Today´s regulated pharmaceutical laboratories must comply with extensive regulatory requirements. Bruker offers together with its high-end FT-IR, FT-NIR and Raman spectrometer line comprehensive system validation tools to achieve systematic and cost-effective compliance.

Instrument Qualification according to USP, PhEur, JP

Internal Validation Unit (IVU) for automated OQ & PQ

Full 21 CRF part 11 support for Data Security, Integrity, Traceability

ALPHA II - Compact and Reliable FT-IR Spectroscopy

State-of-the-Art FT-IR spectrometers should be effi cient and straightforward above all else. The ALPHA II follows this approach and makes FT-IR analysis easier than ever before. The user can swiftly exchange Bruker’s versatile QuickSnap™ sampling modules to ideally fi t the device to almost any kind of sample (e.g. solids, liquids and gases).

BRAVO - Handheld Raman Spectrometer

BRAVO mitigates fluorescence (SSE™), addresses a large spectral range (Duo LASER™) including CH stretching region and is a class 1M Laser product. The intuitive and guide workflow gives the ability for Raman spectroscopy into everybody’s hands

LUMOS II - Fully Automated Stand-Alone FT-IR Microscope

LUMOS II provides best performance for visual inspection and infrared spectral analysis of micro samples with highest comfort in use.

TANGO - The Next Generation of FT-NIR Spectrometer

Faster, simpler, more secure - with TANGO your NIR analysis speeds up. TANGO has exactly what users require of an FT-NIR spectrometer suitable for industrial use: robustness, high precision and straightforward operator guidance.

Bruker South Africa (Pty) Ltd

Unit A-A001-G

Contact us for more details: www.bruker.com/optics info.za@bruker.com

Ground Floor, Lincolnwood Office Park Woodlands Drive, Woodmead Johannesburg 2191 Tel: +27 11 463-6040

FT-IR, FT-NIR, RAMAN

Volume 52 | Number 4 www.pharmacos.co.za

Biotech powerhouses form strategic partnership

Symrise receives prestigious Unilever award

8

Prime Product Manufacturing invests in a new tube filling machine

Anton Paar explores density measurement in five easy steps

Vantage South Africa relocates to bigger premises

How to adapt formulas to meet sustainability demands

An additive to enhance performance in laundry detergents

IMCD’s cleaning solutions for a sustainable future

Explore the versatile power of MMD in cleaning applications

Carst & Walker’s new personal care lab to power innovation

Xpozuki™ biotech ingredient for exposome protection

Vecollage Fortify L emerges as a game-changer in a non-animal collagen

Sabinsa explores a new era of healthcare with plantbased ingredients

CTFA’s Nadia Rashid decodes veganism in the beauty industry

VEGA launches new compact instruments series for pharma production

Tournaire eco-friendly technical packaging for sensitive materials 42

Coschem celebrates a year of growth and innovation

Autumn is upon us, and with it comes our April edition packed with insights into the latest innovations shaping the cosmetics and pharmaceutical industries. This month, we spotlight the continued shift towards sustainability, highlighted in the growing demand for plant-based ingredients like Evonik's Vecollage® Fortify L and recyclable packaging like Tournaire's lightweight Omni Plus solution.

In our feature on home care, we explore how probiotics and enzymes are revolutionising cleaning product formulations to reduce dependency on synthetic surfactants. We also highlight an additive that delivers performancedriven benefits in bar soap and detergent formulations, alongside innovative water conservation technologies like cold-water formulations and low-rinse detergents that address growing environmental concerns.

Exciting local industry news featured this month includes Prime Product Manufacturing’s investment in a state-of-

the-art NORDEN 602 tube filling machine, and Carst & Walker’s new personal care R&D laboratory established in Pretoria. We also celebrate the significant milestone of Vantage South Africa with its relocation to new premises. With this move, the business has more than doubled its operational footprint and positioned itself for a future defined by innovation, customer engagement and strategic growth.

As always, we remain committed to bringing you the most relevant developments in the local and international cosmetics and pharmaceutical industries. If you have an exciting or interesting story to share with our readers, please reach out to me on email (abby.vorster@newmedia.co.za).

Enjoy the read!

EDITORIAL

EDITOR: Abby Vorster

+27 (0)71 359 4519 abby.vorster@newmedia.co.za

LAYOUT & DESIGN: Andipha Nkoloti

COVER IMAGE: gettyimages

CONTRIBUTORS: Belinda Bangisi, Consuelo García, Eva Gómez, Ramón Subirós, Sandra Méndez, Albert Soley, Gemma Mola, Núria Almiñana, Raquel Delgado, Dr Katja Skrabania, Anne Mu, Nadia Rashid

ADVERTISING

KEY ACCOUNT MANAGER: Carla Melless +27 (0)83 260 6060 carla.melless@newmedia.co.za

Germany/Austria/Switzerland: Eisenacher Medien Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

CIRCULATION MANAGER: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

GENERAL MANAGER: Dev Naidoo

PRODUCTION CONTROLLER: Mandy Ackerman

ART DIRECTOR: David Kyslinger

JOHANNESBURG OFFICE

Building 13, The Woodlands Office Park, 20 Woodlands Drive, Woodmead, Sandton PO Box 784698, Sandton 2146 Tel: +27 (0)11 713 9000

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg, 2146 Published by Media24 (PTY) Ltd

An innovator in nutrition, health and beauty, dsm-firmenich and Inscripta, a biotechnology company, are pleased to announce a strategic partnership in the beauty industry. This science-driven collaboration goes beyond wellbeing, creating groundbreaking skincare solutions that bring to consumers elevated moments of care and superior delight –with a positive impact on people and planet.

The partnership will focus on a novel, highly sought-after well-ageing skincare ingredient. The combined expertise of the two companies will enable the exploration of additional opportunities to bring biotech innovations to the global market.

"As a leader in biotechnology, at dsm-firmenich we are thrilled to collaborate with Inscripta"

“As a leader in biotechnology, at dsm-firmenich we are thrilled to collaborate with Inscripta, a well-respected innovator in biotech strain engineering,” says Parand Salmassinia, president of Beauty & Care at dsm-firmenich.

“By integrating Inscripta’s scientific knowledge with our biotechnology skincare expertise, we’re set to deliver nextgeneration well-ageing products that offer superior results while contributing to a more sustainable future. Our biotech leadership will ensure that we not only meet consumer expectations but also exceed them.”

The collaboration between dsm-firmenich and Inscripta combines scientific innovation and environmental responsibility to drive rapid, cost-effective solutions for customers. This partnership ensures supply chain security, scalability, consistent quality and efficient use of natural resources. As demand for eco-friendly solutions grows, it has the potential to deliver a new generation of skincare innovations by combining dsm-firmenich’s and Inscripta’s biotechnology and skincare expertise.

At Unilever’s 2025 Awards Ceremony, hosted in London, UK on 2 April, Symrise received a prestigious accolade recognising its contributions to innovation, sustainability, and collaboration.

Unilever acknowledged Symrise’s initiative ‘Bridging the Gap: Transforming Mint Supply Chains through Decarbonisation, Sustainability, and Empowerment’. The initiative focuses on redefining India’s mint supply chains and addresses environmental, social and economic challenges. By engaging 25 000 farmers in Uttar Pradesh, the programme has successfully implemented renewable energy solutions, water-efficient systems and climatesmart agricultural practices. These efforts have ensured sustainable sourcing for Unilever’s Oral Care brands while enhancing farmer resilience, increasing incomes and stabilising the supply chain.

Representatives from Symrise top management participated in the ceremony and accepted the award. Symrise CEO, Dr Jean-Yves Parisot emphasised the relevance of the award, saying: “We thank Unilever for a great partnership and the recognition of our work. This award highlights the strength of our strategic collaboration, driving innovation and sustainability in the mint supply chain.”

The award also underlines Symrise leadership in sustainable and decarbonised supply chains.

to:

Media24 (Pty) Ltd

PO Box 440, Green Point, Cape Town 8051 Emailfelicity.garbers@newmedia.co.za

(please tick)1 YEAR2 YEAR

Cosmetic Review

Cosmetic Review R690 R1254 R1906 R1064

May

West Africa Pharma & Healthcare

6 to 8 May

Accra, Ghana www.westafricapharmahealthcare.com

Coschem JHB Supplier Day 14 May

Joburg, South Africa www.coschem.co.za

Vitafoods Europe 20 to 22 May

Barcelona, Spain www.vitafoods.eu.com

June

Coschem CT Supplier Day 18 June

Cape Town, South Africa www.coschem.co.za

Propak China 24 to 26 June

Shanghai, China www.propakchina.com/en

July

analytica Lab Africa

8 to 10 July

Midrand, Gauteng analytica-africa.com/en/

Coschem KZN Supplier Day 23 July

KwaZulu-Natal, South Africa www.coschem.co.za

In a bold move that underscores its market leading position as a TPCM, PRIME has significantly expanded its production capabilities with the acquisition of a state-of-theart tube filling machine, the NORDEN 602, as showcased at Propak Africa.

By Abby Vorster

Prime Product Manufacturing (PRIME) has established itself as a trailblaser in the South African third-party contract manufacturing (TPCM) landscape, specialising in high-quality beauty products and cosmetics, with a specialised focus in sun care. The company’s commitment to excellence has attracted entrepreneurial startups and multinational corporations seeking a reliable manufacturing partner.

