Chart Industries is a global leader in the design, engineering, and manufacturing of process technologies and equipment for gas and liquid molecule handling for the Nexus of Clean™ – clean power, clean water, clean food, and clean industrials, regardless of molecule. We take a deep dive into the company’s incredible story with CEO, Jillian Evanko

Writer: Ed Budds | Project Manager: Michael Sommerfield

Molecules are the fundamental building blocks of countless substances and form the basis of chemistry as we know it.

These tiny groups of atoms are fundamental to understanding the world, from the smallest components of life to the immense vastness of the universe.

Helping a worldwide network of customers navigate the entire molecular value chain, Chart Industries (Chart) (NYSE: GTLS) is paving the way in the provision of equipment and solutions for the energy and industrial gas markets.

Chart has worked tirelessly to establish itself as a global leader in the design, engineering, and manufacturing of process technologies and equipment for gas and liquid molecule handling, for what it affectionately refers to as the ‘Nexus of Clean’ – a commitment to clean

power, water, food, and industrials.

The incredible work being pioneered by Chart includes enabling the complex production of a molecule itself.

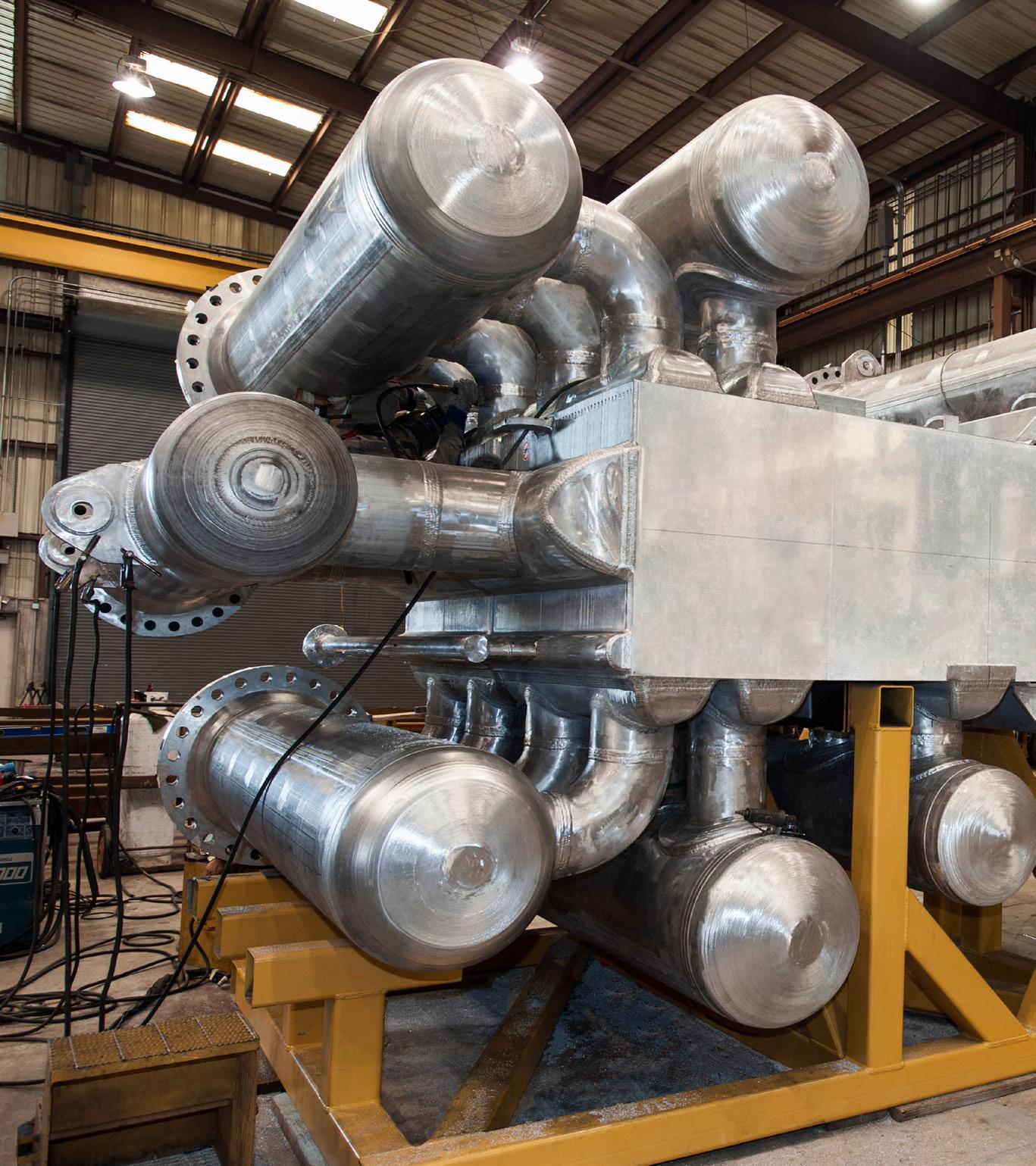

A prime example is the process of creating liquefied natural gas (LNG), where customers use the company’s equipment such as brazed aluminum heat exchangers or its process technology – Integrated Pre-cooled Single Mixed Refrigerant® (IPSMR®) – in order to produce that specific molecule.

Chart then helps its clients to handle the safe transportation of the molecules across a variety of methods, each specific to the individual requirements of the product and the conditions in which they must be kept.

As such, the company’s unique portfolio of products and solutions across stationary and rotating

Jillian Evanko, CEO: “I’m most proud of our team – and how they’ve shown up through numerous stages of growth, transformation, and many different challenges.

“Over the past few years, we’ve more than doubled in size, expanded globally, and accelerated our role in the industry, all while staying grounded in our core values. That is because we have talented people who are adaptable, mission-driven, and willing to lead from every level of the organization.

“We view safety as our number one priority and it is a point of pride at Chart. As such, we’ve achieved some major milestones at several of our global sites, including multi-million-hour streaks without lost time incidents (LTIs) and a record total recordable incident rate (TRIR) of 0.40 at the end of 2024, but we won’t be satisfied until we have zero accidents.

“Each of our team members is authorized, empowered, and expected to stop work if they see a potentially unsafe situation.”

equipment is used in every phase of the liquid gas supply chain, including engineering and service and repair, as well as from installation to preventive maintenance and digital monitoring.

Now utilizing an impressive 64 manufacturing locations and over 50 service centers globally, along with approximately 11,700 dedicated team members, Chart provides industryleading technology, equipment, and services related to LNG, hydrogen, biogas, and carbon dioxide (CO2) capture, amongst other applications.

“Our unique product portfolio is used throughout the liquid gas supply chain in the production, storage, distribution and end-use of atmospheric, hydrocarbon, and industrial gases,” introduces CEO, Jillian Evanko.

“We now leverage domestic operations located across the US and enjoy an international presence

“I QUICKLY REALIZED HOW ENERGIZING IT WAS TO BE PART OF SOMETHING TANGIBLE – TO BUILD, SOLVE PROBLEMS, AND WORK WITH INCREDIBLY SMART, HANDS-ON TEAMS IN THE FIELD”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

in Asia, Australia, Europe, and Latin America,” she informs us.

The company’s impressive global scope and expanding geographical presence continues to level up and develop alongside the broader energy and industrial gas sector, positioning Chart at the forefront of this burgeoning industry.

Evanko didn’t set out to build a career in industrial manufacturing, but once she got into the space, she never looked back.

“My formal education is in finance, and I started my career at accounting firm, Arthur Andersen – just before

the Enron scandal shifted the entire landscape. That unexpected turn pushed me to take a role at Honeywell, where I got my first exposure to industrial operations,” she recalls.

“I quickly realized how energizing it was to be part of something tangible – to build, solve problems, and work with incredibly smart, hands-on teams in the field.”

Since then, Evanko has held numerous leadership roles across finance, operations, and strategy.

“I’ve always been drawn to industries where you can see the real-world impact of your work. That’s what continues to motivate me every day,” she enthuses.

Serving as CEO since June 2018, Evanko initially joined Chart in February 2017 as Chief Financial Officer (CFO).

Prior to joining the company, she was CFO of Truck-Lite and held multiple operational and financial executive positions at Dover Corporation and its subsidiaries.

Before this, Evanko held financial and operational roles at both Honeywell and Sony Corporation. Now, in addition to her role at Chart, she also serves as an independent Director of the Board at Parker Hannifin Corporation.

As recognition of her hard work and exceptional service throughout the industry, in both 2022 and 2023, Evanko was named as one of the Hydrogen Economist’s ‘Top 50 Women in Hydrogen’, as well as making it onto Hart Energy’s ‘25 Most Influential Women in Energy’ list for 2021.

Ingersoll Rand is a global leader in the manufacturing of mission-critical flow creation products and life science and industrial solutions, operating under 80+ brands. Our success is made possible by our 21,000+ employees (and counting!). Powered by an ownership mindset and more than 160 years of expertise, we’re driving differentiated performance with purpose.

Lean on us to help you make life better is deeply embedded in all that we do. We wake up each and every day with the goal of Making Life Better for our employees, our customers, our shareholders, and our planet.

For our Employees For our Customers

For our Shareholders For our Planet

We have a proven track record as an industry leader in sustainability.

Leading sustainably means both growing and operating sustainably. Growing sustainably refers to developing intrinsically sustainable products and services and supporting customers in high-growth, sustainable markets. With a focus on improving efficiency, circularity, and safety, we employ a Design for Sustainability (DfS) process for all new product development. More than 65% of our current product portfolio includes products with sustainable attributes.25 Additionally, we continue to expand our presence in the life sciences, clean energy, food, and water end markets.

