Representative Components

Solar Panels

Q.PEAK DUO ML-G12S SERIES

675-690 Wp | 132 Cells

22.2 % Maximum Module Efficiency

MODEL

Q.PEAK DUO ML-G12S.3 / BFG

The ideal solution for:

Bifacial energy yield gain of up to 21 %

Bifacial Q.ANTUM solar cells make efficient use of light shining on the module rear-side for radically improved LCOE.

Low electricity generation costs

Q.ANTUM DUO technology with optimized module layout to boost module power and improve LCOE.

A reliable investment

Double glass module design enables extended lifetime with 12-year product warranty and improved 30-year performance warranty1

Enduring high performance

Long-term yield security with Anti LID and Anti PID Technology2, Hot-Spot Protect.

Frame for versatile mounting options

High-tech aluminum alloy frame protects from damage, enables use of a wide range of mounting structures and is certified regarding IEC for high snow (5400 Pa) and wind loads (2400 Pa).

TBD

Innovative all-weather technology

Optimal yields, whatever the weather with excellent low-light and temperature behavior.

1 See data sheet on rear for further information.

² APT test conditions according to IEC / TS 62804-1:2015 method B (−1500 V, 168 h) including post treatment according to IEC 61215-1-1 Ed. 2.0 (CD)

Q.PEAK DUO ML-G12S SERIES

Mechanical Specification

Format 93.8 in × 51.3 in × 1.38 in (including frame) (2384 mm × 1303 mm × 35 mm)

Weight 85.3 lbs (38.7kg) (TBD)

Front Cover 0.08 in (2.0 mm) thermally pre-stressed glass with anti-reflection technology

Back Cover 0.08 in (2.0 mm) semi-tempered glass

Frame Anodised aluminium

Cell 6 × 22 monocrystalline Q.ANTUM solar half cells

Junction box

2.09-3.98 × 1.26-2.36 × 0.59-0.71 in (53-101 mm × 32-60 mm × 15-18 mm), Protection class IP67, with bypass diodes

Cable 4 mm² Solar cable; (+) ≥ 29.5 in (750 mm), (−) ≥ 13.8 in (350 mm)

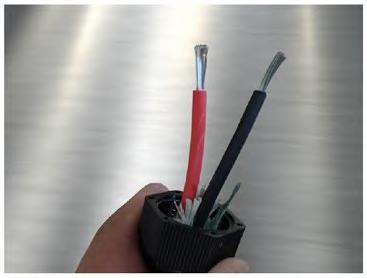

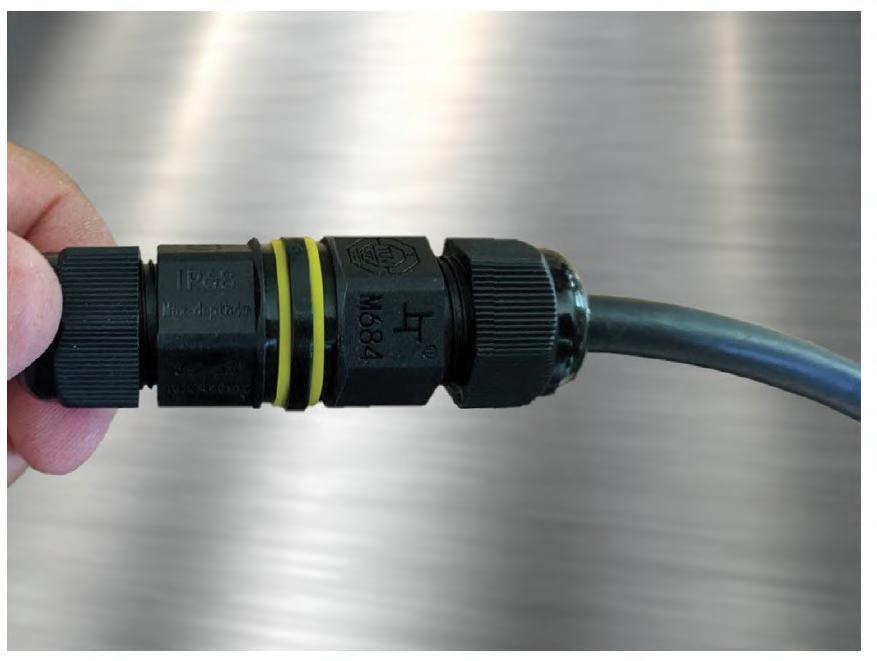

Connector Stäubli MC4; Stäubli MC4-Evo2; - IP68

Electrical Characteristics

Bifaciality of PMPP and ISC 70 % ± 5 % • Bifaciality given for rear side irradiation on top of STC (front side) • According to IEC 60904-1-2

1 Measurement tolerances PMPP ± 3 %; ISC, VOC ± 5 % at STC: 1000 W/m²; *at BSTC: 1000 W/m²

MINIMUM PERFORMANCE AT NORMAL OPERATING CONDITIONS, NMOT2

1Measurement tolerances PMPP ± 3 %;

At least 98 % of nominal power during first year. Thereafter max. 0.45 % degradation per year. At least 93.95 % of nominal power up to 10 years. At least 84.95 % of nominal power up to 30 years.

All data within measurement tolerances. Full warranties in accordance with the warranty terms of the Qcells sales organisation of your respective country.

Properties for System Design

Design Load, Push / Pull3 [lbs / ft2]

Qualifications and Certificates

Installation and operation manual

1 Introduction

With solar modules from Hanwha Q CELLS America Inc. (hereafter referred to as "Qcells") you can directly transform the sun’s limitless energy into environmentally-friendly solar electricity. In order to ensure the maximum performance of your Qcells solar modules, please read the following instructions completely and carefully and observe all guidelines. Non-compliance may result in damage and / or physical injury.

This installation manual provides instructions for the safe installation and operation of crystalline solar modules.

Please read these instructions carefully before proceeding with your installation.

Please retain these instructions for the life of the solar modules.

Please ensure that this Manual is available to the operator at all times.

This Manual should be given to all subsequent owners or users of the solar modules.

All supplements received from the manufacturer should be included.

Please observe all other applicable documents.

If your questions are not satisfactorily answered in the manual, please contact your system supplier.

Additional information can be found on our website at www. qcells.com.

Intended use

This manual is valid in North America for Qcells solar modules. These instructions contain information regarding the safe handling and use of quality crystalline solar modules from Qcells and their installation, mounting, wiring, maintenance.

Symbols and Labels

The following symbols and labels are used throughout the Manual for ease of use.

SYMBOL DESCRIPTION

Procedure with one or more steps. Lists of items.

Ensure that when carrying out a procedure, you check the results of said procedure. Prohibited.

Units

Beware of possible danger or damage. Categories:

■ Danger: Risk of fatal injury

■ Attention: Risk of serious injury or damage to property

■ Note: Risk of damage to product

Where both Imperial and U.S. units (for example inches) are shown, metric units are definitive. References to “Data Sheet” or “Module Data Sheet” refer to the Module Data Sheet applicable to the module being used.

Safety Regulations

The installer and solar module operator are responsible for compliance with all applicable statutory requirements and regulations. The following regulations and standards must be upheld at all times during the installation, operation, and maintenance of the solar modules:

■ Installation and Operation Manual.

■ Other applicable documents (such as country-specific regulations for pressure equipment, operational safety, hazardous goods, and environmental protection).

■ Regulations and requirements specific to the system.

■ Applicable country-specific laws, regulations, and provisions governing the planning, installation, and operation of solar power systems and work on roofs.

■ Any valid international, national and regional regulations governing work with direct current, especially those applicable to the installation of electrical devices and systems, and regulations issued by the respective energy provider governing the parallel operation of solar power systems.

■ Accident-prevention regulations.

Certified Personnel

Both, the operator and installer are responsible for ensuring that the installation, maintenance, connection to the grid, and dismantling are carried out by trained and qualified electricians and engineers with approved training certificates (issued by a state or federal organization) for the respective specialist trade. Electrical work may only be performed by an officially certified tradesperson in accordance with the applicable safety standards, accident prevention regulations, and the regulations of the local energy provider.

1 Introduction

Validity

These instructions are only valid for crystalline solar modules from the company Qcells as specified at chapter “2.1 Technical specifications”. Qcells assumes no liability for damage resulting from failure to observe these instructions.

Please observe the wiring and dimensioning of the system.

The installer of the system is responsible for compliance with all necessary safety regulations during set-up and installation. Qcells assumes no liability on the basis of these instructions. Qcells is only liable in the context of contractual agreements or in the context of accepted guarantees. Qcells accepts no other responsibility for the functionality and safety of the modules. Please observe the instructions for any other system components that may be part of the complete solar power system. It may be necessary to carry out a structural analysis for the entire project.

If your questions are not satisfactorily answered in the manual, please contact your system supplier. Additional information can be found on our website at www.qcells.com.

Information for the Operator

Please keep this manual for the entire life of the solar power system.

Please contact your system supplier for information concerning the formal requirements for solar power systems.

Please be sure to contact the relevant local authorities and energy providers regarding regulations and permit requirements prior to installation of the solar power system. Your financial success depends on the fulfillment of these requirements.

Other applicable documents

This installation manual is only valid in combination with the following technical information.

Document type

Product data sheet

Packaging and transport information

MISUSE OR INCORRECT USE OF SOLAR MODULES VOIDS THE LIMITED WARRANTY AND MAY CREATE A SAFETY HAZARD AND RISK PROPERTY DAMAGE. THIS INCLUDES IMPROPER INSTALLATION OR CONFIGURATION, IMPROPER MAINTENANCE, UNINTENDED USE, AND UNAUTHORIZED MODIFICATION.

Attention!

This marking indicates that this product should not be disposed of with other household waste within the EU. Recycle this product properly to prevent possible damage to the environment or a risk to human health via uncontrolled waste disposal and in order to promote the sustainable reuse of material resources. Please return your used product to an appropriate collection point or contact the retailer where you purchased this product. Your retailer will accept used products and return them to an environmentally-sound recycling facility.

2 Planning

2.1 Technical specifications

For additional information see the relevant datasheet of the module provided at www.qcells.com.

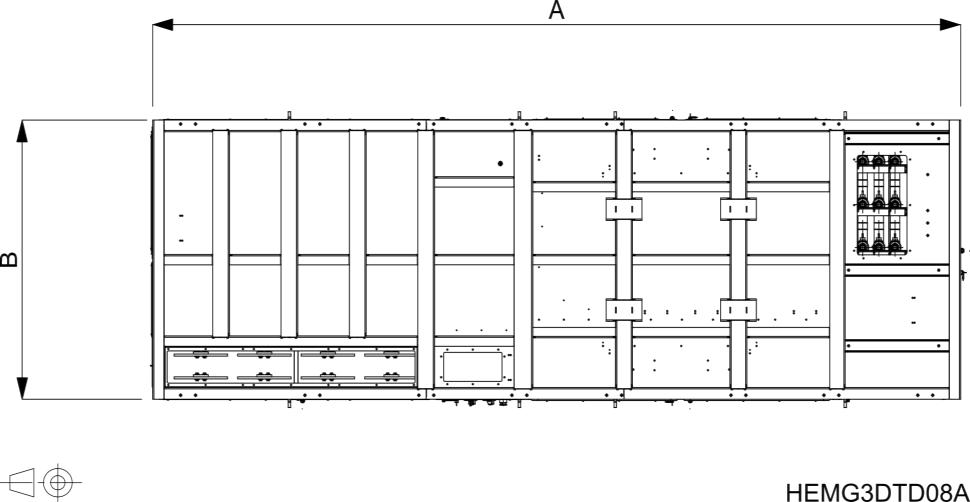

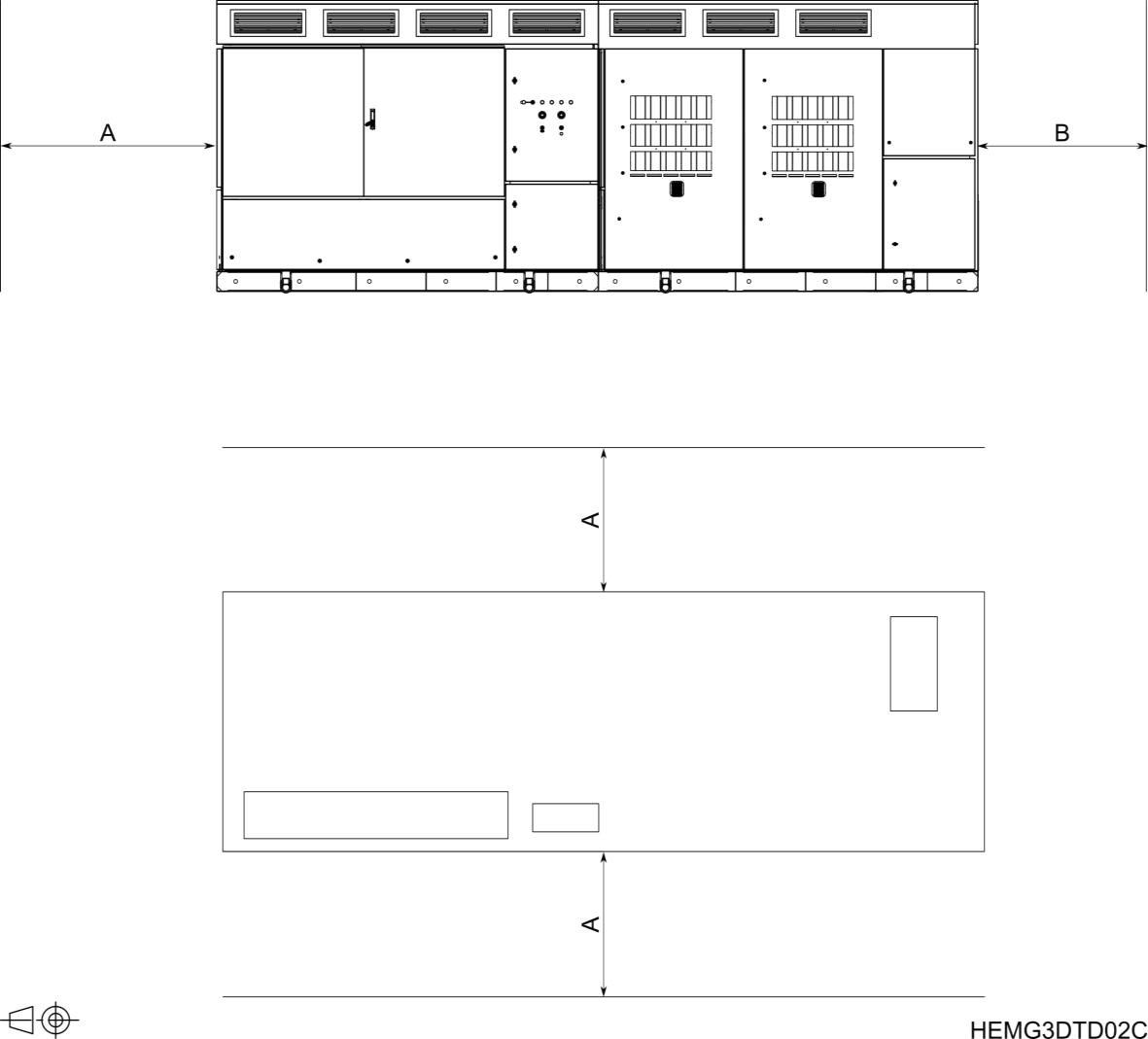

(2462 mm)

(1134 mm) Frame height [in]

(35 mm) Area [yd²]

Weight [lbs]

(2.79 m²)

(34.9 kg)

Max. system voltage VSYS 1500 V (IEC) / 1500 V (UL)

Max. series fuse rating 30 A

Permissible temperature range –40 °F to +185 °F (–40 °C to +85 °C)

Junction box protection class ≥ IP67 with bypass diode

Connector protection class IP67 or IP68

Fire rating based on ANSI /

UL 61730 C / TYPE 29 (New Type is similar to Type 3 but with metallic frame)

Max. Push load1 Test/Design [lbs/ft²] 113 /75 (5,400 Pa / 3,600 Pa)

Max. Pull load1 Test/Design [lbs/ft²] 78 / 52 (3,750 Pa / 2,500 Pa)

Middle rail No

Certificates

Quality Controlled PV by TÜV Rheinland; CE-compliant; IEC 61215:2016; IEC 61730:2016; PV module classification: Class II;

1 Test and design load in accordance with IEC 61215:2016, depending on mounting options (see section “2.3 Mounting options”)

2 Planning

2.2 Requirements

Installation Site

Please note the following guidelines that apply to the installation site:

■ Solar modules are not explosion-proof and are not suitable for use in explosive environments.

Do not operate solar modules near highly flammable gas and vapors (e.g. gas tanks, gas stations).

Do not install modules in enclosed space.

Do not install modules in locations where they may be submerged in water (e.g. floodplains).

Do not use modules as a substitute for the normal roofing (e.g. modules are not watertight).

Do not install modules in close proximity to air conditioning systems.

Do not install modules above 13,120 ft (4,000 m) altitude above sea level.

Contact with saline water (e.g. spray water from the sea) and salt aggregation on the modules must be avoided.

Do not bring any chemical substance (e.g. oil, solvent etc.) into contact with any part of the panel. Only substances, which are released by Qcells, are allowed to be used during installation, operation and maintenance.

Any installation of modules on surfaces of water is prohibited. This includes installations on floating as well as pile-based platforms. Qcells may extend the coverage of its warranty to such installations, based on a case by case assessment of the system design and location. A prior written consent by the warrantor is required in any case.

Prevention of Shadowing Effects

Optimal solar irradiation leads to maximum energy output: For this reason, install the modules so that they face the sun. Avoid shadowing (due to objects such as buildings, chimneys or trees).

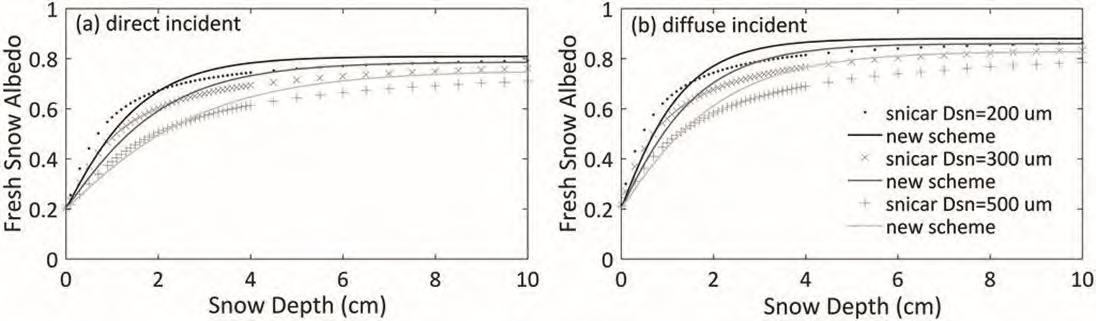

Avoid partial shading (for example through overhead lines, dirt, snow).

Limitations

The solar modules are designed for the following applications:

■ Operating temperatures from –40 °F to +185 °F.

■ Pull loads and push loads according to chapter 2.3 (‘Test Load’ in accordance with IEC 61215 and ‘Design Load ×1.5’ in accordance with UL 61730).

■ Installation using a mounting structure for solar modules.

Mounting Structure Requirements

Requirements for the mounting structure:

■ Conform to the necessary structural requirements.

■ Compliant with local snow and wind loads.

■ Properly fastened to the ground, the roof, or the façade.

■ Forces acting on the module are relayed to the mounting substructure.

■ Ensures sufficient rear ventilation of the module.

■ Avoid the usage of different metals to prevent contact corrosion.

■ Allows for stress-free expansion and contraction due to temperature fluctuations.

Ensure that no additional forces are applied through the mounting system into the module except for the wind and snow loads. Additional forces and moments of torque at the mounting positions caused by torsions, displacements or vibrations in the mounting system are not allowed.

Ensure that the clamps and the mounting frame are compatible.

For tracker installation TB1a / b, TB2a / b :

Maintain a minimal distance (clearance) of at least 5 mm between frame bottom edge and closest substructure element (e.g. torque tube).

Test loads and design loads according to chapter “2.3 Mounting options”.

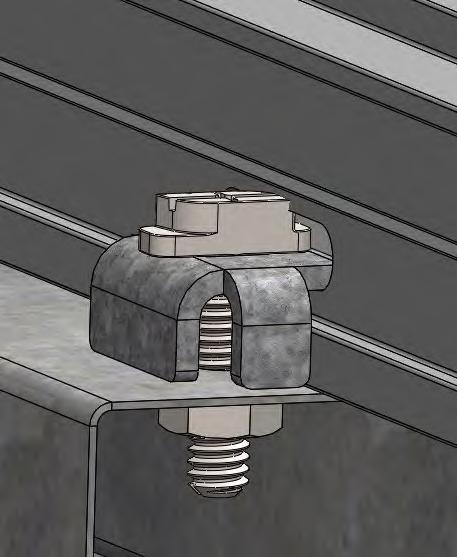

Clamp System Requirements & Recommendations

Use customary clamps that satisfy the following requirements:

■ Clamps are not in contact with the front glass laminate.

■ Clamps do not deform the frame.

■ Clamps that satisfy the structural requirements based on the conditions of the installation site according to the applicable regulation and technical standards.

■ Long-term stable clamps that securely affix the module to the mounting frame.

■ Front side clamp height complaint with the module frame height.

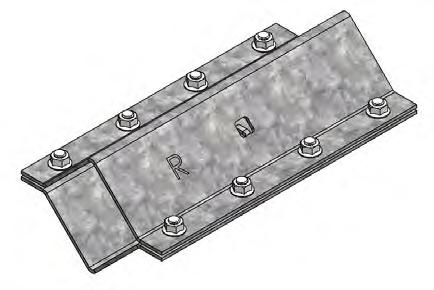

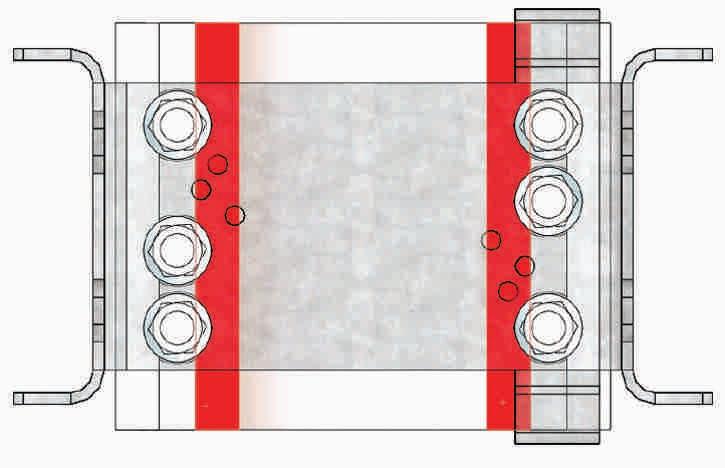

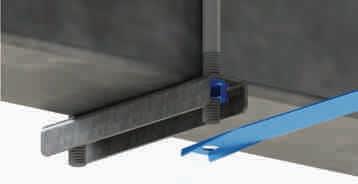

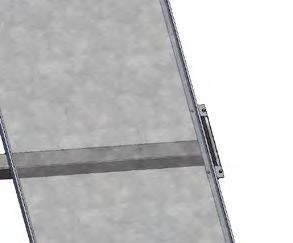

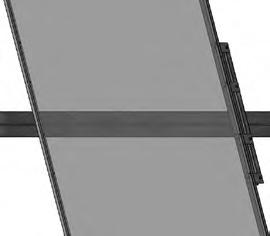

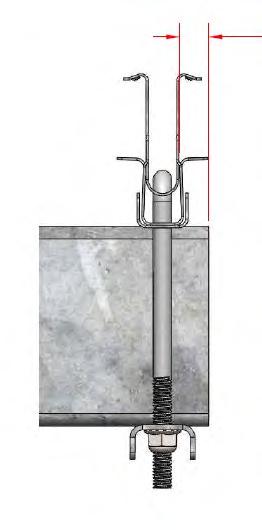

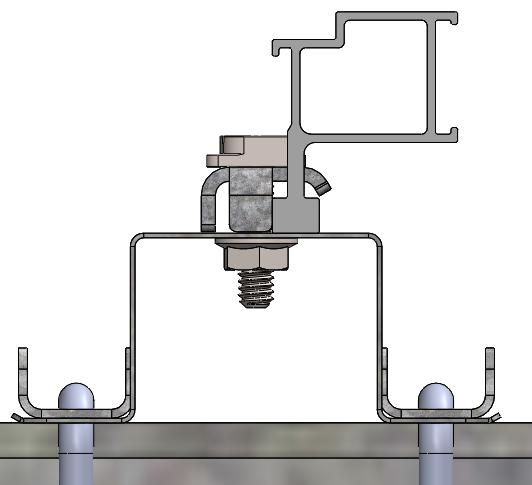

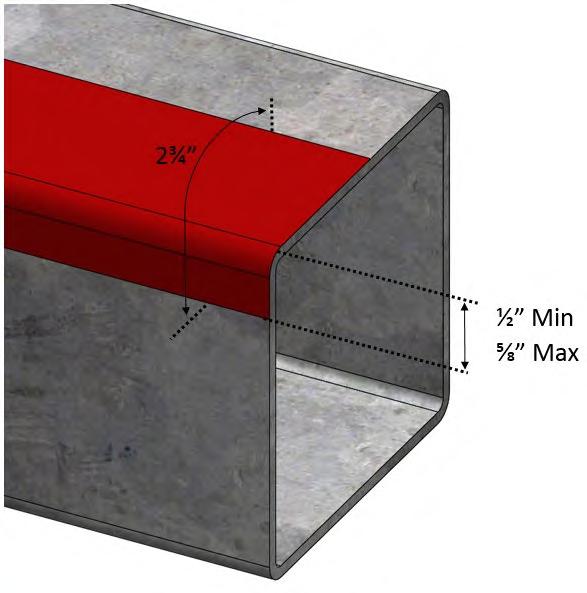

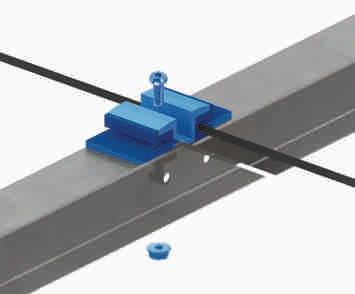

Flange Clamp Requirements

■ Flange clamps must not touch the laminate even under load.

