Microbial contamination, from bacteria like Legionella, is an exponentially growing concern in modern buildings.

n Diagnosing and servicing water softeners

n Water treatment for health concerns

n UV disinfection

n The future of water treatment

A service call should begin with a conversation with the customer regarding water usage habits; an effective troubleshooting call starts with the water analysis.

By Wayne Lamers

View the full presentation on “Water Softener Repair and Service” here:

Water softeners are a foundational component of many residential and commercial plumbing systems, yet diagnosing their faults can be deceptively complex. Service technicians are frequently called to investigate issues such as inconsistent softening, irregular regeneration, or excess water in the brine tank. Effective troubleshooting requires not only mechanical understanding but a step-by-step approach to field diagnosis.

A comprehensive service call should begin with a conversation with the homeowner or facility manager to understand their water usage habits and the nature of the complaint. However, effective troubleshooting starts with a water analysis. Water chemistry can vary dramatically over time, even in the same household, and across neighbourhoods, especially in regions with blended municipal sources or seasonal well variations. Technicians should never assume that a previous test result is still valid.

To properly assess system performance and determine potential causes of malfunction, technicians should perform water testing for water hardness, total dissolved solids (TDS), iron, and chlorine and chloramine.

This is the most critical parameter when servicing a water softener is the hardness of the water. Testing both the untreated source water and the treated output allows the technician to assess whether the softener is effectively

removing hardness. Any detectable hardness in the treated water could indicate bypass, exhausted resin, incorrect programming, or a mechanical failure.

TDS testing provides a quick snapshot of overall water quality by measuring all dissolved ionic content in parts per million (ppm). Although softeners don’t directly reduce TDS, measuring it can help verify changes in water chemistry and identify cross-contamination between treated and untreated lines. A sudden increase in TDS may suggest an incorrect regeneration caused by improper rinsing, or excess brine being used. Iron is a common nuisance contaminant, particularly in private well systems. Even at low concentrations (above 0.3 mg/L), iron can foul resin, stain fixtures, and reduce the effectiveness of softeners. When troubleshooting complaints about poor water aesthetics (staining, odour, discolouration), iron testing is essential. If iron is present in the treated water, existing pre-filtration has failed, or an iron filter may be required to protect the softener.

Optional but recommended in municipal systems, chlorine or chloramine is often added as a disinfectant. These oxidizers can degrade softener resins and rubber components over time, especially in systems without carbon

Technicians should never assume that a previous test result is still valid.

filtration. Testing for free chlorine and total chlorine can help determine if pretreatment is needed to extend the service life of the softener.

Water should be sampled from multiple points for comparison, including the sourced water before treatment equipment (ideally from a bypass or dedicated test port), cold treated water (such as from a kitchen or basement tap to determine current system performance), and hot water (especially from tank heaters, to reveal whether hard water was present in recent days).

This combination of testing not only provides a clear understanding of current water conditions but can also provide a window into the past.

After establishing the water profile, it’s essential to test the softener’s operational cycles. This involves advancing the unit manually (in mechanical models) or initiating a regeneration sequence (in digital versions), and observing each stage — backwash, brine draw, rinse, and brine refill. Each stage must be assessed for proper timing and water flow.

In electronically metered systems, monitoring the flow indicator is a quick verification step. A blinking symbol typically signals active flow recognition. If no blinking is present, a magnet can be passed over the sensor to simulate flow and confirm signal reception by the controller. If this succeeds, the fault likely lies with the paddle or turbine, not the electronics.

The brine tank is a common source of regeneration failure. Loose or misaligned fittings on the brine line can create small air leaks, preventing the softener from drawing brine properly. Even without visible leaks, improper tightening can allow air to enter the system, leading to excess water accumulation and regeneration failure.

Technicians should confirm brine line fittings are securely assembled and fully engaged, salt level is maintained between half and two-thirds full, salt is clean and free of debris, and that the tank is not overfilled (this can cause compaction at the base, creating a sludge that restricts brine movement).

When brine is not drawn effectively, the system may appear operational but deliver hard water. Excess water in the tank and a drop in softening performance are tell-tale signs of this condition.

Meters must be installed on the outlet side of the softener to prevent raw water fouling. A reversed orientation may still register flow but will expose sensitive components to untreated water, leading to premature failure.

