through P1 Brings Improved Methods of Manufacturing, Adding Two New Shops to Meet Demand

P1’s 220,000 sq. ft. off-site construction and in-house fabrication facilities located in Lawrence, KS had room to spare. Today, that has changed as demand for P1’s fabrication capabilities calls for additional dedicated space. This expansion supports our continued growth in client-awarded projects and strengthens P1’s ability to deliver at scale. As a result, P1 has added two new physical locations – also in Lawrence, KS –focusing specifically on advancing polypropylene and millwright manufacturing.

Known informally as the “poly” shop, the 90,000 sq. ft. polypropylene resin (PPR) shop at 910 E. 29th St. in Lawrence, KS, focuses on reforming the way P1 manufactures and streamlines PPR production systems. The shop is in addition to the full carbon, plumbing, and specialty pipe shops at P1’s main Lawrence location.

Pipe Shop Production Manager Jeremy Price said the new facility is dedicated to polypropylene manufacturing, specifically allowing for greater efficiency, precision, and scalability.

“We’ve been doing so much production for both the Aquatherm and Niron products, it required us to invest in more space to handle the capacity of work,” Jeremy said.

He notes the actual demand comes through large customers, such as partnerships with Daikin, who uses Aquatherm, and Ferguson, who uses Niron.

“We are currently shipping throughout North America, as well as internationally, with these two partners,” he said. “These relationships have grown over time due to P1’s outstanding reputation, capacity, capabilities, and commitment to quality.”

The PPR shop is designed specifically to maximize the storage and dynamics of producing polypropylene pipe and parts, with features like

vendor-managed inventory, fitting production, production lines, and conveyors and trolleys to move product faster.

“The shop has been systematically designed for speed and efficiency to ensure consistent quality in mass production,” Jeremy added.

“Everything is stored inside the facility,” Process Controls Supervisor Nathan Peters said.

“That includes indoor receiving and shipping, meaning the trucks can back directly into the shop, and not be affected by weather, so nothing holds us up on schedule.”

For Nathan, the most critical part of the job is organization, which is no small feat.

“We have to stay on top of coordinating material and trucks coming in and out, checking availability, and putting the right product out on the floor, and making sure the process flow stays organized so everyone knows what is where and can get right to the job,” he said.

“We set up production lines to make us more linear in our manufacturing process,” Jeremy added. “Instead of jacks, we now have conveyors and trolleys to move the product faster.”

With the help of Stratus Technician Haydan Walker, the shop also uses Stratus fabrication management software.

“Stratus creates efficiency by integrating Building Information Modeling (BIM) software with manufacturing tools to streamline workflows from design to installation,” Haydan said.

“It increases efficiency by digitizing processes, enabling real-time tracking of parts, and providing automated labeling and analytics to improve project execution.”

Shop Coordinator Heidi Wittman notes this facility improves business development as well.

“We can bring customers and prospects here to see our facility, see what we have, and see how we can do it all in-house, and it’s very impressive,” she said.

In fact, following a recent prospect tour of the shop, the team is in talks with a potential new customer that could bring in a significant amount of work.

Quality Control Supervisor Brennan Walker ensures parts are built correctly and to spec for the customer.

“Each day, I’m keeping track of what’s being built, making sure it’s exactly right, and documenting all of it so everyone has access to that information and can communicate status to customers,” he said.

“Then we have to make sure it’s crated and put on the truck properly, often to meet very meticulous, specific customer guidelines.”

We look forward to seeing what the shop can do in the future!

The poly shop gets special palettes required for overseas shipping to locations like Mexico and South Korea; Color-coded wrap indicates where a shipment is going, for example, white means overseas, blue means domestic.

In the new poly shop location, P1 can now offer a fast, in-house turnaround process.

• Indoor receiving and shipping bays for all-weather operations

• Vendor-managed inventory systems

• Assembly line manufacturing

• Systematic inventory flow

• Belt-driven conveyor distribution

• Wholesale fitting manufacturing of 12”-18” 45’s, 90’s and Tee’s

A Ritmo Sigma band saw prepares pipe to go down the conveyor for a fitting to be assembled (left). A Ritmo Alpha 400 assembles pipe fittings, such as elbows, tees, and crosses, by joining segments of the plastic pipe.

