SAULSBURY

Powering Ontario’s infrastructure with reliable trucking solutions, AM Haulage specializes in material transportation and disposal services for large-scale infrastructure projects. A proud transportation partner of QM Environmental, our hauling capabilities are second to none.

Operating one of Ontario’s most dependable and efficient trucking fleets, complete with over 90 tri-axle dump trucks and live-bottom units, AM Haulage has built a reputation for reliability, safety, and efficiency.

Whether moving aggregates, soil or construction materials, our fleet is ready to meet the demands of the most challenging projects.

Having played a crucial role in several high-profile projects in the region, AM Haulage ensures seamless material transportation solutions while maintaining the highest standards of safety and environmental compliance. We play a significant role in trucking for QM Environmental, working closely with them to support large-scale environmental projects, ensuring safe and responsible material haulage.

One of the largest construction undertakings in Canada, the Toronto Port Lands Flood Protection (Toronto Port Lands) project is transforming the city’s waterfront. QM Environmental was awarded the request for proposal (RFP) 33.6 subcontract in 2021.

Successfully providing tri-axle dump truck haulage solutions on the project for the past three years, AM Haulage has secured its status as a trusted partner on this complex initiative. Handling large volumes of soil and aggregate, we ensure efficient transportation solutions while navigating strict safety regulations.

The Toronto Port Lands project is known for its intricacies, presenting various challenges, however our expertise has continued to ensure success.

AM Haulage’s role in this project showcases our ability to meet stringent timelines, adhere to environmental compliance, and operate efficiently within a high-demand urban setting, and its success is a testament to our commitment to quality and reliability in major infrastructure works.

AM Haulage has also provided material haulage solutions for the Toronto Transit Commission’s Russell Carhouse Upgrades, efficiently transporting soil and aggregates off-site.

Our ability to coordinate logistics for high-traffic urban projects makes us the preferred choice for municipal and transit-related construction.

Further to this, experienced and efficient AM Haulage drivers bring a wealth of experience and efficiency to every project, making us a reliable choice, whilst our dedication to everything we undertake results in clients that are deeply satisfied with our services.

In addition to construction, AM Haulage also manages winter operations for the City of Hamilton’s snow removal program.

Our fleet operates across multiple sites, ensuring roadways remain safe and functional during heavy snowfall.

This large-scale, time-sensitive operation underscores the company’s adaptability and reliability in diverse project settings.

AM Haulage stands out as the best in the industry, and this is why.

• Safety first – With one of the strongest safety track records in the industry, AM Haulage has experience in handling highrisk and complex projects. Our drivers are highly trained and our fleet is equipped with the latest safety technologies.

• Reliable fleet and experienced operators – With over 90 trucks, we provide scalable solutions that meet all types of project demands, from small-scale municipal work to large infrastructure projects.

• Efficiency and compliance – AM Haulage’s operations meet all regulatory standards, ensuring environmentally responsible and legally compliant material transport.

• Proven track record – Partnerships with major contractors, government agencies, and municipalities demonstrate our expertise and commitment to excellence.

Let’s connect and discuss how AM Haulage can support your next project with cost-effective and dependable trucking solutions.

For more information, visit www.amhaulage.ca.

EDITORIAL

Head of Editorial: Jack Salter jack.salter@outpb.com

Deputy Head of Editorial: Lucy Pilgrim lucy.pilgrim@outpb.com

Senior Editor: Lily Sawyer lily.sawyer@outpb.com

Editor: Ed Budds ed.budds@outpb.com

Editor: Rachel Carr rachel.carr@outpb.com

Editor: Lauren Kania lauren.kania@outpb.com

PRODUCTION

Art Director: Stephen Giles steve.giles@outpb.com

Senior Designer: Devon Collins devon.collins@outpb.com

Designer: Louisa Martin louisa.martin@outpb.com

Production Manager: Alex James alex.james@outpb.com

Digital Marketing Director: Fox Tucker fox.tucker@outpb.com

Website Content Manager: Oliver Shrouder oliver.shrouder@outpb.com

Social Media Executive: Jake Crickmore jake.crickmore@outpb.com

BUSINESS

CEO: Ben Weaver ben.weaver@outpb.com

Managing Director: James Mitchell james.mitchell@outpb.com

Chief Technology Officer: Nick Norris nick.norris@outpb.com

ADMINISTRATION

Finance Director: Suzanne Welsh suzanne.welsh@outpb.com

Finance Assistant: Victoria McAllister victoria.mcallister@outpb.com

CONTACT

North America Outlook

Norvic House, 29-33 Chapelfield Road

Norwich, NR2 1RP, United Kingdom

Sales: +44 (0) 1603 804 445

Editorial: +44 (0) 1603 804 431

SUBSCRIPTIONS

Tel: +44 (0) 1603 804 431

jack.salter@outpb.com

www.northamericaoutlookmag.com

Like us on Facebook: @northamericaoutlook

Follow us on X: @OutlookPublish

Welcome to our 29th edition of North America Outlook.

This issue’s pipeline of corporate stories is spearheaded by Saulsbury, a market leader with a proven history of excellent project execution in the oil and gas sector.

The Texas-based full-service engineering, procurement, and construction (EPC) company has a strong track record of delivering integrated solutions for complex capital projects, helping it to stand out from the crowd.

Clients across the country call upon the support of Saulsbury, who provides expert services in engineering, general construction, electrical and instrumentation work, field services, structural and piping module fabrication, insulation, and scaffolding.

While the company’s roots are in oil and gas, Saulsbury has also begun to strategically diversify its portfolio.

“Our increased focus on renewables and non-oil and gas sectors has strengthened our resilience against industry downturns,” reveals CEO, Matt Saulsbury.

As the continent’s largest provider of aviation services, Unifi is likewise called upon from the moment passengers arrive at the airport – whether checking in, picking up bags, or loading them onto the plane – to ensure everything runs smoothly.

The company has a five-year strategy in place comprising two main pillars, namely continued strength in North America and targeted international expansion.

In many global markets, the ground handling space has been dominated by a small number of established providers, creating an opportunity for Unifi to introduce new approaches and drive meaningful innovation in the space.

“We have the scale, experience, and capabilities to disrupt those markets and offer a fresh alternative,” states Chief Commercial Officer, Ying McPherson.

The Trinidad and Tobago Manufacturers’ Association (TTMA), meanwhile, is called upon to promote, encourage, and assist the growth and development of the country’s manufacturing industries.

TTMA is committed to fostering innovation, sustainability, and digital transformation within the manufacturing sector.

“By leveraging technology and sustainable practices, we aim to enhance productivity and competitiveness on a global scale,” outlines CEO, Dr. Mahindra Ramdeen.

We also find out why clients call upon Hondo Resources, Resonac Graphite Business Unit, Rising Edge Group, and more in this issue.

We hope that you enjoy your read.

Jack Salter Head of Editorial, Outlook Publishing

Getting

A

Home

Trusted

120 Albuquerque

International Sunport

The Gateway to New Mexico

An airport with a difference

126 Morbern

Sit in Style

Innovative vinyl upholstery fabrics

Aero Industries

Top-Tier Tarp

Generations of transportation innovation 146 Resonac Graphite

Unit

Leaders in an Evolving Electrode Industry An

Vision

Delivering

Next-Gen

Innovators

178 Rising Edge Group

Trust the Energy

Unparalleled high-voltage electrical services

& BEVERAGE

188 Evo America and Middleby Ventless Solutions

Tomorrow’s Culinary Experiences

The ultimate in kitchen design and flexibility

196 Middleby Marshall

Perfection at Every Pass

The

in conveyor oven cooking 204 Yerba Madre

Honoring the Mother Herb

A regenerative future for the beverage industry

Regulating

AS A RESULT of US President Donald Trump’s trade war, the nation’s airlines are experiencing a notable slump in travel demand, with budget carriers seeing the sharpest declines in their operating margins.

Companies including Southwest, Frontier Airlines, and JetBlue are among those being hit the hardest by faltering consumer demand.

With the anticipation of slower

economic growth and increased inflation, the margin gap between budget and luxury airlines is likely to expand even further.

The surge in demand for premium travel and the growing value of customer loyalty programs have provided full-service airline operators with an advantage over budget carriers, who are struggling to maintain sustained profitability.

A NEW STUDY published in the Communications Earth & Environment journal has found that wildfires ignited by the effects of climate change can be linked to upwards of thousands of deaths annually and billions of dollars in economic burden for the US.

AMID THE RISE of new weightloss drugs dominating the market, WeightWatchers – one of the most recognizable brands in the multibillion-dollar diet industry – has filed for bankruptcy after 62 years in business.

