A YEAR OF GROWTH AND MOMENTUM

It has been a busy and exciting year at Pendennis, and we have had the pleasure of welcoming an impressive selection of superyachts to our world-class facilities in Falmouth and Vilanova. That momentum continued from the shipyard straight into regatta season, where we felt immense pride seeing the Pendennis fleet deliver outstanding performances at both the Antigua Superyacht Challenge and the St Barth’s Bucket, with onboard support from the Pendennis team.

Towards the end of 2024, we were delighted to welcome Cockwells Modern & Classic Boatbuilding to the Pendennis Group. With our full-service facility in Falmouth, a marina and Technical Service Centre in the heart of the Mediterranean, and a luxury bespoke interior manufacturing team based in Norfolk, we are now also able to offer custom-built luxury tenders as part of our expanded offering.

Toby Allies Group Managing Director

We recognise the importance of continuous evolution and improvement –and the opening of our Digital Manufacturing Centre is a testament to that commitment. The successful launch of Silver Raven, the UK’s first all-electric tour boat on the Thames, has further reinforced the need to prioritise sustainability in everything we do. This year, we took a significant step forward by appointing our first Sustainability Transformation Lead, to guide our efforts in making sustainability integral to every part of the business.

2026 promises to be another successful year, with several large projects planned. We look forward to connecting with you throughout the year – whether at sea, in the shipyard, or at the events we’ll be hosting.

NEWS FROM THE GROUP

ALL-ELECTRIC THAMES

CATAMARAN

DELIVERED

Pendennis recently delivered the UK’s first all-electric tourist vessel in collaboration with Woods’ Silver Fleet. Designers and Owners the Woods family have built and crewed sightseeing vessels on the River Thames for over 100 years, yet are best known for private charter events aboard their fleet of river yachts with recent clients

including Google, Net-A-Porter and Lamborghini. The new boat is the first of its kind in the UK, harnessing developments in ultralightweight, aluminium design and construction technology coupled with an innovative industry-first all-battery drive train. Read more about the electric catamaran on page 34

SY ADIX COMPLETES

SEVENMONTH REFIT

The 65-metre sailing yacht Adix has successfully completed an intensive refit that included a Lloyd’s special survey and several other maintenance and refit works. Find out more about how our Digital Manufacturing Centre was able to improve sailing performance by redesigning and reengineering components on page 30

MY SOLACE COMPLETES REFIT AHEAD

OF GLOBAL ODYSSEY

Following an extensive refit at Pendennis, the 57-metre MY Solace (ex Mary A ) has been wholly redesigned as a contemporary, family-oriented superyacht. After leaving Falmouth, Solace will embark on a three-year global circumnavigation. The ‘Solace Odyssey’ will be visiting destinations including the Seychelles, French Polynesia and Antarctica. For a deeper look at how her refit has prepared her for this ambitious journey, see page 6

PENDENNIS VILANOVA

A BUSY SEASON IN VILANOVA

The 2024/25 winter season was one of the busiest on record for Pendennis Vilanova, with more than 100 yachts passing through the site for significant refits with a combined length of over two kilometres. Read more about Vilanova’s success story on page 24

NEW SOLAR PANEL INSTALLATION

Pendennis recently announced the completion of our new solar installation in Falmouth. With the support of the CIOS Good Growth Fund we’ve been able to install a 975KW solar array on our roof, which is predicted to eliminate 155 tonnes of CO2e each year. This is calculated using the UK Government’s 2025 Scope 2 location-based conversion factors.

NORFOLK INTERIORS

INVESTMENT PROGRAMME CONTINUES IN NORFOLK

In Norfolk, a long-awaited state-of-the-art CNC facility has just been installed. This is the next step in our planned investment programme, with plenty more to come. The team has grown to include a CNC operator and two trainees, furthering the specialist capabilities that give Norfolk Interiors the breadth of skills to deliver everything from custom furniture to full turnkey interiors.

HRH THE PRINCESS ROYAL OPENS COCKWELLS’

TRAINING ACADEMY

Cockwells welcomed Her Royal Highness The Princess Royal earlier this year to open its new training academy. The Cockwells Training Academy will deliver the Level 3 Boatbuilder Apprenticeship programme – offering young people the opportunity to develop expert-level skills in traditional boatbuilding. Our dedication to training and development across the Group is demonstrated by apprenticeships offered by all four companies.

Her Royal Highness then launched the all-new Hardy 45 European by pouring a bottle of Cornish Camel Valley champagne over its bow, observing the symbolic maritime tradition that is believed to bring good fortune to a vessel.

Find out more about Cockwells’ plans to invest in the future on page 20

BEHIND THE REFIT OF SOLACE

REBORN FOR A GLOBAL ODYSSEY

When the 55.5-metre Solace (then known as Twizzle ) first emerged from the construction hall at Feadship, it was immediately clear she was destined for greatness. Commissioned by a husband-and-wife team with visions of round-the-world adventure, it was imperative that she possess impeccable seakeeping capabilities and the comfort to support extended voyages. The fact that she was built to a multi-award-winning design was almost incidental.

Two decades later, under new ownership, itineraries are being redrawn for 'Solace Odyssey' – an exciting new approach to chartering in partnership with EYOS. Solace will journey to some of the world’s most isolated locations on a threeyear-long circumnavigation. Pendennis has been busy readying her for the journey. “While I engaged with several yards,” says Solace ’s Owner, “it was Pendennis that truly resonated after my initial visit to the shipyard in Falmouth. There is a special ambience there, something intangible that's felt throughout the yard, and of course, their renown for highly skilled craftsmanship and engineering was a factor.”