The new North Lawrence Millwright shop at 1723 E 1500 Road, Lawrence, KS, is home to the TRUMPF T7000 tube laser.

The laser eliminates the need for sawing, drilling, deburring, and tapping.

Compared with conventional tube cutting, the laser replaces a number of work steps. It can cut very precise complex contours in materials such as mild steel, stainless steel, aluminum or nonferrous metal.

“P1 Construction is invested in high precision material production,” Fabrication Manager Kevin Norris said.

“The new laser gives us more speed, precision, and shortens the distance between design and finished product.”

“The tube laser allows us to cut and machine tubing and structural components faster, more accurately, and directly from the designs,” Kevin added.

Kevin notes that because of their diverse shapes and materials, tubes and profiles are in high demand in many applications, including data centers, industrial framing construction, custom platform construction, and multi-trade rack construction.

“For P1, it has increased our accuracy and productivity, and encouraged creativity,” Kevin noted. “For clients, they appreciate the accuracy and cost savings.”

“With bending frames, for example, you will need fewer parts. Positioning aids facilitate error-free assembly, the amount of work required for downstream work steps, like welding, is noticeably reduced, and it’s all done with just one machine.”

Since beginning laser operations in the spring, Millwright Team Leader Jim Nisely notes the shop has successfully landed significant projects, contributing several hundred thousand toward the investment since March.

• In-house design capability

• Nearly unlimited design option

• Less effort between design and construction

• Product cost reduction

• Process simplification

• Lower organizational effort

• Efficient response times

The laser allows for complex assemblies to happen much faster.

NOTE: for safety purposes, no production was in progress at the above open house event

See it in action! See how the P1 process surrounding Millwright laser processing saves time, improves accuracy, and creates efficiency.

Internal Use Only: Please do not share video

When Guadalupe Centers Middle School reached out in March asking for a complete HVAC reset before students returned in August, there was little room for error. What started as a P1 Service retro-commissioning proposal quickly escalated into a full design-build replacement project — and became a showcase of P1’s speed, teamwork, and quality, with Sales, Service, and Construction all jumping in to help.

P1 was invited to bid the project thanks to the customer remembering the excellent job P1 did on another similar high school HVAC renovation.

“We initially proposed retro-commissioning to diagnose the problems,” Project Manager Andrew Noone explained.

“The very next day, the owner asked what it would cost to gut it and start fresh.”

Andrew says the school had hot and cold spots more than 20°F apart, and just couldn’t keep classrooms comfortable.

P1 responded quickly, providing a preliminary $2–$2.4 million budget. The board approved, and within six weeks the design-build team completed load calculations, equipment selections, and system redesigns.

On-site work began May 27 and wrapped up by August 8, just in time for students to return.

P1 Construction handled sheet metal while P1 Service teams executed mechanical, electrical, and controls scopes, with support from partners for fire alarm, sprinklers, insulation, and minor ceiling and wall repair.

The project finished under budget, on schedule, and with no change orders.

• Replacement of two rooftop units (60-ton and 75-ton)

• 44 VAV boxes

• The entire exhaust system

• Addition of a second-floor return duct

• Installation of a mini-split system for the IT server room

• Complete temperature controls replacement

• Project total: $2,228,366 with zero change orders

• $1,820,822 mechanical

• $277,323 electrical

• $130,221 controls

Ryck Sanders (Project Team Manager)

Bill Frede (Project Development Manager)

Andrew Noone (Project Manager)

Josh Slocum (Development Engineer)

Clinton Gechter (Project Operations Manager)

Alex Van Leeuwen (Electrical Senior Project Manager)

Luke Krehbiel (Controls Engineer)

Thomas O’Connor (Project Engineer)

Jeff Walker (Proactive Solutions Sales Manager)

Brian Heinen (Pipefitting)

Luke Sedgwick (Electrical)

Kevin Colvin and Alex Reilly (Startup and Commissioning)

Alex Gaskill (Controls Engineer II)

James Feigenbaum (Field Technician)

Carey Minihan (Senior Project Manager/Team Leader)

Sam Stewart (Project Engineer)

Keith Carter (Foreman)

“As a result of how smoothly this project went, we’re now working with the customer on a preventative maintenance agreement that would cover more than 15 facilities.”

