A key contributor to the oil and gas industry’s recovery in Angola, Angoil operates as a trusted full-service provider to the country’s and industrial sectors. François Bacci, Managing Director, tells

Writer:

Lucy Pilgrim | Project Manager: Nicholas Kernan

Angola, Ponticelli country’s petrochemical tells us more

Africa has developed a longstanding reputation for being one of the world’s primary oil and gas providers, with a reported 10 million barrels of crude oil generated per day, contributing to approximately 10 percent of global production

Moreover, around 75 percent of the continent’s crude oil is exported across the world, whilst a vast majority of its petroleum products are imported, placing Africa in a highly unique position compared to other regional oil producers.

The continent’s unparalleled position can be attributed to its extensive list of oil and gas producers, including Nigeria, Algeria, and Angola, which stand as key players in Africa’s liquefied natural gas (LNG) production.

For the latter, the oil and gas sector

remains a cornerstone of the country’s economy and a primary pillar in its wider energy landscape, offering numerous opportunities for growth, investment, and innovation.

In recent years, however, the Angolan oil and gas industry has faced significant disruption and turbulence, as a surge in global oil demand coincided with plummeting prices following the COVID-19 pandemic.

This is evidenced by the fact that the nation produced 1.3 million tonnes of oil per day in 2020, which was its lowest production level in a decade.

Limited public and private investment from both domestic and international sources further compounded this, resulting in a major impact on the sector’s growth.

Despite these historical challenges, Angola’s oil and gas industry continues to offer a vibrant and

opportunistic environment.

The sector’s revitalisation is, in part, due to numerous legislations that have driven major industry innovations and increased investment into the country’s mature gas fields, which has helped stabilise production and create a more robust industry landscape.

For example, the Angolan government launched the Hydrocarbon Exploration Strategy in 2020 to incentivise the replacement of ageing oil reserves over a five-year period and combat the country’s decline in hydrocarbon production, paving the way for greater exploration activity.

The industry has also experienced myriad technological enhancements to help make exploration and production more sustainable whilst enhancing existing energy infrastructure.

These advancements offer promising potential for technological innovation, opening the door to new projects in both subsea and topside operations across Angola.

“It is a dynamic and evolving space, balancing stable output from mature fields with exciting new prospects as the industry adapts to global energy trends,” introduces François Bacci, Managing Director of Ponticelli

“TODAY, WE ARE PROUD TO SAY THAT PONTICELLI ANGOIL CAN COVER THE FULL RANGE OF SUBSEA FABRICATION SCOPES, INCLUDING MANIFOLDS AND SUCTION PIPES”

– FRANÇOIS BACCI, MANAGING DIRECTOR, PONTICELLI ANGOIL

Ponticelli Angoil was established as a result of Ponticelli Frères Group’s (Ponticelli Group) international expansion into the Angolan oil and gas market. The parent company has experienced substantial growth over

the past century, as it now stands as one of Europe’s main service suppliers, providing cutting-edge solutions and infrastructure for a vast range of energy sectors, namely oil and gas, nuclear, conventional, and renewable power, and life sciences.

Ponticelli Group’s unmatched energy expertise began in 1921 when the group was born from steadfast determination.

Established in 2009, PE Energy is one of the leading energy servicing companies at the forefront of delivering specialised technologies and services across the energy value chain in Nigeria and Africa.

We are a total energy solutions provider, and our operations are anchored by five primary growth engines – Flow Drives, Flow Control, Flow Measurement, Process Pipeline Services, and Supply Chain Management.

This is powered by our Engineering, Procurement, Integration, Installation, and Maintenance (EPiiMtce) life cycle model.

Our unique propositions lie in this EPiiMtce model, which drives our growth. At the centre of our businesses and operations are sustainability and decarbonisation, which accurately position us through our products and solutions to support broader energy and power solutions in the countries where we operate.

“The EPiiMtce model encourages our customers to leverage our expertise for life cycle projects, from initial development through to long-term turnaround maintenance. These solution-based products cover the entire value chain of the hydrocarbon sector, with a particular focus on the upstream segment,” explains Dr Daere Akobo, Chairman and Group CEO of PANA Holdings.

“We have structured PE Energy around the hydrocarbon content — oil and gas — delivering specialised services across that spectrum and value chain.”

The first growth engine is high-quality process equipment, skids, and modules that are required for production processes.

These effective and efficient process solutions include Pumps and Skid Mounted Pump Systems, Compressors and Compressor Skids, Chemical Injection Skids, Fuel Gas Conditioning Skids, and Heat Exchangers. Other solutions include Pipeline Leak and Theft Detection Systems, Nitrogen Generators, Anti-Surge Systems, Pig Launchers and Receivers, Early Production Facilities, and Mobile Offshore Production Units.

“We have two approaches for Flow Drives – one is compression if it is gas, and the other is pumping if it is liquid,” Dr Akobo says.

“After the flow has been compressed or pumped, we have to control the direction of the flow using valves and actuated systems. This is what we call Flow Control,” he adds. “The second growth engine is Flow Control, where we leverage our expertise to deliver the highest quality flow control (valves and actuation) solutions.

“For us, our strong reputation in the sales and maintenance of valves and actuators is the result of decades of hard

work, a steadfast commitment to quality, and a dedication to supporting energy projects for the betterment of our continent.”

The third is Flow Measurement, and today, we are unequivocally leading in this field.

Our expertise and solutions in metering and analytical systems range from Wellhead Multiphase and Wet Gas Metering, Water Cut Metering, Custody Transfer Metering, and LACT Systems, to Flare Metering as well as online Gas Chromatography, Dew Point Analysers, and Auto-Sampling Applications.

“We are producing and selling oil and gas, so we measure the quantity and quality of what is being sold, and that is what we call Flow Measurement,” states Dr Akobo.

Key completed Flow Measurement projects include a Factory Acceptance Test (FAT) for a Multi-Wellhead Control Panel for the Kalaekule Field, and a FAT on a Multiphase Wet Gas Metering Solution for Shell Projects.

The fourth and fifth are Process Pipeline Services and Supply Chain Management, respectively. Through our experience, resources, and expertise in procurement, we offer cost-effective services and a seamless experience for our customers.

We are primarily focused on serving the oil and gas, energy, power, infrastructure, processing, and broader energy sectors across Africa, given that over 50% of the population do not have access to electricity. With our capabilities spanning upstream, midstream, and downstream operations, we are positioned to support project initiatives across complex energy ecosystems on the continent.

