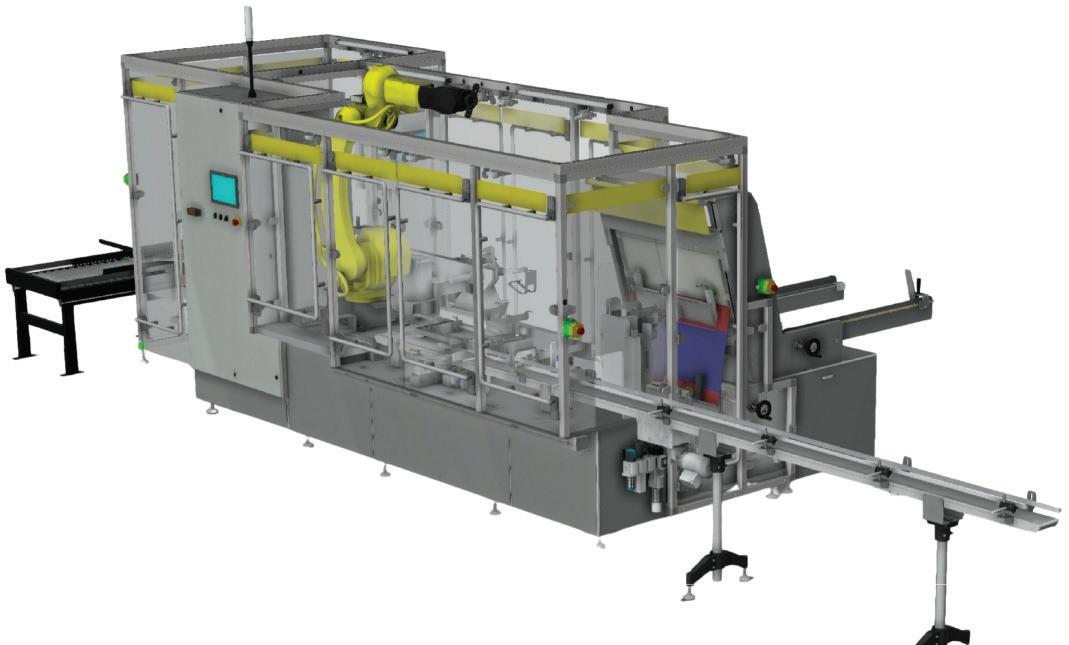

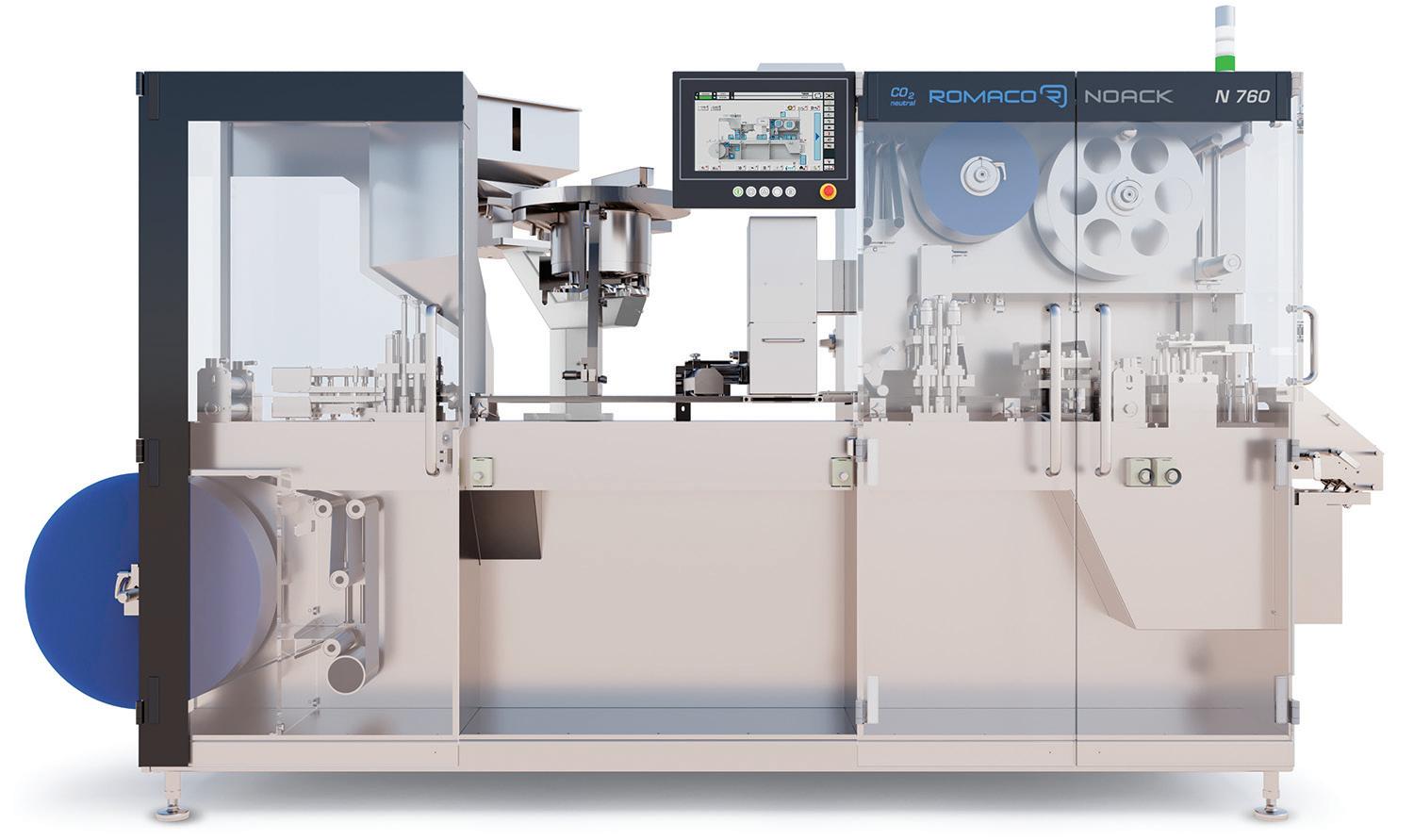

Visit Booth W-900 to find Syntegon’s entry-level to fully automated lines, with seamless automation to reduce labor needs, waste, and downtime, and AHS technology for tight seals and a long shelf life, all compatible with sustainable mono-materials.

Syntegon invites visitors to booth W-900 to discover how the company’s innovative technologies and comprehensive services help attendees improve product quality, boost efficiency, and achieve their sustainability goals. From September 29 to October 1, 2025, Syntegon will present a broad portfolio of scalable solutions—from compact starter machines to fully automated high-speed systems—designed to tackle industry challenges such as labor shortage, rising costs, and the demand for recyclable materials. Syntegon works side-by-side with customers to create high-performing, reliable, and future-ready packaging operations, backed by a global network of service hubs. Whether manufacturers are initiating their automation journey or scaling up with fully integrated high-speed lines, Syntegon serves as a strategic lifecycle partner, supporting customers from consultation and precise planning through seamless integration, reliable operation, and continuous adaptation.

Visitors can experience live demonstrations of how gentle handling meets high-speed automation with Syntegon’s packaging line for bar products. Significantly reducing manual intervention, this system addresses the pressing issues of labor shortage and the need for constant high-quality. At the heart of the system is Syntegon’s HCM highspeed flow wrapping machine. It is equipped with the new, innovative Amplified Heat Sealing (AHS) technology—a PACK EXPO highlight. Compared to conventional rotary heat-sealing, AHS delivers exceptionally tight seals by combining rotational and additional linear sealing movements. AHS ensures consistent sealing quality under varying process speeds. AHS technology is also highly recommended for sustainable mono-materials. Another highlight of this system is the Syntegon TTM integrated topload

cartoner, capable of processing both WIP trays and retail cartons on one compact machine. In addition, new digital features such as Syntegon’s ‘Guide-byLight’ status lighting system, Logbook, and 3D Error View enhance the user experience for reduced downtime and maximum productivity.

Another example of Syntegon’s broad portfolio is the fully automated bakery packaging line for waffles or other baked goods. This line similarly tackles labor shortages with full automation, streamlining

packaging from initial handling to cartoning. With Syntegon’s linear-motor-based Stacking FIT infeed, waffles are gently stacked just moments before primary packaging, preventing product damage and waste. The reliable Pack 202 mid-speed flow wrapping machine securely wraps waffle stacks in convenient perforated two-piece packs. The flexible Kliklok MagTRAC collation system subsequently groups the flow packs into layers of two by two for endload cartoning by the Kliklok BEC. In order to complete the line, customers may opt for one of Syntegon’s Elematic case packers.

—Continued on page 16

Booth # W-3350

At RYCHIGER, we bring precision, flexibility, and innovation to packaging automation. From filling and sealing to cartoning, case/tray packing, and palletizing, our solutions are engineered to adapt to your production demands, no matter the format, speed, or complexity. With fast changeovers, compact footprints, and seamless integration, we help you reduce downtime and scale with confidence. Backed by decades of expertise and in-house support, our systems deliver the reliability you need to stay ahead.

See the future of packaging automation at PackExpo Las Vegas, Sept. 29–Oct. 1, Booth # W-3350. Experience live demos of the VRC-60 Cartoner and RCP-10 Cobot Palletizer, and learn how RYCHIGER makes packaging performance come together.