Electronic controllers must also be correctly programmed to match the type and size of the meter. For instance, programming a paddle-style meter as a turbine will result in undercounting, causing the softener to regenerate too infrequently or not at all. Conversely, programming a turbine as a paddle may lead to excessive regeneration and salt consumption.

Injectors create the vacuum necessary to draw brine into the system. These components, along with brine line flow controls and drain line flow controls, require regular inspection for buildup and obstructions.

Clogged injector screens or mismatched components can prevent proper brine draw and refill. Flow controls must be installed in the correct orientation, usually indicated by a bevel, and matched according to flow rate ratings specific to the system model.

When preliminary checks fail to resolve the issue, disassembling the valve body becomes necessary. A standard softener valve includes a piston assembly, a stack of seals and spacers, and

Continued on page “37”

The EB25 Plus delivers all the performance and pressure reducing ability of costly multi-valve (series and parallel) installations and and automatic control valves with a single, compact, cartridge-based design.

With a 10:1 pressure reduction capacity, the EB25 Plus can regulate from no flow to maximum flow with a single valve. The EB25 Plus can also withstand temperatures between 33°F and 149°F.

Set-up takes less than five minutes with no pilot valve needed.

Wayne Lamers, technical sales representative at Summit Water Group, and Jesse Schenck, territory manager at Summit Water Group, led an hour-long session during the Water Treatment Technical Training Day on water softener repair and service.

Continued from page “35”

various control gears.

Signs that indicate internal component degradation include cracked, stiff, or worn seals, scoring or pitting on the piston and/or on the piston rod, evidence of water leaking from the valve cap, or difficulty advancing or resetting the valve during cycles.

All worn components must be replaced with manufacturer-approved kits. Lubrication of seals and threads using a non-petroleum, NSF-certified product is recommended to ensure smooth operation and longevity. Technicians should avoid applying lubricant excessively, as residue can attract debris and cause early failure.

Upon reassembly, the technician should verify that metering and injectors are correctly oriented and reconnected, programming settings align with the installed components, and that water flow and regeneration cycles are functional and unobstructed.

The softener should be pressurized while in backwash mode to purge air from the system, then manually advanced through a full regeneration cycle to confirm proper operation. If the softener has been delivering hard water prior to service, additional regenerations may be recommended to fully restore resin performance.

Residential systems are often serviced reactively. In contrast, commercial systems typically benefit from scheduled maintenance every 24 to 36 months, particularly in high-usage environments or where oxidizers, like chlorine or chloramine, are present.

A preventative approach may include routine inspection and replacement of seals and spacers, periodic cleaning or replacement of injectors and flow controls, and monitoring resin condition through flow testing and hardness output.

Resin degradation occurs either through capacity attrition over time or chemical damage from oxidizers. Symptoms of degraded resin include premature loss of softening capability during normal use, pressure loss in service mode with normal pressure in bypass, and resin discharge from the tank during valve removal.

If water usage is consistent but the system delivers fewer gallons of soft water between regenerations than expected, and all mechanical components function normally, resin replacement is often the next step. Failing to replace compromised resin can lead to persistent underperformance despite other repairs.

Diagnosing and repairing water softeners requires more than replacing parts. It involves a disciplined approach grounded in observation, verification, and testing. By combining structured diagnostics with proper maintenance practices and client education, technicians can resolve issues faster and reduce repeat service calls.

The key to successful field service lies not only in technical skill, but in process-driven problem-solving — ensuring long-term performance and customer satisfaction.

Wayne Lamers worked in the water treatment industry since 1989. Lamers began as a service and installation technician and eventually managed a full technical service department. In addition to his role at Summit Water, Lamers operates his own business, The Water Genie, where he offers personalized water treatment services. He can be reached at wayne@ summitwater.ca.

Understanding the types of contaminants in the water is the first step towards creating an efficient water treatment system that meets your customers’ needs.

By David Taft and Mike Barone

View the full presentation on “Water Treatment Solutions for Health Concerns” here:

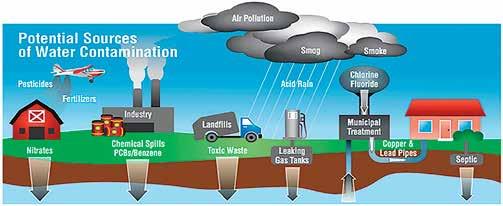

Many Canadians are generally uninformed, unaware, and sometimes complacent on any failings by suppliers to safeguard their health. It is important to understand how the environment can affect our water supply.