The infamous diet company stated that it was seeking Chapter 11 bankruptcy protection to eliminate $1.15 billion in debt, yet remains committed to trusted, science-based, and holistic solutions.

With growing pressure from newly accessible drugs such as Ozempic and Wegovy, WeightWatchers has been facing myriad challenges recently, including Oprah Winfrey’s decision to leave the company’s board in 2024 after revealing she was taking weight-loss medication.

Specifically, the recently published paper states that between 2006 and 2020, climate change directly contributed to approximately 15,000 deaths, resulting from exposure to small particulate matter from wildfire smoke, and cost around $160 billion.

Further evidence is emerging that this fine particulate matter is more toxic than other pollution sources, with burning cars and other toxiccontaining materials from cities adding to the danger.

FIVE YEARS AGO, it was reported that clustered regularly interspaced short palindromic repeats (CRISPR) gene editing technology was in the process of being used to develop a medicine for beta-thalassemia – a genetically inherited blood disorder that affects approximately 60,000 individuals on an annual basis. Recently, the Children’s Hospital

HEALTHCARE

IN A RECENT announcement from the National Institutes of Health (NIH), the agency is now favoring grant proposals that eschew animal testing in an effort to improve the quality of science used in drug development and usher in a new era of innovation.

The agency notes that while humans and animals may share genes, studies have shown functional differences between their organ and body systems that can result in translational limitations.

To integrate human-based science, the NIH will establish an Office of

of Philadelphia (CHOP) developed a new medicine called Zynteglo, which uses patients’ cells to create stem cells with the ability to be reprogrammed to replace faulty genetic copies, directly benefiting those with symptomatic betathalassemia.

This medicine provides more hope for patients, as the only previous available cure was a bone marrow transplant from a closely related donor, which is an expensive and complicated procedure.

Research Innovation, Validation, and Application (ORIVA), which will coordinate efforts to develop, validate, and scale the use of non-animal approaches across the agency’s biomedical research portfolio.

ENVIRONMENT

IN A LANDMARK moment for conservationists, the harpy eagle –South America’s largest bird of prey – has been sighted in a rainforest in Southern Mexico, where it was once believed to be locally extinct.

The giant bird used to reside in the Lancandon Jungle, a tropical rainforest stretching approximately 1.9 million hectares from Southeast Chiapas into the south of the Yucatán Peninsula, and the only environment where the eagle can thrive.

With adults weighing close to 40 pounds and having a wingspan of more than six feet, conservationists and locals alike are celebrating the return of these majestic raptors to Central America.

TECHNOLOGY

MICROSOFT RECENTLY OFFICIALLY shut down Skype, a pioneering telecommunications company that first came to fruition in 2003.

This internet phone service provider was among the first wave of communication services to use Voice over Internet Protocol (VoIP) technology, converting audio into a digital signal.

Having bought the company in 2011, Microsoft announced the imminent shutdown in February 2025, along with its decision to shift many of Skype’s services to Microsoft Teams, the company’s flagship office video conferencing and group collaboration platform.

While Skype numbers won’t immediately expire, calling subscriptions have stopped automatically renewing.

Space junk or debris refers to anything humankind leaves in orbit or on the moon, from large objects such as pieces of machinery to minute paint flecks that have fallen off a rocket. Nonetheless, clutter is creating a crisis in the cosmos, as Richard Jacklin, Commercial Lead at Plextek, explores further

Writer: Richard Jacklin, Commercial Lead, Plextek

With low Earth orbit (LEO) becoming increasingly crowded, satellite operators, space agencies, and aerospace companies are facing rising threats from orbital debris.

With in excess of 10,000 active satellites in space, alongside an ever-accumulating amount of debris, the risk of collisions is escalating, and even small particles – no larger than a grain of sand – pose a serious threat to billion-dollar missions, global connectivity, astronaut safety, and the long-term sustainability of space operations.

Current ground-based systems’ inability to adequately track debris smaller than 10 centimeters (cm) means these types of particles have been an ‘invisible threat’ to space operations over the years. The consequence? Mission planners have been operating with incomplete data and limited options for collision avoidance.

The industry needs more continuous real-time monitoring data, detecting debris as small as one millimeter (mm) and debris clusters at various altitudes and locations around Earth. This data can then be used to improve orbital models and guide mission planners better.

The European Space Agency’s (ESA) Zero Debris Initiative, which aims to significantly limit debris production in Earth and lunar orbits by 2030, depends on this technological evolution to succeed.

mmWave radar plays a significant role in detection capability by offering continuous, high-resolution, real-time space debris detection. Operating at high frequencies, this radar allows operators to:

• Identify high-density debris fields

• Adjust orbital trajectories

• Enhance shielding strategies

• Improve predictive debris modeling

This aligns closely with the ESA’s space situational awareness efforts and Europe’s leadership in responsible space operations.

Momentum is certainly building in the US, with NASA investing heavily in space situational awareness and debris mitigation and the US Space Force prioritizing domain awareness capabilities.

There is clearly a significant demand in the US market for precise, space-based tracking solutions, as the

current tracking infrastructure lacks sub-mm resolution.

Some of the big-hitting firms in the US responsible for these satellite mega-constellations growing include the likes of Elon Musk’s SpaceX, Amazon’s Project Kuiper, and Telesat’s Lightspeed, all of whom are facing increasing regulatory scrutiny over orbital congestion. So, as satellite mega-constellations grow, realtime debris awareness is now an operational necessity.

An integrated mmWave radar system offers agencies the unique opportunity to detect sub-mm debris, marking a breakthrough in monitoring even the smallest fragments. This is unique because, unlike traditional methods, mmWave systems offer high-frequency, non-impact sensing as a compact satellite payload. Scanning within a defined beamwidth, it identifies debris in real-time, which can enhance:

• Collision risk modeling

• Adaptive shielding designs

• Space traffic management strategies

Not only is this technology lightweight, but it also contains a low-power payload that allows for flexible integration into satellites, either as a dedicated module or part of multi-mission platforms. Its scalability supports international debris mitigation efforts, including the ESA’s Zero Debris Initiative.

A unique area is a radar payload operating 24/7 actually in orbit, providing real-time monitoring and data. By having this equipped, agencies enhance detection at the smallest scale, allowing for more effective mitigation strategies and ensuring that avoidance strategies, shielding designs, and debris removal efforts are based on accurate, real-time data.

Detection is crucial, but its true value lies in supporting broader debris

management efforts. By continuously mapping debris fields, operators can take a proactive approach to space traffic control, reducing collision risks through precise forecasting and early intervention.

Bringing new space technologies to market is complex, requiring rigorous testing to withstand extreme conditions such as temperature fluctuations and radiation exposure. Radar technology must be designed to incorporate radiation-hardening measures.

In addition, it should include power regulation systems and compact, lightweight construction to ensure long-term functionality in orbit. Therefore, the move toward more precise, cost-effective, and real-time debris monitoring is inevitable as the space industry faces increasing orbital complexity.

A system capable of detecting and analyzing debris at this level enhances mission planning, spacecraft protection, and active debris mitigation.

Richard Jacklin is the Commercial Lead at Plextek, specializing in space, satellite, wireless, and radio frequency (RF) technologies. He works closely with satellite operators, aerospace firms, and space agencies to develop cutting-edge sensing systems that enhance mission safety and orbital sustainability. With over 30 years in the space, satellites, and telecom sectors, Jacklin now applies his expertise to drive business growth and product innovation.

A new healthcare company dedicated to improving the health outcomes of American Indians and Alaska Natives, Indigenous Pact is committed to building health equity in one generation. We speak to Kurt Brenkus, CEO and co-Founder of Indigenous Pact, and Emma Godfrey, Managing Director of global design consultancy Elmwood New York, to learn more

Writer: Lauren Kania

American Indian and Alaska Native populations have the lowest life expectancy in the US.

Indian Nation adults are nearly three times as likely as non-Hispanic white adults to be diagnosed with and die from diabetes, while women are twice as likely to die of pregnancyrelated causes.

These outcomes are compounded by a history of endemic barriers affecting the provision of quality healthcare, including economic

adversity, rural isolation, cultural differences, and a chronic shortage of medical personnel.

Underfunding is another critical issue. In fact, federal prisoners receive two to three times as much healthcare funding compared to the Indian Health Service – the government agency in charge of providing health services for American Indians and Alaska Natives.

This undeniable crisis in health equity can only be overcome by a

strong, united platform advocating for Native American healthcare.

That is precisely what Indigenous Pact was created to provide.