Scan to learn how our solutions can streamline your end-of-line process

Upgrade your existing line or create a custom conveyor system from the ground up.

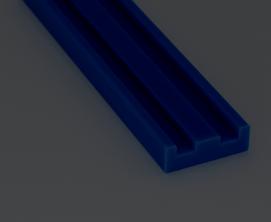

Our modular components range from beams, chains and belts to guide rails, profiles, bends and drive units, as well as pre-assembled modules. We built them to handle everything from lightweight items to heavy cartons.

Whatever your product flow, FlexLink lets you shape it to match your layout and performance needs.

My FlexLink provides a complete range of tools to start planning, from FlexLink Design Tool to Online Store.

—Continued from page 14

Another PACK EXPO highlight: the SVX Agile—a high-speed vertical bagger, specifically designed for frozen food, chilled, or fresh products. With a maximum speed of up to 300 bags per minute and the patented cross-seal drive, the SVX Agile delivers high output in a compact footprint. Its hygienic stainless-steel design allows easy cleaning, while reduced seal height and bag length help save up to 7 percent in packaging material per bag—lowering costs and supporting sustainability goals. The modular design supports various bag styles, making it a future-proof solution for changing market demands and diverse product portfolios.

For manufacturers moving from manual to semi-automated operations, Syntegon introduces a cost-effective entry point with the Pack 103 flow wrapper and the Doboy CBS-D 750 band sealer. Designed for a variety of products, these compact machines combine robust performance and flexibility—making them a good choice for growing businesses. The Pack 103 flow wrapper features a hygienic design, quick format changes, and seamless integration. The Doboy CBS-D 750 band sealer delivers high-integrity seals for heat-sealable bag materials. Offering sealing speeds of up to 25 meters per minute, digital temperature control, and easy maintenance features like tool-free band changes, the CBS-D 750 ensures reliable performance.

From bars to waffles, frozen food and beyond, Syntegon’s line-up at PACK EXPO Las Vegas showcases the company’s extensive expertise and diverse portfolio. Syntegon serves as a strategic lifecycle partner, supporting customers from first planning to completion—and beyond. With comprehensive services, innovative technologies, and cloud-based digital solutions such as Synexio, Syntegon enables manufacturers to confidently navigate today’s complex packaging landscape. “With our holistic approach, we don’t just supply machines - we deliver tailored solutions and ongoing support to help customers grow and adapt,” says Brad Baker, Senior Sales Director, North America.

Visitors can experience firsthand how Syntegon’s lifecycle-focused solutions drive efficiency, flexibility, sustainability, and future readiness. ■

Research shows 68% of companies plan moderate to significant equipment upgrades ahead of PACK EXPO Las Vegas 2025.

As the beverage industry experiences unprecedented shifts driven by consumer demand, sustainability imperatives, and technological evolution, PMMI, The Association for Packaging and Processing Technologies (West Lobby), released the latest findings from its 2025 Beverage Industry Packaging Trends white paper. These findings highlight a surge in investment and innovation—insights that are coming to life at PACK EXPO Las Vegas 2025, the premier packaging and processing trade show produced by PMMI.

According to PMMI’s research, 68% of beverage companies anticipate moderate to significant increases in packaging machinery investments over the next two to three years, with nearly 90% planning to purchase equipment. These investments are fueled by a trio of major factors: company expansion, consumer demand, and advancements in technology. Equipment priorities include:

• Filling, capping, and closing systems (62%).

• Conveying, feeding, and handling equipment (51%).

• Palletizing and load stabilization (50%).

• Coding, labeling, and printing technologies (46%).

Consumer preferences are reshaping packaging strategies, with a strong emphasis on sustainability, recyclability, and variety in beverage sizes, flavors, and types. PMMI’s white paper notes a projected decrease

BASED ON OPINIONS OF THE BEVERAGE INDUSTRY END USER MARKET

Looking ahead to the next 2-3 years, how do you anticipate the following aspects will impact your beverage packaging and processing operations?

MOST POSITIVE INFLUENCING FACTORS MOST NEGATIVE INFLUENCING FACTORS

75% TECHNOLOGY INTEGRATION

46% CHANGING CONSUMER PREFERENCES

39% SUSTAINABILITY AND ENVIRONMENTAL DEMANDS

in rigid plastic and glass use, alongside notable increases in paper-based (+43%), flexible packaging (+30%), and liquid cartons (+16%).

Companies are also adapting packaging formats to cater to single-serve, ready-to-drink, and health-

TYPES OF MACHINERY PLANNING TO PURCHASE

62%

51%

50%

46% CODING, LABELING, PRINTING, AND READING

42% CARTONING, MULTIPACKING, AND CASE PACKING

33% INSPECTION AND TESTING

27% BAGGING, POUCHING, AND WRAPPING

18% SPECIALTY IN THE NEXT THREE YEARS BY CONSUMER PACKAGED GOODS COMPANIES (CPG) AND CONTRACT PACKAGERS IN THE BEVERAGE INDUSTRY

68% INFLATION

45% SUPPLY CHAIN DISRUPTIONS

39% REGULATORY COMPLIANCE

focused beverages such as mocktails, nutraceuticals, and THC-infused drinks. These product trends necessitate more versatile machinery capable of handling new SKUs, packaging formats, and materials.

While the outlook is optimistic, beverage manufacturers face ongoing challenges, including:

• Inflation (68%).

• Supply chain disruptions (45%).

• Sustainability and regulatory compliance (39%).

• Talent acquisition and retention (37%).

Technology integration is viewed as the most positive driver of future growth, helping producers adapt to these hurdles with smarter, more intuitive equipment.

Trade show attendees will find practical insights on reducing material usage, integrating automation, and addressing workforce needs — all while forming partnerships that drive innovation forward.

“Our latest beverage packaging trends report confirms what many in the industry already sense— this is a transformative moment,” says Jorge Izquierdo, vice president, market development, PMMI. “We’re seeing rapid innovation in formats, materials, and machinery, driven by consumer demand and sustainability goals. PACK EXPO Las Vegas is the place where these trends translate into action—where ideas turn into strategies and solutions.” ■

OCTOBER 1, 2025

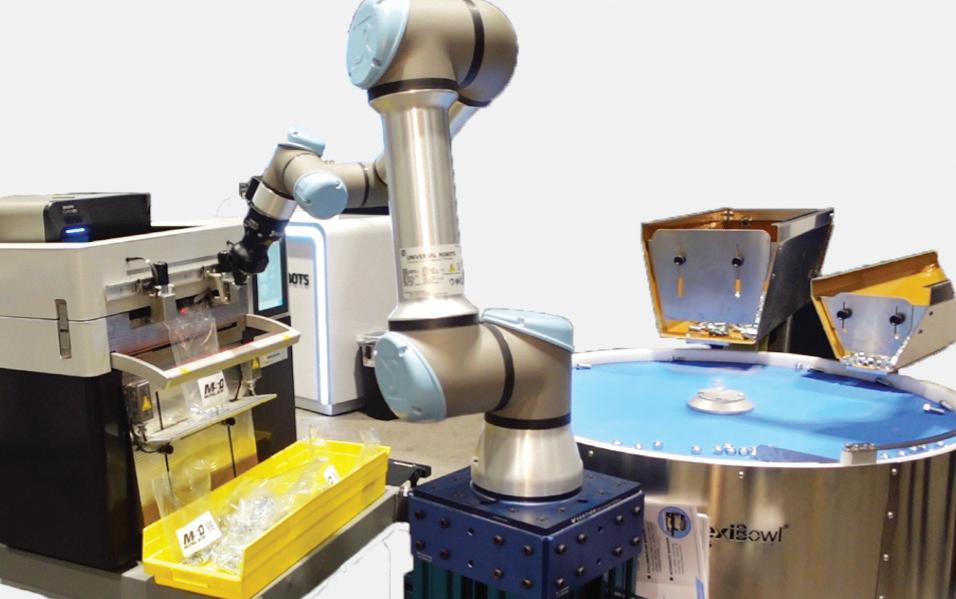

Sustainable bagging systems and robotic integration take center stage at PAC Machinery Booth W-2344.

Get ready for an exciting showcase of packaging innovation as PAC Machinery brings a powerful lineup of a dozen advanced packaging machines to PACK EXPO Las Vegas. Attendees will experience the debut of two all-new automatic baggers that support both paper and poly materials for sustainable packaging, plus two fully integrated bagging and robotic picking systems that redefine automation. Several machines will also feature cutting-edge technology updates, making PAC’s Booth W-2344 a must-visit destination for companies seeking smarter, greener, and faster packaging solutions.

This year, PAC Machinery is proud to be recognized as a 30-Year PMMI Member Legacy Exhibitor, celebrating three decades of continuous innovation and participation in the packaging industry’s premier event, and it’s going to be a fascinating exhibit!

“At this year’s show, we’re excited to unveil our theme of ‘Flexible Sustainability,’ which gives companies the power to run both paper and plastic on the same machine,” said Greg Berguig, President of PAC Machinery. “It’s a future-proof approach to packaging—and with our robotics integrations making a big splash, we’re showing what’s truly possible when automation meets versatility and the latest technologies.”

PAC Machinery is redefining what’s possible in packaging with the launch of its ‘Flexible Sustainability’ lineup—systems built to run both curbside recyclable paper and plastic with up to 100% recycled content. On display at PACK EXPO will be standout machines like the new Rollbag® R985 and Rollbag® R3200 Paper Baggers, designed to help companies stay ahead of regulations and shifting consumer demands. With one of the most diverse equipment lineups at the show, PAC invites attendees to explore the future of flexible packaging, all in one booth.