“Our focus on world-class product development and manufacturing, particularly in sun care, has driven our decision to invest in advanced tube filling technology,” explains a PRIME spokesperson, Celeste de Winnaar. “Tubes offer superior hygiene properties and premium appeal that align perfectly with the high-end market segments served by our customers.”

The acquisition of the NORDEN 602 builds on PRIME’S longstanding partnership with PakMax, the local agent for Norden Machinery out of Sweden. To date, the relationship has evolved to become a cornerstone of the TPCM’S operational strategy. While PRIME once produced most of its manufacturing and production equipment in house, the company has strategically pivoted to leverage PakMax’s expertise in project engineering and equipment supply.

This partnership allows PRIME to concentrate on its core strengths of product development, formulation design, supply chain management, manufacturing excellence and exceptional customer service – while PakMax ensures the technical infrastructure remains cutting-edge.

The newly installed NORDEN 602 tube filling and sealing machine exemplifies PRIME’S commitment to technological advancement. With capacity to fill plastic, laminate and aluminium tubes at speeds of up to 60 tubes per minute, the system dramatically enhances production efficiency while maintaining impeccable quality standards.

"PRIME continues to reinforce its position as the foremost TPCM

within Sub-Saharan

Africa"

What truly distinguishes this investment is its exceptional flexibility. PRIME can now efficiently handle minimum order quantities of 5 000 units for emerging brands while seamlessly scaling to 300 000+ units per month for established players – all without compromising on quality or timelines.

PRIME’S participation in the recent Propak Africa trade show marks another milestone for the company as it continues to set trends as a market leader. The exhibition of the NORDEN 602 before its installation at PRIME’S manufacturing plant demonstrated the company’s confidence and transparency, inviting industry stakeholders to witness firsthand the advanced capabilities that set PRIME apart from its competitors.

After Propak Africa, the new tube filling machine was installed at PRIME and commissioned with three existing product

lines. This underlines the system’s versatility and the company’s readiness to meet growing market demands.

For beauty, sun care and cosmetics brand owners across South Africa and beyond, PRIME’S strategic investment signals a commitment to remaining at the forefront of contract manufacturing excellence. The company’s eco-sustainable approach, evidenced by the NORDEN 602’s small footprint and high operational efficiencies, cements PRIME’S reputation as a responsible industry leader.

As consumer preferences continue to evolve and demand for premium personal care products grows, PRIME stands ready with the expertise, technology and industry partnerships needed to support customers of all sizes, allowing their brands to thrive in a competitive marketplace. •

PRIME has embarked in its investment strategy in planning to further optimise manufacturing and production capability in more viable ways to do business, including ongoing enhancing of its recycling capabilities.

A

liquid product is frequently transferred into retail/ consumer packages by means of weight. To state the volume on the package or on the label, the density of the filled product is needed for the conversion of weight to volume.

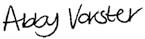

Anton Paar explores density measurement in five easy steps.

The final step in production is normally the filling of the material in its transport container or more importantly, the consumer-suitable retail package.

Especially for low and high viscous liquids or even paste-like substances from various industries, like cosmetics and personal care, this is frequently done by transferring product into the empty package until the desired weight is reached.

" Producers and contract fillers frequently fill products based on weight determination"

Customer protection laws and regulations require that the labelling must indicate the volume in the case of liquid products (in e.g. milliliters or liquid ounces). For Europe, this relates to the ℮ -mark on packages, yet there are also regulations in other countries.1-5

Producers and fillers of cosmetic products must fill exactly the amount that is stated on the package or label for two reasons:

1. Overfilling means adding too much valuable product, resulting in costly output reduction of readily filled packages.

2. Under-filling deceives consumers, is illegal and results in fines.

A reliable procedure to keep the required filling volume within limits and to comply with legal requirements is therefore necessary and economically reasonable. As density

is calculated by dividing the sample’s mass by the volume, it takes up at a certain temperature, a conversion to calculate the volume is simple.

To measure the density of a solution or pasty goods with a digital density meter, the sample is introduced into the U-shaped tube of the density meter. After being excited the U-tube’s oscillations depend on the density of the sample. The lower the density is, the higher is the oscillation frequency. The density is also temperature dependent, so the temperature must be determined precisely.

Anton Paar's density meters measure true density ρ true, which corresponds to the mass of the sample divided by its volume. The mass of a body is independent of environmental conditions such as buoyancy in air or gravity. However, if the filling volume needs to be calculated based on the determined density, the apparent density is required which corresponds to the sample’s weight in air divided by its volume V.6

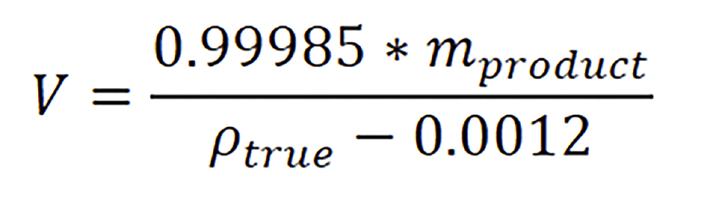

The following formula allows the calculation of the volume V of the sample from its weight mproduct :

Where ρtrue is the true density obtained with an Anton Paar density meter at the reference temperature, the constant 0.0012 corresponds to the density of air at 20 °C.

3. WHY FILL BY WEIGHT AND NOT DIRECTLY BY VOLUME?

3.1 Direct controlled volumetric filling Directly controlling the filling volume mostly

means control via timing of a filling valve. Such measurement depends highly on the flow rate of the product filled and will need separate calibration each time the product properties, specially the viscosity, changes. This action can be difficult and tedious due trapped air bubbles in non-transparent liquids or issues with the leveling to achieve a liquid meniscus in the reference vessel.

3.2 Other means of measuring the filling volume

An alternative way to measure filling volume can be sensors like floating plungers, which pose significant hygiene risks due to possible product carry-overs.

Other sensors in the line based e.g. on the Coriolis force principle may also be used. These need proper regular calibration, can normally lack correlation with a reference instrument in the laboratory and they may be expensive to apply in filling lines for less expensive products.

3.3 Benefits of gravimetric filling

Both balances and load cells for weighing deliver precise results, are simple to calibrate and can be used for alternative purposes in the production process. Often, they are commonly available in a laboratory or production area and are simply integrated in a filling line.

The additional benefits of weighing a container during its filling are:

• Bubble-prone, non-transparent liquids of various viscosity can be measured easily due to little effect of the bubbles on weight.

• Deviation of the weight of an empty container provides additional information. Too little mass allows for the detection of a broken vessel. Exceeding permitted empty weight

indicates residues/contamination in the package.

• Monitoring average filling rate, translating into weight change while filling, and any deviations of it below the reference, points to leakages while filling.

4. THE RIGHT DENSITY METER FOR EVERY APPLICATION

The portable density meter DMA 35 with three decimal places opens the series of devices best suitable for this application. DMA 35 measures the true density at sample temperature, determined directly at the density U-tube.

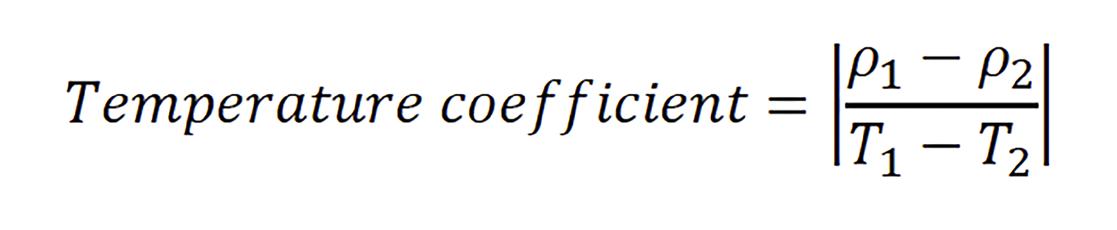

To convert the density to a reference temperature different to the measuring temperature, knowledge of the temperature coefficient is required, which can be determined in a simple way.

Practically, the true density of a sample is measured at two different temperatures – the difference between them is divided by the difference between the two temperature values. The result is the temperature coefficient, which always has a positive sign. Next enter the desired reference temperature and the appropriate temperature coefficient in the ‘Density@’ function.

Entering an offset (density of air at 20°C = 0.0012g/cm³) to compensate for the buoyancy will lead to the apparent density ρ app , which is needed for the determination of the correct volume.

DMA 501 and DMA 1001 are two additional density meters suitable for this application. These compact benchtop instruments allow for thermostatisation of the sample. They are built for operation even in production spaces.

Did you know?

The measuring cell of DMA 35 can also be filled with a syringe. This is especially useful in the case of high viscous and pasty samples.

The portable density meter DMA 35

The apparent density of the sample can be displayed and printed in g/cm³, g/mL, kg/m³ and lb/gal.