As of December 2024, we have 59 green energy sites and 90 sites that have achieved zero waste to landfill since 2020. Operating sustainably also means taking care of our employees. We prioritize employee safety as an important aspect of our culture, holding our first annual company-wide Safety Day in 2024. Our Total Recordable Incident Rate is world class and 72% better than the industrial machinery manufacturing average.26

Our sustainability program has achieved remarkable success and acknowledgment by the top sustainability ratings providers. We were included on the Dow Jones Best-in-Class Indices (formerly the Dow Jones Sustainability Indices) for the third year in a row based on our score on the 2024 S&P Global Corporate Sustainability Assessment.27 For the second year in a row, we were named to CDP’s “A List” for our commitment to global environmental leadership. Additionally, we maintained our low-risk rating from Sustainalytics, with a top 1% performance in our industry and top 3% among all rated companies.28

25 Current management estimation for 2023 indicates that over 65% of our product portfolio incorporates sustainable attributes such as energy efficiency, waste minimization, water conservation, and extending the useful life of the product through remanufacturing.

26 Average Total Recordable Incident Rate (TRIR) for all Industrial Machinery Manufacturing companies in 2023 (most recent data available) was 1.9 according to the U.S. Bureau of Labor Statistics. World Class is defined as the top quartile of manufacturing companies with >1,000 employees per U.S. Bureau of Labor Statistics (2021). 27 Receipt of an S&P Global ESG Score does not represent a sponsorship, endorsement or recommendation on the part of S&P Global to buy, sell or hold any security, and a decision to invest in any subject company should not be made based on the receipt of any such note. S&P, S&P Global, and the S&P Global logo are trademarks of S&P Global Inc. or its subsidiaries, registered in many jurisdictions worldwide.

28 As of November 2024, Ingersoll Rand received an ESG Risk Rating of 10.2 from Morningstar Sustainalytics, ranking it first in the Machinery industry group, which places it in the 1st percentile for its industry. This risk rating also places Ingersoll Rand in the top 3% of all companies rated by Morningstar Sustainalytics. This risk rating is based on information and data developed by Sustainalytics and is proprietary to Sustainalytics and/or its third-party suppliers and is provided for informational purposes only. The risk rating does not constitute an endorsement of any product or project, nor an investment advice and the information upon which it is based is not warranted to be complete, timely, accurate or suitable for a particular purpose. The use of the risk rating is subject to conditions available at: https://sustainalytics.com/legal-disclaimers. In no

Enabling the transition to clean, low-carbon and zero-carbon energy.

Green hydrogen is gaining momentum as a cornerstone of the global energy transition. Ingersoll Rand is supporting this shift by providing four-stage centrifugal compressors that deliver 12 MW of nitrogen refrigeration for a major hydrogen liquefaction facility in the United States. Once complete, the site will be among the largest permitted green hydrogen production centers in the country, powered in part by solar energy. This milestone project reflects Ingersoll Rand’s continued commitment to enabling clean energy infrastructure and accelerating the path to net-zero emissions.

As part of the shift toward cleaner, more resilient energy systems, a U.S. LNG peak shaving facility was developed to store and deliver natural gas during high-demand periods. Ingersoll Rand played a key role in this sustainable energy project by providing a custom-engineered MSG® integrally geared centrifugal (IGC) compressor package. Powered by a gas turbine and equipped with an advanced seal gas recovery system, the compressor enables efficient natural gas liquefaction in remote locations with limited electrical infrastructure. By supporting grid stability and enabling cleaner-burning fuel alternatives for power generation and transportation, Ingersoll Rand continues to deliver compressor solutions that help drive the energy transition forward.

Ingersoll Rand compression equipment supports the world’s largest Direct Air Capture (DAC) plant, located in the Texas Permian Basin. This plant will advance large-scale carbon capture to reduce emissions and accelerate the path to net-zero. Ingersoll Rand provided four centrifugal compressors to a large-scale energy company building the DAC plant. The plant is expected to provide costeffective solutions that hard-to-decarbonize industries can use in conjunction with their own emissions reduction programs to help achieve net-zero. The captured carbon will be safely and securely sequestered in saline formations or used to produce low carbon products. Once operational, the plant is expected to capture up to 500,000 metric tons of CO2 per year with the capability to scale up to one million metric tons annually.

Ingersoll Rand delivers solutions to help drive the energy transition and decarbonization efforts. We have unique expertise in designing essential technologies needed to help on the journey to create a net-zero economy, including energy-efficient equipment and lower GWP refrigerants. Likewise, our services, including digital offerings, promote energy efficiency and improved air quality.

System Performance Manager powered by Ecoplant represents innovative technology which uses machine intelligence to improve compressed air systems offer approximately 15–20% in energy savings. Predictive algorithms assess a company’s daily, weekly, and seasonal energy use and then dynamically control systems via production profiles to lower energy waste, redundancy, and excess utility costs.

Average annual savings for System Performance Manager customers

<1 year payback

For most applications

FEATURES

‣ Patented technology and proprietary algorithms in Al and machine learning (ML)

‣ Real-time, dynamic control of compressed air systems

‣ Brand and technology-agnostic

‣ Subscription-based

BENEFITS

‣ Predict maintenance, minimizing outages, and avoiding costly downtime

‣ Real-time visibility to energy savings, GHG reduction, system health, and alerts

‣ Monitor sites from anywhere in the world using a cloud-based platform

‣ Detection and isolation of leaks

‣ Smart decision enabler with historical data and personalized analytics

‣ Installation within two days

However, despite these numerous prestigious accolades, Evanko cites her proudest workplace accomplishment as being part of an exceptional team at Chart.

“Because of every dedicated member of staff that I’ve had the pleasure to work with across the entire spectrum of our operations, I’ve always enjoyed the immense privilege of leading an amazingly talented team and an awesome company that has more than doubled in size, entered new markets, and shifted its portfolio,” she prides.

Under Evanko’s exceptional leadership since 2018, Chart has worked toward clean energy and sustainability goals, joining the UN Global Compact, a voluntary initiative to implement sustainability principles, and initiating strategic acquisitions that has allowed the company to significantly expand its product offerings.

“I’VE ALWAYS BEEN DRAWN TO INDUSTRIES WHERE YOU CAN SEE THE REAL-WORLD IMPACT OF YOUR WORK. THAT’S WHAT CONTINUES TO MOTIVATE ME EVERY DAY”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

Additionally, in this time, Chart made the decision to take calculated risks that previously would’ve been viewed as too hazardous or something that no one else wanted to do.

However, she believes these types of decisions are critical to give businesses such as Chart an advantage in such a competitive environment.

Meanwhile, as a leading female executive navigating the twists and turns of a male-dominated industry, Evanko firmly believes her gender shouldn’t be seen as a defining issue.

“I just aim be the best CEO, not the best female CEO,” she affirms.

“I would say 100 percent of the accolades that I’ve been lucky enough to receive to date are the result of my incredible team. It’s really a credit to the people out there that are designing and building our products.”

Evanko also stresses the vital importance of being a responsible leader, which is why to this day she answers every message she gets, from a conversation on LinkedIn to a text or email.

“At the heart of the company, we want to profitably grow, and we

want to continue to deliver unique solutions, but I never want any one of our team members or customers to walk away and say that I wasn’t a kind leader who had no time for her staff,” she muses.

Across the globe, a multitude of trends across the industrial manufacturing and energy sectors are always fluctuating.

Evanko views both these industries as exciting and full of potential regarding both the domestic US market and on a more global basis.

“The US energy sector is currently balancing two key forces – rising demand and the need for greater flexibility,” she comments.

“Right now, we’re seeing a renewed focus on energy security and a strong role for LNG as a reliable,

lower-carbon option that can be deployed quickly and at scale. LNG continues to be a critical part of the equation.”

For Chart, what’s clear is that the path forward won’t be linear, and no single energy source will solve everything for everyone.

“That’s why our molecule-agnostic approach is so important. We’re not tied to one fuel or technology – we enable the infrastructure behind a broad range of solutions,” asserts Evanko.

This includes solutions across industries such as energy, industrial, power generation, LNG, nuclear, water, chemical, space, industrial gas, carbon capture, and hydrogen – to name a few.

“Our focus is on delivering flexible, scalable systems that help our customers adapt and lead – no matter where they are on their energy or sustainability journey,” she lays out.

Backed by its 158 years of experience in designing, engineering, and manufacturing hydrogenrelated equipment, Chart now provides customers with all process technologies and major equipment across the entire gaseous and liquid hydrogen value chain.

The vast and fascinating field of cryogenics is at the foundation of what Chart does – and it continues to be a core strength across both established and emerging markets.

“Our cryogenic systems support industrial gas storage and distribution, LNG applications, and energy infrastructure around the world. These are long-standing areas of expertise where we continue to innovate, scale, and serve a global customer base,” Evanko declares.

Burrow Global is a uniquely positioned, full-service Engineering, Procurement and Construction company. We offer the comprehensive EPC capabilities of a larger firm, but can adapt quickly to client-specific needs as a mid-sized organization.

Our Flexibility is just one of the reasons clients choose us. For more than 40 years, Burrow Global has provided general construction services for process industries throughout the United States and abroad with more than 20 years without a lost time incident.