PAC Machinery will also spotlight two innovative robotic integrations developed in partnership with MSD Sales and CMES Robotics. One system pairs the compact Rollbag® R785 with a robotic kitting solution from MSD, designed for high-precision part handling and packaging. The second features the new Rollbag® R3200 Paper

—Continued on page 22

—Continued from page 20 Bagging System integrated with CMES’s AI-driven piece picking technology, offering a sustainable, high-speed automation solution. Both demos showcase how to combine smart robotics with PAC’s proven bagging equipment to deliver greater efficiency, flexibility, and eco-conscious performance on the packaging line.

PAC Machinery invites attendees to experience one of the most comprehensive and forwardthinking packaging exhibits at PACK EXPO 2025. From automation and sustainability to advanced technology and materials, Booth W-2344 will be packed with innovations designed to meet the challenges of today—and tomorrow.

• Rollbag® 985 Auto Bagger—A unique, compact tabletop automatic bagger that can package with both curbside recyclable paper or poly bag material.

• 6800CS Side Sealer with In Zone Labeler—All-electric system that will horizontally bag and label the first bag out. Works with 2x2 product labels up to 4x6 shipping labels. Use clear poly film or white/grey coex mailer film.

• Rollbag® R3200 Fulfillment Paper Automatic Baggers—A NEW innovative bagger that offers the flexibility to choose between PAC’s patented Fiberflex ® curbside recyclable paper mailers and poly mailers made with up to 100% recycled resins. R3200 Fulfillment Paper was entered for the PMMI 2024 Technology Excellence Award competition for “New Sustainable Innovation.”

• PVG Industrial Vacuum Sealer—Considered the industry standard industrial vacuum impulse sealer. Comes standard with gas flush for modified atmosphere packaging, bi-active seal bars for top and bottom heat during sealing, and independent vacuum, gas, seal, and cool timers. Shown with an upgraded PLC and NEW Touchscreen HMI.

• Rollbag® R785—The all-electric R785 tabletop poly bagger is a compact, industrial-grade packaging solution built for multi-shift use. It runs up to 40 bags per minute and handles pre-opened bags up to 12” wide by 20” long. Equipped with a thermal transfer printer, it supports direct-to-bag printing with various label software options.

• Rollbag® R3200XL Automatic Bagger—The largest model in our bagger allows users to package items with bags up to 22” W X 36” L. It will be shown with poly tubing that makes a bag to the product’s length, reducing waste and saving money.

• Materials for Automatic Baggers—Get a competitive edge with our packaging materials for any brand of automatic bagger featuring custom, stock, and eco-friendly bag options for any bagging machine, including PAC’s Fiberflex® curbside recyclable paper and NEW Bar Code Blocking Bags for Amazon fulfillment bagging.

• PAC FW 400F Flow Wrapper—This entry-level flow wrapper is capable of speeds up to 120 packages/min (up to 180 packs/min on twin jaw version). The unit will be shown with our deluxe adjustable former for curbside recyclable paper.

• Clamco 4C Combo—Heavy Duty Combo Shrink Wrap System combines an L-bar sealer with a shrink tunnel in one robust, compact unit. ■

• Up to 40% sensitivity improvement

• Rejects reduced to 1/7 of previous model

• 30% lower power consumption

• Intuitive, smartphone-style user interface

Anritsu’s new XR76 is the next evolution in X-ray inspection . Advanced imaging enables better detection of metal and low-density contaminants while lowering false rejects that result in costly downtime. Simple, touchscreen operation is easy to use for your whole team, reducing training time.

Visit PACK EXPO booth SL-11019 www.anritsu.com/product-inspection

N-7656)

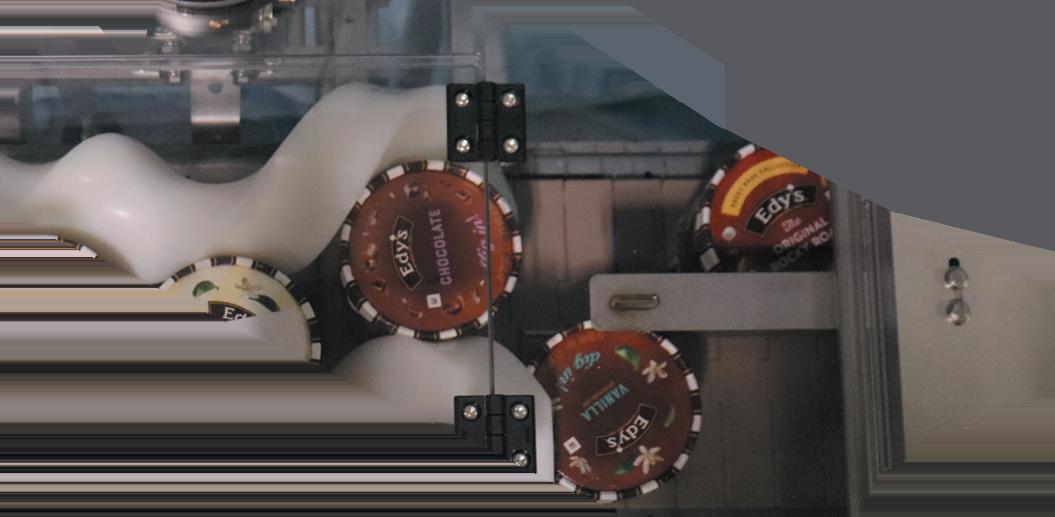

In today’s grocery aisles, convenience meals—from artisan sandwiches and wraps to snack trays—are a growth story that’s impossible to ignore. Evolving lifestyles, busy families, and rising demand for nutritious on-the-go options are fueling a market that

As we celebrate 30 years of PACK EXPO Las Vegas, PMMI proudly honors the PMMI Member Companies who exhibited at the inaugural 1995 show and continue to exhibit with us at this year’s event. Thank you for your support!

Check Out all the Exhibitors at PACK EXPO Las Vegas 2025

is expected to grow at a CAGR rate of more than 5.3% through 2034, according to a Future Market Insights report last year.

To meet this demand, it takes more than having just a good slicing machine or case packer. It requires

A-B-C Packaging Machine Corp.

Accutek Packaging Equipment Co., Inc.

Advanced Poly-Packaging, Inc.

All Packaging Machinery Corp.

All-Fill, Inc.

American Packaging Machinery, Inc.

AMS Filling Systems, Inc.

Auger Fabrication, Inc.

Auto Labe

Avery Dennison

Banner Engineering Corp.

Batching Systems, Inc.

BELL-MARK

BluePrint Automation (BPA)

BW Packaging

CeraTek

CMCO Conveyance Solutions

Coesia Group

Columbia Machine, Inc.

Conflex Incorporated

Cousins Packaging Inc

Decker Tape Products, Inc.

Del Packaging, LTD

Diagraph Marking & Coding, an ITW

Company

Domino North America

Douglas Machine Inc.

Dow

Duravant

Eagle Flexible Packaging

Eastey

Econocorp, Inc.

Elmar Industries, Inc.

Emerson Discrete Automation Group

E-PAK Machinery, Inc.

Fallas Automation, Inc.

Felins, Inc.

Formost Fuji Corporation

FOX IV Technologies, Inc.

General Packaging Equipment Co.

Greener Corporation

Harpak-ULMA Packaging, LLC

Haumiller Engineering

Heat and Control, Inc.

Heisler Industries, Inc.

Highlight Industries

IMA North America Inc.

ITW Hartness

Kaps-All Packaging Systems Inc.

Key International, Inc.

KHS USA, Inc.

Kiwi Coders Corporation

KRONES

Label-Aire, Inc.

Lantech

Laub/Hunt Packaging Systems

Markem-Imaje

MARQ Packaging Systems, Inc.

Massman Companies

For an up-to-date list visit: packexpolasvegas.com/legacy

McBrady Engineering, Inc.

METTLER TOLEDO

Morrison Container Handling Solutions

Murzan, Inc.

Nercon Conveyor Systems

NJM Packaging

Oden Machinery, Inc.

OK International Corp.

Omega Design Corporation

Osgood Industries, LLC

PAC Machinery

Pacmac, Inc.

Pacteon Group

PDC International Corporation

Pepperl+Fuchs, Inc.

Per-Fil Industries, Inc.

PFM Packaging Machinery Corp.

Phoenix Engineering

Piab Inc.

Polypack, Inc

Potdevin Machine Co.

Premier Tech Systems and Automation

Prodo-pak Corporation

ProMach, Inc.

ProSys Fill LLC

Quadrel Labeling Systems

Raque Food Systems, Inc.

REB/Quality Cup

Regal Rexnord Corporation

Reiser

Rockwell Automation

Romaco Group

Ropak Manufacturing Co., Inc.

Ross Industries, Inc.

ROVEMA North America, Inc.

SACMI USA Group

Serac Inc

Shibuya Hoppmann

SMC Corporation of America

Solbern Inc.

Spee-Dee Packaging Machinery, Inc.

Starview Packaging Machinery Inc.

SUREKAP, LLC

Syntegon Packaging Technology

System Packaging

Tawi USA, Inc.

Teledyne TapTone

Telesonic PAK, LLC

TOPPAN Packaging

Triangle Package Machinery Co.