-Project Manager, Andrew Noone

“Our price never changed, we stayed true to the original estimate” Andrew said.

“Following the completion of the project, the school principal told me ‘I haven’t heard a word from teachers, and in this world, silence is the best compliment,’” Andrew added.

The successful outcome also positioned P1 for a long-term partnership.

“As a result of how smoothly this project went, we’re now working with the customer on a preventative maintenance agreement that would cover more than 15 facilities, and they’ve already given us several follow-up projects,” Andrew said.

Andrew emphasized the collaboration that contributed to the project’s success.

“Project Team Manager Ryck Sanders, Project Operations Manager Clinton Gechter, Project Engineer Thomas O’Connor, and Project Development Manager Bill Frede all leaned in to help,” he said.

“P1 Construction’s crew was fantastic,” Andrew noted. “Controls brought the new system to life. Startup was clean. It was truly the ‘expertise of many, the power of one.’”

“It’s not about what it is, but rather what it could be.”

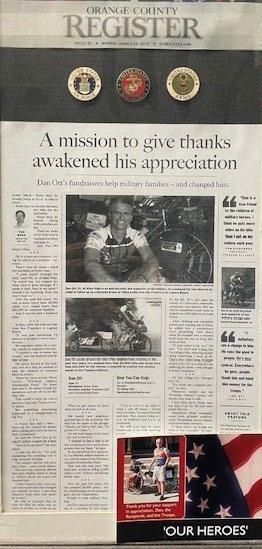

At P1, we often see our associates’ passion for their work AT work, but many P1 people have a passion for serving and leading outside of their profession, putting creativity and heart into projects that change lives.

Such is the case for Las Vegas Senior Estimator Dan Ott.

Dan’s career in construction goes back almost as far as his commitment to supporting the men and women who fight for our country.

“I got into construction right out of high school,” Dan said. “I started washing plumbing trucks for two bucks an hour, and graduated from there!”

Living in California at the time, Dan says he went from ditch digger to general superintendent.

“Around 2020 I tried retiring,” he said. “But I found you can’t go from 120 miles an hour to zero.”

When his four kids were grown, Dan and his wife Lori decided to move to the Las Vegas area.

“I wanted to go back into the construction industry, but I didn’t want to go back into the field.”

In 2022, Dan found an ad for a plumbing estimator with P1 – just 10 minutes from his house. He had some estimating experience so he applied – and the rest is history.

Even though Dan never served, he has been a staunch supporter of the military, a commitment that dates back to the day his sister gave him a gift.

Dan garnered local press attention with his rides for the Freedom Alliance Scholarship Fund.

“Everything about our American way of life is possible because, throughout our history, soldiers have sacrificed their time, their lives, and their families.”

Learn more and follow Dan’s bike journey on YouTube

“When I was 13, my sister put a POW bracelet on my wrist – a soldier lost in 1970 in Cambodia,” he explained. “I still have it on today –because he hasn’t come home.”

“I was actually ready to serve,” Dan said. “But I made the mistake of stopping by my dad’s house before I made it to the recruitment station.”

Even though dad managed to talk him out of it, and he never made it to that recruitment station, Dan says he’s always felt a great amount of gratitude for the efforts and sacrifices of our men and women in the armed forces.

“Growing up I didn’t have scholarship opportunities, and I have four grown kids. I always think that if anything happened to me, the most important thing as a parent would be to make sure my kids were taken care of – that they would have an opportunity to go to college.”

And avid biker at the time, Dan had the idea to do an extended ride that could raise funds, and the Freedom Alliance Scholarship Fund was born.

