NACAT President's Update

Drew Barnes, Vale School District

Thank You Conference Trainers!

Tips & Tricks: How to Start a New Hydraulic Pump - My Life is in Your Hands!

Rory McClaren, Founder and Director at Fluid Power Training Institute

Networking at the NACAT Conference

Thank You Conference Sponsors!

Steve Gibson Named 2024 NACAT MVP!

Mitchell 1 Names Ty Rockney Automotive Technology Outstanding Student

Curt Ward Receives NACAT Award of Appreciation

Hybrid & Electric Vehicle Corner: Adding Hybrid & Electric Vehicle Technology

Curt Ward, Professor at Joliet Junior College

Save the Date! NACAT 2025 in Detroit, Michigan

Dana Shynkaruk Wins Jack Erjavec Innovative Instructor Award

ConsuLab Named Friend of NACAT

Thank You Conference Exhibitors!

Dayne Van Dyke Wins Larry Cotten Memorial Scholarship

NACAT Mentor Program: Classroom Engagement

NACAT Recognizes Fritz Peacock and Al Santini

Mitchell 1 Names Jay Kuykendall Educator of the Year

WD-40, NAPA, and TechForce Foundation Scholarships Available

October 2024 issue - September 10, 2024

December 2024 issue - November 10, 2024

February 2025 issue - January 10, 2025

April 2025 issue - March 10, 2025

June 2025 issue - May 10, 2025

August 2025 issue - July 10, 2025

The latest advertising size and rate information can be found at www.nacat.org.

Greetings Fellow NACAT Members,

It is hard to believe that as many of us are reading this update, we are already back in the shop, preparing for yet another successful school year. Summer just flies by! Hopefully each of one of you enjoyed some kind of a break to help you reset and get motivated for this new school year.

With it already being August, that also means that we just completed another very successful NACAT Conference. We had a great time in Indianapolis for our 50th anniversary conference. We had a fantastic list of training courses to choose from, with a variety of topics offered to meet the needs of all automotive educators. Thank you to all the educators that were able to attend, and if you were not able to attend, we are looking forward to seeing you next year. Also, a special thank you to all those who make this event possible each year. That includes our sponsors, industry partners, course instructors, hotel staff, and our business management team. This year’s event truly was outstanding; However, as with every year we are always looking for ways to improve to best suit the needs of our membership. With that being said, if you have not had a chance to complete the attendee survey, please do so as soon as possible. You should have received a link immediately following the conference. If you have any questions in regards to completing the survey please feel free to reach out to our business manager, Heather Sebben (heather@nacat.org). We truly appreciate the feedback from our members and attendees. If you have any suggestions or concerns outside of what can be shared in the survey, please feel free to reach out to me, any of the other NACAT officers, or board members.

As an organization, we are continually trying to improve/increase our member benefits. Currently, we are working on growing our instructor resources on the membership benefit section of our website. We would like to add more documents and quick resources to further assist automotive educators. We would like to encourage our members to donate to this endeavor, if you have anything that you would like to share please feel free to share that information with us. These items can be downloadable documents, videos, quick links, or anything else that you think would be a valuable resource to fellow members. Within these resources we are planning to include a section for teacher lesson plans, and we are encouraging our members to share specific content lessons that they have created and feel other teachers would benefit from. For more information on this or how to donate materials, please contact Heather Sebben.

Although we just wrapped our 2024 NACAT Conference, that doesn’t mean we aren’t looking to the future and making plans for the 2025 conference. For those who haven’t heard the news, we have already set the dates and conference location for next year. The 2025 NACAT Conference will be held June 9-12, 2025 in Detroit, Michigan! We are very excited about this location, as Motor City has so much to offer in regards to the automotive industry. Be on the lookout for updates about this event, as we continue to make plans for what may be the most exciting NACAT Conference yet!

Continued on Page 6

Chairman of the Board 2023 - 2024

Steve Gibson Riverside, California

Board Member 2022 - 2025

Ron Morris Greensboro, North Carolina

Board Member 2023 - 2026

Todd Richardson Price, Utah Sara Heller Branchburg, New Jersey

Tom Millard Lakewood, Colorado

Board Member 2024 - 2027

Wade Johnson Harper, Oregon Rafael De Leon Trujillo Alto, Puerto Rico

Kenneth Hardy Hawkinsville, Georgia

Continued From Page 5

One of the core values of NACAT is family, and if you have ever been to a NACAT conference you know what I am talking about. We have already begun planning activities for families for next year’s conference. We encourage our members, if it is possible and fits into their summer schedule, to bring along their spouses and children to learn what the NACAT Family is all about.

I hope you all have a very successful school year. Remember to save the dates , June 9-12, 2025, and make plans to join us next summer in Detroit!

Thank you,

Drew Barnes NACAT President

ATech designed the Electronic Power Steering and Suspension System (model 500E) trainer to teach the basic principles of the suspension and steering system. This trainer allows for instructor demonstration/presentation as well as hands-on reinforcement and troubleshooting experience.