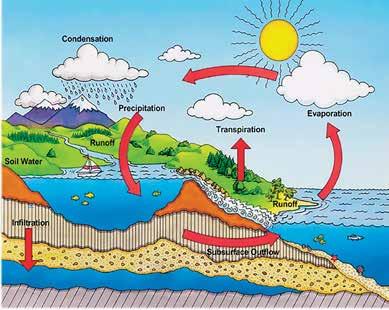

Scientifically, it is determined via the hydrological cycle. It is generally understood that water evaporates and forms into the fluffy clouds we see up in the sky, then the water falls down in the form of precipitation – either in rain, sleet, ice, snow, or some combination. As it enters the Earth’s atmosphere, it collects components, such as air pollution, smog, and smoke. When it enters the ground strata, it picks up things like nitrates, toxic waste, hard minerals, calcium, and magnesium. This is also when chemical spills, like PFAS, start making their way into our water supply. Water is known as a universal solvent, which means it absorbs and retains parts of everything it comes in contact with.

In many of these cases, the laws necessary to prohibit these contaminants from being produced in the first place are a concerning issue. There are many people who feel that they shouldn’t be exposed to harmful substances and that it is the political representatives’ job to safeguard Canadians.

Typically, the source of household water falls into two categories — municipallysourced and well water. From there, it tends to be broken into working water

and drinking water. Chemicals can find their way into the water in the form of pesticides, asbestos, radiation, and air and water pollution. These can result in environmental diseases and just a few of the human-made hazards that are believed to contribute to human illness.

In Canada, there are safeguards put in place to make our air and water safer to consume. However, when manufacturing facilities move out of the country, where regulations are less stringent, these chemicals find their way back into Canadian soil and water.

There are many municipalities that do a great job of creating access to safe water for the masses. In fact, they take the water through several steps before returning it to the end consumer. The process includes collection, screening, straining, chemical additions, coagulation and flocculation, sedimentation and clarification filtration, disinfection, storage, and distribution. This makes the water microbiologically safe for the consumer. Without this process, municipal water systems use chlorine to kill harmful microorganisms, ensuring safe drinking water for millions. Yet, it’s important to weigh the benefits against the drawbacks of its use. Chlorine’s main advantage is its ability to eliminate viruses, bacteria, and parasites that cause serious illnesses like hepatitis and salmonella.

Municipal water must meet minimum standards; it is too expensive for municipalities to treat water to optimal standards. Optimal water would be free of hardness, iron, tannins, chlorine and chloramine, and other contaminants. Drinking water should be of the highest quality, but the quality of the working water has major implications for the plumbing trade. It is easy and affordable to treat both drinking water and working water at the point-of-entry and pointof-use.

Surface water has its own problems that arise from warm blooded creatures.

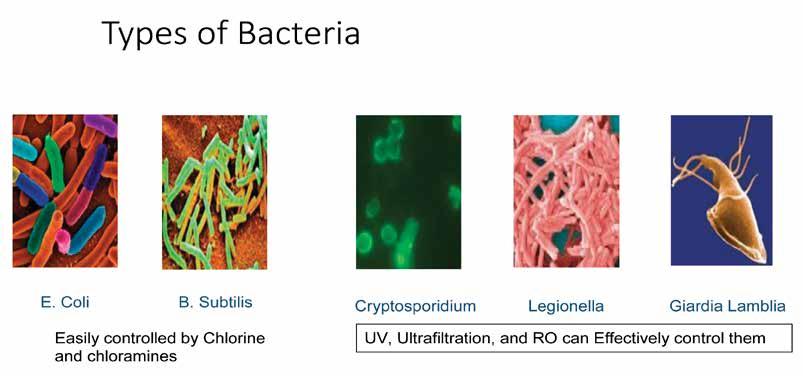

Understanding what types of bacteria is in the water can help the technician determine which types of technology would be needed to improve the water quality.

For instance, Canadian geese, which impart bacteria such as cryptosporidium, giardia, and also Legionella can be found in municipal water and are not easily killed using chlorine or chloramines. The only way they can be taken out would be with ultra filtration, reverse osmosis, or ultraviolet light.

They can cause the average person a 48-hour so-called bug, which could be diarrhea, vomiting, and so on. But, for people with an immune deficiency, it’s another story. They would have a very tough time fighting these creatures off and can be quite debilitating for somebody with an immune deficiency.