Our esteemed client portfolio includes major national and international energy companies such as NNPC, NUPRC, Sonangol, Shell, Chevron, Saipem, Daewoo E&C, ExxonMobil, ENI, Total, Ponticelli Angoil, and more.

At PE Energy, our distinct identity in the market is rooted in a strong core value – the 3Cs and 3Ts, and strategic operating

These guide every interaction and decision, reinforcing a culture of integrity and excellence. The Cs are Character, , and the 3Ts are Time,

in the Nigerian hydrocarbon industry, PE Energy is currently working with the industry regulator in Nigeria, the Nigerian Upstream Petroleum Regulatory Commission (NUPRC), to deliver on the Metering Audit Project to drive hydrocarbon accountability.

“Our 5Ps underpin our internal commitment to consistent Purpose for Sustainability, which is embedded in the heart of all our businesses; the second Philosophy and Process that enables us to Products and Solutions we introduce to the relevant market and territory; the fourth stands for the that are engaged in the endeavour, and Profit and Prosperity,”

For our vision-driven execution, we believe “a dream without ”. This mantra reminds us to set actionable, time-bound goals that bring vision to reality.

PE Energy is helping to develop renewable energy (RE) and decarbonisation solutions in Africa aligned with global sustainable development goals (SDGs).

In Africa, we are contributing to decarbonisation through innovative and sustainable technologies aligned with global SDGs. We have introduced Multiphase pump technologies with ITT Bornemann to Nigeria’s upstream oil and gas sector to curb gas flaring.

Additionally, we have other technological solutions such as zero-emission valves, including Mokveld’s zero-emission valves and Valmet’s zero-leakage control valves, to address the issues of methane emissions, compressors, and turbines to decarbonise and support power generation that addresses energy poverty in Africa.

This is critical for Africa with a population of about 1.48 billion, and over 640 million do not have access to energy according to AfDB, corresponding to an electricity access rate for African countries at just over 40%, the lowest in the world.

A huge portion of our continent is sitting on gas province, which is a transition fuel – how do we valorise these resources, instead of flaring, to address the energy poverty in a mix with RE resources – solar, biomass, hydro, geothermal?

oil recovery techniques and is talking about produced water solutions.

“If you do all of these things together, it must be automated, digitised, and actionable. So, how do you apply digitisation in all of this?” asks Dr Akobo.

“We created a company called AKD Digital Solutions that takes the entire activities in the brain and functions for the eyes, nose, and ears, reducing human errors and increasing what we call repeatability. We produce actionable reports with insights talking about repeatability uncertainties.”

PE Energy plans to utilise cutting-edge technologies to adapt to the evolving energy landscape in the region.

For Africa to progress and resourcefully develop, we need data, and we have developed what we called “Africa’s Data Refinery” driven through AKD Digital Solutions, our first-of-itskind digitisation and digitalisation portfolio.

This massive investment in data refinery will help Nigeria to harness the full potential of the oil and gas industry and other sectors of the economy.

How can we manage our God-given resources and derive values, without knowing how much of it we have? We need data.

Today, over 70% of global cobalt output comes from the DR Congo alone, yet the country is in lack.

It’s the same story for the rest of the continent – we need data to channel the resources to sustainable developments for the best interests of our people and the continent.

So, we have created the first Africa’s Data Refinery which will connect ecosystems of the universe with platforms, deliver a cross-economic approach, and empower informed decisionmaking, insights, efficiency enhancement, and support for Africa’s socio-economic development and transition to a low-carbon economy.

Specifically, our trademarked Hydrocarbon Measurement di²to²™ Dashboard – an all-in-one digital platform – offers secure and auditable data retention, interactive asset navigation, advance analytics, and real-time compliance monitoring.

This ensures every drop counts and every metric is trusted, securing real-time upstream measurement accuracy, regulatory adherence, and operational efficiency.

PE Energy is like a moving lion. Today, we are not just in Nigeria – we are in Uganda, Angola, Mauritius, and we are moving

“Essentially, what we are looking for is a true African services company. Therefore, part of our journey is to Africanise PE Energy and the entire African continent. This is where we are headed to,” outlines Dr Akobo.

Our “African Roadshow” is aimed at helping African countries with their energy and mineral recovery whilst leveraging our patented non-conventional technologies and decarbonisation strategies. Our purpose for sustainability is irresistible and it reflects in all our operations.

PE Energy and NUPRC

Launch Metering Audit

Project to Enhance Transparency in Nigerian Oil & Gas Industry

Factory Acceptance Test (FAT) for Multiwell Head Control Panel for Kalaekule Field

This event was graced by distinguished guests from the Nigerian Content Development and Monitoring Board (NCDMB), Nigerian Agip Oil Company (NAOC) (now OANDO), Shell, TotalEnergies, and various engineering design firms, among others.

Nigerian Oil & Gas Conference (NOG) Awards 2023 & 2024

PE Energy and Mokveld Valves BV Pioneer Nigeria’s First In-Country HIPPS Recertification Programme at the PE Centre of Excellence

PE Energy Ltd, in partnership with Mokveld Valves BV, has launched Nigeria’s first in-country High Integrity Pressure Protection System (HIPPS) Recertification Programme at the PE Centre of Excellence.

This state-of-the-art industrial hub is designed to deliver in-country value addition, driving industrialisation in alignment with the Nigerian Content Development and Monitoring Board (NCDMB) strategy for national growth.

PE Energy & ITT Bornemann Partner to Eliminate Flaring and Reduce CAPEX in Production Fields with Multiphase Pumping Solutions

• Project management and engineering, procurement, and construction (EPC) – Managing end-to-end projects and offering complete EPC services, from design and procurement to construction and commissioning.

• Mechanical engineering and construction – Delivering turnkey solutions in mechanical construction, topside process piping and steel structures, subsea structures, and plant erection for the oil and gas industry.

• Maintenance services – Providing cutting-edge maintenance services for industrial installations with a focus on asset integrity, operational efficiency, and safety.

• Shutdown and turnaround management – Specialising in managing facility shutdowns and turnarounds, ensuring minimal downtime and strict adherence to schedules.

“Its history begins with three Ponticelli brothers – Céleste, Bonfils, and Lazare – who, through courage, hard work, and audacity, established the foundations of this great company from nothing,” Bacci informs.