“Leveraging an approach that blends tradition with innovation and ensuring Native-led solutions drive lasting impact, Indigenous Pact works alongside our Tribal partners to co-create a future where every Native person has access to the quality care they deserve – no matter where they are,” introduces Kurt Brenkus, CEO and co-Founder.

The organization is a Nativeled, woman-owned, certified B Corporation dedicated to achieving health equity for American Indians and Alaska Natives in one generation.

Founded in 2017 by Brenkus and his wife Aimee – Chairwoman of the Board and descendant of the Oneida Nation of Wisconsin – Indigenous Pact works in partnership with Tribal

Nations to develop and deliver sustainable, revenue-generating healthcare solutions that strengthen sovereignty and improve health outcomes for Native communities.

Operating remotely across the US, the organization serves Tribes in diverse regions and tailors solutions to each community’s needs while offering a comprehensive line of care

delivery and strategic services.

Indigenous Pact team members bring decades of experience working and living in Indian Country, and with many being Tribal members themselves, they deeply understand the communities they serve through shared experience.

“True healthcare transformation can only happen when we unite, share

“SPEAKING WITH TRIBAL LEADERS AND ALLOWING THEM TO SHAPE OUR CREATIVE THINKING THIS WAY WAS CRUCIAL FOR MAKING THIS BRANDING PROJECT A SUCCESS. WE HAD TO CULTURALLY IMMERSE OURSELVES IN THE COMMUNITY WHILE EMBODYING A SPIRIT OF EMPATHY-LED IMAGINATION”

– EMMA GODFREY, MANAGING DIRECTOR, ELMWOOD

NEW YORK

knowledge, and work as one,” states Brenkus.

To Indigenous Pact, health equity means ensuring every Tribal citizen has access to quality healthcare regardless of location, funding limitations, or systemic barriers. This is only possible by strengthening Tribal sovereignty and ensuring Native Nations have the resources, infrastructure, and autonomy to lead their own healthcare solutions.

The organization focuses on long-term sustainability, helping Tribes build healthcare systems that generate revenue, expand services, and improve health outcomes.

“By prioritizing self-determination and helping Tribes create long-term, financially sustainable healthcare solutions, we are building a stronger, more resilient healthcare system

that will serve Native people for generations to come,” asserts Brenkus.

By ensuring future generations will inherit a stronger, more robust medical system, Indigenous Pact is working to achieve its mission of creating health equity in one generation.

The organization believes this crisis can only be overcome with a strong, united platform of Native American healthcare advocacy.

“Health equity cannot be achieved in isolation,” states Brenkus.

“A unified front allows us to amplify Native voices, secure critical funding, and share best practices that benefit all Tribal communities.”

For too long, Native healthcare has been underfunded and fragmented. The federal trust responsibility has not translated into adequate healthcare access, leaving many Tribes to struggle alone.

Ultimately, when Native populations stand together, they hold the power to drive systemic change – whether by influencing policy, improving funding models, or advocating for culturally competent care.

Indigenous Pact is committed to building this collective movement by working directly with Tribes to strengthen their healthcare systems and ensure they receive the resources, policies, and protections needed to thrive.

Indigenous Pact’s Community Care service connects Tribes to a network of proactive healthcare providers and delivers advanced specialty care.

“Community Care is designed to help Tribes build sustainable, culturally relevant systems that improve healthcare access, coordination, and long-term outcomes,” details Brenkus.

The service expands access to healthcare through virtual and in-person services, ensuring Tribal members receive seamless, wholeperson support. It also strengthens care coordination so patients can move easily between services – including primary, specialty, behavioral, and traditional medicine –without barriers alongside integrating traditional healing with modern medicine to maintain holistic care that is culturally relevant.

Indigenous Pact helps Tribes strengthen local healthcare infrastructure by training teams and creating systems that are financially

and operationally sustainable.

“Community Care helps Tribes take control of their health systems, reduce disparities, and ensure every Native person has access to the care they deserve,” expands Brenkus.

This service represents a transformational shift away from fragmented, crisis-based treatment toward a sustainable, proactive model of care.

With Native healthcare’s history of being underfunded, overburdened, and difficult to navigate, particularly in rural areas, Community Care directly addresses these challenges and helps Tribes build locally-driven,

revenue-generating medical systems designed to last.

“This model revolutionizes Tribal healthcare by expanding access through virtual and in-person care, tailored to each Tribe’s unique needs and empowering them with the tools and expertise to manage and sustain their own systems,” details Brenkus.

Recently, Indigenous Pact paired with Elmwood New York (Elmwood) – a global design consultancy powering brands for a brave new world – to create a brand identity for its new healthcare model as part of a wider

organizational rebrand.

Elmwood is renowned for its design and branding work in the healthcare sector, making it the ideal partner to help take the visual identity of Indigenous Pact to the next level.

“We were looking for a partner who could help us create a brand that would authentically reach and engage with the diverse communities of American Indians and Alaska Natives,” specifies Brenkus.

“Crucially, the visual identity needed to support our ambition of transforming the health of Indigenous Peoples and building health equity in one generation.”

The organization worked with Elmwood to create a new logo, refresh its color palette, provide new design patterns, and develop a seamless design system across its digital and physical touchpoints.

“Through Indigenous Pact, Aimee and Kurt set out to leverage the collective strength of Tribal Nations to bring about change. This mantra became one of the key guiding principles for our design,” informs Emma Godfrey, Managing Director of Elmwood.

“However, we had to balance this unifying approach with the equally important need to capture the diversity and individual sovereignty of Tribal Nations.”

From the company’s extensive interviews with Indigenous leaders, it learned the extent to which the cultural codes and symbols of each Tribe are distinct.

Tribal Nations have been fighting for individual sovereignty for hundreds of years, making it crucial that the identity created for Indigenous Pact could authentically represent and speak to each community.

“Speaking with Tribal leaders and allowing them to shape our creative thinking in this way was crucial for making this branding project a success. We had to culturally immerse ourselves in the community while embodying a spirit of empathy-led imagination,” details Godfrey.

In the coming year, Indigenous Pact is focused on scaling impact, strengthening Tribal healthcare sovereignty, and ensuring long-term stability.

Its key priorities include:

• SCALING COMMUNITY CARE – Expanding locally driven, culturally rooted healthcare solutions to more Tribal Nations, ensuring greater access to primary, specialty behavioral, and traditional medicine.

• INCREASING REVENUE FOR TRIBES – Helping Tribes navigate Medicaid, the Affordable Care Act (ACA), and Healthcare Information System (HIS) reimbursements to create sustainable healthcare funding models.

• ADVANCING POLICY ADVOCACY – Working at federal and state level to secure funding, influence policy, and protect Tribal healthcare rights.

• ENHANCING WORKFORCE DEVELOPMENT – Investing in Tribal healthcare training and staffing solutions to help build a strong, local workforce.

• EXPANDING PARTNERSHIPS – Strengthening collaborations with Tribal leaders, healthcare organizations, and policymakers to accelerate innovation and create scalable solutions.

“This year, driven by our mission to achieve health equity for American Indians and Alaska Natives in one generation, Indigenous Pact is doubling down on our commitment to ensure more Native communities gain access to sustainable, high-quality healthcare,” Brenkus outlines.

To visualize the diverse Tribal Nations coming together under the mantle of healthcare equity, designers Meg Beckum and Elyanna Blaser leveraged the Indigenous art form of quilt work, specifically looking at the motif of the native star quilt.

A strong cultural tradition across all Tribes, the native star quilt symbolizes

honor and generosity. As a storytelling device, quilt work was a perfect representation of diverse Indigenous communities coming together as one.

Elmwood also designed a logo for the organization’s Community Care services, made up of a red circle placed in the center of a star.

“You can think of this red circle

as the individual surrounded by an expanding circle of support, whether that’s family, doctors, or fellow Tribe members. Everything flows from the single person in the middle to a wider community founded on values of proactive care and support,” Godfrey proudly concludes.

INDIGENOUS PACT’S CORE VALUES

• BRAVERY

• EMPATHY

• WISDOM

• TRANSFORMATION

Fiona Treacy,

Managing Director

of

Industrial

Automation, details how Analog Devices, Inc. bridges the physical and digital worlds to enable breakthroughs at the Intelligent Edge

Writer: Jack Salter

Aglobal semiconductor leader, Analog Devices, Inc. (ADI) combines analog, digital, and software technologies into solutions that help drive advancements in digitized factories, mobility, and digital healthcare, combat climate change, and reliably connect humans and the world.

With revenues of more than $9 billion in FY24 and approximately 24,000 employees globally, ADI ensures today’s innovators stay ‘Ahead of What’s Possible’.

“We don’t just make semiconductors – we work closely with customers and partners across key markets to identify needs and trends and innovate accordingly

to meet these demands,” opens Managing Director of Industrial Automation, Fiona Treacy.

