Colours and flavours shaping food trends Future forward beverage tech processing Lower footprint labelling

It’s the only one of its kind in the country to target decision makers in the manufacturing of food, beverages and their related industries. It offers incisive and authoritative reports on all aspects of the process, from raw material sourcing, to manufacturing and packing, right down to the distribution and marketing of finished goods. Food Review informs readers about the introduction of new ingredients, equipment, products and packing, and provides objective commentary on cuttingedge local and international market trends and issues.

contribute editorially contact Kelebogile (Lebo) Nondzaba kelebogile.nondzaba@newmedia.co.za

New Media, Ground Floor 272 Pretoria Avenue Randburg, 2194 SA_FoodReview www.facebook.com/FoodReview13

+27

For advertising enquiries, contact Anita Raath anita.raath@newmedia.co.za +27

Candida

+27

1918

www.foodreview.co.za

To

(0)78 175 9632

82 976 6541 or

Giambo-Kruger

(0)71 438

candida.giambo-kruger@newmedia.co.za

journal for food and beverage manufacturers

South African

CONTENTS

APRIL • JUNE 2024 Vol. 13 • No. 2

7 WHAT’S NEW

The latest food and beverage products on South Africa’s shelves.

8 NEWS

Exploring Africa’s food potential

New functional water concepts

Cocoa Shortage Grinds Processors to a Halt

10 COMPANY FOCUS

Elevating Vacuum Technology

12 COLOURS & FLAVOURS

Micronized food colours

Elevated visual appeal natually

2024 flavours taste charts

18 INDUSTRY TALK

How metal detectors work

20 BEVERAGE PROCESSING TECH

Optimise CIP with precision instrumentation

Brewing with precision

Nature multipack with a universal adhesive

Crafting bold and flavourful beverages

26 LABELLING

A greener beverage industry

Eco-labels for exquisite drinks

Lower footprint labels

Celebrating 50 years of incredible success

Market – leading versatility

EDITORIAL

Editor: Kelebogile Nondzaba +27 (0)78 175 9632 kelebogile.nondzaba@newmedia.co.za

Sub-editor: Gill Abrahams

Layout & Design: David Kyslinger

ADVERTISING

Key Account Manager: Anita Raath +27 (0) 82 976 6541 anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918

candida.giambo-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien

Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de Italy: Ngcombroker

Giacomo Rotunno +39 370 101 4694

g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318

sydneylai@ringier.com.hk CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za PUBLISHING TEAM

General Manager: Dev Naidoo

Production Manager: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

New Media Publishing, Ground floor 272 Pretoria Avenue, Randburg Tel: +27 11 713 9000

POSTAL ADDRESS

PO Box 784698, Sandton, Johannesburg 2146

Published by New Media a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

HEAD OF HR: Leone Fouche

CEO: MEDIA24: Ishmet Davidson

HEAD OFFICE

New Media, a division of Media24 (Pty) Ltd 8th floor, Media24 Centre, 40 Heerengracht Cape Town, 8001 Tel: +27 21 406 2002

Email: newmedia@newmedia.co.za

PO Box 440, Green Point, Cape Town 8051 www.newmedia.co.za Food

Africa

FOOD Manufacturing

Manufacturing Africa is published by New Media, a division of Media24 (Pty) Ltd quarterly and circulates to executives in the food and beverage industries. Views expressed in this journal, other than where specifically stated, are not necessarily those of the publisher. The editor welcomes for publishing consideration news items, press releases, articles and photographs relating to developments in the food and beverage industries. No responsibility is accepted should contributions be lost.

2309-5334

Manufacturing Africa is printed and bound by CTP Printers.

are prohibited from using the contact details displayed in any advertisement or editorial within the pages of this publication to generate and/or distribute unsolicited bulk emails or other forms of mass marketing correspondence. 2024 Quarter 2 | Food Manufacturing Africa 3

Copyright: all rights reserved. ISSN

Food

Readers

Navigating a changing food landscape

Welcome to another edition of Food Manufacturing Africa!

As we delve into this month's issue, it's impossible to ignore the complex challenges facing our industry. Food security, sustainability, and rising costs are at the forefront of everyone's minds. But amidst these concerns, there's also a wave of innovation that offers solutions and exciting possibilities. One of the themes covered in this issue is colours and flavours and on page 12 ROHA introduces ChromaFine, an innovative range of ultrafine micronized food colours, to its extensive collection of natural food colourants. Find out how it adds rich, authentic colours to

The beverage industry

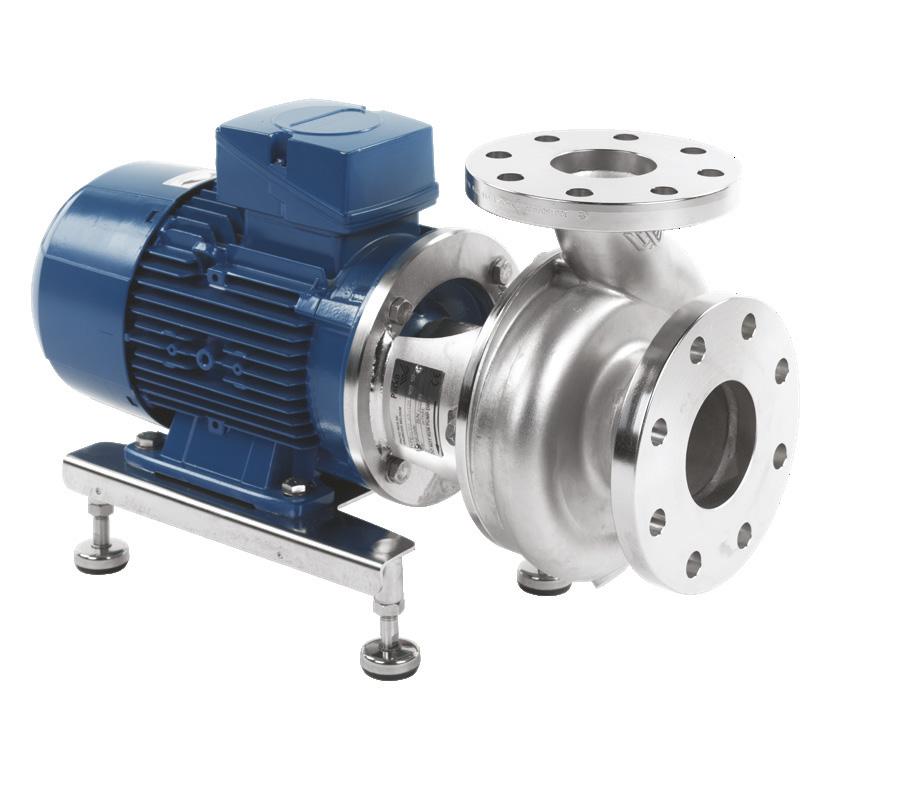

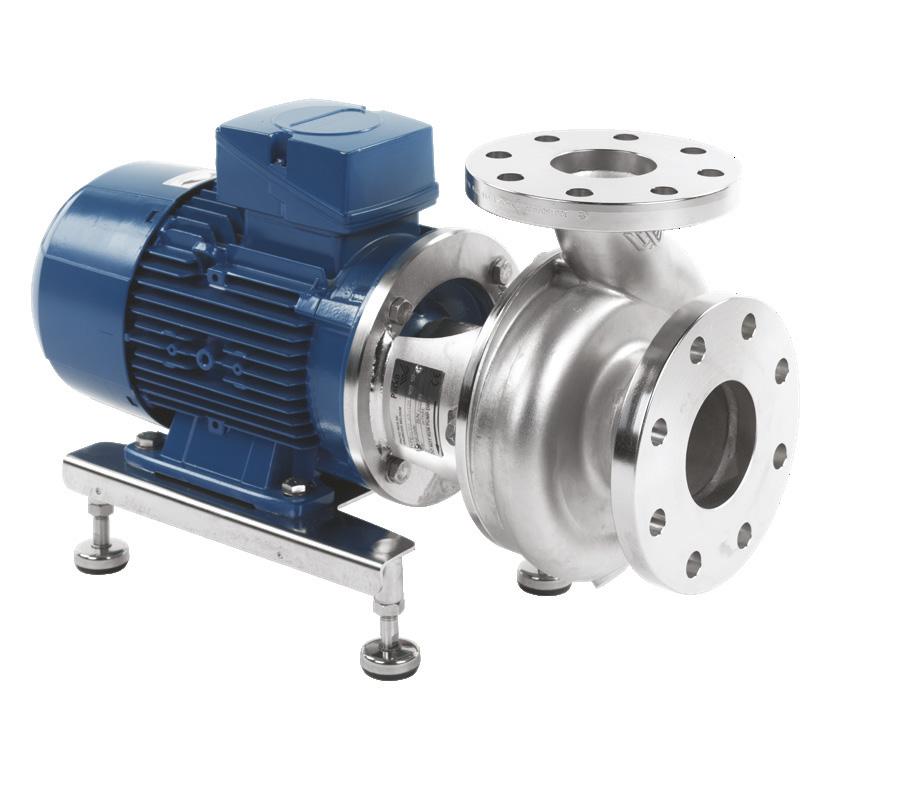

is experiencing a tech boom, and we explore the exciting advancements in beverage processing technology, from high-pressure processing that preserves flavour and nutrition to automation that streamlines production. Verder Pumps, on page 25, highlight the importance of choosing the right pumps to ensure safe, high-quality products and avoid costly downtime. With consumers increasingly demanding transparency, clear and informative labelling is paramount. We discuss the latest trends in food and beverage labelling,clean labels, the importance of highlighting functinal ingredients as well as ethical sourcing. UPM Raflactac showcases a new collection of responsibly sourced label materials for wine, spirits and beverages, see page 28

Join the action at Africa's Big 7 this June at the Sandton Convention Center in Johannesburg, South Africa. Discover more industry events on our diary page 5.