As Dan prepared for that first ride, something happened that bolstered his commitment to the cause even more.

Standing in the cemetery for the burial of his mother 15 years ago, Dan noticed the headstone of a fallen soldier nearby.

Dan says the military families he met through this journey helped keep him going.

The soldier was only 19 when he died.

“It reminded me that the reason I could do that ride is because of his ultimate sacrifice,” Dan said. “Everything about our American way of life is possible because throughout our history, soldiers have sacrificed their time, their lives, and their families.”

“It really struck me. He was only 19 – not even old enough to drink. I was nearly 50 at the time, free to ride 500-plus miles, all because of his – and others’ – sacrifices.”

What was supposed to be one 500-mile ride from San Francisco to Laguna Beach turned into almost four years and 60,000 miles.

The first seven-day ride raised about $4,000 through sponsorships.

But Dan didn’t feel like he was finished. Being able to meet the recipients of those first scholarships fueled his desire to do more.

My rides were anywhere from a week to two weeks long,” Dan said. “I did it solo intentionally – if I made it too easy, it wouldn’t mean as much.”

At one point, Dan said he had more than 1,200 followers on social media, following along as he made his rides.

When a health condition made it difficult to do the bike rides anymore, Dan didn’t give up.

“I create mainly for the joy of it and not the money value. Creativity should be shared and encouraged.”

Above are some of Dan’s creations. Scan the QR code to visit OttShott Creations, where the proceeds are donated to support military familes.

One of Dan’s constant companions in the workshop is rescue dog Watson, his beagle/ dalmatian mix.

P1’s Las Vegas office proudly displays some of Dan’s creations, including customized American flag business card holders and wood-carved maps.

“I have always enjoyed creating and building things with my hands,” he said.

Dan says his father encouraged his creative talents from an early age.

“I remember my dad coming to the garage when I was a kid and ask what I was doing. I said I’m trying to make this thing, and he would say ‘get in the car’.”

That meant a trip to the hardware store.

“Dad would say ‘walk around until you find what you need to make that be what you want’ - and that’s what I did,” he recalled.

So even though he’s not on a bike anymore, Dan still has a way to support military families with the proceeds from OttShott Creations, his own small business out of his home.

Dan’s website explains how he came to make custom items to continue supporting the cause.

“The true honor in making things is creating something that others find nice enough to display or to wear,” he said.

Aside from donating to military families, Dan says his shop is not about profit.

“I create mainly for the joy of it and not the money value, which is why my price points are low. Creativity should be shared and encouraged,” he said.

Together, Dan and his wife Lori keep the shop going.

“My setup is just me and Lori. I create while she sells and supports. All the items are made in my little workshop, in my garage, typically while listening to a plethora of different tunes,” he added.

Dan also does frequent commissioned projects to meet specific customer requests for special occasions. P1 applauds Dan’s efforts and we wish him much success!

Dan took a photo of him and his wife Lori, and created art. “I’ll take a photo and make a wood carving to match the photo – with this one, I put us on the beach.”

P1 Plays a Critical Role in Creating That One-of-A-Kind

On the evening of August 23rd, the final bars of the national anthem were drowned out by the roar of three F-35 fighter jets as they flew over the stadium to the cheers of an at-capacity crowd.

The start of the college football season is always filled with excitement and anticipation, but none more than the home opener for the University of Kansas as they christened the newly renovated David Booth Memorial Stadium in Lawrence, KS.

Memorial Stadium has a rich history and was originally dedicated on November 11, 1922, to honor 129 fallen WWI alumni and students. Over the past century of use, the stadium has undergone several upgrades and renovations, but none as impressive as the most recent $450 million project with phase one completed in August 2025.

Demolition on the stadium started almost immediately after the final football game of the season, in December of 2023.

The general contractor and engineering bids went to Turner Construction and Henderson Engineering, with P1 Construction securing the electrical portion of the project.

Multiple P1 teams contributed to this flagship project, but one thing everyone agreed on was that teamwork definitely “made the dream work” on this complex, fastpaced project.

