EMPOWERING ADVANCED SYSTEMS FOR ENHANCED SECURITY

EMPOWERING ADVANCED SYSTEMS FOR ENHANCED SECURITY

With a long-standing legacy in electronic warfare, Saab Grintek Defence is developing advanced technologies to aid with detecting, deceiving, and countering threats. President and Managing Director, Jan Widerström, discusses recent developments as we reconnect with the company

Writer: Rachel Carr | Project Manager: Josh Whiteside

As a subsidiary of Saab, known for its unique design and engineering innovations, Saab Grintek Defence (SGD) stands at the forefront of the South African defence industry, specialising in electronic warfare (EW) systems, sensor technology, and avionics.

Its expertise in technology design, development, and specialised manufacturing remains unmatched as SGD delivers innovative solutions and services across air, land, and sea domains.

The company offers a fully integrated, multispectral EW selfprotection suite and is a global leader in optical and laser sensors, digital processing, microwave components, and antenna technology.

SGD solutions are trusted to protect

aircraft, helicopters, land vehicles, naval vessels, and submarines, as well as provide signals intelligence systems for radar and communication interception.

Since we last spoke to SGD, the EW sector has been experiencing substantial development, fuelled by the demand for advanced capabilities and their integration into various defence platforms.

“We are experiencing strong and consistent growth in most of the global markets where we operate. Currently, Europe is our largest market, and we are concentrating on expanding our capacity. This involves recruiting new personnel and optimising our production processes,” introduces Jan Widerström, President and Managing Director.

“OUR SUSTAINABILITY INITIATIVES EXTEND TO OUR COLLABORATIONS WITH LOCAL COMMUNITY SCHOOLS, AS WE ARE DEDICATED TO ENSURING ACCESS TO KNOWLEDGE IN THE COUNTRY”

– JAN WIDERSTRÖM, PRESIDENT AND MANAGING DIRECTOR, SAAB GRINTEK DEFENCE

“Our main emphasis right now is on execution, which aligns with the priorities of our colleagues in Europe, but that’s where our key focus currently lies.”

South Africa (SA) faces capacity challenges due to a shortage of skilled labour, reductions in government funding for product development, and global demand that exceeds local capabilities, resulting in backlogs for companies trying to meet local and international needs effectively.

“The biggest challenge currently facing the industry is expanding capacity to meet growing demand, not only in Europe but worldwide. The current global situation puts us under significant pressure,” Widerström acknowledges.

“We export our systems to various regions, including Europe, Asia, and Latin America. Whilst restrictions exist on where we can export, we have a significant presence in the open market overall; currently, the local market represents a small portion of our total sales.”

Therefore, SGD’s primary focus is on building capacity in product development and production to cope with this growth. Indeed, the company has entered into an agreement with Omnigo to expand production, in which the supplier will cover manufacturing for selfprotection systems across the air, land, and sea domains.

This strategic decision will significantly support SGD’s growth and help the company meet the increasing global demand. Additionally, the contract will further commit Omingo to continue providing comprehensive electronic services to SGD, building on their long-standing and mutually beneficial partnership.

“We’ve seen a quadrupling of order backlogs, highlighting this challenge. Finding people with the correct skills is crucial, and we need to create an environment that prevents us from overworking and exhausting our employees to retain them,” Widerström notes.

However, there is an urgent requirement for skilled engineers and technicians, with many companies competing to attract these resources.

SGD’s culture is built on its ‘#Ubuntu Together As One’ philosophy, reflecting a belief in collaboration and shared success.

Guided by the core values of drive, trust, expertise, and diversity, the company strives for excellence in

• Integrated Defensive Aids Suite (IDAS)

• Land Electronic Defence Systems (LEDS)

• Naval Laser Warning Systems (NLWS)

• Electronic Support Measures (ESM)

• Electronic Intelligence (ELINT) for surface vessels and submarines

• Radio frequency (RF) components and EW antennas

• AviCom communications management system

everything it does, from advancing cutting-edge technology to fostering an inclusive, high-performance workplace.

This commitment is further demonstrated through the company’s partnerships. To navigate the recent surge in growth effectively and successfully, it is essential to foster collaboration with suppliers.

“On the one hand, we are focused on expanding our supply chain, which primarily consists of local partners. This involves providing suppliers with more work and supporting them in their development. In doing so, we can assign greater responsibilities to our supply chain, allowing us to concentrate on the areas where we excel,” explains Widerström.

Additionally, SGD is exploring strategic partnerships in Europe and Asia to increase capacity and address the current political climate.

“The issues of security, cybersecurity, and supply chain integrity are becoming increasingly important. We recognise the need to be close to our customers to ensure they feel confident in our suppliers and the overall security of our operations.”

Since 1986, Acu-Turn has been enabling manufacturing excellence across South Africa. What began as a small workshop producing mechanical components for the defence sector has evolved into a trusted manufacturing partner across a wide range of industries, including precision engineering and instrumentation.

Guided by a clear vision “to be a leading force in enabling manufacturing excellence across diverse sectors in South Africa,” Acu-Turn focuses on delivering real-world value through precisionengineered components. Its mission is simple: “to exceed client specifications through a commitment to exceptional quality, cost-efficiency, and timely delivery—empowering clients to achieve operational excellence and maintain a competitive edge.”

