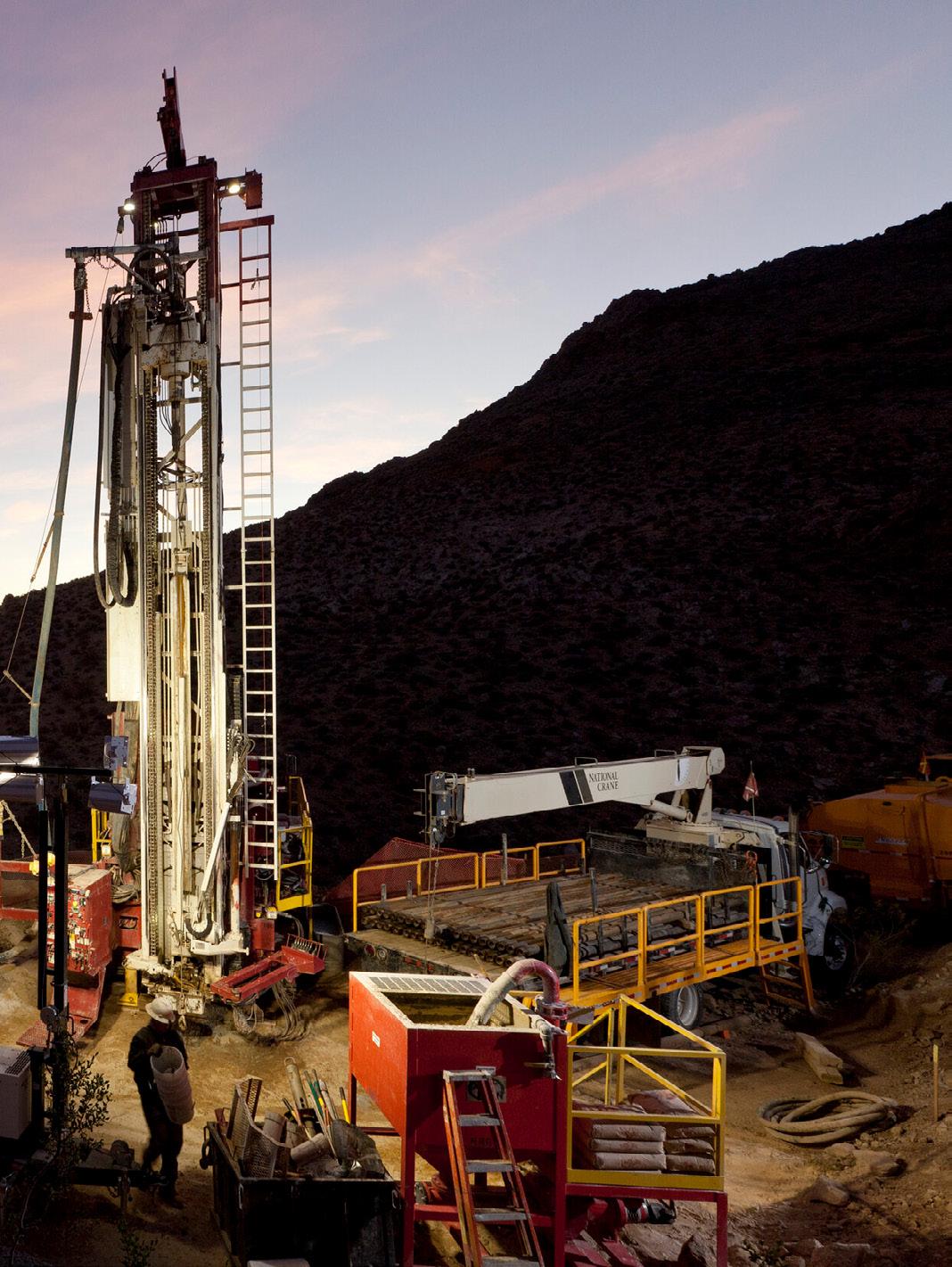

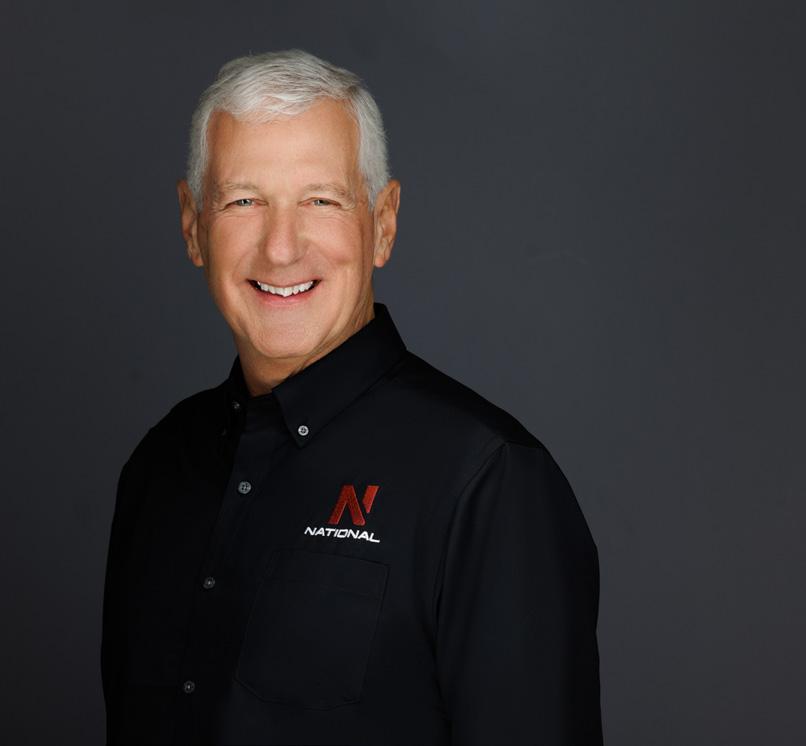

With unique technical capabilities, in-house fabrication and machining expertise, and an unparalleled safety culture, National EWP remains at the forefront of the Western US drilling sector. Jeffery D. Morgan, President and CEO, tells us more

Writer: Lucy Pilgrim | Project Manager: Scarlett Burke

In recent years, North America’s drilling market has been dominated by major international mining corporations, making for a competitive and therefore challenging landscape.

However, it is in these difficult periods that companies such as National EWP (National) are able to test the limits of their creativity and agility.

“Even if we don’t have control of the market, we can control how we respond to it. So, I tend to adopt the mindset that we need to take advantage of the market regardless of the state it is in,” Jeffery D. Morgan, President and CEO, opens optimistically.

Morgan strongly believes in a quote from Roman emperor, Marcus Aurelius – “The impediment to action advances action. What stands in the way becomes the way” – in short, the answer lies within the problem or challenge.

To respond to the competitive market, Morgan emphasizes the importance of finding efficient answers to difficult situations to better the company for the benefit of its clients and employees.

“It’s currently a challenge to get all our rigs out competitively and profitably at the same time, but within that context there is opportunity. It’s up to us to take advantage of it,” he adds.

