Trade Talks

Metalsmiths Over its 78-year history, the Corps of Royal Electrical and Mechanical Engineers has seen multiple changes to the trades that make it up. Today, the Corps consists of eight trades who serve across the whole of the British Army and every REME Soldier becomes an apprentice in their trade of choice. This month, Metalsmiths give us an insight into how this trade is constantly developing to provide the best opportunities for their tradespeople and the Corps.

T

he Metalsmith Career Employment Group (CEG) is a highly versatile trade, specialising in the repair, fabrication and manufacture of field force equipment.

Initial Metalsmith Trade Training (D255) – Where it all begins Scribe: SSgt Parker Metalsmiths start their initial trade training at the Defence School of Electrical and Mechanical Engineers (DSEME). Each trainee will attend a common foundation course that consists of numeracy and English assessments, bench fitting, engineering drawing techniques, health and safety awareness and crane operation applications.

Oxygen and Acetylene Welding (O/A) O/A welding techniques are delivered over a six-week period. These processes include positional welding and brazing of ferrous materials, and O/A cutting. These welding processes are not commonly used in industry; however, they remain an essential part of equipment support delivery within the Field Force.

Arc Welding Metal Inert Gas (MIG), Tungsten Inert Gas (TIG) and Manual Metal Arc (MMA) are more commonly used processes that are used within industry and the MOD. Trainees are assessed over a sixteen-week period and, after progressive training, are expected to weld ferrous and non-ferrous materials in various positions to a high standard.

Blacksmithing During this phase trainees are taught blacksmithing and heat treatment techniques. Trainees forge heated materials into tools, hooks, springs and brackets. This type of training is invaluable as it is applied in the field force on a regular basis.

Sheet Metal Work

manufacturing and forming sheet metal into ducting, toolboxes, funnels and vehicle panels.

The End Product On completion of trade training each tradesperson will be assigned to a designated Workshop or Battalion as qualified Class 3 Metalsmiths, where they will then be awarded Class 2 status after a six-month transition period.

Land (4 ACS Battalion REME) Scribe: SSgt Tidd The Metalsmith department at 4 Armoured Close Support Bn provide an impressive array of Equipment Support (ES) for 101 Logistics Brigade. The Battalion also supports all operational and training requirements of 12 Armoured Infantry Brigade and 3 Division. There are 15 Metalsmiths within the department who provide Third Line ES within the Tidworth/Bulford area and further afield. The main effort is to support and repair Challenger 2, Warrior and other armoured vehicles. We also support 26 Engr Regt with the repair and maintenance of heavy-duty engineering equipment. This equipment includes the Trojan platform that’s designed to breach minefields, and the Titan bridge-laying armoured vehicle. The variety of platforms that we support gives us the ability to gain a vast amount of knowledge and experience across a broad spectrum of ES requirements.

Sea (17 Port and Maritime Regt RLC Wksp) Scribe: LCpl Gardiner 17 Port and Maritime Workshop provides ES to 104 Logistics Brigade. All Metalsmiths who are assigned to 17 Port and Maritime will attend a Shipwright CEQ over a three-month period at HMS Sultan. The

All trainees must demonstrate they have the hand skills and engineering competence needed to fulfil the role of a Metalsmith, by

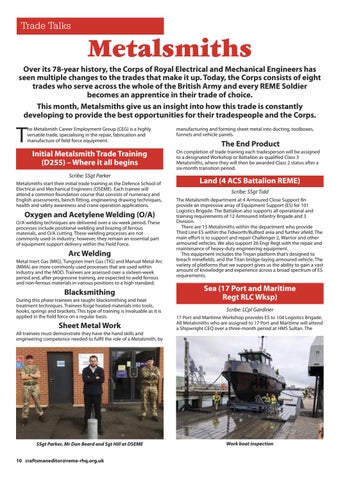

SSgt Parker, Mr Dan Beard and Sgt Hill at DSEME 10 craftsmaneditor@reme-rhq.org.uk

Work boat inspection