Based in Pretoria, Acu-Turn is led by Rupert Stander, alongside a team of skilled engineers and tradespeople who bring decades of technical expertise to every project. The company’s strength lies not only in its machines or materials—but in the way it partners with clients and continually reinvests in its own capabilities to meet their evolving needs.

“At Acu-Turn, we don’t just manufacture parts—we solve problems,” says Rupert. “We see ourselves as an extension of our clients’ operations. When their needs change, we invest to keep pace.”

This investment mindset is reflected in Acu-Turn’s modern CNC milling, turning, and EDM equipment, capable of handling a wide variety of materials and tolerances. The company’s largest milling capacity—1000 x 500 x 500mm—makes it well-suited for everything from delicate gold-plated tubes to large, high-precision components.

The value Acu-Turn delivers extends beyond machining. Through a curated network of suppliers and subcontractors, the company offers turnkey solutions including surface treatments, electroplating, specialized painting, and heat treatments.

This integrated approach ensures that even the most complex projects are delivered with consistency, quality, and efficiency.

The company’s culture is built around three pillars: meeting and exceeding customer quality standards, a commitment to cost-efficiency, and delivering on time. That focus, paired with a deeply relational approach to doing business, has made Acu-Turn a vital contributor to South Africa’s manufacturing landscape.

“Our commitment is long-term,” adds Rupert. “We don’t just serve a client—we grow with them. That’s why we continue to invest in our people, processes, and equipment: so we can help our clients stay competitive, agile, and successful.”

With nearly four decades of experience, Acu-Turn remains grounded in its purpose: enabling excellence. Through partnership, precision, and a commitment to continuous improvement, the company continues to shape the future of manufacturing.

Although these topics are a growing concern for SGD, as a subsidiary company, it has rigorous and centralised management of its tools and IT systems.

“We are undertaking significant work to strengthen all our security systems, which extends to considering big risks and increasingly incorporates cybersecurity within our products. This is particularly relevant as we develop more advanced airborne systems, amongst other products,” Widerström expands.

For political reasons, cyber and supply security are becoming increasingly critical as SGD must comply with such aspects and be close to its customers to ensure they are comfortable with the company’s suppliers.

“Sometimes, we need to be physically located where the customer is, especially for certain parts of our products and support services, as they often want full control over the location of their logistics and equipment,” he outlines.

At SGD, sustainability is a core aspect of its business strategy. Indeed, the company intertwines safety and security with its mission to keep people safe, aligning with broader environmental and socioeconomic progress.

“Sustainability is increasingly important; we need to establish a robust framework for the future as we face significant challenges with power supplies, electricity, and water,” Widerström states.

“We have made a major investment in solar power, and whilst we are not entirely autonomous or independent, we are close to achieving that goal. This step is vital for ensuring we can sustain operations, even during grid failures.”

In a significant stride towards a greener future, SGD completed the

As continuous learning is crucial for employee growth and business success, SGD offers a variety of workshops and resources to equip its team with the skills needed to thrive in a dynamic and innovative workplace. This ongoing development helps the company stay competitive by enhancing talent attraction and retention.

Employees have access to e-learning platforms, including Pluralsight and LinkedIn Learning, with 40 dedicated learning hours per year available during working hours.

SGD is dedicated to nurturing young talent through collaborations with local universities and schools, promoting community engagement and leveraging academic resources for mutual benefits.

• Bursary Programme – Supports students in critical fields to cultivate future leaders whilst addressing the critical skills gap.

• Graduate Programme – Offers hands-on workplace experience and mentorship, with 60 percent of participants in 2024 securing permanent positions.

• Learnerships – Aims to provide essential skills to unemployed youth, including individuals with disabilities, by equipping them with job-ready skills for greater inclusion in the labour market.

SGD strives to positively impact its communities through CSI initiatives focused on poverty alleviation, education, and unemployment reduction. These initiatives include:

• Partnering with schools, like Ribane-Laka Secondary School, to empower high-performing students, some of whom have gone on to join SGD. This creates a full-circle approach; by investing in learners, the company not only uplifts communities but also strengthens its internal talent pipeline.

• Collaborating with the Department of Basic Education to celebrate excellence by recognising top-performing schools and districts at national awards across SA.

• The Small, Medium, and Micro Enterprises (SMMEs) Programme supports local businesses, such as Solve Direct Electronics, Kutleng Engineering Technologies, and Sparcx, contributing to their technical skills and engineering growth.