The forever chemical

PFAS is commonly referred to as the forever chemical in the water quality industry. It is widely used in industry and everyday products.

Products like stain repellents, water repellent coatings for boots, rainwear, carpeting, detergents, cleaning products, makeup, lipstick, dental floss, fast food containers, and paper straws all contain these forever chemicals. In fact, PFAS is found in the blood of over 97 per cent of North Americans. Our skin is a pretty good barrier but the number of products that are taken in through our food supply and drinking supply is overwhelming.

For many years, reusing plastic has led us all to believe that recycling would

There are so many ways that our drinking water can be contaminated before it flows through our taps.

The way that the environment can affect our water supply can be understood via the hydrological cycle.

Continued on page “41”

Continued from page “39”

fix the plastic issue. Now with more research, we find that it is not the case. A very small amount of plastic is being recycled, even though we are sorting it into our homes. Only seven per cent of plastic actually gets recycled; in reality, it ends up in lakes, rivers, and oceans, with 580,000 pieces of plastic per sq. km found in the Atlantic Ocean.

There are many health risks associated with asbestos. Drinking it, above the safe limit, may increase the risk of benign intestinal polyps. Health Canada and the World Health Organization have concluded that there is no consistent convincing evidence that asbestos ingested through water is concretely harmful to human health.

Asbestos can find its way in drinking water from several sources, such as asbestos-cement pipe. These pipes are primarily used in older infrastructure and enter water supply as the pipes break down and the fibres enter our water. In addition, asbestos can also enter our groundwater naturally.

Lead can be addressed through a combination of preventative measures, such as flushing pipes using cold water for drinking and cooking, and installing water filters for more persistent lead contamination. Reverse osmosis systems and other water treatment technologies are available to remove lead from the

water. Most lead enters the water from the supply pipes from municipal water. When it comes to chromium, there are many health effects, such as occupational asthma, eye irritation, perforated eardrums, respiratory irritation, kidney damage, liver damage, and also pulmonary congestion. RO systems with a semi-permeable membrane can filter out dissolved contaminants. Ion exchange water treatment units using base resins are also effective.

Chlorine and chloramines should be removed as they can react with organic matter and create trihalomethanes and nitrosamines. It is important to understand what types of contaminants exist in water as that is the starting point to creating a system that manages your customers’ needs.

David Taft is the director of sales and webinar training manager at Canature WaterGroup. With over 40 years of water treatment experience, Taft has worked with some of the industry-leading companies, providing technical training virtually. He can be reached at david.taft@canaturewg.com.

Mike Barone is a water industry veteran with over 40 years of experience in the industry. Barone has worked with some of the industry’s leading companies providing water quality training. He can be reached at mike.barone@canaturewg.com.

Unique

1”

Timesaving

Four

48-Hour Programming Memory Automatic programming restore for up to 48 hours during power loss.

Aqua Alert® Enabled Ensures your system is performing properly with push notifications to your phone and e-mail.

UV Dynamics, London, Ont., announces that their PEX-compatible GloGuard ports are now available to all residential-sized UV disinfection systems. The PEX-friendly porting blocks UV light from escaping the chamber, eliminating the need for light dams or metal fittings. Plastic plumbing can now be connected directly to UV Dynamics residential-sized systems with both three-quarter and one-inch MNPT ports.

UV Dynamics u www.uvdynamics.com

Navien, Irvine, California, launches its new WEC series tankless electric, salt-free point of entry water treatment system. The new system delivers softer water without salt, brine discharge, or ion exchange media and has a 10-micron sediment pre-filter and a one-micron carbon block post-filter. The new system has a 94 per cent certified scale reduction and is NSF/ ANSI certified for 42, 61-G, and 372 standards, and has up to 85 per cent recovery rate and continuous on-demand treatment.

Navien u www.navieninc.com

Lync, Fort Worth, Texas, introduces its new fully engineered domestic water quality solution that utilizes reverse osmosis. The WQ-RS is a compact, pre-assembled, and configurable reverse osmosis system that purifies water by reducing the presence of dissolved solids in the water. The WQ-RS is available in a variety of configurations, producing from 3,600 to 172,800 gallons of purified water per day. It also features a digital controller, fibreglass reinforced plastic membrane housings, inlet/outlet pre-filter pressure gauges, a low-pressure switch with delayed auto restart, and inputs for tank level and pretreatment interlock. Lync u www.lyncbywatts.com

As building systems age and climate conditions evolve, the threat from Legionella and other pathogens will only continue to grow.