“We’ve now delivered a lot of boats from Falmouth for some pretty intensive cruising,” confirms Charlie Ross, Pendennis Group Operations Director. “To name but a few, there’s Constance, A2, Teleost , Hemisphere, and most recently Jester We’ve got great experience of what works and what doesn’t, and when this Owner came to us with plans to explore some truly remote places, we knew exactly what needed doing.”

“It was Pendennis that truly resonated after my initial visit to the shipyard in Falmouth. There is a special ambience there, something intangible that’s felt throughout the yard, and of course, their renown for highly skilled craftsmanship and engineering was a factor.”

OWNER Solace

Solace required a comprehensive service – upgrading, replacing, and overhauling all technical systems from the engine room to hotel systems. With plans to cruise continuously until 2028, often far from any shipyard, it was essential that her captain could have full confidence in Solace being in turnkey condition. Among the safety and exploration upgrades was the installation of a FarSounder underwater sonar providing a 120-degree, 1,000-metre underwater view to detect hazards like reefs and ice while simultaneously mapping the sea floor. Pendennis fabricated the custom housing and installed and commissioned the system, which will feed data into FarSounder’s global database to enhance >>

charts for future explorers. As with other Pendennis builds and refits that have undertaken similarly ambitious voyages, this refit marks just the beginning of a long-term relationship. The Pendennis Yacht Support team remains on call, ready to provide ancillary support anywhere in the world, should it ever be required.

The refit also demanded expanded dry and cold storage, advanced waste management systems, and technical redundancies. Maximising the interior and exterior living spaces was equally a priority, as Charlie explains. “We extended Solace by 1.5 metres, giving us room to remap her general arrangement and add a new two-berth supernumerary cabin, intended for guests, ice pilots, scientists, or other specialists. A big focus was also placed on improving the usability of exterior areas in both extreme heat and cold. We created flexible, enclosed spaces that can be heated and protected, without compromising the vistas.”

Being a new yacht for this Owner, the interiors were also refreshed to reflect a warmer contemporary feel, one suited to their young family while still honouring the yacht’s original design ethos. The Owner turned >>

“We are a full-service shipyard with an exceptional depth and breadth of knowledge and skill. That’s something that truly sets us apart. We have everything in-house: cabinet makers, carpenters, painters, fabricators. So, when a yacht like Solace comes to us, it really is the full A to Z. We’ve fabricated a new structure, built new furniture, painted her from top to bottom, and done almost all of it right here in Falmouth.”

CHARLIE ROSS Pendennis Group Operations Director

“The result is a yacht primed for true long-distance exploration for several years to come – and reborn in every sense, ready for her odyssey.”

OWNER Solace

to seasoned designer John Vickers, who had been part of the design team that crafted Solace ’s original interiors in the early 2000s.

“Elevating her original spirit and contemporary feel was always the ambition,” says her Owner. “She was built as a family boat for prolonged cruising and that ethos has been reintroduced. Focusing on comfortable places to sit, socialise or ponder, while on long passages with connections and views towards the outside vistas passing by. Combining textures, new and vintage furniture, with soft tones and some contrasting patterns has created the sense of a home, more than a showcase.”

“What began as a focused, four-month refit plan grew into a comprehensive ten-month transformation,” says Solace ’s Owner. “Each layer we uncovered revealed a new consideration – inherently unpredictable and sometimes challenging. Countless decisions were weighing "enough" against "ideal", moments when the rational choice demanded greater investment. Through it all, Pendennis remained steadfast, adapting to an everevolving scope of work. The result is a yacht primed for true long-distance exploration for several years to come – and reborn in every sense, ready for her odyssey.”