■ Clamping at the long module sides only.

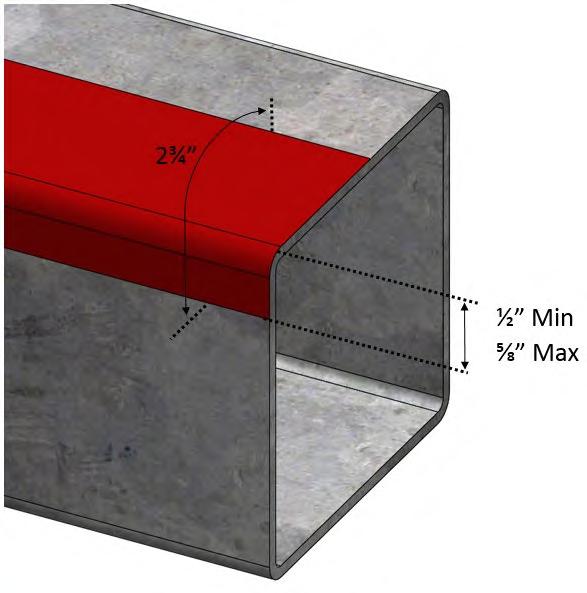

■ Flange clamps type A (Fig. X): Clamp width: ≥ 0.71 in (18 mm)

Clamp depth: ≥ 0.39 in (10 mm)

Contact area: ≥ 0.062 in2 (40 mm2)

The flange clamps type A must contact the flange at least like marked in fig. X (contact width: ≥ 0.07 in (2 mm)).

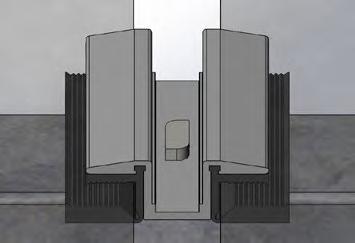

■ Flange clamps type B (Fig. Y):

Clamp depth: ≥ 0.12 in (3 mm)

Contact area: ≥ 0.155 in2 (100 mm2)

Clamp position: contact area ≥ 0.39 in (10 mm) away from flange edge.

For more details regarding flange clamps type B see fig. Y.

2 Planning

2.2 Requirements

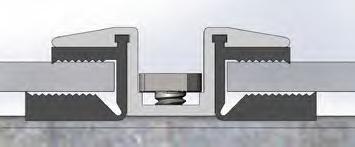

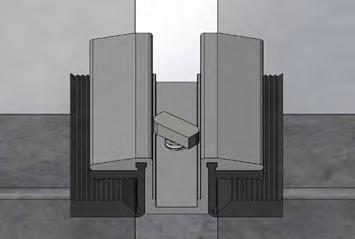

■ Flange clamps type C (Fig. Z):

Clamp diameter: ≥ 0.62 in (15.8 mm)

Contact area: ≥ 0.219in2 (141 mm2) completely flat on the frame flange.

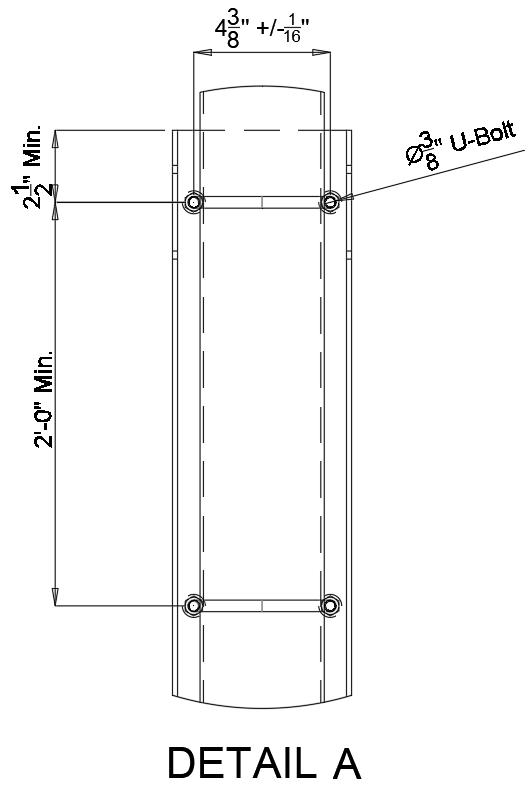

Clamp position: center of contact area in the axis of the mounting slots (Detail A, Fig.1) or closer to the hollow chamber.

For more details regarding flange clamps type C see fig. Z.

Maximum pull design loads: minimum of selected mounting option and FB mounting options (see section “Mounting options with bolts” of chapter “2.3 Mounting options”).

view

Mounting slot (Detail A, Fig.1)

Module Orientation Requirements

■ Vertical or horizontal installation is permitted.

Ensure that rain and melting snow can run off freely. No water accumulation.

Ensure that the drainage holes in the frame are not covered. No sealing.

Maintain the permissible angle of inclination.

■ Minimum angle of inclination: 3°

■ Inclination angles above 75° may be limited by local regulations

Standing water on the modules glass needs to be avoided.

2 Planning

2.3 Mounting options

REQUIREMENTS OF ALL MOUNTING OPTIONS

The loads in the table are related to the mechanical stability of the solar modules. Mounting system and installation equipment (clamps, etc.) are not part of the PV module certification acc. IEC 61215 / 61730. The mechanical stability of the mounting system including clamps and rails has to be evaluated by the system supplier. The listed test load values have been determined with special reusable test clamps and rails with high stiffness in order to be able to apply maximum stress to the module components during the test. The installer has to make sure that the used clamps and rails are capable of securely fastening the module under the specified maximum loads.

The system installer is responsible for the determination of location-specific load requirements.

Ensure that the connection cables of the junction box do not run between laminate and mounting rails.

Modules bend under load. Therefore, sharp objects (e.g. screws, ballast stones, rail ends, rails with burrs or sharp corners) must not be placed near the module backside so as not to touch the laminate under load.

Ensure that the junction boxes do not touch the mounting structure (e.g. shorts rails, ballast, etc.) or the rooftop under load.

Clamps or insertion profiles etc. must not touch the glass (even under load).

Unbalanced loads (e.g. snow overhangs, snowdrifts) which result in locally significantly increased loads must be removed or avoided by technical measures.

A minimum support depth of 0.59 in (15 mm) is required on the back side of the module.

Loads according to IEC 61215-2:2016 and UL 61730-2:2017 except for design loads lower than 1600 Pa which do not fulfill the requirements of the standards. The test procedure is always according to IEC 61215-2:2016.

Design loads result from the safety factor 1.5.

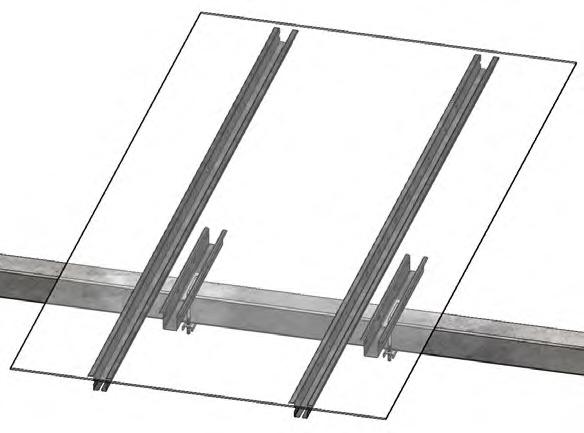

Mounting options with clamps

The illustrated installation options apply for both horizontal and vertical module orientation.

CL1a

CL1b

These mounting options are not recommended as mounting rails will cast shade on the module rear side. Ensure that module frame is fixed directly on the rail of the substructure (no spacer allowed between the module and substructure).

Short mounting rails are permissible, if they overlap with the module less than 14.2 in (360 mm). Maintain a minimum distance (clearance) of ≥ 2.95 in (75 mm) between frame bottom edge and roof top or ballast. In case the clearance of ≥ 2.95 in (75 mm) cannot be maintained please refer to the clearance graph for adjusted push loads. Roof or

Clearance* Overlap Module

*Clearance: minimum distance between frame bottom edge and roof top or ballast.

* Distance between outer edge of module and middle of the clamp.

2.3 Mounting options

4

S 0.79 - 3.9 (20 - 100 mm)

CL2b

CL3

Short mounting rails are permissible, if they overlap with the module less than 4.33 in (110 mm). Maintain a minimum distance (clearance) of ≥ 3.93 in (100 mm) between frame bottom edge and roof top or ballast

Ensure that module frame is fixed directly on the rail of the substructure (no spacer allowed between the module and substructure).

S 0.79 - 3.9 (20 - 100 mm)

L 23.6 - 27.6 (600 - 700 mm)

CL5

2400 / 2400 1600 / 1600

Minimum required support depth on the module backside is 0.39 in (10 mm) on long frame side and 0.59 in (15 mm) on short frame side.

* Distance between outer edge of module and middle of the clamp.

2 Planning

2.3 Mounting options

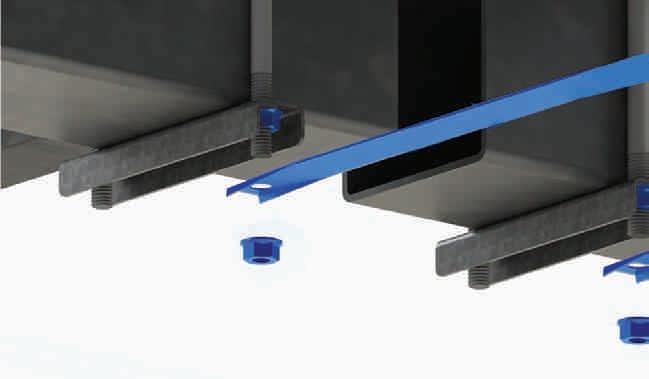

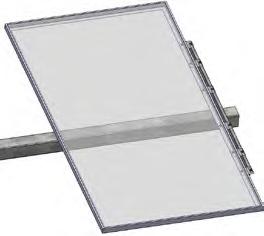

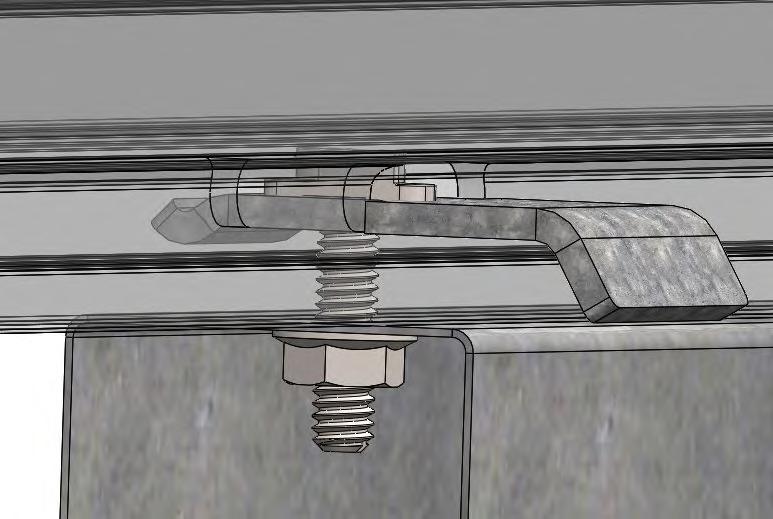

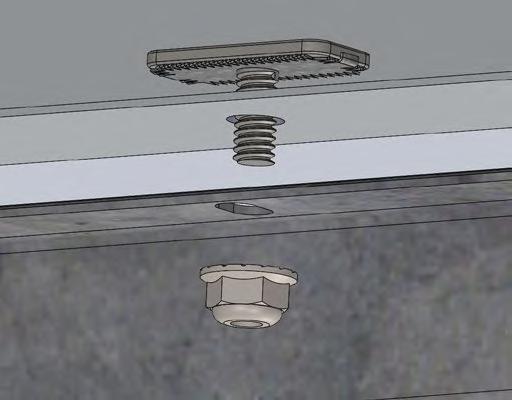

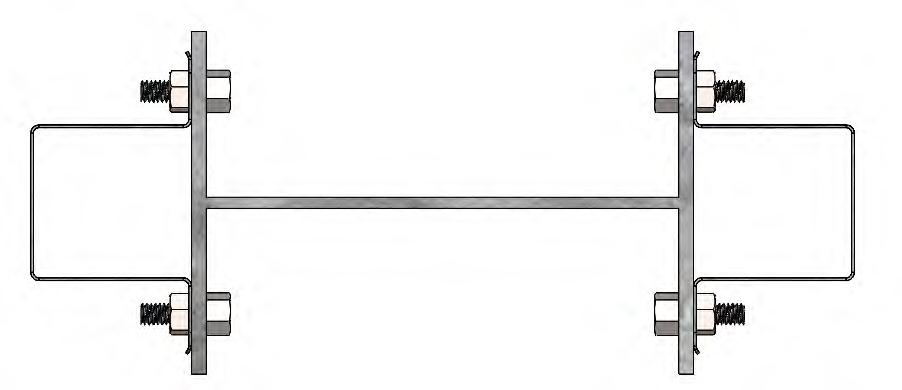

Mounting options with bolts

The illustrated installation options apply for both horizontal and vertical module orientation.

Module Bolt

4

Mounting rail

FB1 These mounting options are not recommended as mounting rails will cast shade on the module rear side.

Ensure that module frame is fixed directly on the rail of the substructure (no spacer allowed between the module and substructure).

L

FB2

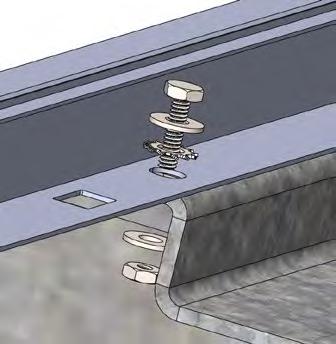

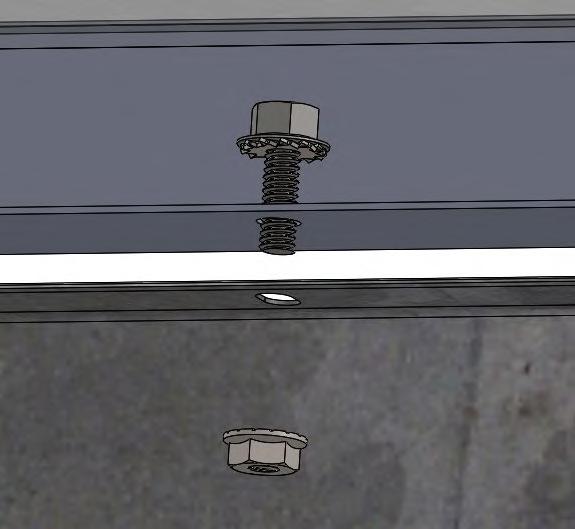

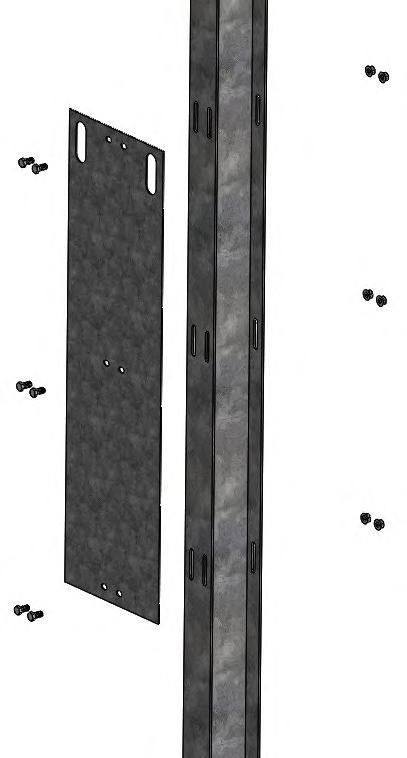

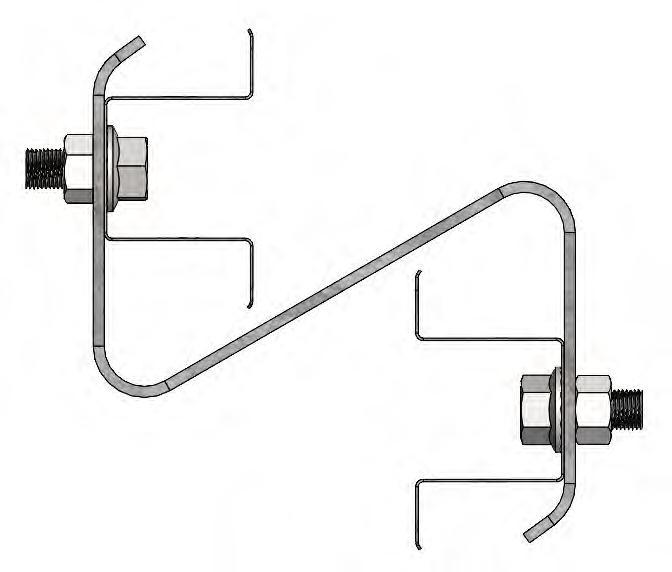

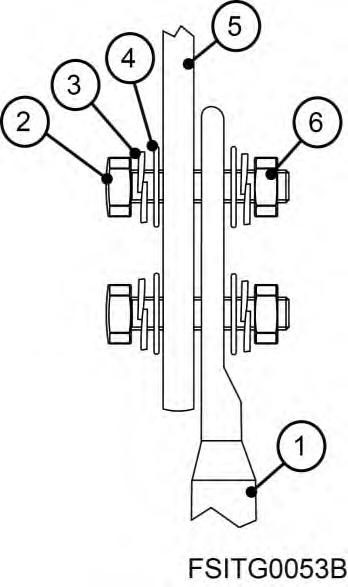

Use M8 corrosion-proof screws and washers (diameter ≥ 0.62 in (15.8 mm)) for mounting slots (Detail A, Fig.1) and M6 corrosion-proof screws and washers or bobtails for tracker slots (diameter ≥ 0.51 in (13 mm); Detail B, Fig. 1). Mounting screws and washers should have the same material properties. 4 BOLTS/SCREWS

Mounting rails need to extend beyond the middle of mounting holes by at least 0.79 in (20 mm). Clamps must not extend beyond the mounting rails.

Use M8 corrosion-proof screws and washers (diameter ≥ 0.62 in (15.8 mm)) for mounting slots (Detail A, Fig.1) and M6 corrosion-proof screws and washers or bobtails for tracker slots (diameter ≥ 0.51 in (13 mm); Detail B, Fig. 1). Mounting screws and washers should have the same material properties.

* Distance between outer edge of module and middle of the clamp.

2 Planning

2.3 Mounting options Tracker mounting options

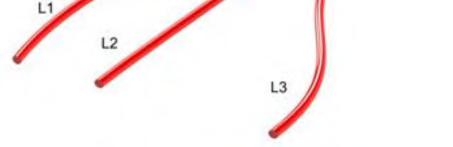

L 40.6 (1031 mm) 2000 / 2400 1330 / 1600 L1

outer side: 40.6 (1031 mm) 2100 / 1800 1400 / 1200 L2

inner side: 20.9 or 32.9 or 40.6 (531 or 836 or 1031 mm)

TB2a

Ensure that module frame is fixed directly on the rail of the substructure (no spacer allowed between the module and substructure).

Mounting rails need to extend beyond the middle of mounting holes by at least 0.7 in (17 mm).

Use M8 corrosion-proof screws and washers (diameter ≥ 0.62 in (15.8 mm)) for mounting slots (Detail A, Fig.1) and M6 corrosion-proof screws and washers or bobtails for tracker slots (diameter ≥ 0.51 in (13 mm); Detail B, Fig. 1). Mounting screws and washers should have the same material properties.

Ensure that module frame is fixed directly on the rail of the substructure (no spacer allowed between the module and substructure). Mounting rails need to extend beyond the middle of mounting holes by at least 0.7 in (17 mm). TB1b, TB2b

Use M8 corrosion-proof screws and washers (diameter ≥ 0.62 in (15.8 mm)) for mounting slots (Detail A, Fig.1) and M6 corrosion-proof screws and washers or bobtails for tracker slots (diameter ≥ 0.51 in (13 mm); Detail B, Fig. 1). Mounting screws and washers should have the same material properties.

* Distance between outer edge of module and middle of the clamp.

2 Planning

2.3 Mounting options

Module Clamp

Mounting rail

TRACKER INSTALLATION USING CLAMPS

L 40.6 - 42.6 (1031 - 1081 mm) 1800 / 1800 1200 / 1200

TC1 Ensure minimum support depth of 0.47 in (12 mm) on the backside and 0.39 in (10 mm) on the front side of the module.

* Distance between outer edge of module and middle of the clamp.

2 Planning

2.3 Mounting options

TB1a, TB2a

Specifications for TB1a, TB1b, TB2a, TB2b and TC1

Mounting Options

Limited area 1 [mm] Limited area 2 [mm]

2: Definition of limited areas.

NOTE!

For a requested push load maintain a minimum distance (clearance) between the bottom module plane (level of bottom frame leg) and closest substructure element below solar module laminate. The minimum clearance is defined by the maximum test push load and the limited area where the substructure element is located beneath the module (see figure 2 and 3).

Fig. 3: Push loads in relation to minimum clearance between frame bottom edge and substructure.

2 Planning

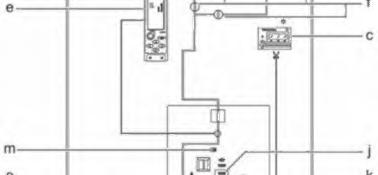

2.4 Electrical layout

Module Selection

For detailed key electrical data, please refer to the actual data sheet referring to the relevant Module (available at www.qcells. com).

For maximum energy yields, mismatches of specified electric current (IMPP) of more than 5 % should be avoided for all modules connected in series.

Safety Factor

During normal operation, a module may generate a greater current and / or higher voltage than that determined under standardized test conditions. Accordingly, the values of ISC and VOC marked on the module should be multiplied by a facot of 1.25 when determining:

■ the component voltage ratings,

■ conductor ampacities,

■ fuse sizes,

■ size of controls connected to the PV output.

Refer to Section 690-8 of the National Electrical Code for an additional multiplying factor of 125 percent (80 percent derating) which might be applicable.

Please follow the valid national guidelines for the installation of electrical systems (refer to section 690-8 of the NEC for an additional multiplying factor of 125 percent [80 percent derating] which may be applicable).

Series Connection

Connection of modules in series is only permitted up to the maximum system voltage as listed in the applicable data sheet.

Take into account all possible operating situations and all relevant technical norms and regulations when designing the system. It has to be ensured that the maximum system voltage, including all necessary safety margins, is not exceeded.

Take the voltage limit of the inverter into account when determining the maximum number of modules in the string.

Parallel Connection

Modules may be damaged by the occurrence of reverse currents (caused by module defects, ground leaks, or defective insulation).

Ensure that the maximum reverse current load capacity indicated in the data sheet is met.

In order to limit reverse currents that may occur, we recommend using the following safety options:

1) Layout with a limited number of parallel connected strings : Without undertaking further current blocking measures, a maximum of two module strings may be operated in parallel on a single inverter or MPP tracker.

2) Layout with string fuses :

Use overcurrent devices (e.g. fuses) according to the relevant standards in each string. Use gPV-fuses according to IEC 602696. Observe the maximum permitted number of strings as indicated in the specifications provided by the respective string fuse manufacturer and the technical guidelines.

NOTE!

When installing different product versions, the lowest minimum permitted reverse current load capacity applies.

Inverters

Inverters with or without transformers may be used.

3 Installation

3.1 Safety and transport

Ensure that all personnel are aware of and adhere to accident-prevention and safety regulations. While working wear clean gloves.

Danger! Risk of fatal injury due to electric shock! Do not install damaged modules. Inform your distributor of any damages immediately.