Happy reading!

(Lebo) Nondzaba +27 (0)78 175 9632 Kelebogile.Nondzaba@newmedia.co.za

Kelebogile Nondzaba 4 Food Manufacturing Africa | 2024 Quarter 2 ADVERTISERS’ INDEX Avery Dennison ........................................................ 31 ............ www.averydennison.com Busch Vacuum SA (Pty) Ltd ............................. 10, 11 ............ www.buschvacuum.com Endress & Hauser (Pty) Ltd ................................... 21 ............. www.endress.com FlavorLogik (Pty) ltd ............................................. OFC ............ www.flavorlogik.co.za Heat & Control SA (Pty) Ltd ................................... 19 ............ www.heatandcontrol.co.za Ink Jet Printers CC ..................................................... 29 ........... www.inkjet.co.za Polyoak Packaging ......................................... 9 ............ www.polyoak.co.za ROHA SA .......................................................... 13 ............ www.roha.com Savannah Fine Chemicals ............................15 ............ www.savannah.co.za Sensetek CC .....................................................17 ............ www.sensetek.co.za Vega Controls SA (Pty) Ltd ......................... 23 ............ www.vega.com Verder Pumps South Africa (Pty) Ltd ..... 25 ............ www.verder.com EDITORIAL

C àndida Giambò -Kruger +27

438 1918 Candida.Giambo-Kruger@newmedia.co.za KEY ACCOUNT MANAGERS Anita Raath +27 (0)82 976 6541 Anita.Raath@newmedia.co.za PRODUCTION CONTROLLER: Mandy Ackerman +27

998 7541 Mandy.Ackerman@newmedia.co.za TO ADVERTISE CONTACT EDITOR'S COMMENT

Kelebogile

(0)71

(0)83

Ishida Europe has extended its range of QX Flex tray sealers with the launch of a new model, which meets market demands for a compact, high-performance solution. The innovative model also maximises output, capacity and flexibility for medium- to high-volume production lines.

Sustainability is an integral part of Multivac’s strategy. For 60 years, the company’s packaging solutions have ensured that sensitive products globally can be processed efficiently, as well as being packed hygienically, reliably and attractively.

Rotolabel is passionate about the environment and focuses on minimising any negative ecological impact of its products. The company subscribes to the four Rs of packaging sustainability: responsible sourcing; reduction of materials; recyclability and increased recycled content

Interested in advertising in

If you are a supplier to the packaging industry, this will be an ideal opportunity to showcase your product offering and create additional brand awareness within the food, beverage, pharmaceutical, cosmetics, personal care, and home care manufacturing sectors.

PACKAGING

REVIEW?

Review A full-service experience ADVERTISING Read more in the latest issue of Packaging Review Out Now! Contact our advertising sales executives to book your space: Anita Raath Sales executive +27 (0)82 976 6541 Carla Melless Sales executive +27 (0)83 260 6060 Càndida Giambò-Kruger Sales executive +27 (0)71 438 1918 SIGNUP

2024 DIARY

June 2024

Africa’s Big 7

Johannesburg, South Africa

11 – 13 June www.africabig7com

Food & Beverage W/Africa

Lagos, Nigeria

11 – 13 June www.fab-westafrica.com

AFMAS Food EXPO

Eastern Africa

12-14 June www.afmass.com

Dairy Manufacturing Africa Expo

Co-located with Afmas Food Expo

12 – 14 June www.dairymanufacturingafrica.com

July 2024

Organic & Natural Expo Africa

Sandton Convention Center

12 – 14 September www.organicandnaturalportal.com

August 2024

Food Show Africa

Johannesburg, South Africa

5 – 7 August www.foodshowafrica.com

Morocco SIEMA Casablanca, Morocco

27 – 29 August www.siemamaroc.com/

6 Food Manufacturing Africa | 2024 Quarter 2

Showcasing Oryx Chilli Salt

Oryx Desert Salt is delighted to announce the launch of their brand-new flavoured salt: Oryx Chilli Salt. The new flavour comes because of their exciting collaboration with Backyard Farms (BYF), a local, social-upliftment enterprise. BYF has created an innovative supply-chain business model, sourcing chillies from township-based, home and community gardeners, grown exclusively for Backyard

Winter flavour trends to savour

South African winters might be far milder than our European counterparts, but the cooler temperatures, longer nights and in some parts, increased rainfall means that our taste buds call for a vastly different array of flavours. Fresh salads, burgers on the braai and fruit platters no longer cut it when the temperature drops. Adi Meintjes, co-founder of Banhoek Chilli Oil, offers a round-up of a few winter flavour trends to inspire culinary endeavours in the months to come:

Comforting spices: Whether it’s morning oats or evening hot chocolate, consider a sprinkle of cinnamon or nutmeg to bring warmth and comfort to old favourites. Ginger and cardamom also feature more prominently in winter dishes. Look out for the Babylonstoren Spicy Citrus Hot

Chocolate, which is only on offer in the winter months. With cinnamon and chilli this is bound to bring warmth on the coldest nights.

Rich umami: The Japanese word "umami” directly translates to the "savoury deliciousness” and can be found in items such as mushrooms, miso, soy sauce, and aged cheeses. These items can add richness and complexity to winter meals, satisfying the craving for hearty, savoury dishes.

Just like your seasonal wardrobe, incorporate some of these trends to transition your taste buds to winter 2024.

To read more, visit: Foodreview.co.za

Farm food products. Oryx Chilli Salt is a fullflavoured salt that now adds a spark of chillifire warmth to any meal. Chilli-flakes make up 20% of the volume of each grinder, so you’re certain to get an umami burst of chilli-heat with every grind.

To read more, visit: Foodreview.co.za

2024 Quarter 2 | Food Manufacturing Africa 7 WHAT’S NEW Images: Supplied by client, Shutterstock.com

New functional water concepts at Vitafoods Europe 2024 Exploring Africa's food potential

In the latest episode of Connecting Africa, CNN International’s Eleni Giokos delves into the untapped opportunities for food production on the continent, exploring the innovative approaches, sustainable practices, and growth trajectories that could revolutionise Africa’s food production.

In Nigeria, an estimated $10 billion is spent importing food to make up for a gap in local production, according to the International Trade Administration. Many are looking to cassava, a root vegetable, to close that gap.

Kola Adeniji, CEO of Niji Farms tells CNN, “Cassava is one of the most valuable crops that we can grow in Africa.”

The root vegetable is similar to a potato, it is gluten free and can be used as a base for many dishes, with its byproducts ranging from flour to ethanol. Yemisi Iranloye, CEO of Psaltry International explains, “We are looking at being able to replace everything that corn and wheat can do with cassava.”

One of the challenges to expanding the market is the difficulties faced while processing cassava. This is why researchers at the International Institute of Tropical Agriculture (IITA) are working to develop crop varieties. Mercy Diebiru-Ojo, Seed System Specialist at IITA talks about the process, “Nigeria is the largest producer of cassava. However, in terms of yield, we are not even around the top 10. And this is because we are not using the right planting materials. So, this is the narrative we are trying to change. We want to change that trajectory. We want farmers to get access to good, healthy planting material of improved varieties. The researchers now, they are breeding or developing varieties that are suited or tailored to meet specific needs.”

In South Africa, the sugar industry is valued at over 20 billion rand annually with sugarcane the country’s second-most valuable crop. But the 2018 introduction of a tax on sugar-sweetened drinks to reduce consumption and address health concerns greatly impacted the industry.

To read more, visit: Foodreview.co.za

Arla Foods Ingredients will showcase the potential of whey protein in beverages that combine hydration with nutritional benefits at Vitafoods Europe 2024.

Research shows that 61% of global active and lifestyle nutrition consumers are looking for functional beverages that provide health benefits beyond nutrition.1 At Vitafoods Europe (14th to 16th May) Arla Foods Ingredients will showcase new functional water concepts demonstrating how its whey protein isolates can meet this need for ‘holistic hydration.’

Designed for powder shake formats, Lacprodan® ISO.WaterShake is rich in both essential amino acids (EAAs) and branched chain amino acids (BCAAs). It is easily combined with other functional ingredients, creating opportunities for additional claims for physical and cognitive wellbeing – perfect for consumers seeking convenient, holistic nutrition. For example, the new concepts will combine zinc and caffeine with protein. Offering water-like refreshment, they include solutions for ready-to-drink applications as well as powder shakes and

also contain on-trend botanical flavours. The concepts meet many of the market needs highlighted by Innova in its top ten food and beverage trends for 2024. Its research shows that 42% of consumers globally see protein as the most important ingredient, and it also predicts a stronger focus on additional functional ingredients in everyday water products.2

Sarah Meyer, Head of Sales Development, Health and Performance, at Arla Foods Ingredients, said: “Active consumers are increasingly adopting a holistic health approach, and seeking out products that offer more than one benefit. Beverages that boost their daily nutrient intake while facilitating hydration are a great example. As these new concepts demonstrate, our whey protein isolate ingredients are a fantastic way to meet this need. Designed to appeal to consumers who are taking a proactive approach to their health, they create opportunities for efficient, on-trend combinations of hydration and nutrition.”

To read more, visit: Foodreview.co.za

NEWS 8 Food Manufacturing Africa | 2024 Quarter 2

Cocoa Shortage Grinds Processors to a Halt

Transcao, an Ivorian processor and one of the largest plants in the country, announced it has ceased buying beans because of these soaring prices.

Although Transcao is currently processing from existing stock, it did not disclose the plant’s operating capacity.