Ponticelli Group still upholds a strong tie to its family roots whilst providing the oil and gas industry’s major global players with critical design, construction, and maintenance expertise for their facilities, ensuring long-term safety and performance.

The group’s engineering services, in particular, span the pre-project design stage to detailed end studies, offering vital support to ensure the success of its clients’ projects.

Ponticelli Group is also proud to be a construction specialist, providing expertise in key mechanics trades, industrial piping, and lifting and rigging. As part of its services, it also constructs new, state-of-the-art plants as well as developing the capacities of existing installations for its onshore and offshore clients across the world. The group is additionally renowned for its specialist maintenance services for industrial facilities. Ponticelli Group ensures the upkeep, modernisation, and compliance of plants to enable operators to maximise productive potential.

With such a vast pool of knowledge to draw from, Ponticelli Angoil leverages and applies Ponticelli

Group’s industry expertise to the Angolan oil and gas landscape.

“We use the knowledge acquired by the group over the decades to operate successfully, maintaining the values that have cemented reputation – quality services with the utmost respect for safety and deadlines to ensure client satisfaction,” Bacci highlights.

Indeed, Ponticelli Group strives to uphold its commitment to quality, innovation, and improving focus, which contributes to the group’s client satisfaction-oriented approach.

As a highly reputable provider of industrial services across Angola,

Ponticelli Angoil specialises in engineering, construction, maintenance, asset management, and decommissioning support for the nation’s oil and gas and petrochemical sectors.

“This end-to-end service capability enables clients to rely on the company as a full-service partner,” Bacci points out.

In recognition of its services, Ponticello Angoil is ISO 9001, 45001, and 14001-certified, solidifying the company’s commitment to quality, safety, sustainability, and efficiency.

Ponticelli Angoil operates four fabrication plants across three strategic locations – Luanda, Cabinda, and Soyo – which allow it to provide localised services and support to clients.

Christiaan Enslin Regional Manager – Southern Africa, Axess Group

How would you describe the current demand for asset integrity and engineering services in Africa?

The demand for asset integrity and engineering in Africa is rising, driven by ageing infrastructure and assets in mature fields across the continent. As these assets approach the end of their intended lifespan, they become more prone to degradation, which can result in increased risk, downtime, and costly repairs if not properly managed.

To address this, companies are placing a greater emphasis on asset integrity management, focusing on proactive maintenance strategies, regular inspections, and detailed assessments to detect potential issues before they lead to major failures or accidents. Simultaneously, engineering services are becoming increasingly essential as companies seek to enhance safety, reduce operational risks, and maximise the value of their assets in a competitive and rapidly evolving market.

What led to the expansion of Axess in the African region?

Founded in Molde, Norway, in 1998, Axess entered the African market by launching operations in Angola in 2014, providing comprehensive support to exploration and production clients in the Oil & Gas sector. The company’s success in Angola has been instrumental in driving its expansion across the continent. In 2017, Axess acquired its partner, Skysite Offshore, in Cape Town, South Africa, establishing it as the regional headquarters.

Today, Axess operates in seven countries across the continent, namely, Angola, Côte d’Ivoire, Ghana, Mozambique, Namibia, Senegal, and the Republic of the Congo, delivering asset integrity management and engineering services to a diverse range of clients.

What are some of Axess’ significant projects in Africa?

Our success is driven by our extensive global footprint and local competence. To date, we have worked on over 40 assets in Africa.

In 2024, we completed the installation and commissioning work on a project in the Republic of the Congo involving mooring, hook-up, complex rigging, and electrical completions. During the peak of the project, we had 140 personnel on-site.

Over the last five years, we have provided engineering services in Angola for a major FPSO operator, performing comprehensive inspections and maintenance on cranes onboard three FPSOs.

In 2017, we conducted a riser and umbilical hook-up project offshore Ghana for a leading FPSO owner. The project encompassed complex rigging, mechanical and electrical umbilical terminations, riser spool installations, bolt torqueing and tensioning, and PFP jacket installation.

How has Axess been supporting Ponticelli in Angola?

Axess has been supporting Ponticelli in Angola since 2019. From the outset, this collaboration has focused on providing high-quality, specialised services tailored to the needs of Ponticelli’s major projects across the country.

As the partnership expanded significantly over the years, Axess continued to leverage its expertise and experience to enhance operational efficiency, support project execution, and drive innovation, reinforcing its commitment to Ponticelli’s long-term success in Angola.

What sets Axess apart in the Oil & Gas industry?

Today, Axess has more than 900 full-time personnel across 27 countries worldwide. Our global presence gives us access to the latest innovations and best practices, which we adapt and apply to meet the unique needs of local markets.

We are committed to delivering exceptional services, products, and solutions. By operating locally within each African country, we optimise operational efficiency, reduce costs and minimise our environmental footprint.

What future trends do you see shaping your industry, and how is Axess preparing for them?

Despite growing pressure to transition to renewable energy sources, fossil fuels will remain a key energy source for the foreseeable future due to the significant investments required. To meet the net-zero emissions target by 2050, there will be a greater focus on decarbonisation and CCUS technologies. Additionally, digital technologies like automation, AI, and big data analytics will drive efficiency and improve predictive maintenance.

We always had a focus on reducing our greenhouse gas emissions and providing low-carbon solutions to clients. We minimise emissions by utilising local talent and consolidating tasks to reduce the frequency of mobilisations. Our solutions include caisson and thruster replacements that eliminate the need for support vessels, double-secured winches to avoid production shutdown and flaring, and drone inspections that reduce manpower requirements while enhancing safety.

In terms of digitalisation, our proprietary Bridge software, developed in-house by our Digital Solutions division, plays a critical role in asset integrity management. It streamlines the inspection process, enhances safety and efficiency, and helps reduce our clients’ cost of ownership.

How has Axess contributed to the environment and local communities?

Since its inception in 2021, our annual global cleanup initiative has evolved from a beach-focused effort to a broader environmental cleanup, including rivers and other areas. In 2024, 14 entities worldwide arranged cleanup activities in alignment with World Cleanup Day, bringing together employees and their families to contribute to a cleaner environment.

In the same year, our South Africa entity donated equipment and sponsored two expert mountain and climbing guides for the inaugural Angola Climbing Festival. These professionals provided essential training on route preparation and climbing gear, participated in a cleanup of Serra da Leba’s cliffs and were part of a crew that conducted a rescue workshop for police, firefighters, and paramedics.