Components:

• Lower Control Arms

• Adjustable Coil Over Springs

• Adjustable Upper Control Arm Assemblies

• Dual Adjustable Coil Over Shocks

• Serviceable Ball Joints

• Tie Rod Ends

• Manual Rack and Pinion Steering Gear Assembly

• Quick Disconnect Steering Wheel

• Aluminum Hubs with Serviceable Tapered Roller Bearings

• Electronic Power Steering Motor and ECU

• Wheel and Tire Assemblies

• Steering Spindles

• Cross Member

• Sway Bar Features:

- Demonstrates front tire alignment angles

- Duplicates on-vehicle troubleshooting

- On-board electronic actuators simulating steering angles under di erent driving conditions

- Trainer is 32” X 66” X 44” allowing it to t through a standard door frame

- Courseware included: Student Manual, Instructor Guide, Service Information

Rory McClaren

The following outline provides a step-by-step method for starting a hydraulic pump correctly. Refer to Figure 2-1 for correct placement of diagnostic equipment.

1. Connect vacuum gauge (A) in parallel with the pump inlet port transmission line.

Why? It will offer visual indication immediately upon start-up of any problems related to the suction side of the pump. Pump manufacturers provide maximum inlet restriction specifications which should be strictly adhered to. Refer to the pump manufacturer's specification for maximum inlet restriction recommendations.

Some common pump inlet start-up problems:

1.1. Low inlet restriction

a. No oil.

b. Low oil level.

c. Loose connectors, filter, and/or clamps.

d. Case drain line above the oil - bent axis pumps.

e. Pump dry - not creating partial vacuum- mounted above oil level.

1.2. High inlet restriction

a. Pump rotating too fast.

b. Incorrect oil - viscosity.

c. Plugged inlet transmission line.

d. Suction screen incorrectly sized.

e. Suction filter incorrectly sized.

f. Suction line incorrectly sized.

g. Suction hose - not suitable for suction line applications.

h. Suction hose - kinked or crimped.

i. Reservoir/pump isolator valve closed or partially closed.

j. Reservoir/pump isolator valve incorrectly sized.

k. Ambient temperature extreme - oil viscosity.

NOTE: If the pump inlet port is incorrectly sized, it will not be detected by a vacuum gauge installed in parallel with the pump inlet port connector. If the vacuum or pump inlet restriction is within specification and cavitation persists, check the pump manufacturer’s specifications for pump inlet port size relative to pump flow.

2. Connect pressure gauge (B) in parallel with the connector at the outlet port of the pump. Where possible, disconnect the pump outlet transmission line, and connect it directly to the inlet port of the return line filter (5) or into the top of the reservoir (if the transmission line is placed directly into the top of the reservoir, it must be securely fastened).

Continued on Page 9

Why? Pressure control is not always the function of a pressure relief valve in a hydraulic system. Certain types of variable displacement hydraulic pumps have pressure compensators which control pressure in the system. Refer to the manufacturer's specifications for recommended pressure relief valve or compensator settings.

2.1. Compensators on new or rebuilt pumps are very rarely adjusted to suit a specific system. Compensator adjustment can be made before introducing the pump to the system.

2.2. Pump performance can be monitored under varying pressure conditions.

2.3. Pressure compensator adjustments can be made safely and accurately.

2.4. Pump manufacturer’s step-level pressure "run-in" procedures can be systematically followed.

Certain types of unbalanced pumps must be "run-in." Manufacturers provide a step-level pressure start-up recommendation. Step-level simply means that the pressure at the pump outlet must be applied gradually and in specific increments.

It is not uncommon for gear pumps, especially aluminum bodied designs, to experience gear-to-housing contact upon start-up. Some larger pumps will remove as much as a half-a-cup of aluminum on start-up. By running the pump outlet directly into the return line or "slave" filter, none of the excess material will enter the system. This procedure is especially important if high pressure filters are not installed in series with the pump outlet transmission line directly ahead of the pump.

About 90% of rebuilt pumps are either not tested, or are not tested to maximum pressure and flow levels. This is due to either an absence of test capability, or insufficient test-stand horsepower.

in series with the pump outlet transmission line.

Why? Satisfactory actuator speed and system performance is dependent on the amount of oil delivered by the pump under various load conditions. Pump flow must be consistent with pump volumetric efficiency and design requirements. Refer to manufacturer's specifications for recommended pump flow specifications.

EXISTING SYSTEM:

1. Suction screen

2. Pump/Isolator valve

3. Pump

4. High pressure filter

5. Return line filter

DIAGNOSTIC EQUIPMENT:

A. Vacuum gauge

B. Pressure gauge

C. Needle valve

D. Flow meter

E. Pyrometer

F. Tachometer

Gain access to comprehensive,

course

diesel and small engines. Each course comes complete with

•

• Automatic Transmissions

• Automotive Service

• Batteries, Starting & Charging

• Brake Systems

• Brakes

•

• Diesel Engines

•

•

• Drivetrain

•

•

•

• HVAC

• Hydraulics

•

•

•

•

•

• Small Engine Technology

• Steering & Suspension

plans, multimedia presentations, engaging projects and activities, and formative and summative assessments. www.icevonline.com/transportation Utilize iCEV’s coursework to prepare for ASE certification exams. Each lesson includes slide decks, video instruction and hands-on activities and projects to help master the domains tested for on ASE certifications.