Inspect the packaging for damages. Contact the transport company regarding any damage to the packaging and follow their instructions. Follow any instructions on the packaging.

Leave modules in their original packaging until installation.

Store the modules securely in cool and dry rooms. The packaging is not weatherproof.

Warning! Fire Risk!

Do not install modules indoors. Do not install modules on moving objects.

3 Installation

3.1 Safety and Transport

Note! Module damage may occur!

Never lift or move the module with the connection cables or junction box. Carry modules upright and horizontally as shown. Stacking of modules is not recommended but if necessary, exercise care and take precautions to avoid physical damage in the act of stacking.

Note! Module damage may occur!

Do not drop modules.

Note! Module damage may occur!

Do not install modules near flammable gas / vapors. Do not install modules in close proximity to air conditioning systems.

Note! Module damage may occur!

Never step on modules.

Do not subject modules to any mechanical stress. Do not allow any objects to fall onto modules

Note! Module damage may occur!

Only make modifications to the module which have been confirmed in writing by Qcells.

confirmation letter

3 Installation

3.2 Preparation of installation

Danger! Risk of fatal injury due to electric shock!

Block off the installation zone. Keep children and unauthorized individuals away from the solar power system.

Warning! Risk of injury due to falling modules! Secure modules during installation. Do not install modules in windy or wet weather.

Danger! Risk of fatal injury due to electric shock!

Only use dry, insulated tools.

Do not carry out the installation alone.

Danger! Risk of fatal injury due to electric shock!

Ensure that modules and tools are not subject to moisture or rain at any time during installation.

■ Only install undamaged modules and components. Do not modify the module (e.g. do not drill any additional holes).

3 Installation

3.3 Module installation

Option 1:

Fasten the module with 4 clamps in the specified clamping range, see section "Mounting options with clamps" of chapter "2.3 Mounting options".

Tighten clamps according to manufacturer’s instructions.

Option 2:

Install the module at the 4 mounting points, see see section “Mounting options with bolts” of chapter “2.3 Mounting options”.

Tighten screws according to manufacturer’s instructions.

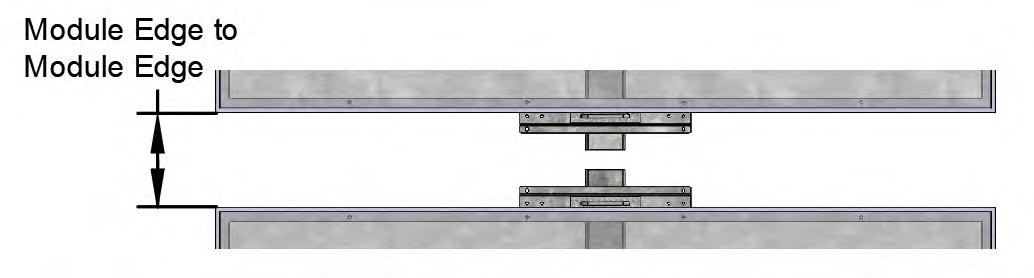

Maintain an interval of at least 0.39 in (10 mm) between two modules along the short side and 0.20 in (5 mm) along the long side.

0.20 in (5 mm)

0.39in(10mm)

Note! Module damage may occur! Do not subject modules to mechanical tension. Max. torsion 0.12 in / ft (10 mm / m).

4 Electrical Connection

4.1 Safety

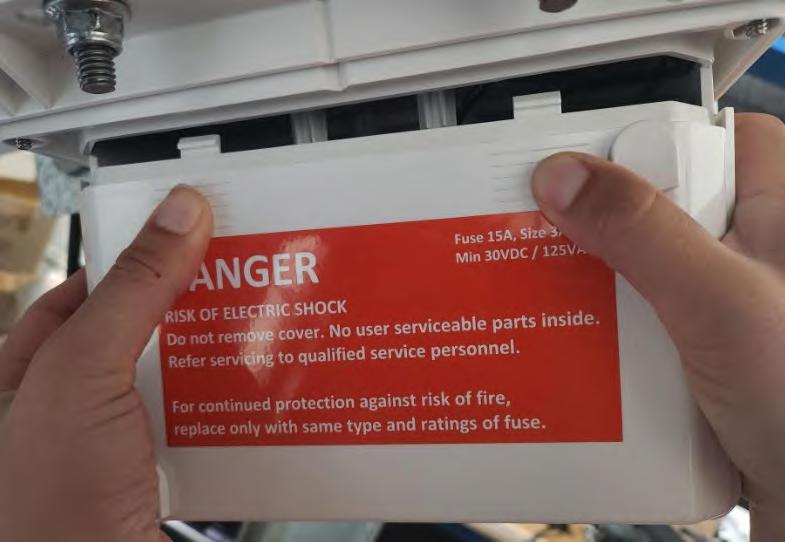

Danger!

Risk of fatal injury due to electric shock!

When disconnecting an electric circuit carrying direct current, electric arcs can occur that may result in life-threatening injuries.

Do NOT unplug the cable when under load.

Do NOT connect any exposed cable ends.

Electrical work may only be performed by qualified and skilled personnel (see page 3).

A solar module generates electrical current and voltage even at a low intensity of illumination. Sparks and electric arcs may result from the separation of a closed circuit. These can result in life-threatening injuries. The danger increases when several modules are connected in series.

Please be aware of that the entire open circuit voltage is active even at low levels of solar irradiation.

Please follow the valid national regulations and safety guidelines for the installation of electrical devices and systems. Please make sure to take all necessary safety precautions. With module or phase voltages of more than 120 V, the safety extra-low voltage range is exceeded.

Carry out work on the inverter and the wiring with extreme caution.

Ensure that the modules are disconnected at the inverter prior to separation.

Be sure to observe the time intervals specified by the inverter manufacturer after switching off the inverter.

Make sure that the plugs can not be connected unintentionally. Before working on the contacts, check them for safety extra-low voltage.

Danger! Risk of fatal injury due to electric shock!

Never open the junction box.

Do not remove bypass diodes.

Danger! Risk of fatal injury due to electric shock!

Only use dry, insulated tools for electrical work.

Danger! Risk of fatal injury due to electric shock!

Never touch live contacts with bare hands.

Cover connectors by suitable protective caps until installation.

Danger! Risk of fatal injury due to electric shock!

Insulate any exposed cable ends.

Only connect cables with plugs.

4 Electrical Connection

4.2 Electrical installation safety

Danger! Risk of fatal injury due to electric shock!

Electrical work may only be performed by qualified and skilled personnel (see page 3). Ensure correct polarity.

Danger! Risk of fatal injury due to electric shock! Never plug or unplug the cable when under load. Modules must not carry any current.

1. Switch off the inverter.

Danger! Risk of fatal injury due to electric shock! Be sure to maintain the time intervals as specified by the inverter manufacturer between switching off the inverter and beginning any further work.

2. Switch off the DC circuit breaker.

3. Measure shutdown in DC String. (no DC current flow).

4. Disconnect plugs by the use of appropriate and qualified tools of the manufacturer.

5. When connecting the modules proceed in reverse order.

4 Electrical Connection

4.3 Connection of modules

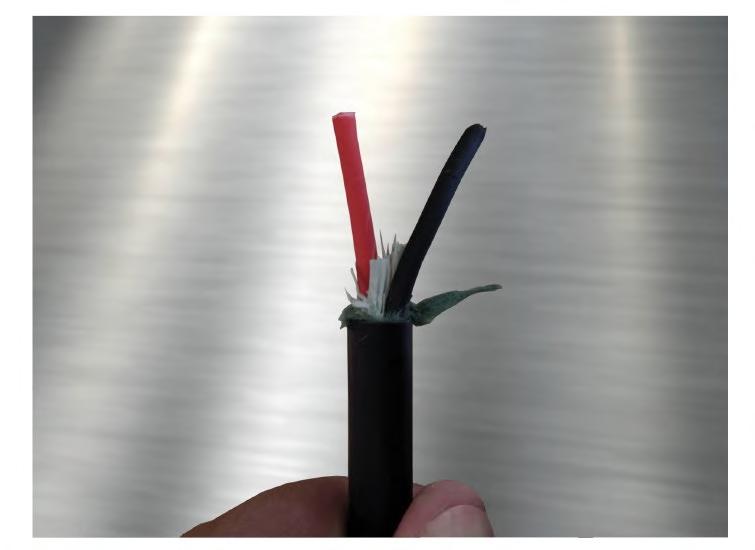

Use solar cables for the connection at the junction box outlet.

Only interconnect connectors of the same type and manufacturer.

According to Staubli, MC4 and MC4-Evo2 connectors are fully compatible with one another. Qcells accordingly does not object interconnecting these particular connector types.

Use minimum No. 12 AWG copper wires insulated for a minimum of 90 °C for field connections.

Note! Module damage may occur!

Ensure that the cabling is not under mechanical stress (Comply with bending radius of ≥ 2.36 in (60 mm)).

Ensure that the cables do not run between module and mounting rail or structure (danger of pinch).

Danger! Risk of fatal injury due to electric shock! Ensure that all electrical components are in a proper, dry, and safe condition.

Position the wiring on the solar modules that additional shading is avoided.

Ensure for a tight connection between the plugs. Plugs click together audibly.

Do not connect modules with different orientations or angles of inclination in the same string.

4 Electrical connection

4.4 After installation

Ensure that all necessary safety and functional tests have been carried out according to applicable standards.

Integrate the system into the existing lightening protection system in accordance with the applicable local regulations.

Note! Module damage may occur! Ensure that the plug connections are secured away from any water-channelling surface.

Ensure that the cabling is not exposed and / or hanging and is protected from dirt, moisture and mechanical friction.

Warning! Fire Risk!

Do not use light concentrators (e.g. mirrors or lenses).

5 Grounding

Protective Grounding

In order to prevent electrical shock or fire, the frame of the module as well as any non-current-carrying metal parts of the system must be grounded. While this section provides some information about grounding the Qcells frames and modules, reference should be made to local statutes and regulations for specific requirements on grounding. The U.S. National Electrical Code addresses these issues in Article 250. A module with exposed conductive parts is considered to be in compliance with this standard only when it is either electrically grounded in accordance with the manufacturer’s instructions and the requirements of the National Electrical Code, ANSI/NFPA 70 (2014-2017), or when the bonding means has been evaluated with this module to UL 2703.

Proper grounding is achieved by bonding all exposed non-currentcarrying metal equipment to the appropriately sized equipment grounding conductor (EGC) or racking system that can be used for integrated grounding.

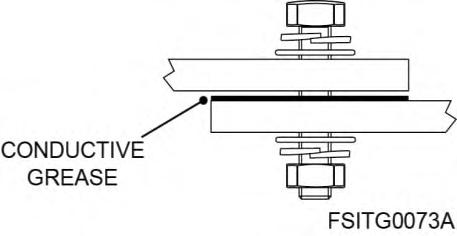

Qcells frames are protected from corrosion with an anodized coating, which has to be penetrated in order to ensure proper bonding. The different methods listed below are suggested methods for an appropriate bond between the frame and the EGC or racking system (that will have to be properly grounded). The method appropriate for any individual installation will depend on multiple factors.

■ Dimensions shown are in inches.

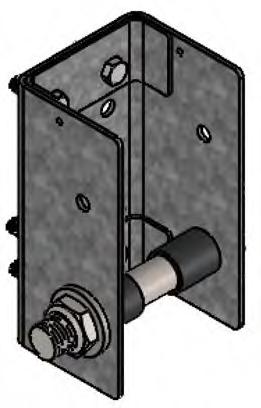

Option A: Use of a grounding lug

A listed grounding lug can be bonded to the frame using the grounding holes pre-drilled in the frame. These holes are marked with a ground symbol, as shown below on the frame section drawing: To install the grounding lug, follow the specified instructions of the manufacturer. The grounding lug should be made of stainless steel or tin plated metals such as aluminum to avoid corrosion.

The grounding lug should be attached to the frame grounding hole using a stainless steel screw, toothed lock washer or KEPS nut (in order to penetrate the anodized layer) and backing nut. Care should be taken to avoid the use of grounding hardware of dissimilar metals, which may lead to corrosion.

Option B: Integrated grounding methods

The Qcells modules can be bonded with the racking system using UL1703 or UL2703 certified integrated grounding methods. The racking system will then have to be grounded so that the overall system is properly grounded. The listed racking system and grounding device should be installed in accordance with the manufacturers’ instructions. An example of such integrated grounding method is the use of a WEEB clip or Schletter plate between the module and the racking system, when mounting the module.

The WEEB washers are generally compatible with Qcells modules, however each combination module / racking system requires a specific WEEB washer size. Note that WEEB clips are intended for single use only; they must not be reused after removal or loosening. Refer to Wiley’s installation instructions for the specific use of WEEB washers.

An example of such integrated grounding method is the use of a washer recognized as meeting UL2703 requirements between the module and the racking system, when mounting the module. For example, WEEB washers are generally compatible with Qcells modules, however each combination module / racking system requires a specific WEEB washer size. Note that WEEB washers are intended for single use only; they must not be reused after removal or loosening. Refer to Wiley’s installation instructions for the specific use of WEEB washers.

6 Faults and

defects

Danger!

Risk of fatal injury due to electric shock!

Do not attempt to fix any problems yourself (e.g., glass cracks, damaged cables).

Please contact an installer or Qcells Technical Customer Service Department.

7 Disposal

Do not disconnect modules by yourself. Please commission a trade specialist.

Dispose of modules in accordance with the local disposal regulations.

8 Maintenance and cleaning

Qcells solar modules are known for a long operating life and minimal maintenance effort and expense. Dirt and grime are usually washed away by rain. If the module is fully or partially shaded by dirt or debris (e.g., plants, bird droppings), it needs to be cleaned to prevent a loss of performance.

Maintenance

The PV system has to be inspected regularly by certified personnel.

The time intervals and extent of the inspection can depend on local circumstances (e.g. salt, ammonia content in the air, high humidity etc.). The customer / operator must inform himself about time intervals and extend of necessary inspections. Inspections have to be performed especially after extraordinary events (e.g. storm, hail, high snow loads etc.)

During the inspections it has to be checked that the components are secure, undamaged and clean.

Cleaning

WARNING!

Risk of injury due to hot and live modules!

Only clean modules that have cooled down.

Do not carry or wear any electrically conductive parts.

WARNING!

Risk of falling due to unsecured access!

Never access the installation area alone or without taking adequate security precautions. Please commission a trade specialist.

NOTE!

Module surface damage may occur!

Remove snow and ice carefully without force (e.g. with a very soft broom).

Do not scratch off dirt.

Module cleaning has to be done by qualified personnel according to the state of the art and taking into account all relevant safety issues and general product properties, e.g., but not restricted to:

■ electrical safety

■ mechanical stability (load limits depending on the actual mounting options)

■ chemical suitability (no effect to any of the module‘s components, e.g. cable, connector, silicone)

■ no abrasive materials.

NOTE!

Dust and dirt are abrasive materials!

The situation for each individual project (or type of dirt) must always be professionally evaluated.

Wrong cleaning may cause damages such as, but not limited to, damages to the glass surface (e.g. scratches) and AR coating, power loss, delamination, loss of frame-to-laminate bond, reduced snow and wind load capability etc.

Apart from the above, each customer is free to choose the method of cleaning. However, possible damages, caused by the cleaning or related to the cleaning tools or agents shall not be covered by the module‘s Product and Performance Warranty. Therefore it is recommended to use only the tools and agents which have already been successfully tested and used with PV modules, to prevent possible damage.

Isopropyl alcohol (IPA) can be used selectively to remove stubborn dirt and stains within one hour after emergence.

Note! Module damage may occur!

Do not clean modules with water if there is a risk of frost.

0°

Free the substructure from any dirt and debris (leaves, bird nests, etc.).

PRODUCT SAFETY DATA SHEET

Qcells SOLAR PV MODULES ARE ARTICLES AS DEFINED BY THE OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION HAZARD COMMUNICATION STANDARD (HCS), 29 C.F.R. § 1910.1200 AND ARE EXEMPT FROM THE LABELING AND SAFETY DATA SHEETS (SDS) REQUIREMENTS OF THE STANDARD.

Qcells provides this product safety data sheet only for convenience of interested parties in the United States of America who are used to the format of safety data sheets in order to assess the product safety. This product safety data sheet does not replace any other documents provided by Qcells such as Safety Information, Installation and Operation Manual, Packaging and Transport Information, Product Data Sheet as well as Warranty Terms of the respective product.

1. SECTION: IDENTIFICATION

Solar PV modules convert light into electricity. Light-sensitive cells are electrically interconnected in series and sealed between glass and plastic foils for this purpose. This product safety data sheet is applicable to the following solar PV modules of the Qcells brand made by Hanwha Qcells America Inc.:

• Q.PEAK DUO L-G6.3 / BFG, Q.PEAK DUO L-G6.3 / BGT,

• Q.PEAK DUO L-G8.3 / BFG, Q.PEAK DUO L-G8.3 / BGT,

• Q.PEAK DUO XL-G10.3 / BFG, Q.PEAK DUO XL-G10.3 / BGT,

• Q.PEAK DUO XL-G10.d / BFG, Q.PEAK DUO XL-G10.d / BGT

• Q.PEAK DUO XL-G11.3 / BFG

• Q.PEAK DUO XL-G11S.3 / BFG

Variants with additional suffixes “ / TAA” and / or “+” are covered by this product safety data sheet. This is also true for B-grade modules, which have minor optical imperfections. Product names of these replace “Q.” with “B.LINE”. B-grade modules of Q.PEAK DUO L-G6.3 / BFG are named B.LINE PEAK DUO L-G6.3 / BFG for example.

Responsible Party as Importer:

Name: Hanwha Q CELLS America Inc.

Address: 400 Spectrum Center Drive, Suite 1400, Irvine, CA 92618, USA

Phone: 1 949 748 59 96

2. SECTION: IDENTIFICATION OF SAFETY RISKS (HAZARDS IDENTIFICATION)

Qcells solar PV modules do not pose any risk of hazardous chemicals. Hazard symbols and precautionary hazard statements for hazardous chemicals are not applicable. No symptoms or effects – neither acute nor delayed – have to be expected when Qcells solar PV modules are handled as stipulated in the Installation and Operation Manual. Qcells provides a Safety Information sheet with all modules shipments. This document contains detailed risk statements and recommendations for installation and operation. Before installing the module, read the Installation and Operation Manual for Qcells modules carefully. You can obtain the complete Installation and Operation Manual from your retailer.

Attention: Only qualified and authorized specialists may install modules and put them into operation. Keep children and unauthorized persons away from the modules.

Risks:

• Risk of death from electrocution! Solar modules generate electricity and are energized as soon as they are exposed to light.

• In rare cases, solar PV modules – as any other electrical device – can cause fire due to worn electrical contacts which result in electrical arching.

• Solar PV modules can reach high temperatures which can cause skin burns.

• Sharp edges, corners and broken glass can cause injuries.

• Solar PV modules can cause Injuries due to their weight.

• Falling solar PV modules can cause injuries.

• Lifting solar PV modules can cause injuries.

For precautionary statements, please refer to the Installation and Operations Manual of the respective product.

MISUSE OR INCORRECT USE OF SOLAR MODULES VOIDS THE LIMITED WARRANTY AND MAY CREATE A SAFETY HAZARD AND RISK PROPERTY DAMAGE. THIS INCLUDES IMPROPER INSTALLATION OR CONFIGURATION,

PRODUCT SAFETY DATA SHEET

3. SECTION: COMPOSITION / INFORMATION ON INGREDIENTS

Safety data sheets are only required for hazardous chemicals covered by the Hazard Communication Standard (HCS). Solar PV modules made by Qcells are not covered by HCS. The following table provides an overview of materials solar PV modules by Qcells are made of. The values given for the share of weight are targets and can vary for the products covered by this Product Safety Data Sheet.

4. SECTION: FIRST-AID MEASURES

In case of electrocution:

• Always protect yourself by taking all necessary safety precautions before rescuing persons injured.

• Attention: Stay away from sources of high voltage and leave the rescue to qualified personnel with appropriate personal protection equipment!

• Call emergency rescue services.

• Do not touch live parts. Qualified personnel should shut down the PV system as far as possible – e.g. disconnect the modules at the inverter before uncovering any live electrical parts. Be sure to observe the specified time intervals after switching off the inverter. High voltage components need time to discharge. Follow OSHA requirements for control of hazardous energy at 29 C.F.R. § 1910.147.

• In the event a person is electrocuted or affected by electrical energy of the solar PV module, CALL 911. Before attempting rescue, SHUTDOWN THE POWER SOURCE.

• Remove the victim from the power source using only insulated tools ONLY IF CONTACT WITH LIVE ELECTRICAL COMPONENTS CAN BE PREVENTED.

• Carefully move the injured from the zone of danger.

• After moving to a safe location, check heartbeat, respiration and consciousness of the injured person.

• Apply appropriate life-saving measures (CPR) accordingly before taking care of minor injuries.

• Consult a medical professional even if there are no visible injuries.

• Flush thermal skin burns caused by touching hot surfaces of solar PV modules with cool water. Consult a medical professional.

• Injuries due to sharp edges, corners and broken glass need to be appropriately treated. Consult a medical professional.

• Other types of injuries need to be treated appropriately as well. Consult a medical professional.

5. SECTION: FIRE-FIGHTING MEASURES

• Qcells solar PV modules are fire rated as Class C according to IEC and UL 1703 / UL 61730 as well as Type 1 and 2 according to UL 1703 / UL 61730.

PRODUCT SAFETY DATA SHEET

• Qcells solar PV modules are extensively tested at the factory to ensure electrical safety of the product before shipment.

• In rare cases, solar PV modules – as any other electrical device – can cause fire due to worn electrical contacts which result in electrical arching.

• In case solar PV modules which are not part of an array are on fire, USE FIRE EXTINGUISHERS RATED FOR ELECTRICAL EQUIPMENT, Class C.

• IN CASE A SOLAR PV MODULE ARRAY IS PRESENT, ANY FIRE SHOULD ONLY BE FOUGHT BY PROFESSIONAL FIREFIGHTERS. FIREFIGHTERS NEED TO TAKE PRECAUTIONS FOR ELECTRICAL VOLTAGES UP TO 1,500 VOLTS (DC).

• Some components of the modules can burn. Potential combustion products include oxides of carbon, nitrogen and silicon.

• In case of prolonged fire, solar PV modules may lose their structural integrity.

General recommendations from the below-mentioned reports:

• Fire service personnel should follow their normal tactics and strategies at structure fires involving solar power systems, but do so with awareness and understanding of exposure to energized electrical equipment. Emergency response personnel should operate normally, and approach this subject area with awareness, caution, and understanding to assure that conditions are maintained as safely as possible.

• Care must be exercised during all operations, both interior and exterior.

• Responding personnel must stay back from the roofline in the event modules or sections of an array may slide off the roof.

• Contacting a local professional PV installation company should be considered to mitigate potential hazards.

• Turning off an array is not as simple as opening a disconnect switch. As long as the array is illuminated, parts of the system will remain energized.

• When illuminated by artificial light sources such as fire department light trucks or an exposure fire, PV systems are capable of producing electrical power sufficient to cause inability to let go from electricity as a result of stimulation of muscle tissue, also known as lock-on hazard.

• Firefighting foam should not be relied upon to block light.

• The electric shock hazard due to application of water is dependent on voltage, water conductivity, distance and spray pattern.

• It is recommendable to fight fire with water instead of foam if a PV system is present. Salt water should not be used.

• Firefighter’s gloves and boots afford limited protection against electrical shock provided the insulating surface is intact and dry. They should not be considered equivalent to electrical personal protection equipment.

Readers interested in more details may refer to the following reports:

• National Fire Protection Association, Fire Protection Research Foundation report “Fire Fighter Safety and Emergency Response for Solar Power Systems” issued May 2010, revised October 2013

• Important recommendations from a report called “Firefighter Safety and Photovoltaic Installations Research Project” issued by Underwriters Laboratories on November 29, 2011

6. SECTION: ACCIDENTAL RELEASE MEASURES

This section is not applicable.

7. SECTION: HANDLING AND STORAGE

Before installing the module, read the Installation and Operation Manual for Qcells modules carefully. Noncompliance with the instructions may result in damage and physical injury or death. Only qualified and authorized specialists may install modules and put them into operation. You can obtain the complete installation manual from your retailer. Details about transport and storage of palletized Qcells solar PV modules can be found in the Packaging and Transport Information of the respective module type.

Storage, transport and unpacking:

• Store the module dry, well-ventilated and properly secured. The original packaging is not weatherproof.

• Always transport the module in its original packaging.

PRODUCT SAFETY DATA SHEET

• Do not stack the modules. This prevents damage of the junction box.

• The module is made of glass. Take great care when unpacking, storing and transporting it.

• Do not subject the module glass to any mechanical stress (e.g. through torsion or deflection). Do not step on the module or place any objects onto the module.

• Protect both sides of the module against scratching and other damage.

• Carry the module by holding the edges with both hands, or use a glass suction lifter.

• Never lift or carry the module using the module junction box or wiring. Avoid pulling on the wiring at all costs.