5. DETERMINING THE ACCURACY OF THE CALCULATED FILLING VOLUME

The accuracy of the instrumentation used, the measurement and as well the sample itself contribute to the minimal detectable filing error. Therefore, the density meter’s accuracy is relevant. The deviation range of the calculated filling volume ΔV depends on the density of the solution and the accuracy of the instrument Δ ρ

Table 1

Instrument

DMA 35

DMA 501

DMA 1001

accuracy Δ ρ

±0.001g/cm³

±0.001g/cm³

±0.0001g/cm³

Accuracies of various DMA density meters

Example: The accuracy of the calculated filling volume ΔV for a density value of 0.7g/cm³, obtained with DMA 35 or DMA 501, amounts to:

SUMMARY

Regulations require the volume of a product to be stated directly on the label of retail or consumer packages containing liquid or semi-solid products.

Producers and contract fillers frequently fill products based on weight determination as weighing versus volumetric determination of such goods offers numerous advantages. Weighing can be done quickly and is non-destructive when the average tare is known.

All these considerations show that density measurement with Anton Paar density meters is a suitable way to go for weight-to-volume conversion when checking the quantity of

a filled product, e.g. prior to delivery, and specifying the correct volume on the label or package. Additionally, density is a versatile quality control parameter throughout the whole production process. This offers multiple uses of the instrument in your process. •

REFERENCES:

1. Verordnung über Fertigpackungen (Fertigpackungsverordnung) FertigPackV 1981 § 7 Kennzeichnung der Füllmenge bei Fertigpackungen mit bestimmten Erzeugnissen

2. EUR-Lex Labelling of pre-packed products Dec 14, 2015

3. Electronic Code of Federal Regulations e-CFR data current as of February 3, 2020 PART 500— REGULATIONS UNDER SECTION 4 OF THE FAIR PACKAGING AND LABELING ACT § 500.7 Net quantity of contents, method of expression

4. NIST Handbook 130 & 133 (2020)

5. SANS 1841:2015 & SANS 289:2016

6. Anton Paar Application report “Determining filling volumes based on density measurement” XDLIA023EN

7. WELMEC 6.4, 2015 Guide for packers and importers of ℮ -marked pre-packed products

For more information, contact Akhona Qambela, Anton Paar’s team leader for measurement on +27 (0)83 325 8069.

Anton Paar –akhona.qambela@anton-paar.com

As an agile provider of forward-looking solutions, we offer a comprehensive range of natural-based ingredients and inspiring formulations for skin, hair and sun care as well as color cosmetics. Our key technologies include anti-acne solutions as well as active ingredients and botanical extracts, sustainable vegetable oils and its sensorial derivatives, sulfate-free and mild surfactants as well as customized product compositions to meet your specific application needs.

Setting new standards for the personal care industry, Vantage South Africa has relocated to bigger premises with state-of-the-art laboratories and expanded warehousing capabilities.

In November 2024, Vantage South Africa reached a significant milestone with the transition to a new regional hub situated in Corporate Park North, Midrand, Gauteng. This strategic relocation marks an ambitious step forward in reinforcing the company’s commitment to our country’s growing personal care and cosmetics industry.

With this move, the business not only more than doubles its operational footprint but also affirmatively positions itself for a future defined by innovation, customer engagement and strategic growth.

Nestled within one of Midrand’s dynamic and growing business corridors, the new premises of Vantage South Africa form part of a strategic plan to overcome past logistical limitations while enhancing operational efficiencies.

Spanning 5 000m², the facilities have been designed with a clear vision for the future. Central to this is the significantly expanded warehousing capability. By increasing pallet positions by a whopping 70%, Vantage South Africa is addressing a critical pain point in supply chain management. This strategic expansion ensures improved stock availability and reduced lead times, which are key elements in meeting and exceeding customer expectations.

The corporate office also boasts meticulously designed operational areas. Safety and efficiency have been prioritised, featuring approved racking systems and comprehensive fire systems that collectively create a secure environment for employees and inventory alike. Each element of the design reflects Vantage South Africa’s forward-thinking ethos, ensuring the site meets current operational demands while standing ready to accommodate future growth.

Innovation is deeply ingrained in Vantage South Africa’s DNA, and nowhere is this more evident than in the company’s state-of-the-art laboratories.

The R&D lab stands as a testament to its commitment to cutting-edge research and development. Significantly expanded, this space is equipped with modern apparatus such as homogenisers, automated scales and Brookfield viscometers. These tools are essential for precision-driven development, allowing the R&D team to push the boundaries of personal care research.

Adjacent to the R&D lab is the training and innovation lab. Here, customers are invited into an engagement space where knowledge sharing and collaboration take centre stage. Featuring sophisticated video conferencing capabilities, this training and innovation lab is a nucleus where global expertise meets local innovation. This interconnectedness provides Vantage South Africa with the tools to offer superior formulation support while cultivating lasting collaborative relationships with customers.

An additional highlight of the new premises is the standalone stability/ wet laboratory. This dedicated area is vital for rigorous product testing. The stability lab operates under controlled temperature settings, which ensure products meet industry standards for performance and reliability.

By placing an emphasis on testing, Vantage South Africa is demonstrating its unwavering commitment to helping customers deliver products that exceed market expectations.

These three laboratories are key enablers for driving the strategic focus of the business for the next few years. They also embody Vantage South Africa’s commitment to creating a future-ready environment that aligns with global trends and customers’ needs in the evolving personal care and cosmetics landscape.

While the company’s new premises are a significant milestone, Vantage South Africa’s strategy for 2025 places equal emphasis on product and market innovation. Its product and solutions launches in the skincare, hair care and sun care segments reflect a deep understanding of the needs of modern consumers – positioning the business as a leader in various personal care industry categories.

"The business is setting new standards in delivering customerfocused solutions"

Key among these initiatives is the ‘All Clear: Acne Reimagined’ collection. This range positions Vantage as a frontrunner in offering anti-acne solutions that blend natural efficacy with innovative formulations. With further product launches planned for 2025, the company aims to cater to the growing demand for holistic skincare solutions that enhance skin health and longevity.

The development of mild surfactants is also a pivotal focus area for Vantage South Africa. With its innovative ‘No Trouble Bubbles’ collection, the business is redefining baby care with formulations that harmonise mildness with unparalleled foaming. This collection, which represents a paradigm shift in consumer perceptions of baby care, underscores the company’s ability to anticipate and respond to market needs effectively.

In tandem with innovation, Vantage South Africa is committed to sustainability. This is reflected in the company’s pioneering use of natural oils and derivatives. Products like jojoba exemplify its commitment, offering full traceability from sustainable farming through to premium certified formulations. With certifications such as COSMOS, kosher, and halal, Vantage South Africa ensures that each product aligns with ethical environmental practices and standards.

These initiatives echo the rising consumer preference for sustainable and ethical products, further enhancing the company’s reputation as a responsible and forward-looking player in the personal care industry.

Vantage South Africa’s overarching message to its stakeholders is one of leadership and commitment. By expanding and enhancing its operational and innovative capabilities, the business is setting new standards in delivering customer-focused solutions.

A customer-first ethos is deeply embedded in its operations, ensuring that each strategic move and innovation resonates with customers’ needs and market demands.

As part of a global network comprising 15 laboratories, Vantage South Africa is uniquely positioned to harness international expertise and insights. This cross-regional collaboration strengthens the ability of the South African business to deliver tailor-made solutions grounded in global trends and local insights.

The relocation and expansion into new premises in Midrand, Gauteng signify more than just a logistical milestone – they herald a transformative era of growth and innovation. Through this strategic expansion, Vantage South Africa is showing its intent to not only lead but also help shape the future of the local personal care industry.

Equipped with cutting-edge resources, a clear strategic focus, and an unwavering dedication to customer success, Vantage South Africa is poised to thrive in this new space. As the company continues to inspire confidence amongst partners and customers, it is set to leave an indelible mark on the landscape of personal care innovation. •

Belinda Bangisi, beauty and care product manager at Brenntag SA, explores ways in which the home care category can adapt to meet the demands of sustainability and price competitiveness.

South African households face challenges with water and energy resources as cleaning and hygiene grow in importance. This makes maintaining clean and healthy homes increasingly difficult. Simultaneously, today’s consumers want effective cleaning solutions while being conscious of their environmental footprint.

Sustainability remains a pivotal trend in the home care category. Sustainable practices have transitioned from niche to mainstream, with sustainability claims beginning to overshadow brand loyalty in the world of cleaning products.

INDUSTRY TRENDS AND CONSUMER INSIGHTS

The use of eco-friendly alternatives in home care formulations is becoming a norm with several base ingredients forming the cornerstone of these changes. Raw materials such as surfactants, solvents, chelating agents, dispersants, opacifiers, rheology modifiers, biocides and preservatives are available in sustainable and eco-friendly alternatives. For example, sustainable surfactants, like biosurfactants, and fully biodegradable options, provide alternative solutions. Similarly, solvents with a biobased origin and chelating agents derived predominantly from natural sources contribute to a more sustainable formulation.

Manufacturers of home care products have access to a diverse portfolio of ingredients,

enabling the formulation of products aligned with sustainability goals. Even traditional materials can undergo a significant sustainability transformation through standards like ISCC+. This allows producers to obtain Mass Balance surfactants, solvents and preservatives like potassium sorbate, maintaining recognisable chemistry with identical molecules. The approach minimises the need for extensive re-formulation and additional studies before introducing a more sustainable alternative to the market.

Notably, probiotics and enzymes stand out as excellent alternatives, emphasising a reduction in the reliance on traditional chemical processes to achieve desired effects.