New Instructor Training Courses COMING SEPTEMBER 1ST

Earn training hours and maintain your ASE Accreditation using iCEV’s new Instructor Training Courses.

Scan to learn more about new training courses »

Attendees to the annual NACAT Conference & Expo are able to take advantage of exceptional industry training while being able to network with peers from schools throughout the United States and Canada. Many go to a first conference not knowing what to expect, but come away life-long friends and training partners with whom they can share information and practices to create the best classroom and laboratory experiences possible.

"I've made lots of great peer contacts through the NACAT conference. We've been able to share ideas, discuss what works and doesn't work, and learn in a group setting through training classes. It's a much better use of my time and my district's funds to attend the NACAT conference than to send me to a "normal classroom teacher" professional development conference."

"Talking all week with like minded people, networking, and meeting future partners, that's what it's all about. Top it off with eye opening classes, getting to work on new electrical boards...Had a great time. Well worth the trip. Other members as well as the trainers."

Pattison,

"Through NACAT I have developed very valuable friendships and relationships. We have met together with other automotive educators from across North America and celebrated in each other's successes and encouraged each other in our most trying times as an educator."

Jacob Craiger, Southeast Kentucky Community and Technical College

Jason Allen

Lafayette, IN

Ian Andrews Columbus, OH

Elaine Bronsther Ottawa, Canada

Jason Bronsther Ottawa, Canada

Michael Chicconi Fresno, CA

Martin Duvic

Denham Spring, LA

Jeff Eligio Pearl City, HI

Russell Ferguson Ann Arbor, MI

David Foor Columbus, OH

Daryl Gerardo Lihue, HI

Thank you to those who have either joined or renewed their membership since June 1, 2024.

Steve Levin

Columbus, OH

Robbie Lindhorst Harrisburg, IL

Mark Mitchell Columbus, OH

Everett Mixon Bowie, MD

Lawrence Pacanas Lihue, HI

Kyle Snover

Tunkhannock, PA

Derek Spann Columbus, OH

Tracey Tamura

Pearl City, HI

George Vail Des Plaines, IL

Jim Voth Winnipeg, Canada

Steve Gibson was named the 2024 NACAT MVP at the recently concluded NACAT Conference & Expo in Indianapolis, Indiana.

Gibson has a long history of excellence within NACAT. He was motivated to join the NACAT Board of Directors at his first eligibility. He quickly became the Board Chair, a position he has held for numerous years and through a transitory period of NACAT's history. He's led the board in many endeavors to enhance benefits and resources available to NACAT's members.

“If there is one individual who demonstrates true passion for our organization, it is this year's MVP,” said Drew Barnes, NACAT President. “He has been involved as an organizational leader of NACAT since I have been part the organization. His leadership, knowledge, automotive experience, work ethic, and commitment to NACAT are second to none. We are forever grateful to have him as part of our team. He is always stepping up to take on new challenges, researching future conference locations, and ensuring the best experiences for our attendees.”

Steve was unable to attend the conference in person but accepted the award remotely. He stated, "I am extremely grateful for this organization. Personally, I have met so many great people through NACAT and I just want it to continue well on into the future for other instructors to have that ability to meet peers, grow their knowledge, and network."

The organization is truly thankful to have him as a dedicated member.

We were honored to receive the Friend of NACAT award during this year’s conference. Thank you to the NACAT board for honoring us.

EV-400 High Voltage Safety Trainer

During NACAT we unveiled our EV-400 High Voltage Safety Trainer

EV-601 Interactive Demonstrative Electric Vehicle

Our EV-601 Interactive Demonstrative Electric Vehicle was a huge hit as well.

The annual NACAT Conference Valve Cover Races, this year sponsored by ConsuLab, were first run at the 1999 conference. Since that time the event has grown in popularity with all who venture to a NACAT conference. There are outstanding racers crafted in Canada and many gravitational chariots made in the USA. Women, men, and children of all ages endeavor to stay just within the rules to make the quickest accelerating, highest velocity obtaining, straightest coasting vehicle to ever run down the NACAT Valve Cover Race Track.

While many battled the track, gravity, friction, mechanical problems, and more in an attempt at victory, we send CONGRATULATIONS to NACAT 2024 CHAMPION Drew Jablonowski, from Garage Gurus, who won the overall title with the super speedy downhill dueler originally crafted by Laurie Dwyer. He was fortunate to win the racer in NACAT's scholarship fund-building silent auction.

Ty Rockney of Chesapeake, Virginia, has been named the 2024 Mitchell 1 Automotive Technology Outstanding Student – a recognition that includes a $2,500 scholarship and an all-expenses-paid trip to attend the 2024 North American Council of Automotive Teachers (NACAT) conference.