“We then co-create solutions at our purpose-built R&D center in Ireland, ADI Catalyst. This puts us at the forefront of shifting secular trends within a wide range of industries and regions.”

The diversity of ADI’s customers, markets, and applications has minimized the impact of sector downturns on the company and accelerated innovation during periods of growth.

By leveraging a global network of manufacturing facilities and external foundry partners, it has also created a more resilient hybrid manufacturing model.

“In light of recent turbulence within the semiconductor supply chain, this strength has shone through, allowing us to continue accessing more technology and create higher-performing solutions for our customers despite supply chain challenges,” Treacy notes.

“Thanks to this diverse approach, we can produce the 75,000+ products needed to meet the needs of our 100,000+ customers.”

The Intelligent Edge era is one of the most exciting developments in technology.

Indeed, it enables real-time computation and data storage near data sources, allowing ADI to glean intelligent insights quicker and save bandwidth.

This connectivity fuels new applications in Industry 4.0,

autonomous driving, advanced communications, digital healthcare, and augmented and virtual reality, increasing the demand for analog semiconductors.

“ADI supplies the intelligent sensing and connectivity essential for these innovations and works closely with customers in many industries to bring intelligence to the edge,” outlines Treacy.

As part of the move to Industry 4.0, manufacturers are redesigning systems for efficiency and reengineering factories to deploy increased automation and robotics for more productive, hyper-agile manufacturing.

The industrial sector was responsible for a quarter of global emissions in 2022, and manufacturers are racing against the clock to meet climate goals, fueling a fundamental shift in how factories are built and upgraded.

“IN A COMPETITIVE ENVIRONMENT WHERE SUSTAINABILITY GOALS ARE CRITICAL, MANUFACTURERS MUST RETHINK THEIR OPERATIONS TO STAY AGILE AND EFFICIENT” – FIONA TREACY, MANAGING DIRECTOR

INC.

The ability to make informed decisions based on real-time data is also critical for the move to more sustainable and efficient manufacturing.

In order for digital factories to be successful, machines – such as cobots – need to be able to securely sense, measure, and interpret the real world.

This requires converting analog data, including pressure measurements or vibrations, to digital data to allow for more signal processing.

“The highest quality data is found at the Intelligent Edge, closest to where it is generated. Edge sensing technologies enable the collection and processing of data at the source, providing immediate insights into operational performance,” Treacy insights.

“WE DON’T JUST MAKE SEMICONDUCTORS – WE WORK CLOSELY WITH CUSTOMERS AND PARTNERS ACROSS KEY MARKETS TO IDENTIFY NEEDS AND TRENDS AND INNOVATE ACCORDINGLY TO MEET THESE DEMANDS”

– FIONA TREACY, MANAGING DIRECTOR OF INDUSTRIAL AUTOMATION, ANALOG DEVICES, INC.

“This real-time data is crucial for identifying inefficiencies, reducing energy consumption, and minimizing waste. In fact, edge-based analytics can reduce power consumption by as much as 98 percent compared to comparable cloud-based solutions.”

Industrial automation technology (IAT) increases productivity across

factory floors and process plants, enables customized output with flexible manufacturing, and produces Intelligent Edge insights that reduce raw material usage and energy consumption.

The transformative power of IAT lies in its ability to integrate realtime insights, edge computing, and precision sensing to re-engineer factory floors.

“In a competitive environment where sustainability goals are critical, manufacturers must rethink their operations to stay agile and efficient,” affirms Treacy.

By capturing data at the Intelligent Edge, IAT empowers manufacturers to make smarter, data-driven decisions in real time, optimizing production flows, enhancing energy efficiency, and reducing waste.

It goes beyond improving existing processes by enabling hyper-agile manufacturing, where operations can quickly adapt to market shifts and changing customer demands.

“IAT drives flexibility and scalability through more automation and robotics, enabling manufacturers to micro-target inefficiencies and optimize energy use,” Treacy concludes.

Fiona Treacy, Managing Director of Automation: “Customers are at the center of our identity, and we are endlessly committed to their success.

“Co-creation is in our DNA; we assist customers in navigating the complexities of product development while enhancing their unique differentiators. ADI Catalyst is pivotal in fostering collaboration with customers and partners across sectors such as Industry 4.0 and sustainable energy.

“By working closely alongside our customers, we aim to significantly accelerate innovation timelines, facilitating faster time-to-market for solutions.”

In a breathtaking feat of design and engineering, the drivers’ parade at the recent Miami Grand Prix was taken over by fully driveable LEGO big build cars representing every team on the Formula 1 grid

Writer: Jack Salter

Ahead of the Miami Grand Prix, there was a fresh take on the Formula 1 (F1) drivers’ parade.

Rather than touring the track on the back of a truck, all 20 drivers had the chance to get behind the wheel of fully drivable LEGO big build cars, lapping the 5.4-kilometer Miami International Autodrome while waving to fans before the race.

Over 22,000 hours, a skilled team of 26 design, engineering, and building specialists from the LEGO Group created these incredible two-seater vehicles at its Kladno factory in Czechia, where the idea initially emerged, marking the first time multiple drivable big builds have been produced by the company at the same time.

The cars are based on the LEGO F1

• The Miami Grand Prix is located 7,626km from the LEGO Group’s headquarters in Billund, Denmark – equating to 1,412 laps of the track.

• The inaugural Miami Grand Prix in 2022 coincided with the 90th anniversary of the LEGO Group, which was founded in 1932 by Ole Kirk Kristiansen.

• 40,000 LEGO bricks would be needed to cover the longest straight at the Miami International Autodrome, which stretches 1.28km.

Speed Champions range and bespoke to each team’s colours and liveries, capturing intricate and unique details such as sponsor logos, and even fitted with authentic Pirelli tires.

Each vehicle is made of nearly 400,000 LEGO bricks and able to reach speeds of 20 kilometers per hour (kph) – a fraction of the ~375kph top speeds that can be achieved by an actual F1 car, which the LEGO big builds are at a near 1:1 scale with.

However, the slower speeds didn’t stop stars such as Max Verstappen, Lewis Hamilton, and Lando Norris from racing – and humorously, crashing into – each other on the parade, to the amusement and excitement of fans and drivers alike as the track was littered with LEGO debris.

• Each car was built using almost 400,000 LEGO bricks, along with a selection of other components to make them capable of driving.

Gasly and Jack Doohan ahead of the 57-lap showpiece.

Both F1 and the LEGO Group are synonymous with pushing the boundaries, and this latest challenge was a true testament to that.

between the two that was first announced in September 2024, bringing together two passionate global fanbases and engaging new audiences.

This partnership will make the sport more accessible to families around the world at a time when F1 has seen

a huge surge in growth with younger

Indeed, data shows that across the US and European Union (EU), over four million children between the ages of eight and 12 now actively follow the pinnacle of motorsport, while 40 percent of Instagram followers are under 25.

It will also promote innovation,

technology, and engineering – which have defined the sport for 75 years –as exemplified by the LEGO big build cars in Miami, along with stronger inclusion and representation.

As well as the driveable big builds, there are a number of other at-race experiences that will ramp up the fun during the 2025 season for people of all ages.

Fans are set to be immersed in the world of F1 by the LEGO Group with interactive activities and challenges designed to celebrate the sport’s engineering and technical heritage.

At select events, the experience of being at an F1 track will also be heightened by brand-new LEGO Fan Zones, where fans can enjoy exclusive make-and-take builds, photo

opportunities, and a chance to see the LEGO Group’s entire F1 product range featuring all 10 teams for the first time.

Following the conclusion of the Miami Grand Prix, all 10 LEGO big builds are now embarking on a world tour with appearances at future races.

Thriving with untapped potential, Trinidad and Tobago’s manufacturing landscape is a significant economic driver for the country thanks to both regional and national governmental support and steadfast dedication across the industry

Writer: Lucy Pilgrim | Project Manager: Krisha Canlas

Most avidly known for its vibrant mixture of cultures, bustling carnival atmosphere, and welcoming locals, Trinidad and Tobago lies at the heart of the Caribbean.

Emerging as a key player in the global industry landscape, the dual-island nation’s burgeoning manufacturing sector is a critical economic driver, with its GDP contributions reported to be TTD$16.1 billion in 2023, marking a 350 percent increase since 1999.

As a result, manufacturing has experienced significant foreign direct investment thanks to the country’s stable and reliable infrastructure, numerous bilateral trade agreements, and continued government support.