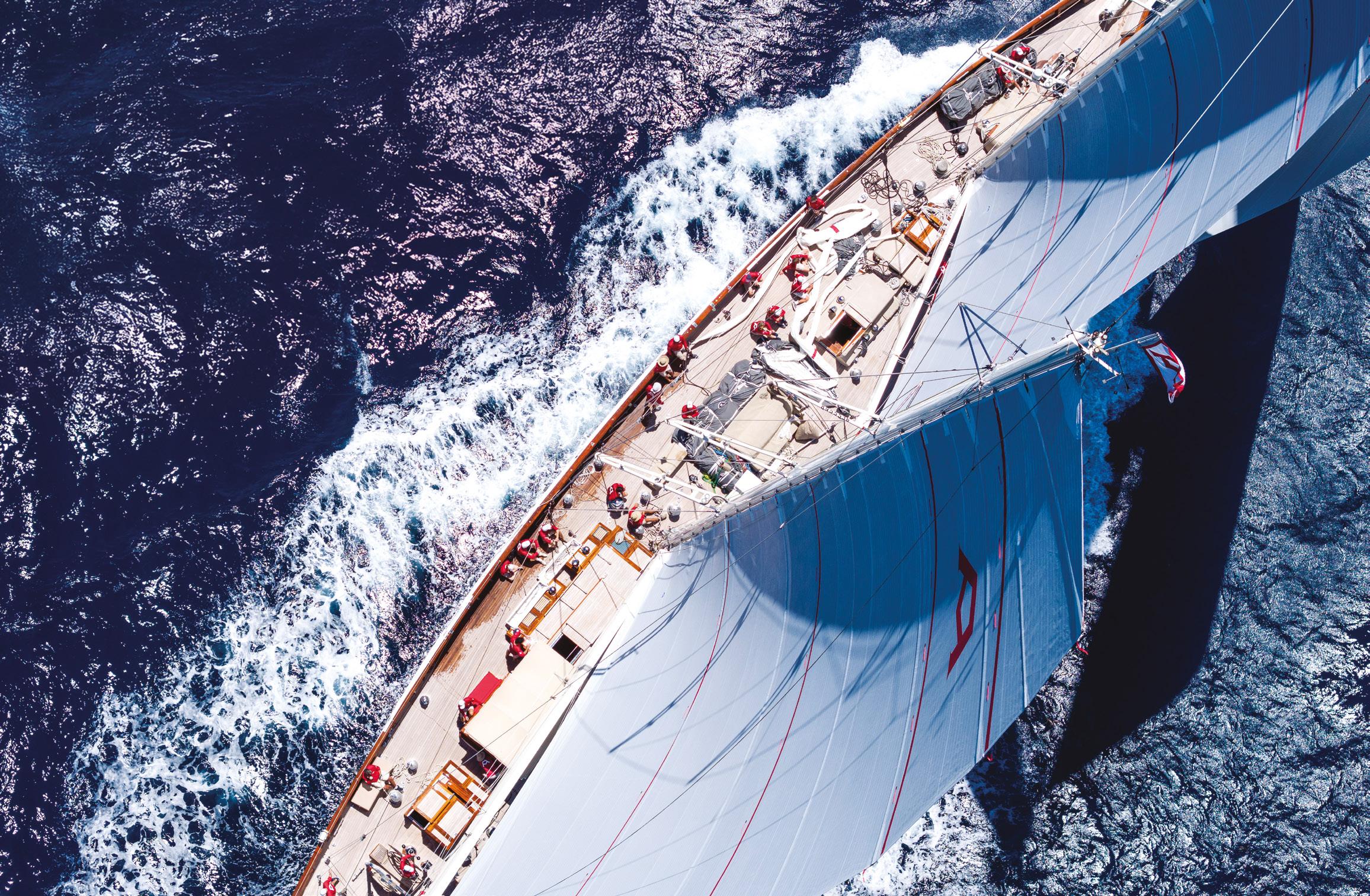

THE RACE

2025: the year of regattas. Pendennis dominates in the Caribbean and the Mediterranean.

Pendennis Vilanova was buzzing with anticipation as six yachts prepared for the Caribbean regatta circuit. Adela was undergoing a major refit, while the others were being fine-tuned and optimised for the St Barth's Bucket and the Antigua Superyacht Challenge.

The boots on the ground in Spain know these boats intimately. “When I joined Pendennis as an apprentice over a decade ago, Adela was one of the first yachts I worked on,” says Jake French, from Pendennis’ Aftersales team. “It was brilliant to then be on board during the regattas, seeing her perform maxed out.”

Jake wasn’t alone. He was one of two former Pendennis apprentices who have progressed within the company and now form part of the Aftersales and Support team. Pendennis keeps close ties with its fleet, and when these owners wanted their yachts race-ready, the team knew exactly what to do.

“We’re known for producing beautiful sailboats,” says Toby Allies, Group Managing Director at Pendennis. “But we’ve built just as strong a reputation for enhancing existing boats to perform at the highest level on the racing circuit. Over the years, we’ve upgraded many from the J Class fleet, as well as other high profile performance sailing yachts."

Out of the six yachts preparing for the Caribbean, three were originally built by Pendennis. Catalina and Gitana have a longstanding relationship with the yard, having completed various refits and maintenance work over the years. Whisper undertook an intense period of race preparation in Vilanova before competing in the Bucket.

Pendennis’ Aftersales team supported each of the yachts throughout the regattas. Here are some of the success stories:

Name Built

Refit/Maintenance

NOSTROMO 2009 2011, 2014, 2015, 2016, 2023, 2025

VIJONARA 2018 2020, 2025

WHISPER 2003 2025

GITANA 2009 2024

ADELA 1903 1995, 2000, 2006, 2011, 2012, 2014, 2016, 2017, 2021, 2023, 2025

CATALINA 2001 2017, 2018, 2024, 2025

NOSTROMO

Going for gold in Greece

Nostromo had been cruising extensively since 2019 and only occasionally unfurled her racing sails. But this year, that changed. A series of performance upgrades gradually shifted her from casual cruiser to serious competitor.

Her final upgrades were completed in Vilanova in early 2025, and she joined the fleet heading west to the Caribbean. She competed in both the St Barth's Bucket and the Antigua Superyacht Challenge. Performance improved steadily, but it was back in the Mediterranean, with the Meltemi winds in her sails, that she truly came into her own.

Racing around Antiparos, Despotiko, and Ios in the second edition of the Cyclades Cup, Nostromo outpaced the fleet. Facing off against Nommo, Plaz, and Tawara in the Skyphian Class, she took top honours on both days and was ultimately named “Head of Fleet,” lifting the Cyclades Cup.

“Following an indifferent performance in Antigua and St Barth's, where uncharacteristic light and fickle winds tended to favour the purer race boats, Nostromo took full advantage of a solid June Meltemi to chalk up both class and overall victory in the Cyclades superyacht regatta.”

ANDREW

COOK Owner of Nostromo

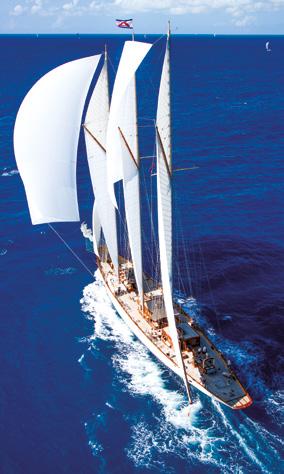

Truly classic, truly owner-driven

When the starting pistol fired at the St Barth's Bucket most yachts had a race professional at the helm – however the hand confidently steering Vijonara belonged to her Owner. And he was formidable. Battling it out in the L’Esprit class against Liberty, Inukshuk , Symmetry, and Red Sky, Vijonara claimed victory on every day of racing and was ultimately named overall winner in her class.