Two cocoa industry sources revealed to the Cocoa Post that major state-run cocoa plants in Côte d’Ivoire could shut down. Additionally, it has been reported that major chocolate trader Cargill is struggling to source cocoa beans for its Ivorian processing plant.

In Ghana, most of the eight cocoa processing plants have suspended operations for weeks since price volatility intensified in October.

The state-owned Cocoa Processing Company (CPC) has also suspended operations, revealing to the Cocoa Post that

1 2024/04/24 10:46

due to a bean shortage.

This bean shortage has destabilised the long-established global cocoa trade system, which is heavily regulated.

Farmers typically sell beans to local dealers, who in turn sell them to global traders or local plants up to a year in advance. Local regulators set farmgate prices that farmers should charge for beans.

Global traders then sell the beans or processed cocoa products like liquor, powder, or butter to global chocolate companies such as Hershey, Nestle, and Mondelez.

During shortages, local dealers buy beans at a premium to the regulated farmgate prices to secure supply. These dealers sell the secured beans at higher prices on the spot market instead of delivering at preagreed prices.

Consequently, global traders are

high prices to meet delivery obligations with big chocolate firms. As a result, many local processors are struggling to find cocoa beans.

Ghanaian and Ivorian authorities have attempted to protect local plants by offering cheap loans and capping the amount of beans global traders can purchase.

However, the current shortage and regulatory inadequacies have inhibited local processors’ access to beans, making it difficult for them to repay loans.

Industry sources predict a market correction around September, when harvests are expected to alleviate the pressure caused by the shortage.

Nonetheless, the International Cocoa Organisation (ICCO) predicts global cocoa production will fall by 11% in the season ending September.

Source: Food Business Africa News

| Food Manufacturing Africa 9 NEWS Images: Progetto, Shutterstock.com

AC008.pdf

New Africa head office elevates vacuum technology

Kelebogile Nondzaba engages in a Q&A with Minal Debipersad, head of marketing at Busch Vacuum and Pfeiffer Vacuum Africa, to talk about the company’s rich history, current offerings, expansion plans, and the significance of their new state-of-the-art premises in Johannesburg.

Busch Vacuum Solutions has a rich history dating back to 1963 when Dr. Karl Busch and his wife, Ayhan Busch, founded the company in Maulburg, Germany. Initially, the company focused on developing vacuum pumps and systems for industrial applications. Over the years, The company has expanded its product line to include a wide range of vacuum, ultra-high vacuum and overpressure technology solutions catering to various industries such as packaging, plastics, food processing, medical, oil and gas, vacuum cooling, and more.

“Driven by a commitment to innovation and quality, Busch Vacuum Solutions has grown into one of the leading manufacturers of vacuum pumps, systems, and service worldwide. With a global presence spanning over 40 countries, our company continues to deliver cutting-edge solutions and service to meet the evolving needs of its customers,” says Debipersad.

The company plays a significant role in Busch Vacuum Solutions’ global operations, serving as the main hub for the company’s presence in the African continent from the head office in Johannesburg. Busch Africa boasts a robust presence with sales and service branches strategically located in Cape Town, Durban, and into Africa in Ghana, Kenya and Egypt.

With a dedicated team of professionals and a strong focus on customer satisfaction and service, Busch South Africa has built a reputation for excellence in providing innovative vacuum solutions tailored to the unique requirements of African markets.

Q. WHAT ARE THE COMPANY’S CURRENT OFFERINGS?

Vacuum pumps and overpressure: We provide a wide range of vacuum pump technologies, including oil rotary vane, dry rotary vane, screw, dry claw, liquid ring pumps, turbo pumps, leak detectors and blowers, catering to various applications and performance requirements.

Vacuum systems: Our vacuum systems are tailored to specific industrial processes, offering central vacuum solutions and turnkey solutions for applications such as packaging, medical and more. These systems integrate pumps, condition monitoring, controls, and accessories to optimise performance and efficiency.

Vacuum and ultra-high vacuum accessories: We offer a variety of accessories such as digital monitoring to monitor equipment health and performance, filters, gauges, valves, and fittings to enhance the functionality and performance of vacuum systems, ensuring reliable operation and maximum productivity.

Service and support: Our national service centres and certified technicians provide comprehensive support, including maintenance, repair, and optimisation services, to ensure the continued performance and reliability of our equipment.

Q. WHAT ARE YOUR FUTURE PLANS?

Expanding market presence across Africa: We aim to further expand our presence in emerging markets and industries, leveraging our expertise and experience to address evolving customer needs and market trends across the African continent. And more so with the Pfeiffer vacuum range of pumps in the high vacuum and ultrahigh vacuum applications.

Developing energy-efficient solutions: The team of engineers develop both proven and tailormade water and energy-efficient vacuum solutions that minimise environmental impact and reduce operating costs for our customers, aligning with global sustainability goals.

Advancing digitalisation: Busch and Pfeiffer have invested in digital technologies to enhance the connectivity, monitoring, and control capabilities of our pumps and systems, enabling predictive maintenance, remote diagnostics, and real-time optimisation. Acquisition of Pfeiffer Vacuum: Busch Vacuum Solutions and Pfeiffer Vacuum

10 Food Manufacturing Africa | 2024 Quarter 2 COMPANY FOCUS

have joined forces to revolutionise vacuum solutions across the globe and specifically in Africa. This expansion broadens Busch Vacuum’s market share across all four vacuum level classes, enabling them to extend their client base from medium and rough vacuum to encompass high and ultrahigh vacuum. This union marked the dawn of a new era in vacuum technology on the African continent.

Overall, our goal is to remain at the forefront of vacuum technology innovation, providing cutting-edge solutions and exceptional service to empower our customers and drive their success in an everchanging world.

WHY THE NEED FOR BIGGER AND BETTER PREMISES?

Busch Vacuum’s decision to build a stateof-the-art vacuum solutions centre in Johannesburg reflects our commitment to enhancing our operations and services across South Africa and the African continent. The new building serves as a strategic hub for various technical initiatives aimed at advancing our products and solutions to better serve our customers.

HERE’S WHY WE PURSUED THIS EXPANSION:

Increased capacity: With growing demand for our products and services in Africa, we needed a larger facility to accommodate our expanding operations, including service and pump overhauls, warehousing of stock, system building, Pfeiffer expansion and

technical testing capabilities.

Advanced facilities: The new building houses state-of-the-art facilities such as a fully equipped service centre, Pfeiffer Class 10 000 clean room, volumetric flow testing equipment, liquid ring test bay, online condition monitoring systems, and a dedicated training room. These facilities enable us to maintain the highest standards of quality, precision, and efficiency in our operations.

Enhanced customer experience: This purpose-built facility, was built to streamline processes, improve lead times, and offer more comprehensive support to our customers. The new premises also provide a platform for showcasing our capabilities and demonstrating the value of our products and services to clients and prospective clients.

Q. TELL US ABOUT THE LAUNCH?

The launch of this building on the 13th of March 2024 is a significant milestone for Busch Vacuum Solutions in Africa. It represents our ongoing commitment to innovation, excellence, and customer satisfaction.

The presence of our Co-CEO, Ayla Busch, and the head of the economic department from the German Embassy, Mr. Enrico Brandt, underlines the importance of this event and highlights the strong partnership between Busch Vacuum Solutions, key stakeholders and clients.

During the launch event we will showcase the capabilities of our new facility, demonstrate our latest technologies, and engage with clients to understand their evolving needs and challenges. It’s an opportunity for us to strengthen relationships, foster collaboration, and demonstrate the teams dedication to driving success for our customers in Africa and beyond.

EXPANDING AND INVESTING INTO AFRICA

Busch Vacuum Solutions boasts a robust presence with sales and service branches strategically located in Cape Town, Durban, Ghana, Kenya and Egypt. The expansion into Africa presents an exciting opportunity for Busch and Pfeiffer Vacuum to bring our cutting-edge vacuum technology to the markets and industries across the continent. “While we have established a strong presence in South Africa, we recognise that the vast potential of the African continent extends far beyond its borders, and there is a growing demand for innovative vacuum solutions across various sectors.” highlights Debipersad.

COMPANY FOCUS

Africa’s diverse economies and industries, ranging from manufacturing and mining to agriculture, oil and gas and healthcare, present numerous opportunities for us to make an impact. By expanding our reach into new regions and countries, we aim to leverage our expertise and experience to address the unique challenges and requirements of African businesses and industries.

With our comprehensive range of products, services, and technical expertise, we are well-positioned to support the development and growth of key sectors across Africa. Whether it’s providing vacuum solutions for packaging and processing applications in the food and beverage industry, supporting mining operations with reliable vacuum pumps, or assisting healthcare facilities with specialised vacuum systems, we are committed to meeting the diverse needs of our customers across the continent.

ACQUISITION OF PFEIFFER VACUUM

Busch has embarked on several transformative projects to introduce and advance Pfeiffer Vacuum’s cutting-edge solutions across Africa. Sean Pieterse, managing director of Busch Africa, elaborates on the acquisition of Pfeiffer Vacuum stating, “Busch Vacuum Solutions Africa has been given a strong boost with the acquisition of Pfeiffer Vacuum. As a full subsidiary of Pfeiffer we now add their world leading range of high and ultrahigh vacuum pumps, vacuum systems and components as well as leak detection services and products. Our focus is on service and being close to our customers, and we strive to be recognised as the smartest solution provider across the continent. I give our Pfeiffer customers my personal commitment that they will receive the same care and attention that Busch offers the market now.”

2024 Quarter 2 | Food Manufacturing Africa 11

Busch Vacuum Solutionswww.buschvacuum.com Pfeiffer Vacuumwww.pfeiffer-vacuum.com Image: Supplied by client

A pinnacle of innovation in micronized food colours

ROHA has recently introduced ChromaFine, an innovative range of ultrafine micronized food colours, to its extensive collection of natural food colourants.