Regarding the latter and the efforts of the then Ministry of Trade and Industry (MTI) specifically, numerous impactful initiatives have been introduced in recent decades to help foster manufacturing growth across

the islands. These include fiscal incentives, grants, additional funding arrangements, achievable targets, and more.

Equipped with these subsidies and government aids, manufacturers across Trinidad and Tobago have had greater access to myriad benefits such as duty-free raw materials and extensive plant and machinery investments. Consequently, the country’s manufacturing output is toptier and able to meet stricter requirements, opening the door to greater regional and international export potential, particularly in the realm of non-energy manufacturing exports.

More broadly, given manufacturing is the most active industry in the English-speaking Caribbean, the support of the Caribbean Community (CARICOM) market has also been invaluable to the sector’s evolution, as it has helped to

protect the landscape from international export competition while also allowing key players to expand into global markets.

The future of Trinidad and Tobago’s manufacturing sector seems bright as the country is prepared to create an environment that fosters growth and encourages innovation. In light of this, manufacturers are focused on expanding the workforce and entering into an era of sustainability.

Dr. Mahindra Ramdeen, CEO of the Trinidad and Tobago Manufacturers’ Association, talks us through its mission to foster market expansion across the industry and emphasizes the importance of local entities

North America Outlook (NA): Could you introduce the Trinidad and Tobago Manufacturers’ Association (TTMA) and provide an overview of your purpose, values, and founding mission?

Dr. Mahindra Ramdeen, CEO (MR): TTMA promotes, encourages, and assists the growth and development of manufacturing industries in Trinidad and Tobago. The Association also acts as a representative for industries when dealing with the government and monitoring legislation affecting manufacturers.

TTMA is additionally responsible for generating market expansion both regionally and internationally through the mounting of local, regional, and global trade fairs, exhibitions, and foreign trade missions. The Association promotes the use of modern methods in manufacturing and the education of all its members. TTMA also focuses on assisting local manufacturers in maintaining required standards of safety, labor relations, wages and benefits, communications, public relations, and advertising. Moreover, the Association provides assistance in the securing of markets for both raw materials and finished products, as well as in the sourcing of investment partners

NA: What is your take on Trinidad and Tobago’s manufacturing sector at the moment? What are the current challenges and opportunities facing the industry?

MR: The non-energy manufacturing sector remains a pillar of Trinidad and Tobago’s economic growth. According to the MTI’s 2023 Year in Review, the non-energy sector’s total exports from the country increased by 54 percent from the year before; exports in 2022 were TTD$55.3 billion and increased to TTD$89.1 billion a year later. Energy exports, meanwhile, increased by 15 percent from TTD$15.6 billion in 2022 to TTD$17.9 billion in 2023.

Trinidad and Tobago’s exports continue to grow due to excess capacities in domestic operations. Thus, local manufacturers are able to meet the demand once it occurs, and if demand outstrips supply, they are prepared to invest in plants and machinery. Presently, on average, most factories operate at approximately 80 percent capacity, meaning that manufacturers can immediately grow by 20 percent if needed.

In the period between 2014 and 2023, exports from the manufacturing sector amounted to over TTD$134 billion, with the contribution to non-energy exports averaging around 94 percent annually.

Several other subsectors of manufacturing have recorded positive growth, including:

• Food and beverages – Valued at TTD$3.2 billion in 2023 (increased by TTD$1.2 billion or 58 percent).

• Plastic and rubber products – Valued at approximately TTD$532 million (increased by TTD$262 million or 97 percent).

• Paper and paper products – Valued at approximately TTD$753 million (increased by TTD$293 million or 64 percent).

• Glass products – Valued at approximately TTD$165 million (increased by TTD$55 million or 50 percent).

• Other chemical products – Valued at approximately TTD$515 million (increased by TTD$158 million or 44 percent).

These gains align with TTMA’s 2020–2025 Non-Energy Manufacturing Export Strategic Plan, aimed at doubling exports and enhancing industry resilience. The plan is supported by key government strategies such as the Export Booster Initiative (EBI), National Apprenticeship Program, Exim Bank’s Foreign Exchange Facility (FX Facility), SME Stimulus Loan Facility, and the Single Electronic Window TTBizLink platform.

Due to the decline in the energy sector, the supply of foreign exchange (FX) to the non-energy sector has been curtailed. Without the reliable source of FX that

“THROUGH STRATEGIC INITIATIVES, COLLABORATIVE EFFORTS, AND A COMMITMENT TO INNOVATION, WE ARE CONFIDENT IN OUR ABILITY TO DRIVE ECONOMIC DIVERSIFICATION AND CONTRIBUTE MEANINGFULLY TO THE NATION’S PROSPERITY”

– DR. MAHINDRA RAMDEEN, CEO, TRINIDAD AND TOBAGO MANUFACTURERS’ ASSOCIATION

would have come from the energy sector, the only other way to realize it is to export. The business community needs FX to purchase raw materials and machinery and engage in international trade. Fortunately, Exim Bank’s FX Facility offers some relief to manufacturers. However, it is imperative that companies earn their own FX to sustain and grow their operations in the non-energy community.

Trinidad and Tobago produces some very high-quality goods and services, and the certification for entry into markets has been met in most instances, meaning our world-class goods and services can compete in many global markets. The potential and capacity are there to meet the needs and standards of entry to all international markets, and TTMA is continuously working with its members so that they can earn their own FX. This also means there is less reliance on the government and the energy sector.

TTMA has continued to work hard over the last couple of years to improve its offerings in education and training, statistical information and data, and member development, allowing them to prepare themselves for exports and earn their own FX.

For example, a major focus has been executing trade missions for companies of all sizes, benefiting over 100 businesses in 2024. These trade missions are done in partnership with the MTI under the EBI and target specific markets with existing trade

agreements. Partnering with CARICOM nations is also a priority, as the trade missions result in increased exports, the security of new or additional orders, and the inclusion of first-time exporters or new market entries.

Additionally, the Trade and Investment Convention (TIC), TTMA’s annual hallmark event, seeks to promote businesses of all sizes to earn FX by providing a platform for them to display their products to regional and international buyers, as well as setting up business-tobusiness (B2B) meetings which may result in export orders.

TTMA also works with the MTI to negotiate trade agreements and, in so doing, creates market opportunities for our members to export. Currently, there are partial scope negotiations with Curaçao taking place, while negotiations with Chile were recently concluded.

NA: What strategies does TTMA deploy to develop and promote local industries?

MR: TTMA has been instrumental in trade policy, advocacy, and market expansion. Through the former, the Association has secured private sector representation in CARICOM’s Front-of-Package Nutrition Labeling (FoPNL) Scheme and engaged extensively in trade negotiations, opening doors in markets of TTD$19 million and 150,000 people.

By representing CARICOM’s Council for Trade and Economic Development (COTED), we have shaped regional trade rules. Through regulatory collaboration, we also worked with the Trinidad and Tobago Bureau of Standards (TTBS) and the National Quality Council (NQC) on 10+ regional standards. The Association has additionally collaborated with commercial attachés in the UK, US, Panama, Jamaica, and Guyana, hosting over 30 traderelated webinars.

TTMA also addressed duty removals and common external tariff (CET) increases in partnership with the MTI. The Association continues to drive international expansion through strategic trade missions. Our outreach has evolved from virtual-only in 2021 to full-scale physical missions across the Caribbean, Latin America, and North America. Key highlights include:

• 2021: Virtual format – Three trade missions in Curaçao, Antigua and Barbuda, and Grenada – 136 B2B meetings.

• 2022: Return to physical missions – Three missions in Suriname, Guyana, and Jamaica – 216 B2B meetings.

• 2023: Expanded reach – Six missions in Grenada, the Dominican Republic, Suriname, St. Lucia, Guyana, and Antigua and Barbuda – 588 B2B meetings.

• 2024: Six missions in Ghana, the Bahamas, Suriname, Canada, St. Vincent, and the Grenadines, along with the first regional mission in Belize – 812 B2B meetings.

• 2025: Completing trade missions in Dominica with additional missions planned for Jamaica, China, New York, Chile, Guyana, and Suriname.

In total, TTMA-led trade missions have facilitated over 1,800 business connections, resulting in millions of dollars in trade opportunities for local manufacturers.

“TTMA

HAS CONTINUED TO WORK HARD OVER THE LAST COUPLE OF YEARS TO IMPROVE ITS OFFERINGS IN EDUCATION AND TRAINING, STATISTICAL INFORMATION AND DATA, AND MEMBER DEVELOPMENT, ALLOWING THEM TO READY THEMSELVES FOR EXPORTS AND EARN THEIR OWN FX”

– DR. MAHINDRA RAMDEEN, CEO, TRINIDAD AND TOBAGO MANUFACTURERS’ ASSOCIATION

Furthermore, our annual TIC is another way TTMA promotes local industry and has evolved significantly over the years. For instance, in 2021, we hosted a virtual event with 21 webinars and over 1,200 participants. In 2022, the TIC partially returned to a physical format, featuring 134 exhibitor booths, eight exhibiting countries, and 8,000 visitors. In 2023, we hosted a full-scale physical event featuring 276 exhibition booths and 20,719 visitors, including 380 B2B meetings, 35 participating countries, and 12 webinars.