8. SECTION: EXPOSURE CONTROLS / PERSONAL PROTECTION

Before installing the module, read the Installation and Operation Manual carefully. Noncompliance with the instructions may result in damage and physical injury. Only qualified and authorized specialists may install modules and put them into operation. You can obtain the complete installation manual from your retailer.

• Please follow the valid national regulations and safety guidelines for the installation of electrical devices and systems.

• Please make sure to take all necessary safety precautions.

• Ensure that all personnel are aware of and adhere to accident-prevention and safety regulations.

• For handling of modules wear suitable protective gloves.

• Do not install damaged modules. Ensure that all electrical components are in a proper, dry, and safe condition.

• Do not modify the module (e.g. do not drill any additional holes). Never open the junction box.

• Ensure that modules and tools are not subject to moisture or rain at any time during installation. Only use dry, insulated tools for electrical work.

• Only connect cables with plugs. Ensure for a tight connection between the plugs. Plugs click together audibly.

• Cover the modules with an opaque material during installation. Cover the modules to be disconnected.

Silicones used in manufacturing release methanol during curing. Once cured, no additional methanol is released during use. Small amounts of these chemicals may be present in shipping cartons. Upon receipt, open container in a well-ventilated location and allow to stand for 5 minutes before removing units from cartons. Exposures above recommended limits for methanol of 200 ppm eight-hour timeweighted-average (TWA) will not occur.

9. SECTION: PHYSICAL AND CHEMICAL PROPERTIES

• Physical state: solid

• Voltage: refer to data sheet (below 50 volts for a single module)

Attention: Voltage of single modules add up when modules are electrically connected in series. Qcells solar PV modules are designed and certified for voltages up to 1,000 volts or even up to 1,500 volts. Connection of modules in series is only permitted up to the maximum system voltage as listed in the applicable data sheet.

• Weight: refer to data sheet

• Solubility in water: insoluble in water

10. SECTION: STABILITY AND REACTIVITY

Under normal operating conditions as specified in the Product Data Sheet, Qcells solar PV modules are chemically stable.

• Qcells solar PV modules are tested for salt spray and ammonia resistance according to IEC 61701 and IEC 62716, respectively.

• Qcells solar PV modules support ambient operating temperatures from −40 °C to +85 °C (−40 °F to +185 °F).

PRODUCT SAFETY DATA SHEET

• Do not install modules above 13.120 ft (4000 m) altitude above sea level.

• Some components of the modules can burn. Potential combustion products include oxides of carbon, nitrogen and silicon.

• Do not scratch off dirt. Use a soft cellulose cloth or sponge to carefully wipe off stubborn dirt. Do not use micro fleece wool or cotton cloths.

• Rinse dirt off with lukewarm water (dust, leaves, etc.)

• Use an alcohol based glass cleaner. Do not use abrasive detergents or tensides.

• Isopropyl alcohol (IPA) can be used selectively to remove stubborn dirt and stains within one hour after it appeared.

• Follow the safety guidelines provided by the IPA manufacturer.

• Do not let IPA run down between the module and the frame or into the module edges.

11. SECTION: TOXICOLOGICAL INFORMATION

Small amounts of methanol may be present inside shipping cartons. Open cartons and allow to vent before removing units. No exposure to hazardous chemicals will occur when the units are in use.

12. SECTION: ECOLOGICAL INFORMATION

Qcells solar PV modules are designed to withstand outdoor operating conditions for 25 years. Biodegradation is not expected due to high chemical stability of the components.

13. SECTION: DISPOSAL CONSIDERATIONS

Qcells solar PV modules should be recycled rather than dumped in a landfill. Raw materials of the product can be recovered by recycling companies. Disposal must be in accordance with national and local laws and regulations for electric / electronic waste.

14. SECTION: TRANSPORT INFORMATION

Qcells solar PV modules can be shipped via standardized container freight. Regulations for hazardous goods do not apply. For further details, please refer to the Packaging and Transport Information which can be provided as a separate document by Qcells.

15. SECTION: REGULATORY INFORMATION

• Qcells solar PV modules are tested according to international standards IEC 61215, IEC 61730 as well as US standards UL 1703 / UL 61730.

• Please refer to the Installation and Operation Manual and Product Data Sheet of the respective Qcells solar PV module.

