A2L Transition Technical Training Day Supplement

Refrigeration industry enters period of change as the days of HFCs transitions into the age of A2Ls.

INSIDE

n Need to know for installers

n A2L basics

n Overcoming fears

n Supply chain impacts

Refrigeration industry enters period of change as the days of HFCs transitions into the age of A2Ls.

n Need to know for installers

n A2L basics

n Overcoming fears

n Supply chain impacts

HEAT PUMPS | VENTILATION | DOMESTIC HOT WATER

u Quality And Reliability You Can Trust

u Efficient Products Designed For The Canadian Climate

u Over 35 Years Of Successful Installation

u Strong Canadian Customer Support Team

u Local Supply of Products THE MITSUBISHI ELECTRIC ADVANTAGE

Another technical training day has come and gone. This might have been my favourite one that we’ve hosted to date. I think part of the reason is because this topic felt so timely. The journalist in me is quite happy.

From what I’ve gathered in the many conversations that I’ve had regarding A2Ls, there seems to be some confusion surrounding the topic. This stems from how the installation process differs from HFCs, like R-410A, what safety protocols are required, and should the installers be scared when they hear the term “mildly flammable.”

I am going to tackle that last one first. The biggest takeaway that I’ve come to learn is that there isn’t a reason to be scared. I know there are some in the industry who are even frustrated with the characterization of these A2Ls as mildly flammable because they are concerned it is going to cause installers to want to run in the opposite direction. But since there is still a possibility, it must still be considered flammable.

This is a great segway into the second point: safety protocols. I am not an installer, so I am not going to sit here and list out all the necessary practices that you are going to need to learn. But this will be something that anyone working with A2Ls is going to need to learn to the point that it’s second nature. For the time being, there are some pretty neat tools available. One highlighted by David Kim from LG Electronics during his presentation, and follow-up article on Page 20, is software that can ensure that the system has been designed to meet ASHRAE 15 and CSA B52. When I was sitting down and coming up with my questions to be asked during the panel discussion, I discovered a very cool and useful tool — Hardi’s AskA2L. Artificial intelligence (AI) is starting to become a lot less scary as it starts to find its way into more and more of our daily lives. The right AI tool can help answer the questions that might not be in your sphere of knowledge. This specific resource was able to help prepare for the conversation that I was tasked with moderating.

These training sessions are important stepping stones for anyone in the industry that finds themselves working with A2Ls in any capacity. I would still challenge anyone reading this column or anyone who participated in our training to keep up with the momentum. You can never receive too much training and its important to stay in the know with what’s going on.

View the full presentation on “Fundamentals of A2L Refrigerants, Safety, System Design, Compliance, and Applications” here:

R-32 and R-454B are the most common A2L refrigerants currently in use.

Depending on the application of the project, each refrigerant has its pros and cons.

By David (Tae Jun) Kim

The Canadian HVAC industry currently stands at a pivotal point in history for HVAC contractors, engineers, developers, and end-users. It should come as no surprise that we are going through yet another refrigerant transition period.

The initial major refrigerant transition occurred with the Montréal Protocol back in 1987, which mandated the phase-down of hydrochlorofluorocarbons (HCFCs) to protect the ozone layer.

The ozone layer was recorded to be around 300 dobson units back in the 1960s, which started to decrease dramatically to 150 dobson units in the Antarctic by the late 1980s. One of the major causes of this was chlorine atoms inside the CFC/HCFC refrigerant. A single chlorine atom can destroy over 100,000 ozone molecules. The Montréal Protocol mandated to use the refrigerant with zero ozone depletion potential (ODP). This was during the time when the industry transitioned from R-12 to R-22 and R-22 to R-410a.

R-410A had an ODP level of zero, but it had another problem: its global warming potential (GWP) level. Its GWP level was 2,088. To put this into perspective, CO2 has a GWP level of one; R-410A has 2,088 times more likelihood to cause negative greenhouse effects.

Due to continuous climate change caused by global warming, the Kigali Amendment was introduced in 2016, which Canada ratified in 2017. Since then,

the Canadian government announced multiple ways to control the import, manufacturing, and use of hydrofluorocarbons(HFCs)andencouragedthe use of environmentally friendly alternatives. Despite all that, Canada has not yet announced a clear product-specifictimelinefortheR-410Aphase-outin residentialandlightcommercialmarkets.