THE INTERSECTION OF INNOVATION AND SUSTAINABILITY

It is crucial to keep cost and performance parameters in mind. Where sustainability takes centre stage, striking a balance is key while ensuring high performance. This equilibrium aims to minimise the end user’s reliance on excessive chemicals for desired effects, while keeping the formulation economically viable.

People are choosing products that work at cooler temperatures and use less water to save money and be more environmentally friendly. This same approach applies to laundry habits, where many consumers now prefer shorter, cooler wash cycles that save water and electricity. In essence, this evolving consumer

behaviour reflects a dual commitment – to financial prudence and sustainable living.

The home care category now faces two main challenges: making products that are both eco-friendly and affordable. Manufacturers are responding by creating concentrated cleaning products like tablets, powders, sheets and monodose formats, which use less water and create less packaging waste.

Mild formulations are a must as consumers prefer cleaning products that are safe for their pets, children and sensitive environments.

Coupled with safety, consumers are keen on products that are appealing and can be openly displayed instead of being hidden inside cupboards. Multi-coloured laundry tablets and diffusers for air care that match their fine fragrance preferences are just a few examples.

In conclusion, these strategies capture a nuanced and thoughtful response to the dual challenge. By adeptly navigating the delicate balance between sustainability and affordability, the home care category charts a course towards a future where environmentally conscious consumers can readily access high-performing and affordable products, transforming sustainable living into an achievable reality.

This comprehensive approach underscores commitment within the category to meeting evolving consumer expectations while simultaneously addressing pressing environmental concerns. As the category continues to evolve, these strategies serve as a blueprint for shaping a sustainable and economically viable future in home care. •

Brenntag SA – www.brenntag.com

SUPRACARE™ 780 Additive elevates home care products with enhanced performance and sustainability benefits. Learn how this innovative cellulosic derivative transforms laundry detergents and bar soaps through improved rheology, structure and foam quality.

Innovation in the home care segment is driven by the need for multifunctionality, efficiency and sustainability.

SUPRACARE™ 780 Additive – a novel cellulosic derivative –offers a range of benefits for formulators working with laundry detergents and in personal care manufacturing.

KEY FEATURES AND BENEFITS

SUPRACARE™ 780 Additive delivers multiple advantages across different applications:

• Its high thickening efficiency provides superior viscosity control, improving formulation stability.

• The electrolyte tolerance ensures consistency in high-salt formulations, making it ideal for detergents and personal care products.

• The non-ionic nature makes it compatible with a broad range of ingredients, allowing flexibility in formulation design.

• It increases the rate of foam generation in laundry and multifunctional bars.

• It reduces mushiness for improved bar durability and enhances the longevity of laundry and non-soap detergent bars.

• The controlled release capability makes it suitable for use in toilet cistern blocks and other time-release applications.

• It is derived from natural raw materials and is inherently biodegradable (OECD 302B compliant).

APPLICATIONS IN LAUNDRY CARE

SUPRACARE™ 780 Additive finds applications in:

• Liquid laundry detergents where it enhances viscosity and stability while improving foam characteristics.

• Hand dishwashing liquids where it increases thickening efficiency and maintains excellent foam profile.

• Hard surface cleaners where it provides structuring benefits and enhances product rheology.

• Laundry and multi-purpose bars where it improves bar integrity, reduces wear rate, and enhances sensory properties.

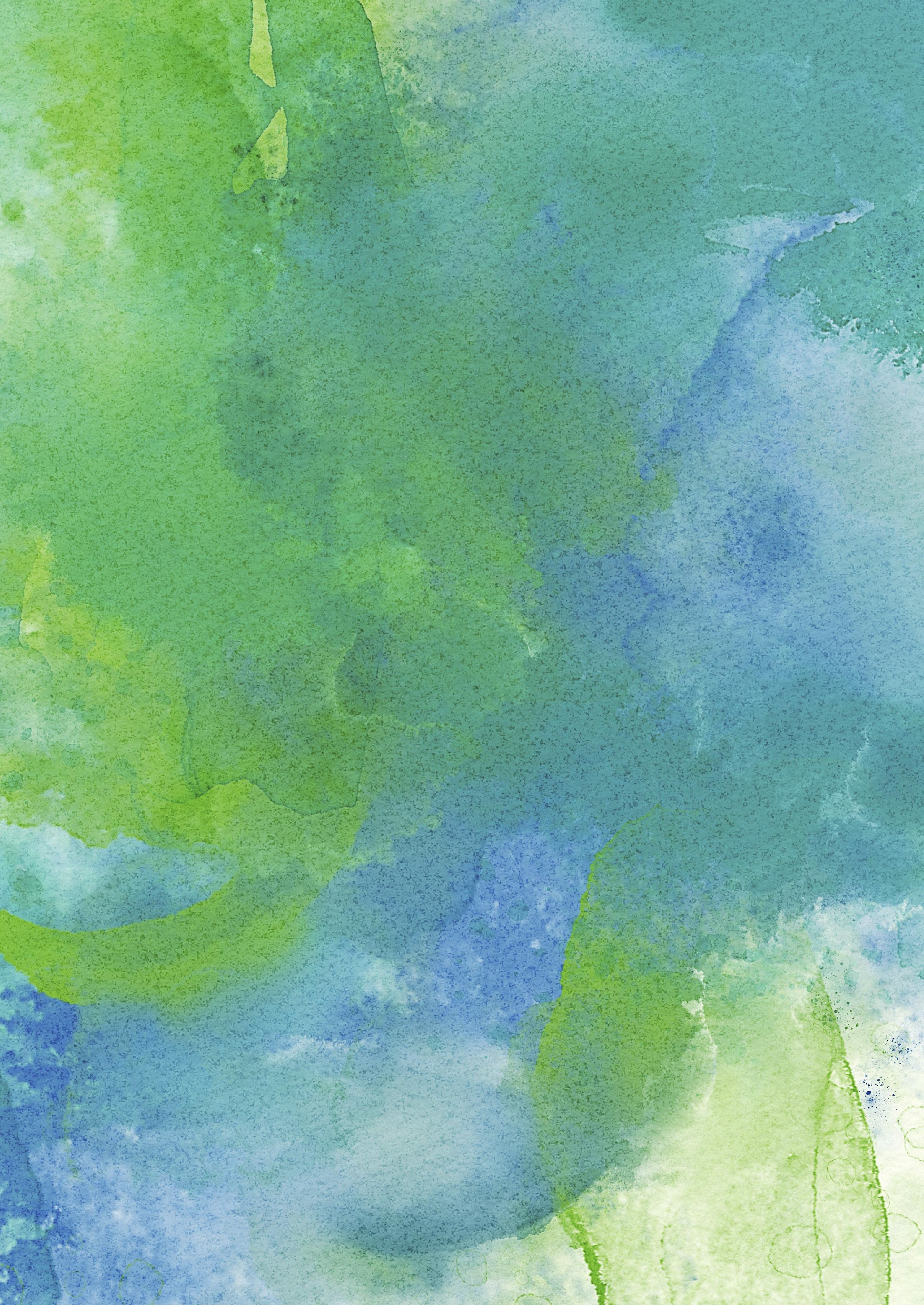

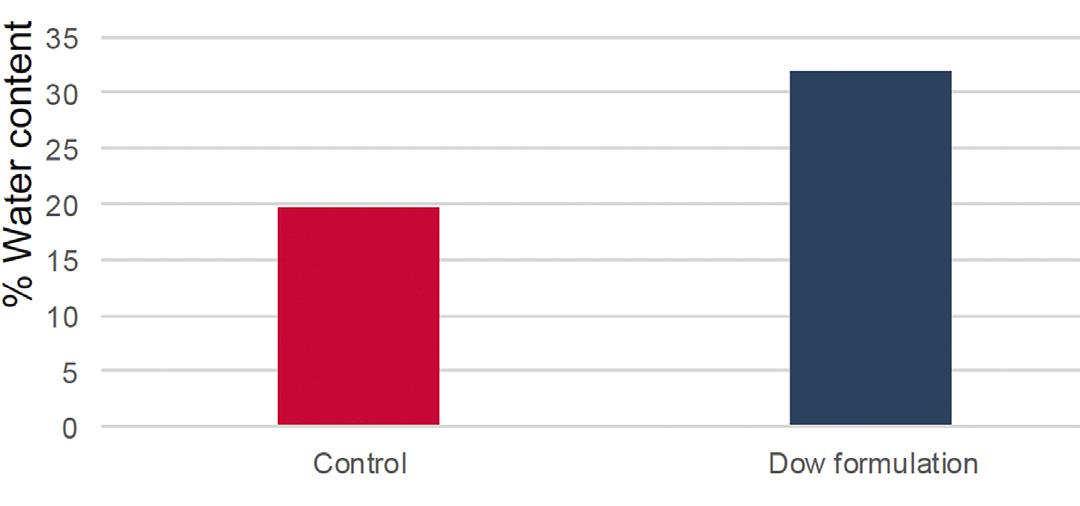

PERFORMANCE IN FORMULATIONS

In comparative studies of a hand dishwashing liquid, SUPRACARE™ 780 Additive demonstrated superior thickening efficiency over traditional rheology modifiers. A formulation with 0.3% SUPRACARE™ 780 achieved a higher viscosity profile, leading to better user experience and product stability. See figure 1.

