your single source

elmbridge has you covered for all your coating needs

spray equipment

spray facilities

professional coatings make it happen

your single source

elmbridge has you covered for all your coating needs

spray equipment

spray facilities

professional coatings make it happen

The dp-specialist range offers a comprehensive selection of gloss and matt surface finishes from market-leading brands, including Alfatherm, Plasfilms, Renolit, Senoplast Designed for trade and volume customers, these surfaces can be laminated directly from the roll onto your substrate of choice.

Egger

Roundel

Laboratory

Renner

Ecogate®

AXYZ

Decorative

Donaldson

Titus

Elmbridge

Live

PCD

Ranheat

The British Woodworking Federation (BWF) is warning that the surge in lithium-ion battery fires from e-bikes and e-scooters – combined with poor fire door maintenance –could put lives and property at risk across the UK.

• Nearly half of people (46%) have spotted fire door problems in their workplace

• 1 in 5 people charge e-bikes/e-scooters at work

• Only 13% report workplace fire door faults - despite widespread problems

• 1 in 10 people have experienced or know someone who

New research, carried out by BWF to mark its Safety Week campaign – ‘Fire Travels Fast’ – has revealed a sharp rise in public concern about the fire risks posed by lithium-ion batteries, particularly those found in e-bikes and e-scooters, with over half (59%) of owners saying their fire risk fears have grown since getting one.

The findings come as a recent FOI request from QBE Insurance Group revealed a 93% increase in lithium-ion battery fires between 2022 and 2024, with e-bikes and e-scooters among the most common causes.

“The findings highlight the essential role of fire doors in containing fires and protecting lives, while also exposing concerning gaps in awareness, maintenance and reporting.

While media focus has largely been on domestic fires, the BWF’s research highlights that 19% of people charge e-bikes or e-scooters at work and 12% do so in public leisure facilities such as cafés, pubs, libraries or leisure centres.

Many employers have introduced facilities for e-bikes and e-scooters - such as indoor parking (31%), charging points (59%) and secure storage (27%) – yet nearly half of respondents (46%) had spotted problems with workplace fire doors, raising the question whether employers are putting the same attention and investment into ensuring fire doors are properly installed and maintained to minimise risk to life.

Issues ranged from fire doors being propped open (18%) and blocked (13%) to having faulty closers (10%) or faulty hinges (10%). Yet just 13% admit to having reported fire door faults in the workplace.

Fire doors are a critical line of defence, slowing the spread of fire and smoke to give people extra time to escape – time that is even more critical when dealing with the intense heat and speed of fires caused by lithium-ion batteries.”

Similarly, schools, colleges and universities have expanded storage and charging provision for e-bikes and e-scooters – and encouragingly, 39% of institutions have educated students on safe storage and dangers of charging. Despite this, of the 40% of students reported spotting issues with fire doors on campus, only 6% had ever reported a problem.

Helen Hewitt added: “We all have a role to play in spotting and reporting problems with fire doors and taking immediate action to protect lives and property. Fire Door Safety Week is an essential reminder that correctly installed, well-maintained fire doors save lives – but only if we all take responsibility for ensuring they can do their job.”

Organisers of Professional Woodworking Expo announced that Robin Clevett will serve as the official Brand Ambassador for the 2026 event, held at NEC Birmingham from 17–19 May. Robin’s return builds on his hands-on involvement and impact at the Materials & Finishes Show 2024, as he continues to inspire and elevate standards in the woodworking community.

Robin will once again bring his deep expertise and authentic voice to this reimagined platform. Robin, whose social media reach and commitment to craftsmanship have made him a household name in the woodworking community, will advise organisers, champion key industry brands, and energise the show’s renowned live demonstration zone and seminar programme.

With over 35 years’ experience across all sectors of carpentry and joinery, as well as a thriving presence on YouTube and FIX Radio’s The Carpentry Show, Robin is committed to advancing both practical skills and professional standards.

Robin’s involvement will drive awareness, engagement, and attendance, reinforcing Professional Woodworking Expo 2026 as the UK’s only event 100% dedicated to woodworking and joinery professionals, with over 6,000 attendees anticipated.

David Todd, Event Director, commented:

“Robin’s practical knowledge and genuine passion for the craft make him an ideal ambassador to help us grow and innovate. Building on the energy he brought to our last event, we’re excited to see new collaborations and hands-on experiences come to life in 2026.”

The Professional Woodworking Expo 2026 will feature expanded live demonstration areas, tailored seminars, and unrivalled opportunities to connect with decision-makers and shape the future of the sector.

Speaking about his renewed role, Robin said: “I’m passionate about supporting emerging talent and encouraging grassroots involvement in our industry. This year, I’ll be bringing third-year construction and joinery students to help with a live demonstration of a roof build at the show. Practical experience is vital, and there’s no better place to learn, share skills, and network than at the Professional Woodworking Expo. I look forward to seeing new and familiar faces, and to helping shape the future of woodworking in the UK.”

David Todd added: “Robin’s knowledge and enthusiasm for the craft are unmatched. We’re excited to build on the momentum of his previous ambassador roles and to see the next generation contribute at the show.”

For companies interested in exhibiting or joining the Live Demo Zone at Professional Woodworking Expo 2026, opportunities are still available. To find out more, please visit the Professional Woodworking Expo website or contact the event team.

www.professionalwoodworkingexpo.com

The HOMAG Group is continuing its major investment program at the Schopfloch site with a new customer centre and a modern company restaurant, with an investment volume of around €40 million.

Dr. Daniel Schmitt, CEO of HOMAG Group AG, emphasized the importance that the headquarters in Schopfloch have for the HOMAG Group. “From our base in Schopfloch, we have become the global market leader and will be presenting our unique range of solutions for trade and industry to our customers here in the new customer centre.”

At the new customer centre, called the HOMAG Experience Centre, visitors will be able to experience the world of woodworking live on an area of around 4,500 m2. There will be over 25 machines and systems, digital products, and integrated customer solutions on display. In addition, there will be a so-called brand world where visitors can experience the history and uniqueness of the HOMAG brand, as well as training and event rooms.

Employees can look forward to a modern company restaurant, which will replace the previous dining hall, which is somewhat outdated and too small. “We intend to create a place for communication and interaction where employees will enjoy spending time,” says Dr. Schmitt.

Both new buildings will be constructed with a timber supporting structure and timber façade cladding, in a sustainable manner. In addition, a large photovoltaic system will be installed on the roof. Completion is planned for the end of 2026.

The new buildings form part of HOMAG’s major investment program at the Schopfloch site, with a total volume of around €100 million. This began as early as in 2021 and by mid-2026, a modern and attractive working environment will be created there, featuring a wide variety of rooms with contemporary workstations, as well as its own café and bistro area.

www.homag.com

At EGGER LONDON, EGGER showcases over 300 finishes for furniture and flooring in a life-size sample library, and some of its most innovative materials in real applications across fitted furniture, working tables, networking spaces and design installations.

Adding to the breadth of inspiring surface finishes, designers are invited to explore CLEAF, an Italian company producing innovative surfaces for furniture and interiors. Renowned for striking texture development and exceptionally tactile finishes, CLEAF exclusively manufactures a considered selection of surfacing solutions at production sites in Brianza, and sees its material installed worldwide by interior architects and furniture designers, building inspiring spaces for living and working. Visitors can explore over 150 CLEAF finishes in the space.

Dallington Street in Clerkenwell, London’s globally leading design community. Opening its showroom doors for the first time at the internationally renowned Clerkenwell Design Week in May, EGGER London welcomed over 1200 visits to experience its remarkable interior design transformation.

EGGER LONDON offers an eclectic experience - its light, bright and flowing interior comprises of design space guests to work and collaborate on projects, digital space to access supporting tools and brand information, space for meetings and workshops, and hospitality space for relaxed networking. Every part of its interior its created with the designer in mind, with real life product application merging form with function throughout. It is packed with large format samples, supporting resources, and on-hand expertise from its team.

One Dallington Street is a striking example of late Century open and fluid architecture, it is flooded with natural light through its double height, glass-blocked façade. Inside, visitors are greeted by its spacious open atrium, centred by a statement, bespoke feature pendant that tells the story of EGGER’s history of celebrating wood

EGGER is a leading, global manufacturer of wood-based materials for interior design and construction. With its unique sole supplier offer for designers, specifiers, architects and fabricators, EGGER supplies a range of decorative materials for interior furniture, surfaces and wall panelling, decorative interior flooring and structural flooring, suitable for commercial and domestic projects. Priding itself on its strong environmental ethos and sustainable product portfolio, EGGER operates environmentally conscious manufacturing processes at 22 facilities worldwide.

BLUM brings movement and fluidity to the space. A globalleading manufacturer of innovative lift, hinge, pull out and pocket systems for furniture and interiors, the brand specialises in motion technologies while advocating responsible growth and preservation for future generations. BLUM is a pioneering business, focussed on solution-led product development, and renowned for its catalogue of innovative fittings and mechanisms designed to make furniture move, rather than be moved, for a better quality of living and working.

Under one roof the three partners provide an integrated

Leitz have helped Roundel Manufacturing Limited improve their nesting, edgebanding and overall manufacturing performance with German-engineered precision tooling and high-quality servicing.

In the highly competitive world of luxury and affordable kitchen and fitted furniture manufacturing, operational efficiency and uncompromising quality are paramount. Working in a strategic partnership, Leitz Tooling a provider of world-class German-engineered precision tooling, has supported Roundel Manufacturing Limited to improve their manufacturing operations and efficiencies.