16. SECTION: OTHER INFORMATION

• Date of initial creation of this product safety data sheet: July 1, 2016

• Date of last revision: March 01, 2023

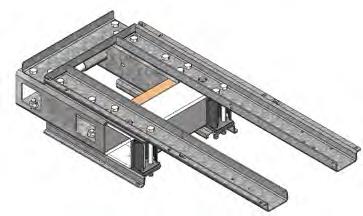

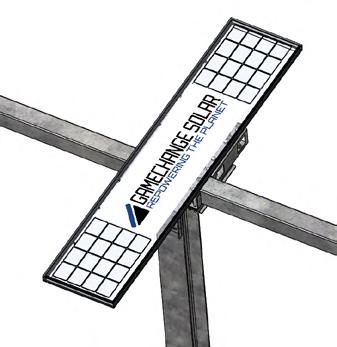

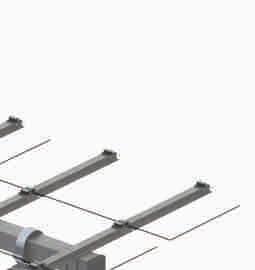

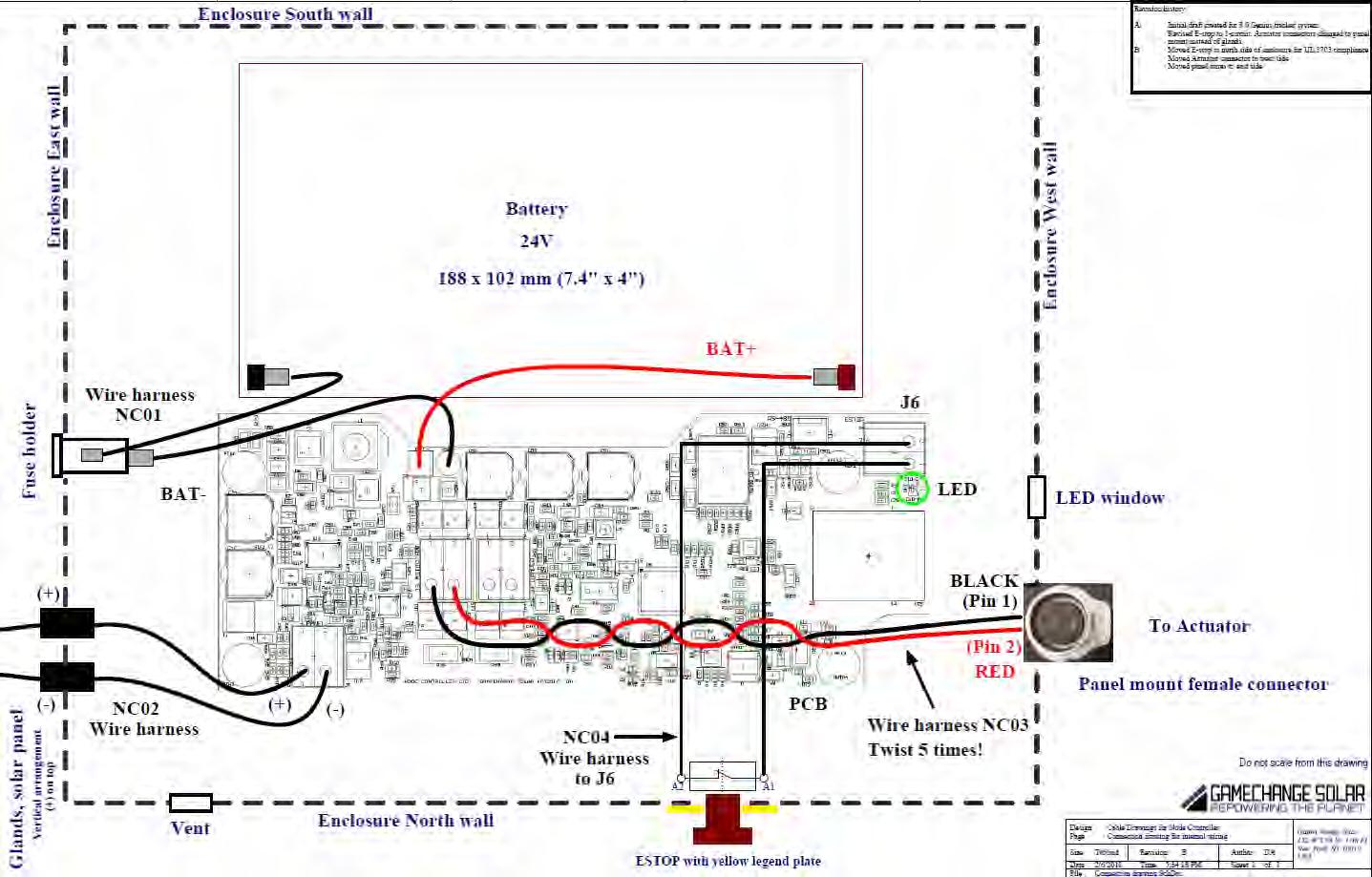

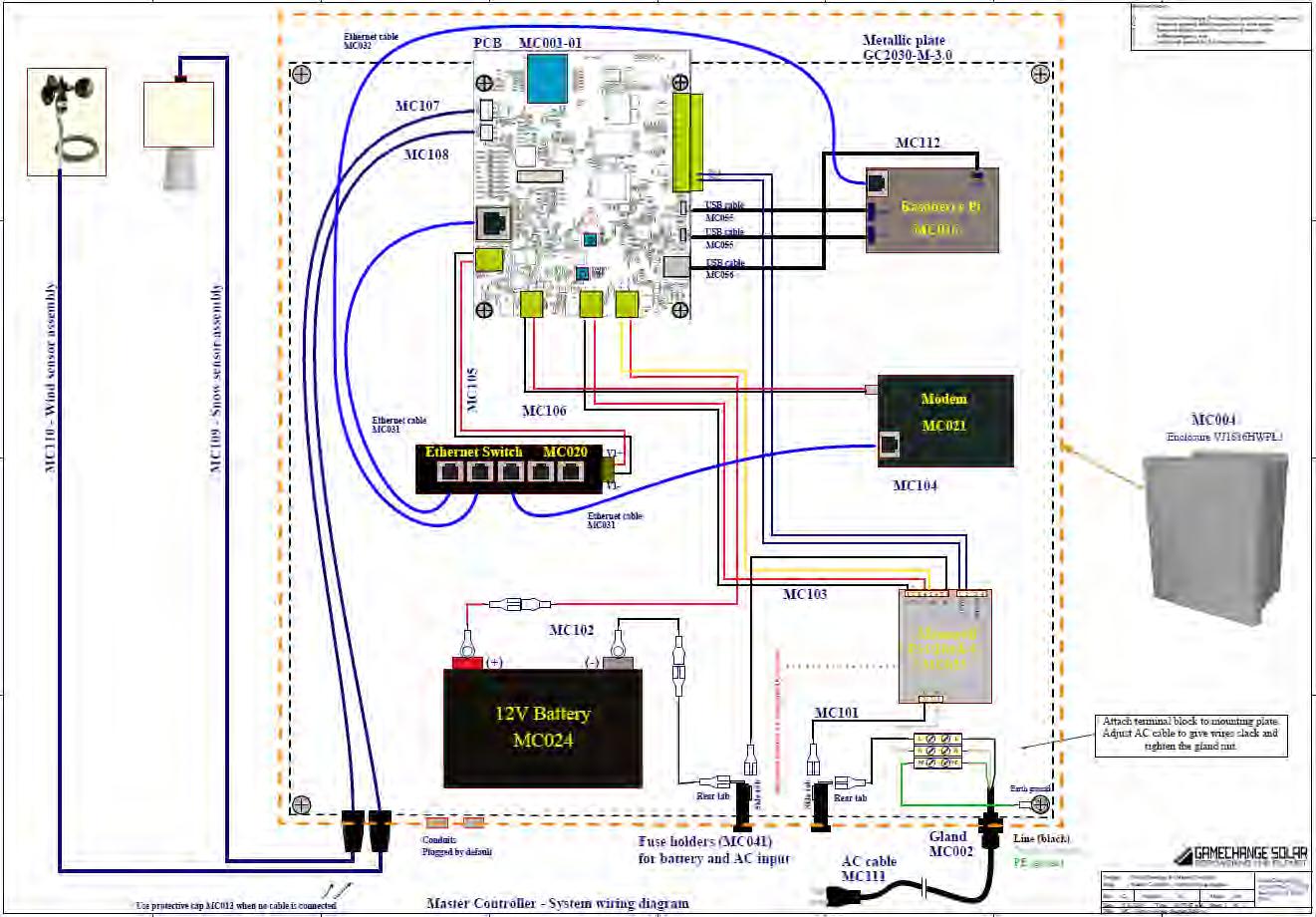

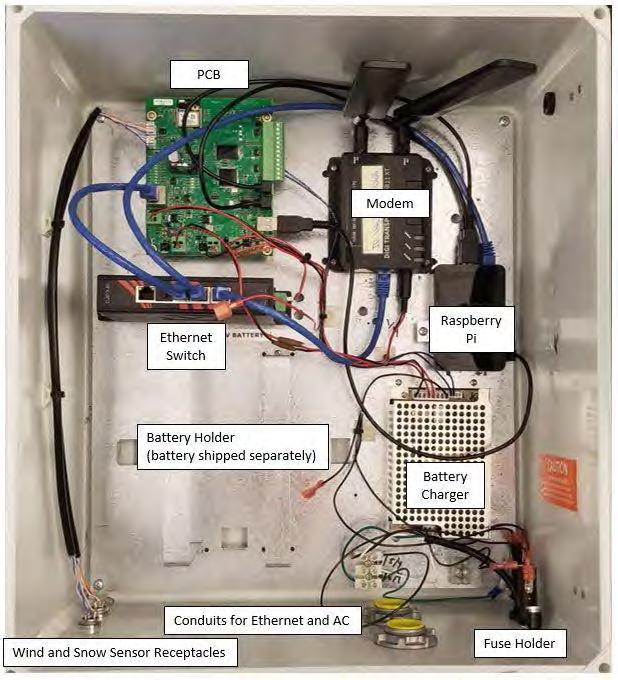

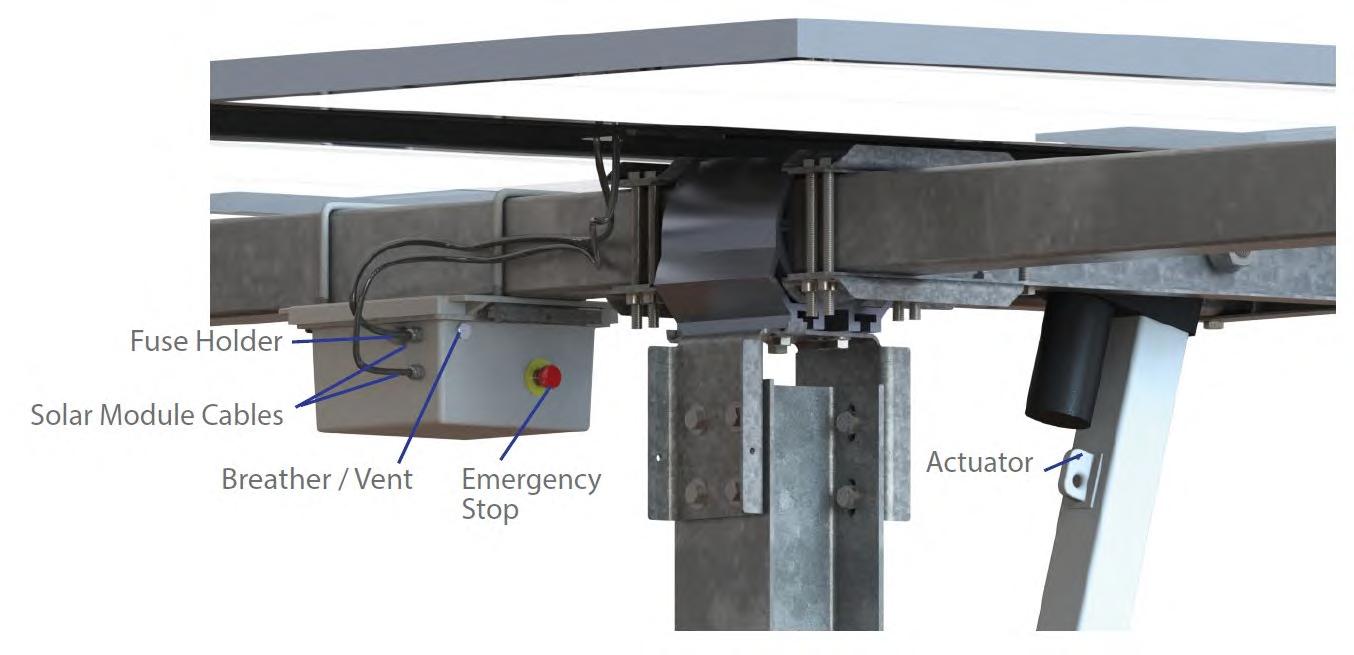

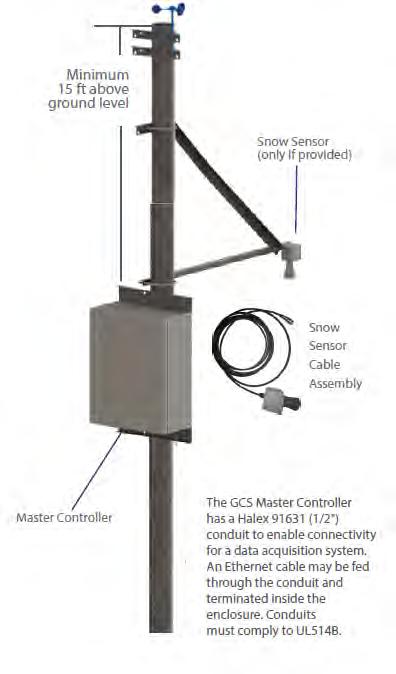

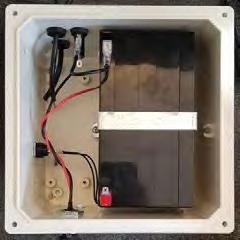

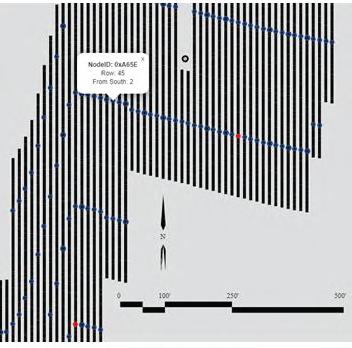

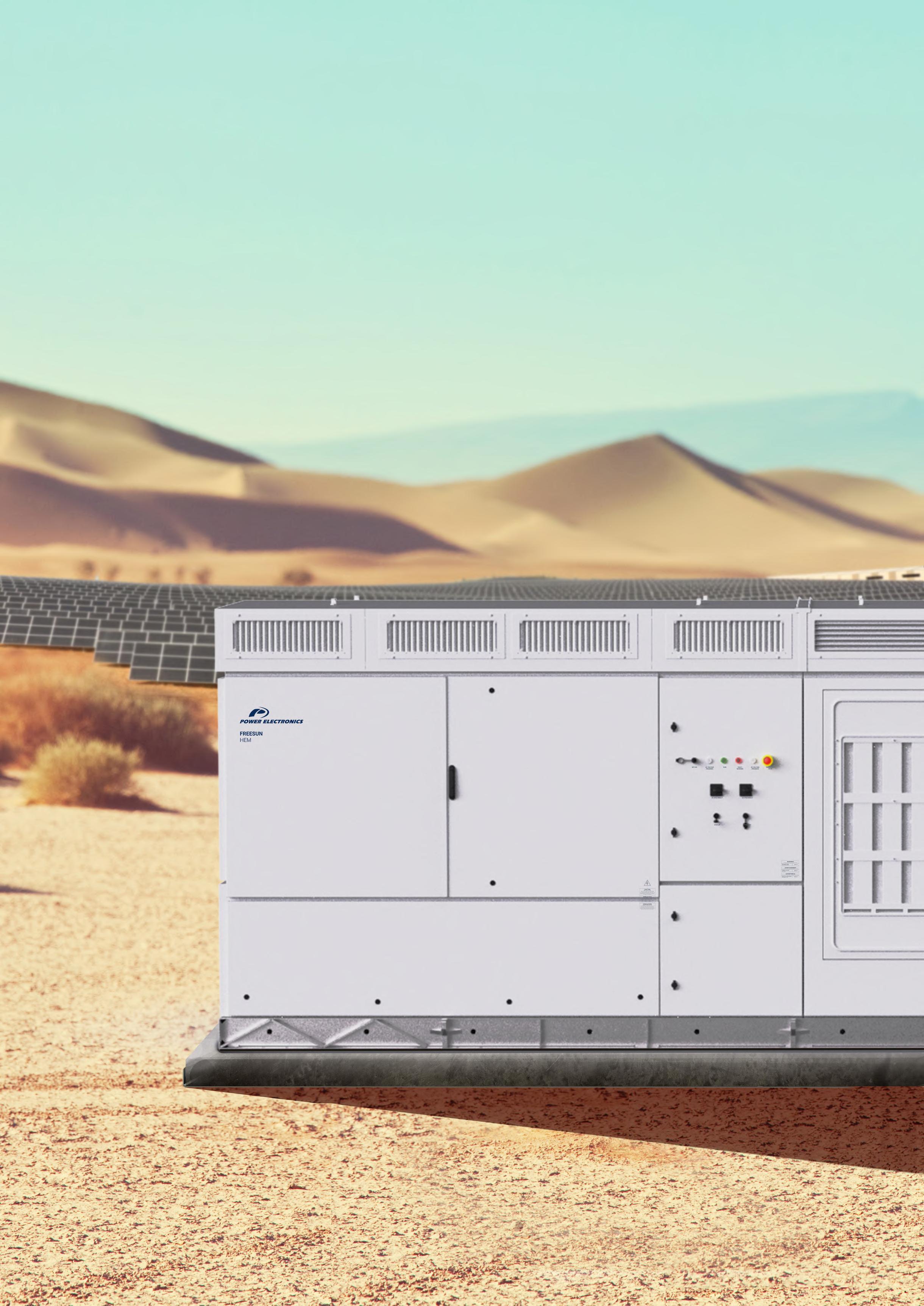

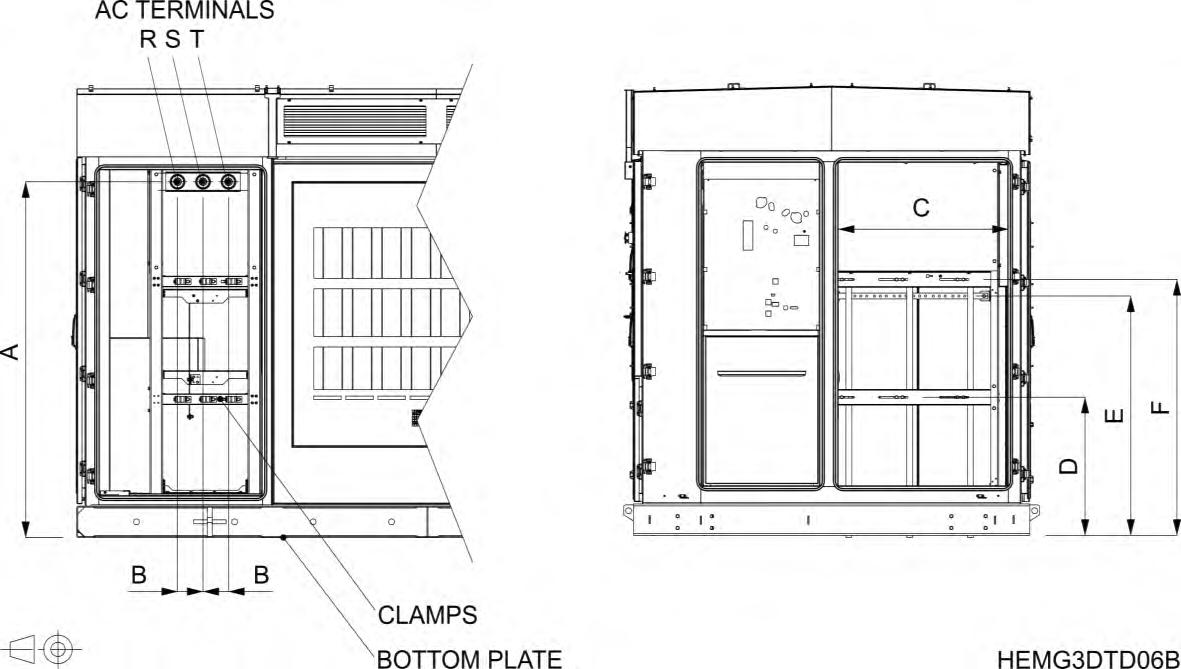

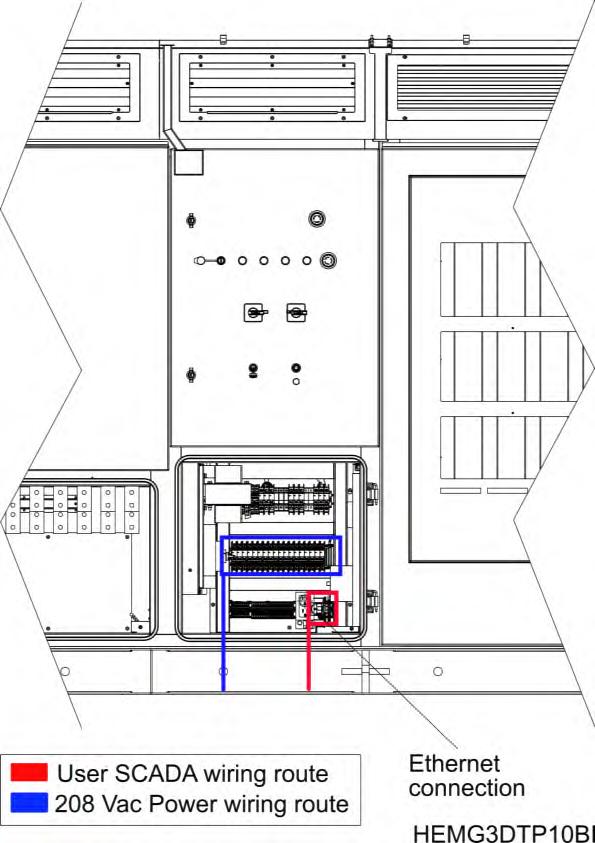

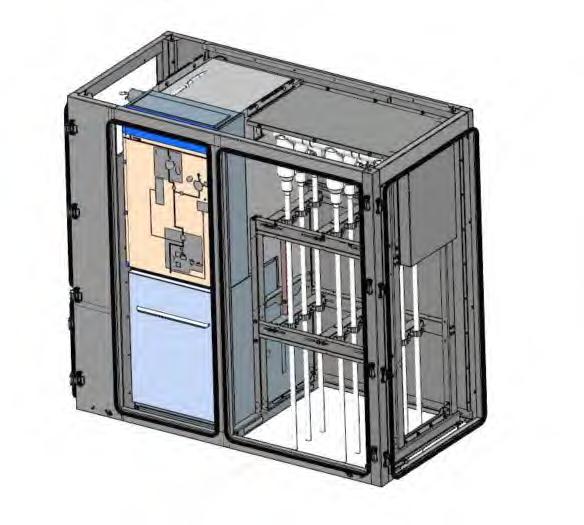

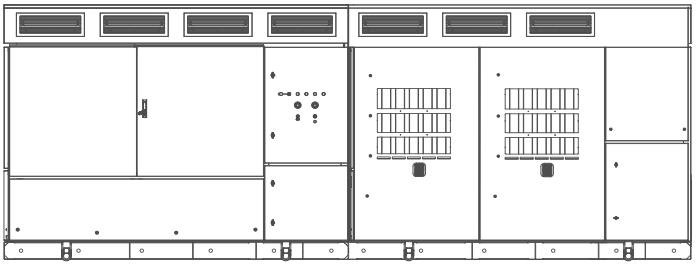

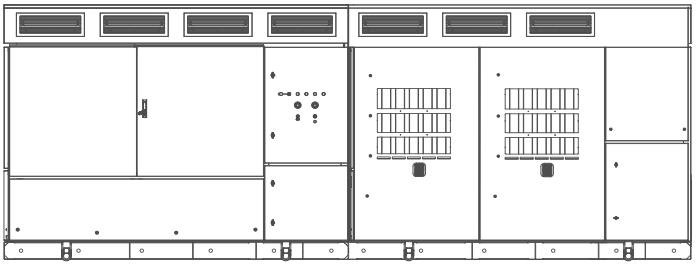

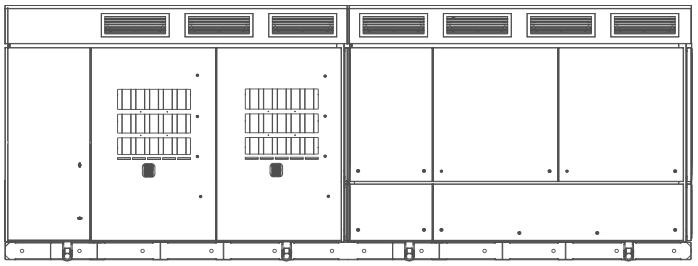

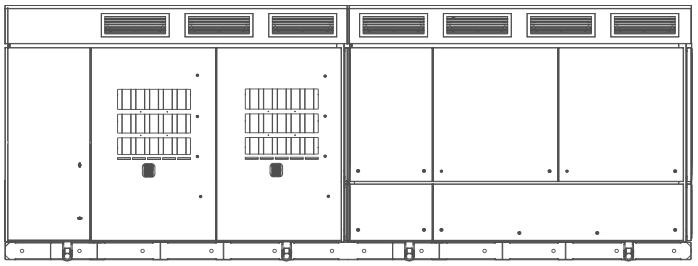

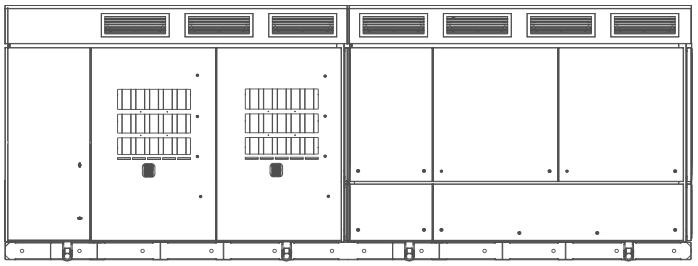

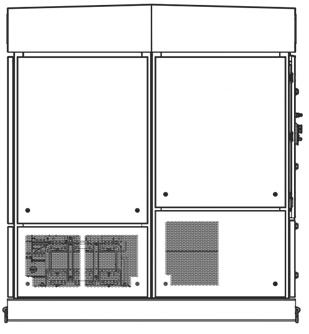

Representative Components

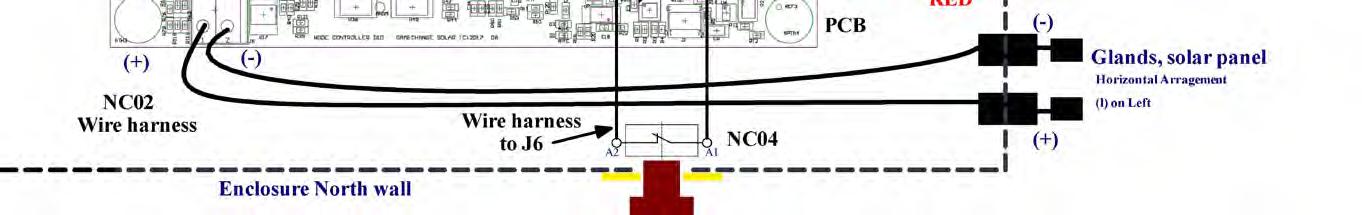

Racking/Trackers

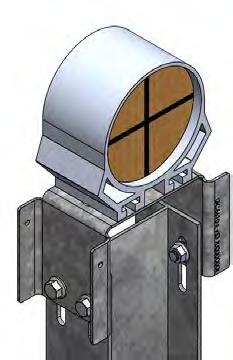

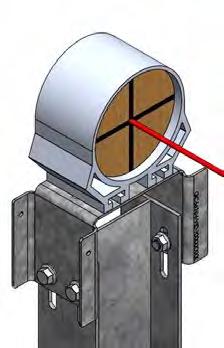

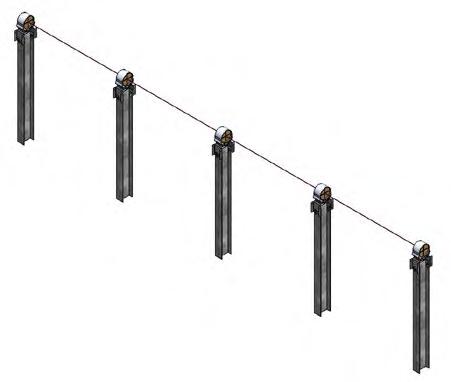

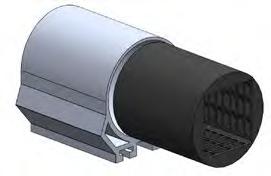

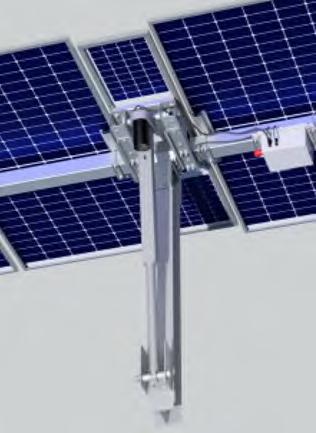

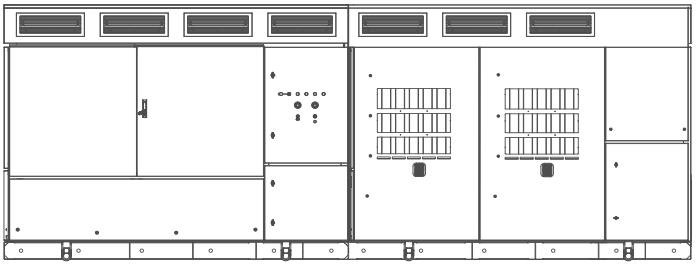

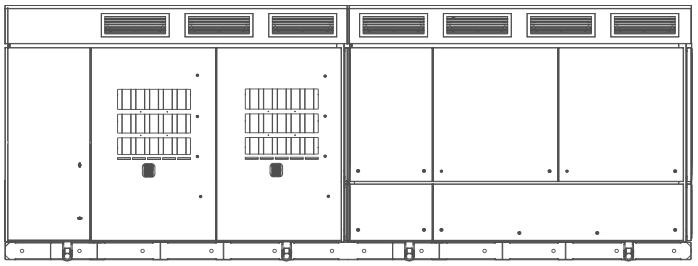

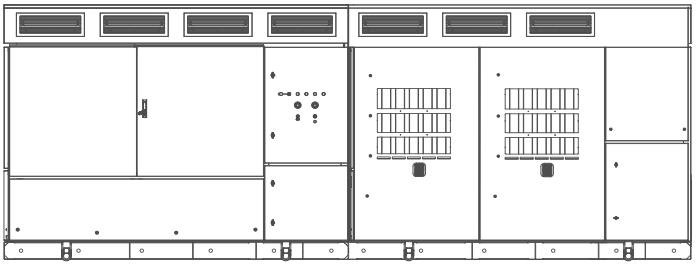

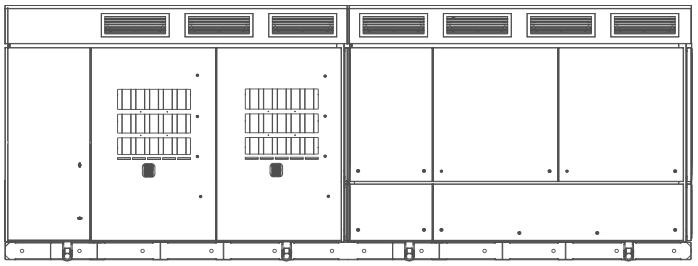

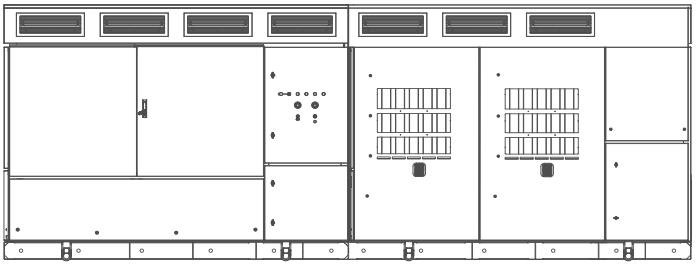

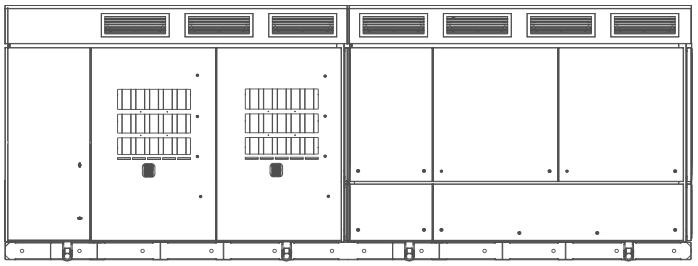

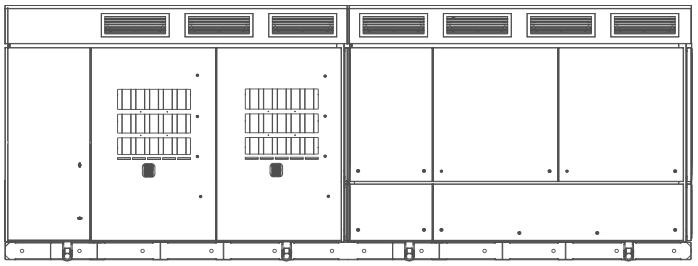

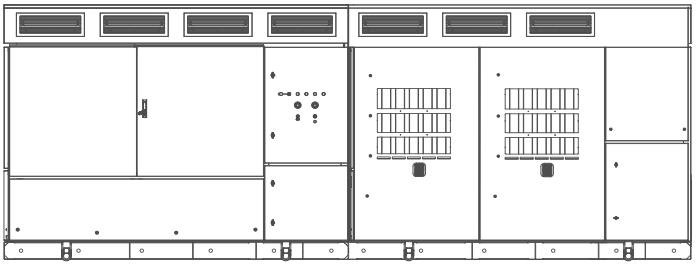

TECHNICAL DATASHEET

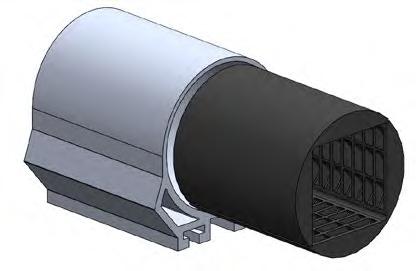

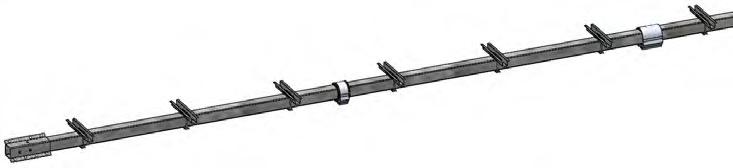

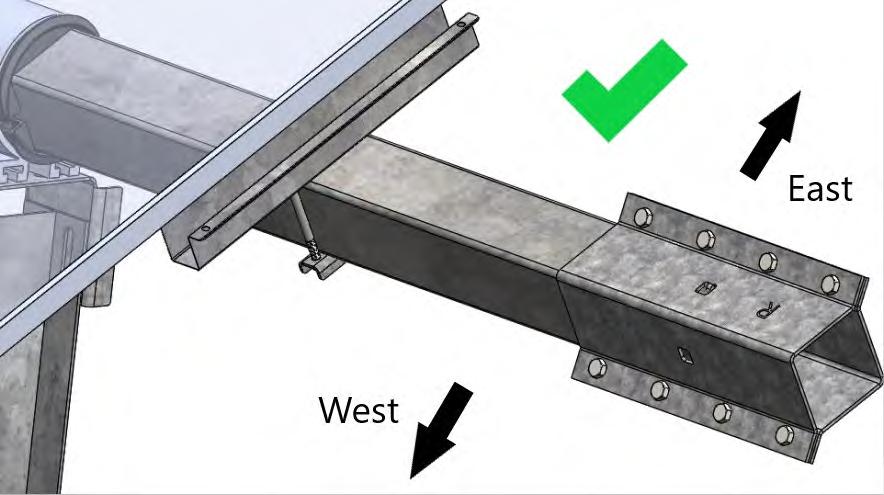

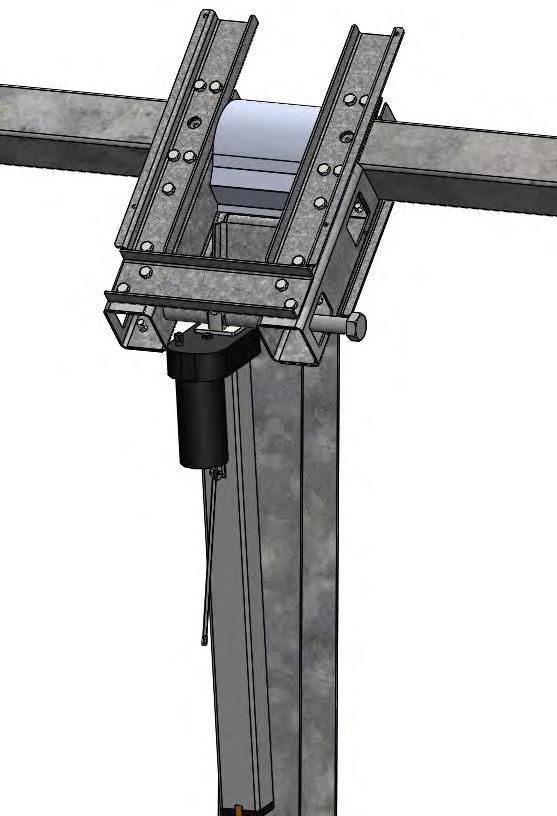

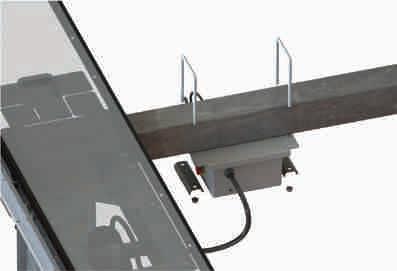

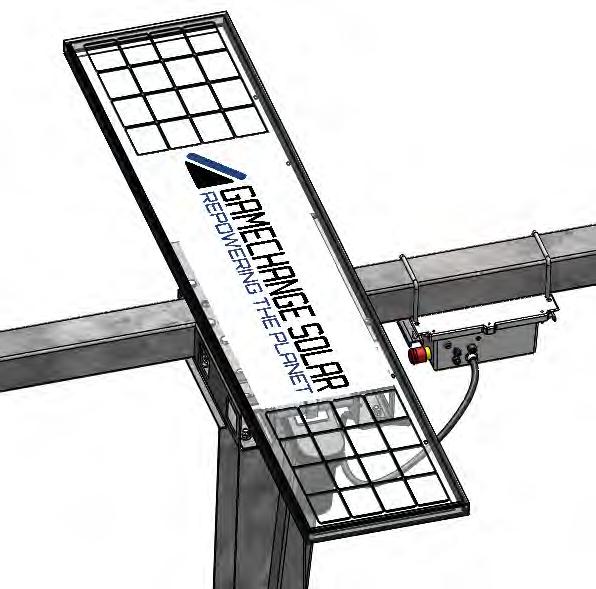

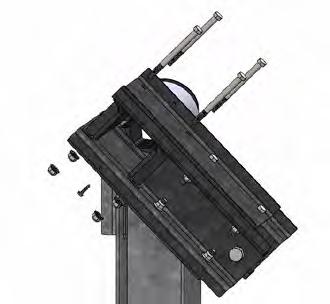

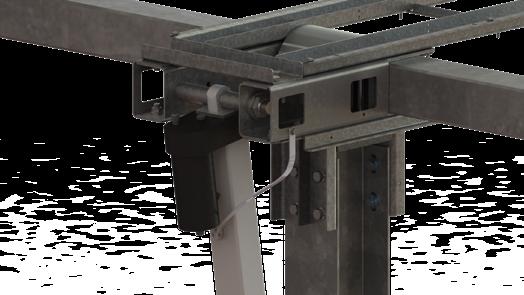

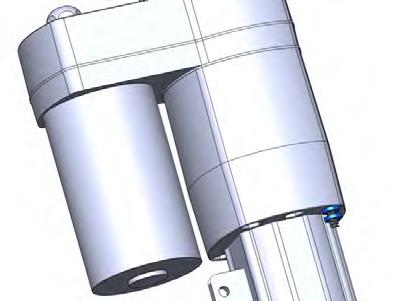

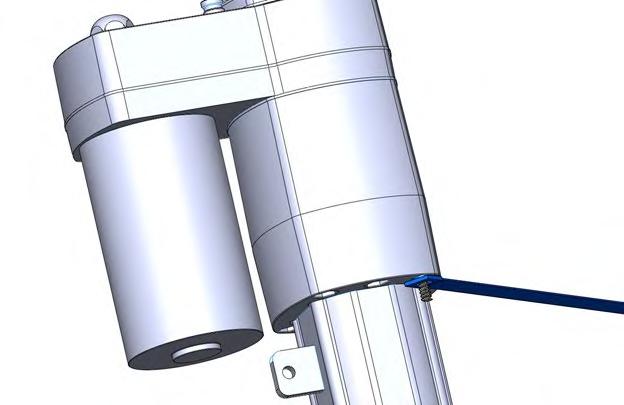

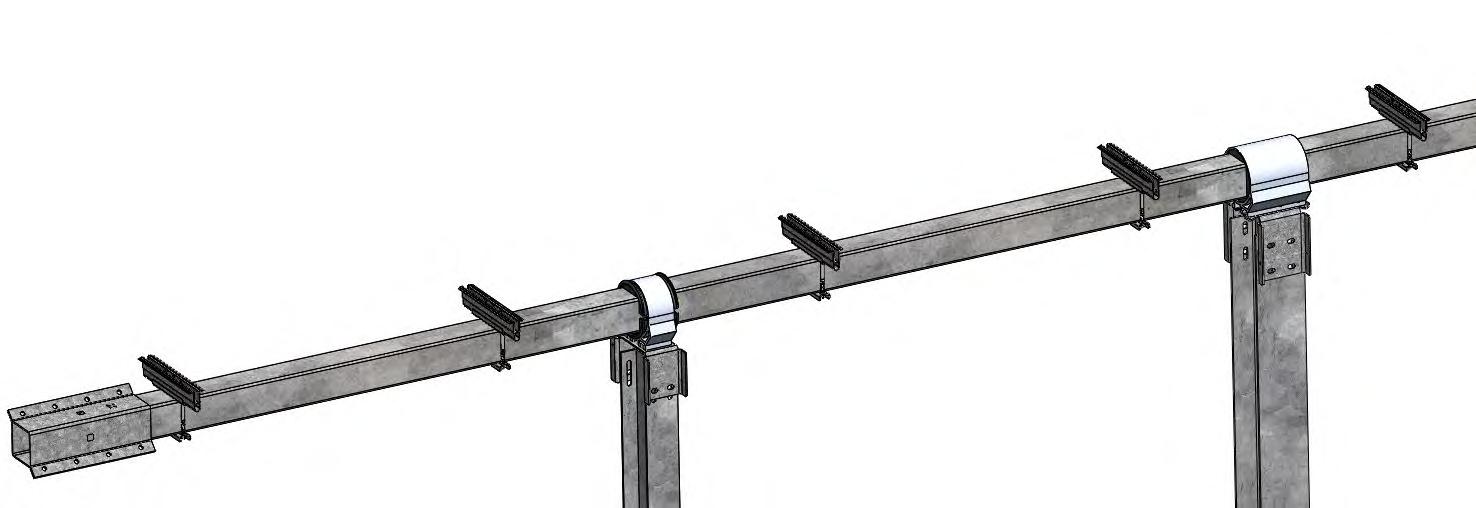

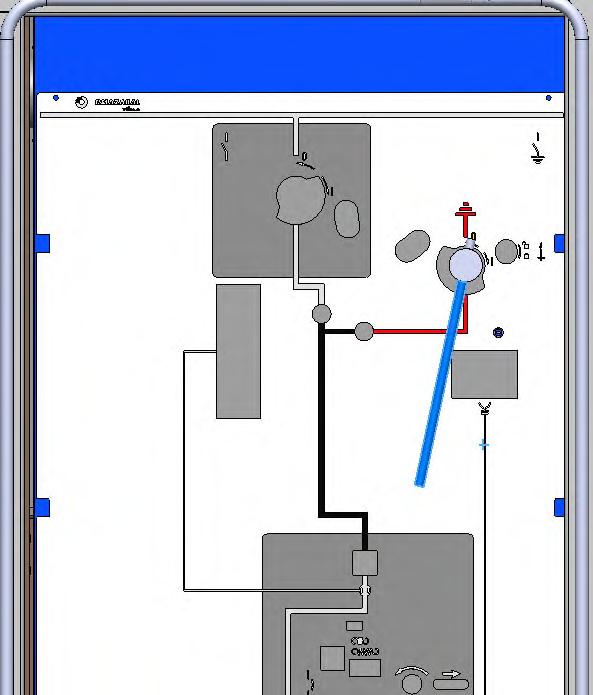

GENIUS TRACKER™ 1P

HIGH POWER PRODUCING & FAST INSTALLING SOLAR TRACKER

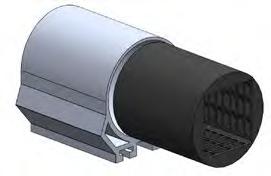

PRE-ASSEMBLED DRIVE SYSTEM

50% FASTER ACTUATOR

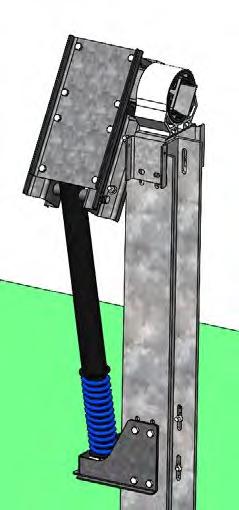

Rugged design for 40-year field life in harsh environmental climate: IP66 rated.