Established in 2010, National was formed to address a gap in the drilling market which, at the time, primarily consisted of major international exploration drilling organizations conducting extensive core and reverse circulation (RC) exploration, with a number of smaller companies having comparably limited operations.

NATIONAL’S SERVICES – AT A GLANCE

• Well casing and installations

• Large-diameter production wells

• Dewatering wells

• Vertical drains

• Piezometers – single and multi-level

• Exploration

- Core drilling

- RC exploration

- Pre-collar

“We were the in-between – we had the capabilities of larger companies but ran like a smaller business. Most of our leadership team had held previous jobs on drill rigs, which meant we had a huge amount of field experience in our management teams,” Morgan tells us.

National is therefore differentiated by its capabilities that compete with multinational drilling organizations while also being responsive and flexible to clients’ needs, which are all underpinned by a consistent focus on improvement.

“As a Western US-based company, we’ve had the opportunity to go global in the past, but we would rather be really good in our own backyard. Instead of forcing growth and going afar, what we are really trying to do is focus on providing better results for our existing client and geographic

base,” he shares.

Therefore, National possesses a continuous drive to better its operations and grow within the US market.

National’s sustained ability to serve its clients’ needs is, in part, due to the fact it operates some of the highest tech machinery and fabrication equipment in the world; its computer numerical control (CNC) milling machines and lathes, for instance, are regulated by the US Department of Defense.

