6 minute read

Monitor the deliveries

Prasanth Sreekumar (UAE), Scott Sutherland (USA), and Stephan Natter (Switzerland), Endress+Hauser, explain why the bunkering industry is deploying mass flowmeters to improve efficiency.

LNG bunkering is the process of providing LNG to a marine vessel for its consumption. LNG offers benefits in reducing the emissions associated with burning traditional bunker fuels such as heavy fuel oil (HFO) and marine gas oil. International Maritime Organization’s (IMO) regulation IMO 2020 has accelerated the use of LNG as a fuel in the shipping sector and the investments continue to develop. LNG bunkering facilities can be classified as shore-to-ship, land-to-ship, and ship-to-ship

bunkering. Compared to traditional bunkering with HFO, LNG bunkering offers unique challenges due to cryogenic conditions and boil-off gas (BOG).

Traditionally, static level measurement devices have been used onboard bunker tankers to determine the delivered bunker fuel quantity. Recently, mass flowmeters (MFMs) have become increasingly popular. Some ports such as Singapore have made the measurement by MFM mandatory. The dynamic flow measurement by MFM offers distinct advantages over static type level gauges such as direct mass flow which makes the calculation from level over volume and temperature obsolete.

MFMs provide instant information about the quantity delivered to reduce the operation time significantly. Process information is available at any time for a maximum of process transparency. Flowmeters offer multivariable measurement and the highest level of accuracy under varying process conditions.

Figure 1. Left: A pilot-E probe installed on the main LNG transfer line from an LNG bunker ship. Right: Cross section showing the direct flange mount of the pilot-E probe and the immersion of the tip of the probe into the flowing LNG stream.

Figure 2. Mass flowmeter (MFM) installed on a traditional oil bunker barge.

Figure 3. Promass Q in LNG service.

Measuring LNG bunker deliveries with mass flowmeter

MFMs are known to be extremely precise, flexible in installation, and require minimum maintenance. MFMs have been used in custody transfer type applications in the oil and gas industry for decades. It has become a logical consequence to also deploy MFMs for LNG bunker operations. Endress+Hauser offers dedicated MFMs which can handle the cryogenic conditions with the precision known from standard hydrocarbon measurement. This makes MFMs an ideal flowmeter type for custody transfer applications such as LNG dispensers, loading/unloading of LNG in terminals, and LNG bunkering from truck, terminal, or ship. Type testing and certification through notified bodies reduces the scope of testing in the installation to a minimum. Calibration on LNG is not required.

Flowmeter health status can be monitored by the onboard feature ‘Heartbeat’ without removing the flowmeter from the line. Heartbeat technology provides a continuous health check of the flowmeter, ensuring key parameters are performing within specification at all times. Deviation from the factory reference values will trigger warnings as per NAMUR NE 107. This diagnostic function is available as standard with the company’s Heartbeat-enabled flowmeters.

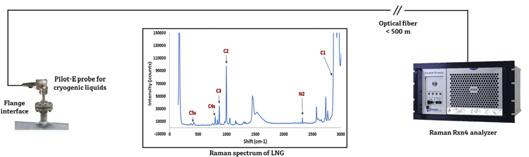

Measuring LNG composition with Raman analyser

Raman spectroscopy is an optical technique capable of providing composition information for both gaseous and condensed phase mixtures. Laser light interacts with molecular vibrations of the components of the gas sample, with some of the incident light losing discrete amounts of energy to excite vibrational modes in the molecules of the sample. The resulting Raman scattered light has a different colour than the original laser light, and each different type of molecule generates one or more colours that are unique to that molecule. The composition of the gas has been effectively encoded into different colours and intensities of light. Kaiser Raman analysers use lasers in the visible and short-wave near-infrared region that are compatible with transmission along low-cost fibre optic cables. This allows fibre-optically coupled probes to be placed hundreds of meters from the main analyser. For the analysis of LNG, a cryogenic probe, such as the Kaiser Pilot-E probe, is inserted directly into the LNG sample, either in the main transfer line, or in a bypass loop1,2 .

The light is collected by the fibre probe at the point of measurement in the sample pipe and is transported back to the analyser along the fibre optic cable, eliminating sample lag times that are inherent in the use of heated gas sample

transport lines. As an in-situ measurement, no sample is removed from the main line or transported from the measurement point to the analyser. By measuring the sample in the liquid phase, no potentially explosive gases are removed from the pipe at the sample tap location, nor transported to the analyser, greatly enhancing the safety of the personnel working on or near the Raman analyser or working with the Raman probe at the sample tap.

Figure 4 shows a diagram of a typical Raman analyser installation, which consists of a Raman analyser base unit that contains the laser source, all electronics and power supplies, detection module, and either an embedded or an external controller and user interface. The optical probe can be located up to 500 m from the base unit, connected to the base unit by an industrial electro-optical cable.

Figure 1 shows the details of a typical Raman probe installation on an LNG transfer line attached via a direct flange mount. The diagram illustrates how the probe passes through the access tee and pipe insulation and into the main transfer line so that the tip of the probe is immersed in the flowing LNG.

Figure 4. Typical installation of a Raman analyser for LNG measurements.

LNG bunker metering system

After the successful deployment of bunker metering systems for oil, Endress+Hauser developed a bunker metering system for LNG, comprising of quantity measurement for LNG and BOG using MFMs, LNG analysis through a Raman analyser, and the calculation of calorific value, density, methane number, and energy through robust flow computers.

The LNG bunkering system of Endress+Hauser provides an intuitive HMI which allows the operator to safely initiate the monitoring of the bunker delivery. The process progress can be viewed at any time. The bunker operation is completed by printing the bunker transfer ticket. All historical process data are stored on the bunker metering system. Optionally, the bunker operation data can be transferred to the ship system for further usage.

Endress+Hauser is providing the LNG bunker metering system as a standardised engineered unit. For the convenience of the operator all components are built in a cabinet and are easy to access for operation and service. Environmental and security requirements are fulfilled by design and are certified by notified bodies to ensure the compliance to the respective custody transfer standards.

References

1. SNYDER, J., CAPERS, R. M., FAIRCHILD, R.C. AND

WIEGAND, P. M., ‘Taking a closer look…’, LNG Industry (Autumn 2009). 2. SUTHERLAND, W. S., ‘Laser Precision Measurement’, LNG

Industry (March 2019).

Marshall Islands Liberia Panama

* Source: Clarksons Research’s World Fleet Register

0.74% 1.11%** 1.03%** 2.32% 3.09% 3.14% USCG Tokyo MoU 1.52% 2.22% 4.78% Paris MoU 4.23% 8.03%*** 6.30%***

AMSA

Sources: 2018-2020 Performance Lists Paris MoU, the 2020 Tokyo MoU and USCG PSC Annual Reports, and the 2018-2020 AMSA PSC Annual Reports.