Micronized food colours undergo a meticulous micronisation process that reduces particle size to the micron level, enhancing dispersion, solubility, and brightness. Derived from carefully sourced natural ingredients, ChromaFine adds rich, authentic colours to seasoning blends, particularly excelling in oil-based applications. Its commitment to clean label and natural solutions aligns seamlessly with consumer preferences, ensuring that seasoning products stand out for their natural appeal and original qualities. ChromaFine’s ease of blending and spreading creates intensely vibrant colour hues, maintaining high standards of quality in culinary offerings.

“With ChromaFine, users have the flexibility to create custom colour blends according to their specific requirements.”

NOTABLY, CHROMAFINE BOASTS

FOLLOWING ADVANTAGES:

Deliver vibrant, intense colour shades: ChromaFine is designed to impart vivid and striking colour shades to food products. Its micronized particles ensure that colours stand out vibrantly, enhancing the visual appeal of the final product.

Custom colour blends: With ChromaFine, users have the flexibility to create custom colour blends according to their specific requirements. Whether it’s achieving bold reds, earthy greens, or any other desired

hue, ChromaFine allows for personalised colour creations.

Evenly coat the food application: ChromaFine’s ultrafine particles enable smooth and even coating of food applications. This ensures that colours are distributed uniformly throughout the product, enhancing its overall appearance. Homogeneous colour effect: The micronised nature of ChromaFine guarantees a homogeneous colour effect. This means that the colour is evenly dispersed throughout the product, resulting in a consistent appearance without any streaks or uneven patches. No specking in fat-based creams, compound coating, and tablets: ChromaFine is specifically formulated to prevent specking in fat-based creams, compound coatings, and tablets. Its fine particles blend seamlessly with these formulations, eliminating any undesirable specks or inconsistencies.

Clean label natural colourants: ChromaFine is derived from natural ingredients, aligning perfectly with the clean label trend in the food industry. It provides manufacturers with a natural colouring solution that meets consumer preferences for clean and transparent ingredient lists.

Stability characteristics: ChromaFine offers excellent stability characteristics, ensuring that colours remain vibrant and consistent throughout the shelf life of the product. Its stability in various food applications makes it a reliable choice for food manufacturers.

In conclusion, micronized food colours, with their advantages of solubility, dispersion, and colour intensity, continue to

ABOUT US

ROHA started out in India and has since grown into a global power in the food colours and ingredients, and the industrial dyes & pigments markets. This has been achieved through a consistent pursuit of natural alternatives, technology, intensive research, sustainable sourcing and staying ahead of the latest trends to develop futureready solutions for clients. It has its beginnings in the Roha district of Maharashtra, India. The company was founded as a manufacturer of synthetic colours for industrial applications in 1972 and has always held clients at the center of what it does. This has shaped how the company does business and managed to evolve over the years. The company has led a revolution in the food colours industry through unmatched quality standards. In its present avatar, ROHA is a multinational giant dealing with natural food ingredients, food colours, pharmaceutical and cosmetic pigments, dried ingredients, and industrial colours & dyes.

play a significant role in the culinary world. ROHA’s ChromaFine leads the innovation, offering transformative possibilities in the realm of micronized food colours.

As ROHA remains at the forefront of tailormade food color solutions, customers are invited to explore the vibrant possibilities of ChromaFine and embark on a transformative journey in micronized food colours.

ROHA - www.roha.com

12 Food Manufacturing Africa | 2024 Quarter 2

Images: Shutterstock. COLOURS & FLAVOURS

Elevate visual appeal naturally

Savannah Fine Chemicals proudly showcases IFF’s revolutionary range of naturally sourced, clean - label and E-number free colours. Transform your products with these exceptional natural colours .

Savannah Fine Chemicals proudly represents IFF’s unique range of colours that are naturally sourced, clean label or E-number free, and designed to optimise visual appearance in a range of food and beverage products. These colour formulations are customised to fit each individual end use, in food and cosmetic applications.

Derived from natural sources we have two main ranges, manufactured by IFF, the BRIGHT’N FREE & BRIGHT’N PURE portfolios, which provide you with an extensive pallet of colours.

EXAMPLE APPLICATIONS:

- The natural colour line offers a full palette of customised colour formulations for beverages, from juices and extracts to cloudy drinks and Explore our range of clear colour formulations for high-colour impact without cloudiness, as well as our allin-one cloud yellow to orange emulsion for cloudy drinks.

Culinary and plant-based –The portfolio offers a wide range of clean label colours and food colourings designed to mimic meat,

such as red beet to replicate the pink colour of raw beef, turning brown when cooked. Savannah currently represents IFF natural colours on the BRIGHT’N RED, red beet juice powder and the BRIGHT’N YELLOW on beta carotene. Please don’t hesitate to contact us about your requirements.

THE RANGE OFFERS:

Water and oil soluble options

Available in liquid and powder form

Full strength concentrated and customised grades

Specific grades optimised for good heat and light stability.

Savannah Fine Chemicals –www.savannah.co.za

It’s the only one of its kind in the country to target decision makers in the manufacturing of food, beverages and their related industries. It o ers incisive and authoritative reports on all aspects of the process, from raw material sourcing, to manufacturing and packing, right down to the distribution and marketing of nished goods. FOOD REVIEW informs readers about the introduction of new ingredients, equipment, products and packing, and provides objective commentary on cutting-edge local and international market trends and issues.

NEWS 14 Food Manufacturing Africa | 2024 Quarter 2 COLOURS & FLAVOURS

Image: Shutterstock.com

www.foodreview.co.za New Media, Ground Floor 272 Pretoria Avenue Randburg, 2194 SA_FoodReview www.facebook.com/FoodReview13 To contribute editorially contact Kelebogile (Lebo) Nondzaba kelebogile.nondzaba@newmedia.co.za +27 (0)78 175 9632 For advertising enquiries, contact Anita Raath anita.raath@newmedia.co.za +27 82 976 6541 or Candida Giambo-Kruger +27 (0)71 438 1918 candida.giambo-kruger@newmedia.co.za South African journal for food and beverage manufacturers FRV 1-2.indd 1 2023/08/02 14:01

of additives to help create the taste, texture, performance and appearance you need for your food & nutritional products. We represent leading global manufacturers & our specialists can provide you with unrivalled sales support bringing the highest quality products to market:

Bakery ingredients: flavour, texture and fortification - Beverage ingredients for innovation - Confectionary: healthier & tastier alternatives to enhance your brandCulinary solutions for sauces, dressings and prepared meals that will innovateDairy & Desserts: texture and functionality - Flavour & fragrance creation - Health & sports nutrition.

2024 Quarter 2 | Food Manufacturing Africa 15

+27 21 830 5306 +27 31 313 3338

2024 flavours taste charts insights

Kerry, a global leader in taste and nutrition unveils its 2024 Taste Charts, offering a comprehensive exploration of future tastes across 13 regional markets, providing key insights into flavour trends and innovations shaping the food and beverage sector.

The culmination of Kerry’s year-long research is a series of incisive, interactive charts created separately for 13 individual regional markets, including some 30 countries in Asia Pacific, Middle East & Africa (APMEA).

The charts list mainstream, key, upand-coming and emerging tastes across five food and beverage categories, provide an in-depth analysis of the flavours, ingredients and trends that will shape innovation in the food and beverage sector in the year ahead, and inspire product and menu developers worldwide.

To illustrate today’s incredible pace of innovation, Kerry researchers conducted a deep dive into the lifecycles of two long-popular flavours — orange and chocolate — and examined how these mainstream ingredients are evolving into all manner of inventive tasty product offerings around the world. These two case studies demonstrate how popular and traditional tastes worldwide are fusing into new, innovative applications as brands source, combine and recombine flavours and ingredients from other places.

Commenting on the 2024 Asia Pacific (APAC) Taste Charts, Avinash Lal, Market Research and Consumer Insights director, Kerry Asia Pacific, Middle East & Africa (APMEA), said: “The APAC flavour scene is a vibrant tapestry, constantly evolving and influenced by diverse cultural traditions, emerging trends, and evolving consumer preferences. Consumers are rediscovering the magic of their own culinary heritage, seeking out unique regional ingredients and

“Think Sichuan peppercorn ice cream in China, Calamansi-infused yogurt in the Philippines, or black sesame latte in Japan.”

flavour profiles. Think Sichuan peppercorn ice cream in China, Calamansi-infused yogurt in the Philippines, or black sesame latte in Japan.”

Thailand and turmeric latte macarons in India.

• Young consumers are craving bold and unusual flavour combinations, driven by social media’s influence and a desire for novelty. This opens opportunities for sweetsavoury pairings like bacon milkshakes, coffee infused with black garlic, and chocolate bars with wasabi.

• The plant-based revolution is taking off, leading to new demand for creative flavour solutions in meat and dairy alternatives, such as jackfruit rendang in Indonesia, mushroom jerky in Australia, or chickpea falafel with a Middle Eastern twist.

INNOVATION

OTHER TOP INSIGHTS FOR 2024 FLAVOUR

ACROSS ASIA PACIFIC, MIDDLE EAST & AFRICA:

• Fruits such as Yuzu are gaining popularity across multiple markets and applications, with recent launches including Yuzu Gose beers in South Africa, Yuzu and pepper mayonnaise in China, and Yuzu low ABV wines and alcoholic beverages in Australia.

• In South Africa, authentic local flavours such as Chicken Dust, creative combinations the likes of chilli lemon/lime, and global culinary influence (jalapeno atchar) reflect the nation’s cultural diversity. Sweet flavour pairings are also gaining popularity, from sweet & salty, sweet & spicy, to sweet & smoky.