Roundel, a leader in bespoke kitchen and fitted furniture manufacturing, has a reputation for crafting kitchens of exceptional quality that is built on a foundation of skilled craftsmanship. Maintaining this standard requires a consistent and reliable source of advanced tooling and technical support, highlighting the value of the partnership with Leitz Tooling.

Roundel approached Leitz Tooling at LIGNA 2023 as they had major service and tool performance issues with their previous tooling supplier and were facing challenges with panel rejects prior to investment in new machinery and tooling. Some of their previous board suppliers’ recycled board contained varying embedded components, causing excess wear on their tooling and accelerating the reject rate. With their primary focus being on product quality, Roundel was facing high panel rejection rates due to their stringent quality control. Roundel operates a variety of panel processing machinery, including Homag Edgebanders, table saws and flatbed CNC nesting machines.

To support Roundel in improving their product quality, Leitz first looked at their panel nesting and sizing processes. Roundel also invested in new machinery and optimised panel processing by oversizing product and hogging off excess material, which significantly contributed to reduced waste. Leitz and Roundel trailed various router designs, moving from a 2-wing design to a 3-wing design for improved edge finish with the additional benefit of higher productivity. The Leitz Diamaster PRO3 has an innovative tooth design that uses “Real-Z3” technology, closing gaps between the individual knives to increase the number of effective teeth. Thanks to this innovative design, the Pro3 can achieve 50% faster feed speeds and tool life than standard PCD routers, resulting in reduced downtime and faster, better-quality nesting. The alternative twist design also allows for tear-free edges on both sides of the workpiece, further reducing the panel reject rate experienced by Roundel. Tony Armstrong, Production Director for Roundel, commented on the impact of trailing the PRO3: “Technically in the market, Leitz stands alone.

We took a recommendation and moved from Z2, which was causing major chipping, to the Diamaster PRO3, which minimised our chipping. Leitz technical representative Neil supported us with tweaking the feed speeds, which also eliminated burnout and improved our quality”.

Leitz also looked at how they could work with Roundel to improve panel quality through edgebander tooling. Roundel invested in a new Homag Edgeteq machine; this enabled Roundel to double capacity on a single shift and reduce panel reject rates. Leitz equipped Roundel’s new edgebander with the flagship WhisperCut EdgeExpert cutter heads. Designed for high-quality milling, the Diamaster WhisperCut is a light and efficient design.

Featuring a lightweight tool body for reduced machine and motor wear, the WhisperCut is an economical solution engineered for exceptional tool life and up to 12 sharpens. With noise reduction of up to -5 dB(A), the design mitigates vibrations and therefore tool wear when machining.

The EdgeExpert variant used by Roundel, combines this economical focus with high shear cutting angles for exceptional finish quality, reduced chipping and tear out. Tony Armstrong comments on the impact of the Diamaster WhisperCut: “We moved to the edge expert to reduce chipping, which lowered our panel reject rate. We also now only change the tooling every three months”. This has led to significant cost savings for Roundel from reducing tool change downtime, wasted materials and the amount of rework required.

The combination of automated Boardstore, CNC nesting, new machinery, and staff training helped Roundel reduce panel waste significantly while maintaining highquality standards. Roundel is committed to creating and maintaining a safe and comfortable working environment for its employees and proactively identified opportunities to further improve air quality. To achieve this, Roundel partnered with Leitz, combining expertise to address dust reduction collaboratively.

Roundel is now using the new Leitz DFC® (Dust Flow Control) Turbine as part of this joint initiative. The DFC® Turbine from Leitz has been specifically designed to direct chips and dust from the machining area towards the extraction system in the most efficient and effective way possible. Designed for CNC systems with HSK-F 63 clamping, the turbine collects up to 90% of created chips, considerably lowering cleaning efforts and extending tool life by eliminating double cutting.

Tony Armstrong comments on the impact of Leitz DFC® solutions: “The DFC® helps significantly reduce dust on both the products and the machinery, while also lowering airborne dust levels, which improves overall air quality and provides better protection for our more delicate materials. Working closely with Leitz throughout this process has been invaluable, allowing both teams to learn and develop together.”

Leitz took over Roundel’s tools sharpening and immediately introduced them to the Leitz Tool Information Management system (TIM). Operating 8 service centres across the UK, Leitz are specialists in tool sharpening and diamond tool erosion. Leitz typically achieves over 16+ sharpens on panel sawblades and boast an extensive portfolio of precision machinery with micron-level accuracy. Leitz have supported Roundel with sharpening to reduce their tooling costs through increased tool performance and have been using the transparent TIM system to share data with Roundel.

All tools on Leitz TIM are tracked and traced, meaning their tool life can be calculated and expected life can be predicted to ensure there is always a fresh replacement ready to go.

Tony Armstrong elaborates on how Roundel uses the data captured by Leitz: “The TIM system is used by our manufacturing teams, they review the data to oversee tooling tests, monitor tool performance and are currently looking for ways to integrate it with RML’s own systems”.

Leitz and Roundel are continuing to strengthen their collaboration. The strategic partnership between Leitz Tooling UK Ltd and Roundel Manufacturing Limited highlights how a tooling supplier can add significant value beyond simply providing tools. By working closely together, Roundel has achieved notable improvements in productivity, finish quality, and reductions in waste, supporting their ongoing sustainability goals. Simon Liddell, Managing Director of Leitz Tooling UK comments on the relationship: “Companies like Roundel are the perfect partners for Leitz, their commitment to quality and constant improvement means we get to have a real impact on their business and help them to grow. Their feedback has been incredible and we are very excited to show the market how we can go above and beyond.”

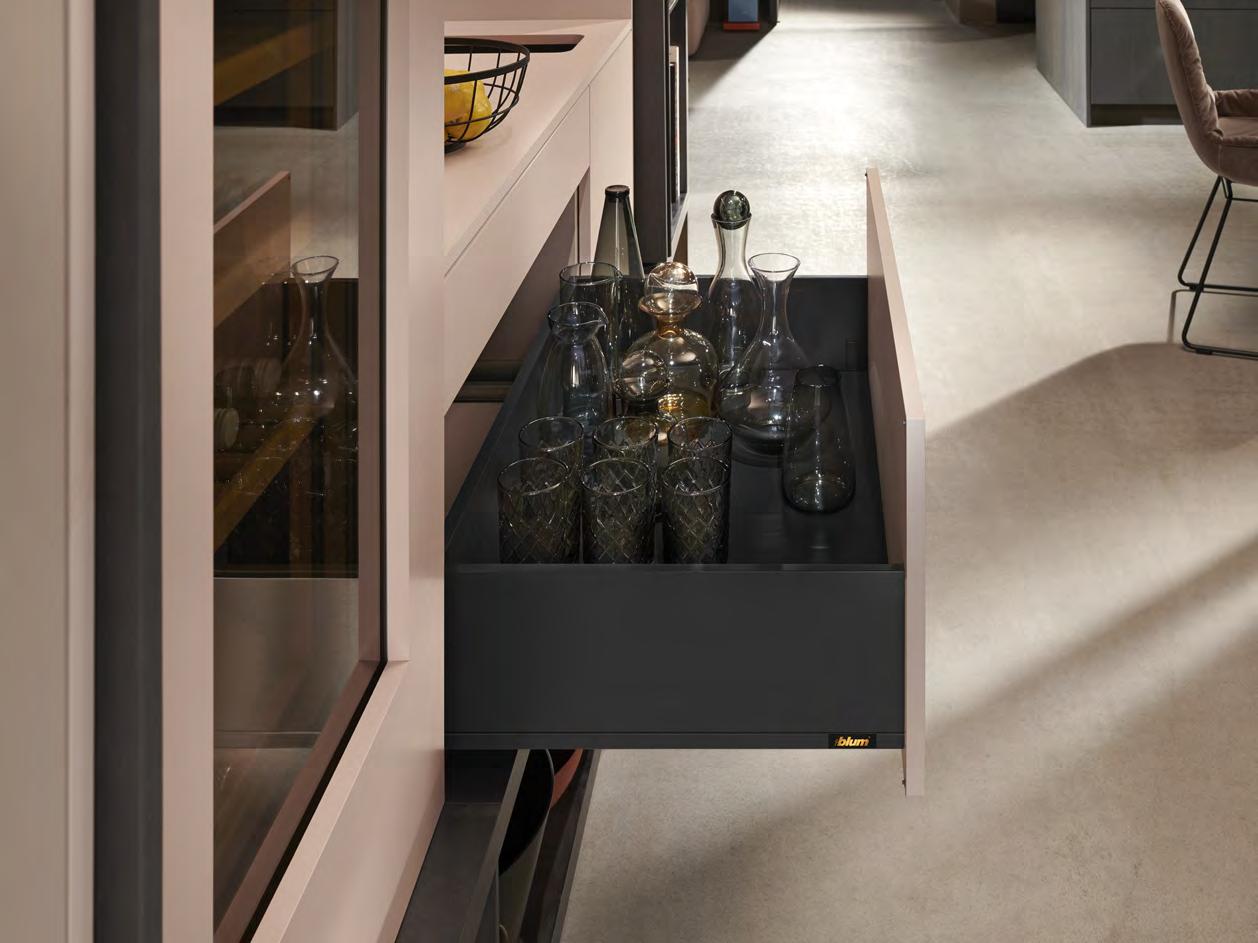

Blum has long been at the forefront of innovative cabinet hardware. Since its foundation in Höchst, Austria, in 1952 by Julius Blum, the company has become a global leader in the sector - setting an impressive benchmark for quality, precision, and forward-thinking design.