Additionally, our Angola team partnered with Otchiva, a non-government organisation, on a mangrove reforestation project. In just one day, the team planted over 1,600 mangrove seeds as part of efforts to restore coastal protection against storms and erosion, promote biodiversity, and mitigate climate change.

We offer a comprehensive range of asset integrity management and engineering solutions, including:

•Design integrity

•Operational integrity

•Inspection and monitoring

•Risk-based inspection (RBI)

•Corrosion management

•Structural integrity

•Maintenance planning

•Decommissioning

Supporting clients in Angola since 2014 axessgroup.com

Our state-of-the-art software comprises several modules:

More flexible and efficient workflow

Gain data quality and control

Comply with safety regulations

Increase uptime and redundancy

No vendor lock-in

Intuitive and user-friendly interface

Reduce cost of ownership

Everything in one platform

The company’s international client base includes the Angolan stateowned oil organisation, Sonangol, as well as TotalEnergies, ExxonMobil, Azule Energy, Chevron, and many other significant players in the oil and gas sectors.

Ponticelli Angoil prioritises building long-term relationships with clients by deeply understanding each of their needs and, therefore, providing customised services, differentiating it from the standardised solutions of its competitors.

Indeed, the company prides itself on its ability to offer tailormade solutions that cater to clients’ particular requirements. This flexibility allows it to adapt to a variety of operational environments, whether on offshore platforms or onshore sites.

Ponticelli Angoil’s ability to not only meet but exceed set targets is demonstrated by its proven operational track record, which has

earned it a strong reputation for consistently delivering complex projects on time and within budget for major oil and gas companies.

“Our extensive experience in managing large-scale, technically demanding projects gives the

company a significant competitive advantage,” Bacci attests.

Additionally, Ponticelli Angoil upholds a steadfast commitment to safety in the workplace, which is of the utmost importance in the oil and gas industry.

• Approximately one-third of the country’s GDP can be attributed to the oil and gas industry.

• Crude oil, natural gas, and refined oil account for almost all of Angola’s exports.

• Several new refineries are in the planning stages, which will increase the nation’s oil refining capacity to 425,000 barrels per day by the end of 2025.

• Foreign direct investment (FDI) in the petroleum industry totalled USD$1.6 billion in Q1 2021.

• The country possesses nine billion barrels of proven oil reserves

• Angola boasts 11 trillion cubic feet of future national gas reserves, offering an abundance of untapped potential.

“WE WORK CLOSELY WITH A NETWORK OF SUPPLIERS AND CONTRACTORS TO ENSURE SEAMLESS OPERATIONS ACROSS ALL OUR PROJECTS”

– FRANÇOIS BACCI, MANAGING DIRECTOR, PONTICELLI ANGOIL

“The company maintains a strong culture of safety, adhering to stringent international standards and regulations. This dedication to safety and compliance ensures operational dependency and instils confidence in clients,” he expands.

Moreover, Ponticelli Angoil is further distinguished by its deep-rooted vision which centres around a strategic approach, making significant investments in technology, infrastructure, and talent development for the future.

“This long-term perspective allows us to build strong, lasting relationships

with clients, consistently improve our service offerings, and adapt to the evolving needs of the oil and gas industry.”

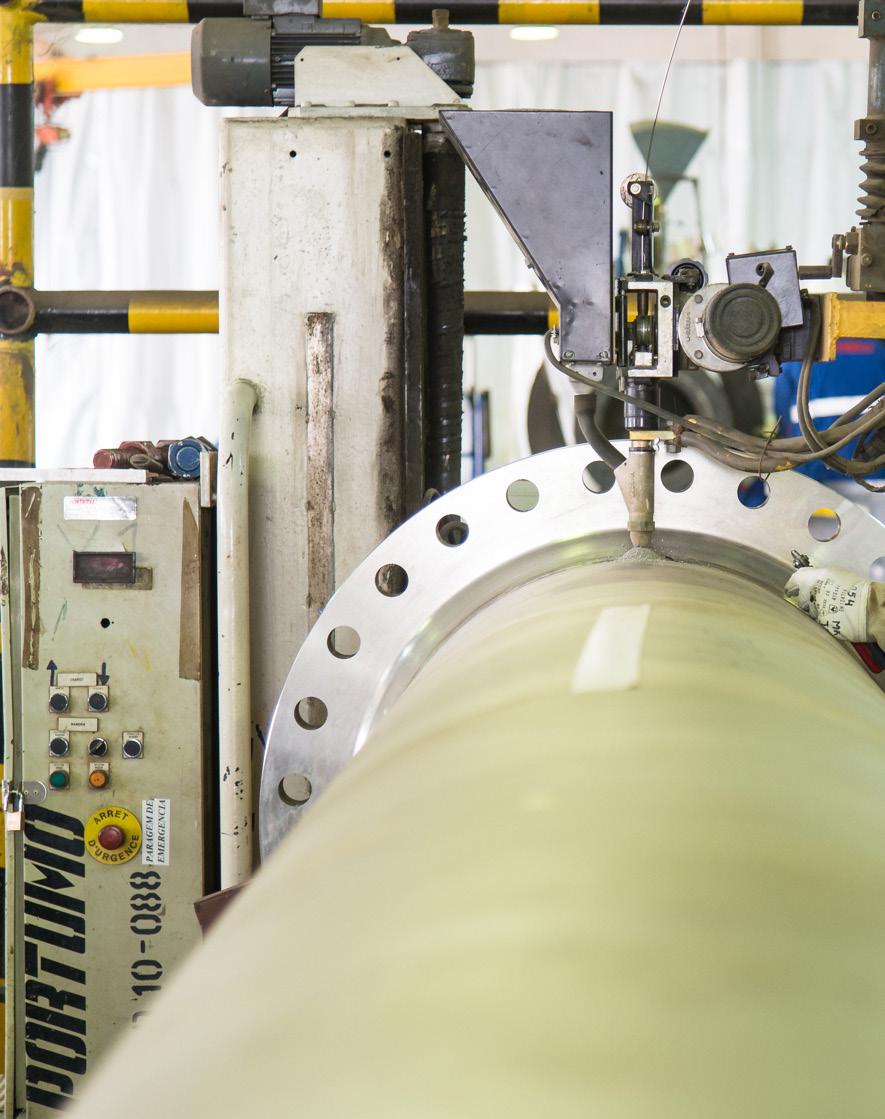

A critical element of Ponticelli Angoil’s success is its unparalleled subsea capabilities, which the company has placed considerable effort and investment into in recent years, expanding its operations and establishing itself as a strong player in subsea fabrication.