• Traditional spices and cooking techniques are getting a modern twist, leading to innovative dishes like charcoal-grilled skewers with fermented chilli paste in

• Passionfruit: considered a niche fruit, this cold beverage flavour appeared in all thirteen different global regions as analysed by the charts. It’s a mainstream ingredient in New Zealand but still only an early-stage emerging flavour in the Middle East.

Soumya Nair, Global Consumer Research and Insights director at Kerry, observed: “Consumers want tasty new innovations or flavours they may have experienced while travelling. We are seeing many unique flavour intersections in foods and beverages. Although rapidly changing times can present great challenges, they also provide an unparalleled opportunity for brands to catch a trend on the rise. The Kerry 2024 Taste Charts are a valuable tool for the food and beverage industry to navigate the new taste environment for products.”

Kerry Group – www.kerry.com

16 Food Manufacturing Africa | 2024 Quarter 2 COLOURS & FLAVOURS

Images: Supplied by client

Tel 011 608 4944 Fax 011 608 4948 Email sales@sensetek.biz FLAVOUR DIRECTLY FROM THE SOURCE

How metal detectors work

Food manufacturers rely on metal detectors to ensure safety. But what causes false alarms? This article explores the culprit: environmental and product factors, plus the different metal detector technologies available. Discover how to minimise downtime and ensure the best possible detection.

There are several types of metal detectors, and each uses a different detection method to operate. In the food industry, metal detectors usually apply the balanced coil method. These metal detectors are equipped with a transmitter coil, which generates an electromagnetic field, and two receiver coils. The receiver coils have an equal but opposite output, creating a balanced state. When a conductive object passes through the detector, it interrupts the balanced state of the electromagnetic field and causes a signal that is detected by the receiver coils. The electronics unit in the metal detector then analyses this signal, evaluates it, signals a metal detection, and either activates the automatic reject units that separates the contaminated product from the production line or alerts the operator.

FACTORS THAT LEAD TO FALSE DETECTIONS

There are two main factors that can lead to false positives in metal detection: environmental factors and product factors:

Environmental factors: Most food manufacturing and packaging lines involve the movement of products via conveyors, and the metal detectors are often installed close to the conveyors and often other electromechanical equipment. The preference today for the use of variable frequency drives, mainly to maximise energy efficiency, means that there is an increased potential for electromagnetic interference across a wide spectrum of frequencies. Such interference can often lead to disruption of the field of the balanced coils in a typical single-frequency or multi-frequency metal detector, leading to false detection.

Product factors: Some food products contain salt, iron, and moisture — each of which can alter the detector’s field and can trigger a false detection. This effect increases with higher inspection frequencies that are typically used to detect smaller particles and can lead to significant levels of wasted product and downtime.

Types of metal detectors: There are three main types of metal detector technologies: single-frequency, multi-frequency and

multi-spectrum metal detectors.

Single frequency detectors: Most metal detectors on the market use only one frequency when inspecting food products. The selected operating frequency depends primarily on the product being inspected. This is satisfactory when the product is dry and non-conductive. Single frequency metal detectors have limited abilities to work with different products and are difficult to optimise for varying conditions of temperature, water content, and packaging types.

" There are two main factors that can lead to false positives in metal detection: environmental factors and product factors."

MULTI-FREQUENCY DETECTORS

Using a metal detector that offers more detection frequencies can result in more sensitive metal detection and fewer product effect errors, as well as being able to use the machine on products with differing characteristics.

Multi-frequency metal detectors can only use one of the available operating frequencies at a time, however. The operator may need to switch from one frequency to another when changing products, or in more advanced multi-frequency systems, the metal detector will switch back and forth between two or more frequencies in rapid succession. However, only one frequency (one electromagnetic field) can be on at any time, and to prevent false rejections on more difficult products, reducing the sensitivity typically is still required.

MULTI-SPECTRUM METAL DETECTORS

Developed by Italian company CEIA, these metal detectors operate over an entire spectrum of frequencies that are simultaneously analysed and applied to eliminate product effects and interference, allowing for an improved inspection of the product.

Equipped with advanced computer technology and patented algorithms, CEIA’s multi-spectrum metal detectors can not only eliminate false positives, but can ‘learn’ the product being scanned, and perform automated testing to ensure correct detection, minimising false negatives.

TRUSTED EXPERTISE

CEIA was founded in 1961 in Turin, Italy –initially to produce electronic components and systems for industrial automation. In 1971 the company began developing metal detectors, their products first gaining recognition in the security industry. They developed advanced walkthrough metal detectors for high-security applications, such as airports, government buildings, and public venues.

18 Food Manufacturing Africa | 2024 Quarter 2 INDUSTRY TALK

Heat and Control –www.heatandcontrol.co.za

Images: Supplied

End of line efficiency that you can count on.

Bringing together leading brands in inspection, weighing and packaging equipment for the food and pharmaceutical industries. Our solutions set the standard for yield, efficiency, and safety across a wide range of industries. Whatever your product needs, we can meet it with precision and passion.

Solutions for:

• Conveying

• Weighing

• Packaging

• Pouch Filling

• Band Sealers

• Inspection

• Tray Sealers

• Optical Sorters

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

info@heatandcontrol.com I heatandcontrol.com

Optimise CIP with precision instrumentation

Many food and beverage manufacturers encounter challenges with CIP (Cleaning-in-Place) processes that take too long. Additionally, some operations aim to reduce costs related to detergents, energy, and water usage. Have you considered exploring potential solutions or improvements to address these issues?

With over ten years of experience in CIP optimisation, I led multiple projects that helped customers to reduce operational costs whilst achieving their sustainability and resource conservation goals. In certain instances, these initiatives resulted in increased production throughput. With my microbiology background I often had to troubleshoot when they experienced microbiological issues or detected soil build-up. I fully understand the criticality of CIP optimisation without compromising product quality.

CONCENTRATION MEASUREMENT

To ensure optimal performance of CIP, the detergent concentration must be monitored during cleaning on the return line, as well as in the make-up tank. This can be done with conductivity measurements, which require the least amount of maintenance and calibration and use less energy, chemicals and water.

We offer multiple conductivity sensor/ transmitter options designed specifically for CIP applications.

INVESTING IN EFFICIENCY: THE DAILY RETURNS OF AUTOMATED CIP SOLUTIONS

The CIP system can be automated to every level desired – from basic installations with low capital expenditure, to hygienic high-end systems that ensure the shortest possible process down time through fast, efficient cleaning. By optimising water, energy, and cleaning detergents, the system ensures a return on investment every day.

SOLUTIONS TO CIP PROCESS CHALLENGES

As raw material and energy costs continue to rise, it becomes even more crucial to exploit the assets of the food industry. Some food processing companies use CIP systems with very little automation, using a purely timed-based process or manual operation. Although the dosage of detergents is sometimes controlled with conductivity, the rinses are often either time- or volume based. Implementing conductivity-based rinses can help avoid the drawbacks associated with excessively long or inadequate rinse cycles. If rinse cycles are too long, it leads to unnecessary consumption of water, cleaning chemicals, and energy. It also means more time is spent on cleaning, which extends the downtime of equipment and reduce production throughput. This increases operational costs and reduces overall efficiency.

On the other hand, insufficient rinse times (too short) may leave behind residues, contaminants, and cleaning agents on the surfaces. This carryover of unwanted substances can compromise product quality and safety. Further to this, build-up of residue may become more challenging to remove, which requires additional CIP’s.

MEASURE TO MASTER

The installation of inline instruments provide

real-time monitoring and control of critical process points, leading to reduced cleaning time, energy and detergent consumption while providing full traceability without interrupting production. The CIP process can be optimised in different ways. It all depends on the level of automation and the size of the existing system. Sometimes small adjustments can lead to substantial savings in operating costs.

It is also important to measure critical control parameters like temperature and flow velocity to ensure effective cleaning and sanitation. Inefficient cleaning results in soil build-up which could lead to the proliferation of microorganisms and ultimately develops into biofilm.

INLINE OPTICAL INSTRUMENTS

One of the major trends now is to use inline optical instruments to measure the soil load of the return run and actively manage the CIP process. Depending on the degree of soil load, the liquids suitable for re-use for the next cleaning cycle can be directed to a storage tank, while highly contaminated liquids are automatically sent for waste¬water treatment. Their rapid reaction time (faster than conductivity <1 second) supports effective phase separation and could potentially reduce water and chemical consumption. •

At Endress+Hauser, we understand the challenge of increased production demands and the drive for operational savings. We would like to hear from you to discuss online instruments that provide real-time monitoring and control of your CIP while providing full traceability. Endress & Hauser – www.endress.com

20 Food Manufacturing Africa | 2024 Quarter 2 BEVERAGE PROCESSING TECH

Images: Supplied by client

BEVERAGE PROCESSING

Craft beer perfection: Brewing with precision

Tired of inconsistent brews? VEGA instrumentation ensures precise pressure and point-level control for perfect beer every time. This article explores the challenges of wort kettle and hops dissolver measurement and how VEGA sensors deliver a solution.

Brewing beer is a complex process that requires utmost precision in every step. Even the slightest variation in ingredients or brewing techniques can significantly impact the final flavour and aroma of the beer. To ensure precision, it is crucial to measure and control the pressure and point levels in the wort kettle and hops dissolver. Using VEGA instrumentation can offer numerous benefits to breweries.

The process of brewing beer involves the use of hops, which give it a distinct flavour and aroma. Achieving the right balance of hops during the brewing process is crucial for producing a high-quality product. Precise measurements play a pivotal role in ensuring this balance. In particular, when blending and cooking wort and hops in the wort kettle, it is essential to have reliable control of dosage and cooking. This is where integrated pressure and point-level measurements come in.