By Ron Blutrich

View

the full presentation on

“UV Solutions for High-Rise Residential” here:

Plumbers and contractors understand better than most how complex plumbing systems can become, particularly in large multifamily buildings. Although these plumbing systems allow us to have a complex network of water fixtures throughout buildings, this complexity can also increase risk. Microbial contamination, particularly from bacteria like Legionella, is an exponentially growing concern in modern buildings, with disease incidence rising almost tenfold in the last two decades.

Microbial risks in building water systems arise from multiple points — the water source, the municipal distribution system, and the building’s own plumbing. While a range of microorganisms can be involved, including viruses, bacteria, and parasites, bacterial risks are often in the spotlight. This is due to both their potential harm and their relative ease of detection

This Clear UV system was installed at the point-of-entry to a 683-unit

through modern testing protocols.

The first key source of bacterial contamination originates from sewage, which is typically the result of water main breaks or cross-connections that allow this sewage to infiltrate drinking water lines. These events introduce enteric bacteria, like E. coli, or coliforms, as well as parasites and other pathogens into the potable water system.

Boil water advisories are often triggered by precisely these kinds of failures. Since enteric bacteria cannot multiply or reproduce in water systems, one or more negative tests in a row are usually sufficient for municipal health regulatory bodies to declare the water safe to drink and end the boil water advisories.

The other key source of bacteria in residential water supplies usually originates from bacterial build-up in pipes, known as biofilm. Biofilms form when bacteria adhere to pipe walls or other wet surfaces and encase themselves in a mucus-like matrix. These complex microbial communities grow quickly and create an ideal environment for pathogens. They also promote pipe corrosion through acidic byproducts and are highly resistant to most forms of chemical disinfection. Biofilms are even resistant to aggressive flushing, making proactive biofilm prevention even more important.

Most dangerous biofilms

Legionella is one of the most dangerous biofilm-associated pathogens, the bacteria responsible for Legionnaires’ disease. Unlike many other waterborne pathogens, Legionella doesn’t infect via ingestion. Instead, it becomes a threat when inhaled through aerosolized water, such as from showers, fountains, or other misting systems. The disease is a severe pneumonia with symptoms that can be fatal, particularly for elderly or immunocompromised individuals.

Urban plumbing systems, especially in multifamily housing, are particularly vulnerable. Warm pipe temperatures, long stagnation periods, and complex recirculating systems all create ideal conditions for Legionella growth.

To combat microbial contamination, a variety of treatment technologies exist. The most common approaches include chlorination, filtration, reverse osmosis, and UV disinfection. Among these, ultraviolet (UV) is one of the most effective and sustainable options, especially when applied at the point-of-entry (POE) to treat all water entering a building.

UV light is a form of electromagnetic energy. When bacteria, viruses, or parasites are exposed to UV light, their DNA, RNA, and proteins become damaged. This renders them unable to reproduce or function.

The effectiveness of a UV system is governed by the UV dose, measured in millijoules per square centimetre (mJ/cm²). A higher dose means more microbial inactivation. The dose is affected by several factors — UV transmittance, or how much light penetrates the water; flow rate, where faster flow means less exposure time; and lamp intensity, brighter lamps deliver more energy. The U.S. EPA recommends a minimum UV dose of 40 mJ/cm² for effective disinfection.

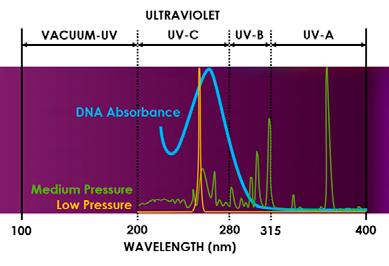

There are generally several different types of UV systems. Low-pressure systems emit a single wavelength (254 nm), which is highly effective against DNA-based organisms. However, some viruses and bacteria can resist this type through repair mechanisms.

Medium-pressure UV systems emit a broader range of wavelengths, damaging DNA, RNA, and proteins. These systems are more effective in highrisk applications like premise plumbing, which refers to the portion of potable water systems found beyond the property line and in buildings, according to the National Research Council. Finally, UV LEDs are a new and emerging technology offering high energy efficiency, multiple wavelength options, and long operational life. These are suitable for specific use cases but are still maturing for large-scale applications.