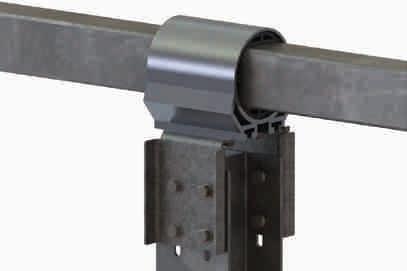

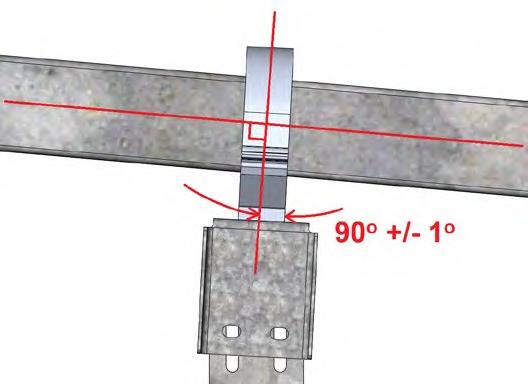

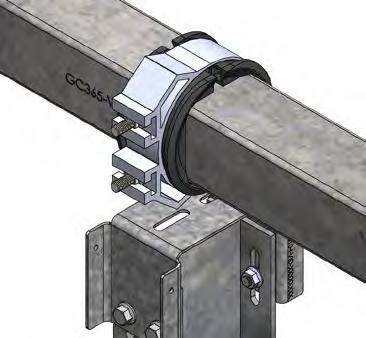

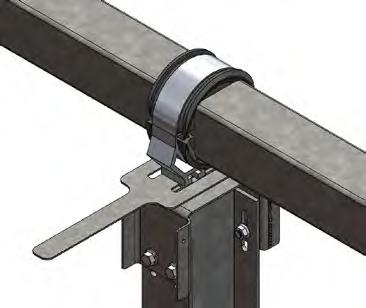

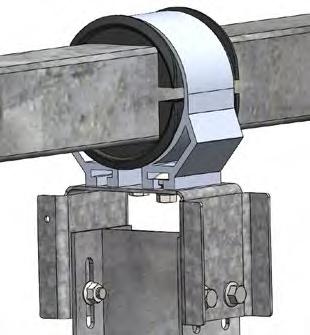

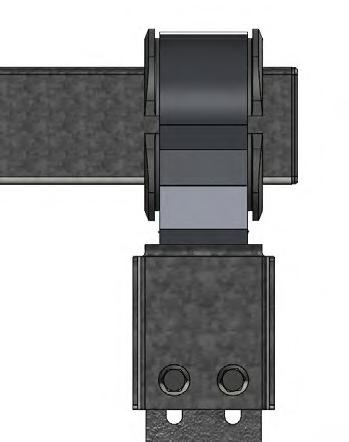

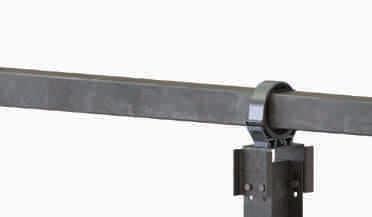

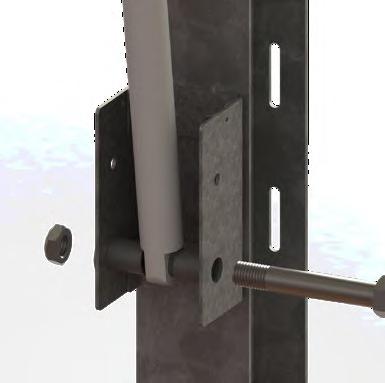

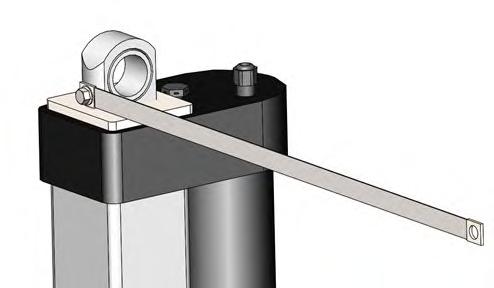

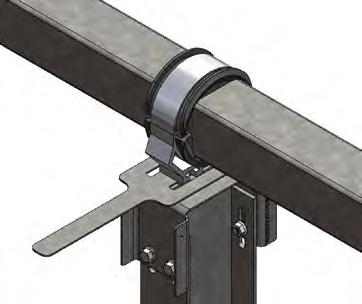

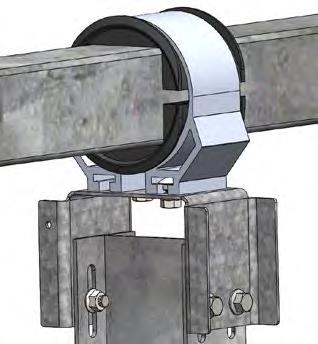

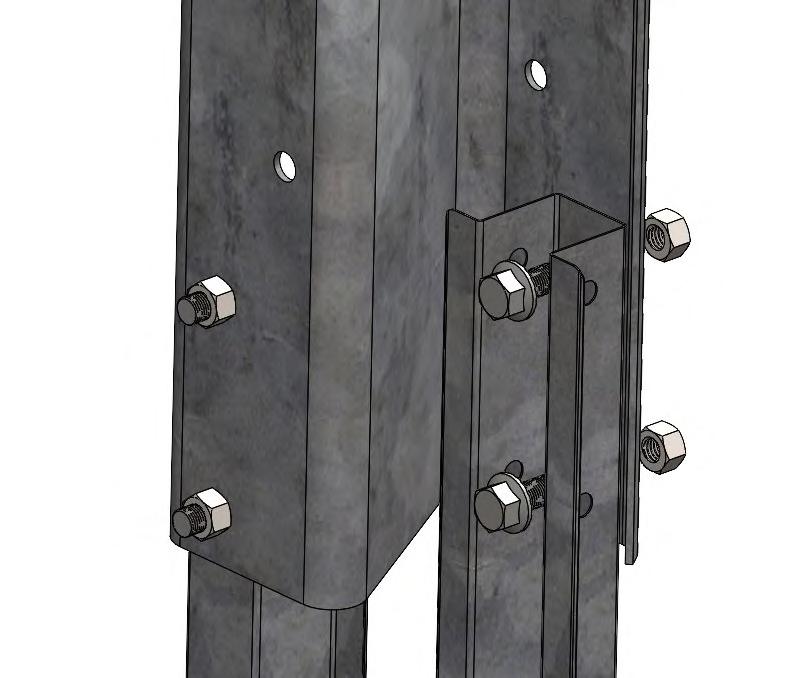

SADDLE BRACKET

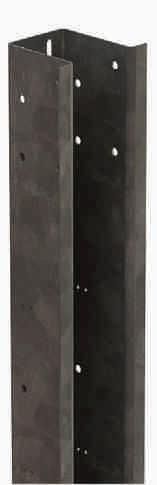

Allows efficient alignment with row tube.

DRIVE POST

Available as either 8 in. [20.3 cm] wide SuperPost™ or Wide Flange.

OWNER BENEFITS

POWER PRODUCTION

No machines or driveline for industry’s fastest install. Global Innovation Leader for Trackers, Fixed Tilt & BOS

INSTALLER BENEFITS

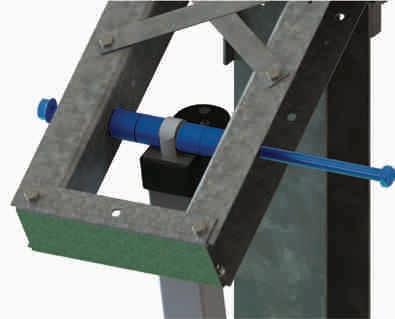

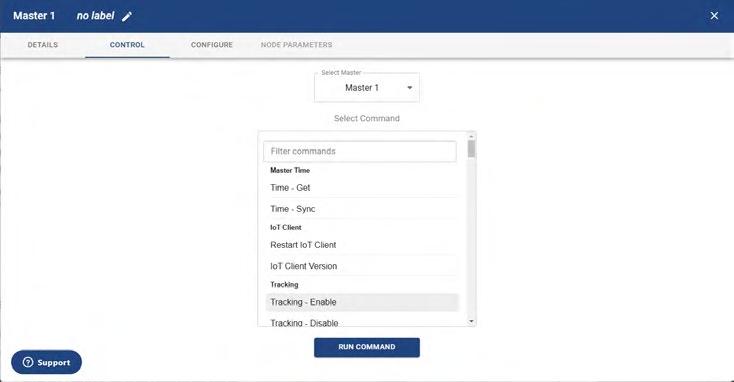

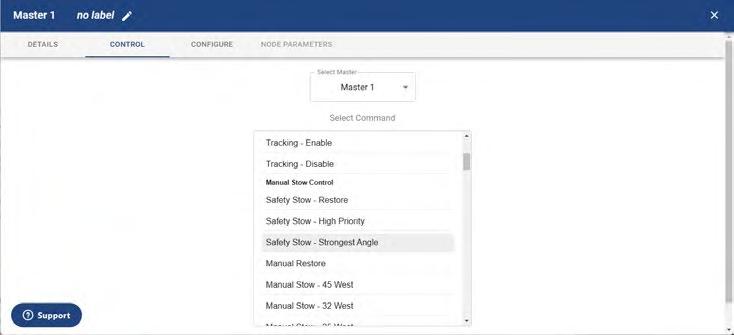

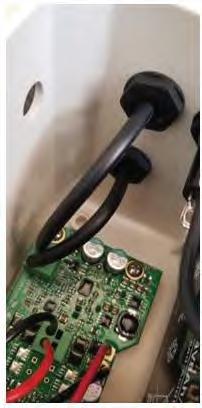

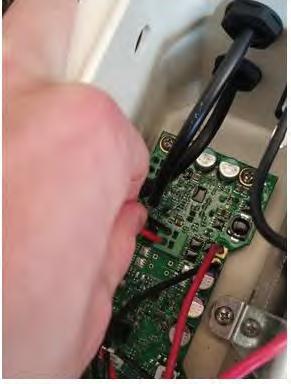

CONTROLLER

24V battery charged by small solar module drives. 24V actuator motor, Zigbee wireless communication.

SELF-LUBRICATING DRIVE BEARING

Self lubricating open form polymer bearing that improves damping.

2% 200% RESULTS IN HIGHER KWH OUTPUT WITH SPEEDCLAMP™ THAN ANY OTHER TRACKER

INSTALL

OVER 29 GW SOLD

OWNER BENEFITS

UP TO 2% MORE POWER PRODUCTION

Results In higher kWh output.

HIGHER MODULE DENSITY

Increased row spacing means more time facing the sun and less time running from the shade. Adds up to 5% more power production than competitors.

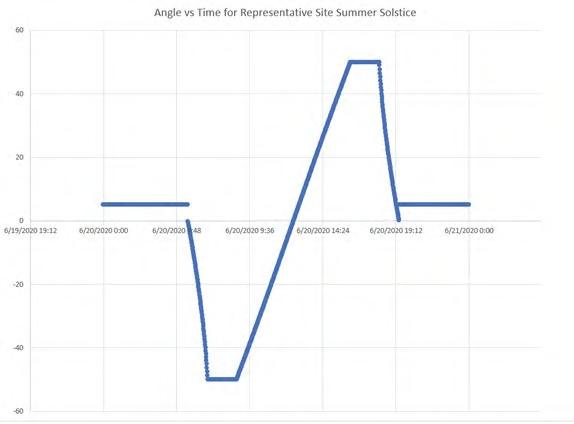

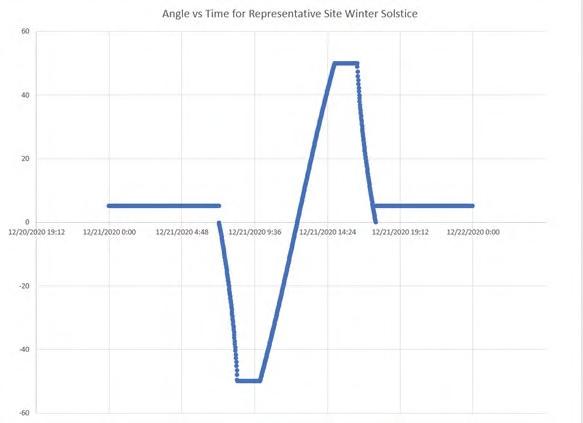

WEATHERSMART™

Proprietary algorithm optimizes tilt angle based on weather data to maximize power production. Adds up to 1.25% additional power production.

LOWEST O&M COST

Lowest grass cutting & module washing cost.

ZERO MAINTENANCE DRIVE SYSTEM

INSTALLER BENEFITS

FASTEST INSTALLING SYSTEM

Advanced design innovations & pre-assembled components.

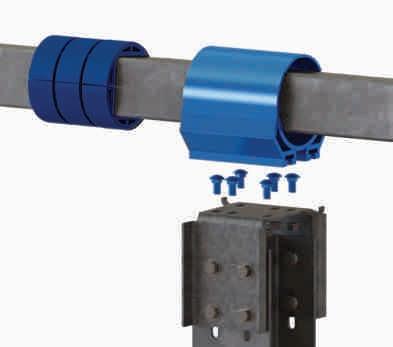

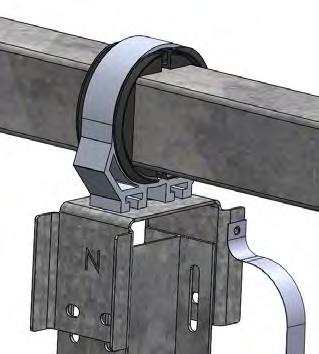

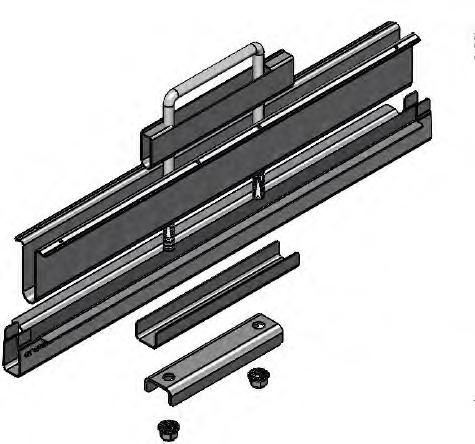

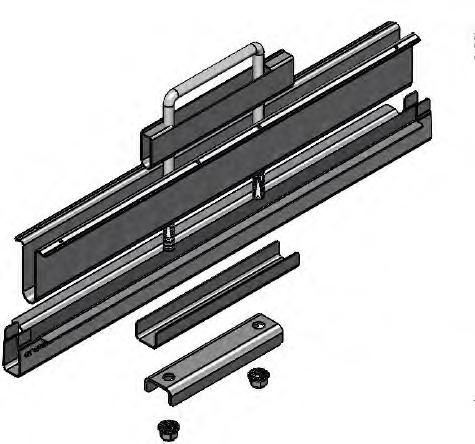

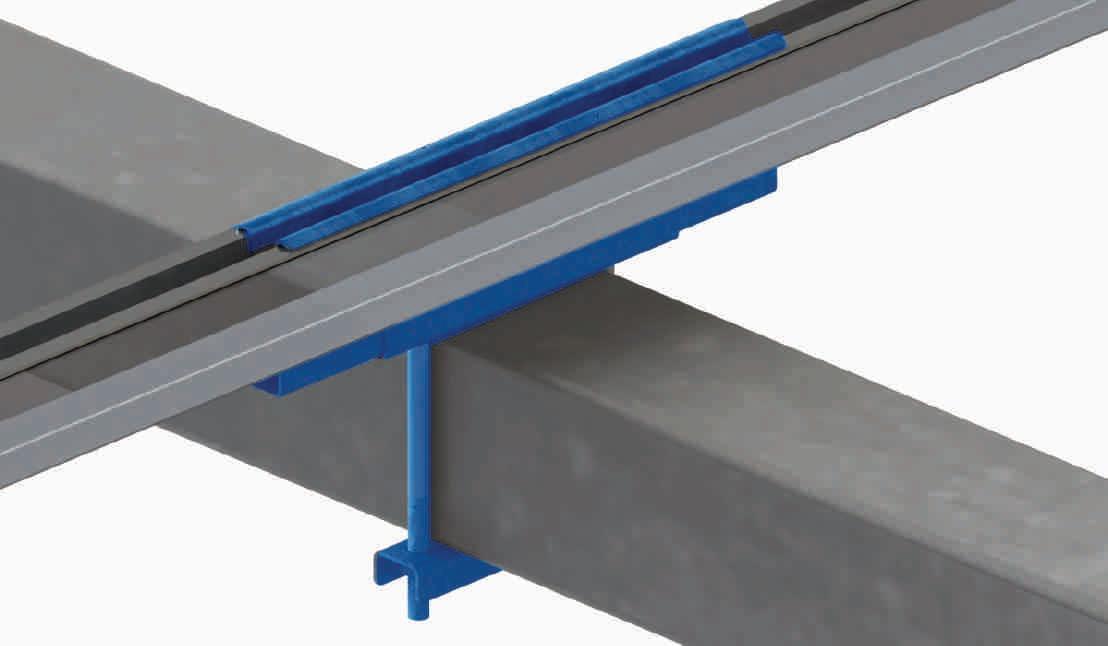

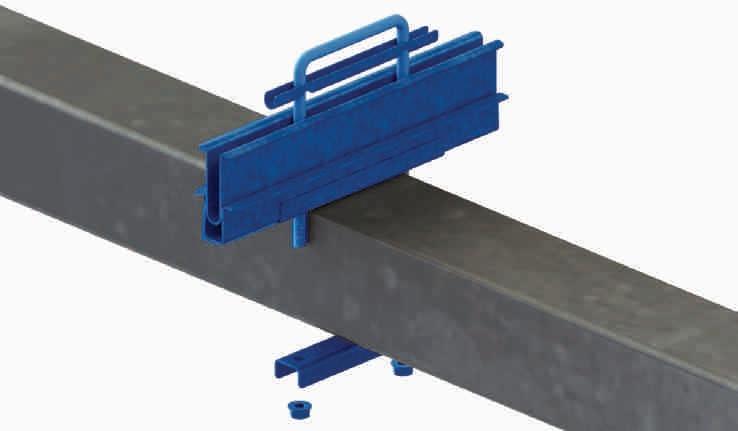

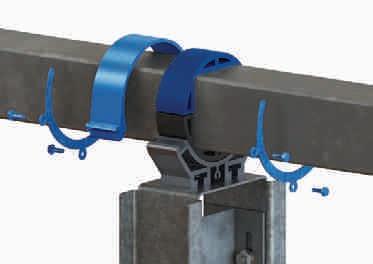

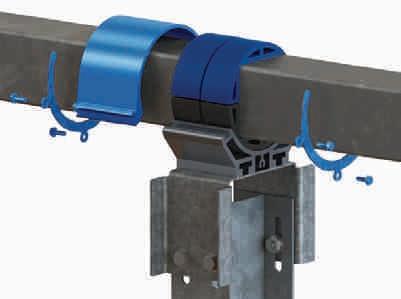

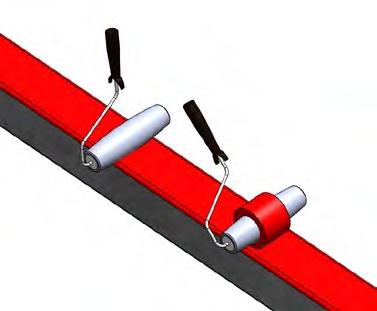

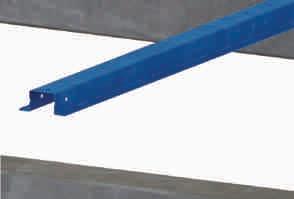

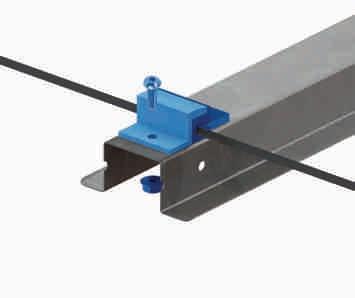

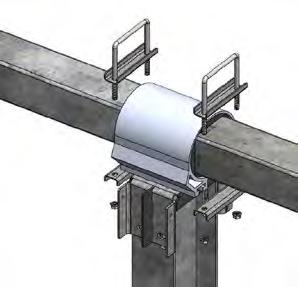

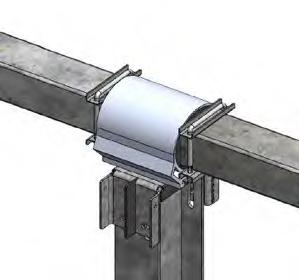

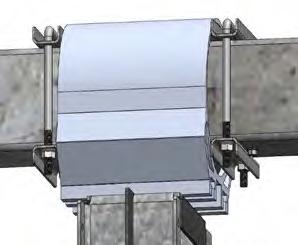

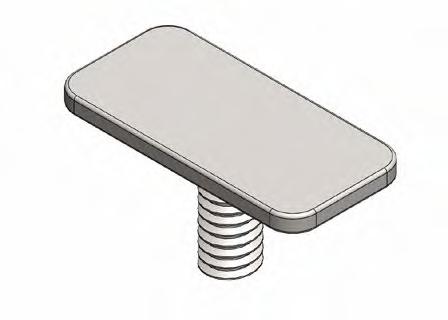

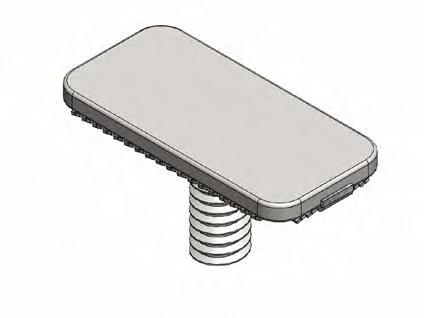

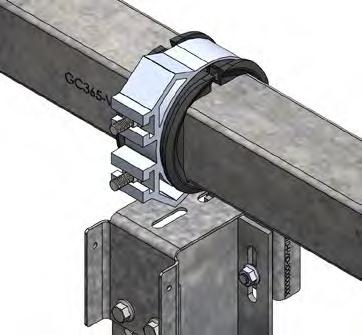

SPEEDCLAMP™

Mounts modules with no mounting hardware, speeds module installation up to 200%.

PRE-ASSEMBLED DRIVE ARM

Can be lifted by one worker. No machine required. 50% faster than most competing systems.

PE STAMPED DRAWINGS

Design loads according to local building codes: ASCE 7, NBC, Eurocode, AS1170, IS 875.

PROPRIETARY INTEGRATED-HARDWARE™

Proprietary hardware allows for faster structure assembly, module mounting, and reduced O&M cost. Oversized Serrated Flange Nyloc Nut and Oversized Flange Star Bolt with integrated star washer eliminates the need for washers and star washers.