The measuring tasks in the wort kettle and hops dissolver encompass pressure and point-level measurements, which cover a range of up to 5 meters. These measurements must be taken under challenging conditions, including

"By employing VEGA instrumentation for pressure and point-level measurement in the wort kettle and hops dissolver, breweries can elevate their quality standards, ensuring consistency and excellence in every batch brewed."

temperatures ranging from 10 degrees Celsius to well over 100 degrees, and pressures of 2 bar and beyond. These conditions introduce unique challenges such as foam, condensation, and the presence of solids in the liquid. However, with the right equipment and expertise, these challenges can be overcome, resulting in a superior product that beer lovers will enjoy.

A SOLUTION FOR BREWERS

VEGA’s process instrumentation is designed to meet the rigorous demands of beer brewing applications. These sensors are not only reliable but also crafted with certified materials compliant with FDA and EC regulations. The benefits extend further with cost-effective, maintenancefree operation, ensuring durability and reliability throughout the brewing process. Additionally, their user-friendly design

simplifies setup and commissioning via a standardised VDMA-compliant interface.

The VEGAPOINT 23 stands out as a compact capacitive limit switch tailored for water-based liquid detection. Equipped with a tube extension, it offers versatility and ease of use. With optional universal connections for hygiene adapters, installation efforts are minimised, making it an ideal choice for hygienic processes in the food, beverage, and pharmaceutical industries. Its compatibility with IO-Link enables continuous digital data transmission, enhancing monitoring capabilities.

Similarly, the VEGABAR 39 serves as a universal pressure transmitter, equipped with a metallic measuring cell suitable for gases, vapours, and liquids up to 130°C. Featuring a display with the on-site operation and a coloured 360° status display, it ensures easy monitoring and control. Its fully welded metallic measuring cell enhances reliability, while IO-Link communication facilitates seamless integration into control systems, further optimising brewery operations.

The meticulous process of brewing beer demands precision at every stage. By employing VEGA instrumentation for pressure and point-level measurement in the wort kettle and hops dissolver, breweries can elevate their quality standards, ensuring consistency and excellence in every batch brewed.

Vega – www.vega.com 22 Food Manufacturing Africa | 2024 Quarter 2

TECH

2024 Quarter 2 | Food Manufacturing Africa 23 MINIMAL EFFORT FOR MAXIMUM PROCESS HYGIENE. THE 6X ®. FROM VEGA. For level applications with maximum hygienic standards, perfection can be achieved with extensive cleaning or, make it simple, just use a VEGAPULS 6X radar level sensor. Made for all media, all ambient conditions and, most importantly, for uncompromising levels of hygiene. VEGA. HOME OF VALUES. www.vega.com/radar

BEVERAGE PROCESSING TECH

Nature MultiPack – now available with a universal adhesive

What initially seems like just a minor adjustment constitutes a major further development that produces even more reliable, future-proof technology: for its Nature MultiPack (NMP) KHS has produced a universal adhesive that can be used on practically all outer coatings on both aluminium and tin cans.

This makes it easier for many beverage producers to convert to this environmentally friendly style of packaging. Since this system became successfully established on the market, the demands made of the adhesive especially have continuously increased. The Dortmund systems supplier has answered this call and now enables customers to create appropriate packs with the new one-fits-all system for beverage cans, thus also helping them to achieve their sustainability targets. When it comes to circular packaging, KHS helps its customers by providing

specific advice and developing and implementing environmentally friendly and circular systems. These include its NMP. As one of the most sustainable types of secondary packaging, this future-proof technology does away with secondary packaging completely, holding packs of six beverage cans, for instance, together with just a few dots of adhesive. To date, choosing the right adhesive was something of a challenge: numerous advance tests had to be run to check how an ideal amount of the same creates the perfect balance between high pack stability and easy-toremove beverage cans when applied to the different coatings can manufacturers use on their containers. There’s a huge variety of can lacquers, running into several hundreds worldwide. They often have very different surface properties, from matte to glossy. The discrepancies in chemical and physical properties such as roughness are enormous.

UNIVERSAL ADHESIVE MAKES ELABORATE TESTING REDUNDANT

These dissimilarities affect the effectiveness of the adhesive which is why elaborate testing at the KHS laboratory used to be required. For interested canners, this was a procedure that first and foremost was very time-consuming. In developing a universally applicable adhesive for practically all outer can lacquers used worldwide, KHS has now risen to this challenge. The new consumable satisfies stringent requirements to ensure stability during transportation, among other things. To do so, the adhesive had to prove its worth both on a

laboratory scale and in industrial application. The goal of producing a universal adhesive that works on practically all coatings was again exceeded. During qualification and practical application in industrial production, it was shown that the exacting requirements were met.

The implemented one-fits-all solution enables beverage producers to form the perfect NMP from all standard formats and sizes. On the one hand, both matte and glossy containers can be processed without complex adhesive changeovers being necessary; on the other, future customers no longer must keep to a given selection of surface lacquers. This makes pack production more flexible and efficient, which in turn also has a positive impact on the supply chain. A selection of predefined lacquers no longer must be kept in stock. This cuts down on the amount of cost and effort needed and greatly simplifies production processes. KHS thus eliminated any entry thresholds when it comes to investing in this standardised, environmentally friendly technology.

INVESTMENT IMPROVES ECO BALANCE

Nature MultiPack also cuts costs – in the long term the system is less expensive than other kinds of secondary packaging as beverage producers save on both materials and resources. This plant engineering is also ideal when specific company sustainability strategies are to be implemented – especially when in the future taxes will possibly be levied according to the amount of CO2 equivalents generated rather than the style of packaging. Independently validated LCA analyses show that a company’s carbon footprint can be massively reduced where NMP technology is used.

24 Food Manufacturing Africa | 2024 Quarter 2 KHS

www.khs.com Images: Supplied by client

-

Crafting bold and flavourful beverages

Eddie Le Roux, hygienic pump specialist at Verder Pumps, explains how choosing the right pumps ensures safe, high-quality products and avoids costly downtime.

The South African beverages market has expanded and subsequently grown exponentially in recent years.

In fact, growing at a CAGR of 5.19% the size of local market is expected to grow from USD 19.01 billion in 2023 to USD 24.47 billion by 2028. Spurred by changes in consumer lifestyles and dietary patterns has increased demand for and ever-expanding options of non-alcoholic drinks that offer immediate benefits in energy, hydration and nutrition, while socially influenced trends and flavour preferences supports the growth in alcoholic beverages.

That said, remaining competitive in an increasingly saturated market is no small feat. For every processor in this market,

ensuring high product quality – both in terms of flavour and safeguarding the health and wellbeing of the public/end consumer – is critical to their business sustainability. Maintaining the highest standards in hygiene in the production of their products is non-negotiable, as even the slightest contamination could mean a batch of product is unusable, or unsafe for consumption, which could lead to product recalls, financial loses and potentially reputational risks.

solutions installed throughout the plant are the backbone of the production line and what keeps the product flowing through the entire processing operation to the final stage of bottling.

Producing high quality beverages every time therefore requires machines that are 100% reliable, equipment that is safe and every part of the production line should be accessible for regular cleaning, sanitisation and sterilisation. And the pump and piping

Understanding the intricate and technical details and implications of selecting the right pumping solutions for specific use applications can be challenging, however, it is an important purchase decisionand continued and sustainable optimum production performance of the plant is dependent on the longevity of the equipment.

Verder Pumps - www.verderpumps.com

2024 Quarter 2 | Food Manufacturing Africa 25 BEVERAGE PROCESSING TECH

PACKO The perfect pumps for beverage processing Visit our website ➔ VERDER is the manufacturer of PACKO® pumps VERDER PUMPS SA TEL +27 (0) 11 704 7500 MAIL info@verder.co.za WEB www.verderliquids.co.za 23-PA-AD_WineBrewery_SA_177x130mm.indd 1 5/14/2024 10:30:08 AM Images: Supplied by client