From hinges and lift systems to pocket doors and motion technologies, Blum’s portfolio is engineered to improve the everyday usability of furniture, balancing refined aesthetics with durable, intelligent functionality.

Today, Blum operates in over 120 countries and is supported by a global network of manufacturing sites and subsidiaries.

Despite its scale, the company remains focused on one clear vision: to help furniture manufacturers, designers and installers create better furniture more efficiently in order to improve quality of living.

MERIVOBOX - more flexibility, more creativity

Now available in the UK, Blum’s newest addition is MERIVOBOX - a drawer box system unlike any other which delivers a compelling combination of flexibility, customisation, and ease of use.

At the heart of MERIVOBOX is a single cabinet profile that enables multiple drawer configurations with fewer parts and simpler manufacturing. It’s a modular system that gives manufacturers and designers the freedom to tailor furniture while maintaining production efficiency, without compromising on performance.

In a recent interview, Krystyna Threlfall, Marketing Manager for Blum UK said:

“With MERIVOBOX, we wanted to answer a real challenge our customers face. There’s growing pressure to differentiate in a competitive market. But doing so often adds complexity. MERIVOBOX addresses this tension, by providing design freedom with smart, simplified assembly.”

This creative potential is supported by adaptable drawer side options. A single cabinet profile can be enhanced with Blum’s gallery rails, BOXCAP metal sides, or BOXCOVER glass design elements, all of which allow visual variation while maintaining a consistent platform.

Additionally, Blum’s “one front for all” concept means a single drilling pattern and front fixing bracket can be used across all configurations: saving time, reducing errors, and increasing flexibility.

The clean, straight lines and slim profiles of MERIVOBOX also offer designers a striking, more modern aesthetic. This makes it an ideal solution for furniture makers seeking high-end visual appeal without the need for additional complexity.

Functionality never looked so good

But the appeal of MERIVOBOX goes far beyond its flexibility. As with all Blum solutions, functionality and practicality underpin the design. So, as you’d expect, these drawers offer exceptional stability, high load-bearing capacity, and a smooth, synchronised running action, ensuring they perform as beautifully as they look.

option to incorporate their own branding elements within the MERIVOBOX design - a feature that enables true differentiation in an increasingly saturated market.

The intelligent design of MERIVOBOX also makes it a central component in several of Blum’s most innovative, spacesaving furniture concepts. One such application is the SPACE TOWER - a full-height larder unit that uses MERIVOBOX to support deep, full-extension pull-outs. This allows users to access stored items from all three sides, making the most of every centimetre and enhancing visibility and convenience in the kitchen.

In tighter spaces, SPACE TWIN uses MERIVOBOX to transform narrow gaps into practical, usable storage. These slim pull-outs are ideal for keeping bottles or small utensils close at hand, making them perfect for compact kitchens.

MERIVOBOX also plays a key role in Blum’s sink drawer concept. Here, the drawer sides help form a clever U-shaped pull-out that works around sink plumbing, turning what is often dead space into valuable storage for cleaning supplies.

, MERIVOBOX supports a dual-purpose solution that integrates hidden storage with a sturdy platform step. This not only provides extra drawer space but also helps make upper storage more accessible without

By enabling such creative applications, MERIVOBOX proves itself as more than just a drawer system and more of a platform for smarter, more adaptable furniture design. This innovative product’s modular approach and smooth performance allow these applications to function seamlessly. Whether in kitchens, bathrooms or living areas, this drawer system supports better, more human-centric design with clear benefits for the end user.

With the addition of MERIVOBOX, Blum now offers its most complete and versatile drawer box range yet. This improved lineup gives furniture manufacturers a more powerful toolkit to deliver on every type of brief, whether the key requirement is for high-volume, high-precision, or highdesign.

It is the creative solution that offers maximum flexibility and simplified customisation on a single platform. Alongside this, effective TANDEMBOX is the proven, reliable performer, widely trusted throughout the industry for over 30 years. While inspirational LEGRABOX is Blum’s ideal solution to deliver distinctive aesthetics and elegant motion in furniture. Collectively, this trio of products ensures that, regardless of project scale or specification, Blum has the right solution to fit the vision every time.

TANDEMBOX: Tried, tested and trusted

Since its introduction nearly three decades ago, TANDEMBOX has become the effective go-to option for durable, everyday performance. Known for its smooth-running action and dependable construction, it is available in a range of drawer heights, and load capacities of 30kg and 65kg.

It’s a staple in many manufacturing environments thanks to its straightforward installation and proven longevity and for cabinet makers who need a high-quality, versatile solution with a long track record, TANDEMBOX remains a reliable choice.

LEGRABOX: A statement in inspired luxury

By comparison, Blum’s LEGRABOX is engineered for projects that demand distinction. With ultra-slim 12.8 mm drawer sides and a refined linear profile, this inspirational product brings sophistication to any setting, from high-spec kitchens to premium living spaces.

Available in a choice of stylish finishes like Carbon Black, Orion Grey, and Stainless Steel, LEGRABOX doesn’t just elevate furniture visually; it also delivers high-performance functionality with load capacities of up to 70 kg.

The inner sides are also completely straight, maximising usable space, while the overall look complements handleless designs and modern interiors.

All backed by the Blum Standard

Whether you choose MERIVOBOX, TANDEMBOX, or LEGRABOX, every Blum drawer is underpinned by the Blum Standard - a consistent benchmark of quality, durability, and support that sets its products apart.

At the heart of this is Blum’s Lifetime Guarantee, offering customers complete peace of mind for the life of the furniture. This long-term assurance reflects the brand’s confidence in its engineering and its commitment to lasting value.

Plus, all Blum drawer systems are fully compatible with Blum’s motion technologies. BLUMOTION for soft-close, whisper-quiet operation, the mechanical push-to-open TIPON system that’s ideal for handleless designs, and SERVODRIVE - an electric, touch-to-open solution that brings a premium experience to any space.

To support efficient and accurate installation, Blum also provides a full suite of precision-engineered jigs, assembly devices, and other tools - solutions that streamline the manufacturing and fitting process, reduce the margin for error, and ensure consistent quality.

Importantly, this commitment to support doesn’t end with the product. Blum’s UK Technical Team is always on hand to provide installation guidance, product selection advice, or technical troubleshooting.

Your more complete drawer box partner

Blum now offers furniture makers, manufacturers and designers a more cohesive portfolio of drawer solutions. So, whether you’re pushing creative boundaries, inspiring with sleek design or just looking for a trusted box system you can rely on day after day, choose Blum - more than just a drawer.

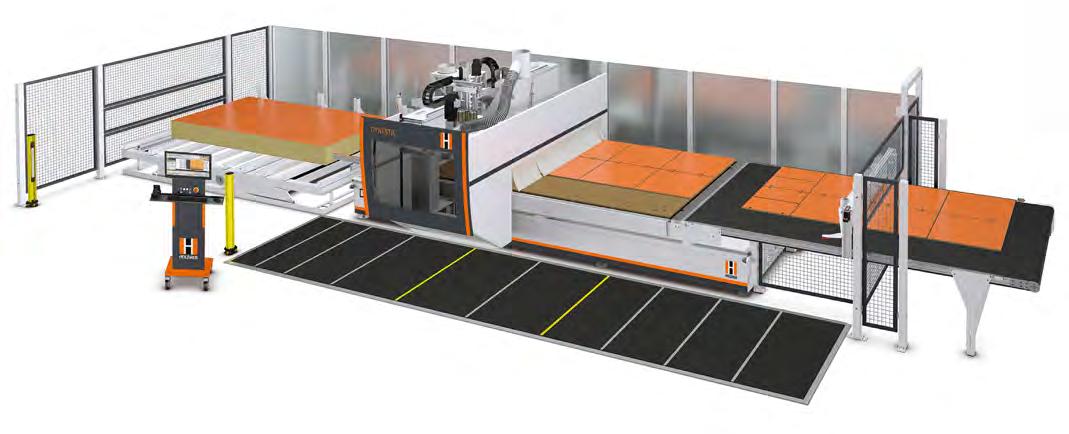

Based in East Kilbride, Laboratory Specialist Services Ltd. (LSS) is one of the UK’s leading manufacturers of specialist laboratory furniture, fume cupboards, and extract systems.

For over five decades the company has served industrial, research, pharmaceutical, and educational clients, delivering tailored solutions and exceptional service either as a turnkey provider or as part of a wider project team.

As their client base has grown and projects have increased in complexity and size, so too have their manufacturing requirements. The company has continual invested in upgrading its workshop to keep pace.

“When I started seven years ago, all we had was a panel saw and an edgebander,” explains Brian Daly, Production Manager at LSS. “Everything was done manually. Since then, we’ve added a beam saw and two CNCs, the most recent being the HOMAG DRILLTEQ V-310 – a transformational investment.”

The company’s previous CNC had become a clear operational bottleneck. With a product range that spans lab furniture and worktops, the team was restricted to producing one or the other at any given time. “We wanted to run both in parallel to effectively double our capacity,” Brian explains. “But to do that, we needed a brand new beast of a machine.” Having used HOMAG equipment throughout his career, Brian was confident in the quality and performance it could deliver. “When we were getting our beam saw a few years back, I gently insisted it be a HOMAG. They have always been exceptional.