As part of the scholarship program, administered through the University of the Aftermarket Foundation, Mitchell 1 annually honors a U.S. or Canadian student for their outstanding achievement in automotive technology and auto shop repair scholastics.

“We are proud to recognize Ty Rockney as the 2024 Mitchell 1 Automotive Technology Outstanding Student for his dedication to pursuing a career in the auto care industry,” said Nick DiVerde, senior director of product management for Mitchell 1. “We have full confidence that he will accomplish his goals and thrive in his career path.”

Rockney is currently enrolled in the automotive technology program at the Advanced Technology Institute (ATI) in Virginia Beach, Virginia. After his graduation in January 2026, he plans to work as an automotive service technician and aspires to become an instructor or own a repair shop.

Rockney discovered his passion for automotive repair after receiving a 1997 Dodge Ram 1500 for Christmas in 2020. His father initially assisted him, but he soon took the initiative to research, purchase parts and work on the truck himself. His great uncle, a technician since the 1970s, also inspired his career choice.

The award was presented during the NACAT awards luncheon on July 24, in Indianapolis, Indiana.

Congratulations, Ty!

Curt Ward, Professor at Joliet Junior College in Joliet, Illinois and author, was recognized with the NACAT Award of Appreciation during the 2024 NACAT Conference & Expo in Indianapolis, Indiana.

“The Award of Appreciation is given to an individual or company who has gone above and beyond for NACAT and the automotive industry,” said NACAT President Drew Barnes. “This year’s honoree has continuously developed his automotive skills, shared his knowledge with both students and educators, and contributed significantly to our community through their writing and mentorship. He has always given so much of his time to NACAT, as a former President and board member. He is always willing to provide us with great, up to date, technical articles in the NACAT news, put on so many great training courses at the NACAT conferences over the years, and has been very active in our online round table discussions. I congratulate and thank Curt Ward!”

Who questions much, shall learn much, and retain much.

Francis Bacon

Lifting It RightTM is the world’s best-selling lift safety training program. It’s the industry standard on how to properly operate any vehicle lift and is the only program developed and backed by the technical experts at the lift safety watchdog Automotive Lift Institute (ALI) and leading lift manufacturers.

Millions of students, professional technicians, and at-home mechanics have learned from Lifting It Right how to lift a car, truck, or SUV without causing injury or property damage. The interactive course teaches how to spot, lift and lower a vehicle, maintain load stability, and more.

With an annual subscription, you can offer the interactive course to all your students. Most students complete it in about an hour and will receive a certificate of completion after passing the final exam.

Lifting It RightTM safety manual second edition completely updated and expanded. Order today at autolift.org/store.

As I write this article, the summer instructor conference schedule is nearly complete. I have enjoyed seeing many of you during my travels. A question that was frequently asked during, or after, my presentations was: How can I add high-voltage electricity and components to our existing curriculum? This is a great question and an excellent way to add hybrid and battery electric vehicle technology materials to the existing classes and increase the interest level in the topic at the same time. I believe the basic electrical classes are a great place to start adding hybrid and electric vehicle content. In this article I will share some ideas and concepts that will help begin the process.

Every basic electrical class covers the measurements of volts, amperes, and ohms. When covering ohms, introduce milliohms at the same time. The students will find it very interesting to see how differently a CAT III multimeter (set to ohms) and milliohm meter will measure the resistance of various lengths of stranded 14-gauge wire. The items shown in photo #1 are used in the milliohm measurement lab (See Photo #1 – Milliohm Meter). Although the measured resistance difference will have little impact on the diagnosis of a tail-light circuit, it makes a major difference when trying to identify a concern with the stator windings in a drive motor.

During the discussion of circuit protection, the operation and diagnosis of fuses, relays, PTC devices, and fusible links are covered. An excellent way to add high-voltage technology to the conversation is to include the topic of pyro fuses (See Photo #2 – Tesla Model S Pyro fuse). These circuit protection devices can be found in a high-voltage battery or the disconnect plug. The pyrotechnic materials used in the fuses are like what is used in an airbag module and ensure the high-voltage circuit is opened rapidly in the event of a short circuit or an airbag deployment.