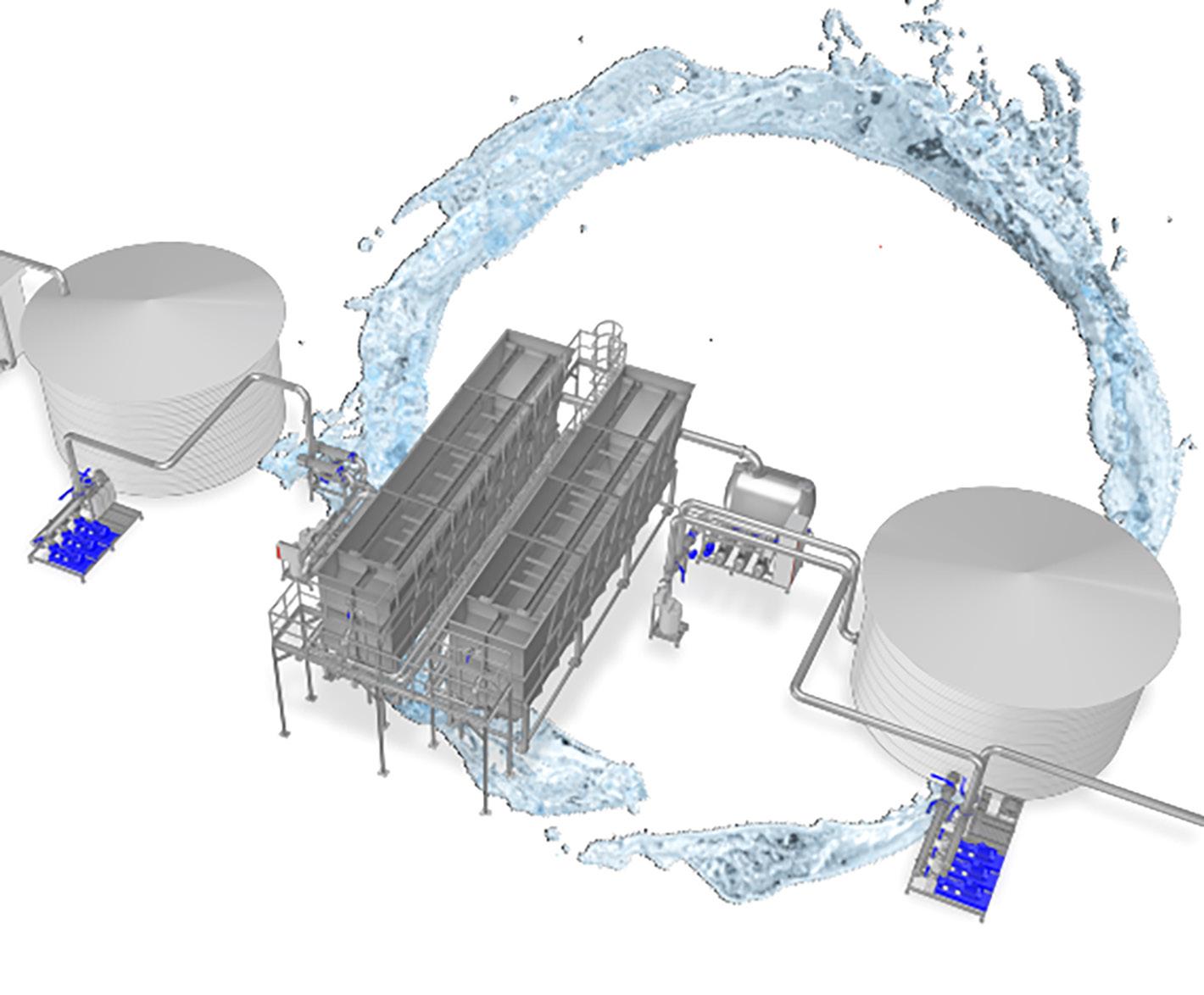

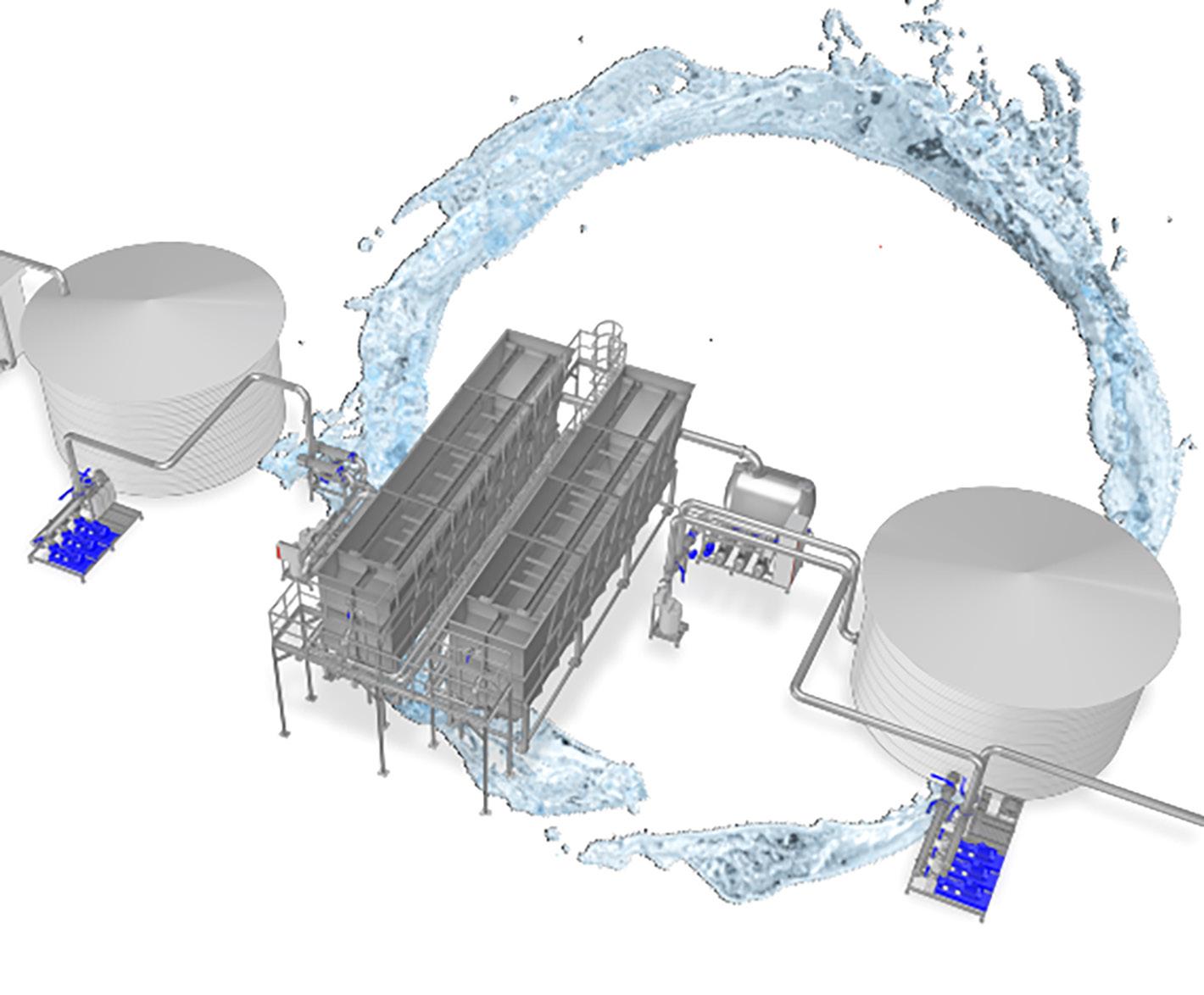

A DUE COMMITMENT TO A GREENER BEVERAGE INDUSTRY

ADUE S.p.A. since 1967 is an Italian company is leader in the field of Automated Beverage preparation equipment and Water treatment plant.

REUSE, RECOVER, RECYCLE: ADUE’s Digital-Green Engineering is to reduce the CO2 emissions from the industrial plants supplied to its customers through circular processes, technological and digital innovations for the optimisation and reuse of natural resources and the reduction of waste and refuse.

ECO-design: ADUE technical staff focus on the proper sizing of all the system components, the optimal P&ID, the energy recovery everywhere thermal processes are involved.

ECO-adaptability: flexible plants which can perform the same process with different parameters depending on the production needs, to reduce waste and consumption and to increase productivity.

ECO-monitoring: once the equipment is up and running, energy and water consumptions are among the key indicators (KPI) supervised by ADUE software for the plant performance control.

Not only ECO-logical, but also ECO-nomic: time, water and energy savings allow to reduce the TCO of your plant. The TCO of ADUE CIP UNIT, for instance, can be lowered through:

• A total thermal insulation (including roof and bottom) of hot or cold fluids storage tanks;

• Appropriate rinsing technologies like burst rinsing;

• The use of alternative chemicals.

THE BLUE GOLD : on the strength of its innovative NIAGARA Technology, ADUE can offer a series of large-scale solutions to purify wastewater coming from the production process, re-using it for:

• Product preparation, hydraulic transport of fruit and vegetables, pipework rinsing, first CIP rinsing step;

• Evaporative tower, steam boiler, service fluids;

• Sanitary facilities, irrigation and general cleaning.

INDUSTRY TALK 26 Food Manufacturing Africa | 2024 Quarter 2

Image: Supplied by client

EVENT

Flavourful careers take flight

The SAAFFI-Wits Flavour & Fragrance Technology Course celebrated its 2022 graduates! Students from Wits University and the industry gathered to mark their achievements and explore exciting careers in this fascinating field.

On the evening of the 7 May, a group gathered in the Atrium, a beautiful venue at Firmenich South Africa’s offices in Midrand, to celebrate the graduation of the students who studied the SAAFFI-Wits Course in Flavour & Fragrance Technology during 2023.

This course, which is held annually at Wits University School of Chemistry, and is also available online, comprises 12 lectures and 3 practical sessions. It is offered to 2nd year Applied Chemistry students at Wits, and is open to interested members of the flavour, fragrance and FMCG industries. While it is a South African based course, students from as far as Chile in South America have participated.

The flavour & fragrance industry is a little-known industry – but touches our lives from the moment we wake up to the moment we go to sleep, enhancing products from air fresheners to zaatar-flavoured snacks.

BALANCING ACADEMIA AND INDUSTRY

The graduating students – 7 from Wits university and 16 from the flavour & fragrance industry, spoke of the value of this course, and are inspired to build their career in this fascinating industry.

DID YOU KNOW

Flavour plays an important role in food and in life. Not only must food offer a balanced and nutritionally adequate diet, but it must also be palatable and diverse. These aspects are largely a function of flavour. Thus, flavourings are an essential constituent of human food.

“The flavour & fragrance industry is a little-known industry – but touches our lives from the moment we wake up to the moment we go to sleep, enhancing products from air fresheners to zaatarflavoured snacks.. ”

Words of welcome and thanks were offered to Shimadzu for their generous annual sponsorship, Mike Capon & Sensetek for their sponsorship of student prizes, Dr Maya Makatini, course-coordinator for the programme and the entire Wits School of Chemistry for their support and partnership, Firmenich for the use of the venue, lecturers who dedicate their time to this course pro bono, facilitators of the practical sessions, the SAAFFI management committee and employers who pay for their employees to enrol, and give them the time needed to complete the course.

The guests invited by the graduates –parents, spouses, family, friends and even a graduate’s children displayed a sense of pride in their “person” for an excellent achievement.