When it came to getting to the CNC, we went through the motions of exploring what else was out there. But in my experience, all roads lead to HOMAG, and this time was no exception.”

The team visited HOMAG UK’s showroom in Castle Donington for a demonstration of the DRILLTEQ V-310, including its software capabilities. “We had a great day out. The HOMAG team was very welcoming, lunch was included, and seeing the V-310 first-hand was a big moment. It’s a thing of beauty. “One of the most appealing things for us was the size of it. We have limited floor space so we needed a CNC that could do a lot without taking up too much space. The DRILLTEQ V-310 is very compact, and yet it’s an absolute powerhouse.”

Another standout feature for Brian was HOMAG’s smartWOP software. “When I saw a demo of smartWOP it blew my mind. We’ll be getting it fully integrated later this year.”

The installation was carried out in collaboration with AWMS, HOMAG’s agent in Scotland. “We’ve worked with AWMS for years and I can’t speak highly enough of them,” says Brian. “This project was no different; all we had to do was sort out extraction and some wiring, and they handled the rest. It was probably the easiest installation I’ve had in my career.”

Training, delivered by AWMS’ Robert Herron, was equally efficient. “It was booked for four days, but Robert, a bonafide CNC wizard, was able to get us up to speed in just two. Since then he’s kept himself available to answer any questions, but for the most part we’ve been able to handle everything ourselves. He taught us well.”

Brian also credits AWMS’s Kenny Dixon, Andrew Carson, and John Small for the seamless process, from pre to post sale. “It’s no wonder HOMAG trusts them with their Scottish accounts. They do a fantastic job.”

With the V-310 now fully operational, LSS is already seeing the benefits. “We no longer have to alternate between manufacturing lab furniture and worktops, and the implications of this for our business are huge. We are well on track to double our capacity.

“What’s more, the capabilities of the machine are such that we can confidently take on bigger projects. Before, £500,000 was a big contract for us. Now, we’re quoting for £2 million jobs. That’s the kind of level we’re looking at now, and with this in mind, we expect the machine to pay for itself within the first year, easily.”

Brian concludes, “You always know what you’re getting with HOMAG: quality beyond compare and the service to back it up. As if I needed reminding, this latest investment has demonstrated the ways in which their machines can transform a business. I don’t think I’ll have any trouble persuading my colleagues at LSS to stick with HOMAG for future investments!”

For more information or a demonstration of HOMAG’s machinery and software, contact HOMAG UK.

In the ever-evolving world of furniture manufacturing, the choice of adhesive can make or break the quality, durability, and efficiency of wrapped products. For decades, EVA and PO-based hot melt adhesives have been the industry standard. Today, however, a new generation is raising the bar: polyurethane hot melt adhesives (HMPUR).

The Limits of Traditional Adhesives

EVA and PO adhesives are still widely used for wrapping profiles and panels due to their immediate physical adhesion and ease of use. However, they present notable limitations:

• Low heat resistance, making them unsuitable for hightemperature environments.

• Poor moisture resistance, a critical flaw for furniture used in kitchens and bathrooms.

• Sensitivity to solvents, which can compromise long-term durability.

These drawbacks are prompting many manufacturers to seek alternatives that offer improved performance and reliability.

The HMPUR Advantage HMPUR adhesives are emerging as the go-to solution for manufacturers aiming to elevate product quality. Here’s why:

• Superior durability: exceptional resistance to heat, humidity, and chemicals.

• Versatility: seamless bonding with a wide range of decorative materials and substrates.

• Efficiency: despite a higher upfront cost, HMPUR adhesives require only half—or even a third—of the quantity compared to traditional hot melts.

• Energy savings: lower application temperatures (130–140°C vs. 190–210°C) significantly reduce energy consumption.

In short, HMPUR adhesives deliver premium performance without compromising cost-effectiveness.

TAKA: Excellence in HMPUR Adhesives for Edgebanding, Profile Wrapping, and Panel Lamination

Based in Marostica, Italy, TAKA Srl is a global leader in the development and production of high-performance polyurethane hot melt adhesives (HMPUR). With roots in the chemical industry dating back to the 1950s and over two decades of specialization, TAKA has become a trusted partner for manufacturers in the furniture and interior design sectors.

TAKA’s product portfolio is structured into three specialized families:

• Edgebanding Adhesives: ideal for bonding PVC, PP, ABS, melamine, wood veneers, and aluminum strips.

• Profile Wrapping Adhesives: designed for complex geometries such as skirting boards, frames, and moldings.

• Panel Lamination Adhesives: optimized for flat lamination of furniture panels, doors, wall elements, and flooring.

TAKA’s fully integrated production process ensures consistent quality and innovation. A major milestone was the

launch of the LESS Line in 2023, following the publication of the European REACH directive on the handling of diisocyanates

This directive requires all users of products with a concentration of monomeric diisocyanates above 0.1% to undergo mandatory safety training every five years.

TAKA’s LESS adhesives contain minimal levels of free MDI, the reactive component typically required for polyurethane cross-linking. Thanks to this ultra-low concentration:

• No hazard labeling is required under the Ordinance on Hazardous Substances.

• No mandatory training is needed, ensuring easier compliance and safer working conditions.

Despite their reduced isocyanate content, LESS adhesives guarantee the same high-performance bonding as traditional HMPUR products, making them the ideal choice for manufacturers seeking both safety and efficiency.

The components you need, now just a click away

• Order direct – exactly when you need to

• Smaller volumes – to suit your operation

• Quick delivery – from our UK warehouse

Our online shop gives furniture manufacturers easy, direct access to our most in-demand components.

Scan the QR code to start shopping –and discover a faster way to source hardware.

Renner Coatings UK, part of the globally respected Renner Italia S.p.A., is redefining standards in the wood coatings industry. Backed by over 20 years of expertise from one of Europeʼs leading manufacturers, Renner Coatings UK delivers premium finishes that combine Italian innovation with the specific needs of the UK market. From cutting-edge technology to a tradition of craftsmanship, every product is designed to help wood reach its full potential.

Whether itʼs for fine interior furniture, bespoke architectural joinery, or demanding exterior projects, Rennerʼs coatings stand out for their durability and reliability. Formulated to withstand the unpredictable British climate, they offer superior resistance to moisture, UV damage, and everyday wear. The result is wood that stays beautiful and protected year after year, making Renner the trusted choice for both residential and commercial applications.

Sustainability is at the core of Rennerʼs vision. With growing demand for eco-friendly solutions, Renner Coatings UK champions waterbased, low-VOC finishes that deliver exceptional performance while reducing environmental impact. As part of Renner Italiaʼs long-standing commitment to green innovation, these advanced coatings empower businesses to meet sustainability goals without ever compromising on quality or style.

What truly sets Renner Coatings UK apart is its dedication to customers. Beyond world-class products, the team provides expert technical advice, tailored solutions, and reliable support at every stage of a project. This commitment ensures customers can achieve not only the but also complete confidence in their choice. With Renner, wood surfaces are more than just protected—they are enhanced, celebrated, and built to last.

Despite the slight reductions seen in more recent times, energy pricing is considerably inflated when compared to levels prior to the pandemic and the invasion of Ukraine and, unsurprisingly, clearly remains high on the agenda for all UK businesses; often palpably so in the woodworking sector.

Operating high-speed drilling, cutting, planing and sanding machinery, as well as running equally high-powered fans to provide effective and continuous dust extraction, furniture and joinery manufacturers are often faced with eyewateringly high electricity bills.

Jake Oldfield, however, a founding director of Extractly Ltd – one of the UK’s leading dust and fume extraction installers, and Master UK Distributor and Installer of the Ecogate® energy-saving system – maintains that Ecogate’s ‘extractionon-demand’ technology has helped many companies in our industry survive this unwelcome assault on overheads by significantly reducing the cost of running the powerful fans that remove harmful dust and woodwaste from our factories. “Many companies that have invested in Ecogate® technology have recouped their capital outlay in under 2 years and, with energy bills typically slashed by at least 50%, those savings just continue to accumulate month in, month out; providing options for further future investment in new technology and machinery.”

Reducing energy usage by such a significant margin can be a great boost for a company’s efforts towards net zero emissions targets but, with Extractly’s finance partner, Shire Leasing, woodworking businesses can now benefit from Ecogate® energy-saving technology without having to make the full upfront capital expenditure. “The cost can now be spread over a period of up to 5 years,” Oldfield explains, “with fixed monthly payments beginning only after the system has been installed, commissioned, and up and running.”

Investing in Ecogate® energy-saving extraction can support a company’s endeavours to achieve net zero targets and, using Green Asset Finance, with fixed monthly payments, could help you go green more affordably.

Whether it’s a new installation, or an existing extraction system, an Ecogate® automatic damper is simply connected into the ductwork serving each individual machine.

To get a customised estimate of the potential savings Ecogate® technology could deliver for your business, just scan the QR code opposite to make use of Ecogate’s new ‘Savings Calculator’.

Ecogate® technology has been making headlines in the UK for the past 15 years, but has been proven worldwide to significantly reduce energy usage for process industries.

Extractly claim that cost savings in excess of 50% are “easily achievable” and, for the woodworking industry, reported data for dust and fume extraction shows that savings are averaging around 68%. With Ecogate® installed, extraction fans no longer need to run at full speed, all day, every day.