Our Quality Program documents and validates that the plant assets have been engineered properly, installed per design and regulatory requirements and commissioned and started up properly. To improve quality and value in project delivery, we have proven programs and processes, optimizing project execution with testing programs that combine mechanical completion and precommissioning requirements.

Multi-Discipline Design and Engineering Capabilities:

• Process

• Piping

• Buildings

• Civil/Structural

• Mechanical

• Instrument

• Electrical

• Architectural

• Automation

• Process Safety

9MM+

7MM+ 0.00

Service Profile:

• EPC Execution with Strategic Offices and Fab Shop Location

• Fabrication (ASME, U, R, S, PP Code Stamps)

• Commissioning, Startup, Planning and Execution

• Turnaround Management

By working cohesively with the designer and owner to understand needs and objectives, our team led by Burrow Global with 51 years of experience to develop optimal solutions to seamlessly solve complex issues. Our integrated teams partner early to drive collaboration to accelerate project delivery.

Whether it’s a greenfield development, projects of all shapes and sizes, firstgeneration fit outs and retrofits of existing structures Burrow Global can provide efficiency to cover your project from planning, budgeting all the way through commissioning. Always considering customer objectives in mind.

Burrow Global offers Design, Construction Management, and HSE Services for building deployment. As the general contractor, we manage subcontractors, suppliers, and schedules across civil, electromechanical, and support systems.

Our Health, Safety, and Environmental team ensures the well-being of all personnel through established safety plans, protocols, and training. Additional disciplines include access control, fire detection and suppression, automation, control, and commissioning.

Burrow Global team which includes fabrication, consultants and partners

of data center practitioners implement the latest digital innovation across the full engineering spectrum, life safety/fire protection, security, interior and landscape design and architecture planning to ensure a tailored design/build.

Burrow Global construction management team’s program management, project controls, vendor/contractor management, procurement, scheduling, commissioning, coupled by our safety record ensures your project’s longterm success.

Building a data center is just the beginning. Keeping it running at peak performance - securely, efficiently, and without disruption - takes a partner with deep technical knowledge and a track record of global success.

That’s where Maintech comes in.

With over 50 years of IT support excellence, Maintech specializes in comprehensive data center management through its full Tower of Services. From legacy hardware to the latest hybrid infrastructure, we ensure missioncritical environments are maintained, monitored, and optimized around the clock, anywhere in the world.

Maintech’s outsourced support model is designed

to give businesses the confidence and control they need, without the overhead of managing complex systems in-house. We provide everything from rapid-response break/fix services and IMAC (Install, Move, Add, Change) work to full-scale hardware lifecycle management, asset tracking, secure disposal, and realtime monitoring. Our global command centers enable seamless oversight and coordination. Meanwhile,

Our goal is simple: To help you deliver uptime, resilience, and operational excellence from the inside out.

our certified field engineers deliver hands-on support when and where it’s needed. What sets Maintech apart is the depth of our third-party maintenance expertise. We’re vendor-agnostic and skilled across all major OEMs, ensuring consistent, expert-level support no matter the equipment mix. For businesses with multiple sites, global operations, or aging infrastructure, this approach delivers flexibility, cost savings, and performance gains without compromise.

Outsourcing data center maintenance to Maintech means you gain access to the right people, trained

to the highest standards, ready to support the full range of your IT environment. Whether you’re consolidating hardware, expanding capacity, or simply need boots on the ground for regular upkeep, our teams integrate seamlessly with yours. This extends your capabilities and reinforces your reliability.

With decades of experience supporting Fortune 100 enterprises, financial institutions, government agencies, and fast-growth businesses, Maintech has become the trusted name in third-party IT services. Our goal is simple: to help you deliver uptime, resilience, and operational excellence from the inside out.

Data centers don’t just need to work. They need to work flawlessly, every hour of every day.

Let Maintech manage the maintenance so your team can focus on innovation.

Learn more about our full suite of IT infrastructure services at www.maintech.com