A trusted partner for over four decades, providing reliable supplies, services and mobility solutions across the oilfield, industrial and commercial sectors.

OILFIELD & INDUSTRIAL SUPPLIES

Reliable, high-quality supply chain solutions across industries.

DUTORX CUSTOM SOLUTIONS

Precision problem-solving and custom-engineered technology.

Corporate and industrial vehicle & fleet rental solutions.

TRANSPORTATION & EQUIPMENT RENTALS

Heavy equipment, haulage, oversized cargo – we move industries.

ALTERNATIVE ENERGY SOLUTIONS

CNG, EVs, and sustainable energy innovations.

Partner with Dumore for the most advanced industrial solutions as your project execution partner.

Solutions Start Here. Let’s Get to Work. industrial@dumore.com 225-4440

TIC 2024 featured the largest exhibition floor plan in the convention’s history, with a total of 20,757 participants and 320 booths representing 38 countries, 13 webinars, and 427 B2B meetings.

TTMA has also been instrumental in supporting small and medium-sized enterprises (SMEs) – defined as companies that employ between six and 25 staff – through initiatives such as SME Pop-Up Shops since 2022. Hosting two per year, we have given an average of 300 SMEs the opportunity to expose their products, enhance brand visibility, and engage directly with consumers.

Further to this, we host a specific SME pavilion within the TIC framework to give export-ready companies the opportunity to gain exposure and participate in B2B meetings that are integral for the growth of their business. Such initiatives are part of TTMA’s broader commitment to fostering SME growth.

NA: How does the Association promote innovation and modern methods across the country’s manufacturing sector?

MR: TTMA has a productivity committee that focuses on promoting strategies to boost productivity among manufacturers. Its primary goal is to drive technologydriven productivity, particularly in areas such as ICT (Digital 4.0), labor, and the improvement of manufacturing efficiencies.

This is achieved using a platform offered by the TIC to host digital webinars and physical seminars with manufacturers exposed to technology, done in collaboration with industry experts under the TIC Business Education Series. Another avenue is via our Learning Factory project – a collaboration with the MIC Institute of Technology and the University of the West Indies’ (UWI) St. Augustine Campus. An injection of funding totaling TTD$1 million has been allocated for Phase 1 and this year’s equipment purchases.

NA: How does TTMA encourage training and skills development among its members?

MR: Over the past four years, TTMA has formed strategic partnerships to encourage training and skills development among its members. The Association is an industry partner lending support to the development of programs in collaboration with the MTI and the MIC Institute of Technology.

Raw Materials: We are your dependable source of raw materials, supporting similar businesses and providing specialty chemicals to our esteemed partners.

• Extensive Inventory: Over 100 products in stock.

• Large Production Capacity: Efficiently meet varying demands.

• Rapid Turnaround: Fast production runs and timely delivery.

As a proud family-owned and operated enterprise, we extend an invitation to join our growing family. We specialize in creating superior products in diverse sectors, ensuring unparalleled quality and service.

• Personal Care: Hair food, gel, pomade, shampoo, conditioner, body lotion, and cream.

• Household: A wide range of household essentials.

• Institutional: Products tailored for institutional use.

• Industrial: Specialty blends for industrial applications.

• Automotive: High-performance automotive products.

• Para Pharmaceutical: Specialty chemicals for para pharmaceutical needs.

From its inception, DSB Marketing Limited has been dedicated to contract manufacturing. Our commitment to quality and service has allowed us to expand our product portfolio, ensuring we meet the evolving needs of our customers.

Experience the DSB Difference

Contact us today to learn more about how we can help your business thrive. Trust in DSB Marketing Limited – where excellence is a tradition.

Over 200 new trainees have been enrolled in the Manufacturing Apprenticeship Program, along with 100+ in the Woodworking Apprenticeship Program (WOODAP). Similarly, TTMA partnered with UWI, where over 70 university students were placed in the manufacturing industry under the TTMA and UWI Summer Internship Program.

Furthermore, SMEs were granted access to free expert-led sessions under a newly established mentorship program, starting with the ‘She Leads’ session, where women-owned SMEs were able to gain invaluable insights and build connections to take their business to the next level.

NA: Looking ahead, how do you see the industry developing over the next five to 10 years?

MR: I am proud to share a forward-looking vision for our manufacturing sector over the next five to 10 years – one rooted in resilience, innovation, and strategic growth.

These include:

Strengthening our contribution to the national GDP

The manufacturing sector has shown commendable growth, with its contribution to Trinidad and Tobago’s GDP increasing from 18 percent in 2021 to 19.2 percent in 2022. In the same year, manufacturing value-adding reached 22.24 percent of GDP. This upward trend underscores the sector’s pivotal role in the nation’s economic landscape.

Our sector is central to Trinidad and Tobago’s diversification strategy, reducing reliance on the energy sector. TTMA has launched a comprehensive manufacturing strategy aimed at producing 40 large manufacturers by the end of 2025, with a target of TTD$3.6 billion in export value, which we are on the way to achieving.

Strategic initiatives and collaborations

To support these ambitions, TTMA is actively engaging in:

1. Trade missions.

2. Infrastructure development, supporting the establishment of special economic zones to attract investment and boost exports.

3. Policy advocacy.

Embracing innovation and sustainability Looking ahead, TTMA is committed to fostering innovation, sustainability, and digital transformation within the manufacturing sector. By leveraging technology and sustainable practices, we aim to enhance productivity and competitiveness on a global scale.

In summary, the manufacturing sector in Trinidad and Tobago is poised for significant growth and transformation. Through strategic initiatives, collaborative efforts, and a commitment to innovation, we are confident in our ability to drive economic diversification and contribute meaningfully to the nation’s prosperity.

NA: With this in mind, what are TTMA’s key future priorities in order to continue representing the interests of its industry members?

MR: Firstly, and perhaps most significantly, our new strategic export goal is to grow non-energy exports from TTD$6.2 billion at the close of 2024 to TTD$10.6 billion by 2030, reflecting a conservative 71 percent increase in non-energy exports over the next five-and-a-half years. We continue to work with those in authority to create an enabling environment that will allow non-energy exports to reach this target.

We will also continue to foster the growth of SMEs in Trinidad and Tobago, which account for over 85 percent of local businesses and employ 200,000+ people directly. Most SMEs in the country have hindrances in engaging in

trade, with some of these challenges including registering their business, creating product barcodes, developing export plans, sourcing financing for equipment, and advocating for their interests, thus curtailing the advancement of their operations. We invite SMEs to reach out to us and join TTMA with lowered membership fees so we can help them grow their business.

The Association would also like to work with the government to acquire a 20-acre parcel of land in a centralized area with highway access to construct a 200,000-square-foot Caribbean trade and convention center to host our TIC and other events that foster global trade. This will assist our vision to position Trinidad and Tobago as the regional manufacturing powerhouse for the next 25 years.

