Llanelec is a precision engineering company which specialises in manufacturing integral parts for vehicles operating in defence and high-precision titanium parts for aerospace.

I understand Llanelec specialises in precision CNC machining of running gear and the supply of solid compound wheels for military vehicles. Could you provide a brief overview of your day-to-day activities, locations across the UK, and the client base you typically serve?

Founded in 1984 in Neath, South Wales, we pride ourselves on our commitment to quality and reliability. Our state-ofthe-art facilities and dedicated team of experts allows us to deliver products that meet the rigorous requirements of the sectors we work in. Our reputation is built on a foundation of reliability, precision, and a relentless commitment to excellence.

With a global customer base and diverse product portfolio, we are proud to be recognised as the partner of choice for many leading manufacturers. We have also been a trusted supplier for the Ministry of Defence for more than 35 years. Our expertise lies in crafting vital products for military vehicles and solid compound wheels, with our extensive product portfolio covering everything from road wheels and gears to final drive components and potential capacity to undertake armour plating for vehicles.

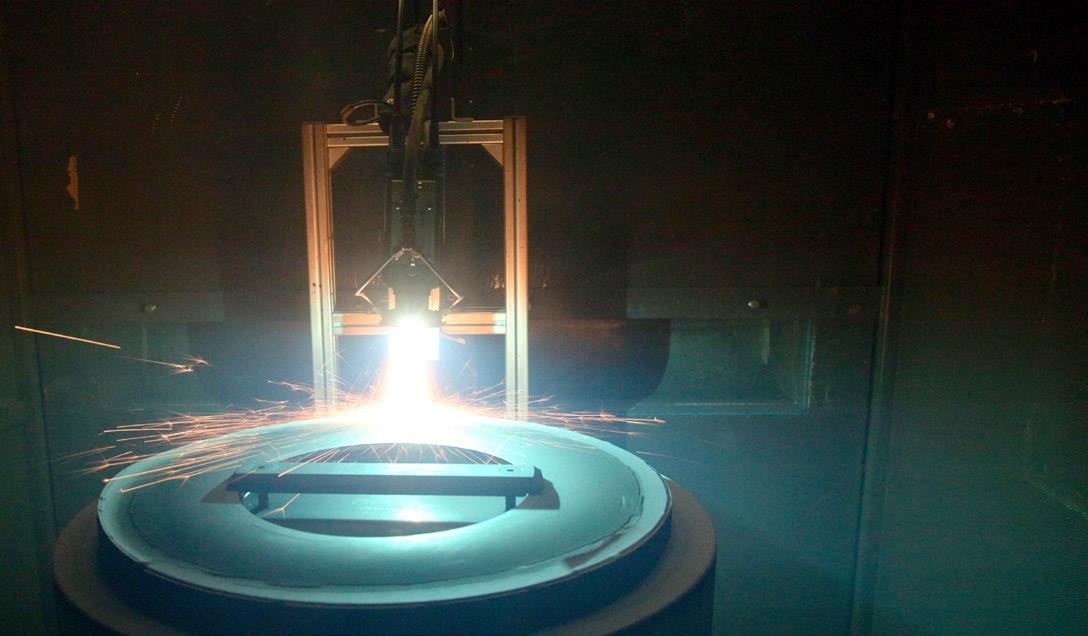

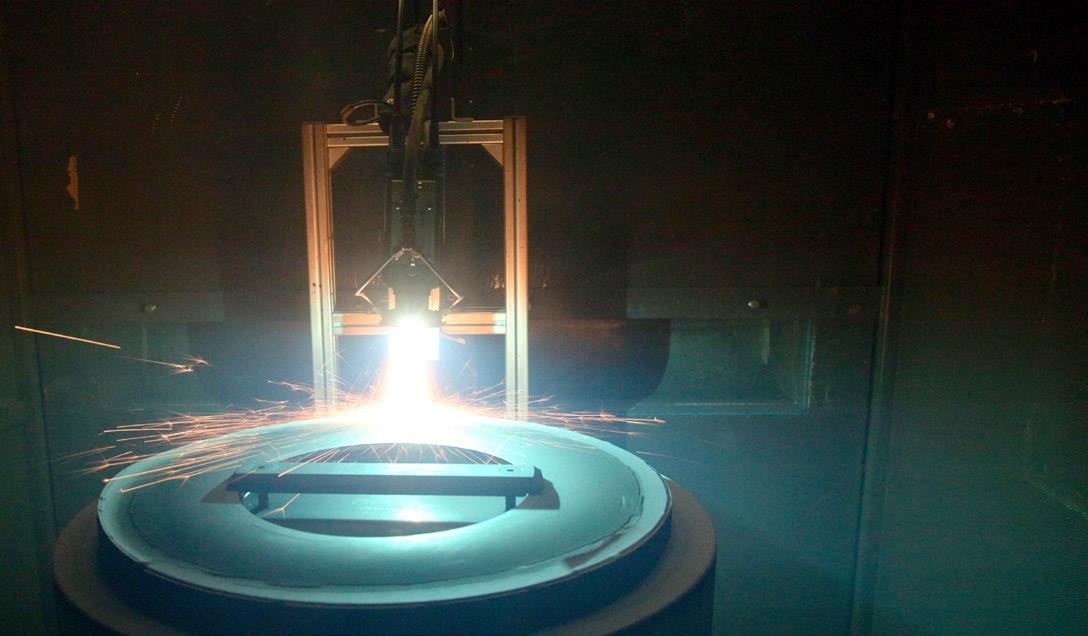

We use advanced CNC machinery and the latest software to produce precision components with exceptional reliability. Our commitment to continuous improvement and innovation ensures that we stay ahead of industry trends and consistently meet our customers’ evolving needs. This guarantees that we not only meet but exceed our customers’ demands in quality, delivery, and cost efficiency. By partnering with leading manufacturers and using cuttingedge technology, we deliver solutions that enhance the performance and durability of military vehicles and the aerospace market.

Our dedicated team of engineers and technicians work tirelessly to refine our processes and develop new techniques, ensuring that every product we create is of the highest standard. Through rigorous testing and quality control measures, we ensure that our components withstand the most demanding environments.