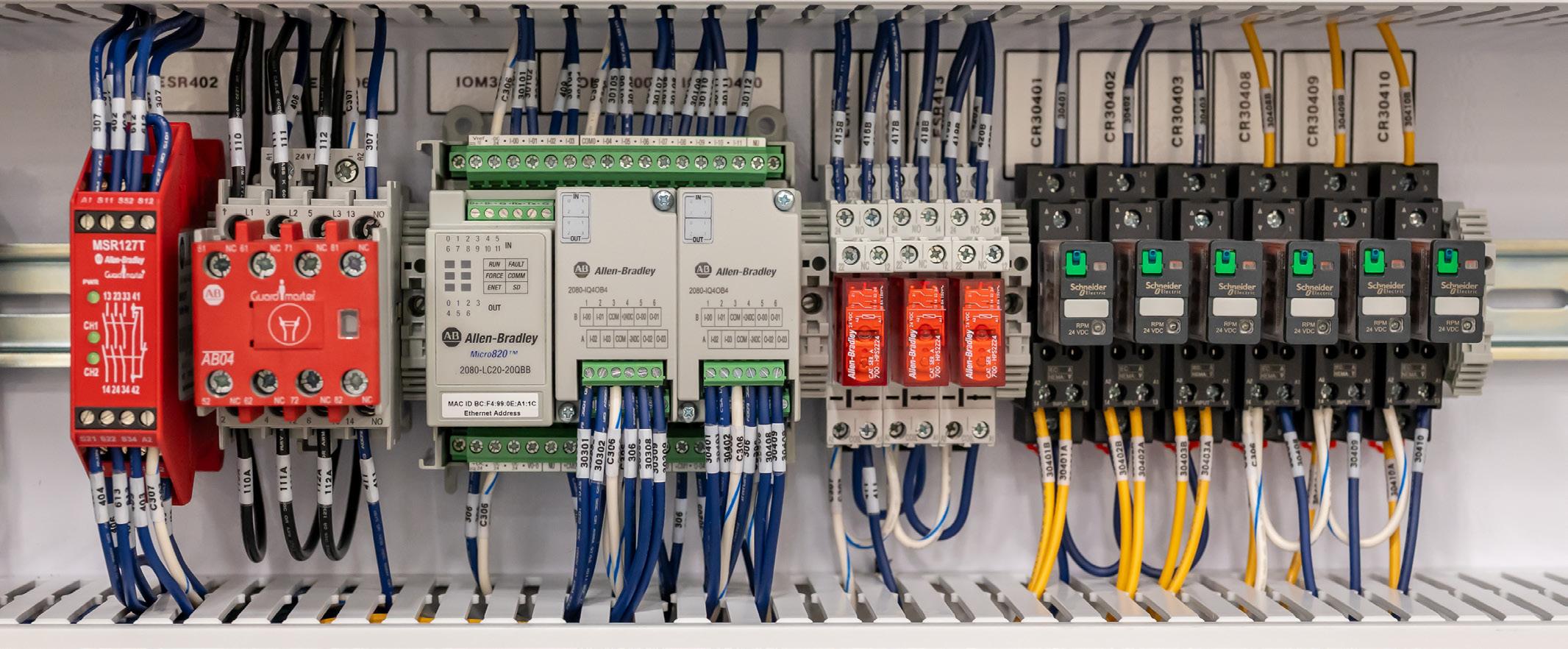

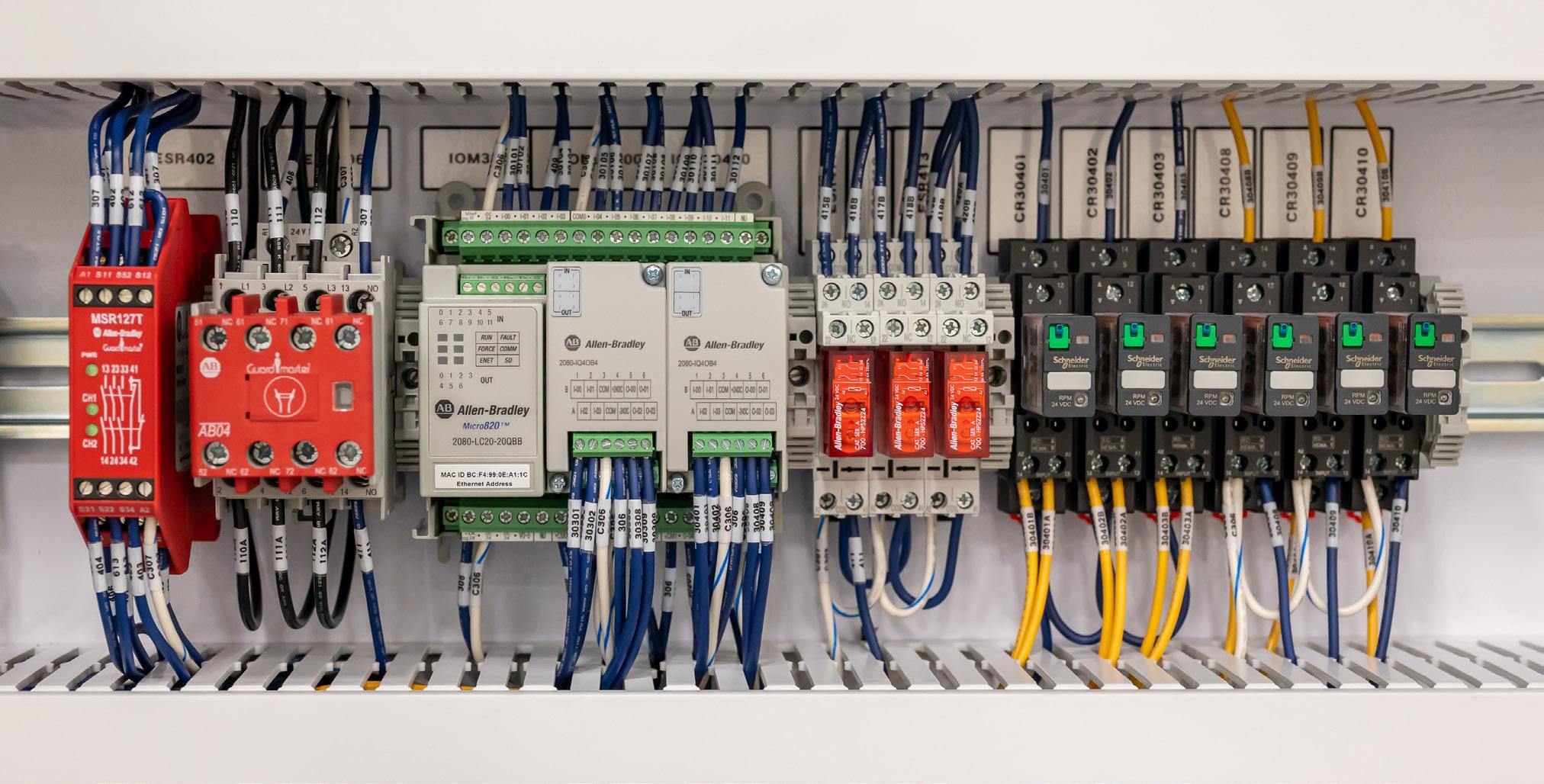

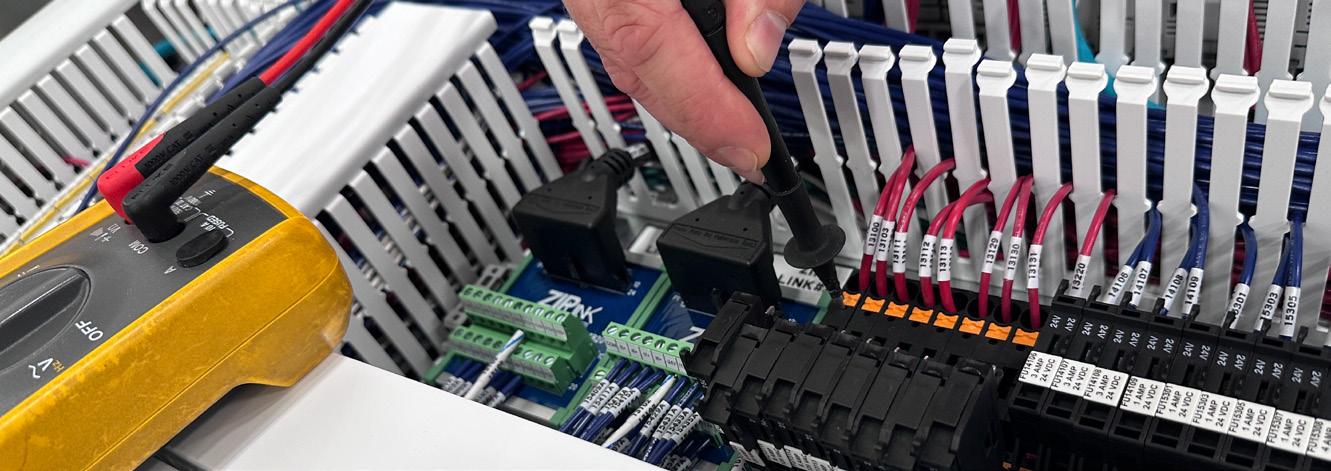

Houston, TX — Burrow Global, a leading full-service EPC and automation firm, continues to showcase executional excellence and industry leadership through its collaboration with CHART Industries at their New Iberia facility.

Through ECCO, A Burrow Global Company, Burrow Global has established itself as a vital service provider to CHART’s New Iberia Operations Team by developing and executing a comprehensive Instrument and Electrical (I&E) installation strategy for cold box assemblies.

To date, Burrow Global has safely, efficiently, and cost-effectively completed I&E installations on more than 100 cold boxes at the New Iberia site. From working alongside CHART Engineering to executing real-world installations, Burrow

Global’s scope of work includes:

• Comprehensive I&E routing and installation

• Extensive testing and data logging of all electrical and instrumentation components

• Long-term system maintenance and support

• Full collaboration with CHART’s Engineering team to ensure design-to-execution alignment

Burrow Global’s smart routing plans and rigorous testing protocols not only ensure system functionality and traceability, but also help CHART meet critical project timelines and reduce maintenance needs postinstallation. This collaborative approach underscores Burrow Global’s commitment to safety, quality, and schedule performance in highly technical environments.

At the same time, the engineering and manufacturing capabilities that serve traditional energy and industrial gas markets are also enabling newer technologies – from hydrogen mobility and aerospace to carbon capture and even clean fuels for marine and aviation.

“For example, we’ve supported rocket launches with liquid oxygen tanks, enabled liquid hydrogen systems for space and trucking, and delivered ultra-large tanks for highcapacity storage applications,” she adds.

“What sets our portfolio apart is the breadth of solutions we offer –from tanks, heat exchangers, fans, compressors, trailers, and vaporizers

COULD YOU TELL US ABOUT THE COMPANY’S SUPPLY CHAIN OPERATIONS AND HOW IMPORTANT PARTNER AND SUPPLIER RELATIONSHIPS ARE TO

Jillian Evanko, CEO: “Our supply chain is critical to Chart’s operations and is a strategic asset to the business. We’ve worked hard to diversify sourcing, localize and globalize where it makes sense, and build strong relationships. In today’s environment, resilience really matters.

“We’ve also invested in digital tools to improve forecasting, transparency, and decision-making across the supply chain.

“Whether we’re serving a project in Texas, Germany, or Southeast Asia, we’re focused on delivering safely, on time, and with the flexibility our customers need.

“We are committed to the highest standards of ethics and business conduct. As stated in the Chart Code of Ethical Business Conduct, we seek to ensure that our product and service suppliers share our commitment to acting with integrity and to open and trusting relationships.

“We therefore require our suppliers to meet our expectations for ethics and compliance with all applicable laws. In addition, Chart understands and expects that our suppliers will have their own internal codes of ethics and conduct.”

to complete integrated systems – and our ability to tailor those solutions to each customer’s needs.”

Within its substantial and varied portfolio, Chart’s bulk cryogenic storage systems are customengineered to meet application specifications for its clients.

The company’s complete system solution package ensures quality liquid or gas, which is used to keep processes operating at peak efficiency. Built for long-term integrity and industry-leading efficiency, these systems give clients the highest performance at the lowest operating cost.

Each Chart tank is engineered with a high degree of standardization for cost-efficient production and to keep delivery times short.

Parallel to this, a diverse range of bolt-on modular options ensure that its standard tanks cater to customer requirements, while further customization options are also available on request.

Boasting superior design and engineering prowess, Chart’s storage tanks feature state-of-the-art modular piping systems which combine high performance, durability, and low levels of required maintenance.

The key features of these tanks include a reduced number of joints which minimizes the risk of external leaks and facilitates simplified installation, as well as a comprehensive range of safety features to afford maximum protection for operators and the equipment itself. Additionally, they possess

easy access to control valves and instrumentation, meet seismic requirements, boast unrivalled engineering and manufacturing capacity, have world-class facilities strategically located in centers of demand, and Chart now leverages a dedicated range for the storage of CO2

Engineered, manufactured, and tested in accordance with all major international design codes and associated regional requirements, these impressive products are truly engineered to excel and built to last.

Cryogenic transport trailers are specialized vehicles designed for the safe and efficient transportation of materials at extremely low

temperatures, typically below -150 degrees Celsius (°C).

These state-of-the-art trailers are essential for industries such as healthcare, energy, and food production, where cryogenic liquids need to be transported safely and securely.

Different transport trailers are designed for specific gases and distances, with features such as a reinforced chassis for overcoming challenging road conditions and optimized designs for maximum payload.

Chart’s cryogenic trailers utilize multi-layer vacuum super insulation and other advanced technologies to maintain the necessary low temperatures and keep them at a constant and ideal level during the course of transit.

Based in Fort Worth, Texas, on a 20-acre manufacturing facility fully equipped with state-of-theart machinery, Baker Tankhead’s legacy of leadership in the US metal fabrication industry sets them apart. We sat down with the company’s executive leadership team to find out more.

Founded in 1977, Baker Tankhead is an expert manufacturer of American Society of Mechanical Engineers (ASME) and noncode tank heads, rolled cylinders, and cones that are custom designed to meet the needs of a wide range of industries and customers.

Keeping pace with rapid changes in North America’s metal fabrication space, the company believes continuous adaptation and improvement is key to securing long-term success.

“As the industry evolves, so do we – whether that means investing in new equipment, streamlining our operations, or recognizing and promoting talent from within. We’re proud of the products we manufacture and the services we provide,” opens Aaron Baker,

Vice President.

One of the most significant shifts shaping the industry today is the rise of automation, robotics, and smart technologies, enabling Baker Tankhead to deliver increasingly customized solutions to its clients. Yet, because dishing and flanging tank heads remain fundamentally handson processes, the company leverages innovation to complement rather than replace human skill.

“Our creative ability is very important to us, so we use technology to make our processes better and faster while still relying on hands-on skills that take years to master,” comments Jorge Sigala, Production Manager.