The company additionally has an expert team of engineers and drafters people who design, build, and fabricate custom-made tooling and equipment in-house, completed in its facilities in Phoenix, Arizona and Elko, Nevada.

EDM designs and builds world-class drill rigs that deliver performance, reliability, and safety in the most demanding conditions. Our range includes diamond, RC, and multipurpose rigs from 30,000–95,000 lbs pullback, as well as horizontal drills for mine site dewatering.

Engineered for productivity and longevity, EDM equipment is fully customizable to meet the needs of any project or environment — including Tier 4 Final engines for US emissions compliance, full EoH control systems, and climate-controlled FOPScertified operator cabins.

Leading the way in safety innovation, EDM specializes in practical and robust independent, hands-free pipe handling systems for all drilling methods — designed to protect drill crews and maximize efficiency.

Address: Avenida Colorado N°01200 - Quilicura - Santiago

Phones: 56 (2) 739 0315 - 56 (2) 739 0358 - 56 (2) 739 0536

Mobile: +44 (0) 7487 600804

Email: info@explorationdrillmasters.com

Website: www.explorationdrillmasters.com

and

Morgan started in the drilling industry at 16 years old, working as a shop hand at Water Development Corporation while in high school.

Through hard work and determination, he advanced from the shop floor to the role of President before purchasing the company – a local California-based water and environmental drilling business – in 1999.

After rebranding it to WDC Exploration & Wells (WDC), he grew and diversified the company geographically, extending its reach to mining in the western states. He sold WDC in 2007, distributing half of the proceeds to his employees.

After briefly stepping away, Morgan returned to the business in 2010, driven by a bigger vision and a desire to raise the industry standard. He reacquired the company, rebranded it as National EWP, and now continues to lead it with the same determination and purpose that shaped his journey from the beginning.

“We are constantly innovating and improving our equipment to be more efficient and make our operations safer,” Morgan highlights.

This is exemplified by the significant improvements made to the cyclones used on National’s RC rigs.

“Given that they have material running through them all day long, the equipment by default tends to wear out fast, so our engineers and operations teams designed a cyclone that has very low wear. Once it has worn out, it also has replacement

sections that can be easily taken out and replaced in the field,” he explains. Having the ability to replace specialist sections of a cyclone on-site, as opposed to transporting it back to a facility for a complete rebuild, makes the RC operation more efficient and effective.

Elsewhere, the company has built a specialist tool for deep hole drilling and has also recently purchased seven LF160 Surface Core Drill Rigs with Freedom loaders, which facilitates hands-free drilling on-site, evidencing the extent to which National consistently upgrades its field equipment.

“Overall, we have the newest fleet of equipment in the industry.”

National made the decision to develop its own machining and fabrication capabilities during the COVID-19 pandemic, which made the

“WE’VE INVESTED SIGNIFICANTLY TO ENSURE OUR PEOPLE ARE NOT ONLY WELL TRAINED BUT HAVE THE RESOURCES THEY NEED IN THE FIELD TO MAKE SURE THEY SUCCEED”

– JEFFERY D. MORGAN, PRESIDENT AND CEO, NATIONAL EWP

industry’s supply chain significantly unreliable, leading the company to curate its own vast inventory.

“During the pandemic, it became obvious that we could not secure a consistent supply of the tools and parts we needed, which is why we decided to make significant internal investments to ensure we had all the parts we required for our drill rigs,” Morgan recalls.

As it stands, the company now has over USD$10 million of inventory across its two facilities and the dog houses on each drill rig. This means that if any equipment fails in the field,

parts are easily available to get them back up and running within 24 hours.

This adheres to National’s 12/24 hours rule, which dictates that any minor downtime issues must be repaired within 12 hours and any major issues within 24.

“It’s a huge commitment, but it pays off because when you’re in the middle of a hole, you don’t want to lose it. The longer you’re not turning the pipe, the higher the chance you’re going to lose the hole.”

The company’s success is a testament to this dedication, as it has less than two percent annual

downtime, thereby ensuring that its clients’ investments in the field consistently remain operational.

National has worked hard to build a culture that ensures its teams can succeed in the field.

Guided by its two core values – People and Results – National emphasizes the company’s broader vision with its employees who share in its success.

National also provides ample support and sets high expectations for its staff, ensuring that leadership effectively guides people and provides the right resources for any given project.