Etion Create (EC) is an Original Design Manufacturer that partners with clients to deliver complete, customised electronic solutions By leveraging proprietary IP and engineering expertise, EC integrates modular technology into client-specific systems Its VF370 and VF365 3U OpenVPX modules exemplify EC’s capabilities in high-performance embedded applications

VF370 – 3U VPX SBC with Intel Atom® The VF370 is a versatile 3U OpenVPX SBC featuring Intel Atom® E3900 CPU, Altera® Cyclone® V FPGA and FMC support for scalable I/O in compact, SWaP-optimized environments Its rugged reliability suits aerospace and industrial use. Proven in Saab’s IDAS-310 EW systems, the VF370 is rated at the highest Technology Readiness Level TRL9 “Etion’s innovative VF370 has extended our product’s life and capability,” says Harry Schultz, Saab Product Manager

The VF365 combines Altera Arria® 10 SoC FPGA and TI KeyStone® DSP technologies to deliver ultra-high bandwidth processing ideal for Radar, SIGINT, EW, SDR, and video-intensive systems Its dual-core ARM Cortex-A9 processor and highspeed AXI bus ensure tight integration between software and hardware

www etioncreate co za

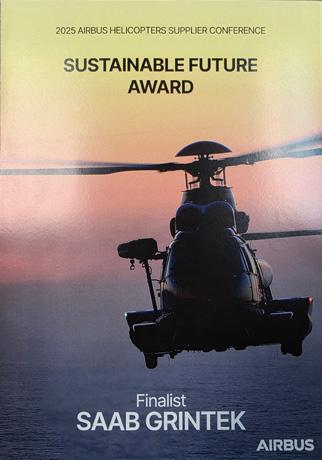

SGD recently achieved second place in the Sustainable Future category at the 2025 Airbus Helicopters Supplier Conference, highlighting its commitment to sustainable business practices within Airbus Helicopters’ global supply chain.

The award reflects SGD’s alignment with the Airbus Supplier Code of Conduct, strong EcoVadis and Carbon Disclosure Project scores, and active initiatives such as substance substitution and local investment, with 87 percent of procurement spending directed to local businesses.

Moreover, sustainability is integrated into SGD’s products and, in collaboration with Airbus, the company received an accolade at the Sustainable Future Awards.

By embedding sustainability into operations and supporting local enterprises, SGD contributes to a safer and more responsible world.

installation of a one megawatt (MW) solar power plant at its Centurion office in SA. This project will enable the company to achieve 70 percent self-sufficiency from the national grid. Aligned with the global Race to

Zero campaign and the company’s broader sustainability goals, the solar plant is complemented by a state-ofthe-art 1MW battery back-up system. This advanced set-up utilises JA Solar 550-watt (W) modules

and cutting-edge battery storage technology, ensuring efficient and reliable on-site energy generation.

The installation embodies SDG’s vision of a sustainable future where innovation and environmental consciousness seamlessly merge, underscoring its commitment to reducing environmental impact whilst ensuring energy reliability for operations.

“Our sustainability initiatives extend to our collaborations with local community schools, as we are dedicated to ensuring access to knowledge in the country. Furthermore, we continuously enhance our facilities and long-term capacity,” Widerström prides.

SGD invests significant effort and resources into its future. This includes focusing on its local product portfolio and contributing to the organisation’s broader vision, emphasising

Let us 10x your staff and ensure your company is well-prepared for the future world of work.

As a proud SETA accredited education and corporate training institute. 10x your-self and company. World-Class Technologies, Latest AI Methodologies, Cosmic and Neuroscience Insights, Local and UK Accreditation!

We use Artificial Intelligence, IT, Neuroscience and a Business School that train individuals, and companies, to deal with change to achieve ROI, be sustainable and manage risk in a VUCA World. Neurons that fire together wire together, and this embeds the learning.

At Shuttleworth Academy, our mission

is to inspire growth in minds, hearts, and organisations through our innovative product offerings. We leverage cutting-edge technology and advanced methodologies to enhance skills and transform mindsets.

Our approach incorporates digital training methods that ensure superior learning outcomes, making education accessible and engaging.

We specialise in Artificial Intelligence Games-Based learning, which is designed to captivate learners whilst equipping them with essential skills for the modern workforce.

Contact us now: info@ShuttleworthAcademy.com www.ShuttleworthAcademy.com

“MUCH OF OUR R&D IS CONDUCTED LOCALLY, AND WE ARE COMMITTED TO INVESTING HEAVILY IN DEVELOPING NEXTGENERATION SYSTEMS”

– JAN WIDERSTRÖM, PRESIDENT AND MANAGING DIRECTOR, SAAB GRINTEK DEFENCE

tomorrow’s technologies.

“We are focused on capacity building and technological advancement by investing in machinery and resources to increase output and improve efficiency. We also prioritise funding R&D for future products to stay at the forefront of technology,” informs Widerström.

“In collaboration with our parent company, Saab, we are proud to be one of the centres of excellence in the EW domain. Much of our R&D is conducted locally, and we are committed to investing heavily in developing next-generation systems,” he sets out.

This will strengthen SGD’s position in the industry, whilst integrating cutting-edge technologies such as artificial intelligence (AI) into its systems will be crucial in maintaining a competitive edge.

“Our goal is to meet current demand whilst planning for the future and identifying where we need to be in the next five to 10 years. The challenge lies in balancing both objectives, but we are actively working to achieve this.”

“Our top priority is to increase capacity whilst recruiting the right candidates – we are actively working to identify new talent. This is essential

for effective project execution and everything that comes with it,” Widerström concludes.

The future of SGD is evidently one of innovation, growth, and a firm commitment to excellence in defence solutions.