Recently, Baker Tankhead expanded its technological

capabilities by adding an 800ton press to its equipment lineup. The company first manufactured their presses in-house before adopting earlier versions of this machine. Now operating with ten presses, Baker continues to acquire new models as advancements emerge.

“The European manufacturer of the press continues to make

improvements, changing up the speed and efficiency, which is very exciting,” Austin Baker, Owner and President, explains.

The new press will enable the company to achieve thicker products, while the machine’s wide frame will allow it to manufacture tank heads up to 30 feet in diameter.

“It’s one of the largest cold forming presses in North America,” Sigala confirms.

“It’s fascinating not only to see what we can build from a flat plate of steel, but what our customer base does with it.”

– Robert Paine, Business Operations Manager, Baker Tankhead

On a mission to provide unparalleled services with a family focused culture, Baker Tankhead sets itself apart from the competition.

Collaboration is central to achieving this ethos, as the company maintains close relationships with both customers and employees.

“When it comes to our clients, we seek to develop long-term relationships – partnerships that are an extension of our family as we listen to their needs and anticipate challenges,” observes Alan Button, COO.

For example, Baker Tankhead is proud to have collaborated with a client in the aerospace industry who had previously struggled to find a manufacturer.

“We opened our doors to this customer, working closely with their engineering department

to provide the quality service they were looking for,” Austin elaborates.

By adopting an open-door approach in this way, the company has since built a strong relationship with the customer as well as countless others.

“We’re always willing to welcome customers with open arms – having been in this business for almost 50 years, I can safely say that’s an advantage we’ve had from the others and how we’ve built the company from the ground-up,” he continues.

Also applying this mentality to its team and employees on the shop floor, consistent collaboration contributes to Baker Tankhead’s greater goal.

“We offer a supportive environment for our staff, ensuring employees feel heard, empowered, and motivated to grow and progress,” Button comments.

Meanwhile, attention to detail and a deep-rooted commitment to quality further contribute to the company’s leading status.

“When you work with us, it doesn’t take long to see why Baker Tankhead has been growing strong for nearly 50 years – and why we’re excited about what’s ahead for the next 50,” says Aaron.

As a company that collaborates with a wide range of clients, Baker Tankhead takes pride in discovering the various uses of its products across different industries.

“It’s fascinating not only to

see what we can build from a flat plate of steel, but what our customer base does with it,” reflects Robert Paine, Business Operations Manager.

Historically, the company’s collaborations have included customers in cryogenics, oil and gas, and water treatment, however it has recently witnessed a boom in data centers.

“We’re seeing increasing demand from companies focused on green energy initiatives and carbon capture technologies,” Paine notes. “In other sectors, our products are used to build boring equipment for horizontal drilling.”

Beyond these diverse

“As the so do means equipment, operations, and promoting within.”

– Aaron Baker

applications, Baker Tankhead’s components have journeyed into space and contributed to oceanographic exploration.

“Tank heads are everywhere – from the food industry to vacuum trucks, water heaters, and liquor distilleries. The list goes on.”

As the diversification of Baker Tankheads’ products continue to evolve alongside its customers’ changing needs, the possibilities for growth are endless.

Having started as a small 1,200 square foot shop that has now expanded to 200,000 square feet across 20 acres, the

the industry evolves, do we – whether that means investing in new equipment, streamlining our operations, or recognizing promoting talent from within.”

Aaron Baker, Vice President, Baker Tankhead

company’s historical growth is tangible.

It has implemented new on-site facilities and technologies over time and is always on the lookout for further opportunities to innovatively fulfil its customers’ requirements.

“We also boast various key differentiators such as maintaining the fastest lead time in the business, alongside our unparallelled service and high-quality products,” Paine prides.

“Once we’ve built a long-term relationship with a customer, I really think they begin to see what they were missing prior to working with us,” Austin adds.

Having been a long-term partner of Chart Industries (Chart) for 20+ years, Baker Tankhead has established a solid partnership with the company.

“We’ve grown alongside Chart across multiple locations, maintaining a great relationship and a lot of repeat business,” Austin recalls.

Equipped with its new 800 ton press, Baker Tankhead is looking forward to manufacturing additional work for Chart, further elevating not only the caliber of products delivered, but their partnership as well.

Meanwhile, Baker Tankhead has never shied away from investing in the business, recognizing financial support as the key to success in the face of constant change – not only in terms of technology but in order to meet customer requirements.

“Companies who are willing to invest in themselves are going to be the ones that continue to succeed, and that’s exactly what we plan to do” Austin confidently concludes.

LinkedIn: Baker Tankerhead inc

Crucially, these trailers are engineered to withstand the high pressures and extreme temperatures associated with cryogenic liquids, meaning Chart ensures safe and reliable transportation every time. With engineering and manufacturing capabilities now stretching across three continents, Chart offers trailers, semi-trailers, swap bodies, liquid tube trailers, and railcars for the safe and efficient distribution of liquid gases including nitrogen, oxygen, argon, CO2, hydrogen, natural gas, and more.

As well as these standard liquid gases, a range of transport solutions for liquid nitrous oxide, ethylene, propane, butane, butadiene, and ethylene oxide are available on request for Chart’s customers.

“WE COMBINE ROTATING AND STATIONARY EQUIPMENT WITH PROCESS EXPERTISE TO SOLVE COMPLEX ENERGY AND INDUSTRIAL CHALLENGES”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

Leveraging unrivaled expertise and exceptional pedigree in this enormous field, Chart manufactures its cryogenic trailers across the US, Europe, and China.

Furthermore, Chart’s engineers dedicate themselves to working with clients to determine the best configuration for their specific requirements.

Meanwhile, regardless of manufacturing location, all equipment

is built to the same high-quality standards and in accordance with all associated relevant pressure vessel and stringent transportation codes and regulations.

In recent years, Chart’s growing plethora of products have found a way to penetrate countless new sectors and markets across the globe. If you’ve ever sat back and enjoyed

a refreshing nitro beer, you can thank Chart’s frost-free, vacuum-insulated liquid nitrogen equipment for making that possible.

A nitro beer is a recent innovation that is primarily carbonated with nitrogen gas instead of the more common CO2, resulting in a noticeably smoother taste and a dense, cascading head.

Nitrogen is less soluble in liquid than CO2, meaning it forms smaller, more numerous bubbles.

Popular examples of nitro beers within this market include Guinness, which has popularized the use of nitrogen in stout beers, and various other beers and porters that utilize this technique.

Furthermore, many of the Chart’s customers are global household

names – from Starbucks, which uses the company’s liquid nitrogen dosing technology for beverages like its Nitro Cold Brew, to Viking Cruise, which is exploring using hydrogen fuel cells with their ocean vessels, and ExxonMobil, which is using Chart’s state-of-the-art liquification technology in Northern Mozambique at the Rovuma LNG project.

“Our company has become particularly adept at taking oldschool designs and equipment and transferring these concepts into new and emerging markets,” Evanko explains.

This expertise undoubtedly stems from over 157 years of hydrogen design and equipment building.

“During the COVID-19 pandemic, many companies became more

focused on sustainability and the future of the world, so having this amount of hydrogen experience gave us a great jumping-off point to be able to serve these different end markets,” she continues.

For Evanko, an element of the business which she sees as of vital importance is that of social sustainability, a concept that the company endeavors to uphold to the highest possible standards.

“We understand that the more variety we have in our perspectives and ideas, the more successful we are. As such, we are actively ensuring that all levels of the Chart family look like the societies we live in,” she tells us.