Her graceful styling is the work of André Hoek, a designer typically associated with powerful, oneof-a-kind sailing yachts. Yet, his Hoek Truly Classic 128 series, of which Vijonara is the second hull, has proven exceptional. Part of the secret is flexibility: each unit is vastly different from the next. And being an impassioned sailor, Vijonara ’s Owner was heavily involved in designing the helm station during the build. Since her delivery in 2018, her Owner has taken

Vijonara around the world, and his experience at the helm was evident on the circuit. “She’s been in cruising mode ever since she first left the blocks,” explains Toby. “When she returned to us, while we were fine-tuning her for the regattas, the Owner and captain developed a race crew and team on board to be extremely competitive on the start line.”

During the regatta itself, Jake ensured she performed at her best. “Our focus was on general functionality,” he says. “We made small changes to her programming and tweaked her peak shaving systems.”

It was a winning formula. After three days of intense racing, Vijonara lifted the Spirit of the Bucket in victory. She then returned to Vilanova for post-race maintenance before setting sail for Palma and the Superyacht Cup.

A class act: Adela returns

With her return to racing in 2024, for Adela , the Superyacht Challenge Antigua was personal. She had something to prove, and her Owner wanted to reignite her racing spirit to see what she could achieve at the top level.

“After many years away from regattas, there were naturally a few cobwebs, a few problems to resolve,” says Toby. “The Owner loved the racing, and before we even left the Caribbean, we were planning with the team how to get her to Grand Prix standard for 2025.”

It was a significant refit. The sails, engine room, and switchboards were all ripped out and upgraded. Her hull was repainted and detailed with hand-drawn gold leaf embellishments. When she left Pendennis Vilanova after a four-month appointment, she looked every inch a champion.

She sailed straight to Antigua from Vilanova, where the Pendennis Aftersales team was waiting to meet her. Hydraulic Trade Manager Alex Butler and Electrical Engineer Joe Hayes supported her through all four days of racing. “We believed having someone on board who had installed the new systems was essential for Adela ’s first post-refit race,” says Joe. “That proved vital when a generator encountered shutdown problems close to the regatta. We were able to respond immediately, diagnose the issue, and resolve it before it impacted racing.”

The combined efforts – from the refit and preplanning to the commitment of the team and ferocity of the crew – led to victory. Adela won every race, took her class at the Superyacht Challenge Antigua, and finished second overall at the St Barth's Bucket.

“Work hard. Get it done,” comments Toby. “Not only do we do the work – we go out and make sure it happens on the water. We are incredibly proud of how well Adela performed.”

“The Owner loved the racing, and before we even left the Caribbean, we were planning with the team how to get her to Grand Prix standard for 2025.”

TOBY ALLIES Pendennis Group Managing Director

CATALINA

From global tour to the Gosnell Trophy

Catalina doesn’t have a homeport. She’s a true nomad. Her journey began in 2016 in the calm waters of the US, followed by a brief fling in the Caribbean, before heading to Pendennis in 2017 for a transformative refit. The work prepared her for daring adventures – from Central America and the Galapagos to British Columbia and Alaska. An 8,000-nautical-mile, award-worthy journey.

Regattas have dotted her voyage. “We’ve done about a half-dozen over the past nine years,” says Captain Sean Whitney. “The boss loves them. He loves the sailing and the camaraderie – and the Antigua Superyacht Challenge truly symbolises this spirit.”

During her second Pendennis refit in 2024, the plan was to race Catalina at the Superyacht Challenge Antigua before continuing her global tour. She left Falmouth with a new main engine, stern tube, propeller, and standing rigging. A brief stop in Vilanova and then westward to the Caribbean, with Pendennis Aftersales in tow. “When we left Vilanova, we had to get to Antigua pretty sharpish,” says Sean. “We arrived just two days before the regatta; it was a huge push to get her ready and bring the race crew on board.”

The Pendennis team met her on arrival. “It was a great cushion for us,” Sean says. “We even had a couple of the guys racing with us."

With a new alarm monitoring system and propeller shaft, the performance parameters needed refining. “After the first day of racing, we tweaked the pitch control of the propeller, feather-tuning its position,” says Jake. “We ran tests that evening before day two.”

Catalina was ultimately awarded the Gosnell Trophy, an award presented to the yacht and crew that best captured the spirit of the event.

“Everyone pulled together. It was a very special moment,” says Sean. “It was even more meaningful because this was the first time the trophy was received by the vessel that originally donated it. The son of the previous owner awarded it to us on the podium. This was a full-circle moment for all of us, reflecting the ethos of the boat.”

“Catalina is a fantastic boat, with lovely Owners and great crew. Supporting them during the event was amazing for Team Pendennis.”

STEPHEN HILLS Group Commercial Director at Pendennis

TRULY CORNISH

Cockwells: the latest member of the Pendennis Group

When Cockwells was founded in the city of Bristol in 1996, little did its founder, Dave Cockwell, know that it would go on to build a world-class reputation for crafting some of the most sought-after superyacht tenders and chase boats. Since then, the company has relocated its headquarters to Falmouth, near Pendennis, and now leads a major operation with a 150-strong team working across two sites.

“We’ve known Cockwells for a long time now,” says Stephen Hills, Group Commercial Director at Pendennis. “It’s pleasing to find such a passionate, committed and knowledgeable bunch of people delivering products to such a high standard. When you walk around their yard, you feel their pride in everything they do.”

In fact, Cockwells has been firmly on Pendennis’ radar for well over a decade, ever since it won the bid to build a custom tender for the 50-metre classic

Camper & Nicholsons motor yacht Malahne, which was redelivered following an extensive 30-month Pendennis refit in 2015. The drive with which Cockwells approached the commission was exactly as you’d expect from such a passionate team: astounding.

This 7.6-metre tender captured the original 1930s spirit of Malahne with a strip-planked yellow cedar hull and chrome fittings cast from period originals. Underneath the classic woodwork lies a punchy 258hp Steyr engine and clever engineering, pairing her classical grace with modern-day performance credentials. The tender for Malahne was just one of a string of deliveries during the early 2010s that proved monumental for Cockwells’ success.