Turck Inc.

U.S. Tsubaki Power Transmission, LLC

Videojet Technologies Inc.

WeighPack Systems, Inc. / Paxiom

Winpak

World Cup Packaging

Yaskawa America, Inc., Drives & Motion

Division

Matthews Marking Systems

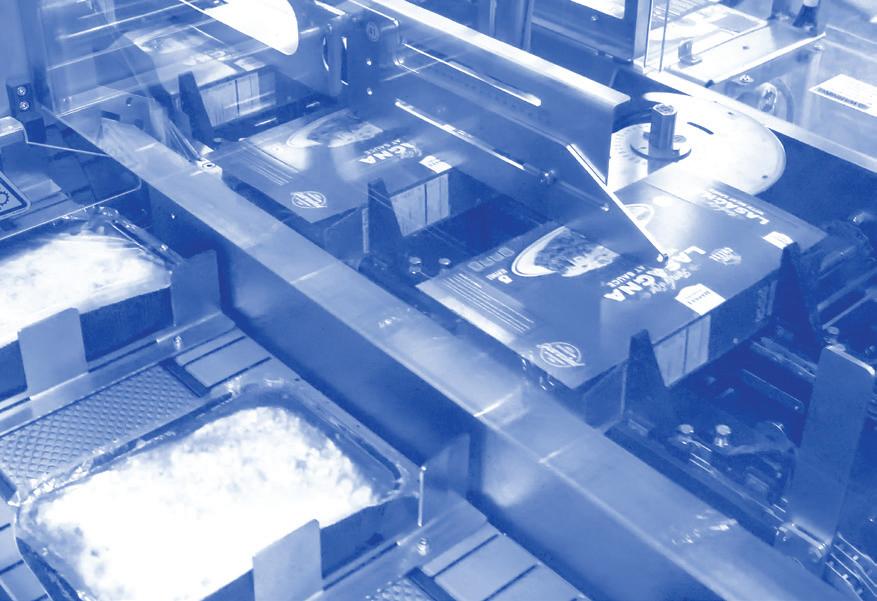

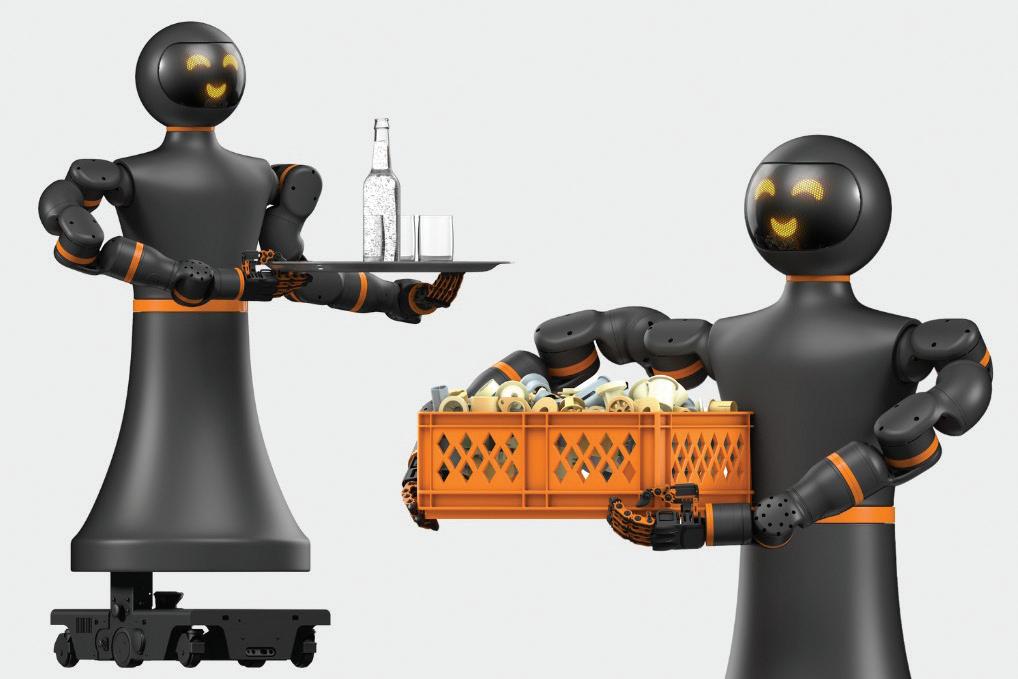

a system that works from end to end. That’s why Weber, Inc. (Booth N-7656) and SOMIC Packaging (Booth SU-26023) formed a partnership that is built on one simple goal: to make it easy for processors to produce high-quality, retailer-ready meal solutions using less labor and real estate with fewer headaches.

Weber’s integrated meal assembly line feeds directly into SOMIC’s compact retail-ready case packer for a seamless end-to-end solution.

“The days of long runs of the same product are gone,” said Jarrod McCarroll, CEO of Kansas Citybased Weber Inc. “Today’s consumers want variety, portion control, and the confidence that every pack stays fresh and looks great on the shelf.”

Consumers also want it across every daypart, from breakfast sandwiches and wraps for lunch, to snack trays in the afternoon and ready-meal kits at dinnertime. Organic, non-GMO, gluten-free, and reduced sugar are no longer niche items. They are table stakes, and food processors and their supplier networks have no choice but to hustle and keep up with the demand.

“Customers told us they wanted a single-source solution for snack trays, wraps, sandwiches, you name it,” added McCarroll. “When we asked them who they trusted on the packaging side, SOMIC’s name kept coming up. They’ve got an incredible track record for retail-ready case packing, especially with their heritage in Europe. Their compact, modular approach was exactly what we needed to close the loop.”

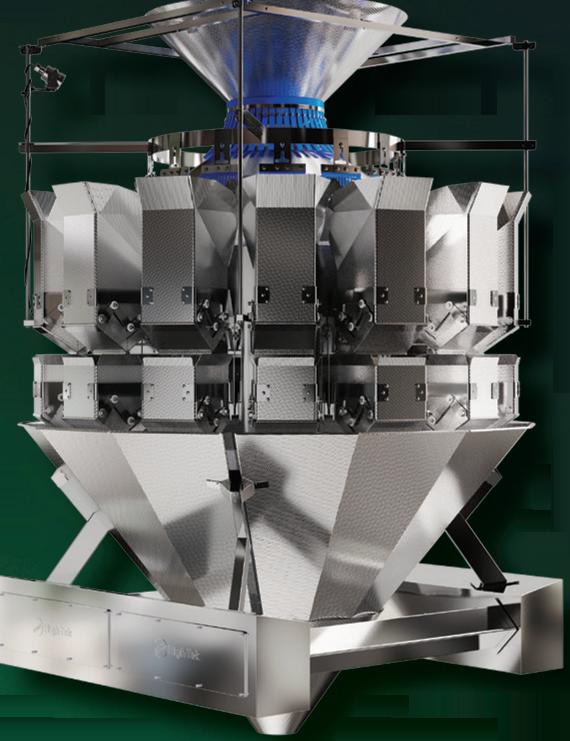

For over 20 years, High Tek has delivered automated weighing and packaging equipment, expert service and training, and a full inventory of parts to keep production running strong and smoothly.

From installation to every ounce of maintenance, our team is your partner—offering personalized support, rapid-response service, and a robust inventory of parts you need, when you need them.

Your uptime is our priority. With proven reliability, 24/7 technical support, and industry-leading know-how, we help you maximize output, minimize downtime, and stay ahead in today’s competitive market.

Experience. Performance. Support. Success!

1, 2025 26

—Continued from page 24

Peter Fox, SOMIC Packaging’s Minneapolis-based CEO, agrees with his assessment.

“Retail-ready is in our DNA. We know how to handle intricate formats, from tear-off trays to club packs for big box stores,” Fox said. “By teaming up with Weber’s upstream slicing and automated meal assembly, we help producers deliver exactly what retailers expect.”

The Weber-SOMIC Packaging partnership wasn’t born overnight. McCarroll credits the early conversations they had with Fox, dating back to 2021, for laying the groundwork.

“We learned a lot from past experiences where lines fell short because too many vendors were pieced together,” he acknowledged. “Now, we can sit at the table with Peter’s team, align on what success looks like, and deliver it as one.”

Fox says that space efficiency is a big deal for prepared meal producers.

“Some customers come in thinking they need an aircraft hangar to automate this, and they are shocked when they see our machine’s footprint,” he said. “They are even more surprised when they realize how fast they can switch formats to handle new SKUs.”

In real-world terms, this means more sandwiches, wraps, and snack trays per square foot, with fewer plant employees needed to touch the product.

Traditional lines rely on long, linear conveyors and big teams of manual labor. The Weber–SOMIC system consolidates that with smart automation and a single, seamless line.

“When you show a customer their product flowing from slicing to portioning to assembly, then straight through to a retail-ready carton and all fully

“We start with the end in mind, that perfect retailready pack and then build backwards,” explained Fox. “It’s not about selling a slicer or a case packer. It’s more about giving the customer what they sell: a premium product in a format that moves fast off the shelf.”

At the heart of the system is Weber’s nextgeneration “we” platform. It includes the weSLICE7500, weSHUTTLE, wePICK, and wePACK, all orchestrated to transport products efficiently through each processing stage. The final step is weSORT, which hands off to SOMIC’s 424 or nextgeneration 434 case packer. From this point, SOMIC organizes finished packs into pristine shelf-ready displays. The result is a line that operates like a smart train system.