“If you give people the vision of where we are headed, high expectations of achievement, and the resources they need to succeed, it’s amazing what people can accomplish,” Morgan surmises.

Indeed, the company’s industryleading field services support team ensures the workforce is in an optimum position to keep the rigs running, operating across the entire supply chain to make sure they have the tools they need to succeed.

This creates an environment where staff take pride in their work and adopt a sense of camaraderie in the field.

National’s strong workplace culture also emphasizes employee value, recognizing the field teams who work long hours in difficult conditions by providing them with special holiday meals on 4th July and Thanksgiving, fostering a sense of belonging.

“This may sound really simple, but it is indicative of our desire to make sure our people know how important they are,” he urges.

National takes care of its staff not only when they are at work but also outside of their jobs, rewarding them with industry-best compensation, benefits packages, gift cards, and regular bonuses.

“I come from a blue-collar background and my dad was a mechanic, so I have a lot of respect for workers who get up every day and make this great country of ours successful,” he prides.

Fundamental to National’s growth, safety is interwoven within the fabric of the company and enables its team to work more efficiently in the field.

“AS A WESTERN US-BASED COMPANY, WE’VE HAD THE OPPORTUNITY TO GO GLOBAL IN THE PAST, BUT WE WOULD RATHER BE REALLY GOOD IN OUR OWN BACKYARD. INSTEAD OF FORCING GROWTH AND GOING AFAR, WE FOCUS ON OUR EXISTING CLIENT AND GEOGRAPHIC BASE”

– JEFFERY D. MORGAN, PRESIDENT AND CEO, NATIONAL EWP

The company goes above and beyond industry standards, starting with its recruitment process and state-of-the-art training program.

“When we hire, we don’t just train people to meet the Mine Safety and Health Administration (MSHA) standards, we train them to meet our own unique standards, keeping them in classes for three to four days beyond what is required,” Morgan states.

Thanks to the company’s advanced training program, conducted in its own facility, new employees can confidently enter the field with a fundamental set of skills and knowledge.

“Not only are they contributing but

they feel like they are more part of the team and much safer, which has also helped improve our retention,” he adds.

National’s safety culture is upheld by a top-notch team of professionals on-site. Notably, the team doesn’t seek to point out wrongdoings, but rather mentors and trains staff on regulations so they have a greater understanding of why the measures are in place.

“Our goal is to ensure people work safer. We’re not trying to catch and punish them - we’re trying to teach them to work according to our standards so they have a better idea of what they’re doing.”

In aid of this, National has

National recently completed an RC exploration project on behalf of a client, which involved the rapid mobilization of rigs to a job site in order to meet a tight timeframe for the customer.

“We completed the project ahead of schedule. This shows that we take a lot of pride in being able to effectively respond to customers’ needs – it’s why we get up for work every day,” Morgan prides.

Elsewhere, a client reached out to National after one of its competitors had installed faulty wells that required millions of dollars in repairs.

The company found a solution in a short timeframe and at a small percentage of the previous cost, making the project’s success a critical component of the clients’ underground mining operations.

developed an internal set of standards called the National Drill Standard that defines every aspect of its operations from the ground up.

These are broken down into clear job safety analysis (JSA) points that are easily accessible to staff who then have a clear understanding of how activities are to be performed within the context of the company’s broader drilling standards.

Similar sets of standards and JSAs have been created across all levels of the organization, creating a comprehensive internal network of support and guidance.

“We’ve invested significantly to ensure our people are not only well trained but have the resources they need in the field to make sure they succeed,” Morgan informs us.

Over the course of the coming year, National aims to ensure all its teams are sufficiently adjusting to the shifting marketplace to remain competitive and grow as a highly profitable organization.

It is additionally looking toward future capital investments, particularly given 90 percent of the company’s operations are currently surface drilling. Therefore, it strives to grow its underground capabilities in the coming year.

Elsewhere, National plans to further simplify its processes and systems, improve tooling and equipment, and better mobilize to jobs in the field, taking steps to improve overall operations.

“We aim to take what we have and make it better by analyzing our processes to see how they can make us more competitive so we can more effectively get the results our clients need,” Morgan closes.

Tel:775-753-7355

info@nationalewp.com

www.nationalewp.com