Blown away by the quality of the products and the charm of Cockwells’ operations, the owner of the 73.3-metre Italian-built Nautilus (ex. Grace E ) placed an order for a 9.5-metre tender. It was the >>

“Cockwells is its own standalone business and will continue as such. Our initial focus is on how to enhance the value of the company during a period of growth. We are also looking at effective ways to transfer skills between us and establish an appropriate synergy. Mobility of the workforce between sites and focusing on specialisms and capabilities in each business is the way we’ll do this.”

first custom Cockwells tender purpose-built to be craned onto a yacht. With a sweeping sheerline and a long, tapered stern exquisitely finished in teak decking, as well as a twin Yanmar-Hamilton package tucked beneath the hydraulic engine cover, T/T Grace E proved to be as sleek in performance as she was in style. She was an instant hit at the 2013 Monaco Yacht Show.

“That Monaco was a real turning point for us,” says Henry Ward, Design Director at Cockwells. “We presented T/T Grace E, and we couldn’t have asked for a better reception. Word quickly spread, and following the show, we had a good, steady stream of tender orders coming through.”

Amongst these orders have been numerous commissions from Pendennis clients, including a second tender for Malahne in 2023 and the refit of two of 85-metre Aquila ’s tenders. And custom tenders were only part of the order book. Cockwells was also seeing tremendous success with its two semi-custom series: Duchy Motor Launches and Hardy Motor Yachts.

“Both series speak to a certain quality and sophistication,” says Stephen, “and the fundamental underlying craftsmanship gives them a great build quality. Those two things combined mean they have a very strong resale value as well. The Duchy and Hardy series are both designed from the heart and are brilliant seakeeping boats, but they’re also very different.”

Each model has its own charm and can be customised. The versatility in build starts from the size; Cockwells offers the series from 6 to 20 metres, and the smallest, Duchy 21 model, makes for an exceptional tender. One was custom finished for the classic 59-metre Marala

While the Duchy delivers grace, the Hardy responds with rugged elegance and a real "go anywhere" design. Ranging from 14 to 20 metres, each Hardy is spacious and well considered for long cruising. Performance and seakeeping are exceptional, even in adverse weather conditions, and every model in the series offers comfortable accommodation for guests and crew.

With an order book stretching into 2027 and big visions to expand the Duchy series even further, Cockwells was keen to strike up a partnership that would help it scale and grow. Being so closely aligned in terms of business principles and location, Pendennis was the perfect shipyard to achieve this. In September 2024, Pendennis acquired Cockwells, bringing it into the wider Pendennis Group.

“We’re a small company transitioning into a large one,” says Henry. “And Pendennis has the expertise to guide us. They’re helping us improve the efficiency of our production, bolstering our management and labour resources, and ensuring that we are sufficiently prepared during this transitional period.”

The benefits are just as rich for Pendennis. The majority of Cockwells’ boats are composite, whether GRP or advanced kevlar construction. Cockwells are currently completing, among other tenders, a set of four high-tech tenders for a 135-metre Lürssen. These include a fishing launch, a beach landing cat, a limo and open tender. All striking in design and very high performance.

“Cockwells has some very high-level carbon composite skill sets, which we just don’t have inhouse,” explains Stephen. “It’s something we’ve traditionally outsourced. Now, when we have projects come in that want carbon tech, we’ve got the expertise we can draw upon in the Group.”

Through its recently launched Training Academy, which was officiated earlier this year by Her Royal Highness The Princess Royal, Cockwells is doubling down on its apprenticeship scheme, building these in-house skills from the ground-up. It currently has 18 apprentices in training. And, by being part of the wider Group, these apprentices now have access to the training initiatives led by Pendennis – and vice versa.

SIX YEARS, SIX HUNDRED PROJECTS

The Mediterranean outpost of Pendennis has been busy. Its modern marina and Technical Service Centre, located less than 30 nautical miles south of Spain’s cultural capital, is a magnet for the global fleet. Six hundred projects in six years is certainly cause for celebration.

ADELA 55M 2024/25

During Adela’s winter 24/25 refit she had a full paint job, and her main engine was transported to Holland for a rebuild. The team installed a new switchboard and overhauled her generators. Her gold leaf work was also refreshed. A lot was accomplished in a short time to prep her for the Caribbean racing season.

VA BENE 48M 2023

MY Va Bene was re-launched in May 2023 after completing her 30-year survey. Works included a full repaint, teak deck refurbishment, and engine room revamp, including engine and generator rebuild.

CHRISTOPHER 46M 2023

Pendennis-built Christopher first visited Pendennis Vilanova in January 2023 for her Lloyd's class survey. She stayed in the marina before being hauled out for antifouling, underwater and support works. She is set to return to Pendennis Vilanova in the upcoming winter months for her 15-year survey.

FARFALLA 32M 2019

In the spring of 2019, Farfalla received technical support while afloat, followed by an autumn haul-out for pre-Caribbean works including a new generator, serviced thrusters and furlers, engineering upgrades, and maintenance. In subsequent years, she has returned for winter storage, berthing, a full repaint, and annual servicing.

A2 47M 2023

In 2023, A2 had her generators upgraded, with removal done via an underwater hull opening in just 60 days. The success of this logistically challenging project was thanks to careful planning and close teamwork between the crew, Vilanova staff, and subcontractors. A2 returns to Vilanova next season for her special survey and full repaint.

“The location helps a lot,” says Miquel Lliteras, General Manager at Pendennis Vilanova. “We have everything you need here in Vilanova. The airport is close, and Barcelona is just down the road, yet we still have the safety and comfort of being a small city.”