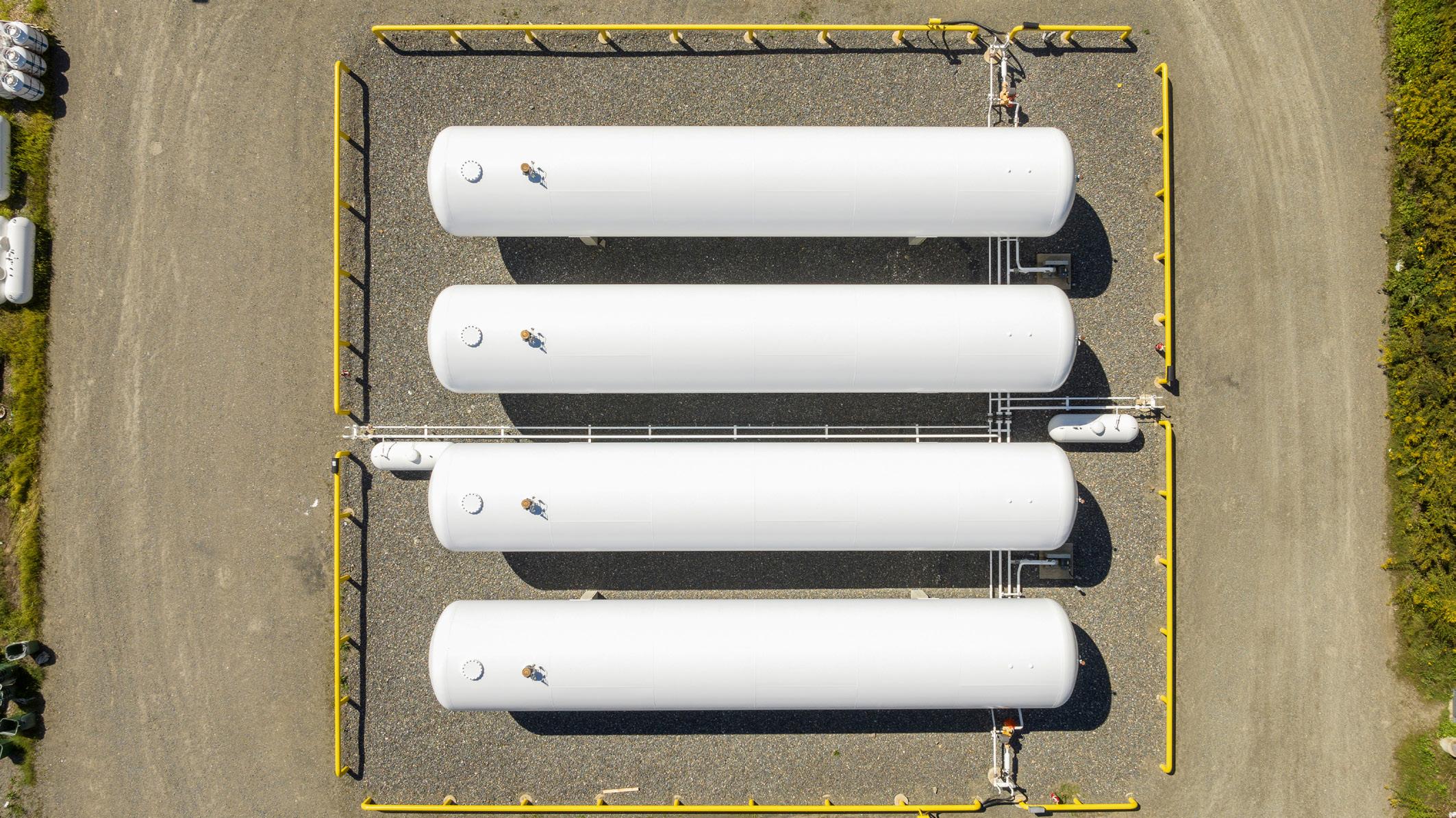

With safety, integrity, excellence, relationships, and community at its core, Saulsbury is more than just an award-winning engineering, procurement, and construction contractor – it is a trusted partner, employer of choice, and a leader in safety. We sit down with CEO, Matt Saulsbury, who is sustaining his father’s legacy as he leads the company toward continued success

Writer: Lily Sawyer | Project Manager: Scarlett Burke

Adominant force in North America’s oil and gas industry, Texas has long been responsible for a significant portion of the nation’s crude oil and natural gas production, contributing considerably to socioeconomic development in terms of job creation and revenue generation.

More widely, the US’ abundance of affordable and reliable energy resources continues to strengthen national security and bolster the country’s overarching goal of achieving energy independence by reducing its reliance on imports and increasing export potential.

“Continuous innovation across the sector has fueled a surge in domestic production, positioning the US as a leading global exporter,” introduces Matt Saulsbury, CEO of Texas-based full-service engineering, procurement, and construction (EPC) company, Saulsbury, a market leader with a proven history of expert project execution in the oil and gas sector.

As the son of Founder, Dick Saulsbury, Matt was appointed as CEO in February 2023, and his deeprooted industry expertise, particularly in Texas, is second to none.

Playing a crucial role in the company’s operations for over three decades and having previously held the position of Vice President of Project Services, Matt is uniquely qualified to lead Saulsbury toward a bright future.

“Over my 30-year tenure at Saulsbury, I’ve witnessed a dramatic transformation in North America’s oil and gas industry, largely driven by technological advancements such as horizontal drilling and hydraulic fracturing,” he insights.

Matt’s wealth of experience, vision for the future, and dedication to the company’s core values has helped Saulsbury continue to deliver on its modus operandi – ‘getting the job done right’.

Despite the historic successes and benefits of the oil and gas sector, those operating within it today must navigate a complex landscape of challenges.

For example, regulatory changes at both federal and state level have prompted a shift away from traditional fossil fuels, necessitating the implementation of robust compliance strategies to minimize environmental impacts, promote air quality, and protect natural water sources.

Market instability also persists, caused by international supply chain disruptions and variable demand.

“Industry challenges are ongoing, particularly oil price volatility driven

by global supply and demand dynamics, geopolitical events, and economic fluctuations,” Matt confirms.

Therefore, in the face of continuous adversity, many oil and gas companies are increasingly partnering with EPC contractors such as Saulsbury to help deliver their projects and achieve their objectives.

By utilizing a fast-track designbuild approach to minimize costs and maximize the efficiency of its clients’ schedules, the company has seen much success thanks to its ability to make timely decisions and react promptly to industry changes.

“Our core values of safety, integrity, excellence, relationships,

and community guide our operations,” he asserts.

As a family-owned company, Saulsbury takes pride in maintaining over 90 percent repeat business with a large proportion of its clients.

Founded as Saulsbury Electric Co. in 1967, the company underwent rapid initial evolution from its humble beginnings.

By the 1980s, client demand eventually led to the business expanding into general construction through Saulcon General Construction, before evolving into a full EPC provider in the 1990s with Saulsbury Engineering and Construction.

As a leading full-service EPC company, Saulsbury provides its services to heavy industrial and renewables clients nationwide, delivering comprehensive integrated solutions.

With over five decades of expertise across a broad range of projects, the company can achieve maximum efficiency and minimum downtime for clients. The industries it serves include:

OIL AND GAS – Saulsbury’s bread and butter, it has established an outstanding reputation for effective execution and project delivery in the oil and gas sector with expertise in terminals, compression, tank batteries, pipelines, slug catchers, pump stations, and more.

GAS PROCESSING AND TREATMENT – Many clients look to Saulsbury for turnkey EPC support as well as focused services in cryogenic gas processing, amine gas treating, dehydration, condensate stabilization, and more.

CARBON DIOXIDE (CO2) – Saulsbury provides industry-leading support to the design and construction of CO2 processing facilities, covering the entire lifecycle from the source field through to transportation, injection, and recovery.

REFINING AND PETROCHEMICALS – The team offers turnkey support for plant reliability, productivity, and process safety projects in the petroleum refining industry with capabilities from engineering and design through to start-up and commissioning.

RENEWABLES – Saulsbury strategically collaborates with key partners to offer EPC solutions in this space, constructing renewable resource or alternative fuel projects including solar power generation, battery storage, hydrogen, carbon capture, and renewable natural gas facilities.

AGRICULTURAL AND FOOD PROCESSING – Whether clients require small modifications to existing facilities or full integration of new process units and grassroots facilities, Saulsbury offers support from balance of plant engineering through to start-up support.

MINING AND METALS – The company provides client support for ore processing, cement, aggregate, and crushing - including auxiliary-related projects such as acid plants, water treatment, control systems, and related infrastructure.

CHEMICALS, SPECIALTY CHEMICALS, AND FERTILIZERS – Saulsbury offers a complete range of EPC solutions, working in close collaboration with industryleading partners for the technology and process integration requirements for these complex projects, including polymers, olefins, and agricultural chemicals and fertilizers, to name a few.

WATER TREATMENT – Comprehensive industrial water treatment services are tailored to client requirements, inclusive of oil and gas field applications and municipal projects.

BuckHorn Services and BuckHorn Rentals are here to provide you with unparalleled expertise in technical bolting, pressure testing, field machining, pipeline maintenance, valve repair services, and so much more for a truly seamless and reliable experience

Buckhorn Services started with very humble beginnings as a small rental company owned and operated by two good ole boys from the bayous of South Louisiana.

What started small soon grew into a multimillion-dollar business that now spans two states with locations in Houma, LA, Gonzales, LA, and Midland, TX.

Within Buckhorns’ three locations, they have created multiple business units. These business units are experienced in providing technical bolting, pressure testing, field machining, Hot Tapping, pipeline maintenance, and valve repair services in the Upstream, Midstream, and Downstream Markets.

Buckhorn can provide experienced professionals to manage your project from inception to commissioning, providing traceable data to meet any QA specification.