Since woodworking machines are constantly stopping and starting throughout the working day for loading and unloading operations, and program and tool changes, for example, as well as at operator break times, a typical extraction installation is only actually required to operate at around 80% of its nominal maximum capacity. So, when extraction demand and fan speed is controlled with Ecogate®, that moderate 20% reduction in usage results in a huge 50% reduction in power consumption – that’s half price electricity!

Ecogate® equipment can be fitted into any new or existing extraction system, and the installation process can be undertaken with only minimal interruption to production schedules. Ecogate’s automatic dampers are connected into the ductwork serving each individual machine, and sensors attached to each machine signal the Ecogate® “greenBOX” controller to open and close the dampers as machines come

on or off-line. Simultaneously, the greenBOX instructs the PowerMASTER variable speed drive unit to adjust the speed of the extraction fan to exactly match the current demand for extraction.

An Ecogate® system can constantly monitor machine usage and recorded data then accessed from any location via any internet-connected device. The system can be configured to run cleaning programs to suit production schedules, and can even start up and shut down automatically – and, if required, send an email to confirm the operation. The technology also ensures that minimum transport speeds are maintained through the system, to avoid any build of waste in the ductwork and, with the reduced fan speeds, noise is also reduced significantly; creating a workplace that is generally a much quieter, cleaner and more comfortable environment.

With Extractly and Shire Leasing’s Green Asset Finance* plans, it seems there’s never been a better time to invest in this innovative technology… save energy, reduce costs, protect your cashflow, achieve sustainability goals, and now, through Shire Leasing’s partnership with Play It Green, a tree will be planted for every new installation they fund… simple, immediate action to make a difference to our environment.

* Actual energy savings will vary depending on your specific circumstances and cannot be guaranteed. Savings examples are for illustrative purposes only and do not form part of your finance agreement. Finance available for non-regulated business use customers only. Subject to status, eligibility, and credit criteria. Finance repayments are required in full, regardless of any savings achieved. Please seek independent advice if you are unsure about your options.

Ecogate’s PowerMASTER variable speed drive unit adjusts fan speed to exactly match the current demand for extraction and displays real-time energy savings.

AXYZ WARDJet has once again demonstrated its leadership in CNC technology and automation with a successful twoday UK CNC Manufacturing Expo held at its headquarters in Telford in July. With over 200 sign-ups and a strong physical turnout, the event proved to be a powerful platform for unveiling cutting-edge innovations, showcasing live demonstrations and deepening relationships with customers, prospects and industry partners.

At the heart of this year’s expo was a showcase of intelligent, production-ready technologies that address the modern demands of manufacturing. Attendees had the opportunity to experience first-hand the latest in AXYZ and WARDJet’s evolving portfolio of CNC routers, waterjet systems and automation enhancements.

Live demonstrations ran throughout both days, with a focus on reducing manual labour, increasing production speeds and improving safety. The energy in the demo space was palpable as engineers, fabricators and shop owners saw innovations brought to life in real time.

One of the show’s standout attractions was the debut of AXYZ WARDJet’s new Automatic Material Transfer (AMT) system—a game-changing robotic solution for lifting, loading and aligning sheet materials with ease. What sets AMT apart is its fully automated operation, decoupled from the CNC machine itself. Attendees saw how dual AMT units can work in tandem, managing sheets of up to 6 metres long with precision.

Supporting features like vacuum flexibility, tandem operation and guided alignment showed how AMT dramatically improves workflow by eliminating traditional bottlenecks in material handling. For many visitors, this innovation sparked serious conversations about shop floor automation and ROI.

Alongside material handling tech, the spotlight was also firmly on new CNC cutting capabilities. The Swivel HP Oscillating Knife impressed with its 12,000 CPM speed and ability to cut dynamic shapes with accuracy across a variety of materials.

Meanwhile, the hands-free Auto Sheet Loader and Unloader system showed how production can be streamlined further with minimal human intervention. Together, these systems presented a unified vision of faster throughput with safer, smarter processes.

With automation comes the need for robust safety solutions and AXYZ WARDJet delivered. New laser scanners and AI-powered camera systems were showcased, offering real-time monitoring, adaptive safety zones and intelligent threat detection. These safety innovations help operators manage multi-machine environments more efficiently, while remaining compliant with evolving safety standards.

The ability to demonstrate all these systems operating together within a live, production-style setup gave visitors confidence in their readiness for real-world application.

A major highlight of the expo was the personal, hands-on experience. Attendees not only watched but also engaged directly with AXYZ and WARDJet’s CNC systems from routers and waterjets to automation tools. The option to bring their own materials and run live tests was particularly well received. For manufacturers working with wood, plastic, metal and composites, the results were eye-opening.

The show also opened the door to private post-event demonstrations. For those unable to attend or interested in further exploration, AXYZ WARDJet extended invitations to return to the Telford HQ in the following weeks. Visitors can book tailored demos with their own production files and materials to explore how CNC automation can fit their unique challenges.

In addition to automation and software, the UK Expo marked the official introduction of the next-generation Woodworker CNC router. Designed for cabinetry, furniture making and high-volume wood processing, the machine features:

• Hands-free loading/unloading

• 9-position drill bank

• Rotary and rack tool changers

• Roller hold down systems

• Auto label printing

This combination enables unmatched throughput and consistency, especially in multi-shift environments. Several woodworking company owners on site expressed immediate interest in upgrading their production lines based on what they saw.

Throughout the event, AXYZ and WARDJet made clear their commitment to custom-engineered solutions for sectors including sign making, metalworking, aerospace and composite machining. Live demonstrations and technical consultations helped customers identify how technologies like waterjet cold-cutting or hybrid router-knife platforms could streamline their operations.

From bespoke applications in medical devices and aerospace parts to custom signage and architectural cladding, attendees left with actionable ideas on how to improve precision, reduce labour costs and accelerate turnaround.

With over 200 registrations and a high level of on-site engagement, the 2025 UK CNC Manufacturing Expo was one of AXYZ WARDJet’s most impactful customer events to date. The combination of live demos, real-time material testing and meaningful face-to-face interactions created lasting value for all involved.

As the machines remain on-site at the Telford HQ for a limited post-show window, AXYZ WARDJet encourages those who couldn’t attend to take advantage of this rare opportunity to experience the full line-up in action.

AXYZ WARDJet continues to push the boundaries of CNC manufacturing by integrating innovation with hands-on support. The success of the UK CNC Manufacturing Expo underlines growing demand for smarter, safer and more scalable production tools. With new technologies like AMT, intelligent safety systems and advanced CNC routing solutions, the future of manufacturing is here and AXYZ WARDJet is leading the way.

Mirka (UK) Ltd is launching a new Profile Foam Interface with Mirlon Total® VF 360, designed to provide a versatile and effective solution for renewing the appearance of industrially coated doors, windows, and furniture quickly and safely.

The ergonomic solution measuring 81x133mm, is designed for use with sanding pads or the Mirka DEOS® II 353 for optimal performance, reducing fatigue and improving productivity. The foam pad adapts effortlessly to profiles, grooves, and curved surfaces, ensuring even pressure and consistent results. Its flexibility makes it ideal for sanding intricate and hard-to-reach areas.

The Mirlon Total® VF 360 offers excellent surface conditioning with a fine abrasive texture, making it suitable for smoothing and preparing surfaces, delivering a highquality finish.

Used together, these pads provide a complete solution for versatile and efficient sanding across a wide range of applications.

The Profile Foam Interface is perfect for profile sanding, achieving precision and speed unattainable with traditional hand sanding. Profiling tasks, which were previously timeconsuming, are now faster and more streamlined with the DEOS II 353 machine.

Neil Newbrook, business sector manager for Wood, Mirka (UK) Ltd, says, “For small-scale tasks like sanding a single door, traditional hand sanding might be sufficient. However, for larger-scale projects, such as profiling 100 doors, using the DEOS II 353 machine paired with the Profile Foam Interface becomes efficient and highly cost-effective.”

In an ever-evolving world of interior design, where texture, finish, and form must come together seamlessly, Decorative Panels once again raises the bar with the introduction of Stripes - a bold, yet refined surface collection developed in collaboration with the renowned brand Surteco. Available now through Decorative Panels Lamination, the Stripes collection brings a new dimension to the dp-specialist range, merging contemporary aesthetic sensibility with cuttingedge surface technology.

At the heart of the Stripes collection is a distinctive fluted texture, crafted with precision and enhanced by a supermatt finish. This combination offers a sophisticated, architectural quality that’s equally at home in residential, commercial, and hospitality interiors. Stripes doesn’t merely follow trends-it redefines them, offering designers and manufacturers an opportunity to inject depth and structure into their projects while maintaining a minimalist visual language.

Engineered for modern living

that’s suitable for a wide range of interior applicationsfrom furniture and cabinetry to wall panelling and retail fixtures.

Each panel is available laminated to either MDF or dp-lite substrate in a convenient 1220mm width. Designers can choose between single-sided lamination with a matching reverse or double-sided options, providing the flexibility needed for both aesthetic and structural requirements.

A colour story in four tones

Understanding that modern design is as much about tone as it is texture, Decorative Panels has introduced the Stripes collection in four carefully selected, trend-forward colours: Reed Green - A muted yet natural hue, ideal for creating calming, biophilic interiors

Soft Black - A bold, sophisticated option that exudes elegance and drama

Cashmere - A warm, neutral tone that brings softness and versatility

Porcelain White - Crisp and clean, perfect for light, airy spaces

These colours have been chosen not only for their standalone appeal but also for how effectively they integrate into broader design palettes.