The weSHUTTLE is built in modular sections which can turn 45, 90, or 180 degrees. “It’s like having flexible, intelligent train cars that know where to go and at what speed since each one has its own IP address,” said McCarroll. “We can fit it around columns, work in tight spaces, and create a flow that reduces our footprint and the labor needed.”

automated, it really clicks,” added McCarroll. “They see they can scale up, launch new SKUs, and still meet tight retailer requirements without adding square footage or people.”

One recently installed system includes SOMIC’s 424 T2W case packer with four case formats, and a case-flipping function to ensure sandwiches are oriented exactly right. “This type of detail matters,” said Fox. “Retailers want consistent shelf presentation, and Weber-SOMIC delivers that.”

With the first full systems up and running, Weber has already invested in SOMIC’s newer 434 case packing platform with even greater format flexibility. “This category is growing fast,” McCarroll said. “Retailers are going to keep pushing for new formats. Our system makes it possible to say ‘Yes’ to those changes without starting from scratch.”

For food producers in the convenience meal space, the message is clear: automation doesn’t have to be a patchwork of siloed machines. It can be one connected platform that turns sliced ingredients into premium, shelf-ready meals quickly, efficiently, and profitably. ■

Live Music

Educational Presentations Demonstrations of Product Inspection Solutions

Monday, Sept. 29

10:00am - 10:15am Metal Detection, X-ray Inspection, or Both?

10:30am - 11:00am Live Music

11:15am - 11:30am Solutions for Data Management of Product Inspection Solutions 1:30pm - 2:00pm Live Music

2:30pm - 2:45pm Detecting Contamination: Single Energy versus Dual Energy

Tuesday, Sept. 30

10:00am - 10:15am All Eyes on X-ray for Big Box Retailers

10:30am - 11:00am Live Music

11:15am - 11:30am Five Ways to Combat Rising Food Manufacturers’ Costs

1:30pm - 2:00pm Live Music

2:30pm - 2:45pm Prevent Recalls with Automatic Vision Inspection

Wednesday, Oct. 1

10:00am - 10:15am Best Metal Detection Testing Practices 10:30am - 11:00am Live Music 11:15am - 11:30am ROI of Product Inspection Systems

LIfe is Sweet When You Partner With METTLER TOLEDO.

New report reveals growing aftermarket opportunities, setting the stage for PACK EXPO Las Vegas.

PMMI, e Association for Packaging and Processing Technologies (West Lobby), has released its 2025 A ermarket Parts & Service Report, a mustread resource for all packaging and processing stakeholders. As a ermarket services increasingly drive business growth and customer loyalty, this report

o ers critical intelligence to help OEMs, suppliers, and end users navigate a rapidly evolving landscape.

e 2025 A ermarket Parts & Service Report reveals that nearly all end users and OEMs anticipate growth in their a ermarket business over the next three years, with 98% of end users expecting to expand or maintain their budgets for a ermarket parts. As companies confront challenges around lead times, technician shortages, and evolving customer expectations, the report emphasizes the urgent need for OEMs and suppliers to optimize inventory management, strengthen remote services, and expand training initiatives.

Key takeaways from the report:

• 75% of end users identi ed immediate parts availability and fast lead times as their top expectations.

• 94% of OEMs predict growth in their a ermarket services business over the next three years.

• Remote services, predictive maintenance, and proactive obsolescence planning are becoming non-negotiable to remain competitive.

“ e data is clear: A ermarket services are no longer secondary—they are critical to business success,” says Jorge Izquierdo, vice president, market development, PMMI. “Companies that align their a ermarket strategies with customer needs today will be tomorrow’s industry leaders.”

At PACK EXPO Las Vegas, attendees can experience rsthand the innovations and strategies highlighted in the A ermarket Parts & Service Report and meet the industry leaders who bring them to life. Explore six expanded, targeted pavilions: the Logistics Pavilion (North Hall), the Containers and Materials Pavilion (South Lower Hall), the Reusable Packaging Pavilion (South Upper Hall), Confectionery Pavilion (South Upper Hall), the Processing Zone (North Hall), and the Healthcare Packaging Pavilion (North Hall). Discover eyeopening innovations and new technologies to improve e ciency, sustainability, and performance. Gauge where your company stands regarding industry trends and generate ideas for future projects.

“With a ermarket playing an increasingly critical role, there’s no better place to prepare your business for the future than PACK EXPO Las Vegas,” says Jim Pittas, president & CEO, PMMI. “ is is where innovation meets opportunity.”

OCTOBER 1, 2025

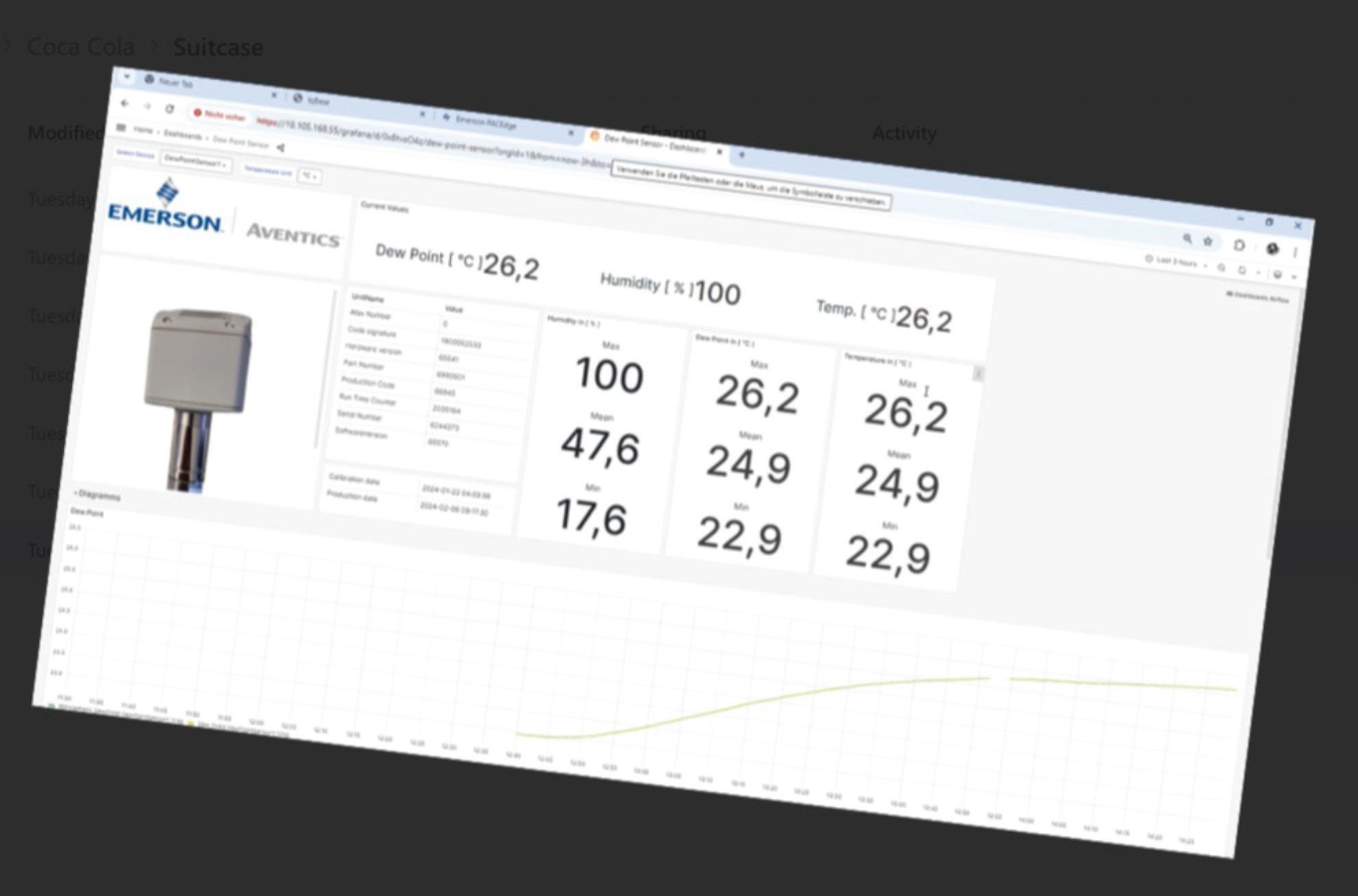

By partnering with Emerson (Booth SL-15009), a bottling company continuously monitors compressed air usage to maximize uptime and minimize consumption across numerous facilities.

In the beverage industry, compressed air is essential for bottling and filling processes. However, most manufacturers have little awareness about the compressed air their machines use. This includes the quality of the air itself, humidity levels, the pressure set for production equipment, leakage, consumption rates, and more.

Without this information, issues such as leaks and component damage can develop that lead to unplanned downtime and excess compressed air use. Although the compressed air that one machine uses may seem negligible, these issues are compounded when looking at a whole line, at a facility, and beyond.

In comparison, compressed air monitoring allows operators to measure critical values in real time to detect and address issues in their earliest stages or prevent them altogether. With greater visibility and control of compressed air quality and consumption, bottling companies can improve overall equipment effectiveness (OEE) values, maximize production uptime, optimize compressed air use, and minimize utility costs.