“We began with simpler structures and equipment, such as well jumpers

and mud mats, and progressively enhanced our expertise, skills, and experience to tackle more complex structures, including pipeline end terminations (PLETS) and flowline end terminations (FLETS),” Bacci outlines.

These projects have strengthened the company’s core competencies in subsea fabrication and allowed it to develop new areas of proficiency.

“Today, we are proud to say that Ponticelli Angoil can cover the full range of subsea fabrication scopes, including manifolds and suction pipes.”

With a commitment to quality and safety, The Monobuoy Company is a trusted partner in the offshore industry, offering comprehensive engineering and support services.

The Monobuoy Company (Monobuoy) designs and manufactures offshore fluid loading systems. Traditionally, this has been for oil and gas, but we are expanding our horizons and moving into the loading of alternative fuels such as ammonia and hydrogen. Additionally, we are venturing into developing offshore charging stations, positioning ourselves at the forefront of the evolving energy landscape.

As a pioneer in the engineering sector of the offshore industry, we specialise in designing, manufacturing, and installing CALM Buoy terminals to the highest standards.

At Monobuoy, we take a personal approach to every project. Our buoys are not off-the-shelf products –they’re built to match each client’s specific needs, with input from our engineering team to adapt the design to the local environment and conditions. Our focus is on providing safe, reliable, and efficient solutions that enhance the effectiveness of marine operations with products that are engineered to withstand harsh climates, ensuring both durability and performance.

We are committed to continuous improvement in all aspects of our operations. By leveraging the latest technology and industry best practices, we strive to deliver superior results that maximise the value of our clients’ offshore assets.

At Monobuoy, our vision is to be the premier terminal solutions provider. With a rich history of over 25 years in the industry, we are committed to delivering innovative, sustainable, and high-quality solutions. We are likewise dedicated to exceeding industry standards and continuously improving our services to achieve exceptional customer satisfaction, which has earned us a reputation as a trusted CALM Buoy terminal industry leader.

As our flagship product, the CALM Buoy Terminal is designed for the safe and efficient loading and offloading of crude oil and other products from tankers. A typical CALM Buoy terminal includes hoses, mooring chains, piles, and a Pipeline End Manifold (PLEM)—a subsea structure that links the buoy’s hoses to the seabed pipeline, enabling the transfer of products to and from the shore or a tanker. We supply the complete system, delivering all necessary components to ensure seamless integration and reliable operation.

At Monobuoy we go beyond just designing and supplying buoys, providing a wide range of products and services.

- Swivels: We design and manufacture our own swivel stacks, custom-built for a range of applications including crude oil, gas, pneumatic systems, and high-pressure toroidal hydraulics. This key component facilitates the transfer of fluids, electricity, and data (via fibre optic or ethernet communication) between the stationary and the rotating parts of the system.

- Advanced Telemetry System: We have designed and developed an in-house telemetry system that integrates seamlessly with our buoys and can also be retrofitted to upgrade existing, outdated systems. We utilize the latest technology to ensure reliable monitoring of critical operations, both offshore and onshore. Built in-house, the system can be customized to meet any customer requirements.

- Spare Parts and Aftersales Support: Monobuoy provides a comprehensive range of spare parts for CALM Buoys, FSOs, and FPSOs to ensure longevity and continuous operation. Our offerings include, but are not limited to, main slewing bearings, chain stoppers, mooring bridle assemblies, water barrages for bearing protection, greasing systems, piping valves, expansion pieces, anchors and chains. Additionally, our dedicated aftersales support team is committed to ensuring continuous performance and customer satisfaction.

- Used buoys: We offer a selection of used CALM Buoys for customers seeking a more cost-effective solution. Our used buoys are thoroughly inspected and refurbished to meet strict quality standards, and we provide various sizes, configurations, and full installation and commissioning services.

• Engineering – Our team specialises in comprehensive engineering design and precision calculations tailored to offshore moored systems. With a deep commitment to collaboration, our dedicated in-house design team engages closely with clients to understand their unique requirements and challenges. This partnership allows us to craft innovative and effective solutions that ensure optimal performance and safety in all our projects.

• Construction – Our team comprises exceptionally skilled professionals who excel in managing every aspect of the fabrication and construction of buoy systems. With a wealth of experience and a commitment to excellence, we ensure that each project is completed with precision and attention to detail, delivering robust and reliable solutions tailored to our clients’ needs.

• Installation – Our dedicated offshore engineers oversee each project’s installation and commissioning phases, meticulously coordinating every detail for the seamless integration of cutting-edge technology. Their hands-on approach guarantees that each step is executed to the highest standards, paving the way for successful project completion and operational excellence.

·

·

·

In the last five years, the Angolan government has made a concerted effort to boost local content and increase economic returns in an attempt to develop the country’s oil and gas landscape.

Efforts to strengthen entrepreneurship and create a stable environment for business growth were first introduced in October 2020 with Presidential Decree 271/20, which brought forth stricter local ownership requirements for investment into Angola’s oil industry.

This, in turn, encourages more local participation and means that any companies in the industry’s value chain must prioritise national service providers and develop a more localised workforce.

As a result, the oil and gas industry will contribute more greatly towards Angola’s socioeconomic growth and facilitate more streamlined skills transfer across other associated industries.

Moreover, the company boasts an ambitious project schedule for the coming year, with its flagship operation being the completion of its subsea works at the Begonia oil field by mid-2025, working with McDermott on a contract for TotalEnergies.

The operation includes the fabrication and load-out of subsea structures, where Ponticelli Angoil’s team plays a crucial role in ensuring the systems are built to strict specifications and adhere to the highest standards of quality.

“We are committed to supporting contractors throughout the process, ensuring that the installation is seamlessly integrated and fully operational, enhancing the facility’s capabilities.”

One Eighty Materials Engineering Solutions (Pty) Ltd (One Eighty) is a professional materials and metallurgical consulting engineering company with an accredited laboratory to the international standard ISO 17025:2017. We are also a uniquely Bureau Veritas Marine and Offshore-approved laboratory, meeting the rule set requirement in this way for the witnessing of tests. The company is based in the innovation hub of South Africa in Cape Town, uniquely positioned to service the entire market in Africa.