GameChange Solar

HEADQUARTERS

230 East Ave, Suite 100

Norwalk, CT, USA

Phone: +1 (203) 769-3900

Fax: +1 (646) 607-2223

gamechangesolar.com media@gamechangesolar.com

GLOBAL LOCATIONS

El Paso, TX Florence, SC Dublin, Ireland

Madrid, Spain

Wuxi, China Bangalore, India

Dubai, UAE

Buenos Aires, Argentina

Johannesburg, South Africa

Newcastle, Australia

SERVICE SUPERCENTERS

Lakeland, FL, USA

Mesa, AZ, USA

Bogotá, Colombia

Modules Modules Supported

Civil Slope Tolerance (N-S)

Most commercially available modules, including frameless crystalline and thin film

7% standard, can go to 15% special order

Slope Tolerance (E-W) 15%

Tracker follows slope (Y/N) Yes

Structural Drive Type

Posts per MW

Design Wind Load

Snow Load

Design

Install

Electrical

O&M

Santiago, Chile Madrid, Spain

RESEARCH & DEVELOPMENT CENTER

Brimfield, MA, USA

DISCLAIMER:

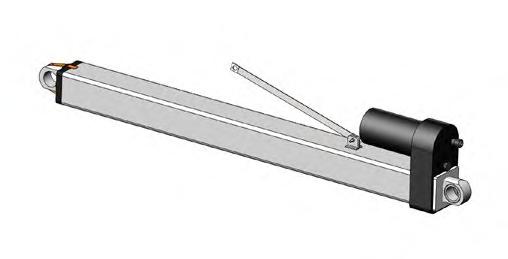

Robust linear actuator stainless steel & aluminum

350-400/MW for 1 up portrait / 2 up landscape or 250-300/MW for 2 up portrait

105 mph [46.9 m/s](Std) / 130 mph [58.1 m/s](Premium 1) / 150 mph [67 m/s](Premium 2)

5 psf [.24 kPa](Std) / 20 psf [.96 kPa](Premium 1) / 40 psf [1.92 kPa](Premium 2) / 60 psf [2.87 kPa](Premium 3)

Tracking Range (Std) 45°, 52°

Tracking Range (Premium) 60°

Post Sections

Post Size (Interior) & (Exterior)

Motor Foundation

Standard Embedment

Flood Plain Allowance

Module Configuration

Length per Table

Module Attachment

Ground Coverage Ratio

Rows per Drive

Powering System

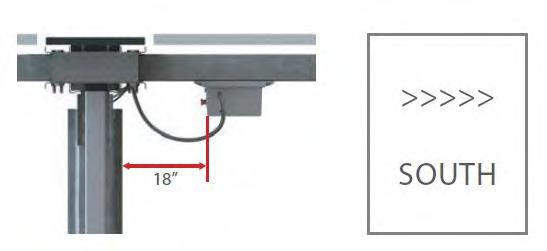

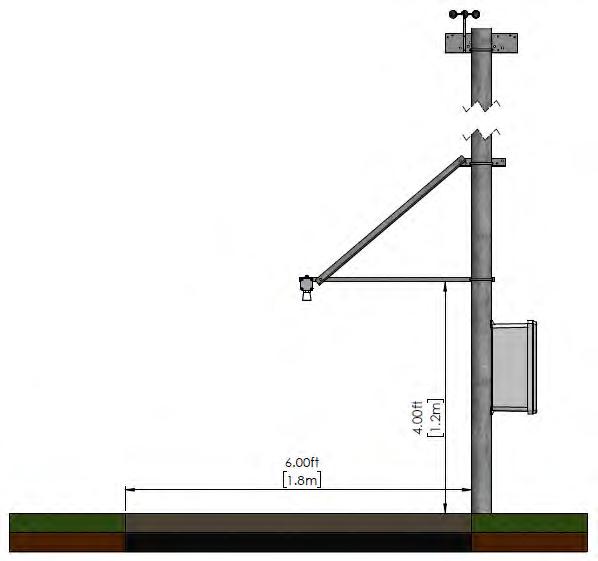

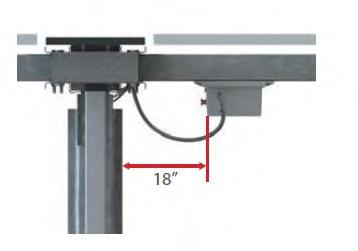

Ground Clearance To Module

G235 [55 μm] galvanized steel (or HDG option) roll formed standard posts, HDG wide flange option also available

6 x 6 in. [15.24 x 15.24 cm] roll form shape or W6x7, W6x9, W6x12 or W6x15 wide flange

6.5 x 8 in. [16.51 x 20.32 cm] roll form hat or W6x15 or larger wide flange

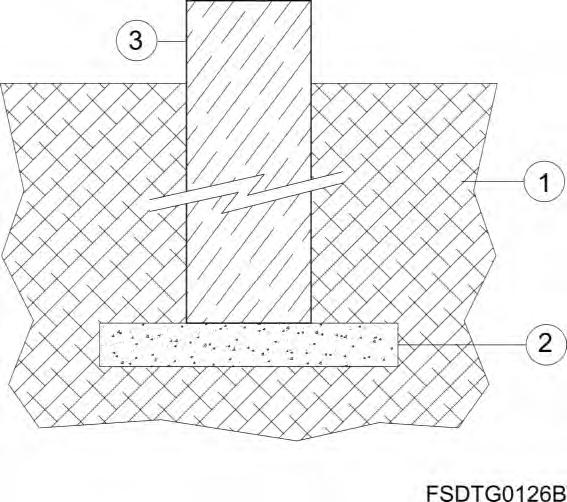

5 - 7 ft. [1.52 - 2.13 m]

Up to 6 ft. [1.83 m]

1 or 2 up in portrait for crystalline & First Solar Series 6™, 2 up landscape or 1 or 2 up in portrait for Bifacial, 3 to 4 up landscape for First Solar Series 4™

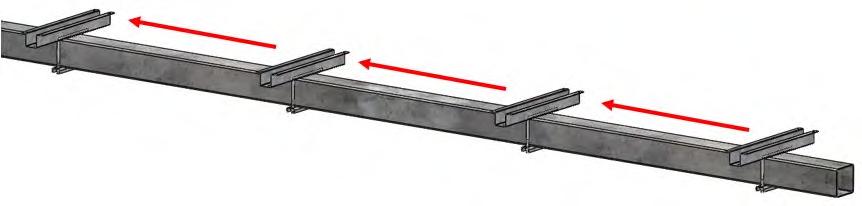

Up to 500 ft. [150 m]

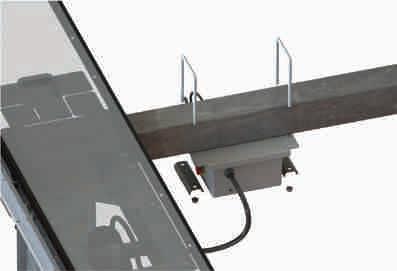

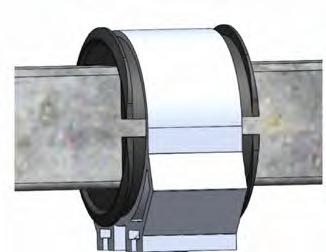

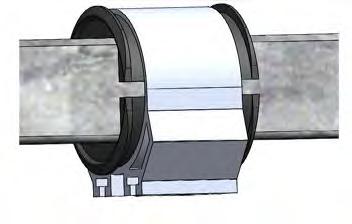

SpeedClamp™ or bolts available for bottom mount frame modules or clamps for glass on glass modules

0.25 to 0.65

1 drive per tracker(table), distributed drive system

Onboard solar module with battery

18 - 48 in. [45.7 - 121.9 cm] typical

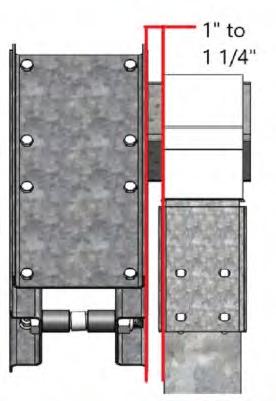

Min / Max Ground to Top of Post 3'-8" [1.12 m] typical + 9 in. [22.86 cm] min. adjustment range

Backtracking / Anti-shading

Temperature Range

Electromagnetic Interference

Specialty Tools Required

Max Offload for Deliveries

Tracking Method

String Design

Cable Supports

Linear Actuator Motor

Parasitic Loss

Controller Box

Control System

# of Motors

1000V System or 1500V System

Grounding Method

UL Compliance

Ingress Protection

# Anemometers

Monitoring System

Snow & Flood Sensors

Backup Power

Warranty

Shipping Max load

Shipping Containers or Flatbeds

Yes, although can be turned off as requested (i.e. for FSLR modules)

-20° C (-40° C also available) + 48° C

Compliant with FCC guidelines/ Applicable sections EN 61000

No

As per customer requirement

Time and location based algorithm

Compatible with any string size

Hole punching per customer requirement for nominal cost

24V DC UL Listed

0 amps

Zigbee wireless communications, 24V solar module and battery

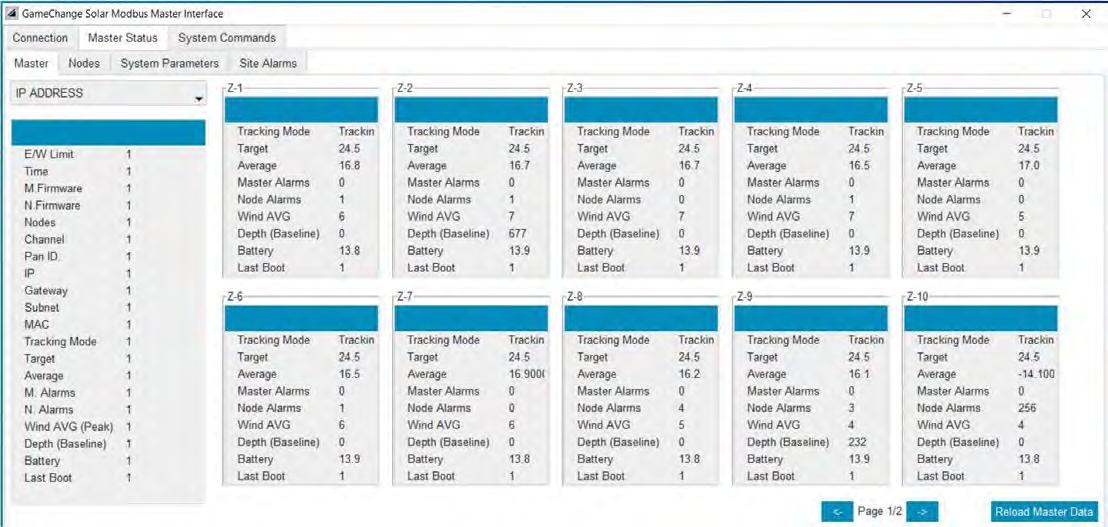

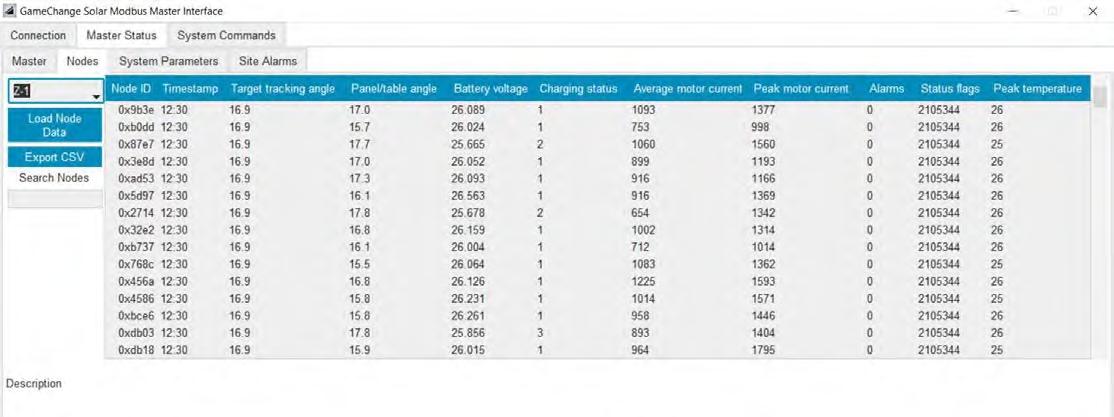

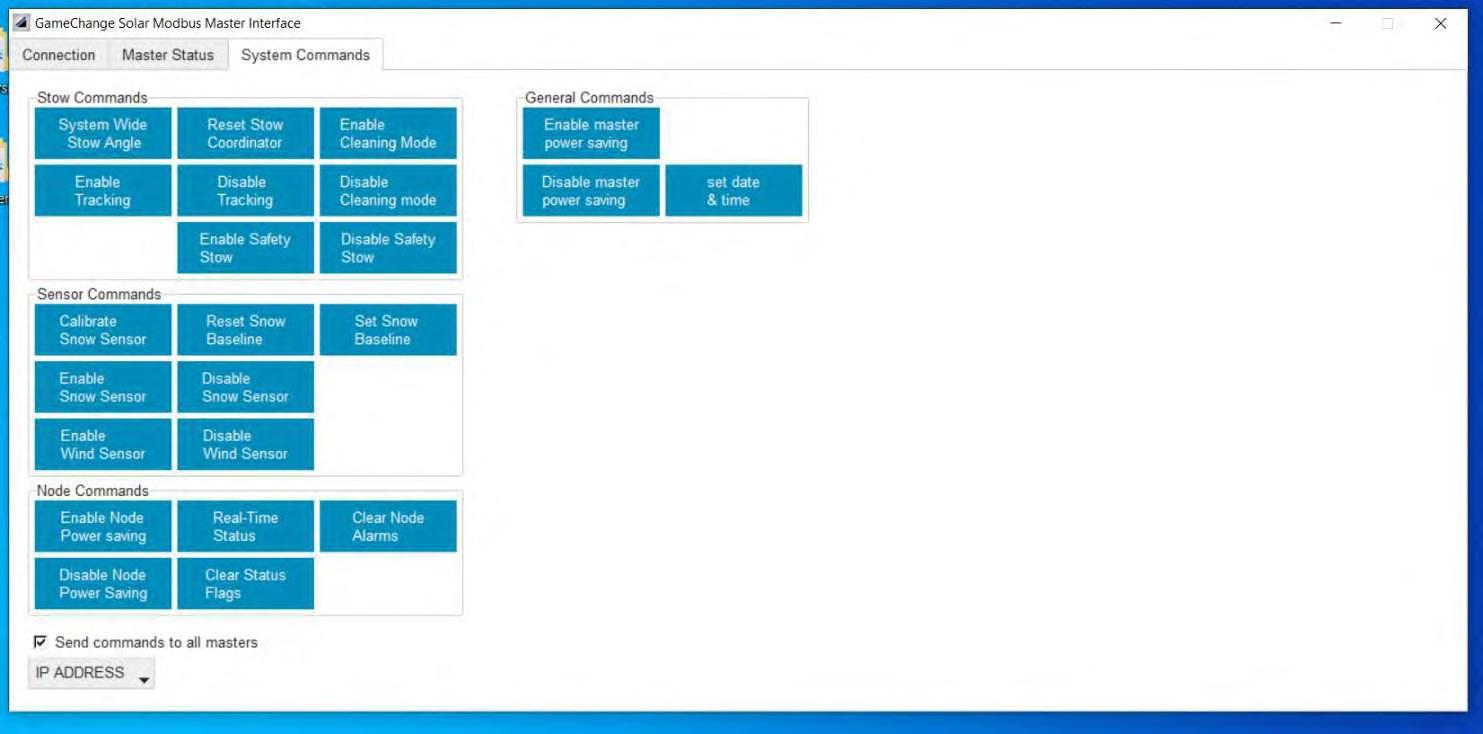

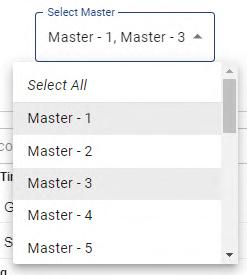

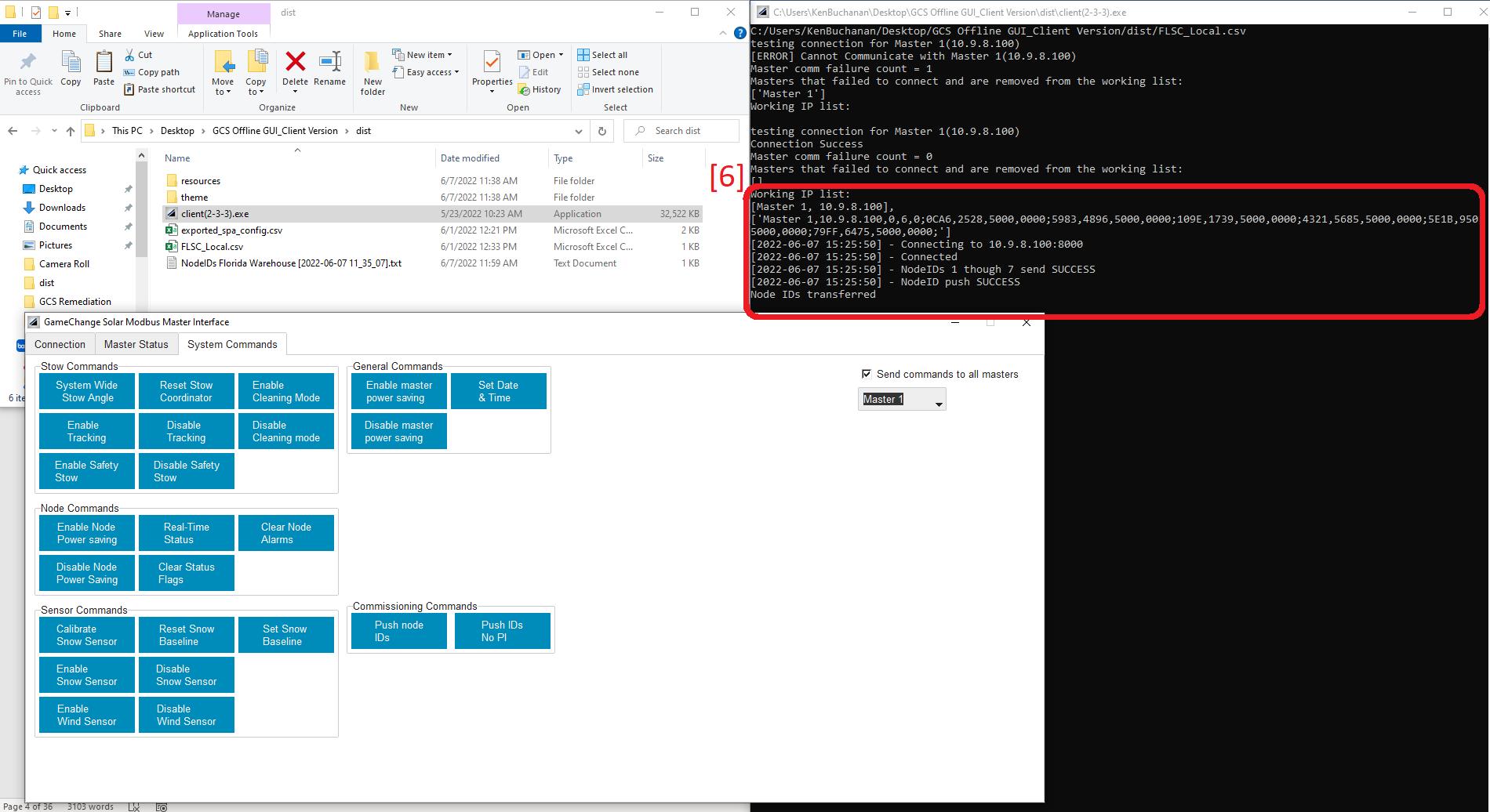

Master to Node: Zigbee wireless communications

Master to SCADA/DAS: Modbus TCP communications

20 to 52 / MW depending on module wattage and loading conditions

(35 for typical conditions)

Both

Tracker structure is part of grounding path per UL 2703

UL 2703 / UL 3703

IP66 Actuator [NEMA 4 equivalent]

1 per 6 MW - 10 MW typical

Web portal interface available

Compatible with all standard third party monitoring vendors

Move modules to optimum location for weather events

Solar module and battery providing integrated backup - 3 days

5 year drive & control, 10 year structural standard, 10 /20 also available

International - 18.5 to 22.5 metric tons per container

USA - 45,000 lbs. [20,411 kg] per truckload, 5,000 lbs. [2,267 kg] maximum

bundle size, 2,900 lbs. [1315.4 kg] or other maximum as requested by customers

Flat beds for structure, dry vans for hardware

# Trucks or Containers per MWdc 4 typical for trucks, 5 typical for containers

Commissioning Backfeed required?

No, generator for power as alternative

GENIUS TRACKER

Norwalk, CT, USA

Phone: +1 (203) 769-3900

Fax: +1 (646) 607-2223

gamechangesolar.com media gamechangesolar.com

Dublin, Ireland

Madrid, Spain

Wuxi, China

Bangalore, India

Brimfield, MA, USA

Dubai, UAE

Buenos Aires, Argentina

Johannesburg, South Africa

Newcastle, Australia

Lakeland, FL, USA

Mesa, AZ, USA

Santiago, Chile

Madrid, Spain

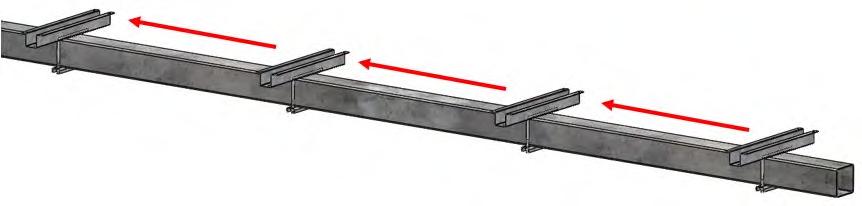

I GENERAL

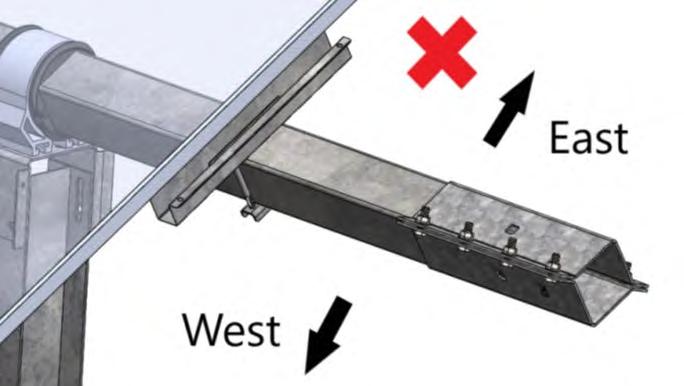

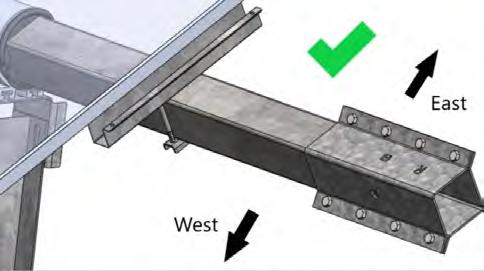

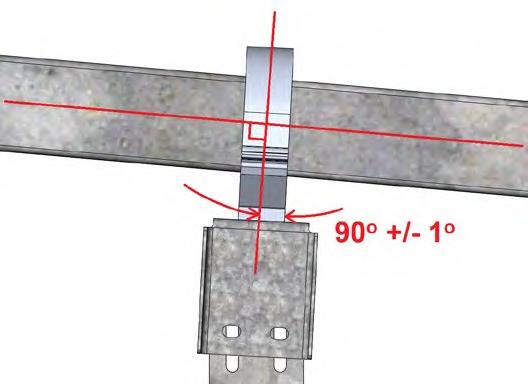

Please carefully follow this manual to learn how to correctly install the GameChange Solar Genius Tracker™ system. The Genius Tracker is engineered and tested to withstand wind and snow loads to specification when installed properly. Failure to precisely follow the install manual may decrease the performance of the Genius Tracker and will void the warranty. It is highly recommended for installation crews including EPC, installer, foundation installer and surveyor to be trained by GameChange Solar personnel, including a complete page turn review of the install manual, construction drawings, and building the golden row.

This is the generic manual and it includes all components utilized in all variations of the Genius Tracker™. Please refer to the Project Construction Drawings and bill of materials for the specific components for your system as some components may not be required. This manual contains dimensions in both Imperial and Metric Units. Should a discrepancy exist, the Imperial Units govern.

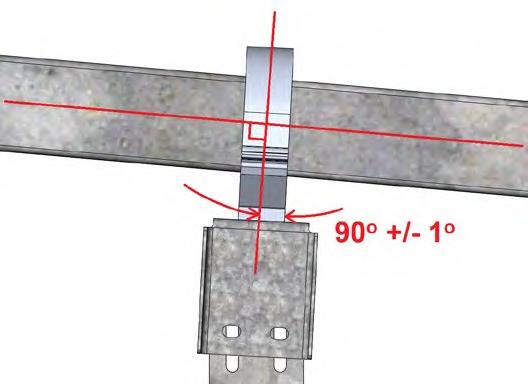

The Genius Tracker has a significant capacity to function on sloping ground. However, the Genius Tracker shall not be installed on ground exceeding maximum north-south slopes of 7% (unless specific approval has been obtained from GameChange in which case slopes up to 15% may be permissible) or east-west slope of 15%.

I CRITICAL INFORMATION INDICATOR: This icon indicates critical and important information that MUST be followed for proper installation. Disregarding it may lead to serious injury and/or irreparable damage to equipment, tools, or components, and will compromise the GameChange warranty. Information indicated with this icon must be followed to meet quality requirements.

H CAUTION - Risk of Electric Shock

\ CAUTION - HOT SURFACES: To reduce the risk of burns – Do not touch.

! IMPORTANT NOTE: This icon indicates information that is useful and important for efficient installation of the system or system O&M.

! BEST PRACTICE INDICATOR: This icon indicates information that facilitates the assembly of tracker components.

II SITE SELECTION

• The Genius Tracker system is intended to be installed in an area where public access is restricted by a fence, secured location, etc.

• Proper preparation of surface must be ensured for a well-performing system to be installed.

• Grading of the ground on the installation area is the responsibility of the customer and should be completed properly to enable the slope tolerance for the Genius Tracker system.

General guidelines include:

• Choose a clear area free of shading.

• Suggested minimum ten (10) foot [3.050 m] border surrounding array to edge of property.