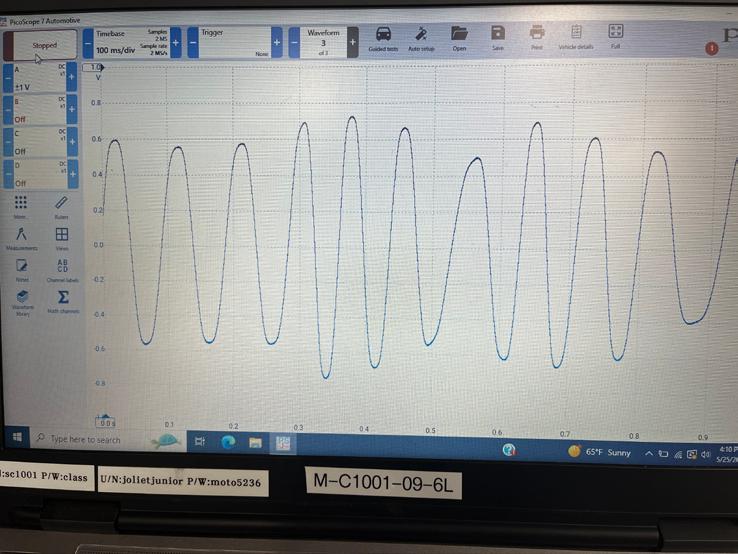

The topic of AC electricity has almost disappeared from the basic electrical class. Other than a brief mention of AC ripple voltage when diagnosing an alternator output concern, it is hardly mentioned. The operation of electric drive motors is a great way to make this topic relevant to the class. The use of a permanent magnet trainer and an oscilloscope is a great way to help our students visualize the difference between AC and DC electricity (See Photo #3 – Trainer and Photo #4 – Scope pattern on the facing page). The single waveform generated on the oscilloscope shows the transition between positive and negative voltage and the total energy potential of the circuit. The same principles can also be applied to brushless AC blower motors and fuel pumps, which are becoming more common.

Continued on Page 19

Lastly, students are always interested in discussions related to powertrain torque and horsepower. During these discussions, include topics such as kilowatts (kW), newton meters (Nm), and kilowatt hours (kWh) and how they are used to measure electric motor power output, torque, and high-voltage battery storage capacity. Make some side-by-side comparisons between electric and internal combustion engine vehicles. The students will be amazed to see how strong an electric motor performs.

None of the suggested ideas or concepts require the program to invest in an electric vehicle. With a relatively small investment in a milliohm meter, and pyro fuse and blowing the dust off the old permanent magnet trainer, the basic electrical class now includes some of the fundamentals that would be covered in a hybrid or electric vehicle class.

I will finish this article with the same offer I make after each of my presentations. If you are interested in getting started in the process of adding hybrid and electric vehicles to your curriculum or want more information, please feel free to reach out. I am more than willing to sit down in-person or online and share my experiences. Are you looking for a classroom textbook? Reach out to Pearson and ask for a review copy of the all-new Electric and Hybrid Electric Vehicle text that Jim Halderman and I co-authored. It is a comprehensive text covering all the latest information on the subject. Continued From Page 18

The annual Silent Auction and 50/50 raffle fundraiser during the 2024 NACAT Conference was a great success. The organization was able to raise $1599.61 to help fund future scholarhips

We would like to thank the many bidders and donors we had this year. Without you, we could not do what we do.

THANK YOU!

Donated items included:

• 2024/25 ATRA Regional Technnical Seminar Ticket

• Milwaukee 191 Piece Mechanics Tool Set

• $200 Snap-On Gift Card

• 2 Cases of Tub O'Towels

• Online ASE Study Guide for Your School

• DSR Collectable Basket

• $50 Amazon Gift Card

• $50 Lowe's Gift Card

• Stanley 40 Ounce Tumbler

• 28" Blackstone Flat Top Griddle

• Valve Cover Racer by Laurie Dwyer

• NACAT Cornhole Set

• Kentucky Bourbon Basket

• New York Maple Products

June 9-12, 2025

Detroit

Please share how you have adapted your curriculum for this transitional period.

nacatnews@nacat.org

Education is the most powerful weapon which you can use to change the world.

Nelson Mandela

his school. His passion for teaching and dedication to student success are unmatched. Dana's dream job has become a reality, and his commitment to furthering his education and enhancing his instructional methods makes him an invaluable asset to Saskatchewan Polytechnic's program. Congratulations, Dana Shynkaruk, on receiving the Innovative Instructor Award!"

The $2000 Jack Erjavec Innovative Instructor Award, sponsored by Cengage, funds a oneyear NACAT membership and attendance to the annual NACAT Conference. The award is open to any automotive technology instructor who works at a public or private secondary or post-secondary school or training center in North America. Full-time faculty nominees will receive higher consideration than part-time faculty nominees.

Congratulations, Dana!

NACAT President Drew Barnes presented the 2024 Friend of NACAT award to ConsuLab at the recently concluded NACAT Conference & Expo in Indianapolis, Indiana.

Barnes stated, "The Friend of NACAT Award recognizes an automotive industry partner who has provided exceptional support to NACAT." He further declared, "This is a difficult award to choose, as we have so many great sponsors and supporters of our organization. This company has offered innovative solutions for automotive educators, promoted NACAT through their sales efforts, supports the NACAT Conference with their hands-on training, and provides invaluable feedback to help us improve. We are very thankful ConsuLab is so committed to NACAT and the automotive education industry."

Please be certain to visit ConsuLab's website to view the products they have available in their Automotive, Truck and Heavy Equipment, Electric and Hybrid Vehicle, and Hydraulics product lines.

The Friend of NACAT has been previously awarded to the late Fred Hines and ATech Training (2007), Cengage (2008), Mitchell 1 (2009), Snap-On (2010), MACS (2011), Gates (2012), ConsuLab (2013), CDX (2014), ACDC Hybrid/EV Training (2015), the late Bob Chabot (2018), Southern Alberta Institute of Technology (2019), James Curry (2022), as well as Heather Sebben and Hamilton & Associates (2023).