Vilanova i la Geltrú has a history entwined with fishing. It’s rich in local knowledge, with deep family traditions. Pendennis Vilanova has forged connections with numerous maritime schools and has already attracted many local apprentices, mirroring the successful programmes that the team in Falmouth has built over the past three decades.

“We’ve just begun formal apprenticeships and are starting to firmly embed ourselves in the local community,” says Kirk Oldfield, Production Manager. “The goal is to develop skills locally.”

hired two graduates from the Faculty of Nautical Studies. It’s also actively recruiting project managers and electricians through university outreach.

Since January 2024, the Pendennis Vilanova team has grown by 40%. Twenty new hires have joined across all departments, bringing the team from 50 to 70. “There’s still work to be done in visibility, though,” admits Kirk. “Many students in Vilanova didn’t even know we were here. But we’re changing that – we’re hosting visits, making connections, and showing that Pendennis Vilanova can be a long-term place to build a career.”

“Many students in Vilanova didn’t even know we were here. But we’re changing that – we’re hosting visits, making connections, and showing that Pendennis can be a long-term place to build a career.”

The yard now works closely with several regional institutions, including Lluch i Rafecas College, Universidad Politécnica de Barcelona, and the Facultad de Náutica de Barcelona. Two students recently completed internships in the painting department, with more trainees in electrical and engineering roles starting this summer.

KIRK OLDFIELD Production Manager

Some of those trainees have already turned into full-time team members. Pendennis Vilanova recently

Another major strength of Pendennis Vilanova is its 48-berth marina. “Not many places in Europe can say they have both a marina and a shipyard,” says Miquel.

“With complete ownership of the marina, we can offer an incredible amount of flexibility.”

The marina, which can welcome yachts up to 130 metres in length, is set in a protected harbour, with each berth serviced by pedestals with complete amenities. The entire site is also ISPS-certified, with 24-hour security.

For a shipyard with global ambition, building local foundations has never been more important. And in Vilanova, Pendennis is doing just that.

A LIFETIME OF SUPPORT

A 30,000-nautical-mile maiden voyage is anything but ordinary. Fresh from the Pendennis build shed in Falmouth, the 39.8-metre Halekai sailed non-stop for five years. From the Pacific to Palau, she chased the world’s wildest waves on a mission built around one thing: surfing. After circling the globe, Halekai returned back to the Mediterranean and home to Pendennis Vilanova.

She’s one of over 600 projects to pass through Pendennis’ growing outpost in Spain. Her return marked a milestone: Halekai was the first full paint job completed by the Pendennis Vilanova team. In addition to this, Halekai ’s seven-month refit included

her five-year special survey and a refresh, ahead of going straight back into service. She even made a star appearance at the Palma Boat Show before heading off again on her second world tour.

As Jake French, Aftersales at Pendennis, puts it, “Halekai is our second truly classic new build, following Vijonara. She's a yacht that's lived the brief – a full world tour, with global support and live service.”

That seamless loop, from build to beyond, is exactly what Pendennis offers. Go to Falmouth for your new build, and head to Vilanova for aftersales, surveys, and support.

PASSING THE TORCH

Some steps are larger than others. And that first step from the schoolyard to the shipyard is more of a leap. Through its apprenticeship mentor programme, Pendennis softens the landing, offering first-year students something no other company does: John Angove, Dave Gilbert, and Trevor Hawken.

Retirement didn’t last long for any of them. All three returned to Pendennis to build a mentorship programme designed to help first-year apprentices gain a broad understanding of the trades and settle into the rhythm of working life. The programme runs

for 12 months, with John leading apprentices through the fabrication departments, Dave the engineering, and Trevor the electrical.

Across the UK, apprenticeships have been structured slightly differently in recent years. Traditionally, apprentices were taught exclusively at college and didn’t join their employer until after their first 12 months of training. But, in practice, this model fell short – practical experience just can’t be gained without getting hands-on.

Craftsmanship isn’t something you learn from a book. Gaining that practical experience in the first year is vital, as after the first 12 months, the apprentices choose a trade to specialise in. The more recent approach is hybrid, blending theory with practical work. At Pendennis, that means Thursdays and Fridays at the shipyard.

“We’ve had a lot of feedback, and this model is much better for the apprentices,” says Dave. “They get a good feel for the yard activities from the get-go, and they learn a lot more on the practical side.

“I focus on fabrication or marking out skills, and then Trevor trains the fundamentals of electrical work.”

Craftsmanship is an art worth sharing. Alongside its awardwinning apprenticeship scheme, Pendennis launched its mentorship programme headed by three retirees who are passing on their combined 80+ years of Pendennis expertise.

John adds, “We keep it basic – measurement skills, using tools properly and safely. Small tasks each week. But by the end of it, they’ve made something. They can point to it and say: I built that.”

Shipbuilding is more than skill – it’s a mindset. From their very first day, apprentices are taught to take pride in their work and understand the weight of responsibility that comes with it. “When you’re working on somebody’s superyacht, the quality of work has to be at its best,” says Dave. “We have a lot of repeat clients here, and it’s something we’re proud of. We try to instil this from day one.”

The mentors also help apprentices understand that respect, cleanliness, and professionalism are all part of the job. “These boats are someone’s home, so we encourage them to leave it better than they found it,” Trevor adds.

It’s not only skills that are being passed on. “Yes, we share tips and guidance,” says John, “but we’re also a bit of an agony aunt. We’re an open ear for these young people, and having someone to trust and lean on goes a long way.”

Safety is also a major focus. Risk assessments are a daily practice at Pendennis, and the mentors help guide the apprentices with best PPE and tool competencies, drilling in the importance of safety at the shipyard.