The United States ratified the Kigali Amendment in 2022 and yet, the Environmental Protection Agency (EPA) announced the GWP limit compliancedateperproductcategoryindetail,whichincludesresidentialand light commercial air conditioning, heat pumps, and variable refrigerant flow Systems.However,theCanadiangovernmenthasnotyetofficiallyannounced anydatesforphasingouttheR-410ArefrigerantsforminisplitsorVRFs.

Even though Canada can still import, manufacture, and install R-410A equipment, we are heavily influenced by the U.S. market, and thus, new refrigerantsystemsarebeingintroducedbymultiplemanufacturers.

TheserefrigerantsareA2Lrefrigerantswitha GWPlevellowerthan700. A2L refrigerants have lower flammability with lower toxicity. Most of the gases, when we think of flammablegas,aremostlyclassifiedas Class3, which are propane, butane, acetylene, etc. Compared to Class 3 refrigerants, Class 2 refrigerantshavelessheatofcombustion,highLFL(lowerflammabilitylimit), and Class 2L have lower burning velocity even compared to Class 2 refrigerants.

LG Electronics conducted a laboratory test with R-32 refrigerant where a wall-mounted indoor unit is installed in a chamber and the refrigerant is leaked through the unit. Multiple candles were placed throughoutthechamberto examine its reaction. During the five minutes of the experiment, R-32 concentration within the chamber exceeded the lower flammability limit of R-32 but it didn’t cause any big explosion; instead, it simply fueled the candle

and increased the height of the flame.

The most common A2L refrigerants that are available in the market right now are R-32 and R-454B. Both refrigerants have a GWP level of less than 700. Depending on the application of the project, each refrigerant has its pros and cons. Please contact the local supplier to determine which refrigerant will be more applicable to your future project. The below chart outlines some of the features of both R-32 and R-454B.

Both R-32 and R-454B have a global warming potential level of less than 700.

LG Electronic’s R-Checker allows installers and engineers to verify if their system complies with CSA B52 and ASHRAE 15.

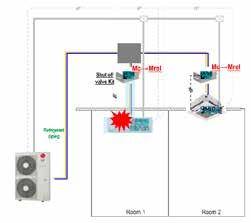

Though A2Ls represent lower flammability refrigerants and are very difficult to cause any flame propagation, the mechanical code had to be updated to provide multiple ways to design using it. ASHRAE 15 was updated in 2022 and CSA B52 was updated in 2023. The challenge in using the A2L refrigerant is its low refrigerant charge limit (RCL). RCL of R-32 is 25 per cent of LFL, which is 4.8 lbs/1,000 ft3. RCL of R-410A is 26 lbs/1,000 ft3, which means that in the same volume, I can only have 18 per cent of R-32 charge compared to R-410A.

This is a big challenge with A2L refrigerants; the updated CSA B52 code provides some options to make A2L more acceptable. First, it gives the option to increase this limit to 9.6 lbs/1,000 ft3 by introducing air circulation initiated by a refrigerant detector (effective dispersal volume charge calculation, 4.5.5.2 refrigerant systems with air circulation).

Second, it gives a way to increase the volume of the room by introducing natural ventilation, which allows the room connected to it to be considered as one zone (Avent calculation, annex N.2.2 effective dispersal volume calculations). Third, it gives the option to use a zoning system, which allows all zones connected to a single unit to be considered as a single volume (annex N.3 connected spaces via ducted

CSA B52 gives the option to introduce a mechanical fan initiated by the leak sensor to allow a higher refrigerant charge.

air distribution system). Fourth, it gives the option to introduce a mechanical fan initiated by the leak sensor to allow a higher refrigerant charge than what is calculated by EDVC calculation.

Lastly, the releasable refrigerant charge can reduce the amount of refrigerant charge released in the zone by limiting the refrigerant flow using the shut-off valve kit. Utilizing all these concepts, A2L refrigerants can be much more flexible in designing around the RCL, allowing the systems to be installed in much smaller rooms than R-410A refrigerant systems.

Manufacturers are introducing their versions of refrigerant-check software to allow installers and engineers to verify if their system complies with CSA B52 or ASHRAE 15.

Despite all speculations on lower flammable refrigerants, it can improve the overall design flexibility using the A2L refrigerant. Each manufacturer will have more detailed training sessions on A2L refrigerant installations and services, so please contact your local reps to register for these training sessions to gain deeper insight into the A2L refrigerant system.

David Kim is the engineering manager at LG Electronics. He graduated from the University of Waterloo with a mechanical engineering degree and has worked in the HVAC market with LG Electronics for the past eight years. He can be reached at david.kim@lge.com.