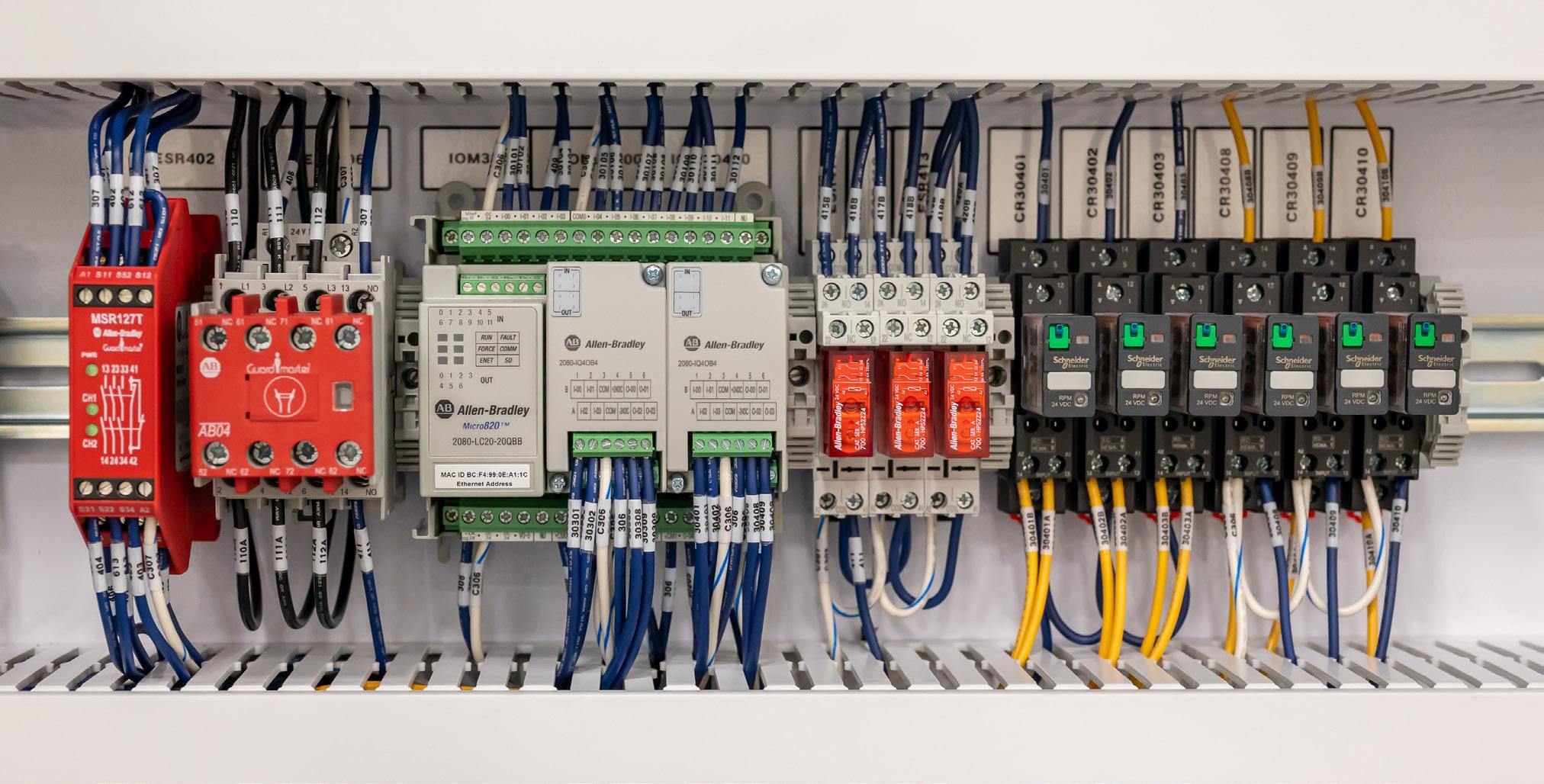

Your full-service provider for control systems, automation, and panel fabrication.

BW Systems Inc. is more than a Control Systems Integrator and UL Panel Shop — we are a trusted partner committed to delivering reliable, high-quality control system solutions. With comprehensive in-house capabilities in design, engineering, and fabrication, we provide fully customized solutions tailored to your specific requirements.

Your full-service provider for control systems, automation, and panel fabrication.

Our 55,000 sq. ft. manufacturing facility is equipped to handle a wide range of control system production needs, from unique, one-off builds, high-volume OEM production, as well as complete on-machine wiring.

• Web Transport Systems with Related Coating & Ovens including Div I and DIv II areas

• Batch & On-Demand Systems used in Food/Chemical/Adhesive Manufacturing

• Plastic Extrusion & Hot Melt Adhesive Systems

• LNG Transport Systems

• Pollution Control Systems

• High Performance Motion, Singleaxis, Multi-axis, Robotics, Assembly & Automation

Since opening its doors in 1997, BW Systems Inc. has been designing and building control systems for both general purpose (UL 508A) and hazardous locations (UL 698A/NNNY). Whether working from comprehensive assembly drawings or a basic set of schematics, our experienced team is fully equipped to fabricate industrial control panels that meet all applicable code and regulatory standards.

Upon completion of construction, all panels and machines are routed to our segregated QA/Testing area for a comprehensive inspection and testing process. This area is equipped with various voltages and current capabilities which allow exhaustive testing for both domestic and foreign systems.

• Warehouse Conveyors, Sorting & Auto-picking

• Factory Floor/ERP Integration

• Machine and Process Safety

• UL508A: Control Panel Fabrication

• UL698A: Extensions into Hazardous Locations NNNY: Hazardous Location Fabrication

t Systems with Related Coating &

• Self-Certified Panel Listing with UL or ETL (Intertek)

ng Div I and DIv II areas

emand Systems used in al/Adhesive Manufacturing

on & Hot Melt Adhesive Systems

t & Pollution Control Systems

To ensure the highest level of safety and compliance, BW Systems Inc. has configured our QA/Testing area to meet Category 0 standards wherever applicable, aligning with customer requirements and industry’s best practices for safety.

or need a quote?

The company’s commitment to equity is evidenced by its diverse board of directors, with 40 percent of its current directors being female.

People are at the heart of the company, and they must be taken care of. As such, Chart looks after its ‘cool communities’ – referring to cryogenics, where it operates in many interesting locations.

“Every seven days, I send a daily spotlight out to our whole organization highlighting a team member or a group of our team members that has done something exceptional, or even just something kind or related to our key themes,” she continues.

‘Cooler By Design’ is more than

just a tagline for the company. Whether it’s volunteering together through its Giving Back Program or team members competing in some friendly competition through the many fun activities on offer, Chart has perfected the art of enjoying each other’s company and having fun as it makes incredible results happen while ensuring that there is a healthy and enjoyable work culture.

“Some weeks, we host Motivational Mondays, which is put together by our teams and built around improving overall health, making sure our staff have a good work-life balance. We ensure they are taking care of their mental health and encourage them to spend more with their families.”

SAFETY ABOVE ALL – Chart’s commitment to zero harm drives every decision it makes and every action that is taken. Everyone at the company is empowered to speak up and stop unsafe actions. Chart continually develops its environment, health, and safety (EHS) culture to prioritize safety and well-being and positively impact the environment.

HERE FOR CUSTOMERS – The company forges strong partnerships with its customers to understand their goals and aspirations. Chart is always responsive and uses its considerable expertise to deliver world-leading solutions and outstanding customer service to drive shared success.

PEOPLE MAKE THE DIFFERENCE – By recognizing the talent and different perspectives that each team member brings, Chart leads with honesty and integrity, fostering an environment where everyone can grow professionally, be themselves, and have fun. The company gives back to local communities, using its time and resources to positively make a difference.

PURSUIT OF EXCELLENCE – The company aims to be proactive and curious, always looking to do things better. Through Chart’s global engineering expertise and world-leading technology, it consistently pushes boundaries and takes on tough challenges to find the best and most innovative customer solutions.

PASSION FOR RESULTS – Chart remains dedicated to delivering profitable growth and takes full ownership of its range of commitments. The company aims to stay flexible, adapting to changing business needs, and continually focus on achieving stakeholder value.

Chart also leverages a slate of geographically specific programs across all of its regions globally, as the company remains conscious of giving back to the communities it serves.

In the US, Chart’s new cryogenic facility in Theodore, Alabama (AL) was unveiled in March 2024.

The plant can manufacture the world’s largest shop-built cryogenic tanks with a capacity of up to 1,700 cubic meters (cbm).

These large tanks are used to store liquid gases including hydrogen, oxygen, and LNG for industries including aerospace, clean power, marine, gas-by-rail, and many others in the ever-expanding science and decarbonization sectors.

Known affectionately as “Teddy 2” because it’s the company’s second facility in Theodore, the facility has an optimal location, including direct access to waterways and railways which are key in providing customers with lower freight costs and faster transportation to site.

The expansion has also contributed significantly to local job creation and economic development efforts for the state of AL and its citizens.

“We were thrilled to officially expand our presence in Theodore with the ability to offer the world’s first shop-built cryogenic tanks of this scale,” Evanko recalls.

“This expansion further supports our customers through increased capacity and scale as well as lower freight costs and shorter lead times.

We look forward to continuing to hire from the strong, skilled workforce in AL,” she prides.

Chart was recently pleased to announce a major milestone for the company and indeed the broader industry with the successful shipment of the first two jumbo cryogenic tanks built at the Teddy 2 facility.

Each with an impressive capacity of 1,700 cbm, they are considered to be the largest shop-built cryogenic tanks ever produced.

Made to support next-generation space launch infrastructure, these tanks reflect the growing demand for large-scale liquid gas storage across a wide range of emerging applications in aerospace, clean energy, maritime

and carbon capture.

In addition to increased storage capacity, the process of shop building reduces on-site construction and facilitates modularization, thereby reducing overall project cost, schedule, and risk.

The expansion has also contributed to local job creation as well as significant economic development and is consistent with the region’s ambitions as an innovation hub for cleantech.

What continues to set Chart apart is that the company is not just an equipment provider – it consistently delivers engineered solutions across a wide range of applications, tailored to the specific requirements of customer needs.

Turboexpanders are the beating heart of midstream natural gas liquid (NGL) operations, helping enable fast and efficient liquid recovery. Bearings are a crucial component of a turboexpander, supporting the weight of the turboexpander’s rotor to maintain correct relative positioning. Active magnetic bearings (AMBs) are an oil-free bearing system that uses electromagnetic forces to maintain the relative position of a rotating assembly (rotor) to a stationary component (stator). An advanced electronic control system adjusts these electromagnetic forces in response to forces generated from machine operation, and any issue that compromises the operation of an AMB controller can bring NGL processing to a halt.

So, when an NGL processing company approached L.A. Turbine (LAT), a Chart Industries company, looking for the best way to upgrade an outdated analog AMB controller, they understood the importance of finding a reliable and expedient solution.

Luckily, LAT had a history of successful collaboration with Waukesha Magnetic Bearings, a subsidiary of Waukesha Bearings, that has been providing complete solutions for AMBs and magnetic bearing controllers in a variety of specialized applications for nearly 40 years. This versatility and experience enable the company to design controllers that are effectively brand-agnostic, making them the perfect partner to help LAT promptly deliver a cost-effective application-specific solution.

The troublesome analog AMB controller and the cabinet in which it was housed were due for an update. Over several months, the company tried to troubleshoot its shortcomings, but the original manufacturer considered the controller obsolete and would no longer provide support. Instead, the OEM pushed its customers to upgrade to new AMBs, which would require significant investment and potential extended turboexpander downtime.

