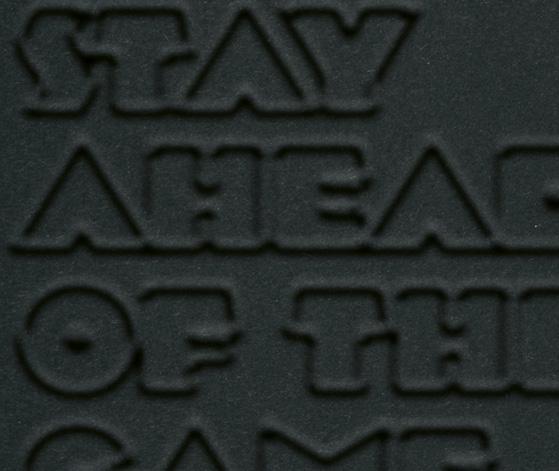

10 minute read

Stay ahead of the game

Jim Chappell, AVEVA, USA, explains why digital twin technology can be a game changer when it comes to maximising LNG operations and boosting plant profitability.

Government policies and operating company sustainability initiatives encouraging transition to clean energy have led to an increase in demand for natural gas, leading to tight market conditions. However, with adequate supply sources in most producing regions around the world and a need to deliver increasing amounts of LNG to regions short in natural gas, there will be significant opportunity to fully utilise the maximum capacity of liquefaction plants when markets favour suppliers. To stay ahead of the game, maximising LNG production at lower cost is imperative for companies to sustain profitability in this competitive market.

Challenges

Although an LNG process plant is designed to operate optimally at a design production level, any variations in feedstock and fuel gas composition, changes in ambient conditions, and degradation of operating assets can impact throughput and optimal processing conditions, affecting its operating profit. Stricter regulations on environment, product quality, and safety have also led to an increase in operating costs, adding pressure on profit margins. Compounding the challenges, the volatile boom-bust business cycle

environment has caused a shortage of skilled operators in most plants, affecting productivity and safety performance. Having skilled and competent operators is key to reducing incidents and plant outages.

Leveraging a digital twin strategy

The concept of a process digital twin is not new and it has been around for more than a decade. A process digital twin is a first principles replica of a chemical process with heat exchangers, turbines, pumps, compressors, and other equipment that enables modelling of process and control, and monitoring of equipment performance. It is the foundation to optimise LNG production and to detect equipment problems before failures occur, uncovering new opportunities for process improvement while reducing plant downtime.

Only in recent years, the advancement in technology – cloud platform, analytics, and computing power – and greater clarity on the use cases have accelerated the adoption of digital twins. LNG companies are starting to realise the benefits of digital twin technology that enables unprecedented real-time insights of their operations, elevating their operational excellence to the next level: a 0.1% increase in production due to improved process and operating efficiency can easily yield several millions of dollars in additional annual revenue.

Building a digital twin

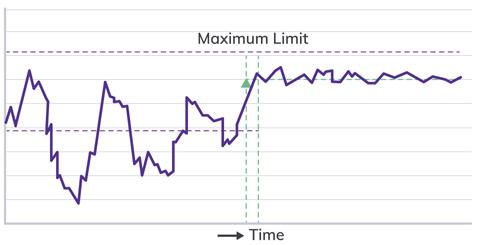

Figure 1. Reducing process variability and operating closer to the optimum points.

Figure 2. Real-time process optimisation approach. To build a digital twin for an asset, description tags and data – such as geometry, layout, connectivity of key components, and process data – must be created around the asset. The common set of data and information is then shared across departments throughout its asset and operations lifecycles – from engineering, to procurement, to construction, to commissioning, and operations. As the operational life continues, the digital copy is updated in real-time with current data and engineering information to optimise maintenance and operational activities.