-30°C

HIGH-EFFICIENCY CENTRAL HEAT PUMPS WITH CASED COILS

Heat pump combination AHRI Certified for installation with ANY 3rd party furnace.

OFFICIAL DISTRIBUTOR IN CANADA

COLD CLIMATE DC INVERTER HEAT PUMP

Two-stage, two-cylinder compression and hot gas injection for unparalleled heating efficiency.

Eligible to financial incentives in certain provinces, contact us for more detail.

TO FULLY SUPPORT OUR DEALER NETWORK

*GREE Canada is not responsible for warranty on units sold outside GREE Canada’s sales channel.

For more detail, contact our team at proservice@gree.ca.

C&D Valve, Oklahoma City, Oklahoma, launches its new A2L red anodized aluminum locking caps. The tamper-resistant caps are engineered to fit standard 1/4-inch schrader valves, providing a secure barrier against unauthorized access to potential refrigerant leaks. These caps are corrosion-resistant thanks to their anodized aluminum exterior. Caps come in packs of two, 10 and 50.

C&D Valve u www.cdvalve.com

Bosch Home Comfort, Watertown, Massachusetts, introduces its new mini-split series with the R-454B refrigerant. The Bosch Climate 5000 ductless mini-split heat pumps are in compliance with low GWP A2L refrigerant requirements and feature a factory-installed A2L sensor on the evaporator coil. The Climate 5000’s outdoor unit runs as low as 53 dB, while the indoor unit runs as low as 23 dB. These heat pumps also feature Intelligent Eye technology, which senses when people are inside the room to offer increased automated temperature controls.

Bosch Home Comfort u www.bosch-homecomfort.com

Johnson Controls, Milwaukee, Wisconsin, announces the creation of its Refrigerant Detection System (RDS) calculator. This feature is available to users via the company’s ducted systems solutions app. This calculator is designed to help users determine the need for refrigerant detection systems based on specific conditions, such as refrigerant volume, space dimensions, supply air discharge height, and total conditioned area.

Johnson Controls u

www.johnsoncontrols.com

Discover the latest innovative HVAC products with LG Air Solutions. LG offers a wide range of electric heating, ventilating, and air conditioning solutions, along with controls, for today’s modern homes.

As the world is working to reduce its reliance on fossil fuels, LG Air Solutions is championing the switch to electric with stylish and dependable electrification solutions. Choose from our ENERGY STAR® certified products, which provide an opportunity to help reduce energy consumption, increase efficiency, and enhance whole-home comfort.

As a technician, it’s important to fully understand the safety protocols and features required when working with A2Ls and not simply follow a checklist.

By Francesco Lo Presti

View the full presentation on “Servicing Commercial Refrigeration Systems Using A2Ls: What Every Technician Must Know” here:

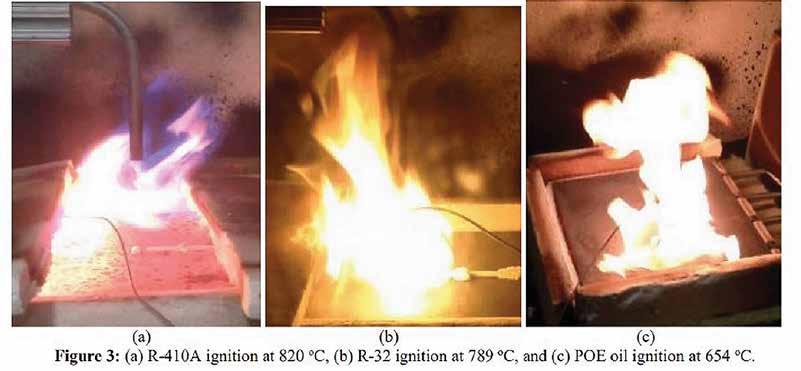

Autoignition of R-32 and R-410 refrigerant mixtures with lubricating oil. PhotoprovidedbyPurdueUniversity

ThereareplentyoftechnicianswhoremainuncertainorcompletelyunawareofwhatA2Lsare,howto handle them, and what changes need to be made in their day-to-day practices. Compared to commonly used HFCs in the field,likeR-410A,A2Lsaredesignedtohavea muchlowerimpactonglobalwarming. A2Lsareaclassofrefrigerantswithlowflammabilityandlowtoxicity

"Safety features and precautions are important and they absolutely help, but they’re not enough on their own. As a technician, you need to truly understand the systems you’re working on and not just follow a checklist."