By incorporating SUPRACARE™ 780 in laundry bars, formulators can reduce total fatty matter while maintaining bar structure. This results in cost-effective formulations with increased water structuring and improved rate of wear resistance.

Figure 1: Comparative viscosity of hand dishwash liquids. When comparing the rheology profile of the HDW liquid formulations, SUPRACARE™ 780 Additive demonstrates a higher yield

Formulation: Affordable laundry bar

In affordable detergent formulations, total fatty matter reduction is one of the desired cost-saving benefits

Processing instructions

Option 1: Ready-made soap noodle-based bars

Charge soap noodles in the sigma mixer and crush them uniformly by mixing them for 15 to 20 minutes. Add SUPRACARE™ 780 Additive and mix it for five minutes. Add glycerin and mix it for two to three minutes. Add sodium silicate and mix it for 10 minutes. Add microfine talc and mix it for two to three minutes. Add TiO 2 and mix it for two to three minutes. Add water, if and when required, under mixing. Add colour and mix it for three and four minutes (until the colour develops in the dough). Add perfume, mix it for one to two minutes, and then discharge it from the sigma mixer. Take the dough from the sigma mixer to the triple roll and then the mix from the triple roll mill to the extruder for plodding the bars.

Option 2: In-situ saponification plant

The SUPRACARE™ 780 Additive can be mixed with the fatty acids and then saponified. In this case, the soap noodles will have built in SUPRACARE™

Rate of Wear Assessment

780 Additive. The rest of the unit operations remain same. Slowly add the ingredients under moderate stirring. Continue mixing until the solution is uniform.

" In liquid detergents or bar soaps, SUPRACARE™ 780 Additive delivers superior efficiency and consumer appeal"

SUSTAINABLE AND EFFICIENT FORMULATION CHOICE

Sustainability is a key driver in today’s market. SUPRACARE™ 780 Additive supports this trend by being biodegradable and derived from natural sources. Its ability to enhance performance while reducing reliance on high-fat

High Thickening Efficiency:

Achieve superior viscosity and stability across a broad range of home care products.

Foam Enhancement:

Boost the rate of foam generation for improved washing efficacy.

Electrolyte Tolerance:

Maintain consistency in high-salt formulations, perfect for diverse cleaning products.

Improved Bar Durability:

Extend the lifespan of your bars, reducing mushiness and enhancing user satisfaction.

Sustainable Choice:

Biodegradable and derived from natural raw materials, supporting eco-friendly initiatives.

content makes it an ideal choice for eco-conscious brands. AECI Specialty Chemicals’ SUPRACARE™ 780 Additive is a game-changer for formulators in the bar soap and laundry care categories.

With its multifunctional benefits, including improved rheology, foam enhancement and superior structuring, it provides an innovative solution for creating highperformance, sustainable formulations. Whether in liquid detergents or bar soaps, SUPRACARE™ 780 Additive delivers superior efficiency and consumer appeal. •

AECI Specialty Chemicals – sc.aecichemicals.co.za

APPLICATIONS:

Hard Surface Cleaners: Liquid Laundry Detergents: Hand Dishwashing Liquids: Provides structuring benefits and enhances product rheology. Enhances viscosity and stability while improving foam characteristics.

Laundry/Multi-Purpose Bars:

Improves bar integrity, reduces wear rate, and enhances sensory properties. Increases thickening efficiency and maintains excellent foam profile.

Sustainability is no longer just a trend – it’s a necessity. As global awareness grows around eco-friendly solutions, South Africa’s home care and industrial cleaning category is following suit.

With the country’s cleaning products market valued at $3.2 billion in 2023 and projected to rise at a CAGR of 5.5% by 2028, the demand for sustainable cleaning solutions is higher than ever.

Consumers and industries alike are searching for products that not only deliver exceptional performance but also align with environmental priorities like water conservation, waste reduction, and regulatory compliance.

Consumers are more conscious of their purchases, and recent research shows that 72% of South Africans are willing to pay a premium for sustainable products. This shift is driving manufacturers to rethink their formulations, focusing on natural ingredients, biodegradable components, and reduced environmental impact. Stricter government regulations further reinforce the need for compliance, pushing companies to innovate to meet evolving standards.

Water shortages have significantly impacted consumer behaviour, leading to a

rise in cold-water formulations and low-rinse cleaning solutions. Waste reduction is another growing focus area, with brands developing concentrated formulas and refillable packaging to cut down on plastic waste and shipping emissions. Meanwhile, surging energy costs are prompting businesses and households to seek energy-efficient solutions such as cold-water detergents and products designed for shorter cleaning cycles.

" 72% of South Africans are willing to pay a premium for sustainable products"

Recognising these critical shifts, IMCD South Africa has developed the Next Gen Cleaning Kit – a comprehensive, eco-conscious toolbox designed to meet modern cleaning demands while minimising environmental impact.

IMCD South Africa’s Next Gen Cleaning Kit is a game-changer in sustainable cleaning. Designed for high performance and versatility,

this toolbox of products incorporates cuttingedge cleaning formulations that require less water, consume less energy, and make use of safer, biodegradable ingredients.

Here’s a closer look at the innovative products in the kit:

• SwiftWash Touchless Car Shampoo has an advanced formula that cleans vehicles without the need for physical cleaning, reducing washing time and water consumption. The touchless application ensures a spotless finish while being gentle on surfaces.

• EZDetail Quick Detailer is a waterless car cleaner, ideal for quick touch-ups or full washes. This powerful yet eco-friendly formulation removes dirt while providing shine and protection.

• EcoTread Tyre Shine promises long-lasting shine with its VOC-free formula designed with green solvents and silicones. It enhances the appearance of tyres while providing anti-static protection, keeping dust at bay.

• PureClean Liquid Laundry Detergent is designed for everyday use, this concentrated detergent delivers effective cleaning power without unnecessary additives. Gentle on fabrics and the environment, it ensures a deep clean, while using less detergent and reducing packaging requirements.

Upgrade your cleaning routine with IMCD South Africa’s Next Gen Cleaning Kit—a breakthrough in highperformance, eco-friendly cleaning. Designed with sustainability in mind, this innovative range features advanced formulations that reduce water usage, minimize energy consumption, and utilize biodegradable ingredients.

The Next Gen Cleaning Kit offers a smarter way to clean while protecting the planet. Experience powerful cleaning without compromise—because a cleaner home shouldn’t come at the cost of a cleaner future.

Contact IMCD South Africa today to learn more!

www.imcdsa.co.za

• BotaniSoft Fabric Softener is formulated with plant-based ingredients. It enhances fabric softness, reduces ironing time, and is gentle on skin and the planet.

• TexGuard Fabguar d protects furniture and fabrics with an easy-to-apply rainrepellent solution. It adds a protective barrier against water and stains, keeping surfaces cleaner for longer.

• PureEco All-Purpose Cleaner is a multipurpose powerful, versatile, and costeffective cleaner. It can be adapted into specialised formulations for solar panels, floors, tiles, carpets, and disinfectants.

It offers effective grease and carbon build up removal.

• NatureLux Dishwashing Liquid Hand Wash is tough on grease yet gentle on hands. This earthfriendly dishwashing liquid boasts a thick consistency for a more economical and effective clean.

• DishMist Dishwasher Powerspray 4-in-1 is an innovative four in one spray designed for machine and manual dishwashing, making kitchen cleaning effortless while eliminating powder buildup.

• GrillFresh Oven/Grill/Braai Cleaner is based on eco-friendly surfactants, and is solvent-free and fluorocarbon-free.

IMCD South Africa’s Next Gen Cleaning Kit offers a step towards a greener future. For businesses and consumers looking to balance high-performance cleaning with environmental responsibility, this kit provides an ideal solution. By embracing these innovative formulations, South Africans can contribute to a cleaner, greener, and more sustainable future. •

REFERENCES:

1. https://www.thebusinessresearchcompany.com/ report/household-cleaning-products-globalmarket-report

2. https://rowater.co.za/the-current-water-shortagein-south-africa-causes-impacts-and-solutions/

3. https://distinctionpass.com/five-main-causes-ofwater-shortage-in-south-africa/

Through an innovative and out the box approach to our clients needs we are able to provide practical, efficient and cost saving solutions to almost every challenge.

Tel: +27 (0)11 609 1488

Email: sales@iswshrink.co.za www.iswshrink.co.za

16 Edendale Rd West, Eastleigh, Edenvale

With the manufacturing plant consisting of 10 colour and 8 colour MPS EPW560’s and a full compliment of the latest offerings in finishing equipment for the conversion and inspection of our shrink sleeves, multi-layer sachets and wrap around labels, ISW is one of only a handful of narrow web printers capable of producing wide Lay Flat shrink sleeves, achieving a L/F of 276mm from a printed web width of 575mm.

MMB offers sustainable, multifunctional benefits in home care, air care and industrial cleaning applications. Find out more in this article.

In formulation design, chemists and manufacturers are constantly seeking multifunctional, sustainable and efficient ingredients. One formulation technology making waves is methoxymethylbutanol (MMB). This transparent, colourless solvent is proving to be an essential tool for formulators across various applications and product formats.

Solubility issues in aqueous systems often present significant challenges. As an amphiphilic solvent, MMB addresses this concern by enhancing solubilisation while optimising formulations. With its robust stability to temperature, pH and oxidation, it allows formulators to minimise reliance on traditional surfactants and hazardous solvents.