One of the standout features of the Stripes collection is its compatibility with essential design components. Matching Surteco edgebanding is available from UK stock with next-day delivery, simplifying the procurement process and ensuring visual continuity. Furthermore, board matches are available from both Egger and Kronospan, allowing for seamless coordination with existing materials commonly used across the industry.

This attention to detail supports a holistic design approach, giving fabricators and designers the tools they need to execute cohesive and high-impact interiors without compromise.

Whether you’re designing sleek kitchen cabinetry, highend retail environments, or contemporary office fit-outs, the Stripes collection brings a compelling mix of form and function. With its tactile finish, curated colours, and thoughtful integration options, Stripes is more than a decorative surface - it’s a design solution.

The woodworking sector continues to evolve, but one recurring challenge remains: how best to store and handle large packs of boards efficiently, safely, and cost-effectively. From sawmills and panel merchants to busy joinery workshops, companies face the twin pressure of maximizing space and protecting valuable stock. Increasingly, the answer lies in smart storage solutions—and OHRA racking systems have become a benchmark in this field.

Traditional floor stacking methods often lead to wasted space and time-consuming material handling. When dealing with oversized or weighty board packs, these inefficiencies can result in operational bottlenecks or even safety concerns. OHRA’s engineered cantilever and heavy-duty pallet racking address these pain points head-on, bringing order, clarity, and accessibility to timber and panel storage.

What distinguishes OHRA racking is its robust design. Systems are constructed using hot-rolled steel profiles, a feature that allows them to confidently support the concentrated weight of large-format materials without risk of distortion. This resilience is paired with flexibility: adjustable arms and shelving can accommodate varying board dimensions and load sizes, a crucial advantage given the diverse requirements within panel and joinery supply chains.

Safety is equally critical. Secure racking reduces manual handling and enables operators to quickly locate and extract specific packs with forklifts or automated systems. Minimizing the movement of heavy stacks by hand not only increases worker safety but also protects sensitive surfaces from damage—an essential consideration when dealing with premium veneers or custom-finished boards.

A further advantage comes into play with chipboard racking. Designed specifically for chipboard packs, these systems offer tailored shelves or supports that prevent bowing and reduce surface wear, which is vital for particle board that can be especially sensitive to edge and face damage. Chipboard racking also improves stock rotation and accessibility: individual packs can be separated and accessed quickly, cutting down on retrieval times and minimizing risk when handling heavier materials.

Optimizing warehouse space is another compelling benefit. As property and logistics costs continue to climb, maximizing cubic storage capacity has become non-negotiable. OHRA’s vertical solutions enable businesses to better utilize warehouse height, providing greater density for stock holding without the need to expand their existing footprint.

For today’s woodworking and joinery industries, efficiency is as much about future readiness as it is present performance. With modular options and customized configurations, OHRA systems are designed with adaptability in mind. Operators can scale or modify their setup as product lines grow or inventory needs shift.

In an industry where both the material and the margins matter, the right racking system can be transformative. With an eye on durability, flexibility, and safety, OHRA offers solutions that let companies handle large board packs—including chipboard—with confidence, efficiency, and control—a timely advantage in a sector where space and time are always at a premium.

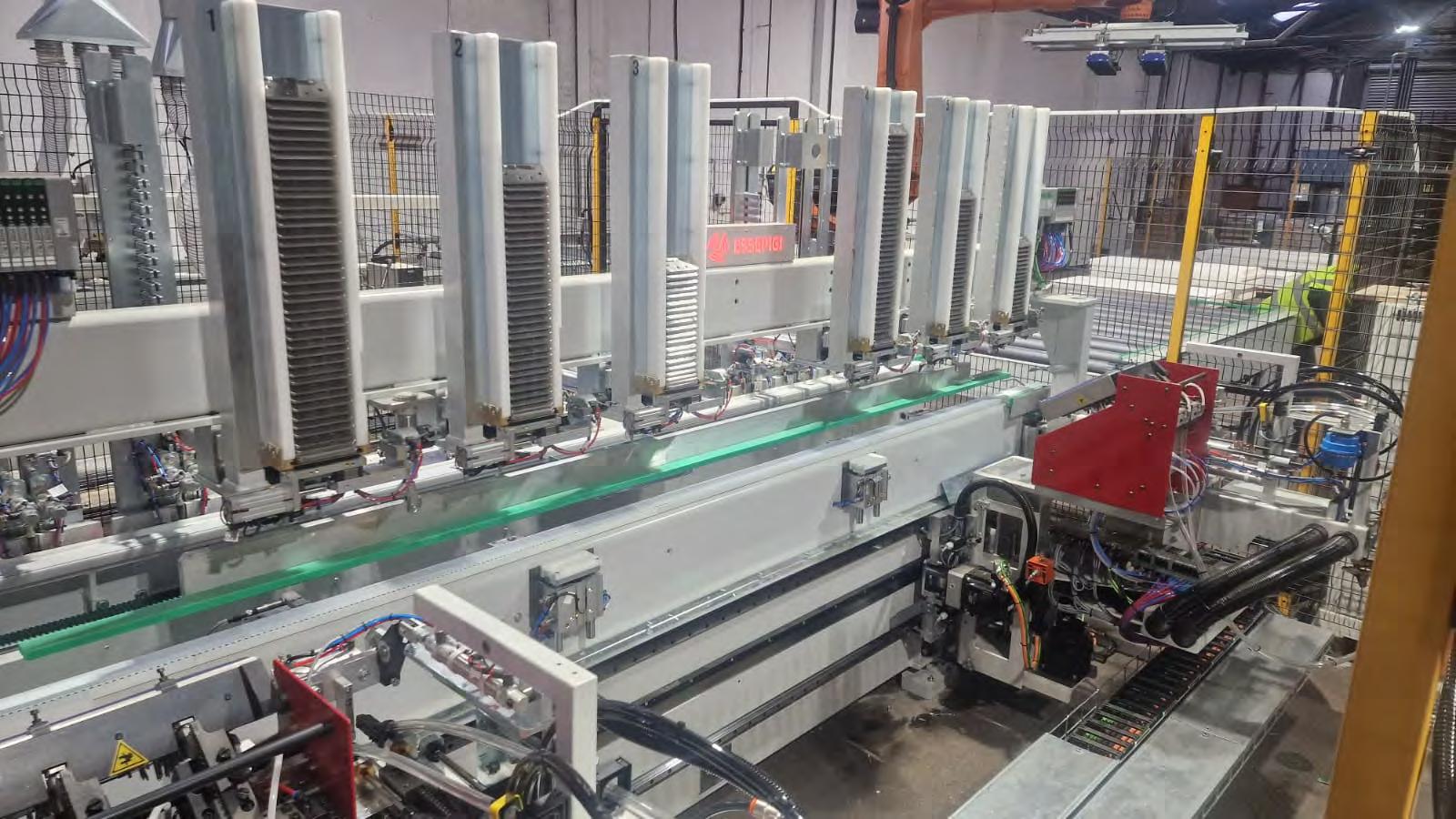

Donaldson Door Systems, part of the Donaldson Group, is one of the UK’s leading manufacturers of high-quality door sets, supplying both internal and external doors, staircases, and bespoke joinery products. With a commitment to delivering value to major housebuilders and local authorities, the business has continued to invest in automation to stay ahead in a competitive construction landscape.

Faced with rising demand, capacity constraints, and a desire to improve manual handling processes, Donaldson Door Systems partnered with JJ Smith to transform its production capabilities.

Prior to automation, Donaldson Door Systems was operating its internal door production across three shifts, running 24 hours a day to meet demand. Their CNC machines were maxed out, and scaling further with existing equipment was no longer viable.

There was also a heavy reliance on manual handling during the production process. The company needed a smarter, safer way to scale up production without compromising quality or putting strain on its workforce.

“We were operating in three shifts and were maxed out across the factory. We needed to introduce more capacity into the business, and that meant looking at new door and frame lines,” said Billy Cameron, Director at Donaldson Door Systems.

Donaldson Door Systems engaged JJ Smith, a specialist in woodworking machinery and automation solutions. The brief was clear: dramatically increase door production speed, reduce manual handling, and accommodate custom ironmongery specifications for various clients.

The outcome was a custom-built Essepigi door and frame line, integrated with industrial robotics for loading and assembly. The new system now enables doors to be processed from raw to fully assembled – with ironmongery installed – in just one minute. What previously took 12 minutes with multiple manual steps is now streamlined and automated.

“We set JJ Smith the challenge of helping us produce a door a minute while taking out a lot of the offline manual handling,” added Billy. “Now, the product goes on via a robot, comes off the other end fully assembled, and goes straight to final assembly. It’s been a game-changer.”

The impact has been transformative:

• 3x Increase in Productivity: What took three shifts can now be done in one.

• Improved Safety: Manual handling is drastically reduced, enhancing workplace safety.

• Greater Flexibility: Freed-up capacity allows for additional shift scheduling or diversification.

• Consistent Quality: Automated ironmongery insertion meets stringent client specs reliably.

“The solution we provided was designed not only to boost throughput but also to address key operational pain points like safety and labour intensity,” said Paul Parker, Sales Director at JJ Smith. “Donaldson Door Systems had a clear vision, and we were proud to help them turn that into a high-performing, automated reality.”