Even before the final electrical contract was awarded, P1 also had the contract for the enabling and preparation, which took place before - and after - demolition.

Before returning to the field to be the superintendent on the stadium portion of the project, Scott Bond Jr. was the project manager for the underground portion of the contract with Dusty Casto as general foreman.

“Keeping manpower on site and productive was a daily battle due to the large spread-out nature of the project. Our superintendents and foreman kept the field updated with the information they needed to stay productive and on schedule.”

“Enabling and preparation for the demo, and having the underground contract, led into the actual stadium construction package,” Scott explained.

The scope for the underground included rough-in for the electrical rooms and all the electrical services, including the scoreboard.

Construction began in April of 2024, and even with the university moving all the football games to other stadiums for the season, it still left a brief 16 months to have everything complete for the start of the 2025 season.

But as always, P1 was up to the challenge and put single-source capabilities to work to provide services for the vast - and fast - construction needs.

P1’s electrical construction and low voltage/Building Technologies divisions worked closely together – along with Turner and subcontractor partners - to deliver a hugely successful project.

For the electrical construction contract, P1 installed the power distribution system throughout the new stadium (one 4000A service, three 3000A services, one 1600KW generator, and all associated switchboards, distribution panels, transfer switches, transformers, branch panelboards, disconnects, and VFD’s).

This also included providing power to the following: wiring devices, kitchen equipment, mechanical equipment (chillers, cooling towers, boilers, AHU’s, RTU’s, MAU’s, FCU’s, pumps, split systems, exhaust fans, the scoreboard, the ribbon boards, and multiple graphic elements).

P1 installed the light fixtures, lighting controls and associated circuitry/control wiring as part of the project. P1 also provided pathways for P1’s low voltage group as well as the other low voltage groups involved, this included security/access control, cameras, broadcast, and AV cabling.

According to Senior Project Manager Dolan Boxberger, the fast pace of the project was a considerable challenge, but P1’s strong team helped push the project schedule and keep it on track.

“The P1 team was very proactive in reviewing the plans, specs, and submittals to get out in front of potential problems,” he said.

“Our superintendents, foreman, and project engineersCamden Wheatley and Mason Hilgenkamp - were a great asset, looking ahead to find discrepancies and getting them squared away before they held up progress or the schedule,” Dolan said.

That’s some manpower! The whole P1 Construction crew gathered for a photo.

Manpower between P1 and electrical subcontractor DL Smith was also challenging with the project handling as many as 200+ electricians at the peak.

“Keeping manpower on site and productive was a daily battle due to the large spread-out nature of the project,” Dolan said. “Our superintendents and foreman, most notably Scott Bond, Jr. and Shawn Norris, kept the field updated with the information they needed to stay productive and on schedule.”

Senior Integrated Solutions Manager Travis Fleming said P1 technologies also had great success on this project thanks to a solid team, led by Foreman Manuia Savea.

“The team was very responsive and worked together toward the common goal with the other teams involved, including our own P1 electrical construction,” Travis said.

P1’s Building Technologies division installed approximately 2500 Cat6A cables feeding building automation, cameras, over 500 wireless access points, numerous cameras,

point of sale, time of day clocks, area of refuge phones and general use ports.

The team built out (13) remote Intermediate Distribution Frames (IDFs) and one Main Distribution Frame (MDF), with basket tray, grounding and bonding, and racking and cable management . They also installed an area of refuge system which required in house engineering to meet code. This emergency system operates 24/7, and if campus police don’t answer for some reason, the system can call other designations such as 911.

“When changes came up, we were all in sync and I saw how much detail the team put into the project,” Manuia said. “This project feels different for me due to the handson involvement from field, office, partners, and GC. It really helped me as a foreman because of how much I learned along the way from all the experts involved.”

“I was able to go to a game and see all the lights and the screens and know how much work went into it. It’s a project that I’m proud to have been involved with.”

“This was my first actual on-site job, so the challenges were all new. Everyone out here was helping everyone, and any time I had a question I never felt bad for asking! Even though it was my first, it felt like a job that went extremely well.”