The company sought an alternative to upgrading to entirely new AMBs and controllers, but most companies proposed replacing the entire AMB system, including the controller, for easy compatibility. It seemed like

there was no choice but to purchase the expensive replacement AMB system until a service call with LAT yielded a different, more satisfying solution.

Rather than replacing the entire system, LAT proposed working with Waukesha Magnetic Bearings to retrofit a new, more modern and feature-rich controller for the existing AMBs and turboexpander. Pairing a new controller with an existing AMB is not typical because most companies require using the same manufacturer for both pieces of equipment. However, LAT and Waukesha Magnetic Bearings had already collaborated on similar projects in the past with great success.

In fact, the two companies had a history of ambitious collaborations. When LAT set out to design the industry’s first and only skid-mounted turboexpander cabinet for hazardous-area applications, they reached out to Waukesha Magnetic Bearings to be a design partner. Together, the companies built the ARES AMB Turboexpander, featuring a skid-mounted Zephyr® controller.

The Zephyr controller also proved to be an ideal solution for retrofitting the midstream energy customer’s obsolete analog controller. The Zephyr controller is highly configurable, making it “bearingagnostic,” or able to integrate with many different sensors and magnets.

Beyond technical compatibility, Zephyr controllers are simple to operate, which was a key requirement for LAT’s customer. After relying on the outdated analog controller for so long, they were also seeking a more robust solution with modern features such as remote monitoring and adjustment capabilities. All in all, Zephyr fit the bill.

While it was clear the new controller and cabinet would be an enormous upgrade, the engineers at LAT and Waukesha Magnetic Bearings most impressed the customer with their responsiveness and customer service.

Because the LAT and Waukesha Magnetic Bearings teams understood the impact downtime has on NGL-processing companies, they worked tirelessly to install the upgraded equipment as quickly as possible.

In this case, that meant constant communication – plus sharing lessons learned from previous retrofitting projects. As a result, the LAT and Waukesha Magnetic Bearings teams were able to install the controller and make it operational quickly.

The new controller has proven to be an optimal solution. Now, LAT’s customer can keep an eye on the AMB remotely and make adjustments if needed. Zephyr’s remote monitoring and adjustment functionality includes multi-coordinate control, runout compensation, an automatic balancing algorithm and an advanced amplifier algorithm for software flux feedback.

With inductive sensor support, Zephyr also boasts simple troubleshooting features – a stark contrast to the old analog controller. Its diagnostic capabilities include a web-server interface, event logging, automatic clearance check, and built-in tools that show compliance with ISO sensitivity performance criteria. It offered everything the customer wanted, and then some.

Backed by the LAT team’s exceptional customer service and field support, the upgraded controller gave the customer renewed peace of mind about the AMB’s long-term performance. In fact, Waukesha Magnetic Bearings’ devices are known to stay operational for decades, and Zephyr controllers have the same reputation for long-term reliability. With no moving parts, predictive maintenance and an extended warranty option, the AMB controller is expected to perform reliably in the field for many years to come.

www.waukeshabearings.com | info-wb@doverprecision.com

“We combine rotating and stationary equipment with process expertise to solve complex energy and industrial challenges,” Evanko explains.

As such, Chart’s moleculeagnostic approach to its operations is another key differentiator.

“We don’t compete with our customers in molecule production. Instead, we focus on enabling infrastructure across hydrogen, LNG, CO2 capture, water, biogas, and more, regardless of the molecule in play,” she adds.

The company also invests in R&D for cryogenic systems, carbon capture, and hydrogen technologies, amongst other areas.

This innovation, combined with a flexible manufacturing footprint and Chart Business Excellence – a unified approach to operations, pricing, and efficiency – allows it to move quickly without sacrificing

“OUR PRODUCTS AND NUMEROUS TECHNOLOGIES ACROSS OUR PORTFOLIO SUPPORT OUR CUSTOMERS’ EMISSIONS REDUCTION, ENERGY EFFICIENCY, AND DECARBONIZATION INITIATIVES”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

even a fraction of quality or performance.

“Finally, we maintain strong proximity to our customers globally, with facilities and service operations across the globe. That local presence, combined with more than 170 years of technical expertise and a culture that prioritizes people and safety, allows us to act as a true partner – not just a supplier.”

Like many companies, Chart has had to navigate supply chain

constraints, inflationary pressures, and global uncertainty.

“What helps us manage these challenges is our diversified footprint, strong supplier and customer relationships, and an innovative culture.

“We continue to localize manufacturing where needed, lean into flexible production models, and use our Chart Business Excellence approach to drive efficiencies across operations,” Evanko reveals.

One partnership Evanko is especially keen to highlight is Chart’s global master service agreement with ExxonMobil, including its ongoing work supporting the Rovuma LNG project in Mozambique.

“We are proud to expand our relationship with ExxonMobil through this enabling agreement. Chart’s industry-leading LNG technology, including our cold boxes and IPSMR® process, aligns with ExxonMobil’s commitment to efficient, scalable, and reliable LNG solutions,” she outlines.

“This agreement further strengthens our role as a trusted partner for ExxonMobil’s energy initiatives worldwide.”

In less than two decades, Chart has made a significant impact on the global LNG industry with its IPSMR® liquefaction technology.

Having curated a formidable reputation within the sector for its decades-long expertise with brazed aluminum heat exchangers, the company has quickly secured a leading position in the mid-scale segment.

With 29 million tons per annum of LNG liquefaction across operational and under-construction facilities, Chart has expertly established

VISION:

Providing engineered solutions to enable a better tomorrow.

MISSION:

Chart connects its people, leading technologies, and global expertise to deliver innovative and sustainable solutions for its customers and the world around us.

strategic partnerships with industry leaders like New Fortress Energy, Wison New Energies, Fluor Corporation, JGC, and various other international oil and gas and engineering, procurement, and construction (EPC) companies.

In the hydrogen market, Chart has delivered state-of-the-art equipment for the world’s largest hydrogen refueling station in China, supported the first green steel project in Sweden, and is enabling liquid hydrogen systems for marine and aviation markets.

“Our broad scope covers the full hydrogen value chain – from liquefaction and storage to transport, fueling, and end use – which allows us to serve a wide range of customers and end markets.”

Elsewhere, on the carbon capture front, Chart is advancing a number of initiatives across different industries and scales.

One example is its partnership with Bloom Energy (Bloom), in which the company is working together on an integrated solution that captures CO2 directly from Bloom’s high-efficiency fuel cells.

“What makes this partnership unique is how it combines commercially available technologies to make carbon capture more accessible and cost-effective. We’re also collaborating with Bloom on emerging opportunities in the data center space, where energy efficiency and emissions reduction are becoming critical priorities,” Evanko enlightens.

Parallel to this, across its portfolio of LNG projects, Chart is continuing to support a growing number of infrastructure projects globally – providing leading liquefaction, storage, and fueling systems that help meet near-term energy needs while enabling a lower-carbon future.

“SUSTAINABILITY DRIVES INNOVATION, STRENGTHENS OUR COMMERCIAL PIPELINE, AND INCREASINGLY, IT’S WHAT OUR CUSTOMERS AND INVESTORS EXPECT. WE DON’T VIEW IT AS A SEPARATE STRATEGY – IT’S FULLY EMBEDDED IN OUR CULTURE AND HOW WE OPERATE AND GROW AS A BUSINESS”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

“Our full lifecycle capabilities range from liquefaction start-up to service, spares, and retrofits.

“One thing we remain very proud of is that all of these efforts reflect the same core principle – enabling our customers to move forward with practical, scalable solutions that balance performance, cost, and sustainability.”

Chart is also trusted supplier of cryogenic equipment and engineered systems to the aerospace industry. Products and systems include cryogenic rocket propellant storage tanks, vacuum-insulated transfer piping, high-pressure pumping systems, knock-out drums, and deluge systems.

To date, the company has been integral in achieving operational success for its customers switching from RP-1 to LNG propellant, while it also provides on-pad storage of liquid oxidizers and upper-stage liquid propellant.

“We have been designing, building, and testing advanced cryogenic system equipment for more than half a century.

“Our team works closely with each customer to ensure that systems are designed in accordance with their requirements, function at their peak performance, and minimize risk to operators,” Evanko tells us.

“Built for long-term integrity, Chart system components and product designs provide the highest level of performance at optimal operating costs,” she asserts.

In June 2025, Chart announced an all-stock merger of equals with Flowserve Corporation (Flowserve).

Flowserve is one of the world’s leading providers of fluid motion and control products and services. Operating in more than 50 countries, the company produces engineered and industrial pumps, seals, and valves, as well as a range of related flow management services.

“This combination takes our strategy to the next level – creating a differentiated leader in industrial process technologies with a broader portfolio, greater scale, and even more opportunity to serve customers across highgrowth markets,” Evanko passions.

“Flowserve brings deep expertise in flow control, and when combined with Chart’s leadership in thermal technologies, we’ll be able to offer fully integrated systems and solutions.

“That means our customers can benefit from project streamlining, shorter lead times, and more efficient process design – particularly in complex, multi-technology applications,” she says.

Furthermore, this merger of equals also aims to enhance Chart’s aftermarket, service, and repair capabilities, expanding the company’s geographic presence and strengthening its balance sheet by accelerating deleveraging.

“We see clear cost and commercial synergy opportunities with this merger of equals, and we’re excited about the long-term potential to return value to shareholders,” Evanko gushes.