Mildly flammabledoesn’tmeanthatthemechanicalroomisgoingtoeruptwhileyou’reconducting maintenanceorservicetothesystem.Weshouldalwaysrefertotheserefrigerantsasflammable;itdoesn’t matterwhetherit’sHFCs,A3s,oreventheoilusedinrefrigerationcompressors,it’sbesttobecautiousand treattheseproductswithrespect.Thereisalwaysaflammabilityrisk.

“Frompersonalexperience,I’veseenflamesshootoutofalineinasupermarketsystem,evenafterthe refrigerant was removed, just from residual oil in the suction line,” shares Trevor Matthews, founder of Refrigeration Mentor, during his presentation on Servicing Commercial Refrigeration Systems Using A2Ls:WhatEveryTechnicianMustKnow.“Evenifyouhavealltherefrigerantout,thesuctionlinecould still be full of oil, so we need to always be diligent and prepared. That doesn’t mean panic. It just means preparation.Thatmeansdoingyourhazardassessmentsandbeingproactive,notjustreactive,withsafety Complacencyiswherepeoplegethurt”

Safety’s not a suggestion, it’s the standard Systems that utilize A2Ls will need to be designed, installed, and serviced differentlythanothertypesof refrigerants. Thisalsoincludesnewtraining,codes,equipment,andtoolsforthejob.“Itmayseemlikea lotischanging,butremember,thisisnotsomethingnew We’vehadotherrefrigerationtransitions,”shares Matthews.

Therearespecificcodesandstandards— suchas UL 60335-2-40andASHRAEStandard15 — that definetheamountofrefrigerantallowed,theroomsize,andthesafetyfeaturesthatmustbeinstalled.These aren’tjustbureaucraticrequirements;they’retheretoprotectyouandthecustomersyouserve.

OneofthesafetyfeaturesneededforsystemswithA2Lsisleaksensors.Thiswillvarydependingonthe size of the system, but these sensors are sensitive and fast-reacting, which is necessary. Thesesensorsalso

Continued on page “27”

comfort with the smart features your customers want and the reliability you need.

• R32 refrigerant – low GWP, in use by Hitachi since 2013

• Built-in Wi-Fi with AirCloud Go™ app

• Reliable heating down to -30°C

• Motion sensor for smart energy savings

• FrostWash™ 3.0 self-cleaning coils

• Models: 400, 600, 800 & multi-zone

• PM2.5 active carbon filter – lab -tested for fine particles It’s not just new to Canada. It’s smarter, cleaner comfort unboxed and ready for spring.

LEARN MORE ABOUT THE

Start at master.ca/hitachi or talk to your Master rep today. Say hello to the

DEALER PROGRAM INCENTIVES

Continued from page “25”

need to be rated for A2L refrigerants and need to be properly calibrated.

When it comes to ventilation, you may need additional ventilation or exhaust fans in the mechanical room or enclosed space in the event of a leak. Another safety note is any electrical components that can produce a spark must be rated for use with A2L refrigerants under certain conditions.

Safety features and precautions are important and they absolutely help, but they’re not enough on their own. As a technician, you need to truly understand the systems you’re working on and not just follow a checklist.

“Let’s say you’re on call and a leak detector sends out a false alarm. That one signal could trigger the liquid line solenoid to shut, the system to pump down, and the condensing unit to isolate. If you don’t understand why that happened or how the system is designed to respond, you’re troubleshooting in the dark,” shares Matthews.

It’s no different than head pressure control — you need to know what’s happening behind the scenes. The mindset is the same. The refrigerants may change, but your role as a technician remains the same — know the system inside and out.

Best practices

System design is changing. Manufacturers are working hard to reduce charge sizes, minimize leak points, and tighten things up. On the job, your approach needs to evolve and there are recommendations that can help you.

The first is to purge with nitrogen when brazing. This should be one of the first things a technician learns, regardless of whether they work in residential or commercial settings. The reason this is important is due to the flammability risk associated with A2Ls.

The steps you need to follow when piping a system are as follows: first, you need to remove cores at the inlet and outlet of the flow path. Then you set up gauges and insert the dry nitrogen with the appropriate regulator and purge lines at high pressure in the refrigerant flow direction. Next, you will start the nitrogen flow – making a faint flow stream at the outlet, down at around two to five cubic ft. per hour of flow. Lastly, properly heat the pipe then joint and fit (should look like a cherry colour) and braze all your joints. At the last joint, you can turn off the flow. It’s important to allow every braze point to naturally cool.