The programme has also involved apprentices in community projects – including helping a local radio station with joinery work – and some have won national awards. “It’s very rewarding to see them develop into fully grown, sensible adults,” says John.

The Pendennis Apprenticeship scheme has run for almost 30 years, this year being a landmark year for the mentorship programme, with its first-ever cohort of apprentices graduating. “It’s such a rewarding job, and I’m so proud of them,” says John. “I wouldn’t do it if I didn’t enjoy it."

Dave agrees: “I thought I’d give it a go for a few months – that was four years ago. Another plus point is that our wives are glad to get rid of us on Thursdays and Fridays too,” he laughs.

Though their focus is on first years, the mentors often find older apprentices returning for advice. “In the fourth year, they’re more or less in full production,” says John. “But it’s nice to know they still come to us – it means something’s working.”

For Trevor, who himself was an apprentice more than 50 years ago, it’s about passing on more than just technical skills. “I’ve done quite a lot in my time here – electrical engineering, trade management, even marketing – and travelled the world with it. I try to share that, show them what’s possible in their career with Pendennis.

"I'm proud to have this position,” he adds. “To see the enjoyment of these young adults, who have never picked up tools before, making something with their own hands – it’s very special.”

A DIGITAL EVOLUTION

How the DMC is redefining refits

No yacht has witnessed the evolution of Pendennis quite like Adix. When Adix arrived at Falmouth for a refit in 1991, she was one of the first to make use of the then-brand-new shipyard at Falmouth Docks. The refit was extensive – award winning, in fact – and launched a three-and-a-half-decade relationship between yacht and yard. She has seen development after development at Pendennis.

Arriving earlier this year for a six-month refit, Adix was greeted by the brand-new Digital Manufacturing Centre (DMC), which the crew made great use of. Equipped with a computer numerical controlled (CNC) high-pressure water jet cutting machine, lathes, and mills, Pendennis can now design, engineer, and fabricate virtually any component in-house, reducing both time and complexity.

“We had more than 1,400 additional hours run through the DMC for Adix,” says Jack Chuter, Machine Shop Manager. “It was all emergent work. Being able to design and engineer components and parts on-site meant the crew could add further jobs to the work list. Without the DMC, these works wouldn’t have been possible this time around. We would have had to plan them for the next visit.” >>

The ability to scan everything from a full hull to a small bracket and create 3D digital replicas makes assessment faster, more accurate, and more comprehensive.

Scan

Draw

Modify Manufacture

Adix was originally in for other improvements, but the crew flagged performance issues under sail. Her 2,100 square-metres of Hydranet sails were placing too much stress on the rigging and hardware. After modelling several components in CAD, it became clear that the yacht’s toggles were to blame. Redesigning them dramatically improved her handling and performance.

Pendennis has been ramping up its 3D modelling for the past five years but traditionally outsourced the physical fabrication of those designs. That meant longer lead times and added logistical complexity. Now, with the DMC, CAD designs can be rapidly translated into physical parts within the yard itself, cut with water jet, or milled to micron precision – all without the potential delays of external vendors, and guaranteeing complete traceability.

“I think of it as reverse engineering,” says Jack. “There might be a part that exists but doesn’t necessarily work as it should. We scan the part and its surrounding area, draw it up in 3D CAD, and then modify it to improve performance or aesthetics. Then, using the CNC water jet cutting machine, we can cut and machine it precisely to size.”

The advantages of the DMC – and digital design

more broadly – are particularly profound in the context of a bespoke refit or restoration, in which no two projects are the same. The ability to scan everything from a full hull to a small bracket and create 3D digital replicas makes assessment faster, more accurate, and more comprehensive.

For classic yachts, it means components can be reproduced exactly to the original specification, preserving pedigree. But it also opens the door to innovative modifications that respect tradition while enhancing capability, as Charlie Ross, Group Operations Director, explains: “We are well positioned as a bespoke full-service shipyard for clients that have an emotional attachment to their yachts and who want to retrofit hybrid propulsion systems. We did this recently for a historic vessel, and I foresee a lot more of these requests coming in, especially now that we have these advanced digital solutions.”

Machine engineering has become integral to the workflow at Pendennis, and among the team of seven there are already three apprentices learning the trade. “The more people use the DMC,” says Jack, “the more they realise its value. It’s added a new level of capability to the shipyard, and I am so excited to see how it will develop in the future.”

THE NEW THAMES FLAGSHIP

A new era of river cruising: Silver Raven joins the Tower of London Fleet

By 2030, more than 2.5 million people will have stepped aboard a new Pendennis-built vessel. Silver Raven was launched in Falmouth this summer and is unlike any Pendennis vessel before her. This is the most public-facing build in the company’s history. Rather than setting off for distant shores, she has joined the Woods’ Silver Fleet as the official Tower of London River Tour sightseeing vessel, in partnership with Historic Royal Palaces.

Silver Raven is a modern, ultra-lightweight, and environmentally conscious 39-metre catamaran designed by One2three Naval Architects. As the UK’s first fully electric tour boat, she features a state-ofthe-art electric drivetrain. Her propulsion system incorporates key technologies from Danfoss (motors) and EST-Floattech (720kW batteries). The innovative propulsion system and resulting lightweight scantlings presented both Pendennis’ technical and production teams with opportunities to address complex challenges – enhancing and refining their capabilities in several increasingly specialised and high-demand areas of expertise.

“When we heard that the Woods family was pursuing such an innovative project,” says Stephen Hills, Group Commercial Director at Pendennis, “we immediately recognised it as an opportunity to showcase the full breadth of Pendennis’ capabilities, while also reigniting aluminium production in our yard.”