Our customer-centric approach and strategic investments in research and development enable us to provide innovative and cost-effective solutions, solidifying our position as a trusted leader in the industry

Having been in business for more than 40 years, how have you seen the UK’s industrial machinery manufacturing landscape evolve? How has this impacted your business?

Llanelec have endured over 40 years in the defence sector and witnessed the highs and lows that coincides with the industry. We have seen many changes in that period, a major one being the advances in technology, not only in the plant that is used for milling and turning but the significant improvements in our measuring capacity as implements become more sophisticated. This has in effect led us to drive back into the design phase the requirement for tighter tolerances and more complex interfaces to be achieved.

Another major shift over the years has been the dramatic change in manpower and personnel skill level. We saw the move from traditional apprenticeships being very attractive to the youth of that day to a desire to have more officebased job roles around the millennium years. This had an impact on the engineering and manufacturing pipeline, causing a shortage in the system. Whilst this trend is starting to change with manufacturing again coming to the fore, the infrastructure to support the development will need to keep pace.

“The Iron Triangle is what Llanelec prides itself on: quality, cost, and delivery.”

We see this point as fundamental and key, and as such we have a strategic goal to support.

Finally, as the defence sector can be quite niche, we have been subjected to the ebb and flow of defence needs. We have worked through defence thinking and shrinking during the 80s and 90s post-Cold War with less reliance and need for heavy armour, through the 90s and 00s with the Gulf Wars requiring more agile vehicles, to the recent RussiaUkraine conflict that has stretched defence manufacturing capacity to its limits.

What, in your opinion, is the company’s key differentiator? What do you do to stand out from the competition?