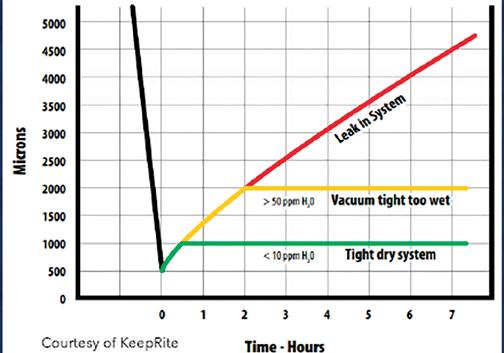

Next is adding a triple evacuation when on the

The

purpose of a triple evacuation is to remove moisture and contaminants from a refrigerant system before it’s charged with refrigerant. Photocourtesyof KeepRite

job. The purpose of this method is to remove moisture and contaminants from a refrigerant system before it’s charged with refrigerant.

“Now, this concept or recommendation is not new, but it should be non-negotiable. Before we even begin the triple evacuation, you should always purge the system first. For example, if there is a ton of moisture in your system and you pressurize it by 500 PSI, those molecules can squish, causing droplets of water in your pipe or system,” states Matthews.

When conducting a deep evacuation, “Evacuate below a minimum of 500 microns, close the valves, and shut off the pump. From there, do a stand test for about 30 minutes and if it does not rise to or about 1,000 microns, your system is tight and try,” adds Matthews.

Take your time on the job because if you rush a job today, it could mean callbacks in the future. Make sure you are doing it right the first time. Most manufacturers will provide system-specific guidelines and they are easy to follow step-by-step instructions. So, when in doubt, follow the script.

A2L safety and compliance also involves knowing how to safely store and transport them. A2L cylinders have relief valves and left-handed threads and should always be transported upright and securely. This isn’t new. It has always been code. When it comes to your personal protective equipment (PPE), you will need to add a gas detector, when needed. Additionally, all tools are safe to use but you need to update your vacuum pump and recovery machines.

“The most important advice or recommendation when discussing A2Ls is to get trained. This isn’t the kind of thing you want to figure out on the fly. There are codes, certifications, and real legal requirements for working on A2L systems,” shares Matthews. “The good news is there are some great resources out there, from both manufacturers and independent trainers, that can walk you through the science, safety, and service practices.”

Remember, A2Ls are just one step. We’re already seeing more CO2 and hydrocarbons in the field and each comes with it’s own learning curve. If you get comfortable learning now, you’ll be ready for what’s next.

As an HVAC professional, you need systems that deliver performance, reliability, and efficiency—without the hassle. Continental’s fully integrated solutions are designed for seamless installation, superior comfort, and long-term energy savings.

Upgrade your installs. Elevate your reputation. Choose Continental.

Easy to Install and Service

High-Efficiency Heating and Cooling

Built for North American Homes

Unmatched Innovation and Reliability

In Canada, the A2L transition is driven by regulations aimed at reducing the impact this industry has on the environment.

By Francesco Lo Presti

View the full presentation on “Reasons for the A2L Transition and What is Changing for the Technician” here:

The heating and cooling industry is embarking on another period of change — the A2L refrigerant transition. This means the industry will have to adapt to the new policy, environmental, and technological changes. A lot is happening and it’s important to know the reasons behind this transition and, more importantly, what is changing for the contractor.

The shift towards A2L refrigerants is driven by regulations aimed at reducing global warming potential (GWP). In Canada, the Ozone-Depleting Substances and Halocarbon Alternatives Regulations (ODSHAR) implements its obligations under the Montreal Protocol, including the Kigali Amendment, according to the Canadian government. Both put into action the phasedown of hydrofluorocarbons (HFCs) in Canada. The phasedown began in 2019, with a final target of 85 per cent reduction of the baseline by 2036.

To put it into perspective, one of the more common HFCs found in the field is R-410A, which has a GWP rating of over 2,000, while A2Ls, like R-32 and R-454B,

Continued on page “33”

The best installs start with the best products. That’s why TML partners with the HVAC brands known for reliability, innovation, and long-term performance.

Our shelves are stocked with top-tier equipment— and our people are trained to help you get the most from it. Whether you need help choosing the right solution or getting it to site same-day, we make your next install smarter, faster, and better backed.

We stock the best so you can install with confidence.

Continued on page “33”

have GWP ratings of 675 and 466, respectively. This is why the industry is turning its attention towards A2Ls.