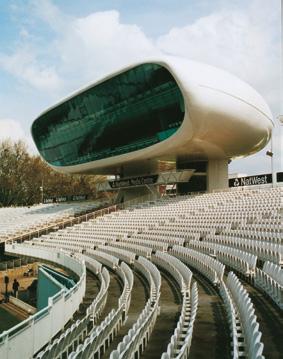

Aluminium has long been a core material for Pendennis – accounting for nearly 70% of its fleet. The most recent is the 39.8-metre Halekai, which

has just returned to Europe after an extensive global voyage. Other notable builds are the 42-metre Rebecca and 42-metre Vijonara , both engineered for high-performance sailing, while the 44.2-metre Hemisphere has circumnavigated the globe twice, visiting nearly 60 countries. Other iconic builds that highlight Pendennis’ expertise in aluminium fabrication are the architecturally award-winning Lord’s Media Centre at Lord’s Cricket Ground, the 9-metre brushed aluminium tunnel entrance to the Comme des Garçons shop in New York, and the King Harry Ferry, which connects the Roseland Peninsula with Feock in Cornwall.

“It’s essential for any business to have work that supports skill transfer between generations,” Stephen explains. “This was the perfect project to pass knowledge from some of the most experienced fabricators in the business to our apprentices and younger managers.”

While Silver Raven ’s cruising profile differs vastly from previous Pendennis builds, the values of quality, performance and long-term usability remain. She had to be ultra-light, all-electric, and resilient – built to withstand high daily footfall, cater to a wide variety of passengers, and celebrate the best of British design.

Kate Woods led the interior styling, weaving together subtle nods to London’s heritage with contemporary innovation. The design recalls the golden era of Thames cruising in the 1920s and ’30s, featuring wide, awning-shaded decks, panoramic single-deck views, and bespoke wool carpets

woven in Axminster. Where possible, materials were sustainably sourced from across the UK.

“We built Silver Raven from the keel up,” says Tim Strasman, Project Manager at Pendennis. “It was ambitious, requiring meticulous attention to detail. Every component had to be lightweight and pass rigorous standards set by class societies such as Lloyd’s Register and the MCA, with whom the innovation surrounding new technologies established a heightened sense of responsibility”.

The most significant challenges centred on the pioneering electric propulsion system, engineered by Vulkan Marine. Careful attention was paid to battery housing and thermal ducting for safety. Two generators serve as range extenders, enabling the vessel to operate independently from shore power if necessary.

The project also benefited from the recent opening of Pendennis’ new Digital Manufacturing Centre (DMC), which enables the engineering and cutting of complex parts such as penetrations, flanges, and containment boxes, on-site.

“This was a young team with an innovative vision, guided by our senior fabricators,” says Tim. “Everyone came together for the project and approached the work with great enthusiasm and readiness.”

FALMOUTH OUR FACILITIES

TO DISCUSS YOUR NEXT FALMOUTH PROJECT, PLEASE CONTACT:

+44 (0)1326 211344 or info@pendennis.com

Pendennis Shipyard Ltd, The Docks, Falmouth, Cornwall TR11 4NR

Pendennis Falmouth is a full-service facility capable of building fully custom yachts, as well as undertaking substantial restoration and remodelling projects or routine class and flag refit works.

Occupying a 14-acre prime waterfront location in Falmouth, UK, the yard’s modern facilities include three bespoke-built construction halls (2x90m and 1x45m) alongside a 150m dry dock, with the capacity for both new build and refit contracts for 30-100m superyachts. The 800t travel hoist enables efficient launching into the 7,500m² non-tidal wet basin, which is purposebuilt to accommodate superyachts of up to 100m. >>

VILANOVA

TO DISCUSS YOUR NEXT PENDENNIS VILANOVA PROJECT, PLEASE CONTACT:

+34 938 10 56 11 or vilanova@pendennis.com

Pendennis Vilanova, Moll de Ponent, SN, 08800 Vilanova I La Geltru (Barcelona)

Pendennis Vilanova is Pendennis’ main base in the Mediterranean and concentrates on providing technical service support to both existing clients and the wider fleet. Focused on small to mediumscale refits, the Pendennis Vilanova Technical Service Centre includes 30,000m2 of hard standing and both a 200t and 620t travel hoist. Projects can be carried out on the hard standing or afloat in the marina itself. Our marina is set in a protected and safe harbour with calm and clean waters and has 48 superyacht berths ranging between 25 and 130 metres for yachts with a maximum draught of 6.5 metres. >>

FALMOUTH

• 2 x 75m fully enclosed dry docks (or one 150m x 24m)

• 2 x 90m construction halls (1,800m²)

• 1 x 45m construction hall (1,200m²)

• 7,564m² of enclosed non-tidal wet basin

• 800t travel hoist

• 1,400m² refit complex (housing paint, joinery, electrical and engineering workshops, and project management offices)

• Bespoke 80m mast hall

• 200m² finishing workshop

• 3,000m² general stores and crew storage

• Crew facilities: training centre, gym and offices

• 420m² hospitality suite

• Private on-site helicopter pad

VILANOVA

• ISPS compliant

• 24-hour security and surveillance

• Dedicated customer service and dockmaster team

• Protected and safe harbour with calm and clean waters

• Mild climate throughout the year

• Technical trade support

• Backed up by parent company Pendennis Falmouth

• Up to 20 refit spaces on hard standing for yachts between 20-60m LOA

• 620t and 200t travel hoists on-site

• Superfast WiFi connection

• Waste and wastewater collection

• Private parking in front of berths

• Stores distribution

• Toilets and changing rooms

• Laundry services

• Free gym, yoga classes and sport sessions for crews

• On-site bar/restaurant

• Waste management areas for special residues

• Bunkering

• Helicopter landing site

• Rent or buy a berth – flexible options

• Mail delivery on board

Global Yacht Support Pendennis can offer global support to any superyacht. For all enquiries, please contact: yachtsupport@pendennis.com