NACAT Names Dayne Van Dyke Larry cotten memorial scholarship recipient

Dayne Van Dyke was named the 2024 Larry Cotten Memorial Scholarship recipient during the NACAT Conference & Expo which was held July 22 - 25 in Indianapolis, Indiana. The $1000 scholarship is given in memory of Larry Cotten, a NACAT Charter member and former president. Cotten’s wife and family established the memorial scholarship, following his death in an accident in 2005, to help pass his passion on to the next generation of collision repair technicians.

Van Dyke is enrolled as a student at Kirkwood Community College in Cedar Rapids, Iowa. He stated that remote learning during Covid cemented an office job was not his passion, as he felt something was absent. He found that missing piece as he acquired an older Chevy Silverado and began to enhance and modernize it daily, just as soon as his online classes would end. As a result, during his senior year he enrolled in the dual credit automotive collision repair and restoration program at Kirkwood Career Academy.

“NACAT congratulates Dayne as he embarks on his automotive career,” said Drew Barnes, NACAT President. “We also would like to thank and congratulate the University of the Aftermarket Scholarship program for the automotive scholarship website, www.automotivescholarships.com, which for the previous academic year helped facilitate the awarding 385 scholarships totaling $642,750. The platform makes it easy and enjoyable to rate and review applicants with information that is up to date and valuable. We are proud to be a part of helping students, like Dayne, achieve their goals and dreams. We look forward to knowing the composite numbers for the upcoming school year.”

Dayne was very gracious in his acceptence, as he stated, "I would like to thank you for your generosity in awarding me this scholarship. This scholarship provides me a straight path to achieving my goals."

Congratulations, Dayne!

NACAT REcognizes: Fritz Peacock and Al Santini

NACAT President Drew Barnes recognized Fritz Peacock and Al Sanitini for their lifelong committment to NACAT during the opening session of the 2024 NACAT Conference & Expo held in Indianapolis, Indiana.

Fritz Peacock is a NACAT Charter Member and Al Santini has been a NACAT member for 45 years! Each has shown unwavering support which has been instrumental in NACAT’s evolution and success. Thank you, Fritz and Al, for your commitment and passion for automotive education and the impact you continue to make in the field.

3.1.The flow meter will:

a. Indicate if the pump is receiving oil at its inlet port.

b. Indicate if the correct amount of flow is being delivered to the system.

c. Indicate an abnormal variation in pump input speed.

d. Indicate pump efficiency under various load conditions.

e. Allow you to make flow adjustments on pumps equipped with mechanical flow adjustment options (variable displacement).

4. Connect needle valve (C) in series with the pump outlet transmission line.

Why? Pump efficiency can only be accurately measured when the pump is pumping against a pressure (load). A needle valve can be used to generate an “artificial” load at the pump outlet to check pump flow at various pressure levels.

4.1. Gradual loads can be introduced at the pump oulet easily without having to load the actuator(s).

4.2. Manufacturer’s start-up procedures can be followed more easily. Certain manufacturers require that pumps be loaded sequentially at step-level pressures for optimum in-service performance.

4.3. Many new and rebuilt hydraulic pumps are not tested under full pressure and flow conditions. This is primarily due to a lack of test-bench horsepower. Therefore, the prime mover can be used as a “dynamometer” or test bench, as it has the horsepower capability to operate the pump at full flow and pressure levels.

4.4. Contamination from catastrophic pump start-up failure will not be transported into the system.

4.5. Warranty claims can be dramatically reduced as a well-documented systematic start-up procedure can rarely be argued against.

5. Check the pump input shaft speed using a tachometer.

Why? Pump flow is directionally proportional to shaft speed. The combined volume of the pumping chambers through one shaft revolution (360º) is called "pump displacement", and is usually expressed in cubic inches per revolution (CIR). An abnormal increase or decrease in shaft speed will have an adverse effect on pump life. Refer to the manufacturer's specification for recommended prime mover speed.

5.1. High Speed Related Problems

a. Bearing life is inversely proportional to pump speed. A pump operating at 1800 RPM will have a life expectancy about 50% lower than one running at 1200 RPM.

b. Excessive speed will result in cavitation because inlet transmission lines may be undersized for the increased velocity, and suction screens may be undersized for the increased flow.

c. Pump balancing is also critical to shaft speed. Excessive speed may cause vibration due to the increased centrifugal force on unbalanced rotating groups.

d. Lubrication may be affected by increased centrifugal force "squeezing" the lubrication film out, causing adhesive wear.

e. Cavitation and vibration will also produce excessive noise.

Continued on Page 28

Women in Auto Care, a community of the Auto Care Association, has achieved a remarkable milestone in its scholarship program, now in its 20th year. Setting a record, the organization has distributed a total of 81 awards, combining cash scholarships and toolkits, with an unprecedented value of $425,000. These awards serve as a powerful investment in the aspirations of female students across the United States, nurturing their interest in pursuing careers within the automotive aftermarket.