Important to note, R-32 is considered a single-component refrigerant, which means it’s a pure substance. This differs from R-454B, which is a blend and contains a mix of R-32 and R-1234yf. R-454B is set to replace R-410A. Equipment manufacturers are already designing systems specifically utilizing A2L refrigerants. It should be noted that R-32 and R-454B cannot simply be dropped-in to replace R-410A.

With any new change, there needs to be familiarity. This is no different when talking about A2L refrigerants. A2L refrigerants are classified by AHSRAE as “mildly flammable,” which is a key difference from the A1 refrigerants that many in the industry have worked with for years. A1 refrigerants, like R-410A, are nonflammable, but A2Ls introduce a small but significant level of flammability.

This doesn’t mean that it’s dangerous to handle. Lower flammability needs to be considered and there needs to be a proper dispersal volume to keep the refrigerant concentration below the lower flammability limit (LFL). This limit is the lower end of the concentration range over which a flammable mixture of gas or vapour in the air can be ignited at a given temperature and pressure. The risk is minimal under normal conditions. However, lower flammability needs to be considered, and there needs to be a proper dispersal volume per refrigerant charge to keep the refrigerant concentration below the LFL.

The reason for this is to prevent the accumulation of refrigerant in the case of an increasing ignition risk. This will depend on the room size, the type of system, the equipment location, and the manufacturer’s requirements. As always, you should follow local building codes, ASHRAE, and CSA standards.

Additionally, equipment using A2Ls must utilize a refrigerant detection system (RDS). This is per UL 60335-2-40. There are also mitigation actions that aren’t related to refrigerant sensors, which include activating fans, pump-down

features, permanent space ventilation, and continuous airflow.

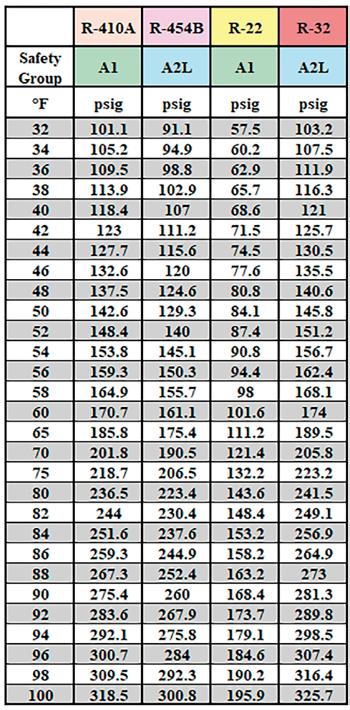

By taking a look at Figure 1, you will also see how the pressure-temperature relationship compares with the previous refrigerants and the newer A2L refrigerants. When looking at this chart, you can see that the refrigerant pressure temperature of R-32 is pretty close to an R-410A system.

It’s worth noting that A2L refrigerants like R-454B can be used in retrofit projects but not as direct replacements without further consideration. It’s important to remember that in retrofit projects, you are working on equipment that was specifically engineered to handle specific refrigerants, and refrigerant oil, from charge limits to leak detection systems and ventilation strategies.

Figure 1: It is good to know the pressure-temperature relationship of common refrigerants used in Canada. Make sure to refer backtotherefrigerant manufacturer’s resources to have the most accurate ratings.

Continued on page “35”

"It’s important to remember that in retrofit projects, you are working on equipment that was specifically engineered to handle specific refrigerants, and refrigerant oil, from charge limits to leak detection systems and ventilation strategies."

Continued from page “33”

application requirements

There isn’t a one-size-fits-all solution when it comes to the designing of these systems. Not all indoor systems will require a sensor. But, as anyone who has been in the field can attest, leaks do happen, and it’s best for the system to be prepared for one.

Since all indoor units will have a minimum mounting height from the floor recommendation, the total refrigerant of the system must not exceed the recommended amount. This means that the room needs to be sized and measured to see if the refrigerant charge would fall below the LFL, in case of a leak. One of the best practices to always keep in mind is to revert to guidelines from the manufacturer.

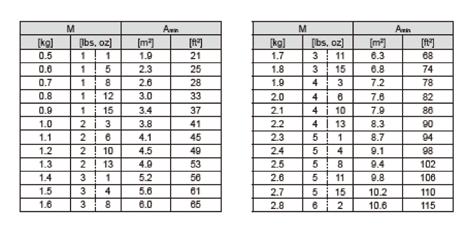

This can be seen in Figure 2 (which is for a system without a branch box). For example, a 100 sq. ft. room cannot have an indoor unit containing more than five pounds and four ounces of refrigerant.

Figure 2: One of the best practices to always keep in mind is to revert to guidelines from the manufacturer. This is an example taken from Mitsubishi Electric’s manual.