"MMB helps formulators reduce the need for excessive surfactants"

Beyond performance, its non-flammable nature coupled with a high flash point of 71°C, make MMB a stock-friendly choice. Unlike many conventional solvents, it is biodegradable with a low toxicological profile, aligning well with the increasing demand for eco-conscious formulations.

SUCCESSFUL ACROSS MULTIPLE APPLICATIONS

The versatility of MMB extends across various product categories, from home care to industrial applications.

In air fresheners MMB provides a powerful solubiliser for aroma chemicals. It ensures a unique evaporation profile that prolongs a scent’s longevity while maintaining low sensitivity to humidity. For formulators in the fragrance industry, this is an essential trait for products like room sprays, reed diffusers, gels and aerosols.

When incorporated into laundry detergents, MMB has a lower impact on enzyme activity than other solvents. This allows for effective cleaning while preserving enzyme functionality. It also enhances stain removal, improves fragrance solubilisation, and enables formulators to use lower levels of surfactants and enzymes without compromising performance. Furthermore, MMB is compatible with hydrosoluble pod films, making it an ideal choice for modern, concentrated detergent formats.

High-performance degreasers and industrial cleaners require solvents that cut through grease efficiently while remaining safe and sustainable. MMB demonstrates high degreasing power from as low as 1%, making it a viable alternative to traditional solvents such as alcohols, D-limonene and glycol ethers like butylglycol. MMB also helps formulators reduce the need for excessive surfactants, which is beneficial for cost-effectiveness and environmental impact.

The efficiency of MMB is not just theoretical –it has been tested across multiple applications. In fragrance solubilisation tests, it provided a clear, stable solution, outperforming other solvents like DPM and ethanol, which resulted in cloudiness. Similarly, in IKW degreasing performance tests, MMB demonstrated superior cleaning power against stains like peanut oil, kaolin and carbon black, even at lower concentrations than ethanol and butylglycol.

As industries move toward safer, more sustainable and high-performance ingredients, MMB is presented as a practical and future-ready solution. This raw material can solve formulation challenges while enhancing product efficiency and sustainability. These benefits make it an indispensable tool for formulators working across air care, home care and industrial applications.

MMB offers a compelling solution to those looking to optimise their formulations, reduce dependency on harsh solvents and improve overall performance. Whether in air fresheners, detergents, or industrial cleaners, its benefits are clear in formulation stability and real-world application. Reach out to CJP Chemicals for more information. •

Formulator Friendly - MMB is a multifunctional solvent, transparent and colorless. It is robust and stable to T˚, pH and oxidation. MMB is amphiphile making it a great ally for solubilization troubles in aqueous systems. With MMB, one can also optimize formulations by removing surfactants, hazardous solvents and solubilizers.

Stock Friendly - MMB is non-flammable with a high flash point of 71˚C and is not considered a dangerous good.

Eco and Customer Friendly - MMB is biodegradable and has a low toxicological profile.

What to expect from MMB?

Air fresheners:

· Good solubilizer for a wide range of aroma chemicals.

· Unique evaporation profile enabling longer lastingness of the

· Low sensitivity to humidity.

(room sprays, reed diffusers, gels, aerosols)

· Lower influence than other solvents on enzyme's activity

· Help with the incorporation of SLES and fragrances.

· Enables us to use less enzyme and surfactant.

· Compatible with hydro soluble pod films.

· Boosts stain removal and cleaning. (stain removers, laundry pods, concentrated laundry detergent, Degreasers:

· High degreasing power and effective from 1%.

· Enables to reduce the amount of surfactant.

· Good alternative to alcohols, D-limonene and glycol ethers

Laundry Care: such as Butylglycol (BG).

(oven cleaners, all purpose cleaners, floor cleaners, window

cleaners, car care) perfume in the room. carpet cleaners)

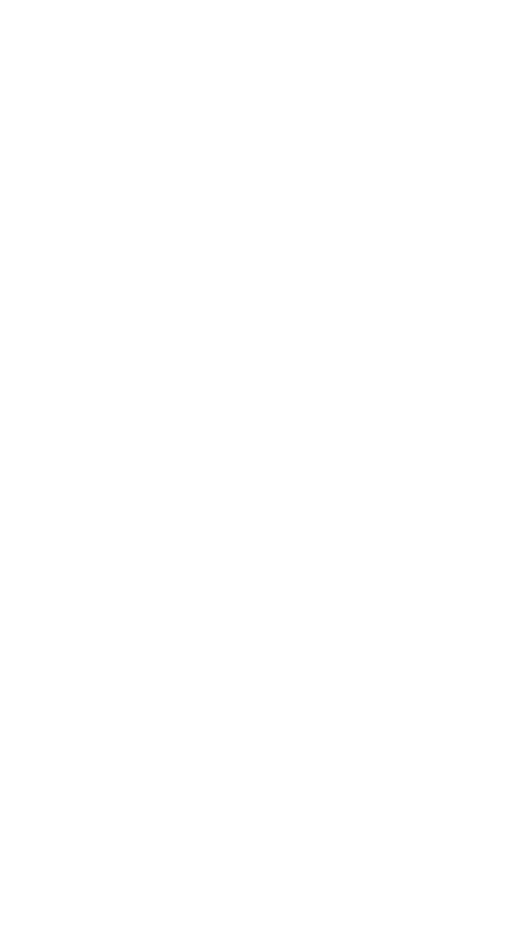

Carst & Walker opens a state-of-the-art personal care laboratory in South Africa, expanding beyond distribution to become a complete solutions provider.

By Abby Vorster

Carst & Walker, a leading supplier of speciality raw materials across multiple industries, has announced the opening of a new personal care laboratory in Pretoria, South Africa. This strategic investment strengthens the company’s position in the local cosmetics manufacturing and personal care industry while transforming its role from pure distributor to full-service “solutionator.”

The new facility represents a significant commitment to innovation, growth and support for the South African personal care industry. Designed as a technical hub, the laboratory will assist customers and Carst & Walker’s sales team with formulation development, product innovation, troubleshooting and factory support.

"

We are also a ‘solutionator’ that can support customers in every way"

“Now, we not only offer raw material distribution, but we are also a ‘solutionator’ that can support customers in every way,” states Nadia Dixon, formulation product manager – consumer specialities at Carst & Walker.

This evolution aligns perfectly with the broader vision of the business in expanding its Consumer Division and capturing greater market share across the regions in which it operates.

The laboratory is equipped to support research and development efforts across multiple categories, with primary focus areas including beauty care, home care and pharmaceuticals.

This complements Carst & Walker’s already robust consumer specialities portfolio, which spans home care, pharmaceuticals, hair care, skin care, colour cosmetics, and fragrances.

Key services offered by the new laboratory include:

• Formulation development and raw material recommendations.

• Concepts and trends exploration, creating innovative textures and helping customers launch products faster.

• Initial stability testing to guide formulation improvements.

South African cosmetics and personal care manufacturers stand to gain significant advantages from this local technical resource. With access to Carst & Walker’s global supplier partnerships, customers can leverage

The personal care lab will facilitate enhanced technical collaboration through face-to-face customer interactions and online meetings with partner teams across the UK, Ireland, Australia, and East Africa. Plans are already underway to develop a specialised sensory team for further service expansion.

cutting-edge solutions and tailored innovations to meet diverse market needs without the delays associated with international consultation.

The industry has responded enthusiastically to the opening of the laboratory.

Customers are immensely excited to work with us, and there has been an influx of requests to support them in development and technical support,” Nadia adds. “Senior and junior developers in the industry are keen to use the laboratory’s expertise for their product development initiatives.”

This new laboratory builds on Carst & Walker’s established reputation as a solution-oriented distributor, specialising in high-quality raw materials. The company serves six main sectors including adhesives and coatings, agricultural chemicals, general chemicals, consumer specialities, food ingredients, and polymers.

With offices and warehousing facilities strategically located across South Africa, East Africa, West Africa, the United Kingdom,

Ireland, and Australia, Carst & Walker combines global reach with local expertise. Its technically trained staff offer consultation and solutions for formulations, sourcing niche ingredients and ensuring compliance with international and local regulations.

In the consumer specialities segment specifically, the company provides essential ingredients for home care products (including pine chemicals, thickeners, and surfactants), pharmaceuticals (excipients and APIs),

hair care, skin care, colour cosmetics, and fragrances etc.

The new personal care laboratory represents Carst & Walker’s commitment to deepening these capabilities, positioning the company as a leading supplier and innovation partner for South Africa’s growing personal care industry. •

In a groundbreaking advancement for inclusive hair care science, Xpozuki™ biotech ingredient emerges as a powerful ally against environmental stressors for all hair types. Consuelo García, Eva Gómez, Ramón Subirós, Sandra Méndez, Albert Soley, Gemma Mola, Núria Almiñana and Raquel Delgado of Lipotec explore the benefits of this novel natural active ingredient.

With the rapid change in environmental conditions, consumers are growing more concerned about the impact of exposure to pollution on human health. In 2005, epidemiologist Christopher Wild coined the term ‘exposome’ to refer to the lifelong totality of exposure to environmental and lifestyle factors.