While UV is effective, it’s not without challenges. Lamps can overheat, and performance can degrade, meaning that cooling systems are sometimes required, depending on the design of the system. UV lamps are usually encased in a quartz sleeve, which can become fouled by the accumulation of minerals or organic matter on the surface. This can reduce UV transmittance, thereby reducing disinfection effectiveness.

Finally, shadowing from suspended solids can shield pathogens from UV light, protecting them. Many UV systems include reflectors that reflect UV energy from the light source back into the water column from many different angles, reducing the effects of shadowing.

Water filters are widely used, with more than 77 per cent of American homes using them. However, filters trap bacteria along with other particulates. Without frequent maintenance, filters can become a breeding ground for biofilms.

UV systems can be installed at either the point-of-use (POU), to treat water at a single fixture, or at the POE, to treat all the water entering the building.

A graphical representation of UV spectra from low and medium-pressure UV lamps, compared against the absorbance for DNA.

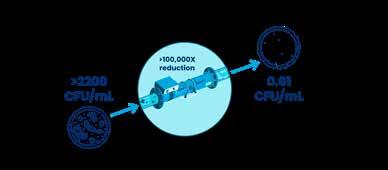

Field tests in downtown Sacramento, California showed significant bacterial contamination in city water and more than 100,000X reduction post-Clear UV.

For residential and affordable housing developments, POE systems are generally more practical and protective, with every tap, shower, and fountain receiving disinfected water. This approach also helps reduce biofilm formation inside building pipes, because bacteria are eliminated before they enter.

Biofilms and microbial risks in plumbing systems are not just theoretical. They are real, measurable, and increasing dramatically with time. As building systems age and climate conditions evolve, the threat from Legionella and other pathogens will only continue to grow.

Contractors and plumbers can play a critical role in mitigating this risk. When designing or retrofitting a plumbing system, consider UV not as an add-on, but as a core component of modern water safety.

Ron Blutrich is the CEO and co-founder of Clear Inc., a Toronto-based company that specializes in UV purification systems for diverse types of real estate. With a background in molecular biology, he aims to bring a scientific approach to the field of water purification and hopes to educate others about risks and risk management in water treatment. He can be reached at ron@clear.inc.

By Francesco Lo Presti

View the full presentation on “Panel Discussion: The Future of Water Treatment” here:

It’s important to know exactly what is in our drinking water. Regulations and certifications have changed a lot in Canada to this regard. An entirely new department was created in Canada that looks to improve freshwater managementcalledtheCanadaWaterAgency

With this ever-changing sector, our editor, Leah Den Hartogh, sat down withapanelofexpertstodiscussthefutureofthewaterqualityindustry

The panel featured Mike Barone, technical trainer at Canature WaterGroup, David Taft, webinar training manager at Canature WaterGroup, Jesse Couperthwaite, owner of Lakeland Water Treatment, Pieter de Vries, president at UV Dynamics, and Shelley Peters, executive directorattheCanadianWaterQualityAssociation

Herearesomehighlightsfromtheconversation.

Question:What are some of the latest innovations in water treatment?

Barone: Most of the innovations have been certificationforcontaminants. We’re findingthattherearehealthissuesassociatedwithcontaminants,so while we’re not using new materials, we’re obtaining certificationforexisting materialslikegranularactivatedcarbon(GAC),carbon,catalyticcarbon,and reverse osmosis. All these differentkindsoftreatmentaregettingcertifiedto handlesubstanceslikePFASandmicroplastics.

Taft: The keyword that Mike used is certification. If it’s not third-party certifiedandverified,thenwhywouldyouuseitorbringittoyourcustomer?

Question: What is the best resource for anyone looking to get into water treatment certifications in Canada?

Peters: Any products in Canada need to be certified to CSA 483.1, which primarily covers drinking water products. Some people think that’s just for reverse osmosis, but in the building code, it does refer to point-of-use and point-of-entry equipment.

Therefore, you must verify that your equipment is certified to the proper NSF standards. There are a multitude of different standards for various levels of certification required, but there are access points you can obtain through the certifying bodies to ensure that the products you’re selling are certified.

Question: Are there any certifications needed to install products like water softeners?

de Vries: Yes. Canada is somewhat more advanced compared to the U.S., even though we use American standards. Many of the water treatment standards examine several key aspects, including whether the products perform as claimed, whether the materials are safe, and whether they’re structurally adequate for the job.