“We gave JJ Smith a very specific set of criteria – from increasing capacity to dealing with complex ironmongery setups – and every challenge was met. It’s been a really positive experience,” concluded Billy Cameron.

For Donaldson Door Systems, this investment is about more than technology – it’s about future-proofing the business By automating a once labour-intensive process, the company can now focus on scaling with agility while delivering quality at volume.

0151

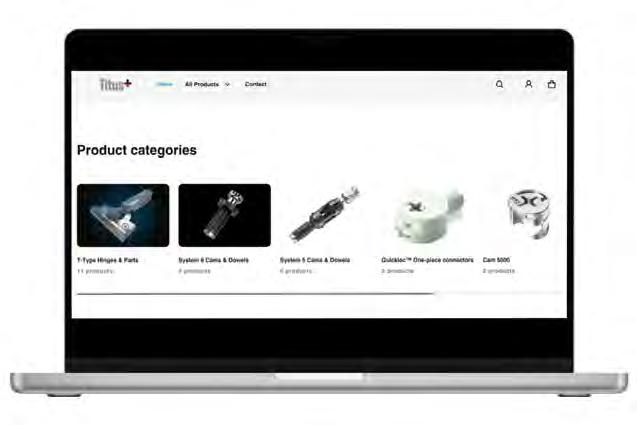

Cabinet hardware expert Titus has announced the launch of its new online shop, providing small furniture manufacturers with quick and convenient access to the company’s most popular high-quality hardware solutions

The shop features no minimum order requirements and rapid dispatch - typically within two working daysaddressing key challenges faced by smaller operations.

“Small manufacturers have always valued our innovative products but often struggle with traditional bulk ordering processes,” explains Phil Beddoe, UK Managing Director of Titus. “Our new online shop eliminates these barriers by offering convenient browsing, zero minimum order requirements, and fast delivery times. We’ve carefully selected our most versatile and popular products to ensure smaller manufacturers can efficiently access the hardware solutions they need to compete in today’s market.”

Streamlined operations for enhanced productivity

The online shop addresses the unique challenges faced by smaller manufacturers who often require flexibility without the burden of large minimum orders. Traditional wholesale purchasing can tie up significant capital in slow-moving inventory, while smaller batch requirements often get overlooked by larger suppliers. Titus’ new platform bridges this gap by providing immediate access to professional hardware solutions with the convenience of e-commerce ordering.

The shop’s carefully curated selection features approximately 60 products from Titus’ most sought-after ranges, ensuring that smaller manufacturers can access proven solutions without navigating an overwhelming product catalogue. This focused approach supports decisionmaking while guaranteeing the availability of essential components.

The innovative T-type range is central to the online offering, featuring unique 3Way snap-on mounting for exceptionally easy installation, even on large doors with multiple hinges.

Available products include the popular T-type 100° hinges for standard applications and T-type 170° hinges for wideopening requirements, along with their matching mounting plates.

All T-type hinges deliver Titus’ renowned Confident Close action - a consumer-preferred soft-close mechanism characterised by late-start deceleration and quiet landing. This consistent performance is achieved through Titus’ proprietary damping technology, positioned transversally in the hinge cup for intuitive adjustment and reliable operation. The high tolerance design accommodates drilling variations and accidental misalignments, ensuring reliable door operation even in challenging installation conditions.

The 3Way mounting system significantly reduces assembly time, particularly beneficial for smaller manufacturers where labour efficiency directly impacts profitability. The tool-free installation process minimises training requirements and reduces the likelihood of assembly errors.

The Tekform Slimline drawer system offers complete drawer solutions along with individual components, including brackets, drawer bars, and drawer fronts. This modular approach allows manufacturers to customise their drawer specifications while maintaining the system’s sleek 14mm side panels that maximise interior drawer space without compromising structural integrity.

The system’s integrated soft-closing mechanism ensures smooth, controlled drawer operation while the precisionengineered runners deliver reliable performance over extended use cycles. The straightforward installation process and adjustment capabilities enable precise alignment, making it suitable for manufacturers with varying levels of assembly experience. The drawer system’s compatibility with various cabinet widths and depths provides flexibility for custom applications without requiring specialised components.

The modular design means smaller manufacturers can stock individual components as needed, reducing inventory investment while maintaining the ability to fulfil varied customer requirements. This flexibility is particularly valuable for businesses producing custom cabinetry where standard drawer sizes may not always suit specific project needs.

Cabinet connectivity is comprehensively covered through multiple connector systems, each engineered for specific applications and performance requirements. System 6.2 provides next-generation square-shaped connectors with enhanced stability and contemporary aesthetics, ideal for modern furniture designs where visual appeal is paramount.

System 5 offers a comprehensive range of cam and dowel fittings featuring Klix and Quickfit technologies for all

drilling tolerances common in smaller-scale production.

The innovative Quickloc™ One-piece connectors from System 4 deliver streamlined installation by combining multiple connection functions in a single component. This reduces inventory requirements while simplifying assembly procedures, particularly valuable for manufacturers producing varied product lines.

The reliable Cam 5000 system ensures robust cabinet construction across all applications, featuring high loadbearing capacity and consistent clamping force for durable furniture assembly.

Essential cabinet fittings complete the comprehensive offering, including push latches for handleless applications, joining plates for secure panel connections, and versatile shelf support systems. These components provide smaller manufacturers with all the hardware essentials for professional cabinet construction without requiring separate supplier relationships.

Push latches enable clean, modern designs while ensuring reliable operation, while joining plates offer invisible connection solutions for seamless cabinet assembly. The shelf support systems accommodate adjustable and fixed shelving requirements across various load capacities.

Seamless ordering experience

The shop accepts all major credit and debit cards, with straightforward online ordering and transparent pricing. Real-time stock availability prevents ordering delays, while the rapid dispatch commitment ensures minimal disruption to production schedules. The carefully curated product selection, combined with detailed technical specifications and installation guidance, makes the shop an ideal resource for smaller manufacturers looking to incorporate premium hardware solutions into their furniture designs.

We sat down with Barrie Freeman, Managing Director of Elmbridge UK, a third generation business and leading player in the paint & finishings industry, to find out more about the company and their plans for the future.

Business overview:

• Founded: 1976

• Employees: 45

• Turnover 2011 (Gloucester): £2.6m

• Turnover 2025: £16–17m

• Sites: Gloucester, UK HQ & Cumbernauld, Scottish distribution centre

Q: What is the family connection with Elmbridge UK?

A: Elmbridge was started back in July 1976 by my Grandfather. In the 1980s his two sons – my dad and my uncle – joined him. Each of them went on to have three boys, so there was always a sense that the business would carry on through the family. I came on board in 2001, and I’m now the Managing Director - my brothers followed me, Rory as Operations Director, and Angus, Sales Director.

KEEPING IT IN THE FAMILY & RISING TO THE CHALLENGE

Q: How did the company move into the world of wood?

A: When I joined, Elmbridge was only supplying paints to the metalworking industry – my Grandfather tasked me with looking at the paint side of the business. My first customer was a window manufacturer in Cheltenham who I was talking to about spraying equipment – I quickly realised that we were missing a huge opportunity by not selling them paint as well as equipment. This led me to explore different suppliers whereupon I came across Sayerlack, who remain our primary partner today. It was a turning point: selling paint and spraying equipment gave us the opportunity to break into the wood industry and become the end to end

Sadly, my father passed away in 2010. During his illness it was agreed that the business should be divided between the two brothers and their sons. We structured it geographically and by product – my uncle took on the Hereford site which focused on welding, while we took on the Gloucester site concentrating on paint and finishing. At that stage, the business was turning over £2.6 million. Fast forward to today and we’re looking at £16–17 million this year. That growth comes from staying focused, investing in our people, and seizing opportunities when they present themselves.

Q: How has the product mix evolved?

A: We’ve deliberately focused on the finishing side of the business. Today it’s roughly a 50:50 split between metal and wood, though our presence within the wood industry is expanding faster. In 2023 we acquired Indu-Coat in Scotland, which gave us additional expertise and a strong distribution base in Cumbernauld. That gave us real momentum – it wasn’t just about territory; it was about strengthening the depth of knowledge in our team.

Q: Growth is clearly part of your story. Where do you go from here?

A: We’re ambitious. We want continual growth, both through acquisitions and by expanding organically. We see opportunity in the wood industry. But growth also has to be responsible. We’re putting a lot of energy into developing sustainable products – water-based paints, bio-based coatings where natural raw materials are used instead of chemicals and making sure our suppliers are energy efficient and ethical. For us, sustainability isn’t just a buzzword; it’s the future of finishing.

Q: Let’s talk about the team.

A: We are a team of 45 with a leadership structure designed to encourage development, supported by extensive industry expertise across our people. Customer service is key. We’ve got a dedicated customer service team, and some progress into other roles in the business. That progression is important – it keeps people engaged and builds knowledge across the company. We’re also just trialling apprenticeships, starting in finance but could extend this into manufacturing roles. For us, it’s not just about filling jobs today, but about creating career paths for the next generation.

Q: Elmbridge is known for being hands-on with customers. Tell us about that.