Buckhorn has established a process for involving employees at all levels within the organization, measuring health, safety, and environmental (HSE) performance, reviewing issues, identifying improvement areas and best practices, managing incidents and their resulting actions, and communicating the effectiveness of the Health, Safety, and Environmental Management System.

Communication is critical to the overall success of our process, providing quality engineering and management practices and maintaining a safe working environment.

Every Buckhorn employee undergoes extensive training in specialized areas, safety and accident prevention, followed by competency tests/operator qualification testing, to ensure that each new hire meets Buckhorn standards. Buckhorn employees specialize in Hydro and Pneumatic Testing, Double Block and Bleed Isolation and Localized Weld Testing, Field Machining, Flange Refacing, Line Boring/ Shaft Turning, Key Groove Cutting, Drilling and Tapping/ Stud Removal, Portable Milling, Hot Tapping/ Line Stop and Line Freezing, Metal Disintegration, Pipe Cutting and Beveling, Controlled Bolt Torquing and Tensioning, Millwright Services, Valve Repair and Preventative Maintenance, and Hydraulic Flushing.

BUCKHORN’S CORE VALUES FOR SERVICES AND RENTALS

Our core values are at the center of everything we do. Buckhorn is committed to conducting business with a high moral standard.

Each value is equally important to the success of the company. Safety and the protection of our most important asset –our employees are at the core of our beliefs.

Buckhorn’s goal moving forward is to create partnerships with all of our customers and contractors to pursue long-term projects and provide support, as well as grow our footprint in the Midland/Odessa area and beyond.

Buckhorn’s pledge is to perform at a high level with efficiency and integrity. Buckhorn looks forward to exceeding your expectations soon!

AtBarracuda Specialty Services, we believe inspection is just the beginning. Our mission is to provide our clients with innovative inspection solutions while nurturing an environment that advocates safe, proficient, and virtuous performance. This drives our commitment to delivering comprehensive, actionable solutions that go beyond simply identifying problems. We combine elite technical expertise with cutting-edge technology to support critical infrastructure, minimize downtime, and enhance operational safety.

Our certified technicians utilize proven NDT methods to evaluate materials and structures without causing damage. From pipelines to pressure vessels, we deliver precise assessments that help clients maintain asset integrity, ensure regulatory compliance, and achieve operational excellence across demanding industries.

Barracuda sets the standard for advanced inspection with state-of-the-art tools and deep technical expertise. Our advanced services include:

• Phased Array Ultrasonic Testing (PAUT) and Time of Flight Diffraction (TOFD) for highprecision flaw detection and sizing

• Corrosion Mapping to visualize wall loss and monitor asset health over time

• 3D Laser Scanning for high-resolution spatial analysis and deformation monitoring

• Eddy Current Applications for surface and nearsurface crack detection in conductive materials

• Computed and Digital Radiography (CR/DR) for detailed internal imaging with minimal exposure risk

We specialize in delivering safe, efficient solutions for hard-to-reach and high-risk environments. Our rope access capabilities include:

• Rope Access Inspections

• Rope Access Maintenance

• API Visual Inspections (internal and external)

• Insulation and Painting

• Welding (R-stamp certified)

• Pipe Fitting

• Torquing of Piping and Equipment

• Ironwork

• Steam Leak Repairs

• Piping Demolition

• Electrical Services (wire pulling and cable tray installation)

• Bull Rigging (handling all types of assets)

• Sandblasting and Painting

Our rope access teams are highly trained to perform inspection and maintenance work with minimal disruption and rapid setup, eliminating the need for scaffolding or heavy lift equipment. On average, rope access solutions deliver cost savings of 40% to 80% compared to traditional methods.

At Barracuda, we don’t just find problems—we solve them. From top-tier inspections to hands-on support, we’re more than a service provider; we’re your solutions partner. Whether it’s a conventional inspection or a complex corrosion analysis, we have the experience, equipment, and expertise to get the job done right.

At BSS, we understand that your work is missioncritical. We proactively manage our operations and resources to ensure shared success. You can count on us to deliver the highest standards of quality, efficiency, and reliability, even on the most complex projects and most demanding production schedules.

“In 2012, we unified these entities under the Saulsbury banner to streamline our operations,” Matt informs.

Today, the company supports clients across the country by providing expert services in engineering, general construction, electrical and instrumentation work, field services, structural and piping module fabrication, insulation, and scaffolding.

Saulsbury supports a broad scope of industries, including oil and gas, gas processing and treatment, nitrogen rejection, CO2 management, renewable energy and infrastructure, water treatment, liquified natural gas (LNG), power, refining and petrochemicals, agriculture and food processing, mining and metals, chemicals, specialty chemicals, and fertilizers.

Headquartered in Odessa, Texas, the company operates across multiple locations in the state, including

“THE WORLD WE LIVE IN TODAY IS A FAR CRY FROM WHEN MY FATHER RAN HIS BUSINESS WITH JUST A HANDSHAKE. EVEN NOW, HE SHARES STORIES AND ADVICE FROM THOSE EARLY DAYS AND OFTEN FOLLOWS UP WITH – ‘IF I HAD KNOWN BACK THEN WHAT IT TAKES TO DO BUSINESS THESE DAYS, I PROBABLY WOULD’VE CLOSED UP SHOP A LONG TIME AGO’”

– MATT SAULSBURY, CEO, SAULSBURY

Corpus Christi, Abilene, Houston, and Port Arthur, as well as a fabrication facility in Henderson.

Elsewhere, it also operates in Bismarck, North Dakota; Carlsbad, New Mexico; and Tulsa, Oklahoma, with a staff base of over 2,000.

“We self-perform the majority of our work and are licensed across most of the US,” he shares.

With a strong track record of

delivering integrated solutions for complex capital projects, Saulsbury stands out from the crowd.

Its comprehensive portfolio of in-house functions eliminates the need for extensive subcontracting, meaning the company not only provides customers with direct access to its 50+ years of expertise but also the ability to control the safety, quality, schedule, and cost of projects.

Proudly recruiting the best talent in the industry, Saulsbury’s experienced teams are known for maintaining the highest standards and delivering exceptionally safe projects on an accelerated timetable.

While the company’s roots are in oil and gas, it has also begun to strategically diversify its portfolio.

“Our increased focus on renewables and non-oil and gas sectors has strengthened our resilience against industry downturns,” Matt reveals.

As such, Saulsbury’s expertise in industrial construction has enabled the company to successfully enter new and emerging markets by applying proven, transferable skills and methodologies.

A frontrunner in more than one area, Saulsbury is honored by the awards it receives. The company has recently been recognized not only for its work in renewable energy infrastructure, but also the core value that it places above all else – safety.

• Saulsbury was recently listed on Solar Power World’s Top Solar Contractors list, ranking 32nd nationwide. These accolades celebrate the top solar installers in the utility, commercial, and residential sectors, and are based on the kilowatts installed in the preceding year.

• In 2024, Saulsbury was recognized on Engineering News-Record’s 2024 Top 400 Contractors and Top 20 Petroleum Contractors lists.

• The company was proud to receive the Safety Merit Award, Safety Milestone Award, Safety Improvement Award, and Community Advancement Award from the North Dakota Safety Council in 2025.

In the early 2000s, Saulsbury experienced a period of significant growth as shale development took off in the region, allowing it to support the industry with natural gas cryogenic processing facilities, power generation infrastructure, turbine and reciprocating compression facilities, and various gathering and production assets.

“Despite industry downturns, including the 2008 financial crisis, we remained disciplined and resilient,” Matt recalls.

The 2010s saw the US emerge as a dominant oil and gas producer and, by 2018, it regained its status as the world’s largest oil and natural gas supplier.

At the time, Saulsbury was executing major projects across the Permian, Midland, Eagle Ford, Bakken, Haynesville, Barnett, Niobrara, Anadarko-Woodford, and Utica Basins, further bolstering the nation’s impressive oil and gas footprint. Since then, the industry has faced

persistent challenges, with the onset of the COVID-19 pandemic serving as a particularly significant setback.

However, the company’s resilience and its commitment to retaining talent allowed it to recover from the aftermath of COVID-19 swiftly, returning to business as usual within a year.

Having said this, post-pandemic supply chain disruptions continue to be a challenge for Saulsbury –particularly where procuring critical equipment and electrical components is concerned.

Elsewhere, industry consolidation through mergers and acquisitions has presented opportunities, with the company’s strong financial position, leading safety programs, operational expertise, and world-class field teams enabling it to maintain and expand beneficial relationships in this regard, such as those with supermajors.

“As we move forward, we are also diversifying our portfolio to support emerging markets and new opportunities beyond traditional oil and gas,” Matt reminds.

1. Briefly introduce us to Cisco Equipment.