Air handler units

Now, onto air handler units (AHU). All AHUs must have a refrigerant leak sensor, as per UL Laboratories and Requirements. Different systems may have different refrigerant sensor requirements, such as whether the system is a single versus a multi-split system and ducted.

In the event of a leak for a one-to-one system, the indoor unit (which would be detecting the refrigerant leak via its sensors) will send information to the outdoor unit and the mitigation process will begin. This starts with an error code, flashing, and beeping sequence at the indoor unit, followed by the indoor unit performing an air circulation and mitigation test. The outdoor unit will stop the compressor and shut down the system.

Indoor units can be installed in a conditioned or unconditioned space. However, there are parameters that need to be met. For a conditioned space, the install area needs to have a supply

3: The install area for conditioned spaces needs to have a supply and return, pass thru grills/louvres, and rooms must be on the same floor.

and return, pass thru grills/louvres, and rooms must be on the same floor. Again, it is always best that manufacturer-specific requirements should be followed.

This is detailed more in Figure 3. In that figure, the example shows that the maximum charge for a 15 sq. ft. mechanical room in an unconditioned space is around one pound. If a louvre/passthrough is added to that mechanical room, it can be considered a conditional space.

At the end of the day, make sure that each technician that works close to A2L refrigerants should be taking the proper training. There’s a knowledge gap when it comes to flammable refrigerants and bridging this gap is essential for safety and compliance.

Experts within the refrigeration industry weigh-in on how the A2L transition affects contractors, wholesalers, the reclamation process, and manufacturers.

By Francesco Lo Presti

View the full presentation on “How the A2L Transition is Impacting the Whole Channel, from Manufacturer to Reclamation” here:

The A 2L t ransition i s c oming, a nd t here i s n o w ay a round i t. To h elp n avigate t he w aters o transition,wegatheredapanelofexpertsduringourA2LTechnicalTrainingDayonMay9todiscuss howtheA2Ltransitionimpactsthewholechannel,frommanufacturingtoreclamation.

The panel discussion featured Trevor Matthews, founder of Refrigeration Mentor, Dr. Charles Allgood, technical fellow/thermal and specialized solutions at Chemours, Devin Thomas, general manager at Refrigerant Services Inc., Maxime Drouin, refrigeration manager at Wolseley Canada, andVictorHyman,executivedirectoratClimateCare.

Herearesomeofthekeypartsoftheconversation,withLeahDenHartogh,editorofPlumbing& HVACmagazine,moderatingthepaneldiscussion.

Question: What are the major differences between A2Ls, like R-32 and R-454B, compared to HFCs, like R-410A?

Allgood: Great question to start. Theobviousansweri s t hatt hefl ammabilitych aracterizationis different.We’reg oingfromASHRAEclassA 1 to A 2L.I f y ou’ref amiliarw ithASHRAE,A o r B is thetoxicityclassification.We’regoingfromA1,whichnominallywecallnonflammable(thespecific

"If you always follow the best practices from 30 years ago, it will be the same as today. Will there be a few variants, for sure, but we used A3s 30 years ago in refrigeration, as we do today. Now there are just some differences."

language in the standard reads no flame propagation), to A2L, which we locally call mildly flammable or lower flammability per the standard.

We have to adopt those changes in the flammability classification. Much of that is built in as the equipment is designed, built, and rolled out by the manufacturers. Then, we need to look at the places and spaces where it’s installed, making sure that it is all compliant with codes and standards.

Finally, there is training for the contractors and the people who are using it, driving around with jugs of it in their vans, and installing and recovering it. Many of the best practices we’ve used for things like R-410A will not change. Some of them are becoming requirements instead of just best practices. But overall, the transition from R-410 to R-454B or R-32 should be even smoother than the transition from R-22 to R-410A for those who are around back then.

Question: Can you walk us through how the reclamation and containment of A2Ls differs from HFCs?

Thomas: As Chuck mentioned, we’ve been here before with the transition from R-22 to R-410A, so not much is different. I mean, it’s just that the recovery units have to be rated for A2Ls. The cylinder is still just the steel cylinder, and all that’s changed is the paint and how it looks visually. It either has a red stripe with the yellow and gray, or it has a red top with the gray bottom. The valve has also changed from a quarter-inch right-hand thread flare to a left-hand thread, and that’s just to avoid putting flammables and nonflammables together, which isn’t a big problem, but it should be avoided to begin with for general safety protection.