The programme for the evening included a welcome from Sharon Bolel, Executive Director, SAAFFI, encouraging words and good wishes form Dr Karina Rogers, chairperson of the SAAFFI management committee, congratulations from Prof Charles de Koning, Head, Wits School of

After the certificates were presented, prizes, sponsored by Sensetek, were presented to the top Wits graduating student – Malvanique Kaiser and the overall top graduating student, Geeta Bhoola.

The evening was concluded in a celebratory mood with delicious refreshments and enjoyable networking.

SAAFFI - www.saaffi.co.za.

ABOUT US

Decades ago, the Flavour and Fragrance Industry in South Africa formed an association to unite local Flavour & Fragrance companies across common non-competitive industry issues, freeing up individual organisations to grow their business. This group has grown to over 60 organisations, all active participants in the Association.

SAAFFI is a Member of IOFI and IFRA, the two international organisations that deal with many aspects of Flavours and Fragrances respectively, including that of safety, on a global level. Through regular circulation of information, Members of the association are kept up to date with what is happening internationally at IFRA, IOFI, Codex Alimentarius and the South African National Department of Health. Within South Africa, SAAFFI maintains good working relations with other relevant institutions and associations of related industries such as SAAFoST, CTFA, and Coschem.

2024 Quarter 2 | Food Manufacturing Africa 27

Chemistry and a delightful speech on behalf of the students, given by Keegan Capito, a graduating student.

Image: Supplied by client

Eco-labels for exquisite drinks

UPM Raflatac launched a new collection of responsibly sourced label materials for wine, spirits, and beverages.

UPM Raflatac d announce the launch of its new collection of wine, spirits and beverage label materials – Rêverie 3 – that embraces circularity by using recycled fibers in aesthetically attractive labels. The new collection demonstrated, via unique collaborations with five leading Spanish designers, that sustainability and impactful design can work together to deliver stunning results.

The Rêverie 3 collection offered packaging designers a toolkit of visually appealing labels that are were made with materials from well-managed, FSC certified (FSC C012530) forests, recycled materials and other controlled sources.

With more and more brands now seeing the inclusion of FSC and PCR packaging as a necessity, UPM Raflatac wanted to showcase the potential of today’s sustainable label materials. With this in mind, five of the company’s responsibly sourced label materials were given to five Spanish design agencies, with the brief to create a new collection.

“The label designs in the Rêverie 3 collection were created for high end wine, spirits, sparkling cider, craft beer and tomato juice drinks, with excellent execution of the artworks with different printing techniques managed by Gráficas Varias,” Joss Ramel, Packaging Solutions Manager for Spain and Portugal at UPM Raflatac states.

TOP FIVE CHOSEN LABEL MATERIALS:

BIARRITZ WSA PCR-FSC (20% recycled fibers) – Created for use with high-quality wine and spirits labelling applications, the natural pigmentation of the material accentuates the premium appearance of

the label. Estudio Series Nemo used this material to create the sparkling cider bottle label design.

DROPS WSA PCR-FSC (100% recycled fibers) – Designed for high-quality wine and spirits labelling applications, this label material features an accentuated uneven, textured surface combining a translucent effect and enhanced tactility, thanks to it having undergone a unique paper-making process. Estudio Maba used this material to create the spirits bottle label design.

FENIX WSA PCR-FSC (40% recycled fibers) – Developed for high-quality wine and spirits labelling applications, this paper shows minimal impurities, giving a delicate hint of the recycled content. Estudio Puigdemont Roca used this material to create the tomato juice bottle label design.

HIPSTER WSA PCR-FSC (100% recycled fibers) – Created for high-quality wine and spirits labelling applications, it has a warm and elegant white shade that is combined with a delicate, uneven, felt marked surface that enables the creation of labels with unique personality. EstudioCalcco used this material to create the wine bottle label design.

VINTAGE WSA PCR-FSC (30% recycled fibers) – This material is ideal for use in wine, spirits and beverage labelling applications where an authentic and artisanal look is desired, as it has a kraft brown shade to it. Bulldog Studio used this material to create the craft beer bottle label design.

SUSTAINABLE LABEL OPTIONS

“We designers have a responsibility and a duty to use materials of this kind. The industry is progressing. Suppliers have more and more options for using

sustainable materials. Having a range of recycled papers with this much personality and quality, that are hyper-specialised, is amazing for us designers,” Miguel Angel del Baño from Estudio Maba, comments on their experience in using UPM Raflatac’s label materials. “It allows for high-quality projects, which to some extent is not often the case with recycled papers,” Albert Puigdemont at Estudio Puigdemont Roca adds. “I was pleasantly surprised by the print quality, especially in the area of relief and stamped finishes, the ease of adherence, fixing and raising. It looked as if it would never be possible to have elegant, high-class recycled paper for premium products. But now, we can say that papers of this quality do exist. The Rêverie 3 series from UPM Raflatac has managed it,” Sergio Aja Iglesias, Estudio Calcco concludes. “Responsible sourcing is in our DNA here at UPM Raflatac. Thanks to our sustainable supply chain, we are able to offer designers FSC-certified labels that have varying percentages of PCR content, suiting any requirement. Rêverie 3 was already an extraordinary range due to the use of the recycled content. However, what the designers have done with the materials has truly taken it to the next level. It just shows what can be done when high quality materials are combined with creativity. This collaboration has shown that recycled fiber materials can stand alongside other labels and deliver in terms of both quality and impact,” Eulalia Alcaraz, business director at UPM Raflatac comments.

28 Food Manufacturing Africa | 2024 Quarter 2 UPM Raflatac – www.upmraflatac.com

LABELLING

Images: Supplied by client

Inline pump filling equipment

equipment

Round bottle labelling

Gravity filling equipment

Entry level filling equipment

Front and back labelling

Pharmaceutical labelling & coding

Rotary filling

Sustainable packaging: Lower footprint labels

UPM Raflatac launches a new "Carbon Action Plastic Labels" portfolio to help brands reduce their packaging footprint. These labels utilise circular economy principles and validated LCA calculations to offer quantifiable emission reductions.

According to the UN, today only 15% of the Sustainable Development Goal targets are on track. In September 2023, UPM joined the UN Global Compact Forward Faster initiative to accelerate this pace. To demonstrate its commitment to the Climate Action initiative and help its customers reduce the carbon footprint of their packaging materials and drive action, UPM Raflatac is proud to announce the launch of its Carbon Action Plastic Labels portfolio.

From 30th April 2024, the first products offered under the Carbon Action portfolio will be available to customers in EMEIA and the Americas. Further products are planned to be launched as part of the portfolio, all of which will focus on supporting the multiple circular economy Rs – Reduced, Recycled, or Renewable materials that enable Recycling or Reuse. Designed to address the entire value chain's impact, the Carbon Action portfolio offers a tangible path towards achieving Scope 3 emissioni reductions for printers and brand owners. This is underpinned by the DEKRA validated LCA calculation process through UPM Raflatac’s Label Life service.

A SUSTAINABLE LEAP FORWARD

The launch of this new portfolio provides a meaningful solution for the packaging industry. It leverages the power of circular economy principles and provides quantifiable emissions reductions to empower customers and brands to reduce the carbon footprint of their packaging materials without compromising on label quality or performance. It marks an important milestone in the company’s journey beyond fossil-based materials.

“The launch of our Carbon Action portfolio is more than an introduction of new products; it’s a declaration of our unwavering commitment to sustainability and our customers’ success. By providing innovative solutions that can directly contribute to reducing carbon footprint

“The launch of our Carbon Action portfolio is more than an introduction of new products; it’s a declaration of our unwavering commitment to sustainability and our customers’ success. "

ABOUT US

UPM Raflatac: UPM Raflatac offers high-quality self-adhesive paper and film products including label materials, graphics solutions and removable self-adhesive products. We operate 12 factories and deliver our innovative and sustainable products through our global network of distribution terminals. We are one of UPM’s growth businesses and employ around 3,100 people. Our sales reached almost EUR 1,5 billion (USD 1,6 billion) in 2023. Find out how we are labeling a smarter future beyond fossils.

UPM

We deliver renewable and responsible solutions and innovate for a future beyond fossils across six business areas: UPM Fibres, UPM Energy, UPM Raflatac, UPM Specialty Papers, UPM Communication Papers and UPM Plywood. As the industry leader in responsibility, we are committed to the UN Business Ambition for 1.5°C and the science-based targets to mitigate climate change.

and enhancing circularity, we empower our customers and brands to take concrete steps towards a low carbon circular economy,” Katja Kivelä, business director, Food and HPC, Films & Specials at UPM Raflatac. The goal of UN Global Compact Forward Faster initiative is to accelerate progress towards the 2030 Sustainable Development Goals in five areas of action: Climate Action, Living Wage, Gender Equality, Water Resilience and Finance & Investment. By joining the Climate Action initiative, UPM commits to setting sciencebased net-zero emission reduction targets in line with a 1.5°C pathway, with the goal of halving global emissions by 2030 and reaching net-zero by 2050 at the latest. For UPM Raflatac, this means not only cutting its own emissions and those of the supply chain, but also committing to innovating products like the new Carbon Action portfolio.

UPM Raflatac – www.upmraflatac.com

LABELLING 30 Food Manufacturing Africa | 2024 Quarter 2

Celebrating 50 years of incredible success

Strength is in flexibility. It’s a fundamental concept that winks at evolutionary principles themselves. Darwin teaches us that it is not the strongest of the species that survives, nor the most intelligent, but rather the one most adaptable to change.

For 50 years P.E. LABELLERS has built its leadership on this key element and the market continues to prove it right. And, in 2024 it confirms itself as the most innovative global company in the creation of labelling solutions.

Technological innovation makes P.E. Labellers a unique company of its