One global bottling company sought to reduce production and energy costs across its network of plants. The company asked Emerson (Booth SL15009) for a plug-and-play solution to detect leaks and measure the quality of compressed air for bottling and filling machines. As an added constraint, the

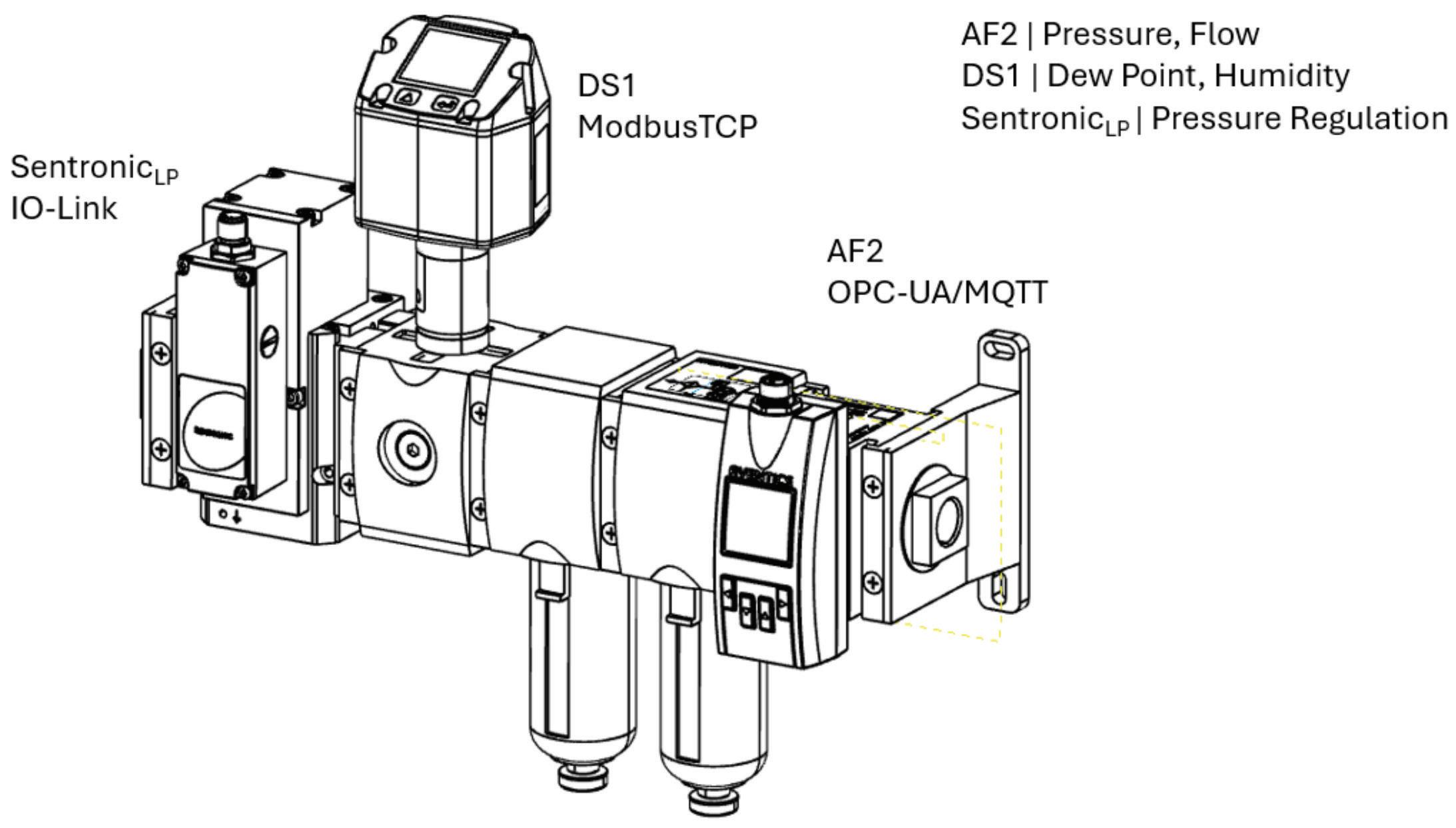

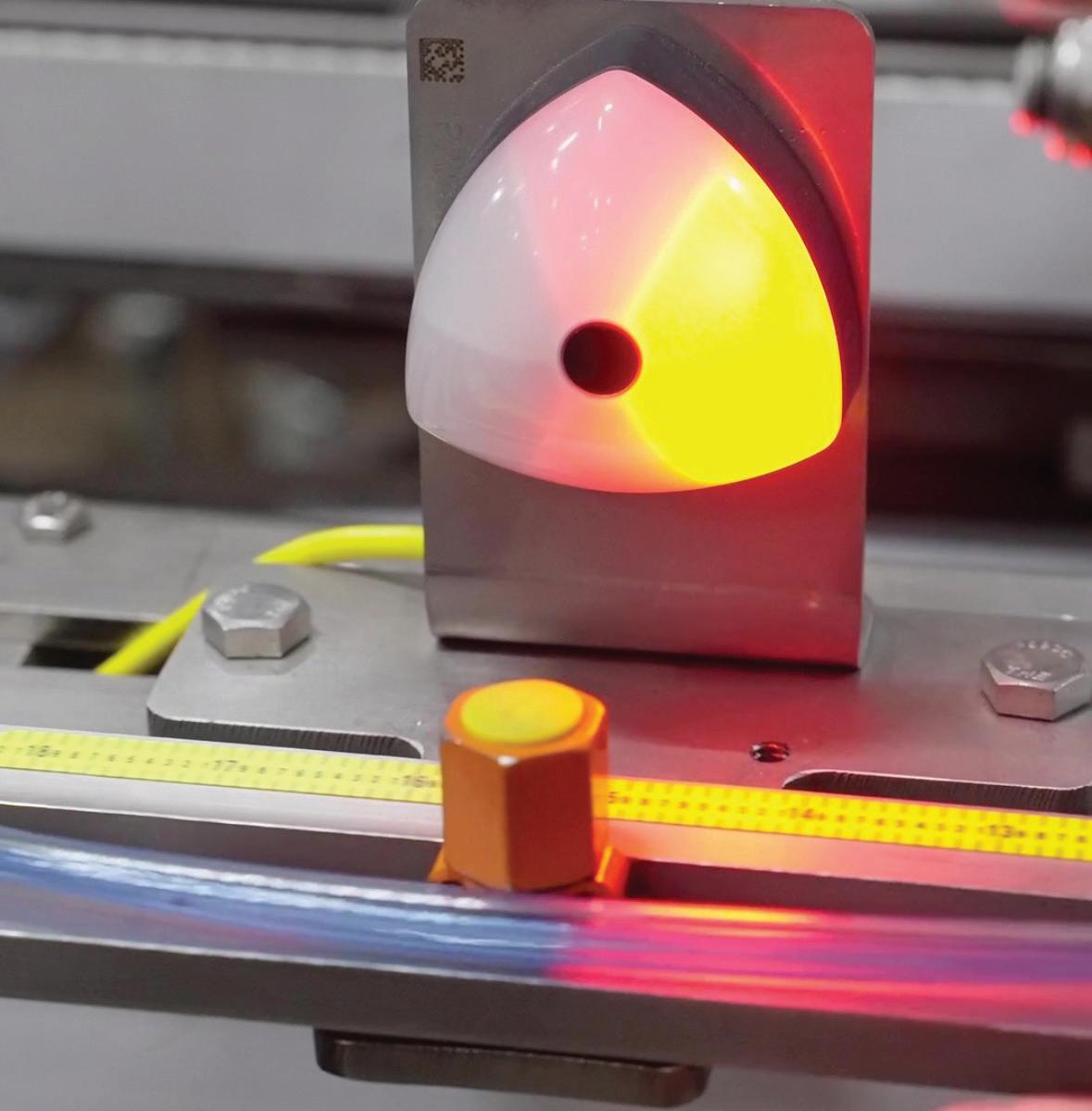

With integrated sensors, air preparation unit, edge gateway and software, the portable AVENTICS Smart Pneumatics Analyzer (SPA) from Emerson monitors pneumatic systems, visualizes the analyzed data and provides actionable insights. (Image courtesy of Emerson)

solution must also be able to be installed within a two-hour window to minimize process interruption. Emerson already had proven technology to identify compressed air leakage, so Emerson engineers immediately set to work to solve the problem.

In bottling plants, pneumatic systems power equipment in filling lines and must run in optimum condition when they’re needed to meet production schedules. Leakage and high humidity in the system can affect processes—even stopping them—incurring unplanned downtime and raising costs.

Excess moisture in the system can cause multiple issues, including corroded components, lubricant washout, product inconsistency and more. Additionally, there are standards that require a certain level of compressed air quality in the food and beverage industry. For bottling specifically, it’s important to prevent moisture from diffusing into the product. By tracking compressed air quality in real time, bottling companies can address excess moisture and prevent premature component wear and associated machine failures, as well as remain compliant and maintain product quality.

Like excess moisture, leaks can lead to equipment

—Continued on page 32

—Continued from page 30 failure and unplanned downtime while also increasing energy use and carbon emissions. Leaks can develop in pneumatic lines and go undetected for long periods of time, wasting air and affecting machine performance. By detecting and addressing leakage in its earliest stages, bottling facilities can prevent compressed air waste and keep machines running in optimum condition.