From a reclamation standpoint, R-32 is a component of R-410A, so it’s just as easy to clean, reclaim and certify. The blends are always more complicated because they can fractionate when we clean them and become off-spec. However, with R-32, we are adapting our equipment to the new flammability component.

To be honest, there are not a lot of huge changes, it’s mostly electrical. For storage, it depends on the volumes, so fortunate for us, we store our flammable material outside, but if it’s internal, it depends province to province and on how much you can store inside and what format (whether it has to be sprinklered or certain shelving).

We are currently working on forming a dedicated cylinder fleet for A2L refrigerants with the left-hand valve, but our storage hasn’t had to change too much.

Question: Why is there an A2L transition in Canada, and why are global warming potential (GWP) refrigerants important to introduce into the Canadian market?

Matthews: One of the things that I see is that with GWP, scientists are looking at the planet, it’s heating up, and there are lots of factors behind it. We’re trying to help the environment, and going forward, this transition is going to happen, and it’s already happened. Because I do a lot of CO2, propane, A3s and A2L training, I really try to get across to all the technicians and contractors is to go back to the basics and go back to what we were supposed to do 25 to 30 years ago.

So, if you always follow the best practices from 30 years ago, it will be the same as today. Will there be a few variants, for sure, but we used A3s 30 years ago in refrigeration, as we do today. Now there are just some differences. I think it will be important that as the globe shifts to refrigeration and regulations, we follow the leaders and try to keep up with them.

For example, Europe is ahead of us in a lot of ways. One of the more

Continued on page “39”

0.98 UEF Uniform Energy Factor

Featuring RXP models with Intelligent Recirculation

Time Saving Features include:

▸Smart Connect™ Bluetooth® Enabled Quick Set-Up

▸Smart Sense™ Adaptive Gas Valve - No Conversion Kits!

▸Smart-Circ™ Intelligent Recirculation™

▸Longer Vent Runs up to 75 ft. on 2” Vent Pipe

▸Advanced Controls with Intuitive Display

▸Easy Hang Bracket

Continued from page “37”

interesting ways is how to purge a line properly Here in Canada, it is not against the law to do a little purge in your hoses. However, in other countries around the world, you are not allowed topurgeandreleaseanyrefrigerantintotheair.So, whatdotheydo?Theyhavetopullanevacuation uptothecylinder.

Question: What safety considerations need to be met with A2Ls and how do they differ from HFCs?

Allgood: To jump on what Trevor said, the best practicesthathavebeendevelopedfordecades— purging,goodevacuation,ventilation,asafework area,andhavingthepropertools.

We have done a lot of studies on the flammabilityofA2Ls;whiletheyareflammable, theyaremoreliketheHFCsthanpropane.

Matthews: Adding onto what Chuck said, I’ve done a lot of training on the fears of CO2, A3s, and A2Ls, and we’ve found out that R-410A ignitessameasPOEoil.We’veknownthesethings canignitebutjustatahighertemperature.

Question: What are some challenges contractors have regarding the A2L transition?

Hyman: The one that stands out the most is what this transition means. There is slightly different messaging across the various training beingoffered,sowearetryingtofindtheonereal versionregardingthetruthofthetransition.

Another topic is the transportation of dangerous goods to sites, which differs from province to province, so we need to get clarity on that. For example, contractors may now have two reclaim cylinders (one for R-410A and one for your A2Ls) and jugs of differentrefrigerants, meaning we will hit the kilograms limit we are allowedtocarry,whichinOntariois150.Wecan’t just throw whatever in the trucks. We need to be veryconsciousofwhatwearedoing.

Attendee Question: Can A2L refrigerant containers be stored outside and in direct sunlight, whether they are full or empty?

Drouin: Thenumberoneruleforstoringoutside is no direct sunlight; it’s the same practice as A1s. There are ways you can put temporary roofing

A2Ls will be required to follow many of the rules associated with HFCs when it comes to the reclamation process.

over where you stock the cylinders, which is what we do at Wolseley. However, storing A2Ls outside and in a temporary shelter requires keeping them about 20 feet apart.

Question: Are there any concerns about how this transition will affect wholesalers?

Drouin: Wholesalers are mostly worried about what is happening and how/if this will affect our business. A lot of wholesalers are also asking how flammable are A2Ls, and will they explode if I put R-32 in a system that used to have R-410A?, and the answer is absolutely no. However, the opposite is possible. But as a whole, there will probably be a bit of efficiency differences.

There are many of the same worries as in 2010 with the transition from R-22 to R-410A.