- Project Engineer Mason Hilgenkamp

P1 Electrical was also subcontracted under Johnson Controls (JCI) for Building Automation (controls), led by Project Engineer Michael Green.

Michael says the team was mostly new to building controls, but everyone took initiative to learn on the fly from the more experienced technicians to understand the nuances of a system this size.

“We had some great help at every level, from apprentices to leadership. This was a wonderful display of teamwork and collaboration by all involved,” Michael said.

“While the basis of our work is conduit and wire, that just scratches the surface of what is needed to understand how BAS (building automation) systems function.”

The controls system does just that, monitors and controls the functions of every aspect of the building, including boiler/chiller plant, air handling units, exhaust fans, and even lighting controls monitoring,” he explained.

“P1 Technologies touched almost every piece of equipment.”

Despite the tight schedule, construction was completed and everything operational for opening day.

The fans may never know the role P1 teams played in creating this exciting experience, but bringing facilities like the stadium to life - building spaces that are safe, fun, healthy, and optimal for users - is what keeps P1 coming to work every day.

P1 ELECTRICAL CONTRACT AMOUNT: $51,270,554

DURATION: 16 months | COMPLETION: 8/1/25

P1 TEAM: Electrical PM/PEs: Dolan Boxberger – Senior PM; Shawn Norris – Project Site Supervisor; Mason Hilgenkamp – Project Engineer; Camden Wheatley – Project Engineer; Electrical Superintendent: Scott Bond Jr.; General Foremen: Jake Massey; Michael Wessel; Jeff Goodman; Darren Ousdahl; Ed Longstaff; Foremen: Josh Fletchall; Tyler Ecord; Lucas Nelson; Jacob Bond; Jacob Reaves; Jerod Wells; Shawn Hastings

• 216,000 feet of conduit (Rensenhouse)

• Total feet of MC cable: 341,500 feet or 23,330 lbs of MC Cable (Van Meter)

• Total feet/lbs of copper wire: 1,003,445 feet or 346,180 lbs of copper wire (Van Meter)

• 5200 light fixtures (Rensenhouse)

• One 4000A and three 3000A 277/480V (Evergy Services)

• One 1500KW/1875KVA Generator

P1 TECHNOLOGIES CONTRACT AMOUNT: $3,400,000

DURATION: 16 months | COMPLETION: 8/1/25

TEAM: Travis Fleming - Senior Integrated Solutions Manager; Dylan Walters – Project Engineer; Manuia Savea – Foreman

• Installation of 2,500 Cat6A Commscope/Systimax cables providing 25-year manufacturer warranty

• Build out of 13 Remote IDF switch rooms and one main switch room, connected with single mode fiber optic cabling and 50 pair copper

• Installation of area of refuge system, time of day clocks, and wireless access points.

• 180' boom lift needed for installation of Cat6A cables feeding upper level

CONTRACT AMOUNT: $1.3 million

TEAM: Michael Green - Project Engineer; Seth O’Brien - Superintendent; Josh LandkamerGeneral Foreman; Derek Haverkamp - Foreman; Aaron Wertz - Foreman; David Young - Foreman

• P1 installed approximately 24,000’ of conduit with 200,000’ of cable

• 17 AHU’s, RTU’s, and MAU’s

• 70 Fan Coil Units

• 163 VAVs

• Boiler Plant with 5 boilers, 4 HW Pumps

• Chilled Water Plant with four Chillers, 10 pumps and one remote Cooling tower

• 200 misc. dampers, fans, and heaters

Did you know? OSHA estimates more than 50,000 injuries each year are caused when people are struck by falling objects. In 2023, the Bureau of Labor Statistics reported 237 workplace fatalities from falling objects.

When working at heights (aerial lifts, ladders, scaffolds, or near leading edges), always take steps to prevent tools and materials from falling.

• INSPECT AND SECURE: Regularly check work areas to ensure tools and materials are properly secured.

• Store items so they can’t slide, fall, or collapse.