Whilst our company absolutely recognises the need for agreements, contracts, and agreed terms and conditions as the framework to do business, at Llanelec we place a great deal of importance on how we manage a change to the plan. We believe that it is more important for customers to have a supplier who will collaborate, and problem-solve effectively without reaching for the contract in the first instance. We welcome a close relationship with both our customer and supply base and have a long-standing track record of keeping calm under adversity, with a laser focus on solving

the problem to achieve the aim. We think that is the essence of engineering and manufacturing. To have the solutions to the problems, Llanelec has built up a strong capability over the years. This means that we have a broader scope within the value chain and can deliver most projects as a turnkey solution, keeping the links in the chain to a minimum and having more control.

Llanelec prides itself on being a problem solver to OEMs and prime defence and aerospace companies.

Can you talk about your work with Rheinmetall Vehicle Systems International, and any recent projects or jobs you have collaborated on?

The first project that comes to mind was a recent problem that RVS International had with a component that was required for a high-profile programme to deliver a vehicle which, without the component, would have compromised the planned roll-out. Llanelec were contacted at the beginning of December 2024 with the notion that it was probably impossible to source the component from anywhere other than the current supplier. Technical specifications were shared which identified that it would be unachievable to source the required raw material in the timeframe.

Llanelec identified a suitable alternative material that was available, RVS International assessed the request and issued approval within 24 hours and the material was sourced.

Llanelec expedited the request, whilst carrying out other operations out of sequence, to benefit the overall delivery time of the finished component. The result was that the components were delivered to RVS International by midJanuary, successfully meeting their need date. From original enquiry to delivery was no more than six weeks, quite remarkable in the current manufacturing sector where there is a real lack of widespread capability and capacity. This is a classic example of how Llanelec solves problems for OEMs and prime defence companies.

How do your values of reputation, quality, flexibility, reliability, expertise, and cost-effectiveness allow you to consistently provide precise, high-quality solutions that surpass expectations?

Almost all business and project plans will change. We believe that embedding our values throughout our organisation, at all levels, is a key facilitator to our ability to deliver consistently to our customers. The values we set and actively reinforce daily basis are what set our high standards. It creates a sense of pride in what we do and for whom we do it.

Throughout all our organisation, individuals and teams challenge themselves and others to go that extra step. The values are there as the standard to remind the business what we stand for and how we have all agreed to operate. The Iron Triangle is what Llanelec prides itself on: quality, cost, and delivery.

Could you tell us more about your long-held vision to grow the business, and how being awarded contracts such as UK MOD Land Forces and Babcock International Group have endorsed recent investments in resources, infrastructure, capability, and capacity?

Being awarded contracts provides an element of certainty, which is crucial to support business cases, particularly in a small to medium-sized enterprise (SME) family-owned business.

Our vision is to grow the business year on year, and to achieve this the business must invest in Llanelec and its infrastructure. The contracts awarded to us provide that stability to not only invest in our equipment but also our staff. We also look to use the contracts to leverage the political desire to level up the surrounding areas, rejuvenating what once was.

The area was once a hotbed of engineering and manufacturing, and the company’s vision is to play an active part in developing that once again.

Llanelec has grown 400% 0ver the past 5 years in revenue, size and capabilities; the new 8.5 acre site, with a state-ofthe-art 120,000 sqft multi-disciplined manufacturing facility allows a further 400% for future growth.

A truly one-stop shop servicing aerospace and defence.

Finally, what are your key priorities, targets, and goals for the year ahead?

Our Strategic Plan describes how we wish to continue to grow the business whilst continuing to maintain our standards. We have several goals contained within, but the one we are most focused on and will be proud of when we deliver is our plan to create an Engineering Training Centre.

Llanelec have planned a new engineering school for both young apprentices and local skills; it will provide quality labour, which is key to our growth, whilst supporting the local community in replacing jobs lost from Tata Steel - Port Talbot.

This will not only support the development of our growing number of apprentices but also provide an opportunity for local people to retrain and attain new skills. We believe that this opportunity will not only benefit the affected people but also increase the manufacturing capability and capacity in the area supporting the defence requirement for many years.

In addition, Llanelec plans to expand its product range internationally in supporting all NATO countries within defence. Our aim at Llanelec is to become a centre of excellence within the defence and aerospace industry!

“Our aim at Llanelec is to become a centre of excellence within the defence and aerospace industry!”