Engineers and operators can quickly access critical up-to-date engineering information and operating data around the assets. Now, engineers can access information and health of an asset easily through tag searching. Previously, the tasks would have taken considerable time and effort, leading to missed opportunities in addressing any flagged issues before failures that result in production outages. In addition, the process data can be fed into simulation and analytics to optimise the liquefaction process, reduce unplanned downtime, and maximise LNG production.

Enabling simulation and analytics in LNG trains

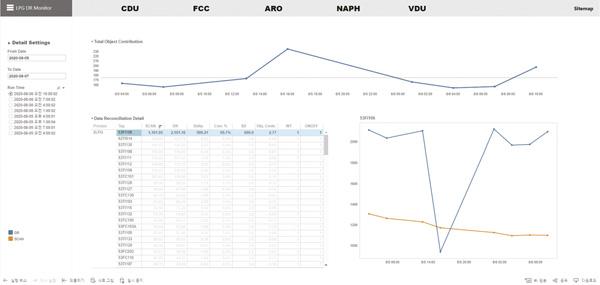

Figure 3. Data reconciliation for performance monitoring. As converting natural gas to a liquid in an LNG train involves a few processing steps from removal of impurities to liquefaction, an integrated approach is key to maximising LNG production. Operating constraints, including pumping capacity, refrigeration availability, pressures, temperatures, and variables such as feedstock composition and ambient temperature must be modelled and optimised with maximum throughput as the final objective. The following five-step approach enabled by a digital twin to maximise LNG production is fundamental to improving performance and boosting profitability.

Steady state and dynamic simulation models of process and controls

At the FEED stage, steady-state simulation models of the plant process can be created to optimise LNG plant design. Engineers and operators can perform engineering studies – such as simulation of various heat exchanger, distillation column, and flare designs – to identify design changes that will significantly increase the plant output and the reliability

and safety of plant operation. With a unified simulation platform, the evolution from a steady state to dynamic simulation can be achieved easily. Dynamic simulation can be performed on these models to validate process design such as relief and flare systems and controls, enabling engineers to optimise design and reduce CAPEX.

Engineers can perform engineering studies to identify design changes that will significantly increase the plant output, to understand process limitations, heat exchanger performance, and reliability and safety of plant operation. In addition, the dynamic simulation can enable effective troubleshooting, control system checkouts, and comprehensive evaluations of standard and emergency operational procedures to shorten time requirements for safe plant start-up and shutdown.

This forms the backbone of an operator training simulator (OTS) where operators can be trained on procedures to address real experiences to perfection in a safe and controlled classroom environment before they are deployed to the plant. Major LNG operators have already reaped significant benefits using simulators as part of their enterprise-wide training programmes, enabling them to reduce training costs and time to proficiency by up to 50%.

Reduce process variability

Advanced process control (APC) has been used widely in cryogenics operations to stabilise operations and reduce process variability due to varying feedstock rates and composition, ambient temperature, product demand, and changing equipment conditions. It does so by adjusting the process conditions in real-time to handle those changes in feedstock rate and quality while maintaining the plant operations within the constraints – pressure, temperatures, and horsepower availability.

Reducing process variability not only improves product quality, but also enables the process to be operated closer to its optimum points, reducing energy consumption and improving yield. For a typical LNG plant, applying APC can yield a 3 - 4% increase in throughput, yield, and a 2 - 5% lower energy consumption (million Btu/t). Other benefits include extended equipment life, reduced operator intervention, and improved plant stability and operation.

Process performance monitoring

In an LNG process, heat exchangers handle complex heat transfer for the liquefaction of gas and are critical to production. Equipment efficiency and instrumentation accuracy should be monitored constantly as degradation of the heat exchanger can lead to inefficiencies and production slowdowns. Having an integrated model to monitor all rotating equipment, distillation towers, and heat exchangers not only analyses the interactions of various plant components, but also provides additional metrics on efficiency and utilisation.