• Keep tools and materials at least three feet from leading edges; never store on ladders or handrails.

• Install and inspect toe boards.

• HOUSEKEEPING: Remove unnecessary tools and materials from elevated areas.

• PPE: Hard hats are required on all job sites.

• SAFE POSITIONING: Avoid working directly under other workers at height or under suspended loads.

• PROTECT BELOW: Use barricades and warning signs. If the area below cannot be secured, tether or secure all tools and materials.

• Use tool tethering attachments rated and labeled by the manufacturer.

• Avoid carrying unsecured items in pockets (phones, pens, small tools).

Add retrofit attachment points on tools and anchor locations.

Use shock-absorbing tethers designed for the tool and weight.

Keep containers (buckets, boxes, bags) closed to prevent spills.

Every solution must be tested for weight and length capacity.

WHY EMAIL SECURITY IS NOT AN EXACT SCIENCE: In the ever-evolving landscape of cybersecurity, email remains one of the most vulnerable and frequently exploited channels. Despite the ongoing evolution of advanced security tools and protocols, email security is far from an exact science. It’s a dynamic challenge shaped by human behavior, technological limitations, and the ingenuity of cybercriminals.

TECHNOLOGY HAS LIMITS: While email security solutions like spam filters, anti-malware scanners, and other policies are essential, they are not foolproof.

• False positives and negatives: Security tools may block legitimate emails or let malicious ones slip through, due to things like:

Filtering based on email address (foreign email addresses, accounts flagged by other users as spam, domain email addresses recently created, etc.)

Filtering triggered by content/key words

Remember: When you as an employee release emails from your quarantine or “On Hold Messages”, you acknowledge the messages were flagged as potentially malicious and should handle them catiously with additional scrutiny.

• Zero-Day Threats: New attack methods can bypass traditional defenses before signatures are updated.

• Encryption G aps: Not all email communications are end-to-end encrypted, leaving room for interception.

ATTACKERS ARE ALWAYS ADAPTING: Cybercriminals are constantly refining their techniques to stay ahead of defenses. From Business Email Compromise (BEC) to polymorphic malware, attackers innovate faster than many organizations can respond.

• AI-generated phishing: Attackers now use AI to craft highly convincing messages.

• Domain spoofing and lookalike domains: These tricks can bypass basic verification checks.

• Compromised accounts: Even legitimate email accounts can be weaponized once breached.

CONTEXT MATTERS: What’s considered suspicious in one organization might be routine in another. For example, for P1: Bid requests/customer platforms with links to a malicious website, or union reporting or request emails with links that are malicious.

Organizations like P1 must adopt an adaptive strategy:

1. TECHNICAL CONTROLS : Use SPF, DKIM, DMARC, sand-boxing, and threat intelligence.

• Without the email SPF record, anyone could pretend to be sending emails from p1group.com even when they are not. It prevents tactics like Spoofing.

• DKIM is a way to digitally sign your emails so that those systems receiving emails can verify the authenticity of that email.

• DMARC are the instructions to follow if an email fails an SPF record check or a DKIM Records check. The rule will either let the email deliver, let it deliver but quarantine, or reject the email.

• At a basic level, the rules above are applied to every email being sent and received at P1 Construction. This is also recommended best practice for every email system in operation on the internet today.

2. USER EDUCATION: Regular training and simulated phishing exercises.

3. CONTINUOUS MONITORING: Stay alert to new threats and adjust defenses accordingly.

Email Volume by Day: 8 Sep 2025 to 14 Sep 2025

Total Email Count: 94,872

• 55% The vast majority of email is internal or employee-to-employee within P1 Construction.

• 30% Inbound emails, or those being received by P1 Construction, subject to spam filtering and other protection rules

• 15% Our smallest footprint is outbound email or email being sent from P1 Construction to individuals outside of P1 Construction.

How much email was rejected for the same time period? In addition to the 94,872 emails, there were 21,361 rejected emails, in other words, 18.4% of the total 116,233 emails were rejected or not released.