The bottling company had an existing information technology (IT) cloud environment and dashboard, and obviously, its filling equipment. What was needed was a way to communicate between the plant floor and the cloud: a solution that was quick and easy to install to collect compressed air data from the filling line and transmit it to the cloud.

To help the company solve its problem, the Emerson team used a Floor to Cloud™ approach and its industry expertise to engineer a solution using proven technology from its extensive factory automation portfolio.

A Floor to Cloud approach to factory automation enables manufacturers to unlock and access trapped data that connects physical and digital processes, to get visibility and insights to make data-driven decisions to optimize operations, and to automate and perform tasks effectively and efficiently. As a result, this approach empowers manufacturers to accelerate and transform their operations, drive efficiency, increase sustainable growth, and unleash workforce potential.

Following this approach, Emerson developed and installed a pre-engineered, preprogrammed suitcase with an advanced airflow sensor, dewpoint sensor, and air supply maintenance unit with defined communication to the appropriate gateways. Known as the AVENTICS™ Smart Pneumatics Analyzer (SPA), the portable solution monitors pneumatic installations and systems and visualizes the analyzed data. Its integrated edge gateway with PACEdge software continuously records data from the integrated sensors of the air preparation unit and provides actionable insights.

The compressed air monitoring solution used at the bottling plants include the AVENTICS AF2 flow sensor, which helps operators detect leaks in their earliest stages, and the AVENTICS DS1 dew point sensor, which helps operators detect excess moisture in compressed air lines. (Image courtesy of Emerson)

The integrated sensors include the AVENTICS AF2 flow sensor and AVENTICS DS1 dew point sensor. The proven AF2 flow sensor has helped plants around the world successfully reduce compressed air consumption and improve energy efficiency. It continuously monitors air consumption in pneumatic systems, allowing rapid intervention if leaks occur.

The AVENTICS DS1 dew point sensor is the only industrial sensor to monitor dew point, temperature, humidity levels, and quality of compressed air and other noncorrosive gases in real time from one device. DS1 measurement values include pressure dewpoint, temperature, relative humidity, absolute humidity, moisture content, moisture content V/V, water vapor partial pressure, and atmospheric dew point. The DS1 can help operators detect and mitigate excess moisture in its early

stages and prevent moisture-related equipment damage.

The Emerson team directly installed the compact, integrated solution on the main compressed air line with minimal disturbance to the running machine and connected it to the cloud within half an hour. This was especially impressive given that the suppliers of other sensing technology the company had installed took six months to complete the same step.

The AVENTICS

Series DS1 dew point sensor from Emerson monitors compressed air quality in real time and alerts personnel if moisture exceeds set thresholds.

(Image courtesy of Emerson)

All relevant information was visible in the company’s cloud. Using the sensor technology from Emerson with its existing software application, operators could now monitor lines and track KPIs, minimize air consumption during non-production times, optimize compressed air consumption during production, detect leakage, and detect air quality. The great possibility for future use cases further increased the added value and cost savings.

After the success of the pilot, the bottling company asked Emerson to scale up the monitoring solution within its entire plant. The Emerson team added an additional gateway and five more sensors.

The company successfully ran this installation for a year and a half. Using the technology, operators noticed that humidity levels were much too high from April to May. Since they were aware of the problem at the moment, they could address it before it caused issues. Again, the company was impressed with the solution and its quick return on investment (ROI) and wanted to integrate the same solution in other plants.

The bottling company then asked Emerson to install 18 units for more of its global plants. Ideal for new construction and retrofit applications, the monitoring solution was installed across nine brownfield projects, and its implementation is planned for another 10 greenfield lines in several different countries. Since Emerson has a global presence that allows for localized support, parts ordering and installation at the other plants went as smoothly as the pilot.

Given the continuous success and ongoing value of the monitoring solution, the company added Emerson to its official line specification. The AF2 flow sensor and DS1 dew point sensor are now specified components in every line, making it possible for Emerson to now support a wide range of original equipment manufacturers (OEMs) that partner with the bottling company with its Floor to Cloud approach and comprehensive range of factory automation solutions.

To minimize downtime and production costs in filling lines, it’s critical to have the visibility and control to prevent issues that could interrupt production. And to successfully realize complex, enterprise-wide digital transformation projects, it’s important to partner with an expert solutions provider that has a proven, scalable approach, global presence, and wide-ranging portfolio to draw from.

Through its partnership with Emerson, the bottling company was able to successfully test its pilot project and easily scale up worldwide after seeing valuable benefits and proving ROI. As a result of the partnership, the company now has realtime compressed air monitoring that allows its operators to continuously track critical values, address anomalies during scheduled maintenance, and keep lines running well into the future. ■

PACK EXPO Las Vegas newcomers benefit from the First-Time Attendee Lounge (Room S-220), sponsored by ProMach, Inc. (Booth W-1500), a dedicated space offering guidance and networking, ensuring everyone leaves with valuable connections.

The First-Time Attendee Lounge is a hub for starting the day right and maximizing the PACK EXPO experience. Holders of a First-Time Attendee badge can access this exclusive lounge offering and receive:

• Personalized guidance: Knowledgeable show staff are on hand to help locate exhibitors, recommend sessions, and create a plan to tackle the show floor.

• Product locators: Quickly find the solutions and suppliers that align with your goals.

• Comfortable seating and refreshments: Enjoy free coffee, tea, and charging stations to recharge yourself and your devices.

• Special Sessions:

How to Navigate the Show Like a Pro

(Monday -Tuesday, 8:30 to 9:00 a.m.) Kickstart the day with helpful insider tips and strategies to help navigate the exhibit halls and make the most of the show experience. Plus, plenty of Q&A opportunities with show staff.

First Time Attendee Breakfast

(Tuesday, 8:00 a.m. – 9:00 a.m) Connect with peers and talk shop with fellow first-timer attendees while enjoying a complimentary breakfast. It’s a great way to kick-start the day. Your First-Time Attendee badge is your ticket. Spaces are limited, first-come, first-served.

Simplify Supplier Sourcing With ProSource

(Monday - Wednesday, 12:30 to 1:00 p.m.) Find trusted suppliers, explore features, and simplify the sourcing process all in one place. PMMI ProSource is a searchable directory that can help you find suppliers year-round. ■

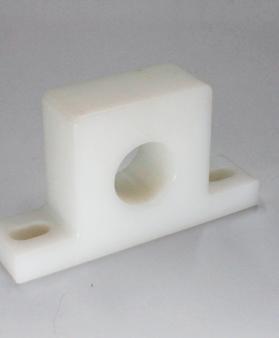

Inserting the plunger rod, torquing it into place, and labeling the syringe using our new, patented ATR technology

The NEW, patented PR-12 and PR-24 from WLS perform high-speed, high-control plunger rod insertion, and syringe labeling in one, single, compact-footprint unit.

By Carl D. Melville, Managing Partner, The Melville Group

The lines are blurring. Once defined by traditional players, today’s brand landscape is a complex, fast-moving arena where consumer trust, loyalty, and shelf space are hardwon. But with new prominence comes new challenges. Brand executives now face intense, multi-front competition—not only from long-established legacy competitors but also from a surge of agile, direct-to-consumer emerging brands. The strategic playbook is being rewritten in real time.

Equivalence in quality and scale has become the baseline. How do you accelerate innovation and deliver the “premiumization” consumers now expect? As you expand into specialized categories like organic, clean-label, or plant-based, how do you identify manufacturing partners with the niche capabilities and certifications required—while safeguarding your brand against quality failures and recall risks?

The success of any brand is now intrinsically linked to the capabilities of its contract packaging and manufacturing partners. Yet, benchmarking and optimizing these relationships remain a complex, high-stakes endeavor.

This is where the Contract Packaging Association’s (Booth W-101) 2025 State of the Industry Report (SOIR) delivers unmatched value. Now in its ninth edition, this 433-page comprehensive report is built on insights from over 200 executive surveys, interviews, and projects, paired with years of primary and secondary research. It stands as the definitive industry benchmark.

Legacy brands, emerging brands, private equity investors, and retail leaders alike rely on SOIR to identify market shifts, assess threats and opportunities, and shape winning strategies. For brand executives, the report is more than data—it’s a blueprint. It offers a clear framework for vetting partners, provides a deep dive into the technology stacks separating leaders from laggards, and includes a thorough analysis of M&A activity that is redefining the competitive landscape.

In addition to the intelligence provided by SOIR, brands can also take advantage of Copack Connect (copackconnect.com)—CPA’s digital matchmaking tool that helps brands quickly identify and connect with qualified contract packaging and manufacturing partners for free. Whether you’re looking to scale into new categories, secure specialized certifications, or expand capacity with reliable partners, Copack Connect translates SOIR’s insights into immediate, actionable connections.

Together, SOIR and Copack Connect give brand leaders both the strategic context and the practical resources to navigate the increasingly complex co-manufacturing landscape.

In an era where your manufacturing partner is a direct extension of your brand, SOIR provides the intelligence needed to de-risk your supply chain and turn it into a competitive advantage—while Copack Connect helps you take the next step in putting those insights into practice.

It’s more than a report; it’s a playbook and a toolkit for navigating the future of food and consumer packaged goods.

To gain the insights shaping the industry and optimize your strategic planning, download a complimentary preview or purchase the full 2025 State of the Industry Report at contractpackagingreport.com—and explore Copack Connect at copackconnect.com. ■

Cama is a leading supplier of advanced technology secondary packaging systems, from stand-alone machines to turnkey systems. We all have a responsibility as individuals, teams, companies and corporations to bring sustainability to everything we do.