In addition to financial support, Women in Auto Care will provide scholarship winners with an Industry Swag Box—a curated collection of items introducing them to the organization and showcasing key companies in the automotive aftermarket. This aims to familiarize recipients with the industry and cultivate community belonging.

Furthermore, Women in Auto Care have introduced monthly virtual Connection Circles for scholarship winners, allowing them to connect with peers and receive mentorship from experienced female technicians and instructors, aimed at fostering ongoing support, professional growth, and networking opportunities for their career success.

The outstanding success of this year's scholarship program is a testament to the unwavering support and generosity of Women in Auto Care's community sponsors and member contributions. Their dedication to fostering diversity and opportunity within the industry has made a significant impact on the lives and futures of aspiring professionals.

For more information about Women in Auto Care scholarship opportunities, visit autocare.org/women-in-auto-care.

5.2.

a. Mobile equipment is particularly vulnerable to prime mover speed reductions due to wear in foot throttle to fuel injection pump linkages and cables.

b. A pump becomes less efficient at lower speeds because of internal leakage which is proportional to system pressure and pump design clearances. Leakage is a higher percentage of reduced flow rates.

Hydraulic motors typically slow down under load when worn. Historical analysis will determine that the problem is viscosity sensitive, i.e. during cold start-up operation they appear to operate normally, and as the oil temperature increases the motor shaft speed decreases.

6. Monitor the oil temperature using a pyrometer.

Why? Monitoring and maintaining oil at a moderate temperature is essential for reliable machine operation. When hydraulic systems are started up, the oil temperature will increase until it reaches a "levelling-off" temperature. This condition occurs when the heat being generated is equal to the heat being removed by radiation through the walls of the reservoir and/or by a heat exchanger. Refer to the manufacturer's specification for maximum & minimum operating temperatures.

6.1. Machine tools and plant power units operate at temperatures between 140ºF (60º C) and 160ºF (71ºC). Mobile equipment systems are forced to operate at temperatures up to 180ºF (82ºC).

6.2. Systems should never be allowed to operate at temperatures above 200ºF (93ºC). At this temperature and above, oil life is greatly reduced.

Viscosity may decrease to a point where:

a. Power loss becomes excessive.

b. Lubrication loss may result in adhesive wear.

c. Rubber seals and filter elements may deteriorate rapidly.

6.3. Studies have shown that oil life decreases by approximately 50% for every 20ºF (-6.6ºC) rise in temperature.

6.4. A pyrometer should be used on a daily basis to allow the user to become thoroughly familiar with system temperatures under all load conditions. Cold ambient conditions will also contribute to poor pump life. High viscosity will cause excessive pump inlet restriction resulting in cavitation.

Introduction

Many premature hydraulic component failures are attributed to poor initial start-up procedures. It is therefore essential to implement strict guidelines when starting new systems or introducing new components to existing systems. This will optimize component reliability and maximize component life.

Common system/component start-up pitfalls

There are some obvious and not so obvious reasons why start-up failures occur:

a. Accumulated contamination in reservoirs, transmission lines, and components during manufacture or repair.

b. Tape and liquid-type connector and pipe sealants used to seal connections.

c. Pieces of rubber from hose assemblies, "O"-rings, and cylinder packings.

Continued on Page 30

The NACAT Conference is an event where educator FAMILIES can come and make lifelong friends. NACAT works to ensure spouses, significant others, children, or whomever is brought with an attendee has a chance to have a week filled with fun and fellowship. There is a BBQ, annual valve cover races, and a special family program that is created by a Families of NACAT Committee which is co-chaired by the wives of NACAT members.

Jay Kuykendall, an automotive instructor at Portland Community College in Portland, Oregon, has been named the 2024 Mitchell 1 Educator of the Year. The award was presented at the North American Council of Automotive Teachers (NACAT) awards luncheon on Wednesday, July 24, in Indianapolis, Indiana.

“We are proud to congratulate Jay Kuykendall as the 2024 Mitchell 1 Educator of the Year,” said Nick DiVerde, senior director, product management for Mitchell 1. “With 32 years of experience in the automotive industry, Jay is not only an outstanding teacher and a master automotive technician, but he is also a successful business owner. We are pleased to acknowledge Jay’s exceptional contributions to the classroom and the auto care industry as a whole.”

Each year, Mitchell 1 recognizes one of the nation’s top teachers for their commitment to educational excellence in the automotive repair industry. As the 2024 recipient, Kuykendall received a complimentary one-year subscription to Mitchell 1’s ProDemand® auto repair information software, a one-year membership to NACAT, and an all-expenses-paid trip to attend the NACAT conference.

In his position at Portland Community College, Kuykendall runs the auto shop lab and teaches engine performance classes as well as elective courses including Subaru U, electrified vehicles and light duty diesel. He is also a certified ASE Master Technician, owns and operates Green Flag Auto Repair in Molalla, Oregon, and is co-founder of the Northwest Automotive Technicians Society.