The reality is that attackers constantly exploit our technological blind spots, probing for weaknesses in filters and policies. The sheer volume and variety of emails that pour into an organization each day make it nearly impossible to guarantee total security. Malicious messages often slip past even the most robust security infrastructure, hiding among legitimate correspondence and preying on the inevitable lapses in human scrutiny.

These are no longer just traditional spam composed of unsolicited emails from advertisers. Today’s attacks are concentrated efforts to compromise organizations and do financial or reputational harm.

ATTACKS ARE CONCENTRATED EFFORTS TO COMPROMISE ORGANIZATIONS AND DO FINANCIAL OR REPUTATIONAL HARM. ORGANIZATIONS TRY TO COUNTERACT THESE RISKS BY EMPLOYING MULTI-FACTOR AUTHENTICATION,

ACCESS

YOU ARE OUR MOST CRITICAL DEFENSE: A key part of the equation is empowering employees to make informed decisions. While technology can shield users from many threats, the final gatekeeper is often the individual faced with a choice. Encouraging a culture of vigilance and skepticism can reduce risk, but it’s a constant uphill battle in an environment where attackers relentlessly seek new opportunities.

Email security is a moving target—shaped by human behavior, technological evolution, and the relentless creativity of attackers. It’s not about achieving perfection, but about building resilience. By combining smart technology with informed users and agile processes, organizations can better navigate the uncertainty and keep their communications secure.

Protections are a balance of accessibility and security. An attacker only needs to be successful one time to compromise a system. The protection of systems needs to be accurate 100% of the time.

Please join us in welcoming our newest P1 associates. KEY: (C) = P1 Construction, (S) = P1 Service

5

JOSEPH EGGERS

DEREK HOUT

CAMDEN LUTZ

PRESTON MARTIN

EASTON SOMMER

This fall, the P1 Construction executive team awarded corporate sponsorships to four applicants instead of the typical two. Each winner received $1,000 for their organizations.

Rossville Junior High Cheer Team, Rossville, KS

Nominated by Foreman Chris Broxterman

The Rossville Jr. High Cheerleaders are known for their top rankings at the Washburn Rural Cheer Showcase. The Cheer team incurs many expenses that are generally paid for by the parents or by fundraising. This sponsorship will help pay for choreography, uniforms, camps and equipment.

R.O.I Fastpitch, Buckner, MO

Nominated by Building Technologies Foreman Bert Smith

The sponsorship money will go towards uniforms, equipment, tournament and league fees for the 2025/26 season.

West Platte Band & Choir Weston, MO

Nominated by Electrical Foreman Zach Rever

The West Platte Band & Choir has the opportunity to perform at the 80th Memorial of the bombing of Pearl Harbor in Hawaii. Sponsorship funds will be used for airfare, lodging and programming.

Wheelhouse Baseball, Peculiar, MO

Nominated by Manpower Supervisor Robb Eder

The sponsorship money will go towards uniforms, equipment, tournament and league fees for the 2025/26 season.

The P1 Construction Corporate Sponsorship program is a bi-annual program to provide financial contributions to selected associate-nominated organizations. The sponsorships help P1 serve the community through organizations that are meaningful to P1 associates. Watch your email in the spring of 2026 for the next opportunity to apply.

Jason White | $ 102,000.00

BT + ELEC + PIPE + PLBG | ST LUKE’S SOUTH STERILE PROCESSING DEPARTMENT BUDGET | OVERLAND PARK, KS | Mike Thome, Daniel Farnan, Rick Drake, Don Erisman | $ 1,254,395.00

PIPE | FERGUSON FABRICATION PRO PLAID WHITE | TX | Mike Mihalchik, Steve Hinshaw | $ 83,264.00 ELEC | NESTLE LIGHT CURTAIN | MO | Shawn Conz, Jason White | $ 50,000.00 SM | PROJECT SANDHILL ASI 007 | OLATHE, KS | Jerry King, Carey Minihan | $ 82,036.00 PLBG + SM | RIO - QUICK SERVE RESTAURANT