Reconciliation of material, energy, and equilibrium balances around a piece of equipment or entire plant can also identify bad instrument readings and pinpoint material and energy loss locations, effectively acting as a data

Figure 4. Closing the performance loop.

validation layer. This is valuable information that cannot be measured directly, but is calculated based on first-principle, rigorous models that have been tuned to actual plant condition.

Predictive analytics to monitor equipment health

As LNG trains are extremely cold during operation, any planned or unplanned shutdown will take longer to restore full production rates than equipment operating near ambient temperatures. Therefore, minimising plant shutdowns is key to improving production. Predictive analytics enables modelling of rotating equipment performance – such as pump, compressor, and turbine – using advanced pattern recognition and machine learning algorithms to identify and diagnose any potential operating issues days or weeks before failures occur. Operating models including past loading, ambient, and operational conditions are used to create a unique asset signature for each type of equipment.

Real-time operating data is then compared against these models to detect any subtle deviations from expected equipment behaviour, allowing reliable and effective monitoring of different types of equipment with no programming required during set-up. The early warning notification allows reliability and maintenance teams to assess, identify, and resolve the problems, preventing a major breakdown that can cost companies millions of dollars in production slowdowns or even stoppages.

Real-time process optimisation

While APC sets the optimal process conditions based on empirical, linear dynamic models, it is difficult to resolve non-linear relationships that may impact the plant throughput. Real-time process optimisation – either open-loop or closed-loop – considers current process performance, process constraints, feedstock, mixed refrigerant composition, and throughput to determine the best set of operating targets based on satisfying material and energy balances.

These targets can then be made available to operators for implementation in their control systems, or they can be automatically downloaded to APC systems directly. In addition, the same performance and optimisation models can be used to conduct offline optimisation and feasibility case studies, enabling plant engineers to plan operations. Engineers can run the same models to analyse various operating scenarios to determine optimal configurations in the plant, to analyse constraints/bottlenecks that impact production, and to evaluate the impact of maintenance activities such as heat exchanger cleaning studies.

The last mile to close the performance loop

Insight and process optimisation advisory do not create value until action is taken to adopt and implement the new optimised set points. Accurate, reliable, and timely information must be channeled not only to the subject matter experts but also to executives who are empowered to make operating decisions that impact the bottom line. This is where enablers such as workflow management are critical to ensuring that actionable data is executed upon to seize any profit improvement opportunities. The right information is delivered to the right person at the right time.

No matter the stage in a digital journey, implementing the solutions in a logical step-wise fashion, as economics and resources allow, enables progressive value building as additional solutions are implemented, allowing each solution to pay for subsequent implementations.

Conclusion

The digital twin framework enables operational excellence by helping LNG operators and owners to take a modelfocused approach that quickly turns the significant amounts of data already available into information and wisdom that generates business value. The breadth and depth of products and services in AVEVA’s portfolio is designed to offer greater choices and flexibility to solutions architects in designing a path to maximise LNG production that best meets the needs of clients in a methodical and extensible manner. Ultimately, it is a journey to continuous improvement, and what the company has learned from successful customers has been outlined in the following: Find a vendor uniquely qualified to implement operational excellence solutions: Extensive experience in the process industries. Numerous years of applicable optimisation expertise. Commitment to each customer’s continuous operational excellence. Choose integrated technology that promotes: Improvements through an asset’s lifecycle including process design, simulation and training, and optimisation. Operational excellence through continuous improvement, actionable intelligence, and workforce optimisation while managing and lowering risk. Implement projects as economics allow: Services team supports client’s efforts through collaborative project development, ongoing engagement, co-operation, and partnership.

Contacting an AVEVA consultant with field experience in planning and implementing analytics architecture can help operations management teams to begin or continue their journey to maximum effectiveness by improving their producing asset’s availability, performance, and quality while ensuring environmental and safety compliance and ultimately improving the business bottom line.

TEM20 adv A5 _ Algemeen _ Contouren.indd 1 10-03-2020 09:09