Kuykendall shared that his interest in the automotive industry began in his childhood. “I grew up with my family racing at the local short track. I helped my dad and brothers work on the race cars, and in high school, my sport was drag racing,” he said. “After high school, I attended trade school and started working in the automotive field right after graduation.”

The Mitchell 1 Educator of the Year award selection criteria requires that the recipient excel in all ASE automotive tests, including A1 – A8 (Engine Repair, Automatic Transmission/Transaxle, Manual Drive Train and Axles, Suspension and Steering, Brakes, Electrical/Electronic Systems, Heating and Air Conditioning, Engine Performance), as well as the L1 (Advanced Engine Performance Exam).

Congratulations, Jay!

d. Burrs from connectors, tube assemblies, metal fabrication, substandard replacement parts and component machining practices.

e. Substandard component storage methods, ports not plugged adequately, masking tape and duct tape covering ports, or rags in ports.

f. Sub-assemblies being "borrowed" from inventoried components leaving the housings open to the elements.

g. Sub-assemblies being "borrowed" from existing operating systems to conduct "process-of-elimination" diagnostic procedures.

h. Due to design clearances, certain "fixed clearance" pumps will not "pick-up" oil upon initial startup. Oil is needed to create a "seal" to initiate a partial vacuum.

i. Pressure manifold systems which are not equipped with air-bleed valves, can cause the pump to become "air-bound." This condition will prevent the pumping chambers from filling with oil.

j. Pump and motor housings are not filled with oil prior to start-up which can cause excessive bearing temperatures and loss of lubrication.

k. Plastic plugs which are inadvertently left in component ports upon start-up.

l. Incorrect prime mover input speed.

m. Incorrectly installed components.

n. Incorrectly adjusted components.

o. Incorrect components.

p. Incorrect rotation of prime mover.

q. Rags or cloths left in reservoir or reservoir transmission lines during fabrication.

r. Reservoir/pump isolation valve left closed upon start-up.

s. Incorrect oil.

t. Return line, directional control valve, heat exchanger, and associated components sized for pump flow rather than cylinder flow.

u. External pressure control valve drain lines inadvertently plugged.

v. Pump and motor case drain lines incorrectly plumbed, sized, or inadvertently plugged.

w. Incorrect hose type used on suction side of pump.

Coming together is the beginning. Keeping together is progress. Working together is success. Henry F d

WD-40® Brand and NAPA Partner

To bridge the skilled trades gap and empower aspiring technicians to pursue a career in the field, WD-40® Brand and NAPA are partnering with TechForce Foundation to offer $50,000 in scholarships, aimed at bolstering a new generation of trade professionals.

For decades, the skilled trades have suffered from a gap in supply and demand, leading to a significant workforce shortage. For the first time in more than ten years, tech school completions have risen. However, to meet demand over the next five years, the skilled trades must grow by 795,000 new technicians.

“The automotive industry’s future depends on the education and training of today’s students,” said Jamie Walton, executive vice president, merchandising of NAPA. “This partnership with WD-40 Brand and the TechForce Foundation ensures we bring broader visibility and accessibility to technician careers.”

WD-40 Brand and NAPA will award 40 scholarships over the next 12 months. Applicants must be enrolled in a post-secondary automotive, collision or diesel program. To apply and learn more, students can visit techforce.org/ napa-wd40brand-scholarships. As part of the partnership, NAPA will be offering WD-40® Multi-Use Product at a discounted price through September 2024

“WD-40 Brand recognizes the critical role that the skilled trades play in driving America forward,” said Erin Bala, vice president of U.S. marketing and Americas innovation at WD-40 Company. “We are honored to join forces with NAPA in backing TechForce Foundation and its crucial mission to champion students to and through their education into careers as professional technicians.”

“This cross-sector partnership demonstrates the value of industry coming together to demonstrate its commitment to powering the next generation of technicians,” said Jennifer Maher, CEO of TechForce Foundation. “By combining their support, WD-40 Brand and NAPA will unlock a multiplier effect that will allow our organizations to inspire and support more students together than we ever could apart. TechForce looks forward to collaborating with our partners to connect even more students to technician careers in an industry that urgently needs their skills.”

The SEMA Memorial Scholarship Fund issued $99,000 in scholarship and loan forgiveness awards to help 46 individuals currently working or planning to pursue careers in the automotive aftermarket industry. The winners include 39 college students and seven employees of SEMA-member companies.

“As the automotive-specialty equipment market grows, so does the need for talented, ready-to-work individuals who are passionate about the industry,” said Jose Escobar, SEMA Project Manager of Recognition Programs. “This year’s winners represent the diversity and interests that the market needs, and we’re excited to support them in their academic and professional journeys.”

Established in 1984, the SEMA Memorial Scholarship Fund is designed to encourage future talent and current leaders to succeed in the automotive industry. Each year, scholarships are awarded to help the next generation get off to a successful start in their education, and the current automotive workforce reduce their college debt. The total amount issued since the program’s inception is over $3 million.

The online application for next year’s awards will open in January 2025 at www.sema.org/scholarships.

C l i c k h e r e t o

s i g n u p f o r t h e N A C A T e N e w s l e t t e r