For example, you’ll see lots of filter housings that the manufacturers claim are NSF certified, but when you start looking into it, you’ll find that they are only NSF certified for material safety and not structural integrity. Under CSA 483.1, you need to be certified for both.

Taft: Peter is spot on with that.

Question: How can a technician choose the correct product for the job, and is it as simple as looking for something that is CSA certified?

Barone: Well, Peter hit it on the head with the certifications.

de Vries: I can give you an example. In London, Ont., we had a lead situation, and the public health officer was telling everyone that if they wanted to remove the lead from the drinking water, they needed an NSF-approved filter.

Well, I called the officer and talked to him about how that was misleading because someone could go to any big box store, see a filter with an NSF logo,

(Left to right, top to bottom) Leah Den Hartogh, editor of Plumbing and HVAC magazine, Mike Barone, technical trainer at Canature WaterGroup, Pieter de Vries, president at UV Dynamics, David Taft, webinar training manager at Canature WaterGroup, Shelley Peters, executive director at the Canadian Water Quality Association, and Jesse Couperthwaite, owner of Lakeland Water Treatment, joined together to discuss the future of water treatment.

buy it, and think it’s going to remove the lead. Now, there was a product on the shelf from a Canadian supplier whose products are fully certified for performance by CSA. People were buying the NSF product without realizing that it needed to be more than NSF rated.

Taft: You also need to ask, “certified for what?” when determining which product to use.

Peters: It’s also important for people to go to their suppliers, manufacturers, and wholesalers and ask questions about whether the products are certified, and, as David mentioned, what they are certified for. Also, the certifications will be listed either on the product or within the installation manual, so it’s also a matter of knowing where to look and what you’re looking for.

Barone: Just one more thing. When you’re dealing with contaminants that can affect people’s health, and you put a product on that is not certified and doesn’t do the job, your liability is crazy.

Question: Why hasn’t there been a lot of change and innovation within the water treatment industry?

de Vries: That’s sort of asking why the sky is blue.

Taft: You know, some things pop up that those of us in the industry who have been around are always a little hesitant about. The reason is that they usually come with a lot of marketing and not many certifications, which gives our industry a sort of black eye. You need to trust the people you’re partnering with to provide you with good products.

Couperthwaite: I think it’s important to refer to advancements in two categories. There are advancements that don’t really mean much, and then there are advancements that change the industry. For example, I think transitioning from time clocks to metered systems was a significant advancement.

Many of the advancements you see now relate to connectivity and providing more information. However, there are some exciting

developments when it comes to combining water softeners with different technologies, such as leak stop, for example.

Peters: To be devil’s advocate, over the years I’ve seen some technologies come through, such as reverse osmosis, ultraviolet lights, and even the valves on top of the water softeners have had advancements.

Question: What lessons have we learned from water testing, and can this help shape the future of the water treatment industry?

de Vries: First, it depends on the type of water you want to test, such as well water or municipal water. Using well water as an example, you need to perform some basic water chemistry, which, unfortunately, many water treatment dealers fail to do. But this water chemistry consists of the hardness of the water, how much iron is in it, what the UV transmission of the water is, and what the organic level is.

Peters: It also comes down to the cost of the water tested to a certain extent. At this point in time, you can get well water tested for bacteria by Ontario public health, and that’s it. They won’t test anything further. Now, in the North, if the well water contains arsenic, it becomes a cost factor for the homeowner and the water professional.

Now this is something I can ask Jesse, who does this on a much regular basis, but what is the average cost for a full water analysis from a lab? Doesn’t it run between $200 and $300?

Couperthwaite: There are levels to this, and as Pieter mentioned, most companies have a standard kit when it comes to well water. But for a homeowner to get their well water tested for everything, it’s a massive broad spectrum for testing.

For example, even if you conduct a test for $500, that wouldn’t cover/ test every single thing you could find in your water. In my opinion, it’s better to test your water for a specific contaminant.

With over 200 voices advocating to federal, provincial, and territorial governing bodies

robust education and certification for water treatment, design, selection, sales, installation, and service Providing networking opportunities through regional meetings and trade shows CWQA provides top-tier certification and training, equipping professionals with essential skills in water treatment, system design, and installation. Stay ahead of industry standards with our recognized programs.

is your trusted partner in water treatment, providing essential resources, certifications, and industry advocacy. Join a community dedicated to improving water quality and advancing industry standards across Canada.