5 minute read

Beating the blast

Berthold Bussieweke, Thorwesten Vent, walks through constructional explosion protection in grinding and storage plants processing coal, alternative fuels, and other explosive media.

Every week, various media outlets publish reports on fires and explosions in pellet, sawdust, and coal storage facilities, as well at their corresponding grinding plants. Whenever a dusty atmosphere is generated and there is sufficient oxygen content, together with an ignition source, the preconditions for an explosion are met.

In order to limit the consequences of an explosion to a manageable degree, reliable constructional explosion protection methods – by means of explosion venting – are required.

State-of-the-art constructional explosion protection e.g. in grinding systems as well as in alternative fuel processing and storage systems is nowadays regulated by international rules and directives. However, as the grinding system is only a part of a very large equipment scope, less attention is paid to this issue during the overall decision-making process. Non-standard design in terms of constructional explosion protection systems leads to negative consequences such as serious, or even fatal, injuries to workers. f European ATEX directives are divided into: f EN European/US American Standards:

Over recent years, several severe explosions in grinding systems, as well as in the alternative fuel processing industry, have emphasised the necessity for properly-working constructional explosion protection. Therefore, the corresponding rules and directives should be implemented in any installation right from the beginning.

European ATEX directives are helpful but their correct implementation is not that easy. ATEX compliance is enabled through the installation of such technology but this largely has to be organised by the operator of the systems themselves.

» Directive 1999/92 EG – relevant for operators covering the aspects of risk assessment, zoning, as well as technical and organisational measures pursuant to the primary target: the protection of workers in potentially hazardous areas.

» Directive 2014/34/EC – relevant for manufacturers of explosion protection devices, covering the requirements of autonomous protection systems, components, as well as safety and control equipment. The significance of this directive is emphasised by the common requirements for equipment and protective systems. The part which is related to constructional explosion protection is as follows: “Should an explosion occur possibly endangering persons directly or indirectly (or for that matter domestic animals or property), such an explosion is to be halted immediately and/or the range of explosion flames and explosion pressures are to be limited to a sufficient level of safety”.

» Only ATEX-approved explosion venting devices assure proper functionality, as well as a properly determined venting area.

» These standards are of great significance for grinding systems in terms of explosion-resistant equipment (EN 14460), dust explosion venting protective systems (EN 14491), and explosion isolation systems (EN 15089).

» Corresponding American Standards issued by the National Fire Protection Association (NFPA) are covered, mainly referring to NFPA 68, as well as NFPA 69.

Another decisive factor in implementing effective constructional explosion protection, is generated as a result of varying coal properties in terms of the highly volatile fuels to be ground. Fuels of a VM content between 35 – 45% are not a rarity. These are designated as high-risk fuels. The fact that high VM coals have the strong tendency to create smouldering fires (even in the coal yard), reflects a potential explosion risk in the coal grinding system. At this point, it must be emphasised that even the milling of pet coke creates an explosive atmosphere and may lead to an explosion.

In this context the explosivity of alternative fuels needs to be highlighted. The risks associated with the handling and processing of alternative fuels are often underestimated or even neglected. The reduction of carbon dioxide in terms of replacing fossil fuels with alternative fuels is one step in the right direction, but requires a strict consideration of reliable constructional explosion protection, based on valid rules and regulations.

For example, safe handling and storage of solid biofuel pellets in commercial and industrial applications for capacities greater than 100 t is nowadays well-regulated by DIN EN ISO 20024. Surely, this is just the beginning of new regulations in this regard, and will be followed by more of its kind.

Constructional explosion protection in coal grinding plants. How does it work?

The issue of constructional explosion protection in grinding plants and storage facilities is multifaceted and needs attention with regard to the following themes:

Explosion venting in combination with explosion pressure shock-resistance to the relevant degree. This is mainly applicable for:

Protection of bag houses – taking the related rule (EN 14491) into account. Apart from the coal characteristic values, K St /p max , the enclosure’s pressure shock-resistance is one of the decisive factors in determining the necessary area in order to sufficiently protect the bag house as part of the coal grinding system. From experience, this value of pressure shock-resistance is between 100 – 400 mbar g. Additionally, the obstruction of the venting path by filter bags should be avoided right from the beginning of the design stage.