A: It’s about trust. Our sales team doesn’t just sell products – they’ll put on overalls, go into the spray shop, and work alongside operators. The sprayers are at the coal face; they’re the ones who use our products and if they believe in us, word spreads. We run training sessions both onsite and at Elmbridge. Our test centre is unique – we’ve invited sceptical customers to bring their work in, prepare it, paint it, cure it, and dry it. They then see that what took them a week could be done in two days with our system. That kind of experience builds lasting partnerships.

Why Customers Choose Elmbridge

• Single-source supplier: paint + equipment + consumables + technical support

• In-house test centre to trial products and processes

• Full end-to-end service: supply, set-up, training & aftercare

• Experienced and knowledgeable staff – industry knowledge runs deep

Q: What’s next in terms of innovation?

A: We’re developing our own house brand, and we’re looking at expanding our team particularly for capital projects. That means having dedicated business development and project managers to keep the sales pipeline flowing steadily. It’s about supporting customers from start to finish – supplying equipment, paint, technical advice, and aftercare. That endto-end service is what sets us apart.

Q: Finally, what makes Elmbridge different?

A: We’re a single source for finishing solutions, backed up with technical support you can rely on. Quick delivery, strong customer service, and a willingness to get our hands dirty –that’s the formula. We have a strong team - they’re part of the journey.

Our message is simple: come and visit us, see what we can offer, and let the products and service speak for themselves.

Tel:

www.elmbridgeuk.com

Professional Woodworking Expo has announced the return of the Live Demo Zone at the 2026 edition, taking place from 17-19 May 2026 at NEC Birmingham.

Following the overwhelming success of previous demonstrations, this interactive feature will once again offer attendees hands-on access to the latest woodworking technology, techniques, and innovations.

The Live Demo Zone brings woodworking machinery and tools to life through real-time demonstrations, guided by experts from some of the industry’s most trusted brands. This creates a unique opportunity for professionals and advanced hobbyists to deepen their product knowledge, learn new skills, and witness cutting-edge solutions in action.

David Todd, Event Director of Professional Woodworking Expo, said: “The Live Demo Zone is one of the most dynamic features of our event. With strong support from leading names like Extractly, Festool, Advanced Machinery Services (AMS), and The Joinery Network, we’re offering visitors an invaluable chance to see precision and safety technologies firsthand.

“This collaboration reflects our commitment to providing practical, inspiring content that helps woodworking professionals elevate their craft and grow their businesses.”

Featured Brands and Contributions:

• Extractly will demonstrate their latest dust extraction systems, focusing on improving workshop air quality and safety without compromising performance.

• Festool returns with expert-led demos featuring their renowned power tools designed for accuracy and ergonomic ease.

• Advanced Machinery Services (AMS) will showcase their premium woodworking machinery, combining technological innovation with proven reliability.

• The Joinery Network joins the Demo Zone as a returning partner, offering expert guidance on quality timber joinery production, factory setup, and growth strategies tailored to timber window and door manufacturers. Their involvement will enrich the zone with specialist advice on sustainable practices and certified standards compliance.

The Live Demo Zone will run throughout all three days of the event, featuring scheduled sessions that allow visitors to engage directly with product experts, ask technical questions, and experience the latest workflows.

Ben Mitchell, Marketing Manager at Leitz Tooling, added: “Leitz Tooling is really excited to be coming back to PWE this year. The last show gave us an incredible opportunity to connect with woodworkers from across the UK. We are especially excited for the demonstration zone, where we look forward to once again demonstrating our tooling for The Joinery Networks LIGNUM system for timber windows and doors.”

Professional Woodworking Expo remains the UK’s only dedicated tradeshow for professional woodworking and joinery manufacturers, attracting over 6,000 industry professionals eager to discover innovations, network, and source new solutions.

Exhibitors and visitors alike are encouraged to plan their visit to include the Live Demo Zone, where hands-on learning meets cutting-edge technology.

For companies interested in exhibiting or joining the Live Demo Zone at Professional Woodworking Expo 2026, opportunities are still available. To find out more, please visit the Professional Woodworking Expo website or contact the event team.

Compared to PO and EVA adhesives, the hot melt polyurethane adhesives produced by TAKA ensure high resistance to heat, water, chemicals, and adapt well to complex geometries. The result is superior bonding quality, long-lasting durability, and an excellent aesthetic finish-without additional costs for energy or adhesive quantity. Discover the full portfolio for edgebanding, flat lamination for panels and profiles wrapping. All the adhesives are available in low emission version with a concentration of monomeric diisocyanates below 0.1%

Our new modular drawer box solution offers true design flexibility.

The latest addition to Blum’s drawer box range, MERIVOBOX adds even more flexibility. Offering a more creative solution, it enables multiple design options on a single cabinet profile. Its interchangeable sides make customisation easy without increasing complexity, so you can create the right drawer for you.

Plus, just like Blum’s effective TANDEMBOX and inspirational LEGRABOX drawers, creative MERIVOBOX offers fast, accurate assembly and is backed by a lifetime guarantee.

Blum drawer box solutions. MORE THAN A DRAWER

Like to know MORE?

Discover our drawer box range

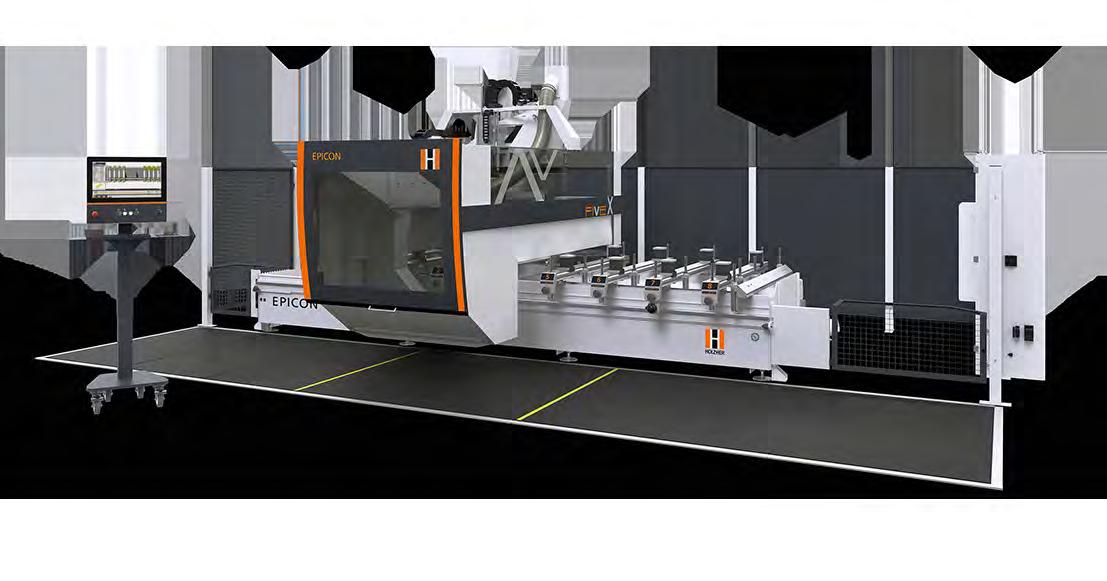

Holz-Her DYNESTIC-7535

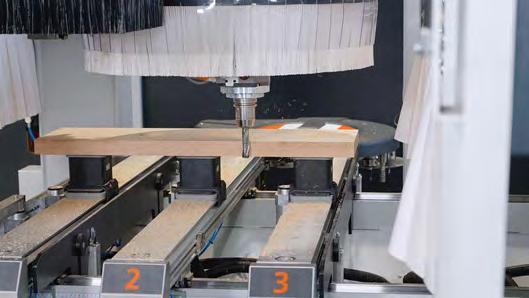

The EPICON range of console routers is typically the perfect solution for solid wood component production. As a genuine 5 axis machine with robust construction, it offers superb levels of stability and vibration absorption which are essential to achieve a perfect surface finish. Lightweight, low cost alternatives do not have these characteristics, resulting in poor finishes and the need for additional offline work, which is not the result you want from a CNC router. The depth of Weinig experience is evident in the EPICON range which is appreciated and valued by discerning buyers and understood by first time adopters.

CNC routers have been around for many years, and a large number of companies are now reliant on them for the precision, accuracy and repeatability they bring to finished products. The ability to produce ‘just one’ of something is entirely feasible and an economic proposition given the right software, the necessary tools and the right machine. This essential trio is what the Weinig Group offer – a complete consultative package designed to deliver the perfect solution for your individual application, whether in solid wood, panel products or even composite man-made materials.

The massive gantry design is built to withstand high cutting forces and speeds. Running on hardened and ground prismatic guides with helical racks on both sides of the gantry. It can move at best in class speeds in the X-axis while still delivering flawless finishes. A wide variety of flexible clamping options further extend the machines versatility and are an important discussion point.

Too often CNC’s are sold without this ‘full package’, so Weinig take care to ensure you know how to hold your product during processing – vacuum, horizontal clamps, vertical clamps and special clamps or even jig construction is all covered by Weinig.

The core of the EPICON design is the 18.5 kW 5 axis PRO TORQUE milling head. This powerful and compact machining head can operate up to 24,000 rpm and is extremely smooth in operation. Featuring ceramic bearings, liquid cooling and PRO TORQUE technology, this innovative system delivers high torque through software-controlled mechanical locking in the A and C axes - making it one of the most rigid and robust solutions available.

Of course, having the right machine is only one part of the equation. Equally important is the software, which is just as critical for a happy long term relationship with this machine and this is where Holz-Her truly excels with its Campus suite.