Today, One Eighty is a trusted industry partner in supplying quality results on time for their fabrication projects. Recently, we have assisted with all the qualifications and 3.2 inspections on the Girflex Project. During the COVID-19 pandemic, we assisted with the Dalia series of projects where TOTAL was the end user. Following this, we have assisted with many other projects, including the Begonia project.

One Eighty is an African company with a strong vision to bring highlevel technology to real-life problems for Africa and emerging economies in Africa. This is our strong vision. Currently, we are the most widely-scoped laboratory in Africa, providing all the necessary testing for the oil and gas sector, and we are expanding all the time. We are able to facilitate, for example, accredited CTOD testing with a relatively short turnaround time, which is becoming more important for LNG projects in Angola. We are able to provide all the necessary tests for duplex stainless steel, inconel cladding, heavy carbon steel sections, and so on, and don’t shy away from challenging projects. Our unique selling point is out turnaround time, which Ponticelli Angoil has certainly come to rely on.

We also take care of all the logistics to have the coupons delivered to our office in record time with the highly competent team at DHL South Africa. If things go wrong, we can also supply root cause analysis of any analytical metallurgical and materials engineering consulting services with our team of six graduate candidate engineers, managed by the Managing Director, Dr Janet Cotton Pr.Eng.

We are truly a one-stop shop for the oil and gas industry in Africa and Angola, and have serviced Angola now for 11 years.

The company was started in 2002 by Dr Janet Cotton, a PhD graduate from the University of Cape Town, South Africa.

In 2012, the company opened its own laboratory and first became accredited in 2013.

With Dr Janet Cotton at the helm, she decided to explore markets in Africa, with Angola being one of them. In 2014, she travelled to Luanda and met with Ponticelli Angoil for the first time, and it was not long before One Eighty was awarded the work for qualifying welding procedures, which is a critical part of the fabrication project that Ponticelli Angoil undertakes.

Being a professional consulting company, One Eighty was also able to assist with the optimisation of duplex stainless steel welding, which was still relatively new to oil and gas in 2014.

Therefore, as subsea technology continues to evolve, this project aligns with the company’s mission to drive innovation and deliver

top-tier service to the oil and gas sector and is vital for boosting Angola’s offshore production capability.

Ponticelli Group’s sustainable development approach is structured around four commitments, which its specialist CSR and Ethics Department strives to implement across the business on a daily basis.

The group’s CSR commitment policy outlines its social, environmental, and ethical responsibilities for a positive impact both on a global and local level:

SOCIAL COMMITMENTS

• Prioritise the safety and well-being of employees

• Promote the development and evolution of staff

• Encourage healthy lifestyles amongst employees to improve their quality of life

• Foster intergenerational exchanges and connections

• Support workforce integration and diversity

• Share corporate value with employees

• Aim to be a reputable employer

SOCIETAL ENGAGEMENT

• Strengthen its positive impact on local communities

• Develop partnerships with organisations that are aligned with Ponticelli Group’s family, health, environment, and educational values

ETHICAL PRACTICES

• Uphold impeccable business practices and ethical standards

• Ensure respect for human rights and fundamental freedoms globally

• Extend commitments throughout the supply chain, especially in procurement

ENVIRONMENTAL INITIATIVES

• Enhance environmental efforts to minimise the impacts of its activities

• Prevent pollution

• Improve waste sorting and recycling

• Work towards its target of carbon neutrality by 2050 with clients and suppliers

• Promote better water resource management and natural resource preservation

• Stay updated with regulatory changes

• Offer innovative solutions to clients to reduce their environmental impacts

A further critical element of Ponticelli Angoil’s success is its extensive supply chain, as the business endeavours to maintain strong partnerships with both local and international partners.

“At Ponticelli Angoil, we work closely with a network of suppliers and contractors to ensure seamless operations across all our projects,” Bacci expands.

Local partnerships are particularly important to the company, as they contribute to the national economy and help develop regional capabilities.

Prioritising regional suppliers also aligns with the government’s drive for increased local content, which it has brought to the fore with a vast range of legislation that it hopes will stimulate domestic market growth.

From an international perspective, global partnerships provide invaluable access to advanced technology, unmatched expertise, and highquality materials that prove crucial for Ponticelli Angoil’s more complex projects, such as its subsea works.

“The balance between leveraging local talent and international knowhow enables us to maintain a high standard of service whilst being competitive in a dynamic market,” he states.

Offices and logistics hubs spread over 4 continents

TFE, an international procurement group strategically located A reputation gained by offering cost effective supply solutions for materials and equipment in the mining, industrial, oil & gas and petrochemical sectors.

TFE, provider of global procurement solutions for international As international procurement market specialists, we offer your our global procurement and supply chain expertise, providing quality products and services with agreed deadlines and budgets.

As such, one of Ponticelli Angoil’s key objectives going forwards is to enhance its local content by empowering regional companies and encouraging global organisations to establish a presence in Angola.

Angola’s labour market has witnessed high unemployment rates in recent years, affecting the construction, manufacturing, energy, and oil and gas sectors most acutely, and Ponticelli Angoil was no stranger to industry-wide adversity.

“We certainly faced significant challenges with labour shortages last year, and the demand for skilled workers was high across the sector due to the number of simultaneous projects in the market,” Bacci recalls.

The group has long been established as a world leader in offshore construction, helping clients across the globe combat difficulties in major new or brownfield projects.

Indeed, Ponticelli Group provides end-to-end assistance, supporting clients through the lifecycle of their facilities.

This is achieved through a comprehensive range of services and solutions, including but not limited to feasibility and constructability studies, detailed engineering and frontend engineering design (FEED), procurement, connection and commissioning, and operations and maintenance.

Elsewhere, the group also offers a multitude of global onshore solutions for a diverse range of clients; whether the operation calls for new installations or the redevelopment of existing ones, Ponticelli Group is on hand around the clock to get the job done.

Equipped with an in-depth knowledge base garnered from onshore oil and gas developments worldwide, the team implements a vast range of solutions for various project components.

These include onshore studies, operational preparation, procurement, manufacturing, transportation, installation,

To address these challenges, Ponticelli Angoil implemented a more structured approach to talent acquisition and invested in training programmes to quickly upskill new recruits.

This is evidenced by the sheer number of welders it has trained and qualified for subsea projects, which have subsequently experienced an outstandingly low repair rate.

The company is currently experiencing a stabilisation in the number of ongoing market projects, which is providing it with the opportunity to focus more on the training and development of its personnel.