The concept would later be adapted to dermatology, which marked a shift in the way scientists viewed the impact of environmental factors on the skin.1 Until then, the impact of these factors was studied separately, and molecular crosstalk was poorly understood. 2, 3 But, when the impact of several environmental aggressors was combined – for example air pollutants and UV radiation, or temperature and

UV radiation – the results could not be explained by the cumulative effect of each of the factors. 4 This suggested that there may be synergistic effects and molecular crosstalk, which could only be interpreted through an exposome approach.

In this article, the Lipotec team reports on the combined effects of UV radiation, air pollution, greenhouse damage and pollen on the hair and scalp. Xpozuki™ biotech ingredient (INCI: Water (and) Glycerin (and) Leuconostoc/Radish Root Ferment Filtrate (and) Phaseolus Angularis Seed Extract (and) Citric Acid (and) Levulinic Acid (and) Sodium Levulinate), which can be used in leave-on and rinse-off hair care applications, was found to protect, defend and repair damage caused by factors of the exposome.

RESULTS AND METHODOLOGY: PROTEIN CARBONYLATION PROTECTION

Human hair shafts from Asian (type 1), African (type 4A) and Caucasian (type 1) donors (according to Andre Walker Hair Typing System) were treated with the natural active ingredient at 1% (v/v) for 30 minutes. Then the hair shafts were dried by natural evaporation at room temperature and stressed with cedar pollen (only for Asian hair), followed by particulate matter PM10 (150 μg/cm ² ) and UV-A irradiation for six hours.

Subsequent to exposome stress, protein carbonylation was measured using a specific fluorescent probe. For hair shaft cross-sections, in each image, the quantification of carbonylation level was independently obtained for the different compartments (cuticle or cortex) and for the whole hair. Three images per condition were used to quantify carbonylation levels.

As shown in figure 1 (for Afrotextured hair shafts type 4A), exposome stress significantly increases protein carbonylation. Because proteins are the major constituents of the hair shaft, it is crucial to protect them against oxidative damage caused by exposome stress. Results from this study indicate that Lipotec’s natural active ingredient has a high efficacy protecting the hair shaft from protein oxidation caused by exposome stress.

"Exposome stress can induce severe damage of the human scalp and hair "

1: Relative carbonylation level in Afro-textured, type 4A hair shaft exposed to exposome stress damage and treated with the natural active ingredient at 1%. Carbonylation level in the whole hair (A) and in the different compartments: cuticle (B) and cortex (C). D) In situ visualisation of oxidised proteins on lateral cuticle view and cross-section of hair (sagittal view). Data shown as MEAN ± SEM of the mean of three images. Statistical significance – ** p<0.01, **** p<0.0001 calculated using one-way ANOVA test.

Lipotec performed an in vivo clinical study using a final formulation containing 2% of the natural active ingredient to confirm the cosmetic benefits of the product under exposome stress damage. The clinical study was carried out on a multi-ethnic panel of 62 healthy, adult female volunteers of Caucasian, Asian, Latin American or African descent, with hair types ranging from 2A to 4B. These volunteers were divided in two different groups:

1. the active group (applying an active formulation containing 2% of the natural active ingredient twice a day, n=32)

2. the placebo group (applying a cosmetic formulation without any active ingredient, n=30).

The formulation was applied once a day on the hair for 14 days.

All the study volunteers spent four hours/daily outdoors in Rio de Janeiro, Brazil, which is one of the top 10 greenhouse gas emitting countries in the world. Different parameters were evaluated at different time points during the study.

"Lipotec’s natural active ingredient has a high efficacy protecting the hair shaft from protein oxidation"

Figure 2: A) Variation in hair frizz after 14 days of treatment (**p<0.01 vs initial time) versus placebo. A Wilcoxon test was used after checking the normality distributions with a Shapiro-Wilk test. B) Hair photographs of a volunteer with Afro-textured hair, type 4B, before and after 14 days of treatment showing frizz control.

Figure 3. A) Variation in hair volume after 14 days of treatment with the natural active ingredient at 2%. Data shown as Mean increase including statistical significance: l.s <0.01 vs initial time. A Wilcoxon test was used after checking the normality distributions with a Shapiro-Wilk test. B) Hair photographs of a volunteer with Afro-textured hair type 3C, before and after 14 days of treatment and overlapping images showing frizz control.

AN EFFECTIVE HAIR TREATMENT

The ability of the natural active ingredient to improve frizz and volume control was evaluated globally on the volunteers’ hair by a hair expert at initial time and after 14 days of product application using a scale of 0 to 4.

The hair expert also graded the volunteers throughout the study. The expert wasn’t allowed to reference previous scores at post-baseline assessments. As shown in figure 2, treatment with the natural active ingredient significantly reduced hair frizz.

For hair volume control, volunteers with curly and coiled hair (hair types from 3A to 4C) were evaluated as described previously at initial time and after 14 days of product application. Figure 3 shows an improvement in hair volume control by 19.9% after treatment with the natural active ingredient.

DISCUSSION AND CONCLUSION

It is well-reported that oxidative stress initiates complex biological processes that lead to the oxidation of major macromolecules (e.g., lipids, proteins and deoxyribonucleic acids), to impact the quality of the hair. 5-9

The Lipotec team has demonstrated that exposome stress can induce severe damage of the human scalp and hair. In hair, their research has shown that exposome damage can lead to a reduction in hair vitality. Exposome damage may cause cuticle damage, which allows moisture to pass through and swell the hair strands, leading to hair frizz.

Xpozuki™ biotech ingredient is a new natural active ingredient that can

protect the scalp and hair against the exposome, including the combined effect of UV radiation, air pollution, greenhouse stress and pollen.

In vitro, the active ingredient can protect scalp cell viability while repairing the damage after exposome stress. It also protects hair fibres from protein carbonylation and lipid peroxidation.

In vivo , applying the active ingredient on hair in a leave-on serum formulation showed a multifunctional effect, improving frizz and volume control on multi-ethnic hair types.

Available in South Africa from Savannah Fine Chemicals, Xpozuki™ biotech ingredient can be used in scalp and hair care formulations to support all consumers in their need to feel more protected from environmental aggressors, empowering them to explore, discover, and enjoy the great outdoors once again. •

The authors thank all the research technicians and scientists from Lipotec´s R&D department for their contributions during the development of this project.

REFERENCES:

1. Krutmann J, Bouloc A, Sore G, Bernard BA, Passeron T. The skin aging exposome. J Dermatol Sci. 2017 Mar;85(3):152-161. doi: 10.1016/j. jdermsci.2016.09.015. Epub 2016 Sep 28. PMID: 27720464.

2. Jacobi U, Engel K, Patzelt A, Worm M, Sterry W, Lademann J. Penetration of pollen proteins into the skin. Skin Pharmacol Physiol. 2007;20(6):297-304. doi: 10.1159/000108101. Epub 2007 Sep 11. PMID: 17851273.

3. Pointner L, Bethanis A, Thaler M, Traidl-Hoffmann C, Gilles S, Ferreira F, Aglas L. Initiating pollen sensitization - complex source, complex mechanisms. Clin Transl Allergy. 2020 Aug 31;10:36. doi: 10.1186/ s13601-020-00341-y. PMID: 32884636; PMCID: PMC7461309.

4. Grover S, R. Global warming and its impact on skin disorders. Indian J Dermatol Venereol Leprol 2009;75:337-339

5. Denisow-Pietrzyk M. Human Skin Reflects Air Pollution – a Review of the Mechanisms and Clinical Manifestations of Environment-Derived Skin Pathologies. Polish Journal of Environmental Studies. 2021;30(4):3433-3444. doi:10.15244/pjoes/130525.

6. Wendy Roberts, Air pollution and skin disorders, International Journal of Women's Dermatology, Volume 7, Issue 1, 2021, Pages 91-97, ISSN 23526475, https://doi.org/10.1016/j.ijwd.2020.11.001

7. Halliwell B, Cross CE. Oxygen derived species: Their relation to human disease and environmental stress. Environ Health Perspect 1994;102 Suppl 10:5 12

8. Kampa M, Castanas E. Human health effects of air pollution. Environ Pollut 2008; 151:362 7

9. Kohen R, Gati I. Skin low molecular weight antioxidants and their role in aging and in oxidative stress. Toxicology 2000; 148:149 57.

Lipotec –www.lubrizol.com/Personal-Care/Lipotec Savannah Fine Chemicals –www.savannah.co.za

The beauty and personal care industry is undergoing a transformation in response to evolving consumer values. Ethical, sustainable and health-conscious products now dominate consumer demand, driving interest in vegan and plantbased ingredients. Dr Katja Skrabania and Anne Mu of Evonik highlight how biotech-based, vegan collagen is emerging as a game-changer, enhancing product formulations and consumer appeal.

Collagen is an essential protein abundantly found in the human body, particularly in the skin, where it plays a key role in maintaining structural integrity, elasticity and strength. However, collagen levels decline upon ageing by approximately 1% to 1.5% annually, leading to visible signs of ageing, including fine lines and wrinkles.

Collagen has been a popular ingredient in the world of cosmetics and dermatology for decades and is traditionally sourced from animal-derived materials. Increasingly, however, consumer expectations around ethical sourcing and sustainability have rendered animal-based supply chains insufficient.