Protection of pulverised fuel silos – taking the related Rule (EN 14491) into account. As a result of the cylindrical shape of such enclosures, it is quite feasible to reach a pressure shock-resistance of 2 bar g (maximum value as stated in the relevant rule). This maximum pressure shock-resistance leads to the lowest possible venting area, depending on the efficiency factor of the venting equipment to be installed.

Explosion venting and explosion decoupling in combination with explosion pressure shock-resistance

In the past, explosion risks caused by the transmission of dust explosions through the pipes and ducts of interconnected plant units, have caused serious damage. This scenario is generated by a secondary dust explosion, the so called ‘flame-jet-ignition’ which results in very high explosion pressures in the connected enclosure. To limit the extent of dust explosions and to prevent violent secondary explosions due to explosion transmission via pipes and ducts, explosion protection using suitable isolation techniques, are mandatory. In coal grinding plants, the installation of explosion diverters, designed in accordance with the relevant rule have proven their efficiency.

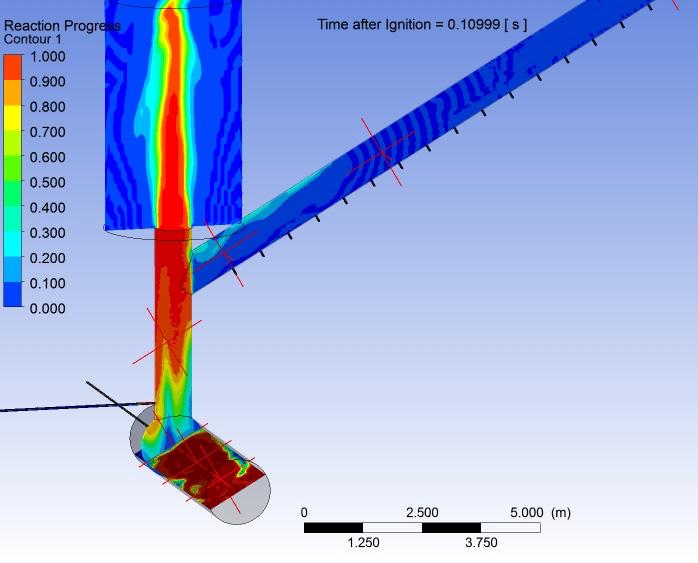

Techniques are available in order to effectively mitigate flame front propagation in dust-laden ducts. Thorwesten Vent conducted further research in the form of various successful field tests with the French notified body Ineris. Apart from field tests, the concept is now subject to computational modelling (Figure 2).

The main aim is the mitigation of pressure pushing the flame front into the riser duct, in combination with the diversion of the largest possible portion of flame body. In coal grinding plants, explosion isolation measures in the form of explosion diverters are often required, e.g. in riser ducts between the mill outlet and bag house inlet, as well as in any ducts used as

Bring emissions down to 0.5 mg/Nm3 -while saving up to 20% energy

The SimControl Advance controller reduces power consumption and maximizes bag lifetime. Our technology determines the setting point based on the real load of the filter, which guarantees optimal operation of the fabric filter.

de-dusting pipes. Other mechanically operated explosion isolation devices such as rotary airlocks and double flap systems of a certain pressure shock-resistant degree are also necessary.

Explosion pressure shock-resistance for full explosion pressure

An explosion pressure shock-resistant design for full explosion pressure is always necessary where venting as well as decoupling measures are not feasible. Typical applications are intermediate hoppers e.g. pump pre-hoppers for pneumatic conveying systems. In coal grinding plants, the full explosion pressure of 9 bar g as a design parameter is deemed as sufficient.

Self-reclosing, reusable explosion venting devices

Self-reclosing explosion venting devices have been invented aiming at mitigating fires inside the equipment. The effective mitigation and extinguishing of fires inside equipment is only possible provided that the ingress of oxygen is prevented and the injected inert gas e.g. CO 2 , N 2 is kept in the system.

Once open, the oxygen in the ambient air will increase the damage caused by the fire while the injected inert gas is lost to the atmosphere