Indeed, with fewer overlapping demands, the company has more time to invest in upskilling its team and ensuring it is fully equipped to meet the needs of future projects.

mechanical construction, and commissioning, amongst others.

Ponticelli Group also delivers cutting-edge refining and petrochemical solutions to overcome the challenges of an evolving oil and gas landscape.

The group combines its extensive experience in the two fields with a dynamic set of skills to conduct routine maintenance work, scheduled shutdowns, and support petrochemical projects through to completion.

Finally, Ponticelli Group also offers trusted distribution and storage services as part of its oil and gas solutions, catering to the rapidly increasing demands of the industry and ensuring the balanced distribution of products across clients’ global markets.

As part of its service, leading players in the oil and gas sector can capitalise on the advantages of highly convenient infrastructure involving storage facilities that are strategically located in proximity to specified demand and strictly adhere to industry standards.

In order to successfully meet clients’ storage and distribution needs, the group also assists in the construction and installation of pipelines and terminals for earthworks, civil engineering, and more.

Our Experience

• Serving Angola since 2010

Our skills

• Providing spare parts

• O&G, Mining and Industrial Equipments

• Worldwide sourcing with presence on 5 continents

• Door to door services (to Luanda, Soyo, Cabinda,Lobito...)

• Supply chain management

• Goods storage facilities

As such, due to this period of stabilisation, Ponticelli Angoil is able to build a stronger and more capable workforce and strengthen its internal resources to improve readiness for future growth.

Employing 1,500 members of staff worldwide, Ponticelli Angoil boasts a highly skilled, technical workforce comprising engineering teams, project managers, and tradespeople dedicated to delivering excellence.

“Our staff are at the heart of the company, and we are proud of their dedication, expertise, and commitment to excellence,” Bacci prides.

Indeed, Ponticelli Angoil recognises that its success is directly linked to the contributions of its employees, which is why empowering them is a core part of the company’s philosophy.

Therefore, once new talent has been onboarded, it heavily invests in training and development to retain teams and ensure they are equipped with the latest skills and knowledge to meet the demands of the oil and gas sector.

The maintenance of staff is also supported by employee shareholding and living by Ponticelli Group’s founding motto – ‘Union, Work, Wisdom’.

This not only helps staff grow professionally but also ensures they are confident in delivering

The group’s commitment to quality, health and safety, and security is surmised in its comprehensive quality, health, safety, and security (QHSS) policy:

QUALITY

• Commits to putting clients first by offering highperformance and innovative solutions within required timelines and budgets.

• Promises to do things right the first time by adopting a forward-thinking attitude and maintaining transparency throughout the entirety of a project.

• Takes into account any changes to projects and assesses their impacts, risks, and opportunities.

• Seeks high performance and promotes continuous improvement.

• Encourages knowledge-sharing and transfer.

HEALTH AND SAFETY

• Places the safety, health, and integrity of individuals at the heart of its strategies and actions.

• Ensures that no other priorities compromise workplace health and safety.

• Implements actions to achieve the group’s objective of zero accidents.

high-quality work on complex projects and possess the in-depth knowledge necessary to operate cutting-edge technologies.

Thus, whether through specialised training or leadership development programmes, Ponticelli Angoil is committed to helping its staff advance their careers.

For Bacci personally, the strong sense of teamwork and collaboration are what distinguish the company from the competition.

“The environment here fosters a culture of shared knowledge and mutual support in which every individual, from field operators to management, plays a vital role in achieving our goals,” he impassions.

Container World, marine shipping the launch of range of Offshore units are certified international safety Strategically located international demand

Our dynamic and and customization assurance and response times, Container World tailored to customer containers are (DNV) and Lloydʼs environments.

• Systematically identifies risks and implements the best preventative measures possible.

• Consults and involves employees in continuous health and safety improvements.

SECURITY

• Identifies scenarios that could threaten the security of employees, the environment, and brand image with the aim to protect the interests of employees and clients.

• Raises awareness and trains all staff on security practices applicable to daily life in the workplace.

• Ensures ongoing security monitoring and regularly checks the protective measures in place.

• Regularly verifies the adequacy of protective measures.

• Prepares for and responds effectively to emergency situations.

World, a South African-based company, has been a leader in the supply of shipping containers since 1983. In 2008, the company expanded its expertise with Container World Offshore, a dedicated division providing a comprehensive Offshore containers, baskets, skips, reefers, and accommodation modules. All certified to DNV 2.7-1 and EN12079 standards, ensuring compliance with safety and quality regulations.

Dry Goods Storage Containers

Office Cabins

Accommodation Cabins

Half-Height Baskets

Container World, a South African-based company, has been a leader in the supply of marine shipping containers since 1983. In 2008, the company expanded its expertise with the launch of Container World Offshore, a dedicated division providing a comprehensive range of Offshore containers, baskets, skips, reefers, and accommodation modules. All units are certified to DNV 2.7-1 and EN12079 standards, ensuring compliance with international safety and quality regulations.

located in Cape Town, Container World Offshore efficiently meets local and demand with short lead times and competitive pricing.

and technically astute team delivers a full turnkey service, from engineering customization to final delivery at the destination. With a commitment to quality and seamless service delivery, we ensure continuous communication, rapid times, and peace of mind for our clients.

Open Topʼs

Boat Shape Waste Skips

Vacuum Mud-Cutting Skips

Gas Bottle Racks

Strategically located in Cape Town, Container World Offshore efficiently meets local and international demand with short lead times and competitive pricing.

Cargo Baskets

Mini Toolboxes

Our dynamic and technically astute team delivers a full turnkey service, from engineering and customisation to final delivery at the destination. With a commitment to quality assurance and seamless service delivery, we ensure continuous communication, rapid response times, and peace of mind for our clients.

World Offshore excels in designing custom, high-quality Offshore products, customer specifications. Manufactured to international standards, our Offshore recognized by leading certifying authorities such as Det Norske Veritas Lloydʼs Register (LR)—guaranteeing durability, reliability, and safety in extreme

Refrigerated (Reefer) Containers

Lifting Cages And Frames

Workshops

Container World Offshore excels in designing custom, high-quality Offshore products, tailored to customer specifications. Manufactured to international standards, our offshore containers are recognised by leading certifying authorities such as Det Norske Veritas (DNV) and Lloyd’s Register (LR)—guaranteeing durability, reliability, and safety in extreme environments.