Modern consumers demand more than effective beauty solutions – they expect ethical sourcing, sustainability and transparency. This has inspired innovative approaches to collagen production, leading to three distinct vegan collagen alternatives:

1. Plant-based collagen mimics: Ingredients such as soy protein or natural gums can mimic collagen’s functionality without being true collagen structures, presenting a plant-based solution for consumers.

2. Animal cell-based collagen: Although not strictly vegan, this method utilises animal cells to produce collagen in a cruelty-free manner that is more sustainable than traditional animal sourcing.

traceability. Biotech-based production and its inherent design flexibility open doors to unique collagen sequences, which were previously unattainable.

For instance, it is now possible to produce collagen that matches human skin collagen with 100% accuracy or create ‘designer collagens’ with amino acid sequences tailored for optimal performance.

Recognising the growing demand, Evonik has pioneered advancements in fermentation-based ingredients, leading to the introduction of Vecollage® Fortify L (INCI: Water, Glycerin, sh-Polypeptide-69).

Biotech-based collagen: Perhaps the most exciting development, collagen from precision fermentation harnesses recombinant microorganisms, such as bacteria and yeast, or plants to produce collagen.

The controlled nature of the biotechnological production process ensures vegan certification, consistent quality, and enhanced

This revolutionary vegan and skinidentical collagen polypeptide is 100% identical to human collagen type III, offering dual benefits by protecting against degradation of the extracellular matrix (ECM) and stimulating the biosynthesis of vital ECM components, including various collagen types (I, III and IV), elastin, and fibronectin.

Additionally, the collagen polypeptide promotes intercellular communication between keratinocytes and fibroblasts through exosome-mediated microRNA regulation, notably downregulating keratinocyte-derived exosomal miRNA

"It is now possible to produce collagen that matches human skin collagen with 100% accuracy "

let-7b, which upregulates COL4A1, a gene marker for collagen type IV in the basement membrane of the dermalepidermal junction.

Clinical studies highlight the ingredient's rejuvenation efficacy.

Over 30 and 60 days, a formulation containing Vecollage® Fortify L showed substantial improvements in skin ageing markers, firmness, elasticity and dermal density among 35 female participants aged 38 to 58.

Key results include:

• Wrinkle reduction across multiple facial areas: 7% to 10% at 30 days

(D30) and 12% to 17% at 60 days (D60).

• Skin firmness: +8.3% at D30 and +19.2% at D60.

• Elasticity: +8.8% at D30 and +18.2% at D60.

• Dermal density: +16.6% at D30 and +31% at D60.

By delivering exceptional performance with ethical and sustainable sourcing, Vecollage® Fortify L sets a new benchmark in the cosmetics market, aligning with the values of environmentally conscious consumers.

Biotech-based collagen represents a lasting trend in consumer values towards sustainability and transparency. Evonik is innovating non-animal, sustainable collagen ingredients, shaping the future of beauty with ethical innovation.

Keep an eye on Evonik’s upcoming collagen launches, and for enquiries, send an email to Jacques.strydom@evonik.com . •

DISCOVER OUR MODERN ANSWER TO THE AGE-OLD QUEST FOR BEAUTY & LONGEVITY

Vecollage® Fortify GP

Vegan & skin-identical collagen polypeptide

Dual mechanism to protect & replenish collagen in the skin

Precision fermentation-based process using renewable feedstock

Self-preserved without listed preservatives

Plants have long been valued for their healing properties, forming the foundation of traditional medicine and modern nutraceuticals. With rising demand for vegan, ecofriendly and plant-based solutions, nutraceuticals now bridge ancient wisdom and cutting-edge science to offer therapeutic benefits.

Since ancient times, plants have been recognised for their medicinal properties, offering a holistic approach to health and wellness. The 21st century has been met with an urge for plant-based substances that provide health benefits beyond basic nutrition giving rise to the term ‘nutraceuticals’, which help in the management of specific conditions.

Most nutraceuticals are plant-based and represent a fascinating intersection of tradition and modern science. The discovery of bioactive compounds in plants – such as alkaloids, flavonoids and terpenoids – has led to the creation of standardised herbal extracts with therapeutic effects on the body’s biological systems. As veganism and cruelty-free products gain popularity, the nutraceutical industry has expanded to include a broad range of options such as dietary supplements, functional foods and herbal medicines. With precision and science at its core, the market for nutraceuticals has flourished to $117 billion and is projected to grow by over 7% annually in the coming years.

Increased awareness of environmental and animal welfare concerns is driving a shift toward eco-friendly and vegan products across industries – and nutraceuticals is of no exception. Sustainable practices like ethical sourcing and advanced extraction methods reduce waste while supporting local communities and social responsibility.

Cutting–edge techniques such as precision fermentation offer more sustainable, plantbased alternatives that often outperform traditional options. Prioritizing sustainability helps meet regulatory demands, opens new markets, and enhances product transparency, fostering further innovation.

Over the past few decades, plant-based and vegan nutraceuticals have undergone a significant evolution, with some gaining widespread recognition for their efficacy and ability to replace traditional pharmaceutical options.

For instance, curcumin, the active compound found in turmeric (Curcuma longa ), has become a central focus in the realm of natural health due to its extraordinary anti-inflammatory, antioxidant and therapeutic properties. This golden-yellow wonder is now firmly established as a key player in the natural health arena, offering a healthier, more sustainable alternative to many conventional medications.

Different formulations and metabolites of curcumin have also been developed to address issues like poor solubility and bioavailability. It’s this adaptability that makes plant-based nutraceuticals, including curcumin, a valuable tool for preventative healthcare in the modern age.

Garlic ( Allium sativum ) is another herb that has gained significant attention in modern science for its powerful immune-boosting properties and ability to ease cold and

flu symptoms. This has sparked growth in standardised garlic extracts, including aged garlic, in the nutraceuticals market.

Black cumin (Nigella sativa), is another highly regarded herb. It boasts a wide range of health benefits, including support for metabolic and cardiovascular health and protection against digestive, liver, kidney and neurological issues. With so much potential, black cumin has drawn increased interest within the global nutraceuticals market.

The rhizome of ginger (Zingiber officinale) has a long history of use for supporting digestion and inflammation control. Modern science has validated its benefits, leading to its wide use in nutraceuticals to manage conditions like cold, nausea, arthritis, migraine, and hypertension.

Personalised nutrition and precision medicine continue to evolve, nutraceuticals based on vegan ingredients and plant-based extracts are likely to play a key role in tailoring health solutions

Sabinsa – sabinsa.co.za

"Plant-based nutraceuticals are a valuable tool for preventative healthcare in the modern age"

Can a product be plant based but not cruelty free? If so, would the product be considered vegan? What does it mean to be vegan? In this article, Nadia Rashid, technical and regulatory affairs manager of CTFA, answers these questions.

The movement of veganism has made its mark worldwide, permeating many industries. Research and development is churning out vegan alternatives in just about everything from cows’ milk to faux fur. With the onset of the green revolution in the past decade, environmental awareness has struck a chord with many. Diving deeper into a more sustainable way of living has

influenced lifestyle choices, arguably for mainly health and ethical reasons. ‘Better for the planet, better for you’ mantras resonate globally.

Vegetarianism has been around since before farming began, steeped in traditional cultures. The predominantly plant-based diet is not a novel concept.

A ‘stricter’ version of vegetarianism is veganism, and it is far more complex than simply limiting food choices to mainly plant-based substances. Like vegetarianism, which has various levels such as ovo-lacto vegetarians or lacto vegetarians whereby eggs and milk or just milk respectively is added to the core plant-based diet, degrees exist within the sphere of adherence to veganism.

A vegan diet excludes all products of animal origin. Unlike vegetarians, who may consume animal by-products such as honey, eggs or dairy, vegans avoid these entirely. However, veganism often extends beyond just dietary choices. Some vegans consider additional factors, such as whether to

patronise restaurants that also serve animal products, despite offering vegan options. The most committed vegans may further examine whether animal-derived materials like leather, wool or animalhair brushes are used in the preparation or service of their food. This spectrum of commitment raises an interesting question: where along this continuum do most vegans begin their practice, and what represents a reasonable boundary for ethical veganism?

Let us explore how the vegan trend has played out in the cosmetics industry and clarify some often-misunderstood concepts. When it comes to the ingredients used to formulate a cosmetic product, we can identify various levels of compliance, like those in vegan food practices. Levels one to three are explained below:

1. The product does not contain any substance of animal origin. Regardless of whether the substance was sustainably sourced, if it is of animal origin, including beeswax,

honey, lanolin, it is not permitted. By deduction, this means that it will have plant-based or synthetic substances only in the formulation. It is important to note that the use of synthetic ingredients is not totally in line with the green concept but it is technically allowed.

2. Neither the ingredients used, nor the end product have been tested on animals. When it comes ingredients non-animal testing is assessed from a historical perspective. The non-animal testing of substances or ingredients for cosmetics is a prevalent ruling followed by South Africa and Europe. The ingredient’s history of animal testing lends itself to ethical reasons, which forms part of the next layer of veganism, but the concept of not testing on animals is not isolated to vegans alone.

3. No part of the packaging, process and manufacture has been tainted with substances of animal origin, or the cruelty of any animal, plus the brand is entirely vegan.

According to the Vegan Society, “Veganism is a philosophy and way of living which seeks to exclude – as far as is possible and practicable – all