III SAFETY PRECAUTIONS AND RESPONSIBILITY OF INSTALLER

I WARNING ELECTRIC SHOCK HAZARD. THE DC CONDUCTORS OF THIS PHOTOVOLTAIC SYSTEM ARE UNGROUNDED AND MAY BE ENERGIZED.

H CAUTION – RISK OF ELECTRIC SHOCK: When the photovoltaic array is exposed to light, it supplies a dc voltage to this equipment. Cover PV Module with opaque material or take other appropriate safety measures before connecting or disconnecting PV Circuits and Power Boxes.

Responsibilities of Installers:

• Follow all instructions in this Install Manual and Project Construction Drawings.

• Installer must provide permanent AC power to Master Controller for commissioning and system operation.

• Installer must provide hardwired Ethernet or fiber optic network connections to all Master Controllers. Depending on the installation type, the network connections may connect to plant SCADA, the GeniusHub onsite operator console, or the internet.

• Use qualified personnel only.

• Use only GameChange parts. Using other parts to complete the installation as substitutes may void the warranty.

• Verify the ground can support the load resulting from the Genius Tracker system.

• Follow all safety procedures as outlined in this Install Manual, both for mechanical and electrical aspects of the solar PV array installation.

• Follow all safety instructions that are required by relevant local, regional and national organizations.

• Store materials in optimal manner to protect components. See Materials, Storage and Warranty section below for more information.

I General Safety Precautions:

• Plan for safe practice during any installation activity with respect to hazards from tripping, falling, lifting, repetitive stress, and any overhead or electrical hazards. Refer to OSHA safety guidelines.

• Metal components often have sharp edges. Handle carefully. Wearing gloves and protective sleeves is good practice.

• This document is not prescriptive regarding safety and does not purport to address all the safety concerns that may arise with its use. Contractors should become familiar with all applicable safety, health and regulatory requirements before beginning work.

H Electrical safety notice – The Genius Tracker™ is a mechanical system with a low voltage power and control system. Mechanical installers and electricians shall coordinate in order to ensure that all personnel are aware of electrical hazards that may occur once modules have been placed on the racking structure. Grounding and Wiring methods shall be done in accordance with NEC ANSI/ NFPA 70 or equivalent local electrical code.

I Field modifications and workarounds – Unauthorized field modification and workarounds of GameChange components or assemblies may affect GameChange warranty coverage. Provide marked up drawings for GameChange’s review, comment and written approval prior to attempting any field modifications. Installers laying out or installing arrays may encounter undocumented or unexpected obstacles requiring a workaround. Since PV arrays are intended to be primarily regular and repeating structures, workarounds should be brought to the attention of GameChange personnel prior to being done. If approved by GameChange in writing, they should be noted on working drawings or in the RFI log.

I All local, regional and national safety requirements should be followed when installing the Genius Tracker system. All equipment/ tools should be properly maintained, calibrated, and inspected prior to use. This installation manual is intended for use by professional installers with a working knowledge of construction principles. If the install manual is not followed completely the warranty may be voided and the solar power system may not operate optimally.

Periodic maintenance of the system should be performed based on information in the O&M Manual. The O&M Manual includes a list of requirements to be verified/performed on an annual basis or following a significant weather event. Failure to follow the O&M instructions will result in sub-optimal, potentially dangerous operation of the system and will void the warranty. Any loose components or fasteners shall be re-tightened in accordance with the Project Construction Drawings. Any components showing signs of damage that compromise safety shall be replaced immediately.

Proper preventative maintenance includes following the practices specified by AAMA 609 & 610-02 – “Cleaning and Maintenance for Architecturally Finished Aluminum” (www.aamanet.org) and equivalent standards for galvanized steel products. All installations in corrosive atmospheric conditions or areas of periodic submersion or ponding, or where components were subject to any ponding or moisture while still bundled prior to installation at the site, are excluded from the Warranties, at the sole discretion of GameChange. Notify GameChange immediately upon discovery of any potential or suspect defect at time of discovery. Any alteration, modification or repair of the system without written authorization from GameChange Solar will void warranty. Any use of the system in a manner or for a purpose other than that specified by GameChange, or installed in any manner not specified by, or recommended against in, the installation manual provided by GameChange will void warranty.

Snow/Flood Sensors must be properly maintained and calibrated. Failure to do so could cause false positives or negatives which could adversely affect production and void the warranty. It is the responsibility of the Purchaser and/or subsequent Warranty holder that snow accumulations of 6 inches or more is removed from the solar modules before the System resumes tracking. In addition, snow must be cleared from the area under tracker tables to prevent damage from tracker tables rotating into snow banks.

See the Project Construction Drawings for post-to-post spans as well as maximum cantilever lengths for Beams and Cantilevers. Installation of components outside of tolerances shown in Project Construction Drawings may result in structural failure and will lead to voiding of product warranty.

IV MATERIALS, STORAGE AND WARRANTY

All materials are made from non-corrosive materials: galvanized steel, Magni coated steel, stainless steel, aluminum, polypropylene or polyethylene.

Galvanization is the application of zinc to steel to prevent rust. When the galvanized component is installed and air circulates over the zinc, a chemical reaction takes place which forms a protective coating of zinc carbonate. This ensures the zinc will properly protect the steel from corrosion.

I Storage of recently galvanized components left for a significant amount of time in a tightly bundled state in moist environments can cause a condition where the parts have water on their surface, preventing air flow across the surface. This inhibits the zinc from forming a protective zinc carbonate layer, which in turn may result in a condition called storage stain. The resulting zinc compound can balloon in volume and have the appearance of white powder. This condition can be minor and result in only a nominal loss of zinc coating thickness. However, if the parts are left for several weeks in a tightly bundled state this condition can result in more severe damage to the zinc coating, which could lead to premature corrosion damage, including but not limited to red rust spots. Leaving the components in this state for an extended period of time can result in loss of mass of the base metal and reduce the life span of the structural component.

I Unbundle loads and install parts within three weeks of delivery, so air is able to flow around parts and thus prevent storage stain formation. Prior to unbundling, place blocking under one side of loads so that parts are at a slope of at least 8 degrees. This will allow rain water to run off and not pool on components. In order to best maintain the longest life possible for the protective zinc coating under the warranty, it is important to monitor for any severe storage stain development and if a severe storage stain condition appears to take proper maintenance steps to remediate it.

I Bundled materials should not be stored directly on the ground. They need to be elevated above ground level using dunnage. Bundles should be stacked to a maximum of 2 levels, with dunnage between each level.

! Actuators, Controllers, Charging Module, and sensors are sensitive electronic devices and should be handled with extreme care. Disregarding this notice may result in damage to this equipment and will void warranty.

! Actuators, Controllers, Charging Module, and sensors should be stored inside a job site connex whenever possible. If this is not possible they should be single stacked in a dry, well drained area or laydown yard, elevated off ground with weatherproof tarp loosely covering the equipment to keep rain, snow and dew off the equipment, and allowing moisture to evaporate and not condense on the equipment.

V TOOLS REQUIRED

Tool requirements:

• String line, laser level or transit

• 48 inch [1219 mm] long level

• 30 and 100 foot [9 m and 30 m] tape measure

• Barrel laser suggested for aligning bearings (Recommended but not required)

• Drill with interchangeable socket adapters

• 11/32” Drill Bit to pre-drill Row Tube for TEK screw (optional)

• 7/32” Drill Bit to pre-drill Drive Housing for TEK screw

• Rated sockets and wrenches, both standard and deep, in the following sizes:

- 7/16 inch (for 1/4-inch hex bolts and nuts)

- 9/16 (for 3/8-inch hex bolts and nuts)

- 3/4 (for 1/2-inch hex bolts and nuts)

- 1 1/8 (for 3/4-inch hex bolts and nuts)

- 1 11/16 (for 1 1/8-inch hex bolts and nuts)

- 1 3/16 (for M20 bolts and nuts)

• Open end crowfoot wrench for 1/2 inch serrated flange nuts

• Torque wrench(s) capable of applying 6 ft. lbs. [8.2 N-m] to 140 ft. lbs. [189.8 N-m]

• Outdoor rated gray paint approved for plastic such as Rustoleum Industrial Enamel

• GameChange Solar System components (see page 4)

• Inclinometer with digital degree read out

• GameChange Solar Project Construction Drawings

• Cold galvanizing paint with a dry film zinc content of at least 92% (if required)

• Torque limited screwdriver

• Smart Phone or cell-enabled Tablet with GameChange Solar Web App and login

• Hellermann Tyton Aerial Support Tie (Part PA66HIRHSUV) or equivalent UV-resistant cable ties.

It is the responsibility of the installer to install fasteners within the finishing torque ranges shown in the project construction documents. The method in which this is achieved, including but not limited to torque wrenches or blue tooth enabled drill guns, with or without torque marks, is at the sole discretion of the contractor.

! Recommended practice is to run the nut up the bolt just enough to engage the bolt head and nut with the components they are connecting. A torque wrench should be used to finish the connection to the specified torque.

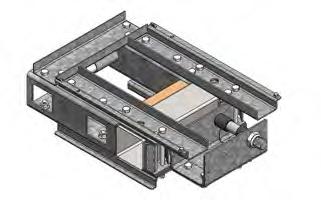

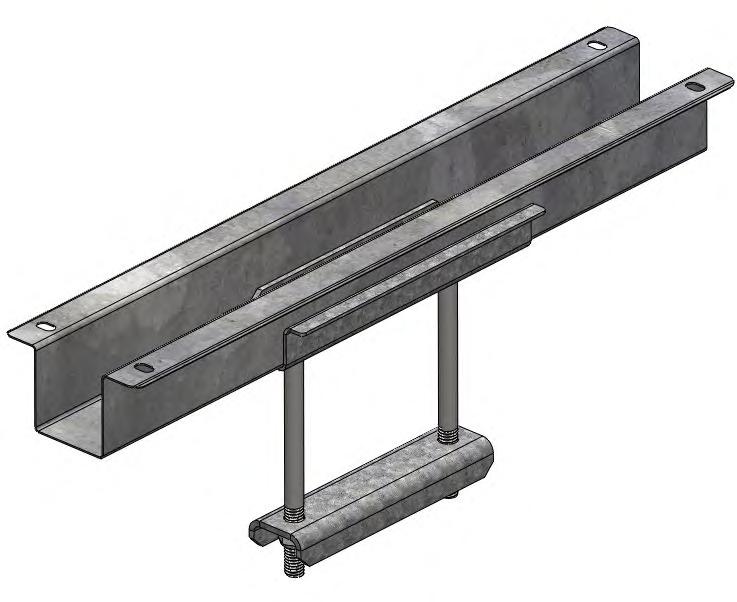

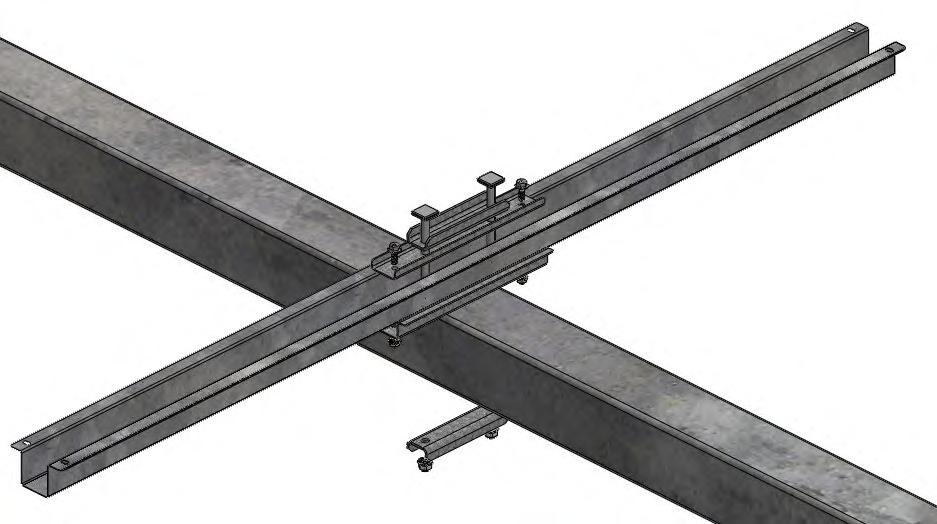

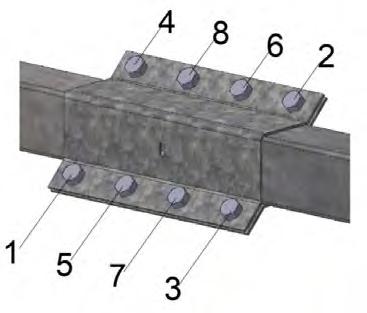

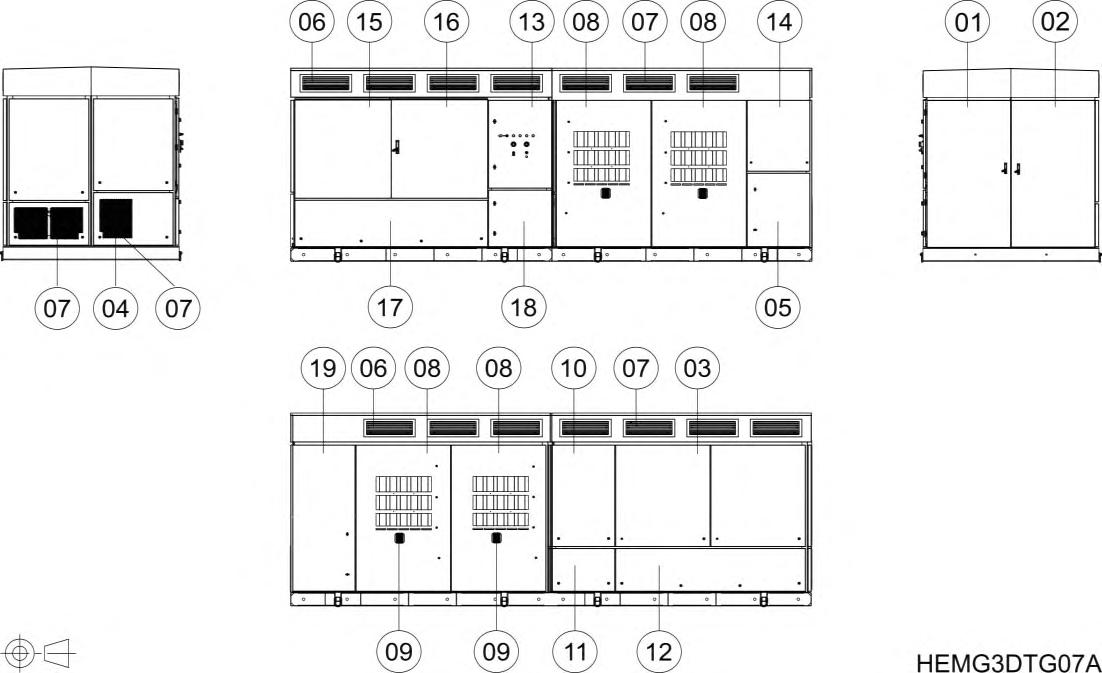

VI SYSTEM COMPONENTS

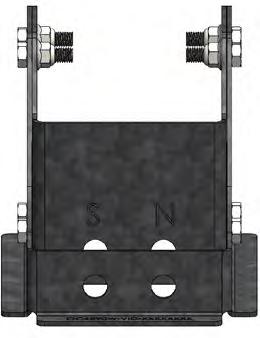

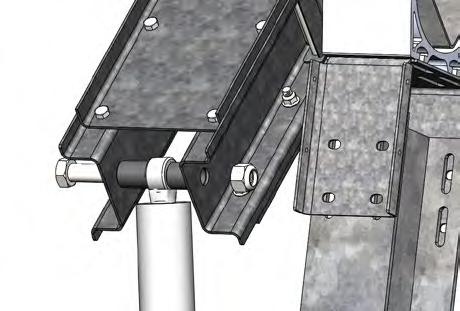

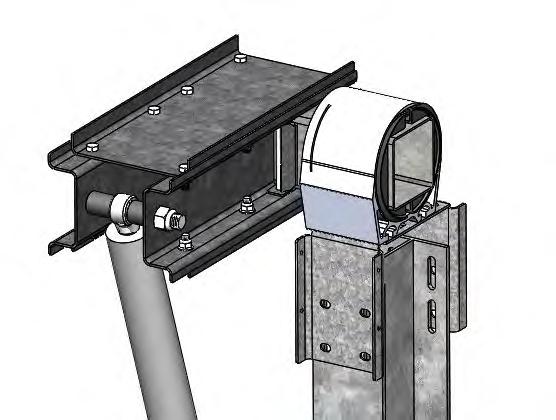

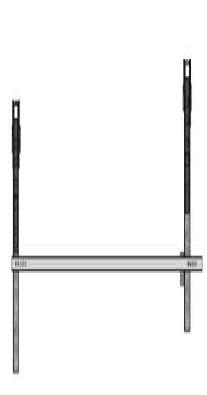

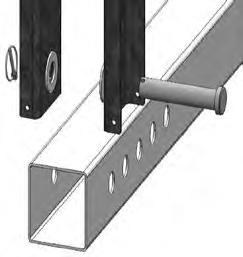

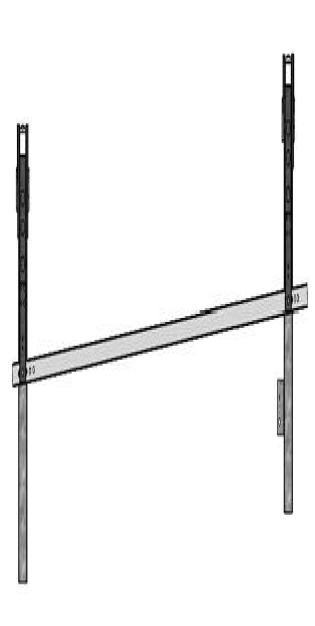

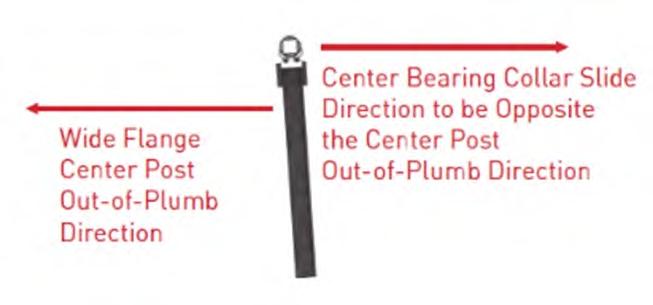

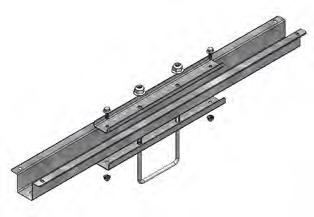

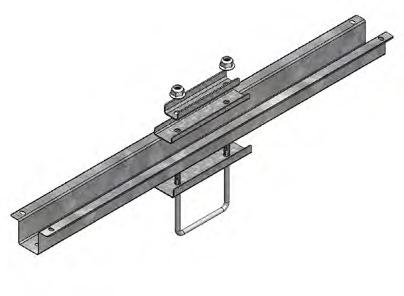

Cold Formed Center Post & Bearing Standard Post & Bearing

Center Post (GC61HGT)

Wide

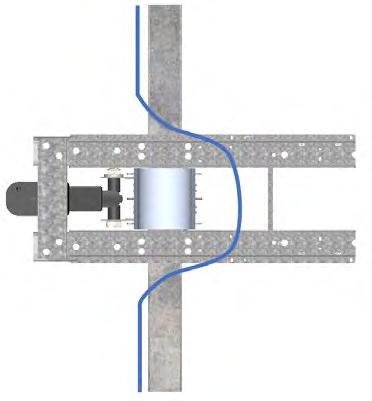

Preassembled Center Bearing (GC6601S-7.22-GC4367NL-LCH-6.75-P) or (GC5601S-7.22-GC5367NL-LCH-6.75-P)

Center Saddle Bracket (GC1610 - 3.6 - 61HGT)

Flange

Wide Flange Center Post (GC461C) or (GC561C)

Row Tube

Row Tube (GC365) or (GC565)

Center

Post Bracket (GC1611)

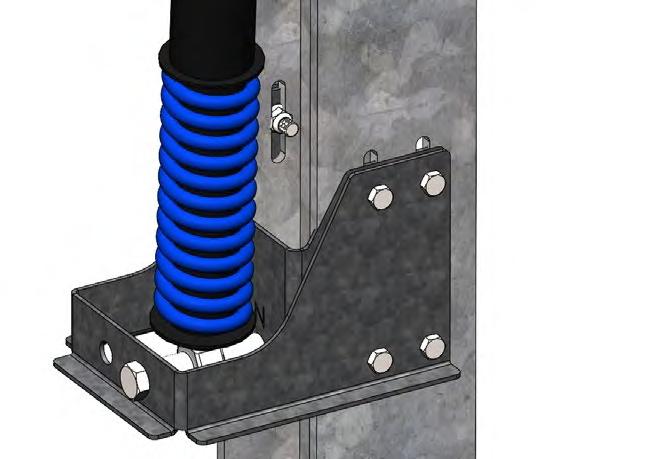

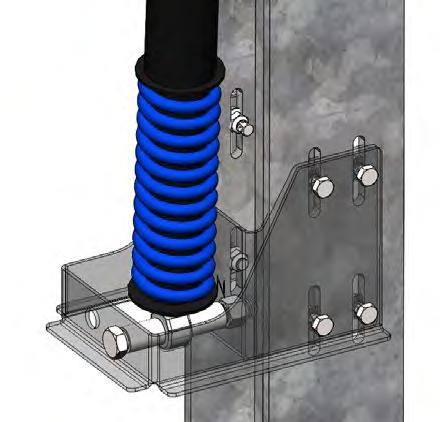

Bottom Bracket (GC1612)

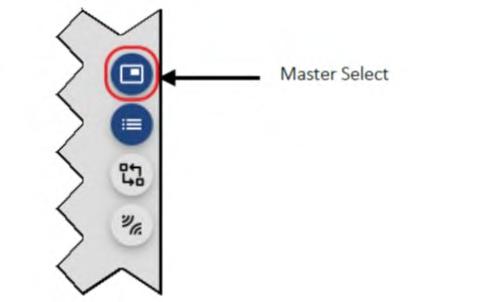

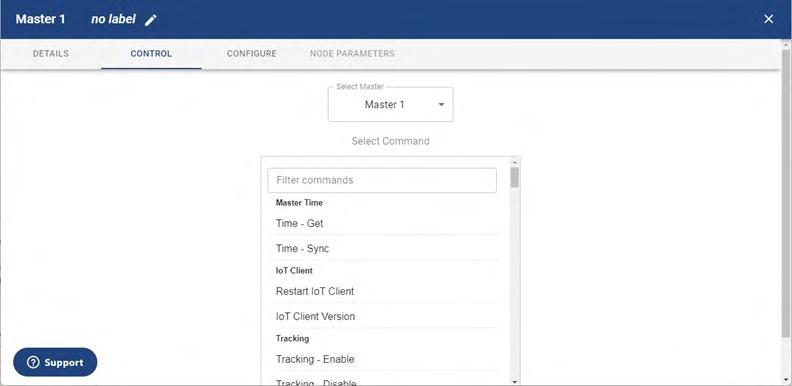

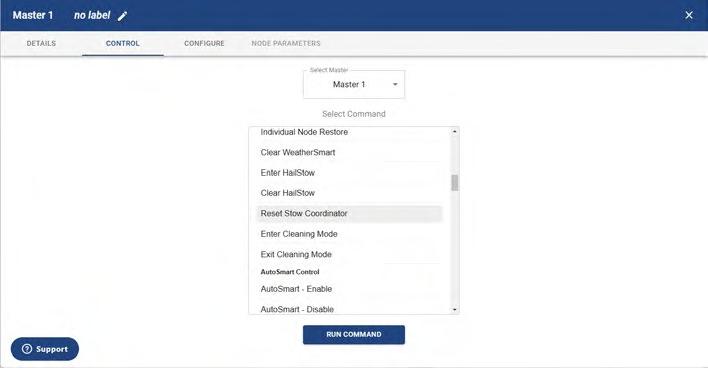

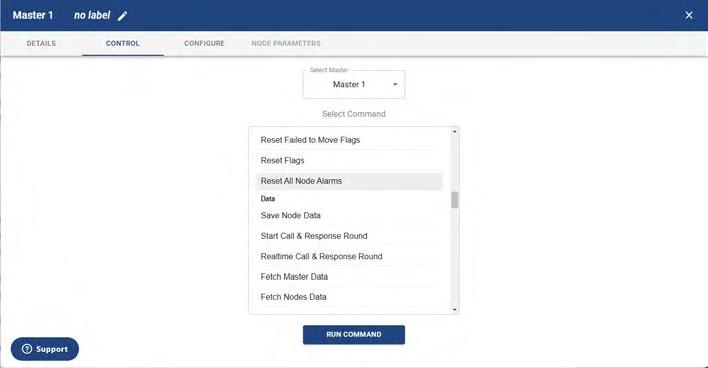

Post & Bearing (if provided)