Most importantly, the two sets of teams across both companies are energized about what this means for the future of each business.

“By bringing together our complementary technologies, commercial pipelines, and digital capabilities, we’re creating a platform that’s positioned to accelerate innovation, strengthen customer

partnerships, and drive long-term growth.”

Together, they are expected to have an enterprise value of approximately $19 billion based on the exchange ratio and the closing share prices for Chart and Flowserve as of 3rd June 2025.

With an installed base of more than 5.5 million assets in more than 50 countries, the combined company will expertly address the full customer lifecycle from process design through to aftermarket support.

There are numerous strategic and financial upsides to the merger of equals for both Chart and Flowserve.

Firstly, with a comprehensive suite of world-class, differentiated solutions, it seamlessly brings

together Chart’s leading expertise in process technologies across compression, thermal, cryogenic, and specialty solutions alongside Flowserve’s leading capabilities in flow management.

Combining digital platforms that underpin this full suite of solutions will enable further opportunities to differentiate solutions, offering a comprehensive digital overlay, including monitoring and predictive capabilities.

Elsewhere, the combined company will boast leading capabilities across countless areas including industrial gases, data centers, space, transportation, carbon capture, energy, power generation, nuclear, chemical, LNG, water, mining, and minerals.

As such, with this wealth of capabilities, the combined company will be more predictable and resilient.

“THE US ENERGY SECTOR IS CURRENTLY BALANCING TWO KEY FORCES – RISING DEMAND AND THE NEED FOR GREATER FLEXIBILITY”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

A further benefit is that it will have significant recurring revenue streams, with a global installed base of more than 5.5 million assets and 42 percent of total combined revenue from aftermarket and service.

Chart and Flowserve expect to grow the aftermarket businesses by offering enhanced services and

solutions to customers through an expanded global installed base and broad geographic reach.

Upon closing, the combined company board of directors will comprise 12 members – six each from Chart and Flowserve – with Evanko proudly serving as Chair of the Board.

Across each individual facet of the company, sustainability is central to who Chart is as a business and what it does.

“Our products and numerous technologies across our portfolio support our customers’ emissions reduction, energy efficiency, and decarbonization initiatives,” Evanko tells us.

“We provide the state-of-the-art infrastructure that enables lowercarbon fuels, scalable CO2 capture, water treatment, and cleaner industrial processes,” she follows up.

Beyond its products and solutions, Chart also holds itself accountable internally. This includes environmental, social, and governance (ESG)-linked compensation, supplier sustainability reviews, and operational efficiency programs across its entire global footprint.

“Sustainability drives innovation, strengthens our commercial pipeline, and increasingly, it’s what our customers and investors expect. We don’t view it as a separate strategy – it’s fully embedded in our culture and how we operate and grow as a business.”

Across the entire spectrum of Chart’s operations, every individual team member is encouraged to fulfill their potential, while their culture, identity, and experience is respected and valued.

“We understand that the more variety we have in our perspectives and ideas, the more successful we are. We not only take strides to give Chart team members the resources they need to make of their career whatever they dream it, but also ensure they feel good while doing it,” Evanko confirms.

HOW DO YOU REFLECT ON YOUR JOURNEY THROUGH THE INDUSTRY AND YOUR TIME WITH CHART SO FAR?

Jillian Evanko, CEO: “The beauty of our company is that we design and we build. This is something that I believe is really fun when you start to see the world’s need for more sustainable solutions, whether that’s what we do regarding LNG or all the way to green hydrogen.

“Elsewhere, we also serve water treatment, carbon capture, utilization, and storage (CCUS), food and beverage, and multiple different industrial applications. Now, every single one of these fields makes up one part of our Nexus of Clean™ strategy, which aims to help the world become cleaner and more efficient.

“This is also embedded in what we do every single day in our design and manufacturing operations, and I remain very proud of our work and the legacy that we are creating.”

“Our people are the reason we’re able to do what we do. From welders and machinists to engineers and sales teams, there’s a shared sense of purpose across the organization.”

One of Evanko’s personal priorities is creating an environment where people feel valued, heard, and are given access to a multitude of exciting career opportunities.

To date, Chart has launched several key programs focused on career and talent development and mentorship – including its numerous employee resource groups (ERGs) such as Chart Network of Women, which aims to empower women both personally and professionally.

As well as this, the company is proud of its Chart Rise and Prime initiative, created for young and emerging professionals as well as seasoned, experienced professionals focused on mentorship and Chart veterans.

“In 2024, each of our talent development programs expanded and continued to grow – including our Emerging Leaders Program, Rotational Engineering Program, Operational Leaders Program, Global Diversity and Inclusion Committee,

“OUR FOCUS IS ON DELIVERING FLEXIBLE, SCALABLE SYSTEMS THAT HELP OUR CUSTOMERS ADAPT AND LEAD – NO MATTER WHERE THEY ARE ON THEIR ENERGY OR SUSTAINABILITY JOURNEY”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

Global Sustainability Committee, and Global Welding Council,” Evanko lists.

“We also hit record participation in our Internship Program this summer as we welcomed 38 interns, ranging from high school to graduate school level,” she acclaims.

Of the 38 interns, over a quarter are returning – including three who are with the company for a third year running.

“As both a leader and a working mom, it’s important to me that we show the next generation that manufacturing is a place where they can build meaningful, exciting careers.”

Corporate social responsibility (CSR) is built into every facet of how Chart operates.

“CSR FOR US IS ABOUT MAKING A TANGIBLE, LASTING IMPACT IN THE COMMUNITIES WE SERVE AND EMPOWERING OUR PEOPLE TO LEAD THAT EFFORT”

– JILLIAN EVANKO, CEO, CHART INDUSTRIES

“Through our Giving Back Program, the company offers every team member globally one extra day of paid time off per year to support a charitable initiative of their choosing as well as funding-matched opportunities up to $250,” Evanko grins.

Meanwhile, Chart supports global and local giving programs, STEM education, and environmental initiatives across its numerous locations.

“Our teams regularly lead efforts such as tree planting and ‘Adopt-aHighway’ initiatives, volunteering

at food banks and other charities, as well as supporting disaster relief and environmental conservation programs – not because they have to, but because it’s part of our businesswide culture,” she explains.

“Internally, we’ve launched initiatives like our Global Diversity and Inclusion Committee, our ERGs, which are active in over 10 countries across our global organization, and ESG-linked performance targets at leadership level.”

In addition to this, Chart is also a proud participant of the United Nations (UN) Global Compact.

“CSR for us is about making a tangible, lasting impact in the communities we serve and empowering our people to lead that effort,” assures Evanko.

Moving forward into a bright future, Evanko is keen to emphasize that the next phase for Chart – especially following its merger of equals with Flowserve – is about scaling smarter, growing faster, and delivering even greater value across thermal and flow technologies.

“One of the most compelling

KÖNIG + CO. is a global leading tank head manufacturer with two plants in Germany. With over 95 years of experience, we bring a relentless pursuit of excellence to manufacturing tank heads and components. We work with plastically deformable materials in sizes up to 323" for a single piece or 530" in crown and petals to deliver heads of all shapes and sizes to our customers.

For over four decades, Uni-Form Components Co. has been North America’s trusted leader in the manufacturing of ASME Code Heads, Cylinders, and Custom Formed Parts. Backed by 45 years of experience and the right equipment and tooling, we have the most diverse offering of pressure vessel components in the industry.

ASME Section VIII Div. 1, Div. 2, and Section 1 Code Stamps, NSF Certification for Drinking Water Applications

• Heat Treating and Quenching

• Forming Capabilities from 0.0625” to 12” Thick

email: info@koenig-co.de web: www.koenig-co.de/en phone: +49 (0) 2738/601- 0

aspects of this exciting new combination is the ability to offer customers a single-point supplier for integrated systems, which streamlines projects, reduces complexity, and improves efficiency across the board,” she excites.

“As we level up, we will continue to focus on execution, safety, and innovation – and we’re deeply committed to creating impact for our customers and opportunities for our team members.”

As such, Chart has meticulously developed and grown to become a company that has combined deep technical expertise with adaptability and an entrepreneurial culture –supporting traditional infrastructure while also helping to accelerate the shift to cleaner, more efficient systems.

“Our major upcoming and ongoing priorities are continuing to drive results, focusing on securing a high

• Specializing in Carbon, Stainless, Aluminum, Clad, Nickel Alloys

From emergency services to complex custom forming, we deliver uncompromising quality and unmatched versatility. Our deep material inventory, skilled team, and rigorous in-house quality system ensure every component meets or exceeds ASME Code requirements.

When precision, reliability, and quality matter— trust the name that’s built on it. Trust Uni-Form Components Co.

level of safety, scaling solutions across our end markets to better support our customers, investing in people, and successfully integrating our merger of equals with Flowserve,” Evanko follows up.

Today, with a successful culture built on safety, integrity, innovation, and kindness, the company wants to be remembered not just for the solutions it has historically delivered, but for the way it empowers its people and has made a lasting impact on the industries and communities it serves.

From the early days of pioneering heat transfer solutions for cryogenic liquefaction to today’s green energy challenges, Chart has been there every single step of the way and will continue to build on its already impressive legacy and considerable influence and contribution to this burgeoning industry.

“The future we’re carefully building is one where engineering,

manufacturing, sustainability, and strong industry leadership come together to make a meaningful difference,” Evanko concludes firmly.

Tel: 1-770-721-8899

john.walsh@chartindustries.com www.chartindustries.com