These dedicated spaces make it easy to navigate the show floor, zero in on solutions, and compare options side by side.

PACK EXPO Las Vegas is a massive showcase of cutting-edge technology and solutions, but finding exactly what you need is simple in distinct pavilions. These “shows within a show” feature solutions that address many industry challenges, making it easy to navigate the show floor, zero in on targeted solutions, and compare your options side by side. All of the pavilions have expanded, reflecting the tremendous market growth in packaging and processing.

The Logistics Pavilion (North Hall):

With the rapid expansion of e-commerce, this pavilion features cutting-edge supply chain solutions, including warehousing, fulfillment, distribution logistics, and transportation providers.

The Processing Zone (North Hall):

This area showcases the latest processing innovations, including homogenizing, heat treating, forming/sizing, and coating solutions.

The Healthcare Packaging Pavilion (North Hall):

Focused on life sciences, this pavilion showcases packaging innovations for pharmaceuticals, biopharmaceuticals, nutraceuticals, and medical devices.

The Containers and Materials Pavilion (South Lower Hall):

From paperboard to films and foils, right-sized containers and all kinds of consumables, this pavilion houses solutions to increase sustainability, enhance usability, and improve convenience.

The Confectionery Pavilion (South Upper Hall):

Sponsored by the National Confectioners Association (Booth SU-26000), this pavilion delves into the latest trends in candy, baking, and snack production.

The Workforce Development Pavilion (North Hall Lobby):

The ultimate resource hub for strengthening the existing workforce and nurturing the future workforce.

The Showcase of Packaging Innovations (West Hall Concourse, Level 2):

Sponsored by Smurfit Westrock (Booth W-2300), this attendee favorite displays award-nominated packaging solutions.

The Reusable Packaging Pavilion (South Upper Hall):

Sponsored by the Reusable Packaging Association (Booth SU-34000), this area explores sustainable, reusable transport packaging that reduces waste, improves material handling performance, offers superior product protection, and improves the freshness and quality of perishable foods.

The Association Partner Pavilion (West Hall):

Serves as a vibrant hub for industry collaboration, connecting attendees with the foremost organizations across the packaging and processing spectrum.

Scan the QR codes below or visit the show app sponsored by ProMach (Booth W-1500) for descriptions, times, and locations.

For up-to-the-minute content, head to the always-popular Innovation Stages (Booths W-4300, W-4310, and W-4318). Exhibitors and subject matter experts present packaging industry breakthroughs, new products, and best practices during fast-paced, 30-minute seminars presented on three stages.

Education session topics include:

• Be Future Ready: Advanced TIJ Technology for Enhanced Efficiency, Global Coding Standards Compliance, and Better TCO

• AI and Automation in Labeling and Artwork Management : Are You Ready?

• Building Traction with ERP and Gen AI

• Sustainable by Design: Energy-Efficient Packaging Machines Transforming the Industry

• Leadership and Change Management in the Age of Industry 4.0

Industry Speaks (Booth W-4324) features thought leaders from PACK EXPO Las Vegas Partner Associations, giving attendees a snapshot of the trends and issues shaping their specific industries and their effect on the marketplace. Explore diverse perspectives from representatives of all corners of the packaging and processing world for insights that make an impact on business decisions.

Industry Speaks Sessions at PACK EXPO Las Vegas include:

• How Smart Packaging Helps Grow Consumer Transparency

• Before You Buy: What Equipment Specs Really Matter?

• The Latest Trends in Robotics

• Top Packaging Policies Impacting Your Business

• Inside the Workforce Gap: Insights from PMMI’s Latest Research

• Ordinary But Extraordinary: The Tried-and-True Benefits of Corrugated Packaging

Got 30 minutes? Take a seat at the Processing Innovation Stage (Booth N-9100) to hear about the latest food and beverage processing breakthroughs and improvements to make in operations. Content is targeted to food and beverage manufacturers. Exhibitors and subject matter experts present packaging industry breakthroughs, new products, and best practices during fast-paced seminars.

Education session topics include:

• Advancing Sustainability Through Innovative Food & Beverage Factory Solutions

• Processing Foods without Preservatives

• Automation Solutions for HPP: Success Story by Bay Center Foods (Chick-fil-A)

• Packaging Line Startups: A Proven Blueprint for Success

• Scaling Quality and Efficiency Through Continuous Mixing: Three Bakery Success Stories

Within PACK EXPO Vegas’ Sustainability Central, attendees get different takes on sustainability from industry experts and gain insight into making brands more sustainable for the future.

Education session topics in Booth S-35000 include:

• Sustainable Packaging Impact on Consumer Behavior

• Packaging Waste, Circularity, and the EPR Mandate to Create ROI

• Legislation is Here—Is Your Packaging Ready?

• Driving Sustainable Savings & Circularity in Packaging

• Evolving E-Commerce Packaging Materials

• Driving Efficiency in Compressed Air with Data & AI

OCTOBER 1, 2025

Discover innovative ways to optimize logistics and make the supply chain more efficient and sustainable with reusable assets. In the Reusable Packaging Learning Center (Booth SU-34000), attendees hear from suppliers and their clients who’ve successfully transformed their operations to incorporate reusables. Sessions discuss enhancing supply chain performance, sustainability, and technology usage through reusable transport packaging.

Sessions at this year’s event include:

• Panel: When Products Are No Longer Reusable, Achieve Maximum Value and Sustainability

• Panel: Market Outlook: Sustainable Packaging Trends in the Fresh Produce Industry

• Optimizing the Cube: GPO strategies for Smarter Packaging

• State of the Industry: The Game-Changing Opportunity with ArtificialIntelligence in a Reusable Transport Packaging System

• Drive Warehouse and Storage Efficiency with Versatile Bulk Packaging

PACTEON Group (Booth W-2944) offers a single-source stop for packaging solutions.

Through the acquisition of businesses offering complementary products and shared core values— Schneider Packaging Equipment, ESS Technologies, Phoenix Wrappers, and Descon Conveyor Systems PACTEON Group (Booth W-2944) is one source for end-of-line packaging solutions. PACTEON brands provide expert solutions for a variety of markets, including consumer packaged goods, food, beverage, dairy, paper products, pharmaceuticals, nutraceuticals, cosmetics, and health and beauty.

Descon’s high-speed robotic layer forming table is redefining beverage palletizing. The continuous layer configuration paired with a robotic layer palletizing tool streamlines operations for maximum throughput. Utilizing FANUC robots, the layer forming table is flexible for a wide range of case sizes and pallet patterns. This efficient solution offers a lower total cost of ownership over conventional palletizers.

This compact, servo-driven vertical case packer from ESS Technologies effortlessly packs a wide range of pharmaceutical, nutraceutical, and health & beauty products. Featuring integrated FANUC robots, customizable infeed and sealing options, and serialization-ready design, the V30 case packer delivers with precision and low energy usage.

The PRRA is a cutting-edge rotary ring-style automatic pallet wrapper designed for high speeds. It wraps loads from bottom to top without returning to the clamp, eliminating wasted film. This innovation saves over 30 feet of stretch film per wrap cycle while maintaining optimal load retention. Compared to similar wrappers, the PRRA delivers a significant annual film savings and has one of the smallest footprints in the industry. The PRRA sets a new standard in stretch wrapping technology.

Schneider is demonstrating their portfolio of automatic changeover options for case packers. Learn how precise machine adjustments are made at the push of a button with ProAdjust and ProAdjust Lite systems. See how a series of power packs and position verification removes the risk of error or lengthy operator training. ■

OCTOBER 1, 2025 46

The Partner Program returns to PACK EXPO Las Vegas 2025, where the entire packaging and processing industry will gather to explore breakthrough innovations, connect with peers, and experience machinery in action.

Now celebrating 30 years since its inception, PACK EXPO Las Vegas, produced by PMMI, The Association for Packaging and Processing Technologies, (West Lobby) will connect packaging and processing professionals from more than 40 vertical markets with over 2,300 exhibitors displaying the latest solutions across over 1 million net square feet of show floor. At the center of it all, the Association Partner Pavilion—located in the West Hall (Booths W-100 – W-130)—will serve as a vibrant hub for industry collaboration, connecting attendees with the foremost organizations across the packaging and processing spectrum.

“The PACK EXPO Las Vegas Partner Program demonstrates the importance of PACK EXPO Las Vegas bringing the entire industry together under one roof,” says Laura Thompson, vice president, trade shows, PMMI. “We’re thrilled to welcome back this impressive lineup of associations, including five new partners, each contributing expertise and connections that make this event truly unmissable. It’s a one-of-a-kind opportunity to discover solutions and build meaningful relationships that move business forward.”

This year’s Partner Program includes over 30 participating organizations and will feature the Industry Speaks stage, where thought leaders will present expert-led sessions on the latest trends in packaging and processing, from sustainability and automation to digital transformation and workforce development.

Participating Associations Include:

• 3-A Sanitary Standards, Inc

• AIM, Inc.

• APPMA | Australian Packaging & Processing Machinery Association

• Association for Roll-to-Roll Converters

• Association of Plastic Recyclers

• Automate UK

• CANAINCA

• Cold Pressure Council

• Composite Can & Tube Institute (CCTI)

• Consumer Brands Association

• CPA, The Association for Contract Packagers & Manufacturers

• Fibre Box Association (new)

• Fispal Tecnologia