Bespoke Customised Units

Container World, a South African-based company, has been a leader in the supply of marine shipping containers since 1983. In 2008, the company expanded its expertise with the launch of Container World Offshore, a dedicated division providing a comprehensive range of Offshore containers, baskets, skips, reefers, and accommodation modules. All units are certified to DNV 2.7-1 and EN12079 standards, ensuring compliance with

Strategically located in Cape Town, Container World Offshore efficiently meets local and international demand with short lead times and competitive pricing.

A note to the Ponticelli team:

We at Container World, extend our heartfelt gratitude towards your unwavering support.

Our dynamic and technically astute team delivers a full turnkey service, from engineering and customization to final delivery at the destination. With a commitment to quality assurance and seamless service delivery, we ensure continuous communication, rapid response times, and peace of mind for our clients.

Your team’s dedication and professionalism have been instrumental in our shared successes, we deeply value the strong partnership we have cultivated together.

As your establishment embarks on new ventures, we wish you continued prosperity and triumph throughout these endeavours.

Container World Offshore excels in designing custom, high-quality Offshore products, tailored to customer specifications. Manufactured to international standards, our Offshore containers are recognized by leading certifying authorities such as Det Norske Veritas (DNV) and Lloydʼs Register (LR)—guaranteeing durability, reliability, and safety in extreme environments.

May your journey be filled with evolution, innovation, and extraordinary achievements.

Thank you once again for being an integral part of our story.

CONTACT:

Tall-Miniʼs

Dry Goods Storage Containers

Office Cabins

Accommodation Cabins

Half-Height Baskets

Open Topʼs

Boat Shape Waste Skips

Vacuum Mud-Cutting Skips

Gas Bottle Racks

Cargo Baskets

Mini Toolboxes

Refrigerated (Reefer) Containers

Lifting Cages And Frames

Workshops

Bespoke Customised Units

Ponticelli Angoil’s dedication to corporate social responsibility (CSR) stems from its parent company’s steadfast commitment to civic duty and community investment, which is deeply integrated into its business strategy.

Indeed, Ponticelli Group believes economic development is impossible without the key consideration of environmental, social, and ethical initiatives.

In light of this, CSR is at the core of its corporate strategy, ensuring that the group’s long-term operations contribute meaningfully to a better, more sustainable world.

Ponticelli Group’s devotion to environmental responsibility is exemplified by the fact that, since 2017, it has been a signatory of the UN’s Global Compact – a voluntary initiative that pursues sustainable development goals for businesses.

The group proactively communicates with the UN annually on its sustainable actions and how it hopes to continue these initiatives going forwards.

A dedicated subsidiary of the group, Ponticelli Angoil proactively engages in a number of CSR activities, spanning several key areas such as educational programmes to support local communities, vocational training, and regional job creation.

“We collaborate with local organisations to promote healthcare,

social welfare, and infrastructure development, contributing to the long-term growth and well-being of the regions where we operate,” Bacci shares.

For example, the company has distributed approximately 5,000 mosquito nets to local communities since 2015.

Elsewhere, over the last seven years, Ponticelli Angoil has donated vast numbers of food products annually to the Boa Vista community in Luanda.

The company also prioritises environmental responsibility by implementing eco-friendly practices and reducing its carbon footprint.

“As the energy sector shifts towards more sustainability, Ponticelli Angoil is leading the way by integrating environmentally responsible practices into its operations. We are committed to reducing emissions, minimising waste, and embracing greener technologies,” Bacci divulges.

The Angolan oil and gas sector is set for substantial growth in the coming year, as it was projected to grow by 15 percent between 2022 and 2027 and is well on the way to achieving this target.

This progression is spurred by encouraging a sustainable market within the industry, complemented by the promotion of upstream investment.

In light of this, Ponticelli Angoil’s priorities for 2025 are centred around

further growth, diversification, and operational excellence.

Indeed, one of its main priorities is the ongoing expansion of its subsea capabilities, tapping into new technologies and methodologies that have recently inundated the industry in order to enhance its service offerings.

Furthermore, to help stay abreast with industry changes and solidify its leading position in the Angolan oil and gas sector, the company hopes to pursue new contracts and reinforce its relationships with key clients such as Sonangol, TotalEnergies, ExxonMobil, Azule Energy, and Chevron.

In addition to expanding its operational reach, Ponticelli Angoil is placing a strong emphasis on sustainability and innovation.

This is emphasised by the company’s plan to invest in digitalisation and green technologies to support Angola’s transition to cleaner energy sources and ensure that its services remain future-proof in an evolving energy landscape.

On top of this, Ponticelli Angoil is focused on achieving operational excellence by streamlining its internal processes and maintaining high safety and quality standards.

Its targets specifically include reducing project lead times, optimising resources, and streamlining project management to deliver better results for clients.

“Another critical priority for us is to continue improving our local content by training and upskilling Angolans at every level of our organisation. We see this as a long-term investment in both the local economy and the future of our business,” Bacci concludes.

Sistran Engenharia Angola is Emerson’s local business partner, and a 100% Angola owned company by Dionisio Viegas. Currently, it is working with Ponticelli Angoil repairing and testing valves and verifying, testing, and certifying transmitters, pressure gauges and manifolds for both Chevron and Azule Energy.

In addition to other achievements in recent times, it is with great pride that Sistran has successfully tested two highly complex 8” antisurge valve for Ponticelli Angoil Offshore in its Benfica workshop in Luanda.

Both our Luanda and Cabinda workshops have been accredited by Emerson and currently provide certified services in manual valves, control valves, actuators and pressure relief valves (PRVs), adding great value to our clients.

To get this accreditation, Sistran went through a strict approval process to ensure that all valves comply with international regulations.

CBL-FB is an Angolan company, provider of training services in HES and HST and Business Consulting. Our staff includes competent and qualified professionals that respond to the needs of our customers.

SERVICES WE PROVIDE

• Safety Training certified by OSHA/ISSO/ STCW

• HES Training and Consulting (Safety)

• Building evacuation plan, f planogo

• Man power services

• Skilled and Unskilled Work

• Plumbing, Electricity, Mechanics and HVAC

• Maintenance and Technical Assistance to Generating Stations

• Procurements services

(+244) 222 333 444 | geral@sistran-eng.com www. sistran-eng.ao Ph:+244 926810127/927184522 |

| www.cblsafetyangola.com